Page 1

NL100/105 Network Link Interface

Revision: 12/10

POWER

G 12V

RS485

Logan, Utah

CS I/O

CS I/O

NL100

RS232

RS232

SN:

MADE IN USA

LAN

LINK

10 BASE T

LAN

LINK

10 BASE T

NETWORK LINK INTERFACE

RS485

Copyright © 2000-2010

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The NL100/105 NETWORK LINK INTERFACE is warranted by Campbell

Scientific, Inc. to be free from defects in materials and workmanship under

normal use and service for twelve (12) months from date of shipment unless

specified otherwise. Batteries have no warranty. Campbell Scientific, Inc.'s

obligation under this warranty is limited to repairing or replacing (at Campbell

Scientific, Inc.'s option) defective products. The customer shall assume all

costs of removing, reinstalling, and shipping defective products to Campbell

Scientific, Inc. Campbell Scientific, Inc. will return such products by surface

carrier prepaid. This warranty shall not apply to any Campbell Scientific, Inc.

products which have been subjected to modification, misuse, neglect, accidents

of nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. Campbell Scientific, Inc. is not liable for special, indirect,

incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact Campbell

Scientific, Inc., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to repair@campbellsci.com

435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed to

Page 3

NL100/105 Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Introduction..................................................................1

1.1 Physical Description of the NL100/105 ...................................................1

1.2 Specifications............................................................................................2

2. Preparing to Set Up the NL100/105 ............................3

2.1 Computer to NL100/105 Physical Connection.........................................4

2.2 Communication with the NL100/105 .......................................................4

2.2.1 Setup Using the Device Configurator .............................................4

2.2.2 Setup Using a Terminal Program....................................................5

2.2.3 Establishing Communication Outside of ConfMon Mode..............5

2.3 Port Configuration ....................................................................................7

2.3.1 TCPSer............................................................................................7

2.3.2 PakBus ............................................................................................7

2.3.3 PakBusSer.......................................................................................7

2.4 NL100/105 Menu Options........................................................................7

2.4.1 Ver ..................................................................................................8

2.4.2 Show ...............................................................................................8

2.4.3 Edit..................................................................................................8

2.4.3.1 TLink Config.........................................................................8

2.4.3.2 RS485 Config........................................................................9

2.4.3.3 CS I/O Config .....................................................................10

2.4.3.4 RS-232 Config ....................................................................12

2.4.3.5 Ethernet 10 Base-T..............................................................14

2.4.3.6 PakBus Address of the NL100/105.....................................15

2.4.3.7 PakBus/Tcp Server Config..................................................15

2.4.3.8 PakBus/Tcp Client Config...................................................16

2.4.3.9 MODBUS/TCP Gateway Config ........................................16

2.4.3.10 Telnet IP Port Number ......................................................16

2.4.3.11 DevConfig Security Code .................................................16

2.4.4 Defaults.........................................................................................17

2.4.5 Reset..............................................................................................18

2.4.6 Help...............................................................................................18

2.4.7 Bye ................................................................................................18

2.4.8 Other Commands ..........................................................................18

2.4.9 Serial Server Watchdog ................................................................19

3. Connecting the NL100/105 to a Network .................19

3.1 Network to NL100 Connection ..............................................................19

3.2 Typical Configurations ...........................................................................19

3.2.1 Direct Connect from the NL100/105 to a Datalogger...................20

3.2.2 MD9 Connection from NL100/105 to Datalogger........................21

3.2.3 MD485 Connection from NL100/105 to Datalogger....................22

3.2.4 RF Connection from NL100/105 to Datalogger ...........................22

3.2.5 Short Haul Modem Connection from NL100/105 to Datalogger .23

i

Page 4

NL100/105 Table of Contents

Appendices

A. CS I/O Port ............................................................... A-1

B. Null-Modem Cable ................................................... B-1

C. 10 Base-T Cabling ................................................... C-1

Glossary

Figures

3.2.6 Phone Modem Connection from NL100/105 to Datalogger........ 23

3.3 NL100/105 to Datalogger Connections - CR9000/CR5000 .................. 24

3.3.1 Software Setup ............................................................................. 24

3.3.2 Hardware Setup for NL105 Communication with the CR9000 via

TLink ...................................................................................... 25

1. NL100 ........................................................................................................ 2

2. NL100/105 Jumper Placement................................................................... 6

3. Typical NL100/105 Setups in LoggerNet................................................ 20

4. LoggerNet Setup for NL100/105 to MD9 to Datalogger Connection ..... 21

5. LoggerNet Setup for NL100/105 to RF to Datalogger Connection......... 23

6. LoggerNet Setup for NL100/105 to Phone to Datalogger Connection.... 24

7. PC9000 Setup for TCP/IP Communication ............................................. 25

ii

Page 5

NL100/105 Network Link Interface

1. Introduction

The NL100 and NL105 Network Link Interfaces are devices used to

communicate with Campbell Scientific dataloggers using an Ethernet 10 BaseT communications link. The NL100 includes a CS I/O port (see Appendix A)

an RS-232 port, and an RS-485 port for communication; the NL105 adds a

TLink interface for communication with a CR9000(C) system.

The NL100/105 can be configured to act as a Serial Server in a standard

TCP/IP network, to act as a PakBus node in a PakBus network, or to transfer

MODBUS/TCP packets. All of the available settings are described in Section

2.4. However, not all settings are required for all configurations. This manual

will focus mainly on setting up the NL100/105 for a standard TCP/IP network.

For PakBus and MODBUS configurations, please contact Campbell Scientific

for applications notes or other information that may be available.

Campbell Scientific's LoggerNet software is used to communicate with the

dataloggers once the NL100/105 is configured properly and connected to a

network (refer to Section 2.). Communication with CSI’s mixed-array

dataloggers (CR10X, CR510, CR23X, CR7, and 21X) and table-data

dataloggers (CR10X-TD, CR510-TD, CR23X-TD, CR5000, and CR9000)

requires LoggerNet version 2.0 or greater. Communication with CR10XTDPB, CR510TD-PB, CR23XTD-PB, and CR200 dataloggers requires

LoggerNet 2.1 or greater. Communication with the CR1000 requires

LoggerNet 3.0 or greater. Communications with the CR3000 require

LoggerNet 3.2 or greater and with the CR800 and CR850 require LoggerNet

3.3 or greater. PC208W version 3.2 or higher may also be used with mixed

array dataloggers (CR10X, CR510, CR23X, CR7, 21X). PC9000 may also be

used for CR9000 and CR5000 dataloggers.

