Page 1

INSTRUCTION MANUAL

CS470/CS471 Compact

Copyright © 2009- 2014

Campbell Scientific, Inc.

Bubbler System

Revision: 7/14

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning (435) 227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is highly

recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact with

overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, 20 feet, or the distance

required by applicable law, whichever is greater, between overhead utility lines and the

structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 6

Page 7

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 1

3.1 Shipping Kit and Accessories .............................................................. 2

3.1.1 Shipping Kit .................................................................................. 2

3.1.2 Accessories ................................................................................... 2

4. Quickstart .................................................................... 2

5. Overview ...................................................................... 5

6. Specifications ............................................................. 5

7. Installation ................................................................... 6

7.1 DIP Switch Settings ............................................................................. 7

7.2 Installation/Water Depth Considerations ............................................. 7

7.3 Mounting the CS470/CS471 ................................................................ 8

7.4 Connect Tubing to the CS470/CS471 .................................................. 9

7.5 Bubble Chamber Installation................................................................ 9

7.6 Purging Function ................................................................................ 11

7.7 Wiring ................................................................................................ 12

7.8 Programming ...................................................................................... 14

7.8.1 CRBasic Programming ............................................................... 14

7.8.2 Edlog Programming .................................................................... 14

8. Operation ................................................................... 15

8.1 SDI-12 Commands ............................................................................. 15

8.2 Measurements at Fast Scan Rates ...................................................... 15

8.3 Long Cables ....................................................................................... 15

8.4 Measuring Multiple SDI-12 Sensors .................................................. 16

9. Maintenance .............................................................. 16

9.1 Replacing Tubing ............................................................................... 17

10. Troubleshooting........................................................ 17

10.1 Status LED ......................................................................................... 17

i

Page 8

Table of Contents

Appendices

Importing Short Cut Code ...................................... A-1

A.

A.1 Importing Short Cut Code into a Program Editor ............................ A-1

A.1.1 CRBasic Datalogger ................................................................. A-1

A.1.2 Edlog ........................................................................................ A-2

B. Example Programs .................................................. B-1

B.1 CRBasic Programs .......................................................................... B-1

B.1.1 Example CR200(X) Program ................................................... B-1

B.1.2 Example CR1000 Program ....................................................... B-2

B.2 Edlog Program................................................................................. B-3

C. 4 to 20 mA Operation .............................................. C-1

C.1 Setting Operating Parameters using DIP Switches .......................... C-2

D. SDI-12 Sensor Support ........................................... D-1

D.1 SDI-12 Command Basics ................................................................ D-1

D.1.1 Address Query Command (?!) ................................................. D-1

D.1.2 Change Address Command (aAb!) .......................................... D-1

D.1.3 Send Identification Command (aI!) .......................................... D-2

D.1.4 Start Measurement Commands (aM!) ...................................... D-2

D.1.5 Aborting a Measurement Command ........................................ D-2

D.1.6 Send Data Command (aDv!) .................................................... D-2

D.2 SDI-12 Transparent Mode ............................................................... D-3

D.2.1 CR200(X) Series Datalogger Example .................................... D-3

D.2.2 CR1000 Datalogger Example ................................................... D-4

D.2.3 CR10X Datalogger Example .................................................... D-5

D.3 Advanced SDI-12 Commands ......................................................... D-7

Figures

Tables

7-1. Securing the CS470/CS471 to a DIN Rail........................................... 8

7-2. Bubble Chamber Installation ............................................................. 10

7-3. Connection of the Bubble Tube ......................................................... 11

7-4. Purge Button and Status LED ........................................................... 12

7-5. CS470/CS471 Screw Terminals ........................................................ 13

C-1. Diagram to determine the maximum load resistance as a function

of the power supply. ..................................................................... C-1

D-1. CR200(X) example of using the SDI-12 transparent mode to

change the SDI-12 address from 0 to 1. ....................................... D-4

D-2. CR1000 example of using the SDI-12 transparent mode to

change the SDI-12 address from 3 to 1. Sensor is connected

to control port 1. ........................................................................... D-5

D-3. CR10X example of using the SDI-12 transparent mode to

change the SDI-12 address from 0 to 1. Sensor is connected

to control port 1. ........................................................................... D-6

