Page 1

INSTRUCTION MANUAL

Model HFP01SC Self-Calibrating

Copyright © 2002- 2014

Soil Heat Flux Plate

Revision: 3/14

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 1

4. Overview ...................................................................... 1

5. Specifications ............................................................. 2

6. Installation ................................................................... 3

6.1 Placement in Soil.................................................................................. 3

6.2 Wiring .................................................................................................. 6

6.3 Programming ........................................................................................ 6

Example 1. Sample CR3000 Program Using a Differential

6.3.1

Measurement Instruction ........................................................... 6

6.3.2 Example 2. Sample CR10(X) Program Using a Single-Ended

Measurement Instruction ........................................................... 9

6.3.3 Example 3. Sample CR23X Program Using a Differential

Measurement Instruction ......................................................... 13

6.3.4 Example 4. Sample CR10X Program Using External Power

and Relay ................................................................................. 17

6.4 Soil Heat Flux and Storage ................................................................. 22

6.5 In-Situ Calibration Theory ................................................................. 23

7. Maintenance .............................................................. 24

8. References ................................................................ 24

Figures

6-1. Placement of heat flux plates ............................................................... 3

6-2. HFP01SC plate ..................................................................................... 4

Tables

6-1. Datalogger Connections for a Single-Ended Measurement ................. 5

6-2. Datalogger Connections for a Differential Measurement ..................... 5

6-3. Wiring for Example 1 ........................................................................... 6

6-4. Wiring for Example 2 ........................................................................... 9

6-5. Wiring for Example 3 ......................................................................... 13

6-6. Sensor Wiring for Example 4 ............................................................. 17

6-7. Datalogger-to-A21REL-12 Wiring for Example 4 ............................. 17

6-8. Hukseflux and Campbell Scientific Variable Names ......................... 24

i

Page 6

Table of Contents

ii

Page 7

Model HFP01SC

Self-Calibrating Soil Heat Flux Plate

1. Introduction

The HFP01SC Self-Calibrating Heat Flux Sensor measures soil heat flux,

typically for energy-balance or Bowen-ratio flux systems. It is intended for

applications requiring the highest possible degree of measurement accuracy.

At least two sensors are required for each site to provide spatial averaging.

Sites with heterogeneous media may require additional sensors.

Before installing the HFP01SC, please study

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

The installation procedure is provided in Section 6, Installation.

2. Cautionary Statements

• Care should be taken when opening the shipping package to not damage or

cut the cable jacket. If damage to the cable is suspected, consult with a

Campbell Scientific applications engineer.

• Although the HFP01SC is rugged, it should be handled as a precision

scientific instrument.

3. Initial Inspection

• Upon receipt of the HFP01SC, inspect the packaging and contents for

damage. File damage claims with the shipping company.

• The model number and cable length are printed on a label at the

connection end of the cable. Check this information against the shipping

documents to ensure the correct product and cable length are received.

• The HFP01SC is shipped with a calibration sheet and an instruction

manual or a ResourceDVD.

4. Overview

The HFP01SC Soil Heat Flux plate consists of a thermopile and a film heater.

The thermopile measures temperature gradients across the plate. During the insitu field calibration, the film heater is used to generate a heat flux through the

plate. The amount of power used to generate the calibration heat flux is

measured by the datalogger. Each plate is individually calibrated, at the

factory, to output flux.

1

Page 8

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

In order to measure soil heat flux at the surface, several HFP01SCs are used to

measure the soil heat flux at a depth of eight centimeters. A TCAV, Averaging

Soil Thermocouple, is used to measure the temporal change in temperature of

the soil layer above the HFP01SC. Finally, a CS650, CS655, or CS616 water

content reflectometer is used to measure the soil water content. The temporal

change in soil temperature and soil water content are used to compute the soil

storage term.

The -L option on the model HFP01SC Soil Heat Flux Plate (HFP01SC-L)

indicates that the cable length is user specified. The HFP01SC-L has two

cables; the first cable is the signal output cable and the second is the heater

input cable. Two analog inputs are required to measure the HFP01SC-L. This

manual refers to the sensor as the HFP01SC.

The sensor’s cable can terminate in:

• Pigtails that connect directly to a Campbell Scientific datalogger

(option –PT).

• Connector that attaches to a prewired enclosure (option –PW). Refer

to www.campbellsci.com/prewired-enclosures for more information.

5. Specifications

Features:

• Corrects for errors due to differences in thermal conductivity between

the sensor and the surrounding medium, temperature variations, and

slight sensor instabilities

• Compatible with most of our dataloggers

• Uses Van den Bos-Hoeksema self-calibration method to provide

high-degree of measurement accuracy

Compatibility

Dataloggers: CR800 series

CR1000

CR3000

CR5000

CR9000(X)

CR7X

CR10(X)

CR23X

21X

Operating Temperature: –30° to +70°C

Storage Temperature: –30° to +70°C

2

Plate Thickness: 5 mm (0.2 in)

Plate Diameter: 80 mm (3.15 in)

