Page 1

INSTRUCTION MANUAL

NL115 Ethernet and

Copyright © 2006- 2014

Campbell Scientific, Inc.

CompactFlash® Module

Revision: 2/14

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 2

4. Quickstart .................................................................... 2

4.1 Physical Setup ...................................................................................... 2

4.2 Communicating via Ethernet ................................................................ 3

4.2.1 Step 1: Configure Datalogger ........................................................ 3

4.2.2 Step 2: LoggerNet Setup ............................................................... 4

4.2.3 Step 3: Connect ............................................................................. 5

4.3 Programming the Datalogger to Send Data to the NL115 .................... 5

4.4 CF Card Data Retrieval ........................................................................ 6

5. Overview ...................................................................... 6

5.1 Status LEDs .......................................................................................... 6

5.2 Power ................................................................................................... 7

5.3 CF Card Data Retention ....................................................................... 7

6. Specifications ............................................................. 7

7. Operation ..................................................................... 9

7.1 TCP/IP Functionality ........................................................................... 9

7.1.1 Communicating Over TCP/IP ....................................................... 9

7.1.1.1 Data Callback ..................................................................... 9

7.1.1.2 Datalogger-to-Datalogger Communication ...................... 10

7.1.2 HTTP Web Server ....................................................................... 11

7.1.3 FTP .............................................................................................. 12

7.1.3.1 FTP Server ....................................................................... 12

7.1.3.2 FTP Client ........................................................................ 14

7.1.4 Telnet .......................................................................................... 14

7.1.5 Ping ............................................................................................. 14

7.1.6 Serial Server ................................................................................ 14

7.1.6.1 Serial Input ....................................................................... 15

7.1.6.2 Serial Output .................................................................... 15

7.1.7 TCP ModBus .............................................................................. 15

7.1.8 DHCP .......................................................................................... 15

7.1.9 DNS ............................................................................................ 16

7.2 File Formats ....................................................................................... 16

7.2.1 Data Files .................................................................................... 16

7.2.2 Program Files .............................................................................. 16

7.2.3 Power-up Files (Powerup.ini) ..................................................... 16

7.2.3.1 Creating and Editing Powerup.ini .................................... 17

i

Page 6

Table of Contents

7.2.3.2 Applications ..................................................................... 18

7.2.3.3 Program Execution .......................................................... 19

7.2.3.4 Example Powerup.ini Files .............................................. 19

7.2.4 Camera Files ............................................................................... 20

7.3 Programming ..................................................................................... 20

7.3.1 The CardOut() Instruction .......................................................... 20

7.3.2 Program Examples ..................................................................... 20

7.3.2.1 Ring Mode ....................................................................... 20

7.3.2.2 Fill-and-Stop Mode.......................................................... 21

7.3.2.3 Mixed Modes ................................................................... 21

7.3.3 Table Size and Mode .................................................................. 22

7.4 CF Card Data-Retrieval Details ......................................................... 23

7.4.1 Via a Communication Link ........................................................ 23

7.4.1.1 Fast Storage/Data-Collection Constraints ........................ 23

7.4.2 Transporting CF Card to Computer ............................................ 23

7.4.2.1 Converting File Formats .................................................. 24

7.4.2.2 Reinserting the Card ........................................................ 25

7.4.2.3 Card Swapping ................................................................ 25

Appendix

CF Card Maintenance ............................................. A-1

A.

Figures

Table

A.1 Formatting CF Card ......................................................................... A-1

A.1.1 Windows Explorer .................................................................... A-1

A.1.2 CR1000KD ............................................................................... A-2

A.1.3 LoggerNet File Control ............................................................ A-2

A.2 Checking CF Card Integrity ............................................................ A-3

4-1. NL115 attached to a CR1000 .............................................................. 2

4-2. DevConfig setup .................................................................................. 3

4-3. LoggerNet setup .................................................................................. 4

6-1. NL115 Ethernet/CompactFlash Module .............................................. 8

7-1. Datalogger home page ....................................................................... 11

7-2. FTP root directory ............................................................................. 12

7-3. FTP CRD directory............................................................................ 13

7-4. CardConvert ...................................................................................... 24

7-1. Powerup.ini Commands .................................................................... 18

ii

Page 7

NL115 Ethernet and CompactFlash®

Module

1. Introduction

Campbell Scientific’s NL115 Ethernet/CompactFlash® Module provides two

independent capabilities: (1) it enables 10Base-T Ethernet communications

and (2) stores data on a removable CompactFlash (CF) card. It allows the

datalogger to communicate over a local network or a dedicated Internet

connection via TCP/IP. It also expands on-site data storage and provides the

user with a convenient method of transporting data from the field back to the

office. This small, rugged communication device connects to the 40-pin

peripheral port on a CR1000 or CR3000 datalogger.

This manual describes how to use LoggerNet to connect to your datalogger

with an NL115 attached. You can also use other software packages such as

PC400, RTDAQ, or LoggerLink Mobile Apps for iOS and Android.

Campbell Scientific recommends that only FMJ CF cards be used with the

NL115. For more information on CF cards, see Campbell Scientific’s

application note CF Card Information (3SM-F). Note that it is not necessary to

purchase the FMJ CF cards directly from Campbell Scientific as long as the

FMJ model number matches those shown in the application note.

Before using the NL115, please study:

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 4. Quickstart

The Quickstart section explains how to quickly begin using an NL115 for

straightforward Ethernet communications and data-storage operations. The

remainder of the manual is a technical reference which describes in detail such

operations as: TCP/IP functionality, file formats, datalogger programming, and

data retrieval.

2. Cautionary Statements

• The NL115 is rugged, but it should be handled as a precision scientific

instrument.

• The 28033 surge suppressor and/or a shielded 10Base-T Ethernet cable

should be used for locations susceptible to power surges and for cable

lengths longer than 9 ft.

• Always power down the datalogger before installing to or removing the

NL115 from the datalogger.

• The first time an NL115 is attached to a datalogger, the datalogger’s

memory has to be reorganized to allow room in memory for the IP stack.

To avoid the loss of data, collect your data before attaching the NL115 to a

datalogger.

1

Page 8

NL115 Ethernet and CompactFlash® Module

CAUTION

NOTE

• An NL115 with a serial number less than 10297 requires a firmware

update to function properly when attached to a CR3000 datalogger with a

serial number greater than 6260. This update must be performed by

Campbell Scientific. If you require this firmware update, see the

Assistance section at the front of this manual for information on returning

your NL115 to Campbell Scientific.

3. Initial Inspection

Upon receipt of the NL115, inspect the packaging and contents for damage.

File damage claims with the shipping company.

4. Quickstart

This section describes the basics of communicating via Ethernet and storing

and retrieving datalogger data. These operations are discussed in detail in

Section 7, Operation.