7-1. Dip Switch Settings for SDI-12 Communications............................... 7

7-2. Datalogger Wiring ............................................................................. 13

ii

Page 9

Table of Contents

10-1. Status LED ......................................................................................... 17

D-1. CS470/CS471 SDI-12 Command and Response Set ...................... D-1

D-2. Send Data Return Values ................................................................ D-3

D-3. Advanced SDI-12 Commands ......................................................... D-7

iii

Page 10

Table of Contents

iv

Page 11

CS470/CS471 Compact Bubbler System

1. Introduction

The CS470 and CS471 are designed for general liquid level measurements.

They use SDI-12 or RS-232 communications protocols to communicate with a

SDI-12 or RS-232 recorder simplifying installation and programming.

2. Cautionary Statements

• READ AND UNDERSTAND the Precautions section at the front of this

manual.

• Remember that although the CS470/CS471 is designed to be a rugged and

reliable device for field use, it is also a highly precise scientific instrument

and should be handled as such.

• NEVER open the housing of the CS470/CS471. There are no user-

serviceable parts inside the sensor housing and any attempt to disassemble

the device will void the warranty.

• While connecting the tubing, keep contamination or moisture from

entering the tubing.

• Do not damage or kink the tubing during installation.

• Always use a sharp knife instead of scissors to cut the tubing.

3. Initial Inspection

• Upon receipt of the CS470/CS471, inspect the packaging for any signs of

shipping damage, and, if found, report the damage to the carrier in

accordance with policy. The contents of the package should also be

inspected and a claim filed if any shipping related damage is discovered.

• Care should be taken when opening the package not to damage or cut the

polyethylene tubing (if ordered). If there is any question about damage

having been caused to the tubing, a thorough inspection is prudent.

• The model number and serial number is printed on the housing. Check

this information against the shipping documentation to ensure that the

expected model number was received.

• Refer to Section 3.1, Shipping Kit and Accessories, to ensure you have all

of the components

1

Page 12

CS470/CS471 Compact Bubbler System

3.1 Shipping Kit and Accessories

3.1.1 Shipping Kit

The CS470/CS471 ships with:

• (1) Installation Kit (top DIN rail with fastening parts; screw terminal

• (2) #505 Screws

• (2) #6044 Grommets

• (1) #1113 Flat-bladed screwdriver

3.1.2 Accessories

The following are ordered as Common Accessories:

• CABLE4CBL-L 4-Conductor 22 AWG Cable — used to connect the

• Polyethylene Tubing, 3/8 inch OD, 1/8 inch ID (pn 25503) — used as

• OTT EPS-50 Bubble Chamber (pn 25502) — includes an NPT

blocks, pin jumpers)

CS470/CS471 to a datalogger. Cable length is user-specified. This

cable can either terminate in stripped and tinned leads that connect

directly to the datalogger or a connector that mates with a prewired

enclosure.

the measuring tube and is submerged in the liquid. Specify length, in

feet, when ordering.

adapter allows the bubble chamber to be connected to standard

plumbing materials.

4. Quickstart

Short Cut is an easy way to program your datalogger to measure the sensor and

assign datalogger wiring terminals. The following procedure shows using

Short Cut to program the CS470/CS471.

1. Install Short Cut by clicking on the install file icon. Get the install file

from either www.campbellsci.com, the ResourceDVD, or find it in

installations of LoggerNet, PC200W, PC400, or RTDAQ software.

2. The Short Cut installation should place a Short Cut icon on the desktop of

your computer. To open Short Cut, click on this icon.