Average Power Consumption: 0.02 to 0.04 W

Page 9

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

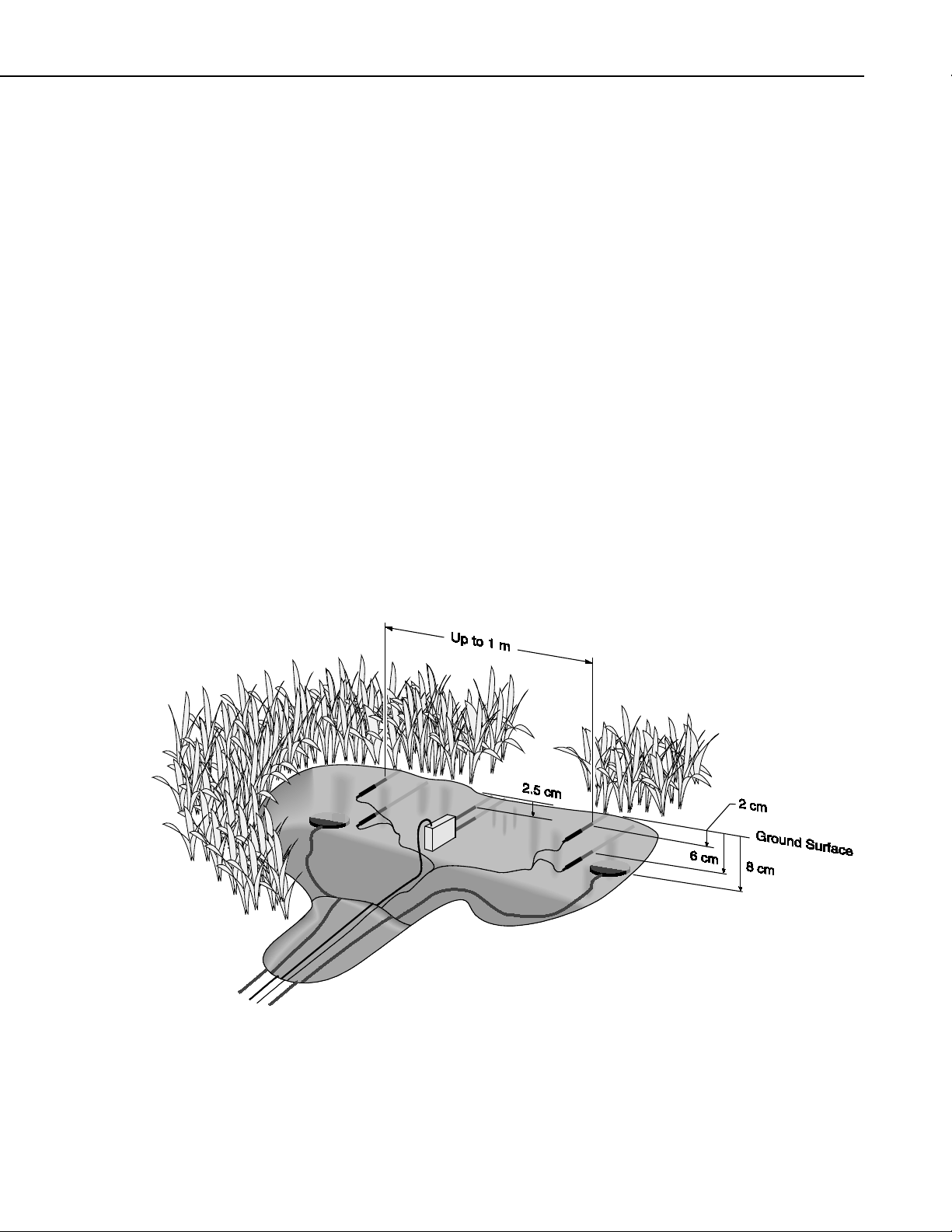

Partial emplacement of the HFP01SC and the TCAV

Sensor: Thermopile and film heater

Heater Voltage Input: 9 to 15 Vdc

Heater Voltage Output: 0 to 2 Vdc

Expected Accuracy: ±3% of reading

6. Installation

6.1 Placement in Soil

Sensitivity (nominal): 50 µV W

Sensor Resistance (nominal): 2 Ω

Heater Resistance (nominal): 100 Ω

Duration of Calibration: ±3 min. @ 1.5 W; typically done every 3 to

6 hours

Weight without Cable: 200 g (7.05 oz)

The HFP01SC soil heat flux plates, the TCAV averaging soil temperature

probes, and the CS616, Water Content Reflectometer, are installed as shown in

FIGURE 6-1.

–1 m–2

sensors is shown for illustration purposes. All sensors

must be completely inserted into the soil face before

the hole is backfilled.

FIGURE 6-1. Placement of heat flux plates

3

Page 10

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

NOTE

CAUTION

Signal (White)

Signal Reference (Green)

Shield (Clear)

Heater Resis

Heater Resistor Signal Reference (Purple)

Shield (Clear)

Power (Red)

Power Reference (Black)

The location of the heat flux plates and thermocouples should represent the

area of study. If the ground cover is extremely varied, it may be necessary to

have additional sensors to provide a valid spatial average of soil heat flux.

Use a small shovel to make a vertical slice in the soil. Excavate the soil to one

side of the slice. Keep this soil intact to ensure replacement with minimal

disruption.

The sensors are installed in the undisturbed face of the hole. Measure the

sensor depths from the top of the hole. With a small knife, make a horizontal

cut eight centimeters below the surface into the undisturbed face of the hole.

Insert the heat flux plate into the horizontal cut.

Install the HFP01SC in the soil such that the side with the text

“this side up” is facing the sky.

In order for the HFP01SC to make quality soil heat flux

measurements, the plate must be in full contact with the soil.

