Page 1

INSTRUCTION MANUAL

DCP100

Data Collection Platform

2/99

Copyright (c) 1999

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The DCP100 DATA COLLECTION PLATFORM is warranted by

CAMPBELL SCIENTIFIC, INC. to be free from defects in materials and

workmanship under nor mal use and service for twelve (12) months from date of

shipment unless specifi ed otherwise. Batteries have no warranty. CAMPBELL

SCIENTIFIC, INC.'s obligation under this warranty is limited to repairing or

replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective products.

The customer shall assume all costs of removing, reinstalling, and shipping

defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle repairs

for customers wi thin their territories. Please visi t www.campbellsci.com to

determine which Campbell Scientific company serves your country. To obtain

a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

WARNINGS FOR DCP100 USERS

1. The datalogger operating system must be compatible for use with the TGT-1. CR10X dataloggers

must have version 1.6 or later. All CR510 datalogger operating systems are compatible with the

DCP100. CR500 dataloggers need version 1.4 or later. CR23X dataloggers should have version

1.4 or later. CR10 and 21X dataloggers require a special PROM. CR10 PROM is item number

8131-00, 21X PROM is item number 8132-04. Check *B mode for operating system version. If you

did not purchase the TGT-1 and datalogger together, make sure you have the latest operating

system. Contact a Campbell Scientific Applications Engineer if you have any questions.

2. The datalogger clock must be set to Coordinated Universal Time. All references to time are based

on Coordinated Universal Time.

3. If you are using the keypad (CR10KD) when the datalogger initiates a P120 or P123 instruction, the

instruction will fail without reporting a failure.

4. Due to atmospheric interference and other sources of error, it is possible for a data transmission to

be missed by the ground station. If this happens, your missed data is still in the datalogger until

overwritten by new data.

5. The antenna must be connected before transmission or the transmitter will be damaged.

Page 4

Page 5

DCP100 DATA COLLECTION PLATFORM OPERATOR’S MANUAL

TABLE OF CONTENTS

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

PAGE

1. INTRODUCTION.........................................................................................................................1

2. GOES SYSTEM..........................................................................................................................1

2.1 Orbit ...........................................................................................................................................1

2.2 NESDIS and TransmitWindows .............................................................................................1

2.3 Data Retrieval.............................................................................................................................1

3. TGT1 TRANSMITTER SPECIFICATIONS.........................................................................2

4. REQUIRED EQUIPMENT........................................................................................................2

4.1 Computer Base Station..............................................................................................................2

4.2 Field Station ...............................................................................................................................2

5. POWER SUPPLIES...................................................................................................................4

5.1 12 and 24 AHr Sealed Rechargeable Batteries .........................................................................4

5.2 AC Power and Deep-Cycle Rechargeable Batteries..................................................................4

5.3 Datalogger’s Batteries................................................................................................................4

6. INSTALLATION ..........................................................................................................................4

6.1 Wiring.........................................................................................................................................4

6.2 Battery........................................................................................................................................4

6.3 Antenna......................................................................................................................................4

7. FORWARD AND REFLECTED POWER............................................................................7

8. PROGRAMMING THE TRANSMITTER..............................................................................8

8.1 Star Pound Mode .......................................................................................................................8

8.2 Establishing and Editing Parameters .........................................................................................8

8.3 Status Information and Test Transmissions ..............................................................................9

8.4 Error Messages..........................................................................................................................9

9. PROGRAMMING THE DATALOGGER............................................................................10

9.1 CR10X, CR10, CR510, and CR500.........................................................................................10

9.2 Program Instruction 123 - TGT-1 Auto Setup ..........................................................................12

9.3 21X...........................................................................................................................................14

I

Page 6

TABLE OF CONTENTS

APPENDICES

A. INFORMATION ON ELIGIBILITY AND GETTING ONTO THE

GOES SYSTEM................................................................................................................A-1

A.1 Eligibility..................................................................................................................................A-1

A.2 Acquiring Permission .............................................................................................................A-1

B. DATA CONVERSION COMPUTER PROGRAM..........................................................B-1

C. ANTENNA ORIENTATION COMPUTER PROGRAM................................................C-1

D. DETAILED FORWARD/REFLECTED POWER INFORMATION............................D-1

D.1 Impedance Matching..............................................................................................................D-1

D.2 Calculating Pow e r-Out...........................................................................................................D-1

D.3 Impedance Match Datalogger Program.................................................................................D-1

E. CHANNEL/FREQUENCY CORRELATION...................................................................E-1

F. DATA DUMP DATALOGGER PROGRAM ....................................................................F-1

F.1 Introduction............................................................................................................................. F-1

F.2 Toggling User Flag 1 High .....................................................................................................F-1

F.3 Checking the Buffer................................................................................................................ F-1

F.4 Test Transmission..................................................................................................................F-1

F.5 Toggling User Flag 2 High .....................................................................................................F-1

F.6 CR10X Data Dump Program ................................................................................................. F-1

F.7 21X Data Dump Program.......................................................................................................F-2

G. LOCAL MAGNETIC DECLINATION................................................................................G-1

G.1 Determining True North..........................................................................................................G-1

G.2 Prompts from GEOMAG........................................................................................................G-1

H. CHANGING THE CR10’S RAM OR PROM CHIPS....................................................H-1

H.1 Disassembling the CR10........................................................................................................H-1

H.2 Installing New RAM Chips in CR10s with 16K RAM..............................................................H-1

H.3 Installing New PROM.............................................................................................................H-1

I. 21X PROM REPLACEMENT PROCEDURE.................................................................. I-1

I.1 Tools Required........................................................................................................................ I-1

I.2 Procedure................................................................................................................................ I-1

J. TELONICS MODEL TGT1 GOES CERTIFICATION BY NOAA/NES DIA.............J-1

FIGURES

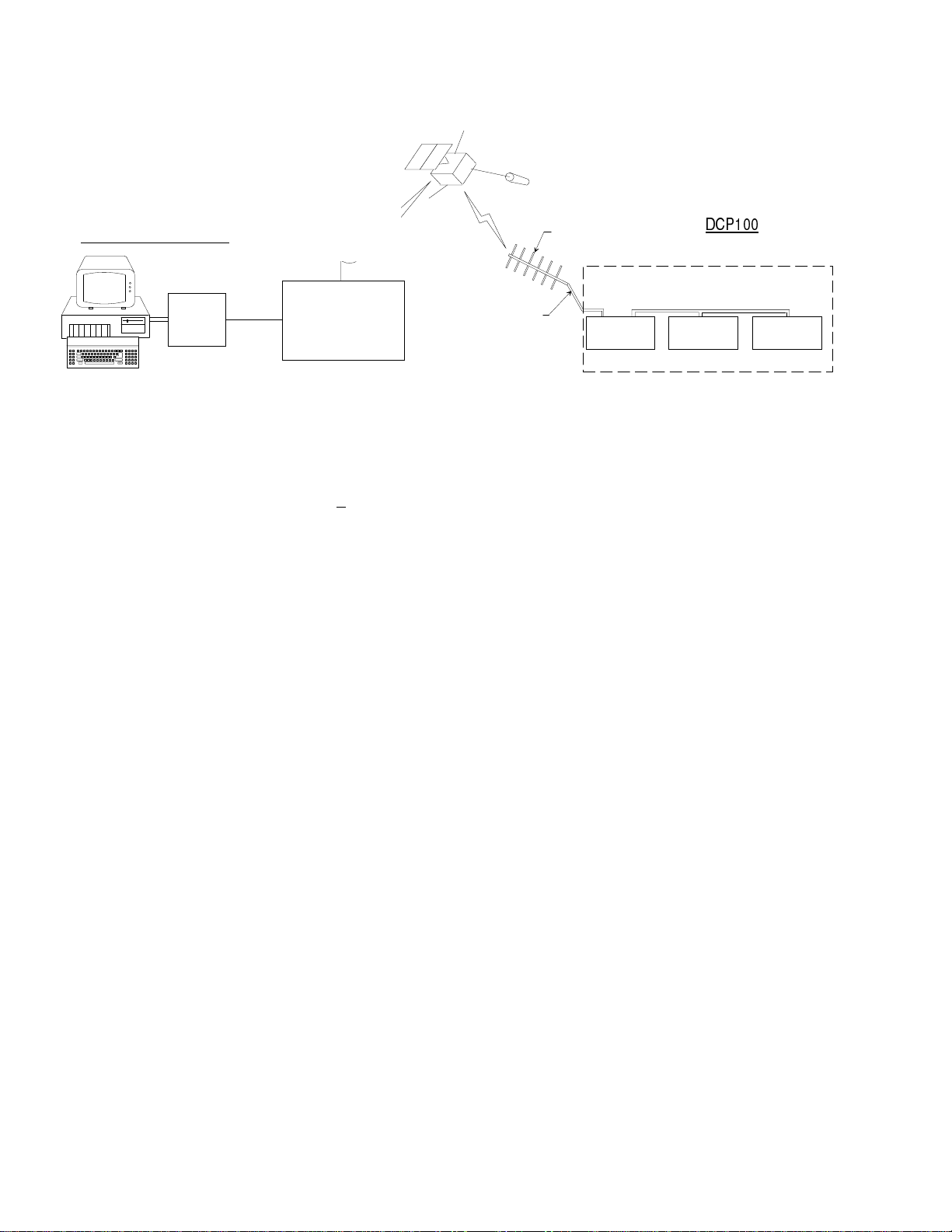

2-1 Data Retrieval Diagram..............................................................................................................2

