Campbell Scientific CS470, CS471 User Manual

INSTRUCTION MANUAL

CS470/CS471 Compact

Copyright © 2009- 2014

Campbell Scientific, Inc.

Bubbler System

Revision: 7/14

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning (435) 227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is highly

recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact with

overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, 20 feet, or the distance

required by applicable law, whichever is greater, between overhead utility lines and the

structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 1

3.1 Shipping Kit and Accessories .............................................................. 2

3.1.1 Shipping Kit .................................................................................. 2

3.1.2 Accessories ................................................................................... 2

4. Quickstart .................................................................... 2

5. Overview ...................................................................... 5

6. Specifications ............................................................. 5

7. Installation ................................................................... 6

7.1 DIP Switch Settings ............................................................................. 7

7.2 Installation/Water Depth Considerations ............................................. 7

7.3 Mounting the CS470/CS471 ................................................................ 8

7.4 Connect Tubing to the CS470/CS471 .................................................. 9

7.5 Bubble Chamber Installation................................................................ 9

7.6 Purging Function ................................................................................ 11

7.7 Wiring ................................................................................................ 12

7.8 Programming ...................................................................................... 14

7.8.1 CRBasic Programming ............................................................... 14

7.8.2 Edlog Programming .................................................................... 14

8. Operation ................................................................... 15

8.1 SDI-12 Commands ............................................................................. 15

8.2 Measurements at Fast Scan Rates ...................................................... 15

8.3 Long Cables ....................................................................................... 15

8.4 Measuring Multiple SDI-12 Sensors .................................................. 16

9. Maintenance .............................................................. 16

9.1 Replacing Tubing ............................................................................... 17

10. Troubleshooting........................................................ 17

10.1 Status LED ......................................................................................... 17

i

Table of Contents

Appendices

Importing Short Cut Code ...................................... A-1

A.

A.1 Importing Short Cut Code into a Program Editor ............................ A-1

A.1.1 CRBasic Datalogger ................................................................. A-1

A.1.2 Edlog ........................................................................................ A-2

B. Example Programs .................................................. B-1

B.1 CRBasic Programs .......................................................................... B-1

B.1.1 Example CR200(X) Program ................................................... B-1

B.1.2 Example CR1000 Program ....................................................... B-2

B.2 Edlog Program................................................................................. B-3

C. 4 to 20 mA Operation .............................................. C-1

C.1 Setting Operating Parameters using DIP Switches .......................... C-2

D. SDI-12 Sensor Support ........................................... D-1

D.1 SDI-12 Command Basics ................................................................ D-1

D.1.1 Address Query Command (?!) ................................................. D-1

D.1.2 Change Address Command (aAb!) .......................................... D-1

D.1.3 Send Identification Command (aI!) .......................................... D-2

D.1.4 Start Measurement Commands (aM!) ...................................... D-2

D.1.5 Aborting a Measurement Command ........................................ D-2

D.1.6 Send Data Command (aDv!) .................................................... D-2

D.2 SDI-12 Transparent Mode ............................................................... D-3

D.2.1 CR200(X) Series Datalogger Example .................................... D-3

D.2.2 CR1000 Datalogger Example ................................................... D-4

D.2.3 CR10X Datalogger Example .................................................... D-5

D.3 Advanced SDI-12 Commands ......................................................... D-7

Figures

Tables

7-1. Securing the CS470/CS471 to a DIN Rail........................................... 8

7-2. Bubble Chamber Installation ............................................................. 10

7-3. Connection of the Bubble Tube ......................................................... 11

7-4. Purge Button and Status LED ........................................................... 12

7-5. CS470/CS471 Screw Terminals ........................................................ 13

C-1. Diagram to determine the maximum load resistance as a function

of the power supply. ..................................................................... C-1

D-1. CR200(X) example of using the SDI-12 transparent mode to

change the SDI-12 address from 0 to 1. ....................................... D-4

D-2. CR1000 example of using the SDI-12 transparent mode to

change the SDI-12 address from 3 to 1. Sensor is connected

to control port 1. ........................................................................... D-5