2

Page 13

CS470/CS471 Compact Bubbler System

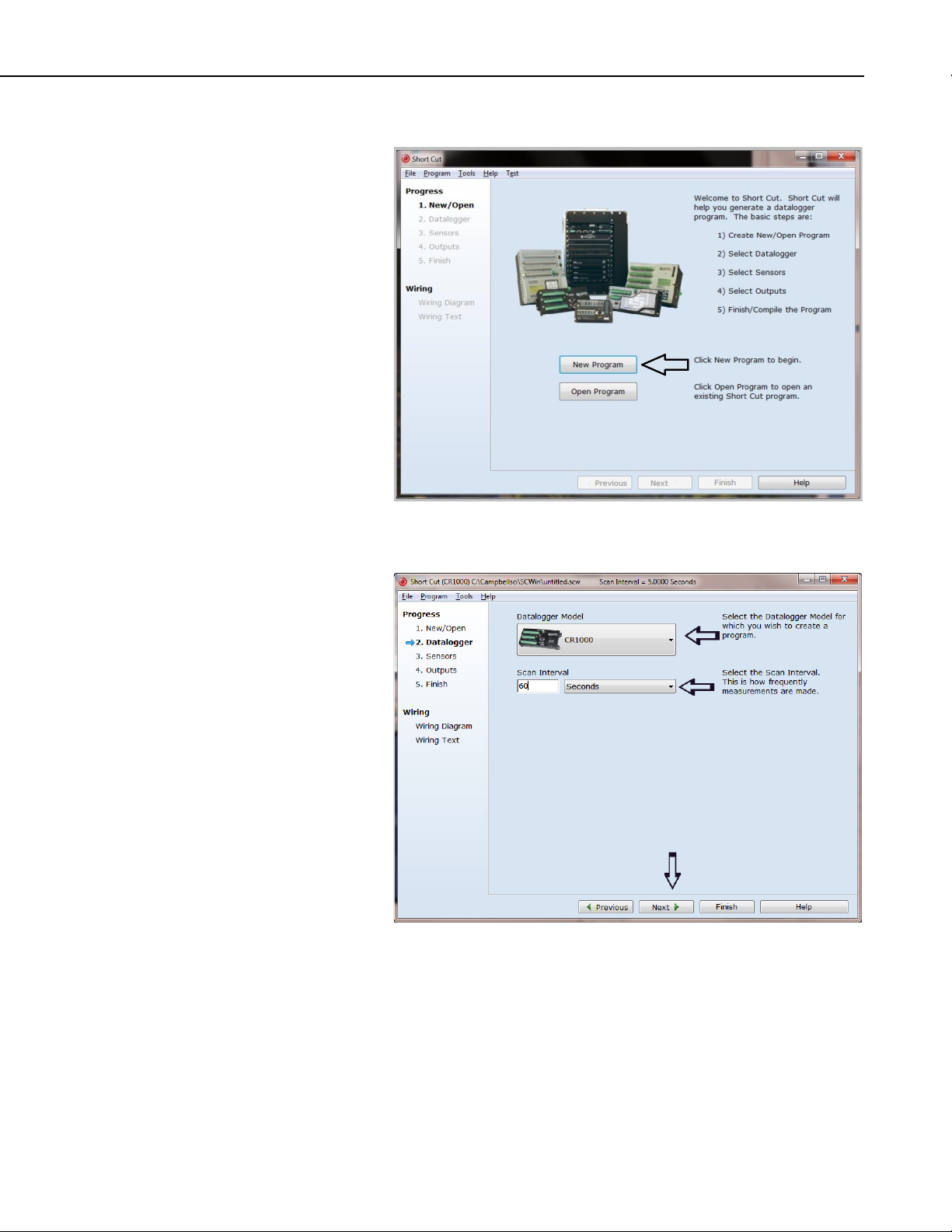

3. When Short Cut opens, select New Program.

4. Select Datalogger Model and Scan Interval (60 second or higher scan

interval is recommended). Click Next.