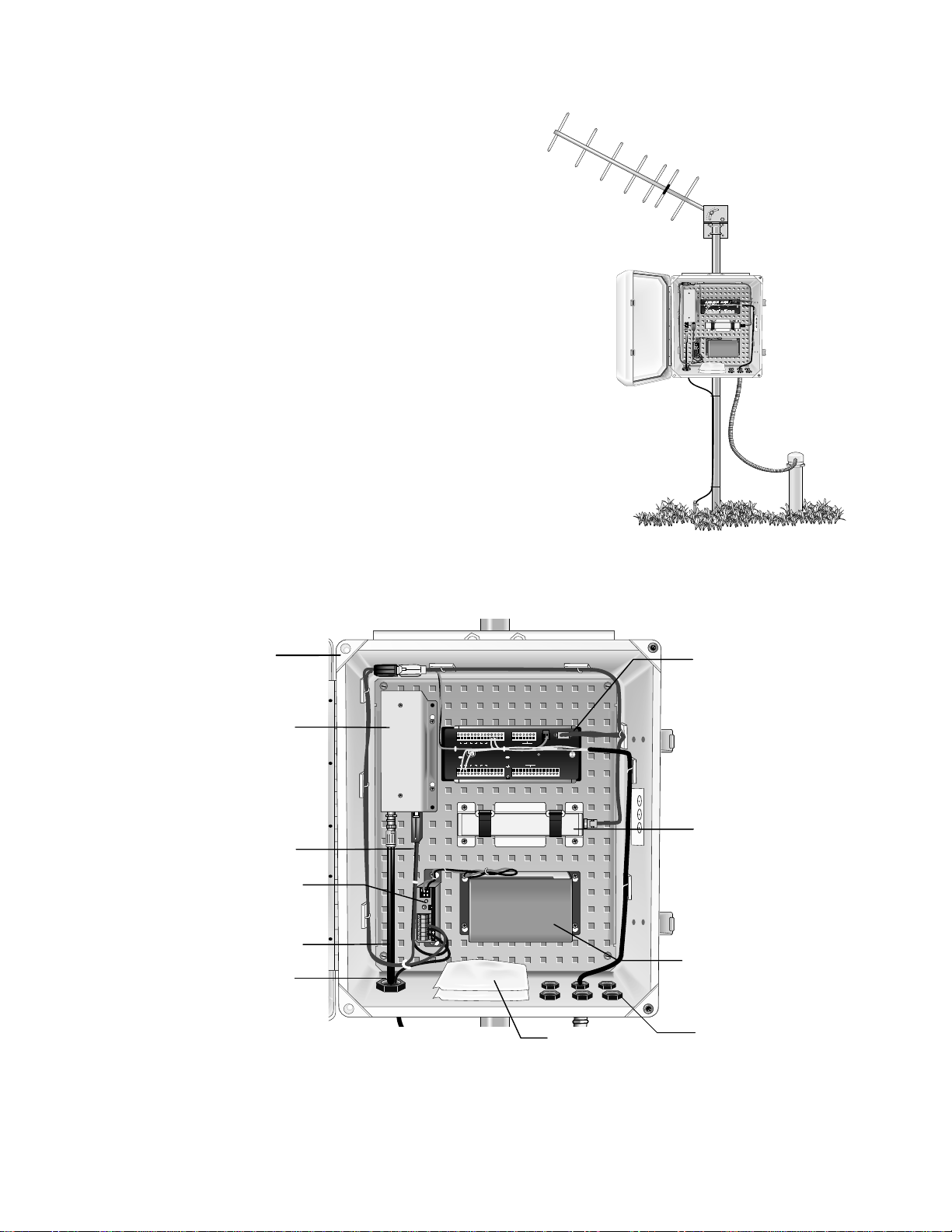

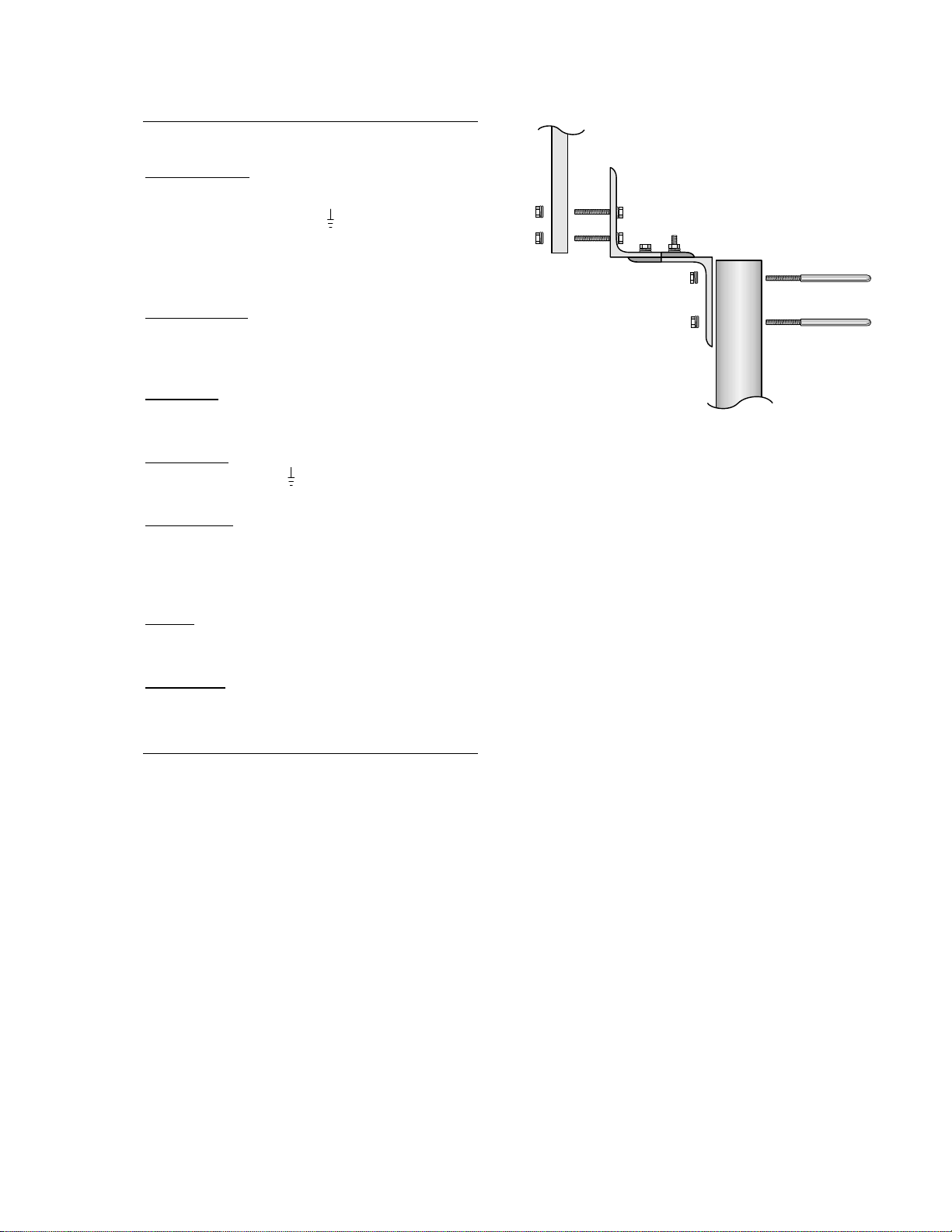

4-1 A Field Station Monitoring a Well’s Depth..................................................................................3

4-2 Inside the Enclosure of a Typical Field Station ..........................................................................3

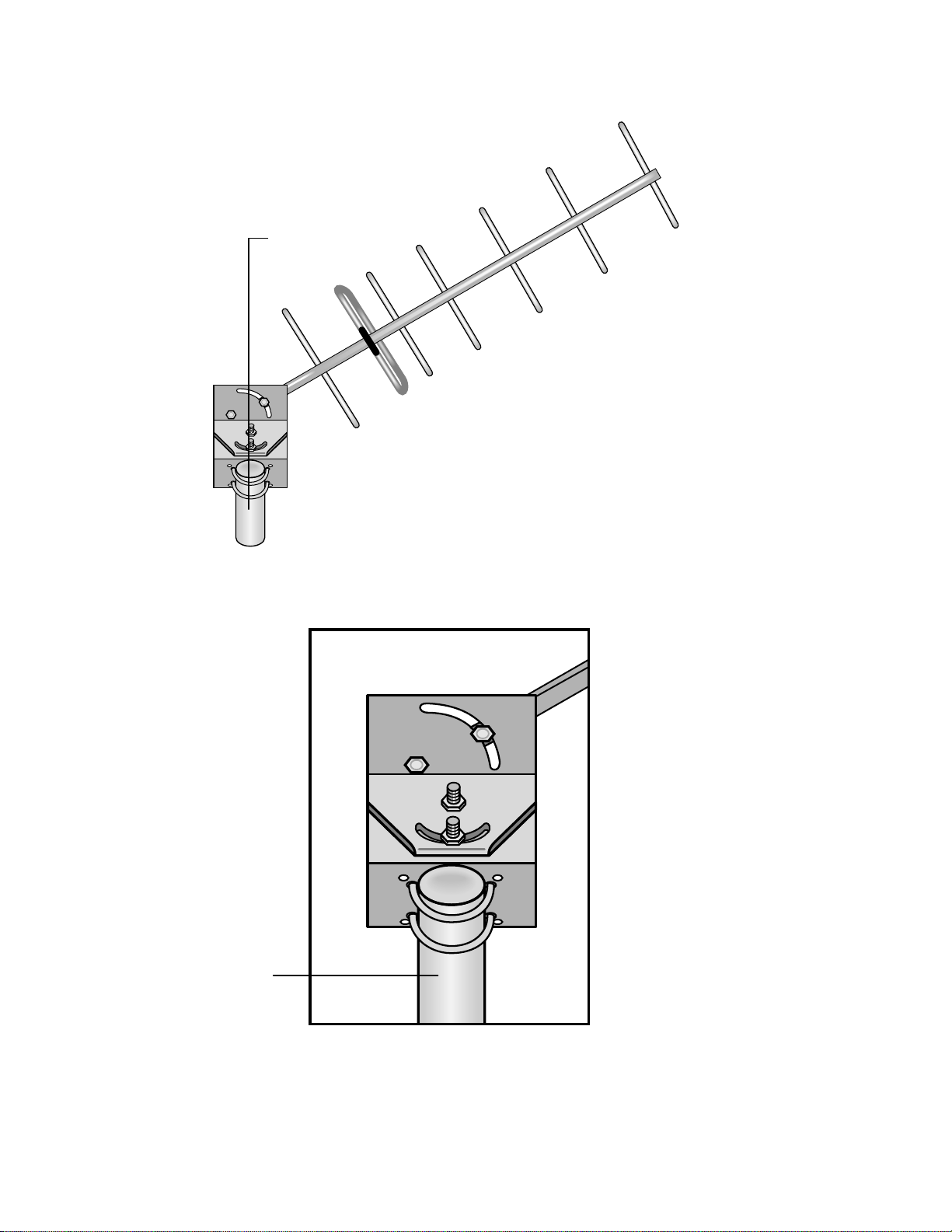

6.3-1 Antenna Mounting Hardware, Exploded View............................................................................5

6.3-2 Antenna Mounting Hardware, Assembled View 1......................................................................6

II

Page 7

TABLE OF CONTENTS

6.3-3 Antenna Mounting Hardware, Assembled View 2......................................................................6

