Page 1

CS705 Snowfall Adapter

Revision: 5/13

Copyright © 1997-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements............................................... 1

3. Initial Inspection .........................................................2

3.1 Ships With............................................................................................2

4. Quickstart .................................................................... 2

5. Overview......................................................................5

5.1 Antifreeze.............................................................................................5

5.1.1 Standard Car or RV Antifreeze is NOT Recommended ...............5

5.2 Tipping Bucket Compatibility..............................................................6

6. Specifications .............................................................6

7. Installation...................................................................6

7.1 Siting ....................................................................................................6

7.2 Mounting Pole......................................................................................7

7.3 Datalogger Programming .....................................................................9

8. Maintenance ................................................................9

9. References ................................................................11

Appendix

MSDS for Campbell Scientific CS705 Antifreeze .A-1

A.

Figures

4-1. CS705 mounted to pole using the CM270 Mounting Kit.....................3

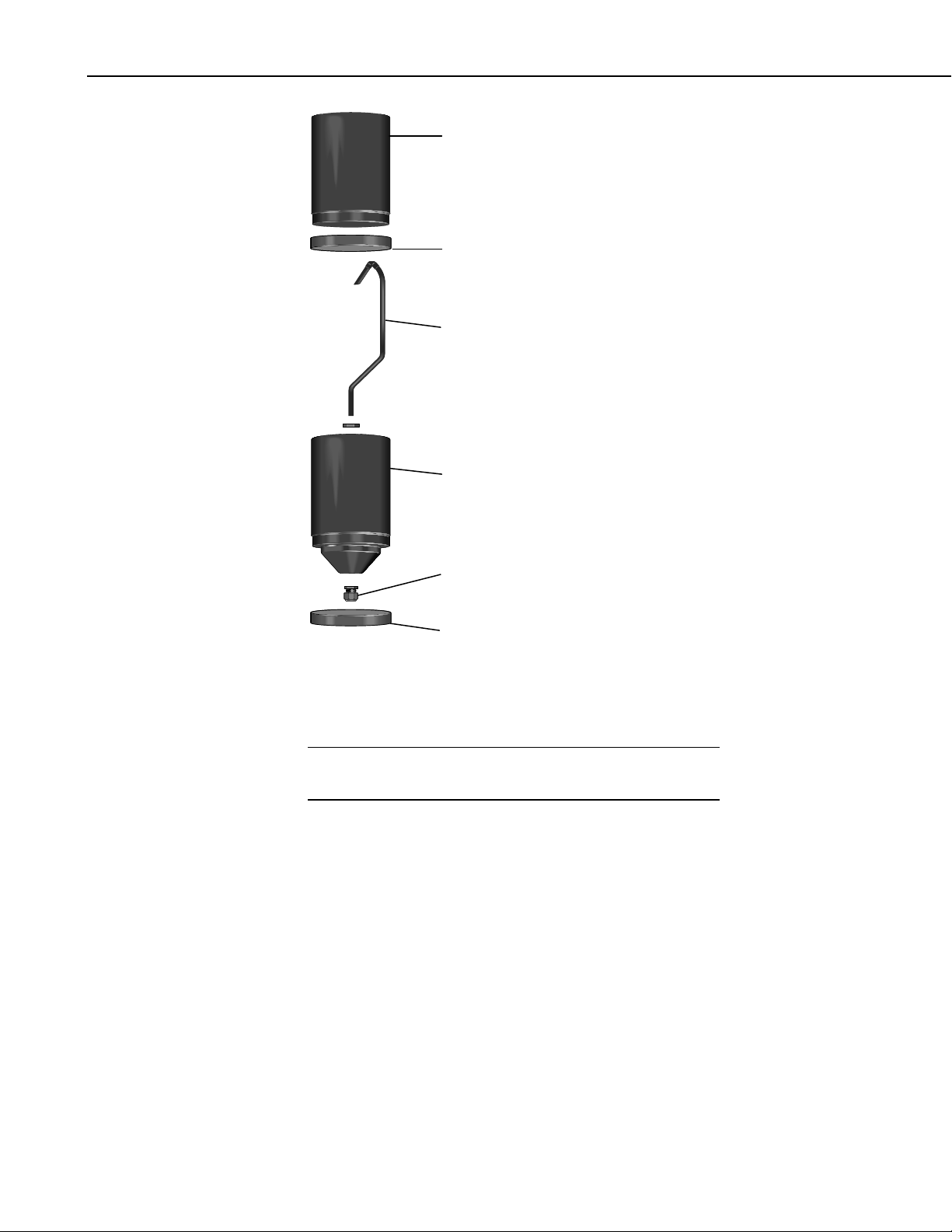

4-2. CS705 exploded view ..........................................................................4

