Page 1

INSTRUCTION MANUAL

EC150 CO2/H2O Open-Path

Copyright © 2010- 2014

Campbell Scientific, Inc.

Gas Analyzer

Revision: 6/14

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning 435-227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is highly

recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact with

overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, or 20 feet, or the

distance required by applicable law, whichever is greater, between overhead utility lines and

the structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 6

Page 7

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 2

4. Overview ...................................................................... 2

4.1 General ................................................................................................. 2

4.2 Features ................................................................................................ 2

4.3 Gas Head Memory ............................................................................... 3

4.4 Self-diagnostics and Data Integrity ...................................................... 3

4.5 Field Zero/Span Capabilities ................................................................ 3

4.6 EC100 Electronics Module .................................................................. 4

4.6.1 EC100 Communications and Control ........................................... 4

4.6.2 EC100 Outputs .............................................................................. 4

4.6.2.1 SDM Output ....................................................................... 5

4.7 Automatic Heater Control .................................................................... 5

4.8 Theory of Operation ............................................................................. 6

5. Specifications ............................................................. 7

5.1 Measurements ...................................................................................... 7

5.2 Output Signals ...................................................................................... 9

5.3 Physical Description ............................................................................ 9

5.4 Power Requirements .......................................................................... 10

6. Installation ................................................................. 11

6.1 Orientation ......................................................................................... 11

6.2 Mounting Analyzer to Support Hardware .......................................... 11

6.2.1 Preparing the mounting structure ................................................ 14

6.2.2 Mounting EC150 with optional CSAT3A ................................... 14

6.2.3 Mounting EC150 without CSAT3A ........................................... 16

6.2.4 Attaching EC100 Electronics Enclosure to Mounting

Structure .................................................................................. 17

6.2.5 Install the EC150 Temperature Probe ......................................... 18

6.3 Wiring and Connections ..................................................................... 19

6.3.1 Connecting the EC150 Gas Analyzer Head ................................ 20

6.3.2 Connect the CSAT3A Sonic Head .............................................. 20

6.3.3 Connect the EC150 Temperature Probe ...................................... 21

6.3.4 Ground the EC100 Electronics ................................................... 21

6.3.5 Connect SDM Communications to the EC100 ........................... 21

6.3.6 Wire Power and Ground the EC100 ........................................... 22

7. Zero and Span ........................................................... 22

7.1 Introduction ........................................................................................ 22

i

Page 8

Table of Contents

7.2 Zero and Span Procedure .................................................................. 23

8. Maintenance and Troubleshooting .......................... 28

8.1 Routine Site Maintenance ................................................................. 28

8.2 Gas Analyzer Wicks .......................................................................... 28

8.3 Cleaning Analyzer Windows ............................................................. 29

8.4 Zero and Span.................................................................................... 29

8.5 Replacing CO2 Scrubber Bottles ....................................................... 30

8.6 Factory Recalibration ........................................................................ 31

8.7 Troubleshooting ................................................................................ 32

8.7.1 Data Loss During Precipitation Events ...................................... 32

8.7.2 EC100 Diagnostics for Gas Analyzer Troubleshooting ............. 32

8.7.3 LED Status Lights ...................................................................... 32

8.7.4 Diagnostic Flags ......................................................................... 33

Appendices

EC150 Settings ........................................................ A-1

A.

A.1 Factory Defaults .............................................................................. A-1

A.2 Details ............................................................................................. A-1

A.2.1 SDM Address ........................................................................... A-2

A.2.2 Bandwidth ................................................................................ A-2

A.2.3 Unprompted Output ................................................................. A-2

A.2.4 Unprompted Output Rate ......................................................... A-2

A.2.5 RS-485 Baud Rate .................................................................... A-3

A.2.6 Analog Output .......................................................................... A-3

A.2.7 ECMon Update Rate ................................................................ A-3

A.2.8 Temperature Sensor ................................................................. A-3

A.2.9 Fixed Temperature Value ......................................................... A-3

A.2.10 Pressure Sensor ........................................................................ A-4

A.2.10.1 Pressure Gain ................................................................. A-6

A.2.10.2 Pressure Offset ............................................................... A-6

A.2.10.3 Fixed Pressure Value ..................................................... A-6

A.2.11 Pressure Differential Enable ..................................................... A-6

A.2.12 Heater Control .......................................................................... A-7

A.2.13 Head Power Off........................................................................ A-7

A.3 ECMon ............................................................................................ A-7

A.4 Device Configuration Utility ........................................................... A-9

A.5 EC100Configure() Instruction ......................................................... A-9

A.5.1 ConfigCmd 11 Zero-and-Span Control .................................. A-11

A.6 Example CRBasic Program ........................................................... A-12

B. Filter Bandwidth and Time Delay ........................... B-1

C. Alternate EC100 Outputs ........................................ C-1

C.1 USB or RS-485 Output.................................................................... C-1

C.1.1 Specifications ........................................................................... C-1

C.1.2 Detailed Information ................................................................ C-1

C.2 Analog Output ................................................................................. C-3

C.2.1 Specifications ........................................................................... C-3

C.2.2 Detailed Information ................................................................ C-3

ii

Page 9

Table of Contents

D. Useful Equations .................................................... D-1

E. Material Safety Data Sheets (MSDS) ..................... E-1

E.1 Magnesium Perchlorate MSDS ........................................................ E-1

E.2 Decarbite MSDS .............................................................................. E-8

F. Packing Information ............................................... F-1

F.1 EC150-GH Packing Information ...................................................... F-1

F.2 EC150-SH Packing Information ...................................................... F-2

Figures

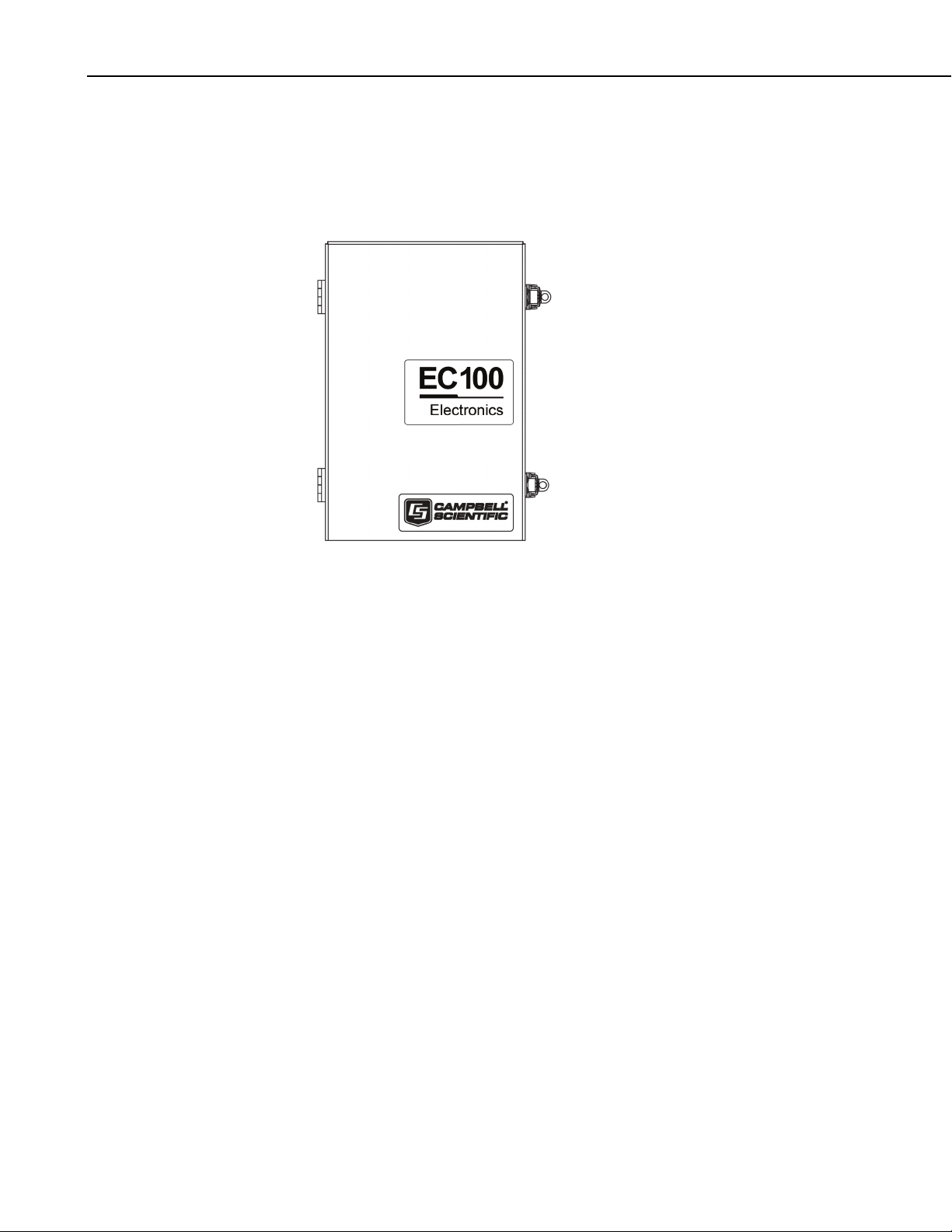

4-1. EC100 electronics module ................................................................... 4

