Page 1

KH20

Revision:

Copyright ©

Campbell Scientific, Inc.

Krypton Hygrometer

05/2020

2010 – 2020

Page 2

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction................................................................ 1

2. Precautions ................................................................ 1

3. Initial Inspection ........................................................ 1

3.1 Components .........................................................................................1

4. Overview .................................................................... 1

5. Specifications ............................................................ 2

5.1 Measurements ......................................................................................2

5.2 Electrical ..............................................................................................2

5.3 Physical ................................................................................................2

6. Installation ................................................................. 3

6.1 Siting ....................................................................................................3

6.2 Mounting ..............................................................................................3

6.2.1 Parts and Tools Needed for Mounting ..........................................3

6.2.2 Mounting the KH20 Sensor ..........................................................3

6.2.3 Mounting the Electronics Box ......................................................4

6.3 Wiring ..................................................................................................6

6.4 Data Logger Programming ...................................................................7

6.4.1 KH20 Calibration ..........................................................................7

7. Maintenance and Calibration .................................... 7

7.1 Visual Inspection ..................................................................................8

7.2 Testing the Source Tube .......................................................................8

7.3 Testing the Detector Tube ....................................................................8

7.4 Managing the Scaling of KH20 ............................................................8

7.5 Calibration ............................................................................................9

Appendices

A.

Calibrating KH20 .................................................... A-1

A.1 Basic Measurement Theory ............................................................. A-1

A.2 Calibration of KH20 ........................................................................ A-1

B. Example Program .................................................. B-1

i

Page 3

Table of Contents

C. EasyFlux® DL CR6KH20 ........................................ C-1

C.1 Introduction ...................................................................................... C-1

C.2 Precautions ....................................................................................... C-2

C.3 Wiring .............................................................................................. C-2

C.3.1 Required Sensors ...................................................................... C-3

C.3.2 Optional Sensors ....................................................................... C-3

C.3.2.1 VOLT116 Module .......................................................... C-3

C.3.2.2 Barometer ....................................................................... C-4

C.3.2.3 Fine Wire Thermocouple ................................................ C-4

C.3.2.4 GPS Receiver ................................................................. C-5

C.3.2.5 Radiation Measurements Option 1 ................................. C-5

C.3.2.6 Radiation Measurements Option 2 ................................. C-6

C.2.3.7 Precipitation Gage .......................................................... C-8

C.2.3.8 Soil Temperature ............................................................ C-9

C.2.3.9 Soil Water Content ......................................................... C-9

C.3.2.10 Soil Heat Flux Plates .................................................... C-10

C.4 Operation ........................................................................................ C-12

C.4.1 Set Constants in CRBasic Editor and Load Program .............. C-12

C.4.2 Enter Site-Specific Variables with Data Logger Keypad or

LoggerNet ............................................................................ C-14

C.4.3 Data Retrieval ......................................................................... C-19

C.4.4 Output Tables .......................................................................... C-19

C.4.5 Program Sequence of Measurement and Corrections ............. C-36

C.5 References ...................................................................................... C-37

D. Equations and Algorithms of Water Vapor

Density and Water Flux in KH20 Eddy-

Covariance Systems ........................................... D-1

D.1 Fundamental Equation .................................................................... D-1

D.2 Working Equation ........................................................................... D-2

D.3 Eddy-Covariance Water Flux .......................................................... D-2

D.4 Frequency Response of KH20 ......................................................... D-3

D.5 References ....................................................................................... D-4

Figures

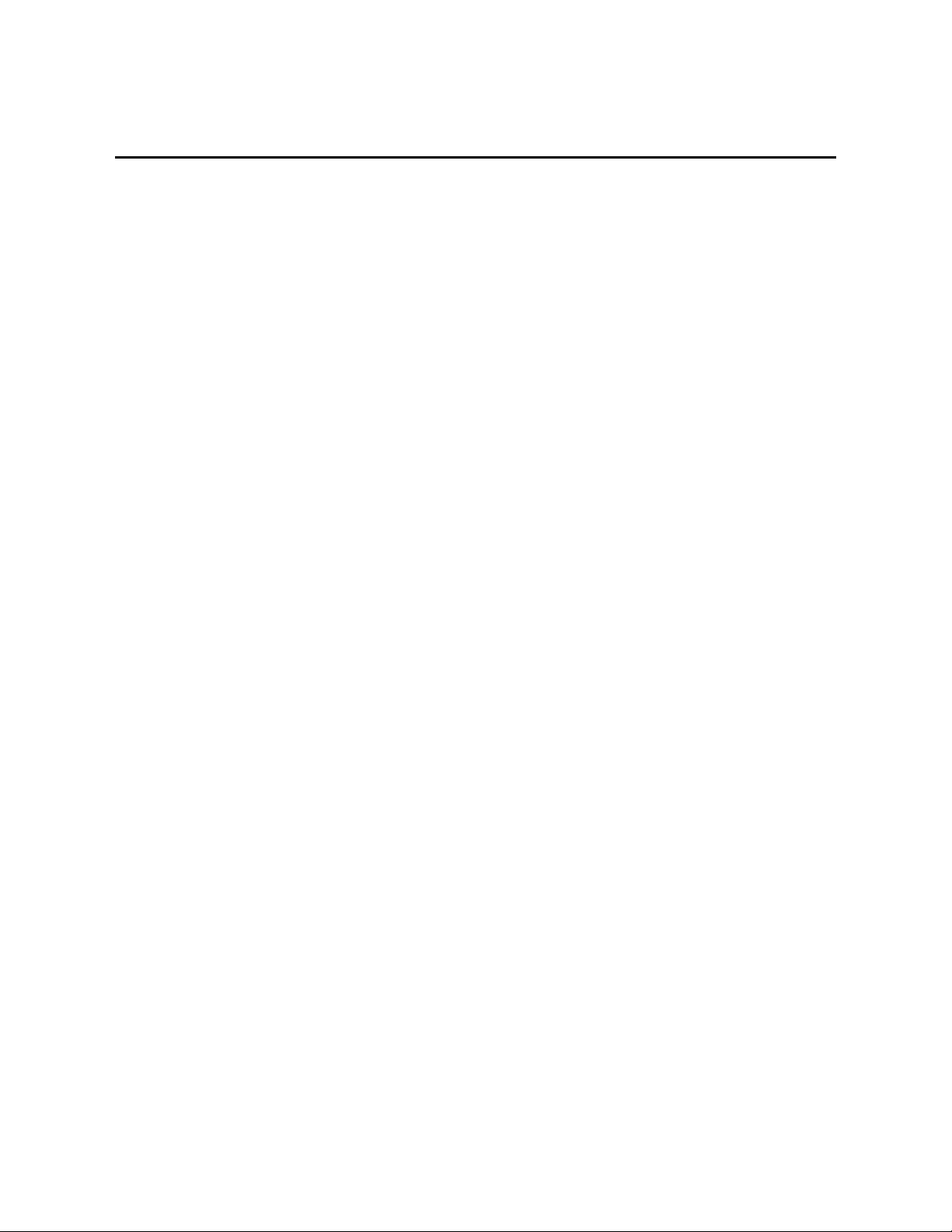

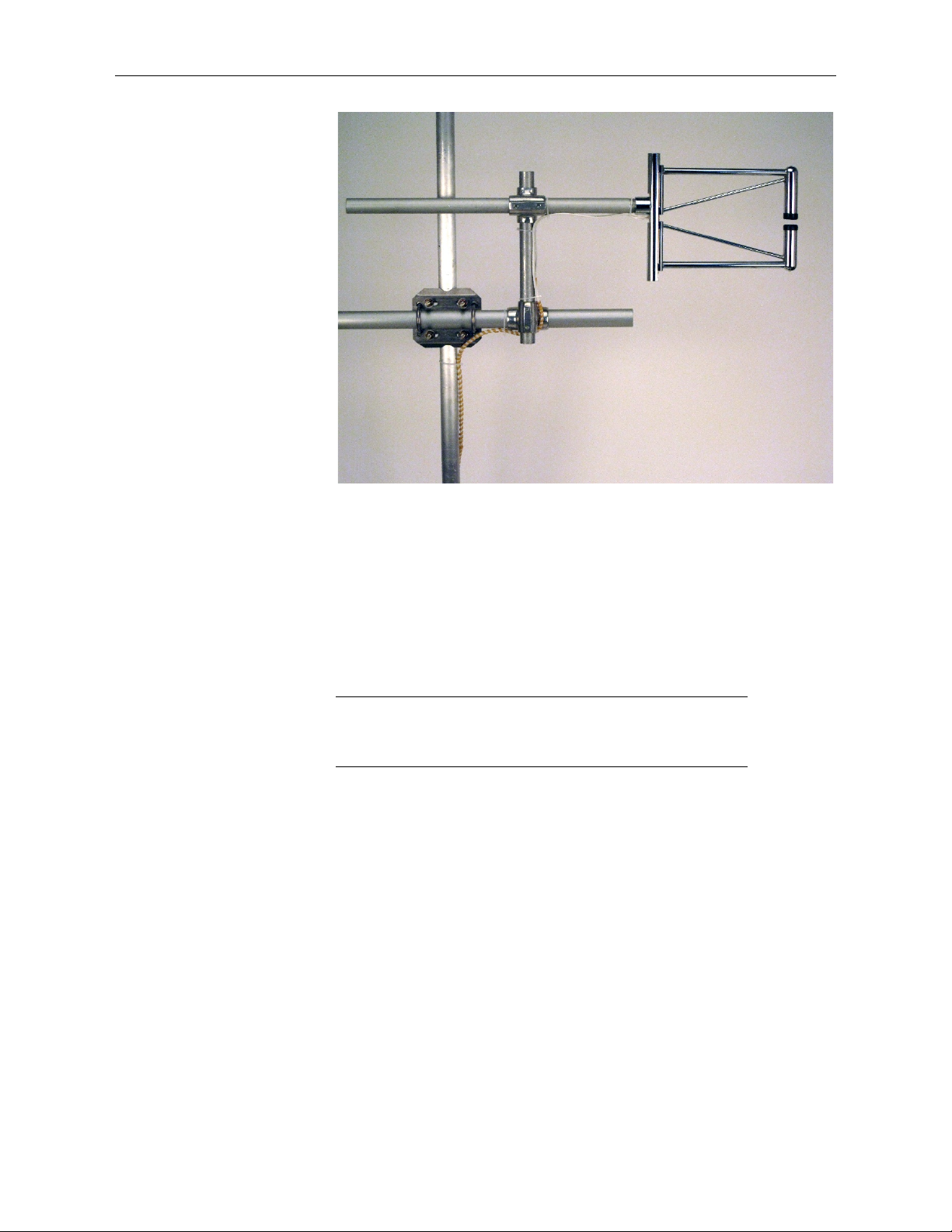

6-1. Mounting KH20 to a tripod. .................................................................4

6-2. Proper mounting position of the electronics box. .................................5

