Page 1

GPS16X-HVS

GPS Receiver

Revision

Copyright ©

Campbell Scientif

: 05/2020

2003 – 2020

ic, Inc.

Page 2

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Overview .................................................................... 1

1.1 Default Settings ....................................................................................1

1.2 Compatible Data Loggers.....................................................................2

1.3 Common Accessories ...........................................................................2

2. Precautions ................................................................ 2

3. Initial Inspection ........................................................ 3

4. QuickStart .................................................................. 3

5. Specifications ............................................................ 5

6. Installation ................................................................. 6

6.1 Wiring ..................................................................................................6

6.1.1 Using with an A300 ......................................................................8

6.2 Mounting ..............................................................................................9

7. GPS Data .................................................................... 9

7.1 $GPGGA Sentence (Position and Time) ............................................ 10

7.2 $GPRMC Sentence (Position and Time) ............................................ 11

8. CRBasic Programming ............................................ 11

8.1 GPS() Instruction ............................................................................... 11

8.2 Example Program Using GPS() Instruction ....................................... 13

9. Troubleshooting ...................................................... 14

9.1 Testing and Evaluating Serial Communications ................................ 15

9.1.1 Through a Direct Connection to the GPS16X-HVS ................... 15

9.1.2 Through a Data Logger Connected to the GPS16X-HVS ........... 15

9.2 NMEAStrings Variable Populated, but Clock Not Setting ................ 16

Appendices

A. Changing GPS16X-HVS Settings .......................... A-1

A.1 Computer Connections .................................................................... A-1

A.1.1 Using the A200 ........................................................................ A-1

A.1.1.1 Driver Installation .......................................................... A-1

A.1.1.2 Wiring ............................................................................ A-2

A.1.1.3 Powering the Sensor ...................................................... A-3

i

Page 3

Table of Contents

Determining which COM Port the A200 has been

A.1.1.4

Assigned .................................................................... A-3

A.1.2 Using the DB9-Female-to-Terminal-Block Interface .............. A-3

B. Serial Programming ............................................... B-1

Figures

1-1. The GPS16X-HVS terminates in pigtails for direct connection to

our data loggers.................................................................................1

6-1. CR1000 to GPS16X-HVS connection .................................................7

6-2. GPS16X-HVS mounted using a CM235 Magnetic Mounting Stand ...9

A-1. A200 Sensor-to-PC Interface .......................................................... A-2

Tables

1-1. Default Settings ....................................................................................1

6-1. Data Logger Wiring .............................................................................7

6-2. CR9000X Wiring .................................................................................8

6-3. GPS16X-HVS Wiring to A300 Terminals and Data Logger

Terminals ..........................................................................................8

6-4. A300 Cable Wiring to Data Logger Terminals ....................................9

7-1. NMEA $GPGGA String Definition ................................................... 10

A-1. A200 Wiring .................................................................................... A-2

A-2. DB9-Female-to-Terminal-Block Interface Wiring .......................... A-3

CRBasic Examples

8-1. Reading the GPS Using the GPS() Instruction ................................... 14

B-1. Reading the GPS Using Serial Programming ................................... B-1

ii

Page 4

TABLE 1-1. Default Settings

GPS16X-HVS GPS Receiver

1. Overview

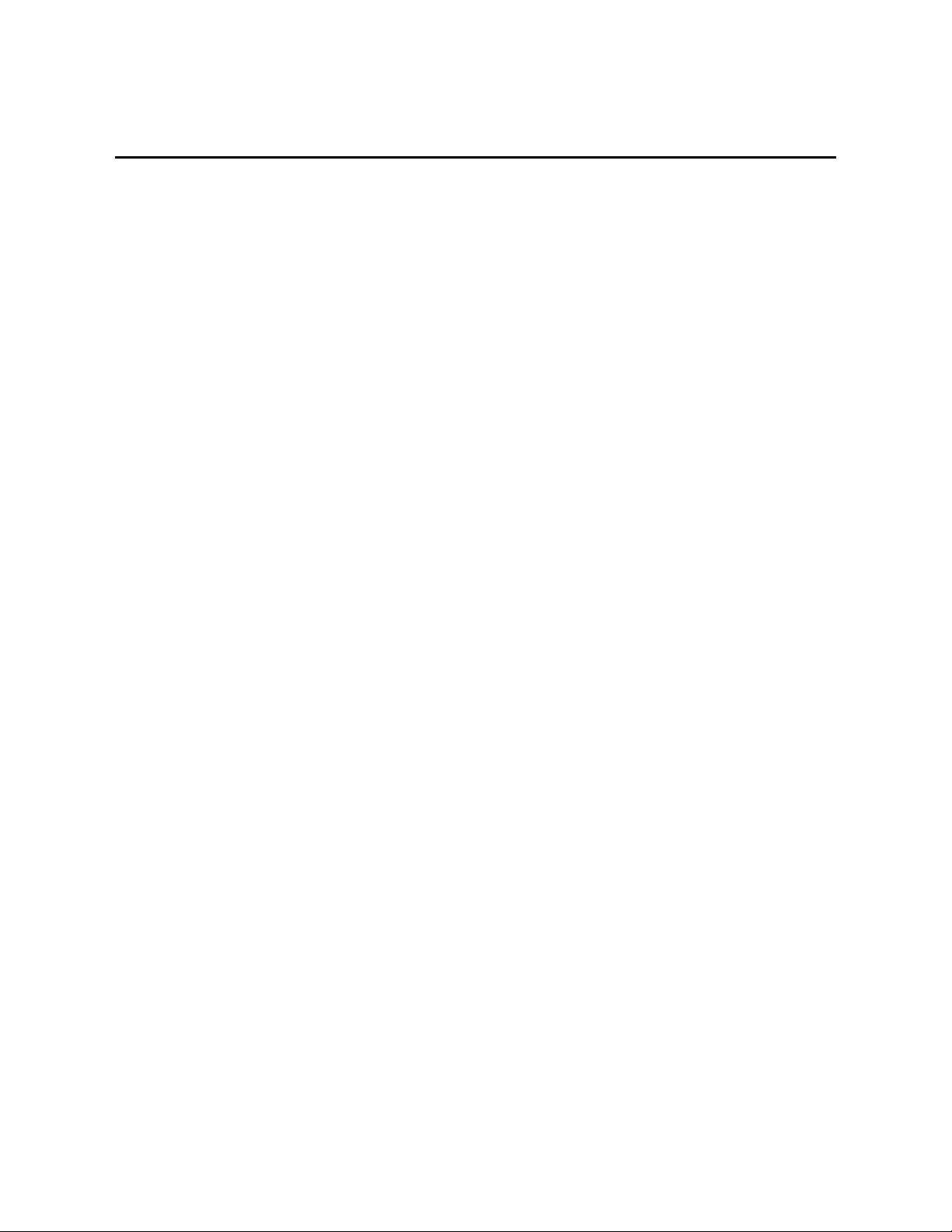

FIGURE 1-1. The GPS16X-HVS terminates in pigtails for direct

connection to our data loggers

The GPS16X-HVS is a complete GPS receiver manufactured by Garmin

International, Inc. Campbell Scientific configures the GPS16X-HVS to work

with our data loggers and modifies its cable so that the cable terminates in

pigtails. The pigtails connect directly to the control terminals of our data

loggers or with the aid of an A300.

The GPS16X-HVS includes the GPS receiver and antenna in the same housing

with one cable for the power supply and communications. The GPS antenna

must have a clear view of the sky. Generally, the GPS antenna will not work

indoors.

