Page 1

INSTRUCTION MANUAL

NL240 Wireless

Copyright © 2011- 2014

Campbell Scientific, Inc.

Network Link Interface

Revision: 9/14

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning (435) 227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is

highly recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact

with overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, 20 feet, or the

distance required by applicable law, whichever is greater, between overhead utility lines and

the structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 6

Page 7

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Quickstart .................................................................... 1

3.1 Physical Setup ...................................................................................... 2

3.2 Configuring the NL240 ........................................................................ 2

3.3 LoggerNet Setup .................................................................................. 4

3.4 Connect ................................................................................................ 4

4. Overview ...................................................................... 5

5. Specifications ............................................................. 8

6. Wi-Fi ........................................................................... 10

6.1 Introduction to Wi-Fi for WLANs ..................................................... 10

6.2 Wireless Network Modes ................................................................... 10

6.3 RSSI ................................................................................................... 11

6.4 Antennas ............................................................................................ 12

6.5 Power ................................................................................................. 12

6.6 LEDs .................................................................................................. 12

7. Configuring the NL240 ............................................. 13

7.1 Configuring the NL240 with DevConfig via USB ............................. 13

7.2 Configuring the NL240 with DevConfig via Wi-Fi WLAN .............. 14

7.3 Configuring the NL240 with Telnet via Wi-Fi WLAN ...................... 14

7.4 Configuring the NL240 via RS-232 ................................................... 15

8. Operation ................................................................... 15

8.1 Wi-Fi Connection ............................................................................... 16

8.1.1 Join an Existing Network ............................................................ 16

8.1.2 Create an Ad hoc Network .......................................................... 16

8.2 Operational Mode .............................................................................. 17

8.2.1 PakBus® Router ......................................................................... 17

8.2.1.1 Physical Setup .................................................................. 17

8.2.1.2 Configuring the NL240 .................................................... 18

8.2.1.3 LoggerNet Setup ............................................................... 19

8.2.1.4 Connect ............................................................................ 20

8.2.2 Bridge Mode ............................................................................... 20

8.2.2.1 Physical Setup .................................................................. 20

8.2.2.2 Configuring the NL240 .................................................... 20

8.2.2.3 Configuring the Datalogger .............................................. 20

8.2.2.4 LoggerNet Setup ............................................................... 21

i

Page 8

Table of Contents

8.2.2.5 Connect ............................................................................ 22

8.2.3 TCP Serial Server ....................................................................... 22

8.2.3.1 Physical Setup ................................................................. 22

8.2.3.2 Configuring the NL240 ................................................... 22

8.2.3.3 LoggerNet Setup .............................................................. 23

8.2.3.4 Connect ............................................................................ 24

8.2.3.5 Serial Sensors .................................................................. 24

8.2.4 TCP Serial Client ....................................................................... 24

8.2.5 Modbus TCP/IP to RTU Gateway.............................................. 25

8.2.6 TLS ............................................................................................ 25

8.2.6.1 TLS Proxy Server ............................................................ 26

8.2.6.2 DevConfig TCP Encrypted Communication to the

NL240 .......................................................................... 28

9. Applications............................................................... 29

9.1 Working Around Firewalls ................................................................ 29

9.1.1 Configuring the NL240 .............................................................. 29

9.1.2 Configuring the Datalogger ........................................................ 30

10. Troubleshooting ........................................................ 30

11. Attribution .................................................................. 33

Appendices

Glossary ................................................................... A-1

A.

B. Cables, Pinouts, LED Function, and Jumper ....... B-1

B.1 CS I/O.............................................................................................. B-1

B.2 RS-232 ............................................................................................. B-1

B.3 USB ................................................................................................. B-2

B.4 Power............................................................................................... B-2

B.5 LEDs ............................................................................................... B-2

B.6 Power Jumper .................................................................................. B-3

C. NL240 Settings ........................................................ C-1

C.1 Main Tab ......................................................................................... C-1

C.2 Wi-Fi Tab ........................................................................................ C-4

C.3 RS-232 Tab ..................................................................................... C-8

C.4 CS I/O Tab .................................................................................... C-11

C.5 Net Services Tab ........................................................................... C-12

C.6 TLS Proxy Server Tab ................................................................... C-14

C.7 TLS Tab ........................................................................................ C-16

D. Sending a New OS to the NL240 ............................ D-1

D.1 Sending an OS via USB .................................................................. D-1

D.2 Sending an OS via Wi-Fi ................................................................. D-1

E. Radio Frequency Emission .................................... E-1

ii

Page 9

Figures

Tables

Table of Contents

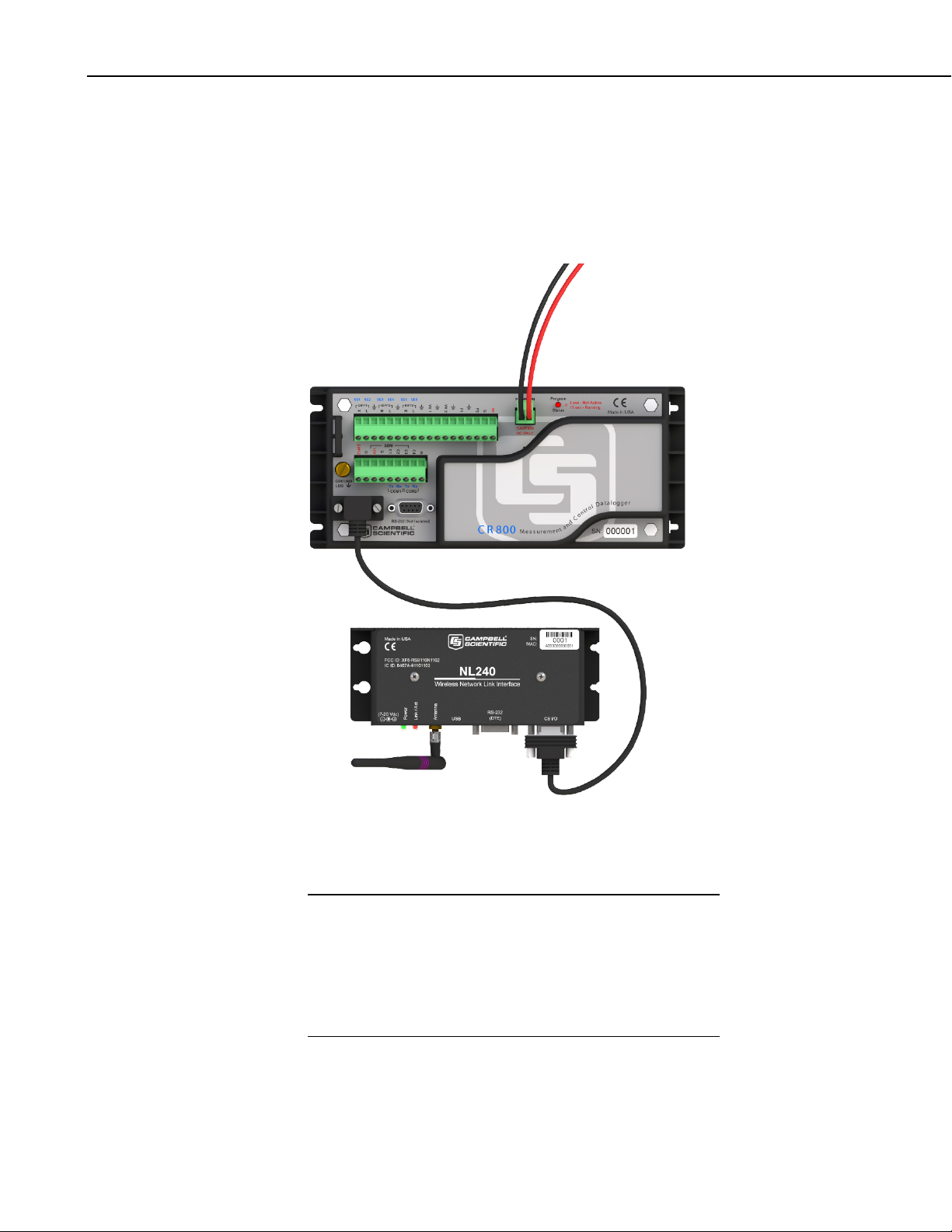

3-1. NL240 with CR800 (powered through CS I/O port) ............................ 2