4.1 Physical Setup

Always power down the datalogger before installing to or

removing the NL115 from the datalogger.

After powering down the datalogger, plug the NL115 into the datalogger

peripheral port (see FIGURE 4-1). Attach Ethernet cable to the 10Base-T port.

If using the 28033 surge protector, connect the other end of the Ethernet cable

to the 28033 and connect another Ethernet cable to the other end of the 28033.

Restore power to the datalogger. Insert formatted CF card. (For instructions

on formatting a CF card, see Appendix A, CF Card Maintenance.)

A CF card does not need to be present in order to use the NL115’s

TCP/IP functionality.

FIGURE 4-1. NL115 attached to a CR1000

2

Page 9

4.2 Communicating via Ethernet

NOTE

NOTE

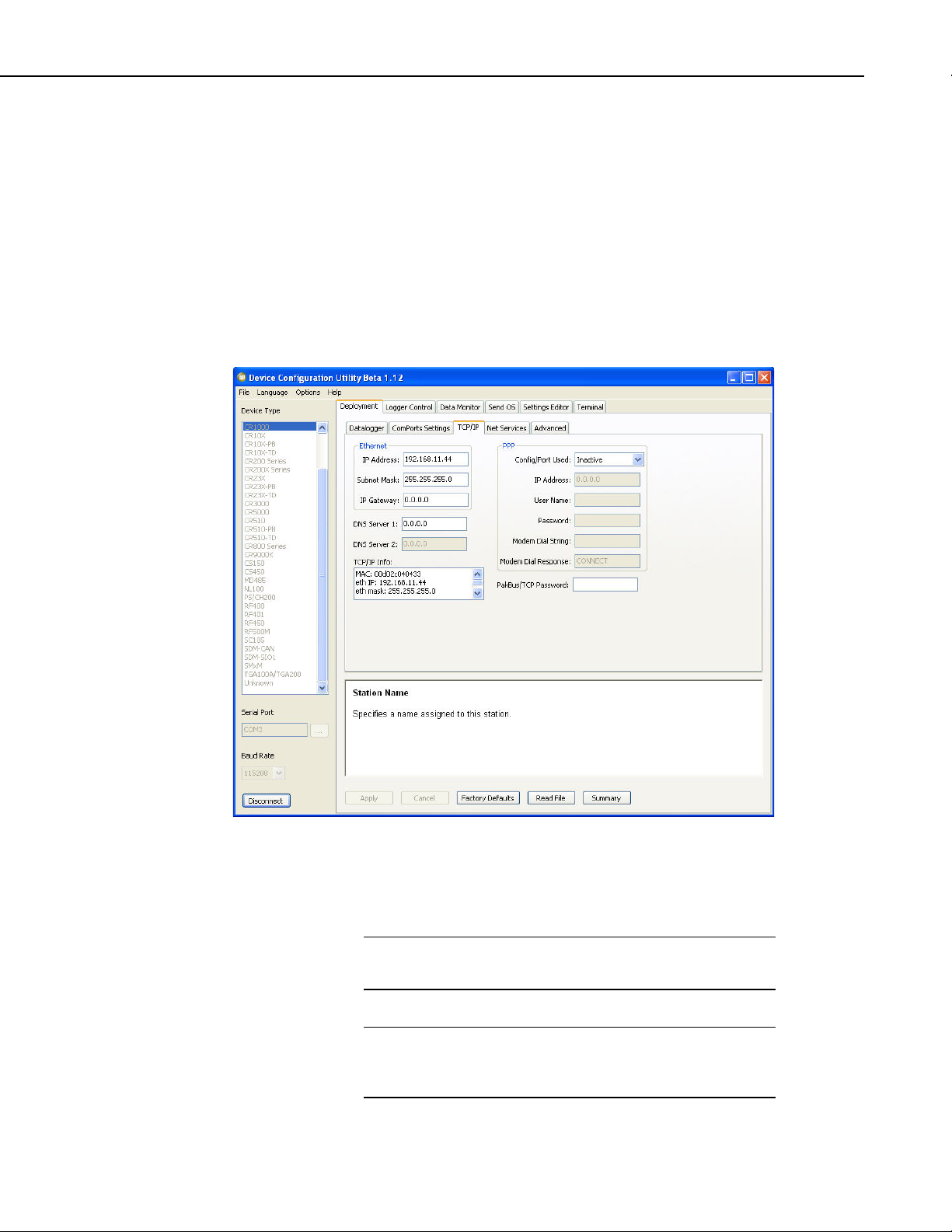

4.2.1 Step 1: Configure Datalogger

a. Connect serial cable from PC COM port to the datalogger RS-232 port.

b. Open Campbell Scientific’s Device Configuration Utility. Select the

device type of the datalogger (CR1000 or CR3000), the appropriate serial

port, and baud rate. Connect to the datalogger.

c. Under the TCP/IP tab, input the IP Address, Subnet Mask, and IP

gateway. These values should be provided by your network

administrator.

NL115 Ethernet and CompactFlash® Module

FIGURE 4-2. DevConfig setup

d. Press the Apply button to save the changes and then close the Device

Configuration Utility.

A temporary IP address may be obtained from a DHCP server.

For more information, see Section 7.1.8, DHCP.

The NL115 must be connected to the datalogger before

configuring the datalogger with the Device Configuration Utility.

If it is not connected, the TCP/IP settings will not be displayed.