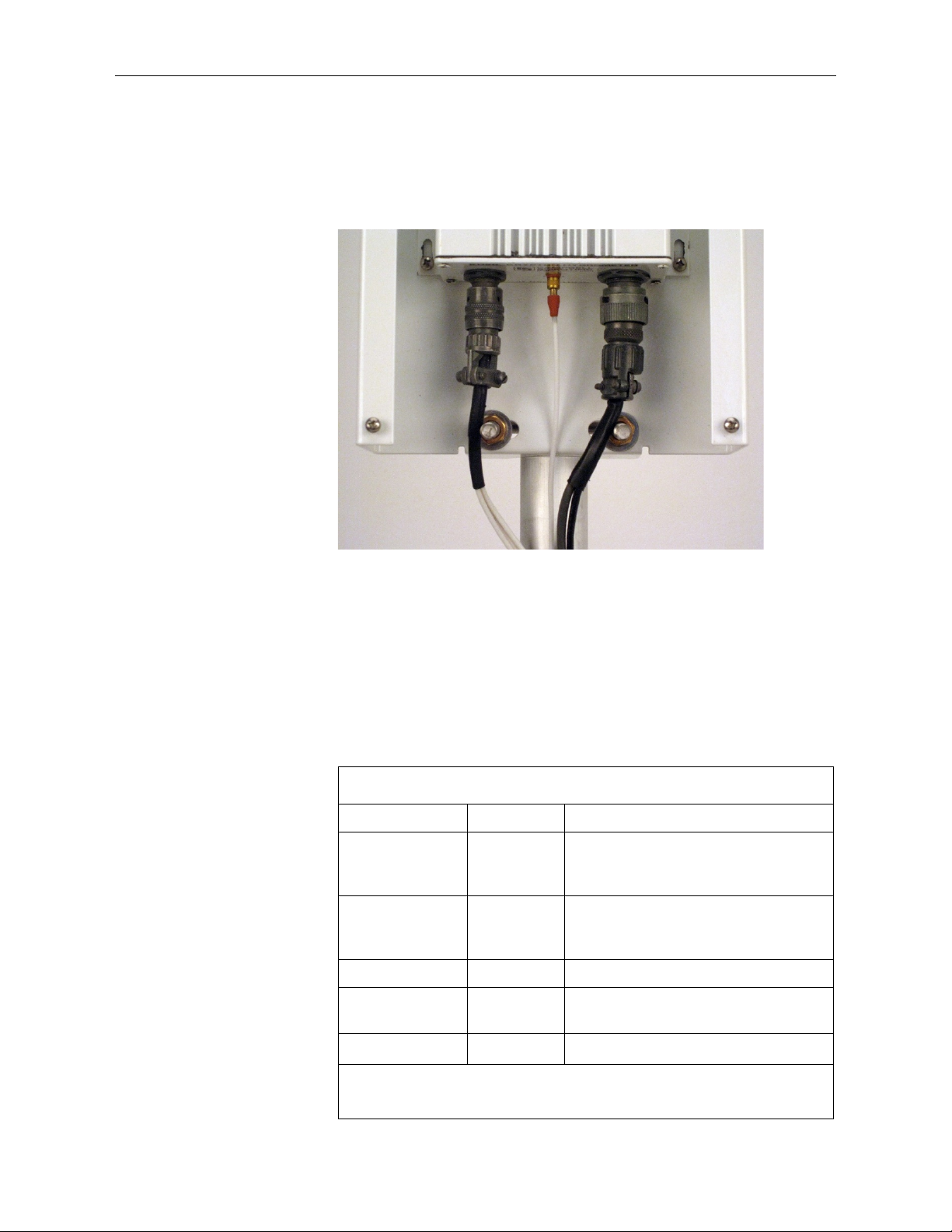

6-3. Attaching cables to the electronics box. ...............................................6

A-1. KH20 ln(mV) vs. Vapor Density .................................................... A-2

C-1. Example screen from CRBasic Editor showing user-defined

configuration constants ............................................................... C-13

C-2. Custom keypad menu; arrows indicate submenus .......................... C-14

Tables

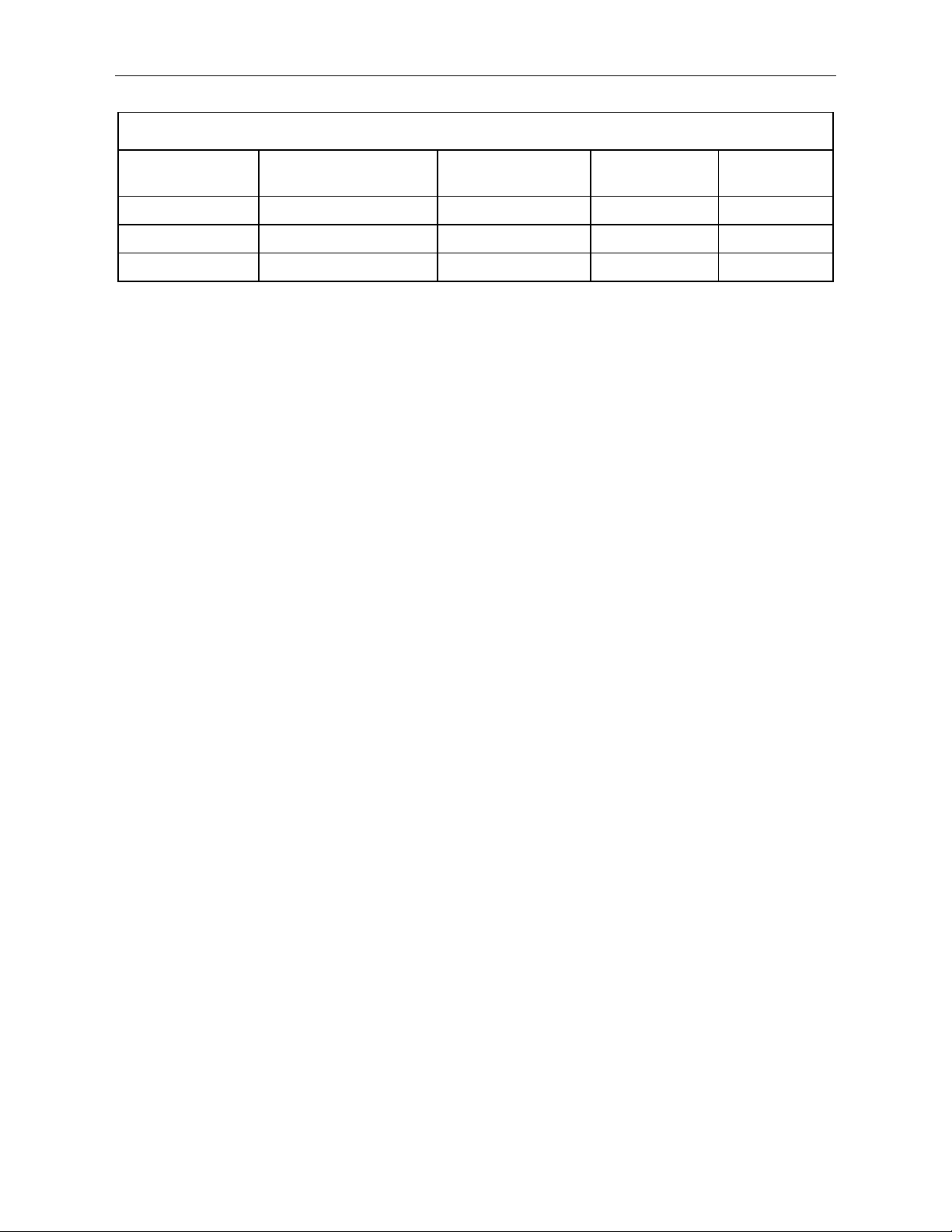

6-1. Wire Color, Function, and Data Logger Connection............................6

6-2. KH20 Calibration Ranges ....................................................................7

A-1. Linear Regression Results for KH20 ln(mV) vs. Vapor Density .... A-2

A-2. Final Calibration Values for KH20 ................................................. A-3

C-1. Default Wiring for Required Sensors ............................................... C-3

C-2. Default Wiring for CS106 Barometer .............................................. C-4

C-3. Default Wiring for Fine Wire Thermocouple ................................... C-4

ii

Page 4

C-4. Default Wiring for GPS Receiver .................................................... C-5

C-5. Default Wiring for Radiation Measurement Option 1 ...................... C-5

C-6. Default Wiring for Radiation Measurements Option 2 .................... C-6

C-7. A21REL-12 Wiring .......................................................................... C-8

C-8. CNF4 Wiring .................................................................................... C-8

C-9. Default Wiring for Precipitation Gage ............................................. C-9

C-10. Default Wiring for Soil Thermocouple Probes ................................ C-9

C-11. Default Wiring for Soil Water Content Probes .............................. C-10

C-12. Default Wiring for Non-Calibrating Soil Heat Flux Plates ............ C-10

C-13. Default Wiring for Soil Heat Flux Plates (Self Calibrating) .......... C-11

C-14. Station Variables with Descriptions ............................................... C-15

C-15. microSD Flash Card Fill Times with 10Hz Measurement Rate ..... C-19

C-16. Data Output Tables ........................................................................ C-20

C-17. Data Fields in the Time_Series Data Output Table ........................ C-21

C-18. Data Fields in the Diagnostic Output Table ................................... C-22

C-19. Data Fields in the Monitor_CSAT3B Output Table ....................... C-22

C-20. Data Fields in the Flux_AmeriFluxFormat Output Table .............. C-22

C-21. Data Fields in the Flux_CSFormat Data Output Table .................. C-25

C-22. Data Fields in the Flux_Notes Output Table .................................. C-29

CRBasic Example

B-1. CR3000 Program to Measure Water Vapor Fluctuations ................. B-1

Table of Contents

iii

Page 5

KH20 Krypton Hygrometer

1. Introduction

The KH20 is a highly sensitive hygrometer designed for measurement of rapid

fluctuations in atmospheric water vapor, not absolute concentrations. It is

typically used together with a CSAT3B in eddy-covariance systems.

2. Precautions

• READ AND UNDERSTAND the Safety section at the back of this

manual.

• Although the KH20 is rugged, it should be handled as precision scientific

instrument.

3. Initial Inspection

• Upon receipt of the KH20, inspect the packaging and contents for damage.

• The model number and cable length are printed on a label at the

3.1 Components

The KH20 sensor consist of a sensor head with 2 m (6 ft) cables and an

electronics box. The following are also shipped with the KH20:

File damage claims with the shipping company.

connection end of the cable. Check this information against the shipping

documents to ensure the correct product and cable length are received (see

Section 3.1, Components

• KH20CBL-L25 Power/Signal cable with 8 m (25 ft) length. If a

longer cable is desired, order a KH20CBL-L replacement cable and

specify the desired length after -L (for example KH20CBL-L50).

• 1/2 Unit Desiccant Bag

• Rain Shield

• Horizontal Mounting Boom (51 cm 20 mm DN (20-inch 3/4 IPS)

threaded aluminum pipe)

• 3/4 x 3/4 in. Nu-Rail Crossover Fitting

• 4 mm (5/32 in) Allen Wrench

(p. 1)).

4. Overview

The KH20 is a krypton hygrometer for measuring water vapor fluctuations in

the air. The name KH20 (KH-twenty) was derived from KH2O (K-H

the sensor has been known with this name since 1985. It is typically used with

O), and

2

1

Page 6

KH20 Krypton Hygrometer

NOTE

the CSAT3B 3-D sonic anemometer for measuring latent heat flux (LE), using

eddy-covariance technique.

The KH20 sensor uses a krypton lamp that emits two absorption lines: major

line at 123.58 nm and minor line at 116.49 nm. Both lines are absorbed by

water vapor, and a small amount of the minor line is absorbed by oxygen. The

KH20 is not suitable for absolute water vapor concentration measurements due

to its signal offset drift.

The KH20 heads are sealed and will not suffer damage should they get wet. In

addition, the electronics box and the connectors are housed inside a rain shield

that protects them from moisture. The KH20 is suitable for long-term

continuous outdoor applications.

The KH20 sensor is comprised of two main parts: the sensor head and the

electronics box. The sensor head comes with cables that connect the sensor to

the electronics, a power/signal cable, and mounting hardware.

Discussion on the principles and theory of measurement is

included in Appendix A, Calibrating KH20 (p. A-1).

Features:

5. Specifications

5.1 Measurements

Calibration Range: 1.7 to 19.5 g/m3 (nominal)

Frequency Response: 100 Hz

Operating Temperature Range: –30 to 50 °C

5.2 Electrical

Supply Voltage: 10 V to 16 VDC

Current Consumption: 20 mA max at 12 VDC

Power Consumption: 0.24 Watts

Output Signal Range: 0 to 5 VDC

• High frequency response suitable for eddy-covariance applications

• Well-suited for long-term, unattended applications

• Compatible with Campbell Scientific CRBasic data loggers: CR6,

CR3000, CR1000X, CR800 Series, CR1000, CR5000, and

CR9000(X)

5.3 Physical

Dimensions

Sensor Head: 29 x 23 x 3 cm (11.5 x 9 x 1.25 in)

Electronics Box: 19 x 13 x 5 cm (7.5 x 5 x 2 in)

Rain Shield with Mount: 29 x 18 x 6.5 cm (11.5 x 7 x 2.5 in)

Mounting Pipe: 50 cm (20 in)

Carrying Case: 64 x 38 x 18 cm (25 x 15 x 7 in)

2

Page 7

6. Installation

6.1 Siting

6.2 Mounting

6.2.1 Parts and Tools Needed for Mounting

KH20 Krypton Hygrometer

Weight

Sensor Head: 1.61 kg (3.55 lb)

Electronics Box: 0.6 kg (1.4 lb)

Rain Shield with Mount: 2.2 kg (4.75 lb)

Mounting Pipe with Nu-rail: 0.45 kg (1.0 lb)

Carrying Case: 4.3 kg (9.45 lb)

Shipping: 9.2 kg (20.15 lb)

When installing the KH20 sensor for latent heat flux measurement in an eddycovariance application, proper siting, sensor height, sensor orientation and

fetch are important.