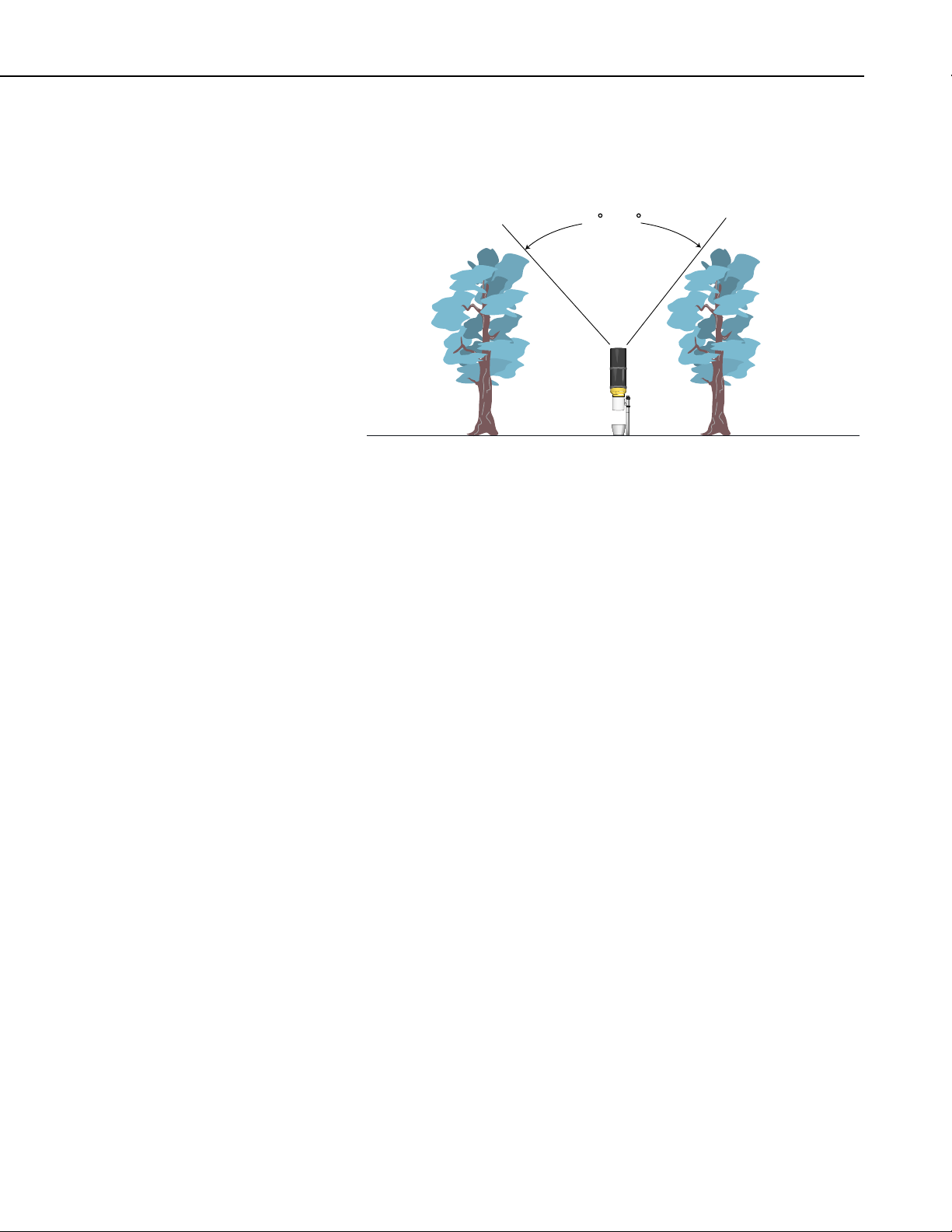

7-1. Proper gage siting.................................................................................7