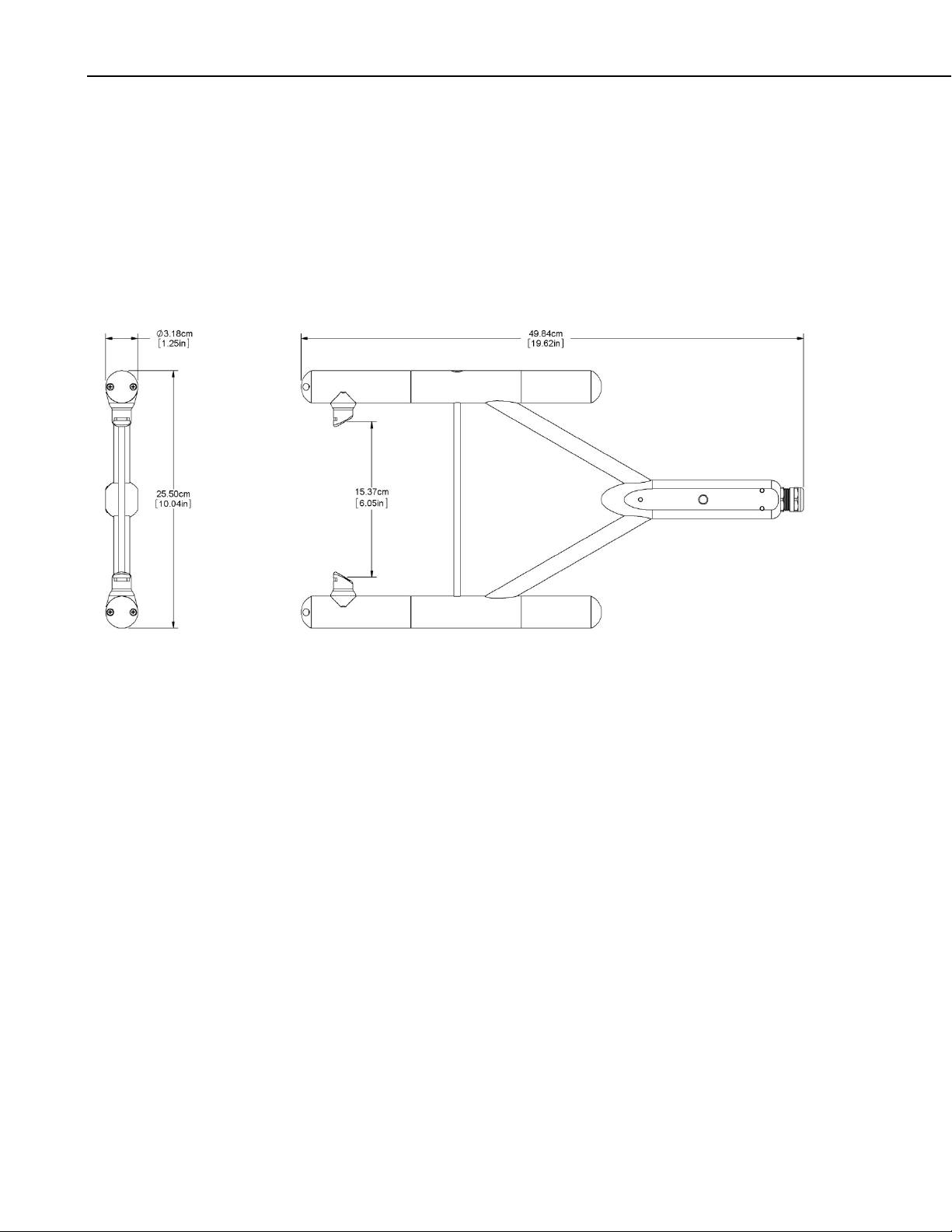

5-1. Optical path and envelope dimensions of EC150 analyzer head........ 10

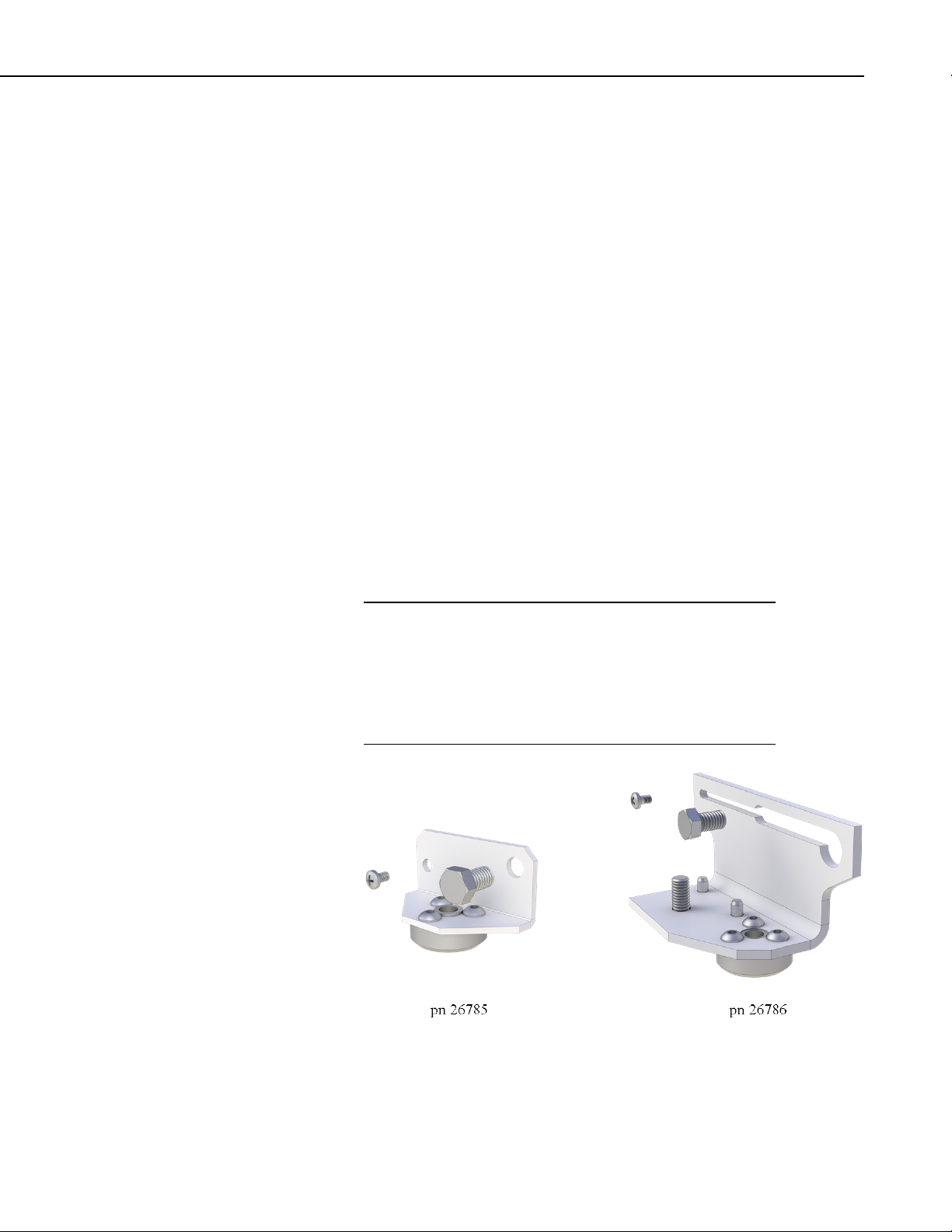

6-1. Mounting bracket options for EC150 head only (pn 26785) or

EC150 head with CSAT3A (pn 26786) .......................................... 11

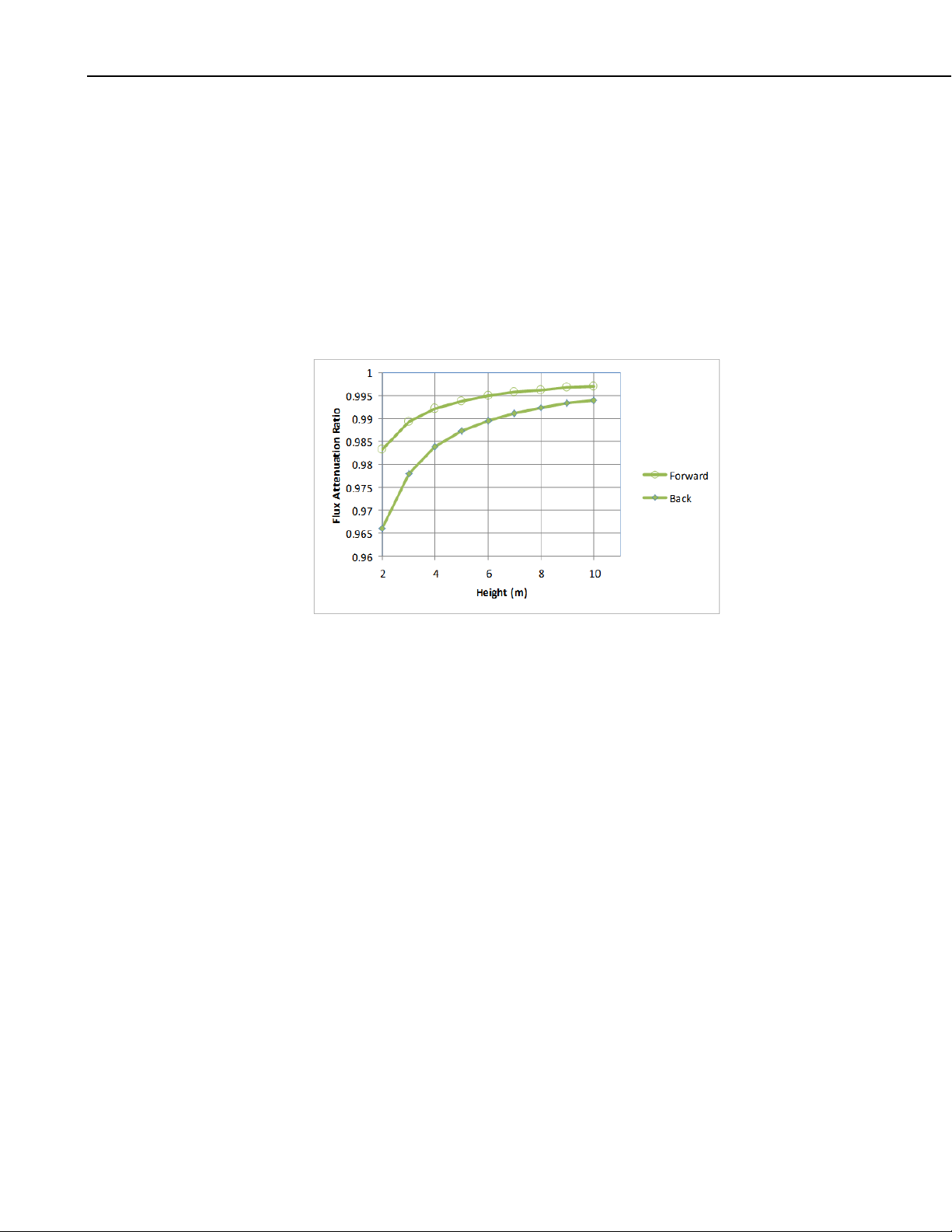

6-2. Changes in flux attenuation ratio relative to sensor height at the

most fore and aft positions .............................................................. 12

