Page 1

INSTRUCTION MANUAL

LI200S Pyranometer

Revision: 2/96

Copyright (c) 1981-1996

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The LI200S SENSOR is warranted by CAMPBELL SCIENTIFIC, INC. to be

free from defects in materials and workmanship under normal use and service

for twelve (12) months from date of shipment unless specified otherwise.

Batteries have no warranty. CAMPBELL SCIENTIFIC, INC.'s obligation

under this warranty is limited to repairing or replacing (at CAMPBELL

SCIENTIFIC, INC.'s option) defective products. The customer shall assume

all costs of removing, reinstalling, and shipping defective products to

CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. will

return such products by surface carrier prepaid. This warranty shall not apply

to any CAMPBELL SCIENTIFIC, INC. products which have been subjected

to modification, misuse, neglect, accidents of nature, or shipping damage. This

warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability or fitness for a particular purpose. CAMPBELL

SCIENTIFIC, INC. is not liable for special, indirect, incidental, or

consequential damages.

Products may not be returned without prior authorization. The following

act information is for US and International customers residing in countries

cont

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country. To obtain a Returned Materials Authorization (RMA),

contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an

applications engineer determines the nature of the problem, an RMA number

will be issued. Please write this number clearly on the outside of the shipping

container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 W

Logan, Ut

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

est 1800 North

ah 84321-1784

Page 3

LI200S PYRANOMETER

1. GENERAL

This manual provides information for interfacing

a CR10, 21X, and CR7 datalogger to a LI200S

Pyranometer. An instruction manual provided

by LI-COR contains the sensor calibration

constant and serial number. Cross check this

serial number against the serial number on your

LI200S to ensure that the given calibration

constant corresponds to your sensor.

2. SPECIFICATIONS

Stability: <±2% change over a 1 year

period

Response Time: 10 µs

Temperature

Dependence: 0.15% per °C maximum

Cosine Correction: Cosine corrected up to 80°

angle of incidence

Operating

Temperature: -40 to 65°C

Relative Humidity: 0 to 100%

Detector: High stability silicon

photovoltaic detector (blue

enhanced)

Sensor Housing: Weatherproof anodized

aluminum case with acrylic

diffuser and stainless steel

hardware

Size: 0.94” dia x 1.00” H (2.38 x

2.54 cm);

Weight: 1 oz. (28 g)

Accuracy: Absolute error in natural

daylight is ±5% maximum;

±3% typical

Typical Sensitivity: 0.2 kWm

Linearity: Maximum deviation of 1%

up to 3000 Wm

Shunt Resistor: Adjustable, 40.2 to 100 Ω,

factory set to give the

above sensitivity

Light Spectrum

Waveband: 400 to 1100 nm

-2mV-1

-2

NOTE: The black outer jacket of the cable

is Santoprene® rubber. This compound was

chosen for its resistance to temperature

extremes, moisture, and UV degradation.

However, this jacket will support

combustion in air. It is rated as slow

burning when tested according to U.L. 94

H.B. and will pass FMVSS302. Local fire

codes may preclude its use inside buildings.