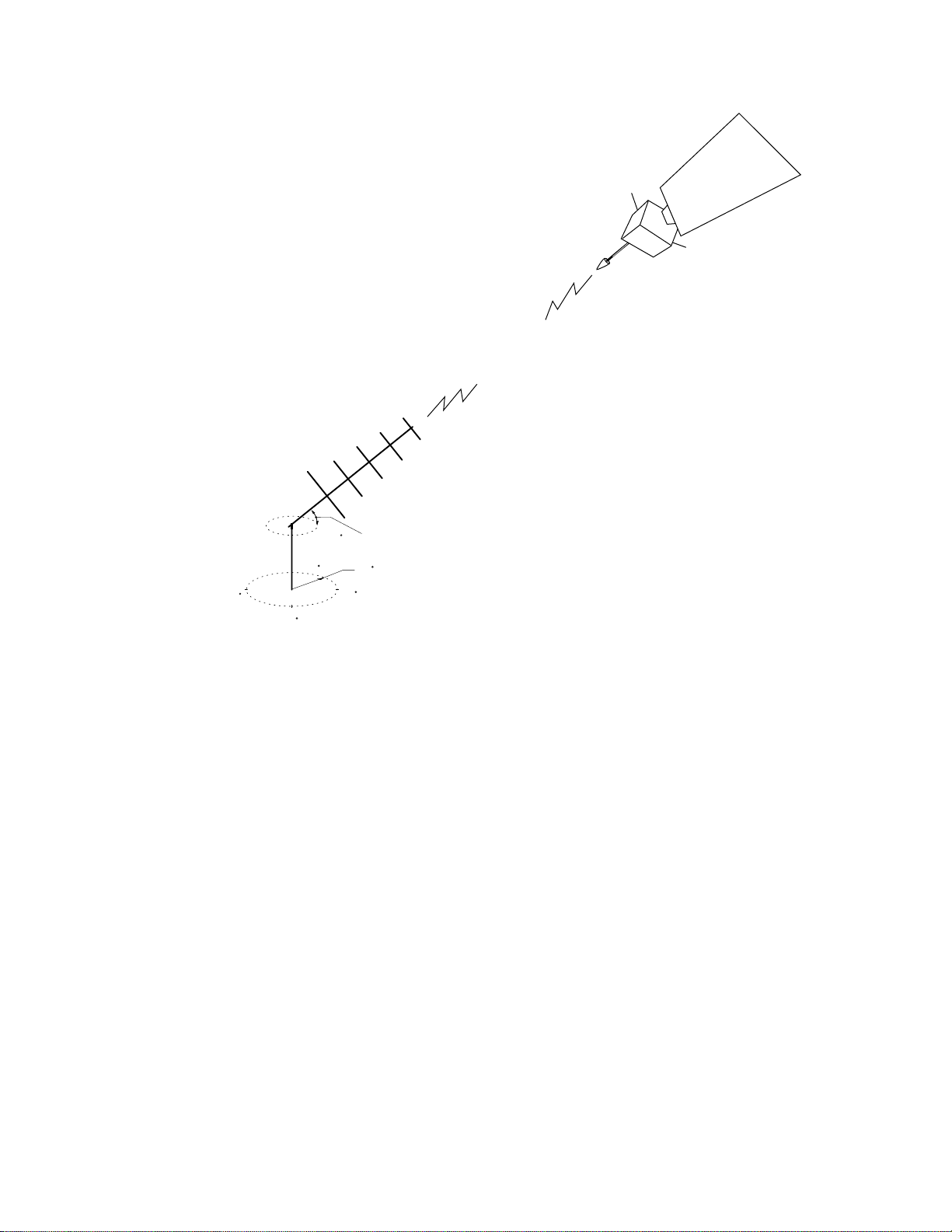

6.3-4 Example Antenna Orientation Diagram......................................................................................7

G-1 Magnetic Declination for the Contiguous United States.........................................................G-1

G-2 Declination Angles East of True North...................................................................................G-2

G-3 Declination Angles West of True North..................................................................................G-2

H-1 Disassembling CR10..............................................................................................................H-2

H-2 Jumper Settings for Different RAM Configurations................................................................H-2

I-1 Removing Faceplate Screws ...................................................................................................I-1

I-2 Separating the Faceplate from the Base..................................................................................I-1

I-3 Removing the Back Cover of the Faceplate ............................................................................I-2

I-4 Inside the Faceplate.................................................................................................................I-2

I-5 Removing the PROM with a Screwdriver.................................................................................I-2

I-6 Inserting the New PROM.........................................................................................................I-3

TABLES

6.1-1 Wiring Diagram ..........................................................................................................................5

8.2-1 *# Parameter’s Descriptions.......................................................................................................8

8.2-2 Decimal Equivalent ....................................................................................................................9

8.3-1 *#60 Commands ........................................................................................................................9

9.1-1 CR10X, CR10, CR510 and CR500’s Instruction Parameters..................................................10

9.1-2 CR10X Example Program........................................................................................................11

9.2-1 P123 Parameter’s Descriptions................................................................................................13

9.3-1 21X’s Instruction 99 Parameters..............................................................................................14

9.3-2 21X Example Program.............................................................................................................14

D.1-1 Impedance Matching Correlation...........................................................................................D-1

D.2-1 P

Values..............................................................................................................................D-1

out

III

Page 8

TABLE OF CONTENTS

This is a blank page.

IV

Page 9

DCP100 DATA COLLECTION PLATFORM

OPERATOR'S MANUAL

1. INTRODUCTION

The DCP100 combines the measurement and

control capabilities of Campbell Scientific’s

dataloggers with the broad geographic

coverage afforded by GOES (Geogstationary

Operational Environmental Satellite) telemetry.

Satellite telemetry offers a convenient

telecommunication alternative for field stations

where phone lines or RF systems are

impractical.

The DCP100 contains the following

components:

• Datalogger: Campbell’s CR23X, CR10X,

CR510, CR500, CR10, or 21X with

appropriate PROMs. A CR10KD

keyboard/display is required when using a

CR10X, CR10, or CR500.

• Transmitter: TGT1 satellite transmitter and

power cable.

• Antenna: Yagi antenna, mounting bracket

and coaxial cable.

• Enclosure: Campbell's 16” by 18” fiberglass

enclosure with a water-tight compression

fitting for the antenna, 6 water-tight

compression fittings for the sensors and the

solar panel.

• Power Supply: Typically a 12 AHr or 24 AHr

sealed rechargeable battery, a charging

regulator, and a solar panel.

This allows a user to point the GOES antenna

at a fixed position in the sky.

There are two satellites, GOES East and GOES

West. GOES East is located at 75° West

longitude and GOES West is located 135° West

longitude. Both satellites are located over the

equator. Within the United States, odd

numbered channels are assigned to GOES

East. Only even numbered channels are

assigned to GOES West. Channels used

outside the United States are assigned to either

spacecraft.

2.2 NESDIS AND TRANSMIT−WINDOWS

GOES is managed by the National

Environmental Satellite Data Information

Service (NESDIS). NESDIS assigns

addresses, uplink channels, and selftimed/random transmit time windows. Selftimed windows allow data transmission only

during a predetermined time frame (typically 1

minute every 3 or 4 hours). The self-timed data

is erased from the transmitter's buffer after

each transmission. Random windows are for

critical applications (e.g., flood reporting) and

allow transmission immediately after a

threshold has been exceeded. The

transmission is then randomly repeated to

ensure it is received. A combination of selftimed and random windows can be executed by

the TGT-1.

2.3 DATA RETRIEVAL

The TGT1 transmitter supports one-way

communication, via satellite, from a Campbell

Scientific datalogger to a ground receiving

station. This transmitter features a crystal

oscillator that is digitally temperaturecompensated to prevent the frequency from

drifting into adjacent channels. The TGT1 is

manufactured for CSI by Telonics Inc. and interfaces directly to the datalogger's 9-pin I/O port.

2. GOES SYSTEM

2.1 ORBIT

The TGT1 transmitter sends data via

Geostationary Operational Environmental

Satellites (GOES). GOES satellites have orbits

that coincide with the Earth's rotation, allowing

each satellite to remain above a specific region.

Data retrieval via the TGT1 and the GOES

system is illustrated in Figure 2-1. The User

Interface Manual, provided by NOAA/ NESDIS,

describes the process of retrieving the data

from the NESDIS ground station. The data are

in the form of 3-byte ASCII (see Appendix B for

a computer program that converts the data to

decimal). You can also retrieve data directly

from the NESDIS ground station via the

DOMSAT satellite downlink. DOMSAT is only

practical for organizations with many GOES

users; contact NESDIS for more information

(see Appendix A).

NOTE: Array IDs less than 255 are not

transmitted.

1

Page 10

DCP100 DATA COLLECTION PLATFORM

NESDIS

Wallops Station, VA

Computer Base Station

Phone

modem

Phone

ground station has

10 asynchronous

Wallops Station, VA

ground station has

line

10 asynchronous

dial-up circuits

NESDIS

dial circuits

FIGURE 2-1. Data Retrieval Diagram

Antenna cable

Yagi antenna

Transmitter

Data Collection Platform

DCP100

Environmental enclosure

communication/power cable

Datalogger

Power

supply

3. TGT1 TRANSMITTER SPECIFICATIONS

Output level: +40 dBm (10 watts), +1.0 dBm

at 12 VDC with automatic leveling control

Typical current drain: 9 mA quiescent, 2200

mA active

Operating temperature range: −40° to +60°C

Supply voltage range: 10.5 to 14.0 VDC

Dimensions: 3.5" x 7.2" x 4.4" (8.9 x 18.3 x

11.2 cm)

Weight: 2.1 lbs (1.0 kg)

Self-timed buffer: 2000 bytes

Random buffer: 2000 bytes

Transmission rate: 100 bits per second

Typical number of data points transmitted:

118 for a 1 minute transmit-window (with 15

second guard bands)

Maximum EIRP allowed by NESDIS: +50 dB

Antenna's maximum gain: +9 dB with right-

hand circular polarization, +12 dB with linear

polarization.

Clock accuracy: Capable of running 420 days

without adjustment.

4. REQUIRED EQUIPMENT

4.1 COMPUTER BASE STATION

• Phone modem with MNP level 4 error

correction. (Most commercially available

Hayes-compatible modems contain this

error-checking protocol. Check the

operator's manual for your modem).

• Computer with user-supplied communication software (e.g., Procomm Plus,

Crosstalk).

4.2 FIELD STATION

The field stations equipment is illustrated in

Figures 4-1 and 4-2. The required equipment is

listed below.

• TGT1 satellite transmitter.

• Datalogger (CR23X, CR10X, CR500,

CR510, CR10, or 21X). A CR10KD

keyboard/display is required when using a

CR10X, CR10, CR510, or CR500. The

CR10 and 21X require a special PROM.

When using a 21X with both a TGT1 and a

storage module (SM192, SM716, or CSM1),

hardware and datalogger programming

modifications are required. Contact a

Campbell Scientific applications engineer

for more information.

