Page 1

Revision: 03/2021

Copyright © 2020 – 2021

Campbell Scientific, Inc.

Page 2

Table of contents

1. Introduction 1

2. Precautionary statements 1

3. Initial inspection 1

4. Overview 2

5. Specifications 4

5.1 Pressure transducer 4

5.2 Air flow 4

5.3 Power 5

5.4 Communications 5

5.5 Enclosure 6

5.6 Environmental 6

6. Installation 6

6.1 Verify operation 6

6.2 Wiring 7

6.3 Power considerations 8

6.4 Default settings 9

6.5 Setup using keypad/display 11

6.6 Campbell Scientific data logger programming 13

6.6.1 SDI-12 programming 13

6.6.2 RS-485 programming 13

6.7 Field installation 14

6.7.1 Site selection 14

6.7.2 Enclosure mounting 14

6.7.3 Desiccator installation 15

6.7.4 Orifice line and conduit installation 17

7. Operation 19

7.1 Principles of operation 19

7.2 Keypad/display menu 20

7.2.1 Stage setup 21

7.2.2 Bubbler setup 21

Table of Contents - i

Page 3

7.2.3 System setup 22

7.2.4 Communication setup 23

7.2.5 Diagnostic/Test 23

7.2.6 System information 27

7.3 SDI-12 measurement and extended commands 27

7.4 Modbus register map 30

7.5 Secured orifice line 35

7.6 Long orifice lines 37

7.7 Orifice-line outlet orientation 37

7.8 Orifice-line outlet types 38

8. Maintenance and troubleshooting 39

8.1 Replacing desiccant 39

8.2 Lithium battery replacement 40

8.3 Plugged orifice outlet 41

8.4 Cold weather 42

8.5 Preventing or fixing orifice-line leaks 42

8.6 Updating operating system 42

8.7 Troubleshooting 43

Appendix A. Example program 46

Appendix B. SDI-12 sensor support 48

B.1 SDI-12 command basics 48

B.1.1 Acknowledge active command (a!) 49

B.1.2 Send identification command (al!) 49

B.1.3 Start verification command (aV!) 50

B.1.4 Address query command (?!) 50

B.1.5 Change address command (aAb!) 50

B.1.6 Start measurement commands (aM!) 51

B.1.7 Start concurrent measurement commands (aC!) 51

B.1.8 Start measurement commands with cyclic redundancy check (aMC! and aCC!) 53

B.1.9 Stopping a measurement command 53

B.1.10 Send data command (aD0! … aD9!) 53

B.1.11 Extended commands 54

B.1.12 SDI-12 version 1.4 identify measurement commands and responses 54

B.2 SDI-12 transparent mode 55

B.2.1 Changing an SDI-12 address 56

Table of Contents - ii

Page 4

B.3 References 58

Appendix C. Field calibration check 59

Table of Contents - iii

Page 5

1. Introduction

The LevelVUE B10 is a continuous-air-flow bubbler that measures ground water, surface water, or

any liquid level. It consists of an integrated circuit board, pressure sensors to measure and control

tank and line pressures, a 12VDC industrial compressor, a 0.8 liter air tank, and an integrated

keypad/display. Three pressure ranges are available: 15psi (34.6ft, 10.5m), 30psi (69.2ft,

21.0m), or 50psi (115ft, 35.0m). The bubbler communicates with a data logger or RTU using

either SDI-12 or Modbus protocols. Although this document only includes example programs for

Campbell Scientific CRBasic data loggers, any data logging device capable of SDI-12 or Modbus

communications can be used to retrieve the LevelVUE B10 measurements.

2. Precautionary statements

l READ AND UNDERSTAND the Safety section at the back of this manual.

l Not using a desiccator will void your warranty. Campbell Scientific offers a desiccator kit,

which is recommended for use with the LevelVUE B10.

l The sensor can survive temporary operation for 1.5 times the maximum rated pressure

(Table 5-1 (p. 4). However, measurements made beyond the rated pressure range will be

inaccurate.

l Do not use quick connect fittings as these tend to leak.

l Mount the LevelVUE B10 in a location where it will not get jarred or shift during operation.

3. Initial inspection

l Upon receipt of the LevelVUE B10, inspect the packaging for shipping damage, and, if

found, report the damage to the carrier in accordance with policy.

l Carefully open the package to avoid damaging or cutting the orifice-line tubing (if

ordered). A thorough inspection of the tubing is prudent.

LevelVUE™B10 Water-Level Bubbler 1

Page 6

l Compare the pressure range printed on the bottom of the enclosure with the pressure

range listed in the shipping document to ensure that the correct pressure range was

received.

l Verify that the orifice line Swagelok® fitting and air intake line barbed fitting were shipped

with the LevelVUE B10. They are shipped in a small bag inside the enclosure. Do the

following to locate these items:

o

Open the enclosure lid

o

Press on the black magnet

o

Lift the keypad panel

l

NOTE:

The orifice line Swagelok® fitting may already be installed on the LevelVUE B10.

l Verify that all bubbler accessories were sent. The following accessories (ordered separately)

are often shipped with the LevelVUE B10:

o

Orifice line

o

Desiccator kit

o

Desiccant

4. Overview

The LevelVUE B10 bubbler incorporates all the components of a self-contained pressurized air

supply system. It has an air compressor, air tank, and other components of older conoflow

systems. However, instead of pressurized air tanks and manual valves used in conoflow systems,

the LevelVUE B10 meters the airflow to create a constant flow in the line regardless of the water

depth above the orifice. Precision sensors monitor the tank and line pressures to consistently

maintain the same airflow. The precision sensor monitoring the pressure on the orifice line

precisely detects the pressure required to push air through the line. This pressure value is directly

related to water depth. A simple conversion is applied to the pressure value to generate water

depth in feet, meters, or other units. Proprietary electronics control the pump and calculate the

measurements. The LevelVUE B10 has a digital SDI-12 or RS-485 output that allows any data

logger that supports SDI-12 or Modbus protocols to retrieve the LevelVUE B10 measurements.

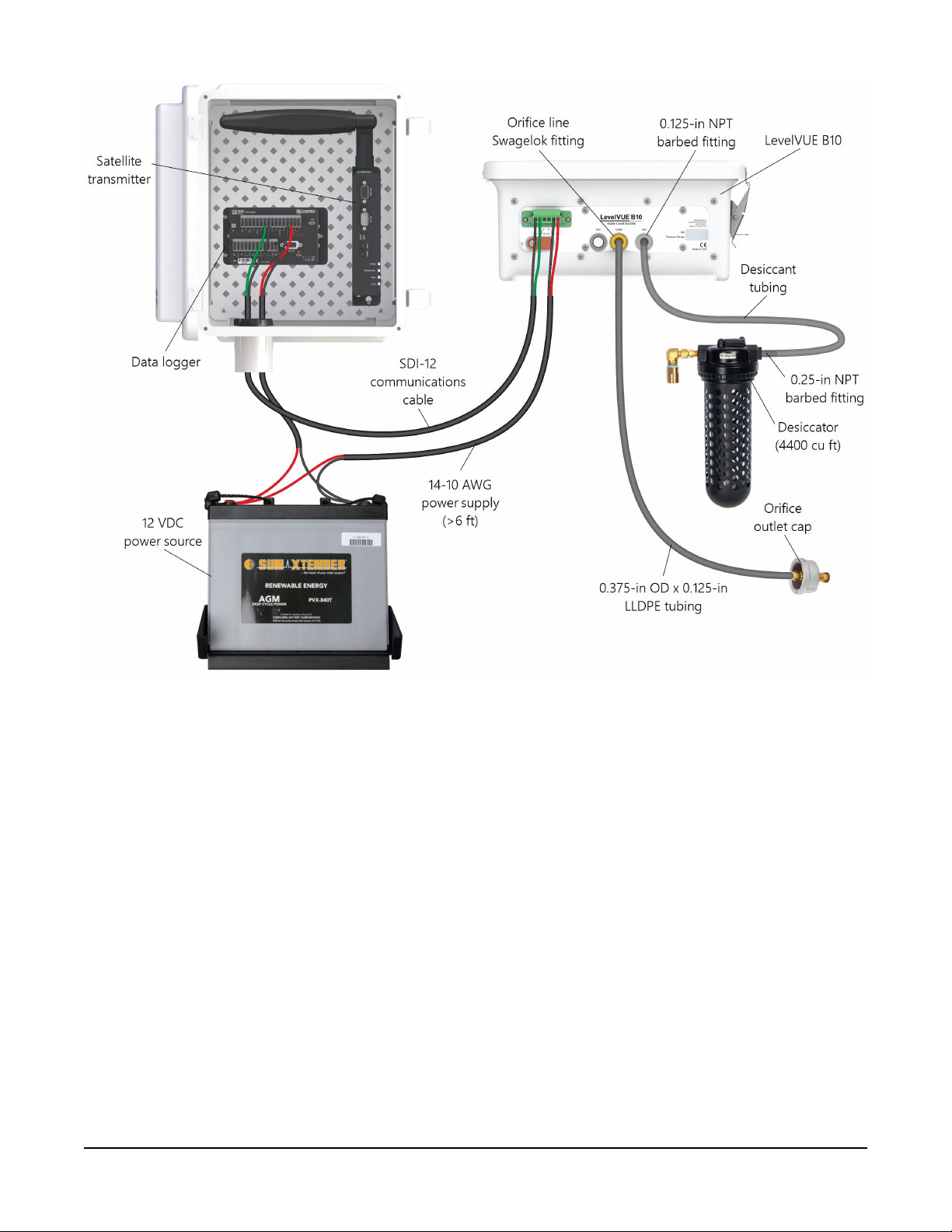

FIGURE 4-1 (p. 3) shows a LevelVUE B10-based system that uses a Campbell Scientific data logger

and SDI-12 protocol.

LevelVUE™B10 Water-Level Bubbler 2

Page 7

FIGURE 4-1. Components in a LevelVUE B10-based system

The LevelVUE B10 environmental enclosure can be mounted next to rivers, in stilling wells, or on

or near bridges. Only the orifice line contacts the water, which allows the bubbler to work in

areas that would damage submersed sensors due to corrosion, contamination, flood-related

debris, lightning, or vandalism. It also can be used in stream beds that periodically dry up or in

sub-zero temperatures if the water is still flowing. Unlike radar gages, bubbler measurements are

not affected by wind.

