Page 1

INSTRUCTION MANUAL

CS615

Water Content Reflectometer

version 8221-07

Revision: 10/96

Copyright (c) 1995-1996

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The CS615 WATER CONTENT REFLECTOMETER is warranted by

CAMPBELL SCIENTIFIC, INC. to be free from defects in materials and

workmanship under nor mal use and service for twelve (12) months from date of

shipment unless specifi ed otherwise. Batteries have no warranty. CAMPBELL

SCIENTIFIC, INC.'s obligation under this warranty is limited to repairing or

replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective products.

The customer shall assume all costs of removing, reinstalling, and shipping

defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle repairs

for customers wi thin their territories. Please visi t www.campbellsci.com to

determine which Campbell Scientific company serves your country. To obtain

a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

CS615 WATER CONTENT REFLECTOMETER

INSTRUCTION MANUAL

TABLE OF CONTENTS

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

PAGE

1. INTRODUCTION.........................................................................................................................1

2. DESCRIPTION............................................................................................................................1

3. SPECIFICATIONS

3.1 Dimensions ................................................................................................................................2

3.2 Weight........................................................................................................................................2

3.3 Electrical.....................................................................................................................................2

4. PERFORMANCE SPECIFICATIONS

4.1 Accuracy.....................................................................................................................................2

4.2 Resolution ..................................................................................................................................2

4.3 Operating Range........................................................................................................................2

5. INSTALLATION

5.1 Orientation..................................................................................................................................3

5.2 Potential Problems with Improper Insertion ...............................................................................3

6. WIRING..........................................................................................................................................4

7. DATALOGGER INSTRUCTIONS

7.1 Introduction ................................................................................................................................4

7.2 Pulse Count................................................................................................................................4

7.3 Period Measurement..................................................................................................................5

8. MAINTENANCE..........................................................................................................................5

9. CALIBRATION

9.1 General ......................................................................................................................................5

10. SAMPLE PROGRAMS.............................................................................................................6

10.1 Sample Program 1.....................................................................................................................7

10.2 Sample Program 2.....................................................................................................................7

10.3 Sample Program 3.....................................................................................................................8

10.4 Sample Program 4.....................................................................................................................9

I

Page 4

This is a blank page.

Page 5

CS615 WATER CONTENT REFLECTOMETER

1. INTRODUCTION

NOTE: There is more than one version of

the CS615. This manual is written for

version 8221-07. The version number is

listed on a cable label near the end of the

probe cable. All CS615s are similar in

measurement method but the calibration

varies with version.

The CS615 Water Content Reflectometer

provides a measure of the volumetric water

content of porous media. The water content

information is derived from the effect of

changing dielectric constant on electromagnetic

waves propagating along a wave guide.

The reflectometer output is a square wave and

can be connected to Campbell Scientific

dataloggers CR10X, CR10, CR500, 21X, or

CR7. The measured period can be converted

to volumetric water content using calibration

values.

2. DESCRIPTION

The Water Content Reflectometer consists of

two stainless steel rods connected to a printed

circuit board. A shielded four-conductor cable is

connected to the circuit board to supply power,

enable the probe, and monitor the pulse output.

The circuit board is encapsulated in epoxy.

High speed electronic components on the circuit

board are configured as a bistable multivibrator.

The output of the multivibrator is connected to

the probe rods which act as a wave guide. The

oscillation frequency of the multivibrator is

dependent on the dielectric constant of the

media being measured. The dielectric constant

is predominantly dependent on the water

content. Digital circuitry scales the multivibrator

output to an appropriate frequency for

measurement with a datalogger. The CS615

output is essentially a square wave with an

amplitude swing of ±2.5VDC. The period of the

square wave output ranges from 0.7 to 1.6

milliseconds and is used for the calibration to

water content.

+12 V Red

ground Black

output Green

enable Orange

shield Clear

FIGURE 1. CS615 Water Content Reflectometer

1

Page 6

CS615 WATER CONTENT REFLECTOMETER

3. SPECIFICATIONS

3.1 DIMENSIONS

Rods: 30.0 cm long

3.2 mm diameter

3.2 cm spacing

Head: 11.0 cm x 6.3 cm x 2.0 cm

3.2 WEIGHT

Probe: 280 g

Cable: 35 g m

3.3 ELECTRICAL Power

70 milliamps @ 12VDC when enabled

less than 10 microamps quiescent

Power Supply Voltage

9VDC minimum, 18VDC maximum

Enable Voltage

-1

4.3 OPERATING RANGE

4.3.1 Soil Electrical Conductivity

The quality of soil moisture measurements

which apply electromagnetic fields to wave

guides is affected by soil electrical conductivity.

The propagation of electromagnetic fields in the

configuration of the CS615 is predominantly

affected by changing dielectric constant due to

changing water content, but it is also affected by

electrical conductivity. Free ions in soil solution

provide electrical conduction paths which result

in attenuation of the signal applied to the

waveguides. This attenuation both reduces the

amplitude of the high-frequency signal on the

probe rods and affects the shape of the

oscillating signal. The attenuation reduces

oscillation frequency at a given water content

because it takes a longer time to reach the

oscillator trip threshold.