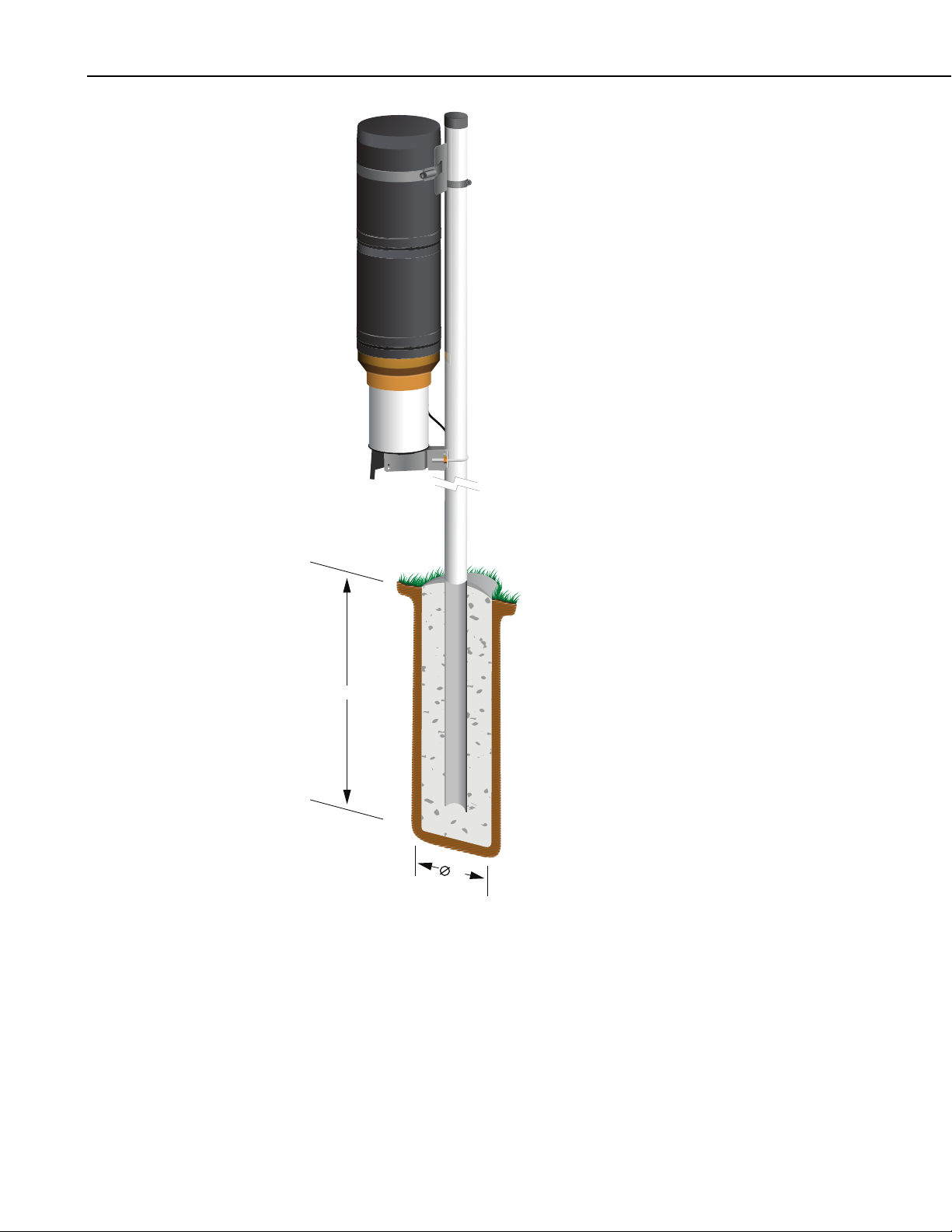

7-2. CM310 56-inch pole embedded in a concrete foundation....................8

7-3. Pedestal kit options ..............................................................................9

8-1. Mix ratio versus precipitation received ..............................................10

i

Page 6

Table of Contents

ii

Page 7

CS705 Snowfall Adapter

1. Introduction

The CS705 Snowfall Adapter converts a TE525WS Texas Electronics Rain

Gage to a rain and snow gage. It consists of an antifreeze reservoir, overflow

tube, and catch tube. Snow captured in the catch tube dissolves into the

antifreeze raising the overall level. The mixture flows through the overflow

tube into the tipping bucket where it is measured. A slot in the top of the

overflow tube prevents the tube from developing a siphon.

Before installing the CS705, please study

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 4, Quickstart

2. Cautionary Statements

• The CS705 possesses inherent delays and is not suitable for real-time

precipitation measurements (see Section 5, Overview).

• Since regular maintenance is required, choose a site that is easily

accessible throughout the winter.

• Wear safety glasses and rubber or neoprene gloves while handling and

pouring antifreeze.

• Campbell Scientific strongly recommends using antifreeze consisting of a

1:1 mixture of propylene glycol and ethanol (PGE). Appendix A provides

MSDS information for the PGE antifreeze offered by Campbell Scientific.

• Avoid using the antifreeze commonly used in cars or RVs. This

antifreeze, which consists of propylene glycol or ethylene glycol, increases

the likelihood of ice bridging (see Section 5.1, Antifreeze).

• The antifreeze/snowfall mixture needs to be captured from the tipping

bucket gage and properly disposed of in accordance with local, state, and

federal regulations.

• The CS705 should be removed and cleaned in the summer, and reinstalled

before the winter season.

1

Page 8

CS705 Snowfall Adapter

3. Initial Inspection

• Upon receipt of the CS705, inspect the packaging and contents for

damage. File damage claims with the shipping company.

• Immediately check package contents against the shipping documentation

(see Section 3.1, Ships With). Contact Campbell Scientific about any

discrepancies.

3.1 Ships With

The CS705 is shipped with the CM270, CS705 Mounting Kit (pn 20621).