• Yagi antenna, mounting bracket, and

coaxial cable.

• Weather-proof enclosure.

• 12 Volt power supply, charging regulator, and

a solar panel.

The equipment required at the computer base

station is listed below.

2

• A filter is also required when measuring

sensor(s) requiring equalization with the

atmosphere (e.g., vented pressure transducers,

Page 11

barometers). Campbell Scientific’s pn 6832 fits

into one of the enclosure’s compression fittings

to allow pressure equalization between the inside

and outside of the enclosure. The filter retards

the entry of water vapor into the enclosure

protecting the transmitter and measurement

electronics.

DCP100 DATA COLLECTION PLATFORM

12V12V

DIFFSEAGHL AGH LAGH LAG GGE3AG

GGGG

G12V

SERIAL I/O

4 5 6

POWER

789101112

SWITCHED

IN

12V

CAMPBELL

CR10

SCIENTIFIC

INC.

MADE IN USA

WIRING PANEL NO.

SWITCHED

12V

1234 56

SE

CONTROL

EARTH

1 2 3

G5V5VP1P2C8C7C6C5C4C3C2C1

AGHL AGH LAGH LAG GGE1E2

DIFF

INT

BATT

EXT

ON

OFF

CHG

CHG

+12

+12

UNITED D

ASLFJO AKD

U

N

D

DO NOT EAT

IT

E

D

E

ASLFJO AKD

D

ESICC

S

E

S

IC

I P

UNITED DESICCANTS-G

C

U

ANTS-G

A

N

ASLFJO AKD

ASLFJO AKD

N

D

DO NOT EAT

IT

A

T

E

S

D

E

-G

K

D

ATES

A

S

E

.

T

S

E

IC

I P

S

C

A

ASLFJO AKD

N

A

T

S

-G

K

ATES

A

.

T

E

S

thia ia

thia ia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

tryu to read this whoever

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

KALDHFI;O AKJI AI AJHFHO ALDLIFJ

ASLFJO AKD

U

ASLFJO AKD

U

SPECIFICATION MIL-D-3463

N

A

N

S

A

ITED

L

DESI PAK.

S

F

A

L

ITE

J

F

K

S

O

J

L

A

O

A

F

A

J

DO

K

O

L

D

K

A

S

D

D

D

ASLFJO AKD

D

K

DESI PAK.

P

H

D

D

ASLFJO AKD

E

F

N

ES

C

I;O

ESIC

IF

A

S

O

A

A

IC

IC

L

S

KALDHFI;O AKJI AI AJHFHO ALDLIFJ

F

A

L

J

K

F

S

A

ASLFJO AKD

O

T EA

J

UN

L

ASLFJO AKD

C

J

A

O

F

T

ASLFJO AKD

U

A

J

I A

C

K

O

SPECIFICATION MIL-D-3463

IO

D

K

AN

A

A

N

D

S

AN

A

K

I A

ITE

N

L

DESI PAK.

S

D

F

A

L

ITE

ASLFJO AKD

J

M

F

K

S

O

TS-G

J

J

L

A

O

A

T

F

TS-G

H

A

IL

J

D

K

D D

L

O

D

K

F

A

S

D

D

-D

D

H

ASLFJO AKD

O

K

DESI PAK.

P

A

ASLFJO AKD

H

D

D

O

S

-3

A

ASLFJO AKD

E

L

F

S

N

A

F

E

A

A

L

C

4

I;O

J

F

S

A

ESICC

O

J

6

L

TES

IF

SICC

L

A

O

F

A

3

TES

A

J

D

S

K

O

A

A

IC

O

D

L

K

S

A

F

L

A

D

L

J

K

F

K

S

A

IF

O

T E

J

D

L

J

A

O

F

T

A

J

J

I A

K

O

IO

D

AN

K

A

D

ANTS-G

ASLFJO AKD

K

I A

N

D

AT

ASLFJO AKD

M

TS-G

J

H

IL

F

-D

H

A

O

-3

S

A

L

S

A

F

A

A

L

4

J

F

S

A

O

6

J

L

TES

L

A

O

F

3

TES

A

J

D

K

O

D

K

A

L

D

K

IF

D

J

16/18 Enclosure

TGT1

SC925G Cable

CH12R

Antenna Cable

Ground Lug

INT

BATT

EXT

ON

OFF

CHG

CHG

+12

+12

DIFFSEAG H L AG H L AG H L AG GGE3AG

4 5 6

78 9101112

CAMPBELL

SCIENTIFIC

INC.

12 34 56

SE

1 2 3

AG H L AG H L AG H L AG GGE1E2

DIFF

KALDHFI;O AKJI AI AJHFHO ALDLIFJ

ASLFJO

UNITED DESICCANTS-GATES

ASLFJO

ASLFJO

UNITED DESICCANTS-GATES

SPECIFICATION MIL-D-3463

AKD

AKD

DESI PAK.

DO NOT EAT

AKD

ASLFJO AKD

ASLFJO

ASLFJO

AKD

AKD

KALDHFI;O AKJI AI AJHFHO ALDLIFJ

ASLFJO

UNITED DESICCANTS-GATES

ASLFJO

ASLFJO

UNITED DESICCANTS-GATES

SPECIFICATION MIL-D-3463

ASLFJO

AKD

ASLFJO

AKD

DESI PAK.

DO NOT EAT

ASLFJO

AKD

AKD

AKD

AKD

ASLFJO AKD

ASLFJO

ASLFJO

AKD

AKD

ASLFJO

ASLFJO

ASLFJO

AKD

AKD

AKD

UNITED DESICCANTS-GATES

UNITED DESICCANTS-GATES

DESI PAK.

UNITED DESICCANTS-GATES

UNITED DESICCANTS-GATES

DESI PAK.

FIGURE 4-1. A Field Station Monitoring a

Well's Depth (Solar Panel Not Shown)

CR10X

Datalogger

12V12V

G 12V

SERIAL I/O

GGGG

POWER

SWITCHED

IN

12V

CR10

MADE IN USA

WIRING PANEL NO.

SWITCHED

12V

CONTROL

EARTH

G5V5VP1P2 C8C7C6C5C4C3C2C1

thia ia

thia ia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

tryu to read this whoever

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

thia

Optional

Storage

l

M

12 AHr or 24 AHr

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

DO NOT EAT

DO NOT EAT

KALDHFI;O AKJI AI AJHFHO ALDLIFJ

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

KALDHFI;O AKJI AI AJHFHO ALDLIFJ

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

ASLFJO AKD

SPECIFICATION MIL-D-3463

DESI PAK.

SPECIFICATION MIL-D-3463

DESI PAK.

Battery and

Bracket

Desiccant

Compression Fittings

FIGURE 4-2. Inside the Enclosure of a Typical Field Station

3

Page 12

DCP100 DATA COLLECTION PLATFORM

5. POWER SUPPLIES

5.1 12 AND 24 AHR SEALED RECHARGEABLE BATTERIES

Typically, the system is powered with a 12 Volt,

12 AHr sealed rechargeable battery that

connects to a charging regulator and a solar

panel. The 12 AHr battery lasts 15 to 20 days

per charge. A 24 AHr sealed rechargeable

battery which lasts 30 to 40 days is available.

NOTE: This assumes the data are

transmitted for 30 seconds at 3 hour

intervals. The datalogger's scan rate is 1

second, and the sensors have negligible

power consumption.

A discharged 12 AHr battery is recharged by a

10 watt solar panel in 2 to 3 days when there

are a 1000 watts per square meter of

illumination and the solar panel temperature is

25°C. A 20 watt solar panel is available. The

minimum daily battery voltage should be

monitored with datalogger program Instruction

10, and output as a part of the user’s data

stream.

5.2 AC POWER AND DEEP-CYCLE RECHARGEABLE BATTERIES

NOTE: The datalogger's batteries should

be removed when not in use.

Rechargeable batteries should be trickle

charged with either Solar or AC power

through a charging regulator.

6. INSTALLATION

6.1 WIRING

The DCP100 hardware (excluding the battery

and solar panel) and the datalogger are

premounted and prewired. The enclosure's

ground lug must be connected to an

appropriate earth ground (see Table 6.1-1).

6.2 BATTERY

Before installing the battery, turn OFF the

charging regulator’s (CH12R) power switch. To

install the battery, remove the battery bracket

from the DCP100 and insert the battery facing

outward into the bracket. When inserting the 24

AHr battery into its bracket, the battery’s power

connections (posts) go on the top side where a

section of the bracket has been cut away.

Reattach the bracket to the DCP100’s

enclosure, and connect the battery cable (see

Table 6.1-1). The antenna must be connected

to the transmitter before turning on the

CH12R's power switch.

Although either the 12 or 24 AHr battery is

sufficient for most systems, applications with

high current drain sensors or peripherals (e.g.,

SDM devices) might require AC power or a

user-supplied deep-cycle rechargeable battery

that is trickle-charged with a 20 Watt solar

panel. Campbell Scientific's power supply

brochure and application note provide

information about determining your system's

power requirements.

5.3 DATALOGGER'S BATTERIES

The transmitter's power consumption is too high

for alkaline batteries. The 21XL's rechargeable

batteries do not source sufficient current for the

transmitter. Although the PS12LA 7 AHr battery

can power the transmitter, the battery only lasts

3 to 7 days per charge. One option is to have

the datalogger's batteries power the datalogger

and sensors, while the transmitter uses a 12

AHr battery, a 24 AHr battery, or a deep-cycle

battery.

6.3 ANTENNA

You mount the antenna to a tripod, tower, or

vertical 1.5" OD pipe (see Figures 6.3-1 through

6.3-3). The antenna is then oriented towards

the satellite by using a computer program (see

Appendix C). This program prompts you for the

satellite's longitude (provided by NESDIS) and

the antenna's longitude, latitude, and height. It

then calculates the antenna's elevation and

azimuth (see Figure 6.3-4). You must also

account for local magnetic declination (see

Appendix G).

After the antenna is properly oriented, insert the

antenna cable into the enclosure's largest

compression fitting and connect the cable to the

transmitter.

CAUTION: The antenna must be connected

before transmission or the transmitter will be

damaged.

4

Page 13

TABLE 6.1-1 Wiring Diagram

GOESBKT2

(satellite)

SC925G Cable

25-Pin connector connects to TGT1 I/O port

Black connects to CH12R

Red connects to CH12R +12 Terminal

9-Pin connector connects to datalogger I/O port

Antenna Cable

BNC male connector connects to TGT1 BNC

female port

Red Cable

Connects to CH12R +12 and datalogger 12 V

(Ground)

DCP100 DATA COLLECTION PLATFORM

Black Cable

Connects to CH12R and datalogger G (Ground)

Green Cable

Connects to datalogger G (Ground) and is

routed through the enclosures ground lug

and connected to earth ground

Battery

Connects to CH12R INT white connector

Solar Panel

Black and white leads connect to the two

CH12R CHG Ports. Polarity does not

matter.