Soil electrical conductivity can be described by

(Rhoades et al., 1976)

=+

σσθσ

bulk solution

Τ

v solid

minimum voltage to enable probe is 1.3VDC

4. PERFORMANCE SPECIFICATIONS

4.1 ACCURACY

See the Calibration section for a discussion of

accuracy. The accuracy is ±2% when using

calibration for specific soil. The accuracy when

using the general calibrations depends on soil

texture and mineral composition.

4.2 RESOLUTION

The resolution of the volumetric water content

measurement depends on which datalogger

instruction is used. When the CR10X, CR10 or

CR500 Instruction 27, Period Measurement, is

used, the resolution is on the order of 10

Period Measurement is not available on the CR7

or 21X.

When Instruction 3, Pulse Count, is used, the

resolution with an execution interval of 1.0

second is 10

-4 m3 m-3

when pulse period is 1.3

milliseconds. The resolution improves as the

water content decreases and as the execution

interval increases. A shorter execution interval

of 0.1 seconds yields a resolution of 10

at the same water content.

-6 m3 m-3

-2 m3 m-3

with σ the electrical conductivities of the bulk

soil, the soil solution, and the solid constituents,

θ

the volumetric water content and Τ a soil-

v

specific transmission coefficient intended to

account for the tortuosity of the flow path as

water content changes. See Rhoades et al.,

1989 for a form of this equation which accounts

for mobile and immobile water. The above

equation is presented here the show the

relationship between soil solution electrical

conductivity and soil bulk electrical conductivity.

Soil solution electrical conductivity, σ

solution

can

be determined in the laboratory using extraction

methods. Soil bulk electrical conductivity can

be measured using time domain reflectometry

(TDR) methods. Most expressions of soil

.

electrical conductivity are given in terms of

solution conductivity. Discussion of the effects

of soil electrical conductivity on CS615

performance will be on a soil solution basis

unless stated otherwise.

When soil solution electrical conductivity values

exceed 1 dS m

-1

, the slope of the calibration

begins to change. The slope decreases with

increasing electrical conductivity. The probe will

still respond to water content changes with good

stability, but the calibration will have to be

modified. (See the Calibration section.) At

2

Page 7

CS615 WATER CONTENT REFLECTOMETER

electrical conductivity values greater than

5 dS m

-1

the probe output can become unstable.

4.3.2 Soil Organic Matter and Clay Content

The amount of organic matter and clay in a soil

can alter the response of dielectric-dependent

methods to changes in water content. This is

apparent when mechanistic models are used to

describe this measurement methodology.

The electromagnetic energy introduced by the

probe acts to re-orientate or polarize the water

molecules which are polar. If other forces are

acting on the polar water molecules, the force

exerted by the applied signal will be less likely to

polarize it. This has the net effect of ‘hiding’

some of the water from the probe.

Organic matter and most clays are highly polar.

Additionally, some clays sorb water interstitially

and thus inhibit polarization by the applied field.

It would be convenient if the calibration of water

content to CS615 output period could be

adjusted according to some parameter of the

soil which reflects the affect of the intrinsic

forces. However, identification of such a

parameter has not been done, and it is likely

that measurement of the correlation parameter

would be more difficult than calibrating the

CS615 for a given soil.

4.3.3 Cable Length

Probe cable length is not a limitation under

typical applications. Laboratory measurements

show no degradation in measurement quality

with cable lengths up to 100 meters. Cable

lengths greater than 50 m may increase the

potential for damage from electrostatic

discharge (lightning). The performance may be

degraded if a cable type other than that

provided with the probe is used.

temperature coefficient for a range of volumetric

water content (θ

Coef

temperature v v

) values.

v

−

=− + −

3 46 10 0019 0045

.* . .

42

θθ

To apply this correction, the following equation

can be used.

θθ

vcorrected vuncorrected temperature

=−−

T Coef

()*20

Application of this correction yields a maximum

difference between corrected and uncorrected

water content of approximately 1.6%.

Considering the accuracy of the measurement

and the potential spatial variability of soil

temperature along the length of the probe rods,

the correction is not necessary in most cases.

An example for using the temperature correction is a

measurement taken on a soil at a water content of

about 0.23 and a temperature of 25°C. The

temperature coefficient value is 0.00164 m

which means that the measured water content is

5°C *(0.00164 m

3 m-3

°C-1) or 0.8% high.

5. INSTALLATION

5.1 ORIENTATION

The probe rods can be inserted vertically into

the soil surface or buried at any orientation to

the surface. A probe inserted vertically into a

soil surface will give an indication of the water

content in the upper 30 cm of soil. The probe

can be installed horizontal to the surface to

detect the passing of wetting fronts or other

vertical water fluxes. A probe installed at an

angle of 30 degrees with the surface will give an

indication of the water content of the upper 15

cm of soil.

3 m-3

°C

-1

4.3.4 Temperature Dependence

The CS615 output is sensitive to temperature,

and compensation can be applied to enhance

accuracy. The magnitude of the temperature

coefficient varies with water content.