Refer to FIGURE 4-1 for information on positioning the various mounting

hardware.

The CM270 mounting kit includes the following:

• (1) band clamp (pn 20605)

• (1) band clamp (pn 20606)

• (1) storage mount (pn 20636)

• (3) screws (pn 14108, 8-32)

• (1) tipping bucket rain gage mount (pn 20637)

• (1) U-bolt with matching nuts (pn 17492)

• (2) flat washers (pn 4365)

• (2) lock washers (pn 4366)

• (1) U-bolt bracket (pn 20638)

• (1) funnel (pn 14087)

4. Quickstart

Siting considerations and mounting pole options are listed in Section 7,

Installation.

Equipment required:

• Pail

• Hose with a 0.5 inch inner diameter (must be long enough to span the

distance from the funnel to the pail)

• CM300-series mounting pole or user-supplied pole (see Section 7.2,

Mounting Pole)

• TE525WS Texas Electronics Rain Gage

• CS705 Snowfall Adapter

• CM270 Mounting Kit (included with the CS705)

• PGE antifreeze

2

Page 9

N

Band Clamp

b

(pn 20605)

CS705 Snowfall Adapter

Band Clamp

(pn 20606)

Catch Tube

Antifreeze

Reservoir

TE525WS

(purchased

separately)

Funnel

(pn 14087)

0.5 in O.D.

(connect

Stu

hose here)

Storage Mount

(pn 20636)

U-bolt Bracket

(pn 20638)

Flat Washers (pn 4365)

Lock Washers (pn 4366)

uts (pn 18126)

U-bolt (pn 17492)

FIGURE 4-1. CS705 mounted to pole using the CM270 Mounting Kit FIGURE 4-1. CS705 mounted to pole using the CM270 Mounting Kit

1. Install the mounting pole. 1. Install the mounting pole.

2. Align the funnel and mounting base to the three holes found on the bottom

2. Align the funnel and mounting base to the three holes found on the bottom

of the TE525WS rain gage. The funnel is sandwiched between the rain

of the TE525WS rain gage. The funnel is sandwiched between the rain

gage and mounting base as shown in FIGURE 4-1. Three screws mount

gage and mounting base as shown in FIGURE 4-1. Three screws mount

the funnel to the TE525WS.

the funnel to the TE525WS.

3. Attach the mounting base and TE525WS to the pole via the U-bolt

3. Attach the mounting base and TE525WS to the pole via the U-bolt

bracket, U-bolt, flat washers, lock washers, and nuts (see FIGURE 4-1).

bracket, U-bolt, flat washers, lock washers, and nuts (see FIGURE 4-1).

4. Take one of the black bands supplied with the CS705 and stretch over the

4. Take one of the black bands supplied with the CS705 and stretch over the

TE525WS funnel (see FIGURE 4-2).

TE525WS funnel (see FIGURE 4-2).

3

Page 10

CS705 Snowfall Adapter

(

p

)

(

p

)

(

p

)

Catch Tube

n 13641

Band

n 10786

Overflow

Tube

(pn 10750)

Antifreeze

Reservoir

(pn 13645)

CAUTION

Entry Seal

n 10785

Band (pn 12319)

FIGURE 4-2. CS705 exploded view

5. Insert the CS705 antifreeze reservoir into the rain gage funnel.

Wear safety glasses during handling and pouring of

antifreeze.

6. Fill the reservoir with PGE antifreeze (pn 10869) until a small amount

flows out the overflow tube. The reservoir holds ≈2.5 gallons.

7. Add ≈8 ounces of a low-freezing-point, environmentally-safe oil to the

antifreeze reservoir. This oil prevents the antifreeze solution from

evaporating. The oil should cover the entire liquid surface. Some

unscented baby oils (lightweight mineral oil) work well.

8. Stretch the second black band over the lip of the antifreeze reservoir.

9. Insert the catch tube into the antifreeze reservoir.

10. Reposition the two black bands to cover the joints between the catch tube

and the antifreeze reservoir and between the reservoir and the rain gage

funnel.

4

Page 11

5. Overview

CS705 Snowfall Adapter

11. Fasten the catch tube of the CS705 to the mounting pole using the band

clamps and storage mount (see FIGURE 4-1).

12. Connect the hose to the 0.5 inch stub at the base of the funnel (see

FIGURE 4-1).

13. Place the pail below the rain gage and place the other end of the hose in it.

The CS705 is manufactured by Campbell Scientific and is based on the paper

“Measuring Winter Precipitation with an Antifreeze-Based Tipping Bucket

System” presented at the 1996 Western Snow Conference (McCaughey and

Farnes, 1996). The design possesses inherent delays and is not suitable for real

time precipitation measurements. Three design factors contribute to

measurement delays:

• air / antifreeze mixture temperature

• surface tension in the overflow tube

• precipitation form

NOTE

5.1 Antifreeze

All precipitation falling into the catch tube eventually flows through the overflow

tube and is measured by the tipping bucket gage. A delay of minutes is expected

for liquid precipitation so long as a minimum volume of water (≈0.03 inches) is

reached. A delay of several hours (up to tens) is expected for snow. Lightest

density snow at very cold temperatures has the longest delay.