The GPS16X-HVS is a 12-channel GPS receiver that supports FAA Wide Area

Augmentation System (WAAS) or RTCM differential GPS. Also supported is

the 1 Pulse Per Second (PPS) timing signal. The cable connections provided

with the GPS16X-HVS do not support differential GPS correction. The cable

can be modified by the user if differential correction is required.

1.1 Default Settings

TABLE 1-1 shows the default settings of the GPSX16-HVS.

Baud Rate 38400 bps

Sentences Output GPGGA, GPRMC

Parity N (no parity)

Stop Bit 1

PPS 100 ms

1

Page 5

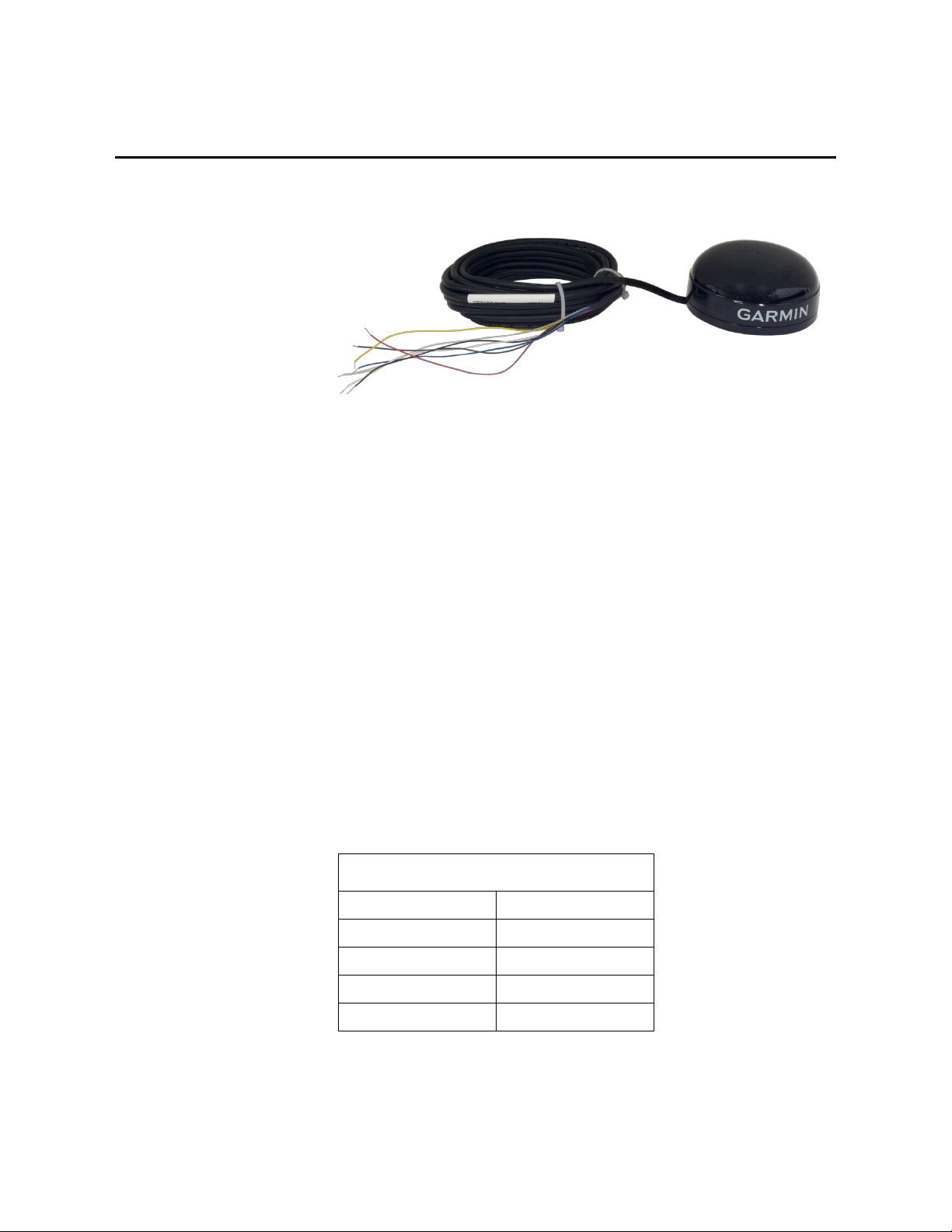

1.2 Compatible Data Loggers

NOTE

Compatible Contemporary Data Loggers

GPS16X-HVS GPS Receiver

CR300

Series

CR800

Series CR6 Series CR1000X CR1000 CR3000 CR9000X

*

*If PPS is required, the A300 Power and Signal Converter is needed.

**CPU Card RS-232 port only.

This manual provides information only for CRBasic data loggers.

For retired Edlog data logger support, see an older manual at

www.campbellsci.com/old-manuals.

Except for the CR9000(X), our data loggers use the CRBasic GPS() instruction

to read the GPS16X-HVS. To use the PPS functionality, some data loggers

need an updated clock chip. The clock chip is factory replaced (refer to

Assistance page for more information). Data loggers with the following serial

numbers need an updated chip:

Data Logger Serial Number

CR1000M < 20409

CR800 Series < 7920

CR3000 < 3168

In August 2014, Garmin changed the PPS output signal from 5 V to 3 V. Units

with serial numbers greater than 1A4189318 have a 3 V PPS output signal.

Because of this, the CR800-series, CR1000, and CR3000 data loggers need the

A300 power and signal converter to use the PPS signal output. The A300 is

NOT required for the CR6-series, CR1000X, or CR300-series data loggers.

* * **

1.3 Common Accessories

2. Precautions

The following common accessories are described at

www.campbellsci.com/gps16x-hvs:

• GPS16X-HVS Magnetic Mount

• CM235 Magnetic Mounting Stand

• A200 Sensor to PC Interface

• A300 Power and Signal Converter

• DB9 Female to Terminal Block with Hood and Hardware Kit

• READ AND UNDERSTAND the Safety section at the front of this

manual.

• When wiring the GPS16X-HVS, connect Ground before connecting 12V.

2

Page 6

3. Initial Inspection

Upon receipt of the GPS16X-HVS, inspect the packaging and contents for

damage. File damage claims with the shipping company.

4. QuickStart

A video that describes data logger programming using Short Cut is available at:

www.campbellsci.com/videos/cr1000x-datalogger-getting-started-programpart-3. Short Cut is an easy way to program your data logger to measure the

GPS16X-HVS and assign data logger wiring terminals. Short Cut is available

as a download on www.campbellsci.com. It is included in installations of

LoggerNet, RTDAQ, PC400, or PC200W.

The following procedure also describes using Short Cut to measure the

GPS16X-HVS.