Laboratory measurements were performed at

various water contents and over the

temperature range from 10°C to 30°C. The

calibration information presented in Section 9 is

for a temperature of 20°C. The following

equation can be used to interpolate the

5.2 POTENTIAL PROBLEMS WITH IMPROPER INSERTION

The method used for probe installation can

affect the accuracy of the measurement. The

probe rods should be kept as close to parallel

as possible when installed to maintain the

design wave guide geometry. The sensitivity of

this measurement is greater in the regions

closest to the rod surface than at distances

away from the surface. Probes inserted in a

manner which generates air voids around the

rods will reduce the measurement accuracy. In

3

Page 8

CS615 WATER CONTENT REFLECTOMETER

some applications, installation can be improved

by using insertion guides or a pilot tool.

Campbell Scientific offers the CS615G and

CS615P insertion tools. The CS615G is a

probe insertion guide which holds the rods

parallel during rod insertion. The CS615P pilot

tool is essentially the CS615 rods which are

inserted into the soil then removed. This makes

proper installation of the CS615 easier in soils

which are difficult to insert probes into.

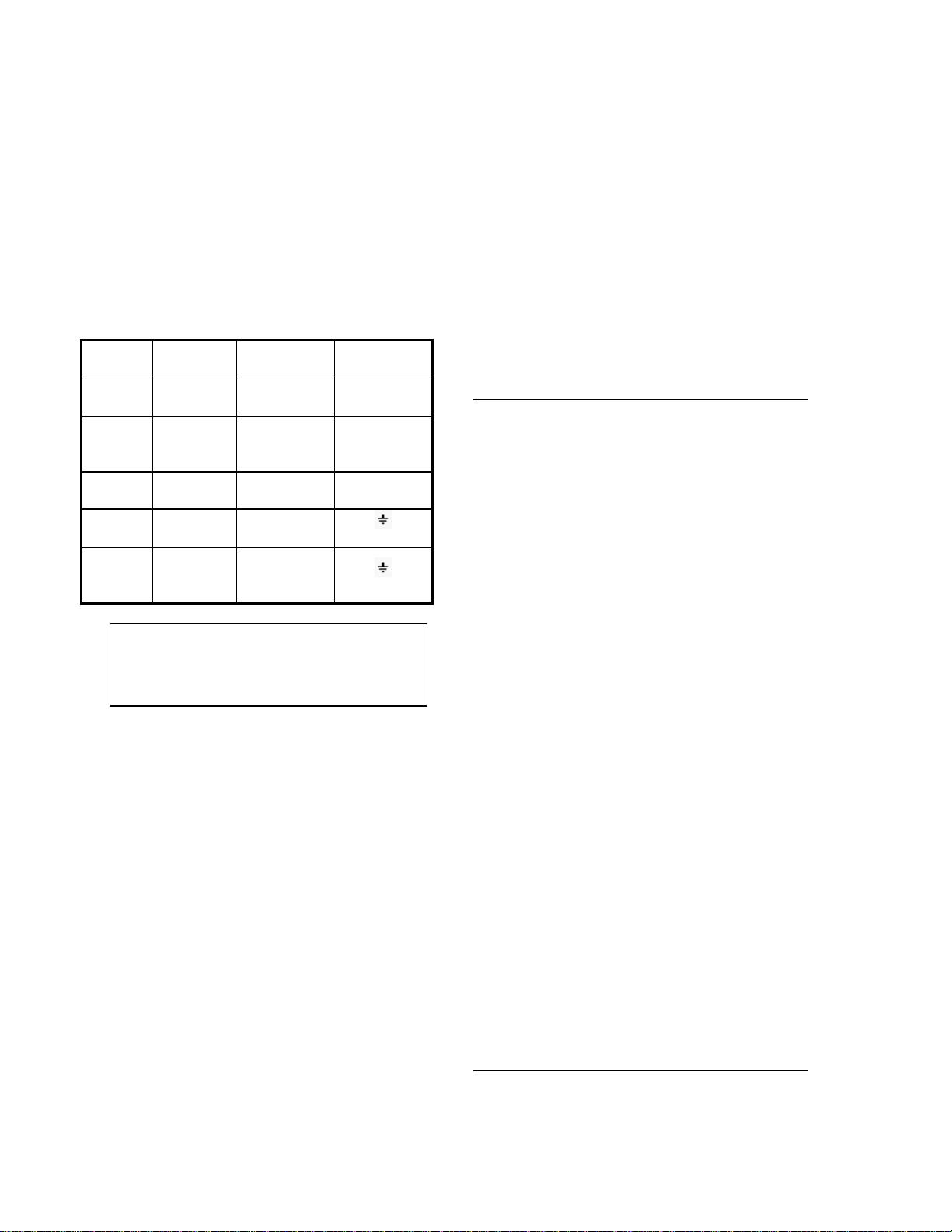

6. WIRING

color function CR10(X) 21X/CR7

red +12 V +12 V +12 V

green output

orange enable control port control port

black ground G

clear shield

(ground)

NOTE: CS615s manufactured before

12/95 have the green and black leads

reversed. Consult the wiring label near the

end of the cable.

SE analog

channel

G

pulse

channel

7.2 PULSE COUNT

It is important to understand the event

sequence during the Instruction 3 Pulse Count

Measurement when using it with the CS615.

See the Instructions section of the datalogger

manual for a detailed explanation of the Pulse

Count instruction.

A brief explanation of pulse count use in a

CS615 application is presented here. The LOW

LEVEL AC option for the configuration code is

used, and the output is selected for frequency

(Hz). Period (msec) is easily obtained with the

Inverse instruction (42).