3

Page 10

NL115 Ethernet and CompactFlash® Module

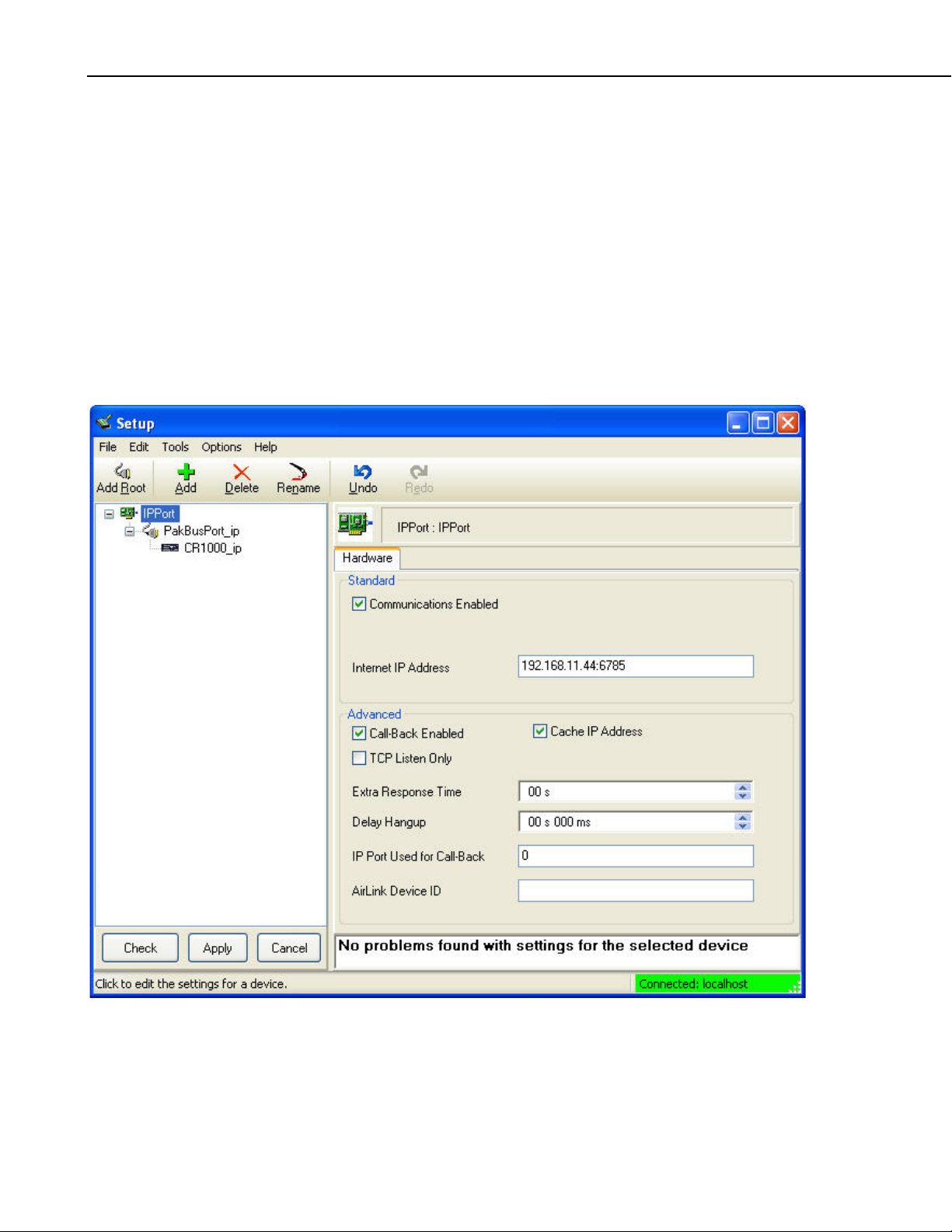

4.2.2 Step 2: LoggerNet Setup

The next step is to run LoggerNet and configure it to connect to the datalogger

via the Ethernet port.

a. In LoggerNet’s Setup Screen, press Add Root and choose IPPort. Input

the datalogger’s IP address and port number. The IP address and port

number are input on the same line separated by a colon. (The datalogger’s

default port number is 6785. It can be changed using Device

Configuration Utility or by modifying its value in the Status Table.)

b. Add a PakBus port and set the desired baud rate.

c. Add the datalogger (CR1000 or CR3000). Input the PakBus address of

the datalogger.

4

FIGURE 4-3. LoggerNet setup

Page 11

NL115 Ethernet and CompactFlash® Module

CAUTION

4.2.3 Step 3: Connect

You are now ready to connect to your datalogger using the LoggerNet Connect

Screen.

Datalogger program transfer, table-data display, and data collection are now

possible.

4.3 Programming the Datalogger to Send Data to the NL115

The CardOut() instruction is used in the datalogger program to send data to

the CF card. CardOut() must be entered within each DataTable declaration

that is to store data on the CF card. The file is saved on the card with the name

stationname.tablename and a .DAT extension.

The CardOut() instruction has the following parameters:

StopRing: A constant is entered for the StopRing parameter to specify whether

the DataTable created should be a ring-mode table (0) or a fill-and-stop table

(1).

Size: The Size parameter is the minimum number of records that will be

included in the DataTable. If –1000 is entered, the size of the file on the card

will be the same as the size of the internal table on the datalogger. If any other

negative number is entered, the memory that remains after creating any fixedsize tables on the card will be allocated to this table. If multiple DataTables are

set to a negative number, the remaining memory will be divided among them.

The datalogger attempts to size the tables so that they will be full at the same

time.

In the following example, the minimum batt_voltage and a sample of PTemp

are written to the card each time the data table is called. The StopRing

parameter is 0 for ring mode. This means that once the data table is full, new

data will begin overwriting old data. The size parameter is –1, so all available

space on the card will be allocated to the table.

DataTable(Table1,1,-1)

CardOut(0 ,-1)

Minimum(1,batt_volt,FP2,0,False)

Sample(1,PTemp,IEEE4)

EndTable

To prevent losing data, collect data from the CF card before

sending the datalogger a new or modified program. When

a program is sent to the datalogger using the Send button in

the Connect Screen of LoggerNet or PC400, an attribute is

sent along with the program that commands the datalogger

to erase all data on the CF card from the currently running

program.

5

Page 12

NL115 Ethernet and CompactFlash® Module

CAUTION

CAUTION

CAUTION

4.4 CF Card Data Retrieval

Data stored on cards can be retrieved through a communication link to the

datalogger or by removing the card and carrying it to a computer with a CF

adapter. With large files, transferring the CF card to a computer may be faster

than collecting the data over a communication link. CF card-data retrieval is

discussed in detail in Section 7.4, CF Card Data-Retrieval Details.

Removing a card while it is active can cause garbled data

and can actually damage the card. Always press the

Initiate Removal button and wait for a green light before

removing card.

LoggerNet’s File Control should not be used to retrieve data

from a CF card. Using File Control to retrieve the data can

result in a corrupted data file.

5. Overview

The NL115 Ethernet/CompactFlash Module enables 10Base-T Ethernet

communication with the datalogger. It also has a slot for a Type I or Type II

CompactFlash (CF) card (3.3 V, 75 mA).

The NL115/CF card combination can be used to expand the datalogger’s

memory, transport data/programs from the field site(s) to the office, upload

power-up functions, and store JPEG images from the CC640 camera. Data

stored on cards can be retrieved through a communications link to the

datalogger or by removing the card and carrying it to a computer. The

computer can read the CF card either with the CF1 adapter or 17752

reader/writer. The CF1 adapter allows the PC’s PCMCIA card slot to read the

CF card; the 17752 reader/writer allows the PC’s USB port to read the CF card.

User-supplied CF adapters may also be used.

LoggerNet’s File Control should not be used to retrieve data

from a CF card. Using File Control to retrieve the data can

result in a corrupted data file.

5.1 Status LEDs

There is one red-green-orange LED (light-emitting diode) and two buttons:

Initiate Removal and eject. The LED indicates the status of the module. The

LED will flash red when the CF card is being accessed, solid green when it is

OK to remove the card, solid orange to indicate an error, and flashing orange if

the card has been removed and has been out long enough that CPU memory

has wrapped and data is being overwritten without being stored to the card.