The following user-supplied hardware is required to mount the KH20 sensor:

1. Tripod (CM115 standard) or tower

2. Campbell Scientific crossarm (CM204 standard)

3. 3/4-inch IPS Aluminum Pipe, 12 inches long

4. 3/4-inch-by-1-inch Nu-Rail Crossover Fitting

5. Small Phillips and flat-head screwdrivers

6. 1/2-inch wrench

6.2.2 Mounting the KH20 Sensor

Mount the KH20 sensor head as follows:

1. Attach the 51 cm (20 in) mounting boom to the KH20.

2. Mount a crossarm to a tripod or tower.

3. Mount the 12-inch-long pipe to a crossarm via 1-inch-by-3/4-inch Nu-Rail

Crossover Fitting.

4. Mount the KH20 onto the 30 cm (12 in) pipe using a 3/4-inch-by-3/4-inch

Nu-Rail Crossover Fitting. Mount the KH20 such that the source tube, the

longer of the two tubes, is positioned on top, as shown in FIGURE 6-1.

Use cable ties to secure loose cables to the tripod or tower mast.

3

Page 8

FIGURE 6-1. Mounting KH20 to a tripod.

NOTE

KH20 Krypton Hygrometer

6.2.3 Mounting the Electronics Box

Mount the electronics box as follows:

1. Remove the front cover of the rain shield by loosening the two pan-head

screws on the bottom front of the rain shield, and then pushing the cover

all the way up, and sliding it out.

It will be difficult to mount the rain shield to a mast with the front

cover on, since the 1/2-inch nut holding the bottom U-bolt is

located inside the rain shield.

2. Before mounting the rain shield to a tripod, first mount the electronics box

inside the rain shield. Remove the four pan-head screws from the back

panel of the rain shield. Align the electronics box and use the four panhead screws to secure the electronics box onto the back panel. Make sure

the electronics box is pushed all the way up, and the screws are positioned

at the bottom of the mounting slot on the electronics box (see FIGURE

6-2). This will provide enough room to attach the connectors to the bottom

of the electronics box later.

4

Page 9

KH20 Krypton Hygrometer

NOTE

FIGURE 6-2. Proper mounting position of the electronics box.

If the electronics box is not pushed all the way up during

mounting, you will not have enough room to attach the connectors

to the bottom of the electronics box, as the U-bolt for the rain

shield will block the position of the connectors.

3. Mount the rain shield onto the tripod or tower mast using the U-bolt

provided. Make sure that the distance between the KH20 sensor head and

the rain shield is within 5 feet so that the cables from the sensor head will

be within reach of the electronics box. Also make sure that the rain shield

is mounted vertically with an opening pointing downward so that the rain

will effectively run down the rain shield and not penetrate inside.

5

Page 10

KH20 Krypton Hygrometer

TABLE 6-1. Wire Color, Function, and Data Logger Connection

⏚

4. Connect the three cables to the bottom of the electronics box around the

U-bolt on the rain shield (see FIGURE 6-3). If there is not enough room

for the connectors around the U-bolt, make sure the electronics box is

mounted at a highest possible position (see step 2).

6.3 Wiring

FIGURE 6-3. Attaching cables to the electronics box.

5. Place the front cover back on the rain shield and tighten the two pan-head

screws to secure it in place.

6. Gather any loose cables and tie them up, using cable ties, onto the tripod or

tower mast.

Wire Wire Label Data Logger Connection Terminal

1, 2

1

,

,

White Signal

Black (from

white/black set)

Signal

Reference

U configured for differential input

DIFF H (differential high, analog-

voltage input)

U configured for differential input

DIFF L (differential low, analog-

2

voltage input)

Red Power 12V 12V

Black (from

red/black set)

Clear Shield

1

U terminals are automatically configured by the measurement instruction.

2

Jumper to ⏚ with a user-supplied wire.

Power

Ground

G

(analog ground)

6

Page 11

6.4 Data Logger Programming

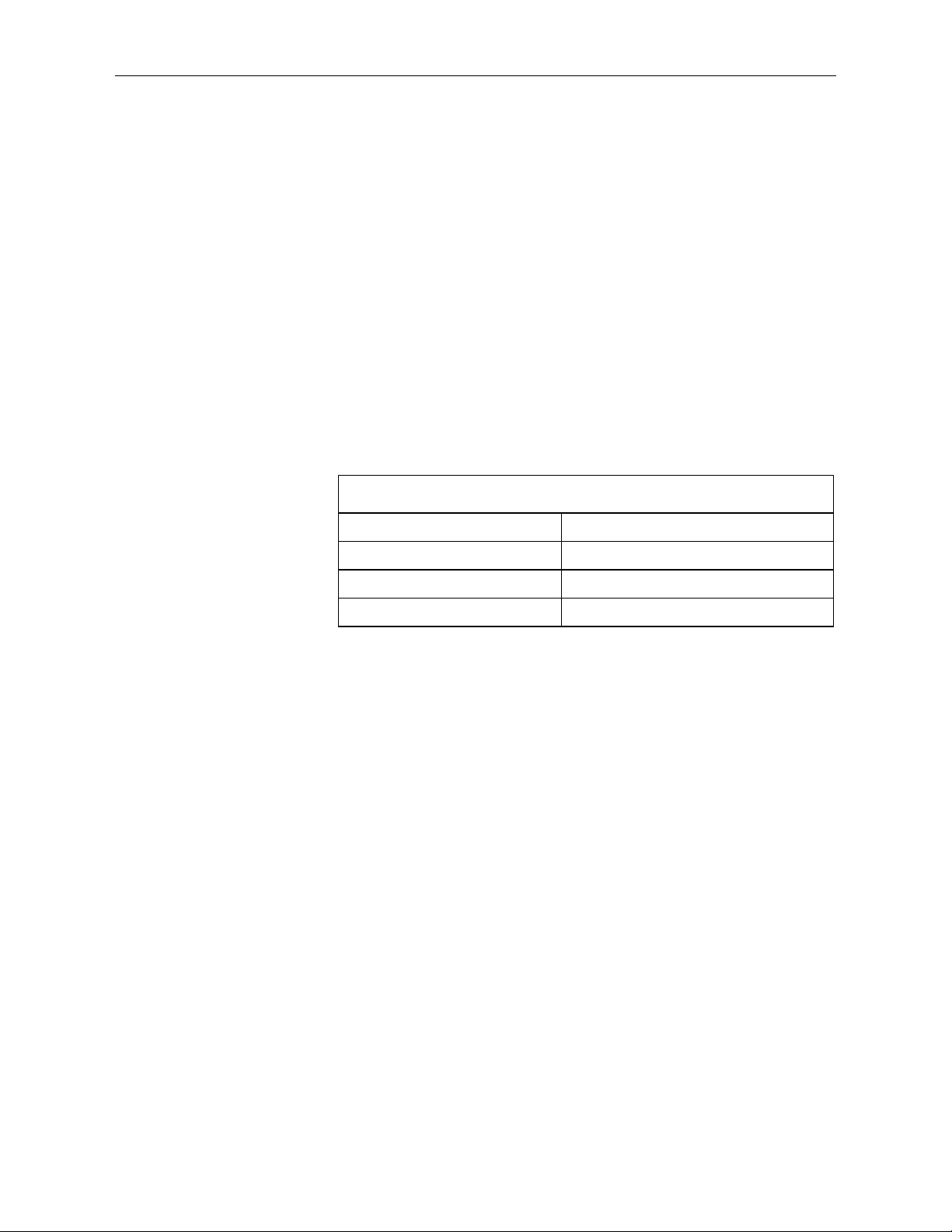

TABLE 6-2. KH20 Calibration Ranges

The KH20 sensor outputs 0 to 5 VDC analog signal. These signals can be

measured using the VoltDiff instruction on the CRBasic data loggers.

Programming basics for CRBasic data loggers are in the following sections.

Complete program examples for select CRBasic data loggers can be found in

Appendix B, Example Program

6.4.1 KH20 Calibration

Each KH20 is calibrated over a vapor range of approximately 2 to 19 g/m3. The

calibration is performed twice under the following two conditions: window

clean, and scaled. The water vapor absorption coefficient for three different

vapor ranges are calculated from the collected calibration data: full range, dry

range, and wet range. TABLE 6-2 shows a sample of the KH20 vapor ranges

over which three different water vapor absorption coefficients are calculated.

See Appendix A, Calibrating KH20

calibration.

KH20 Krypton Hygrometer

(p. B-1).

(p. A-1), for more information on KH20

Ranges Vapor Density (g/m3)

Full Vapor Range 2 – 19

Dry Vapor Range 2 – 9.5

Wet Vapor Range 8.25 – 19

Before the water vapor absorption coefficient, k

logger program for the KH20, the following decisions must be made:

• Will the windows be allowed to scale?

• What vapor range is appropriate for the site?

Once the decision is made, the appropriate k

calibrations sheet. The calibration sheet also contains the path length, x, for a

specific KH20. Using the water vapor absorption coefficient for either the dry

or the wet vapor range will produce more accurate measurements than using

that for the full range. If the vapor range of the site is unknown, or if the vapor

range is on the border line between the dry and the wet vapor ranges, the full

range should be used.

7. Maintenance and Calibration

The KH20 sensor is designed for continuous field application and requires little

maintenance. The tube ends for the KH20 have been sealed with silicone

elastomer using an injection-mold method. Therefore, the tubes are protected

from water damage, and the KH20 continues to make measurements under

rainy or wet conditions. If the water tends to pool up on the tube window and

blocks the signal, turn the sensor head at an angle so as to shed the water off

the tube window. The rain shield protects the electronics box and the

connectors from moisture.

, is entered into the data

w

can be chosen from the

w

7

Page 12

7.1 Visual Inspection

NOTE

• Make sure the optical windows are clean.

• Inspect the cables and connectors for any damage or corrosion. If you see

a discoloration on the white co-axial cable, you may suspect that the cable

has water damage.

7.2 Testing the Source Tube

The source tube is the longer of the two tubes. Check to see if the source tube

is working properly by performing the following test.

First, make sure the UV light is emitted from the source tube. To do this, you

may look into the source tube (the longer of the two tubes), and you should see

a bright blue light emitted from it.

Avoid looking into the source tube for an extended period of time

when the KH20 is powered on to minimize the prolonged

exposure to the UV light.

KH20 Krypton Hygrometer

If you see a faint or flickering blue light, perform the following test.

Check the current drain on the KH20

Typical current drain for the KH20 during normal operation should be

15 ~ 20 mA. The current drain of around 5 mA or less indicates the

problem on the source tube. Obtain an RMA from Campbell Scientific

and send the unit in for repair.

Check the voltage signal output from the KH20

If the voltage output reading is below 50 mV, you may have problems

with either the source tube or the detector tube (Section 7.3, Testing the

Detector Tube

(p. 8)).

7.3 Testing the Detector Tube

If the source tube tests fine but the output from KH20 is still in question,

perform the following test. Prepare a piece of paper and insert it between the

source tube and the detector tube to completely block the optical path. You

should see an immediate decrease in the voltage reading, and it should go close

to zero. No noticeable change in the voltage output, when the optical path is

completely blocked, indicates a problem in the detector tube. If the decrease in

the voltage reading takes place but the reading remains below 50 mV, when the

paper is removed from the optical path, the source tube may be at fault. Obtain

an RMA from Campbell Scientific and send the unit in for repair.