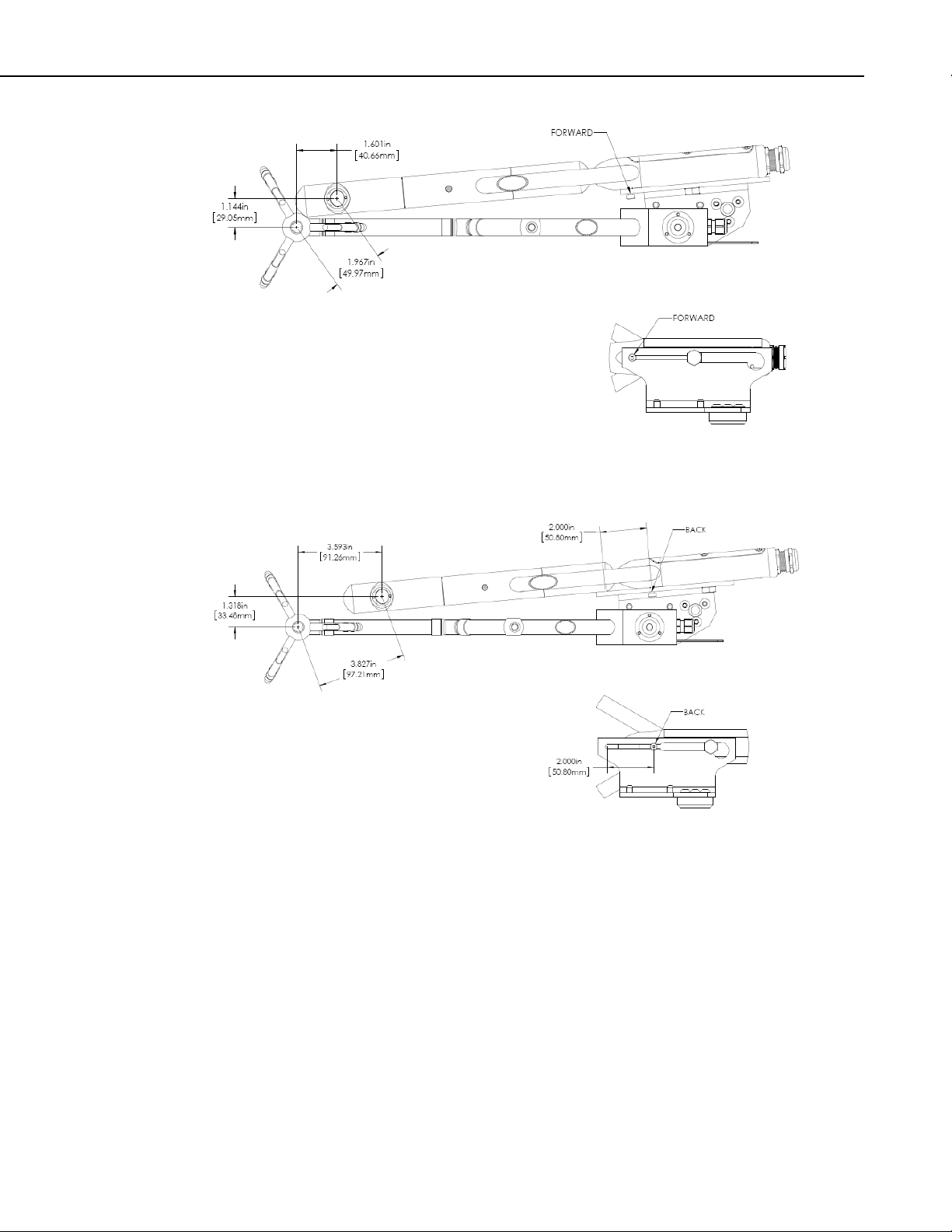

6-3. Mounting position of CSAT3A and EC155 with a 4.9 cm sensor

separation. ....................................................................................... 13

6-4. Mounting position of CSAT3A and EC155 with a 9.7 cm sensor

separation. ....................................................................................... 13

6-5. Exploded view of mounting CSAT3A and EC150 ............................ 15

6-6. Exploded view of mounting the EC150 without the CSAT3A .......... 16

6-7. EC100 enclosure mounting bracket mounted on a vertical mast

(left) and a tripod leg (right) ........................................................... 17

6-8. Exploded view of mounting the EC100 enclosure ............................. 18

6-9. EC150 temperature probe .................................................................. 19

6-10. Solar radiation shield with EC150 temperature probe ....................... 19

6-11. EC100 electronics front panel showing EC100 as shipped (left)

and after completed wiring and connections (right) ....................... 19

6-12. Bottom of EC100 enclosure ............................................................... 20

7-1. Zero-and-span shroud mounted on the zero-and-span stand .............. 24

7-2. ECMon zero-and-span window .......................................................... 26

8-1. Proper location of the gas analyzer top wick (left) and bottom

wick (right) ..................................................................................... 29

8-2. Replacing the desiccant/CO2 scrubber bottles .................................... 31

8-3. LED status during normal operation .................................................. 32

A-1. Location of EC100 basic barometer ................................................ A-4

A-2. Location of EC100 enhanced barometer ......................................... A-5

A-3. Comparison of error in basic versus enhanced barometer over

operational temperatures .............................................................. A-5

A-4. Main screen of ECMon ................................................................... A-8

A-5. Setup screen in ECMon ................................................................... A-8

B-1. Amplitude response of EC100 filter at various bandwidths ............. B-1

B-2. Frequency response comparison of EC100 10-Hz bandwidth

and a 50-msec moving average ..................................................... B-2

C-1. USB data output in terminal mode ................................................... C-2

Tables

6-1. EC100 SDM output to a Campbell Scientific CR1000, CR3000,

or CR5000 Datalogger .................................................................... 22

8-1. Rain Wick Replacement Parts ............................................................ 28

iii

Page 10

Table of Contents

8-2. Diagnostic Flags of Sonic Status LED .............................................. 33

8-3. Diagnostic Flags and Suggested Actions........................................... 34

A-1. Factory Default Settings .................................................................. A-1

A-2. ConfigCmd Values for Setting and Retrieving Settings ................ A-10

B-1. Filter Time Delays for Various Bandwidths .................................... B-3

C-1. USB and RS-485 Output Elements ................................................. C-1

C-2. Multipliers and Offsets for Analog Outputs .................................... C-4

D-1. Variables and Constants .................................................................. D-1

iv

Page 11

EC150 CO2/H2O Open-Path Gas

Analyzer

1. Introduction

The EC150 is an in situ, open-path, mid-infrared absorption gas analyzer that

measures the absolute densities of carbon dioxide and water vapor. The EC150

was designed for open-path eddy covariance flux measurements as part of an

open-path eddy covariance measurement system. It is most often used in

conjunction with the CSAT3A sonic anemometer and thermometer, which

measures orthogonal wind components along with sonically determined air

temperature.

Before attempting to assemble, install or use the EC150, please study:

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 6, Installation

Greater detail is available in the remaining sections.

Other manuals that may be helpful include:

• CR3000 Micrologger Operator’s Manual

• CFM100 CompactFlash Module Instruction Manual

• NL115 Ethernet and CompactFlash Module Instruction Manual

• Application Note 3SM-F, PC/CF Card Information

• LoggerNet Instruction Manual, Version 4.1

• CSAT3 Three Dimensional Sonic Anemometer Manual

• ENC10/12, ENC12/14, ENC14/16, ENC16/18 Instruction Manual

• CM106 Tripod Instruction Manual

• Tripod Installation Manual Models CM110, CM115, CM120

2. Cautionary Statements

• DANGER:

o The scrubber bottles in the EC150 contain sodium hydroxide

(NaOH) and anhydrous magnesium perchlorate (Mg(ClO

not attempt to access or remove these chemical bottles before

reviewing Section 8.5, Replacing CO

Avoid direct contact with the chemicals.

Ensure your work area is well ventilated and free of

Store used chemical bottles in a sealed container until

Dispose of chemicals and bottles properly.

• WARNING:

o Do not carry the EC150 by the arms or the strut between the

arms. Always hold it by the mounting base where the upper and

lower arms connect.

Scrubber Bottles.

2

reactive compounds and combustible materials.

disposal.

4)2

). Do

1

Page 12

EC150 CO2/H2O Open-Path Gas Analyzer

o Handle the EC150 carefully. The optical source may be damaged

o Overtightening bolts will damage or deform the mounting

• CAUTION:

o Grounding the EC100 measurement electronics is critical. Proper

o Do not connect or disconnect the gas analyzer or sonic

o Resting the analyzer on its side during the zero-and-span

3. Initial Inspection

Upon receipt of your equipment, inspect the packaging and contents for

damage. File damage claims with the shipping company.

Model numbers are found on each component. On cables, the model number is

located both on the sensor head and on the connection end of the cable. Check

this information against the enclosed shipping document to verify the expected

products and that the correct accessories are included.

by rough handling, especially while the analyzer is powered.

hardware.

grounding to Earth will ensure maximum electrostatic discharge

(ESD) and lightning protection and improve measurement

accuracy.

anemometer connectors while the EC100 is powered.

procedure may result in measurement inaccuracy.

4. Overview

4.1 General

4.2 Features

The EC150 measures absolute densities of carbon dioxide and water vapor.

The EC150 analyzer was designed specifically for open-path, eddy covariance

flux measurement systems. The EC150 gas analyzer head connects directly to

Campbell Scientific’s EC100 electronics. The EC150 is commonly used with a

CSAT3A sonic anemometer head. When the CSAT3A is used in conjunction

with the EC150, the EC100 can make gas and wind measurements

simultaneously. Similarly, the EC100 can simultaneously record

measurements from temperature sensors and a pressure transducer.

The EC150 analyzer has a rugged, aerodynamic design with low power

requirements, making it suitable for field applications including those with

remote access.

The EC150 has been designed specifically to address issues of aerodynamics,

power consumption, spatial displacement, temporal synchronicity, and to

minimize sensitivity to environmental factors.

The analyzer windows are scratch resistant and treated with a durable

hydrophobic coating that facilitates shedding of raindrops from critical

surfaces. The coating also impedes the accumulation of dust and deposits, and

keeps the surfaces cleaner over longer periods of time. To minimize data loss

due to humid environments, the EC150 is provided with window wicks that

draw moisture away from the measurement path and are easily replaceable

during routine maintenance.