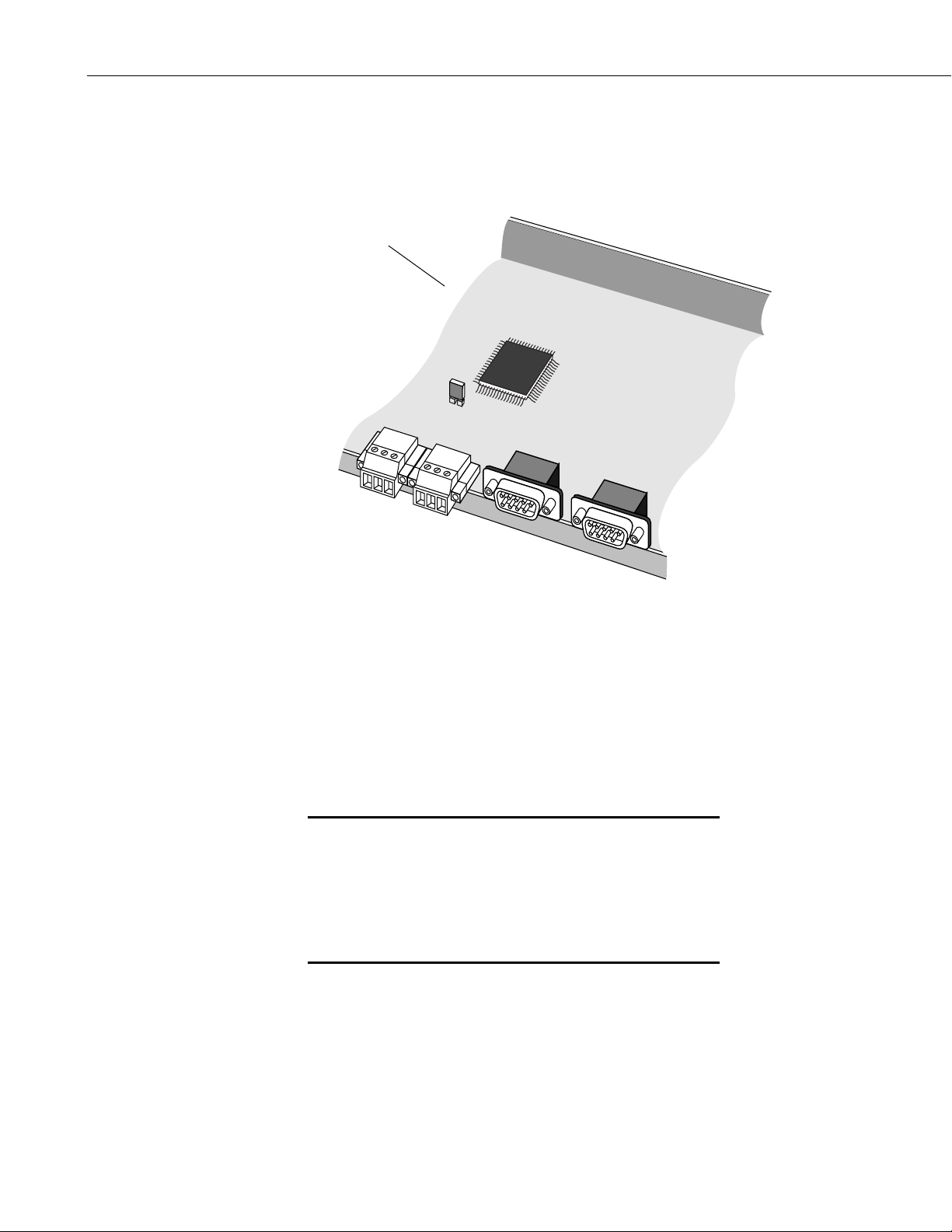

1.1 Physical Description of the NL100/105

The NL100/105 is housed in a rectangular case with all power and

communication connections on one edge. On the opposite outside edge are tabs

for mounting the NL100/105 in an enclosure. Figure 1 below shows the

position of these connections and the mounting tabs.

1

Page 6

NL100/105 Network Link Interface

t

t

Logan, Utah

Corner Screws

Mounting Tabs

12 V Power

Connection

POWER

G 12V

RS485

RS485

RS-485 Ports

CS I/O Por

1.2 Specifications

RS-485 and CS I/O Port Communication Rate

Up to 38.4 kbps

NETWORK LINK INTERFACE

NL100

CS I/O

RS232

CS I/O

RS232

RS-232

DTE Por

Communication

Indicator LEDs

FIGURE 1. NL100

LAN

LAN

LINK

MADE IN USA

LINK

10 BASE T

10 B

ASE T

SN:

10 Base-T Link

RS-232 DTE Port Communication Rate

Up to 115.2 kbps

Weight

13.3 oz (377 g)

Standards

Ethernet Standard IEEE 802.3 (CSMA/CD Access Method)

TCP/IP Protocol

Case Dimensions

9 ¼” x 4 ¼” x 1” (23.5 x 10.8 x 2.54 cm)

Temperature

-25 to +50°C

2

Page 7

NL100/105 Network Link Interface

Power Supply Requirements

The NL100/105 is powered via the green G 12V connector (11 to 16

VDC at 140 mA average current) on the front panel of the unit.

Cable Specifications

The Ethernet 10 Base-T cable should be a Category 5 twisted pair cable.

Campbell Scientific recommends the 13658. The two active pairs in an

Ethernet 10 Base-T network are pins 1 & 2 and pins 3 & 6. Use only

dedicated wire pairs (such as blue/white & white/blue, orange/white &

white/orange) for the active pairs.

RJ-45 Pin-Outs: Pin 1 = TD+, Pin 2 = TD-, Pin 3 = RD+, Pin 6 = RD-

A DB9 female to DB9 male cable such as the 10873 is used to connect

the NL100’s RS-232 port to the datalogger’s RS-232 port. A DB9 female

null modem cable such as the 13657 is used to connect the NL100’s RS232 port to a PC’s RS-232 port. The RS-232 cable should be kept at

lengths of ≤ 6 feet to maintain high data throughput rates.

The CS I/O 9 Pin cable is a straight through cable with all 9 pins

connected. Campbell Scientific’s SC12 cable is recommended.

The cable for the RS-485 connection is a 2 twisted pair, 22 awg cable.

CSI recommends the CABLE3CBL-L for use with the MD485s.

Compliance

The NL100/105 is encased in metal and meets requirements for a Class A

device under European standards:

APPLICATION OF COUNCIL DIRECTIVE(S)

89/336/EEC as amended by 89/336/EEC and 93/68/EEC.

STANDARD(S) TO WHICH CONFORMITY IS DECLARED:

ENC55022-1; 1995 AND ENC 50082-1: 1992

EUROPEAN REGULATIONS

WARNING: This is a Class A product. In a domestic environment

this product may cause radio interference in which case the user may

be required to correct the interference at the user’s expense.

2. Preparing to Set Up the NL100/105

The NL100/105 must be set up by configuring one or more of the

communications ports for communication with your datalogger or other

devices in the network. To do this, you must establish a direct communication

link with the NL100/105 using a PC computer. You will need a null modem

cable to physically connect the NL100/105 to the computer. The Device

Configurator or a terminal communication software package (such as

HyperTerminal, which ships with Microsoft Windows operating system

software) is used to configure the settings in the NL100/105.

3

Page 8

NL100/105 Network Link Interface

2.1 Computer to NL100/105 Physical Connection

An RS-232 null-modem cable is required to establish communication between

the NL100/105 and your computer. One end of the cable is connected to the

computer's 9-pin RS-232 communications port and the other end is connected

to the RS-232 port of the NL100/105. If the null-modem cable does not have a

female connector on both ends, you may also need a female-to-female adapter.

For additional information on null-modem cables, refer to Appendix B.

The NL100/105 requires 12 VDC for operation. This power source can be

supplied by the datalogger's 12 V supply or by a regulated external power

source. When connecting the power leads, the ground lead should be

connected first and then the 12 V lead.

2.2 Communication with the NL100/105

2.2.1 Setup Using the Device Configurator

Campbell Scientific's datalogger support software ships with a utility called the

Device Configurator (or DevConfig). This tool is used to set up dataloggers

and other devices for communication or to download a new operating system.

DevConfig can also be downloaded from Campbell Scientific's web site.

NOTE

The NL100/105 must have at least operating system version 7 to

be compatible with DevConfig's NL100 setup. If your

NL100/105 does not have a compatible operating system, load a

new one in using DevConfig's Send OS utility or u se a terminal

emulation program to set up the device.

To use DevConfig to set up the NL100/105, first connect the NL100/105 to the

computer as noted above and follow the steps below:

1. Remove power from the NL100/105.

2. Open DevConfig.

3. Highlight the NL100 in the list of devices which appears in the left-hand

portion of the window. Select the COM port to which the NL100/105 is

connected from the drop down list box at the bottom left of the window.