7.4 Managing the Scaling of KH20

The KH20 cannot be used to measure an absolute concentration of water vapor,

because of scaling on the source tube windows caused by disassociation of

atmospheric continuants by the ultra violet photons (Campbell and Tanner,

8

Page 13

KH20 Krypton Hygrometer

NOTE

1985 and Buck, 1976). The rate of scaling is a function of the atmospheric

humidity. In a high humidity environment, scaling can occur within a few

hours. That scaling attenuates the signal and can cause shifts in the calibration

curve. However, the scaling over a typical flux averaging period is small. Thus,

water vapor fluctuation measurements can still be made with the hygrometer.

To see if the source tube window has been scaled, get a clean, dry cotton swab

and slide it across the source tube window. The scale is not visible to the naked

eye, but if the window is scaled, you will feel a slight but noticeable resistance

while you slide the swab across the window. There will be little resistance if

the window is not scaled. If you determine the window is scaled, you can clean

it with a wet cotton swab.

Use distilled water and a clean cotton swab to clean the scaled window. After

cleaning the window, slide a clean, dry swab across the window to confirm the

scale has been removed.

You can use the water vapor absorption coefficient for scaled

window from the calibration sheet if the window will be allowed

to scale during measurements.

7.5 Calibration

For quality assurance of the measured data, Campbell Scientific recommends

the KH20 be recalibrated every two years. Calibrations require a returned

material authorization (RMA) and completion of the “Declaration of

Hazardous Material and Decontamination” form. Refer to the Assistance page

at the end of this manual for more information.

For more information on the calibration process, refer to Appendix A,

Calibrating KH20

(p. A-1).

9

Page 14

ww

xk

eT

ρ

−

=

ww

xk

e

V

V

ρ

−

=

0

)ln(ln

1

0

VV

xk

w

w

−

−

=

ρ

0

lnln VxkV

ww

+−=

ρ

Appendix A. Calibrating KH20

A.1 Basic Measurement Theory

The KH20 uses an empirical relationship between the absorption of the light

and the material through which the light travels. This relationship is known as

the Beer’s law, the Beer-Lambert law, or the Lambert-Beer law. According to

the Beer’s law, the log of the transmissivity is anti-proportional to the product

of the absorption coefficient of the material, k, the distance the light travels, x,

and the density of the absorbing material, ρ. The KH20 sensor uses the UV

light emitted by the krypton lamp: major line at 123.58 nm and the minor line

at 116.49. As the light travels through the air, both the major line and the minor

line are absorbed by the water vapor present in the light path. This relationship

can be rewritten as follows, where k

vapor, x is the path length for the KH20 sensor, and ρ

density.

A-1

is the absorption coefficient for water

w

is the water vapor

w

If we express the transmissivity, T, in terms of the light intensity before and

after passing through the material as measured by the KH20 sensor, V and V

respectively, we obtain the following equation.

Taking the natural log of both sides, and solving for the density, ρ

following equation.

If the path length, x, and the absorption coefficient for water, k

becomes possible to measure the water vapor density ρ

signal output, V, from KH20.

A.2 Calibration of KH20

The KH20 calibration process is to find the absorption coefficient of water

vapor, k

. To do this, we rewrite the equation A-3, and solve for ln(V).

w

,

0

A-2

, yields the

w

A-3

are known, it

w

, by measuring the

w

A-4

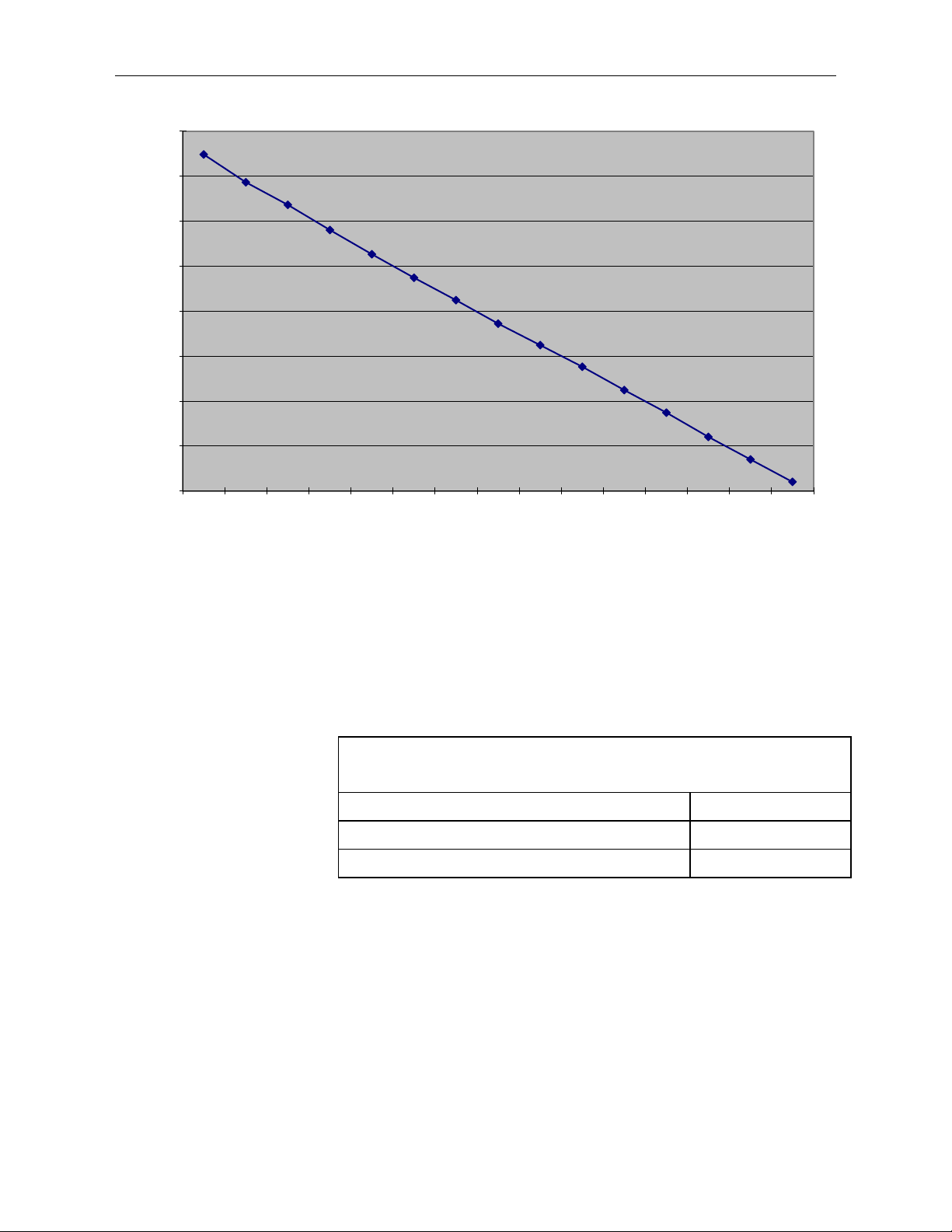

It now becomes obvious from the equation A-4 that there is a linear

relationship between the natural log of the KH20 measurement output, lnV, and

the water vapor density, ρ

after we ran a KH20 over a full calibration vapor range.

. FIGURE A-1 shows the plot of the equation A-4

w

A-1

Page 15

Appendix A. Calibrating KH20

TABLE A-1. Linear Regression Results for KH20 ln(mV)

KH2O Output (mV)

Vapor Density (g/m3)

8

7.5

7

6.5

6

5.5

5

4.5

4

1.74 3.02 4.17 5.44 6.71 7.95 9.2 10.47 11.69 12.9 14.22 15.46 16.78 18.04 19.25

FIGURE A-1. KH20 ln(mV) vs. Vapor Density

We can perform the linear regression on the plot to obtain the slope for the

relationship between the ln(mV) and the vapor density. The slope for the graph

is the coefficient, k

x. TABLE A-1 shows the result of linear regression

w

analysis. The slope is the product of the absorption coefficient of water vapor,

, and the KH20 path length, x.

k

w

vs. Vapor Density

Description Values

Slope (xkw) –0.205

Y Intercept (ln(V0) 8.033

If we substitute these values, along with the measured lnV into equation A-3,

we can obtain the water vapor density, ρ

. Campbell Scientific performs the

w

calibration twice for each KH20: once with the window cleaned, and again

with the window scaled. We then break up the vapor density range into dry and

wet ranges, and compute the k

range. If you know the vapor density range for your site, it is recommended

that you select the coefficient, k

values for each sub range, as well as for the full

w

, that is appropriate for your site, the dry range

w

or the wet range. If the vapor range for the site is unknown, or if the vapor

range is on the border line between the dry and the wet ranges, use the value

for the full range. TABLE A-2 shows the final calibration values the KH20

calibration certificate contains. The data shown in TABLE A-2 is from an

actual KH20.

A-2

Page 16

Appendix A. Calibrating KH20

TABLE A-2. Final Calibration Values for KH20

Vapor Range

3

)

(g/m

Slope

(xkw)

Y Intercept

ln (V0)

Coefficient

(kw)

Full Range 1.74 ~ 19.25 -0.205 3087 -0.144

Dry Range 1.74 ~ 9.20 -0.216 3259 -0.151

Wet Range 7.95 ~ 19.25 -0.201 2899 -0.141

A-3

Page 17

Appendix B. Example Program

CRBasic Example B-1. CR3000 Program to Measure Water Vapor Fluctuations

'CR3000 Series Data Logger

Units kh_mV = mV

NOTE

'This data logger program measures KH20 Krypton Hygrometer.

'The station operator must enter the constant and the calibration value for the KH20.

'Search for the text string "unique" to find the locations of these constants

'and enter the appropriate values found from the calibration sheet of the KH20.

'*** Unit Definitions ***

'Units Description

'ln_mV ln(mV) (natural log of the KH20 millivolts)

'mV millivolts

'rho_w g/m^3

'*** Wiring ***

'ANALOG INPUT

'1H KH20 signal+ (white)

'1L KH20 signal- (black)

'gnd KH20 shield (clear)

'EXTERNAL POWER SUPPLY

'POS KH20 power+ (red)

' data logger POWER IN 12 (red)

'NEG KH20 power- (black)

' KH20 power shield (clear)

' data logger POWER IN G (black)

PipeLineMode

'*** Constants ***

'Measurement Rate '10 Hz

Const SCAN_INTERVAL = 100 '100 mSec

'Output period

Const OUTPUT_INTERVAL = 30 'Online flux data output interval in minutes.

Const x = 1 'Unique path length of the KH20 [cm].

Const kw = -0.150 'Unique water vapor absorption coefficient [m^3 / (g cm)].

Const xkw = x*kw 'Path length times water vapor absorption coefficient [m^3 / g].

'*** Variables ***

Public panel_temp

Public batt_volt

Public kh(2)

Public rho_w

Alias kh(1) = kh_mV

Alias kh (2) = ln_kh

Units panel_temp = deg_C

Units batt_volt = volts

The following example program measures the KH20 at 10Hz, and stores the

average values into a data table called ‘stats’, as well as the raw data into a data

table called ‘ts_data’.

The KH20 does not monitor absolute water vapor concentration.

B-1

Page 18

Units ln_kh = ln_mV

EndProg

Appendix B. Example Program

Units rho_w = g/m^3

'*** Data Output Tables ***

'Processed data

DataTable (stats,True,-1)

DataInterval (0,OUTPUT_INTERVAL,Min,10)

Minimum (1,batt_volt,FP2,False,False)

Average (1,panel_temp,FP2,False)

Average (2,kh(1),IEEE4,False)

EndTable

'Raw time-series data.

DataTable (ts_data,True,-1)

DataInterval (0,SCAN_INTERVAL,mSec,100)

Sample (1,kh_mV,IEEE4)

EndTable

'*** Program ***

BeginProg

Scan (SCAN_INTERVAL,mSec,3,0)

'data logger panel temperature.

PanelTemp (panel_temp,250)

'Measure battery voltage.

Battery (batt_volt)

'Measure KH20.