Features:

l Proprietary high-pressure/high-volume purge operation to prevent sediment buildup

l High-volume industrial air compressor

l Low power consumption

l –40 to 60 °C operation

LevelVUE™B10 Water-Level Bubbler 3

Page 8

l Three pressure ranges: 15 psi, 30 psi, and 50 psi

l Built-in keypad/display for full setup, measurement, and maintenance operations

l Proprietary air flow/bubble generation for years of trouble-free operation

l Large volume desiccator to minimize maintenance frequency

l Incorporated SDI-12 version 1.4 metadata commands for identification of data

l Compatible with SDI-12 and Modbus controllers including Campbell Scientific CR300

series, CR6 series, CR800 series, CR1000X series, CR3000, and GRANITE-series data loggers

l High water mark detection (crest stage) between normal SDI-12 measurement requests

5. Specifications

Compliance documents:

View at www.campbellsci.com/levelvueb10

5.1 Pressure transducer

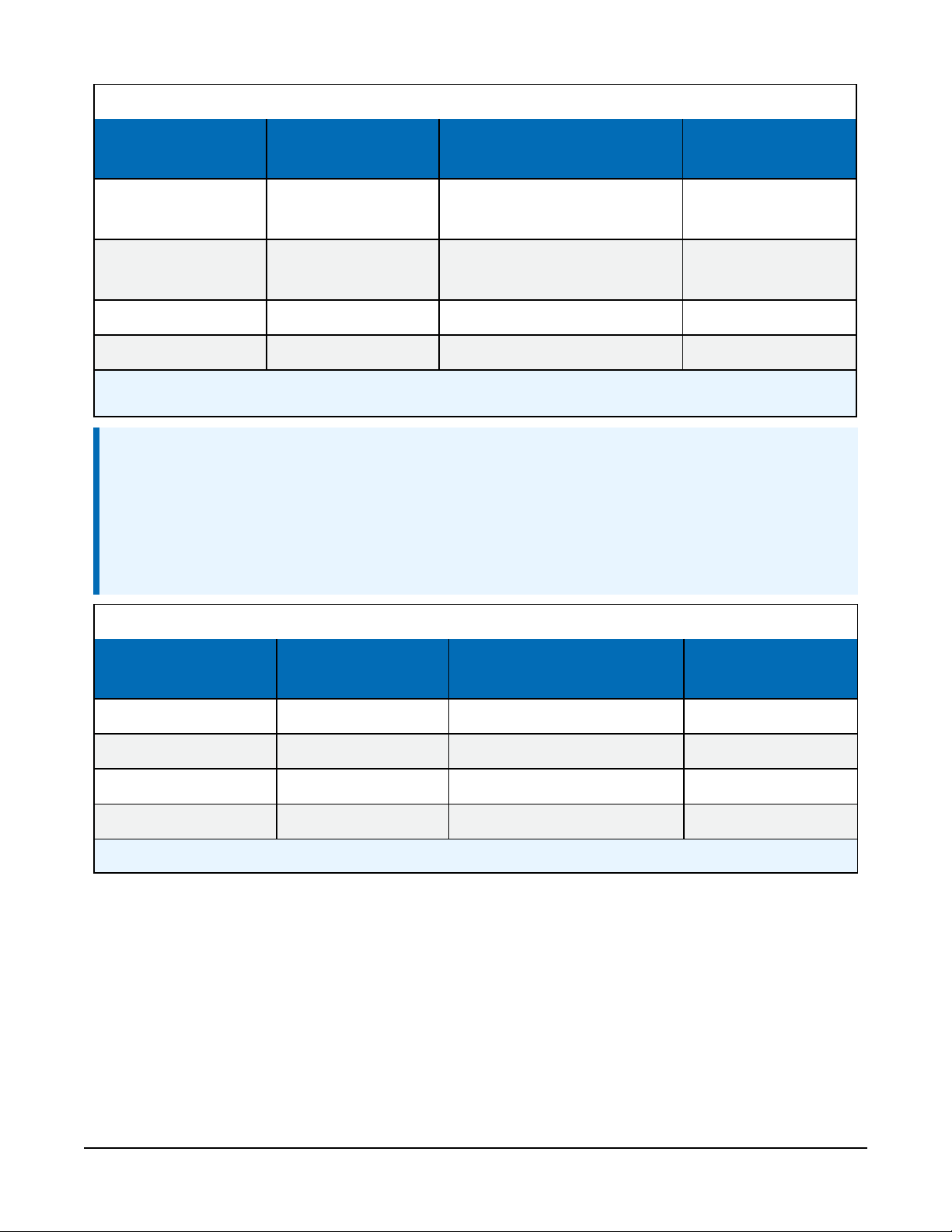

Table 5-1: Pressure range, depth, and resolution

Pressure range

0 to 15 psi 0 to 10.54 m (34.6 ft) ±2.1 mm (0.007 ft)

0 to 30 psi 0 to 21 m (69.20 ft) ±4.26 mm (0.014 ft)

0 to 50 psi 0 to 35.16 m (115.35 ft) ±7.11 mm (0.023 ft)

1

Level calculations assume 1 psi = 0.7031 m (2.3067 ft) of water.

Accuracy:

Sensor overpressure rating:

≤ 0.02% of full scale output (FSO)

over temperature range

1.5 times the pressure range

Water depth range

1

Resolution

5.2 Air flow

Description:

Bubble rate: Programmable 30 to 120 bubbles per minutes;

Microprocessor controlled constant air flow

over full pressure range and temperature.

based on 6.35 mm (0.25 inch) inner-diameter outlet.

60 bubbles per minute default

LevelVUE™B10 Water-Level Bubbler 4

Page 9

Purge operation

Manual:

SDI-12:

Modbus:

Automatic-timed purge:

Purge pressure:

Purge sustain time:

Pressure inlet port:

Orifice-line outlet port:

Requested from keypad/display

Command for purge under program control

Command for purge under program control

Once a day to once a month with 1 day resolution

30 to 90 psi, programmable

0 to 30 s, programmable

1/8-inch female NPT

1/8-inch female NPT

5.3 Power

Input voltage range: 11.5 to 16.5 VDC

Current

Standby: 5 mA

Compressor active: 7 A typical, 10 A maximum

Start-up surge current: 18 A maximum

5.4 Communications

SDI-12

Response time:

Default address:

RS-485

Protocol:

Default address:

Default configuration:

Data type:

Built-in keypad/display: Graphical 8-line-by-20-character display.

SDI-12 V 1.4 compliant

10 s forM!SDI-12 command with default averaging time of

5seconds

0

Modbus

1

8-bit, even parity, 1 stop bit, 19200 bps baud rate

32-bit float, no reversal of the byte order (ABCD)

Menu fully supports system setup.

LevelVUE™B10 Water-Level Bubbler 5

Page 10

5.5 Enclosure

Material:

Width:

Height:

Depth:

Weight:

Fiberglass

28.9 cm (11.4 in)

34 cm (13.4 in)

13 cm (5.2 inch)

7.5 kg (16.5 lb)

5.6 Environmental

Operating temperature:

Storage temperature:

Relative humidity:

–40 to 60 °C

–40 to 80 °C

0 to 95%, non-condensing

6. Installation

6.1 Verify operation 6

6.2 Wiring 7

6.3 Power considerations 8

6.4 Default settings 9

6.5 Setup using keypad/display 11

6.6 Campbell Scientific data logger programming 13

6.7 Field installation 14

6.1 Verify operation

Before installing the LevelVUE B10, verify its operation using the following procedure:

1. Remove the plug from the orifice line Outlet fitting on the LevelVUE B10. Save the plug for

use later.

2. Connect the LevelVUE B10 to the power supply (Wiring (p. 7)). After connecting the

bubbler to the power supply, the bubbler will take an initial atmospheric measurement and

LevelVUE™B10 Water-Level Bubbler 6

Page 11

calibrate itself. The compressor also will turn on to initially charge the tank and start the

flow of air out of the system. If the compressor does not turn on, check the power supply.

The LevelVUE B10 must be connected directly to the battery.

3. Connect a short piece of orifice line tubing to the Outlet fitting and place the end of the

tubing in a bucket or tube of water, and bubbles should appear in 15 to 20 seconds.

4. Press the soft key button directly under Measure on the display to initiate a measurement

sequence. Once the measurement is complete ensure that the reading is reasonable based

on the depth of the orifice line and an offset of 0.00.

5. Press the soft key button directly under Purge on the display to initiate a line purge. The

compressor will charge the tank to 60 psi and release the air out the orifice line. This may

take a few seconds.

6.2 Wiring

Terminals and connectors are on the bottom of the LevelVUE B10 enclosure (FIGURE 6-1 (p. 7)).

FIGURE 6-1. LevelVUE B10 connector panel

Table 6-1 (p. 8) provides wiring to a data logger when using SDI-12 and Table 6-2 (p. 8) provides

wiring to a data logger when using Modbus. The air compressor and electronics connect directly

to the battery using a 16 to 20AWG wire. Keep wire lengths less than 3m (6ft).

The SDI-12 output can be directly read by many devices including all Campbell Scientific data

loggers. RS-485 output can be directly read by a CR6-series, CR1000X-series, or Modbus RTU

RS-485 network. Other Campbell Scientific data loggers can use an MD485 multidrop interface

to read the RS-485 output. Refer to the MD485 manual for information about using the MD485.

LevelVUE™B10 Water-Level Bubbler 7

Page 12

Table 6-1: LevelVUE B10 terminal, function, and connections for SDI-12 measurements

LevelVUE B10

Function Data logger or RTU terminal Power supply

terminal

SDI-12 Data, C, SDI-12,

SDI-12 Data SDI-12 signal

or U configured for SDI-12

1

⏚ or G (digital ground

SDI-12 G Ground

connection)

12Vdc + Power 12V

12Vdc – Power ground G, GND

1

U and C terminals are automatically configured by the measurement instruction for Campbell Scientific CR6 data

logger.

NOTE:

For Campbell Scientific CR6 and CR1000X data loggers making SDI-12 measurements,

conflicts may occur when a companion terminal is used for a triggering instruction such as

TimerInput(), PulseCount(), or WaitDigTrig(). For example, if the LevelVUE

B10 is connected to C3 on a CR1000X, C4 cannot be used in the TimerInput(),

PulseCount(), or WaitDigTrig() instructions.

Table 6-2: LevelVUE B10 terminal, function, and connections for Modbus measurements

LevelVUE B10

Function

terminal

Data logger or RTU

terminal

1

Power supply

RS-485 A– RS-485A A–, C odd

RS-485 B+ RS-485B B+, C even

12Vdc + Power 12V

12Vdc – Power ground G, GND

1

Assumes the sensor directly connects to the data logger.

6.3 Power considerations

The current load of the internal compressor requires the LevelVUE B10 to be connected directly to

the 12VDC battery. The battery should be recharged using AC power or a solar panel. Do not

power the LevelVUE B10 using the 12 V excitation terminal from the data logger and do not use

the PS150 or PS200 because the current limit switch on these devices will trip when the

LevelVUE™B10 Water-Level Bubbler 8

Page 13

compressor tries to turn on. Specific power requirements depend on communications methods,

frequency of site visits, and site location. Contact Campbell Scientific for more information.

6.4 Default settings

For most applications, the default settings (Table 6-3 (p. 9)) allow the LevelVUE B10 to work out

of the box with only minor changes such as setting an offset. Settings can be changed by using

the keypad/display, the SDI-12 extended commands, or Modbus commands (Modbus register

map (p. 30)).

Table 6-3: LevelVUE B10 user options

Option Default value Comments/quick reference

Stage setup menu options

Displays the last measured stage value.

Stage N/A

Enter a floating point value of the

desired stage reading to automatically

calculate the stage offset

Units Feet

Slope 2.3067 (feet)

Offset 0.0

Num Stage Digits 2

Measure Average 5 s Range is 1 to 255 s

Bubbler setup menu options

60 bubbles per

Bubble Rate

minute

Purge Pressure 60 psi Purge-pressure range is 30 to 90 psi

Options are feet, meters, inches, centimeters,

millimeters, psi, and user-defined

Automatically set based on stage units.

If stage units are user defined, this

option accepts a floating point value.

Either automatically calculated based on the

stage entry or entered as a floating point

value

Digit range is 2 to 4. Sets the number of digits

to the right of the decimal for the stage value

Bubble-rate range is

30 to 120 bubbles per minute

Purge Sustain 10 s Purge-sustain range is 0 to 60 s

LevelVUE™B10 Water-Level Bubbler 9

Page 14

Table 6-3: LevelVUE B10 user options

Option Default value Comments/quick reference

Range is 0 to 30 days

Auto Purge 0

System setup menu options

Date Does not reset System date in format of yyyy/mm/dd

Time Does not reset System time in format of hh:mm:ss

Display Sleep 5 minutes Range is 1 to 15 minutes

Display Brightness 80% Range is 10 to 100%

Temperature Units ° C Options are ° C or ° F

Reset to Defaults N/A Resets options to default values

Communications setup menu options

0 disables auto purge

1 to 30 = once a day to once every 30 days

SDI-12 Address 0

ModbusAddress 1 Possible addresses: 1 to 247.