4. Press the Connect button and reapply power to the NL100/105. The device

may take up to 60 seconds to respond to DevConfig, and for the current

settings to be loaded into the Settings Editor.

The Settings Editor is the active tab when you are first connected. Settings can

be changed in this window by clicking within a field and entering a new value.

If the value being set has a finite list of choices, a second click within the field

will enable a drop down list box from which to select a valid option.

4

DevConfig has built-in help for each setting, which is displayed at the bottom

of the window. Use this information, along with Section 2.4 of this manual, to

configure the settings for communication in your network. Once the settings

have been defined, press Apply to save the changes to the NL100/105.

Page 9

You can also use the Terminal tab in DevConfig to set up the NL100/105 using

the menus, as explained in the following section.

2.2.2 Setup Using a Terminal Program

Once the physical connection has been made, communication can be

established with the NL100/105 using a terminal communications package.

The steps below demonstrate configuring the NL100/105 using

HyperTerminal, which is shipped with Windows operating systems.

NL100/105 Network Link Interface

NOTE

The NL100/105 is shipped from the factory with its RS-232 port

set in the ConfMon mode (configuration monitor). Refer to

Section 2.2.3 if the RS-232 port has been set to some other

configuration and direct communication is necessary.

Ensure the NL100/105 has an appropriate power source applied. (Refer to

Section 2.1, above.)

Create a new connection in HyperTerminal. Choose the COM port to which

the null-modem cable is connected, and set the baud rate to 115,200 bps. Most

of the other settings can be left at the default (data bits = 8, parity = none, stop

bits = 1). Flow control should be set to none.

Once HyperTerminal indicates you are connected, press <Enter> a couple of

times to gain the attention of the NL100/105. When communication is

established, the current port settings will be returned, followed by the

NL100/105 prompt line:

NL100/105 (ver, show, edit, defaults, reset, help, bye):

To set up the NL100/105 for communication with the network, go into the Edit

menu (Section 2.4.3 Edit) and complete the appropriate information. Note that

the Ethernet 10 Base-T connection must be configured (Section 2.4.3.5) and at

least one of the other port options.

2.2.3 Establishing Communication Outside of ConfMon Mode

If the RS-232 port has been disabled or set to some configuration other than

ConfMon, communication can still be established with the NL100/105 using

one of two options.

When power is first applied to the NL100/NL105, there is a 0.5-second

window in which communication can be established with the NL100 using the

RS232 port, regardless of the port's configuration. Therefore, if power is

already applied, simply disconnect power and then reconnect it, then attempt to

establish communication within the 0.5-second period. Holding down the

enter key should allow you to hit this 0.5-second window.

The other option is to connect a boot jumper, which bypasses the boot

sequence of the NL100/105. To access the boot jumper, remove the

NL100/105's cover by removing the four screws at the corners.

5

Page 10

NL100/105 Network Link Interface

The boot jumper is shown in Figure 2 below. The NL100/105 ships with this

jumper connected to only one post. Place the jumper so that it connects the two

posts.

Jumper

WARNING

FIGURE 2. NL100/105 Jumper Placement

When the jumper is in place, open the HyperTerminal connection to the

NL100/105 and power up the device. The prompt "NL100 boot" will appear.

At this prompt, press <Enter> a few times to ring up the NL100/105. If

communication is successfully established, a message will be returned

indicating that the NL100/105 is initialized, along with the jumper setting (1 =

on, 0 = off), the TCP/IP address, Telnet port address, and current

communication configuration. If <Enter> is pressed again, the NL100/105

menu prompt will appear.

After reconfiguring the NL100/105 for communication,

the jumper should be disconnected. If this jumper

remains in place and power to the NL100/105 is cycled

off and back on, the NL100/105 will remain at the

"NL100 boot" prompt and will not boot up. This will

render the NL100/105 inaccessible via remote

communications.

6

Page 11

2.3 Port Configuration

An important step in configuring an NL100/105 for use is setting up the

communication port(s) that you will be using. Regardless of whether you are

connecting the datalogger (or a communication peripheral) to the RS485 port,

the CS I/O port, or the RS232 port, you must set up the port to support the

mode of communication that will be used for that portion of your network.

The three options supported are explained briefly, below.

2.3.1 TCPSer

When the port is set to TCPSer, it will act as a TCP serial server. Any packet

that is transmitted via the port will be sent using the TCP/IP protocol. This is

the simplest way to set up a port and will work in many scenarios, regardless

of whether the datalogger has a mixed-array or PakBus operating system.

One disadvantage of using this mode when communicating with PakBus

dataloggers is that no PakBus routing can occur via the port. It may also be less

efficient in some instances when communicating with PakBus dataloggers.

2.3.2 PakBus

NL100/105 Network Link Interface

2.3.3 PakBusSer

PakBus is a packet-based communications protocol developed by CSI. It is

used in the CR1000, CR800/850, CR3000, and CR200 dataloggers, as well as

CR10X, CR510, and CR23X dataloggers with a special operating system. One

of the advantages of PakBus communication is that PakBus devices in the

network can communicate directly with and route packets between other

PakBus devices in the network. In addition to the native PakBus packets, other

packet types, such as TCP/IP or ModBus, can be “wrapped” in a PakBus

packet and transferred among the PakBus devices in the network, thus

allowing for various communication protocols within one network.

By configuring a port for PakBus communication, the NL100/105 is set up as a

PakBus router in the network. The NL100/105 can then route packets to other

devices in the network that it has “learned” about through beaconing or

PakBus neighbor filters. When a port is configured for PakBus, the

NL100/105’s PakBus/TCP Server Config option must be enabled or

communication will not take place via TCP/IP with the PakBus devices on that

port.

This option is used only in a PakBus network. In this mode when a packet is

routed out the port, the PakBus framing is removed from the packet. Typically,

the attached device would be one that does not support PakBus communication

(such as a ModBus device).

2.4 NL100/105 Menu Options

The following discusses the menu options and settings that you will see when

connected to the NL100/105 using a terminal emulation package. DevConfig

provides these same options in a graphical user interface.

7

Page 12

NL100/105 Network Link Interface

The NL100/105 prompt lists all of the available menu options. Only the first

few characters of the main menu options need to be typed – the remaining

characters will be completed automatically. Press <Enter> to execute the

command. Each menu option is explained below.

2.4.1 Ver

Ver returns version information about the NL100/105. The ROM number, OS

version, Ethernet physical address, and some diagnostic statistics are

displayed. Version information may be requested by a Campbell Scientific

Applications Engineer when troubleshooting a communication problem.

NOTE

2.4.2 Show

2.4.3 Edit

The Ethernet physical address that is displayed is a hexadecimal

representation of the address assigned to this device. An Ethernet

address is unique to the specific device to which it is assigned.

This assignment is made at the factory and cannot be changed by

the user. The Ethernet physical address is not the same as the

TCP/IP address.

The Show command displays the current settings for the NL100/105.

The Edit menu option is used to set up the communications link for the

NL100/105. You should work closely with your network administrator to

determine the correct settings for your specific network.

You can progress through the menu options by pressing <Enter>. If you make

a mistake after entering a setting, press the up cursor arrow on your keyboard

to return to the previous setting. All available selections will be listed on the

prompt line enclosed in parentheses, with the current setting displayed in

brackets at the end of the selections (e.g., [disabled]). Help for a setting can be

displayed by entering the ? key and pressing <enter>, or by pressing F1.

8

Once changes have been made and you have come to the end of the prompts

for the communication options, you can choose "save" to put the new settings

into effect or "cancel" to disregard the changes and keep the current settings.