D-3. CR10X example of using the SDI-12 transparent mode to

change the SDI-12 address from 0 to 1. Sensor is connected

to control port 1. ........................................................................... D-6

7-1. Dip Switch Settings for SDI-12 Communications............................... 7

7-2. Datalogger Wiring ............................................................................. 13

ii

Table of Contents

10-1. Status LED ......................................................................................... 17

D-1. CS470/CS471 SDI-12 Command and Response Set ...................... D-1

D-2. Send Data Return Values ................................................................ D-3

D-3. Advanced SDI-12 Commands ......................................................... D-7

iii

Table of Contents

iv

CS470/CS471 Compact Bubbler System

1. Introduction

The CS470 and CS471 are designed for general liquid level measurements.

They use SDI-12 or RS-232 communications protocols to communicate with a

SDI-12 or RS-232 recorder simplifying installation and programming.

2. Cautionary Statements

• READ AND UNDERSTAND the Precautions section at the front of this

manual.

• Remember that although the CS470/CS471 is designed to be a rugged and

reliable device for field use, it is also a highly precise scientific instrument

and should be handled as such.

• NEVER open the housing of the CS470/CS471. There are no user-

serviceable parts inside the sensor housing and any attempt to disassemble

the device will void the warranty.

• While connecting the tubing, keep contamination or moisture from

entering the tubing.

• Do not damage or kink the tubing during installation.

• Always use a sharp knife instead of scissors to cut the tubing.

3. Initial Inspection

• Upon receipt of the CS470/CS471, inspect the packaging for any signs of

shipping damage, and, if found, report the damage to the carrier in

accordance with policy. The contents of the package should also be

inspected and a claim filed if any shipping related damage is discovered.

• Care should be taken when opening the package not to damage or cut the

polyethylene tubing (if ordered). If there is any question about damage

having been caused to the tubing, a thorough inspection is prudent.

• The model number and serial number is printed on the housing. Check

this information against the shipping documentation to ensure that the

expected model number was received.

• Refer to Section 3.1, Shipping Kit and Accessories, to ensure you have all

of the components

1

CS470/CS471 Compact Bubbler System

3.1 Shipping Kit and Accessories

3.1.1 Shipping Kit

The CS470/CS471 ships with:

• (1) Installation Kit (top DIN rail with fastening parts; screw terminal

• (2) #505 Screws

• (2) #6044 Grommets

• (1) #1113 Flat-bladed screwdriver

3.1.2 Accessories

The following are ordered as Common Accessories:

• CABLE4CBL-L 4-Conductor 22 AWG Cable — used to connect the

• Polyethylene Tubing, 3/8 inch OD, 1/8 inch ID (pn 25503) — used as

• OTT EPS-50 Bubble Chamber (pn 25502) — includes an NPT

blocks, pin jumpers)

CS470/CS471 to a datalogger. Cable length is user-specified. This

cable can either terminate in stripped and tinned leads that connect

directly to the datalogger or a connector that mates with a prewired

enclosure.

the measuring tube and is submerged in the liquid. Specify length, in

feet, when ordering.

adapter allows the bubble chamber to be connected to standard

plumbing materials.

4. Quickstart

Short Cut is an easy way to program your datalogger to measure the sensor and

assign datalogger wiring terminals. The following procedure shows using

Short Cut to program the CS470/CS471.

1. Install Short Cut by clicking on the install file icon. Get the install file

from either www.campbellsci.com, the ResourceDVD, or find it in

installations of LoggerNet, PC200W, PC400, or RTDAQ software.

2. The Short Cut installation should place a Short Cut icon on the desktop of

your computer. To open Short Cut, click on this icon.