Never run the sensors leads directly to the surface. Rather, bury the sensor

leads a short distance back from the hole to minimized thermal conduction on

the lead wire. Replace the excavated soil into its original position after all the

sensors are installed.

tor Signal (Yellow)

4

FIGURE 6-2. HFP01SC plate

Page 11

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

TABLE 6-1. Datalogger Connections for a Single-Ended Measurement

TABLE 6-2. Datalogger Connections for a Differential Measurement

Description

Color

CR10X

CR3000, CR5000,

CR23X, CR9000(X),

CR7, 21X

CR800, CR850,

CR1000

Sensor Signal White Single-Ended Input Single-Ended Input Single-Ended Input

Sensor Signal

Reference

Green AG

Shield Clear G

Heater Resistor Signal Yellow Single-Ended Input Single-Ended Input Single-Ended Input

Heater Resistor Signal

Reference

Purple AG

Shield Clear G

Power Red SW12 SW12 SW12

Power Reference Black G G G

External Power Control Jumper

Wire

SW12-CTRL to

Control Port

External Power Control

Not Needed

External Power Control

Not Needed

Description

Color

CR10(X)

CR3000, CR5000,

CR23X, CR9000(X),

CR7, 21X

CR800, CR850,

CR1000

Sensor Signal White Differential Input (H) Differential Input (H) Differential Input (H)

Sensor Signal

Green Differential Input (L) Differential Input (L) Differential Input (L)

Reference

Shield Clear G

Heater Resistor Signal Yellow Differential Input (H) Differential Input (H) Differential Input (H)

Heater Resistor Signal

Purple Differential Input (L) Differential Input (L) Differential Input (L)

Reference

Shield Clear G

Power Red SW12 SW12 SW12

Power Reference Black G G G

External Power

Control

Jumper

Wire

SW12-CTRL to

Control Port

External Power Control

Not Needed

External Power

Control Not Needed

5

Page 12

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

TABLE 6-3. Wiring for Example 1

NOTE

6.2 Wiring

Connections to Campbell Scientific dataloggers are given in FIGURE 6-1,

TABLE 6-1, and TABLE 6-2. The output of the HFP01SC can be measured

using a single-ended analog measurement (VoltSE() or Instruction 1),

however, a differential analog measurement (VoltDiff() or Instruction 2) is

recommended.

The wiring convention is that the white wire is positive with respect to the

green wire, when energy is flowing through the transducer from the side with

the text “this side up” to the other side.

The switched 12 Vdc port can source enough current to calibrate

four HFP01SC plates. If additional HFP01SC plates are needed,

an external relay is required to power the additional plates (see

example 4).

For dataloggers without a SW12V output (CR7X, 21X and CR10), a relay

(A21REL-12) is required for the in-situ calibration (see Example 4).

6.3 Programming

The HFP01SC has a nominal calibration of 15 W m-2 mV-1. Each sensor is

accompanied by a calibration certificate. Each sensor also has a unique

calibration label on it. The label is located on the pigtail end of the sensor

leads.

6.3.1 Example 1. Sample CR3000 Program Using a Differential Measurement Instruction

TABLE 6-3 provides the wiring for Example 1.

Description Color CR3000

Sensor Signal #1 White 9H

Sensor Signal Reference #1 Green 9L

Shield #1 Clear

Sensor Signal #2 White 10H

Sensor Signal Reference #2 Green 10L

Shield #2 Clear

Sensor Signal #3 White 11H

Sensor Signal Reference #3 Green 11L

6

Shield #3 Clear

Sensor Signal #4 White 12H

Sensor Signal Reference #4 Green 12L

Shield #4 Clear

Page 13

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

Heater Resistor Signal #1 Yellow 13H

Heater Resistor Signal Reference #1 Purple

Shield #1 Clear

Power #1 Red SW12-1

Power Reference #1 Black G

Heater Resistor Signal #2 Yellow 13L

Heater Resistor Signal Reference #2 Purple

Shield #2 Clear

Power #2 Red SW12-1

Power Reference #2 Black G

Heater Resistor Signal #3 Yellow 14H

Heater Resistor Signal Reference #3 Purple

Shield #3 Clear

Power #3 Red SW12-1

Power Reference #3 Black G

Heater Resistor Signal #4 Yellow 14L

Heater Resistor Signal Reference #4 Purple

Shield #4 Clear

Power #4 Red SW12-1

'CR3000 Series Datalogger

Const OUTPUT_INTERVAL = 30 'Online mean output interval in minutes.

Const CAL_INTERVAL = 1440 'HFP01SC insitu calibration interval (minutes).

Const END_CAL = OUTPUT_INTERVAL-1 'End HFP01SC insitu calibration one minute before the next Output.

Const HFP01SC_CAL_1 = 15 'Unique multiplier for HFP01SC #1 (1000/sensitivity).

Const HFP01SC_CAL_2 = 15 'Unique multiplier for HFP01SC #2 (1000/sensitivity).

Const HFP01SC_CAL_3 = 15 'Unique multiplier for HFP01SC #3 (1000/sensitivity).

Const HFP01SC_CAL_4 = 15 'Unique multiplier for HFP01SC #4 (1000/sensitivity).

'*** Variables ***

Public shf(4)

Public shf_cal(4)

Units shf = W/m^2

Units shf_cal = W/(m^2 mV)

'HFP01SC calibration variables.

Dim shf_mV(4)

Dim shf_mV_0(4)

Dim shf_mV_180(4)

Dim shf_mV_end(4)

Dim V_Rf(4)

Dim V_Rf_180(4)

Dim shf_cal_on_f As Boolean

Dim sw12_1_state As Boolean 'State of the switched 12Vdc port 1.