Prior to configuring one or more of the ports for communication (TLink

Config, RS485 Config, CS I/O Config, or RS232 Config) refer to the

discussion on Port Configuration above.

2.4.3.1 TLink Config

This setting is applicable to the NL105 only, and is used when communicating

with a CR9000 datalogger. TLink is an interface used to communicate with a

CR9000 datalogger over an Ethernet connection. A physical connection is

made between the TLink port on the CR9000's 9031 CPU module and the port

marked TLink on the NL105. TLink Config is used to set the TLink

communications port to one of three options:

Page 13

2.4.3.2 RS485 Config

NL100/105 Network Link Interface

TcpSer - The NL105 acts as a serial server for the TLink port. A serial server

is a device that allows serial communication over a TCP/IP communications

link. When configured as a serial server, there is one parameter to set:

TLink Serial Server Port Number - Enter the port number, in the range of

3000 to 65000, that will be used for TLink communication. The default

port number is 6781.

232-Bridge - The NL105 transparently passes data between the TLink port and

its RS-232 ports. The 232-Bridge configuration has only one setting, RS-232

bps. This is the bits per second (bps) at which the NL105 will communicate

with the device connected to the RS-232 port. This is a fixed rate (i.e., it is not

a maximum baud rate or an autobaud rate). The default is 115k bps.

Disabled - The TLink communications port is disabled.

This option is used to configure the NL100's RS485 port for communication

with an RS485 device. Campbell Scientific offers the MD485 for

communication with its dataloggers via RS485. The port can be configured for

PakBus communication, as a TcpSer serial server, or as a PakSer serial server.

PakBus - This option is used to set up the NL100/105 to communicate with

PakBus devices over the RS485 port. Packets transferred over the port in this

mode are framed as PakBus packets; therefore, any device attached to the port

must be configured for PakBus communication also. When a port is configured

for PakBus, the NL100/105’s “PakBus/Tcp Server Config” option must be

enabled (Section 2.4.3.7) or you will no t be able to communicate with TCP/IP

through the NL100/105 to the PakBus devices on that port.

When configured for PakBus the NL100/105's RS485 port has the following

settings:

RS485 Bps - This option is used to set the bits per second (bps) at

which the NL100/105 will communicate using the RF485 port. The

default value is 38K.

RS485 Beacon Interval - The NL100/105 can be set to transmit a

beacon to a PakBus network via the selected port. The beacon allows

the NL100/105 to determine which devices in the PakBus network it

can communicate with. Note that because a beacon is broadcast to all

devices, it can interfere with other communication in the network

(such as RF), so a frequent beacon may not be desirable. If 0 is

entered, no beacon will be sent; the default beacon is 60 seconds.

RS485 Verify Interval - This is the interval at which a PakBus

communication link will be verified over the RS485 port. If

communication does not take place with a PakBus device within the

verify internal, a packet will be sent to test the communication link.

In most instances, this setting should be left at the default of 0, which

will set a verify interval of 2.5 times the Beacon Interval.

9

Page 14

NL100/105 Network Link Interface

TCPSer - This option configures the NL100 to act as a TCP/IP based serial

server when communicating with the datalogger over its RS485 port.

If both the beacon interval and verify interval are set to 0, a verify

interval of 5 minutes will be used.

RS485 Neighbor list - Enter a list of addresses for PakBus devices

with which the NL100/105 can communicate over the RS485 port.

The addresses are specified individually, with a space separating each

address, or a range of addresses can be entered by separating them

with a hyphen (e.g., 1 3 6 10-15, sets PakBus addresses 1, 3, 6, 10,

11, 12, 13, 14, and 15 as neighbors). If a Neighbor list is entered, the

NL100/105 will ignore packets from any device which is not in the

list (unless the address of the device sending the packet is 4000 or

greater). If 0 is entered for this parameter, the NL100/105 will

respond to any device that sends a packet and will automatically add

that device to its neighbor list.

RS485 Bps - This is the bits per second (bps) at which the

NL100/105 will communicate using the RS485 port. This is a fixed

rate (i.e., it is not a maximum baud rate or an autobaud rate). The

default rate is 38K bps.

NOTE

2.4.3.3 CS I/O Config

RS485 Serial server port number - Enter the port number, in the

range of 1 to 65000, that will be used for communication. The default

port number is 6782.

PakSer - The RS485 port of the NL100/105 is configured as a PakBus serial

server.

RS485 Bps - This is the bits per second (bps) at which the

NL100/105 will communicate using the RS485 port. This is a fixed

rate (i.e., it is not a maximum baud rate or an autobaud rate). The

default rate is 38K bps.

RS485 serial server AppId Number - Enter the application ID, in the

range of 1 to 65000, that will be used identify the device in the

network. The default ID is 6782.

The usual AppId for MODBUS devices is 502.

This option is used to configure the NL100/105's CS I/O port. The port can be

configured for PakBus communication, as a TcpSer serial server, or as a

PakSer serial server.

10

Page 15

NL100/105 Network Link Interface

NOTE

CR10X, CR510, CR23X, 21X, and CR7 dataloggers ship with a

mixed array operating system. Mixed array dataloggers do not

support the PakBus communications protocol. Therefore, you

cannot communicate with them over a port configured for

PakBus. However, the CR10X, CR510, and CR23X dataloggers

can be special-ordered with a PakBus operating system. Check

with your technical support representative for details.

PakBus - This option is only used when setting up the NL100/105 to

communicate with other PakBus devices in the network. Packets transferred

over the CS I/O port in this mode are framed as PakBus packets; therefore, any

device attached to the port must be capable of PakBus communication. When a

port is configured for PakBus, the NL100/105’s “PakBus/Tcp Server Config”

option must be enabled (Section 2.4.3.7) or you will not be able to

communicate with TCP/IP through the NL100/105 to the PakBus devices on

that port.

When configured for PakBus, the NL100/105's CS I/O port has the following

settings:

CS I/O SdcAddr/bps - This option is used to set up the CS I/O port to

communicate with the datalogger as an addressable SDC device or a

modem enabled device. If SDC7 or SDC8 is chosen, the NL100/105 will

use that address to communicate with the datalogger in a synchronous

communication mode. If one of the baud rates is chosen, the NL100/105

will communicate with the datalogger as a modem enabled device using

the selected baud rate. If another SDC device is connected to the

NL100/105, the two devices must use different SDC addresses.

NOTE

CS I/O Beacon Interval - The NL100/105 can be set to transmit a beacon

to a PakBus network via the selected port. The beacon allows the

NL100/105 to determine which devices in the PakBus network it can

communicate with. Note that because a beacon is broadcast to all devices,

it can interfere with other communication in the network (such as RF), so

a frequent beacon may not be desirable. If 0 is entered, no beacon will be

sent; the default beacon is 60 seconds.

CS I/O Verify Interval - This is the interval at which a PakBus

communication link will be verified over the CS I/O port. If

communication does not take place with a PakBus device within the

verify internal, a packet will be sent to test the communication link. In

most instances, this setting should be left at the default of 0, which will

set a verify interval of 2.5 times the Beacon Interval.

If both the beacon interval and verify interval are set to 0, a verify interval

of 5 minutes will be used.

A neighbor list is not specified because there is only one possible

neighbor.

TcpSer - This option configures the NL100 to act as a TCP/IP based serial

server when communicating with the datalogger over its CS I/O port.

11

Page 16

NL100/105 Network Link Interface

PakSer - The CS I/O port of the NL100/105 can be configured as a PakBus

serial server. This sets up the device as a serial server.