The Initiate Removal button must be pressed before removing a card to allow

the datalogger to store any buffered data to the card and then power off. The

eject button is used to eject the CF card. Note that if the eject button cannot be

pressed, it may have been disabled by bending it to the right. Straighten and

press the eject button to eject the CF card.

6

Page 13

5.2 Power

The Ethernet/CompactFlash module is powered by 12 Vdc received from the

datalogger through the peripheral port.

Additional power consumption occurs if the Status LED is continuously lit. At

12 Vdc, an additional 1 mA is drawn by the red or green LED; an additional

2 mA is drawn by the orange LED.

5.3 CF Card Data Retention

The module accepts CompactFlash (CF) cards which do not require power to

retain data.

Typically, a CF card can be erased and rewritten a minimum of 100,000 times.

Industrial CF cards, graded for 2,000,000 write cycles, are recommended for

most applications.

6. Specifications

Datalogger Compatibility: CR1000, CR3000

NL115 Ethernet and CompactFlash® Module

Storage Capacity: Depends on card size (up to 16 GB

supported; to use card size greater than 2

GB, the datalogger operating system must

be OS 25 or greater)

Power Requirements: 12 V supplied through datalogger’s

peripheral port

Current Drain: 19 mA (CR1000 with NL115 attached, no

Ethernet cable attached, not actively

communicating over Ethernet nor

accessing the CF card)

20 mA (CR1000 with NL115, Ethernet

cable attached)

20 mA (CR1000 with NL115

communicating over Ethernet)

43 mA (CR1000 with NL115

communicating over Ethernet and

accessing CF card)

2 mA (Ethernet port has been put to sleep

using the IPNET Power() CRBasic

instruction)

Add 1 mA to current drain if red or green

Status LED is continuously on.

Add 2 mA to current drain if orange Status

LED is continuously on.

Operating Temperature Range: –25° to +50°C Standard

–40° to +85°C Extended

7

Page 14

NL115 Ethernet and CompactFlash® Module

EMI and ESD Protection: Meets requirements for a class A device

Application of Council Directive(s):

Standards to which conformity is declared:

Cable Requirements: Use a straight-through Ethernet cable

Typical Access Speed: 200 to 400 kbits s

Memory Configuration: User-selectable for either ring style

under European Standards

89/336/EEC as amended by 89/336/EEC

and 93/68/EEC

EN55022-1; 1995 and EN50082-1: 1992

when the cable is run from the hub to the

NL115. Use a crossover Ethernet cable

when the cable is run directly from the

computer to the NL115. Use a shielded

cable and/or the 28033 surge suppressor

when the cable length is more than 9 ft.

–1

(default) or fill-and-stop.

Software Requirements: LoggerNet 3.2 or later

PC400 1.3 or later

Dimensions: 10.2 x 8.9 x 6.4 cm (4.0 x 3.5 x 2.5 in)

Weight: 154 g (5.4 oz)

8

FIGURE 6-1. NL115 Ethernet/CompactFlash Module

Page 15

7. Operation

7.1 TCP/IP Functionality

7.1.1 Communicating Over TCP/IP

NL115 Ethernet and CompactFlash® Module

This section describes the main TCP/IP functionality of a datalogger with an

NL115 attached. Additional functionality may be added in the future. For

more information, refer to the Information Services section of the datalogger

manual and CRBasic Editor Help.

Once the datalogger, the NL115, and LoggerNet have been set up as described

in Sections 4.1, Physical Set-up, and 4.2, Communicating via Ethernet,

communication is possible over TCP/IP. This includes program send and data

collection. These are straightforward operations and are accomplished through

LoggerNet’s Connect Screen. For more information, see the LoggerNet

manual.

Data callback and datalogger-to-datalogger communications are also possible

over TCP/IP, as well as the creation of simple HTML pages to view datalogger

variables using a web browser.

7.1.1.1 Data Callback

The following program is an example of doing data callback over TCP/IP. It

first checks to see if a port to the LoggerNet Server already exists. (The

LoggerNet Server is assumed to be at the default PakBus address, 4094.) If

not, a socket to LoggerNet is opened using the TCPOpen() instruction. The

SendVariables() instruction is then used to send data.

PROGRAM

' CR1000

' IP_Callback.cr1

' LoggerNet server Pak Bus Address assumed = 4094

' PC IP address assumed = 192.168.7.231

' LoggerNet IPPort "IP Port Used for Call-Back" = 6785

' LoggerNet IPPort "Call-Back Enabled" is checked

' LoggerNet CR1000 "Call-Back Enabled" is checked

' LoggerNet PakBusPort "PakBus Port Always Open" is checked

' IP Call-back using auto-discover (-1) neighbor in SendVariables

Public PanelTemperature, BatteryVoltage, Result1, dummy1

Dim Socket as LONG

DataTable (CLBK1,1,1000)

DataInterval (0,0,Sec,10)

Sample (1,PanelTemperature,FP2)

Sample (1,BatteryVoltage,FP2)

EndTable

BeginProg

Scan (5,Sec,6,0)

PanelTemp (PanelTemperature,250)

Battery (BatteryVoltage)

If not Route(4094) then Socket = TCPOpen ("192.168.7.231",6785,0)

9

Page 16

NL115 Ethernet and CompactFlash® Module

SendVariables (Result1,Socket,-1,4094,0000,100,"Public","Callback",dummy1,1)

CallTable CLBK1

NextScan

EndProg

7.1.1.2 Datalogger-to-Datalogger Communication

Communication between dataloggers is possible over TCP/IP. In order to do

this, a socket must be opened between the two dataloggers using the

TCPOpen() instruction. The socket opened by this instruction is used by the

instructions performing datalogger-to-datalogger communication.

The example program below gets the battery voltage from a remote datalogger

and sends its panel temperature to the remote datalogger. The remote

datalogger is at IP address 192.168.7.125 and port 6785 is used for

communication between the dataloggers. The remote datalogger must have its

battery voltage stored in a public variable, BattVolt. It must also have a Public

variable declared, PTemp_Base. This will be used to store the panel

temperature of the base datalogger.