FIGURE 6.3-1. Antenna Mounting

Hardware, Exploded View

5

Page 14

DCP100 DATA COLLECTION PLATFORM

Fits onto the

1.5" OD pipe

Fits onto the

1.5" OD pipe

FIGURE 6.3-2. Antenna Mounting Hardware,

Assembled View 1

FIGURE 6.3-3. Antenna Mounting Hardware,

Assembled View 2

6

Page 15

DATA

COLLECTION

PLATFORM

ANTENNA

DCP100 DATA COLLECTION PLATFORM

GOES SATELLITE

(22,300 miles)

36 (Elevation Angle)

E

(90 )

EXAMPLE ORIENTATION

N

(360 )

S (180 )

213 (Azimuth Angle)

W

(270 )

FIGURE 6.3-4. Example Antenna Orientation Diagram

7. FORWARD AND REFLECTED POWER

Forward and reflected power are measured (in

decimal units) and updated during each

transmission (see Sections 8 and 9). The

forward power must be between 165 and 215

for the transmitter's output level to be within

specifications. The antenna/cable assembly is

operating properly when the percentage of

power reflected is less than 5. A reflected

power reading of 27 is 5% of 165 and 2.7% of

215.

This percentage can be estimated with the

following equation (see the datalogger program

in Appendix D.3).

When the percentage of power reflected is

greater or equal to 5, one or more of the

following situations exist and must be corrected:

• The antenna is not connected.

• The antenna is too close to metal.

• You are transmitting inside a building.

• The antenna is covered with snow or ice.

• The frequency that the antenna is tuned to

does not match the transmitter's frequency.

• There is a problem with the coaxial cable

connector or connection.

• There is a problem with the antenna cable.

% power reflected =

[((ref + 17.4)/(fwd + 17.4))

2

x 100] - 1

7

Page 16

DCP100 DATA COLLECTION PLATFORM

8. PROGRAMMING THE TRANSMITTER

8.1 STAR POUND MODE

The star/pound (*#) mode is for programming the

transmitter. It establishes and edits parameters,

displays status information, and performs test

transmissions. The *# mode can only be

accessed via a keyboard/display (not with a

computer).

NOTE: *# mode cannot be accessed

without a P120 instruction in the program

table.

8.2 ESTABLISHING AND EDITING PARAMETERS

The parameters set the transmitter's clock and

define the address, transmission intervals, and

uplink channels (see Table 8.2-1). The

parameters are temporarily stored in the

datalogger. The clock parameters are transferred

to the TGT-1 after parameter 3 is entered with the

“A” key. The remaining parameters are

transferred to the TGT-1 after parameter 26 is

entered with the “A” key. If the keyboard/display

sits idle for 2 minutes, the datalogger will discard

all changes that have not been transferred to the

TGT-1.

Before establishing the parameters, type in *0.

The display should show only LOG, not LOG1,

LOG2, or LOG12.

CAUTION: The *# mode will not run when

*1 and *2 are active, therefore their scan

rates must be set to zero.

Enter the *# mode by typing in *#. The colon

disappears during the upload process and

reappears when the process is complete. 12:00

is displayed when you are in *# mode. Press A

to edit parameters. 01: is then displayed

indicating the datalogger is ready for parameter

1. You type an A to store each parameter and

to advance to the next one. Individual

parameters can also be edited by typing in *#

and the parameter number. Remember, the

TGT-1 clock is not changed until the “A” key is

pressed after the 3

changes are saved until the “A” key is pressed

after the 26

th

rd

parameter. No other

parameter.

TABLE 8.2-1. *# Parameter's Descriptions

Parameter Description

1 - 3 Set the transmitter's clock. All

scheduled operations are referenced to this clock. Because

timing is critical, it must be set to

Coordinated Universal Time (CUT).

CUT can be obtained by calling the

WWV or WWVH time services (call

(303) 499-7111 for WWV time and

(808) 335-4363 for WWVH). The

clock must be reset at least once a

year. Parameter 1 is hours; 2 is

minutes and 3 is seconds. The

TGT-1 clock is set and starts to run

when the “A” key is pressed after

rd

parameter. Note: This is a

the 3

24-hour format.

4 - 11 The NESDIS-assigned address.

Convert the letters in the address to

their decimal equivalent (Table 8.2-2).

For example when the address is

0104C186, parameters 4 through 11

are the following:

Parameter Number User Types

04: 0 A

05: 1 A

06: 0 A

07: 4 A

08: 12 A

09: 1 A

10: 8 A

11: 6 A

12 NESDIS-assigned self-timed uplink

channel (see Appendix E channel/

frequency correlation). If not assigned

a self-timed channel, type in zeros.

13 NESDIS-assigned random uplink

channel (see Appendix E for channel/

frequency correlation). If not assigned a

random channel, type in zeros.

14 - 17 Self-timed transmission interval is

NESDIS-assigned and usually 3 or 4

hours (minimum interval is 15 minutes).

Parameter 14 is days; 15 is hours; 16 is

minutes and 17 is seconds. Note: This

is a 24-hour format.

8

Page 17

DCP100 DATA COLLECTION PLATFORM

18 - 20 Random transmission interval (the

NESDIS-assigned time period that

the transmission is randomly repeated, minimum interval is 5

minutes). Parameter 18 is hours; 19

is minutes and 20 is seconds.

21 - 23 Set the time of the initial self-timed

transmission (NESDIS-assigned).

The “initial” time is not the first time

but an offset. Self-timed

transmissions occur on multiples of

the self-timed transmission interval

plus the offset. Parameter 21 is

hours; 22 is minutes and 23 is

seconds. Note: This is a 24-hour

format.

24 Transmit window length is NESDIS-

assigned and usually 1 minute.

Type 0 for a 1 minute window or 1

for a 2 minute window. The

transmission is automatically

centered around the middle of the

transmit window.

25 Sets the preamble length. In

general, type 0 to use a short

preamble (0.98 seconds) for

stationary land based stations.

Random mode requires the short

preamble. Type 4 for a long

preamble (7.3 seconds). A long

preamble increases the time the

satellite can lock onto the signal but

reduces the time for transmitting

data.

26 Selects the buffer or buffers used.

Type 1 to select only the self-timed

buffer, a 2 to select only the random,

and a 3 to select both buffers. These

buffers must match Instruction 120's

parameters (see Section 9).

TABLE 8.2-2 Decimal Equivalent

Number Decimal

or letter equivalent

11

22

33

44

55

66

77

88

99

A10

B11

C12

D13

E14

F15

8.3 STATUS INFORMATION AND TEST TRANSMISSIONS

The *#60 mode is for displaying status information and performing test transmissions. *#60

mode is entered by typing *#60A. The

execution interval must be set to zero in table 1

and 2. You perform each command by typing

the command number (see Table 8.3-1) and an

A. Multiple parameter commands require

typing an A to advance to the next parameter.

8.4 ERROR MESSAGES

There are two error messages. The E101

message appears after the user types *# and

indicates the transmitter is not communicating

with the datalogger (i.e., TGT1 is not powered

or connected to datalogger). E102 appears

after a parameter is entered incorrectly.

TABLE 8.3-1 *#60 Commands

Command

Number Description

1 Displays the current TGT-1 time;

hours, minutes, and seconds are the

parameters. The TGT-1 time is

retrieved when the “A” key is pressed.

2 The amount of time until the next

transmission of the active buffer;

parameters are days, hours, minutes,

and seconds. If [31:31:63:63] is

displayed, the active buffer contains

no data. The time is retrieved when

9

Page 18

DCP100 DATA COLLECTION PLATFORM

the “A” key is pressed. The active

buffer is set using command 7 and 8.

3 Forward power is the first parameter

and reflected power is the second (see

Section 7).

4 The first parameter displays the

number of errors. Parameters 2-9 list

the history of errors, where parameter

2 is the most recent (see Section 8.4).

5 Number of bytes in self-timed or

random buffer (used after command

6 or 7).

6 Selects self-timed buffer (used before

command 5).

7 Selects random buffer (used before

command 5).

8 Initiates test transmission of data in

the random buffer. You must be

assigned a random channel (see *#

parameter 13) or obtain from NESDIS

a channel for testing. The random

buffer must contain data. The TGT-1

will not perform a test transmission

more often then once each minute.

Clear the random buffer before final

TGT-1 setup. Appendix F contains a

datalogger program that dumps data

into the random buffer.

TABLE 9.1-1 CR10X, CR10, CR510 and

CR500’s Instruction Parameters

01: ABC Where: A = 0 binary mode (3-bytes

per data point)

A = 1 ASCII mode (7-bytes

per data point)

B = 0 self-timed buffer

B = 1 random buffer

C = 0 appends the new data

to the old data

C = 1 writes over the old data

02: z Where: z > 0 Starting input location

for the forward power

reading (see Section

7). The next input

location automatically

contains the reflected

power reading (e.g.,

when the forward

power's input location

is 10, the reflected

power's input location

is 11). By placing

these readings into

input locations, you can

sample and output the

forward and reflected

power as part of the

data stream

(Instruction 70).

9. PROGRAMMING THE DATALOGGER

9.1 CR10X, CR10, CR510, AND CR500

9.1.1 Instruction

CR10X, CR500, and CR510 dataloggers

contain program Instruction 120 which transfers

the final storage data to the transmitter's buffer

and designates locations for the

forward/reflected power. The CR10s use

Instruction 99 instead of Instruction 120. The

CR10 Instruction 99 and CR10X Instruction 120

are identical except for the instruction number.

This instruction also automatically compares

the datalogger to the transmitter clock. If the

clocks differ more than 3 seconds, the

datalogger's clock is set to the transmitter's.

However, only the seconds are compared.

Therefore, the datalogger's clock is NOT reset

when the minutes or hours differ. The complete

time (HH:MM:SS) will be updated if the clocks

differ by more than 3 seconds. Table 9.1-1 lists

and describes Instruction 120's parameters.

z = 0 The forward and

reflected power

readings are NOT

placed into input

locations.

NOTE: The ASCII option (1xx) requires

approximately 7 bytes per data point which

is double the number of bytes required for

the binary option (0xx). This is a convenient

method of sending data since no postprocessing conversion is required.

However, the required transmission time for

ASCII is doubled. With a typical

transmission window of one-minute, you

can send up to 59 data points in ASCII or

118 data points in binary (this allows 15

second guard bands before and after

transmission to allow for normal clock drift).