CS I/O SdcAddr/bps - This option is used to set up the CS I/O port to

communicate with the datalogger as an addressable SDC device or a

modem enabled device. If SDC7 or SDC8 is chosen, the NL100/105 will

use that address to communicate with the datalogger in a synchronous

communication mode. If one of the baud rates is chosen, the NL100/105

will communicate with the datalogger as a modem enabled device using

the selected baud rate. Note that mixed array dataloggers (CR10X,

CR510, CR23X, 21X, CR7) can be configured only as modem enabled

devices; e.g., they do not support communication using SDC7 or SDC8.

CS I/O serial server port number - Enter the port number, in the range of

1 to 65000, that will be used for communication. The default port number

is 6783.

CS I/O SdcAddr/bps - This option is used to set up the CS I/O port to

communicate with the datalogger as an addressable SDC device or a

modem enabled device. If SDC7 or SDC8 is chosen, the NL100/105 will

use that address to communicate with the datalogger in synchronous

communication mode. If one of the baud rates is chosen, the NL100/105

will communicate with the datalogger as a modem enabled device using

the selected baud rate.

NOTE

2.4.3.4 RS-232 Config

NOTE

CS I/O Serial Server AppId number - Enter the application ID, in the

range of 1 to 65000, that will be used to identify the device in the

network. The default ID is 6783.

The usual AppId for MODBUS devices is 502.

This option configures the NL100/105's RS-232 port for communication. The

port can be set up to communicate with a datalogger or other communications

device (short haul modem, RF modem, phone modem), or to be connected to

directly and configured for communication. The setup options for the port are

PakBus, TcpSer serial server, PakSer PakBus serial server, or ConfMon

(configuration monitor).

CR10X, CR510, CR23X, 21X, and CR7 dataloggers ship with a

mixed array operating system. Mixed array dataloggers do not

support the PakBus communications protocol. Therefore, you

cannot communicate with them over a port configured for

PakBus. However, the CR10X, CR510, and CR23X dataloggers

can be special-ordered with a PakBus operating system. Check

with your technical support representative for details.

12

PakBus - This option is only used when setting up the NL100/105 to

communicate with other PakBus devices in the network. Packets transferred

over the RS-232 port in this mode are framed as PakBus packets; therefore,

any device attached to the port must be capable of PakBus communication.

When a port is configured for PakBus, the NL100/105’s “PakBus/Tcp Server

Page 17

NL100/105 Network Link Interface

Config” option must be enabled (Section 2.4.3.7) or you will not be able to

communicate with TCP/IP through the NL100/105 to the PakBus devices on

that port.

When configured for PakBus, the NL100/105's RS-232 port has the following

settings:

RS-232 bps - This is the bits per second (bps) at which the NL100/105

will communicate using the RS-232 port. This is a fixed rate (i.e., it is not

a maximum baud rate or an autobaud rate). Note that the CR10XTD-PB

and the CR510TD-PB can communicate at a maximum baud rate of 9600

bps, so to communicate with one of those dataloggers, this setting must be

9600 bps or less. The default rate is 115K bps.

PakBus Beacon Interval - The NL100/105 can be set to transmit a beacon

to a PakBus network via the selected port. The beacon allows the

NL100/105 to determine which devices in the PakBus network it can

communicate with. Note that because a beacon is broadcast to all devices,

it can interfere with other communication in the network (such as RF), so

a frequent beacon may not be desirable. If 0 is entered, no beacon will be

sent; the default beacon is 60 seconds.

RS232 Verify Interval - This is the interval at which a PakBus

communication link will be verified over the RS232 port. If

communication does not take place with a PakBus device within the

verify internal, a packet will be sent to test the communication link. In

most instances, this setting should be left at the default of 0, which will

set a verify interval of 2.5 times the Beacon Interval.

If both the beacon interval and verify interval are set to 0, a verify interval

of 5 minutes will be used.

RS232 Neighbor list - Enter a list of addresses for PakBus devices with

which the NL100/105 can communicate over the RS232 port. The

addresses are specified individually, with a space separating each address,

or a range of addresses can be entered by separating them with a hyphen

(e.g., 1 3 6 10-15, sets PakBus addresses 1, 3, 6, 10, 11, 12, 13, 14, and 15

as neighbors). If a Neighbor list is entered, the NL100/105 will ignore

packets from any device which is not in the list (unless the address of the

device sending the packet is 4000 or greater). If 0 is entered for this

parameter, the NL100/105 will respond to any device that sends a packet

and will automatically add that device to its neighbor list.

TcpSer - This option configures the NL100 to act as a TCP/IP based serial

server when communicating with a datalogger over its RS-232 port.

RS-232 bps - This is the bits per second (bps) at which the NL100/105

will communicate using the RS-232 port. This is a fixed rate (i.e., it is not

a maximum baud rate or an autobaud rate). Note that the CR10(X),

CR510, and CR200 can communicate at a maximum baud rate of 9600

bps, so to communicate with one of those dataloggers, this setting must be

9600 bps or less. The default setting is 115K bps.

13

Page 18

NL100/105 Network Link Interface

PakSer - The RS-232 port of the NL100/105 can be configured as a PakBus

serial server.

RS-232 serial server port number - Enter the port number, in the range of

1 to 65000, that will be used for communication. The default port number

is 6784.

RS-232 bps - This is the bits per second (bps) at which the NL100/105

will communicate using the RS-232 port. This is a fixed rate (i.e., it is not

a maximum baud rate or an autobaud rate). Note that the CR10(X),

CR510, and CR200 can communicate at a maximum baud rate of 9600

bps, so to communicate with one of those dataloggers, this setting must be

9600 bps or less. The default setting is 115K bps.

RS-232 Serial Server AppId number - Enter the application ID, in the

range of 1 to 65000, that will be used to identify the device in the

network. The default ID is 6784.

NOTE

The usual AppId for MODBUS devices is 502.

ConfMon - Configuring the RS-232 port as a ConfMon allows you to connect

directly to the NL100/105 via a computer. There are no parameters; the baud

rate is automatically set to 115,200 bps. Refer to the previous information on

setting up the NL100/105 for communication.

2.4.3.5 Ethernet 10 Base-T

The 10 Base-T communications link is used to connect the NL100/105 to a

TCP/IP network using a Category 5 twisted pair cable. The Ethernet 10 Base-T

link must be configured or you will not be able to co mmunicate with the

NL100/105 over a TCP/IP connection. The following options must be

configured. These values should be provided by your network administrator.

10BASE-T Port IP Address - This number is the address of the

NL100/105 on a TCP/IP network. It is written as 32-bit number written in

four 8-bit decimal-equivalent syllables separated by periods, in the format

XXX.XXX.XXX.XXX. The IP Address must be a static IP Address -- the

NL100/105 does not support DHCP (dynamic host configuration

protocol).

10BASE-T Port Network Mask - The network mask is used to help a

network router to more efficiently transfer information. Typically, a class

C mask will be 255.255.255.0, a class B mask will be 255.255.0.0, and a

Class A mask will be 255.0.0.0. The tighter the mask, the more the

NL100/105 will rely on the default gateway to route packets.

14

IP Address of the Default Gateway - Enter the IP address of the device

that is responsible for forwarding information to destinations outside the

internal network, defined by the network mask. To disable a default

gateway, use the default value of 0.0.0.0.

Page 19

2.4.3.6 PakBus Address of the NL100/105

If the NL100/105 is to be used as a router in a PakBus network, a PakBus

Address must be assigned. If the NL100/105 will not be used to route packets

in a PakBus network, this setting can be ignored. All devices in the network

must have a unique PakBus Address. Valid addresses are 1 through 4094. The

default ID is 678.

NL100/105 Network Link Interface

NOTE

By default LoggerNet software uses PakBus Address 4094,

PC400 uses 4093, PC200W uses 4092, and PConnect/

PConnectCE uses 4091. The use of these addresses in the

NL100/105 should be avoided.