PROGRAM

'CR1000

'DL-to-Dl_Comms_1.cr1

'Send this program to CR1000 #1

'Remote CR1000 #2 has PBA = 2, IP addr = 192.168.7.125, and port 6785

Public BattVolt,, BattVolt_Remote

Public PTemp

Public Result1, Result2

Dim Socket as LONG

DataTable (Test,1,-1)

DataInterval (0,12,Sec,10)

Minimum (1,BattVolt,FP2,0,False)

EndTable

BeginProg

Scan(2,Sec,0,0)

Socket = TCPOpen("192.168.7.125",6785,0)

BatteryVoltage(BattVolt)

PanelTemp(PTemp,250)

GetVariables (Result1,Socket,-1,2,0000,50,"Public","BattVolt",BattVolt_Remote,1)

SendVariables (Result2,Socket,-1,2,0000,50,"Public","PTemp",PTemp_Base,1)

CallTable(Test)

NextScan

EndProg

10

Page 17

7.1.2 HTTP Web Server

NOTE

Typing the datalogger’s IP address into a web browser will bring up its home

page, as shown in FIGURE 7-1. This default home page provides links to the

current record in all tables, including data tables, the Status table, and the

Public table. Clicking on a Newest Record link will bring up the latest record

for that table. It will be automatically refreshed every 10 seconds. Links are

also provided to the last 24 records in each data table. Clicking on a Last 24

Records link will bring up the last 24 records for that table. The Last 24

Records display must be manually refreshed. In addition, links are provided to

all HTML files, all XML files, and all JPEG files in the datalogger.

NL115 Ethernet and CompactFlash® Module

FIGURE 7-1. Datalogger home page

If there is a default.html file on the datalogger, this will automatically become

the user-configurable home page.

The WebPageBegin/WebPageEnd declarations and the HTTPOut()

instruction can be used in a datalogger program to create HTML or XML files

that can be viewed by the browser. For more information on using these

instructions, see the datalogger manual or CRBasic Editor Help.

FileOpen() and FileWrite() can be used to create HTML pages,

but this requires first writing the file to the datalogger’s USR

drive. It is less convenient, and the page will be only as current as

it is written to the file.

11

Page 18

NL115 Ethernet and CompactFlash® Module

7.1.3 FTP

7.1.3.1 FTP Server

With an NL115 attached, the datalogger will automatically run an FTP server.

This allows Windows Explorer to access the datalogger’s file system via FTP.

In the FTP world, the “drives” on the datalogger are mapped into directories

(or folders). The “root directory” on the datalogger will include CPU and

possibly USR and/or CRD. The files will be contained in one of these

directories. Files can be pasted to and copied from the datalogger “drives” as if

they were drives on the PC. Files on the datalogger drives can also be deleted

through FTP.

12

FIGURE 7-2. FTP root directory

Page 19

NL115 Ethernet and CompactFlash® Module

NOTE

FIGURE 7-3. FTP CRD directory

In order to use FTP, the datalogger’s FTP User Name and FTP Password must

be set. This is done using Device Configuration Utility.

Step 1: Configure Datalogger

a. Connect serial cable from PC COM port to datalogger RS-232 port.

b. Open Campbell Scientific’s Device Configuration Utility. Select the

device type of the datalogger (CR1000 or CR3000), the appropriate serial

port and baud rate. Connect to the datalogger.

e. Under the Net Services tab, verify that FTP Enabled is checked. Input the

FTP User Name and FTP Password.

f. Press the Apply button to save the changes and then close the Device

Configuration Utility.

Using “anonymous” as the user name with no password allows

FTP access without inputting a user name or password.

Step 2: Access File System

a. The datalogger must be set up for Ethernet communications as explained

in Sections 4.1, Physical Setup, and 4.2, Communicating via Ethernet

(Step 1 only).

13

Page 20

NL115 Ethernet and CompactFlash® Module

NOTE

b. Open a Windows Explorer window. Enter

ftp://username:password@nnn.nnn.nnn.nnn where nnn.nnn.nnn.nnn is

the IP address of the datalogger.

If the user name is “anonymous” with no password, enter

ftp://nnn.nnn.nnn.nnn where nnn.nnn.nnn.nnn is the IP address

of the datalogger.

7.1.3.2 FTP Client

The datalogger can also act as an FTP Client to send a file to or get a file from

an FTP Server (for example, another datalogger or web camera). This is done

using the FTPClient() instruction. The following program is an example of

using FTPClient() to send a file to another datalogger and get a file from that

datalogger. The first parameter in the instruction is the FTP Server’s IP

address. The second parameter is the FTP username. The third parameter is

the FTP password. The fourth parameter is the local filename. The fifth

parameter is the remote file name. The final parameter is the put/get option: 0

for put and 1 for get. The instruction returns –1 if the instruction was

successful and 0 if it was not.

PROGRAM

' CR1000

' FTPClient.cr1

Public Result1, Result2

BeginProg

Scan (20,Sec,1,1)

Result1 = FTPClient("192.168.7.85","user","password","CRD:pic.jpg","CRD:pic.jpg",0)

Result2 = FTPClient("192.168.7.85","user","password","CRD:file.html","CRD:file.html",1)

NextScan

EndProg

7.1.4 Telnet

Telnetting to the datalogger’s IP address allows access to the same commands

as the Terminal Emulator in the LoggerNet Connect Screen’s Datalogger

menu.

7.1.5 Ping

Pinging the datalogger’s IP address may be used to verify communications.

7.1.6 Serial Server

14

With an NL115 attached, the datalogger can be configured to act as a serial

server over the 10Base-T port. (A serial server is a device that allows serial

communication over a TCP/IP port.) This function may be useful when

communicating with a serial sensor over an Ethernet.

Page 21

7.1.6.1 Serial Input

NL115 Ethernet and CompactFlash® Module

The TCPOpen() instruction must be used first to open up a TCP socket. An

example of this instruction is shown below. The first parameter in TCPOpen()

is the IP address to open a socket to. “” means to listen on this port rather than

connect. The second parameter is the port number to be used. The third

parameter is buffer size. For a SerialIn() instruction that will use this

connection, it gives a buffer size. The TCPOpen() instruction returns the

socket number of the open connection or ‘0’ if it cannot open a connection.

socket = TCPOpen(“”,6784,100)

Once a socket has been opened with the TCPOpen() instruction, serial data

may be received with a SerialIn() Instruction. An example of this instruction

is shown below. The first parameter is the string variable into which the

incoming serial data will be stored. The second parameter is the socket

returned by the TCPOpen() instruction. The third parameter is the timeout.

The fourth parameter is the termination character. The last parameter is the

maximum number of characters to expect per input. For more information on

this instruction, see the CRBasic Editor Help.

SerialIn(Received,socket,0,13,100)

7.1.6.2 Serial Output

The TCPOpen() instruction must be used first to open up a TCP socket. An

example of this instruction is shown below. The first parameter in TCPOpen()

is the IP address to open a socket to. The second parameter is the port number

to be used. The third parameter is buffer size. The TCPOpen() instruction

returns the socket number of the open connection or ‘0’ if it cannot open a

connection.

socket = TCPOpen(“192.168.7.85”,6784,100)

Once a socket has been opened with the TCPOpen() instruction, serial data

may be sent out with SerialOut(). An example of this instruction is shown

below. The first parameter is the socket returned by the TCPOpen()

instruction. The second parameter is the variable to be sent out. The third

parameter is the wait string. The last parameter is the total number of times the

datalogger should attempt to send the variable. For more information on this

instruction, see the CRBasic Editor Help.

result = SerialOut(socket,sent,"",0,100)

7.1.7 TCP ModBus

With an NL115 attached, the datalogger can be set up as a TCP ModBus

Master or Slave device. For information on configuring the datalogger as a

TCP ModBus Master or Slave, see the ModBus section of the datalogger

manual.

