Page 1

CSAT3B

Dimensional

Sonic Anemometer

Revision

Copyright ©

Campbell Scientific, Inc.

Three-

: 09/2020

2015 – 2020

Page 2

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction................................................................ 1

2. Precautions ................................................................ 1

3. Initial Inspection ........................................................ 1

4. QuickStart .................................................................. 2

4.1 Hardware Connections .........................................................................2

4.2 Communications Connections ..............................................................4

4.3 Factory Settings ....................................................................................7

5. Overview .................................................................... 8

5.1 Features ................................................................................................8

5.2 Sensor Components ..............................................................................9

5.2.1 Standard Components ...................................................................9

5.2.1.1 CM250 Leveling Mounting Kit ..........................................9

5.2.1.2 USB Data Cable .................................................................9

5.2.2 Optional Components ................................................................. 10

5.2.2.1 Sonic Environment Option ............................................... 10

5.2.2.2 Sonic Carrying Case ......................................................... 10

5.2.3 Common Accessories .................................................................. 10

5.2.3.1 Power and Communications Cables ................................. 10

5.2.3.2 FW05 Thermocouple ........................................................ 13

5.2.3.3 FWC-L Cable ................................................................... 14

5.2.3.4 Thermocouple Cover ........................................................ 14

5.2.3.5 Thermocouple Cover Backplate ....................................... 14

5.2.3.6 FW/ENC Thermocouple Enclosure .................................. 14

5.2.4 Other Accessories ....................................................................... 14

5.2.4.1 Power/SDM Splitter ......................................................... 15

5.2.4.2 CPI/RS-485 Splitter .......................................................... 15

5.2.4.3 HUB-SDM8...................................................................... 17

5.2.4.4 SDM Cable CABLE5CBL-L............................................ 17

5.2.4.5 HUB-CPI .......................................................................... 17

5.2.4.6 CAT6 Ethernet Cable ....................................................... 18

6. Specifications .......................................................... 18

6.1 Measurements .................................................................................... 19

6.2 Communications ................................................................................ 20

6.3 Power Requirements .......................................................................... 21

6.4 Physical Description ........................................................................... 21

7. Installation ............................................................... 22

7.1 Settings ............................................................................................... 23

7.2 Orientation ......................................................................................... 27

i

Page 3

Table of Contents

Sonic Azimuth ............................................................................ 27

7.2.1

7.3 Mounting ............................................................................................ 29

7.4 Leveling ............................................................................................. 30

7.5 Additional Fast-response Sensors ...................................................... 32

7.5.1 Fine-Wire Thermocouple ............................................................ 32

7.5.2 Other Gas Analyzers ................................................................... 34

7.6 Wiring ................................................................................................ 34

7.7 Communications ................................................................................ 35

7.7.1 SDM Communications ................................................................ 36

7.7.2 CPI Communications .................................................................. 40

7.7.3 RS-485 Communications ............................................................ 45

7.7.4 USB ............................................................................................. 46

8. Operation ................................................................. 48

8.1 Theory of Operation ........................................................................... 48

8.1.1 Algorithm Version 5 ................................................................... 48

8.1.2 Effects of Crosswind on the Speed of Sound .............................. 48

8.1.3 Sonic Transducer Shadow Correction ......................................... 49

8.2 Operating Modes ................................................................................ 50

8.2.1 Measurement Trigger .................................................................. 52

8.2.2 Data Filter ................................................................................... 52

8.2.3 Data Output ................................................................................. 53

8.2.4 Operating Mode Recommendations ............................................ 56

8.3 Synchronization with other sensors .................................................... 56

8.4 Data Logger Programming using SDM or CPI .................................. 57

8.4.1 CRBasic Instructions................................................................... 57

8.4.1.1 CSAT3B() ........................................................................ 57

8.4.1.2 CSAT3BMonitor() ........................................................... 58

8.4.2 Diagnostic Word ......................................................................... 59

8.4.3 SDMTrigger() ............................................................................. 60

8.5 Programming ...................................................................................... 61

9. Maintenance and Troubleshooting ......................... 61

9.1 General Maintenance ......................................................................... 61

9.2 Sonic Wicks ....................................................................................... 61

9.3 Desiccant ............................................................................................ 62

9.4 Calibration .......................................................................................... 64

9.4.1 Test for Wind Offset ................................................................... 64

9.5 Troubleshooting ................................................................................. 66

9.5.1 Sending an OS to the CSAT3B ................................................... 67

9.6 Returning the CSAT3B ...................................................................... 68

10. Reference and Attributions ..................................... 68

10.1 References .......................................................................................... 68

Appendices

A. CSAT3B Orientation .............................................. A-1

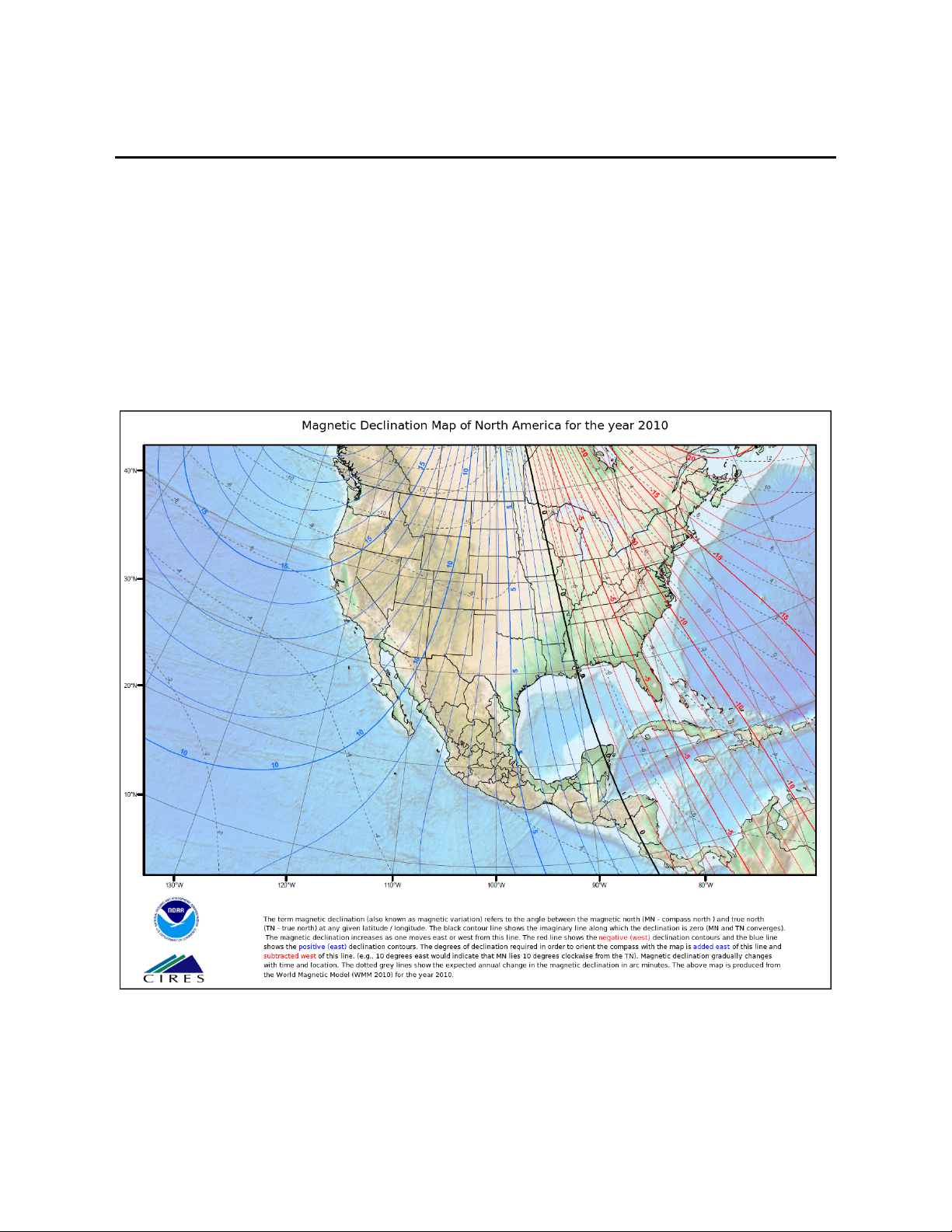

A.1 Determining True North and Sensor Orientation ............................ A-1

A.2 Online Magnetic Declination Calculator ......................................... A-3

ii

Page 4

Table of Contents

B. CSAT3B Measurement Theory ............................. B-1

B.1 Theory of Operation ......................................................................... B-1

B.1.1 Wind Speed ............................................................................... B-1

B.1.2 Temperature .............................................................................. B-2

B.2 References ........................................................................................ B-3

Figures

4-1. Mounting a CM20X crossarm with crossarm-to-pole bracket .............2

4-2. CSAT3B mounting...............................................................................3

4-3. Grounding lug of CSAT3B ..................................................................3

4-4. Cable connection for SDM ...................................................................4

4-5. Cable connections for CPI....................................................................5

4-6. SDM and power wiring to a CR6 data logger ......................................6

4-7. CPI and power connections to a CR6 data logger ................................6

4-8. Lit status light on CSAT3B block ........................................................7

5-1. CM250 mount ......................................................................................9

5-2. USB data cable ................................................................................... 10

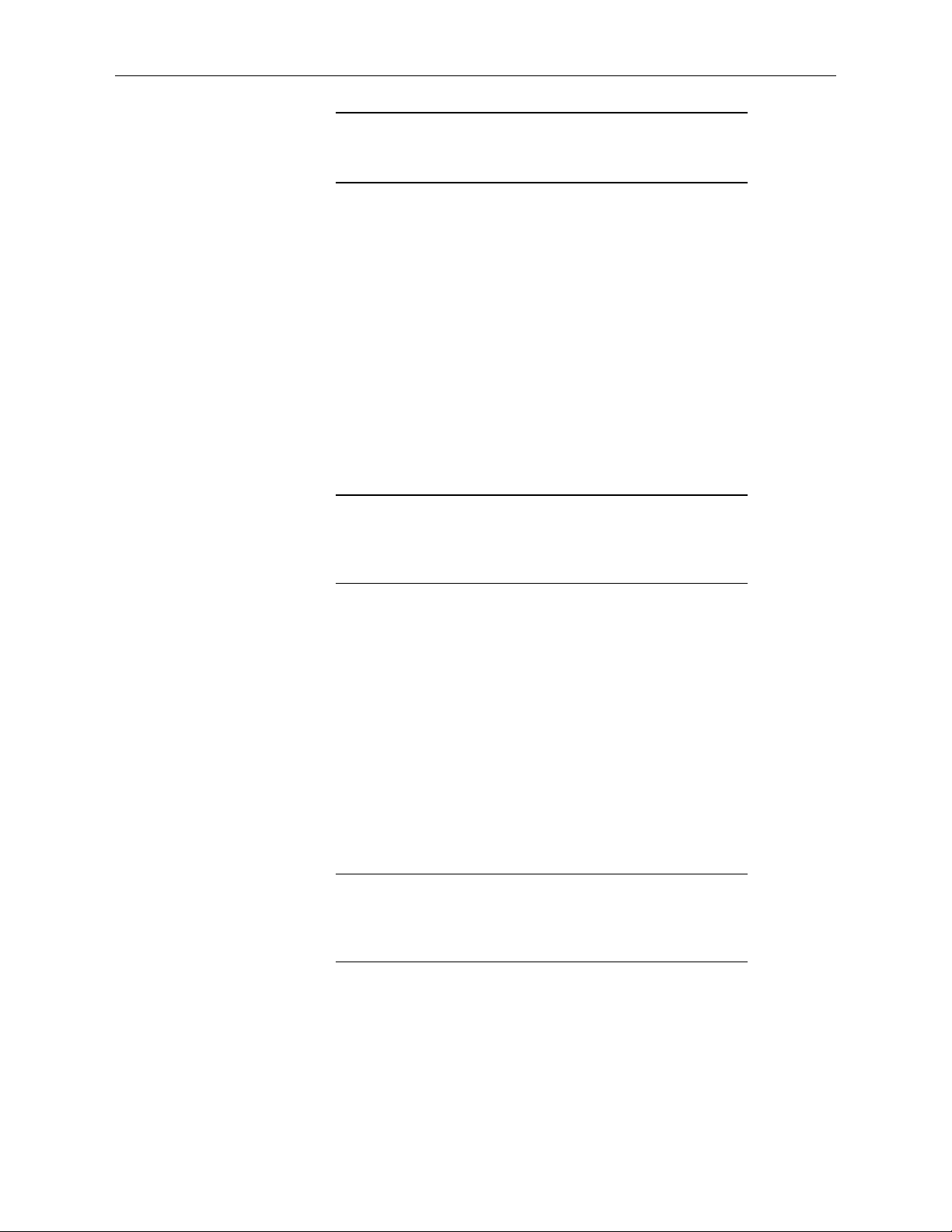

5-3. Options for CSAT3BCBL1 Power/SDM cable .................................. 12

5-4. Options for CSAT3BCBL2 power cable ............................................ 12

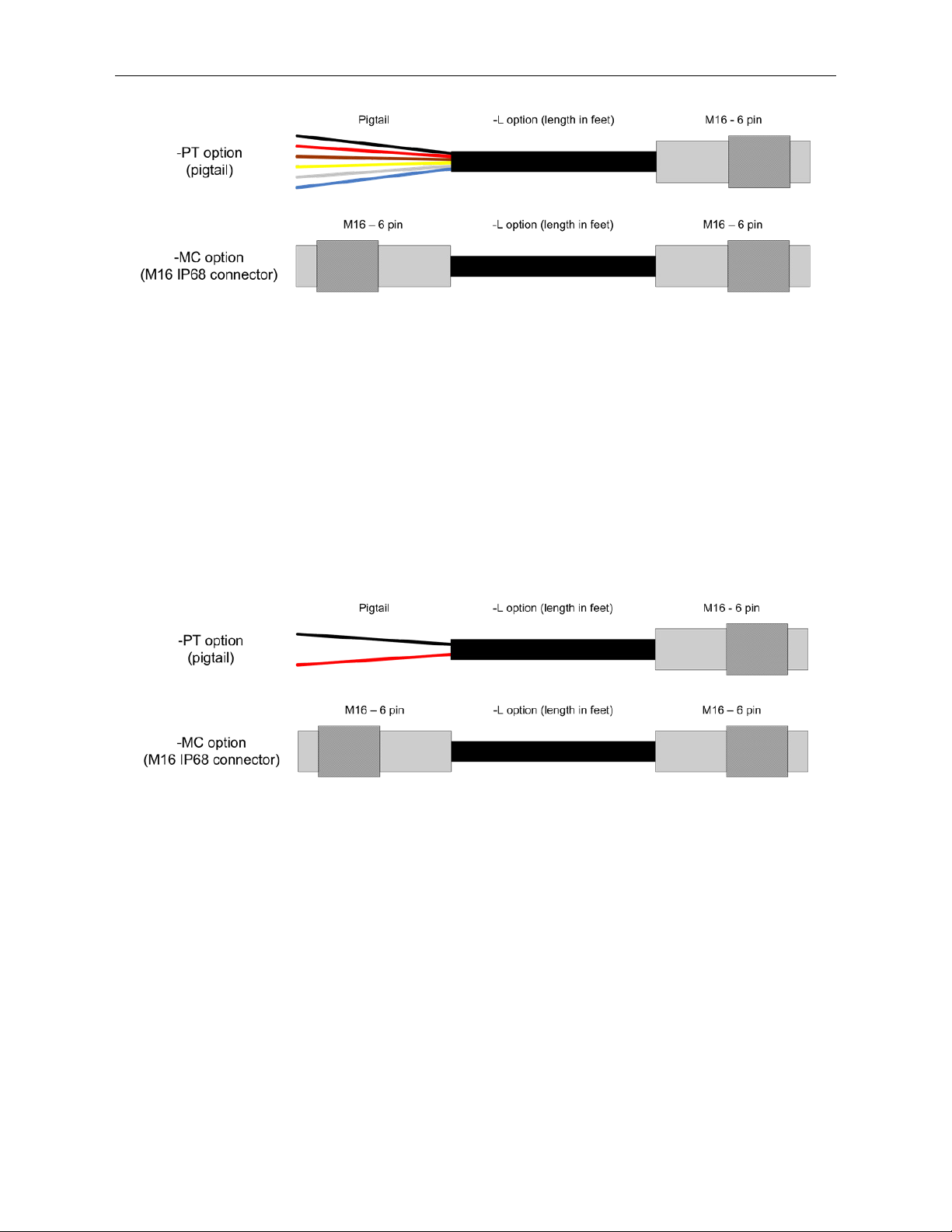

5-5. Options for cabling CPI or RS-485 communications ......................... 13