TABLE 1. Instruction 3 Pulse Count

Measurement Sample Program

;{21X}

;Simple program to demonstrate use of

;pulse count instruction with CS615

;

*Table 1 Program

01: 2.0 Execution Interval (seconds)

1: If time is (P92)

1: 0000 Minutes into a

2: 15 Minute Interval

3: 30 Then Do

2: Do (P86) ;set CS615 enable high

1: 41 Set Port 1 High

The enable line is set high to put the probe in

the measuring mode.

7. DATALOGGER INSTRUCTIONS

7.1 INTRODUCTION

The output of the CS615 is essentially a square

wave with amplitude ±2.5 volts and a frequency

which is dependent on the dielectric constant of

the material surrounding the probe rods. The

frequency range is approximately 600 to 1500

Hz. The period (0.7 to 1.6 milliseconds) is used

in the calibration for water content.

The Pulse Count instruction of a CR10, CR500,

21X or CR7 dataloggers can be used with the

CS615 output connected to a pulse count

channel. The Period Measurement instruction

of the CR10 or CR500 can be used with the

CS615 output connected to a single-ended

analog channel.

4

3: Beginning of Loop (P87)

1: 1 Delay

2: 2 Loop Count

4: End (P95)

5: Pulse (P3)

1: 1 Reps

2: 1 Pulse Input Channel

3: 21 Low Level AC, Output Hz

4: 1 Loc [ kHz ]

5: .001 Mult ;convert Hz to kHz

6: 0.0 Offset

6: Do (P86) ;set CS615 enable low

1: 51 Set Port 1 Low

7: End (P95)

End Program

Page 9

CS615 WATER CONTENT REFLECTOMETER

The Pulse Count instruction uses accumulators

to monitor pulses on the datalogger Pulse

Count Channels. At the beginning of each

execution interval for the table containing the

Pulse Count instruction, the accumulator count

is dumped to a section in datalogger RAM, the

accumulator is then reset to zero and begins

accumulating counts again. When the Pulse

Count instruction is reached, the value in RAM

is modified by the multiplier and offset in the

Pulse Count instruction and the result written to

input storage. The RAM is then reset to zero.

Consider the simple 21X program in Table 1.

Additional instructions which might be needed for

multiplexer control or other functions have been

omitted for simplicity. This program is written to

obtain a CS615 reading every 15 minutes.

When the program is compiled by the

datalogger, the accumulators begin monitoring

the Pulse Count Channels. Immediately

following compilation by the datalogger, there is

no signal on the input channels because the

CS615 is not enabled until the 15 minute interval

specified in the Instruction 92 is reached. When

the 15 minute interval is reached, Instruction 86

is executed which sets the enable of the CS615

high and the probe outputs a signal which is

detected by the pulse counters.

The Loop Instruction in this application uses a

Delay of 1 and a Loop Count of 2. Program

execution pauses during the first loop count

until the execution interval of 2 seconds is

complete. This delay is necessary because the

probe has not been enabled for the entire

execution interval which means a complete

count is not obtained. More complex programs

will contain additional instructions prior to the

instruction to enable the CS615, and these

instructions can take a significant amount of

time to execute. During the second time

through the Loop Instruction the pulse counters

see the CS615 output for the full execution

interval. At the end of this interval the

accumulators transfer to RAM and are reset.

When the program execution then moves to the

Pulse Count Instruction (P3) the value in RAM

is converted to kHz and written to input storage.

7.3 PERIOD MEASUREMENT

Instruction 27, Period Measurement is available

only on the CR10, CR10X, or CR500. For

convenience, the following tables from the

datalogger manual are presented here. See the

datalogger manual for detailed description of

the instruction and the example programs for

typical values.

8. MAINTENANCE

The CS615 does not require periodic

maintenance.

9. CALIBRATION

9.1 GENERAL

The information in this calibration section

applies only to CS615 version 8221-07. The

version number is listed on a cable label near

the end of the probe cable.

The CS615 provides an indirect measurement

of soil water content by using the effect of

changing dielectric constant on applied

electromagnetic waves. The probe rods act as

a wave guide and the material surrounding the

rods (soil) varies in dielectric constant with the

amount of water in the material.

The dielectric constant of the soil is a weighted

summation of the dielectric constants of the soil

constituents. The dielectric constant for water

is significantly higher than that of other

constituents. Changes in the dielectric constant

of the soil system can be attributed to changes

in water content. This is the basis for the

measurement technique.

There are two soil properties which affect the

response of the CS615 to changes in water

content. High clay contents (greater than 30%)

or high electrical conductivity (greater than

1 dS m

adjusted or generated for the specific soil.