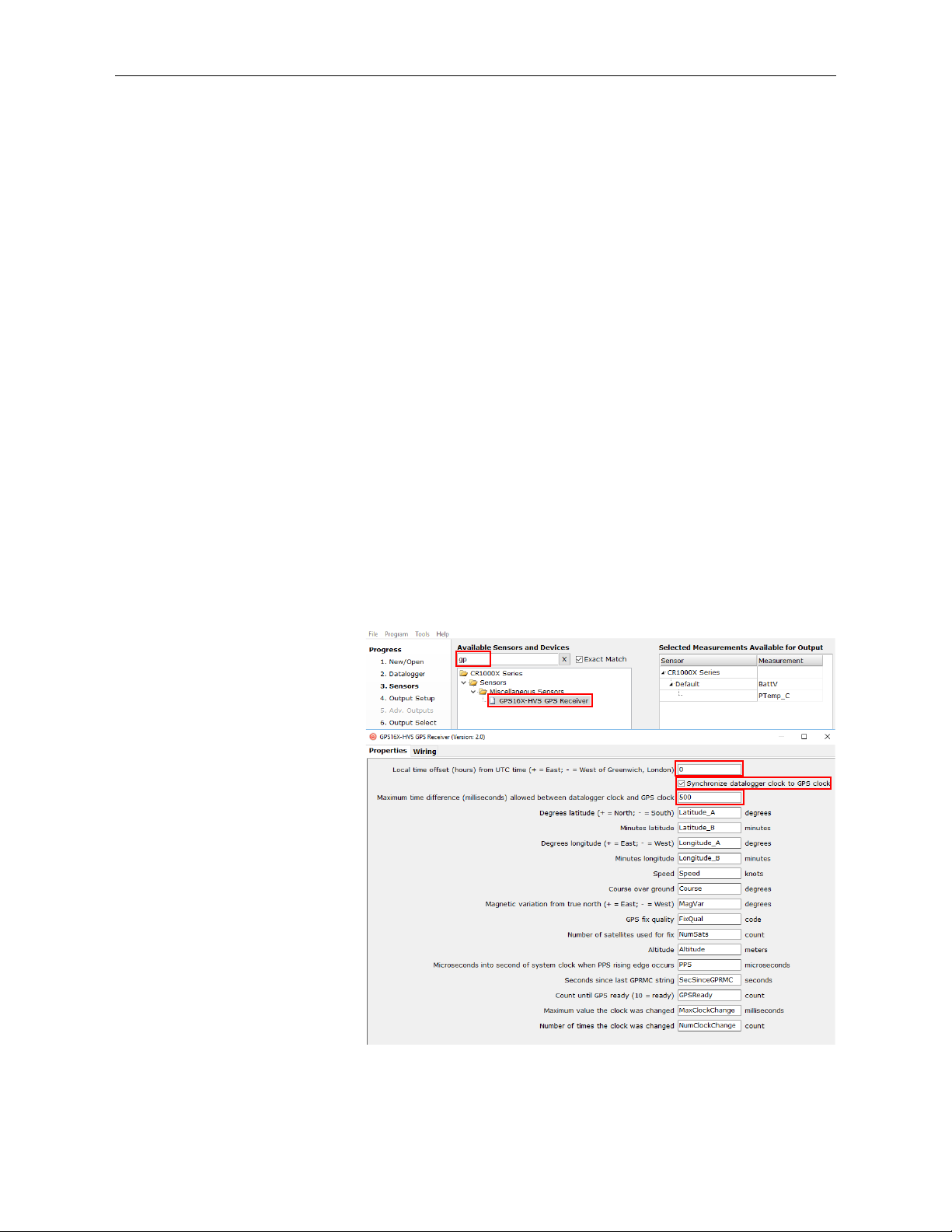

1. Open Short Cut and select to create a new program.

2. Double-click the data logger model.

3. In the Available Sensors and Devices type GPS16X-HVS or find the

sensor in the Sensors > Miscellaneous Sensors folder. Double-click

GPS16X-HVS. Specify the Local time offset, whether to synchronize

datalogger clock to GPS clock, and the Maximum time difference

allowed between datalogger clock and GPS clock. You may also change

any of the default labels for the returned GPS values.

GPS16X-HVS GPS Receiver

3

Page 7

GPS16X-HVS GPS Receiver

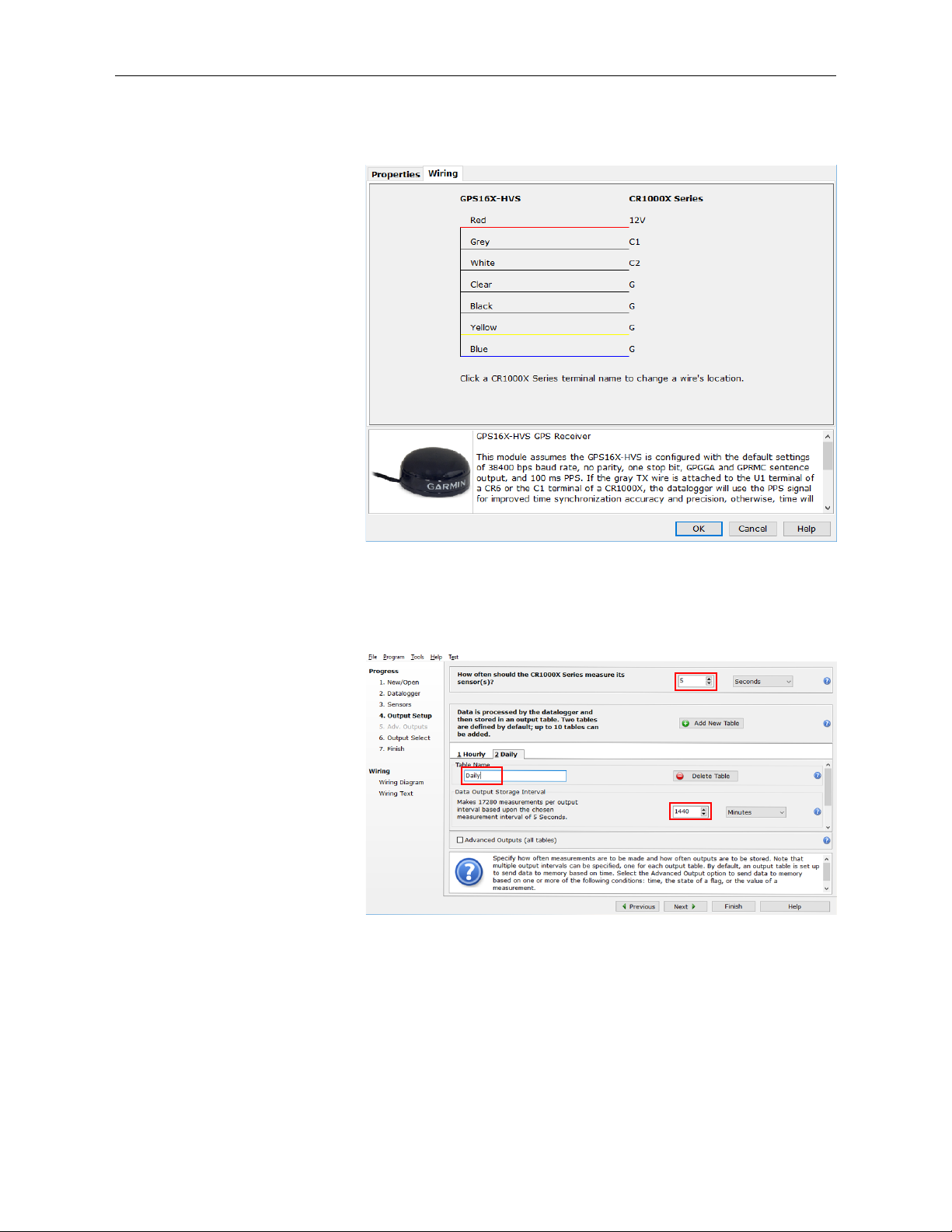

4. Click on the Wiring tab to see how the sensor is to be wired to the data

logger. Click OK after wiring the sensor.

5. Repeat steps three and four for other sensors. Click Next.

6. In Output Setup, type the scan rate, meaningful table names, and Data

Output Storage Interval.