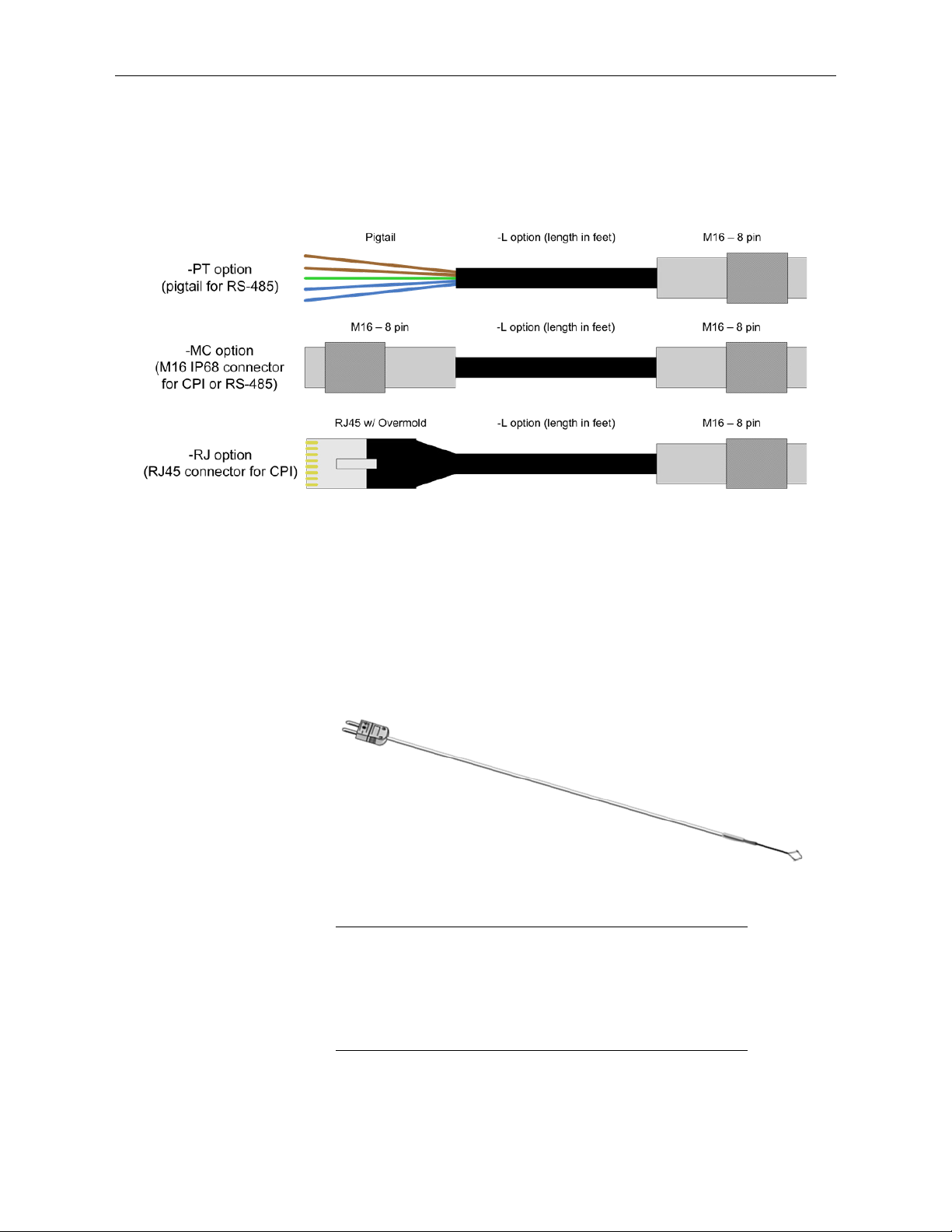

5-6. FW05 thermocouple ........................................................................... 13

5-7. FW/ENC for storing fragile thermocouples ....................................... 14

5-8. CSAT3B Power/SDM splitter (showing pin configuration) .............. 15

5-9. CSAT3B power cable compensation plug ......................................... 16

5-10. CSAT3B CPI/RS-485 splitter (showing pin configuration) ............... 16

5-11. HUB-SDM8 for multiple CSAT3B connections with SDM

communications .............................................................................. 17

5-12. HUB-CPI for multiple CSAT3B connections to CPI

communications .............................................................................. 18

5-13. CAT6 Ethernet cable .......................................................................... 18

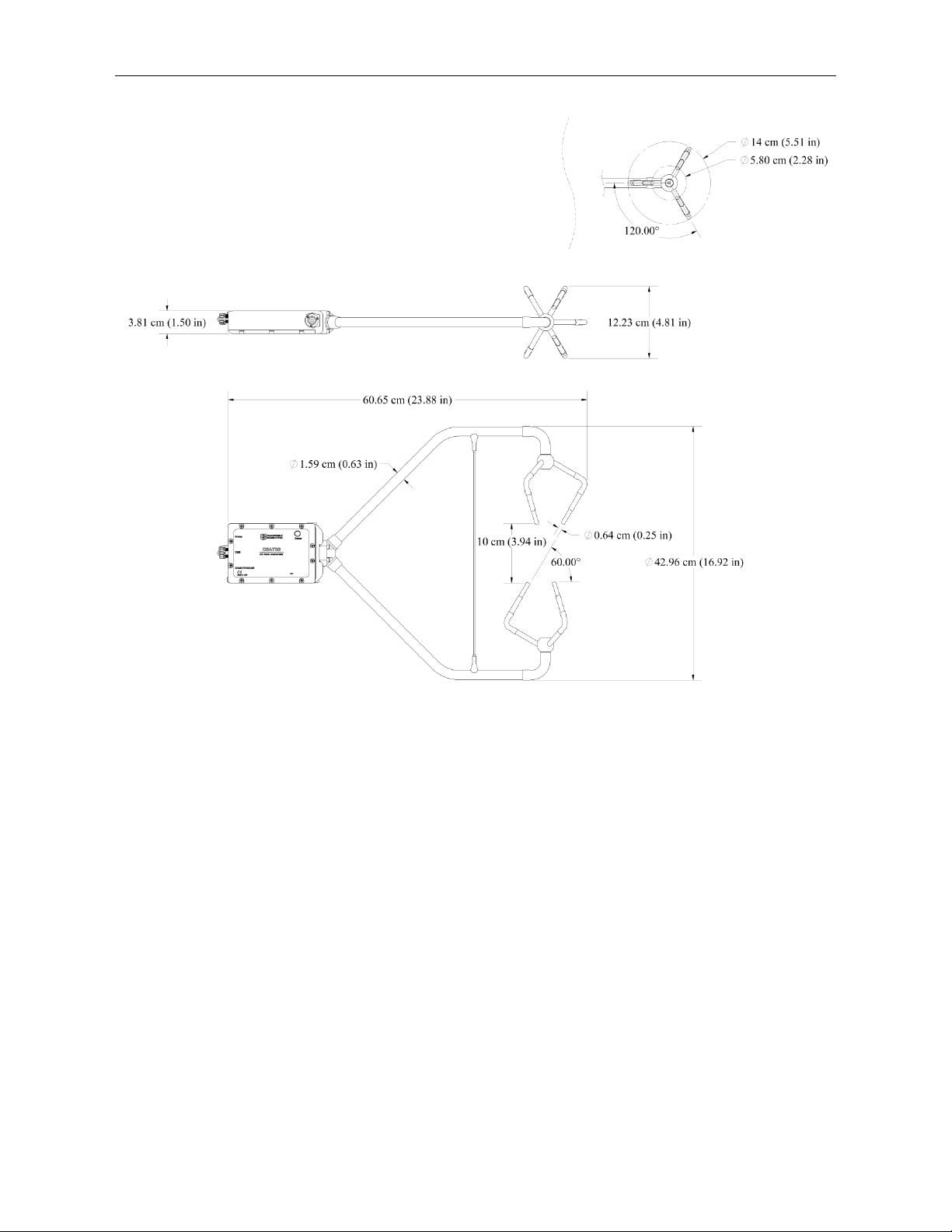

6-1. Dimensions of CSAT3B .................................................................... 22

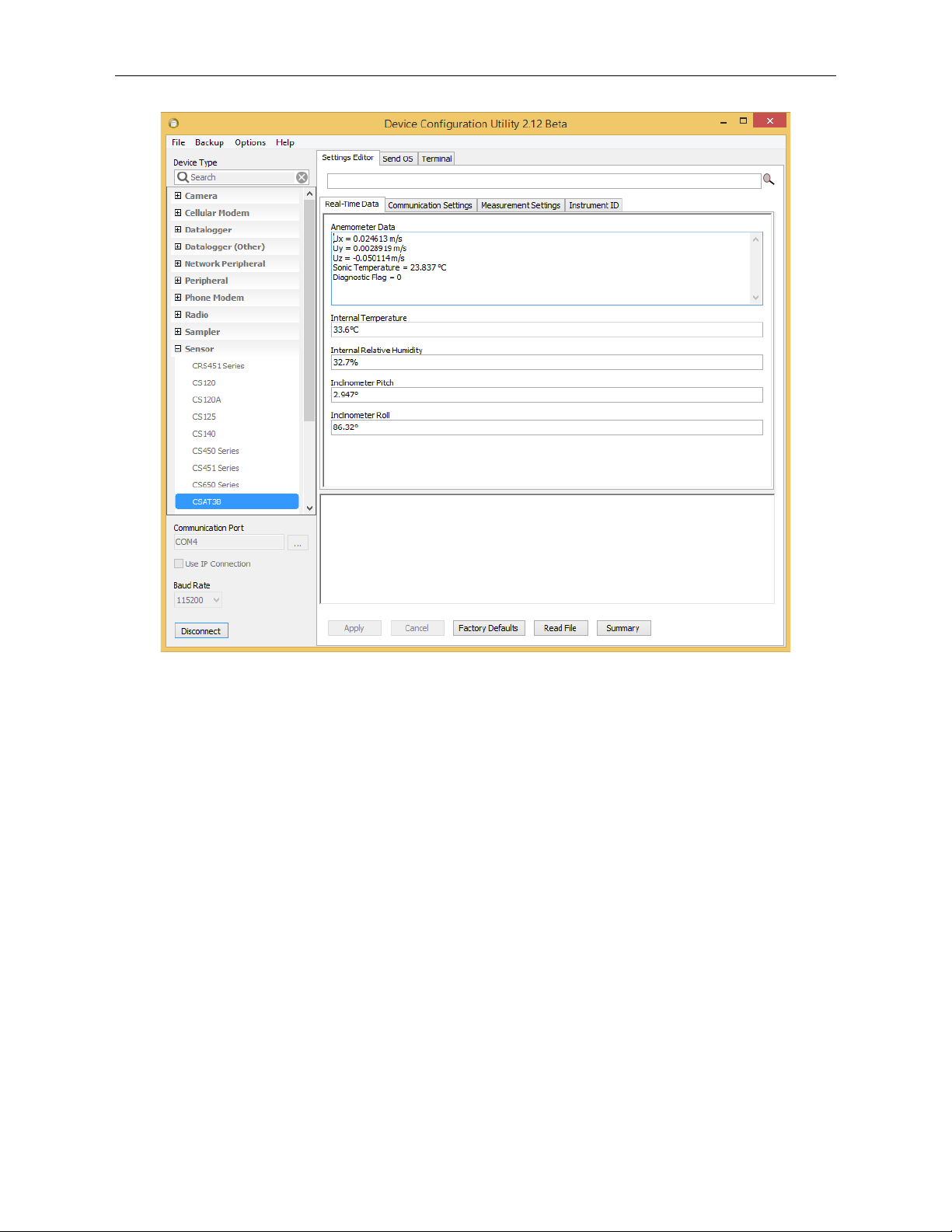

7-1. Connecting CSAT3B using Device Configuration Utility ................. 24

7-2. Real-time data subscreen while connected to CSAT3B with

Device Configuration Utility .......................................................... 27

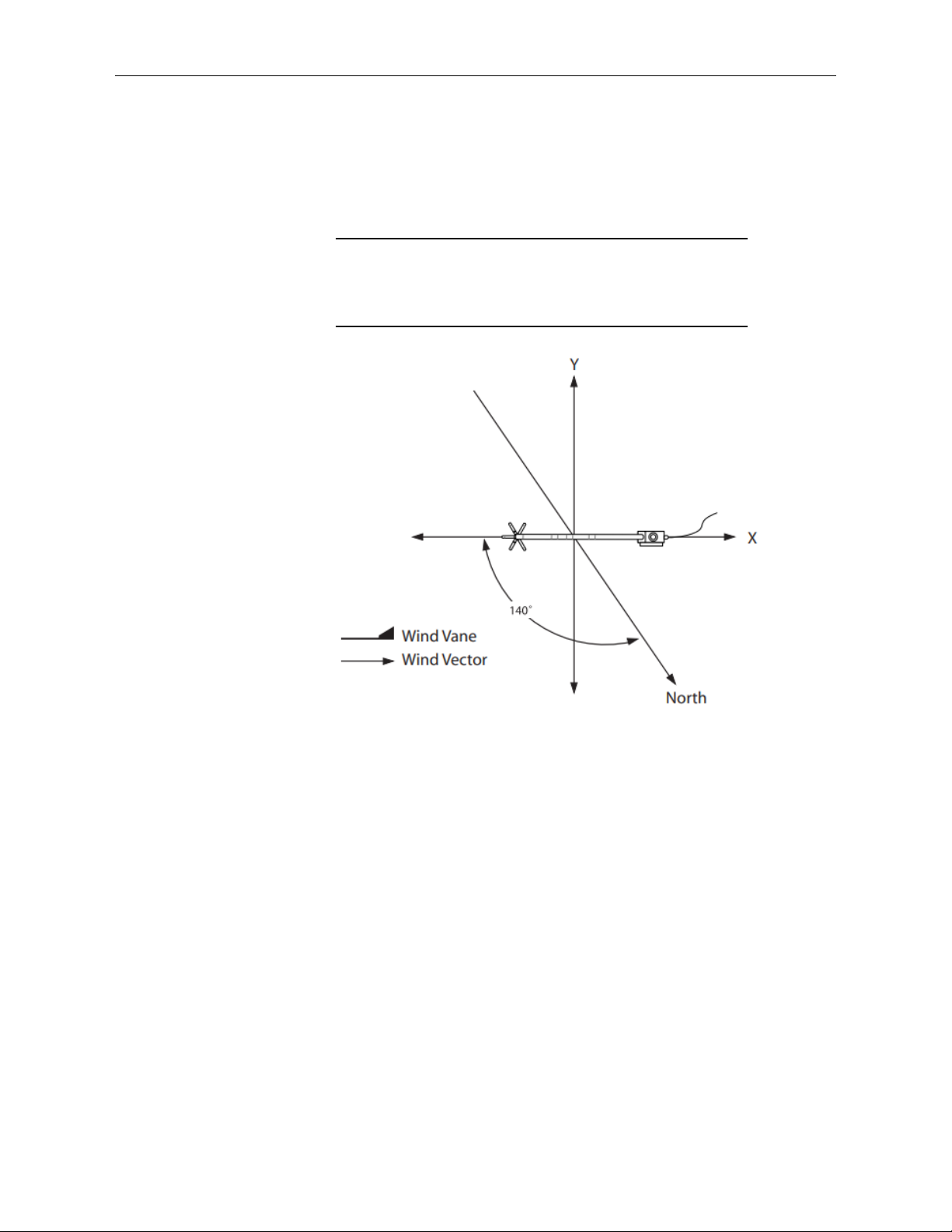

7-3. Right-hand coordinate system, horizontal wind vector angle is 0

degrees ............................................................................................ 28

7-4. Compass coordinate system, compass wind direction is 140

degrees ............................................................................................ 29