The CS705 converts the TE525WS Texas Electronic Rain Gage, into a yearround precipitation gage. The CS705 is intended for use only during winter.

Like any sensor, optimum performance is obtained by regular site visits. Any

antifreeze-based precipitation gage orifice is susceptible to capping or snow

bridging.

The CS705 is coated with a smooth black coating to minimize

surface adhesion and maximize solar loading, but snow bridging

may still not occur.

Campbell Scientific recommends a 1:1 mixture of propylene glycol and ethanol

(PGE). PGE is available from Campbell Scientific in a package of four, onegallon containers. Antifreeze can only be shipped in multiples of four gallons

via UPS Ground and cannot be shipped outside of the continental United

States.

5.1.1 Standard Car or RV Antifreeze is NOT Recommended

Standard car or RV antifreeze consists of propylene glycol or ethylene glycol,

which have a specific gravity >1. This allows a layer of water to sit on top of

the antifreeze that may freeze and form an ice cap that prevents snowfall from

being dissolved into the solution. Mixing the antifreeze with ethanol solves the

specific gravity issue and prevents the ice cap. PGE is also more

environmentally friendly.

5

Page 12

CS705 Snowfall Adapter

5.2 Tipping Bucket Compatibility

The CS705 is equipped with a specially sized cylinder that allows it to nest

within the 8-inch orifice of the TE525WS Texas Electronic Rain Gage. The

CS705 cannot be directly used with TE525, TE525MM, CS700, or TB4 rain

gages. However, the TE525 and TE525MM gages can be converted to a

TE525WS at Campbell Scientific. Refer to the Assistance section at the front

of this manual for the steps required to return equipment to Campbell

Scientific.

6. Specifications

Construction: Black powder coated aluminum

Capacity: 20.32 cm (8 in) of liquid @ –20°C

Recommended Antifreeze: 1:1 mixture of propylene glycol and

Antifreeze Capacity: ≈9.5 L (2.5 gallons)

operating temperature (assuming 1:0

starting ratio of anti-freeze to water).

ethanol (PGE)

7. Installation

7.1 Siting

Catch Tube Height: 25.4 cm (10 in)

Catch Tube Orifice: 21 cm (8.25 in) diameter

Antifreeze Reservoir Height: 36 cm (14 in)

Antifreeze Reservoir Diameter: 21 cm (8.25 in)

Total Weight (CS705 + Antifreeze): ≈9 kg (20 lb)

Choose a site that is easily accessible throughout the winter.

The CS705 Snowfall Adapter and associated rain gage should be mounted in a

relatively level spot that is representative of the surrounding area. The lip of

the funnel needs to be horizontal and 76 cm (30 in) above the ground or higher

to prevent burial by snow. The ground cover around the gage should be natural

vegetation or gravel. Avoid mounting the gage over concrete or paved

surfaces.

The under catch of winter precipitation by antifreeze-based gages is directly

related to wind speed. Errors due to wind can be minimized by properly siting

the gage. The preferred gage site is in a natural well protected location. To

ensure proper catch, an angle of 30° to 45° from a vertical line drawn through

the center of the gage orifice to the surrounding obstructions should be

maintained. FIGURE 7-1 illustrates the proper siting of a gage.

6

Page 13

CS705 Snowfall Adapter

6

0

t

o

9

0

Gages sited improperly and subjected to high winds will under catch winter

precipitation generating erroneous data. An improperly sited gage subjected to

high winds can be damaged by the wind.

FIGURE 7-1. Proper gage siting

7.2 Mounting Pole

A user-supplied mounting pole or Campbell Scientific CM300-series stainlesssteel mounting pole can be used to mount the CS705 away from the tripod or

tower.

CM300-series poles can be embedded directly into a concrete foundation

(FIGURE 7-2) or used with a pedestal kit. Campbell Scientific offers a j-bolt

pedestal kit, a short-leg (23 in) pedestal kit, and a long-leg (39 in) pedestal kit

(see FIGURE 7-3).

7

Page 14

CS705 Snowfall Adapter

24”

8”

FIGURE 7-2. CM310 56-inch pole embedded in a concrete foundation

8

Page 15

CS705 Snowfall Adapter

3.5”

1.5”

FIGURE 7-3. Pedestal kit options

7.3 Datalogger Programming

Refer to the manual supplied with the TE525WS Texas Electronics Rain Gage.

The manual is also available at www.campbellsci.com.

8. Maintenance

The CS705 requires regular site visits. The number of required visits mainly

depends on snowfall. Frequent or heavy snows require more site visits.