VoltDiff (kh_mV,1,mV5000,1,TRUE,200,250,1,0)

ln_kh = LOG(kh_mV)

rho_w = ln_kh/xkw

CallTable stats

CallTable ts_data

NextScan

B-2

Page 19

NOTE

EasyFlux is

Appendix C. EasyFlux® DL CR6KH20

C.1 Introduction

EasyFlux® DL CR6KH20 is a CRBasic program that enables a CR6 data

logger, along with a KH20 and CSAT3B, to collect fully corrected fluxes of

latent heat (H

EC data using commonly used corrections in the scientific literature. The

program can also calculate the ground surface heat flux and energy closure by

adding an optional suite of energy balance sensors. Because the energy balance

sensors require more analog terminals than the CR6 has, the program supports

the addition of a VOLT116 (or CDM-A116) analog terminal expansion

module.

Specifically, the program supports data collection and processing from the

following sensors.

REQUIRED SENSORS:

KH20 Krypton Hygrometer (qty 1)

CSAT3B Sonic Anemometer (qty 1)

Temperature/Relative Humidity (RH) Probe (qty 1). Supported Models:

OPTIONAL SENSORS:

CS106 Barometer (qty 0 to 1)

FW3 Fine Wire Thermocouple (qty 0 to 1)

GPS16X-HVS GPS Receiver (qty 0 to 1)

Radiation measurements

TE525MM Rain Gage (qty 0 to 1)

TCAV Soil Thermocouple Probe (qty 0 to 3)

Soil Water Content Reflectometer (qty 0 to 3)

Soil Heat Flux Plates

O), sensible heat, and momentum. The program processes the

2

o HMP155A

o EE181

o Option 1

− NR-LITE2 Net Radiometer (qty 0 to 1)

− CS301 or CS320 Pyranometer (qty 0 to 1)

− CS310 Quantum Sensor (qty 0 to 1)

− SI-111 Infrared Radiometer (qty 0 to 1)

o Option 2

− SN500SS, or NR01, or CNR4 4-Way Radiometer

(qty 0 to 1; if using CNR4, the CNF4 Ventilation

and Heating Unit is also supported)

o CS650

o CS655

o Option 1: HFP01 plates (qty 0 to 3)

o Option 2: HFP01SC self-calibrating plates (qty 0 to 3)

It may be possible to customize the program for other sensors or

quantities in configurations not described here. Contact Campbell

Scientific for more information.

a registered trademark of Campbell Scientific, Inc.

C-1

Page 20

C.2 Precautions

NOTE

NOTE

NOTE

Appendix C. EasyFlux® DL CR6KH20

The VOLT116 and CDM-A116 are functionally the same,

however their OSes are not interchangeable. If updating an OS,

make sure it is for the correct model.

EasyFlux DL CR6KH20 requires the CR6 to have operating system (OS)

version 09.02 or newer. If using a VOLT116, it must have OS v.01 or

newer, or if using a CDM-A116, it must have v.06 or newer.

The program applies the most common EC corrections to fluxes. However, the

user should determine the appropriateness of the corrections for their site.

Campbell Scientific always recommends saving time-series data in the event

reprocessing of raw data is warranted. Further, the user should determine

the quality and fitness of all data for publication, regardless of whether

said data were processed by EasyFlux DL CR6KH20 or another tool.

As EasyFlux DL CR6KH20 is not encrypted, users have the ability to view and

edit the code. However, Campbell Scientific does not guarantee the

function of an altered program.

C.3 Wiring

When wiring the sensors to the data logger or VOLT116, the default wiring

schemes, along with the number of instruments EasyFlux DL CRKH20

supports, should be followed if the standard version of the program is being

used. TABLE C-1 through TABLE C-13 present the wiring schemes.

A KH20 and CSAT3B are the only required sensors for the program. The

additional sensors described in the following tables are optional, although the

CS106 and FW3 are recommended. Many of the optional sensors are wired to a

VOLT116 (or CDM-A116) module, which effectively increases the CR6

analog terminals. If one or more of the optional sensors are not used, the data

logger or VOLT116 terminals assigned to those sensor wires should be left

unwired.

If the standard data logger program is modified, the wiring

presented in TABLE C-1 may no longer apply. In these cases,

refer directly to the program code to determine proper wiring.

If using an analog expansion module, all wiring and connections

are the same whether using a VOLT116 or a CDM-A116.

Therefore, throughout this appendix, the wiring terminals are only

listed for the VOLT116.

C-2

Page 21

Appendix C. EasyFlux® DL CR6KH20

TABLE C-1. Default Wiring for Required Sensors

⏚

G

3/

⏚

⏚.

C.3.1 Required Sensors

A KH20, CSAT3B, and Temp/RH Probe must be wired to the CR6 for

EasyFlux DL CR6KH20 to be functional. TABLE C-1 shows the default wiring

for these sensors.

Sensor Quantity Wire Description Color Terminal

Signal White U3

Signal Reference Black U41/

KH20 1

CSAT3B 1

Power Cable, Ground

HMP155A/EE1812/

Temp/RH Probe

1/

Wire a user-supplied jumper from U4 to

2/

Wire colors for the HMP155A are shown in normal font, while colors for the EE181 are italicized.

3/

Due to terminal constraints, the Temp/RH Probe is a single-ended (SE) voltage measurement. As an SE

measurement from a sensor that is powered continuously, wire the signal reference and power ground wires

both to G.

1

Power Red 12V

Power Ground Black G (power ground)

Shield Clear

CSAT3BCBL3 CPI

Cable

CSAT3BCBL2

Power Cable, 12V

CSAT3BCBL2

RJ45 Connector

Red 12V

Black G

(analog ground)

CR6 CPI Port (if no

Volt116) or

Volt116 CPI Port

Temp Signal Yellow/Yellow U5

RH Signal Blue/Blue U6

RH Signal Reference White/Black

Shield Clear/Clear

Power Red/Red +12 V

Power Ground Black/None G3/

C.3.2 Optional Sensors

C.3.2.1 VOLT116 Module

Due to the limitations on terminal count of the CR6, a VOLT116 (or

CDM-A116) module is required when adding optional sensors. Prepare the

module as follows:

1. Connect the module to a 10-32 VDC power source.

2. Launch Campbell Scientific Device Configuration Utility software (v2.12

or newer) and select VOLT116. If this is the first time connecting, follow

the instructions on the main screen to download and install the USB driver

to the computer.

3. Select the appropriate COM port and click Connect.

C-3

Page 22

Appendix C. EasyFlux® DL CR6KH20

TABLE C-2. Default Wiring for CS106 Barometer

⏚

⏚

TABLE C-3. Default Wiring for Fine Wire Thermocouple

⏚

4. Once connected, a list of settings is shown. Navigate to CPI Address and

change the value to 1. Press Apply and exit the software.

5. Use an Ethernet cable (included with the module) to connect the module

CPI port to the CR6 CPI port.

C.3.2.2 Barometer

A CS106 Barometer is recommended for increased accuracy due to

calculations and unit conversions that use ambient pressure. TABLE C-2

shows the default wiring for EasyFlux DL CR6KH20.

Sensor Quantity Wire Description Color CR6 Terminal

Signal Blue U7

Signal Reference Yellow

CS106 Barometer 0 or 1

Shield Clear

12V Red 12V

Power Ground Black G

Trigger (not used) Green G

C.3.2.3 Fine Wire Thermocouple

A fine wire thermocouple is recommended for a more accurate and direct

measurement of sensible heat flux. If no fine wire thermocouple is used, an

estimate of sensible heat flux is still given; it is derived using the covariance of

sonic temperature and vertical wind and applying the SND correction. The

EasyFlux DL CR6KH20 can support from zero to one fine-wire thermocouple.

Shown in TABLE C-3 are the available types and default wiring for adding a

fine-wire thermocouple.

VOLT116

Sensor Quantity Wire Description Color

Signal

FW3 Fine Wire

Thermocouple

1/

The FW05 and FW1 may be used instead of the FW3, although they are more fragile and may require more

frequent replacement.

1/

0 or 1

Signal Reference

Shield Clear

Purple

Red

Terminal

Diff 15H

Diff15L

C-4

Page 23

Appendix C. EasyFlux® DL CR6KH20

TABLE C-4. Default Wiring for GPS Receiver

⏚

TABLE C-5. Default Wiring for Radiation Measurement Option 1

Signal

White

CR6 U11

⏚

⏚

C.3.2.4 GPS Receiver

A GPS receiver such as the GPS16X-HVS is optional, but will keep the data

logger clock synchronized to GPS time. If the CR6 clock differs by one

millisecond or more, EasyFlux DL CR6OP will resynchronize the data-logger

clock to match the GPS. The GPS receiver also calculates solar position.

TABLE C-4 shows the default wiring for the GPS16X-HVS.

Sensor Quantity Wire Description Color CR6 Terminal

PPS Grey U1

TXD White U2

Shield Clear

GPS16X-HVS 0 or 1

12V Red 12V

Power Ground Black G

Unused Yellow and Blue G

C.3.2.5 Radiation Measurements Option 1

There are two options for making radiation measurements with

EasyFlux DL CR6KH20 . The program can support a combination of the

sensors described in TABLE C-5. Alternatively, it can support one of the three

types of four-way radiometers described in TABLE C-6. TABLE C-5 gives the

default wiring for Option 1. TABLE C-6 shows the details of the default wiring

for Option 2.

Sensor Quantity Wire Description Color

Radiation Signal Red CR6 U8

NR-LITE2 Net

Radiometer

CS301

Pyranometer

1/

0 or 1

0 or 1

Signal Reference Blue

Shield Black

Signal White VOLT116 Diff 9H

Signal Reference Black VOLT116 Diff 9L2/

Shield Clear

Signal Reference Blue

CS320 Digital

Pyranometer

1/

0 or 1

Shield Clear

12V Power Red CR6 12V

Terminal

CR6 ⏚

CR6 ⏚

VOLT116 ⏚

CR6

CR6

Power Ground Black CR6 G

Signal Red

CS310

Quantum Sensor

0 or 1

Signal Reference Black VOLT116 Diff 10L

Shield Clear

VOLT116 Diff

10H

VOLT116 ⏚

C-5

Page 24

Appendix C. EasyFlux® DL CR6KH20

TABLE C-5. Default Wiring for Radiation Measurement Option 1

TABLE C-6. Default Wiring for Radiation Measurements Option 2

⏚

Sensor Quantity Wire Description Color

Target Temp Signal Red/White

Terminal

VOLT116 Diff

11H

Target Temp Reference Black/Black VOLT116 Diff 11L

SI-111/SI-111SS

Infrared

Radiometer

0 or 1

Sensor Temp Reference Blue/Blue

Shield Clear/Clear

Sensor Temp Signal Green/Green

VOLT116 ⏚

VOLT116 Diff

12H

VOLT116 ⏚

Voltage Excitation White/Red VOLT116 X3

1/

Use only one pyranometer, the CS301 or the CS320. Use the CS320 for applications where a digital,

optionally-heated sensor is preferred.

2/

Jumper to ⏚ with user-supplied wire

C.3.2.6 Radiation Measurements Option 2

Three models of four-way radiometers are compatible with

EasyFlux DL CR6KH20, however only one may be used at a given time. The

default wiring for each of the four-way radiometers is shown in TABLE C-6.