4

Page 8

GPS16X-HVS GPS Receiver

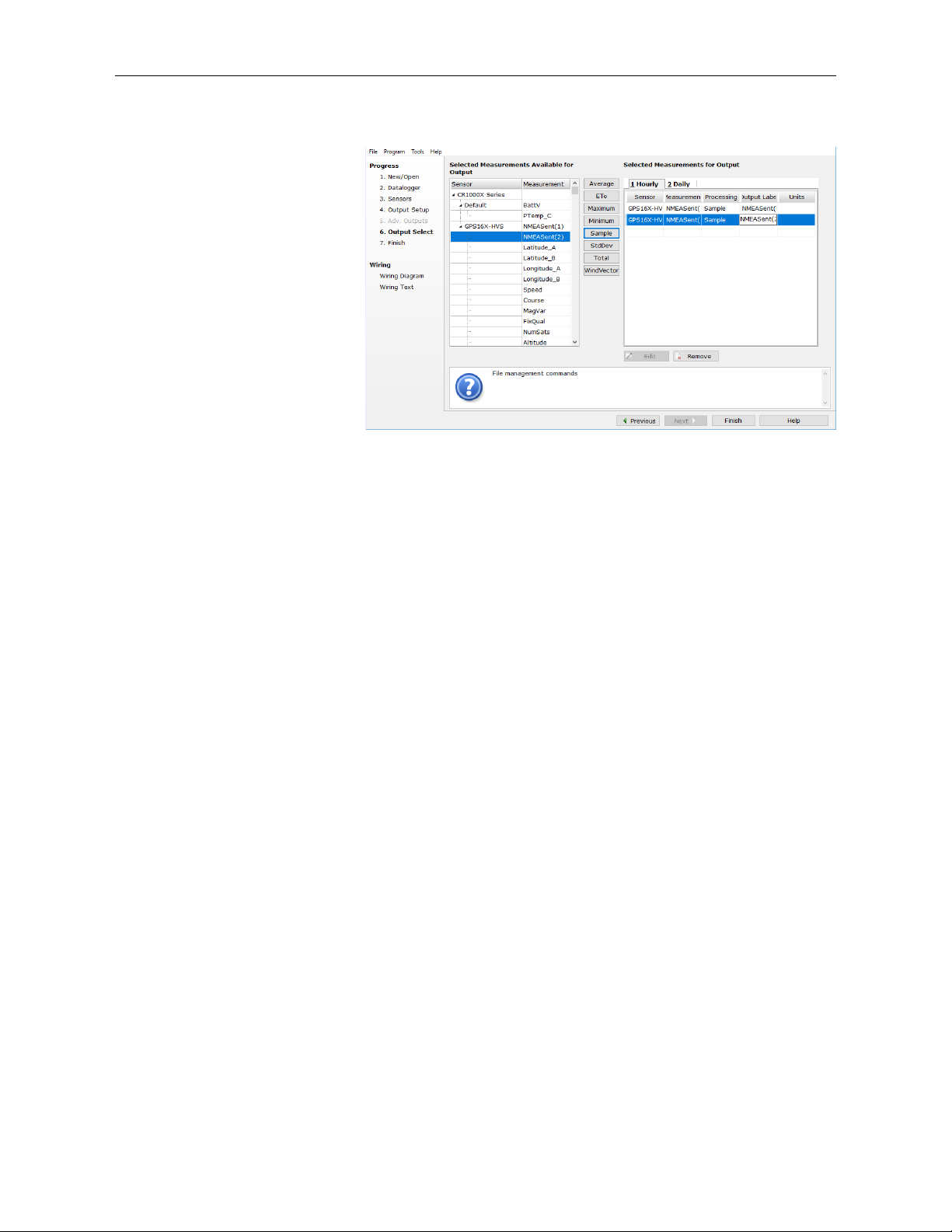

7. Select the output options.

8. Click Finish and save the program. Send the program to the data logger if

the data logger is connected to the computer.

9. If the sensor is connected to the data logger, check the output of the sensor

in the data display in LoggerNet, RTDAQ, PC400, or PC200W to make

sure it is making reasonable measurements.

5. Specifications

Physical

Size: 86 mm (3.39 in) diameter, 42 mm (1.65 in) high

Weight: 181 g (6.4 oz) without cable, 332 g (11.7 oz) with 5 m

Cable: PVC-jacketed, 5 m, foil-shielded, 8-conductor, 28 AWG

Electrical Characteristics

Input Voltage: 8.0 VDC to 40 VDC unregulated

Current Drain: 65 mA @ 12 VDC

GPS Receiver

Sensitivity: –185 dbW minimum

GPS Performance

Receiver: WAAS enabled; 12 parallel channel GPS receiver

cable

continuously tracks and uses up to 12 satellites, 11 if

PPS is active

5

Page 9

GPS16X-HVS GPS Receiver

Acquisition Times (Approximate)

Reacquisition: Less than 2 s

Hot: 1 s (all data known)

Warm: ~38 s (initial position, time and almanac known,

ephemeris unknown)

Cold: ~45 s

SkySearch: 5 min (no data known)

Sentence Rate: 1 s default; NMEA 0183 output interval configurable

from 1 to 900 s in one second increments

Accuracy: GPS Standard Positioning Service (SPS)

Position: Less than 15 m, 95% typical (100 m with selective

availability on)

Velocity: 0.1 knot RMS steady state

DGPS (USCG/RTCM)

Position: 3-5 m, 95% typical

Velocity: 0.1 knot RMS steady state

DGPS (WAAS)

Position: Less than 3 m

Velocity: 0.1 knot RMS steady state

6. Installation

6.1 Wiring

PPS Time: ±1 microsecond at rising edge of PPS pulse (subject to

selective availability)

Dynamics: 999 knots velocity (limited above 60,000 ft, 6g

dynamics)

Interfaces: True RS-232 output, asynchronous serial input

compatible with RS-232 or TTL voltage levels, RS-232

polarity. Selectable baud rates (4800, 9600, 19200,

38400)

PPS: 1 Hz pulse, programmable width, 1 microsecond

accuracy

Power Control

Off: Open circuit

On: Ground or pull to low logic level < 0.3 VDC

Environmental Characteristics

Temperature: –30 to 80 °C operational, –40 to 80 °C storage

The GPS16X-HVS connects directly to a CR6-series, CR3000, CR1000X,

CR800-series, CR300-series, or CR1000 data logger (see TABLE 6-1).

However, if PPS is required, the A300 Power and Signal Converter may be

required for use with the CR800 series, CR1000, and CR3000. See Section

6

Page 10

GPS16X-HVS GPS Receiver

TABLE 6-1. Data Logger Wiring

⏚

6.1.1, Using with an A300

(p. 8). The CR6 series, CR1000X series, and CR300

series do not require the A300.

Use the DB9-Male-to-Terminal-Block interface to connect the GPS16X-HVS

to the RS-232 port of the CR9000X CPU card. See TABLE 6-2.

To change the default settings, connect the GPS16X-HVS to a computer.

Either use the A200 interface to connect to a computer USB port or the

DB9-Female-to-Terminal-Block interface to connect to a computer serial port

(see Appendix A, Changing GPS16X-HVS Settings

(p. A-1)).

GPS16X-HVS Data Logger Function

Red 12V Power In

Black G Power Ground

Yellow G or C (control terminal)

Ground or

Power Switch

White C or U configured for Rx1 TXD

Gray C or U configured for Tx or PPS1 RXD or PPS

Blue G Ground

Shield

1

U terminals are automatically configured by the measurement instruction.

Shield

FIGURE 6-1. CR1000 to GPS16X-HVS connection

7

Page 11

GPS16X-HVS GPS Receiver

TABLE 6-2. CR9000X Wiring

TABLE 6-3. GPS16X-HVS Wiring to A300 Terminals

GPS16X-HVS CR9000X Function

*All of the grounds to the RS-232 pin 5 (using the DB9-Male-to-Terminal Block

interface). A 5-position terminal connector can be used to facilitate connecting all of the

wires into the same terminal.