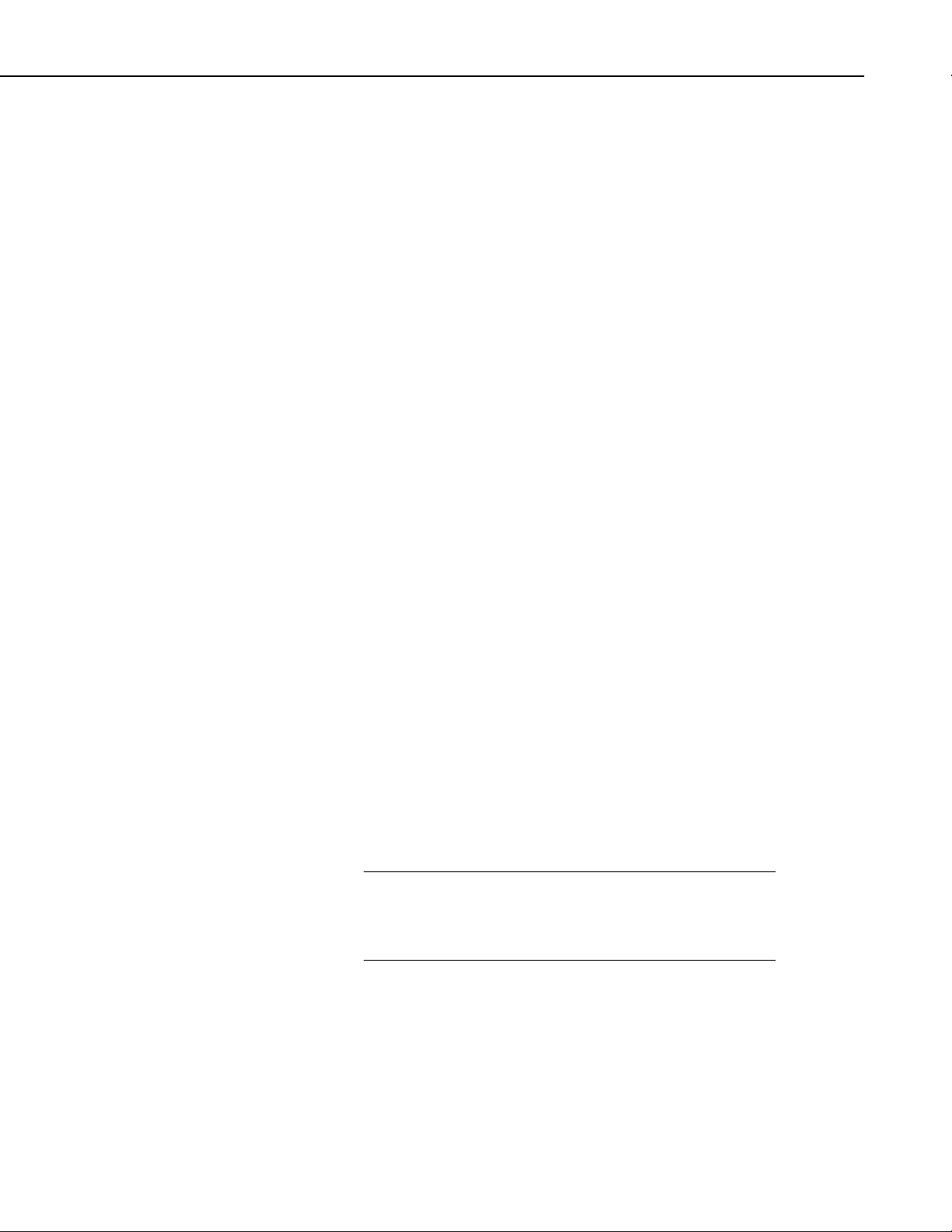

3-2. LoggerNet setup ................................................................................... 4

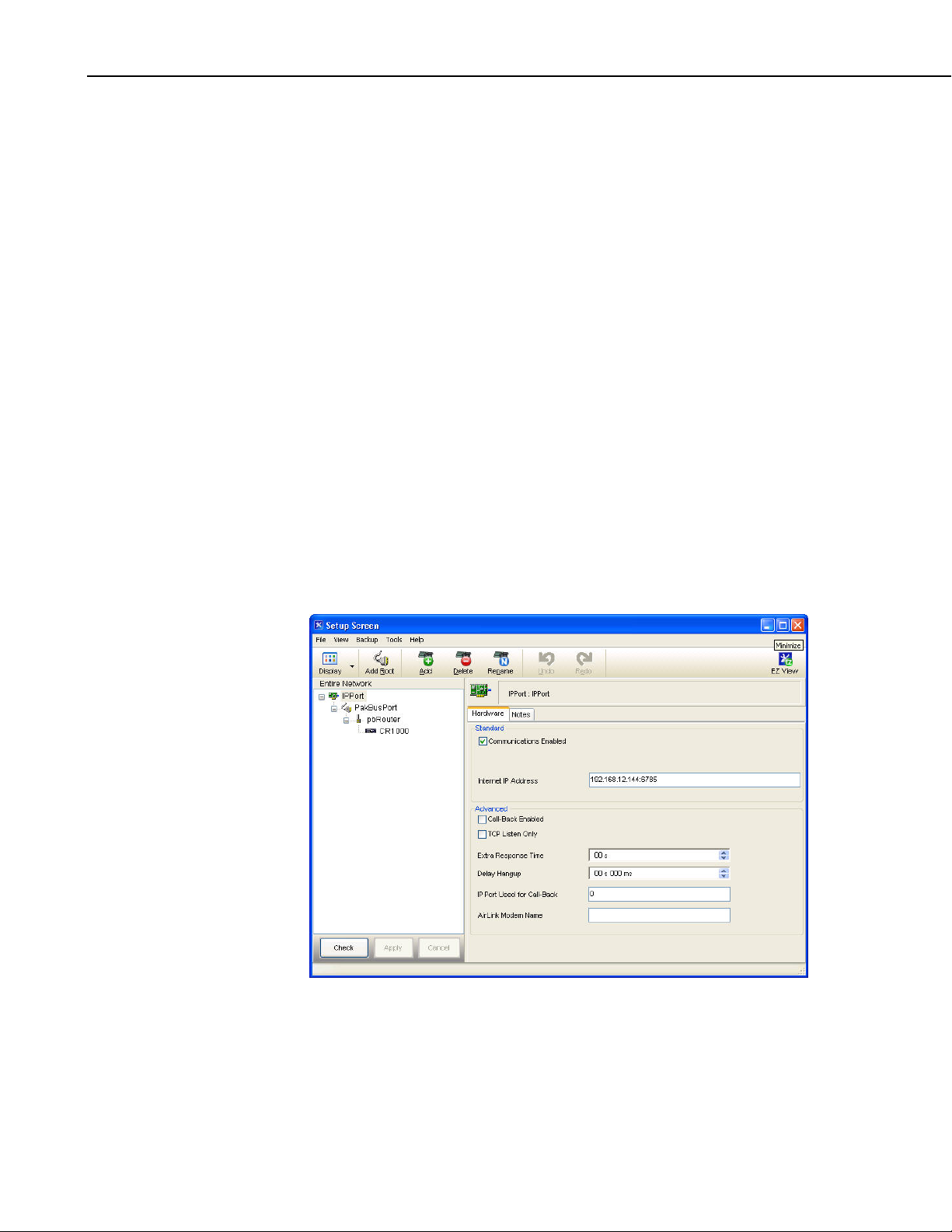

4-1. NL240 .................................................................................................. 5

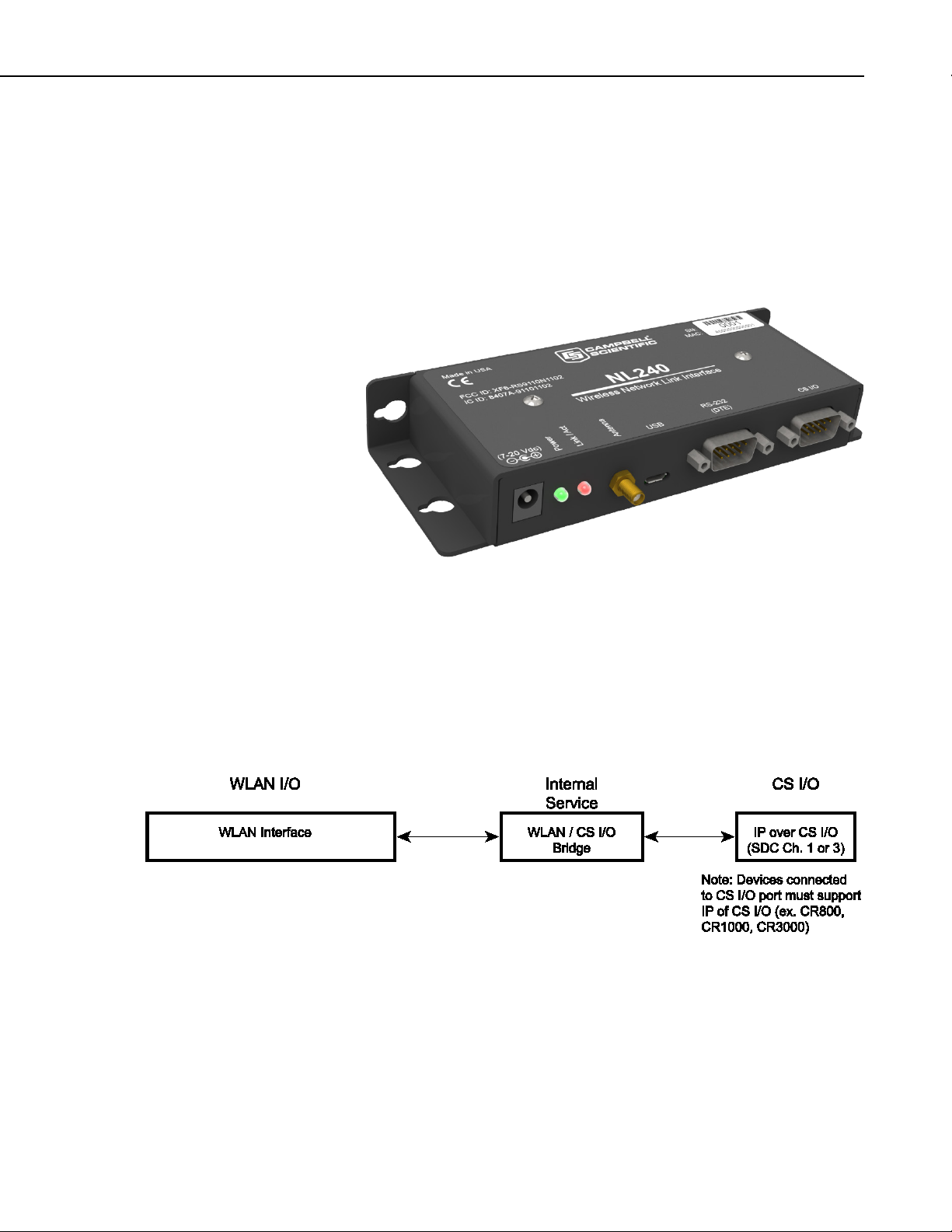

4-2. Bridge Mode enabled ........................................................................... 5

4-3. Bridge Mode disabled .......................................................................... 6

5-1. NL240 dimensions ............................................................................... 8

6-1. Infrastructure network ........................................................................ 11

6-2. Ad hoc network .................................................................................. 11

8-1. PakBus® router LoggerNet setup ...................................................... 19

8-2. Bridge mode LoggerNet setup ........................................................... 22

8-3. CS I/O Serial Server LoggerNet Setup ............................................... 24

8-4. TLS proxy server configurations ....................................................... 27

9-1. Working around firewalls .................................................................. 29

B-1. CS I/O Pinout ................................................................................... B-1

B-2. RS-232 Pinout .................................................................................. B-1

B-3. USB Micro-B ................................................................................... B-2

B-4. Power In ........................................................................................... B-2

B-5. Power LED (Red) ............................................................................ B-2

B-6. Wi-Fi LED (Green) .......................................................................... B-3

iii

Page 10

Table of Contents

iv

Page 11

NL240 Wireless Network Link Interface

1. Introduction

The NL240 is a WLAN (Wireless Local Area Network) interface that allows

Campbell Scientific dataloggers and peripherals to communicate with a Wi-Fi

network or wireless ad hoc network. This WLAN interface can be connected

to a datalogger’s CS I/O port or RS-232 port.