-1

) may require that the calibration be

5

Page 10

CS615 WATER CONTENT REFLECTOMETER

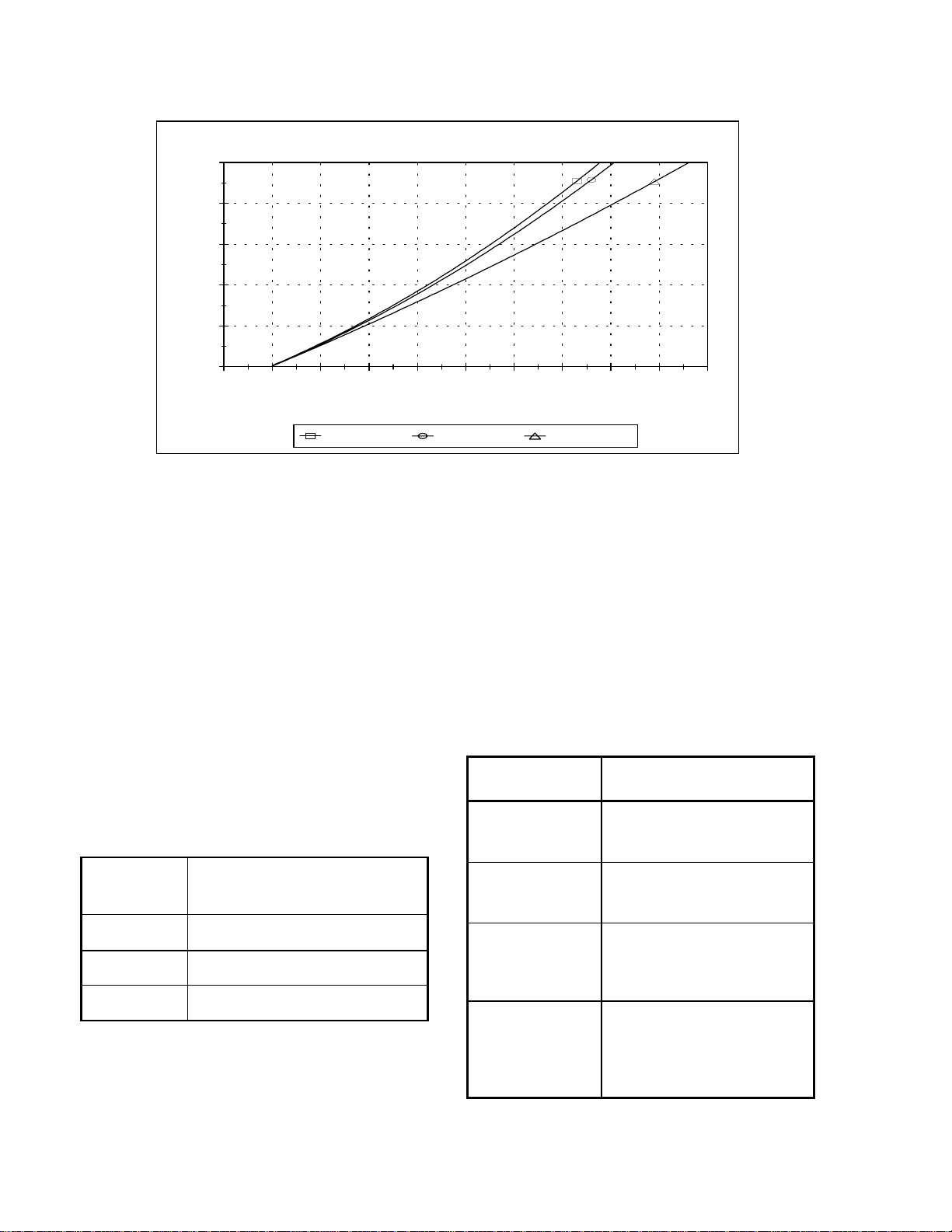

CS615 calibration for version 8221-07

0.5

0.4

0.3

0.2

volumetric water content

0.1

0

0.6 0.7 0.8 0.9 1 1.1 1.2 1.3 1.4 1.5 1.6

ec = 0.8 dS/m ec = 1.8 dS/m ec = 3.0 dS/m

CS615 output period (msec)

FIGURE 2. CS615 Calibration Curves

Figure 2 demonstrates the effect of electrical

conductivity on the calibration. At electrical

conductivity values of 1 dS m

calibration shown for 0.8 dS m

-1

and below, the

-1

works well for a

wide range of soil textures. The calibration

curves for the higher electrical conductivities

show that the slope decreases with increasing

conductivity. The response of the CS615 to

changes in water content at higher electrical

conductivity values is well-behaved up to

approximately 5 dS m

-1

. The calibration can be

approximated from figure 2 if the soil solution

electrical conductivity is known or if soil

measurements are made with the CS615 and

the actual water content is independently

determined. High clay content has a similar

affect on the calibration but the magnitude is

dependent on the clay type.

electrical

conductivity

θ

is the volumetric water content on a fraction

v

(dS m

≤

1.0

1.8

3.0

-1

)

θτ τ τ

() . . * . *

v

θτ τ τ

() . . * . *

v

θτ τ τ

() . . * . *

v

calibration

=− + +

0187 0 037 0 335

=− + +

0 207 0 097 0 288

=− + +

0 298 0361 0 096

basis i.e. 0.20 is 20% volumetric water content.

τ

is the CS615 output period in milliseconds.

9.2 CALIBRATION FOR A SPECIFIC SOIL

The calibration relationship between volumetric

water content and CS615 output period for a

specific soil may need to be established if

increased accuracy is needed or if the

composition of the soil deviates from what might

be considered typical. High electrical

conductivity, high clay content, high quartz

content and high organic matter content are

conditions which will affect probe response.