2

Page 13

EC150 CO2/H2O Open-Path Gas Analyzer

• Unique design contains little obstruction surrounding the sample

volume

• 5W total power consumption

• Synchronously samples data from the EC150 and CSAT3A

• Automatically configured via a Campbell Scientific datalogger

• Minimal spatial displacement between sample volume and CSAT3A

• Slim housings located away from the measurement volume to

minimize body heating effects due to solar radiation

• Symmetrical design for improved flux measurements without a bias

for updrafts and downdrafts

• Slanted windows to prevent water from pooling and blocking the

optical path

• Scratch-resistant windows for easy cleaning

• Hydrophobic coating on windows to repel water, dust and pollen and

to prolong time between window cleaning

• Equipped with internal window heaters to keep the windows surfaces

free from condensation and frost – especially beneficial in humid

environments or conditions with frequent frost formation

• Optical layout that is not affected by solar interference

• Mercury cadmium telluride (MCT) detector for low-noise

measurements and long-term stability of factory calibration

• Chopper housing without thermal control results in significantly

reduced power consumption

4.3 Gas Head Memory

The EC100 electronics (see Section 4.6, EC100 Electronics Module) are

universal for the entire Campbell Scientific family of gas analyzer heads. In

addition to the EC150 gas analyzer head, the IRGASON or EC155 gas

analyzer head can be connected to the EC100 electronics (one gas analyzer

head per EC100). All sensor heads have dedicated, non-volatile memory,

which stores all calibration, configuration, and setting information. The EC100

electronics can be mated with any of these gas analyzers or an optional

CSAT3A sonic anemometer head.

4.4 Self-diagnostics and Data Integrity

EC100 electronics provide an extensive set of diagnostic tools which include

warning flags, status LEDs, and signal strength outputs to identify instrument

malfunctions and warn the user of compromised data. These flags are further

described in Section 8.7.4, Diagnostic Flags. The flags also prompt the user

when the instrument needs servicing and can facilitate troubleshooting in the

field. The EC150 outputs the optical strength of signals, which can be used to

filter data when the path of the instrument is obstructed due to precipitation or

dirty windows.

4.5 Field Zero/Span Capabilities

A zero/span for CO2 and H2O can be accomplished in the field with an

optional shroud. The shroud allows the flow of a gas with known composition

in the measurement path of the analyzer to account for instrument drift and

changing environmental conditions.

3

Page 14

EC150 CO2/H2O Open-Path Gas Analyzer

4.6 EC100 Electronics Module

The EC100 electronics module (shown in FIGURE 4-1) controls the EC150

and optional CSAT3A sonic anemometer head. The EC100 synchronizes

measurements and processes data from the EC150 and the CSAT3A.

FIGURE 4-1. EC100 electronics module

4.6.1 EC100 Communications and Control

The EC100 supports several serial communication interfaces, including USB,

RS-485, and Synchronous Device for Measurement (SDM). SDM is a

Campbell Scientific communication protocol that allows synchronized

measurement and rapid communication between a Campbell Scientific

datalogger and multiple devices including the EC150. Although nearly all

Campbell Scientific dataloggers support SDM, only the CR1000, CR3000, and

CR5000 dataloggers support communications with the EC100 electronics with

the EC100() instruction.

The SDM protocol allows the user to configure and control the analyzer

through CRBasic instructions in the datalogger. For example, in solar-powered

applications with limited daylight, battery power can be conserved by

programming the datalogger to turn off the EC150 at night or when conditions

are not suitable for eddy-covariance measurements. The datalogger can also be

used to change settings such as bandwidth, and perform the zero/span

procedure in the field.

4.6.2 EC100 Outputs

The EC100 outputs data in one of four types: SDM, USB, RS-485, or analog.

In general, Campbell Scientific recommends that SDM be used if a Campbell

Scientific datalogger is collecting data. However, RS-485 output is

recommended over SDM if cable lengths exceed 100 meters. If a PC is being

used as the data collection platform, USB and RS-485 are suitable outputs.

4

Information for SDM, the preferred output, is detailed below. See Appendix C,

Alternate EC100 Outputs, for USB, RS-485, and analog outputs.

Page 15

4.6.2.1 SDM Output

EC150 CO2/H2O Open-Path Gas Analyzer

To use SDM data output, connect an SDM communications cable from the

EC100 (see Section 6.3, Wiring and Connections) to a CR1000, CR3000, or

CR5000 datalogger. On CR1000 dataloggers, the SDM protocol uses ports C1,

C2, and C3. These are multipurpose control ports that are SDM-activated

when an SDM instruction is used in the datalogger’s program. On CR3000 and

CR5000 dataloggers, the SDM protocol uses SDM-dedicated ports SDM-C1,

SDM-C2, and SDM-C3.

Each SDM device on the SDM bus must have a unique address. The EC150

has a factory default SDM address of 1, but may be changed to any integer

value between 0 and 14 (see Appendix A.2.1, SDM Address).

The sample rate for SDM output is determined by the datalogger program.

Data are output from the EC100 when a request is received from the datalogger

(for example, a prompted output mode). The number of data values sent from

the EC100 to the datalogger is also set by the user in the datalogger program.

CRBasic, the programming language used by Campbell Scientific dataloggers,

uses the EC100() instruction to get data from an EC150. This instruction is

explained in greater detail under Appendix A, EC150 Settings, and in

Appendix A.5, EC100 Configure() Instruction.

4.7 Automatic Heater Control

An advantage of the EC150’s low power consumption (5W) is that the

instrument remains at a temperature very close to ambient air temperature,

which is an important feature for eddy-covariance measurements. Under some

environmental conditions, however, the analyzer can become colder than

ambient air temperature which may increase the likelihood of frost or

condensation building on the optical windows. This will affect signal strength.

The EC150 design includes internal heaters located at the optical windows,

which aid in minimizing data loss during these specific environmental

conditions.

An automatic heater control algorithm can be activated from either Device

Configuration or ECMon by putting in a value of −2, or deactivated by putting

in a value of −1.

temperature that is a couple of degrees above the ambient dewpoint (or frost

point) to prevent condensation and icing from forming on the surface of the

optical windows.

The heater control will be disabled under any of the following conditions:

• Temperature of the detector housing is outside the −35°C to +55°C

• Temperature of the source housing exceeds 40°C

• Ambient temperature is outside the −35°C to +55°C range

• The supply voltage is below 10 V

range

i

The algorithm uses the internal heaters to maintain a

i

Automatic heater control is available in EC100 OS version 4.07 or greater and is turned on by

default starting with the OPEC program version 3.2.

5

Page 16

EC150 CO2/H2O Open-Path Gas Analyzer

cl

o

ePP

ε

−

=

The algorithm uses the following environmental parameters to control the

heater:

• Analyzer body temperature, measured inside the source housing

(heater control does not allow the body temperature to drop below

ambient air temperature)

• Ambient relative humidity (in humidity greater than 80% heaters will

try to maintain internal temperature 2 degrees warmer than ambient)

• CO

cause the heater to turn on maximum power until the signals recover)

• Average slope of the CO

• Standard deviation of the CO

4.8 Theory of Operation

The EC150 is a non-dispersive mid-infrared absorption analyzer. Infrared

radiation is generated in the upper arm of the analyzer head before propagating

along a 15.0 cm (5.9 in) optical path as shown in FIGURE 5-1. Chemical

species located within the optical beam will absorb radiation at characteristic

frequencies. A mercury cadmium telluride (MCT) detector in the lower arm of

the gas analyzer measures the decrease in radiation intensity due to absorption,

which can then be related to analyte concentration using the Beer-Lambert

Law:

signal level (1 min average CO2 signal level; below 0.7 will

2

signal level over 1 min

2

signal over 1 min

2

where:

P is irradiance after passing through the optical path

is initial irradiance, ε is molar absorptivity, c is analyte

P

o

concentration, and

l is path length.

In the EC150, radiation is generated by applying constant power to a tungsten

lamp which acts as a 2200 K broadband radiation source. Specific

wavelengths are then selected using interference filters located on a spinning

chopper wheel. For CO

measurements, light with a wavelength of 4.3 µm is

2

selected as that corresponds to the asymmetric stretching vibrational band of

the CO

molecule. For H2O, the symmetric stretching vibration band is 2.7

2

µm.

The EC150 is a dual wavelength, single-beam analyzer. This design eliminates

the need for a separate reference cell and detector. Instead, the initial intensity

of the radiation is calculated by measuring the intensity of nearby, nonabsorbing wavelengths (4.0 µm for CO

and 2.3 µm for H2O). These

2

measurements mitigate measurement inaccuracy that may arise from source or

detector aging, as well as for low-level window contamination. For window

contamination that reduces the signal strength below 0.8, windows should be

cleaned as described in Section 8.3, Cleaning Analyzer Windows.

The chopper wheel spins at a rate of 50 revolutions per second and the detector

is measured 1024 times per revolution, resulting in a detector sampling rate of

51.2 kHz. The detector is maintained at −40°C using a three-stage

thermoelectric cooler and is coupled to a low noise pre-amp module.

6

Page 17

The EC100 electronics module digitizes and process the detector data (along

with ancillary data such as ambient air temperature and barometric pressure) to

give the CO

high measurement rate is beneficial when there is a need to synchronize the gas

measurements with additional sensors measured by the datalogger. To prevent

aliasing, measurements are filtered to a bandwidth that is specified by the user.