Dim ii As Long

DataTable (mean,TRUE,100)

DataInterval (0,OUTPUT_INTERVAL,Min,10)

Average (4,shf(1),IEEE4,shf_cal_on_f)

Sample (4,shf_cal(1),IEEE4)

EndTable

7

Page 14

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

BeginProg

'HFP01SC factory calibration in W/(m^2 mV) = 1000/sensitivity.

shf_cal(1) = HFP01SC_CAL_1

shf_cal(2) = HFP01SC_CAL_2

shf_cal(3) = HFP01SC_CAL_3

shf_cal(4) = HFP01SC_CAL_4

Scan (1,Sec,3,0)

'Measure the HFP01SC soil heat flux plates.

VoltDiff (shf_mV(1),4,mV50C,9,TRUE,0,_60Hz,1,0)

'Apply calibration to HFP01SC soil heat flux plates.

For ii = 1 To 4

shf(ii) = shf_mV(ii)*shf_cal(ii)

Next ii

'Power the HFP01SC heaters.

PortSet (9,sw12_1_state)

'Measure voltage across the heater (Rf_V).

VoltSe (V_Rf(1),4,mV5000,25,TRUE,0,_60Hz,0.001,0)

CallTable (mean)

'Begin HFP01SC calibration on a fixed interval.

If ( IfTime (1,CAL_INTERVAL,Min) ) Then

shf_cal_on_f = TRUE

Move (shf_mV_0(1),4,shf_mV(1),4)

sw12_1_state = TRUE

EndIf

If ( IfTime (4,CAL_INTERVAL,Min) ) Then

Move (shf_mV_180(1),4,shf_mV(1),4)

Move (V_Rf_180(1),4,V_Rf(1),4)

sw12_1_state = FALSE

EndIf

If ( IfTime (END_CAL,CAL_INTERVAL,Min) ) Then

Move (shf_mV_end(1),4,shf_mV(1),4)

'Compute new HFP01SC calibration factors.

For ii = 1 To 4

shf_cal(ii) = V_Rf_180(ii)*V_Rf_180(ii)*128.7/ABS (((shf_mV_0(ii)+shf_mV_end(ii))/2)-shf_mV_180(ii))

Next ii

shf_cal_on_f = FALSE

EndIf

NextScan

EndProg

8

Page 15

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

TABLE 6-4. Wiring for Example 2

6.3.2 Example 2. Sample CR10(X) Program Using a Single-Ended Measurement Instruction

TABLE 6-4 provides the wiring for Example 2.

Description Color CR10(X)

Sensor Signal White 1H

Sensor Signal Reference Green AG

Shield Clear G

Heater Resistor Signal Yellow 1L

Heater Resistor Signal

Reference

Shield Clear G

Power Red SW12

Power Reference Black G

External Power Control jumper wire SW12-CTRL to

;{CR10X}

;

*Table 1 Program

01: 1 Execution Interval (seconds)

;Measure HFP01SC on smaller range.

;

1: Volt (SE) (P1)

1: 1 Reps

2: 22 7.5 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 2 Loc [ shf_mV ]

5: 1 Mult

6: 0 Offset

;Measure HFP01SC on larger range.

;

2: Volt (SE) (P1)

1: 1 Reps

2: 23 25 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 8 Loc [ shf_mV_a ]

5: 1 Mult

6: 0 Offset

;Load in the factory calibration.

;

3: If (X<=>F) (P89)

1: 3 X Loc [ cal ]

2: 1 =

3: 0 F

4: 30 Then Do

Purple AG

C8

9

Page 16

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

;Factory calibration in W/(m^2 mV) = 1000/sensitivity.

;

4: Z=F (P30)

1: 1 F ; <- Enter the unique calibration here

2: 0 Exponent of 10

3: 3 Z Loc [ cal ]

5: End (P95)

;Use data from the larger measurement range.

;

6: If (X<=>F) (P89)

1: 2 X Loc [ shf_mV ]

2: 4 <

3: -99990 F

4: 30 Then Do

7: Z=X (P31)

1: 8 X Loc [ shf_mV_a ]

2: 2 Z Loc [ shf_mV ]

8: End (P95)

;Apply custom calibration to the raw soil heat flux measurement.

;

9: Z=X*Y (P36)

1: 2 X Loc [ shf_mV ]

2: 3 Y Loc [ cal ]

3: 1 Z Loc [ shf ]

;Output data.

;

10: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 20 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

11: Real Time (P77)

1: 0110 Day,Hour/Minute (midnight = 0000)

12: Resolution (P78)

1: 1 High Resolution

;Do not include the calibration data in the soil heat flux.

;

13: If Flag/Port (P91)

1: 18 Do if Flag 8 is High

2: 19 Set Intermed. Proc. Disable Flag High (Flag 9)

14: Average (P71)

1: 1 Reps

2: 1 Loc [ shf ]

15: Do (P86)

1: 29 Set Intermed. Proc. Disable Flag Low (Flag 9)

16: Sample (P70)

1: 1 Reps

2: 3 Loc [ cal ]

;Add other processing here.

;Call calibration routine.

;

17: Do (P86)

1: 8 Call Subroutine 8

10

Page 17

*Table 2 Program

02: 0 Execution Interval (seconds)

*Table 3 Subroutines

;Calibration routine.

;

1: Beginning of Subroutine (P85)

1: 8 Subroutine 8

;Perform in-situ calibration.

;

2: If time is (P92)

1: 1 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

3: Z=X (P31)

1: 2 X Loc [ shf_mV ]

2: 4 Z Loc [ mV_0 ]

;Begin heating for calibration.

;

4: Do (P86)

1: 48 Set Port 8 High

;Used to filter data during and after calibration.