7.1.8 DHCP

The IP address of the datalogger may be obtained through DHCP, if a DHCP

server is available. The DHCP address will be automatically assigned if there

is a DHCP server available and no static IP address has been entered. The IP

address should be available a few minutes after the datalogger has been

15

Page 22

NL115 Ethernet and CompactFlash® Module

powered up with the NL115 attached and Ethernet cable plugged in. The IP

address can be found with the Device Configuration Utility’s Settings tab

under TCP/IP info. It can also be found using a CR1000KD attached to the

datalogger. Go to Configure, Settings | Settings, scroll down to IP Status and

press the right arrow.

An IP address obtained through DHCP is not static but is leased for a period of

time set by the network administrator. The address may change, if the

datalogger is powered down.

7.1.9 DNS

The datalogger provides a DNS client that can query a DNS server to resolve a

fully qualified domain name. When a DNS server is available, domain names

can be used in place of the IP address in the datalogger instructions.

7.2 File Formats

This section covers the different types of files stored on the CF card.

7.2.1 Data Files

The datalogger stores data on the CF card in TOB3 format. TOB3 is a binary

format that incorporates features to improve reliability of the CF cards. TOB3

allows the accurate determination of each record’s time without the space

required for individual time stamps.

TOB3 format is different than the data file formats created when data are

collected via a communication link. Data files read directly from the CF card

generally need to be converted into another format to be used.

When TOB3 files are converted into another format, the number of records

may be slightly greater or less than the number requested in the data-table

declaration. There is always some additional memory allocated. When the file

is converted, this will result in additional records if no lapses occurred. If more

lapses occur than were anticipated, there may be fewer records in the file than

were allocated.

The CardConvert software included in LoggerNet, PC400, and PC200 will

convert data files from one format into another.

7.2.2 Program Files

The CF card can be used to provide extra program-storage space for the

datalogger. Program files can be copied to the card while it is attached as a

drive on the computer. They can also be sent to the card using LoggerNet’s

File Control. They may also be copied from CPU memory to the card (or from

the card to CPU memory) using the CR1000KD.

7.2.3 Power-up Files (Powerup.ini)

Users can insert a properly-configured CF card into the NL115, cycle through

the datalogger power, and have power-up functions automatically performed.

16

Page 23

NL115 Ethernet and CompactFlash® Module

CAUTION

NOTE

Power-up functions of CompactFlash® cards can include:

a) Sending programs to the CR1000 or CR3000

b) Setting attributes of datalogger program files

c) Setting disposition of old CF files

d) Sending an OS to the CR1000 or CR3000

e) Formatting memory drives

f) Deleting data files

Test the power-up functions in the office before going into

the field to ensure the power-up file is configured correctly.

The key to the CF power-up function is the powerup.ini file, which contains a

list of one or more command lines. At power-up, the powerup.ini command

line is executed prior to compiling the program. Powerup.ini performs three

operations:

1) Copies the specified program file to a specified memory drive

2) Sets a file attribute on the program file

3) Optionally deletes CF data files from the overwritten (just previous)

program

Powerup.ini takes precedence during power-up. Though it sets file attributes

for the programs it uploads, its presence on the CF does not allow those file

attributes to control the power-up process. To avoid confusion, either remove

the CF card or delete the powerup.ini file after the powerup.ini upload.

7.2.3.1 Creating and Editing Powerup.ini

Powerup.ini is created with a text editor, then saved as “powerup.ini”.

Some text editors (such as WordPad) will attach header

information to the powerup.ini file, causing it to abort. Check the

text of a powerup.ini file with the datalogger keyboard display to

see what the datalogger actually sees.

Comments can be added to the file by preceding them with a single-quote

character ('). All text after the comment mark on the same line is ignored.

Syntax

Syntax allows functionality comparable to File Control in LoggerNet.

Powerup.ini is a text file that contains a list of commands and parameters. The

syntax for the file is:

Command,File,Device

where

Command = one of the numeric commands in TABLE 7-1.

File = file on CF associated with the action. Name can be up to 22

characters.

17

Page 24

NL115 Ethernet and CompactFlash® Module

TABLE 7-1. Powerup.ini Commands

Device = the device to which the associated file will be copied

Options are CPU:, USR:, and CRD:. If left blank or with an invalid

option, it will default to CPU:.

Command Description

1 Run always, preserve CF data files

2 Run on power-up

5 Format

6 Run now, preserve CF data files

9 Load OS (File = .obj)

13 Run always, erase CF data files now

14 Run now, erase CF data files now

By using PreserveVariables() instruction in the datalogger CRBasic program,

with options 1 and 6, data and variables can be preserved. The powerup.ini

code is shown below.

EXAMPLE 7-1. Powerup.ini code.

'Command = numeric power-up command

'File = file on CF associated with the action

'Device = the device to which File will be copied. Defaults to CPU:

'Command,File,Device

13,Write2CRD_2.cr1,CPU:

7.2.3.2 Applications

• Commands 1, 2, 6, 13, and 14 (Run Now and / or Run On Power-up). If a

device other than CRD: drive is specified, the file will be copied to that

device.

• Commands 1, 2, and 13 (Run On Power-up). If the copy (first application,

above) succeeds, the new Run On Power-up program is accepted. If the

copy fails, no change will be made to the Run On Power-up program.

• Commands 1, 6, 13, and 14 (Run Now). The Run Now program is

changed whether or not the copy (first application, above) occurs. If the

copy does succeed, the Run Now program will be opened from the device

specified.

• Commands 13 and 14 (Delete Associated Data). Since CRD:powerup.ini

is only processed at power-up, there is not a compiled program to delete

associated data for. The information from the last-running program is still

available for the datalogger to delete the files used by that program.

18

Page 25

NL115 Ethernet and CompactFlash® Module

7.2.3.3 Program Execution

After File is processed, the following rules determine what datalogger program

to run:

1) If the Run Now program is changed, it will be the program that runs.

2) If no change is made to the Run Now program, but the Run on Power-up

program is changed, the new Run on Power-up program runs.

3) If neither the Run on Power-up nor the Run Now programs are changed,

the previous Run on Power-up program runs.

7.2.3.4 Example Powerup.ini Files

Examples 7-2 through 7-7 are example powerup.ini files.

EXAMPLE 7-2. Run Program on Power-up.