6.1.1 Using with an A300

In 2014, Garmin changed the pulse-per-second (PPS) output of the

GPS16X-HVS from 5 V to 3 V. Units with a serial number 1A4189318 or

greater have a PPS output of 0 to 3 V. For those units, an A300 is needed to

connect the PPS output to a CR800-series, CR3000, or CR1000 data logger.

Those data loggers require the PPS line to have a voltage of 3.8 V or greater.

Red

Black

Yellow

White

Gray

12 V (SDM or 9011

connector)

Ground (SDM or 9011

connector)*

Ground (SDM or 9011

connector)*

RS-232 pin 3 (using

28841)

RS-232 pin 9 (using

28841)

Power In

Power Ground

Power Switch

TXD

PPS

Blue No Connection N/A

Shield

Ground (SDM or 9011

connector)*

Shield

GPS16X-HVS

Wire Color

Red 12 V 12V

Black Ground G

Yellow Enable G or C terminal

White TXD (Output) C (even) (Rx)

Gray PPS 3.3V IN

Blue Ground Ground

Shield Shield Ground

and Data Logger Terminals

GPS16X-HVS

Wire Function

A300

Terminal

Data Logger

8

Page 12

TABLE 6-4. A300 Cable Wiring to Data Logger Terminals

A300 Wire Color

A300 Wire Function

Data Logger

G

G

6.2 Mounting

GPS16X-HVS GPS Receiver

Red 12 V 12V

Black Ground

Green 5 V Signal Input

White 5 V Signal Output C (Tx)

The GPS16X-HVS mounts to a mast or crossarm using the CM235 Magnetic

Mounting Stand. Typically, the GPS16X-HVS mounts to the CM235

magnetically with the Magnetic Mount. Alternatively, the GPS16X-HVS can

be mounted directly to the CM235 using three M4 screws supplied with the

17212 or by the customer.

FIGURE 6-2. GPS16X-HVS mounted using a CM235 Magnetic

Mounting Stand

7. GPS Data

The GPS16X-HVS has several data formats available. The GPS16X-HVS is

configured to output the NMEA $GPGGA and $GPRMC time and position

string. It is possible to configure the GPS16X-HVS to output other NMEA

strings including the $GPVTG track made good and ground speed string. See

Appendix A, Changing GPS16X-HVS Settings

(p. A-1), for details.

9

Page 13

7.1 $GPGGA Sentence (Position and Time)

TABLE 7-1. NMEA $GPGGA String Definition

Sample NMEA $GPGGA data string:

$GPGGA,hhmmss,llll.lll,a,nnnnn.nnn,b,t,uu,v.v,w.w,M,x.x,M,y.y,zzzz*hh<CR><LF>

Field Description

0 $GPGGA NMEA string identifier

1 hhmmss UTC of Position: Hours, minutes, seconds

2 1111.111 Latitude: Degrees, minutes, thousandths of minutes

3 a N (North) or S (South)

4 nnnnn.nnn Longitude: Degrees, minutes, thousandths of minutes

5 b E (East) or W (West)

GPS16X-HVS GPS Receiver

6 t

7 uu Number of Satellites in Use

8 v.v Horizontal Dilution of Precision (HDOP)

9 w.w Antenna Altitude in Meters

10 M M = Meters

11 x.x Geoidal Separation in Meters

12 M

13 y.y

14 zzzz Differential Reference Station ID (0000 to 1023)

15 * Asterisk, generally used as the termination character

16 hh Checksum

17 <CR><LF> Carriage return, line feed characters.

Sample $GPGGA output strings:

GPS Quality Indicator: 0 = No GPS, 1 = GPS, 2 =

DGPS

M = Meters. Geoidal separation is the difference

between the WGS-84 earth ellipsoid and mean-sealevel.

Age of Differential GPS Data. Time in seconds since

the last Type 1 or 9 Update

Cold Start

No satellites acquired, Real Time Clock and Almanac invalid:

$GPGGA,,,,,,0,00,,,,,,,*66

Warm Start

No satellites acquired, time from Real Time Clock, almanac valid:

$GPGGA,235032.0,,,,,0,00,,,,,,,*7D

Warm Start

One satellite in use, time from GPS Real Time Clock (not GPS), no position:

$GPGGA,183806.0,,,,,0,01,,,,,,,*7D

10

Page 14

Valid GPS Fix

NOTE

Three satellites acquired, time and position valid:

$GPGGA,005322.0,4147.603,N,11150.978,W,1,03,11.9,00016,M,-016,M,,*6E

7.2 $GPRMC Sentence (Position and Time)

Example (signal not acquired):

$GPRMC,235947.000,V,0000.0000,N,00000.0000,E,,,041299,,*1D

Example (signal acquired):

$GPRMC,092204.999,A,4250.5589,S,14718.5084,E,0.00,89.68,211200,,*25

Field Example Comments

Sentence ID $GPRMC

UTC Time 092204.999 hhmmss.sss

Status A A = Valid, V = Invalid

Latitude 4250.5589 ddmm.mmmm

N/S Indicator S N = North, S = South

Longitude 14718.5084 dddmm.mmmm

GPS16X-HVS GPS Receiver

E/W Indicator E E = East, W = West

Speed over ground 0.00 Knots

Course over ground 0.00 Degrees

UTC Date 211200 DDMMYY

Magnetic variation Degrees

Magnetic variation E = East, W = West

Checksum *25

Terminator CR/LF

8. CRBasic Programming

This section describes programming a CR6-series, CR3000, CR1000X,

CR800-series, CR300-series, CR1000, or CR9000X data logger.

8.1 GPS() Instruction

The GPS() instruction is used along with a GPS device to set the data logger

clock. This instruction will also provide information such as location

(latitude/longitude) and speed, and store NMEA sentences from the GPS

device.

To use the GPS() instruction, the data logger operating system

(OS) should be OS17 or higher for the CR1000; OS10 or higher

for the CR3000; or OS08 or higher for the CR800 series. Go to

www.campbellsci.com/downloads to upgrade the data logger OS.

11

Page 15

GPS16X-HVS GPS Receiver

The resolution of accuracy for the clock set is typically 10 microseconds. Some

older CR3000, CR800-series, and CR1000 data loggers (hardware revision

number less than or equal to 007 in RevBoard field in the data logger Status

table) have a resolution of 10 milliseconds. The clock set relies on information

from the GPRMC sentence. If this sentence is not returned, a clock set will not

occur.

By default, the instruction expects the GPS unit to be set up at 38400 baud,

outputting the GPRMC and GPGGA sentences once per second. The data

logger expects the start of the second to coincide with the rising edge of the

PPS signal. If there is no PPS signal or if the required sentences come out at

less than once per second, the data logger will not update its clock.

GPS units with lower baud rates can be used with the GPS() instruction but the

baud rate has to be set for the relevant Com port it is to be connected to either

in the data logger settings or by including a SetStatus() command after the

BeginProg() instruction in the program (for example,

SetStatus("BaudrateCOM4",19200)).

Baud rates of 2400 bps or lower will not work as the GPS unit will not transmit

the two GPS sentences once per second reliably. Similar problems can be

encountered even at higher baud rates if too many optional GPS strings are

selected to be output.

The GPS() instruction has the following syntax:

GPS(GPSArray,ComPort,TimeOffset,MaxTimeDiff,NMEAStrings)

Description of the parameters follows:

GPSArray The GPSArray parameter is the variable in which to store the

information returned by the GPS. Fifteen values are returned.