RS-485Baud Rate 19200 bps Standard baud rates from 9600 to 115200 bps

RS-485 Parity even Options are even, odd, none

RS-485 Stop Bits 2 Options are 1 or 2

Diagnostics/test menu options

Status Errors N/A

Test Line Noise N/A Press Enter to perform a line noise test

Test Line Leak N/A Press Enter to perform a line leak test

Reset Min / Max N/A

Possible addresses: 0 to 9 (Standard),

A to Z, a to z

Displays error (Table 7-1 (p. 24) or

none if no errors are detected

Press Enter to reset the min and max

battery values to the current battery value

level

Min Battery Voltage N/A

Displays the minimum voltage detected

on the battery

LevelVUE™B10 Water-Level Bubbler 10

Page 15

Table 6-3: LevelVUE B10 user options

Option Default value Comments/quick reference

Max Battery Voltage N/A

System information menu options

Clear Purge Counter N/A Press Enter to reset purge counter to zero

Clear System Reset

N/A

Counter

Purge Counter N/A Displays the number of purges since last reset

System Reset Counter N/A

Sensor SN N/A Displays the sensor serial number

OS version N/A Displays the current operating system version

Displays the maximum voltage detected

on the battery

Press Enter to reset the system reset counter to

zero

Displays the number of system resets since last

reset

6.5 Setup using keypad/display

The LevelVUE B10 includes a keypad/display to set up, make measurements, and troubleshoot

the unit. Although the LevelVUE B10 can be completely setup using the SDI-12 or Modbus

protocols, using the keypad/display is more convenient for setting up and testing. Open the

enclosure lid to access the keypad/display.

LevelVUE™B10 Water-Level Bubbler 11

Page 16

FIGURE 6-2. LevelVUE B10 keypad/display

Press the right arrow key to open a menu and show the available options. Fixed values are shown

next to an equal sign (=), while editable options are displayed inside square brackets ([ ]). To edit

a menu, press the right arrow key at the chosen menu and use the up and down arrow keys to

make the changes to the parameter.

The following example shows the process for changing the stage setting.

1. Press the down arrow key to move to the setup screen.

2. Press the right arrow key to access the stage setup screen.

3. Press the right arrow key and press the Enter key.

4. Use the right and left arrow keys to move the cursor to the digit you want changed, then

use the up and down arrow keys to change the number.

5. Press Enter when the number is changed to the correct value.

LevelVUE™B10 Water-Level Bubbler 12

Page 17

6.6 Campbell Scientific data logger programming

A data logger or RTU can remotely control and retrieve LevelVUE B10 data. Programming basics

for Campbell Scientific CRBasic data loggers are provided in the following sections. If using

another manufacturer's data logger or RTU, refer to their documentation for programming

information. An SDI-12 program example for a Campbell Scientific data logger is provided in

Example program (p. 46).

6.6.1 SDI-12 programming

The SDI12Recorder() instruction is used to measure a LevelVUE B10 configured for SDI-12

measurements. This instruction sends a request to the sensor to make a measurement and then

retrieves the measurement from the sensor. See SDI-12 measurement and extended commands

(p. 27) for more information.

For most data loggers, the SDI12Recorder() instruction has the following syntax:

SDI12Recorder(Destination, SDIPort, SDIAddress, “SDICommand”, Multiplier,

Offset, FillNAN, WaitonTimeout)

For the SDIAddress, alphabetical characters need to be enclosed in quotes (for example,

“A”). Also enclose the SDICommand in quotes as shown. The Destination parameter must

be an array. The required number of values in the array depends on the command (see Table 7-2

(p. 28)).

FillNAN and WaitonTimeout are optional parameters (refer to CRBasic Help for more

information).

6.6.2 RS-485 programming

The RS-485 output can be directly read by a CR6-series, CR1000X-series, or Modbus RTU RS-485

network. Other Campbell Scientific data loggers can use an MD485 multidrop interface to read

the RS-485 output. Refer to the MD485 manual for information about using the MD485.

A CR6 or CR1000X data logger programmed as a Modbus Master can retrieve the values stored in

the Input Registers (). To do this, the CRBasic program requires SerialOpen() followed by

ModbusMaster(). The SerialOpen instruction has the following syntax:

SerialOpen (ComPort, Baud, Format, TXDelay, BufferSize, Mode)

LevelVUE™B10 Water-Level Bubbler 13

Page 18

The Format parameter is typically set to logic 1 low; even parity, one stop bit, 8 data bits. The

Mode parameter should configure the ComPort as RS-485 half-duplex, transparent.

The ModbusMaster() instruction has the following syntax:

ModbusMaster (Result, ComPort, Baud, Addr, Function, Variable, Start, Length,

Tries, TimeOut, [ModbusOption])

The Addr parameter must match the sensor Modbus address. To collect all of the values, the

Start parameter needs to be 1 and the Length parameter needs to correspond with the

register count (see Modbus register map (p. 30). For ModbusOption parameter use 2, which

means the Modbus variable array is defined as a 32-bit float or a Long, with no reversal of the

byte order (ABCD).

6.7 Field installation

6.7.1 Site selection 14

6.7.2 Enclosure mounting 14

6.7.3 Desiccator installation 15

6.7.4 Orifice line and conduit installation 17

6.7.1 Site selection

The site selection is often based on the type of water being measured. Water in rivers and

streams will act differently than in lakes and reservoirs. In rivers and streams, choose a location

where the water velocity remains constant regardless of water levels. Care must also be taken to

prevent errors caused by drawdown and buildup such as around a bridge pier. In lakes and

reservoirs, wind can cause wave action and buildup on the face of the dam or other structure.

Select a location that will be less affected by these conditions.

6.7.2 Enclosure mounting

1. Choose a location that is accessible for servicing electrical connections and plumbing

fittings, but will not get jarred or shifted during operation.

2. Place the enclosure at the desired height with connectors pointing down so that moisture

or condensation that could collect on the connectors do not access the inner components

of the equipment.

LevelVUE™B10 Water-Level Bubbler 14

Page 19

3. Secure the enclosure to a wall or flat surface using user-supplied bolts. The enclosure

includes holes at the top and bottom of the enclosure for mounting the LevelVUE B10.

4. Route a 14 AWG copper wire from the enclosure grounding lug to an earth ground.

6.7.3 Desiccator installation

WARNING:

Not using a desiccator will void your warranty.

An external desiccator is required to dry the compressor intake air and prevent accumulation of

moisture in the tank, manifold, and other areas in the system. Campbell Scientific offers a

desiccator kit (FIGURE 6-3 (p. 16)), which is recommended for use with the LevelVUE B10.

LevelVUE™B10 Water-Level Bubbler 15

Page 20

FIGURE 6-3. Desiccator kit (indicating desiccant not shown)

Desiccator installation procedure:

1. Use the desiccator kit bracket to mount the desiccator as close to the LevelVUE B10

enclosure as possible.

NOTE:

Campbell Scientific offers a long desiccant tube if the desiccator needs to be located

farther away from the bubbler than normal, such as when air must be drawn from

outside the main enclosure.

2. Insert the threaded end of the 1/4-inch NPT barbed fitting included in the desiccator kit

into the desiccator connector.

3. Insert the threaded end of the air-intake 1/8-inch NPT barbed fitting into the Inlet port of

the LevelVUE B10, then connect the desiccator output tubing to both barbed fittings.

NOTE:

The LevelVUE B10 is shipped with a plug inserted in the intake port that needs to be

removed before inserting the 1/8-inch NPT barbed fitting.