'Copy pwrup.cr1 to USR:, will run only when powered up later

2,pwrup.cr1,usr:

EXAMPLE 7-3. Format the USR: Drive.

'Format the USR: drive

5,,usr:

EXAMPLE 7-4. Send OS on Power-up.

'Load this file into FLASH as the new OS

9,CR1000.Std.04.obj

EXAMPLE 7-5. Run Program from CRD: Drive.

'Leave program on CRD:, run always, erase CRD: data files

13,toobigforcpu.cr1,crd:

EXAMPLE 7-6. Run Program Always, Erase CF Data.

'Run always, erase CRD: data files

13,pwrup_1.cr1,crd

EXAMPLE 7-7. Run Program Now, Erase CF Data.

'Copy run.cr1 to CPU:, erase CF data, run CPU:run.cr1, but not if later powered up

14,run.cr1,cpu:

19

Page 26

NL115 Ethernet and CompactFlash® Module

Parameter

Data Type

Enter

StopRing

Constant

A code to specify if the Data Table on the CF card is fill-and-stop or ring (newest data

overwrites oldest).

Value

Result

0

Ring

1

Fill and stop

Size

The size to make the data table. The number of data sets (records) for which to allocate

table. This data is called a record.

Note

Enter –1000 and the size of the table on the card will match the size of the

partitioning algorithm attempts to have the tables full at the same time.

7.2.4 Camera Files

JPEG images taken by a CC640 digital camera (retired) connected to the

datalogger can be stored to the CF card rather than CPU memory. This is done

by configuring the PakBus setting Files Manager for the datalogger. This can

be done using Device Configuration Utility or PakBus Graph.

7.3 Programming

7.3.1 The CardOut() Instruction

The CardOut() instruction is used to send data to a CF card. CardOut() must

be entered within each DataTable() declaration that is to store data to the CF

card. Data is stored to the card when a call is made to the data table.

CardOut(StopRing, Size)

Constant

memory in the CF card. Each time a variable or interval trigger occurs, a line (or row) of

data is output with the number of values determined by the output instructions within the

7.3.2 Program Examples

7.3.2.1 Ring Mode

The following program outputs the maximum and minimum of the panel

temperature to the card once a second. The first parameter of the CardOut()

instruction is 0, which sets the table on the card to ring mode. The second

parameter is negative, so all available memory on the card will be allocated to

the data table. Once all available memory is used, new data will begin

overwriting the oldest.

internal table on the datalogger. Enter any other negative number and all

remaining memory (after creating any fixed-size data tables) will be allocated to

the table or partitioned among all tables with a negative value for size. The

20

Page 27

PROGRAM

'CR1000

Public temp

DataTable (Table1,1,-1)

CardOut (0, -1)

Maximum (1,temp,FP2,False,False)

Minimum (1,temp,FP2,False,False)

EndTable

BeginProg

Scan(1,SEC,3,0)

PanelTemp(temp,250)

CallTable Table1

NextScan

EndProg

7.3.2.2 Fill-and-Stop Mode

The following program outputs a sample of the panel temperature to the card

once a second. The first parameter of the CardOut() instruction is 1, which

sets the table on the card to fill-and-stop mode. The second parameter (1000)

is the number of records which will be written before the table is full and data

storage stops. Once 1000 records have been stored, data storage to the

specified table on CRD: and CPU: datalogger memory drives will stop.

NL115 Ethernet and CompactFlash® Module

'CR1000

Public temp

DataTable (Table1,1,1000)

CardOut (1,1000)

Sample(1,temp,IEEE4)

EndTable

BeginProg

Scan(1,SEC,3,0)

PanelTemp(temp,250)

CallTable Table1

NextScan

EndProg

7.3.2.3 Mixed Modes

PROGRAM

To restart data storage to the fill-and-stop table, the table must be reset.

To reset a table after a fill-and-stop table has been filled and stopped, either use

the reset button in LoggerNet (LN Connect | Datalogger | Station Status | Table

Fill Times, Reset Tables) or use the CRBasic ResetTable() instruction.

The following program stores four data tables to the card. The first two tables

will output samples of the panel temperature and battery voltage to the card

once a second. The first parameter of the CardOut() instruction is 1, which

sets the tables on the card to fill-and-stop mode. The second parameter is

1000, so 1000 records will be written to each table before stopping.

21

Page 28

NL115 Ethernet and CompactFlash® Module

Tables 3 and 4 will output the maximum and minimum of the panel

temperature and battery voltage to the card every five seconds. (The tables will

be called once a second. The DataInterval() instruction causes data to only be

stored every five seconds.) The first parameter of the CardOut() instruction is

0, which sets the tables on the card to ring mode. The second parameter is

negative, so all available memory on the card will be allocated to these tables,

once space for the fixed-size tables has been allocated. The datalogger will

attempt to size the tables so that both will be full at the same time.

PROGRAM

'CR1000

Public temp

Public batt

DataTable (Table1,1,-1)

CardOut (1,1000)

Sample(1,temp,IEEE4)

EndTable

DataTable (Table2,1,-1)

CardOut (1,1000)

Sample(1,batt,IEEE4)

EndTable

DataTable (Table3,1,1000)

DataInterval(0,5,sec,4)

CardOut (0 ,-1)

Maximum (1,temp,FP2,False,False)

Minimum (1,temp,FP2,False,False)

EndTable

DataTable (Table4,1,1000)

DataInterval(0,5,sec,4)

CardOut (0 ,-1)

Maximum (1batt,FP2,False,False)

Minimum (1,batt,FP2,False,False)

EndTable

BeginProg

Scan(1,SEC,3,0)

PanelTemp(temp,250)

Battery(Batt)

CallTable Table1

CallTable Table2

CallTable Table3

CallTable Table4

NextScan

EndProg

22

7.3.3 Table Size and Mode

The size of each data table in CPU memory is set as part of the DataTable()

instruction and the size of each data table on the CF card is set with the

CardOut() instruction. Because they are set independently, they can be

different. It is important to note that if the CPU memory is set to fill-and-stop

mode, once a table is full, all data storage to the table will stop. No more

records will be stored to the CPU memory or the card.

Page 29

7.4 CF Card Data-Retrieval Details

CAUTION

Data stored on CF cards can be retrieved through a communication link to the

datalogger or by removing the card and carrying it to a computer.

7.4.1 Via a Communication Link

Data can be transferred to a computer via a communication link using one of

Campbell Scientific’s datalogger support software packages (for example,

PC200W, PC400, LoggerNet). There is no need to distinguish whether the

data is to be collected from the CPU memory or a CF card. The software

package will look for data in both the CPU memory and the CF card.

The datalogger manages data on a CF card as final-storage table data, accessing

the card as needed to fill data-collection requests initiated with the Collect

button in datalogger support software. If desired, binary data can be collected

using the File Control utility in datalogger support software. Before collecting

data this way, stop the datalogger program to ensure data are not written to the

CF card while data are retrieved. Otherwise, data corruption and confusion

will result.