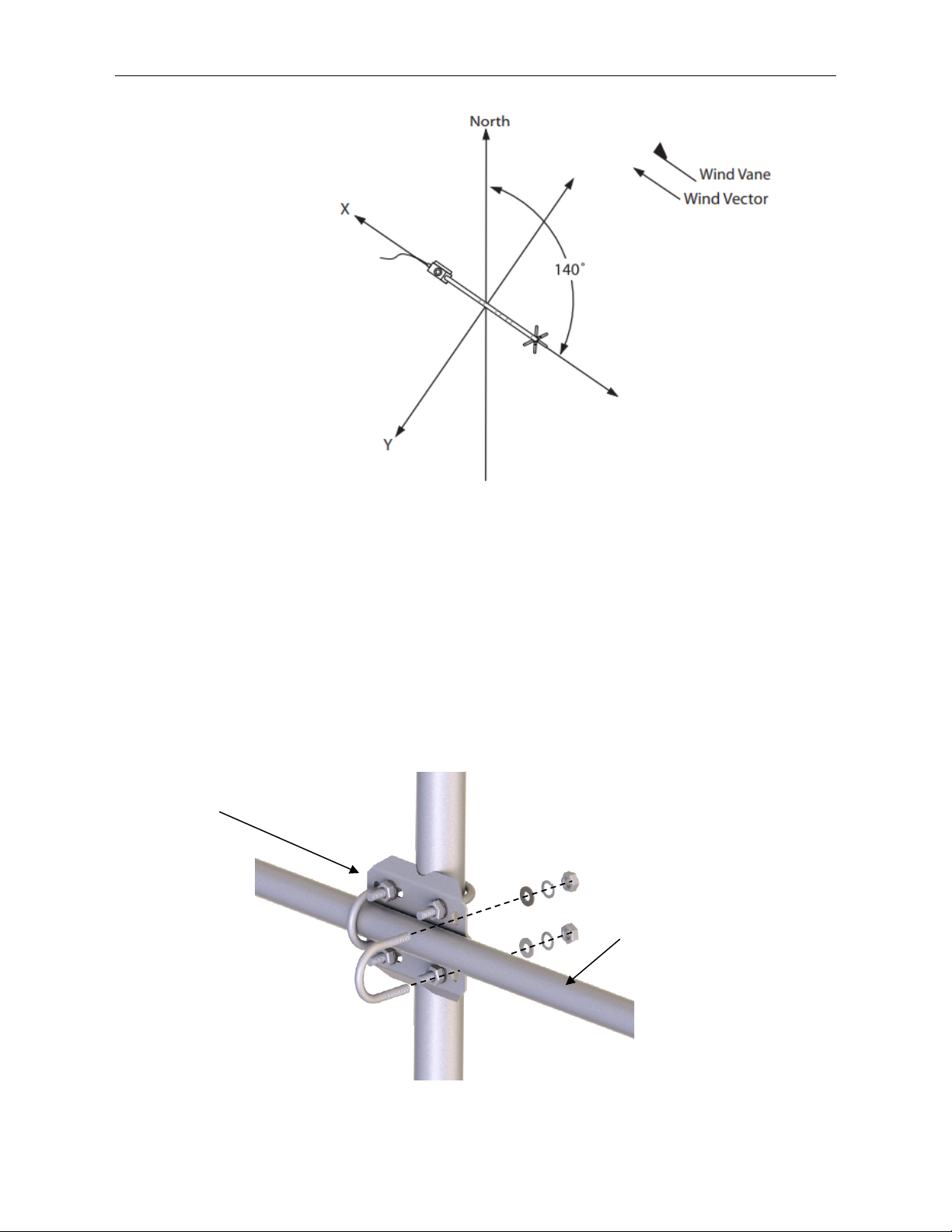

7-5. CM210 mounting kit with CM20X crossarm ..................................... 29

7-6. CSAT3B mounting............................................................................. 30

7-7. CSAT3B shown with coordinate system, with arrows representing

positive x, y, and z axes; curved arrows indicate positive

rotations of pitch and roll angles ..................................................... 32

7-8. Exploded view of fine-wire thermocouple (TC) with CSAT3B ........ 33

7-9. CSAT3B with fine-wire thermocouple mounted ............................... 33

7-10. SDM/Power connections .................................................................... 37

7-11. Wiring to power and SDM ports on CR6 data logger ........................ 37

7-12. SDM daisy chain (CSAT3B sensor arms and grounding cables

not shown) ...................................................................................... 39

7-13. SDM star topology (CSAT3B sensor arms and grounding cables

not shown) ...................................................................................... 40

7-14. Power and CPI cable connections ...................................................... 41

7-15. CPI connection to a CR6 data logger ................................................. 41

iii

Page 5

Table of Contents

7-16. CPI daisy chain (CSAT3B sensor arms and grounding cables not

shown) ............................................................................................ 43

7-17. CPI star topology (CSAT3B sensor arms and grounding cables

not shown) ...................................................................................... 44

7-18. RS-485 cable connections .................................................................. 46

8-1. Angle θa is defined as the angle between the vector of oncoming

wind, U, and the wind component along the a-sonic path, U

8-2. Measurement settings in Device Configuration Utility ...................... 51

8-3. Example of unprompted RS-485 or USB output to computer ............ 55

9-1. Proper orientation of sonic top wick (left) and bottom wick (right) ... 62

9-2. Exploded view of CSAT3B desiccant canister .................................. 64

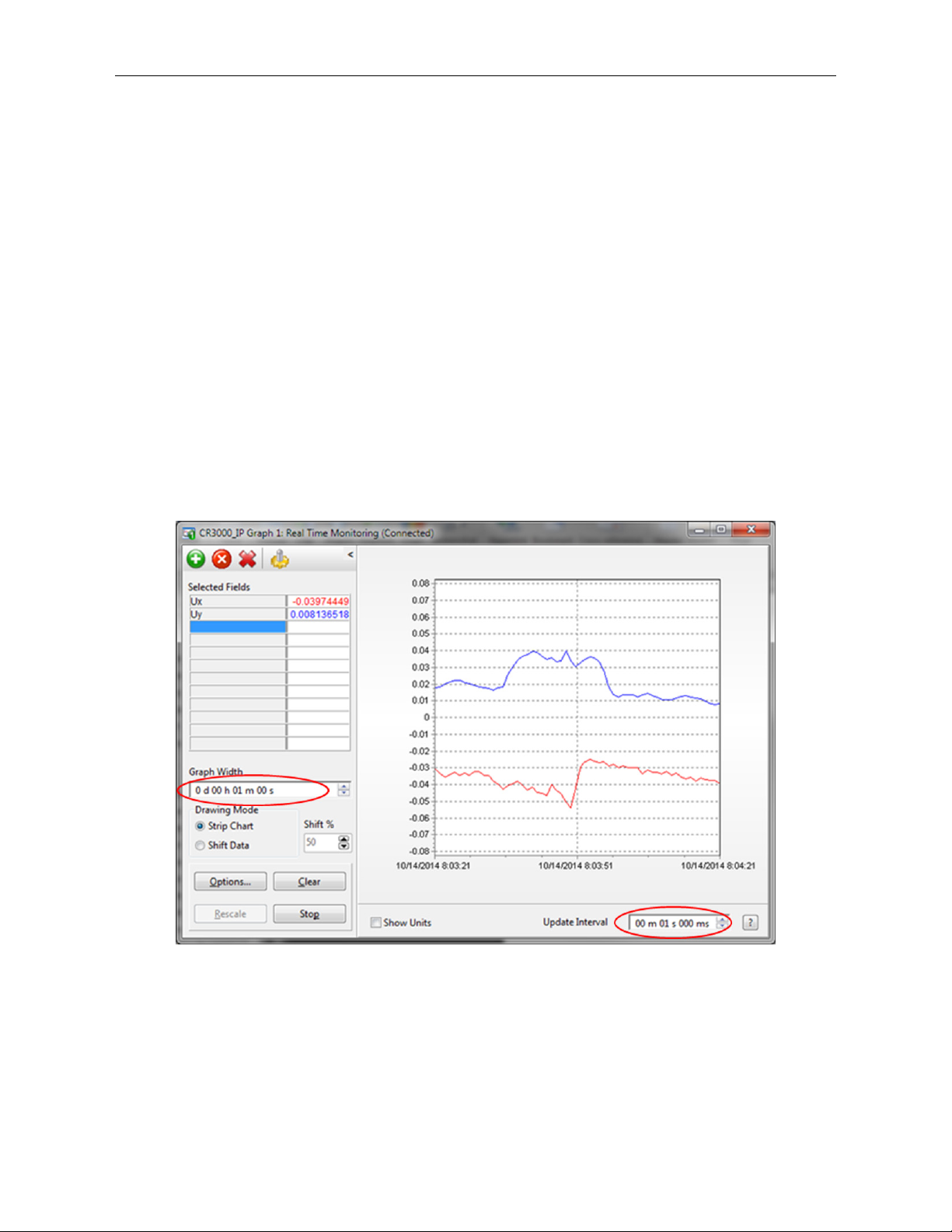

9-3. CSAT3B real-time data with 1 sec update and ux and uy wind

component graphed ......................................................................... 65

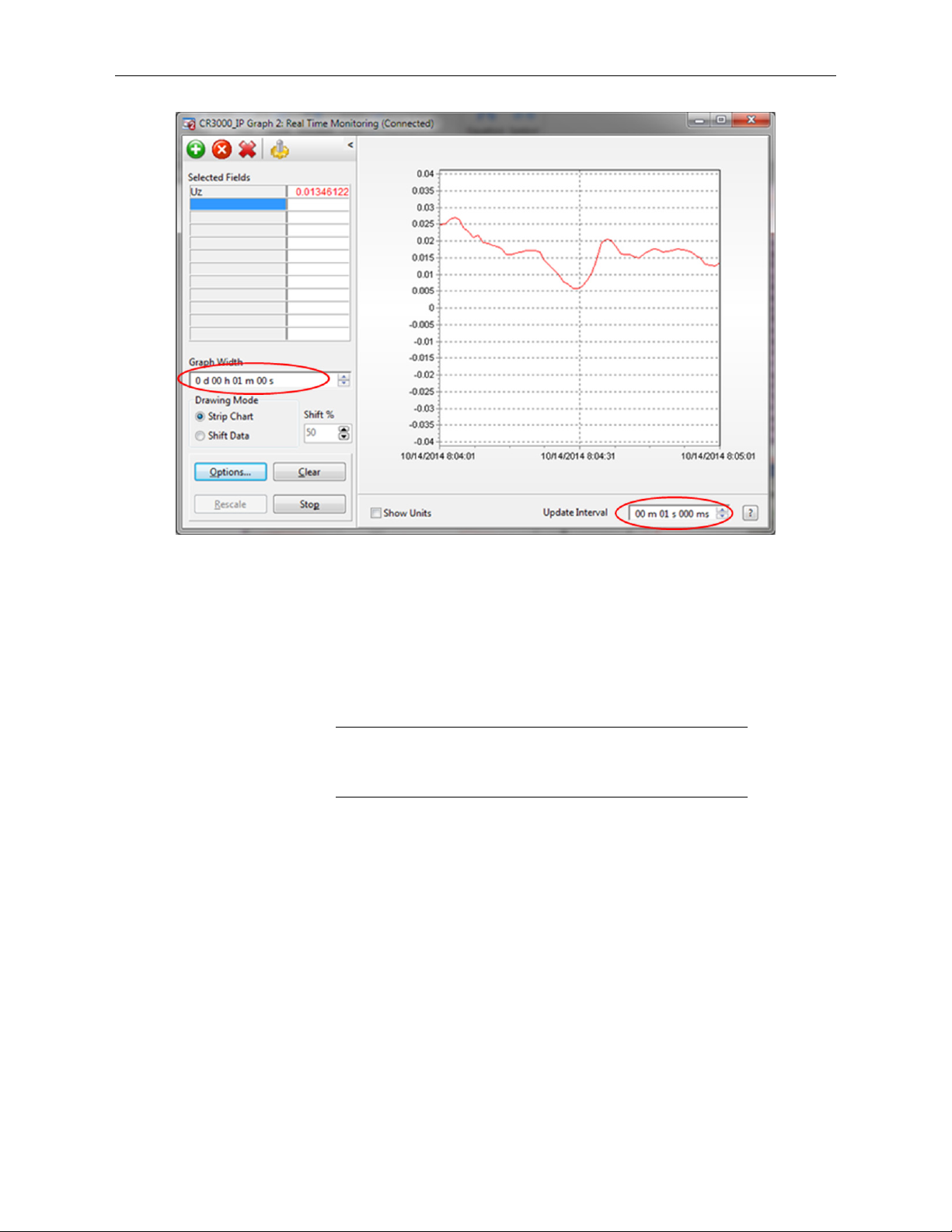

9-4. CSAT3B real-time data with 1 sec update and uz wind component

graphed ........................................................................................... 66

9-5. The Send OS screen in the Device Configuration Utility .................. 68

A-1. Magnetic declination for the conterminous United States (2010) ... A-1

A-2. A declination angle east of true north (positive) is subtracted

from 360 (0) degrees to find true north ........................................ A-2

A-3. A declination angle west of true north (negative) is subtracted

from 0 (360) degrees to find true north ........................................ A-2

A-4. NOAA magnetic declination calculator .......................................... A-3

A-5. NOAA magnetic calculator results.................................................. A-4

. ....... 50

a

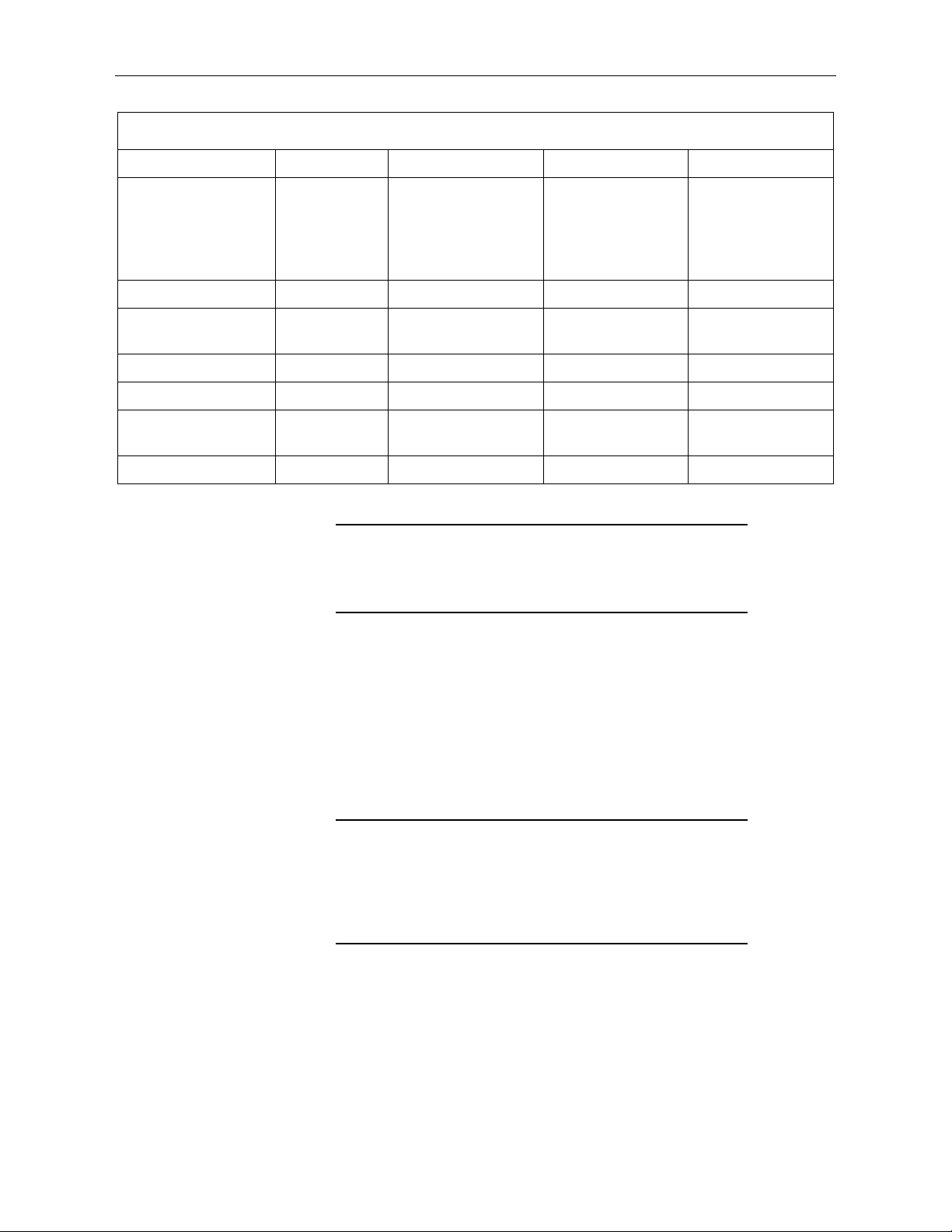

Tables

4-1. Wiring Diagram for CSAT3B with SDM Communications ................5

4-2. CSAT3B Factory Settings ....................................................................8