5. Specifications

5.1 Measurements

To compute carbon dioxide and water vapor fluxes using the eddy-covariance

method, the EC150 and a sonic anemometer measure:

These measurements are required to compute carbon dioxide and water vapor

fluxes using the:

EC150 CO2/H2O Open-Path Gas Analyzer

and H2O density for each chopper wheel revolution (50 Hz). This

2

• Absolute carbon dioxide density (mg·m

–3

• Water vapor density (g·m

)

• Three-dimensional wind speed (m·s

–3

)

–1

; requires the CSAT3A)

• Sonic air temperature (°C; requires the CSAT3A)

• Air temperature (°C; requires an auxiliary temperature probe)

• Barometric pressure (kPa; requires an auxiliary barometer)

• Standard outputs:

o CO

density, H2O density

2

o Gas analyzer diagnostic flags

o Air temperature

o Air pressure

o CO

o H

signal strength

2

O signal strength

2

• Additional outputs from auxiliary instruments:

o u

, uy, and uz orthogonal wind components (requires the

x

CSAT3A)

o Sonic temperature (requires the CSAT3A, and is based on the

measurement of c, the speed of sound)

o Sonic diagnostic flags (from the CSAT3A)

Datalogger Compatibility: CR1000

CR3000

CR5000

Measurement

Rate: 100 Hz

ii

Output bandwidth

Output rate

ii

: 5, 10, 12.5, 20, or 25 Hz

: 10, 25 or 50 Hz

Operating temperature: −30° to 50°C

ii

user selectable

7

Page 18

EC150 CO2/H2O Open-Path Gas Analyzer

Gas analyzer

iii

Measurement precision

density: 0.2 mg·m

CO

2

O density: 0.004 g·m

H

2

–3

Factory calibrated range

: 0 to 1000 µmol·mol–1

CO

2

H

O: 0 to 72 mmol/mol (37°C dewpoint)

2

Temperature: −30° to 50°C

Barometric pressure: 70 to 106 kPa

CO

performance

2

Zero max drift

iv

: ±0.55 mg·m–3·°C–1 (± 0.3

μmol·mol·°C

Gain drift: ±0.1% of reading·°C

Sensitivity to H

H

O performance

2

Zero max drift

O: ±1.1 x 10–4 µmol CO2·mol–1 H2O (max)

2

iv

: ±0.04 g·m–3·°C–1

(± 0.05 mmol·mol

Gain drift: ±0.3% of reading·°C

Sensitivity to CO

CSAT3A sonic measurement precision

: 1.0 mm·s–1

u

x

: 1.0 mm·s–1

u

y

: 0.5 mm·s–1

u

z

: ±0.1 mol H2O·mol–1 CO2 (maximum)

2

v

Sonic temperature: 0.025°C

(0.15 µmol·mol–1)

–3

(0.006 mmol·mol–1)

–1

)

–1

(maximum)

–1

·°C–1)

–1

(maximum)

CSAT3A sonic accuracy

vi

Offset error

, uy: < ±8 cm·s–1

u

x

: < ±4 cm·s–1

u

z

Gain error

Wind vector ±5° horizontal: < ±2% of reading

Wind vector ±10° horizontal: < ±3% of reading

Wind vector ±20° horizontal: < ±6% of reading

iii

noise rms, assumes:

o 25°C

o 85 kPa

o 14 g·m-3 H2O

o 597 mg·m

o 25 Hz bandwidth

iv

−30° to 50°C

v

noise rms

vi

assumes:

o −30° to +50°C

o wind speed <30 m·s

o azimuth angles between ±170°

-3

CO2

-1

8

Page 19

EC150 CO2/H2O Open-Path Gas Analyzer

CSAT3 sonic reporting range

Full scale wind: ±65.6 m/s

Sonic temperature: −50° to 60°C

Auxiliary sensors

Barometer

EC150 temperature sensor

5.2 Output Signals

The EC100 electronics can output data from the EC150 by several means.

• Campbell Scientific SDM

• RS-485

• USB

• Analog out

vii

Internal basic barometer

Accuracy

−30° to 0°C: ±3.7 kPa at −30°C, falling linearly to

±1.5 kPa at 0°C

0° to 50°C: ±1.5 kPa

Measurement rate: 10.0 Hz

Optional enhanced barometer

Manufacturer: Vaisala

Model: PTB110

Accuracy: ±0.15 kPa (−30°C to 50°C)

Measurement rate: 1.0 Hz

Manufacturer: BetaTherm

Model: 100K6A1A Thermistor

Accuracy: ±0.15°C (−30

o

to 50°C)

Synchronous Device for Measurement communications protocol, or SDM, is a

proprietary serial interface developed by Campbell Scientific for

communication between a datalogger and a peripheral or sensor. In almost all

cases, SDM is the preferred communications protocol with the exception of

measurement heights requiring cable lengths greater than 100 meters. In this

case, RS-485 output is recommended. See Section 4.6.2.1, SDM Output, for

details on SDM output, see Appendix C, Alternate EC100 Outputs, for greater

detail on RS-485, USB, or analog outputs.

SDM communications are output as the FLOAT data type.

5.3 Physical Description

Optical measurement path length: 15.37 cm (6.05 in)

Spatial separation from

CSAT3A sampling volume: 5.0 cm (2.0 in)

vii

refer to manufacturer’s product brochure or manual for details

9

Page 20

EC150 CO2/H2O Open-Path Gas Analyzer

Dimensions

Head housing diameter: 3.2 cm (1.3 in)

Head length: 29.7 cm (11.7 in)

EC100 enclosure: 24.1 cm x 35.6 cm x 14 cm (9.5 in x

14.0 in x 5.5 in)

Weight

Analyzer and cable: 2 kg (4.4 lbs)

EC100 electronics and

EC100 enclosure: 3.2 kg (7.0 lbs)

FIGURE 5-1. Optical path and envelope dimensions of EC150 analyzer

head

5.4 Power Requirements

Voltage supply: 10 to 16 Vdc

Power at 25°C excluding CSAT3A: 4.1 W

Power at 25°C including CSAT3A: 5.0 W

Power at 25°C in power-down mode

(CSAT3A fully powered and EC150 off): 3.0 W

10

Page 21

6. Installation

NOTE

6.1 Orientation

6.2 Mounting Analyzer to Support Hardware

EC150 CO2/H2O Open-Path Gas Analyzer

During operation, the EC150 should be positioned vertically (±15°) so that the

product label reads right side up and the upper arm (source) is directly above

the lower arm (detector). If the sensor is being used with a sonic anemometer,

the anemometer should be leveled and pointed into the prevailing wind to

minimize flow distortion from the analyzer’s arms and other supporting

structures.

The EC150 is supplied with mounting hardware to attach it to the end of a

horizontal pipe of 3.33 cm (1.31 in) outer diameter, such as the CM202 (pn

17903), CM204 (pn 17904), or CM206 crossarm (pn 17905).

There are two different mounting brackets for the EC150. A head only

mounting bracket (pn 26785), and the EC150/CSAT3A mounting bracket (pn

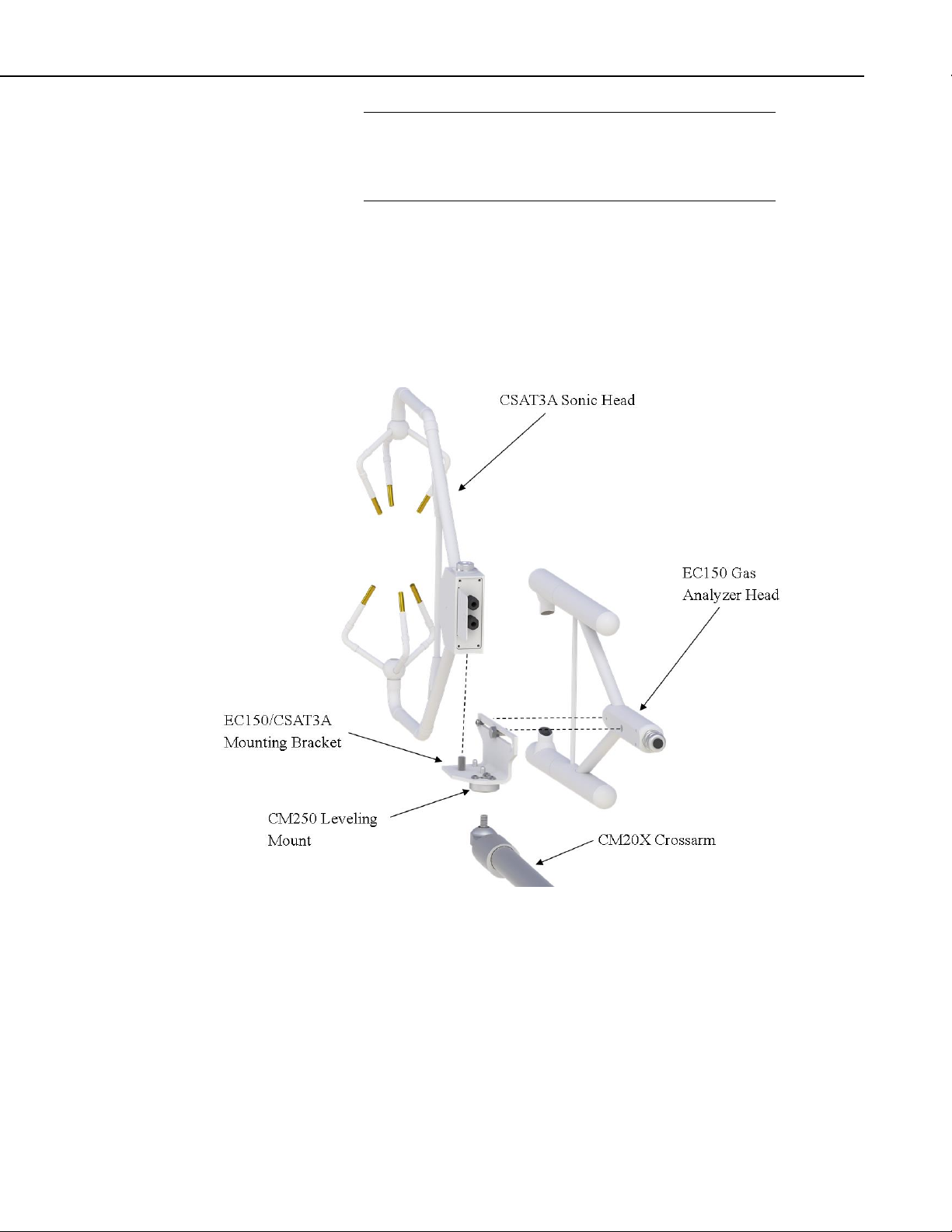

26786). The two mounting brackets are shown in FIGURE 6-1.

The CSAT3A sonic anemometer head is an option when ordering the EC150

and the appropriate mounting bracket is included with the EC150 depending on

if the CSAT3A is ordered. If the user is already in possession of a CSAT3A

and intends to use it with the EC150, the proper mounting bracket should be

specified at time of order.

The screws and bolts for either mounting bracket are easily lost in

the field. Replacements are available through Campbell Scientific

or can be sourced elsewhere. For mounting bracket 26785, use pn

15807 (screw #8-32 x 0.250 socket head) and pn 26712 (screw

3/8-16 x 0.625 hex cap). For mounting bracket 26786, use pn

26711 (screw #8-32 x 0.250 shoulder cap) and pn 26712 (screw

3/8-16 x 0.625 hex cap).

FIGURE 6-1. Mounting bracket options for EC150 head only (pn

26785) or EC150 head with CSAT3A (pn 26786)

11

Page 22

EC150 CO2/H2O Open-Path Gas Analyzer

The mounting bracket for the EC50 with CSAT3A, pn 26786, allows the intake

source of the CSAT3A and EC150 to be positioned at varying degrees up to

approximately a 5.0 cm (2.0 in) offset. The positioning and offset is illustrated

in FIGURES 6-3 and 6-4. The change in positioning allows a small but

significant difference in the flux attenuation ratio. Campbell Scientific

generally recommends that the EC150 is positioned in the most forward

position to minimize errors caused by sensor separation. The tradeoff,

however, is greater flow distortion. The effect of spatial separation on flux

attenuation is greatest at lower measurement heights as shown in FIGURE 6-2.