LevelVUE™B10 Water-Level Bubbler 16

Page 21

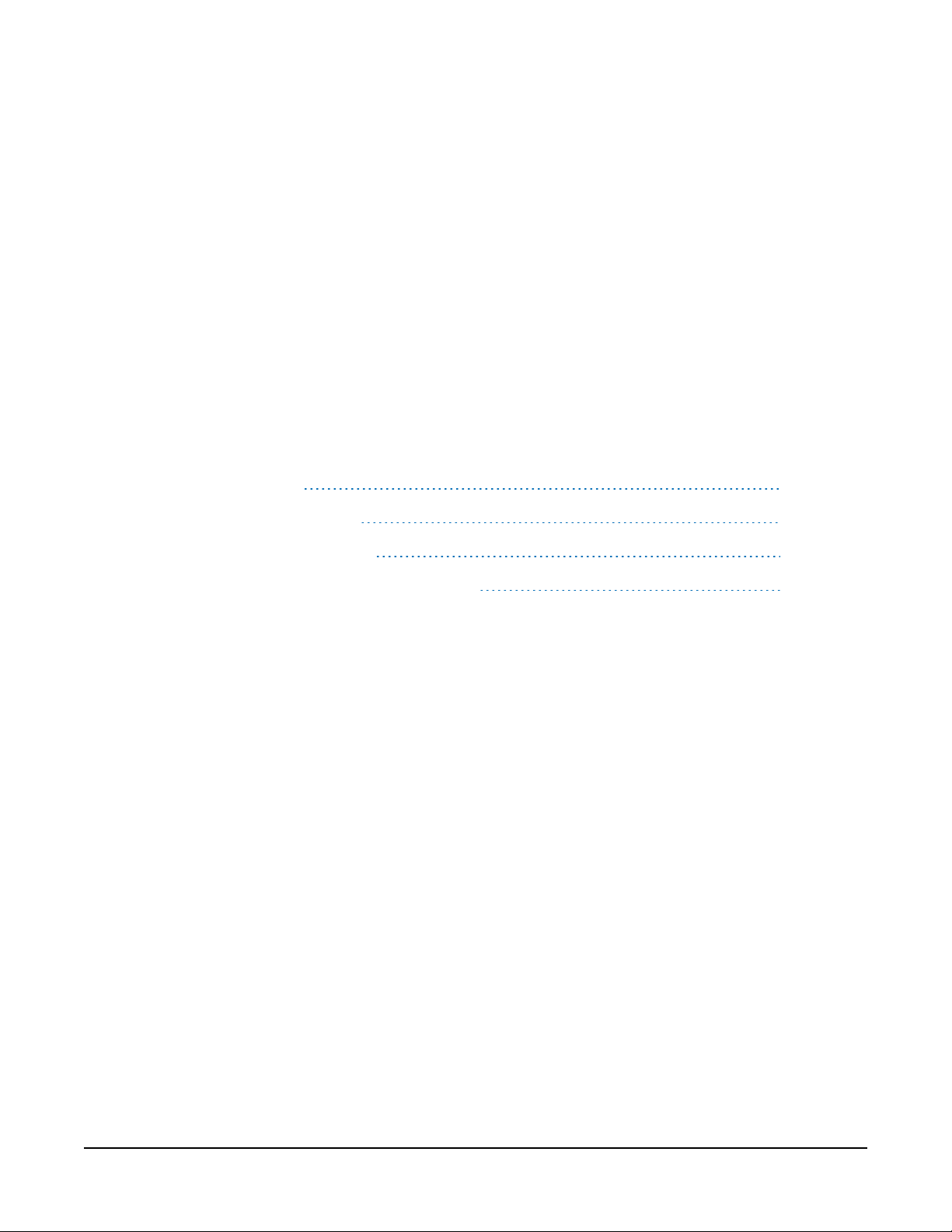

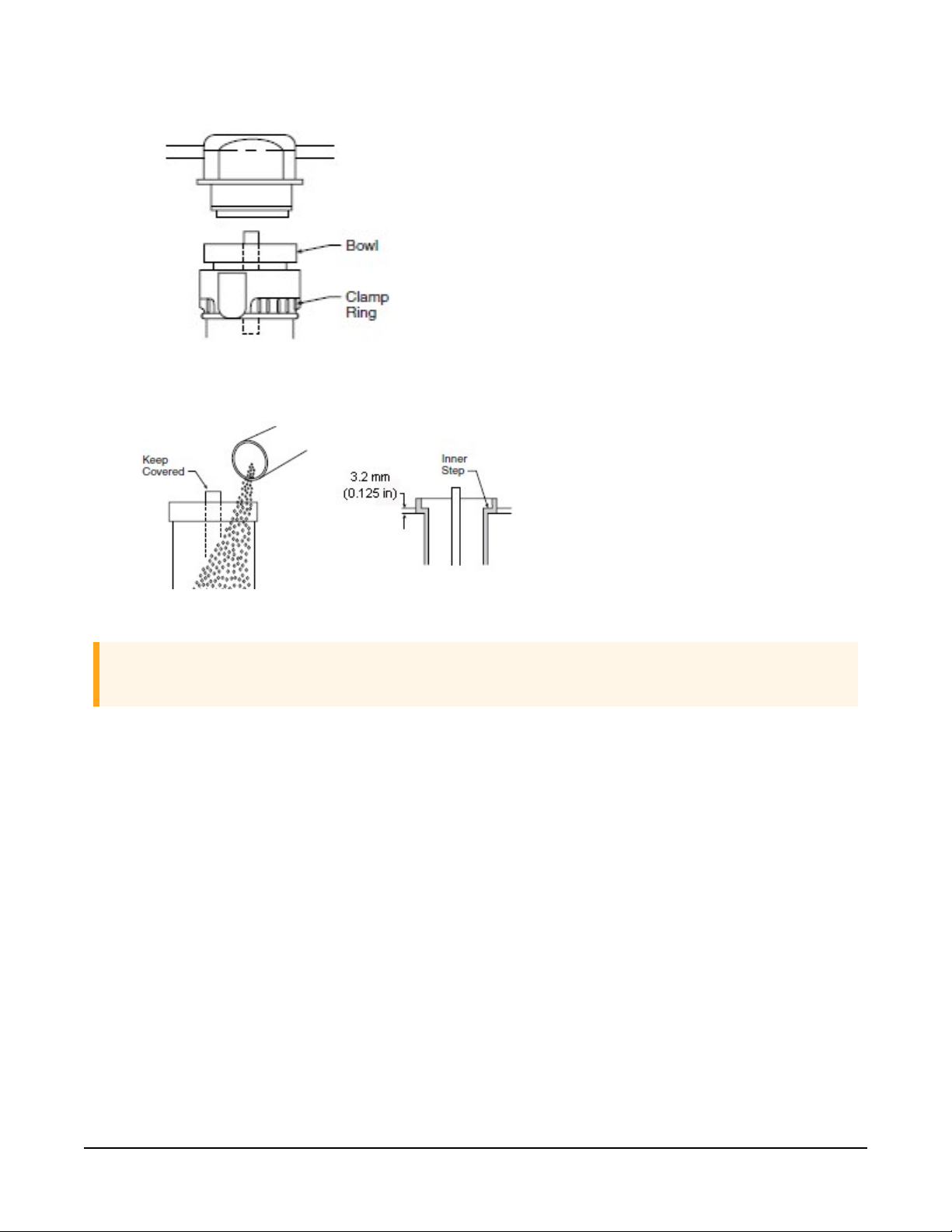

4. Loosen the clamp ring on the desiccator and remove the bowl from the top housing.

5. Pour desiccant into the bowl; shake and tap bowl while filling to settle desiccant. Fill to

3mm (0.1in) below inner step of bowl.

6. Replace the bowl and bowl guard.

CAUTION:

Ensure that the clamp ring is securely locked in place before operating the unit.

6.7.4 Orifice line and conduit installation

To ensure accurate data, consider the following while siting and installing the orifice line:

l Install the orifice line in an area that will remain relatively calm. A stilling well is a good

option.

l Install the orifice line at a continuous downward slope from the LevelVUE B10 to the outlet,

avoiding swells, dips, and depressions.

l If possible, use one continuous orifice line to eliminate junctions or splices, which are

potential sources for leaks. Campbell Scientific offers orifice line that comes in 152m

(500ft) rolls, which suits most applications. If a continuous line is not possible, install the

junction or splice in a serviceable enclosure.

l Do not use quick connect fittings as these tend to leak.

LevelVUE™B10 Water-Level Bubbler 17

Page 22

l Protect the orifice line inside a 53mm (2-inch) steel conduit that is fastened to a

permanent and secure structure such as bridge pier, cement slab, or pilings.

l Avoid sharp bends in the conduit during installation. Sharp bends can result in kinks and

make installation more difficult.

l If the orifice line crosses a road, ensure that it is buried deep enough to prevent the line

from being crushed from vehicles using the road.

l Use an orifice-line cap to secure the orifice line output to the conduit. The orifice-line cap

offered by Campbell Scientific works for most installations. Refer to Orifice-line outlet types

(p. 38) for more information.

l Mount the orifice-line outlet vertically or slightly turned to the horizontal position and

perpendicular to the primary direction of flow. Refer to Orifice-line outlet orientation (p.

37) for more information.

The installation procedure follows:

1. Secure the conduit to a permanent and secure structure such as bridge pier, cement slab,

or pilings.

2. Route the orifice line inside the conduit.

3. Insert the orifice line into the Swagelok® compression fitting of the orifice outlet cap and

tighten the fitting (FIGURE 6-4 (p. 18)).

FIGURE 6-4. Orifice outlet cap

4. Loosen the big nut on the outside of the cap to allow the brass fitting to freely turn inside

the end cap.

5. Screw the end cap onto the 2-inch conduit. While screwing on the end cap, ensure that the

brass fitting does not move, which means the orifice line is not being twisted.

6. Once the end cap is secure, tighten the big nut on the end of the cap to secure the brass

fitting.

7. At the bubbler end, cut off excessive amount of orifice line.

LevelVUE™B10 Water-Level Bubbler 18

Page 23

8. Remove the plug from the Swagelok® fitting on the Outlet port.

9. Insert this orifice line into the Swagelok® compression fitting on the bubbler outlet and

tighten.

10. Secure any extra orifice line and orient it horizontally to avoid low points in the line.

7. Operation

7.1 Principles of operation 19

7.2 Keypad/display menu 20

7.3 SDI-12 measurement and extended commands 27

7.4 Modbus register map 30

7.5 Secured orifice line 35

7.6 Long orifice lines 37

7.7 Orifice-line outlet orientation 37

7.8 Orifice-line outlet types 38

7.1 Principles of operation

A bubbler operates by establishing a constant flow of air that is independent of the water level

(pressure) above the orifice line outlet. As the water level rises, the bubbler increases the pressure

in the tank to maintain a constant flow of bubbles. The water level is proportional to the pressure

required to move the air to the end of the orifice line. The bubbles indicate air at the end of the

line:

Pressure = ρ x g x h

Where:

Pressure (Pa)

ρ = density of the water (1000 kg/m3)

g = gravitational constant (9.8 m/s2)

h = height of the column of water (m)

100 kPa = 14.5 psi

LevelVUE™B10 Water-Level Bubbler 19

Page 24

7.2 Keypad/display menu

LevelVUE™B10 Water-Level Bubbler 20

Page 25

7.2.1 Stage setup

Stage: Displays the last measured stage. The user can enter a new stage and the system will

calculate a new offset based on the new stage.

Units: Units used to report the water level. Default is feet. When changed, the slope value is

automatically adjusted to provide water level measurements in the selected units. The userdefined option allows the user to manually enter a slope that does not match a predefined value.

Slope: Slope or conversion factor used to convert the raw psi reading into units of feet, meters, or

user-defined. If the Units option is set to user-defined, the slope can be changed to any value.

Offset: Difference between the water-level reference point and the level of the orifice-line outlet.

The user can enter the offset here. Alternatively, the user can enter a value for the Stage [xx.xx]

option and the LevelVUE B10 will calculate the correct offset.

Num Stage Digits: Number of digits used to display the stage value on the display. Default is 2.

Measure Average: Averaging time (in seconds) that the LevelVUE B10 uses to make a water level

measurement. Default is 5 seconds. Entering a longer averaging time can reduce noise caused by

water conditions such as waves or turbulence. Please note that the actual measurement time will

be 3 to 4 seconds longer than this value due to internal processing.

7.2.2 Bubbler setup

Bubble Rate: Rate of the airflow in the orifice line. Range is 30 to 120 bubbles per minute. The

rate is affected by the orifice-outlet size, orientation of the outlet, and the pressure difference in

the tank and line, etc. With a lower bubble rate, the air compressor may run less frequently.

Higher rates allow the system to respond more quickly to water level increases. Default setting is

60 bubbles per minute, which is sufficient for most applications. With a standard 1/8 ID orifice

LevelVUE™B10 Water-Level Bubbler 21

Page 26

line and a 1/4inch outlet, 60 bubbles per minute tracks a rise of 1 foot per 10 seconds. A rise

faster than 1 foot per 10 seconds requires a faster bubble rate.

Purge Pressure: Default is 60 psi. Regularly use a high-pressure purge to keep the orifice line

clear of debris. Silty streams or installations with long orifice lines may require a higher purge

pressure. More frequent purges are also recommended for silty streams.

Purge Sustain: Length of time (in seconds) that the compressor runs after reaching the purge

pressure and opening the purge valve. Default is 10. Increasing the purge sustain time may make

the purge more efficient and may increase the air flow.

Auto Purge: Automatic purge rate (in days). The automatic purge rate can be once a day to once

every 30 days. A setting of 0 disables automatic purging.

NOTE:

See the note following the Date and Time options (System setup (p. 22)) for more

information on the Auto Purge function.

7.2.3 System setup

Date: A correct date is needed for the Auto Purge option. Set this up when you initially set up

the system.

Time [HH:MM:SS]: The correct time is needed for the Auto Purge option. Set this up when you

initially set up the system or if it changes.

NOTE:

The Date and Time are only used for the Auto Purge option and should be set to the local

time. The Auto Purge occurs immediately after the measurement at or just after 12:00 noon,

local time. This schedule allows the line to stabilize before the next measurement and ensures

that the purge occurs during the day light hours when the battery is at a higher charge level

when using solar power. If the Date and Time are not set, the Auto Purge occurs at an

unpredictable schedule.

Display Sleep: Amount of time (in minutes) that the keypad can be idle before the display turns

off. Default is 5 minutes.

Dsp Brightness: Brightness or contrast of the display. Default is 80.

LevelVUE™B10 Water-Level Bubbler 22

Page 27

Temperature Units: Options are degree C and F.

Reset to Defaults ?: Resets to default values (Table 6-3 (p. 9)).

NOTE:

This option does not reset the date, time, minimum and maximum battery voltage, and error

and status flags.

CAUTION:

Resetting the LevelVUE B10 to the defaults changes the SDI-12 and Modbus addresses to the

defaults. Therefore, SDI-12 or Modbus communications will be unresponsive until the data

logger program is changed to match the default addresses or the SDI-12 or Modbus address

in the LevelVUE B10 is changed to match the data logger.

7.2.4 Communication setup

SDI-12 Address: Valid addresses are 0 through 9, a through z, and A through Z. Each SDI-12

device connected to the same SDI-12 signal terminal needs a unique SDI-12 address. Default is 0.

Modbus Address: Each Modbus device connected to the same RS-485 terminals needs a unique

Modbus address. Default is 001.