7-1. CSAT3B Settings and Status Values in Device Configuration

Utility .............................................................................................. 24

7-2. Summary of Communications Options for the CSAT3B ................... 35

7-3. CSAT3B Cable Wire Assignments .................................................... 47

7-4. FW05/FWC-L Fine-Wire Thermocouple ........................................... 47

8-1. Overview of CSAT3B Operating Modes ........................................... 51

8-2. Time Delays by Mode and Filter ........................................................ 53

8-3. CSAT3B Synchronicity Errors ........................................................... 56

8-4. Measurement Lags (N

Measurements with No Delay ......................................................... 57

8-5. CSAT3B Modes (Trigger Source and Filter) ..................................... 58

8-6. Diagnostic Word Flags ....................................................................... 60

) for Analog Measurements or

lag

iv

Page 6

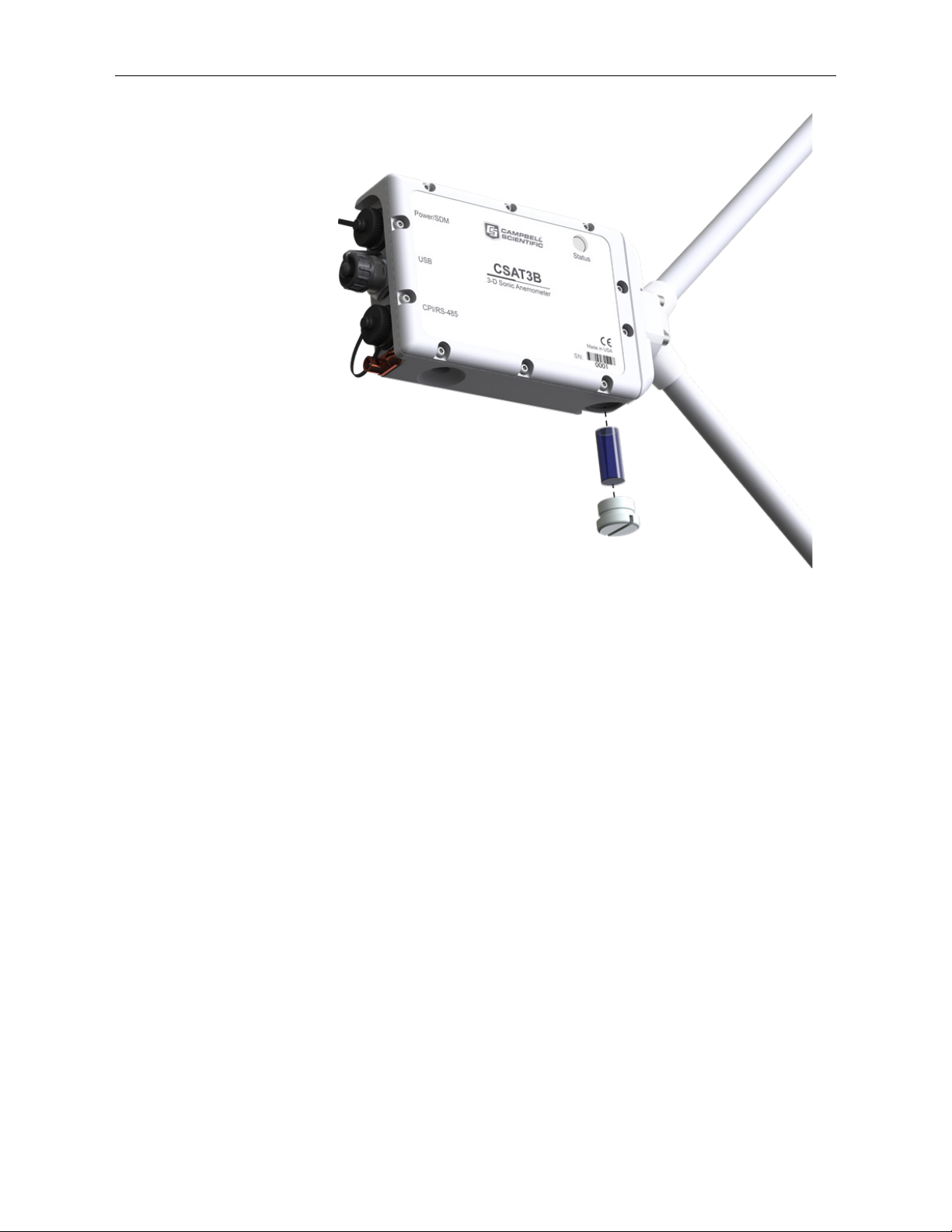

CSAT3B Three-Dimensional Sonic

Anemometer

1. Introduction

The CSAT3B is an ultrasonic anemometer for measuring sonic temperature

and wind speed in three dimensions. The CSAT3B can measure average

horizontal wind speed and direction, or turbulent fluctuations of horizontal and

vertical wind, and sonic temperature. Further, momentum flux and sensible

heat flux can be calculated from the turbulent wind and sonic temperature

fluctuations. Latent and sensible heat flux and gas fluxes may be determined by

computing the covariance between vertical wind measured by the CSAT3B and

scalar quantities measured by other appropriate sensors.

Before attempting to use or install the CSAT3B please review:

2. Precautions

• Section 2, Precautions

• Section 3, Initial Inspection

• Section 4, QuickStart

• READ AND UNDERSTAND the Safety section at the back of this

manual.

• CAUTION

o Voltage input must be within range of 9.5 − 32 VDC

o The CSAT3B head should be handled by holding the block at the back

of the sensor. Handling it by the arms or transducers could cause

geometric deformation, which degrades the measurements.

o The transducer faces are fragile. Care should be taken to avoid

scratching or rubbing the surface of the transducer.

o Grounding the CSAT3B is critical. Proper grounding to Earth will

ensure maximum electrostatic discharge (ESD) and lightning

protection and improve measurement accuracy.

• IMPORTANT

o Install USB drivers and Device Configuration Utility before attaching

sensor to computer

(p. 1)

(p. 1)

(p. 2)

3. Initial Inspection

Upon receipt of the CSAT3B, inspect the packaging and contents for damage.

File damage claims with the shipping company. Contact Campbell Scientific to

facilitate repair or replacement.

Immediately check package contents against shipping documentation.

Thoroughly check all packaging material for product that may be trapped

inside. Contact Campbell Scientific about any discrepancies. Model numbers

are found on each product. On cables, the model number is often found at the

connection end of the cable. Check that correct lengths of cables are received.

1

Page 7

4. QuickStart

Crossarm-to-Pole

Bracket

CM20X Crossarm

4.1 Hardware Connections

CSAT3B Three-Dimensional Sonic Anemometer

The CSAT3B ships with:

• CM250 leveling mounting kit

• USB data cable

• Certificate of conformance

This QuickStart section covers only the very basic steps in setting up a

CSAT3B using SDM or CPI communications with a Campbell Scientific data

logger. It is intended primarily as an overview and general reference for setup

of a CSAT3B, and is not intended as a replacement for the more detailed

information on installation found in Section 7, Installation

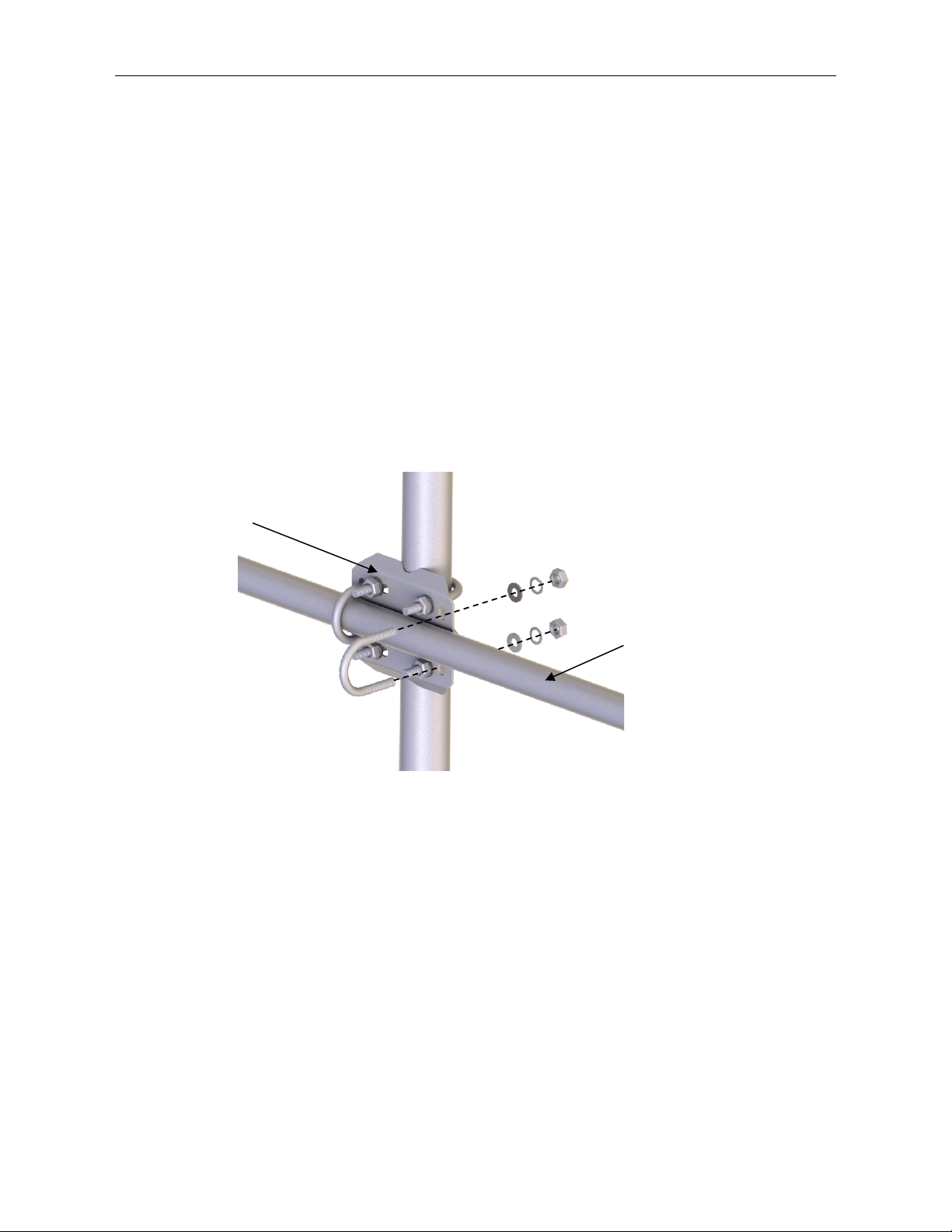

1. Mount a 3.33 cm (1.31 in) outer diameter pipe or crossarm (such as a

CM20X) to a tripod mast or tower as shown in FIGURE 4-1.

(p. 22).

FIGURE 4-1. Mounting a CM20X crossarm with crossarm-to-pole

bracket

2. Mount the CM250 leveling mount to the end of the crossarm as shown in

FIGURE 4-2.

3. Use the captive bolt on the CM250 to mount the CSAT3B (FIGURE 4-2).

The orientation of the CSAT3B should be level and pointing in the

direction of the prevailing wind.

2

Page 8

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

CM20X Crossarm

CM250 Leveling Mount

CSAT3B Grounding Lug

FIGURE 4-2. CSAT3B mounting

4. Ground the CSAT3B to the tower by attaching a user-supplied, heavy-

gauge wire from the copper grounding lug on the back of the CSAT3B

block (FIGURE 4-3).

5. Earth (chassis) ground the other end of the wire to the CSAT3B mounting

structure or to a grounding rod. For more details on grounding, see the

grounding section of the CR3000 data logger manual.

If connecting multiple CSAT3Bs together either in a series or a

star topology, each CSAT3B must be separately grounded to

either the mounting structure or a grounding rod.

FIGURE 4-3. Grounding lug of CSAT3B

3

Page 9

CSAT3B Three-Dimensional Sonic Anemometer

CAUTION

CSAT3BCBL1-L-PT

Grounding Cable

Grounding the CSAT3B is critical. Proper grounding to Earth

(chassis) will ensure maximum ESD protection and improve

measurement accuracy.

4.2 Communications Connections

1. Connect power and communication cable(s).

SDM Communications

If using SDM communications, connect a CSAT3BCBL1-L (“L” denotes

the cable length in feet) cable to the connector on the back of the CSAT3B

block labeled Power/SDM as shown in FIGURE 4-4.

CPI Communications

If using CPI communications connect a CSAT3BCBL2-L cable and a

CSAT3BCBL3-L-RJ to the connectors on the back of the CSAT3B block

labelled Power/SDM and CPI/RS-485, respectively as shown in FIGURE

4-5.

FIGURE 4-4. Cable connection for SDM

4

Page 10

CSAT3B Three-Dimensional Sonic Anemometer

TABLE 4-1. Wiring Diagram for CSAT3B with SDM

CSAT3BCBL2-L-PT

CSAT3BCBL3-L-RJ

Grounding Cable

FIGURE 4-5. Cable connections for CPI

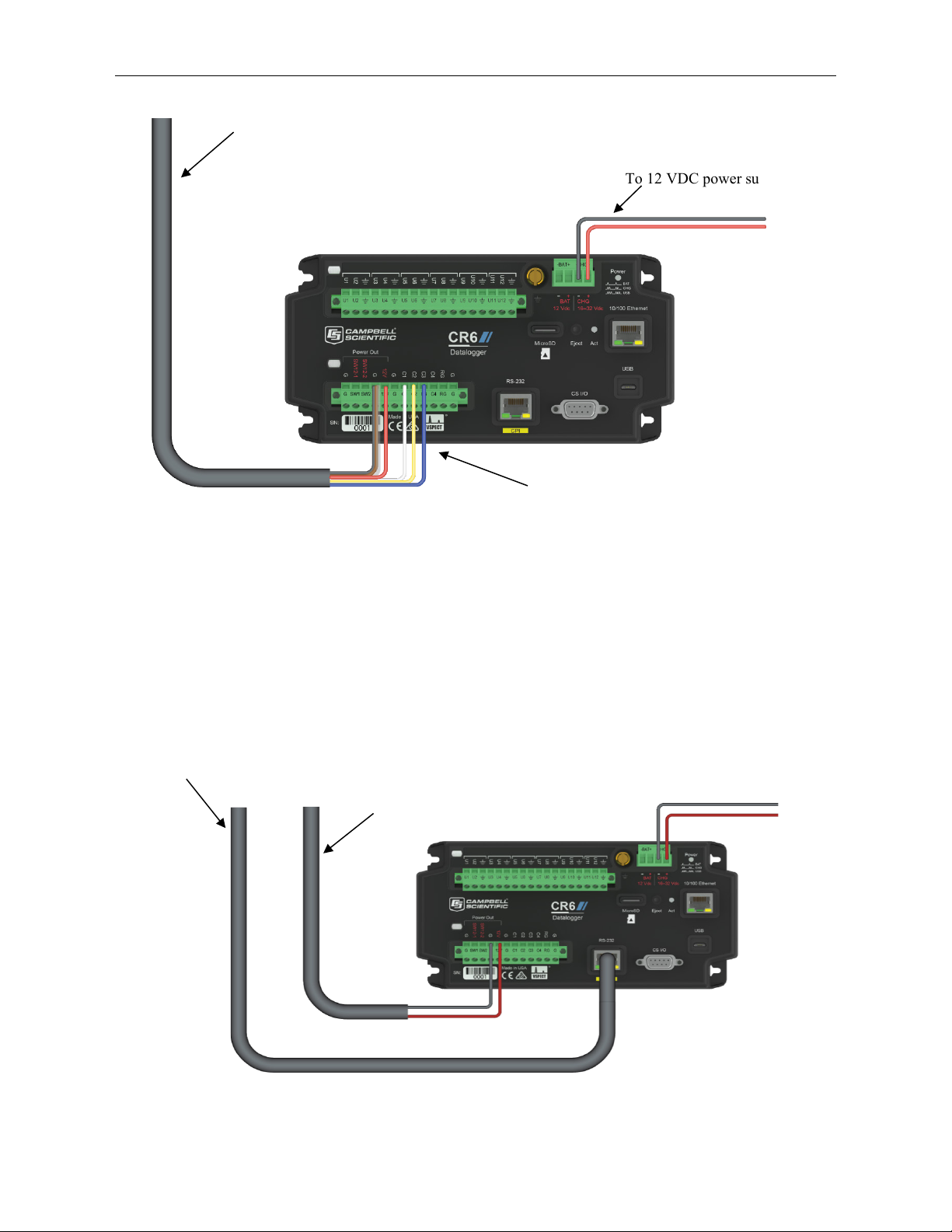

2. Connect power and communication cable(s) to data logger.

SDM Communications

If using SDM communications, connect the wires on the end of the

CSAT3BCBL1-L cable to the data logger SDM and power ports according

to TABLE 4-1. Refer to FIGURE 4-6 which shows these connections to a

CR6 data logger.

