Page 1

CSBUOY-DT

Revision: 11/08

Copyright © 2002-2008

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The CSBUOY-DT is warranted by CAMPBELL SCIENTIFIC, INC. to be

free from defects in materials and workmanship under normal use and service

for twelve (12) months from date of shipment unless specified otherwise.

Batteries have no warranty. CAMPBELL SCIENTIFIC, INC.'s obligation

under this warranty is limited to repairing or replacing (at CAMPBELL

SCIENTIFIC, INC.'s option) defective products. The customer shall assume

all costs of removing, reinstalling, and shipping defective products to

CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. will

return such products by surface carrier prepaid. This warranty shall not apply

to any CAMPBELL SCIENTIFIC, INC. products which have been subjected

to modification, misuse, neglect, accidents of nature, or shipping damage. This

warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability or fitness for a particular purpose. CAMPBELL

SCIENTIFIC, INC. is not liable for special, indirect, incidental, or

consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to shanna@campbellsci.com

to 435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

CSBUOY-DT Shipping List

Items packaged with the CSBUOY-DT for shipment include:

• CSBUOY-DT

• Solar panel with mounting brackets and cable

• Lid

• Instrument housing with antenna hole plug

• Float with two (2) eye-bolts

• Float plug unscrewed

• Instrument shroud

• Instrumentation mounting bracket

• CR206

• Antenna with cable

• Relay with cable

• 7 AH battery with cable

• Sensors

• Dissolved oxygen/temperature probe

• Wiper brush

• Two (2) large desiccant packs

• Humidity card

• CSBUOY-DT manual

• CR206 manual/CD-ROM

Page 4

This is a blank page.

Page 5

Special Operating Notes

1. Check the shipping list in the front of the manual and make sure that all

the parts checked off the list are with the CSBUOY-DT. If any parts are

missing, please contact Campbell Scientific, Inc. (435) 753-2342.

2. When connecting the battery avoid shorting the battery to the CR206.

3. Damage to the electronics will occur if moisture builds up inside the

CSBUOY-DT instrument housing.

4. The Heyco pressure fittings seal the cable entry points against water

intrusion. These fittings must be tightened periodically to ensure a tight

fit.

Page 6

This is a blank page.

Page 7

CSBUOY-DT Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Introduction...............................................................1-1

1.1 Specifications........................................................................................ 1-1

2. CSBUOY-DT Description..........................................2-1

2.1 System Components .............................................................................2-1

2.2 Standard Sensors................................................................................... 2-1

2.3 Communication Options....................................................................... 2-2

2.4 Power Supply........................................................................................ 2-2

3. CSBUOY Installation ................................................3-1

3.1 Site Selection........................................................................................3-1

3.2 CSBUOY-DT Assembly ...................................................................... 3-1

4. Communication.........................................................4-1

4.1 Direct Connection to PC....................................................................... 4-1

4.1.1 Device Configuration Utility Software Installation................... 4-1

4.1.2 RF401 Connection...................................................................... 4-1

4.2 CSBUOY-DT as a Wireless Sensor ..................................................... 4-1

5. Maintenance..............................................................5-1

5.1 Instrumentation Maintenance ............................................................... 5-1

5.1.1 Batteries ...................................................................................... 5-1

5.1.2 Desiccant..................................................................................... 5-1

5.1.3 Sensor Maintenance.................................................................... 5-1

5.1.4 Calibration .................................................................................. 5-2

i

Page 8

This is a blank page.

Page 9

Section 1. Introduction

The CSBUOY-DT is programmed to communicate directly with a personal

computer operating Device Configuration Utility software and/or as a wireless

sensor providing data for other Campbell Scientific dataloggers. A 5-watt

solar panel is used to trickle charge the battery.