;

5: Do (P86)

1: 18 Set Flag 8 High

6: End (P95)

;End site calibration three minutes after calibration started.

;

7: If time is (P92)

1: 4 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

;Measure voltage across current shunt resistor (10 ohm 1% 0.25 W 50

;ppm/deg C) during calibration. This measurement is used to

;compute power.

;

8: Volt (SE) (P1)

1: 1 Reps

2: 25 2500 mV 60 Hz Rejection Range

3: 2 SE Channel

4: 7 Loc [ V_Rf ]

5: .001 Mult

6: 0 Offset

9: Z=X (P31)

1: 2 X Loc [ shf_mV ]

2: 5 Z Loc [ mV_180 ]

;Turn off the soil heat flux plate heater.

;

10: Do (P86)

1: 58 Set Port 8 Low

11: End (P95)

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

11

Page 18

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

;Stop filtering data.

;

12: If time is (P92)

1: 39 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

13: Do (P86)

1: 28 Set Flag 8 Low

;Compute in-situ calibration.

;

14: Z=X (P31)

1: 2 X Loc [ shf_mV ]

2: 6 Z Loc [ mV_end ]

15: Z=X*Y (P36)

1: 7 X Loc [ V_Rf ]

2: 7 Y Loc [ V_Rf ]

3: 3 Z Loc [ cal ]

16: Z=X*F (P37)

1: 3 X Loc [ cal ]

2: 128.7 F

3: 3 Z Loc [ cal ]

17: Z=X+Y (P33)

1: 4 X Loc [ mV_0 ]

2: 6 Y Loc [ mV_end ]

3: 9 Z Loc [ work ]

18: Z=X*F (P37)

1: 9 X Loc [ work ]

2: .5 F

3: 9 Z Loc [ work ]

19: Z=X-Y (P35)

1: 9 X Loc [ work ]

2: 5 Y Loc [ mV_180 ]

3: 9 Z Loc [ work ]

20: Z=ABS(X) (P43)

1: 9 X Loc [ work ]

2: 9 Z Loc [ work ]

21: Z=X/Y (P38)

1: 3 X Loc [ cal ]

2: 9 Y Loc [ work ]

3: 3 Z Loc [ cal ]

22: End (P95)

23: End (P95)

End Program

-Input Locations1 shf

2 shf_mV

3 cal

4 mV_0

5 mV_180

6 mV_end

7 V_Rf

8 shf_mV_a

9 work

12

Page 19

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

TABLE 6-5. Wiring for Example 3

6.3.3 Example 3. Sample CR23X Program Using a Differential Measurement Instruction

TABLE 6-5 provides the wiring for Example 3.

Description Color CR23X

Sensor Signal White 9H

Sensor Signal Reference Green 9L

Shield Clear

Heater Resistor Signal Yellow 10H

Heater Resistor Signal Reference Purple 10L

Shield Clear

Power Red SW12

Power Reference Black G

;{CR23X}

;

*Table 1 Program

01: 1 Execution Interval (seconds)

;Measure HFP01SC on smaller range.

;

1: Volt (Diff) (P2)

1: 1 Reps

2: 21 10 mV, 60 Hz Reject, Slow Range

3: 9 DIFF Channel

4: 2 Loc [ shf_mV ]

5: 1 Mult

6: 0 Offset

;Measure HFP01SC on larger range.

;

2: Volt (Diff) (P2)

1: 1 Reps

2: 25 5000 mV, 60 Hz Reject, Fast Range

3: 9 DIFF Channel

4: 8 Loc [ shf_mV_a ]

5: 1 Mult

6: 0 Offset

;Load in the factory calibration.

;

3: If (X<=>F) (P89)

1: 3 X Loc [ cal ]

2: 1 =

3: 0 F

4: 30 Then Do

13

Page 20

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

;Factory calibration in W/(m^2 mV) = 1000/sensitivity.

;

4: Z=F (P30)

1: 1 F ; <- Enter the unique calibration here

2: 0 Exponent of 10

3: 3 Z Loc [ cal ]

5: End (P95)

;Use data from the larger measurement range.

;

6: If (X<=>F) (P89)

1: 2 X Loc [ shf_mV ]

2: 4 <

3: -99990 F

4: 30 Then Do

7: Z=X (P31)

1: 8 X Loc [ shf_mV_a ]

2: 2 Z Loc [ shf_mV ]

8: End (P95)

;Apply custom calibration to the raw soil heat flux measurement.

;

9: Z=X*Y (P36)

1: 2 X Loc [ shf_mV ]

2: 3 Y Loc [ cal ]

3: 1 Z Loc [ shf ]

;Output data.

;

10: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 20 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

11: Real Time (P77)

1: 0110 Day,Hour/Minute (midnight = 0000)

12: Resolution (P78)

1: 1 High Resolution

;Do not include that calibration data in the soil heat flux.

;

13: If Flag/Port (P91)

1: 118 Do if Flag 18 is High

2: 19 Set Intermed. Proc. Disable Flag High (Flag 9)

14: Average (P71)

1: 1 Reps

2: 1 Loc [ shf ]

15: Do (P86)

1: 29 Set Intermed. Proc. Disable Flag Low (Flag 9)

16: Sample (P70)

1: 1 Reps

2: 3 Loc [ cal ]

;Add other processing here.

;Call calibration routine.

;

17: Do (P86)

1: 8 Call Subroutine 8

14

Page 21

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

*Table 2 Program

02: 0 Execution Interval (seconds)

*Table 3 Subroutines

;Calibration routine.