During site visits, verify the slot in the top of the overflow tube is free from ice

or debris and remove any debris from the catch orifice. If the slot in the

overflow tube becomes plugged, the overflow tube may create a siphon and

draw down the antifreeze level.

24”

14”

The PGE solution gets diluted as precipitation is captured and mixed. Initially,

the CS705 is charged with a pure antifreeze mixture giving it a 1:0 antifreeze to

water ratio. The ratio increases to 1:1 with the equivalent of six inches of

liquid, 1:2 with eight inches, and 1:3 with nine inches. The 1:1 solution

becomes slushy at a temperature of ≈–35°C, the 1:2 solution becomes slushy at

≈–20°C, and the 1:3 solution at ≈–10°C (McGurk, 1992). Ratios greater than

9

Page 16

CS705 Snowfall Adapter

4.500

4.000

3.500

3.000

2.500

2.000

1.500

Mix Ratio (Water to Antifreeze)

1.000

1:3 are not recommended. Refer to FIGURE 8-1 to determine the amount of

remaining antifreeze based on precipitation (water equivalent) recorded.

0.500

0.000

012345678910

Water Equivalent Received (inches)

FIGURE 8-1. Mix ratio versus precipitation received

The TE525WS rain gage is designed to discharge precipitation out its base and

onto the ground. This means the toxicity of any antifreeze solution used in this

application needs to be considered. The PGE antifreeze consists of propylene

glycol and denatured ethanol. Propylene glycol is a non-toxic biodegradable

solution. Denatured ethanol, however, contains toxic additives to discourage

ingestion. These additives are toxic to mammals. Fortunately, because ethanol

evaporates rapidly when exposed to air, the denatured reagent should pose a

limited risk. However, in consultation with the appropriate agency or land

owner, an assessment of risk to animals should be conducted for each site and

appropriate mitigation measures taken.

When recharging, the solution should be disposed of in accordance with local,

state, and federal regulations.

The CS705 is recommended only for use during winter. It should be removed,

cleaned, and carefully stored after the last snowfall, then reinstalled prior to the

first snowfall of the coming winter.

10

Page 17

9. References

CS705 Snowfall Adapter

McCaughey, W. and Farnes, P.: 1996, “Measuring Winter Precipitation with an

Antifreeze-Based Tipping Bucket System”, Proceedings 64

Snow Conference, 130-136.

McGurk, B.J.: 1992, “Propylene Glycol and Ethanol as a Replacement

Antifreeze for Precipitation Gauges: Dilution, Disposal, and Safety”,

Proceedings 60

th

Western Snow Conference, 56-65.

th

Western

11

Page 18

CS705 Snowfall Adapter

12

Page 19

Appendix A. MSDS for Campbell Scientific CS705 Antifreeze

Date Printed: 09-26-1997 Page 1

Interstate Chemical Co.

MSDS for CAMPBELL SCIENTIFIC CS705 ANTIFREEZE 1899--

1 — Site Specific Information

Customer:

2 — Section I – General Information

MANUFACTURER’S NAME: Interstate Chemical Co.

EMERGENCY TELEPHONE NUMBER: (412) 981-3771

CHEMTREC EMERGENCY TELEPHONE NUMBER: (800) 424-9300

ADDRESS (NUMBER, STREET, CITY, STATE, ZIP): 2797 Freedland Rd.

Hermitage, Pa. 16148

CHEMICAL NAME AND SYNONYMS: CAMPBELL SCIENTIFIC CS705 ANTIFREEZE

TRADE NAME AND SYNONYMS: Same as above.

CHEMICAL FAMILY: Solvent blend.

FORMULA: Mixture

DATE OF PREPARATION: 09/26/97

REVISION DATE: N/A

PREPARED BY: Erik S. Bielata, Chemist

ICC MSDS #: IC-00891

DISCLAIMER: All information contained in this data sheet is believed to be true and accurate at this time.

However, there is no guarantee expressed or implied. The physical data has been calculated from available

information.

3 — Section II – Hazardous Ingredients

COMPONENT: CAS #: VOL % TLV (units)

INTERSOL 84 200 PF. MIXTURE <55% 1000 ppm

1, 2 – PROPANEDIOL 57-55-6 <55% N/A

A-1

Page 20

Appendix A. MSDS for Campbell Scientific CS705 Antifreeze

Date Printed: 09-26-1997 Page 2

Interstate Chemical Co.

MSDS for CAMPBELL SCIENTIFIC CS705 ANTIFREEZE 1899--

4 — Section III – Physical Data

BOILING POINT (INDICATE IF “F” OR “C”): 174-212 F

VAPOR PRESSURE (mm Hg): 23 @ R.T.