A Campbell Scientific application engineer can help determine the best

positioning of the EC150 relative to the CSAT3A in scenarios where the

measurement height is below 10 meters.

FIGURE 6-2. Changes in flux attenuation ratio relative to sensor height

at the most fore and aft positions

12

Page 23

EC150 CO2/H2O Open-Path Gas Analyzer

FIGURE 6-3. Mounting position of CSAT3A and EC155 with a 4.9 cm

sensor separation.

FIGURE 6-4. Mounting position of CSAT3A and EC155 with a 9.7 cm

sensor separation.

The following steps describe the normal mounting procedure. Refer to

FIGURE 6-5 and 6-6 throughout this section.

13

Page 24

EC150 CO2/H2O Open-Path Gas Analyzer

WARNING

6.2.1 Preparing the mounting structure

1. Secure a CM20X crossarm to a tripod or other vertical structure using a

CM210 crossarm-to-pole bracket (pn 17767).

2. Point the horizontal arm into the direction of the prevailing wind.

3. Tighten all fitting set screws.

Do not carry the EC150 by the arms or the strut between the

arms. Always hold the sensor by the block where the upper

and lower arms connect.

6.2.2 Mounting EC150 with optional CSAT3A

The guideline below gives general instructions for mounting an EC150 and

optional CSAT3A to a mounting structure. The order of assembly will

somewhat be determined by the user’s application; primarily the height of the

tower. Steps 6, 7, and 8 should be performed in sequential order.

Please refer to all steps and the referenced figure of this section before deciding

on an assembly strategy. In general, Campbell Scientific suggests that if the

equipment is to be mounted at heights above what can be reached while

standing, to preassemble as much as possible and then hoist that assembly into

a position to be mounted on the appropriate crossarm.

1. Bolt the EC150/CSAT3A mounting bracket (pn 26786; see FIGURE

6-1) to the CM250 leveling mount (pn 26559).

2. Install the CSAT3A sonic head to the EC150/CSAT3A mounting

bracket by aligning the threaded hole on the CSAT3A sonic head with

the hole on the bracket.

3. Insert and finger-tighten the bolt, making sure the bolt is not cross-

threaded. Finish tightening with a wrench.

4. Install the assembly to the end of the crossarm by fitting the leveling

mount over the end of the crossarm.

5. Tighten the set screws on the leveling mount.

6. Install the EC150 gas analyzer head to the EC150/CSAT3A mounting

bracket by tightening the mounting screw and loosely thread the

mounting bolt into the analyzer head.

7. Align the analyzer parallel with the vertical plate of the mounting

bracket and insert the mounting screw and bolt into the slot of the

mounting bracket.

8. Carefully slide the analyzer forward to the desired position. For a

more detailed discussion of positioning the EC150 relative to the

CSAT3A, see Section 6.2, Mounting Analyzer to Support Hardware.

14

Page 25

EC150 CO2/H2O Open-Path Gas Analyzer

CAUTION

Avoid crashing the arms of the sensors together. The arms

of the analyzer should slide in between the claws of the

CSAT3A; the sonic head may need to be loosened and

repositioned to do this.

10. Tighten bolts and check that the analyzer is oriented vertically such

that the label is right-side-up and the upper arm (source) is directly

above the lower arm (detector).

11. If the assembly is not level, slightly loosen the bolt that holds the

mounting bracket on the leveling mount and adjust the assembly until

the leveling bubble on the top of the CSAT3A head is within the

bullseye. Retighten the bolt.

FIGURE 6-5. Exploded view of mounting CSAT3A and EC150

15

Page 26

EC150 CO2/H2O Open-Path Gas Analyzer

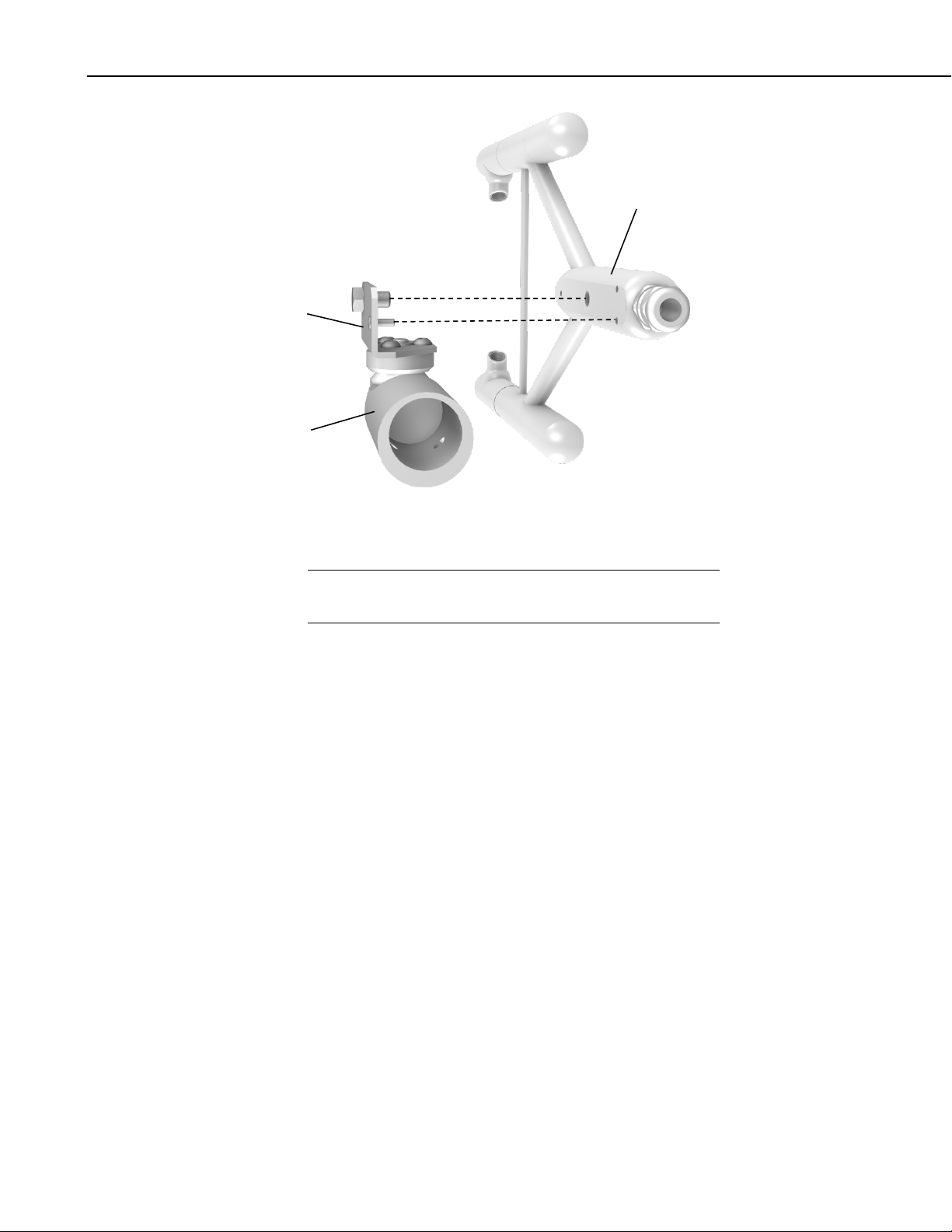

CAUTION

EC150 Gas

Analyzer Head

EC150 Head-Only

Mounting Bracket

CM250 Leveling Mount

FIGURE 6-6. Exploded view of mounting the EC150 without the

CSAT3A

Over-tightening bolts will damage or deform mounting

hardware.

6.2.3 Mounting EC150 without CSAT3A

The instructions for mounting the EC150 without the CSAT3A should

generally follow those in Section 6.2.2, Mounting EC150 with optional

CSAT3A, but requires the use of a different mounting bracket as described

below and in Section 6.2, Mounting Analyzer to Support Hardware.

1. Bolt the EC150 head-only mounting bracket (pn 26785; see FIGURE

6-1) to the CM250 leveling mount (pn 26559).

2. Mount the EC150 gas analyzer head to the EC150 head-only

mounting bracket and follow the steps outlined in Section 6.2.2,

Mounting EC150 with Optional CSAT3A, for preassembly.

3. Mount this assembly to the end of the crossarm by fitting the leveling

mount over the end of the crossarm.

4. Tighten the set screws on the leveling mount.

5. If the assembly is not level, slightly loosen the bolt that holds the

mounting bracket on the leveling mount and adjust the assembly.

Retighten the bolt.

16

Page 27

EC150 CO2/H2O Open-Path Gas Analyzer

CAUTION

NOTE

Use caution when handling the EC150 gas analyzer head.

The optical source may be damaged by rough handling,

especially while the EC150 is powered.

The CSAT3A sonic anemometer is an updated version of the

CSAT3, designed to work with the EC100 electronics. An existing

CSAT3 may be upgraded to a CSAT3A. Contact a Campbell

Scientific application engineer for details.

6.2.4 Attaching EC100 Electronics Enclosure to Mounting Structure

The EC100 electronics enclosure can be mounted to the mast, tripod leg, or

other part of the mounting structure but must be mounted within 3.0 m (10.0 ft)

of the sensors due to restrictions imposed by the cable length.

1. Attach the EC100 enclosure mounting bracket (pn 26604) to the pipe

of the mounting structure by loosely tightening the u-bolts around the

pipe. The u-bolts are found in the mesh pocket inside the EC100

enclosure.

2. For configurations in which the pipe is not vertical (such as a tripod

leg as in FIGURE 6-7) rotate the bracket to the side of the pipe so that

when the enclosure is attached it will hang vertically upright. Make

any necessary angle adjustments by loosening the four nuts and

rotating the bracket plates relative to one another. If the necessary

angle cannot be reached in the given orientation, remove the four nuts

completely and index the top plate by 90° to allow the bracket to

travel in the other direction (see FIGURE 6-7).