7.4.1.1 Fast Storage/Data-Collection Constraints

NL115 Ethernet and CompactFlash® Module

When LoggerNet collects data from ring tables that have filled, there is the

possibility of missing records due to the collection process. LoggerNet uses a

“round-robin” collection algorithm that collects data from multiple tables in

small blocks as it sequences around to all the tables. Collection starts at the

oldest data for each table. When a ring table has filled, the oldest data is

overwritten by current data.

With filled ring tables, as collection begins LoggerNet queries the datalogger

for the oldest data starting with the first table. When this data block is

returned, LoggerNet goes to the next table and so on until all of the tables are

initially collected. By the time LoggerNet makes the second pass requesting

more data from the tables, the possibility exists that some of that data may have

been overwritten, depending on how fast the datalogger is storing data (that is,

data storage rate, number of table values, and number of tables).

Normally, LoggerNet gets ahead of the storing datalogger and the remaining

data is collected without gaps; however, if the datalogger is storing data fast

enough, it is possible to get into an always-behind scenario where LoggerNet

never catches up and the datalogger repeatedly overwrites uncollected data.

The possibility of missing records is greater when collecting data via IP. This

is due to the high demand of IP on processor time. The risk is greatest with a

CR1000 datalogger using IP, because of its slower processor speed relative to

the CR3000.

7.4.2 Transporting CF Card to Computer

With large files, transferring the CF card to a computer may be faster than

collecting the data over a link.

Removing a card while it is active can cause garbled data

and can actually damage the card. Do not switch off the

datalogger power if a card is present and active.

23

Page 30

NL115 Ethernet and CompactFlash® Module

NOTE

To remove a card, press the Initiate Removal button on the NL115. The

datalogger will transfer any buffered data to the card and then power off. The

Status LED will turn green when it is OK to remove the card. The card will be

reactivated after 20 seconds if it is not removed.

When the CF card is inserted into a computer, the data files can be copied to

another drive or used directly from the CF card just as one would from any

other disk. In most cases, however, it will be necessary to convert the file

format before using the data.

When dealing with large data files, it may be faster to use an

external card reader (such as pn 17752) rather than a PC card slot.

7.4.2.1 Converting File Formats

Files can be converted using LoggerNet’s CardConvert. Go to Data |

CardConvert and click on “Select Card Drive”. Select where the files to be

converted are stored and press OK. Next, click on “Change Output Dir” and

select where you would like the converted files to be stored. Place check

marks next to the files to be converted. A default destination filename is given.

It can be changed by right-clicking with the filename highlighted. Press the

“Destination File Options” button to select what file format to convert to and

other options. Press “Start Conversion” to begin converting files. Green

checkmarks will appear next to each filename as conversion is complete. Refer

to CardConvert online help for more information.

24

FIGURE 7-4. CardConvert

Page 31

7.4.2.2 Reinserting the Card

CAUTION

NOTE

If the same card is inserted again into the NL115, the datalogger will store all

data to the card that has been generated since the card was removed that is still

in the CPU memory. If the data tables have been left on the card, new data will

be appended to the end of the old files. If the data tables have been deleted,

new ones will be generated.

Check the status of the card before leaving the datalogger.

If a CF card was not properly accepted, the NL115 will flash

orange. In that case, the user needs to reformat and erase

all data contained on the CF card. Formatting or erasing a

CF card might be done on a PC or datalogger. The

procedure for formatting a CF card is explained in

, CF Card Maintenance.

A

7.4.2.3 Card Swapping

When transporting a CF card to a computer to retrieve data, most users will

want to use a second card to ensure that no data is lost. For this method of

collection, use the following steps.

1. Insert formatted card (“CF-A”) in NL115 attached to datalogger.

NL115 Ethernet and CompactFlash® Module

Appendix

2. Send Program containing CardOut() instruction(s).

3. When ready to retrieve data, press the NL115 Initiate Removal button to

remove the card. The LED will be red while the most-current data is

stored to the card and then turn green. Eject the card while the LED is

green.

4. Put in the clean card (“CF-B”).

5. Use CardConvert to copy data from CF-A to PC and convert. The default

CardConvert filename will be TOA5_stationname_tablename.dat. Once

the data is copied, use Windows Explorer to delete all data files from the

card.

Windows98 and WindowsME users need to shift-delete to

completely delete files. Using standard delete may create an

invisible recycle bin on the CF card.

6. At the next card swap, eject CF-B and insert the clean CF-A.

7. Running CardConvert on CF-B will result in separate data files containing

records since CF-A was ejected. CardConvert can increment the filename

to TOA5_stationname_tablename_0.dat.

8. The data files can be joined using a software utility such as WordPad or

Excel.

CardConvert File CF-A Record Numbers CF-B Record Numbers

TOA5_tablename.dat 0-100

TOA5_tablename.dat 101-1234

TOA5_tablename.dat 1235-….

25

Page 32

NL115 Ethernet and CompactFlash® Module

26

Page 33

Appendix A. CF Card Maintenance

A.1 Formatting CF Card

The CF card can be formatted using 1) Windows Explorer, 2) the CR1000KD,

or 3) LoggerNet File Control.

A.1.1 Windows Explorer

To format card using Windows Explorer:

1) Insert CF card into CF adapter or CF reader.

2) Windows Explorer should identify a drive as a removable disk (F:\).

3) Select that drive and right-click.

4) Choose Format.

A-1

Page 34

Appendix A. CF Card Maintenance

5) Choose FAT32 under file system, give the card a label, and press Start.

(The datalogger will work with either FAT or FAT32.)

A.1.2 CR1000KD

To format card using the CR1000KD:

1) Insert CF card into NL115.

2) From the main menu of CR1000KD, choose PCCard.

3) Choose Format Card.

4) Choose Yes to proceed.

A.1.3 LoggerNet File Control

To format card using LoggerNet File Control:

1) Insert CF card into NL115.

2) Use LoggerNet to connect to datalogger.

A-2

Page 35

Appendix A. CF Card Maintenance

3) Choose FileControl under the Tools menu of the Connect Screen.

4) Highlight CRD.

5) Press Format.

6) Press Yes to confirm.

A.2 Checking CF Card Integrity

The Windows Check Disk tool can be used to check the integrity of a CF card.

To access the Check Disk tool:

1) Insert CF card into CF reader.

2) Windows Explorer should identify a drive as removable disk.

3) Select that drive and right-click.

4) Choose Properties.

A-3

Page 36

Appendix A. CF Card Maintenance

5) Navigate to the Tools tab.

6) Press Check Now.

7) Select both options.

8) Press Start.

A-4

Page 37

Page 38

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...