VAPOR DENSITY (AIR = 1): 2.1

SPECIFIC GRAVITY (H2O=1): 0.9164

PERCENT VOLATILE BY VOLUME (%): 100%

EVAPORATION RATE (But Ac = 1): 1.7

SOLUBILITY IN WATER: Complete

APPEARANCE AND ODOR: Clear, colorless, liquid; mild odor.

5 — Section IV – HMIS Rating

HEALTH FLAMMABILITY REACTIVITY

2 4 0

0 = Minimal 1 = Slight 2 = Moderate 3 = Serious 4 = Severe

6 — Section V – Figure and Explosion Hazard Data

FLASH POINT (METHOD USED): 68 F (TCC

FLAMMABLE LIMITS: Volume % in Air

LEL: 3.0

UEL: 15.8

EXTINGUISHING MEDIA:

Use water spray, carbon dioxide, dry chemical, or alcohol-type foam applied to manufacturer’s

recommended techniques.

SPECIAL FIRE FIGHTING PROCEDURES:

Use self-contained breathing apparatus and protective clothing.

A-2

Page 21

Appendix A. MSDS for Campbell Scientific CS705 Antifreeze

Date Printed: 09-26-1997 Page 3

Interstate Chemical Co.

MSDS for CAMPBELL SCIENTIFIC CS705 ANTIFREEZE 1899--

6 — Section V – Fire and Explosion Hazard Data (continued)

UNUSUAL FIRE AND EXPLOSION HAZARDS:

Vapors form from this product and may travel or be moved by air currents and ignited by pilot lights or

other ignition sources.

7 — Section VI – Health Hazard Data

THRESHOLD LIMIT VALUE: See sect. II.

EFFECTS OF ACUTE OVEREXPOSURE:

EYE CONTACT: Liquid may cause discomfort w/ slight excess redness and possible swelling of the

conjunctiva; corneal injury may occur.

SKIN CONTACT: Frequent or prolonged contact may cause discomfort and local redness.

INHALATION: May cause drowsiness, dizziness, disturbances of vision; tingling, numbness, and

shooting pains in the hands and forearms.

INGESTION: May cause nausea, abdominal pain, vomiting, headache, dizziness, shortness of

breath, weakness, fatigue, leg cramps, confusion, restlessness, visual disturbances,

drunken behavior, drowsiness, coma, and death (THERE MAY BE A DELAY OF

SEVERAL HOURS BETWEEN SWALLOWING METHANOL AND THE ONSET

OF SIGNS OF ANY SYMPTOMS).

• Visual effects include blurred vision, diplopia, changes in color perception,

restriction of visual fields, and complete blindness.

• Ingestion of moderate quantities of methanol also produces metabolic acidosis;

onset of symptoms may be delayed up to 48 hrs.

60 – 200 mL OF METHANOL IS A FATAL DOSE FOR MOST ADULTS.

INGESTION OF AS LITTLE AS 10 mL HAS CAUSED BLINDNESS.

• With massive overdoses, liver, kidney, and heart muscle injuries have been

described.

A-3

Page 22

Appendix A. MSDS for Campbell Scientific CS705 Antifreeze

Date Printed: 09-26-1997 Page 4

Interstate Chemical Co.

MSDS for CAMPBELL SCIENTIFIC CS705 ANTIFREEZE 1899--

7 — Section VI – Health Hazard Data (continued)

EFFECTS OF REPEATED OVEREXPOSURE:

• Long-term repeated overexposure to methanol vapor concentrations of 3000 ppm or greater may

allow a cumulative effect to occur w/ resulting nausea, vomiting, headache, ringing in the ears,

insomnia, trembling, unsteady gait, vertigo, clouded double vision.

• Liver and kidney damage may occur, especially when overexposed to ethanol, which may cause liver

injury w/ fibrosis.

• Due to its defatting properties, methanol may aggravate an existing skin condition, e.g. eczema;

methanol may also aggravate existing liver and kidney diseases.

OTHER HEALTH HAZARDS:

• Repeated ingestion of ethanol by pregnant mothers has been shown to adversely effect the CNS of

the fetus, producing a collection of effects which together constitute the fetal alcohol syndrome.

Symptoms include mental and physical retardation, learning disorders, motor and language

deficiencies, behavioral disorders, and small size head.

EMERGENCY AND FIRST AID PROCEDURES:

EYE CONTACT: Flush eyes with large amounts of water until irritation subsides. If irritation persists,

get medical attention.

SKIN CONTACT: Immediately flush with large amounts of water; use soap if available. Remove

contaminated clothing, including shoes, after flushing has begun.

INHALATION: Using proper respiratory protection, immediately remove the affected victim to fresh

air. Administer artificial respiration if breathing has stopped. Keep at rest, Call for

prompt medical attention.

INGESTION: If swallowed, DO NOT induce vomiting. Keep at rest. Get prompt medical

attention. Small amounts which accidentally enter the mouth should be rinsed until

taste is gone.