;

1: Beginning of Subroutine (P85)

1: 8 Subroutine 8

;Perform in-situ calibration.

;

2: If time is (P92)

1: 1 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

3: Z=X (P31)

1: 2 X Loc [ shf_mV ]

2: 4 Z Loc [ mV_0 ]

;Begin heating for calibration.

;

4: Do (P86)

1: 49 Turn On Switched 12V

;Used to filter data during and after calibration.

;

5: Do (P86)

1: 118 Set Flag 18 High

6: End (P95)

;End site calibration three minutes after calibration started.

;

7: If time is (P92)

1: 4 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

;Measure voltage across current shunt resistor during calibration.

;This measurement is used to compute power.

;

8: Volt (Diff) (P2)

1: 1 Reps

2: 25 5000 mV, 60 Hz Reject, Fast Range

3: 10 DIFF Channel

4: 7 Loc [ V_Rf ]

5: .001 Mult

6: 0 Offset

9: Z=X (P31)

1: 2 X Loc [ shf_mV ]

2: 5 Z Loc [ mV_180 ]

;Turn off the soil heat flux plate heater.

;

10: Do (P86)

1: 59 Turn Off Switched 12V

11: End (P95)

;Stop filtering data.

;

12: If time is (P92)

1: 39 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

15

Page 22

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

13: Do (P86)

1: 218 Set Flag 18 Low

;Compute in-situ calibration.

;

14: Z=X (P31)

1: 2 X Loc [ shf_mV ]

2: 6 Z Loc [ mV_end ]

15: Z=X*Y (P36)

1: 7 X Loc [ V_Rf ]

2: 7 Y Loc [ V_Rf ]

3: 3 Z Loc [ cal ]

16: Z=X*F (P37)

1: 3 X Loc [ cal ]

2: 128.7 F

3: 3 Z Loc [ cal ]

17: Z=X+Y (P33)

1: 4 X Loc [ mV_0 ]

2: 6 Y Loc [ mV_end ]

3: 9 Z Loc [ work ]

18: Z=X*F (P37)

1: 9 X Loc [ work ]

2: .5 F

3: 9 Z Loc [ work ]

19: Z=X-Y (P35)

1: 9 X Loc [ work ]

2: 5 Y Loc [ mV_180 ]

3: 9 Z Loc [ work ]

20: Z=ABS(X) (P43)

1: 9 X Loc [ work ]

2: 9 Z Loc [ work ]

21: Z=X/Y (P38)

1: 3 X Loc [ cal ]

2: 9 Y Loc [ work ]

3: 3 Z Loc [ cal ]

22: End (P95)

23: End (P95)

End Program

-Input Locations1 shf

2 shf_mV

3 cal

4 mV_0

5 mV_180

6 mV_end

7 V_Rf

8 shf_mV_a

9 work

16

Page 23

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

TABLE 6-6. Sensor Wiring for Example 4

Description

Color

CR10X

A21REL-12

Sensor Signal #1

White

1H Sensor Signal #2

White

1L Sensor Signal #3

White

2H Sensor Signal #4

White

2L Sensor Signal #5

White

3H Sensor Signal #6

White

3L All Signal References

Green

AG

All Shields

Clear G

Heater Resistor Signal #1

Yellow

4H Heater Resistor Signal #2

Yellow

4L Heater Resistor Signal #3

Yellow

5H Heater Resistor Signal #4

Yellow

5L

Heater Resistor Signal #5

Yellow

6H

Heater Resistor Signal #6

Yellow

6L

All Heater Resistor Signal References

Purple

AG

All Shields

Clear G

Sensor Power #1

Red

REL 1 NO

Sensor Power #2

Red

REL 1 NO

Sensor Power #3

Red

REL 2 NO

Sensor Power #4

Red

REL 2 NO

Sensor Power #5

Red

REL 3 NO

Sensor Power #6

Red

REL 3 NO

All Power Reference

Black G

TABLE 6-7. Datalogger-to-A21REL-12 Wiring for Example 4

Description

CR10X

A21REL-12

Power

12V

+ 12V

Power Reference G GROUND

Control

C8

CTRL 1

Control

jumper from CTRL 2 to CTRL 1

Control

jumper from CTRL 3 to CTRL 2

Power

jumper from REL 1 COM to +12V

Power

jumper from REL 2 COM to REL 1 COM

Power

jumper for REL 3 COM to REL 2 COM

6.3.4 Example 4. Sample CR10X Program Using External Power and Relay

TABLE 6-6 provides the sensor wiring for Example 4, and TABLE 6-7

provides the datalogger wiring for Example 4.

17

Page 24

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

;{CR10X}

;

*Table 1 Program

01: 1 Execution Interval (seconds)

;Measure HFP01SC on smallest range.

;

1: Volt (SE) (P1)

1: 6 Reps

2: 22 7.5 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 7 Loc [ shf_mV_1 ]

5: 1 Mult

6: 0 Offset

;Measure HFP01SC on larger range.

;

2: Volt (SE) (P1)

1: 6 Reps

2: 23 25 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 44 Loc [ shf_mV_1a ]

5: 1 Mult

6: 0 Offset

;Load in the factory calibration.

;

3: If (X<=>F) (P89)

1: 13 X Loc [ cal_1 ]

2: 1 =

3: 0 F

4: 30 Then Do

;Factory calibration in W/(m^2 mV) = 1000/sensitivity.

;

4: Z=F (P30)

1: 1 F ;<- Enter the unique calibration for plate 1 here.