2

CS470/CS471 Compact Bubbler System

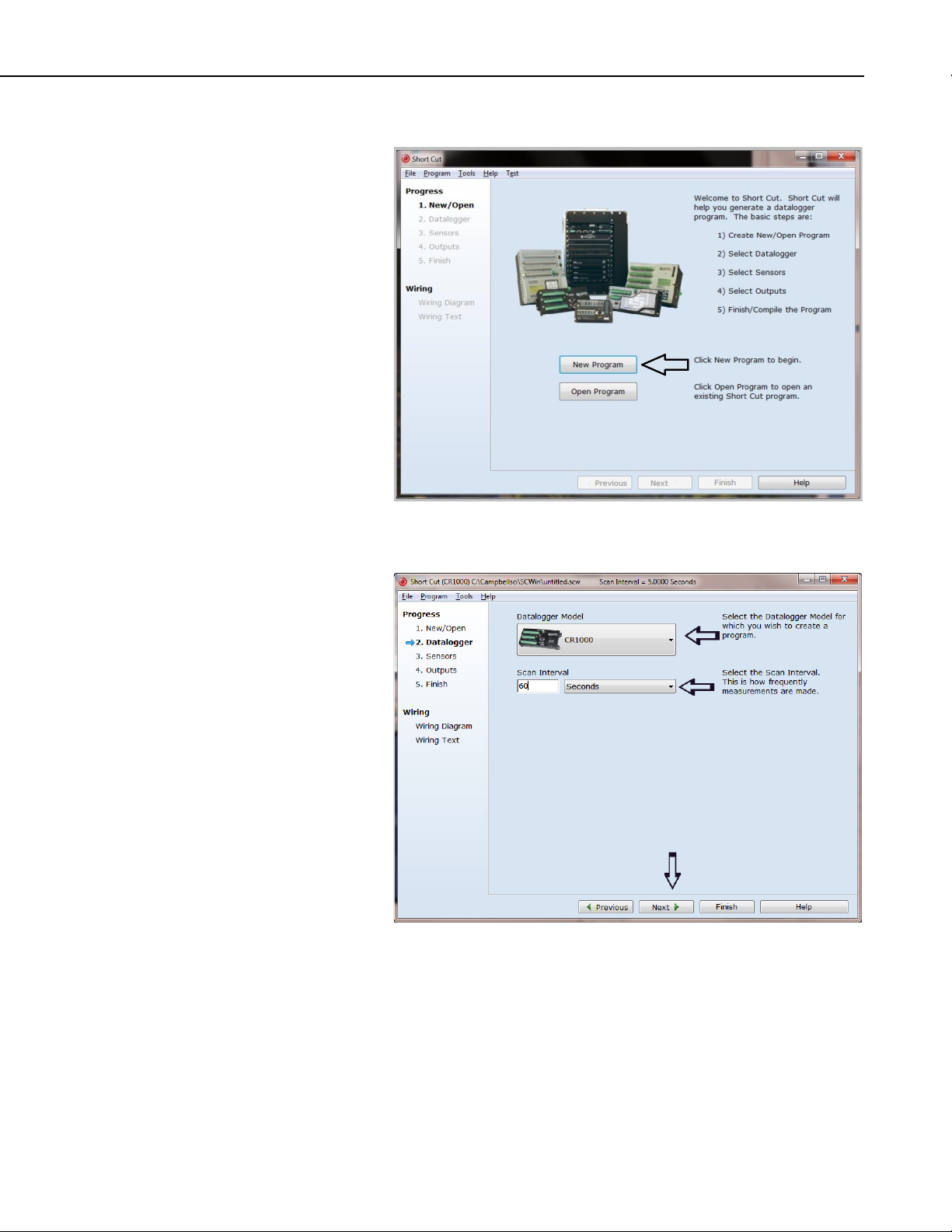

3. When Short Cut opens, select New Program.

4. Select Datalogger Model and Scan Interval (60 second or higher scan

interval is recommended). Click Next.