Communications

Data Logger Terminal Wire Color

12 V (or other 9.5 to 32 VDC source) Red

Ground Black

Ground Brown

SDM C1 White

SDM C2 Yellow

SDM C3 Blue

Ground Clear

5

Page 11

CSAT3B Three-Dimensional Sonic Anemometer

CSAT3BCBL1 SDM/Power cable from CSAT3B

Wire to power and SDM ports

To 12 VDC power supply

CSAT3BCBL3-L-RJ

CSAT3BCBL2-L-PT

To power supply

FIGURE 4-6. SDM and power wiring to a CR6 data logger

CPI Communications

With CPI communications, connect the red and black wires on the end of

the CSAT3BCBL2-L-PT to the 12 V and ground terminals of a data logger

or to a 9.5 to 32 VDC power supply. Connect the RJ-45 connector on the

end of the CSAT3BCBL3-L-RJ to the CPI port on the CPI-compatible

data logger. Use FIGURE 4-7 as a reference.

FIGURE 4-7. CPI and power connections to a CR6 data logger

6

Page 12

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

3. Use LoggerNet, PC400, or PC200W to send a data logger program to the

data logger. See Section 8.4, Data Logger Programming using SDM or

(p. 57), for more information on data logger instructions and

CPI

programming.

4. Verify that measurements are being made by ensuring the green Status

light (FIGURE 4-8) on the CSAT3B block is blinking, indicating that

measurements are being made and recorded in the data logger without

diagnostic error conditions.

In the default operating Mode 0, where the CSAT3B measurement

and output are triggered by a data logger (see Section 8.2,

Operating Modes

(p. 50), for more details), the CSAT3B Status

light will flash red until a data logger is connected to the CSAT3B

and its program is running and sending measurement triggers.

FIGURE 4-8. Lit status light on CSAT3B block

4.3 Factory Settings

The CSAT3B is shipped from the factory with the default settings that are

shown in TABLE 4-2. These settings can be changed with a computer running

Campbell Scientific Device Configuration Utility, version 2.10 or newer, and

the USB cable that shipped with the CSAT3B. Device Configuration Utility is

available from the Campbell Scientific website in the Support | Downloads

section and is included with LoggerNet, PC400, and PC200W and software

packages.

7

Page 13

CSAT3B Three-Dimensional Sonic Anemometer

TABLE 4-2. CSAT3B Factory Settings

Setting Default

SDM address 3

CPI address 30

Communication

Settings

Measurement

Setting

CPI/RS-485 Communication Port Protocol CPI Enabled

5. Overview

CPI Baud Rate Auto

RS-485 Baud Rate 115200

Unprompted Output Port Disabled

Unprompted Output Rate 10 Hz

Operating Mode

The CSAT3B is an ultrasonic anemometer for measuring sonic temperature

and wind speed in three dimensions. It is often used for studies of turbulence

and flux measurement, where turbulent fluctuations of wind speed and sonic

temperature must be measured at high frequencies; at 10Hz, for example.

From the turbulent wind fluctuations, momentum flux can be calculated. The

covariance of vertical wind and sonic temperature yields sonic sensible heat

flux. By finding the covariance between vertical wind and scalar measurements

made by other fast-response sensors, such as fine-wire thermocouples or gas

analyzers, other fluxes can be calculated. For example, sensible and latent-heat

fluxes, carbon-dioxide flux, and other trace-gas fluxes, can all be measured by

combining the CSAT3B with other sensors.

Mode 0: Data Logger Trigger/No Filter/

Data Logger Prompted Output

5.1 Features

The CSAT3B can communicate measurements using SDM (Synchronous

Device for Measurements), USB, RS-485, and CPI (CAN Peripheral Interface)

communications. For optimal synchronization with other fast-response sensors

for applications such as eddy covariance, Campbell Scientific recommends

using SDM or CPI communications with an appropriate Campbell Scientific

data logger.

The CSAT3B offers the following key features:

• Integrated electronics provide easy mounting of a single piece of

hardware

• Integrated inclinometer

• High-precision measurements ideal for turbulence and eddy

covariance studies

• An improved design with a thin, aerodynamic support strut close to

the ends of the sensor arms, creating greater rigidity and improved

accuracy of sonic temperature

• Supports data logger sampling at any frequency between 1 and 100 Hz

8

Page 14

• New CPI communications for more robust, higher bandwidth

measurements

• Multiple communication options including SDM, CPI, USB, and RS-

485

• Internal temperature and humidity measurements with easily replaced

desiccant

• Version 5 algorithm for calculating data outputs; combines the signal

sensitivity of version 3 with the rain performance of version 4

• Includes options to filter high frequencies for applications requiring

analysis of non-aliased spectra

5.2 Sensor Components

The CSAT3B consists of several components. Some components come

standard with every CSAT3B; others are considered accessories that must be

ordered separately. Some common accessories such as cables are required to

operate a CSAT3B.

5.2.1 Standard Components

Standard components are items that are included or shipped with the CSAT3B.

The following sections describe these items.

CSAT3B Three-Dimensional Sonic Anemometer

5.2.1.1 CM250 Leveling Mounting Kit

The CM250 leveling mounting kit is shipped with the CSAT3B and comes

with an adapter (FIGURE 5-1) that facilitates mounting a CSAT3B at the end

of a 3.33 cm (1.31 in) OD crossarm or pipe. The kit includes a captive 3/8-in

bolt that screws into the bottom of the CSAT3B block, and a 3/16-in Allen

wrench to tighten the adapter on the pipe.

FIGURE 5-1. CM250 mount

5.2.1.2 USB Data Cable

The USB data cable is a 5 m (16 ft) USB cable included with the CSAT3B.

One end has a standard type-A male connector to connect to a computer, while

the opposite end has a mini-B male connector, which connects to the USB port

on the back of the CSAT3B block. The mini-B male connector is rated to

Ingress Protection 68 (IP68) to exclude fine dust and water. When connected

with the cable, Device Configuration Utility allows the user to view or set

settings, send a new operating system to the CSAT3B, or view real-time

measurements. It is also possible to use this cable to collect data with a

computer in unprompted USB mode. Section 6.2, Communications

provides additional information.

(p. 20),

9

Page 15

FIGURE 5-2. USB data cable

NOTE

5.2.2 Optional Components

5.2.2.1 Sonic Environment Option

If the CSAT3B is intended to be located in harsh environments such as marine

or heavily fertilized locations, coated transducers, which help prevent

corrosion, can be purchased as an option.

CSAT3B Three-Dimensional Sonic Anemometer

5.2.2.2 Sonic Carrying Case

A large, hard plastic Pelican™ carrying case is available for the CSAT3B. It is

watertight and highly durable. This case is recommended for transporting and

storing the CSAT3B. It includes a set of foam inserts that hold the CSAT3B in

a protected position while providing space for additional components.

If opting out of the sonic carrying case, the CSAT3B will be shipped in a large

cardboard box. The same set of foam inserts used in the sonic carrying case is

used in the cardboard box to securely hold the CSAT3B.

If choosing the cardboard box for shipping, it is recommended to

keep the foam inserts and box. When returning a CSAT3B for

factory recalibration or repair, it is important to ship the unit with

the foam inserts provided from the factory.

5.2.3 Common Accessories

Common accessories for the CSAT3B include cables as well as other

equipment to make sensible heat flux measurements. A fine-wire thermocouple

is an example of an additional sensor often used with a CSAT3B. Descriptions

of cables and other common accessories are described in greater detail in the

following sections.

5.2.3.1 Power and Communications Cables

Cables required for the CSAT3B to be functional, must be ordered along with

the CSAT3B. The types of cables needed for a specific communications mode,

are outlined below.

10

Page 16

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

NOTE

NOTE

Unlike the earlier CSAT3, default-length cables are not included.

This allows the user to specify the exact length, communication

type, and connector type of the cable(s) needed for the application.

Campbell Scientific uses a system for naming cables that provide specific

information about details of the cable and some information about the use of

the cable.

• The ‘–L’ in the cable model name is an option that denotes a user-

specified length of cable in feet.

• The ‘–PT’ is a cable option that specifies one end of the cable to have

pigtail wires for wiring to a power source, data logger terminals, or a

wiring bus. The other end has an M16 connector for connecting to the

corresponding port at the back of the CSAT3B block.

• The ‘–MC’ option designates an M16 connector on both ends of the

cable and is used to daisy-chain several CSAT3B instruments together

in series.

Daisy chaining requires ordering the 30293 splitter (see Section

5.2.4.1, Power/SDM Splitter (p. 15), and Section 5.2.4.2, CPI/RS-

485 Splitter

(p. 15)) for each CSAT3B in series, except the terminal

one.

• The ‘–RJ’ option has an RJ-45 connector on one end for connecting

directly to the CPI port on a data logger such as the CR6 or to a CPI

port on the HUB-CPI if a network of several CPI devices are being

installed in a star topology. The other end of the cable has an M16

connector for connecting to the CSAT3B block. The types of cables

needed for a specific communications mode are outlined below. For

information on maximum cable lengths, refer to the communications

specifications in Section 6.2, Communications

(p. 20).

Power/SDM Cable (CSAT3BCBL1)

To use SDM communications to collect data from a CSAT3B with a data

logger, the CSAT3BCBL1-L-PT or CSAT3BCBL1-L-MC should be ordered.

FIGURE 5-3 shows the two versions. This cable transmits both power and

SDM communication signals.

To collect data through another means (CPI, RS-485, USB), the

CSAT3BCBL1 Power/SDM cable may still be used to provide

power to the CSAT3B, in which case the SDM wires should be

left unwired to any ports on the data logger.

11

Page 17

CSAT3B Three-Dimensional Sonic Anemometer

FIGURE 5-3. Options for CSAT3BCBL1 Power/SDM cable

Power Cable (CSAT3BCBL2)

To use CPI, RS-485, or USB communications to collect data from a CSAT3B,

the CSAT3BCBL2-L-PT or CSAT3BCBL2-L-MC should be ordered to

provide power to the sensor. A second cable to transmit the communications is

also required (for example, CSAT3BCBL3 CPI/RS-485 cable for CPI or

RS-485, or the 30179 USB data cable).

For installations with long cable lengths, the CSAT3BCBL2 is preferred over

the CSAT3BCBL1 for providing power due to the heavier gauge wires that

reduce voltage drop over long distances. Allowed length is 1 to 550 ft.

Although the maximum cable length is 550 feet, users requiring a cable length

of 401 to 550 feet should use a 24 V power supply.

FIGURE 5-4. Options for CSAT3BCBL2 power cable

12

Page 18

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

CPI/RS-485 Cable (CSAT3BCBL3)

To use CPI or RS-485 communications to collect data from a CSAT3B, the

CSAT3BCBL3-L-PT, CSAT3BCBL3-L-RJ, or CSAT3BCBL3-L-MC, should

be ordered in addition to a cable to provide power to the sensor (for example,

either the CSAT3BCBL1 or CSAT3CBL2).

FIGURE 5-5. Options for cabling CPI or RS-485 communications

5.2.3.2 FW05 Thermocouple

The FW05 is a Type E thermocouple with a 0.0127 mm (0.0005 in) diameter

(FIGURE 5-6). The thermocouple measures atmospheric temperature

fluctuations and may be used with the CSAT3B to directly calculate sensible

heat flux. Larger size fine-wire thermocouples, such as the FW1 and FW3,

which are more robust but have slower response times, may also be used with

the CSAT3B.

FIGURE 5-6. FW05 thermocouple

Users requiring fine-wire thermocouples for atmospheric

temperature measurements should consider their data logger

choice. The CR6 data logger is not optimal for taking fine-wire

thermocouple measurements. For help in choosing the best data

logger when fine-wire thermocouples are required, contact

Campbell Scientific.

13

Page 19

5.2.3.3 FWC-L Cable

NOTE

The FWC-L is a cable with connector that mates with the connector on a

FW05, FW1, or FW3 fine-wire thermocouple. The other end of the cable has

pigtail wires to wire to a pair of differential voltage terminals on a data logger.

The –L denotes the length of cable in feet, which can be designated at the time

of ordering.

5.2.3.4 Thermocouple Cover

The TC cover is a white metal, thermocouple cover that is placed over the

connectors of the FW05 and the FWC-L cable. It is used to mount the

connectors to the side of the CSAT3B block. It also minimizes temperature

gradients across the connectors.

5.2.3.5 Thermocouple Cover Backplate

The CSAT3B fine-wire thermocouple cover backplate attaches to the CSAT3B

block and is used to cover the back side of the thermocouple (TC) cover.

The backplate is required for the CSAT3B but not for other

Campbell sonic anemometers. In the case of previous models, the

back side of the TC cover is covered by the sensor block.

CSAT3B Three-Dimensional Sonic Anemometer

5.2.3.6 FW/ENC Thermocouple Enclosure

The FW/ENC is a small case (FIGURE 5-7) that is used for storing up to four

fine-wire thermocouples. Due to the fragile nature of the FW05 thermocouple,

it should always be stored in an FW/ENC when not in use. It is also

recommended to order, at a minimum, a set of four FW05 thermocouples for

every CSAT3B as the FW05 will break during normal wear and tear in the

field.

FIGURE 5-7. FW/ENC for storing fragile thermocouples

5.2.4 Other Accessories

The other accessories available for the CSAT3B are used when combining

multiple CSAT3B units into a network of sensors, the data from which are

collected by a single data logger. Networks of CSAT3Bs using SDM or CPI

communications may be configured in one of three different configurations:

• In a series, using a daisy-chain topology

• In parallel, using a star topology

• In a combination of daisy-chain and star topology

14

Page 20

When designing an SDM or CPI network, careful attention should be given not

to exceed a total network cable length that will excessively attenuate the sensor

signals. The exact total length will depend on factors such as sample rate and

topology, but in general the maximum cable lengths (given in Section 6.2,

Communications

followed.

Because CPI communications can support longer network cable lengths, it is

generally recommended as the communication method for sensor networks.

For more detailed information on network topologies and limits on cable

lengths for CPI networks, see the white paper titled Designing Physical

Network Layouts for the CPI Bus, available at www.campbellsci.com.

5.2.4.1 Power/SDM Splitter

The Power/SDM splitter has three 6-pin M16 connectors. The splitter, shown

in FIGURE 5-8, allows connection at the Power/SDM port on the back of the

CSAT3B block to two CSAT3BCBL1 or CSAT3BCBL2 cables. The splitter is

IP68 rated, meaning it is dust and watertight. It is used for daisy-chaining

multiple CSAT3Bs in series. A Power/SDM Splitter is required for each

CSAT3B in the daisy chain (regardless of communication method used) except

for the terminal one.

CSAT3B Three-Dimensional Sonic Anemometer

(p. 20)) for each communication type and data rate should be

FIGURE 5-8. CSAT3B Power/SDM splitter (showing pin configuration)

5.2.4.2 CPI/RS-485 Splitter

The CPI/RS-485 splitter has three 8-pin M16 connectors. The splitter allows

connection at the CPI/RS-485 port on the back of the CSAT3B block to two

CSAT3BCBL3 cables. The splitter is IP68 rated. It is used for daisy-chaining

multiple CSAT3Bs in series that use CPI or RS-485 communications. A splitter

is required for each CSAT3B in the daisy-chain, except for the terminal one.

For a daisy-chain of CSAT3Bs using SDM communications, the CPI/RS-485

splitter is not needed. Only the Power/SDM splitter (see Section 5.2.4.1,

Power/SDM Splitter

Transient voltage drop is commonly caused by the large series inductance

introduced by either long power cables, multiple CSAT3Bs connected by

(p. 15)) is needed.

