Page 1

Getting Started With Your Campbell Scientic Equipment

NOTES:

QUICK DEPLOY GUIDE

Getting Started With Your Campbell Scientic Equipment

Program Filename:

Station Names:

Serial Numbers:

PakBus Addresses:

READ THIS FIRST

This guide outlines the general steps for setting up a Campbell Scientic measurement and control system.

The Resource DVD included with each order contains all of Campbell Scientic's current manuals, along with product brochures and

starter software. Detailed instructions and programming help for Campbell Scientic products are found in these les.

Unpack the shipping boxes.

• Pull apart all packing materials to ensure no small parts are

1

2

Insert the Resource DVD into a computer.

• Review the appropriate sensor manuals on the DVD for

installation guidelines. Manuals are also available at

www.campbellsci.com/manuals.

• Review the appropriate tripod/tower/mounting pole manual

for the proper setup procedure (if ordered).

• Review the datalogger manual Quick Start section, along

with any other pertinent information needed in that manual.

• Install LoggerNet, PC400, or RTDAQ. If this software was not

purchased, install the PC200W software found on the

Resource DVD.

• If the order includes components requiring drivers (such

as network interfaces, USB devices, spread spectrum radios, or

modems), install the drivers from the Resource DVD or using

DevCong as instructed in the product manuals. Typically, the

drivers need to be installed prior to connecting the device to

the computer.

missed. Check for additional layers of parts below the top layer.

• Check the equipment against the order's packing list.

• File the sales order and packing list.

• Locate the Resource DVD.

LoggerNet

RTDAQ

PC400

PC200W

815 W 1800 N | Logan, UT 84321-1784 | (435) 227-9342 | www.campbellsci.com

USA | AUSTRALIA | BRAZIL | CANADA | COSTA RICA | ENGLAND | FRANCE | GERMANY | SOUTH AFRICA | SPAIN

Copyright © 2014

Campbell Scientic, Inc.

Printed May 2014

3

+12V

Basic hardware setup (prewired systems skip this step).

• With the power supply disconnected or switched to OFF, attach

one end of the red wire to the 12V terminal on the datalogger

power connector. Attach one end of the black wire to the G

terminal on the connector. Connect the free end of the red

power wire to one of the 12V terminals on the power supply

and the free end of the black power wire to one of the G

terminals.

12VGG

• Connect the datalogger to the computer using an RS-232 cable

or USB cable. For dataloggers using the RS-232 cable, if the

computer does not have a serial port, a USB to serial cable (pn:

17394) may be used.

NOTE: For the purpose of this test, the hardware will be tested

using battery power only. No external power will be applied

until the system is deployed to the eld.