A-4

Page 23

Appendix A. MSDS for Campbell Scientific CS705 Antifreeze

Date Printed: 09-26-1997 Page 5

Interstate Chemical Co.

MSDS for CAMPBELL SCIENTIFIC CS705 ANTIFREEZE 1899--

8 — Section VII – Reactivity Data

STABILITY (choose one): ( ) UNSTABLE

( x ) STABLE

* CONDITIONS TO AVOID: None.

INCOMPATBILITY (MATERIALS TO AVOID): Strong oxidizers, strong inorganic acids.

HAZARDOUS DECOMPOSITION PRODUCTS: CO AND CO2

HAZARDOUS POLYMERIZATION (choose one): ( ) MAY OCCUR

( x ) WILL NOT OCCUR

* CONDITIONS TO AVOID: None.

9 — Section VIII – Spill or Leak Procedures

STEPS TO BE TAKEN IN CASE MATERIAL IS RELEASED OR SPILLED: Contain spill; provide adequate

ventilation; keep people away; EXTINGUISH ALL IGNITION SOURCES; keep material out of public waters;

use dry absorbent on small spills.

WASTE DISPOSAL METHOD: Dispose of according to all federal, state and local regulations.

10 — Section IX – Special Protection Information

RESPIRATORY PROTECTION (SPECIFY TYPE): NIOSH approved organic vapor cartridge.

VENTILATION:

LOCAL EXHAUST: preferred

MECHANICAL (GENERAL): acceptable

SPECIAL: N/A

OTHER: N/A

PROTECTIVE GLOVES: Rubber or neoprene.

EYE PROTECTION: Safety glasses or goggles.

OTHER PROTECTIVE EQUIPMENT: Rubber apron and boots; eye bath, safety shower.

A-5

Page 24

Appendix A. MSDS for Campbell Scientific CS705 Antifreeze

Date Printed: 09-26-1997 Page 6

Interstate Chemical Co.

MSDS for CAMPBELL SCIENTIFIC CS705 ANTIFREEZE 1899--

11 — Section X – Shipping Data

D.O.T. SHIPPING NAME: FLAMMABLE LIQUIDS, N.O.S.

(contains Ethanol)

PRODUCT NAME: CAMPBELL SCIENTIFIC CS705 ANTIFREEZE

D.O.T. HAZARD CLASS: 3

U.N./N.A. NUMBER: UN-1993 (PG II)

PRODUCT RQ: N/A/

D.O.T. LABEL: FLAMMABLE

D.O.T. SUBSIDIARY LABEL: N/A

D.O.T. PLACARD: FLAMMABLE

12 — Section XI – Special Precautions

PRECAUTIONS TO BE TAKEN IN HANDLING AND STORING:

***DANGER!!! May cause eye damage and blindness if swallowed.

• FLAMMABLE • DO NOT SWALLOW

• Harmful if inhaled • Keep away from heat, sparks, flame

• Harmful if absorbed through skin • Avoid breathing vapor

• Causes eye irritation • DO NOT get on skin, on clothing

• May cause drowsiness, dizziness • Avoid contact w/ eyes

• May cause heart muscle damage • Keep container closed

• May cause liver and kidney damage • Use w/ adequate ventilation

• Wash thoroughly after handling

OTHER PRECAUTIONS: FLAMMABLE LIQUID – Clean equipment thoroughly prior to maintenance and/or

repair.

PROCESS HAZARD – Sudden release of hot organic chemical vapors or mists from

equipment operating at elevated temperature and pressure, or sudden ingress of air into

vacuum equipment, may result in ignitions w/ out the presence of obvious ignition

sources. ANY USE OF THIS PRODUCT IN ELEVATED-TEMPERATURE

PROCESSES SHOULD BE THOROUGHLY EVALUATED TO ESTABLISH AND

MAINTAIN SAFE OPERATING CONDITIONS.

A-6

Page 25

Appendix A. MSDS for Campbell Scientific CS705 Antifreeze

Date Printed: 09-26-1997 Page 7

Interstate Chemical Co.

MSDS for CAMPBELL SCIENTIFIC CS705 ANTIFREEZE 1899--

12 — Section XI – Special Precautions (continued)

TRANSFER HAZARD – Vapors of this product may be ignited by static sparks.

13 — Section XII – SARA Title III

This product contains the following toxic chemical that is claimed as a trade secret, but disclosed as an upper

bound concentration to comply with the reporting requirements of Section 313 of the Emergency Planning and

Community Right-to-Know Act of 1986 and of 40 CFR Park 372.

**METHANOL (CAS #67-56-1) ---- <5%

14 — Section XIII – Section Revisions

Revisions have been made to the following sections:

A-7

Page 26

Appendix A. MSDS for Campbell Scientific CS705 Antifreeze

A-8

Page 27

Page 28

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...