2. Cautionary Statements

• The first time an NL240 is attached to a datalogger and Bridge Mode is

enabled, the datalogger’s memory has to be reorganized to allow room in

memory for the IP stack. To avoid the loss of data, collect your data

before enabling Bridge Mode.

• This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. See Appendix E for

more information.

3. Quickstart

• Device Configuration Utility (DevConfig) 2.03 or higher is required to

communicate with the NL240. The latest version of DevConfig can be

downloaded from our website at www.campbellsci.com/downloads.

• The device driver for the NL240 must be installed on your computer

before you can connect to the NL240 via USB. To install the device

driver, verify you have the latest version of DevConfig (see previous

bullet). Under Device Type, select Network Peripheral | NL240. Click the

Install the device driver for the NL240 link and follow the prompts.

• CR1000, CR3000, and CR800-series dataloggers require operating system

version 25 or higher in order to operate with the NL240 in bridge mode.

(OS version 25 or higher is not required to operate as a serial server or

PakBus router.) The latest operating systems can be downloaded from our

website at www.campbellsci.com/downloads.

• Ensure maximum protection against surges. Use coaxial surge protection.

Keep RS-232 and CS I/O connections short.

• When downloading a new operating system to the NL240, do not remove

power until the red LED stops blinking.

Out of the box, the NL240 is configured for operation as a PakBus® Router.

In this mode, the NL240 can be used to communicate with Campbell Scientific

PakBus devices over a Wi-Fi network connection.

1

Page 12

NL240 Wireless Network Link Interface

NOTE

3.1 Physical Setup

Attach an antenna to the NL240’s antenna connector. Using the supplied serial

cable, connect the NL240’s CS I/O port to the datalogger’s CS I/O port.

Alternatively, power the NL240 through the barrel-connector jack located on

the edge of the device. Ensure that the device is powered up by inspecting the

Power LED.

2

FIGURE 3-1. NL240 with CR800 (powered through CS I/O port)

3.2 Configuring the NL240

INSTALL THE DEVICE DRIVER BEFORE plugging the

NL240 into your PC for the first time. You will need the device

driver properly installed before you can connect to the NL240 via

USB. To install the device driver, download the latest version of

DevConfig from our website. Under Device Type, select Network

Peripheral | NL240. Click the Install the device driver for the

NL240 link and follow the prompts.

Page 13

NL240 Wireless Network Link Interface

NOTE

• Ensure the NL240 is powered.

• Connect the supplied USB cable between a USB port on your computer

and the USB port on the NL240.

• Open DevConfig.

• Under Device Type, select Network Peripheral | NL240.

• Click the Browse button next to Communication Port.

• Select the virtual com port labeled NL240.

• Click OK.

• Click Connect.

• Click on the Wi-Fi tab.

• By default, the NL240 will attempt to connect to the strongest, unsecured

network available. This network will be shown in the Status field. If this

is not the network you wish to connect to, press the browse button next to

the SSID field. A dialog box showing all of the available wireless

networks will be displayed. Select the network you wish to connect to and

click OK. If this is a secured network, enter the password in the

Password field.

• Click on the NL240 tab.

• To enter a static IP address, select disable in the Use DHCP field. Then

input the IP Address, Network Mask, and Default Gateway. These

values can be provided by your network administrator.

• If a dynamic address is to be used, the network information acquired via

DHCP can be seen on the NL240 tab. (Note that if you have selected a

different network than the default network, you will need to press Apply

to save this change, then press the Connect button to reconnect to the

NL240 and view the network information.)

• Click Apply to save your changes.

It is recommended that a static IP address be given to the NL240

for most applications so that the path to the device is always

known. If using a dynamic IP address acquired via DHCP, you

may wish to configure the NL240 as a PakBus/TCP client.

3

Page 14

NL240 Wireless Network Link Interface

3.3 LoggerNet Setup

The next step is to run LoggerNet and configure it to connect to the datalogger

via the NL240.

• In the LoggerNet Setup screen, press Add Root and choose IPPort. Input

the NL240 IP address and port number. The IP address and port number

are input on the same line separated by a colon. IPv6 addresses will need

to be enclosed in square brackets when specifying a port number. An

IPv4 address may look like 192.168.1.100:6785. An IPv6 address may

look like [2001:db8::1234:5678]:6785. A fully qualified host name entry

may look like yourlogger.com:6785.

• Add a PakBus® Port (PakBusPort).

• Add a PakBus® Router (pbRouter). Input the PakBus address of the

NL240. The NL240 default PakBus address is 678.

• Add the datalogger and input the PakBus® address of the datalogger.

• Press Apply to save the changes.

• You can verify that your settings are correct by selecting the datalogger in

the Network Map, selecting the Clock tab, and pressing Check Clocks. If

your settings are correct, you should see the current clock of your server

and datalogger.

4

FIGURE 3-2. LoggerNet setup

3.4 Connect

You are now ready to connect to your datalogger using the LoggerNet Connect

screen.

Page 15

4. Overview

NL240 Wireless Network Link Interface

The NL240 Wireless Network Link Interface is designed for communication

with Campbell Scientific dataloggers and peripherals over a Wi-Fi network.

The Wi-Fi network can be an infrastructure network or an ad hoc (point-topoint) network. See Section 6, Wi-Fi, for more information.

The NL240 includes a CS I/O port and an RS-232 port for communication. A

USB device port is used for configuring the NL240 device.

FIGURE 4-1. NL240

Bridge Mode Enabled

The NL240 can be configured to bridge WLAN and CS I/O communications

(see FIGURE 4-2). This mode is used for providing access to the internal IP

functionality of the CR800/850, CR1000, and CR3000 (e.g., web page access,

email, FTP, etc.). Bridge mode does not use PPP. Instead, raw IP packets are

transferred between the WLAN and CS I/O connections.

FIGURE 4-2. Bridge Mode enabled

Bridge Mode Disabled

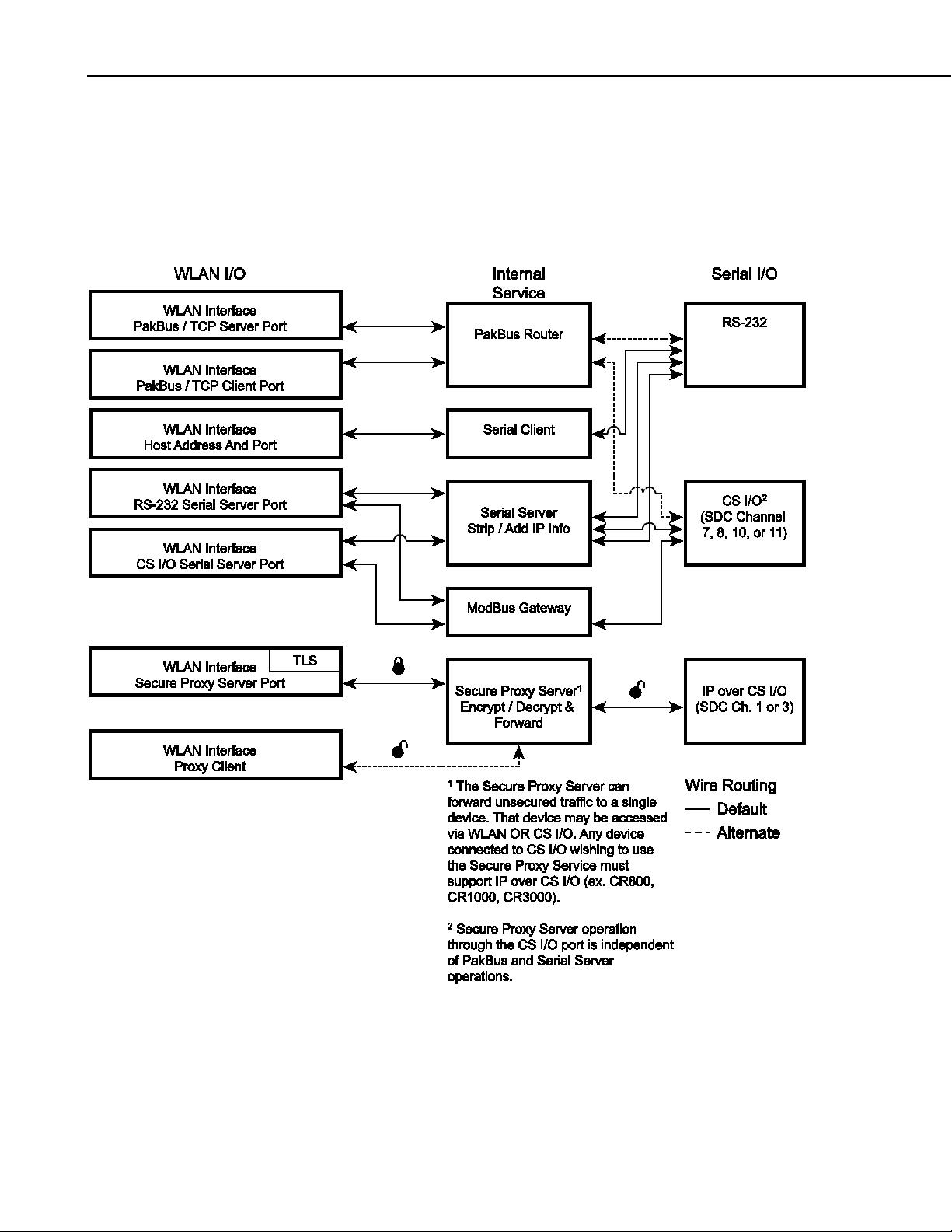

With Bridge Mode disabled (see FIGURE 4-3), the NL240 can provide

multiple services simultaneously including TCP Serial Server, TCP Serial

Client, Modbus TCP/IP Gateway, and PakBus® router. The NL240 can act as

a serial server and PakBus router simultaneously. However, each physical port

5

Page 16

NL240 Wireless Network Link Interface

(R2-232 and CS I/O) is only associated with one service (PakBus router, serial

server, Modbus/TCP Gateway, etc.) at a time. For example, you can have an

RS-232 serial server and a CS I/O serial server, an RS-232 serial server and a

CS I/O PakBus router, an RS-232 PakBus router and a CS I/O serial server, or

an RS-232 PakBus router and a CS I/O PakBus router. In addition, the NL240

can act as TLS proxy server. The TLS proxy server is independent of other

modes.