10

Page 19

DCP100 DATA COLLECTION PLATFORM

9.1.2 Datalogger Programming Theory

Campbell Scientific dataloggers are

programmed via a keyboard/display or an IBMPC compatible computer running PC208

software. Please see the appropriate

datalogger manual for detailed programming

information.

To transmit two different arrays the datalogger's

program must have this structure:

Set Output Flag 0 high (10) based on condition 1

Output Processing Instructions

Conditional Statement; if true “Then Do”

(Command Code 30)

P120 Data transfer to TGT1

Set Output Flag 0 high (10) based on

condition 2

Output Processing Instructions

Conditional Statement; if true “Then Do”

(Command Code 30)

P120 Data Transfer to TGT1

Table 9.1-2 illustrates the correct programming

structure.

TABLE 9.1-2 CR10X Example Program

This example makes a thermocouple and

battery voltage measurement and sends data to

the TGT1's buffer only when the CR10X

generates an output.

NOTE: Use a conditional statement (i.e.,

Instruction 92) to transfer data only when

there is an output to final storage.

;

*Table 1 Program

01: 10.0 Execution Interval

(seconds)

;Measure reference temperature.

01: Internal Temperature (P17)

1: 1 Loc [ RefTemp ]

;Measure thermocouple temperature.

02: Thermocouple Temp (DIFF) (P14)

1: 1 Reps

2: 1 ± 2.5 mV Slow Range

3: 5 DIFF Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp Loc [ RefTemp ]

6: 2 Loc [ TCDeg_C ]

7: 1 Mult

8: 0 Offset

;Measure battery voltage every 10 seconds.

03: Batt Voltage (P10)

1: 3 Loc [ Battery ]

;Set Output Flag High (10) for hourly data (user

defined).

04: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High

;Timestamp data

05: Real Time (P77)

1: 220 Day,Hour/Minute (prev day

at midnight, 2400 at

midnight)

;Output hourly the average reference Temp, TC

Temp, and battery voltage.

06: Average (P71)

1: 3 Reps

2: 1 Loc [ RefTemp ]

;Sample the forward and reflected power.

07: Sample (P70)

1: 2 Reps

2: 4 Loc [ FwdPwr ]

;Transfer data to TGT1 every hour.

08: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as

above)

3: 30 Then Do

;Transfer datalogger's final storage data to the

TGT1, read the transmitter's latest forward and

reflected power readings, and place the results

in two sequential input locations.

09: Data Transfer to GOES (P120)

1: 00 Buffer Selection

2: 4 FWD/Ref Power Loc

[ FwdPwr ]

10: End (P95)

11

Page 20

DCP100 DATA COLLECTION PLATFORM

;Set Output Flag High (10) for daily output.

11: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1440 Interval (same units as

above)

3: 10 Set Output Flag High

;Timestamp data

12: Real Time (P77)

1: 220 Day,Hour/Minute (prev day

at midnight, 2400 at

midnight)

;Average, maximize, and minimize the reference

and thermocouple temperatures, the battery

voltage, and the forward and reflected power

readings.

13: Average (P71)

1: 5 Reps

2: 1 Loc [ RefTemp ]

14: Maximize (P73)

1: 5 Reps

2: 0 Value Only

3: 1 Loc [ RefTemp ]

15: Minimize (P74)

1: 5 Reps

2: 0 Value Only

3: 1 Loc [ RefTemp ]

is used in place of the Star Pound Mode (*#).

P123 will transfer all the information needed to

properly transmit data via the TGT-1 satellite

transmitter. The information is assigned by

NESDIS. See table 9.2-1 for a complete

description of each parameter of P123.

P123 is only available on CR10X dataloggers

with version 1.6 operating system or later,

CR500 dataloggers with version 1.4 or later,

and all CR23X and CR510 dataloggers.

NOTE: P123 should only be run once.

See program example for one way to run P123.

Some guidelines for using P123:

1. Before the datalogger is connected to the

TGT-1, the datalogger clock must be set to

“Coordinated Universal Time”.

2. P123 should only be run once, usually the

first time through Program Table 1.

3. P123 will not execute properly if the keypad

is in communications with the datalogger. If

the keypad is connected to the logger, the

keypad display must show “LOG 1” or

“LOG12”.

4. P123 will not execute properly if the

datalogger is connected to a PC.

;Sends data to TGT1 once a day. Note: this is

set for 5 minutes after midnight to give ample

transfer time for the hourly data initiated by the

P120 in instruction 09.

16: If time is (P92)

1: 5 Minutes (Seconds --) into a

2: 1440 Interval (same units as

above)

3: 30 Then Do

17: Data Transfer to GOES (P120)

1: 00 Buffer Selection

2: 4 FWD/Ref Power Loc [

FwdPwr ]

18: End (P95)

9.2 PROGRAM INSTRUCTION 123 - TGT-1 AUTO SETUP

9.2.1 Functional Description

The program instruction P123 is used for

automatic setup of the TGT-1. This instruction

12

5. P123 requires about 8 seconds to execute.

To avoid table overrun errors, program

table execution rate should not be less then

10 seconds.

6. After the initiation of P123 the datalogger

and TGT-1 should not be interrupted for 1

minute or 2 times the execution rate,

whichever is longer.

7. The hardware must be completely setup

before power is applied to the system.

Page 21

DCP100 DATA COLLECTION PLATFORM

TABLE 9.2-1. P123 Parameter Descriptions

Parameter

Number Description

1 - 8 The NESDIS-assigned address.

Convert the letters in the address to

their decimal equivalent (Table 8.2-

2). Each digit of the address is

placed in one parameter.

09 NESDIS-assigned self-timed uplink

channel (see Appendix E channel/

frequency correlation). If not assigned

a self-timed channel, type in zeros.

10 NESDIS-assigned random uplink

channel (see Appendix E for

channel/ frequency correlation). If

not assigned a random channel,

type in zeros.

11 - 14 Self-timed transmission interval is

NESDIS-assigned and usually 3 or 4

hours. Parameter 11 is days, 12 is

hours, 13 is minutes, and 14 is seconds.

Note: This is a 24-hour format.

15 - 17 Random transmission interval (the

NESDIS-assigned time period that

the transmission is randomly

repeated). Parameter 15 is hours,

16 is minutes, and 17 is seconds.

18 - 20 Set the time of the initial self-timed

transmission (NESDIS-assigned).

Parameter 18 is hours, 19 is

minutes, and 20 is seconds. Note:

This is a 24-hour format.

21 Transmit window length is NESDIS-

assigned and usually 1 minute.

Type 0 for a 1 minute window or 1

for a 2 minute window.

22 Sets the preamble length. A long

preamble increases the time the

satellite can lock onto the signal but

reduces the time for transmitting

data. The random mode requires

the short preamble. For a long

preamble (7.3 seconds), type 4.

For a short preamble (0.98

seconds), type 0.

23 Selects the buffer or buffers used.

Type 1 to select only the self-timed

buffer, a 2 to select only the

random, and a 3 to select both

buffers. These buffers must match

Instruction P120 parameters (see

Section 9).

Program example using P123 instruction

This is not the only way to run P123. The

programming theory used in this example is as

follows. Using a P91 statement determine if

Flag x is low, if true set Flag x high and execute

P123. When the datalogger is powered up all

Flags are automatically set low. The datalogger

will detect that Flag 1 is low, set Flag 1 high,

and execute P123. If power is lost, P123 will

automatically be executed when power is

restored.

In this example the datalogger will configure the

TGT-1 transmitter to use the NESDIS assigned

address of “0104C186”, interval or self-timed

channel number 151, with a 1 minute window

every 4 hours. Preamble will be set to short.

The random channel is not used.

1: If Flag/Port (P91)

1: 21 Do if Flag 1 is Low

2: 30 Then Do

2: Do (P86)

1: 11 Set Flag 1 High

3: Automatic Setup of TGT1 (P123)

1: 0 Address

2: 1 Address

3: 0 Address

4: 4 Address

5: 12 Address

6: 1 Address

7: 8 Address

8: 6 Address

9: 151 Assigned Uplink Channel

10: 0 Random Uplink Channel

11: 0 Self-timed Interval Days

12: 4 Self-timed Interval Hours

13: 0 Self-timed Interval Minutes

14: 0 Self-timed Interval Seconds

15: 0 Random Interval Hours

16: 0 Random Interval Minutes

17: 0 Random Interval Seconds

18: 1 Initial Self-timed Hours

19: 33 Initial Self-timed Minutes

20: 0 Initial Self-timed Seconds

21: 0 One Minute Window

22: 0 Short Preamble

23: 1 Self-Timed Buffer

4: End (P95)

13

Page 22

DCP100 DATA COLLECTION PLATFORM

9.3 21X

9.3.1 Instruction 99 Theory

The 21X's Instruction 99 is the same as the

CR10X’s Instruction 120, except there is an

extra parameter that specifies the array of data

that is transferred to the TGT1 buffer.

Instruction 99 also automatically compares the

datalogger and transmitter's clocks. If the

clocks differ more than 3 seconds, the

datalogger's clock is set to the transmitter's.

However, only the seconds are compared;

therefore, the datalogger's clock is not reset

when the minutes or hours differ. The complete

time (HH:MM:SS) will be uploaded to the 21X if

the clocks differ by more than 3 seconds. Table

9.3-1 lists and describes Instruction 99’s

parameters.

TABLE 9.3-1 21X's Instruction 99

Parameters

01: xy Where: x = 0 self-timed buffer

x = 1 random buffer

y = 0 appends the new data to

the old data

y = 1 writes over the old data

03: ID Where: ID>0 The array ID for the data

that is transferred to the

TGT1's buffer.

9.3.2 Datalogger Programming Theory

Campbell Scientific dataloggers are

programmed via a keyboard/display or an IBMPC compatible computer running PC208

software. Please see your 21X manual for

detailed programming information.

To transmit two different arrays the datalogger's

program must have this structure:

Set Output Flag 0 high (10) based on

condition 1

Output Processing Instructions

Conditional Statement; if true “Then Do”

(Command Code 30)

P99 Data transfer to TGT1

Set Output Flag 0 high (10) based on

condition 2

Output Processing Instructions

Conditional Statement; if true “Then Do”

(Command Code 30)

P99 Data Transfer to TGT1

02: z Where: z>0 Starting input location for

the forward power

reading (see Section 7).

The next input location

automatically contains

the reflected power

reading (e.g., when the

forward power's input

location is 10, the

reflected power's input

location is 11). By

placing these readings

into input locations, you

can sample and output

the forward and reflected

power as part of the data

stream (21X Instruction

70).

z = 0 The forward and

reflected power readings

are NOT placed into

input locations.