PakBus addresses of greater than 3999 are typically reserved for

PakBus routing devices and ports. This is because when a

neighbor filter is set up in a PakBus datalogger, the datalogger

will answer a Hello message from any device with an ID greater

than 3999, but it will ignore devices with IDs less than 4000 that

are not in their neighbor list.

Clock Source Address - In a PakBus network, a "neighbor" is another

PakBus device that the NL100/105 can communicate with directly

(e.g., it does not have to route data through another PakBus device to

reach the neighbor). A neighbor can be designated for the NL100/105

as the device from which the NL100/105 will accept a clock set

command. If this setting is enabled, once the NL100/105 has received

a clock set from its designated neighbor, it will broadcast its clock

information along with its beacon. Thus, the NL100/105 can be used

to set the clock of other PakBus devices in the network. Set this

address to 0 to disable the function.

Central Routers - The Central Routers setting is used to set up the

NL100/105 either as a Central Router or a Branch Router. If 0 is used

for this setting, then the NL100/105 is set up as a Central Router;

otherwise, a list of Central Routers for the NL100/105 is entered and

the device is set up as a Branch Router. While a Central Router learns

the routes of all devices in the PakBus network, a Branch Router

learns the routes for devices only within its branch. The use of

Branch Routers allows branches of the network to be isolated from

other branches. When the NL100/105 is set up as a branch router, the

addresses for the Central Routers are specified individually with a

space separating each address. A range of addresses can be entered

by separating them with a hyphen (e.g., 1 3 6 10-15, sets PakBus

addresses 1, 3, 6, 10, 11, 12, 13, 14, and 15 as Central Routers).

2.4.3.7 PakBus/Tcp Server Config

This option enables the NL100/105 to use an Ethernet connection to

communicate with other PakBus devices in the network. The NL100/105 can

support up to 16 concurrent connections. The NL100/105 will listen for

incoming TCP/IP packets on the socket designated by the PakBus/Tcp server

port number setting. If the NL100/105 will not be used in a PakBus network,

or if the PakBus communication among PakBus devices in the network will

15

Page 20

NL100/105 Network Link Interface

take place over a port other than the Ethernet connection, this setting can be

disabled. When enabled, there is one option to configure:

2.4.3.8 PakBus/Tcp Client Config

Enabling this option will set up the NL100/105 to act as a client in a PakBus

network. In this mode, the NL100/105 will actively maintain a TCP/IP

connection with a PakBus/Tcp server over the 10 Base-T connection.

This option is typically used when the NL100/105 is configured to

communicate with another NL100/105 over an Ethernet connection, so that the

two PakBus networks served by the NL100/105s can be merged. In most

situations, this setting can be disabled.

PakBus/TCP server port number - Enter the port number, in the range

of 1 to 65000, that will be used for communication. The default port

number is 6785.

Server IP Address - The Server IP address is the address of the server

to which the NL100/105 will attempt to connect and act as a client.

Server IP Port Number - The Server IP port number is used to specify

the port number of the PakBus/TCP server to which the client will

attempt to connect.

2.4.3.9 MODBUS/TCP Gateway Config

When this setting is enabled, the NL100/105 will translate MODBUS/TCP

packets that arrive on the 10 Base-T link for use in a PakBus network. The

translation provided by this mode is MODBUS/TCP message format to

MODBUS RTU serial message format. Unless you are setting up a PakBus

network to also handle MODBUS communication packets, this setting can be

disabled.

2.4.3.10 Telnet IP Port Number

This setting is used to specify the IP port number that will be used for Telnet

sessions with the NL100/105. The default value is 23.

Telnet Session Password - The Telnet Session Password is the string

that must be entered to communicate with the NL100/105 over a

Telnet session. The string can range from 1 to 20 alphanumeric

characters and is case-sensitive. This security measure is

implemented to help prevent unauthorized users from gaining access

to the NL100/105 device.

2.4.3.11 DevConfig Security Code

Campbell Scientific's Device Configurator (or DevConfig) is an application

that is used to configure dataloggers and peripheral devices for communication

and to download new operating systems. A security code can be set in the

NL100/105 so that communication using DevConfig is not possible unless the

security code is sent when the application tries to communicate with the

device. This security code helps to prevent unauthorized changes to a device.

16

Page 21

2.4.4 Defaults

NL100/105 Network Link Interface

By default the address is 0. To enable security, enter a value between 1 and

65535.

The Defaults option displays the factory default settings for the different

telecommunication options. Following the display is a prompt to Save or

Cancel. If Save is selected, the NL100/105 will be reset to the factory defaults.

If Cancel is chosen, the current settings will remain in effect and the user will

be returned to the main menu prompt. The default settings are as follows:

TLink config: [disabled]

RS485 config: [disabled]

CS I/O config: [Tcp Ser]

CS I/O SdcAddr/bps: [9600]

CS I/O serial server port number [6783]

RS-232 config: [ConfMon]

EtherNet 10BASE-T: [enabled]

10BASE-T port IP address: [192.168.111.222]

10BASE-T port network mask: [255.255.0.0]

IP address of the default gateway: [0.0.0.0]

PakBus Address of the NL100/105: [678]

Clock source address: [0]

Central Routers: [0]

PakBus/Tcp server config: [disabled]

PakBus/Tcp client config: [disabled]

MODBUS/TCP gateway config: [disabled]

Telnet IP port number: [23]

Telnet session password: [nl100]

DevConfig security code: [0]

This option is different from the Reset menu item. The Default menu item

resets the NL100/105 back to the factory defaults. Reset reboots the device

using the last-saved configuration.

After the NL100/105 reboots, it may take a few moments to reestablish

communication. Press enter a few times until the NL100/105 status line is

returned.

17

Page 22

NL100/105 Network Link Interface

2.4.5 Reset

This option reboots the NL100/105, using the last saved settings that have been

programmed by the user. This option is different from the Defaults menu item.

The Defaults menu item resets the NL100/105 back to the factory defaults.

After the NL100/105 reboots, it may take a few moments to reestablish

communication. Press enter a few times until the NL100/105 status line is

returned.

NOTE

When using the NL100/105 in a PakBus network, resetting the

NL100/105 (or making other changes to the network that might

change the known route to remotes), may result in lengthy

communication interruptions until the new routes can be learned

by all the devices in the network.

2.4.6 Help

The Help option provides tips for navigating within the NL100/105 menu

prompts and gives a brief description of each menu item. Help for a particular

setting can be displayed by pressing F1 or ? at the prompt for that setting.

2.4.7 Bye

The Bye option is used to close the Socket connection at the end of a Telnet or

terminal communication session.

2.4.8 Other Commands

Additional commands are available for the NL100/105, which are not shown

on the prompt line for the device or in DevConfig. The commands are used for

troubleshooting.

18

Command Description

io This command is a toggle, which turns on or off the monitoring

of low level I/O

o (or old) This command shows historic diagnostic trace information for

the NL100/105. The object handle, name, and state are provided

for all active objects and the object handle, name, and event type

are provided for all recent events.

c (or

current)

t (or tables) This command displays the PakBus routing table information for

This command shows current diagnostic trace information for

the NL100/105. The object handle, name, and state are provided

for all active objects and the object handle, name, and event type

are provided for all recent events.

the NL100/105:

Page 23

NL100/105 Network Link Interface

2.4.9 Serial Server Watchdog

If no communication is detected for a specified number of minutes, the

NL100/105 will drop the communications link. This feature is called a

"watchdog". The watchdog alleviates the problem of a communications port

being held open, thus rendering the device inaccessible, if the NL100/105 and

the remote device failed to terminate the communications link in a "normal"

manner. The NL100/105 will wait two minutes for activity on a port before

timing out. This affects all communication modes, including when the

NL100/105 is configured as a PakBus based or TCP/IP based serial server, and

when communicating with the NL100/105 during a Telnet session.