Complete info here: 435.227.9100

campbellsci.com/dataloggers

Page 2

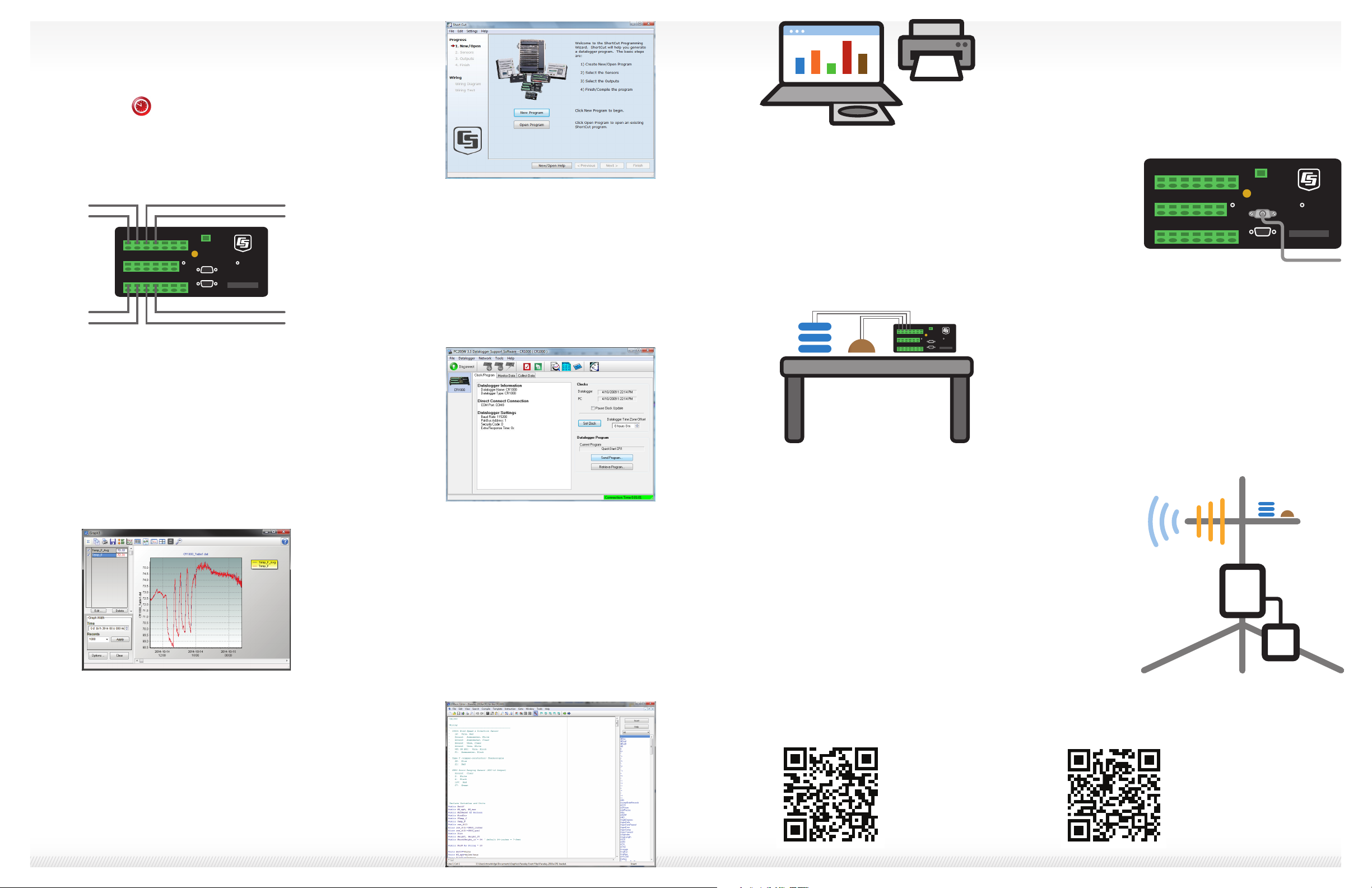

4

5

Open the Short Cut datalogger program creation software. In LoggerNet,

Short Cut is found under Program. In PC200W and PC400, Short Cut is

found in the Tools menu (or clicking on the red ‘clock’ icon).

• Use Short Cut to generate a basic datalogger program for all

the sensors that will be attached to the datalogger.

Short Cut

NOTE: Video tutorials covering datalogger programming and other

topics relevant to Campbell Scientic products are available at:

www.youtube.com/user/CampbellScientic

Follow the wiring diagram created by Short Cut to attach the sensors to the

datalogger. The wiring must match the diagram exactly for the sensors to

be measured correctly.

9

10

Make an archival copy of the program and wiring diagram by saving them

to a second computer or storage device. Printing a hard copy to place in

the enclosure is also recommended.

Connect any communication devices to the datalogger.

• Congure and test each communication device.

• Refer to the device's manual on the ResourceDVD for additional

information.

• If using LoggerNet, use Network Planner to assist in the

conguration of each device. The Network Planner is in the

LoggerNet Launch | Tools category. Alternatively, use the

Device Conguration Utility (found on the Resource DVD) to set

up the device as indicated in the user manual.

Use PC200W, PC400, LoggerNet, or RTDAQ to send the program to the

datalogger. Connect to the datalogger and view the real-time sensor

6

measurements in the Public table.

• Are the sensors making good measurements?

• If any sensor is not reading as expected, change the sensor

setting in Short Cut and repeat steps 6–7. Also verify that all

sensors wires are properly wired to the datalogger.

After giving the datalogger sucient time to take multiple measurements,

7

collect and review the data.

• Are the data values within the range of what is expected for

each sensor?

• Are the records being stored correctly to the data table(s) and

at the desired interval?

• If the data will be post-processed, is it in a le format that can

be used?

• Do the data values provide the information expected?

11

12

Before deploying the system in the eld, assemble the system as much

as possible. Note what tools and hardware are needed to complete the

assembly. Make sure these tools and hardware are available for nal

assembly in the eld.

Deploy the system in the eld and test by repeating steps 5–7 to conrm

the system is functioning.

[Optional] Using the CRBasic Editor (not available in PC200W), expand the

program for any need beyond the basic Short Cut program. Take the time

8

to add comments to the program to explain.

13

Campbell Scientic resources on the internet.

Manuals: Support Videos:

https://www.campbellsci.com/manuals https://www.youtube.com/user/CampbellScientic

Loading...

Loading...