Sensor Quantity Wire Description Color Terminal

SN500SS 4-Way

Radiometer

NR01 4-Way

Radiometer

0 or 1

0 or 1

SDI-12 Signal White CR6 U11

Shield Clear

CR6

Power Red CR6 12V

Power Ground Black G

Pyranometer Up Signal Red (cbl 1) VOLT116 Diff 9H

Pyranometer Up Reference Blue

1/

(cbl 1)

Pyranometer Down Signal White (cbl 1)

Pyranometer Down

Reference

Green

1/

(cbl 1)

Pyrgeometer Up Signal Brown (cbl 1)

Pyrgeometer Up Reference

Yellow

(cbl

1)

1/

Pyrgeometer Down Signal Purple (cbl 1)

Pyrgeometer Down

Reference

Grey

1/

(cbl 1)

PT100 Signal White (cbl 2) VOLT116 Diff 4H

PT100 Reference Green (cbl 2) VOLT116 Diff 4L

VOLT116 Diff

1/

9L

VOLT116 Diff

10H

VOLT116 Diff

1/

10L

VOLT116 Diff

11H

VOLT116 Diff

1/

11L

VOLT116 Diff

12H

VOLT116 Diff

1/

12L

C-6

Page 25

Appendix C. EasyFlux® DL CR6KH20

TABLE C-6. Default Wiring for Radiation Measurements Option 2

Sensor

Quantity

Wire Description

Color

Terminal

⏚

VOLT116 Diff

⏚

⏚

Current Excite Red (cbl 2) VOLT116 X1

Current Return Blue (cbl 2)

VOLT116 ⏚

CNR4 4-Way

Radiometer

1/

Jumper to ⏚ with user-supplied wire

Shields Clear

VOLT116

Pyranometer Up Signal Red VOLT116 Diff 9H

VOLT116 Diff

1/

9L

VOLT116 Diff

10H

VOLT116 Diff

1/

10L

VOLT116 Diff

11H

11L1/

VOLT116 Diff

12H

VOLT116 Diff

1/

12L

0 or 1

Pyranometer Up Reference Blue1/

Pyranometer Down Signal White

Pyranometer Down

Reference

Black

1/

Pyrgeometer Up Signal Grey

Pyrgeometer Up Reference Yellow1/

Pyrgeometer Down Signal Brown

Pyrgeometer Down

Reference

Green

1/

Thermistor Signal White VOLT116 Diff 4H

Thermistor V Excite Red VOLT116 X1

Thermistor Reference Black

Shields Clear

VOLT116

VOLT116

A CNF4 Ventilation and Heater Unit may be used with the CNR4 4-way

Radiometer for more accurate radiation measurements. The CNF4 requires a

solid state relay to control the ventilator and heater. The A21REL-12

4-Channel Relay Driver, sold separately, is recommended. Install the A21REL12 inside the system enclosure near the VOLT116 and data logger. TABLE

C-7 lists the wiring connections needed to power and control the A21REL-12;

a CABLE3CBL-1 or similar 3-conductor 22 AWG cable is recommended for

connections from the A21REL-12 to the VOLT116, and a CABLEPCBL-1 or

similar 16 AWG 2-conductor power cable is recommended for power

connections from the A21REL-12 to system 12V power source. TABLE C-8

lists the wiring for the CNF4.

C-7

Page 26

Appendix C. EasyFlux® DL CR6KH20

A21REL-12 Terminal

Connecting Terminal

Cable/Wire

CABLEPCBL-1,

CABLE3CBL-1,

TABLE C-8. CNF4 Wiring

Sensor

Quantity

Wire Description

Color

Terminal

A21REL-12

TABLE C-7. A21REL-12 Wiring

+12V

System +12V

1/

Ground System GND1/

CTRL 1

CTRL 2

CTRL 3

The +12V terminal on the A21REL-12 needs to be in common with the REL 1 COM, REL 2

COM, and REL 3 COM terminals. To do this, use jumper wires to connect the +12V

terminal to REL 1 COM, and then REL1 COM to REL 2 COM, and finally REL2 Com to

REL 3 COM.

1/

For the A21REL-12 power connections, connect +12V and G to a system or external

power supply. Do not connect to the +12V or G terminals on the CR6 or VOLT116.

VOLT116 SW5V #1

VOLT116 SW5V #2

VOLT116 SW5V #3

CABLEPCBL-1,

red wire

black wire

CABLE3CBL-1,

red wire

black wire

CABLE3CBL-1,

white wire

Tachometer Output Green CR6 U11

CNF4

0 or 1,

only use

with a

CNR4

Tachometer

Reference

Ventilator Power Yellow

Ventilator Ground Brown

Heater #1 Power White

Grey

A21REL-12

REL 1 NO

A21REL-12

A21REL-12

REL 2 NO

CR6 ⏚

REL G

Heater #1 Ground Red

Heater #2 Power Black

Heater #2 Ground Blue

C.2.3.7 Precipitation Gage

EasyFlux DL CR6KH20 can support a single TE525MM tipping rain gage. The

default wiring for the precipitation gage is shown in TABLE C-9.

REL G

A21REL-12

REL 3 NO

A21REL-12

REL G

C-8

Page 27

Appendix C. EasyFlux® DL CR6KH20

TABLE C-9. Default Wiring for Precipitation Gage

⏚

⏚

TABLE C-10. Default Wiring for Soil Thermocouple Probes

VOLT116 Terminal

⏚

⏚

⏚

CAUTION

NOTE

Sensor Quantity Wire Description Color

TE525MM

Tipping Rain

Gage

0 or 1

Pulse Output Black U12

Signal Ground White

Shield Clear

C.2.3.8 Soil Temperature

The TCAV is an averaging soil thermocouple probe used for measuring soil

temperature. EasyFlux DL CR6KH20 can support up to three TCAV probes.

The order of wiring, however, is important. If only one TCAV sensor is used, it

must be wired as described for TCAV #1 in TABLE C-10. A second or third

TCAV sensor would be wired according to TCAV #2 or TCAV #3,

respectively, in TABLE C-10.

If only one TCAV is being used and it is wired according to

TCAV #2 or #3, the data logger will not record any TCAV

measurements.

Sensor Quantity Wire Description Color

Signal Purple Diff 1H

TCAV #1 1

TCAV #2 1

Signal Reference Red Diff 1L

Shield Clear

Signal Purple Diff 2H

Signal Reference Red Diff 2L

Shield Clear

CR6 Terminal

Signal Purple

TCAV#3

1

Signal Reference Red

Shield Clear

The CS650 or CS655 sensors also measure soil temperature. If the

CS650 or CS655 sensors are used but no TCAV probes are used,

EasyFlux DL CR6KH20 will use soil temperature from the CS650

or CS655 to compute ground-surface heat flux. If available, soil

temperature from the TCAV probe is preferred since it provides a

better spatial average. See wiring details for these sensors in

TABLE C-11.

C.2.3.9 Soil Water Content

EasyFlux DL CR6KH20 supports one of two models of soil water content

sensors: the CS650 or CS655; up to three of one model is supported. A soil

Diff 3H

Diff 3L

C-9

Page 28

TABLE C-11. Default Wiring for Soil Water Content Probes

Sensor

Quantity

Wire Description

Color

CR6 Terminal

CS650/CS655

⏚

⏚

U9

G

⏚

G

TABLE C-12. Default Wiring for Non-Calibrating Soil Heat Flux Plates

⏚

CAUTION

SDI-12 address 1

CS650/CS655

SDI-12 address 2

CS650/CS655

SDI-12 address 3

Appendix C. EasyFlux® DL CR6KH20

water content sensor can also be omitted without affecting function. The

default wiring for each is shown in TABLE C-11.

If only one soil water content sensor is being used, wire it

according to the first probe as described in TABLE C-11. If only

one sensor is being used and it is wired according to the second or

third sensor, EasyFlux DL CR6KH20 will not record any

measurements from the soil water content sensor.

SDI-12 Data Green U9

SDI-12 Power Red +12 V

1

1

1

SDI-12 Reference Black G

Shield Clear G

Not Used Orange

SDI-12 Data Green U9

SDI-12 Power Red +12 V

SDI-12 Reference Black G

Shield Clear

Not Used Orange G

SDI-12 Data

SDI-12 Power

SDI-12 Reference

Shield Clear

Not Used

Green

Red

Black

Orange

+12 V

C.3.2.10 Soil Heat Flux Plates

EasyFlux DL CR6KH20 can support from zero to soil heat flux plates. The user

has the option to use one of two supported models: the HFP01 or HFP01SC

(self-calibrating). The default wiring for the HFP01 soil heat flux plates is

shown in TABLE C-12, and the default wiring for the HFP01SC plates is

shown in TABLE C-13.

Sensor Quantity Wire Description Color VOLT116 Terminal

Signal White Diff 5H

HFP01 #1 1

Signal Reference Green Diff 5L

Shield Clear

C-10

Page 29

Appendix C. EasyFlux® DL CR6KH20

TABLE C-12. Default Wiring for Non-Calibrating Soil Heat Flux Plates

Sensor

Quantity

Wire Description

Color

VOLT116 Terminal

⏚

⏚

TABLE C-13. Default Wiring for Soil Heat Flux Plates (Self Calibrating)

Sensor

Quantity

Wire Description

Color

VOLT116 Terminal

⏚

⏚

⏚

⏚

⏚

⏚

Signal White Diff 6H

HFP01 #2 1

Signal Reference Green Diff 6L

Shield Clear

Signal White Diff 7H

HFP01 #3 1

Signal Reference Green Diff 7L

Shield Clear

Signal White Diff 5H

Signal Reference Green Diff 5L

HFP01SC #1 1

Shield Clear

Heater Signal Yellow Diff 13H

Heater Reference Purple Diff 13L

Shield Clear

Heater Power Red SW12-11/

Power Reference Black G

Signal White Diff 6H

Signal Reference Green Diff 6L

Shield Clear

Heater Signal Yellow Diff 14H

HFP01SC #2 1

Heater Reference Purple Diff 14L

Shield Clear

Heater Power Red SW12-11/

Power Reference Black G

Signal White Diff 7H

Signal Reference Green Diff 7L

Shield Clear

Heater Signal Yellow Diff 16H

HFP01SC #3 1

Heater Reference Purple Diff 16L

Shield Clear

Heater Power Red SW12-21/

Power Reference Black G

1/

The SW12 terminals on the VOLT116 are limited to 200mA output. Accordingly, no more than two

HFP01SC sensors may be connected to each terminal. Connect heater power wires from HFP01SC #1 and #2

to SW12-1, and connect heater wires from HFP01SC #3 to SW12-2.

C-11

Page 30

C.4 Operation

C.4.1 Set Constants in CRBasic Editor and Load Program

Appendix C. EasyFlux® DL CR6KH20

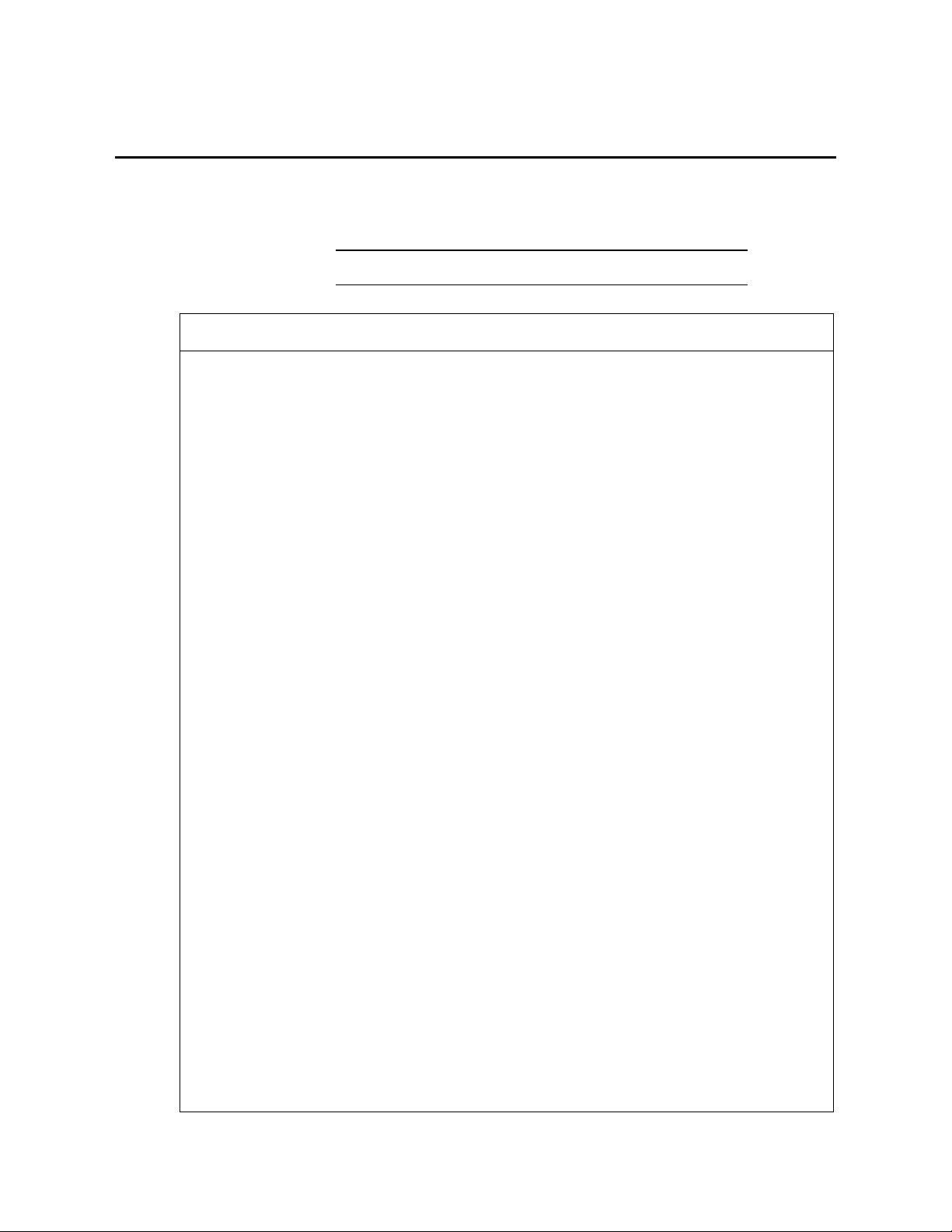

Operating EasyFlux DL CR6KH20 requires the user to enter or edit certain

constants and input variables unique to the program or site. Constants are

typically edited only once when first initializing the program, whereas sitespecific variables are edited upon initial deployment and periodically as site

conditions change; for example, canopy height is a variable that may need to be

adjusted throughout a growing season. Appendix C.4.1, Set Constants in

CRBasic Editor and Load Program

constants, and Appendix C.4.2, Enter Site-Specific Variables with Data Logger

Keypad or LoggerNet

Before operating the station, the values for configuration constants should be

verified in the program code using CRBasic Editor.