2: 0 Exponent of 10

3: 13 Z Loc [ cal_1 ]

5: Z=F (P30)

1: 1 F ;<- Enter the unique calibration for plate 2 here.

2: 0 Exponent of 10

3: 14 Z Loc [ cal_2 ]

6: Z=F (P30)

1: 1 F ;<- Enter the unique calibration for plate 3 here.

2: 0 Exponent of 10

3: 15 Z Loc [ cal_3 ]

7: Z=F (P30)

1: 1 F ;<- Enter the unique calibration for plate 4 here.

2: 0 Exponent of 10

3: 16 Z Loc [ cal_4 ]

8: Z=F (P30)

1: 1 F ;<- Enter the unique calibration for plate 5 here.

2: 0 Exponent of 10

3: 17 Z Loc [ cal_5 ]

9: Z=F (P30)

1: 1 F ;<- Enter the unique calibration for plate 6 here.

2: 0 Exponent of 10

3: 18 Z Loc [ cal_6 ]

10: End (P95)

18

Page 25

11: Beginning of Loop (P87)

1: 0 Delay

2: 6 Loop Count

;Use data from the larger measurement range.

;

12: If (X<=>F) (P89)

1: 7 -- X Loc [ shf_mV_1 ]

2: 4 <

3: -99990 F

4: 30 Then Do

13: Z=X (P31)

1: 44 -- X Loc [ shf_mV_1a ]

2: 7 -- Z Loc [ shf_mV_1 ]

14: End (P95)

;Apply custom calibration to raw soil heat flux measurement.

;

15: Z=X*Y (P36)

1: 7 -- X Loc [ shf_mV_1 ]

2: 13 -- Y Loc [ cal_1 ]

3: 1 -- Z Loc [ shf_1 ]

16: End (P95)

;Output data.

;

17: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 20 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

18: Real Time (P77)^25251

1: 0110 Day,Hour/Minute (midnight = 0000)

19: Resolution (P78)

1: 1 High Resolution

;Do not include that calibration data in the soil heat flux.

;

20: If Flag/Port (P91)

1: 18 Do if Flag 8 is High

2: 19 Set Intermed. Proc. Disable Flag High (Flag 9)

21: Average (P71)^21989

1: 6 Reps

2: 1 Loc [ shf_1 ]

22: Do (P86)

1: 29 Set Intermed. Proc. Disable Flag Low (Flag 9)

23: Sample (P70)^21779

1: 6 Reps

2: 13 Loc [ cal_1 ]

;Add other processing here.

;Call calibration routine.

;

24: Do (P86)

1: 8 Call Subroutine 8

*Table 2 Program

02: 0 Execution Interval (seconds)

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

19

Page 26

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

*Table 3 Subroutines

;Calibration routine.

;

1: Beginning of Subroutine (P85)

1: 8 Subroutine 8

;Perform in-situ calibration.

;

2: If time is (P92)

1: 1 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

3: Beginning of Loop (P87)

1: 0 Delay

2: 6 Loop Count

4: Z=X (P31)

1: 7 -- X Loc [ shf_mV_1 ]

2: 19 -- Z Loc [ mV_0_1 ]

5: End (P95)

;Begin heating for calibration.

;

6: Do (P86)

1: 48 Set Port 8 High

;Used to filter data during and after calibration.

;

7: Do (P86)

1: 18 Set Flag 8 High

8: End (P95)

;End site calibration three minutes after calibration started.

;

9: If time is (P92)

1: 4 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

;Measure voltage across current shunt resistor during calibration.

;This measurement is used to compute power.

;

10: Volt (SE) (P1)

1: 6 Reps

2: 25 2500 mV 60 Hz Rejection Range

3: SE Channel

4: 37 Loc [ V_Rf_1 ]

5: .001 Mult

6: 0 Offset

11: Beginning of Loop (P87)

1: 0 Delay

2: 6 Loop Count

12: Z=X (P31)

1: 7 -- X Loc [ shf_mV_1 ]

2: 25 -- Z Loc [ mV_180_1 ]

13: End (P95)

;Turn off the soil heat flux plate heaters.

;

14: Do (P86)

1: 58 Set Port 8 Low

20

Page 27

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

15: End (P95)

;Compute in-situ calibration.

;

16: If time is (P92)

1: 39 Minutes (Seconds --) into a

2: 180 Interval (same units as above)

3: 30 Then Do

17: Do (P86)

1: 28 Set Flag 8 Low

18: Beginning of Loop (P87)

1: 0 Delay

2: 6 Loop Count

19: Z=X (P31)

1: 7 -- X Loc [ shf_mV_1 ]

2: 31 -- Z Loc [ mV_end_1 ]

20: Z=X*Y (P36)

1: 37 -- X Loc [ V_Rf_1 ]

2: 37 -- Y Loc [ V_Rf_1 ]

3: 13 -- Z Loc [ cal_1 ]

21: Z=X*F (P37)

1: 13 -- X Loc [ cal_1 ]

2: 128.7 F

3: 13 -- Z Loc [ cal_1 ]

22: Z=X+Y (P33)

1: 19 -- X Loc [ mV_0_1 ]

2: 31 -- Y Loc [ mV_end_1 ]

3: 43 Z Loc [ work ]

23: Z=X*F (P37)

1: 43 X Loc [ work ]

2: .5 F

3: 43 Z Loc [ work ]

24: Z=X-Y (P35)

1: 43 X Loc [ work ]

2: 25 -- Y Loc [ mV_180_1 ]

3: 43 Z Loc [ work ]

25: Z=ABS(X) (P43)

1: 43 X Loc [ work ]