RS485 Baud: Baud rate for the RS-485 port used for Modbus operations. Default is 19200.

RS485 Parity: Setting must match the data logger or Modbus RTU setting. Default is Even.

RS485 Stop Bits: Number of stop bits used for the RS-485 (Modbus) interface. Default is 2.

7.2.5 Diagnostic/Test

LevelVUE™B10 Water-Level Bubbler 23

Page 28

Status Errors

Displays True if errors are detected or None if errors are not detected. If errors are detected, press

the Enter key and the first error will be displayed (Table 7-1 (p. 24)).

The error code returned with an SDI-12 command is the sum of the weighted value for each error.

Weighted values were chosen to ensure the sum is unique for each error combination. For

example, if error 1 and error 6 were detected, the SDI-12 error code will be 33 (1+32).

Some errors or status messages are automatically cleared once the error is resolved. The more

serious errors remain active until they are manually reset by the user.

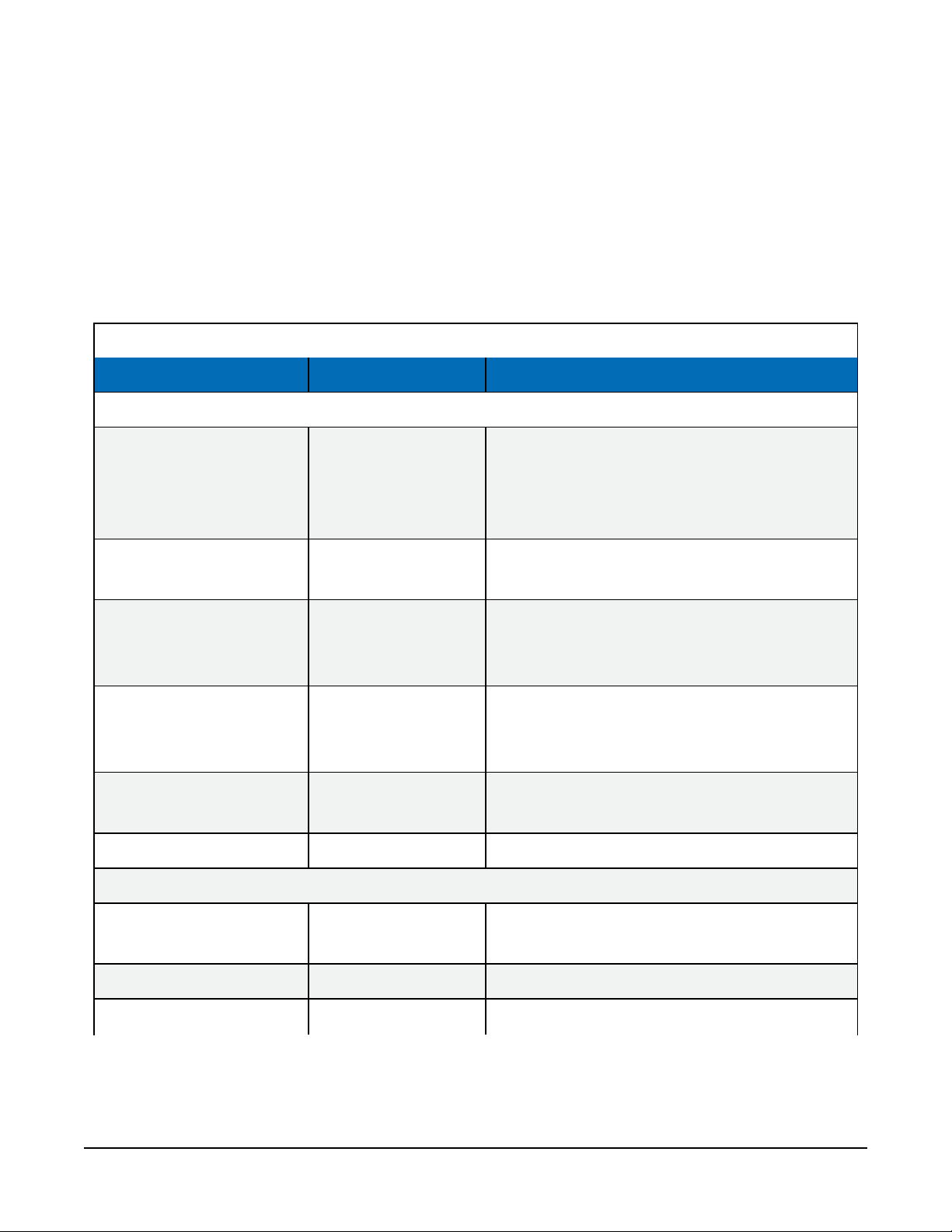

Table 7-1: Error flag descriptions

Error

number

1 1 Error

2 2 Error

3 4 Error Temperature value exceeded range.

4 8 Error

5 16 Error

6 32 Error Tank offset calculation timeout.

7 64 Error

SDI-12

Weighted

Value

Type

Error description and

recommended action

Line sensor exceeded pressure range.

Check for plugged line.

Tank sensor exceeded pressure range.

Check for plugged line.

Pressure not increasing (stalled

compressor or leak).

Pressure not decreasing. Check for

obstruction or plugged orifice line.

Tank offset calculation out of range

error.

Message

displayed on

screen

Line Sen

Rnge Err

Tank Sen

Rnge Err

Temperature

Rnge Err

Pressure Up

Err

Pressure Dwn

Err

Tank Offset

TO

Tank Offset

Error

Reset

Manual

Manual

Manual

Manual

Manual

Manual

Manual

8 128 Error

9 256 Error

Compressor over current. Check

battery/charge system.

RTC battery low voltage warning.

Change the RTC battery.

LevelVUE™B10 Water-Level Bubbler 24

Compressor

Manual

Over Amps

RTC Battery

Manual

Low

Page 29

Table 7-1: Error flag descriptions

Error

SDI-12

Weighted

number

Value

13 4096 Status

14 8192 Status

15 16384 Status

16 32768 Status

Test Line Noise

Type

Error description and

recommended action

Input supply or battery voltage is below

10.6V, which is the voltage needed to

power the compressor. The LevelVUE

B10 will not do an auto or manual purge

while condition persists.

Compressor stall or leak detected.

Check battery/charge system.

Compressor on time exceeded time out.

Observe tank pressure and power for

proper operation during purge.

Compressor flow on time exceeded time

out.

Message

displayed on

screen

Low Battery Auto

Stalled Pump

or Leak

Purge Pump

On TO

Flow Pump

On TO

Reset

Auto

Auto

Auto

Checks the integrity of the orifice line regarding noise and stability. Initially, the LevelVUE B10

measures stage, atmospheric pressure, and temperature. This takes about 7 seconds. The

LevelVUE B10 stores the initial stage measurement as both the max and min values. The screen

displays the difference between the max and min values, which is 0.000 for the initial

measurement.

After the initial measurements, the LevelVUE B10 measures stage using the original atmospheric

and temperature readings at a 1 second measurement rate. The max and min values are updated

as new max or min values are detected and the difference is displayed on the screen. If the line is

secure, the difference between the max and min values is small and will not significantly increase.

A large difference that continues to increase indicates a problem with the orifice line.

Test Line Noise can be used while installing a new orifice line to find the best orifice line outlet

position. Temporarily position the outlet and run this test to see if the position is relatively quiet.

Reposition the line if it is too noisy. After the line is repositioned, restart the test.

Test Line Noise can be used to test the bubbler. Disconnect the orifice line and run the test. The

difference between the max and min values should be less than the resolution of the system

(Table 5-1 (p. 4)). While doing this test, ensure there isn't any breeze or air movement around the

outlet port, which can cause noise in the system.

LevelVUE™B10 Water-Level Bubbler 25

Page 30

Test Line Leak

Leaks are one of the biggest problems with bubbler systems. Normally, the leak is at the fitting

that connects the orifice line to the bubbler or somewhere between that fitting and the end of

the orifice line. Tightening the orifice line fitting an 1/8 turn often resolves the problem. When a

leak exist, the stage value will remain equal to the offset value.

However, a small percentage (1%) of the leaks are in the bubbler itself. This test verifies the

bubbler is not leaking. To use this test, disconnect the orifice line and replace it with the plug

shipped on the LevelVUE B10 outlet fitting. This test turns on the compressor and fills the tank to

a pressure slightly below the pressure range of the bubbler. The system lets the pressures in the

system equalize for about 15 seconds before displaying the max pressure, min pressure, and the

difference of the max and min pressures. The test displays a count-down timer and runs for about

5 minutes (300 seconds). The difference value may rise while the system is equalizing, but after 15

seconds, the difference should be less than 0.15. After 1 or 2 minutes, the difference should be

stable. Contact Campbell Scientific if the difference value continues to rise significantly.

Field Cal Check

Use this option in conjunction with an off-the-shelf field calibration tool to regularly verify the

field calibration. Some agencies require this. Refer to Field calibration check (p. 59) for more

information.

Reset Max/Min

Use this option at the end of a site visit to reset the minimum and maximum battery voltage

detected. At the beginning of the next site visit look at the value of the minimum and maximum

battery voltages detected since the last site visit to help determine the status of the battery and

the charging system.

Min Batt V. XX.XX

Displays the minimum battery voltage detected since the last time this was reset. A low reading

indicates a weak battery or an inadequate charging system.

Max Batt V. XX.XX

Displays the maximum battery voltage detected since the last time this was reset. A high reading

may indicate a faulty regulator or other charging system problem.

LevelVUE™B10 Water-Level Bubbler 26

Page 31

7.2.6 System information

Clear Purge CNTR: Clears the purge counter. To see if the system is purging as often as expected,

use this option at the end of a site visit to set the purge counter to zero. At the beginning of the

next site visit, check that the purge counter has a value that corresponds with the expected

number of purges.

Clear SysRST CNTR: Sets the system reset counter to 0. See Sys RST CNTR that follows.

Purge CNTR = X: Number of orifice-line purges since the last reset.

Sys RST CNTR = X: Number of system resets. If the Clear SysRST CNTR is used at the end of each

site visit, this will show the number of resets since the last visit. System resets indicate that the

battery may be weakening, inadequate power wiring, or the charge system needs servicing.

Sensor SN = XXXX: Serial number of the LevelVUE B10. A support person may ask for this number

if the LevelVUE B10 needs servicing.

OS Ver = X.XX: Operating system (OS) version number currently loaded into the system.

Campbell Scientific recommends using the latest OS. Use Campbell Scientific Device

Configuration Utility to update the OS. Also, if service is needed, a support person may ask for

the OS version number.

7.3 SDI-12 measurement and extended commands

The LevelVUE B10 responds to the SDI-12 commands shown in Table 7-2 (p. 28). Because of

delays, the M! commands require, the measurement scans should be 10 seconds or more. The C!

commands follow the same pattern as the M! commands with the exception that they do not

require the data logger to pause its operation until the values are ready.

NOTE:

SDI-12 sensor support (p. 48) describes the SDI-12 commands. Additional SDI-12 information

is available at www.sdi-12.org .

LevelVUE™B10 Water-Level Bubbler 27

Page 32

Table 7-2: LevelVUE B10 SDI-12 measurement and extended commands

SDI-12 command

(a is the sensor address)

aM!, aC!, aMc!, or aCc!

aXWSR=rrr.rr!

Where, rrr.rr= stage

reference

Values returned or function Description

1. Stage (m or ft)

2. Line pressure (psi)

3. Tank pressure (psi)

4. Temperature (°C)

5. Battery voltage (VDC)

6. Error code

1

The stage crest time is a time

offset. It is the number of

seconds in the past from the

current measurement that

the crest stage value was

detected.