6

FIGURE 4-3. Bridge Mode disabled

Some reasons you might want to use each of these modes are described below.

Refer to Section 7, Configuring the NL240, and Section 8, Operation, for

information on setting up your NL240 for each mode.

Page 17

NL240 Wireless Network Link Interface

Campbell Scientific’s LoggerNet software is used to communicate with the

dataloggers once the NL240 is configured properly and connected to a

network.

Bridge Mode

• Allows access to datalogger’s internal IP functionality when a peripheral

port is not accessible. For example, accessing the HTTP/webpage, email,

and FTP capabilities of a CR800/850, ET107, RAWS, or CS110.

Serial Server

• Allows access to a CR10X over a Wi-Fi network (RS-232 serial server)

when used in conjunction with an RS-232 to CS I/O (ME) adapter like the

SC32B or SC105.

• Allows access to a serial sensor over a Wi-Fi network (RS-232 serial

server).

• Allows access to an RF500M Base over a Wi-Fi network (RS-232 serial

server).

PakBus® Router

• Allows access to a CR10X-PB over a Wi-Fi Network.

• Allows access to a CR200X over a Wi-Fi Network.

• Allows you to connect to a PakBus® Device on the RS-232 port and a

PakBus Device on the CS I/O port using only one TCP port.

• Allows a PakBus® device on the RS-232 port and a PakBus device on the

CS I/O port to communicate with each other without routing through the

WLAN.

• Allows multiple computers to concurrently talk to PakBus® devices

connected to the RS-232 and CS I/O ports.

TLS Proxy Server

• Adds an encrypted WLAN interface to a datalogger that supports CS I/O

IP (bridge mode) communications.

7

Page 18

NL240 Wireless Network Link Interface

NOTE

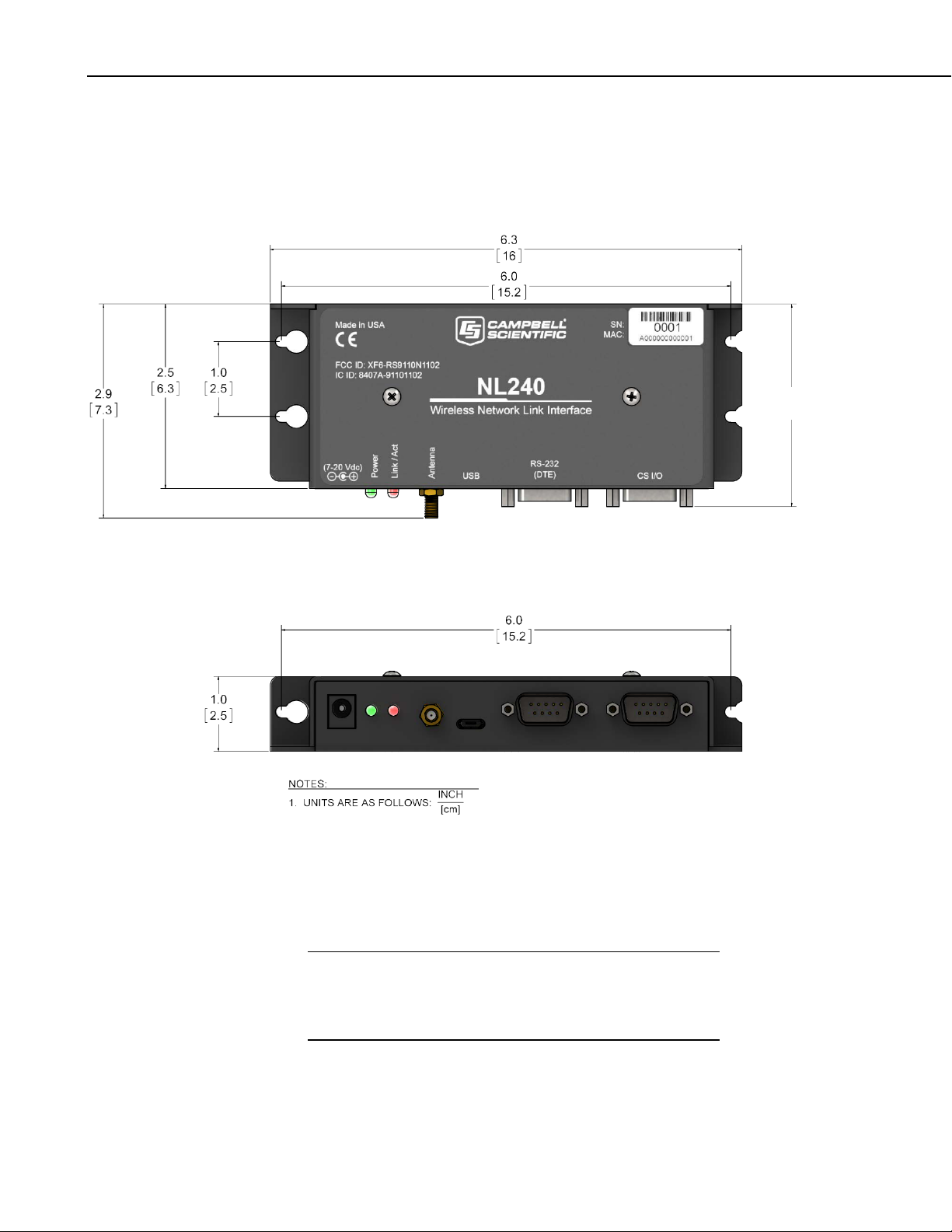

2.65

5. Specifications

General

177 g (6.3 oz)

16 x 6.73 x 2.54 cm (6.3 x 2.65 x 1 in)

[6.73]

FIGURE 5-1. NL240 dimensions

Power

CS I/O or DC Barrel Connector (not USB)

7 to 20 Vdc

If you wish to prevent the NL240 from being powered over the CS

I/O port, you can do so by removing a jumper. See Appendix B,

Cables, Pinouts, LED Function, and Jumper, for more

information.

8

Page 19

NL240 Wireless Network Link Interface

NOTE

Power Consumption

Maximum: 950 mW

Typical, Low Power Disabled

connected to Access Point: 600 mW idle, 670 mW communicating

searching for out of range network: 65 mW

Typical, Low Power Enabled

connected to Access Point: 73 mW idle, 480 mW communicating

searching for out of range network: 50 mW

Sleep: 16 mW

Standby power is when the IPNetPower instruction has been used

to turn off power to the Wi-Fi. See the CRBasic help for an

example of using the IPNetPower instruction. Note that the

IPNetPower instruction is only applicable when the NL240 is

configured with Bridge Mode Enabled

Operating Temperature

Standard: –25 to +50 °C

Extended: –55 to +85 °C

Configuration

DevConfig over USB or Wi-Fi

Telnet console over Wi-Fi

Terminal menu over RS-232

CS I/O Port

SDC 7, 8, 10, 11 (does not support ME)

9600 to 460.8 kbps

RS-232 Port

DTE

1200 bps to 115.2 kbps

WLAN

Antenna Connector: RPSMA

Supported Technologies: 802.11b/g/n, WPA, WPA2 (Personal

only)/TKIP or AES, WEP, WEP(open), APIPA/AutoIP, IPv4, IPv6,

ICMP/Ping, ICMPv6/Ping, TCP, DHCP Client, SLAAC, DNS Client,

HTTPS Proxy, Telnet Server, TLS, PakBus®, Modbus, TCP/IP

Topologies: infrastructure and ad hoc

Transmit Power: 5 to 50 mW, 7 dBm at low power level, 10 dBm at

medium power level, 16 to 17 dBm at high power level

Rx Sensitivity: –97 dBm (<8% PER)

Frequency: 2.4 to 2.5 GHz (2.4 GHz ISM band)

Miscellaneous

Supports 20 simultaneous TCP connections

Up to 10 of the 20 TCP connections can be used for TLS

PakBus® router supports 50 routes

Supports up to 15 concurrent Modbus server transactions

9

Page 20

NL240 Wireless Network Link Interface

Compliance

RoHS Compliant

Complies with the limits for a Class B digital device, pursuant to part 15

of the FCC Rules.

Contains an embedded radio transmitter with the following approvals:

FCC Identifier: XF6-RS9110N1102

Industry Canada: 8407A-91101102

Europe ETSI EN 301 489-17 V1.2.1:2002

Europe ETSI EN 300 328 V1.7.1:2006

6. Wi-Fi

6.1 Introduction to Wi-Fi for WLANs

Wi-Fi is a technology that allows data transfer among electronic devices using

specific radio frequencies over a wireless local area network (WLAN). A

wireless network is like a wired network, except it uses radio waves just like

cell phones, televisions, and other radios. Over-the-air speeds vary depending

on protocol, distance, and network activity. When using the NL240, please

note that your total throughput to the datalogger will generally be governed by

the speed of serial communication.

Wi-Fi transmits at frequencies around 2.4 and 5 GHz (the NL240 only uses 2.4

GHz). The high frequency allows fast rates but reduced communication

distance. These frequencies can be used by anyone and do not require a license

from the FCC to use or transmit (unlike most UHF and VHF frequencies) as

long as certain power levels are maintained.

The NL240 supports the 802.11b, 802.11g, and 802.11n wireless network

standards.

The NL240 Wi-Fi device also supports several wireless security protocols.

These include WEP (Wired Equivalent Privacy), WPA (Wi-Fi Protected

Access)(personal) with TKIP (Temporal Key Integrity Protocol),

WPA(personal) with AES (Advanced Encryption Standard), WPA(personal)

with TKIP+AES, WPA2(Wi-Fi Protected Access II)(personal) with TKIP,

WPA2(Wi-Fi Protected Access II)(personal) with AES, and WPA2(Wi-Fi

Protected Access II)(personal) with TKIP+AES. These security protocols

allow network traffic to be encrypted and help protect data transmitted over the

Wi-Fi network.