15

Page 21

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

splitters, or a combination of both. Because the measurements are

synchronized, multiple CSAT3Bs connected to the same power cable each

draw a pulse of current at the same moment. This has a cumulative effect on

the voltage drop. If the voltage drop is sufficiently large, then the low-voltage

detection circuit inside the CSAT3B sensor can be tripped which forces the

device to reset. A power cable compensation plug for the CSAT3B (FIGURE

5-9) is needed if voltage drop creates problems. The plug is compatible with all

CSAT3Bs. The plug should be placed on the final Power/SDM splitter in the

CSAT3B daisy-chain, farthest from the power supply.

FIGURE 5-9. CSAT3B power cable compensation plug

The primary indicator of low voltage is in the diagnostic flags returned by the

CSAT3B to the data logger. Flag number 32 (0x0020) indicates a low-voltage

condition was detected. If the instrument returns flag 32, first measure the

power source voltage and ensure that its DC value meets specifications. If that

value is appropriate, the voltage at the far end of the cable should be checked.

This must be tested under load so a splitter at the end of the cable will be

required to measure the terminal voltage. These two tests will eliminate the DC

voltage as the source of the problem. Any DC voltage below 12 V at the sensor

would be suspect for susceptibility to droop. In larger systems, even DC

voltages of 13-15 V can still experience enough droop to trigger the detection

under the right conditions. Power systems of 24 V are very unlikely to

experience enough droop to observe this problem. If the DC case checks out

but the flag is still observed, then the system would probably benefit from the

addition of a power compensation plug (FIGURE 5-9).

Both splitters, the CPI/RS-485 and the Power/SDM, look similar;

however, they have a different number of pins and are not

interchangeable.

FIGURE 5-10. CSAT3B CPI/RS-485 splitter (showing pin configuration)

16

Page 22

5.2.4.3 HUB-SDM8

CSAT3B Three-Dimensional Sonic Anemometer

The HUB-SDM8 (shown in FIGURE 5-11) allows up to six SDM devices

(typically, one data logger and multiple SDM sensors) to be connected together

in parallel. In the case of the CSAT3B, up to five CSAT3Bs, or CSAT3B

daisy-chains using CSAT3BCBL1 cables, may be connected to the HUBSDM8. In cases where multiple CSAT3Bs are installed some distance from the

data logger, the HUB-SDM8 can be placed near the CSAT3Bs with a single

SDM cable extended from the hub to the data logger. This decreases the total

network cable length, which limits signal attenuation.

The HUB-SDM8 has eight terminal strips and features spring-loaded guillotine

terminals for easy wiring. It comes in a watertight enclosure and includes a Ubolt for mounting to a vertical pipe or mast. An SDM Cable (CABLE5CBL-L;

see Section 5.2.4.4, SDM Cable CABLE5CBL-L

(p. 17)) should be ordered to

connect the HUB-SDM8 to a data logger and a power supply.

FIGURE 5-11. HUB-SDM8 for multiple CSAT3B connections with SDM

communications

5.2.4.4 SDM Cable CABLE5CBL-L

The SDM cable, CABLE5CBL-L, is a 22 AWG, five-conductor cable with a

Santoprene jacket and an aluminum Mylar shield. By default, the conductors

are stripped and tinned.

The CABLE5CBL-L is used to connect the power and SDM connection from a

HUB-SDM8 to the power and SDM connections on a power source and data

logger.

5.2.4.5 HUB-CPI

The 8-channel RJ45 HUB-CPI allows up to eight CPI devices to be connected

together in parallel. In the case of the CSAT3B, up to seven CSAT3Bs, or

CSAT3B daisy-chains using CSAT3BCBL3 cables, may be connected in

parallel to the HUB-CPI. The remaining port may be used with a CAT5e or

CAT6 Ethernet cable (see Section 5.2.4.4, SDM Cable CABLE5CBL-L

connect the HUB-CPI to the CPI port on a data logger such as the CR6.

(p. 17)) to

17

Page 23

CSAT3B Three-Dimensional Sonic Anemometer

The HUB-CPI (shown in FIGURE 5-12) is not weatherproof and should be

housed in an enclosure, typically alongside the data logger.

FIGURE 5-12. HUB-CPI for multiple CSAT3B connections to CPI

communications

5.2.4.6 CAT6 Ethernet Cable

The CAT6 Ethernet cable is a 61 cm (2 ft), unshielded CAT6 network cable

with RJ45 connectors. Typically, it connects the HUB-CPI to the CPI port on a

data logger such as the CR6.

FIGURE 5-13. CAT6 Ethernet cable

6. Specifications

The CSAT3B measures wind speed and the speed of sound along the three

non-orthogonal sonic axes. The wind speeds are then transformed into the

orthogonal wind components u

, uy, and uz, and are referenced to the

x

18

Page 24

CSAT3B Three-Dimensional Sonic Anemometer

anemometer head. The reported ultrasonic air temperature (T

between the temperatures computed for the three non-orthogonal sonic axes.

The vector component of the wind that is normal to each sonic axis (such as a

crosswind) leads to a measurement error that is corrected online by the

CSAT3B before the wind speed is transformed into orthogonal coordinates.

Because of this correction, it is not necessary to apply the speed of sound

correction described by Liu et al., 2001 (see Section 10.1, References

The CSAT3B has several operating modes to suit different applications. The

anemometer can be configured to make a single measurement per data logger

trigger, or it can operate in a self-triggered mode. When self-triggering, the

CSAT3B will make measurements at a high rate, apply an optional userselectable bandwidth filter, and provide the latest output upon receiving an

output prompt. An output prompt may come from the data logger, or in the

case of unprompted output mode (such as computer data collection), the output

is prompted by the CSAT3B itself. The default operating mode of the CSAT3B

is to make measurements when triggered by a data logger (SDM or CPI),

which does not apply any low-pass (high-cut) filtering. See Section 4.2,

Communications Connections

Section 8.2, Operating Modes

6.1 Measurements

Operating Temperature

Standard: –30 to 50 °C

Wind Accuracy (–40 to 50 °C, wind speed < 30 m·s

Offset Error

: ± 8 cm·s

u

x

: ± 8 cm·s–1 max

u

y

: ± 4 cm·s–1 max

u

z

Gain Error

Wind Vector ± 5° of horizontal: ± 2% of reading max

Wind Vector ± 10° of horizontal: ± 3% of reading max

Wind Vector ± 20° of horizontal: ± 6% of reading max

Wind Resolution

: 1.0 mm·s–1 RMS

u

x

: 1.0 mm·s–1 RMS

u

y

: 0.5 mm·s–1 RMS

u

z

Wind Full Scale Range: ± 65 m·s

Sonic Temperature Resolution: ± 0.002 °C RMS at 25 °C

Sonic Temperature Reporting Range: –30 to 50 °C

Measurement Rates

Data Logger Triggered: 1–100 Hz

Unprompted Output (to computer): 10, 20, 50, or 100 Hz

Internal Self-Trigger Rate: 100 Hz

) is the average

s

(p. 68)).

(p. 4), for a list of all default settings, and see

(p. 50), for more information on modes.

–1

, azimuth angles between ± 170 °C)

–1

max

–1

19

Page 25

Measurement Delay

Data Logger Triggered (no filter): 1 trigger period (1 scan interval)

Unprompted Output (no filter): 10 ms

Filtered Output (Data Logger Prompted or Unprompted to computer):

795 ms with 5 Hz bandwidth filter

395 ms with 10 Hz bandwidth filter

155 ms with 25 Hz bandwidth filter

Filter Bandwidths: 5, 10, or 25 Hz

Internal Monitor Measurements

Update Rate: 2 Hz

Inclinometer Accuracy: ± 1 °

Relative Humidity Accuracy: ± 3% over 10 − 90% range

± 7% over 0 − 10% range

± 7% over 90 − 100% range

Board Temperature Accuracy: ± 2 °C

6.2 Communications

SDM: Used for data logger based data acquisition.

Bit Period: 10 µs to 1 ms

Cable Length: 7.6 m (25 ft) max @ 10 µs bit period

76 m (250 ft) max @ 1 ms bit period

Address Range: 1 – 14

Bus Clocks per Sample: ~200

CPI: Used for data logger based data acquisition.

Baud Rate: 50 kbps to 1 Mbps

Cable Length:

122 m (400 ft) max @ 250 kbps

853 m (2800 ft) max @ 50 kbps

Address Range: 1 – 120

Bus Clocks per Sample: ~300

RS-485: Used for anemometer configuration or computer-based data acquisition.

Baud Rate: 9.6 kbps to 115.2 kbps

Cable Length: 305 m (1000 ft) max @ 115.2 kbps

610 m (2000 ft) max @ 9.6 kbps

Bus Clocks per Sample: ~500 (ASCII formatted)

USB: Used for anemometer configuration or computer-based data acquisition.

Connection Speed: USB 2.0 full speed 12 Mbps

Cable Length: 5 m max

i

15 m (50 ft) max @ 1 Mbps

CSAT3B Three-Dimensional Sonic Anemometer

i

For additional details, refer to CSI whitepaper “Designing Physical Network Layouts for the CPI

Bus”

20

Page 26

6.3 Power Requirements

Voltage Requirement: 9.5 – 32 VDC

Current Requirement (10 Hz Measurement Rate)

Current @ 12 VDC: 110 mA

Current @ 24 VDC: 65 mA

Current Requirement (100 Hz Measurement Rate)

Current @ 12 VDC: 145 mA

Current @ 24 VDC: 80 mA

6.4 Physical Description

Dimensions

Anemometer Overall: 60.7 cm (23.9 in) length

43.0 cm (16.9 in) height

12.2 cm (4.8 in) width

Measurement Path: 10.0 cm (3.9 in) vertical

5.8 cm (2.3 in) horizontal

Transducer Angle: 60 degrees from horizontal

Transducer Diameter: 0.64 cm (0.25 in)

Transducer Mounting Diameter: 0.84 cm (0.33 in)

Support Arm Diameter: 1.59 cm (0.63 in)

Cardboard Box with Foam: 73.7 x 45.7 x 25.4 cm (29 x 18 x 10 in)

Carrying Case with Foam: 79.5 x 51.8 x 31 cm (31.3 x 20.4 x 12.2 in)

Weight

Anemometer Head: 1.45 kg (3.2 lb)

Including Cardboard Box Option: 5.3 kg (11.7 lb)

Including Carrying Case Option: 13.4 kg (29.5 lb)

Shipping (Both cardboard and carrying cases options are shipped within a second box)

Cardboard Box Option

Weight: 9.1 kg (20.0 lb)

Dimensions: 91 x 51 x 41 cm (36 x 20 x 16 in)

Carrying Case Option

Weight: 16.3 (36.0 lb)

Dimensions: 81 x 66 x 43 cm (32 x 26 x 17 in)

CSAT3B Three-Dimensional Sonic Anemometer

21

Page 27

CSAT3B Three-Dimensional Sonic Anemometer

7. Installation

FIGURE 6-1. Dimensions of CSAT3B

Campbell Scientific recommends that the CSAT3B and data acquisition system

is setup in a laboratory setting before field installation. This provides an

opportunity to verify that settings and programs are correct in a controlled

environment. Prior to setup, the user needs to know information about the

desired sensor settings, orienting, mounting, and leveling the CSAT3B, which

is covered in the following sections.

If the CSAT3B is to be used in a marine environment, or in an environment

where it is exposed to corrosive chemicals (for example, the sulfur-containing

compounds in viticulture), attempt to mount the CSAT3B in a way that reduces

the exposure of the sonic transducers to saltwater or corrosive chemicals. In

marine or viticulture environments, the sonic transducers are expected to age

more quickly and require replacement sooner than a unit deployed in an inland,

chemical-free environment.

22

Page 28

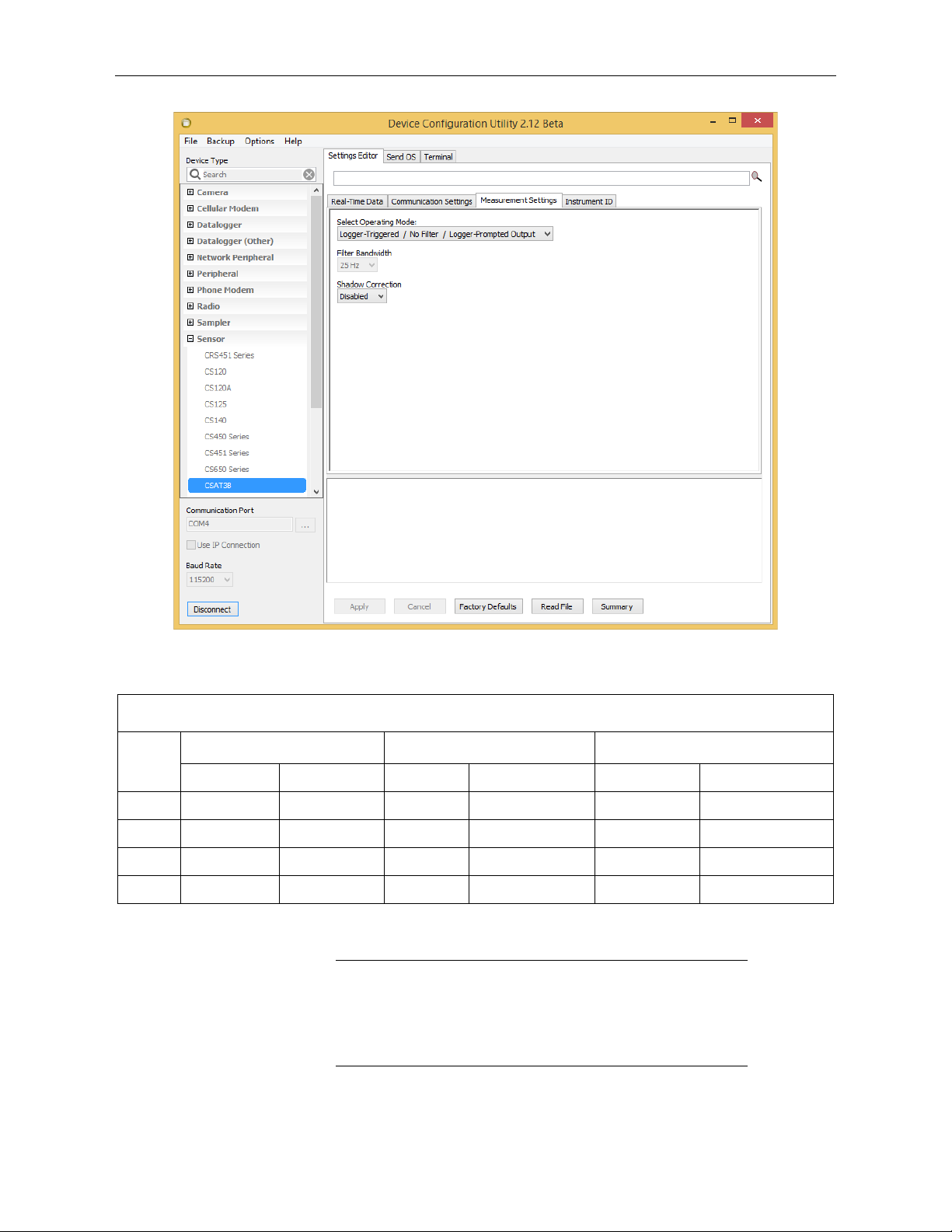

7.1 Settings

CSAT3B Three-Dimensional Sonic Anemometer

Prior to installation, the CSAT3B settings should be verified. This is done by

the following steps:

1. Provide power to the CSAT3B by connecting the M16 connector of

either a CSAT3BCBL1 or CSAT3BCBL2 to the Power/SDM port on

the back of the CSAT3B block. The other end of this cable will have

red and black wires that should be connected to a 9.5 to 32 VDC

power source. (In the case of the CSAT3BCBL1, the other wires need

not be connected.)

2. Connect the circular connector on the USB data cable included with

the CSAT3B to the port labelled USB on the back of the CSAT3B

block. Connect the other end of the cable to a USB port on a

computer.

3. Launch Device Configuration Utility (downloaded from

www.campbellsci.com).

4. From the left side of the main screen, select the CSAT3B among the

list of sensors. Select the appropriate communication port and baud

rate (refer to the left side of FIGURE 7-1).

5. If this is the first time the computer has connected to a CSAT3B and

depending on the computer settings, the USB driver may need to be

manually installed. To do this, make sure the computer is connected to

the internet and click on the install the USB driver link as shown in

FIGURE 7-1).