2: 43 Z Loc [ work ]

26: Z=X/Y (P38)

1: 13 -- X Loc [ cal_1 ]

2: 43 Y Loc [ work ]

3: 13 -- Z Loc [ cal_1 ]

27: End (P95)

28: End (P95)

29: End (P95)

End Program

-Input Locations1 shf_1 1 1 1

2 shf_2 0 0 0

3 shf_3 0 0 0

4 shf_4 0 0 0

21

Page 28

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

(

)

C

C C C C

s b d m w b d v

w w

= + = +ρ θ ρ θ ρ

5 shf_5 0 0 0

6 shf_6 0 0 0

7 shf_mV_1 1 5 2

8 shf_mV_2 1 0 1

9 shf_mV_3 1 0 1

10 shf_mV_4 1 0 1

11 shf_mV_5 1 0 1

12 shf_mV_6 1 0 1

13 cal_1 5 5 3

14 cal_2 9 0 1

15 cal_3 9 0 1

16 cal_4 9 0 1

17 cal_5 9 0 1

18 cal_6 9 0 1

19 mV_0_1 9 1 1

20 mV_0_2 1 0 0

21 mV_0_3 0 0 0

22 mV_0_4 0 0 0

23 mV_0_5 0 0 0

24 mV_0_6 0 0 0

25 mV_180_1 1 1 1

26 mV_180_2 0 0 0

27 mV_180_3 0 0 0

28 mV_180_4 0 0 0

29 mV_180_5 0 0 0

30 mV_180_6 0 0 0

31 mV_end_1 1 1 1

32 mV_end_2 0 0 0

33 mV_end_3 0 0 0

34 mV_end_4 0 0 0

35 mV_end_5 0 0 0

36 mV_end_6 0 0 0

37 V_Rf_1 5 2 1

38 V_Rf_2 9 0 1

39 V_Rf_3 9 0 1

40 V_Rf_4 9 0 1

41 V_Rf_5 9 0 1

42 V_Rf_6 17 0 1

43 work 1 4 4

44 shf_mV_1a 5 1 1

45 shf_mV_2a 9 0 1

46 shf_mV_3a 9 0 1

47 shf_mV_4a 9 0 1

48 shf_mV_5a 9 0 1

49 shf_mV_6a 17 0 1

6.4 Soil Heat Flux and Storage

22

The soil heat flux at the surface is calculated by adding the measured flux at a

fixed depth, d, to the energy stored in the layer above the heat flux plates. The

specific heat of the soil and the change in soil temperature, ∆T

, over the output

s

interval, t, are required to calculate the stored energy.

The heat capacity of the soil is calculated by adding the specific heat of the dry

soil to that of the soil water. The values used for specific heat of dry soil and

water are on a mass basis. The heat capacity of the moist is given by Equation

1 and Equation 2:

(1)

Page 29

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

θ

ρ

ρ

θ

m

w

b

v

=

S

T C d

t

s s

=

∆

G G S

sfc cm

= +

8

(2)

where C

density of water, C

water content on a mass basis, θ

and C

is the heat capacity of moist soil, ρb is the bulk density, ρw is the

S

is the heat capacity of a dry mineral soil, θm is the soil

d

is the soil water content on a volume basis,

v

is the heat capacity of water.

w

This calculation requires site specific inputs for bulk density, mass basis soil

water content or volume basis soil water content, and the specific heat of the

dry soil. Bulk density and mass basis soil water content can be found by

sampling (Klute, 1986). The volumetric soil water content is measured by the

-1 K-1

CS616 water content reflectometer. A value of 840 J kg

for the heat

capacity of dry soil is a reasonable value for most mineral soils (Hanks and

Ashcroft, 1980).

The storage term is then given by Equation 3 and the soil heat flux at the surface is

given by Equation 4.

(3)

(4)

where S is the storage term, G

is the soil heat flux at 8 cm, and G

8cm

is the

sfc

soil heat flux at the surface.

6.5 In-Situ Calibration Theory

For detailed information on the theory of the in-situ calibration, see the Theory

section of the Hukseflux manual or visit the application section of the

Hukseflux web site at

www.hukseflux.com/downloads/thermalScience/applicAndSpec.pdf.

Equation 6 in the Hukseflux manual is used to compute a new calibration every

three hours. The heater is on for a total of 180 seconds. TABLE 6-8 lists the

variables used in the Hukseflux manual and those in the example datalogger

programs.

23

Page 30

Model HFP01SC Self-Calibrating Soil Heat Flux Plate

TABLE 6-8. Hukseflux and Campbell Scientific

Variable Names

7. Maintenance

The HFP01SC requires minimal maintenance. Check the sensor leads monthly

for rodent damage.

Description

Soil Heat Flux

Output of Sensor in mV V

1/Sensitivity 1/E

Output of Sensor during

calibration at t=0 seconds

Output of Sensor during

calibration at t=180 seconds

Output of Sensor after

calibration and just before

output

Voltage Across fixed

10 Ω resistor

Hukseflux

ϕ

sen

sen2

V (0) mV_0

V (180) mV_180

V (360) mV_end

V

cur

Campbell

Scientific

shf

shf_mV

cal

V_Rf

8. References

Hanks, R. J., and G. L. Ashcroft, 1980: Applied Soil Physics: Soil Water and

Temperature Application. Springer-Verlag, 159 pp.

Klute, A., 1986: Method of Soil Analysis. No. 9, Part 1, Sections 13 and 21,

American Society of Agronomy, Inc., Soil Science Society of America,

Inc.

24

Page 31

Page 32

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...