If this array is not dimensioned to 15, values will be stored to

fill the array and no error will be returned. If no values are

available, NAN will be returned. The following values are

returned by the GPS:

Array(1) = Latitude, degrees

Array(2) = Latitude, minutes

Array(3) = Longitude, degrees

Array(4) = Longitude, minutes

Array(5) = Speed over ground, knots

Array(6) = Course over ground, degrees

Array(7) = Magnetic variation (positive = East, negative =

West)

Array(8) = Fix Quality (0 = invalid, 1 = GPS, 2 = differential

GPS, 6 = estimated)

Array(9) = Number of Satellites

Array(10) = Altitude, meters

Array(11) = Pulse per second (PPS) length, microseconds

Array(12) = Seconds since last GPRMC sentence

Array(13) = GPS Ready, 10 = ready

Array(14) = Maximum clock change, milliseconds (10 msec

resolution)

Array(15) = Clock change count

12

Page 16

GPS16X-HVS GPS Receiver

ComPort The ComPort parameter is the control terminal pair to which

the GPS device is attached. Valid options are COM1 (C1/C2),

COM2 (C3/C4), COM3 (C5/C6), and COM4 (C7/C8). Rx is

used to read in the NMEA sentences and Tx is used to monitor

the PPS from the GPS. This instruction defaults to a baud rate

of 38,400 bps. If a different baud rate is required, use the

SetStatus() instruction to override the default.

TimeOffset The TimeOffset parameter is the local time offset, in seconds,

from UTC.

MaxTimeDiff The MaxTimeDiff parameter is the maximum difference in

time between the data logger clock and the GPS clock that will

be tolerated before the clock is changed. If a negative value is

entered, the clock will not be changed.

For data loggers prior to hardware revision 08, the

MaxTimeDiff parameter should not be set to 0. A minimum

value of 20 ms is recommended. With this hardware, when a

GPS() instruction is in the program the clock is checked each

second (regardless of how often the GPS() instruction is run).

The clock is set if any difference is found. This can result in

the clock being set each second, resulting in skipped records in

the data table(s). This restriction does not apply to hardware

revisions 08 or greater.

NMEAStrings The NMEAStrings parameter is the string array that holds the

NMEA sentences. If it exists, the GPRMC sentence will reside

in NMEAStrings(1), and the GPGGA sentence will reside in

NMEAStrings(2). Any other sentences will reside in

subsequent indexes into the array (on a first-in basis). Once an

index in the array is used to store a particular sentence, that

sentence will always be stored in that location when updates to

the sentence are received.

8.2 Example Program Using GPS() Instruction

The following wiring and short program provide an example of using the

GPS() instruction with the Garmin GPS16X-HVS.

13

Page 17

CRBasic Example 8-1. Reading the GPS Using the GPS() Instruction

'Program the GPS16-HVS to use 38.4 kbaud, no parity, 8 data bits, and 1 stop bit

PipeLineMode

EndProg

Const LOCAL_TIME_OFFSET = -6 'Local time offset relative to UTC time

Dim nmea_sentence(2) As String * 100

Public gps_data(15)

Alias gps_data(1) = latitude_a 'Degrees latitude (+ = North; - = South)

Alias gps_data(2) = latitude_b 'Minutes latitude

Alias gps_data(3) = longitude_a 'Degress longitude (+ = East; - = West)

Alias gps_data(4) = longitude_b 'Minutes longitude

Alias gps_data(5) = speed 'Speed

Alias gps_data(6) = course 'Course over ground

Alias gps_data(7) = magnetic_variation 'Magnetic variation from true north (+ =

'East; - = West)

Alias gps_data(8) = fix_quality 'GPS fix quality: 0 = invalid, 1 = GPS, 2 =

'differential GPS, 6 = estimated

Alias gps_data(9) = nmbr_satellites 'Number of satellites used for fix

Alias gps_data(10) = altitude 'Antenna altitude

Alias gps_data(11) = pps 'usec into sec of system clock when PPS

'rising edge occurs, typically 990,000 once

'synced

Alias gps_data(12) = dt_since_gprmc 'Time since last GPRMC string, normally less

'than 1 second

Alias gps_data(13) = gps_ready 'Counts from 0 to 10, 10 = ready

Alias gps_data(14) = max_clock_change 'Maximum value the clock was changed in msec

Alias gps_data(15) = nmbr_clock_change 'Number of times the clock was changed

'Define Units to be used in data file header

Units latitude_a = degrees

Units latitude_b = minutes

Units longitude_a = degrees

Units longitude_b = minutes

Units speed = knots

Units course = degrees

Units magnetic_variation = unitless

Units fix_quality = unitless

Units nmbr_satellites = unitless

Units altitude = m

Units pps = ms

Units dt_since_gprmc = s

Units gps_ready = unitless

Units max_clock_change = ms

Units nmbr_clock_change = samples

BeginProg

'Use SetStatus prior to scan if baud rate needs to be changed for device

Scan (1,Sec,0,0)

GPS (latitude_a,Com4,LOCAL_TIME_OFFSET*3600,100,nmea_sentence(1))

NextScan

GPS16X-HVS GPS Receiver

9. Troubleshooting

Testing and evaluation of serial communications is best done by reducing the

whole system to small manageable systems. Usually some portions of the

whole system are working. The first steps involve finding what is working.

During this process, you may find parts of the system that are not working or

mistakes that can be easily corrected. Fix each subsystem before testing others.

14

Page 18

GPS16X-HVS GPS Receiver

DB9-Female-to-Terminal-Block Connections

9.1 Testing and Evaluating Serial Communications

9.1.1 Through a Direct Connection to the GPS16X-HVS

Test the GPS16X-HVS for proper operation including the baud rate and output

string. Use a computer, terminal emulator software, a serial port (RS-232), and

a DB9 to Terminal Block Interface. The computer and serial port can be the

same as used to communicate with the data logger. Terminal emulation

software is common. Hyperterm is supplied as part of Windows™ and works.

Procomm™ is another communication software package that works well.

Set up the software for the correct serial port, 38.4 kbps, 8 data bits, 1 stop bit

and no parity. Flow control should be none. Using the DB9-Female-to-TerminalBlock interface, connect the GPS16X-HVS to the computer serial port. Power up

the GPS16X-HVS. The GPS antenna should have a clear view of the sky. Don’t

expect the GPS antenna to work indoors. The $GPGGA and GPRMC strings

should be displayed once a second. Make sure the $GPGGA string is showing a

valid GPS fix. A valid GPS fix will display time, position and have a GPS

quality number greater than zero.

GPS16X Receiver DB9 to Terminal Block Interface

White Pin 2

Black and Yellow Pin 5 (shares power ground)

9.1.2 Through a Data Logger Connected to the GPS16X-HVS

Serial communication can also be tested using the data logger terminal mode

watch command, also known as sniffer mode. To enter sniffer mode:

1. Connect to your data logger in the Device Configuration Utility and select

the Terminal tab. (You can also use the Terminal Emulator in PC200W,

PC400, or the LoggerNet Connect screen.)

2. Press Enter until a datalogger_type> prompt (for example, CR1000X>)

appears.

3. Type W and press Enter.

4. In response, the query Select: is presented with a list of available

terminals. Enter the port number assigned to the terminal to which the

GPS16X-HVS is connected, and press Enter.

5. In answer to Enter timeout (secs):, type 100 and press Enter.

6. In response to the query ASCII (Y)?, type Y and press Enter.

7. Communication between the data logger and GPS16X-HVS is now open

If you see no communication, the GPS16X-HVS is hooked up incorrectly, is

not powered, or does not have the yellow wire tied to ground. If you see

readable NMEA strings coming in but many fields are not populated, you most

for viewing.