6. Once the driver has been installed, if needed, press the Connect

button at the bottom left of the window.

23

Page 29

CSAT3B Three-Dimensional Sonic Anemometer

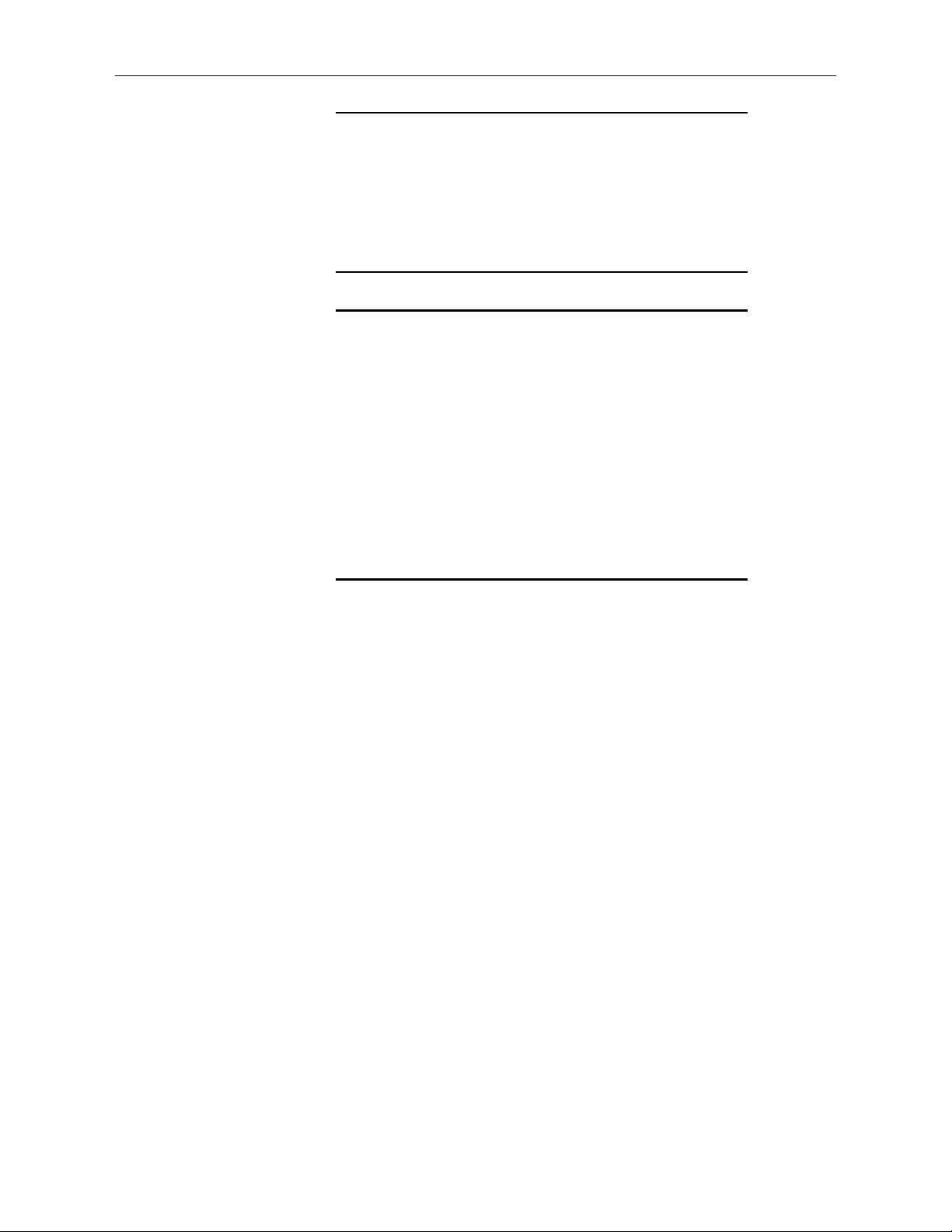

TABLE 7-1. CSAT3B Settings and Status Values in Device Configuration Utility

Shows real-time measurements of Ux, Uy, Uz,

Setting or Status

Subscreen

Real-Time Data

Value Options Description

Anemometer

Data

FIGURE 7-1. Connecting CSAT3B using Device Configuration Utility

7. Once connected, the main screen will have a section with tabs to view

the following four subscreens: Real-Time Data, Communication

Settings, Measurement Settings, and Instrument ID. TABLE 7-1

describes each of the settings or status values in these subscreens. For

each setting or status value, the factory default setting is noted by the

footnote. Ensure that the appropriate settings are enabled for the

communication protocol that will be used. An example subscreen is

shown in FIGURE 7-2.

sonic temperature (Ts), and the diagnostic

word. If operating in Mode 0 (see Section

Operating Modes

-

second. The Status light on the CSAT3B will

(p. 50)), values will flash each

8.2,

also flash red if in Mode 0 when no

measurement triggers are being received from

a data logger (for example, if a data logger is

not connected to the CSAT3B).

24

Page 30

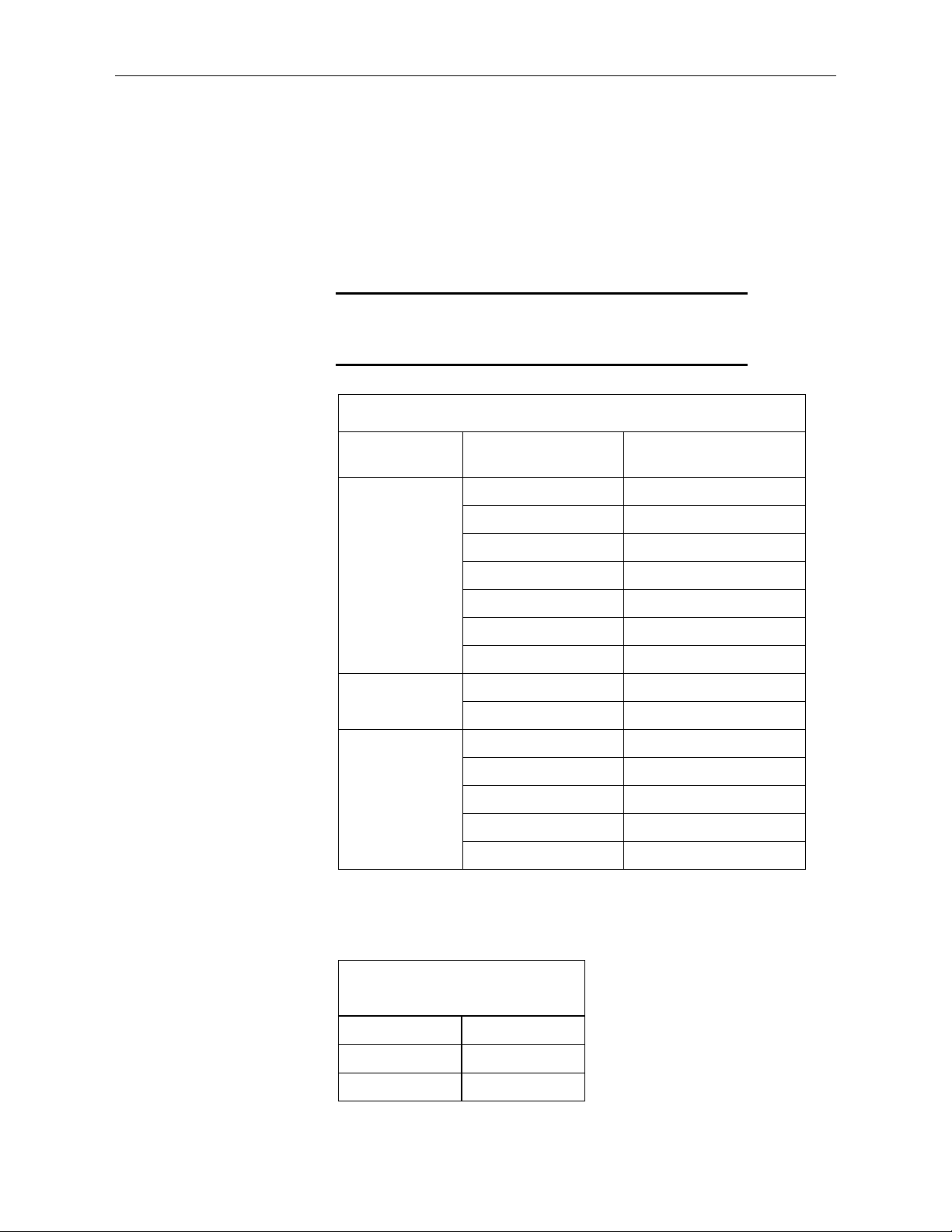

TABLE 7-1. CSAT3B Settings and Status Values in Device Configuration Utility

Subscreen

Internal

1 through 120

10 Hz1/

CSAT3B Three-Dimensional Sonic Anemometer

Setting or Status

Value Options Description

Communication

Settings

Temperature

Internal Relative

Humidity

Inclinometer

Pitch

Inclinometer Roll -

SDM Address

CPI Address

Communication

Port Protocol

1 through 14

3

301/

Disable Both

CPI Enabled

RS-485 Enabled

Auto

1000 kbps

CPI Baud Rate

500 kbps

250 kbps

125 kbps

50 kbps

1200

2400

4800

RS-485 Baud

Rate

9600

19200

38400

57600

115200

230400

Unprompted

Output Port

Disabled

USB Port

RS-485 Port

- Temperature inside CSAT3B block

Relative humidity inside CSAT3B block.

-

-

Change desiccant if greater than 50% (see

Section 9.3, Desiccant

(p. 62)).

Pitch angle of CSAT3B head (see Section 7.3,

Mounting

(p. 29))

Roll angle of CSAT3B head (see Section 7.3,

Mounting

1/

Unique address for SDM device

(p. 29))

Unique address for CPI device

Identifies whether the RS-485/CPI port will be

1/

disabled, enabled for CPI, or enabled for

RS-485

1/

Baud rate for CPI communications

(in most circumstances this setting should

remain set to Auto)

Baud rate for RS-485 communications

1/

1/

Identifies the port to output unprompted data

Unprompted

Output Rate

20 Hz

50 Hz

100 Hz

Identifies the rate at which to output

unprompted data

25

Page 31

TABLE 7-1. CSAT3B Settings and Status Values in Device Configuration Utility

Subscreen

Mode 0: Data logger

A unique identifier in addition to the serial

NOTE

NOTE

Measurement

Settings

Instrument ID

CSAT3B Three-Dimensional Sonic Anemometer

Setting or Status

Value Options Description

triggered | No filter |

Data logger

1/

prompted output

Mode 1: Self

Operating Mode

triggered | Filtered |

Data logger

prompted output

Mode 2: Self

triggered | No filter |

Unprompted output

Identifies the source of the measurement

trigger, whether a low pass filter will be

applied, and the output mode (see Section 8.2,

Operating Modes

(p. 50), for more details on

operating mode)

to computer

Mode 3: Self

triggered | Filtered |

Unprompted output

to computer

5 Hz

Filter Bandwidth

10 Hz

25 Hz

Sonic Transducer

Shadow

Correction

Anemometer

Serial Number

Disabled

Enabled

Serial Number

User ID String Blank1/

Factory ID String Blank1/

OS Version -

The cut-off frequency of the low pass filter.

Only applicable if in Operating Mode 1 or 3.

Applies an optional Kaimal correction for

wind shadowing of the sonic transducers. See

Section 8.1.3, Sonic Transducer Shadow

Correction

1/

The serial number of the CSAT3B

(p. 49).

A unique identifier in addition to the serial

number that the user may assign

number that the factory may assign

The version number of the CSAT3B operating

system

OS Date - The date the loaded operating system was built

1/

Denotes a factory default setting

Factory defaults for all setting may be restored by clicking the

Factory Defaults button at the bottom of the screen in the Device

Configuration Utility.

The SDM communications port is always enabled.

26

Page 32

CSAT3B Three-Dimensional Sonic Anemometer

FIGURE 7-2. Real-time data subscreen while connected to CSAT3B

7.2 Orientation

The three components of wind are defined by a right-handed orthogonal

coordinate system. The CSAT3B points into the negative x direction (see

FIGURE 7-7). If the anemometer is pointing into the wind, it will report a

positive u

In general, the anemometer should be pointed into the prevailing wind to

minimize interference from support structures such as the tower or tripod.

Typically, the anemometer should be mounted level to the ground as described

in Section 7.4, Leveling

7.2.1 Sonic Azimuth

The example programs report the wind direction in both the sonic coordinate

system (a right-handed coordinate system; FIGURE 7-3) and in the compass

coordinate system (a left-handed coordinate system; FIGURE 7-4). The sonic

coordinate system is relative to the sonic itself and does not depend on the

sonic orientation (azimuth of the negative x-axis). The compass coordinate

system is fixed to Earth. For the program to compute the correct compass wind

direction, the azimuth of the sonic negative x-axis must be entered into the

with Device Configuration Utility

wind.

x

(p. 30).

27

Page 33

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

program. The program default value for the variable CSAT_AZIMUTH is 0.

This assumes that the prevailing wind is from the north (e.g., the sonic is

mounted such that the negative x-axis points to the north). To change this to the

appropriate azimuth, open the CRBasic program and navigate to Const

CSAT_AZIMUTH and input the correct azimuth and send this updated

program to the data logger.

Remember to account for the magnetic declination at the site; see

Appendix A, CSAT3B Orientation (p. A-1), for details. If using an

app on a cellular phone, magnetic declination is most likely

already taken into consideration.

FIGURE 7-3. Right-hand coordinate system, horizontal wind vector

angle is 0 degrees

28

Page 34

CSAT3B Three-Dimensional Sonic Anemometer

CM210 Mounting Kit

CM20X Crossarm

FIGURE 7-4. Compass coordinate system, compass wind direction is

140 degrees

7.3 Mounting

The CSAT3B is supplied with mounting hardware to attach it to the end of a

horizontal pipe with an outer diameter of 3.33 cm (1.31 in), such as the

Campbell Scientific CM202, CM204, or CM206 crossarm (referred to

generically as a CM20X crossarm). The following steps describe the normal

mounting procedure.

1. Secure the chosen crossarm to a tripod or other vertical structure using

a CM210 crossarm-to-pole mounting kit as shown in FIGURE 7-5.

FIGURE 7-5. CM210 mounting kit with CM20X crossarm

29

Page 35

CSAT3B Three-Dimensional Sonic Anemometer

CAUTION

CAUTION

CM20X Crossarm

CM250 Leveling Mount

2. Point the horizontal arm into the direction of the prevailing wind and

tighten the nuts and bolts of the mounting hardware.

3. Attach the CM250 leveling mount (included with the CSAT3B) to the

crossarm by tightening the set screws on the boom adapter with a

3/16-in hex socket head wrench. Refer to FIGURE 7-6.

4. Attach the CSAT3B to the leveling mount by inserting the bolt on the

mount into the threaded hole on the bottom of the CSAT3B block as

shown in FIGURE 7-6.

5. Lightly tighten the bolt and then proceed to the leveling steps.

Do not carry the CSAT3B by the arms or the strut between

the arms. Always hold the CSAT3B by the block, where the

upper and lower arms connect.

Over-tightening bolts will damage the screw threads in the

CSAT3B block.

FIGURE 7-6. CSAT3B mounting

7.4 Leveling

Leveling the CSAT3B within a couple degrees is usually sufficient. The user

commonly applies coordinate rotations to time-series data to report the threedimensional wind in a coordinate system where the x- and y-axis lie along the

stream-wise wind plane.

Adjust the anemometer head so that the bubble within the level on top of the

CSAT3B block is in the bullseye. Firmly grasp the sonic anemometer block,

loosen the bolt underneath the block, and adjust the head accordingly. Finally,

tighten the bolt with a 9/16-in wrench.

30

Page 36

CSAT3B Three-Dimensional Sonic Anemometer

If an application requires greater accuracy in inclination of the CSAT3B, or if

an application requires a measurement that shows if, and when, the inclination

of the CSAT3B changes over time (for example, a sagging crossarm or tower

tilt), an integrated inclinometer in the CSAT3B can give pitch and roll

measurements.

Pitch is the angle between the gravitationally horizontal plane and the CSAT3B

x-axis. A positive pitch angle corresponds to a clock-wise rotation about the yaxis when looking down on the y-axis (see FIGURE 7-7). In other words, a

positive pitch angle occurs when the transducer end of the CSAT3B is pointed

downwards, while a negative pitch angle occurs when CSAT3B is pointed

upwards.