Open the program in CRBasic Editor. After the introductory comments at the

top is a section titled “USER-DEFINED CONFIGURATION CONSTANTS”

(see FIGURE C-1). Review the constants in this section and modify as needed.

If having difficulty locating the correct lines of code, search the program for

the word “unique”. This will locate all lines of code containing constants that

need to be verified. Look for the text comments on the right side of each line of

code for more explanation of the constant. Generally, the constants fall into

four categories:

(p. C-14), provides details on setting variables.

(p. C-12), provides instructions on setting

1. Program Function Constants

These are constants that determine the timing of code execution,

frequency of writing to output tables, memory allocation, etc. In most

cases, the default constants for these values may be retained.

A program function constant worth mentioning is

ONE_FULL_TABLE. If this is set to TRUE, all of the intermediate

and auxiliary measurements will be included as data fields in the

main FLUX_CSFormat output table, rather than being in a separate

output table called FLUX_NOTES. For more information, see

Appendix C.4.4, Output Tables

2. Sensor Selection Constants

All sensor selection constants begin with the prefix SENSOR. The

value is set to TRUE in the constant table if the system includes the

sensor. For example, if a system has a fine-wire thermocouple, the

constant SENSOR_FW should be set to TRUE. When set to TRUE,

the wiring in TABLE C-13 will apply to the sensor and the data from

that sensor will be included in the data output tables.

If a sensor is not used, ensure the constant is set to FALSE.

3. Sensor Quantity Constants

The value for these constants indicates the number of each type of

sensor in the system. For example, if three soil heat flux (SHF) plates

were being used, the constant NMBR_SHF would be set to 3.

(p. C-19).

4. Sensor Calibration Constants

Some sensors have unique parameters for their measurement

C-12

Page 31

Appendix C. EasyFlux® DL CR6KH20

NOTE

equations; for example, multipliers and/or offsets for linear working

equations that are used to convert their raw measurements into the

values applicable in analysis. Typically, these parameter values are

found on the calibration sheet from the sensor original manufacturer.

For example, if an NR-LITE2 net radiometer is being used, a unique

multiplier is set in the following line of code: Constant

NRLITE_SENSITIVITY = 16. The comments in the code explain

that the value entered is the sensor sensitivity provided in the NRLITE2 calibration sheet.

Constants relating to a particular sensor have been grouped

together and have the sensor selection constant at the beginning,

such that if the sensor selection constant is set to FALSE, the other

constants for that sensor may be ignored. For example, the

constants dealing with the SI-111SS Infrared Radiometer are

grouped together with the SENSOR_SI111 constant at the top. If

a SI-111SS is not being used, SENSOR_SI111 should be set to

FALSE and the next five constants dealing with calibration

coefficients will be ignored in the program.

After all constants are verified, save the program under a new or modified file

name to keep track of different program versions. Finally, send the program to

the CR6 using LoggerNet, PC400, or PC200W software.

FIGURE C-1. Example screen from CRBasic Editor showing user-

defined configuration constants

C-13

Page 32

Appendix C. EasyFlux® DL CR6KH20

System Control

Site Var Settings >

Site Var Settings:

Latitude

Hemisph_NS

Longitude

Hemisph_EW

Altitude

Meas height

Surface Type >

Canopy Height

d, 0 = auto

z0, 0 = auto

Sonic Azmth

KH20 Coord x

KH20 Coord y

FW Coord x

FW Coord y

FW Dim

GPS Height

Bulk Density

C_dry_soil

HFP Depth

Planar Fit Alpha >

Planar Fit Beta >

Footprt Dist Intrst >

Surface Type:

CROP

GRASS

FOREST

SHRUB

BARELAND

WATER

ICE

Planar Fit Alpha:

≤60 or ≥300

>60 & ≤170

>170 & <190

≥190 & <300

Planar Fit Beta:

≤60 or ≥300

>60 & ≤170

>170 & <190

≥190 & <300

Footprt Dist Intrst:

≤60 or ≥300

>60 & ≤170

>170 & <190

≥190 & <300

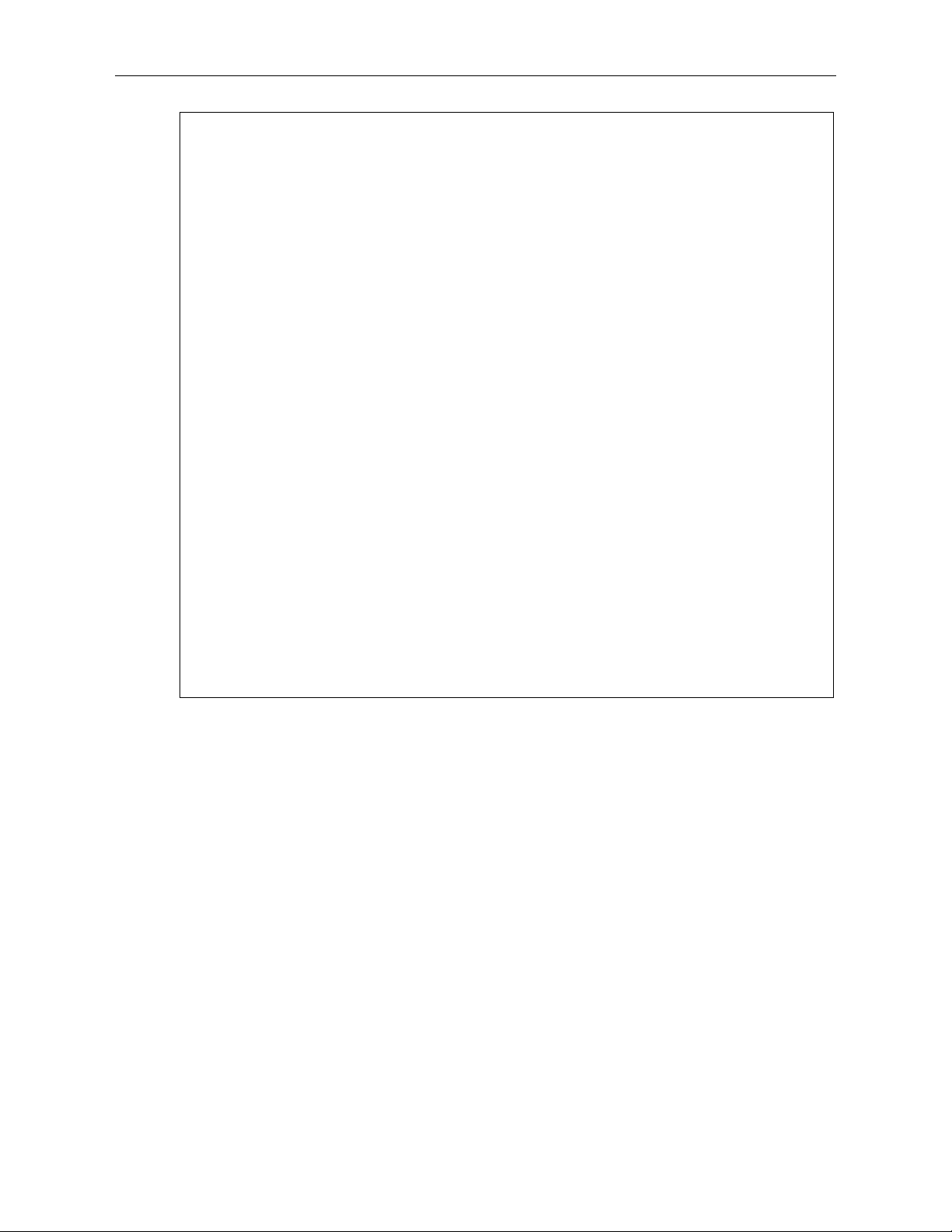

C.4.2 Enter Site-Specific Variables with Data Logger Keypad or

LoggerNet

After the eddy-covariance station is installed and the data logger is running the

program, connect a CR1000KD Keyboard Display to the CR6 CS-I/O port to

view a custom menu of station-specific variables (FIGURE C-2). Use this

menu to enter, view, and modify these variables. Use the up and down arrow

buttons to navigate to different variables. Press Enter to select a variable or to

set a new value after typing it. Press Esc to return to the previous menu.

FIGURE C-2 depicts the structure of the custom menu. Bypass the custom

menu to interact directly with the data logger through the data logger default

menus. To bypass the custom menus, select < System Menu >. If no

CR1000KD is available, these same variables may be viewed and edited using

the LoggerNet connect screen numeric display of variables from the Public

table.

FIGURE C-2. Custom keypad menu; arrows indicate submenus

Before fluxes are processed correctly, the user must go through each of the

station variables and set or confirm the assigned values. TABLE C-14 gives

short descriptions of each station variable.

C-14

Page 33

Appendix C. EasyFlux® DL CR6KH20

TABLE C-14. Station Variables with Descriptions

The height of the center of the

Distance along the sonic x-axis

Station Variable Units Default Description

Latitude

Hemisph_NS none NORTH

Longitude

Hemisph_EW none WEST

Altitude m 1356 The site altitude altitude

decimal

degrees

decimal

degrees

41.766

111.855

The site latitude in degrees North

or South.

The site latitudinal hemisphere.

Options are NORTH or SOUTH.

The site longitude in degrees

East or West.

The site longitudinal

hemisphere. Options are EAST

or WEST.

Name of variable in

Public Table (in

case no CR1000KD

available)

Latitude

hemisphere_NS

1 = North

–1 = South

Longitude

hemisphere_EW

1 = East

–1 = West

Meas Height m 2

Surf Type none GRASS

Canopy Height m 0.5

d m 0 (Auto)

z0

Sonic Azmth

m 0 (Auto)

decimal

degrees

0

eddy-covariance sensor

measurement volumes above

ground.

Type of surface at the

measurement site. Options are

CROP, GRASS, FOREST,

SHRUB, BARELAND, and

WATER. This is used to

estimate displacement height.

The average height of the

canopy.

Displacement height. Set to zero

(0) for program to auto-calculate.

See the Aerodynamic Height

appendix in the EasyFlux DL

CR6OP manual for details.

Roughness length. Set to zero (0)

for program to auto-calculate.

See the Programmatic Approach

appendix in the EasyFlux DL

CR6OP manual for details.