3. MEASUREMENT INSTRUCTION

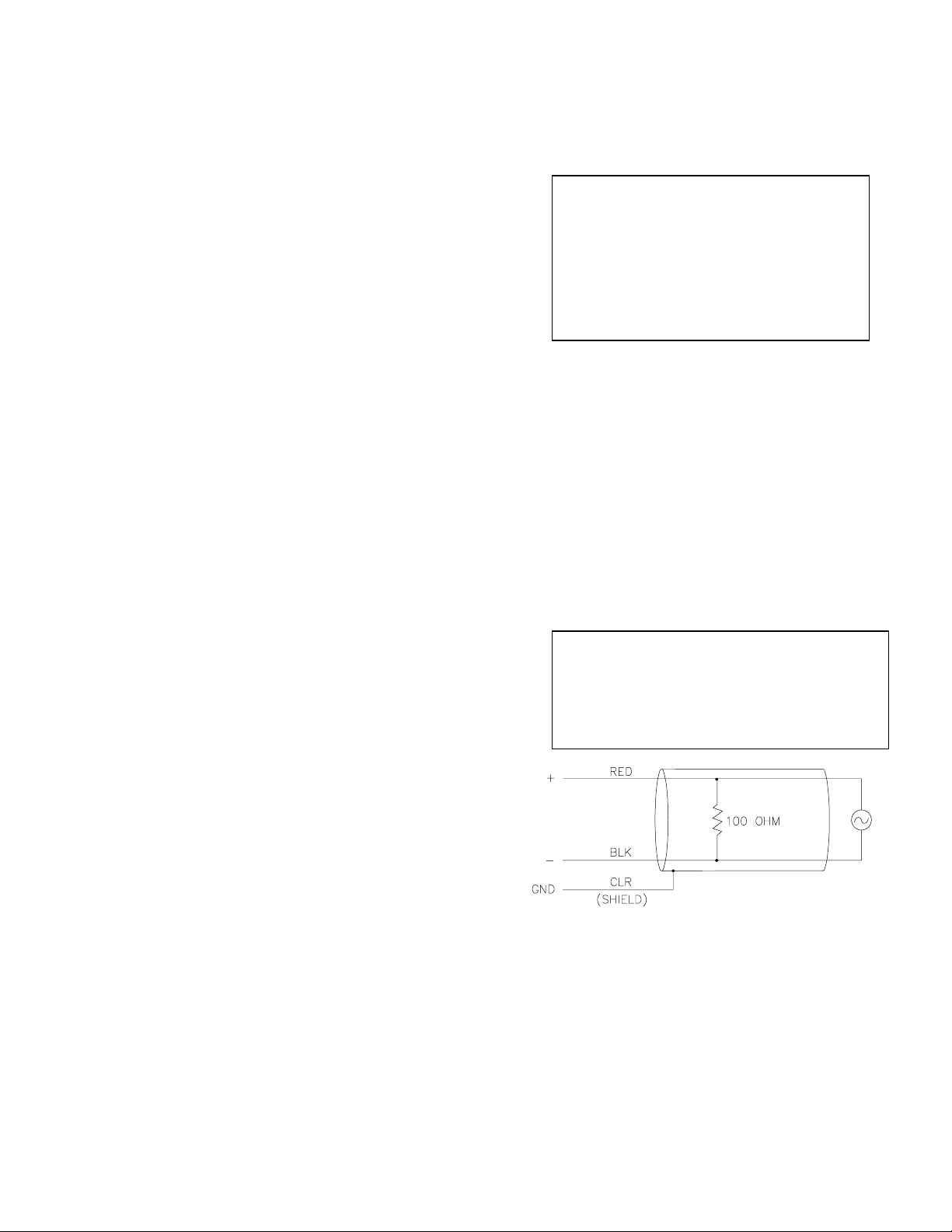

The LI200S (refer to Figure 1) outputs a low

level voltage ranging from 0 to a maximum of

about 12mV depending on sensor calibration

and radiation level. A differential voltage

measurement (Instruction 2) is recommended

because it has better noise rejection than a

single-ended measurement.

If a differential channel is not available, a singleended measurement (Instruction 1) is a

possibility. As a test, wire the LI200S as shown in

Figure 2 and make single-ended and differential

measurements. Compare results to determine

the acceptability of a single ended measurement.

NOTE FOR 21X USERS:

potential differences are created along the 21X

analog terminal strip when the datalogger

power supply is powering external peripherals.

If the peripherals draw about 30mA or greater,

the LI200S must be measured differentially.

Figure 1. LI200S Schematic

INPUT RANGE

An example showing how to determine the

optimum input range for a given sensor

calibration and maximum irradiance follows.

This is an example only. Your values will be

different.

Slight ground

1

Page 4

LI200S PYRANOMETER

EXAMPLE

-Sensor Calibration: Assume the sensor

calibration is 87 microamps kW-1 m-2. The

LI200S outputs amperage which is converted to

voltage by 100 ohm shunt resistor in the cable,

as shown in Figure 1. To convert the calibration

from microamps to millivolts, multiply the

calibration by 0.100. The example calibration

-1 m-2

changes to 8.7 mV kW

.

-Maximum Irradiance: A reasonable estimate

of maximum irradiance at the earth’s surface is

-2

1 kW m

.

-Input Range Selection: An estimate of the

maximum input voltage is obtained by

multiplying the calibration by the maximum

expected irradiance. That product is 8.61mV

for this example. Select the smallest input

range which is greater than the maximum

expected input voltage. In this case the 15mV

range for the 21X and CR7, and the 25mV

range for the CR10 are selected.

Measurement integration time is specified in the

input range parameter code. A more noise free

reading is obtained with the slow or 60 Hz

rejection integration. A fast integration takes

less power and allows for faster throughput.

EXAMPLE

Assume that daily total flux is desired, and the

datalogger scan rate is 1 second. With a

multiplier that converts the readings to units of

-2

and an average irradiance of .5 kW m-2,

kJ m

the maximum low resolution output limit will be

exceeded in less than four hours.

Solution #1 - Record average flux density and

later multiply the result by the number of

seconds in the output interval to arrive at total

flux.

Solution #2 - Record total flux using the high

resolution format. The drawback to high

resolution is that it requires 4 bytes of memory

per data point, consuming twice as much

memory as low resolution.

5. CONNECTIONS

Differential and single-ended connections to the

datalogger are shown in Figures 2 and 3,

respectively.

MULTIPLIER

The multiplier converts the millivolt reading to

engineering units. Commonly used units and

how to calculate the multiplier are shown in

Table 1.

Table 1. Multipliers Required for Flux

Density and Total Fluxes

UNITS

MULTIPLIERS

kJ m-2 (1/C)*t (Total)

kW m-2 (1/C) (Average)

*t*

cal cm-2 (1/C)

cal cm-2 min-1 (1/C)

(0.0239) (Total)

*

(1.434) (Average)

C = (LI-COR calibration)*0.100

t = datalogger program execution

interval in seconds

4. OUTPUT FORMAT CONSIDERATIONS

The largest number that the datalogger can

output is 6999 in low resolution and 99999 in

high resolution (Instruction 78, set resolution). If

the measurement value is totalized, there is

some danger of overranging the output limits,

as shown in the following example.

Figure 2. Differential Measurement

Connection

*AG in Figure 2 refers to Analog Ground in the CR10

which is the same as ground for the 21X and CR7.

On a differential measurement, jumper the low

side of the signal to AG to keep the signal in

common mode range, as shown in Figure 2.

Figure 3. Single-ended Measurement Connection

*AG in Figure 3 refers to Analog Ground in the

CR10, which is the same as ground for the 21X

and CR7.

2

Page 5

LI200S PYRANOMETER

3

Page 6

Page 7

This is a bla nk page.

Page 8

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

sales@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringo wa Cent ra l

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda . (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...