Roll is the angle between the gravitationally horizontal plane and the CSAT3B

y-axis. A positive roll angle corresponds to a counter-clockwise rotation about

the x-axis when looking down the x-axis (see FIGURE 7-7).

The inclinometer is sampled at a rate of 2 Hz and is not necessarily

synchronized with the wind and sonic temperature data outputs. For

applications that require correction for a moving measurement platform (on a

buoy or ship, for example), a separate fast-response inclinometer, gyrometer,

and accelerometer sensor should be used and sampled at the same rate as the

CSAT3B wind measurements.

The outputs of the CSAT3B integrated inclinometer can be viewed by

connecting the USB data cable to the CSAT3B and a computer running

Campbell Scientific Device Configuration Utility. It can also be output using

the CRBasic instruction CSAT3BMonitor. See Section 8.4.1.2,

CSAT3BMonitor()

(p. 58), for more information about setting this instruction.

31

Page 37

CSAT3B Three-Dimensional Sonic Anemometer

x y z

roll

pitch

FIGURE 7-7. CSAT3B shown with coordinate system, with arrows

representing positive x, y, and z axes; curved arrows indicate

positive rotations of pitch and roll angles

7.5 Additional Fast-response Sensors

7.5.1 Fine-Wire Thermocouple

A fine-wire thermocouple (model FW05 with a FWC-L cable, TC cover, and

TC cover backplate) can be mounted to the side of the anemometer block to

measure temperature fluctuations.

First, attach the thermocouple (TC) cover backplate to the CSAT3B with the

screw that was included. Next, attach the female connector from the FWC-L to

the side of the anemometer with the short screw (#2-56 x 0.437 inch) that was

provided with the white thermocouple cover. Insert the male connector of the

FW05 into the female connector of the FWC-L. Finally, attach the

thermocouple cover to the anemometer block using the thumb screw so that

both the FW05 and FWC-L connectors are covered. See FIGURE 7-8 for

positioning and FIGURE 7-9 with the FW05 fully installed.

32

Page 38

CSAT3B Three-Dimensional Sonic Anemometer

TC Cover Backplate

TC Cover

FWC-L

FW05

FIGURE 7-8. Exploded view of fine-wire thermocouple (TC) with

CSAT3B

FIGURE 7-9. CSAT3B with fine-wire thermocouple mounted

33

Page 39

7.5.2 Other Gas Analyzers

NOTE

If a fast-response gas analyzer is being used with the CSAT3B, care should be

taken to mount the analyzer (open-path) or the analyzer intake (closed-path) as

close as possible to the sonic sampling volume in order to obtain good spatial

and temporal synchronicity between vertical wind and gas concentration

fluctuations while also retaining adequate spatial separation. This will avoid

excessive wind distortion. In general, mount the analyzer or its intake

downwind of the sonic sampling volume.

7.6 Wiring

On the back of the CSAT3B block there is a copper grounding lug (refer to

FIGURE 4-3). Use a standard flat-head screwdriver to pinch an 8 AWG to

14 AWG wire between the lug and the lug screw. Campbell Scientific offers a

10 AWG copper wire that is suitable for grounding sensors. Connect the other

end of the wire to the tripod or tower, which should be grounded to Earth.

The CSAT3B has three watertight circular ports or connectors at the rear of the

block. These are labeled Power/SDM, USB, and CPI/RS-485 as shown in

FIGURE 4-3. Unless a port is in use and connected to a cable, they should be

securely covered by one of the caps that are captive to the CSAT3B.

CSAT3B Three-Dimensional Sonic Anemometer

The appropriate port and cable type to be used are determined by the chosen

communication method. TABLE 7-2 shows some of the criteria to use when

determining the best communication method for a given application. Once a

suitable method is determined, the appropriate combination of cables,

connectors, and lengths should be used (see Section 5.2.3.1, Power and

Communications Cables

(p. 10), for information about ordering cables).

If the CSAT3B is going to be operated using SDM or CPI communications

where the data logger triggers the measurement and the data are unfiltered (see

Mode 0 in Section 8.2, Operating Modes

(p. 50)), then the CSAT3B default

settings are appropriate and do not require modification. If, however, the

CSAT3B will be operated in another mode that either requires data filters or

uses USB or RS-485 communications, the settings must be modifying as

described in Section 7.1, Settings

(p. 23).

Unlike previous CSAT3 models, the CSAT3B does not include

7.6 m (25 ft) lengths of all cable types. Only the 5 m (16 ft) USB

cable for initial configuration of the sensor is included. Other

cables must be ordered separately.

34

Page 40

CSAT3B Three-Dimensional Sonic Anemometer

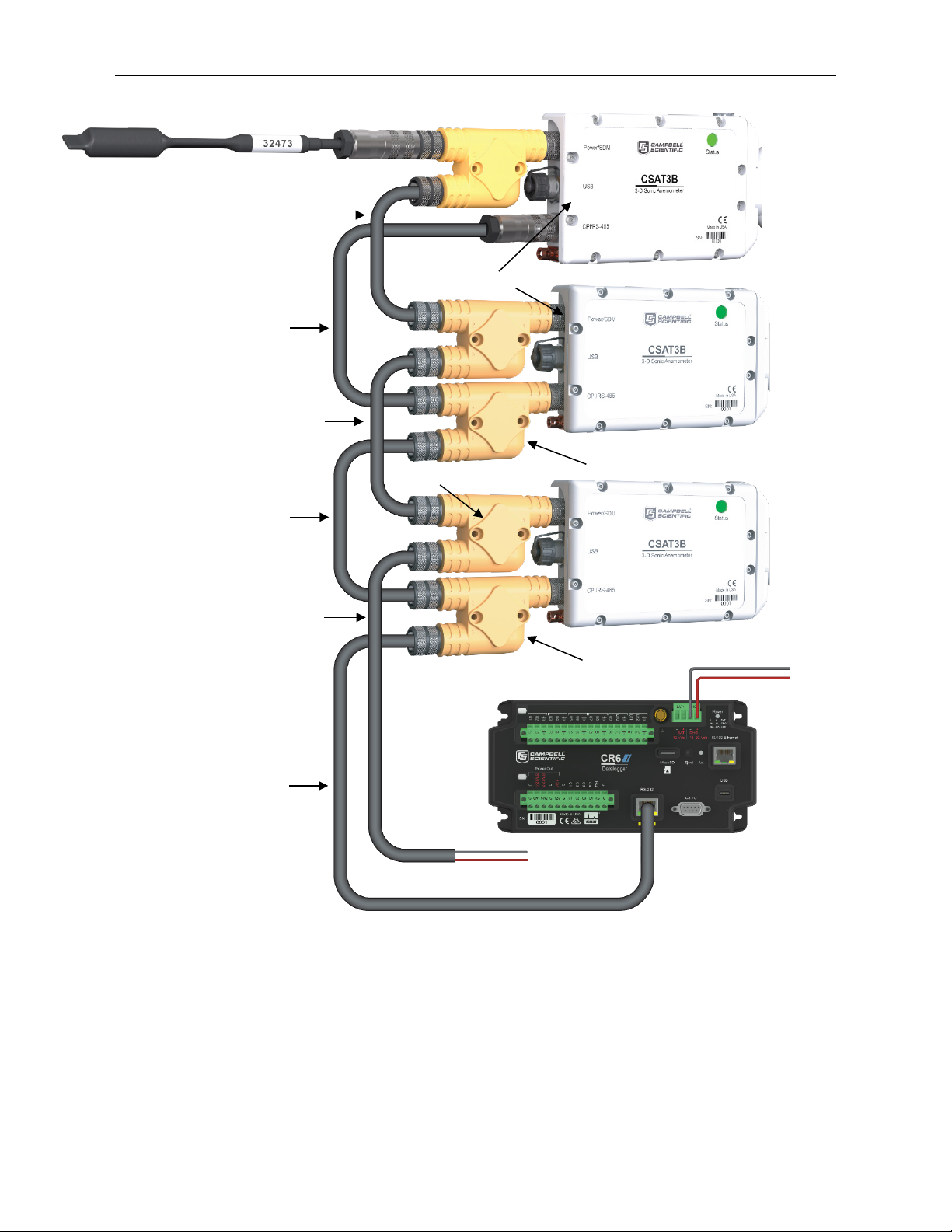

TABLE 7-2. Summary of Communications Options for the CSAT3B

NOTE

NOTE

SDM USB CPI RS-485

Data collection

Data loggers:

• CR6

• CR800

• CR1000X

• CR3000

Computer

Data loggers:

• CR6

1/

• CR800

• CR1000X

• CR3000

1/

1/

Computer

Cable length Medium Short, < 5 m Longest Long

Required cables CSAT3BCBL1

CSAT3BCBL2 and

USB cable (included)

CSAT3BCBL2 and

CSAT3BCBL3

CSAT3BCBL2 and

CSAT3BCBL3

Robustness Better Worse Best Better

Bandwidth OK Best Best OK

Synchronization

with other sensors

Best Worse Best Worse

Noisy environments OK OK Best Better

1/

Requires using the SC-CPI Interface

CPI communications is preferred over SDM communications

when using a CR6 or CR1000X data logger. See TABLE 7-2 to

examine the suitability of communications type based on various

parameters for other combinations.

7.7 Communications

There are many possible configurations of multiple CSAT3Bs and other

sensors on a single measurement station or system. Accordingly, power

requirements and sensor cable lengths should be taken into account to

appropriately power all sensors and avoid excess attenuation of signals. The

following sections describe different types of communications and different

configurations that may be helpful when designing the layout and configuration

of a system. For additional help, contact Campbell Scientific.

For all communications types, if the total number of CSAT3Bs

and other sensors powered by the data logger exceeds the limit of

output current from the data logger, the power wires must be

connected to a separate 12 to 32 VDC power supply. For long

cables, a higher voltage power supply is recommended as there

will be voltage loss over long distances.

35

Page 41

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

WARNING

For CSAT3B sensor networks with relatively long cables, the

inductive impedance can be great enough to lead to short dips in

voltage. If the voltage drops below 9.5 VDC at the input of any

CSAT3B sensor, that sensor will report a Low Voltage diagnostic

bit (see

TABLE 8-6) and the Status light will flash red. To resolve

this issue, power the CSAT3B network using a higher voltage (up

to 32 VDC) or install a capacitor at one of the current loads. If

needed, contact Campbell Scientific for assistance.

Not all of the data loggers that are compatible with the

CSAT3B support the same voltage input range as the

CSAT3B. While the CSAT3B supports voltage of up to

32 VDC, many data loggers require lower voltage. For

example, the CR800 and CR3000 require 9.6 to 16 VDC

when connecting to the front panel voltage input, the

CR1000X requires 10 to 18 VDC.

If a CR3000 has a rechargeable base, then a 17 to

28 VDC power supply may be connected to the base.

Unlike most of the data loggers, the CR6 does support

up to 32 VDC if the power supply is connected to the

CHG input terminals. For more details, refer to a data

logger user manual.

7.7.1 SDM Communications

If data collection from the anemometer is to be accomplished using a data

logger with SDM communications, connect a CSAT3BCBL1 to the

Power/SDM port by screwing in the M16 connector into the port until tight as

shown in FIGURE 7-10. No other cables are required for SDM

communications, as the CSAT3BCBL1 contains both power and SDM wiring.

If only one CSAT3B is being measured, the opposite end of the cable will have

wire pigtails if connecting directly to the ports on a data logger. Refer to

Section 4.2, Communications Connections

white, yellow, and blue wires to the SDM-C1, SDM-C2, and SDM-C3 ports

respectively, on a data logger (FIGURE 7-11). On a data logger or another 9.5

to 32 VDC power supply, connect the red and black wires to the 12 V and G

ports, respectively. See FIGURE 7-11 and TABLE 7-3 for wiring and wire

color designations.

For applications requiring very long cable lengths, a higher voltage power

supply is recommended as voltage drop over long distances will occur and the

CSAT3B requires a minimum of 9.5 VDC.

(p. 4), for this wiring. Connect the

36

Page 42

CSAT3B Three-Dimensional Sonic Anemometer

CSAT3BCBL1-L-PT

Grounding Cable

CSAT3BCBL1 SDM/Power cable from CSAT3B

Wire to power and SDM ports

To 12 VDC power supply

FIGURE 7-10. SDM/Power connections

FIGURE 7-11. Wiring to power and SDM ports on CR6 data logger

For an application that requires SDM communications from multiple

CSAT3Bs in series, or with a daisy-chain topology, first connect to each

CSAT3B as described in Section 7.1, Settings

(p. 23), to ensure each sensor has

been assigned a unique SDM address. Connect a CSAT3BCBL1 to the

Power/SDM port of the terminal CSAT3B. The opposite end will have an M16

connector that mates with one of the split M16 connectors on the Power/SDM

37

Page 43

CSAT3B Three-Dimensional Sonic Anemometer

splitters. Next, screw the side of the splitter with only one M16 connector to

the Power/SDM port of the second CSAT3B. Connect another CSAT3BCBL1

to the splitter and down to the next CSAT3B. Continue the daisy chain until the

last CSAT3B. The final CSAT3BCBL1 should have pigtail wire ends to

connect to the SDM and 12 V ports of a data logger. See FIGURE 7-12.

If several CSAT3Bs using SDM communications are being connected in

parallel or with a star topology, connect a CSAT3BCBL1 cable to the

Power/SDM port of each CSAT3B, and connect the other wires on the pigtail

end of the cables to a HUB-SDM8 bus (see Section 5.2.4.3, HUB-SDM8

(p. 17)).

Connect the wires so that all wires of a common color or signal are on the same

rail. Then, use a CABLE5CBL with pigtail wires to connect the HUB-SDM to

the SDM and 12 V ports of a data logger. See FIGURE 7-13.

38

Page 44

CSAT3B Three-Dimensional Sonic Anemometer

CSAT3BCBL1-L-MC

CSAT3BCBL1-L-MC

CSAT3BCBL1-L-PT

To power supply

To power supply

Power/SDM Splitter

Power/SDM Splitter

FIGURE 7-12. SDM daisy chain (CSAT3B sensor arms and grounding

cables not shown)

39

Page 45

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

To power supply

CSAT3BCBL1-L-PT

CABLE5CBL-L

FIGURE 7-13. SDM star topology (CSAT3B sensor arms and

grounding cables not shown)

7.7.2 CPI Communications

If data collection from the anemometer is to be done by a data logger using CPI

communications, then connect a CSAT3BCBL2 to the Power/SDM port by

screwing in the M16 connector into the port until tight.

A CSAT3BCBL1 may also be used for power, but the SDM wires

will not be used. The CSAT3BCSBL1 also has lighter gauge

power wires, which increases voltage loss over long cable length,

so it should only be used for shorter cable lengths.

Next, connect a CSAT3BCBL3 to the CPI/RS-485 port in the same manner. If

only one CSAT3B is being measured, the opposite end of the power cable

should have pigtail wires which may be wired to the 12 V and G terminals on a

data logger or to another 12 to 32 VDC power supply. The CPI cable should

have the RJ-45 connector plugged into the CPI port of the data logger.

40

Page 46

CSAT3B Three-Dimensional Sonic Anemometer

CSAT3BCBL2-L-PT

CSAT3BCBL3-L-RJ

Grounding Cable

CSAT3BCBL3-L-RJ

CSAT3BCBL2-L-PT

To power supply

FIGURE 7-14. Power and CPI cable connections

FIGURE 7-15. CPI connection to a CR6 data logger

41

Page 47

CSAT3B Three-Dimensional Sonic Anemometer

NOTE

CPI Daisy-chain Topology

For an application that requires CPI communication from multiple CSAT3Bs

in series, or with a daisy-chain topology, first connect to each CSAT3B as

described in Section 7.1, Settings

(p. 23), to give each sensor a unique CPI

address. Then connect a CSAT3BCBL2 to the Power/SDM port and a

CSAT3BCBL3 to the CPI/RS-485 port on the terminal CSAT3B. The opposite

end of the power cable should use an M16 connector to mate with one of the

split M16 connectors on the power/SDM splitter. The opposite end of the CPI

cable should use an M16 connector to mate with one of the split M16

connectors on the CPI/RS-485 splitter.

Screw the side of the splitters with only one M16 connector to the Power/SDM

and CPI/RS-485 ports of the second CSAT3B. Connect another set of cables