7. Stage crest (m or ft)

8. Stage crest time

Write stage value

Use to change stage

reference to rrr.rr in

configured units.

Write stage units

Use to change the stage

units, where:

0=in

aXWSU=x!

Where, x = units value

aXRSU!

aXWSS=s.sssssss!

Where, s.sssssss=2.3066587

or 0.7032496

1=ft

2=mm

3=cm

4=m

5=psi

6=user-specified (used with

the aXWSS=s.sssssss!

command)

Read stage units

Write stage slope Use to change the units for

stage. This command is only

used when the stage units

are set to user-specified

(aXWSU=6!).

Feet = 2.3066587 (default)

Meters = 0.7032496

LevelVUE™B10 Water-Level Bubbler 28

Page 33

Table 7-2: LevelVUE B10 SDI-12 measurement and extended commands

SDI-12 command

(a is the sensor address)

aXRSS! Read stage slope.

aXWCO=o.oo!

Where, o.oo= stage offset

aXRCO!

aXWBR=bb!

Where, bb= bubble rate

aXRBR!

aXWPP=pp!

Where, pp= purge pressure

Values returned or function Description

Write calculated stage offset

Read calculated stage offset.

Write bubble rate (bubbles per

minute)

Read bubble rate Bubbles per minute

Write purge pressure (psi). Use to change the purge

Use to update stage offset.

Use to change the bubble

rate.

Default = 60 bubbles per

minute

pressure.

Default = 60 psi

Range: 30 to 90 psi

aXRPP!

aXP!

aXWPA=tt!

Where, tt= purge time

aXRPA!

aXWSD=dd!

Where, dd= digits

aXRSD!

Read purge pressure (psi)

Initiate bubbler purge sequence

Write purge assist time

(seconds)

Read purge assist time (seconds)

Write stage digits Use to set the number of

Read stage digits

Use to set the time the

compressor runs during the

purge sequence after the

purge valve opens.

Default = 20 s

digits to the right of the

decimal for the stage value.

Default = 2

LevelVUE™B10 Water-Level Bubbler 29

Page 34

Table 7-2: LevelVUE B10 SDI-12 measurement and extended commands

SDI-12 command

(a is the sensor address)

aXWMT=tt!

Where, tt= stage mean time

aXRMT!

aXWAP=tt!

Where, tt= auto purge

setting

aXRAP! Read auto-purge setting (days)

aXATZ!

aXTEST!

Values returned or function Description

Write stage mean time (seconds) Use to increase or decrease

Read stage mean time (s)

Write auto-purge setting (days) 0 = off (no auto-purge)

Reset sensor to defaults (Default

settings (p. 9))

1. Stage (m or ft)

2. Line pressure (psi)

3. Tank pressure (psi)

4. Temperature (°C)

5. Battery voltage (VDC)

6. Error code

1

the averaging time of stage

measurements

Default = 5 s

Range = 1 to 30 days

Use to put the sensor into a

continuous output mode

with data being transmitted

to the terminal every second.

Any command will interrupt

the continuous output mode

and resume normal

operation.

aXHELP!

1

The error code is the sum of the weighted value for each error. The errors and weighted values are listed in

the Error flag descriptions table.

Returns the supported SDI-12

commands by the

LevelVUE B10

7.4 Modbus register map

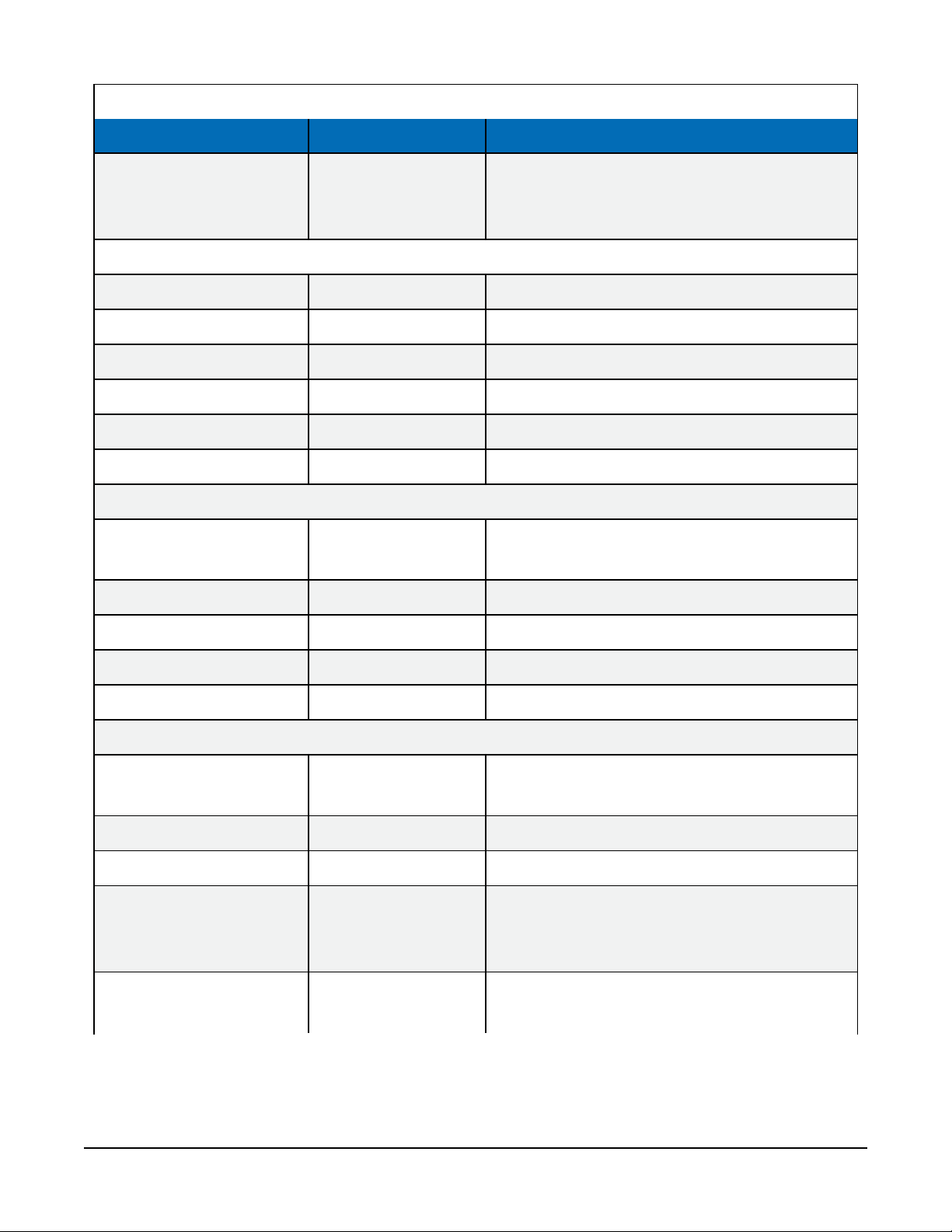

The Modbus data type is 32-bit float with no reversal. Table 7-3 (p. 31) provides the input register

map (function code 4). Table 7-4 (p. 32) provides the holding register map (function code 3).

LevelVUE™B10 Water-Level Bubbler 30

Page 35

Table 7-3: ModBus input register map

Label Input Register Value stored

Stage 30001 Current stage measurement value

Temperature 30003 Current temperature measurement

Tank pressure 30005 Current tank pressure

Line pressure 30007

Battery voltage 30009

Min battery volt 30011

Max battery volt 30013 Maximum battery voltage

Purge count 30015 Number of purge events since counter was reset

System resets 30017 Number of system resets since counter was reset

Purge date 30019 Last purge date in the form of YYMMDD.00

Purge time 30021 Last purge time in the form of hhmmss.00

Status bits 30023

Current line pressure used to calculate stage with

current slope and offset values

Current battery measurement. Updated every 30

seconds or during the stage measurement

Minimum battery voltage (normally detected while

compressor was running)

256 = RTC battery low voltage warning. Change the

RTC battery.

4096 = Input supply or battery voltage is below

10.6V, which is the voltage needed to power the

compressor. The LevelVUE B10 will not do an auto or

manual purge while condition persists.

8192 = Compressor stall or leak detected. Check

battery/charge system.

16384 = Compressor on time exceeded time out.

Observe tank pressure and power for proper

operation during purge.

32768 = Compressor flow on time exceeded time out.

LevelVUE™B10 Water-Level Bubbler 31

Page 36

Table 7-3: ModBus input register map

Label Input Register Value stored

Crest max 30025

Crest offset 30027

Table 7-4: Modbus holding register map

Label

Stage Ref 40001 Last stage value

Stage Units 40003

Holding

register

(function code 3)

Returns a number

from 0 to 6

indicating the units,

where:

0 inches

1 feet (default)

2 millimeters

3 centimeters

4 meters

5 psi

6 User-defined

Maximum crest stage observed between two

successive stage measurements

This is a time offset. It is the number of seconds in the

past from the current measurement that the crest

stage value was detected.

Read

Write (function code 16)

Measures and recalculates the offset

required to make the current stage

value equal to the value written to this

register

Enter a value in a range of 0 to 6,

where:

0 inches

1 feet (default)

2 millimeters

3 centimeters

4 meters

5 psi

6 User-defined (must enter a stage

slope value described in the following

row)

LevelVUE™B10 Water-Level Bubbler 32

Page 37

Table 7-4: Modbus holding register map

Label

Holding

register

Stage Slope 40005

Stage Offset 40007

Date 40009

Read

(function code 3)

Returns the

following values

depending on the

stage units:

27.68 inches

2.3067 feet (default)

703.08 millimeters

70.308 centimeters

0.70308 meters

1 psi

User-defined

Returns the stage

offset value.

Returns the system

date in the format of

YYMMDD.00

Write (function code 16)

To write a user-defined value the stageunits register must first be set to 6.

Enter the stage offset value.

Enter the system date, as a float, in the

format of YYMMDD.00

Time 40011

Measurement

40013

Average Duration

Temperature Units 40015

Bubble Rate 40017

Returns the system

time in the format of

hhmmss.00

Returns the

measurement

averaging time in

seconds.

Returns:

0 Celsius

1 Fahrenheit

Returns the bubble

rate. Range is 30 to

120

Enter the system time, as a float, in the

format of hhmmss.00

Enter the measurement averaging time

in seconds. The range is from 1 to 255.

Enter 0 for Celsius or 1 for Fahrenheit

Enter the bubble rate. Range is 30 to

120

LevelVUE™B10 Water-Level Bubbler 33

Page 38

Table 7-4: Modbus holding register map

Label

Holding

register

Purge Pressure 40019

Purge Sustain

40021

Duration

Auto Purge Interval 40023

Display Sleep 40025

Display Brightness 40027

Read

(function code 3)

Returns purge

pressure in psi.

Range is 30 to 90.

Returns purge

sustain time in

seconds. Range is 0

to 30.

Returns auto purge

interval in days.

Returns display sleep

timeout period in

minutes.

Returns the display

brightness option.

Range is 10 to 100

Write (function code 16)

Enter the purge pressure in psi. Range is

30 to 90.

Enter purge sustain time in seconds.

Range is 0 to 30.

Enter auto purge interval in days. Range

is 0 to 30 days

Enter display sleep timeout period in

minutes. Range is 1 to 15.

Enter the display brightness between 10

and 100. Value will be rounded to

nearest ten.

Reset Status Values 40029 Returns 0.00

Returns the Modbus

Modbus Address 40031

device address

Entering a non-zero value such as 1.00

will reset status values to the following:

Purge count: 0

Minimum battery value: current battery

voltage

Maximum battery value: current battery

voltage

System Resets: 0

Enter a new Modbus address. Range is 1

to 247.