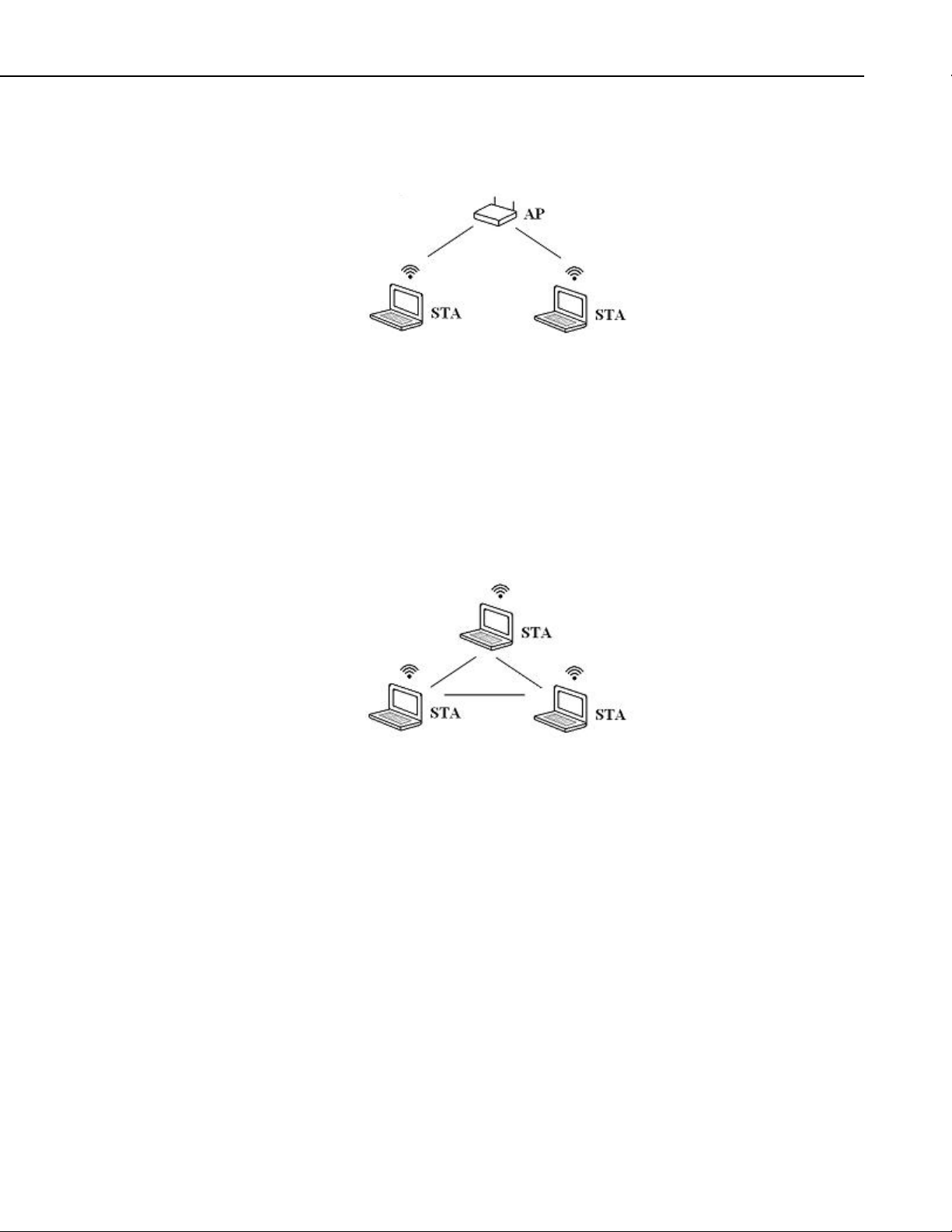

6.2 Wireless Network Modes

The NL240 works in two types of wireless modes, infrastructure and ad hoc.

In infrastructure mode (see FIGURE 6-1, Infrastructure network), the NL240

connects to an already established wireless network (WLAN). This wireless

network is usually controlled by a single Wireless Access Point (WAP). This

WAP will typically connect the wireless network (and the NL240) to a larger

wired company or home network and/or the internet. The WAP device also

controls and routes all the traffic on the wireless network. The WAP,

furthermore, controls security for network access, the wireless frequency

(channel) to use, and has the pre-established Service Set Identifier (SSID) for

the wireless network. Infrastructure mode wireless networks are usually the

10

Page 21

NL240 Wireless Network Link Interface

easiest wireless network to connect the NL240 to. (See Section 8.1, Wi-Fi

Connection, for details.) The network password/key (if required) and SSID

can be obtained from your network administrator.

FIGURE 6-1. Infrastructure network

Unlike infrastructure networks, ad hoc or peer-to-peer networks do not have a

single device (like a WAP) that controls access to the wireless network (see

FIGURE 6-2, Ad hoc network). Instead, network management and access is

decentralized. Ad hoc networks are created on the fly and all network devices

communicate directly with each other. Usually the first device on the network

(a NL240, PC, or iOS smart phone) establishes the security type, the SSID, and

the channel (frequency) that the wireless network will operate on. IP addresses

can be set statically or via AutoIP. It can take up to two minutes to find a

usable IP address using AutoIP.

6.3 RSSI

FIGURE 6-2. Ad hoc network

Once the network is established by the first wireless device, subsequent

wireless devices can connect to the ad hoc network if the correct SSID and

password (if needed) are specified in the configuration settings. Ad hoc

networks are usually small with up to five wireless devices connecting to the

wireless network. Also, ad hoc networks can only use WEP security or no

security (open). WPA security is not available in ad hoc networks.

RSSI is Received Signal Strength Indication. It is a generic radio receiver

technology metric used to determine the strength of the link between a receiver

and a transmitter. In the NL240’s case, RSSI is the measurement between the

NL240 and a wireless access point, a computer in ad hoc or another NL240 in

ad hoc. The strength of this link is recorded in dBm (power ratio in decibels)

and can be found under the Wi-Fi tab under the Settings Editor in DevConfig.

11

Page 22

NL240 Wireless Network Link Interface

RSSI in the NL240 is measured in a scale between –100 dBm and 0 dBm. The

higher the number (i.e. –12 dBm as compared to –72 dBm), the better the

connection between Wi-Fi devices. A reliable connection will be maintained if

the RSSI reading in the NL240 stays between –85 dBm and –15 dBm. A

weak, and thus intermittent, connection will have readings between –85 dBm

and –95 dBm. For every 3 dBm increase, the NL240 is receiving twice as

much signal (radiated power). For every 3 dBm lost, the NL240 is receiving

50% less signal.

To improve your RSSI readings, shorten antenna cable lengths and use

frequency matched antennas with higher gain. An NL240 with a 0 db gain

antenna can achieve ranges of up to 32 meters (120 feet) indoors and 95 meters

(300 feet) outdoors. Ranges can be improved by installing higher gain

antennas on both the NL240 and/or the wireless access point. Remember that

RSSI can also be affected by weather, vegetation, terrain, interference, and

antenna cable length and type.

6.4 Antennas

Antenna selection and placement can greatly affect the strength of the signal

you transmit and receive and therefore can impact the quality of

communications with your device. The NL240 should be paired with an

antenna designed for Wi-Fi communications at 2.4 GHz (2.401 to 2.483 GHz).

Ideally the antenna will be connected directly to the NL240 or positioned in

such a way as to minimize coaxial cable length. Note that coaxial cables

attenuate signals more as frequency increases; care should be taken when

selecting the type and length of coaxial cable used with the NL240. The

NL240 antenna connector is RPSMA male. When connecting directly to the

NL240, select a coaxial cable or antenna with a mating RPSMA female

connector.

6.5 Power

6.6 LEDs

One advantage of using the NL240 in your application is its low power

consumption capabilities. With careful planning, you can reduce your station’s

power needs while still meeting your critical communication needs. See

Section 5, Specifications (Power Consumption), and Appendix C.2, Wi-Fi Tab,

for more details.

There are two LEDs on the NL240 that serve as indicators as described below.

Normal Operation

After power-up, the red LED stays solid while the NL240 is searching for and

trying to join a Wi-Fi network (or while creating an ad hoc network).

After joining the network (or failing to join the network) the red LED will

indicate the power mode of the NL240. A double strobe indicates that the

NL240 is in low-power mode. If the red LED stays solid, low-power mode is

not enabled. If the NL240 is in Bridge Mode and the datalogger executes the

IPNetPower instruction, the NL240 will power down and the red LED will

single strobe approximately every four seconds.

12

Page 23

After the NL240 has joined a network, the green LED will flash with network

NOTE

activity. If the NL240 is configured for DHCP, the green LED will blink once

a second while it is attempting to acquire a network address from DHCP.

Operating System Upgrade

When a new operating system is sent to the NL240, the red LED will blink

repeatedly while the NL240 copies the operating system into its internal flash.

This process takes about 10 seconds. While the LED is blinking, the NL240 is

in a vulnerable state where a removal of power will leave the NL240 without a

valid operating system. Do not remove power until the LED stops blinking.

If an operating system upgrade includes an upgrade to the internal Wi-Fi

module’s firmware, after the typical re-flashing and blinking of the red LED,

the device will power up and start copying the new firmware to the Wi-Fi

module. The red LED will also blink during this process. It will start out as a

slow blink and get faster and faster as the process nears completion. This

process can take around 1.5 minutes. Again, do not remove power until the

LED stops blinking.

7. Configuring the NL240

NL240 Wireless Network Link Interface

The NL240 is configured using DevConfig version 2.03 or greater. You can

connect your NL240 to DevConfig using either a Wi-Fi connection or USB.

7.1 Configuring the NL240 with DevConfig via USB

INSTALL the DEVICE DRIVER BEFORE plugging the NL240

into your PC for the first time. You will need the device driver

properly installed before you can connect to the NL240 via USB.

To install the device driver, download the latest version of

DevConfig from our website. Under Device Type, select Network

Peripheral | NL240. Click the Install the device driver for the

NL240 link and follow the prompts.

• Ensure the NL240 is powered.

• Connect the supplied USB cable between a USB port on your computer

and the USB port on the NL240.

• Open DevConfig.

• Under Device Type, select Network Peripheral | NL240.

• Click the Browse button next to Communication Port.

• Select the port labeled NL240.

• Click OK.

• Click Connect.

• Configure the NL240 as needed for your application.

• Click Apply to save your changes.

13

Page 24

NL240 Wireless Network Link Interface

NOTE

NOTE

7.2 Configuring the NL240 with DevConfig via Wi-Fi WLAN

The NL240 is configured by default to join the strongest, open WiFi network it finds. If there is no open network in the area or if the

NL240 has not been previously configured to join an existing WiFi network, it is not possible to configure the NL240 via Wi-Fi.

• Apply power to the NL240.