1.1 Specifications

General

CSBUOY-DT Weight: 37 lbs

Environment: Freshwater and brackish ponds and small lakes;

quiet water marine (no wave or tidal activity)

Buoy

Material: Polyethylene

Dimensions: 47” (119 cm) height, 30” (76 cm) float diameter

Instrument Housing: 6.36” (16.15 cm) OD, 6” (15.24 cm) ID

Wireless Transmitter

Storage: 512 Kbytes Flash Final Storage; data format is 4

Radio Type: RF401, 916 MHz Spread Spectrum Transceiver

Average Continuous

Current Drain: 20 mA radio always on, 2.2 mA radio in 1 s duty

Antenna

Frequency: 900 Mhz

Distance: 5000 ft (1524 m) assuming line of sight

Gain: 0 dBd

Length: 3.25” (8.26 cm)

bytes per data point (table-based); 60 Kbytes Flash

(OS/program)

cycle, 0.6 mA radio in 8 s duty cycle

1-1

Page 10

Section 1. Introduction

Solar Panel

Dissolved Oxygen/Water Temperature Probe

Typical Peak Power: 5 W

Voltage @ Peak Power: 17.1 Vdc

Current @ Peak Power: 300 mA

Dimensions: 9.45” (24 cm) length, 10.4” (26.4 cm) width

Membrane Type: PTFE (Teflon®)

Output at 100% Saturation: 24 to 42 mV

Temperature Range: 0° to 50°C

Accuracy: +/- 2%

Response Time: 2 minutes to reach 90% of final reading

Minimum Water Flow Rate: 2” (5 cm) per second across membrane

Material: Delrin®

PRT: 100 Ohm

Power Requirements

for Agitator Brush: 12 Vdc, 1.1 A

1-2

Page 11

Section 2. CSBUOY-DT Description

The CSBUOY-DT is designed to eliminate the use of hard-wire cable to

connect the dissolved oxygen and water temperature sensors with the

datalogger (CR510, CR10X, CR23X, CR800, CR850, CR1000, CR3000).

Operation is simplified through a modular design, prewired sensors, and

preprogrammed interface. This manual covers installation, communication,

and maintenance.