LevelVUE™B10 Water-Level Bubbler 34

Page 39

Table 7-4: Modbus holding register map

Label

Holding

register

Measure Now 40033

Purge Now 40035

Read

(function code 3)

Returns a 0.00 or

time till current

measurement is

ready in seconds.

Returns a 0 when not

purging. Returns a 1

if in the process of

running a purge.

Write (function code 16)

Entering a non-zero value causes the

unit to make a stage measurement. The

register will then hold the number of

seconds till the measurement is

complete. Once the register becomes

zero, new measurement values will be

available in the following Input

Registers:

Stage, Line Pressure , Tank pressure,

Battery Voltage , and Temperature.

Writing a non-zero value (1.00) will

cause system to purge.

7.5 Secured orifice line

Campbell Scientific recommends protecting the orifice line inside a 53mm (2-inch) steel conduit.

Fasten the conduit to a permanent and secure structure such as bridge pier, cement slab, or

pilings to prevent movement. If the conduit moves, the orifice line can stretch, kink, or break. A

stretched orifice line restricts the air flow, which increases pressure, causing erroneously high

stage measurements. A broken orifice line leaks. If a leak is present, the measured stage value

will be the same or close to the offset value. Kinks create erratic data. These same problems can

also occur if the orifice line crosses a road and the line is not properly protected from the traffic

on the road.

If the outlet of the orifice line shifts but is still stable, the vertical shift will be seen in the data.

This problem occurs when the orifice line mount near the outlet has been hit by large debris such

as a log. Scour can also cause mounts to shift. FIGURE 7-1 (p. 36) shows the sharp rise in water

level, possibly indicating that the orifice line shifted down by about 0.20 feet.

LevelVUE™B10 Water-Level Bubbler 35

Page 40

FIGURE 7-1. Sharp rise in water level indicating orifice line shift.

The orifice outlet cap must be secure the keep the outlet of orifice line from moving. If the outlet

of the orifice line shifts vertically, the water level measurement will show a sharp rise or fall.

Horizontal movement can create an unwanted pressure or vacuum on the line causing noise in

the data. This type of noise is often called painting. The frequent fluctuations in gageheight in

FIGURE 7-2 (p. 37) could be due to a loose orifice end cap. Regardless of the source of noise, the

measurement averaging time can be increased to minimize the noise in the data.

LevelVUE™B10 Water-Level Bubbler 36

Page 41

FIGURE 7-2. Data painting

The conduit should be installed to withstand or protected against large debris such as logs or

other items that may be in the water from jarring or loosening the conduit from its mounts.

7.6 Long orifice lines

When purging long orifice lines, the friction in the line is significant and the purge is less

effective. When the orifice line is longer than a few hundred feet, always set the Purge Pressure

setting to the highest value and set the Purge Duration option to its maximum value. This helps

keep the line free from silting or other growth at the outlet.

7.7 Orifice-line outlet orientation

Undesired pressures on the orifice line can affect the water level measurement. The main source

of the unwanted pressures is from the flow of the water and the orientation of the outlet. This

can be a positive or negative pressure and will change based on water levels and velocities. For

example, if the orifice line outlet is slightly horizontal and pointing upstream, as the water flow

pushes against the outlet, it will create an artificially high pressure. If the outlet is facing

downstream, a vacuum will be imposed on the line. Build up and draw down around a bridge

pier will also affect the pressure on the orifice line. Eddie currents are much less predictable and

affect the pressure on the orifice line. Wave action is another source of unwanted pressures on

the orifice line.

LevelVUE™B10 Water-Level Bubbler 37

Page 42

In most cases, the unwanted pressured due to water flow will have less impact on the orifice line

when mounted vertically or slightly turned to the horizontal position and perpendicular to the

primary direction of flow. However, a bubble can form on a vertically oriented orifice line outlet

that adds to the water depth. In still water, this increase can be as much as 0.003m (0.01ft). In

moving water, the bubble is ripped off the end of the outlet before it has time to grow. In a

system that has an error specification of 0.02% or 0.002m (0.007ft) of water for a 15psi unit, this

unwanted pressure can double that error percentage if the outlet is not properly oriented.

Bubbler systems are designed to reduce or eliminate the noise caused by the unwanted pressures

and the bubble growth. In most cases, the default measurement averaging time of 1 second is

sufficient, but if noise is still noticed in the data and the line is stable, increasing this averaging

time to 5 to 10 seconds will reduce noise in the system.

7.8 Orifice-line outlet types

Campbell Scientific offers an orifice-line outlet that consists of a 1/4-inch ID fitting mounted in

the end cap for the 53mm (2-inch) conduit. This type of outlet can be mounted vertically or

slightly horizontal, and responds quickly to small rises in the water level. The LevelVUE B10

average bubble rate is based on using this type of orifice outlet cap.

An end cap with a large air chamber may be better for sites with quick rises in water levels (faster

than 0.3m/10s (1ft/10s)), heavy wave action, or silting issues. With the standard outlet, water

pushes up the orifice line at a rate equal to the rise of the water. Depending on the level change,

it may take a few to several seconds for the system to start bubbling again. Measurements made

during this time will be lower than the actual level. An end cap with a large air chamber greatly

reduces the errors caused by the rapid and large rises in water levels because it acts as an

integrator.

In shallow streams, silt may cover the outlet when the river bottom shifts. Silt can restrict the air

flow, causing data errors. Silt is less likely to restrict the air flow when the air chamber is large.

The timed purge option should also be activated when in silty environments.

Drawbacks to an end cap with a large air chamber include that it must be mounted horizontal, it

may be harder to protect from large debris, and it takes more time for the system to fill the air

chamber. Measurements made while the air chamber is filling will be inaccurate. Noisier data

also occurs during small rises in the water level.

LevelVUE™B10 Water-Level Bubbler 38

Page 43

8. Maintenance and troubleshooting

NOTE:

All factory repairs and recalibrations require a returned material authorization (RMA) and

completion of the “Statement of Product Cleanliness and Decontamination” form. Refer to

the Assistance page at the end of this manual for more information.

8.1 Replacing desiccant 39

8.2 Lithium battery replacement 40

8.3 Plugged orifice outlet 41

8.4 Cold weather 42

8.5 Preventing or fixing orifice-line leaks 42

8.6 Updating operating system 42

8.7 Troubleshooting 43

8.1 Replacing desiccant

Regularly replace the desiccant. Desiccant replacement frequency depends on the humidity of

the site and the size of the desiccator. For new installations, Campbell Scientific recommends

checking the desiccant at least once a month. After a few months, users can adjust how often

they check the desiccant. Replacement silica gel desiccant is available at: www.campbellsci.com .

Desiccant replacement procedure:

1. Remove power from the LevelVUE B10.

2. Depressurize the input line.

LevelVUE™B10 Water-Level Bubbler 39

Page 44

3. Loosen the clamp ring on the desiccator and remove the bowl from the top housing.

4. Pour out used desiccant and dispose of it according to the safety data sheet originally

shipped with the desiccator kit.

5. Open new desiccant container.

6. Pour desiccant into the bowl; shake and tap bowl while filling to settle desiccant. Fill to

3mm (0.1in) below inner step of bowl.

7. Replace the bowl and bowl guard.

CAUTION:

Ensure that the clamp ring is securely locked in place before operating the unit.

8.2 Lithium battery replacement

A 3V coin-cell lithium battery maintains the system clock when there is no power to the

LevelVUE B10. Campbell Scientific recommends replacing the lithium every 2 to 3 years, or more

frequently when operating continuously in high temperatures. The battery should be replaced if

its voltage falls below 2.4VDC.

NOTE:

When the LevelVUE B10 is connected to 12 VDC, there is no power draw from the lithium

battery.

LevelVUE™B10 Water-Level Bubbler 40

Page 45

Lithium battery replacement procedure:

1. Open the swing panel located at the bottom-left edge of the plate that protects the circuit

board below the USB port (FIGURE 8-1 (p. 41)).

FIGURE 8-1. Lithium battery location

2. Remove the old battery.

3. Insert the new battery with the positive side up (plus sign facing the metal plate).

NOTE:

Although inserting the battery incorrectly will not damage the system, the lithium battery will

be drained quickly.

DANGER:

Misuse of the internal lithium battery can cause severe injury. Do not recharge, disassemble,

heat above 100°C (212°F), solder directly to the cell, incinerate, or expose contents to water.

Dispose of spent lithium batteries properly.

8.3 Plugged orifice outlet

The orifice line outlet can become plugged from silt build up, moss growth, or debris. Often

these conditions occur over a long period of time. Silt or moss build up restricts air flow that can

increase the water level readings. This restriction in air flow is not consistent causing the data to

fluctuate.

LevelVUE™B10 Water-Level Bubbler 41

Page 46

Manually purge the system during each site visit to keep the orifice line free from blockage.

When the water is lower and the outlet is accessible, inspect the outlet for growth. Clean the

outlet with a wire brush, as needed. Use a pipe cleaner or heavy stiff wire such as a coat hanger

to remove buildup from inside the outlet. Purge the system while cleaning the orifice outlet to

help keep the line cleared.

Relocate the outlet if it is constantly being covered in silt.

8.4 Cold weather

In cold and humid weather areas, disable the purge feature during the cold season. If in a cold

and humid area, the desiccant is less effective in preventing frozen particles from accessing areas

of the system that could cause problems when the frozen particles melt.

Ice formed at the surface of the water can compress the orifice line and restrict the air flow. Water

in the conduit that freezes has no place to expand, causing erroneously high water-level

measurements.

8.5 Preventing or fixing orifice-line leaks

Because bubblers contain several tubes, fittings, and valves, leaks are one of the biggest

problems with bubbler systems. Campbell Scientific designed and manufactured the LevelVUE

B10 to ensure these internal components are installed properly and to be leak free. However, care

must also be taken when connecting and installing the orifice line to avoid leaks. Do not use

quick connect fittings as these tend to leak, and avoid extra fittings when possible. Try to use one

continuous orifice line to eliminate junctions or splices, which are potential sources for leaks.

Campbell Scientific offers orifice line that comes in 500-foot rolls, which suits most applications.

The rare application that requires orifice lines longer than 500 feet should include the junction or

splice in a serviceable enclosure.

Find leaks in orifice lines or connectors by using a mixture of water and dish soap. Apply a small

amount of the dish-soap mixture to fittings that are suspected of leaking. The dish-soap mixture

will bubble where the fitting is leaking. Always wipe the fitting off with a dry rag.

8.6 Updating operating system

Campbell Scientific Device Configuration Utility is used to update the operating system (OS). The

Device Configuration Utility is available as a download on www.campbellsci.com . It is

included in installations of LoggerNet, PC400, or RTDAQ.

LevelVUE™B10 Water-Level Bubbler 42

Page 47

1. Open the Device Configuration Utility.

2. In the Device Type box, type LevelVUE B10 and click on LevelVUE B10

3. Before connecting this product to your computer for the first time, click the Install USB

Driver button to install the driver.

4. Apply power (+12VDC) to the Power connector.

5. Connect a USB cable between one of your computer USB ports and the USB port on the

device .

6. In the left panel, select the appropriate serial port. If you browse for the serial port, it

should be identified with the LevelVUE B10 designation in the browse dialogue.

7. Click the Start button below.

8. A file open dialogue box will appear that will allow you to select the file to be sent. When

you have selected the file, click the OK button.

9. After the operating system has been successfully sent, the device will reboot and should be

ready to use in approximately 30 seconds.

CAUTION:

Do not remove power for at least 30 seconds.