• The NL240 will power up and join the strongest, open Wi-Fi network it

finds or the Wi-Fi network it has already been configured to join. The

green LED on the NL240 will come on and start blinking once it has

joined the network. Once it has successfully obtained an IP address, it will

stop blinking and flicker with network activity.

• Launch DevConfig.

• Under Device Type, select Network Peripheral | NL240.

• Check the box labeled Use IP Connection.

• Enter the IP address of the device in the Communication Port field. (If

you do not know the address of the device and the device is connected to

your local area network, you may be able to use the browse button to the

right of Communication Port to discover the devices on the network.)

The IP address must be followed by :6786 (i.e., 192.168.10.55:6786) in

order to connect the device configuration service.

• Enter nl240 in the TCP Password box. (nl240 is the default administrative

password. It can be changed via the DevConfig Deployment/NL240 tab.)

• Click OK.

• Click Connect.

• Configure the NL240 as needed for your application.

• Click Apply to save your changes.

7.3 Configuring the NL240 with Telnet via Wi-Fi WLAN

The NL240 must have an IP address before connecting via Telnet.

Configuration via Telnet is not available in bridge mode.

• Ensure the NL240 is powered and connected to your network.

14

• Create a Telnet session with the device over port 23.

• Input the NL240 Admin Password (default password is nl240).

• Type help to see a list of the functionality available when connected to the

NL240 through Telnet.

Page 25

NL240 Wireless Network Link Interface

NOTE

• Type edit and press Enter to edit the settings of the NL240.

• As each NL240 setting is shown, press Enter to accept the current value

shown in parenthesis. Type a new value and press Enter to change the

value.

• After progressing through all of the NL240 settings, type save to accept

the changes or cancel to discard the changes.

• Type bye to exit Telnet.

7.4 Configuring the NL240 via RS-232

Accessing the configuration terminal menu via RS-232 requires

the NL240 to be power cycled, so physical access to the device

will be required. A null modem serial cable will be needed; one

is not provided with the NL240.

• Using a null modem serial cable, connect your computer’s serial port to

the port labeled “RS-232” on the NL240.

8. Operation

• Connect to the NL240 using a terminal emulator. DevConfig’s “unknown”

device type or HyperTerminal are examples of simple terminal emulators.

The default settings for this interface are 115200 baud, 8 stop bits, no

parity, 1 stop bit, no flow control.

• Power cycle the NL240 and repeatedly press Enter at the terminal.

• Type help to see a list of the functionality available when connected to the

NL240 through Telnet.

• Type edit and press Enter to edit the settings of the NL240.

• As each NL240 setting is shown, press Enter to accept the current value

shown in parenthesis. Type a new value and press Enter to change the

value.

• After progressing through all of the NL240 settings, type save to accept

the changes or cancel to discard the changes.

• Disconnect your computer and power cycle the NL240.

This section describes how to configure the Wi-Fi connection and operational

mode of your NL240. See Section 6, Wi-Fi, for more information about the

types of Wi-Fi connections available. See Section 4, Overview, for help in

determining which operational mode to use.

15

Page 26

NL240 Wireless Network Link Interface

NOTE

NOTE

8.1 Wi-Fi Connection

8.1.1 Join an Existing Network

In this configuration, the device will scan for available networks and attempt to

join the network (infrastructure or ad hoc) specified by the SSID setting.

• Connect to the NL240 in DevConfig (see Section 7, Configuring the

NL240).

• Click on the Wi-Fi tab.

• Set Configuration to Join an Existing Network.

• Press the Browse button next to the SSID field to see a list of the available

networks in the area. Select the network you wish to connect to and click

OK. If the SSID field is left blank, the device will attempt to join the

strongest unsecured network it finds.

• If this is a secured network, enter the password in the Password field.

• Under Advanced, set the TX Power Level and Lower Power mode.

(Note that these settings can often be left at their default values. See

Section 6.5, Power.)

• Click Apply to save your changes.

If for some reason the device cannot join the desired network (for

example, out of range or incorrect parameters), it will go to a lowpower state and periodically retry to join the network

approximately once every minute. If the device has successfully

joined a network and then detects a loss of connectivity with the

network, it will begin periodically searching for the network at

approximately the one-minute interval.

8.1.2 Create an Ad hoc Network

In this configuration, the device will be the creator of an ad hoc network. An

ad hoc network created by the module supports up to 4 joinees.

Please remember when joining an ad hoc network with Windows

or iOS, it can take some time to successfully join the network.

• Connect to the NL240 in DevConfig (see Section 7, Configuring the

NL240).

• Click on the Wi-Fi tab.

• Depending on whether or not you want your Ad hoc network to be

encrypted, set Configuration to Create an Open Ad hoc Network or

Create an Ad hoc Network with WEP Security.

16

Page 27

• If you have chosen WEP Security, enter the WEP key to be used for the

network in the Password field. (See Appendix C for details on the WEP

key requirements.)

• Select the Channel to be used for the network. (The Suggest Channel

button can be used to have the NL240 scan the networks for the channel

that is least likely to encounter interference from other networks.)

• Select the TX Power Level, Low Power Mode, Low Power Interval,

and Low Power On Time. (Note that these settings can often be left at

their default settings. See Section 6.5, Power.)

• Click Apply to save your changes.

8.2 Operational Mode

8.2.1 PakBus® Router

When the RS-232 or CS I/O port is configured as a PakBus® router, the

NL240 can route packets to other devices in the network that it has in its

routing table. These are devices that the NL240 has learned about through

beaconing or allowed-neighbor lists.

NL240 Wireless Network Link Interface

Beacon Interval – Devices in a PakBus® network may broadcast a hellomessage to other devices in order to determine “neighbor” devices. Neighbor

devices are devices that can be communicated with directly by the current

device without being routed through an intermediate device. A beacon in a

PakBus network helps to ensure that all devices in the network are aware of

which other devices are viable in the network. The beacon interval determines

how often a beacon will be sent out. Set the beacon interval to 0 to disable

beacons.

Verify Interval – This interval, in seconds, determines the rate at which the

NL240 will attempt to start a hello transaction with a neighbor if no other

communication has taken place within the interval. If Verify Interval is set to

0, the verify interval becomes 2.5 times the Beacon Interval. If both the

Beacon Interval and Verify Interval are set to 0, the verify interval becomes

300 seconds. Generally, the Verify Interval should be set greater than or equal

to the interval at which you will be talking to the attached PakBus devices. For

example, if you are using the NL240 as a PakBus router to allow scheduled

collection of a network of dataloggers every 15 minutes, consider setting the

Verify Interval to 30 minutes.

PakBus Neighbors Allowed – You can set a list of “acceptable neighbors”

which the NL240 expects to hear from within set intervals (the Verify

Interval). If the NL240 does not hear from neighbors in this list within the

Verify Interval, it will attempt to contact them on its own. It will ignore all

devices it hears that are not on the PakBus Neighbors Allowed list except if the

PakBus® address is ≥4000. Hellos from devices with PakBus address ≥4000

are automatically accepted as neighbors.

8.2.1.1 Physical Setup

Using the supplied serial cable, connect the NL240 CS I/O port or RS-232 port

to the datalogger CS I/O or RS-232 port, respectively. The NL240 will be

powered if connected via CS I/O. Alternatively, power the NL240 through the

17

Page 28

NL240 Wireless Network Link Interface

barrel-connector jack located on the edge of the device. Connect the NL240 to

your local wireless network by attaching an antenna to the NL240 antenna

connector. Ensure that the device is powered up by inspecting the Power LED.

8.2.1.2 Configuring the NL240

RS-232 PakBus® Router

• Connect to the NL240 in DevConfig (see Section 7, Configuring the

NL240).

• On the NL240 tab:

o Set Bridge Mode to disable.

• On the RS-232 tab:

o Set Configuration to PakBus.

o Set Baud Rate to baud rate of attached device.

o Set Beacon Interval, Verify Interval, and PakBus Neighbors

Allowed as described above. Often the default values can be used.

However, an allowed neighbors list can be useful in restricting

communication paths.

• On the Network Services tab:

o Make note of the PakBus\TCP Server Port. (The default

PakBus/TCP Server Port is 6785. Unless firewall issues exist, it is

not necessary to change the port from its default value.)

CS I/O PakBus® Router

• Connect to the NL240 in DevConfig (see Section 7, Configuring the

NL240).

• On the NL240 tab:

o Set Bridge Mode to disable.

• On the CS I/O tab:

o Set Configuration to PakBus.

o Set SDC address. (Note that if multiple peripherals are connected to

a datalogger’s CS I/O port, each must have a unique SDC address.)

o Set Beacon Interval and Verify Interval as described above. Often

the default values can be used.

18

Page 29

• On the Network Services tab:

8.2.1.3 LoggerNet Setup

• In the LoggerNet Setup screen, press Add Root and choose IPPort. Input

• Add a PakBus® Port (PakBusPort).

• Add a PakBus® Router (pbRouter). Input the PakBus address of the

• Add the datalogger and input the PakBus® address of the datalogger.

• Press Apply to save the changes.

NL240 Wireless Network Link Interface

o Make note of the PakBus\TCP Server Port. (The default

PakBus/TCP Server Port is 6785. Unless firewall issues exist, it is

not necessary to change the port from its default value.)

the NL240’s IP address and port number. The IP address and port number

are input on the same line separated by a colon.

NL240. The NL240 default PakBus address is 678.

FIGURE 8-1. PakBus® router LoggerNet setup

19

Page 30

NL240 Wireless Network Link Interface

NOTE

8.2.1.4 Connect

You are now ready to connect to your datalogger using the LoggerNet Connect

screen.

8.2.2 Bridge Mode

With Bridge Mode Enabled, the device will act as a bridge from WLAN to CS

I/O. All IP packets that come into the device via WLAN will be

communicated as a complete Ethernet/TCP packet to the datalogger over the

CS I/O port. This enables the datalogger to use its TCP/IP stack to interpret the

packet and, therefore, all of the datalogger’s TCP services are available. In

bridge mode, none of the other device settings are valid and all other

functionality is disabled. All settings (that is, IP, netmask, gateway) are

configured in the datalogger. However, in bridge mode, the device will

intercept any TCP traffic on the TCP Configuration Port Number. This

allows the device to still be configured remotely by IP connection using

DevConfig. The TCP Configuration Port Number is a user setting with a

default value of 6786.