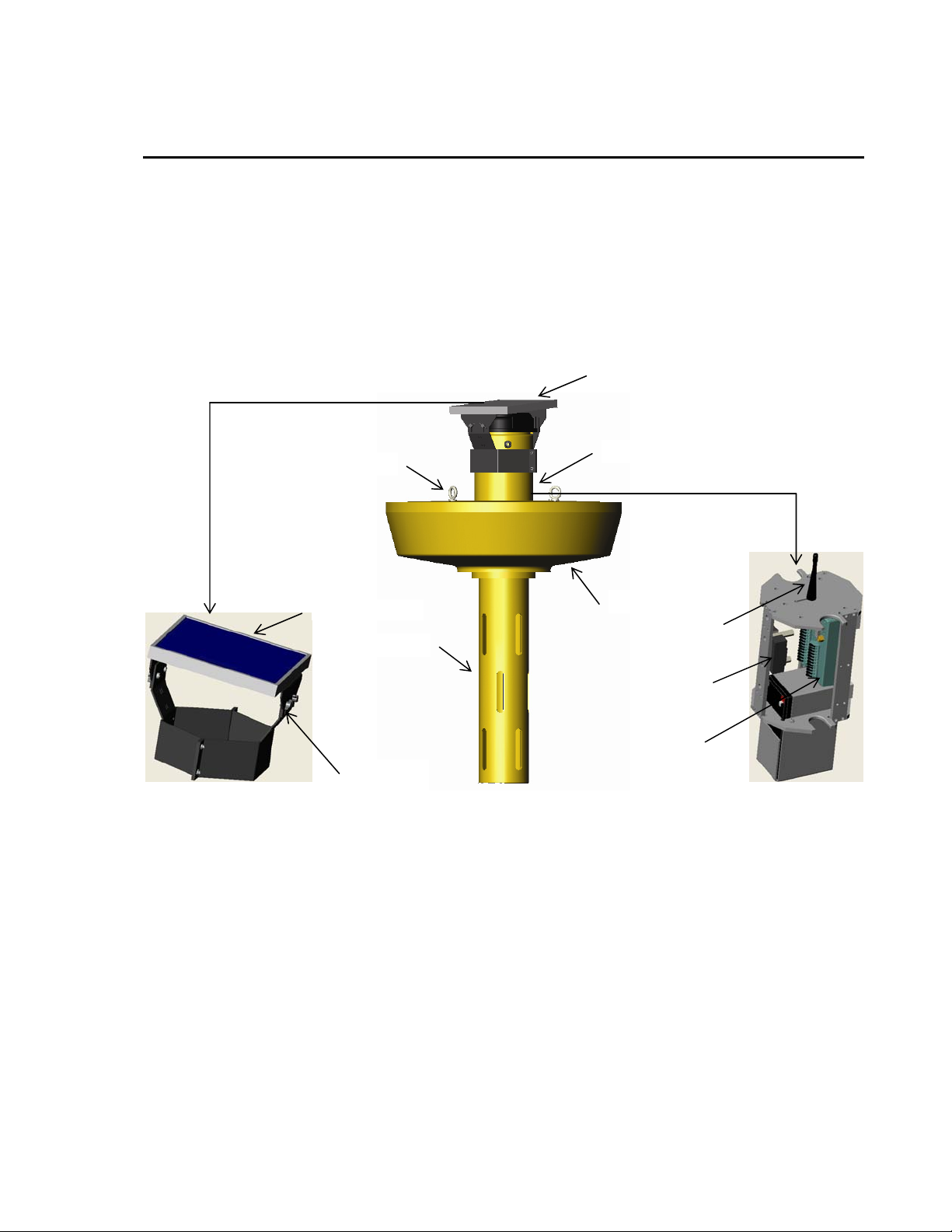

2.1 System Components

Mooring Eyebolts

5 W Solar Panel

Sensor Shroud

Solar Panel

Mounting

Brackets

5 W Solar Panel

Instrument Housing

Float

Antenna

Relay

CR206

2.2 Standard Sensors

Prewired sensors include:

• Dissolved Oxygen

• Water Temperature

• Battery Voltage

• Wiper Brush

• Relative Humidity (optional)

2-1

Page 12

Section 2. CSBUOY-DT Description

2.3 Communication Options

• Direct RS-232 Connection to PC

• RF401 Spread Spectrum Radio Connection to PC

• Rf401 Spread Spectrum Radio Connection to Datalogger (CR510,

CR10X, CR23X, CR800, CR850, CR1000, CR3000)

2.4 Power Supply

• 7 Amp/hr 12 VDC Rechargeable Battery

• 5 W Solar Panel Trickle Charger

2-2

Page 13

Section 3. CSBUOY Installation

3.1 Site Selection

The site should represent the general area being measured. Placement should

allow the buoy to float freely without obstruction from the bottom of the water

compound being monitored. The buoy solar panel should not have any

obstruction from full sunlight. Keep away from overhanging trees or other

obstructions. The solar panel should be angled towards the south to maximize

full solar capabilities.

3.2 CSBUOY-DT Assembly

CR206 Relay DO/WT Probe Wiper Solar Panel Batt

Battery- Black

Battery+ Red

Charge- Black

Charge+ Red

1 Brown

Battery+ 2+ White

SW Batt 3+ Black

G 4 Clear

G Blue

SE1 Red - DO Sig+

GND Black - DO Sig-

SE2 Green - PRT V1

GND White - PRT G

EX1 Purple Vex (2.5v)

G Clear - Shield

Ensure that each wire is in the proper place on the CR206. Connect the battery

cable to the battery. Using a wrench, tighten the Heyco Pressure fitting to

ensure a watertight seal around the sensor cables exiting the instrument

housing. Insert the instrument mounting bracket into the instrument

housing, paying particular attention that the cable are not pinched. Tighten the

instrument housing lid.

With a wrench, tighten the vent plug into the float.

Attach the solar panel to the solar panel brackets. Tighten the connection

with the thumb screws.

3-1

Page 14

Section 3. CSBUOY Installation

Secure the mooring eye-bolts to a mooring line or the anchor eye-bolt to the

anchor line to secure placement of buoy in desired location.

3-2

Page 15

Section 4. Communication

The CSBUOY-DT can be used as a stand-alone monitoring system that

communicates directly with the PC, or as a wireless sensor that is integrated

with other Campbell Scientific dataloggers (CR510, CR10X, CR23X, CR800,

CR850, CR1000, CR3000) with table-based operating systems using the

PakBus communication protocol.