3. Connecting the NL100/105 to a Network

3.1 Network to NL100 Connection

The connection from the computer network to the NL100/105 10 Base-T port

should be a twisted pair cable. A male RJ-45 plug connector should be on the

cable end going into the 10 Base-T port.

If the cable is to be run directly from the computer to the NL100/105, a

crossover cable is required. If the cable will be run from a hub to the

NL100/105, a straight through cable should be used. Appendix C shows the

pin-outs for these two cable types.

3.2 Typical Configurations

The cases below assume the NL100/105 is being connected to a mixed array

datalogger using the datalogger's CS I/O port (CR10X, CR510 CR23X) or RS232 port (CR23X). TD-based dataloggers (CR10X-TD, CR510-TD, and

CR23X-TD) are configured similarly. In these instances, the communication

port(s) being used on the NL100/105 should be set up as TcpSer (TCP/IP

based serial server). When communicating with PakBus devices (CR1000,

CR3000, CR800/850, CR200, CR10XPB, CR510PB, or CR23XPB), the

communication port on the NL100/105 can be configured for PakBus or

TcpSer, depending upon the role the NL100/105 is to play in the network. In

many cases, the TcpSer option can be selected.

For mixed array and TD dataloggers, the network map for the LoggerNet

software should depict an IPPort root device with the datalogger attached

directly to the IPPort (see Figure 3) unless otherwise noted. For PakBus

dataloggers, a PakBus Port must first be added to the IP Port in the network

map, and then the PakBus datalogger attached to the PakBus Port. In instances

where the NL100/105 is to be a PakBus router, a pbRouter must be added after

the PakBus Port and before the PakBus datalogger. In some instances, extra

response time (3 to 4 seconds) may need to be added to the IPPort and/or the

datalogger to account for network traffic delays over a TCP/IP connection.

NOTE

The IP Address entered in the software for the NL100/105

should not contain leading zeros. If leading zeros are used, the

communications attempts will fail.

19

Page 24

NL100/105 Network Link Interface

Some of the communication links require additional peripherals or cables that

can be purchased from Campbell Scientific. In some cases, a standard RS-232

9 to 25 pin or 25 to 25 pin cable is required. RS-232 cables can be purchased

from Campbell Scientific or from a computer accessories supplier.

FIGURE 3. Typical NL100/105 Setups in LoggerNet

3.2.1 Direct Connect from the NL100/105 to a Datalogger

Either the CS I/O port or the RS-232 port can be used to directly connect a

datalogger to the NL100/105. Cabling or additional peripherals are required as

listed below. Note that multiple dataloggers can be connected to one

NL100/105 by using combinations of the connections described below. Each

port must be assigned a unique port number.

NL100/105 CS I/O port to datalogger CS I/O port - An SC12 cable is

connected between the CS I/O ports on both devices. An SC12 is typically

shipped with all datalogger peripherals.

NL100/105 RS-232 port to datalogger RS-232 port - A standard 9 to 9 pin

communications cable should be connected between the RS-232 ports on both

devices.

NL100/105 RS-232 port to datalogger CS I/O port - A serial communications

cable should be connected to the RS-232 port of the NL100/105. This cable

should be connected to an SC32A or SC32B optically isolated interface, and

the datalogger should be connected to the 9 pin port of the SC32A/B with an

SC12 cable.

20

Page 25

NL100/105 Network Link Interface

3.2.2 MD9 Connection from NL100/105 to Datalogger

Campbell Scientific's MD9 Multidrop Interface can be used to connect one or

more dataloggers to the NL100/105 via the NL100/105’s RS-232 port. A

multidrop network is capable of addressing up to 254 dataloggers, but the

actual number of dataloggers that can be connected depends upon attenuation

of the signal due to coax cable length, the number of devices on the network,

and the number of coax terminator pairs used. Refer to the MD9 manual for

determining the maximum number of dataloggers that can be connected based

on these factors.

An SC532 or SC532A Interface device should be connected to the serial port

of the NL100/105. The cable to an SC532 should be a standard 9 to 25 pin RS232 cable, with the 25 pin male connection mated to the RS-232 side of the

SC532. The cable to an SC532A should be a standard 9 to 9 pin RS-232 cable.

Note, however, that the RTS line in the cable must be disabled (pin 7 on the 9pin connector or pin 4 on the 25-pin connector). An SC12 cable is used to

connect the 9 pin peripheral connection of the SC532/SC532A to the serial I/O

port of the MD9. Coax cable, running from the coax port of the base MD9, is

run to each of the remote MD9 devices, which are connected to the dataloggers

with SC12 cables. Refer to the MD9 User's Manual for additional information.

The Setup window in LoggerNet should depict an MD9 Base modem attached

to the IPPort, with the datalogger attached to an MD9Remote Modem. Refer to

Figure 4 below.

FIGURE 4. LoggerNet Setup for NL100/105 to MD9 to Datalogger Connection

21

Page 26

NL100/105 Network Link Interface

3.2.3 MD485 Connection from NL100/105 to Datalogger

Campbell Scientific's RS485 communication device, the MD485, can be

attached to an NL100/105 to provide a communication link to one or more

dataloggers. The MD485 has three communication ports: RS485 (two

terminals but the same physical port), CS I/O, and RS232. It can be configured

for communication on any two of its three ports at one time. The most typical

use of the MD485 is to set up a network of dataloggers linked together in an

RS485 network. However, you can also attach a datalogger or other

compatible peripheral to the CS I/O port or the RS-232 port of the MD485.

The MD485 can be configured to communicate in a transparent (point to point)

mode, as an MD9 emulator, or as a peripheral in a PakBus network. For

transparent or PakBus communication, the MD485 is attached to the

NL100/105's RS485 port using a 3-wire shielded cable (i.e., a 2 twisted pair

shielded cable). For MD9 emulation, at least two MD485s are required. One

MD485 is attached to the NL100/105's RS232 port using an SC12 cable. This

MD485 acts as a base MD9 device, since the NL100/105 is, in itself, not

capable of MD9 communication. A second MD485 is attached to each of the

dataloggers.

An appendix in the MD485 manual provides complete information on setting

up the NL100/105 and the MD485s for each of the above configurations, along

with information on the settings used in LoggerNet.

3.2.4 RF Connection from NL100/105 to Datalogger

Interfacing the NL100/105 to an RF Base station enables wireless

communication to remote datalogger stations over a TCP/IP network. The

preferred configuration uses the NL100/105's RS-232 port (DTE) for

connection to the RF Base as follows:

For connecting to the RS-232 port (DCE) of the RF4xx series or RF450 Spread

Spectrum radios, a standard RS-232 serial cable (CSI# 10873 or equivalent) is

used.

For connecting to the RS-232 port (DTE) on an RF500M RF Modem, a nullmodem RS-232 serial cable (CSI# 13657 or equivalent) must be used. If

connecting to the CSI/O port on the RF500M, an SC532A 9-Pin Peripheral to

RS-232 interface adapter and standard serial cables are required.

NOTE

When connecting to an RF310B Base Station or its predecessors

(or directly to an RF310M RF Modem via an SC532A), the RTS

line in the standard RS-232 serial cable (pin seven on a 9-pin

connector or pin four on a 25-pin connector) must be disabled.

This is done to prevent driving the SDE signal (pin 6) on the RF

Modem's CSI/O port high and inhibiting the ME communication

cycle.

If circumstances should require the utilization of the NL100/105's CS I/O port

for connection to an RF base, please contact a Campbell Scientific

Applications Engineer for information about how this might be achieved.