10. SAMPLE PROGRAMS

Sample Program

number

1 Monitor 1 CS615 with CR10

datalogger using Period

Averaging Instruction (P27)

2 Monitor 1 CS615 with 21X

datalogger using Pulse

2

2

2

3 Monitor 48 CS615s with 21X

4 Monitor 48 CS615s with

Count Instruction (P3)

datalogger and AM416

multiplexer using Pulse

Count Instruction (P3)

CR10 datalogger and

AM416 multiplexer using

Period Averaging Instruction

(P27)

Description

6

Page 11

CS615 WATER CONTENT REFLECTOMETER

The calibration coefficients in the example

programs are demonstrative only. See Section

9 for information on calibration.

10.1 SAMPLE PROGRAM 1

Simple program using the Period Averaging

Instruction (P27) of a CR10 datalogger to read a

single CS615. The measurement is taken

hourly and the period and water content are

written to output storage.

CR10 CS615

Single-Ended

Channel 1 (SE1)

Control Port 5 (C5) orange

The red lead is connected to 12VDC and the

black and shield are connected to ground.

;{CR10}

;

*Table 1 Program

01: 5.0 Execution Interval (seconds)

1: If time is (P92) ;take reading hourly

1: 0000 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 30 Then Do

2: Do (P86)

1: 45 Set Port 5 High;enable CS615

3: Period Average (SE) (P27)

1: 1 Reps

2: 4 2 V Peak to Peak/200 kHz

Max. Freq.

3: 1 SE Channel

4: 10 No. of Cycles

5: 5 Timeout (units = 0.01 seconds)

6: 1 Loc [ 615period ]

7: .001 Mult

8: 0.0 Offset

4: Do (P86) ;disable CS615

1: 55 Set Port 5 Low

5: Polynomial (P55) ;convert period to water content

1: 1 Reps

2: 1 X Loc [ 615period ]

3: 2 F(X) Loc [ 615water ]

4: -0.187 C0

5: 0.037 C1

6: 0.335 C2

7: 0.0 C3

8: 0.0 C4

green

9: 0.0 C5

6: Do (P86)

1: 10 Set Output Flag High

7: Real Time (P77)

1: 0220 Day,Hour/Minute

8: Sample (P70)

1: 2 Reps

2: 1 Loc [615period]

9: End (P95)

End Program

10.2 SAMPLE PROGRAM 2

Simple program using the Pulse Count Instruction

(P3) of a CR10, CR500 or 21X datalogger to read

a single CS615. The Water Content

Reflectometer is queried when Flag 1 is set high.

The measurement is made and the period and

water content values are written to output storage.

CR10 or 21X CS615

Pulse Count

Channel 1 (P1)

Control Port 5 (C5) orange

The red lead is connected to 12VDC and the

black and shield are connected to ground.

;{CR10, CR500 or 21X}

;

*Table 1 Program

01: 1.0 Execution Interval (seconds)

1: If Flag/Port (P91) ;set flag1 high to initiate

reading

1: 11 Do if Flag 1 is High

2: 30 Then Do

2: Do (P86) ;enable CS615

1: 45 Set Port 5 High

3: Beginning of Loop (P87) ;delay for complete

count interval

1: 1 Delay

2: 2 Loop Count

4: End (P95)

5: Pulse (P3) ;determine CS615 output frequency

1: 1 Reps

2: 1 Pulse Input Channel

3: 21 Low Level AC, Output Hz

4: 1 Loc [ 615kHz ]

5: .001 Mult ;convert to kHz

6: 0.0 Offset

green

7

Page 12

CS615 WATER CONTENT REFLECTOMETER

6: Do (P86) ;disable CS615

1: 55 Set Port 5 Low

7: Z=1/X (P42) ;convert kHz to milliseconds

1: 1 X Loc [ 615kHz ]

2: 2 Z Loc [ 615msec ]

8: Polynomial (P55) ;convert period to water content

1: 1 Reps

2: 2 X Loc [ 615msec ]

3: 3 F(X) Loc [ 615water ]

4: -0.187 C0

5: 0.037 C1

6: 0.335 C2

7: 0.0 C3

8: 0.0 C4

9: 0.0 C5

9: Do (P86)

1: 10 Set Output Flag High

10: Real Time (P77)

1: 0220 Day,Hour/Minute

11: Sample (P70)

1: 2 Reps

2: 2 Loc [615msec]

9: Do (P86)

1: 21 Set Flag 1 low

12: End (P95)

End Program

Attention to program structure when using the

Pulse Count Instruction with sensors that are

periodically enabled is necessary to ensure

accurate results. See Section 7.2 for a detailed

description of the Pulse Count Instruction.

CAUTION:

1. The probe rods of the CS615 are

essentially antennae which transmit and

receive radio waves. Interference can

occur when enabled probes are in close

proximity and electrical conductivity of

the measured medium is high.

Generally, interference is not a problem

when the distance between enabled

probes is greater than 20 cm. It may be

necessary to configure probe

placement and multiplexer connection

to alleviate probe interaction.

2. Reading 48 CS615s using the Pulse

Count Instruction will take

approximately 32 seconds. This may

conflict with other measurements.