8.2.2.1 Physical Setup

Attach an antenna to the NL240 antenna connector. Using the supplied serial

cable, connect the NL240 CS I/O port to the datalogger CS I/O port. Ensure

that the device is powered up by inspecting the Power LED.

8.2.2.2 Configuring the NL240

Connect to the NL240 in DevConfig (see Section 7, Configuring the NL240). In

the NL240 tab, set Bridge Mode to enable.

In bridge mode, the IP address, subnet mask, and IP gateway to be

used by the NL240 are configured in the datalogger.

8.2.2.3 Configuring the Datalogger

• Connect a serial cable from the PC COM port to the datalogger’s RS-232

port.

• Open DevConfig. Select the device type of the datalogger (CR800,

CR1000, or CR3000), the appropriate Communication Port, and the

Baud Rate. Press Connect to connect to the datalogger.

• If using a static IP address, select the CS I/O IP tab and input the IP

address, subnet mask, and IP gateway for the correct CS I/O Interface.

The default for the NL240 is CS I/O IP Interface #2 (SDC1). DNS

server settings are shared by all active IP interfaces and can be entered on

the TCP/IP tab. These values can be provided by your network

administrator. If using DHCP, leave the CS I/O IP address settings as

0.0.0.0. You will find the information acquired by DHCP in the TCP/IP

info box on the TCP/IP tab.

20

• Press Apply to save the changes and then close DevConfig.

Page 31

The NL240 must be connected to the datalogger before

NOTES

configuring the datalogger with DevConfig. If it is not connected,

the TCP/IP settings will not be displayed.

By default, the NL240 uses the datalogger’s CS I/O Interface #2.

If connecting more than one NL240 to a datalogger, one NL240

can be configured to use CS I/O Interface #1. This is done by

connecting to the NL240 in DevConfig, going to the Settings

Editor tab, and changing the CS I/O IP Interface Identifier from 2

to 1. If this setting is changed, the IP address, Subnet Mask, and

IP gateway should be input under CS I/O Interface #1 on the

datalogger’s CS I/O IP tab. CS I/O Interface #2 communicates

over SDC address 1. CS I/O Interface #1 communicates over SDC

address 3.

8.2.2.4 LoggerNet Setup

The next step is to run LoggerNet and configure it to connect to the datalogger

via the Wi-Fi port. (See example in FIGURE 8-2 below.)

• In the LoggerNet Setup screen, press Add Root and choose IPPort. Input

NL240 Wireless Network Link Interface

the datalogger’s IP address and port number. The IP address and port

number are input on the same line separated by a colon. (The datalogger’s

default port number is 6785. It can be changed using DevConfig. Unless

firewall issues exist, the port number does not need to be changed from its

default value.)

• Add a PakBus® Port.

• Add the datalogger (CR800, CR1000, or CR3000) and input the PakBus®

address of the datalogger.

• You can verify that your settings are correct by selecting the datalogger in

the Network Map, selecting the Clock tab, and pressing Check Clocks. If

your settings are correct, you should see the current clock of your server

and datalogger.

21

Page 32

NL240 Wireless Network Link Interface

FIGURE 8-2. Bridge mode LoggerNet setup

8.2.2.5 Connect

You are now ready to connect to your datalogger using the LoggerNet Connect

screen.

8.2.3 TCP Serial Server

The NL240 can tunnel RS-232 and CS I/O serial communications over Wi-Fi.

Any packet sent to the configured IP port will have the IP layer removed, and

the data is then directed to the serial connection.

8.2.3.1 Physical Setup

Using the supplied serial cable, connect the NL240 CS I/O port or RS-232 port

to the datalogger CS I/O or RS-232 port, respectively. The NL240 will be

powered if connected via CS I/O. Alternatively, power the NL240 through the

barrel-connector jack located on the edge of the device. Connect the NL240 to

your local wireless network by attaching an antenna to the NL240 WLAN

connector. Ensure that the device is powered up by inspecting the Power LED.

8.2.3.2 Configuring the NL240

RS-232 Serial Server

22

• Connect to the NL240 in DevConfig (see Section 7, Configuring the

NL240).

Page 33

NL240 Wireless Network Link Interface

• On the NL240 tab:

o Set Bridge Mode to disable.

• On the RS-232 tab:

o Set Configuration to TCP Serial Server.

o Set Baud Rate to baud rate of attached device.

o Make note of the Service Port. (The default RS-232 Service Port is

6784. Typically, it is not necessary to change this entry from its

default.)

CS I/O Serial Server

• Connect to the NL240 in DevConfig (see Section 7, Configuring the

NL240).

• On the NL240 tab:

o Set Bridge Mode to disable.

• On the CS I/O tab:

8.2.3.3 LoggerNet Setup

The next step is to run LoggerNet and configure it to connect to the datalogger

via the Wi-Fi port. (See example in FIGURE 8-3 below.)

• In the LoggerNet Setup screen, press Add Root and choose IPPort. Input

• Add a PakBus® Port.

• Add the datalogger and input the PakBus® address of the datalogger.

• Press Apply to save the changes.

o Set Configuration to TCP Serial Server.

o Set SDC address. (Note that if multiple peripherals are connected to

a datalogger’s CS I/O port, each must have a unique SDC address.)

o Make note of the Service Port. (The default CS I/O Service Port is

6783. Typically, it is not necessary to change this entry from its

default.)

the NL240’s IP address and port number. The IP address and port number

are input on the same line separated by a colon.

• You can verify your settings are correct by selecting the datalogger in the

Network Map, selecting the Clock tab, and pressing Check Clocks. If

your settings are correct, you should see the current clock of your server

and datalogger.

23

Page 34

NL240 Wireless Network Link Interface

FIGURE 8-3. CS I/O Serial Server LoggerNet Setup

8.2.3.4 Connect

You are now ready to connect to your datalogger using the LoggerNet Connect

screen.

8.2.3.5 Serial Sensors

The NL240 configured as an RS-232 serial server as described above can be

used to communicate with a serial sensor. However, LoggerNet is not capable

of communicating with the serial sensor. You must have some other method of

communicating with the sensor.

8.2.4 TCP Serial Client

When the RS-232 port is configured as TCP Serial Client, the NL240 will

initiate and maintain a TCP socket connection to the IP address and port

number specified by the Serial Client Address and Serial Client Port

settings. Data received on the RS-232 port will be forwarded to this TCP

connection, and data received on the TCP connection will be forwarded to the

RS-232 port. This mode can be particularly useful when an RF base or serial

sensor is behind a firewall and needs to be the party responsible for initiating

the TCP socket connection to the data collection server.

The NL240 will attempt to open a connection with the remote server, and, if

the connection fails to open, the device will continue to retry at an interval of

60 seconds. If data arrives on the RS-232 port when no TCP connection exists,

the device will buffer the data (up to 1500 bytes) and immediately attempt to

open a connection to deliver the data. If the remote server closes the

connection due to error, the NL240 will make a best effort to save any data that

was in process and re-queue it to be sent on the next successfully-opened TCP

connection.

24

Page 35

8.2.5 Modbus TCP/IP to RTU Gateway

The NL240 can serve as a Modbus TCP/IP to RTU Gateway. It will listen for

incoming Modbus TCP/IP connections from a Modbus TCP/IP master client.

The port number of the listening connection is specified in the RS-232 Service

Port Number setting and is typically set to a value of 502. The NL240 will

convert incoming Modbus TCP/IP frames to Modbus RTU and forward them

to the RS-232 port. The NL240 will wait for a response from the Modbus RTU

device and forward that response back to the remote Modbus TCP/IP master

client over the established TCP connection. The Modbus RTU device is

generally a datalogger, such as a CR200(X), connected to the RS-232 port or a

datalogger located remotely over a transparent radio (for example, RF450)

connection, but can be any Modbus RTU device. When the NL240 is

connected directly to a CR800 series, CR1000, or CR3000 being polled by a

Modbus TCP/IP master client, the NL240 is most commonly configured with

Bridge Mode enabled instead of as a Modbus TCP/IP to RTU Gateway.

8.2.6 TLS

The NL240 supports transport layer security (TLS) for proxy functions

including HTTPS. TLS versions 1.0 and 1.1. are supported. The TLS

implementation supports symmetric algorithms AES-256, AES-128, and RC4

and RSA keys up to 4096 bits. For any TLS connection, the unit will

preferentially use AES-256, then AES-128, and finally RC4. X.509 certificates

are supported, with the exception of v3 extensions. Certificates should be PEM

format. Up to 10 certificates can be chained. 10 kB of space is provided for

certificate storage. The Private Key should also be in PEM format and, if

encrypted, use AES-256 or AES-128 (SHA).

NL240 Wireless Network Link Interface

The implementation of TLS in the NL240 is provided so that secure, encrypted

communications can be established between a TLS client and the NL240.

With the TLS Proxy Server enabled, the NL240 can act as a TLS proxy server

for a datalogger. The NL240’s TLS Proxy Server maintains a secure TLS

connection with a remote TLS client and forwards data onto a datalogger using

a standard TCP connection thus enabling communication with TLS clients.

The TLS client can be a web browser using HTTPS or other user-supplied TLS

client. This offloads from the datalogger the intensive computations that are

necessary for a TLS server to perform.

Also, with the NL240 configured for TLS, it can establish a secure TLS

configuration session with DevConfig.

In order to use TLS, the user must configure the NL240 with a user-supplied

TLS Private Key and TLS Certificate. The key and certificate are loaded using

DevConfig.

Using DevConfig, navigate to the Settings Editor tab and then to the TLS tab.

• Load the user-supplied, PEM-formatted TLS Private key using the Set

TLS Key … button. A file dialog will open. Navigate to the key file

and click Open.

• Load the user-supplied, PEM-formatted TLS Certificate using the Set

TLS Certificate … button. A file dialog will open. Navigate to the

certificate file and click Open.

25

Page 36

NL240 Wireless Network Link Interface

NOTE

NOTE

• Enter the TLS Private Key Password if the TLS Private Key is

• After loading the key and certificate, click the Apply button. The

The TLS Settings described above cannot be edited over a

standard TCP DevConfig link. The TLS Private Key, TLS Private

Key Password and TLS Certificate can only be edited/transmitted

over a secure DevConfig link (USB or TLS).

If the status of the TLS stack is Initialized, the NL240 will

automatically negotiate a secure TLS connection with DevConfig

as long as the Use IP Connection option is selected.