4.1 Direct Connection to PC

In order to communicate with the CSBUOY-DT directly from the PC:

1. Device Configuration Utility software must be installed in the PC.

2. An RF401 Spread Spectrum Radio must be connected via com port to the

PC.

3. The RF401 and CSBUOY-DT Transceiver (CR206) must be configured to

communicate with each other (refer to RF401 and CR206 manuals).

4.1.1 Device Configuration Utility Software Installation

Refer to the Device Configuration Utility Manual for installation an d operation

instructions.

4.1.2 RF401 Connection

Refer to the RF401 Manual for configuration instructions.

4.2 CSBUOY-DT as a Wireless Sensor

A CSBUOY-DT acting as a wireless sensor can communicate with a CR800,

CR850, CR1000, or CR3000 datalogger using the GetVariable instruction.

With a CR10X, CR510, or CR23X, the program instruction P193 is used.

These instructions open the communication between CSBUOY-DT and the

datalogger allowing data to be sent and received. In addition to this

instruction:

1. The datalogger requires a RF401 Spread Spectrum Radio configured with

a datalogger CDSC current port configuration.

2. The RF401 connected to the datalogger and the CSBUOY-DT must be

configured with the same radio address, net address and hopping

sequence.

4-1

Page 16

Section 4. Communication

‘CR1000 Series Datalogger

Public Result, Remotedata (3)

DataTable (Test,1,-1)

DataInterval (0,60,Sec,10)

Sample (3,Remotedata(),FP2)

EndTable

Alias Remotedata(1) = DOmV

Alias Remotedata(2) = WaterTempC

Alias Remotedata(3) = BatteryVolt

BeginProg

Scan (30,Sec,0,0)

GetVariables (Result,ComSDC7,0,1,0000,0,“Public”,“Buoydata()”,Remotedata(),3)

‘where 1 is the PakBus address of the CSBUOY-DT

CallTable Test

NextScan

EndProg

Programming Examples

The following example allows the CR1000 to communicate with one

CSBUOY-DT.

This example allows the CR10X to communicate with one CSBUOY-DT.

;{CR10X-PB}

;

*Table 1 Program

01: 30 Execution Interval (seconds)

1: Batt Voltage (P10)

1: 1 Loc [ Batt ]

2: PakBus - Wireless Network Master (P193)

1: 1 Number of Remotes

2: 10 First Remote Address

3: 0 Time Into Transmit Interval (sec)

4: 300 Transmit Interval (sec, 0 = use execution interval)

5: 0 Transmit Delay Between Remotes (sec)

6: 5 Swath to Receive

7: 7 First Loc for Data Received [ RID_1 ]

8: 0 Swath to Send

9: 18 First Loc to Send [ Scratch ]

10: 2 Result Code Loc [ RCom_1 ]

3: Data Table (P84)

1: 0 Seconds into Interval

2: 300 Seconds Interval

3: 0 (0 = auto allocate, -x = redirect to inloc x)

4: Hist Table Name

4-2

Page 17

4: Sample (P70)

1: 13 Reps

2: 1 Loc [ Batt ]

For further instruction on programming, please refer to the CR10X manual.

Section 4. Communication

4-3

Page 18

Section 4. Communication

4-4

Page 19

Section 5. Maintenance

The CSBUOY-DT has been engineered to provide many years of reliable

service. However, periodic maintenance is required to help ensure that the

system performs up to its potential. Equipment must be in good operating

condition, which requires a program of regular inspection and maintenance.

Routine and simple maintenance can be accomplished by the person in charge

of the CSBUOY-DT.

5.1 Instrumentation Maintenance

The instrumentation requires a minimum of routine maintenance. A few

preventative maintenance steps will optimize battery life and decrease the

chances of system failure.

5.1.1 Batteries

The CSBOUY-DT has been programmed to record battery voltage. This will

allow the user to determine how long a fresh battery will last. The

CSBUOY-DT is supplied with a fresh 12 VDC, 7.0 Ahr rechargeable battery.

This battery is continually recharged by the 5-watt solar panel mounted on top

of the instrument housing. Be aware of battery voltage that consistently

decreases over time, which indicates a failure in the charging circuitry.