;{21X}

;

*Table 1 Program

01: 1.0 Execution Interval (seconds)

10.3 SAMPLE PROGRAM 3

Program using the Pulse Count Instruction (P3)

of 21X datalogger and AM416 multiplexer to

read 48 CS615 probes.

.

below

This program is written to read 48 CS615s

every hour and write the water content value to

output storage. The AM416 multiplexer is a 16

channel multiplexer with 4 lines per channel.

See figure 3 for wiring schematic. Three CS615

outputs and a common enable for all 3 probes

are attached to each AM416 channel. Three

CS615s connected to a AM416 channel are

enabled simultaneously while the Pulse Count

Instruction uses a repetition value of 3 to

sequentially read the probe outputs. The

frequency value of the Pulse Count Instruction

is converted to period by the Z=1/X Instruction

(P42) and the calibration to volumetric water

content is invoked using the Polynomial

Instruction. The water content values are

written to output storage.

See the cautions listed

1: If time is (P92) ;take CS615 readings hourly

1: 0000 Minutes into a

2: 60 Minute Interval

3: 30 Then Do

2: Do (P86) ;enable AM416

1: 41 Set Port 1 High

3: Do (P86) ;set CS615 enable high

1: 43 Set Port 3 High

4: Beginning of Loop (P87) ;multiplexing loop

1: 0000 Delay

2: 16 Loop Count

;loop index of 3 so 3 readings measured

;by pulse instruction are advanced 3

;locations each pass through measurement

loop.

5: Step Loop Index (P90)

1: 3 Step

6: Do (P86) ;clock AM416

1: 72 Pulse Port 2

8

Page 13

CS615 WATER CONTENT REFLECTOMETER

;delay loop to wait remainder of execution

;interval once AM416 is clocked, and one

;complete execution interval for precise

;pulse count interval.

7: Beginning of Loop (P87)

1: 1 Delay

2: 2 Loop Count

8: End (P95) ;end of delay loop

9: Pulse (P3) ;read CS615s

1: 3 Reps

2: 1 Pulse Input Channel

3: 21 Low Level AC, Output Hz

4: 1 Loc [ kHz#1 ]

5: .001 Mult

6: 0.0 Offset

;convert frequencies to period. 0.001 multiplier

;converts kHz to milliseconds.

10: Z=1/X (P42)

1: 1 X Loc [ kHz#1 ]

2: 4 Z Loc [ period#1 ]

11: Z=1/X (P42)

1: 2 X Loc [ kHz#2 ]

2: 5 Z Loc [ period#2 ]

12: Z=1/X (P42)

1: 3 X Loc [ kHz#3 ]

2: 6 Z Loc [ period#3 ]

13: Polynomial (P55) ;apply calibration

1: 3 Reps

2: 4 X Loc [ period#1 ]

3: 7-- F(X) Loc [ water#1 ]

4: -.187 C0

5: .037 C1

6: .335 C2

7: 0.0 C3

8: 0.0 C4

9: 0.0 C5

14: End (P95)

10.4 SAMPLE PROGRAM 4

Program using the Period Averaging Instruction

(P27) of CR10 datalogger and AM416

multiplexer to read 48 CS615 probes

CAUTION:

1. The probe rods of the CS615 are

essentially antennae which transmit and

receive radio waves. Interference can

occur when enabled probes are in close

proximity and electrical conductivity of

the measured medium is high.

Generally, interference is not a problem

when the distance between enabled

probes is greater than 20 cm. It may be

necessary to configure probe

placement and multiplexer connection

to alleviate probe interaction.

;{CR10}

;

*Table 1 Program

01: 1.0 Execution Interval (seconds)

;Once an Hour, Read Probes

1: If time is (P92)

1: 0 Minutes into a

2: 60 Minute Interval

3: 30 Then Do

; enable multiplexer

2: Do (P86)

1: 41 Set Port 1 High

; turn on port that enables 615s

3: Do (P86)

1: 43 Set Port 3 High

15: Do (P86) ;set CS615 enable low

1: 53 Set Port 3 Low

16: Do (P86) ;set AM416 reset low

1: 51 Set Port 1 Low

17: Do (P86)

1: 10 Set Output Flag High

18: Sample (P70)

1: 48 Reps

2: 7 Loc [ water#1 ]

19: End (P95)

End Program

;Multiplexer loop

4: Beginning of Loop (P87)

1: 0 Delay

2: 16 Loop Count

; clock multiplexer

5: Do (P86)

1: 72 Pulse Port 2

9

Page 14

CS615 WATER CONTENT REFLECTOMETER

; loop index multiplied by 3 so that 3 readings

measured by pulse

; instruction are advanced 3 locations each pass

through measurement loop

6: Step Loop Index (P90)

1: 3 Step

7: Period Average (SE) (P27)

1: 3 Reps

2: 4 2 V Peak to Peak/200 kHz

Max. Freq.