15

Page 19

GPS16X-HVS GPS Receiver

likely need to go outside to obtain a better signal. If you see “garbage”

characters coming in (that is, non-NMEA strings), there is likely a baud rate

mismatch.

9.2 NMEAStrings Variable Populated, but Clock Not Setting

Look at the GPSReady variable. It will increment from 0 to 10 when the data

logger has received good GPRMC strings and a synchronized PPS signal. Once

GPSReady reaches 10, the data logger will begin to use GPS time for clock

setting. The 12th value populated in GPSArray indicates elapsed time since a

GPRMC string was received and should not exceed 1. If the GPRMC string is

being received and GPSReady remains at zero, the PPS signal is not being

received by the data logger.

16

Page 20

Appendix A. Changing GPS16X-HVS Settings

As configured by Campbell Scientific, the GPS16X-HVS will output the

NMEA 0183 $GPGGA and $GPRMC data strings once a second, the PPS

signal is enabled with a duration of 100 milliseconds and the baud rate is set to

38,400 baud.

Special software (SNRSRCFG.EXE) is available from Garmin International

for system setup. The GPS16X-HVS user manual available from Garmin

International provides technical details beyond the scope of the Campbell

Scientific user manual.

Settings used by Campbell Scientific for GPS16X-HVS setup:

GPS Base Model = GPS 16(X)

Fix Mode = Automatic

Baud Rate = 38,400

Dead Reckon Time = 30 sec

NMEA output time = 1 sec

Position pinning = off

NMEA 2.30 mode = off

Power Save Mode = off (Normal mode)

PPS mode = 1 Hz

PPS Length = 100 mS

Phaze output Data = off

DGPS Mode = WAAS only

Differential mode = Automatic

Earth Datum Index = WGS 84

Selected Sentences = GPGGA and GPRMC

Common changes would be baud rate and selected sentences. The NMEA 0183

GPVTG data sentence gives ground speed and direction, which may be

required for some applications. Changes can be made with the Garmin

software, or with a terminal emulator and the Garmin technical user manual.

Contact Garmin International (www.garmin.com) for either resource.

A.1 Computer Connections

Either an A200 interface or a DB9-Female-to-Terminal-Block interface is

required to connect the GPS16X-HVS to a computer. The A200 is used to

connect to a computer USB port, and the DB9 Female to Terminal Block is

used to connect to a computer 9-pin serial port.

A.1.1 Using the A200

A.1.1.1 Driver Installation

If the A200 has not been previously plugged into your computer, the A200

driver needs to be loaded onto your computer.

A-1

Page 21

A.1.1.2 Wiring

TABLE A-1. A200 Wiring

NOTE

Appendix A. Changing GPS16X-HVS Settings

Drivers should be loaded before plugging the A200 into the

computer. The A200 drivers can be downloaded, at no charge,

www.campbellsci.com/downloads.

from:

One end of the A200 has a terminal block while the other end has a type B

female USB port. The terminal block provides 12V, G, TX, and RX terminals

for connecting the GPS16X-HVS (see FIGURE A-1 and TABLE A-1).

A data cable ships with the A200. This cable has a USB type-A male connector

that attaches to a computer USB port, and a type B male connector that

attaches to the A200 USB port.

Color

Red 12V +12 Vdc

Black G G

Yellow G G

White Tx Tx

Gray PPS No Connection

Blue Rx Rx

Shield sig ground G

Sensor

Cable Label

A200

Terminal

FIGURE A-1. A200 Sensor-to-PC Interface

A-2

Page 22

Appendix A. Changing GPS16X-HVS Settings

TABLE A-2. DB9-Female-to-Terminal-Block

A.1.1.3 Powering the Sensor

The A200 provides power to the GPS16X-HVS when it is connected to a

computer USB port. An internal DC/DC converter boosts the 5 VDC supply

from the USB connection to a 12 VDC output that is required to power the

sensor.

A.1.1.4 Determining which COM Port the A200 has been Assigned

When the A200 is loaded, the A200 is assigned a COM port number. Often, the

assigned COM port will be the next port number that is free. However, if other

devices have been installed in the past (some of which may no longer be

plugged in), the A200 may be assigned a higher COM port number.

Often, the assigned COM port will be the next port number that is free.

However, if other devices have been installed in the past (some of which may

no longer be plugged in), the A200 may be assigned a higher COM port

number. To check which COM port has been assigned to the A200, you can

monitor the appearance of a new COM port in the list of COM ports offered in

your software package, such as LoggerNet, before and after the installation, or

look in the Windows Device Manager list under the ports section (access via

the control panel).

A.1.2 Using the DB9-Female-to-Terminal-Block Interface

The DB9-Female-to-Terminal-Block interface includes a hood for covering the

connections and is only needed for permanent installations. TABLE A-2 shows

wiring.

Interface Wiring

Interface Pin

Number

Pin 3 Blue N/A

Pin 2 White N/A

Pin 5 Shield N/A

N/A Red +12 V

N/A Black Ground

N/A Yellow Ground

Wire Color of

GPS16X-HVS

Power

Supply

A-3

Page 23

CRBasic Example B-1. Reading the GPS Using Serial Programming

'GPS16X-HVS at Campbell Scientific Factory Defaults

Sample (1,ggae_w_ind,String)

Appendix B. Serial Programming

Serial programming allows the retrieval of all values of GPRMC and GPGGA

values. The GPS() instruction is a subset of the values that are available.

Const GPSPort = Com4 'Com port where GPS is connected

Public GGAstring As String * 500

Public RMCstring As String * 500

'rmc variables

Public rmcid As String

Public rmcutc As String

Public rmcstatus As String

Public rmclatitude As String

Public rmcin_s_ind As String

Public rmclongitude As String

Public rmce_w_indicator As String

Public rmcspeed As String

Public rmccourse As String

Public rmcutcdate As String

Public rmcmagvariation As String

Public rmcmage_w As String

Public rmcchecksum As String

'gga variables

Public ggaid As String

Public ggautc As String

Public ggailatitude As String

Public ggan_s_ind As String

Public ggalongitude As String

Public ggae_w_ind As String

Public ggapositionfix As String

Public gganumsatellites As String

Public ggahdop As String

Public ggaaltitude As String

Public ggaaltutudeunits As String

Public ggageoidsep As String

Public ggageoidunits As String

Public ggachecksum As String

Dim NBytesReturned As Long

Dim SubStrings(16) As String * 32, rawdata As String * 500

Dim CalculatedChecksum As Long, ReportedChecksum As Long

DataTable (gpsdata,True,-1)

DataInterval (0,1,Sec,10)

Sample (1,rmcid,String)

Sample (1,rmcutc,String)

Sample (1,rmcstatus,String)

Sample (1,rmclatitude,String)

Sample (1,rmcin_s_ind,String)

Sample (1,rmclongitude,String)

Sample (1,rmcspeed,String)

Sample (1,rmccourse,String)

Sample (1,rmcutcdate,String)

Sample (1,rmcmagvariation,String)

Sample (1,rmcmage_w,String)

Sample (1,rmcchecksum,String)

Sample (1,ggaid,String)

Sample (1,ggautc,String)

Sample (1,ggan_s_ind,String)

Sample (1,ggalongitude,String)

B-1

Page 24

Sample (1,ggapositionfix,String)

Sample (1,gganumsatellites,String)

ggageoidunits=Left(SubStrings(13),1)

Sample (1,ggahdop,String)

Sample (1,ggaaltitude,String)