22

The configuration of the Setup window in LoggerNet will vary depending on

the equipment and configuration settings employed. Please consult the

relevant manual(s) for configuration specifics. Figure 5 depicts the LoggerNet

Page 27

NL100/105 Network Link Interface

Setup window for an RF Network using VHF/UHV radios and a mixed array

datalogger.

FIGURE 5. LoggerNet Setup for NL100/105 to RF to Datalogger Connection

Refer to Campbell Scientific's Radiotelemetry Network Instruction Manual for

more information on setting up RF stations.

3.2.5 Short Haul Modem Connection from NL100/105 to Datalogger

The use of Short Haul Modems (SRM-5A, SRM6-A) allows a connection to a

datalogger via TCP/IP to a twisted pair cable. The short haul modem at the

NL100/105 should be connected to the device using a standard RS-232 9 to 25

pin communication cable. It is recommended that a short haul surge protection

device (P/N 5563) be connected next and then the twisted pair cable. Another

surge protection device is recommended between the cable and the remote

short haul modem. The short haul modem should be connected to an SC932

RS-232 9 to 25 pin DCE interface, which is then connected to the datalogger's

CS I/O port via an SC12 cable.

3.2.6 Phone Modem Connection from NL100/105 to Datalogger

A Hayes-compatible phone modem can be connected to the NL100/105 to

allow a TCP/IP to phone link between a computer and a datalogger. The phone

modem should be connected to the NL100/105's RS-232 port using an

appropriate RS-232 serial cable. Connection of the remote phone modem to the

datalogger will vary, depending upon the type of remote modem used. Refer to

the user's manual for the system you purchased for additional information on

assembling the remote site.

23

Page 28

NL100/105 Network Link Interface

In the LoggerNet communications software, the phone modem on the

NL100/105 side should be shown attached to the IPPort. The datalogger is then

shown as connected to the remote phone modem. Refer to Figure 6 below.

FIGURE 6. LoggerNet Setup for NL100/105 to Phone to Datalogger Connection

3.3 NL100/105 to Datalogger Connections - CR9000/CR5000

3.3.1 Software Setup

As an alternative to LoggerNet, PC9000 software (version 3.5 or higher) can

be used to communicate with the CR9000 and CR5000 dataloggers via the

NL100/105 and a TCP/IP Network. To configure the software for

communication, choose the Tools | CommLink menu option. From the I/O Port

drop-down list box, select NET. On the bottom left side of the screen, there are

fields in which to type the TCP/IP address and the port number. The setup

should look similar to Figure 7, below.

24

Page 29

NL100/105 Network Link Interface

FIGURE 7. PC9000 Setup for TCP/IP Communication

3.3.2 Hardware Setup for NL105 Communication with the CR9000 via TLink

A CR9000 can be connected to a TCP/IP network by connecting the TLink

port of the CR9000 9031 CPU module to the TLink port of the NL105 (note

that the NL100 does not have this communication port). A twisted pair cable is

used to make this connection.

25

Page 30

NL100/105 Network Link Interface

26

Page 31

Appendix A. CS I/O Port

The CS I/O port is Campbell Scientific's input/output port. It is not a standard

RS-232 pin-out. The following table provides pin-out information on the port

when connected to a datalogger.

Pin Name

1 5 V (supplied by the

datalogger)

2 Signal Ground Provides reference for voltage

3 Ring Output Raised by a NL100/105 to put

4 RXD Output Serial data transmitted to the

5 Modem Enable Input Raised by the datalogger when

6 Synchronous Device

Enable

7 Clock/Handshake Input Used by the datalogger with

Signal

Type

Input Not used by NL100/105

Input Used by the datalogger to

Description

levels

the datalogger into the

telecommunications mode

datalogger

it determines that the

NL100/105 raised the ring line

address the NL100/105 when

the NL100/105 is configured

as a synchronous device

SDE and TXD lines to address

and transfer data to

synchronous devices

8 12 V (supplied by the

datalogger)

9 TXD Input Serial data received from the

Not used by the NL100/105

datalogger

A-1

Page 32

This is a blank page.

Page 33

Appendix B. Null-Modem Cable

A null-modem cable allows communication between two similar devices. It is

sometimes called a crossover cable, because the transmit and receive lines are

crossed so that the two devices can communicate. An RS-232 null modem

cable usually also crosses other handshaking lines.

An RS-232 null-modem cable can be purchased at a local computer store. The

pin-outs for this cable are provided below.

Carrier Detect

Transmit Data

Receive Data

Data Terminal Ready

Signal Ground

Data Set Ready

Request to Send

Clear to Send

Not Used 9 9 Not Used

1 ⇔ 4

2 ⇔ 3

3 ⇔ 2

4 ⇔ 1, 6

5 ⇔ 5

6 ⇔ 4

7 ⇔ 8

8 ⇔ 7

Data Terminal Ready

Receive Data

Transmit Data

Carrier Detect, Data Set Ready

Signal Ground

Data Terminal Ready

Clear to Send

Request to Send

B-1

Page 34

This is a blank page.

Page 35

Appendix C. 10 Base-T Cabling

The cable that runs from the computer to the NL100/105 should be a Category

5 twisted pair cable. If the NL100/105 will be connected directly to the

computer, a crossover cable should be used. If the NL100/105 will be

connected to the computer through a hub, a straight through cable should be

used. The pin-outs for each of these cables is shown below.

Straight Through Cable

Twisted Pair 1

1 ⇔ 1

Twisted Pair 2

Crossover Cable

Twisted Pair 1

Twisted Pair 2

2 ⇔ 2

3 ⇔ 3

6 ⇔ 6

1 ⇔ 3

2 ⇔ 6

3 ⇔ 1

6 ⇔ 2

C-1

Page 36

This is a blank page.

Page 37

Appendix D. RS-485 Connector, 3-Pin Terminal Block

The RS-485 port is for connecting an MD485 multidrop interface to the

NL100. The MD485 attaches to the NL100 via a twisted pair cable such as the

#9720. The following table shows the pin-out information for the RS-485 port.

PIN I/O FUNCTION

1 GND Signal Ground

2 I/O 485_IO- (A)

3 I/O 485_IO+ (B)

I = Signal Into the NL100, O = Signal Out of the NL100

D-1

Page 38

This is a blank page.

Page 39

Glossary

Beacon Interval - Devices in a PakBus network may broadcast a message to

other devices, in order to determine "neighbor" devices. Neighbor devices are

devices that can be communicated with directly by the current device without

being routed through an intermediate device. A beacon in a PakBus network

helps to ensure that all devices in the network are aware of which other devices

are viable in the network.

If configured to do so, a clock set command may be transmitted with the

beacon interval. This function can be used to synchronize the clocks of devices

within the PakBus network.

MODBUS - MODBUS is a communications protocol developed by Modicon

which was designed to provide a common communications protocol among

intelligent devices in the manufacturing industry.

Neighbor (PakBus Neighbor) - Neighbor devices are devices that can be

communicated with directly by the current device without being routed

through an intermediate device.

PakBus - PakBus is a packet-based communications protocol developed by

Campbell Scientific. One of the advantages of PakBus is that other

communications protocol packets, such as TCP/IP or MODBUS, can be

"wrapped" in a PakBus packet and transferred among PakBus devices in the

network, thus allowing various communication protocols within one network.

Devices that are capable of PakBus communication include the CR10XTD-PB,

CR510TD-PB, CR23XTD-PB dataloggers, the RF400 modem, and the

NL100/105.

PakBus Node - A device in the PakBus network with a unique PakBus ID.

The device can be a datalogger, a computer, or an NL100/105.

Serial Server - A serial server is a device that allows serial communication

over a TCP/IP communications link.

Page 40

This is a blank page.

Page 41

Page 42

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...