FIGURE 6-7. EC100 enclosure mounting bracket mounted on a vertical

mast (left) and a tripod leg (right)

3. Tighten all nuts after final adjustments have been made.

4. Attach the EC100 enclosure to the bracket by loosening the bolts on

the back of the enclosure, hanging the enclosure on the mounting

17

Page 28

EC150 CO2/H2O Open-Path Gas Analyzer

bracket (it should slide into place and be able to securely hang from

the bracket), and retightening the bolts (see FIGURE 6-8).

FIGURE 6-8. Exploded view of mounting the EC100 enclosure

5. Remove the EC100 enclosure desiccant from the plastic bag and put it

back in the mesh pocket of the enclosure.

6. Adhere the humidity indicator card to the inside of the door of the

enclosure.

6.2.5 Install the EC150 Temperature Probe

The temperature probe should be mounted such that it measures at the same

height as the sample volume of the EC150 and the CSAT3A.

1. Attach the R.M. Young 41303-5A 6-plate solar radiation shield (pn

4020) to the mast with the included u-bolt.

2. Insert the end of the temperature probe into the hole on the bottom of

the shield, see FIGURE 6-10.

3. Tighten screws to hold the probe in place.

18

Page 29

EC150 CO2/H2O Open-Path Gas Analyzer

FIGURE 6-9. EC150 temperature probe

FIGURE 6-10. Solar radiation shield with EC150 temperature probe

6.3 Wiring and Connections

FIGURES 6-11 and 6-12 show EC100 electronics panel and the bottom of the

EC100 enclosure, respectively. Refer to these figures during the wiring and

connecting of the various auxiliary sensors.

FIGURE 6-11. EC100 electronics front panel showing EC100 as

shipped (left) and after completed wiring and connections (right)

19

Page 30

EC150 CO2/H2O Open-Path Gas Analyzer

NOTE

FIGURE 6-12. Bottom of EC100 enclosure

6.3.1 Connecting the EC150 Gas Analyzer Head

1. Remove the black rubber cable entry plug (pn 26224) that is located on the

bottom right of the EC100 enclosure labeled Cable 3. (This plug can be

stored in the mesh pocket of the enclosure.)

2. Insert the cable entry plug that is attached to the large cable of the EC150

gas analyzer head into the vacant slot.

3. Push the connector at the end of the cable onto its mating connector

(labeled Gas Analyzer) and tighten the thumbscrews (see FIGURE 6-12).

The EC150 gas analyzer cable is approximately 3.0 m (10.0 ft) in length.

6.3.2 Connect the CSAT3A Sonic Head

Skip the following two steps if not using a CSAT3A.

1. Similar to connecting the gas analyzer head, remove the black rubber cable

entry plug found on the bottom left of the EC100 enclosure.

2. Insert the cable entry plug on the CSAT3A cable into the slot and connect

the male end to the female connector labeled Sonic Anemometer on the

EC100 electronics (see FIGURE 6-12).

20

Unlike previous models of the CSAT3 3D sonic anemometer, the

CSAT3A sonic head and the EC150 gas analyzer head have

embedded calibration information. This means that any CSAT3A

and any EC150 may be used with any EC100.

Page 31

EC150 CO2/H2O Open-Path Gas Analyzer

CAUTION

CAUTION

6.3.3 Connect the EC150 Temperature Probe

1. Unscrew the temperature connector cover which is found on the bottom of

the EC100 enclosure labeled Temperature Probe (see FIGURE 6-12).

2. Insert the three-prong temperature probe connector into the female

connector on the enclosure and screw it firmly in place. The EC150

temperature probe cable is approximately 3.0 m (10.0 ft) in length.

6.3.4 Ground the EC100 Electronics

1. Attach a user-supplied heavy gauge wire (12 AWG would be appropriate)

to the grounding lug found on the bottom of the EC100 enclosure.

2. Earth (chassis) ground the other end of the wire using a grounding rod.

For more details on grounding, see the CR3000 datalogger manual

grounding section.

Grounding the EC100 is critical. Proper grounding to earth

(chassis) will ensure maximum electrostatic discharge

(ESD) protection and improve measurement accuracy.

Do not connect or disconnect the EC150 gas analyzer head

or CSAT3 sonic head once the EC100 is powered.

6.3.5 Connect SDM Communications to the EC100

The EC150 supports SDM communications with datalogger. SDM is the

preferred communications to the EC100. RS-485 may be necessary in some

situations. The USB is used mainly for diagnostic and trouble shooting.

Connection instructions for these modes can be found in Appendix C, Alternate

EC100 Outputs.

CABLE4CBL-L (pn 21972) is used for connecting SDM communications to

the EC100. The “L” designation denotes the length of the cable which is userspecified.

1. Loosen the nut on one of the cable entry seals (Cable 1) on the bottom of

the EC100 enclosure (refer to FIGURE 6-12).

2. Remove plastic plug and store in mesh pocket of enclosure.

3. Insert the cable while referring to TABLE 6-1 for details on which color of

wire in the cable should be connected to each terminal found on the SDM

connector of the EC100 panel.

4. Once the wires of the cable are fully connected, retighten the nut on the

appropriate cable entry.

21

Page 32

EC150 CO2/H2O Open-Path Gas Analyzer

TABLE 6-1. EC100 SDM output to a Campbell Scientific CR1000,

EC100 Channel Description Color

SDM-C1 SDM Data Green

SDM-C2 SDM Clock White

SDM-C3 SDM Enable Brown

G Digital Ground Black

G Shield Clear

6.3.6 Wire Power and Ground the EC100

1. Feed cable CABLEPCBL-L (pn 21969-L) through Cable 2 at the bottom

of the EC100 enclosure (see FIGURE 6-12) and attach the ends into the

green EC100 power connector (pn 3768).

2. Plug the connector into the female power connector on the EC100 panel.

Ensure that the power and ground ends are going to the appropriate

terminals labeled 12V and ground, respectively.

CR3000, or CR5000 Datalogger

3. Connect the power cable to a power source. The power and ground ends

may be wired to the 12V and G ports, respectively, of a Campbell

Scientific datalogger or to another 12 Vdc source.

Once power is applied to the EC100, three LED status lights on the EC100

panel will illuminate. The power LED will be green if the power supply

voltage is between 10 to 16 Vdc. The gas LEDs will be orange until the gas

head has warmed up. The sonic LED will be red while the sonic acquires the

ultrasonic signals. The sonic and gas LEDs will turn green if there are no

diagnostic warning flags. Three green LEDs indicate that the instrument is

ready to make measurements.

The EC150 power-up sequence takes under two minutes to complete. During

power up the gas LED will be orange. If after two minutes the gas LED turns

green, power-up sequence has been completed successfully. If the gas LED

turns red, a diagnostic flag has been detected. Check the individual diagnostic

bits to determine the specific fault.

Diagnostics may be monitored using the Status window of ECMon (see

Appendix A.3, ECMon), the user interface software included with the EC150

(see Appendix A, EC150 Settings), or with a datalogger. The diagnostics may

reveal that the unit needs to be serviced (for example, cleaning the optical

windows on the EC150, cleaning the CSAT3A transducers of ice or debris, etc.

See Section 8, Maintenance and Troubleshooting).

7. Zero and Span

7.1 Introduction

Calibration of optical instrumentation like the EC150 may drift slightly from

the calibration that was performed in the factory with time and exposure to

22

Page 33

EC150 CO2/H2O Open-Path Gas Analyzer

NOTE

CAUTION

natural elements. A zero-and span procedure should be performed after

installation of the instrument to give appropriate baseline readings as a

reference. A zero-and-span procedure should also be performed occasionally

to assess drifts from factory calibration. In many cases, a zero and span can

help resolve problems that are being experienced by the user during operating

the EC150. For example, a zero-and-span procedure should always be

performed on the analyzer after changing the internal chemicals. Before

performing a zero-and-span procedure, clean the windows of the EC150 as

described in Section 8.3, Cleaning Analyzer Windows.

After the first several zero-and-span procedures, the rate of drift in gain and

offset (explained later in this section) should be analyzed to better determine

how frequently the zero-and-span procedure should be performed once the

instrument has been put into service.

The first part of the procedure listed below simply measures the CO

span and zero without making any adjustments. This allows the CO

and H2O

2

and H2O

2

gain factors to be calculated. These gain factors quantify the state of the

analyzer before the zero-and-span procedure and, in theory, could be used to

correct recent measurements for drift. The last part of the zero-and-span

procedure adjusts internal processing parameters to correct subsequent

measurements.

If the zero-and-span procedure is being performed off site (for example, in a

laboratory), be sure to mount the EC150 on the zero-and-span stand (refer to

FIGURE 7-1). This will ensure the analyzer is in the correct upright

orientation and has the correct optical alignment.

The zero-and-span procedure must be performed correctly and not rushed.

Allocate at least one hour (preferably more) for the procedure. Ensure that the

readings are stable and all sensors are properly connected and functioning.

It is conceivable that there are circumstances in which both a zero and a span

cannot be performed by the user. In these instances, it is recommended that the

user attempt to perform a zero of the instrument even if spanning is not

possible or inconvenient. The information gained through zeroing the

instrument can help troubleshoot problems that may be encountered during

field operations.

The water vapor measurement is used in the CO2 concentration

calculations to correct instrument and pressure broadening effects.

To achieve good CO

calibration, it is imperative to maintain a

2

reasonable water vapor calibration.

7.2 Zero and Span Procedure

Resting the analyzer on its side during the zero-and-span

procedure may result in measurement inaccuracy.

This section gives instructions for performing a zero-and-span procedure, and

should be referred to any time a zero-and-span procedure is undertaken.

Check and then set the EC150 zero and span according to the following steps:

23

Page 34

EC150 CO2/H2O Open-Path Gas Analyzer

CAUTION

1. Remove power from the EC100/EC150. Unplugging the power cable

from the EC100 is the easiest way to accomplish this.

2. Remove wicks from the snouts of the analyzer.

3. Clean windows and snouts with isopropyl alcohol and a lint-free, non-

abrasive tissue or cloth as described in Section 8.3, Cleaning Analyzer

Windows.

Make sure any residual alcohol and water completely

evaporate from the analyzer before proceeding with the

zero-and-span procedure.

4. Position the EC150 zero-and-span shroud (pn 26390) over the upper and

lower snouts. See FIGURE 7-1 for guidance with the following steps.

a. Twist the two ends of the shroud together to minimize the length of

the shroud. Make sure the rubber seals on the ends of the shroud are

clean and in good condition.

b. Position one end of the shroud over the lower snout and twist the top

part of the shroud, allowing it to extend and cover the upper snout.

c. Continue twisting the shroud until it is fully extended and covering

both snouts.

d. Twist the shroud so that the gas lines and temperature thermistor

cable are directed towards the back of the sensor.

e. Hang the lines and cable over the trunk of the sensor to alleviate any

strain on the optical arms. See FIGURE 7-1.