8.2.6.1 TLS Proxy Server

A TLS proxy server is a device that acts as a secure intermediary for requests

from clients seeking resources from other servers. A client connects to the

proxy server, requesting some service, such as a file, connection, web page, or

other resource, available from a different server. The proxy server evaluates

the request according to its filtering rules. For example, it may filter traffic by

IP address or protocol. If the request is validated by the filter, the proxy

provides the resource by connecting to the relevant server and requesting the

service on behalf of the client.

encrypted. Otherwise, leave the setting blank.

NL240 will reboot. Connect with DevConfig again and navigate to

the Settings Editor tab and then to the TLS tab. The TLS Status

should say Initialized.

When the TLS Proxy Server function is enabled, the NL240’s TLS Proxy

Server maintains a secure TLS connection with a remote TLS client and

forwards data onto a datalogger using a standard TCP connection thus enabling

communication with TLS clients. The TLS client can be a web browser using

HTTPS or other user-supplied TLS client. Any other client program that

encrypts a standard TCP connection using TLS may be used to establish a

connection with the NL240 TLS Proxy Server and the NL240 will forward

unencrypted TCP data to a datalogger. In this way, a remote TLS client can

establish a TLS connection with a datalogger.

The settings found in the TLS Proxy Server and TLS tab in DevConfig are used

to configure the NL240 TLS Proxy Server.

Two physical configurations are possible and the required settings differ

depending on the configuration chosen. The possible configurations are shown

in the following figure.

26

Page 37

NL240 Wireless Network Link Interface

FIGURE 8-4. TLS proxy server configurations

Configuration A

In Configuration A, the NL240 decrypts TLS traffic and forwards the

unencrypted TCP traffic to the datalogger over the CS I/O port. The NL240 is

able to “learn” the IP address of the attached datalogger and will open a TCP

connection on the “learned” IP address.

Configuration B

In Configuration B, the NL240 decrypts TLS traffic and forwards the

unencrypted TCP traffic to the datalogger back out on the Wi-Fi port. The user

must specify an IP address and TCP port number for the forwarding TCP

connection.

To configure the NL240 TLS Proxy Server to communicate with a datalogger

attached to the CS I/O port or with a datalogger over an Wi-Fi connection,

open DevConfig and configure the following settings.

Settings Editor | TLS Proxy Server Tab

• Set the TLS Proxy Server setting to enable.

• Set the TLS Proxy Server Port Number. This is the TCP port number

on which the proxy server will listen for incoming connections. The TLS

Client also needs to be set to communicate on this port number. When

TLS communications are received on this port number, the NL240 will

decrypt the data and attempt to open a TCP connection to the datalogger

and forward the unencrypted data. In HTTPS communications, web

browsers use port 443. The NL240 will always listen on port 443

regardless of the value of this setting. Therefore, if HTTPS

communications are desired, it is unnecessary to configure this setting.

• Set the TLS Proxy Forward Physical Port to CS I/O Port for

Configuration A or to Wi-Fi for Configuration B.

27

Page 38

NL240 Wireless Network Link Interface

• For Configuration A, leave the TLS Proxy Forward IP Address set to

0.0.0.0. For Configuration B, enter the datalogger’s IP address in the TLS

Proxy Forward IP Address setting. This address must be configured in

the datalogger. It must be a unique, static IP address on the same subnet as

the NL240 IP address. For example, if the NL240 IP address is

192.168.5.1 with subnet 255.255.255.0, a valid IP address for the

datalogger would be 192.168.5.2 provided there are no other devices on

the subnet with that address.

• Set the TLS Proxy Forward Port Number. This is the TCP port number

that the proxy server will use when it opens a TCP connection to the

datalogger to forward unencrypted data. The datalogger’s TCP server port

must be set to communicate on this port number. The default value for the

datalogger’s PakBus/TCP server is 6785, so this setting can likely be left

at the default. The datalogger listens for HTTP traffic on port 80. The

NL240 will always forward TLS traffic received on port 443(HTTPS) to

port 80(HTTP) regardless of this setting. Therefore, if HTTPS

communications are desired, it is unnecessary to configure this setting.

• It is recommended to leave the TLS Proxy Timeout set to 90 seconds

although it can be changed if desired. This will determine how fast the

NL240 proxy server and client connections will timeout if no activity is

detected.

To configure the datalogger for Configuration A, connect to the datalogger

using DevConfig and select the CS I/O IP tab. Set the CS I/O Interface IP

Address to a static IP address. Use the datalogger’s CS I/O Interface that

corresponds to the NL240’s CS I/O IP Interface Identifier setting. To

configure the datalogger for Configuration B, connect to the datalogger using

DevConfig and select the TCP/IP tab. Set the Ethernet Interface IP Address

to a static IP address.

For either configuration, the IP address must not be 0.0.0.0, and it must be

unique on the same subnet as the NL240 IP address. For example, if the

NL240 IP address is 192.168.5.1 and Subnet Mask is 255.255.255.0, the

datalogger address could be set as 192.168.5.2 provided there are no other

devices on the subnet with that address. Also set the datalogger’s Subnet Mask

to match that of the NL240.

The datalogger must be listening on the same TCP port that the NL240 is

configured to forward TCP traffic on (NL240 setting: TLS Proxy Forward Port

Number). The datalogger always listens on port 80 for HTTP, therefore, no

TCP port configuration is necessary for using HTTP.

8.2.6.2 DevConfig TCP Encrypted Communication to the NL240

In order to use DevConfig TCP Encrypted Communication to the NL240, you

will need to load your TLS Private Key and TLS Certificate into the NL240.

This is done from the Settings Editor | TLS tab in DevConfig. Once the private

key and certificate are loaded successfully, the TLS Status field should read

Initialized.

28

To use TCP Encrypted Communication, select the Use IP Connection check

box in DevConfig. Input the NL240’s IP address (or press the browse button

to select it from a list of NL240s connected to the network) and press Connect.

Page 39

9. Applications

NOTES

9.1 Working Around Firewalls

NL240 Wireless Network Link Interface

If the status of the TLS stack is Initialized, the NL240 will

automatically negotiate a secure TLS connection with DevConfig

as long as the Use IP Connection option is selected.

Encrypted Communication is required to change the TLS Private

Key and/or TLS Certificate via TCP. The private key and

certificate cannot be initialized via TCP, since the connection is

not encrypted. They must be initialized through a direct USB

connection to the NL240.

When the NL240 is in bridge mode, it cannot be configured via a

secure network connection, because in bridge mode the TLS stack

is not initialized. It can be configured via USB, RS-232, or an

unsecured network connection.

The NL240 can be used to provide a connection between LoggerNet and a

datalogger when both are behind firewalls. The NL240 must be on a public IP

address and will act as a common meeting place for all PakBus®

communications.

FIGURE 9-1. Working around firewalls

9.1.1 Configuring the NL240

• Connect to the NL240 in DevConfig (see Section 7, Configuring the

• On the NL240 tab:

NL240).

o Set Bridge Mode to disable.

o Set Use DHCP to disable.

29

Page 40

NL240 Wireless Network Link Interface

NOTE

o Input the IP Address, Network Mask, and Default Gateway. These

• On the Network Services tab:

o Make note of the PakBus/TCP Server Port.

9.1.2 Configuring the Datalogger

The datalogger must first be configured for internet

communication (i.e., through an NL115, an NL120, a second

NL240, or a cellular modem).

• Connect a serial cable from the PC COM port to the datalogger’s RS-232

port.

• Open DevConfig. Select the device type of the datalogger (CR800,

CR1000, or CR3000), the appropriate Communication Port, and Baud

Rate. Press Connect to connect to the datalogger.

• On the Network Services tab:

values can be provided by your network administrator.

o Under PakBus TCP Client Connections, input the NL240’s IP

• Press Apply to save the changes and then close DevConfig.

10. Troubleshooting

This section covers some common problems that might be encountered when

using the NL240. This is not comprehensive but should provide some insight

and ability to correct simple errors without a call to Campbell Scientific

technical support.

When your Campbell Scientific software cannot establish a link to a remote

datalogger that is connected to the NL240, do the following:

1. Check all your power connections.

• Your NL240 and any wireless access point (WAP) and/or wireless

2. Check all your cables and antenna.

• Verify that your antenna is securely attached to the NL240 and

address and PakBus TCP Server Port.

router being used must be connected to power. Check power indicator

lights to make sure your devices are powered.

oriented in the same direction as the antenna of your WAP. The green

Link/Act light on the NL240 should start blinking when it is

connected to a WLAN or ad hoc network. Also, the WLAN activity

light on your WAP (if it has one) should be blinking with activity as

well.

30

Page 41

NL240 Wireless Network Link Interface

3. Power cycle the NL240 and your WAP/hub/router/PC.

• Turn off or unplug your WAP/hub/router/PC and NL240. Wait 10

seconds and then plug them back in or turn them on. A full restart

may take 30 to 60 seconds.

4. Check the settings of the NL240.

• Make sure you have entered the correct SSID and Key/Passphrase (if

needed) for your network.

• Make sure the NL240 is connected to the right WLAN (Wi-Fi Status

in DevConfig or show | Wi-Fi settings | Wi-Fi in a Telnet session).

• Make sure the Wireless Network you are connecting to has a RSSI

level of greater than (>) –90dBm (in DevConfig under the Settings

Editor tab | Wireless Networks in Area list).

• Make sure the assigned NL240 IP address (DHCP or static) and the IP

address of the PC you are trying to connect from are able to

communicate with each other. (Your network administrator can help

you with this.)

For example, the following addresses are able to communicate:

NL240: IP address: 192.168.0.2, Network Mask: 255.255.255.0

PC: IP address: 192.168.0.3, Network Mask: 255.255.255.0

• If you are using DHCP to assign an IP address to the NL240, use

DevConfig to read the IP address assigned to your NL240. This is

done through a USB connection to the NL240 while the NL240 is

connected to your network (if bridge mode is not being used).

• The IP address assigned to the NL240 must be unique on your

network.

• When Bridge Mode is enabled, the datalogger controls how the IP

address is assigned. Make sure your datalogger is connected correctly

to the NL240 via the CS I/O port and SC12 cable.

• Try to ping the NL240 from your PC. (From the Windows Start

Menu, choose Accessories | Command Prompt. Then type ping

xxx.xxx.xxx.xxx where xxx.xxx.xxx.xxx is the IP address of your

NL240.) If no packets are returned, this indicates that there is no

network connection to that IP address.