Also, when a storage module is connected,

special datalogger programming and a serial

cable for the storage module are required;

contact a Campbell Scientific applications

engineer for more information.

Table 9.3-2 illustrates the correct programming

structure.

TABLE 9.3-2 21X Example Program

This 21X program measures the battery

voltage, performs a thermocouple

measurement, and transfers an array of data to

the TGT1's self-timed buffer.

NOTE: Use a conditional statement (i.e.,

Instruction 92) to transfer data only when

there is an output to final storage.

14

Page 23

DCP100 DATA COLLECTION PLATFORM

;{21X}

;

*Table 1 Program

01: 10.0 Execution Interval

(seconds)

;Measure reference temperature.

01: Internal Temperature (P17)

1: 1 Loc [ RefTemp ]

;Measure thermocouple temperature.

02: Thermocouple Temp (DIFF) (P14)

1: 1 Reps

2: 1 ± 5 mV Slow Range

3: 5 DIFF Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp Loc [ RefTemp ]

6: 2 Loc [ TCDef_F ]

7: 1.8 Mult

8: 32 Offset

;Measure battery voltage every 10 seconds.

03: Batt Voltage (P10)

1: 3 Loc [ Battery ]

;Set Output Flag High (10) every hour

04: If time is (P92)

1: 0 Minutes into a

2: 60 Minute Interval

3: 10 Set Output Flag High

;Transfer data to TGT1 every hour.

09: If time is (P92)

1: 0 Minutes into a

2: 60 Minute Interval

3: 30 Then Do

;Transfer data array ID 111 to the TGT1's selftimed buffer and places the transmitter's latest

forward and reflected power readings into Input

Locations 4 and 5.

10: Data Transfer to GOES (P99)

1: 00 Buffer Selection

2: 4 FWD/Ref Power Loc

[ FwdPwr ]

3: 111 Array ID (ID>0) Transferred

to TGT1'S Buffer

11: End (P95)

;Set Output Flag High (10) for daily output

12: If time is (P92)

1: 0 Minutes into a

2: 1440 Minute Interval

3: 10 Set Output Flag High

;Timestamp data

13: Real Time (P77)

1: 220 Day,Hour/Minute (prev day

at midnight, 2400 at

midnight)

;Designate 111 as ID for hourly data

05: Set Active Storage Area (P80)

1: 1 Final Storage

2: 111 Array ID or Loc

[ _________ ]

;Timestamp data

06: Real Time (P77)

1: 220 Day,Hour/Minute (prev day

at midnight, 2400 at

midnight)

;Output hourly the average reference Temp, TC

Temp, and battery voltage.

07: Average (P71)

1: 3 Reps

2: 1 Loc [ RefTemp ]

;Sample the forward and reflected power.

08: Sample (P70)

1: 2 Reps

2: 1 Loc [ RefTemp ]

;Designate 222 as the array ID.

14: Set Active Storage Area (P80)

1: 1 Final Storage

2: 222 Array ID or Loc

[ _________ ]

;Average, maximize, and minimize the reference

and TC temperatures, battery voltage, and the

forward and reflected power readings.

15: Average (P71)

1: 5 Reps

2: 1 Loc [ RefTemp ]

16: Maximize (P73)

1: 5 Reps

2: 0 Value Only

3: 1 Loc [ RefTemp ]

17: Minimize (P74)

1: 5 Reps

2: 0 Value Only

3: 1 Loc [ RefTemp ]

;Sends data to the TGT1 once a day. Note: this

is set for 5 minutes after midnight to give ample

15

Page 24

DCP100 DATA COLLECTION PLATFORM

transfer time for the hourly data initiated by the

P99 in instruction 10.

18: If time is (P92)

1: 5 Minutes into a

2: 1440 Minute Interval

3: 30 Then Do

19: Data Transfer to GOES (P99)

1: 00 Buffer Selection

2: 4 FWD/Ref Power Loc

[ FwdPwr ]

3: 222 Array ID (ID>0) Transferred

to TGT1'S Buffer

20: End (P95)

16

Page 25

APPENDIX A. INFORMATION ON ELIGIBI LI TY AND GETTING ONTO

THE GOES SYSTEM

A.1 ELIGIBILITY

U.S. federal, state, or local government

agencies, or users sponsored by one of those

agencies, may use GOES. Potential GOES

users must receive formal permission from

NESDIS.

A.2 ACQUIRING PERMISSION

1. The user contacts NESDIS at the following

address and submits a formal request to

transmit data via GOES. Non-U.S. or

private users must also submit a written

statement indicating that their sponsor

requires all or part of the transmitted data.

NESDIS will fax or mail the user a question

form to complete and submit for approval.

Mr. Marlin Perkins

NOAA/NESDIS

E/PS, Room 3320

4700 Silver Hill Road

Stop 9909

Washington, D.C. 20233-9909

Phone (301) 457-5681

FAX (301) 457-5620

Beacon Registration 888-212-7283

Email mperkins@nesdis.noaa.gov

2. Following approval, NESDIS sends a

Memorandum of Agreement (MOA). The

MOA must be signed and returned to

NESDIS.

3. After the MOA is approved, NESDIS will

issue a channel assignment and an ID

address code. The user must then submit

Application Form 442 and Form 159/159-C

to the Federal Communications

Commission (FCC) to acquire an FCC

license. To order these forms, call

(800) 418-3676, or access their web site,

http://www.fcc.gov.

4. After an FCC license is acquired, NESDIS

MUST BE contacted to coordinate a “startup” date.

A-1

Page 26

Page 27

APPENDIX B. DATA CONVERSION COMPUTER PROGRAM

(WRITTEN IN BASIC)

1 REM THIS PROGRAM CONVERTS 3-BYTE ASCII DATA INTO DECIMAL

5 INPUT "RECEIVE FILE?", RF$

6 OPEN RF$ FOR OUTPUT AS #2

10 INPUT "NAME OF FILE CONTAINING GOES DATA"; NFL$

20 DIM DV$(200)

25 WIDTH "LPT1:", 120

30 OPEN NFL$ FOR INPUT AS #1

40 WHILE NOT EOF(1)

50 LINE INPUT #1, A$

55 A$ = MID$(A$, 38)

56 PRINT A$

100 J = INT(LEN(A$) / 3)

105 PRINT J

110 FOR I = 1 TO J

120 DV$(I) = MID$(A$, 3 * I - 2, 3)

130 NEXT I

140 B$ = RIGHT$(A$, LEN(A$) - 3 * J)

160 A$ = B$ + A$

170 K = INT(LEN(A$) / 3)

180 L = J

190 FOR I = J + 1 TO L

200 DV$(I) = MID$(A$, 3 * (I - J) - 2, 3)

210 NEXT I

270 FOR I = 1 TO L

280 A = ASC(LEFT$(DV$(I), 1)) AND 15

290 B = ASC(MID$(DV$(I), 2, 1)) AND 63

300 C = ASC(RIGHT$(DV$(I), 1)) AND 63

310 IF (A * 64) + B >= 1008 THEN DV = (B - 48) * 64 + C + 9000: GOTO 400

320 IF A AND 8 THEN SF = -1 ELSE SF = 1

330 IF A AND 4 THEN SF = SF * .01

340 IF A AND 2 THEN SF = SF * .1

350 IF A AND 1 THEN DV = 4096

360 DV = (DV + ((B AND 63) * 64) + (C AND 63)) * SF

400 PRINT #2, USING "####.### "; DV;

405 IF I MOD 17 = 0 THEN PRINT #2, CHR$(13)

406 DV = 0

410 NEXT I

1000 WEND

B-1

Page 28

Page 29

APPENDIX C. ANTENNA ORIE NTATION COMPUTER PROGRAM

(WRITTEN IN BASIC)

5 REM THIS PROGRAM CALCULATES THE AZIMUTH AND ELEVATION FOR AN

6 REM ANTENNA USED WITH A DCP FOR GOES SATELLITE COMMUNICATIONS

10 CLS : CLEAR 1000

20 INPUT "SATELLITE LONGITUDE (DDD.DD)"; SO

30 INPUT "ANTENNA LONGITUDE (DDD.DD)"; SA

40 PRINT "ANTENNA LATITUDE (DDD.DD)--(SOUTH LATITUDE ENTERED"

45 INPUT "AS NEGATIVE NUMBER)"; AA: A = 90 - AA

50 INPUT "ANTENNA HEIGHT ABOVE SEA LEVEL IN FEET"; AH

60 T = SO - SA: TR = T * .01745329#: BR = 90 * .01745329#: AR = A * .01745329#

70 X = COS(AR) * COS(BR) + SIN(AR) * SIN(BR) * COS(TR)

80 CR = -ATN(X / SQR(-X * X + 1)) + 1.5708

90 C = CR * (1 / .01745329#)

100 X1 = (SIN(BR) * SIN(TR)) / SIN(CR)

110 BR = ATN(X1 /SQR(-X1 * X1 + 1)): B = BR * (1 / .01745329#)

115 GOSUB 300

120 A1 = 90 - C: R1 = A1 * .01745329#

130 S1 = (6378 + (AH * .0003048)) / SIN(R1)

140 S2 = 35785! + 6378 - S1

150 A2 = 180 - A1: R2 = A2 * .01745329#

155 S4 = SQR(S1 ^ 2 - (6378 + AH * .0003048) ^ 2)

160 S3 = SQR(S4 ^ 2 + S2 ^ 2 - 2 * S4 * S2 * COS(R2))

170 X2 = (SIN(R2) / S3) * S2

180 ER = ATN(X2 / SQR(-X2 * X2 + 1)): E = ER * (1 / .01745329#)

190 PRINT "ANTENNA ELEVATION ANGLE="; E; " DEGREES"

200 PRINT "ANTENNA AZIMUTH ANGLE="; B; " DEGREES"

210 PRINT : PRINT : PRINT "HIT ANY KEY TO CONTINUE"

220 I$ = INKEY$: IF I$ = "" THEN 220 ELSE CLS : GOTO 20

300 IF T < 0 AND AA > 0 THEN B = B + 180: GOTO 380

310 IF T < 0 AND AA < 0 THEN B = B * -1: GOTO 380

320 IF T > 0 AND AA < 0 THEN B = 360 - B: GOTO 380

330 IF T > 0 AND AA > 0 THEN B = B + 180: GOTO 380

340 IF T = 0 AND AA > 0 THEN B = 180: GOTO 380

350 IF T = 0 AND AA < 0 THEN B = 360: GOTO 380

360 IF AA = 0 AND T > 0 THEN B = 270: GOTO 380

370 IF AA = 0 AND T < 0 THEN B = 90

380 RETURN

400 RETURN

460 RETURN

C-1

Page 30

Page 31

APPENDIX D. DETAILED FORWARD/REFLECTED

POWER INFORMATION

D.1 IMPEDANCE MATCHING

The reflected power to forward power ratio

shows the degree of impedance match between

the transmitter and the cable/antenna assembly.