Sample (1,ggaaltutudeunits,String)

Sample (1,ggageoidsep,String)

Sample (1,ggageoidunits,String)

Sample (1,ggachecksum,String)

EndTable

'Main Program

BeginProg

SerialOpen (GPSPort,38400,3,0,1001)

Scan (1,Sec,0,0)

SerialInRecord (GPSPort,rawdata,36,0,&h0D0A,NBytesReturned,11)

CalculatedChecksum = CheckSum (rawdata,9,Len(rawdata) - 3)

CalculatedChecksum = CalculatedChecksum AND 255

ReportedChecksum = HexToDec(Right(rawdata,2))

If CalculatedChecksum = ReportedChecksum Then

If InStr (1,rawdata,"GPRMC",2) Then

RMCstring = rawdata

ElseIf InStr (1,rawdata,"GPGGA",2) Then

GGAstring = rawdata

EndIf

EndIf

SerialInRecord (GPSPort,rawdata,36,0,&h0D0A,NBytesReturned,11)

CalculatedChecksum = CheckSum (rawdata,9,Len(rawdata) - 3)

CalculatedChecksum = CalculatedChecksum AND 255

ReportedChecksum = HexToDec(Right(rawdata,2))

If CalculatedChecksum = ReportedChecksum Then

If InStr (1,rawdata,"GPRMC",2) Then

RMCstring = rawdata

ElseIf InStr (1,rawdata,"GPGGA",2) Then

GGAstring = rawdata

EndIf

EndIf

'parse rmc data

SplitStr (SubStrings(),RMCstring,",",16,5)

rmcid = SubStrings(1)

rmcutc = SubStrings(2)

rmcstatus = SubStrings(3)

rmclatitude = SubStrings(4)

rmcin_s_ind =SubStrings(5)

rmclongitude=SubStrings(6)

rmce_w_indicator=SubStrings(7)

rmcspeed=SubStrings(8)

rmccourse=SubStrings(9)

rmcutcdate=SubStrings(10)

rmcmagvariation=SubStrings(11)

rmcmage_w =Left(SubStrings(12),1)

rmcchecksum=Right(RMCstring,2)

'parse gga data

SplitStr (SubStrings(),GGAstring,",",16,5)

ggaid=SubStrings(1)

ggautc=SubStrings(2)

ggailatitude=SubStrings(3)

ggan_s_ind=SubStrings(4)

ggalongitude=SubStrings(5)

ggae_w_ind=SubStrings(6)

ggapositionfix=SubStrings(7)

gganumsatellites=SubStrings(8)

ggahdop=SubStrings(9)

ggaaltitude=SubStrings(10)

ggaaltutudeunits=SubStrings(11)

ggageoidsep=SubStrings(12)

Appendix B. Serial Programming

B-2

Page 25

ggachecksum=Right(GGAstring,2)

EndProg

CallTable gpsdata

NextScan

Appendix B. Serial Programming

B-3

Page 26

Limited Warranty

Products manufactured by Campbell Scientific are warranted by Campbell

Scientific to be free from defects in materials and workmanship under normal

use and service for twelve months from the date of shipment unless otherwise

specified on the corresponding product webpage. See Product Details on the

Ordering Information pages at www.campbellsci.com. Other manufacturer's

products, that are resold by Campbell Scientific, are warranted only to the

limits extended by the original manufacturer.

Refer to www.campbellsci.com/terms#warranty for more information.

CAMPBELL SCIENTIFIC EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. Campbell Scientific

hereby disclaims, to the fullest extent allowed by applicable law, any and

all warranties and conditions with respect to the Products, whether

express, implied or statutory, other than those expressly provided herein.

Page 27

Assistance

Products may not be returned without prior authorization.

Refer to www.campbellsci.com/repair for up-to-date repair information.

The following contact information is for US and international customers

residing in countries served by Campbell Scientific, Inc. directly. Campbell

Scientific regional offices handle repairs for customers within their territories.

Please visit www.campbellsci.com/contact to determine which Campbell

Scientific office serves your country.

To obtain a Returned Materials Authorization (RMA) number, contact

CAMPBELL SCIENTIFIC, INC., phone (435) 227-9000. Please write the

issued RMA number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 28

Safety

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design limits. Be familiar and

comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com. You are responsible for conformance with

governing codes and regulations, including safety regulations, and the integrity and location of structures or land to which towers, tripods, and any

attachments are attached. Installation sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation,

use, or maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Protect from over-voltage.

• Protect electrical equipment from water.

• Protect from electrostatic discharge (ESD).

• Protect from lightning.

• Prior to performing site or installation work, obtain required approvals and permits. Comply with all

governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and any

attachments to tripods and towers. The use of licensed and qualified contractors is highly recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while working on or

around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take reasonable

precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are installing,

constructing, using, or maintaining, or a tool, stake, or anchor, come in contact with overhead or

underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, 20 feet, or the distance required by

applicable law, whichever is greater, between overhead utility lines and the structure (tripod, tower,

attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all underground utilities

marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should be installed by a

licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-essential

personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks, frayed cables,

loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

Internal Battery

• Be aware of fire, explosion, and severe-burn hazards.

• Misuse or improper installation of the internal lithium battery can cause severe injury.

• Do not recharge, disassemble, heat above 100 °C (212 °F), solder directly to the cell, incinerate, or expose

contents to water. Dispose of spent batteries properly.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS, THE

CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR MAINTENANCE OF

TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS,

ETC.

Page 29

Campbell Scientific regional offices

Australia

Location:

Phone:

Email:

Website:

Brazil

Location:

Phone:

Email:

Website:

Canada

Location:

Phone:

Email:

Website:

China

Location:

Phone:

Email:

Website:

Garbutt, QLD Australia

61.7.4401.7700

info@campbellsci.com.au

www.campbellsci.com.au

São Paulo, SP Brazil

11.3732.3399

vendas@campbellsci.com.br

www.campbellsci.com.br

Edmonton, AB Canada

780.454.2505

dataloggers@campbellsci.ca

www.campbellsci.ca

Beijing, P. R. China

86.10.6561.0080

info@campbellsci.com.cn

www.campbellsci.com.cn

France

Location:

Phone:

Email:

Website:

Vincennes, France

0033.0.1.56.45.15.20

info@campbellsci.fr

www.campbellsci.fr

Germany

Location:

Phone:

Email:

Website:

Bremen, Germany

49.0.421.460974.0

info@campbellsci.de

www.campbellsci.de

India

Location:

Phone:

Email:

Website:

New Delhi, DL India

91.11.46500481.482

info@campbellsci.in

www.campbellsci.in

South Africa

Location:

Phone:

Email:

Website:

Stellenbosch, South Africa

27.21.8809960

sales@campbellsci.co.za

www.campbellsci.co.za

Thailand

Location:

Phone:

Email:

Website:

UK

Location:

Phone:

Email:

Website:

USA

Location:

Phone:

Email:

Website:

Bangkok, Thailand

66.2.719.3399

info@campbellsci.asia

www.campbellsci.asia

Shepshed, Loughborough, UK

44.0.1509.601141

sales@campbellsci.co.uk

www.campbellsci.co.uk

Logan, UT USA

435.227.9120

info@campbellsci.com

www.campbellsci.com

Costa Rica

Location:

Phone:

Email:

Website:

San Pedro, Costa Rica

506.2280.1564

info@campbellsci.cc

www.campbellsci.cc

Spain

Location:

Phone:

Email:

Website:

Barcelona, Spain

34.93.2323938

info@campbellsci.es

www.campbellsci.es

Loading...

Loading...