The compass direction in which

the sonic negative x-axis points

(the compass direction in which

the sonic head is pointing).

height_measurement

surface_type

1 = CROP

2 = GRASS

3 = FOREST

4 = SHRUBLAND

5 = BARELAND

6 = WATER

7 = ICE

height_canopy

displacement_user

roughness_user

sonic_azimuth

KH20 Coord x

m 0.15

between the sonic sampling

volume and KH20 sampling

volume.

separation_x_kh20

C-15

Page 34

Appendix C. EasyFlux® DL CR6KH20

TABLE C-14. Station Variables with Descriptions

Station Variable Units Default Description

Distance along the sonic y-axis

KH20 Coord y

m 0.15

between the sonic sampling

volume and KH20 sampling

volume.

Distance along the sonic x-axis

between the sonic sampling

FW Coord x m 0.01227

volume and fine-wire

thermocouple. If no fine-wire

thermocouple is being used, this

variable is omitted.

Distance along the sonic y-axis

between the sonic sampling

FW Coord y m -0.02408

volume and the fine-wire

thermocouple. If no fine-wire

thermocouple is being used, this

variable is omitted.

Identifies which fine-wire

thermocouple is being used and

loads the appropriate diameter.

For FW05_DIA, FW1_DIA and

FW Dim m FW3_DIA

FW3_DIA, the diameters are

-5

1.27 x 10

x 10

, 2.54 x 10-5, and 7.62

-5

m, respectively. If no finewire thermocouple is being used,

this variable is omitted.

The height of the GPS reciever

GPS Height m 2

above the ground surface. If GPS

is not used, this variable is

omitted.

Average bulk density of soil. If

Bulk Density kg·m-3 1300

energy balance sensors are not

used, this variable is omitted.

Specific heat of dry mineral soil.

C_dry_soil J·kg-1 K-1 870

If energy balance sensors are not

used, this variable is omitted.

Depth of the soil heat flux plates.

HFP Depth m 0.16

If energy balance sensors are not

used, this variable is omitted.

Alpha angle used to rotate the

wind when the mean horizontal

Planar

Fit Alpha

≤ 60

or

≥ 300

decimal

degrees

0

wind is blowing from the sector

of 0 to 60 and 300 to 360

degrees in the sonic coordinate

system (wind blowing into sonic

1/

head).

Name of variable in

Public Table (in

case no CR1000KD

available)

separation_y_kh20

separation_x_FW

separation_y_FW

FW_diameter

height_GPS16X

soil_bulk_density

cds

thick_abv_HFP

alpha_PF_60_300

C-16

Page 35

Appendix C. EasyFlux® DL CR6KH20

TABLE C-14. Station Variables with Descriptions

Alpha angle used to rotate the

Beta angle used to rotate the

Station Variable Units Default Description

Alpha angle used to rotate the

wind when the mean horizontal

Planar

Fit Alpha

> 60

&

≤ 170

decimal

degrees

0

wind is blowing from the sector

of 60 to 170 degrees in the sonic

coordinate system (wind blowing

from the sector left and behind

1/

sonic head).

Alpha angle used to rotate the

wind when the mean horizontal

Planar

Fit Alpha

> 170

&

< 190

decimal

degrees

0

wind is blowing from the sector

of 170 to 190 degrees in the

sonic coordinate system (wind

blowing from behind sonic

1/

head).

Name of variable in

Public Table (in

case no CR1000KD

available)

alpha_PF_60_170

alpha_PF_170_190

Planar

Fit Alpha

Planar

Fit Beta

Planar

Fit Beta

Planar

Fit Beta

≥ 190

&

< 300

≤ 60

or

≥ 300

> 60

&

≤ 170

> 170

&

< 190

decimal

degrees

decimal

degrees

decimal

degrees

decimal

degrees

wind when the mean horizontal

wind is blowing from the sector

0

of 190 to 300 degrees in the

alpha_PF_190_300

sonic coordinate system (wind

blowing from the sector right

1/

and behind sonic head).

wind when the mean horizontal

wind is blowing from the sector

0

of 0 to 60 and 300 to 360

beta_PF_60_300

degrees in the sonic coordinate

system (wind blowing into sonic

1/

head).

Beta angle used to rotate the

wind when the mean horizontal

wind is blowing from the sector

0

of 60 to 170 degrees in the sonic

beta_PF_60_170

coordinate system (wind blowing

from left and behind sonic

1/

head).

Beta angle used to rotate the

wind when the mean horizontal

wind is blowing from the sector

0

of 170 to 190 degrees in the

beta_PF_170_190

sonic coordinate system (wind

blowing from behind sonic

1/

head).

C-17

Page 36

Appendix C. EasyFlux® DL CR6KH20

TABLE C-14. Station Variables with Descriptions

Name of variable in

Public Table (in

case no CR1000KD

Station Variable Units Default Description

available)

Beta angle used to rotate the

wind when the mean horizontal

Planar

Fit Beta

≥ 190

&

< 300

decimal

degrees

0

wind is blowing from the sector

of 190 to 300 degrees in the

sonic coordinate system (wind

beta_PF_190_300

blowing from right and behind

1/

sonic head).

The upwind distance of interest

from the station when the mean

horizontal wind is blowing from

the sector of 0 to 60 and 300 to

360 degrees in the sonic

coordinate system (wind blowing

into sonic head).

Footprint

Dist of

Interest

≤ 60

or

≥ 300

m 100z

Note: The program will report

the percentage of cumulative

dist_intrst_60_300

footprint from within this

distance. The default value is

100 times the aerodynamic

height, z. Recall that z is the

difference between the

measurement height and

displacement height.

The upwind distance of interest

from the station when the mean

Footprint

Dist of

Interest

> 60

&

≤ 170

m 100z

horizontal wind is blowing from

the sector of 60 to 170 degrees in

the sonic coordinate system

dist_intrst_60_170

(wind blowing from left and

behind sonic head).

The upwind distance of interest

from the station when the mean

Footprint

Dist of

Interest

> 170

&

< 190

m 100z

horizontal wind is blowing from

the sector of 170 to 190 degrees

in the sonic coordinate system

dist_instrst_170_190

(wind blowing from behind

sonic head).

The upwind distance of interest

from the station when the mean

Footprint

Dist of

Interest

≥ 190

&

< 300

m 100z

horizontal wind is blowing from

the sector of 190 to 300 degrees

in the sonic coordinate system

dist_intrst_190_300

(wind blowing from right and

behind sonic head).

1/

Leave all planar fit alpha and beta angles set to 0 to use Tanner and Thurtell (1969) method of double coordinate rotations.

C-18

Page 37

The CSAT3B offers a user-enabled correction for transducer wind

TABLE C-15. microSD Flash Card Fill Times with 10Hz Measurement Rate

Fill time with required sensors, FW,

NOTE

NOTE

CAUTION

shadowing. The correction is disabled as a default state but may

be enabled by connecting the CSAT3B to a computer using the

CSAT3B USB Data Cable, launching the Device Configuration

Utility, and changing the setting for correction. For more

information on the correction, see the CSAT3B manual.

C.4.3 Data Retrieval

The program stores a limited amount of data to the internal CPU of the data

logger, so a microSD Flash card should be used with the CR6. TABLE C-15

shows the number of days of data a 2 GB, 8 GB, and 16 GB card will typically

hold before the memory is full and data starts to be overwritten. In cases where

real-time remote monitoring is desired, various telemetry options (for example,

cellular, radio, etc.) are available to transmit the processed flux data. Certain

conditions may also allow remote transmittal of time series data. Contact

Campbell Scientific for more details.

Appendix C. EasyFlux® DL CR6KH20

microSD Flash

card size

Fill time with required

sensors only

CS106, and biomet/energy balance

1/

sensors)

2 GB ~41 days ~35 days

8 GB ~170 days ~141 days

16 GB ~339 days ~281 days

1/

Biomet and energy balance sensors used for this fill time estimate include the following: NR-LITE2, CS301,

CS310, SI-111, TE525MM, TCAV (qty 3), CS616 (qty 3), and HFP01 (qty 3)

microSD Flash cards from various manufacturers may have

slightly different memory sizes on their 2 GB, 8 GB, and 16 GB

cards, respectively. Also, as a card ages some of its sectors may

become unusable, decreasing the available memory. Fill time

estimates given in

TABLE C-15 are approximations for new

cards.

Campbell Scientific recommends and supports only the use

of microSD cards obtained from Campbell Scientific. These

cards are industrial grade and have passed Campbell

Scientific hardware testing. Use of consumer grade cards

substantially increases the risk of data loss.

C.4.4 Output Tables

Besides the standard Public, Status, and TableInfo tables that every data

logger reports, the program has six output tables. TABLE C-16 gives the

names of these output tables, along with a short description, the frequency at

which a record is written to the table, and the amount of memory allocated

from the CPU and microSD card for each table.

C-19

Page 38

Appendix C. EasyFlux® DL CR6KH20

TABLE C-16. Data Output Tables

Table Name

Description

Recording Interval

Memory on

CR6 CPU

Memory on

microSD Card

NOTE

The variable naming conventions used by AmeriFlux and other

flux networks have been adopted in EasyFlux DL CR6KH20.

Additionally, an output table called Flux_AmeriFluxFormat

reports the variables in the order and format prescribed

by AmeriFlux (see

variables/

).

https://ameriflux.lbl.gov/data/aboutdata/data-

If the user would prefer to have the data fields contained in the Flux_Notes

table appended to the end of the Flux_CSFormat table rather than being

placed in a separate output table, this is possible by changing the constant

ONE_FULL_TABLE from FALSE to TRUE (see Appendix C.4.1, Set

Constants in CRBasic Editor and Load Program

(p. C-12), on changing

constants).

Time_Series

Diagnostic

Monitor_CSAT3B

Flux_AmeriFluxFormat

Flux_CSFormat

Flux_Notes

Time series data

(aligned to

account for

electronic delays)

Reports most

recent diagnostic

flags from select

sensors

Reports roll and

pitch of the

CSAT3B, as well

as temp & RH in

CSAT3B sensor

housing

Processed flux

and statistical data

following

reporting

conventions and

order of

AmeriFlux

Processed flux

and statistical data

Intermediate

variables, station

constants, and

correction

variables used to

generate flux

results

SCAN_INTERVAL

(default 100 ms)

SLW_SCN_INTV

(default 6 s)

SLW_SCN_INTV

(default 6 s)

OUTPUT_INTERVAL

(default 30 minutes)

OUTPUT_INTERVAL

(default 30 minutes)

OUTPUT_INTERVAL

(default 30 minutes)

Auto-Allocate

(typically less than

1 hour)

1 record (most

recent scan)

1 day

7 days

7 days

NUM_DAY_CPU

(default 7 days)

See TABLE

C-15 for total

days. Data

broken into

daily files.

0 records

See TABLE

C-15 for total

days. Data

broken into 30-

day files.

See TABLE

C-15 for total

days. Data

broken into 30-

day files.

See TABLE

C-15 for total

days. Data

broken into 30-

day files.

See TABLE

C-15 for total

days. Data

broken into 30-

day files.

C-20

Page 39

Appendix C. EasyFlux® DL CR6KH20

TABLE C-17. Data Fields in the Time_Series Data Output Table

NOTE

NOTE

TABLE C-16 through TABLE C-22 give a description of all data fields found

in each data output table and when each data field is included in the table.

Prior to coordinate rotations, the orthogonal wind components

from the sonic anemometer are denoted as Ux, Uy, and Uz.

Following coordinate rotations, the common denotation of u, v,

and w is used, respectively.

Variables with _R denote that the value was computed after

coordinate rotations were done. Variables with a _F denote that

the value was calculated after frequency corrections were applied.

Similarly, _SND and _WPL refer to variables that have had the

SND correction or the WPL correction applied, respectively.

Data Field

Name

Ux m·s-1 Wind speed along sonic x-axis Always

Uy m·s-1 Wind speed along sonic y-axis Always

Uz m·s-1 Wind speed along sonic z-axis Always

T_SONIC

diag_sonic none Raw sonic diagnostic value (0 indicates no diagnostic flags set) Always

volt_KH20 mV Raw signal voltage from KH20 Always

diag_KH20 none

PA kPa Ambient pressure Always

TA_1_1_1

RH_1_1_1 % Relative humidity measured by the temp/RH probe Always

FW

Units Description

deg

Sonic temperature Always

C

Diagnostic value from KH20 (a non-zero result indicates

volt_KH20 was returned as not a number, less than -10 mV, or