24

FIGURE 7-1. Zero-and-span shroud mounted on the zero-and-span

stand

Page 35

EC150 CO2/H2O Open-Path Gas Analyzer

NOTE

5. Disconnect the EC150 temperature probe from the EC100 and connect the

shroud temperature probe in its place.

6. Connect the EC100 to a PC with the EC100 USB cable (pn 26563).

7. Resume power to the EC100/EC150.

8. Wait for all the Gas and Power LED status lights on the EC100 panel to

turn green.

9. Launch ECMon, select the appropriate USB port, and click Connect. The

main screen should now be reporting real-time CO

and H2O

2

concentrations.

10. Click Zero/Span. A graph will appear in the lower half of the zero-and-

span window showing measured CO

and H2O concentrations (see

2

FIGURE 7-2).

11. Connect a gas cylinder of known CO

concentration to a pressure

2

regulator, then to a flow controller, and finally to the intake of the shroud.

Optimally, the concentration of span CO

being measured in the field.

of CO

2

should be near the concentration

2

12. Beginning with both the pressure regulator and flow controller turned off,

use the pressure regulator to slowly increase pressure to the recommended

setting for the flow controller.

13. Set the flow between 0.2 and 0.4 LPM.

14. Monitor the ECMon zero-and-span graph and wait for the CO

2

measurement readings to stabilize (5 to 10 minutes). Once stable, record

the reported CO

concentration.

2

Use a mixture of CO2 in air (not nitrogen) for the CO2 span gas.

The use of pure nitrogen as the carrier gas will lead to errors

because the pressure-broadening of the CO

absorption lines is

2

different for oxygen and nitrogen.

25

Page 36

EC150 CO2/H2O Open-Path Gas Analyzer

NOTE

FIGURE 7-2. ECMon zero-and-span window

15. Remove the CO

O span gas from a dew-point generator or another standard reference.

H

2

span gas from the inlet of the shroud and replace it with

2

As water molecules can adsorb to inside of the tubing and the shroud, it

may take 30 minutes or more for the H

O concentration to stabilize. The

2

user may increase the flow rate for the first several minutes to more

quickly stabilize the system before returning it to between 0.2 and 0.4

LPM to make the H

O measurement. Record the reported H2O

2

concentration. If a stable reading is not achieved within 45 to 60 minutes,

troubleshooting steps should be undertaken.

16. Remove the H

O span gas, and connect a zero air source (no CO2 or H2O)

2

to the inlet tube of the shroud. As described in step 11, use a pressure

regulator and flow controller so that zero air flows through the shroud

between 0.2 and 0.4 LPM. Wait for the measurement readings to stabilize

and record the reported values for CO

and H2O concentrations. If the

2

readings remain erratic, ensure that flow of the zero air is sufficient and

the shroud is correctly seated on the snouts.

If the quality of a zero gas is unknown or suspect, a desiccant and

CO2 scrubber should be added between the zero gas tank and the

shroud to confirm that the gas being sampled during the zero

procedure is actually a zero air source.

26

17. Along with recording the CO2 and H2O zero and span values, also record

the date and time, and temperature. With this information the user can

examine zero/span drift with time and temperature.

Page 37

EC150 CO2/H2O Open-Path Gas Analyzer

measmeas

actual

zerospan

span

gain−=

NOTE

Compute the drift in instrument gain using the following equation:

where,

• span

• span

• zero

Note that in the zero-and-span window of ECMon, span

= known concentration of the span gas

actual

= measured concentration of the span gas

meas

= measured concentration in zero gas

meas

actual

the right of the box where the user enters the span dewpoint temperature.

The software calculates span

by taking into account the dewpoint

actual

temperature and current ambient temperature and pressure. The equations

used for this calculation may be found in Appendix D, Useful Equations.

If drift (offset or gain) for CO

replace the desiccant and CO

Scrubber Bottles).

CO

2

or H2O is excessive, it may be time to

2

scrubber bottles (see Section 8.5, Replacing

2

18. With zero air still flowing and measurements stabilized, click on the Zero

CO

and H2O button in the ECMon zero-and-span window.

2

Air flow into the shroud should be close to the recommended rate. If the

flow is too low, the shroud will not be properly flushed. If it is too high, the

air pressure within the shroud will be too high, and the analyzer will not be

zeroed and spanned properly.

19. Remove the zero air source and replace it with the CO2 span gas.

20. Allow the gas to flow through the shroud, maintaining a flow between 0.2

and 0.4 LPM. Wait for readings to stabilize.

is reported to

21. In the zero-and-span window, enter the known concentration of CO

(in

2

ppm) in the box labeled Span Concentration (dry) and press Span.

22. Replace the CO

span gas with an H2O span gas of known dewpoint.

2

Allow the gas to flow through the shroud. Higher flows may be desired

for a couple of minutes to more quickly establish equilibrium before

resuming a flow between 0.2 and 0.4 LPM. Wait for the readings to

stabilize.

23. Enter the known dewpoint (in °C) in the box labeled Span Dewpoint and

press Span.

24. The zero-and-span procedure is now complete. Remove the shroud,

reconnect the EC150 temperature probe, and prepare the site for normal

operation. Verify that readings from the instrument are reasonable.

Record the zero and span coefficients for future reference and to keep

track of the rate of the analyzer drift. Make sure that the coefficients are

between 0.9 and 1.1. Negative or numbers larger than 1.1 are usually an

indication of improper calibration.

27

Page 38

EC150 CO2/H2O Open-Path Gas Analyzer

TABLE 8-1. Rain Wick Replacement Parts

8. Maintenance and Troubleshooting

EC150 operation requires six maintenance tasks:

• Routine site maintenance

• Wick maintenance

• Analyzer window cleaning

• Zero and span

• Replacing the analyzer desiccant/scrubber bottles

• Factory recalibration

8.1 Routine Site Maintenance

The following items should be examined periodically:

• Check the humidity indicator card in the EC100 enclosure. If the highest

dot has turned pink, replace the desiccant bags. Replacement desiccant

bags may be purchased as pn 6714.

• Make sure the Power and Gas LED status lights on the EC100 panel are

green. If not, check the individual diagnostic bits for the specific fault.

See TABLE 8-2, Diagnostic Flags of Sonic Status LED, and Section 8.7.3,

LED Status Lights, for more information.

8.2 Gas Analyzer Wicks

The windows of the EC150 gas analyzer are polished and slanted at an angle to

prevent water from collecting on their surfaces. However, due to increased

surface tension at the interface with the snout, water can pool at the edges and

partially block the optical path and attenuate the signal. To minimize the

occurrence of such events and the resulting data loss, consider using the wicks

listed in TABLE 8-1. The weave of the wicking fabric promotes capillary

action that wicks the water away from the edge of the windows. The seam and

the straight edge of the wicks are permeated with a rubberized compound to

prevent them from shifting during operation.

Proper installation of the wicks is critical. They should not block or encroach

on the optical path. Before installation, record signal strengths for both H

and CO

that these values are unchanged.

. Following installation, repeat testing of signal strength and check

2

Wick

Bottom wick 28652 Fab EC150/IRGASON rain

Top wick 28653 Fab EC150/IRGASON rain

Campbell Scientific, Inc.

Part Number

2

Campbell Scientific, Inc.

Description

wick bottom

wick top

O

The top wick has a short seam which must be aligned with the short side of the

top snout. The angled edge of the wick must closely follow the edge of the

window without encroaching on the optical path. See FIGURE 8-1 for

guidance on proper positioning of the wick.

28

Page 39

EC150 CO2/H2O Open-Path Gas Analyzer

The bottom wick is installed in a similar manner, except the long seam should

be aligned with the long side of the bottom snout. Once in place, the wicks

should fit snuggly over the cylindrical part of the snout without any creases or

wrinkles. The windows should be cleaned after the installation of the wicks to

ensure that there are no fingerprints left on critical surfaces. See Section 8.3,

Cleaning Analyzer Windows, for specifics on cleaning the EC150 windows.

Wicks are constructed with a UV-resistant fabric and should be functional for

an extended period of time but should be inspected every six months. Check

for contamination from dust, pollen, pitch or other debris. If needed, wash the

wicks in warm water with mild detergent or replace them.

FIGURE 8-1. Proper location of the gas analyzer top wick (left) and

bottom wick (right)

8.3 Cleaning Analyzer Windows

The windows of the analyzer should be cleaned if the signal strength for CO2

O drops below 0.7 (70% of the original value). These values may be

or H

2

monitored in the output data, or they can be viewed with ECMon.

To clean the windows, use isopropyl alcohol and a cotton swab or a lint-free

tissue or cloth. Signal strengths should be restored to values close to 1.0 after

cleaning the analyzer windows. In some cases, depending on the contaminant,

cleaning with distilled water can achieve better results. In severe cases a mild

detergent similar to ordinary hand soap can be used.

8.4 Zero and Span

As discussed in Section 7, Zero and Span, the zero-and-span procedure can

resolve many of the issues a user may encounter. Along with being a valuable

troubleshooting method, a zero-and-span procedure should be performed as

routine maintenance even when the EC150 is producing expected results.

Campbell Scientific recommends that a zero-and-span procedure be performed

at least every six months, but may be required more frequently depending on

conditions.

29

Page 40

EC150 CO2/H2O Open-Path Gas Analyzer

DANGER

NOTE

Performing frequent zero-and-span procedures when the instrument is first put

into use to determine the drift from factory calibration, will give a good

guideline for the frequency that the procedure should be performed.

To perform a maintenance zero and span, follow the same steps as in Section 7,

Zero and Span.

8.5 Replacing CO2 Scrubber Bottles

If more than one year has passed since replacing the desiccant/scrubber or if

the zero-and-span readings have drifted excessively (see Section 7, Zero and

Span), the desiccant/scrubber bottles within the EC150 analyzer head should be

replaced. FIGURE 8-2 gives the details needed for the following steps.

The scrubber bottles contain strong oxidizing agents. Avoid

direct contact with the chemicals inside the bottles. Also

ensure your work area is well ventilated and free of any

reactive compounds, including liquid water. Store used

chemical bottles in a sealed container until disposal.

Replacing Scrubber Bottles

1. Twist the scrubber bottle covers of the upper and lower arms counter

clockwise until they detach (they should loosen by hand).