3: 1 SE Channel

4: 10 No. of Cycles

5: 5 Timeout (units = 0.01 seconds)

6: 1-- Loc [ msec#1 ]

7: .001 Mult

8: 0.0 Offset

8: End (P95)

; set ports enabling mux and probes low

9: Do (P86)

1: 51 Set Port 1 Low

11: Polynomial (P55)

1: 48 Reps

2: 1 X Loc [ Period#1 ]

3: 49 F(X) Loc [ WatCont#1 ]

4: -0.187 C0

5: 0.037 C1

6: 0.335 C2

7: 0.0 C3

8: 0.0 C4

9: 0.0 C5

12: Do (P86)

1: 10 Set Output Flag High

13: Real Time (P77)

1: 10 Hour/Minute

14: Sample (P70)

1: 48 Reps

2: 49 Loc [ WatCont#1 ]

15: End (P95)

End Program

10: Do (P86)

1: 53 Set Port 3 Low

; apply calibration

10

Page 15

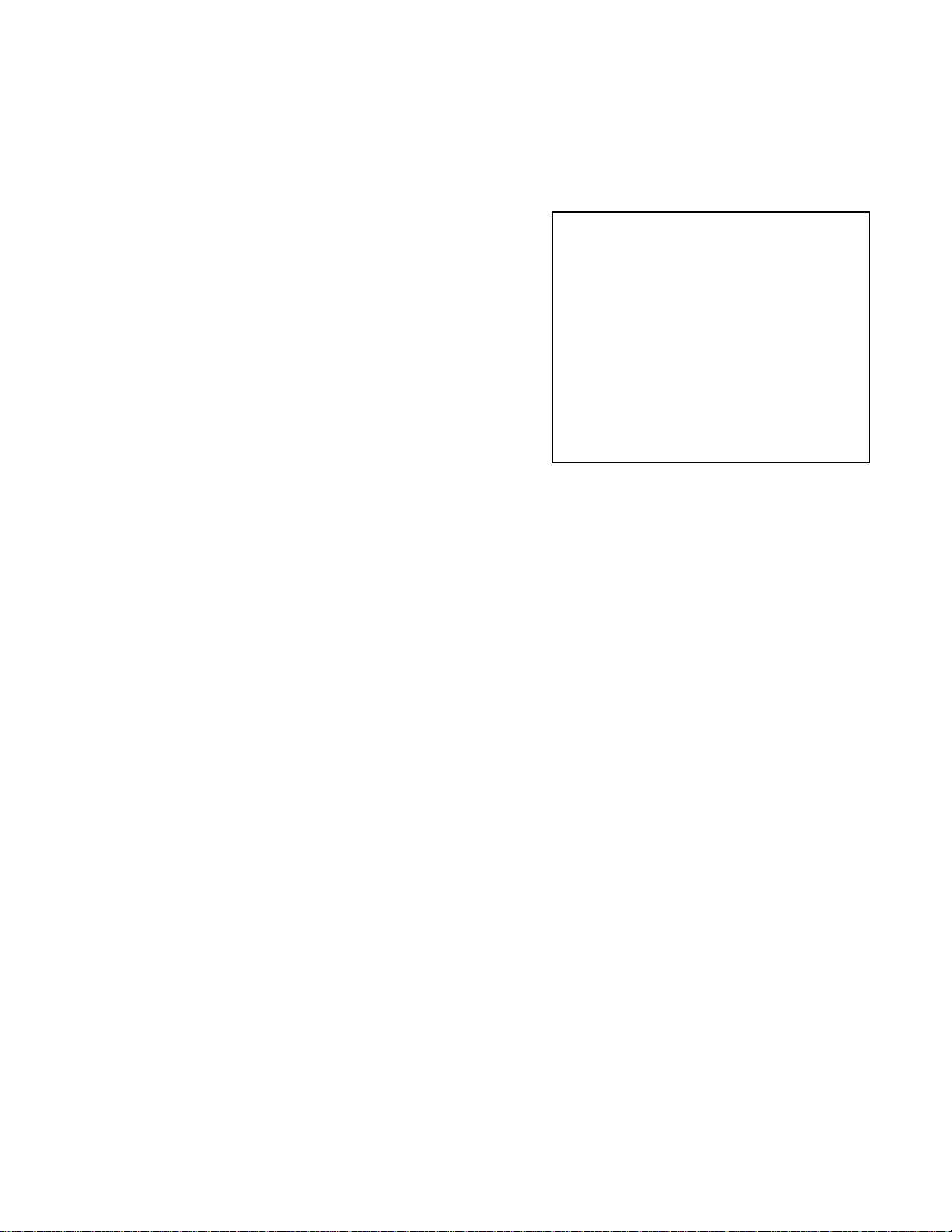

CS615 WATER CONTENT REFLECTOMETER

CR10 or 21X AM416 CS615

enable

signal

enable

signal

enable

signal

enable

signal

SE1

SE2

SE3

CR10

Using

Period

Measurement

C1

C2

C3

P1

P2

P3

21x

Using

Pulse

Count

Reset

Clock

H1

L1

H2

L2

H1

L1

1

H2

L2

H1

L1

2

H2

L2

enable

signal

enable

signal

#1

#2

#3

#4

#5

#6

(SE = Single

Ended Input

Channel)

H1

16

L1

H2

L2

signal #46

signal #47

signal #48

FIGURE 3. Wiring configuration for multiplexing 48 CS615s

with AM416 and CR10 or 21X datalogger.

#48

enable

signal

11

Page 16

Page 17

This is a bla nk page.

Page 18

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

sales@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringo wa Cent ra l

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda . (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...