8.7 Troubleshooting

Table 8-1 (p. 44) provide symptoms, causes, and solutions for problems. Most problems are

caused by orifice line or programming issues. A line noise test can be used to determine whether

noisy data is caused by an orifice line issue or a problem with the LevelVUE B10. Refer to

Diagnostic/Test (p. 23) for more information.

LevelVUE™B10 Water-Level Bubbler 43

Page 48

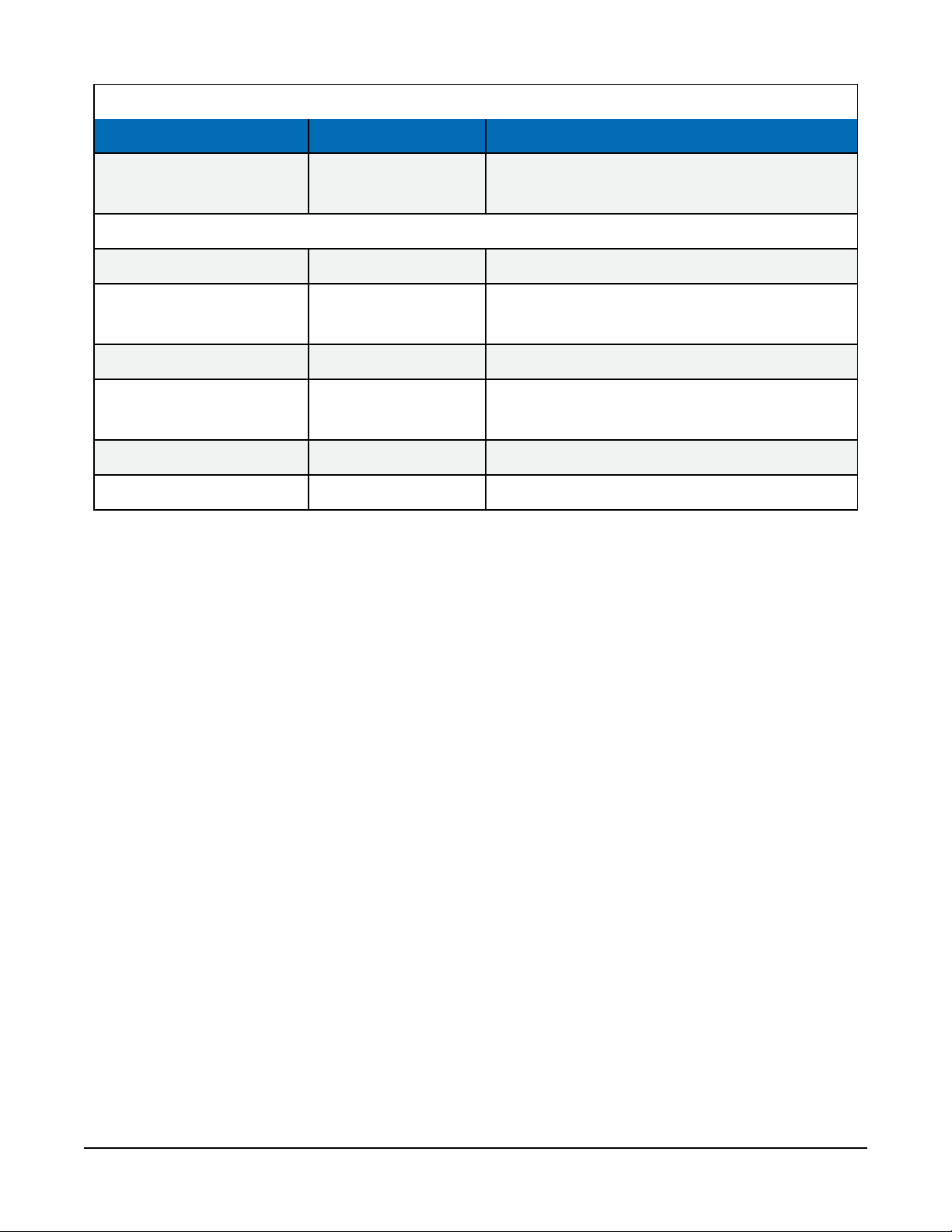

Table 8-1: Symptoms, possible causes, and solutions

Symptom Possible cause Solution

A leak is in the orifice line between

Stage is always

the same value as

the offset

Data is painting

the water surface and the LevelVUE

B10. A leak in this area can result in a

line pressure value of zero. This causes

the stage value to equal the offset

value because of the equation used to

calculate stage:

Stage = Pressure • Slope + offset

1. Orifice line outlet is not stable.

Any movement in the orifice line

outlet will have a direct effect on

the data.

2. Moisture in the orifice line can

create friction for the air flow

and cause abnormal pressures in

the line that affect the pressure

caused by water depth.

3. Waves, choppy water,

fluctuations in water flow

creates different pressures and

vacuums on the orifice line

outlet, which creates noise in

the line.

4. Loose orifice end cap

Use water/dish soap mixture to look

for leaks in the orifice line. Normally

the leak will be at one of the fittings

connecting the orifice line to the

LevelVUE B10. See Preventing or

fixing orifice-line leaks (p. 42).

1. Ensure that the orifice line is

inside a conduit that is

fastened to a permanent and

secure structure such as bridge

pier, cement slab or pilings.

The conduit should be

protected from large debris

such as logs to prevent the

debris from jarring or

loosening the conduit from its

mounts. See Secured orifice

line (p. 35).

2. Regularly purge the line to

help keep moisture out. Also

make sure there are no low

points in the orifice line that

allow moisture to collect.

3. Increase the averaging time by

5 to 10 seconds.

4. Tighten end cap.

An unexpected

sharp rise or fall

in water level

data

The orifice-line outlet mount may

Clear debris and secure the mount.

Ensure that the conduit is installed to

have shifted because of large debris

withstand or is protected from large

such as a log hitting the orifice line

debris that may jar or loosen the

mount near the outlet or because of

conduit from its mounts. . See

scour.

Secured orifice line (p. 35).

LevelVUE™B10 Water-Level Bubbler 44

Page 49

Table 8-1: Symptoms, possible causes, and solutions

Symptom Possible cause Solution

Make sure the battery is sufficiently

Compressor

Battery may not have sufficient

seems to run

voltage to run the compressor.

slow.

charged to handle the needed power

requirements to run the compressor.

Check the charging system. Clean

the solar panel

Water level

values drift low at

night

All LevelVUE B10

output values

read 0

First value reads

NAN and all

other values read

0 or never

change from one

measurement to

another.

The battery may be weak and only

able to turn on the compressor when

the solar charging system is also

supplying power.

1. No SDI12Recorder()

instruction in data logger

program.

2. Conditional statement that

triggers reading is not

evaluating as true

1. LevelVUE B10 SDI-12 address

does not match address

specified in data logger program

2. LevelVUE B10 is not connected

to the SDI-12 terminal specified

in data logger program

3. LevelVUE B10 not being

powered

Check the battery voltage and

replace the battery if needed. Check

the charging system. Clean the solar

panel

1. Add SDI12Recorder()

instruction to data logger

program

2. Check logic of conditional

statement that triggers

readings

1. Change LevelVUE B10 SDI-12

address or modify program so

that they match

2. Connect wire to correct

terminal or modify program to

match wiring

3. Make sure the LevelVUE B10 is

wired correctly and matches

the data logger program

Readings erratic,

including NANs

and 9999999s

Connect each SDI-12 device to

a different U or C terminal

Multiple devices with same

or give them unique SDI-12

SDI-12 address sharing same

addresses. Ensure that you revise

U or C terminal

the data logger program to

account for these changes.

LevelVUE™B10 Water-Level Bubbler 45

Page 50

Appendix A. Example program

Table A-1 (p. 46) provides wiring for the SDI-12 example program (CRBasic Example 1 (p. 46)).

Table A-1: Wiring for SDI-12 example program

LevelVUE B10 terminal Function CR1000X terminal Power supply

SDI-12 Data SDI-12 signal C1

SDI-12 G Ground ⏚

12Vdc + Power 12V

12Vdc - Power ground G

CRBasic Example 1: CR1000X program measuring the LevelVUE B10 using SDI-12

'CR1000X Series Data Logger

'Declare variables and Units

Public BattV

Public PTemp_C

Public LVData(8)

'Rename the variable names

Alias LVData(1)=Stage

Alias LVData(2)=Line_psi

Alias LVData(3)=Tank_psi

Alias LVData(4)=LVB10_Temp

Alias LVData(5)=LVB10_Batt

Alias LVData(6)=LVB10_ErrorCode

Alias LVData(7)=Crest_Stage

Alias LVData(8)=Crest_Tm_Offs

Units BattV=Volts

Units PTemp_C=Deg C

Units Stage=feet

Units Line_psi=psi

Units Tank_psi=psi

Units LVB10_Temp=Deg C

Units LVB10_Batt=volts

Units LVB10_ErrorCode=code

LevelVUE™B10 Water-Level Bubbler 46

Page 51

CRBasic Example 1: CR1000X program measuring the LevelVUE B10 using SDI-12

Units Crest_Stage=feet

Units Crest_Tm_Offs=seconds

'Define a data table

DataTable(MainData,True,-1)

DataInterval(0,5,Min,10)

Sample (1,Stage,FP2)

Sample (1,Line_psi,FP2)

Sample (1,Tank_psi,FP2)

Sample (1,LVB10_Temp,FP2)

Sample (1,LVB10_Batt,FP2)

Sample (1,LVB10_ErrorCode,FP2)

Sample(1,Crest_Stage,FP2)

Sample(1,Crest_Tm_Offs,FP2)

Sample(1,BattV,FP2)

Sample(1,PTemp_C,FP2)

EndTable

'Main program

BeginProg

'Main scan

Scan(5,Sec,1,0)

'Default CR1000X data logger Voltage measurement 'BattV'

Battery(BattV)

'Default CR1000X data logger Wiring Panel Temperature measurement 'PTemp_C'

PanelTemp(PTemp_C,60)

'LevelVUEB10 Water-Level Continuous Flow Bubbler measurements

If TimeIntoInterval(0,5,Min) Then

SDI12Recorder (LVData(),C1,0,"M!",1.0,0)

EndIf

'Call the data tables and store data

CallTable MainData

NextScan

EndProg

LevelVUE™B10 Water-Level Bubbler 47

Page 52

Appendix B. SDI-12 sensor support

SDI-12, Serial Data Interface at 1200 baud, is a protocol developed to simplify sensor and data

logger compatibility. Only three wires are necessary — serial data, ground, and 12 V. With unique

addresses, multiple SDI-12 sensors can connect to a single SDI-12 terminal on a Campbell

Scientific data logger.

This appendix discusses the structure of SDI-12 commands and the process of querying SDI-12

sensors. For more detailed information, refer to version 1.4 of the SDI-12 protocol, available at

www.sdi-12.org .

For additional information, refer to the SDI-12 Sensors | Transparent Mode and SDI-12 Sensors |

Watch or Sniffer Mode videos.

B.1 SDI-12 command basics

SDI-12 commands have three components:

l Sensor address (a) – a single character and the first character of the command. Use the

default address of zero (0) unless multiple sensors are connected to the same port.

l Command body – an upper case letter (the “command”), optionally followed by one or

more alphanumeric qualifiers.

l Command termination (!) – an exclamation mark.

An active sensor responds to each command. Responses have several standard forms and always

terminate with <CR><LF> (carriage return and line feed). Standard SDI-12 commands are listed

in Table B-1 (p. 48).

Table B-1: Campbell Scientific sensor SDI-12 command and response set

Name Command

Acknowledge Active

Send Identification