The percent of power reflected approximates

the impedance match with the following

equation:

% power reflected = [((ref + 17.4)/(fwd + 17.4))

x 100] - 1

This equation is an approximation because

some of the power reflected to the transmitter

can be reflected back to the antenna and then

reflected back to the transmitter. These

multiple reflections can cause incorrect

readings, especially when the reflected

power is large.

Impedance matching is also measured as

reflection coefficient (Γ), Voltage Standing

Wave Ratio (VSWR), and Return Loss (RL).

Table D.1-1 correlates values between the

different measurements.

Table D.1-1. Impedance Matching

Correlation

% power ref

Γ VSWR

1 0.1 1.2 20

2 0.14 1.3 17

5 0.22 1.6 13

10 0.32 1.9 10

20 0.44 2.6 7

50 0.71 5.8 3

80 0.89 17.9 1

D.2 CALCULATING POWER-OUT

RL

TABLE D.2-1. P

FWD P

110 +35.9

130 +37.2

150 +38.3

165 +39.0

2

175 +39.5

185 +39.9

195 +40.4

205 +40.8

215 +41.1

230 +41.7

250 +42.4

D.3 IMPEDANCE MATCH

DATALOGGER PROGRAM

D.3.1 CR10X, CR10, CR510, AND CR500

This example calculates the percent of power

reflected and the amount of power going out to

the transmitter if the percent of power reflected

is less than 5.

;

*Table 1 Program

01: 10.0 Execution Interval

(seconds)

;USER DEFINED PROGRAM

;Calculate the percent of power reflected with

this equation: % power reflected = [((ref

+17.4)/(fwd + 17.4))^2 x 100] -1

01: Z=X+F (P34)

1: 5 X Loc [ RefPwr ]

2: 17.4 F

3: 8 Z Loc [ RefPlus ]

Values

out

(dBm)

out

The amount of power going out of the

transmitter at the BNC connector is

approximated by the following equation:

Approx P

0.0100077)

= (10 log[((fwd + 17.4) x

out

2

x 1000/50]) + 20.8

This equation assumes the dBm is 50 ohms

and the impedance match between the transmitter and the cable/antenna assembly is good

(% power reflected less than 5). Table D.2-1

lists P

for various values of forward power.

out

02: Z=X+F (P34)

1: 4 X Loc [ FwdPwr ]

2: 17.4 F

3: 9 Z Loc [ FwdPlus ]

03: Z=X/Y (P38)

1: 8 X Loc [ RefPlus ]

2: 9 Y Loc [ FwdPlus ]

3: 10 Z Loc [ Scratch1 ]

D-1

Page 32

APPENDIX D. DETAILED FORWARD/REFLECTED POWER INFORMATION

04: Z=X*Y (P36)

1: 10 X Loc [ Scratch1 ]

2: 10 Y Loc [ Scratch1 ]

3: 10 Z Loc [ Scratch1 ]

05: Z=X*F (P37)

1: 10 X Loc [ Scratch1 ]

2: 100 F

3: 10 Z Loc [ Scratch1 ]

06: Z=X+F (P34)

1: 10 X Loc [ Scratch1 ]

2: -1 F

3: 7 Z Loc [ PerRef ]

;Calculate the amount of forward power going

out to the transmitter if the % reflected is less

than 5.

07: IF (X<=>F) (P89)

1: 7 X Loc [ PerRef ]

2: 4 <

3: 5 F

4: 30 Then Do

08: Z=F (P30)

1: 99.923 F

2: 0 Exponent of 10

3: 11 Z Loc [ Scratch2 ]

09: Z=1/X (P42)

1: 11 X Loc [ Scratch2 ]

2: 11 Z Loc [ Scratch2 ]

15: Z=X+F (P34)

1: 11 X Loc [ Scratch2 ]

2: 20.8 F

3: 6 Z Loc [ Fwd_dBm ]

16: Else (P94)

17: Z=F (P30)

1: 0 F

2: 0 Exponent of 10

3: 6 Z Loc [ Fwd_dBm ]

18: End (P95)

;Set the Output Flag High (10) every hour

19: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High

;Timestamp hourly data

20: Real Time (P77)

1: 220 Day,Hour/Minute (prev

day at midnight, 2400

at midnight)

;Sample the percent of power reflected and the

forward power in dBm.

21: Sample (P70)

1: 2 Reps

2: 6 Loc [ dBmFwd ]

10: Z=X*Y (P36)

1: 4 X Loc [ FwdPlus ]

2: 11 Y Loc [ Scratch2 ]

3: 11 Z Loc [ Scratch2 ]

11: Z=X*Y (P36)

1: 11 X Loc [ Scratch2 ]

2: 11 Y Loc [ Scratch2 ]

3: 11 Z Loc [ Scratch2 ]

12: Z=X*F (P37)

1: 11 X Loc [ Scratch2 ]

2: 20 F

3: 11 Z Loc [ Scratch2 ]

13: Z=LN(X) (P40)

1: 11 X Loc [ Scratch2 ]

2: 11 Z Loc [ Scratch2 ]

14: Z=X*F (P37)

1: 11 X Loc [ Scratch2 ]

2: 4.3429 F

3: 11 Z Loc [ Scratch2 ]

D-2

;Transfer data to the TGT1 when Output Flag is

set High (10).

22: Data Transfer to GOES (P120)

1: 00 self-timed

buffer/append new

data to old data

2: 4 FWD/Ref Power Loc [

FwdPwr ]

D.3.2 21X

The 21X's program is the same as the CR10X,

CR10, CR510, and CR500's, except Instruction

99 has an extra parameter. With this

parameter, you specify the array of data that is

transferred to the buffer (see Section 9.2).

Page 33

APPENDIX E. CHANNEL/FREQUENCY CORRELATION

Channel Frequency (MHz) Channel Frequency

1 401.7010 50 401.7745

2 401.7025 51 401.7760

3 401.7040 52 401.7775

4 401.7055 53 401.7790

5 401.7070 54 401.7805

6 401.7085 55 401.7820

7 401.7100 56 401.7835

8 401.7115 57 401.7850

9 401.7130 58 401.7865

10 401.7145 59 401.7880

11 401.7160 60 401.7895

12 401.7175 61 401.7910

13 401.7190 62 401.7925

14 401.7205 63 401.7940

15 401.7220 64 401.7955

16 401.7235 65 401.7970

17 401.7250 66 401.7985

18 401.7265 67 401.8000

19 401.7280 68 401.8015

20 401.7295 69 401.8030

21 401.7310 70 401.8045

22 401.7325 71 401.8060

23 401.7340 72 401.8075

24 401.7355 73 401.8090

25 401.7370 74 401.8105

26 401.7385 75 401.8120

27 401.7400 76 401.8135

28 401.7415 77 401.8150

29 401.7430 78 401.8165

30 401.7445 79 401.8180

31 401.7460 80 401.8195

32 401.7475 81 401.8210

33 401.7490 82 401.8225

34 401.7505 83 401.8240

35 401.7520 84 401.8255

36 401.7535 85 401.8270

37 401.7550 86 401.8285

38 401.7565 87 401.8300

39 401.7580 88 401.8315

40 401.7595 89 401.8330

41 401.7610 90 401.8345

42 401.7625 91 401.8360

43 401.7640 92 401.8375

44 401.7655 93 401.8390

45 401.7670 94 401.8405

46 401.7685 95 401.8420

47 401.7700 96 401.8435

48 401.7715 97 401.8450

49 401.7730 98 401.8465

99 401.8480

E-1

Page 34

APPENDIX E. CHANNEL/FREQUENCY CORRELATION

100 401.8495 150 401.9245

101 401.8510 151 401.9260

102 401.8525 152 401.9275

103 401.8540 153 401.9290

104 401.8555 154 401.9305

105 401.8570 155 401.9320

106 401.8585 156 401.9335

107 401.8600 157 401.9350

108 401.8615 158 401.9365

109 401.8630 159 401.9380

110 401.8645 160 401.9395

111 401.8660 161 401.9410

112 401.8675 162 401.9425

113 401.8690 163 401.9440

114 401.8705 164 401.9455

115 401.8720 165 401.9470

116 401.8735 166 401.9485

117 401.8750 167 401.9500

118 401.8765 168 401.9515

119 401.8780 169 401.9530

120 401.8795 170 401.9545

121 401.8810 171 401.9560

122 401.8825 172 401.9575

123 401.8840 173 401.9590

124 401.8855 174 401.9605

125 401.8870 175 401.9620

126 401.8885 176 401.9635

127 401.8900 177 401.9650

128 401.8915 178 401.9665

129 401.8930 179 401.9680

130 401.8945 180 401.9695

131 401.8960 181 401.9710

132 401.8975 182 401.9725

133 401.8990 183 401.9740

134 401.9005 184 401.9755

135 401.9020 185 401.9770

136 401.9035 186 401.9785

137 401.9050 187 401.9800

138 401.9065 188 401.9815

139 401.9080 189 401.9830

140 401.9095 190 401.9845

141 401.9110 191 401.9860

142 401.9125 192 401.9875

143 401.9140 193 401.9890

144 401.9155 194 401.9905

145 401.9170 195 401.9920

146 401.9185 196 401.9935

147 401.9200 197 401.9950

148 401.9215 198 401.9965

149 401.9230 199 401.9980

E-2

Page 35

APPENDIX F. DATA DUMP DATALOGGER PROGRAM

F.1 INTRODUCTION

The data dump program inserts 20 data points

(60 bytes) into the transmitter's random buffer

when user FLAG 1 is manually toggled HIGH.

The buffer is cleared when the user FLAG 2 is

set HIGH.

F.2 TOGGLING USER FLAG 1 HIGH

You start by typing in *6AD to enter the FLAG

Status Mode. [00:00:00:00] is displayed,

indicating user FLAGS 1 through 8 are set low.

To toggle user FLAG 1 HIGH, type 1. After the

display shows [10:00:00:00], type *0. When the

data points are in the buffer, [00:00:00:00] is

displayed.

If the display shows [00:00:00:00] before *0 is

typed, the data dump failed. To try again, type

a 1 and a *0. Twenty seconds after the display

shows LOG1, type *6AD. When [00:00:00:00]

is displayed, the data points are in the buffer.

The FLAG Status Mode is exited by setting the

scan rate to 0 (*1A0A) then typing in *0.

F.5 TOGGLING USER FLAG 2 HIGH