5.1.2 Desiccant

Damage to the CR206 and wiring panel will occur if high moisture levels

inside the CSBOUY-DT instrument housing are not corrected. Enclosure

humidity is monitored by a humidity indicator card provided with the

CSBUOY-DT. It can also be more accurately monitored using the 10162

Enclosure Humidity Sensor, which is an optional sensor that can be purchased

with the CSBUOY-DT. The CSBOUY-DT is programmed to provide data

from this sensor.

Regardless if the humidity sensor or the humidity indicator card is used to

monitor humidity inside the instrument housing, desiccant packs should be

replaced when relative humidity inside the instrument housing exceeds 35%.

5.1.3 Sensor Maintenance

Sensor maintenance should be performed at regular intervals, depending on the

desired accuracy and the conditions of use. A suggested maintenance schedule

is outlined below.

First week

• Check the wiper brush to ensure it is removing biological growth from the

dissolved oxygen sensor membrane.

• Check the Heyco pressure seals to ensure a tight fit.

5-1

Page 20

Section 5. Maintenance

• Check inside of the instrument housing to ensure against water leakage.

Any leakage will also be indicated by increase in humidity inside the

instrument housing.

• Check the dissolved oxygen probe to ensure a correct reading.

Each month

• Check wiper brush to ensure it is removing biological growth from the

dissolved oxygen membrane.

• Check humidity indicator card (or humidity readings from sensor).

Replace desiccant pack and tighten Heyco pressure fittings if needed.

• Check dissolved oxygen readings; calibrate probes if required.

Every Six Months

• Replace dissolved oxygen probe membrane and refill electrolyte solution.

Calibrate dissolved oxygen probe.

Each Year

• Check cable for rodent or environmental damage.

• Replace humidity indicator card if necessary.

Every Three to Five Years

• Check anode and cathode metals inside dissolved oxygen probe. Replace

• Replace 10162 Humidity Sensor (if being used).

General Maintenance

• An occasional cleaning of the glass on the solar panel will improve its

• Check sensor leads and cables for cracking, deterioration, and rodent

• Check the CSBUOY-DT float, instrument housing, instrument shroud, and

5.1.4 Calibration

if corrosion is extensive.

efficiency.

damage.

cap for structural damage, poor fittings, loose fittings.

5-2

The multiplier is used to calibrate the dissolved oxygen probe. The calibration

of the probe when using it as a wireless sensor in conjunction with another

datalogger is then a function of the datalogger. Generally this is made simple

by using the feature of PondView software. When using the CSBUOY-DT as

a stand-alone direct to PC connection then the multiplier is changed in the

Device Configuration Utility software.

Page 21

5.1.4.1 Air Calibration

1. Place the dissolved oxygen probe in the air, shaded from the sun. Wait for

the measurement reading to stabilize. This may take 15 minutes or more.

2. Determine the air temperature (use the temperature reading from the

probe; this is found on the Device Configuration Utility screen) and the

barometric pressure(preferred) or elevation.

3. Using the calibration chart determine the oxygen concentration in the air.

4. Use the following equation to calculate the multiplier:

M = P/R

M = Multiplier

P = Concentration in PPM of the air (from calibration chart).

R = The signal output in mV of the dissolved oxygen probe.

5. Enter the multiplier in Device Configuration Utility or LoggerNet from the

calculated number.

5.1.4.2 Hand Calibration

Section 5. Maintenance

1. Use a hand-held dissolved oxygen meter to determine the correct

concentration of dissolved oxygen in the water (the accuracy of the

method will be dependent upon the accuracy of the hand held device).

2. Use the following equation to calculate the multiplier:

M = D/R

M = Multiplier

D = measured dissolved oxygen in PPM.

R = The signal output in mV of the dissolved oxygen probe.

3. Enter the multiplier in Device Configuration Utility or LoggerNet from the

calculated number.

5-3

Page 22

Section 5. Maintenance

This is a blank page.

5-4

Page 23

This is a blank page.

Page 24

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

cleroux@csafrica.co.za

Campbell Scientific Australi

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

info@campbellsci.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

a Pty. Ltd. (CSA)

Loading...

Loading...