3

CS470/CS471 Compact Bubbler System

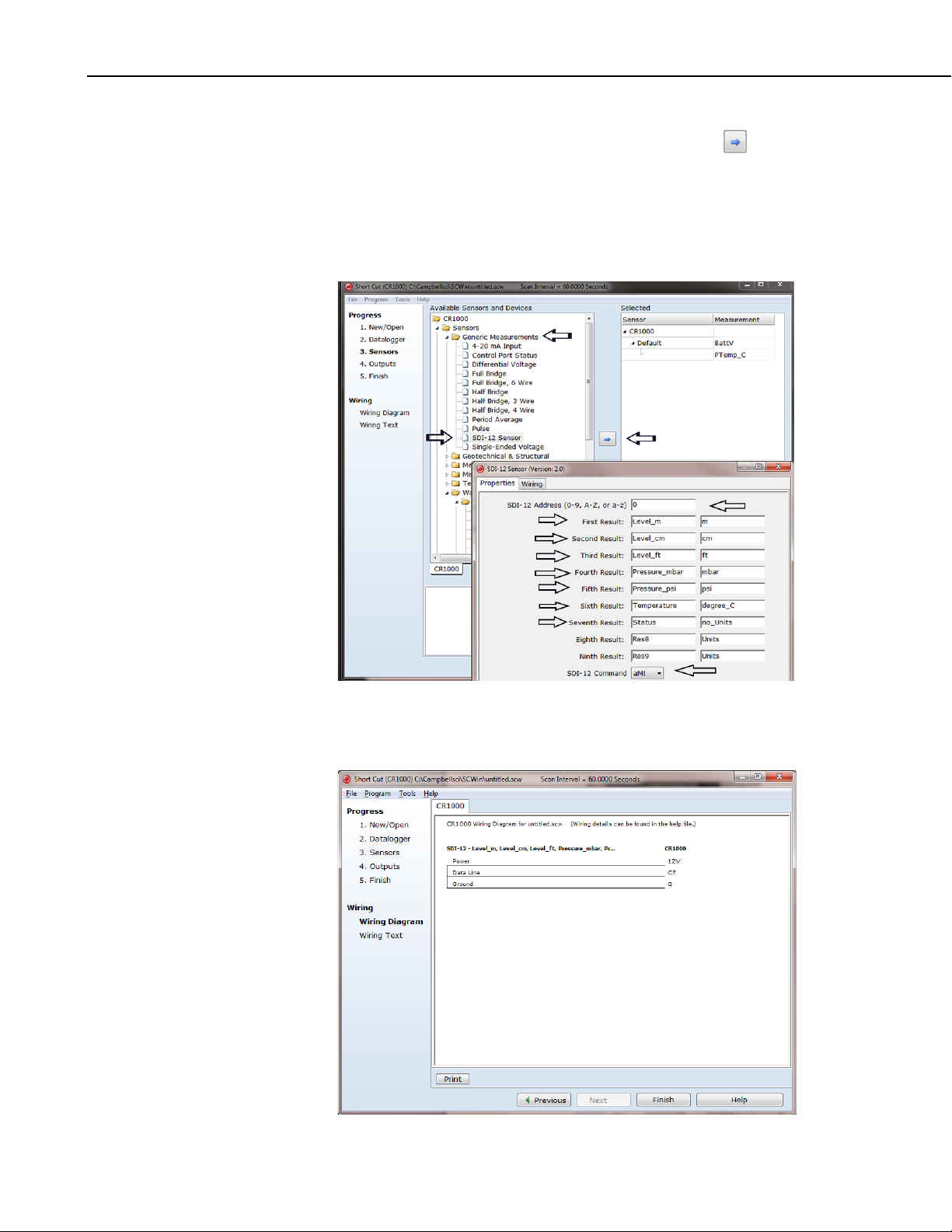

5. Under the Available Sensors and Devices list, select the Sensors |

Generic Measurements folder. Select SDI-12 Sensor, click to move

the selection to the Selected device window. Enter the result names and

units. The default SDI-12 address is 0 and the default SDI-12 command is

aM!. The SDI-12 address should only be changed from the default when

more than one sensor is connected to the same datalogger channel. The

SDI-12 command can be changed by clicking the SDI-12 Command box

and selecting one of the other options.

6. After selecting the sensor, click at the left of the screen on Wiring

Diagram to see how the sensor is to be wired to the datalogger. The

wiring diagram can be printed out now or after more sensors are added.

4

Loading...

Loading...