3

Page 14

CS470/CS471 Compact Bubbler System

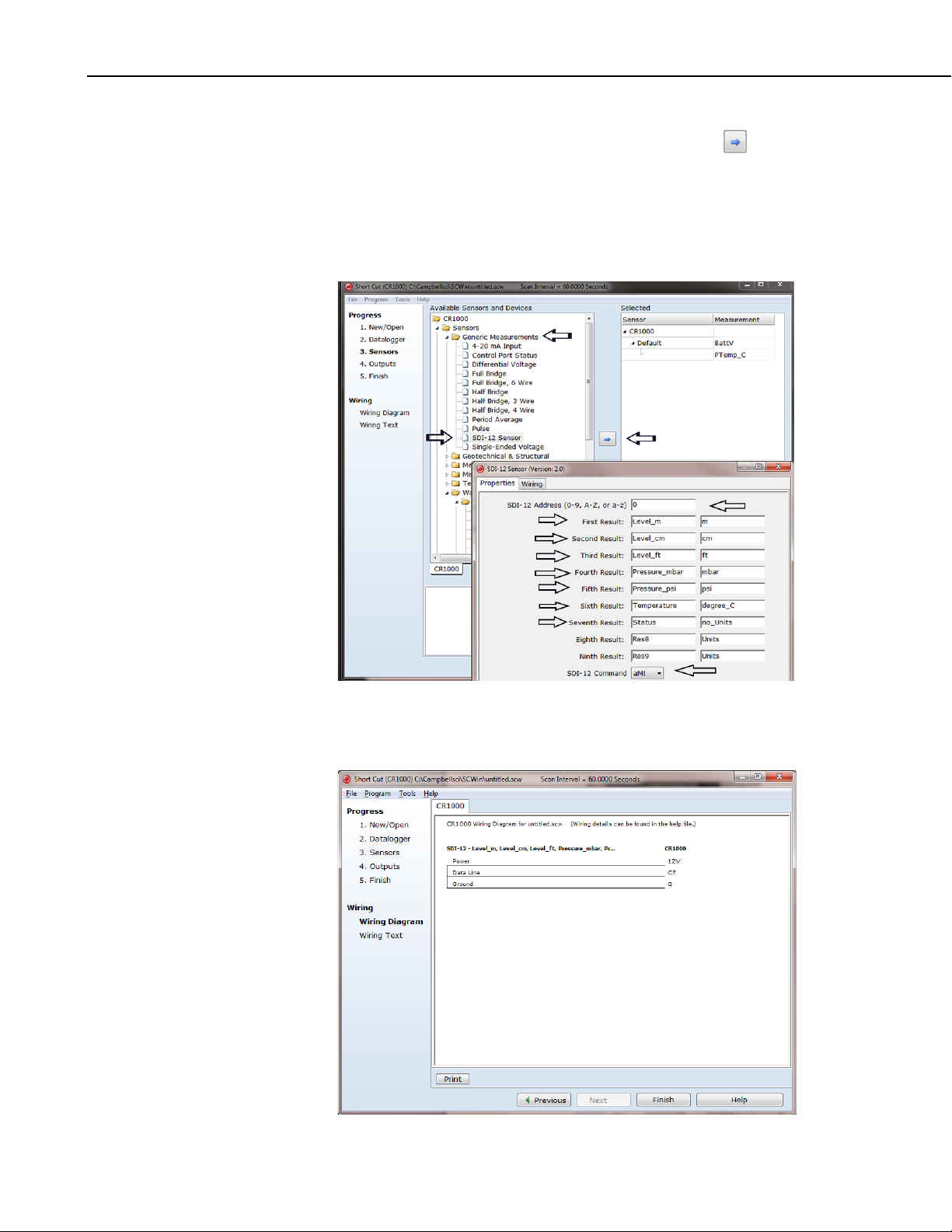

5. Under the Available Sensors and Devices list, select the Sensors |

Generic Measurements folder. Select SDI-12 Sensor, click to move

the selection to the Selected device window. Enter the result names and

units. The default SDI-12 address is 0 and the default SDI-12 command is

aM!. The SDI-12 address should only be changed from the default when

more than one sensor is connected to the same datalogger channel. The

SDI-12 command can be changed by clicking the SDI-12 Command box

and selecting one of the other options.

6. After selecting the sensor, click at the left of the screen on Wiring

Diagram to see how the sensor is to be wired to the datalogger. The

wiring diagram can be printed out now or after more sensors are added.

4

Page 15

5. Overview

CS470/CS471 Compact Bubbler System

7. Select any other sensors you have, then finish the remaining Short Cut

steps to complete the program. The remaining steps are outlined in Short

Cut Help, which is accessed by clicking on Help | Contents |

Programming Steps.

8. If LoggerNet, PC400, or PC200W is running on your PC, and the PC to

datalogger connection is active, you can click Finish in Short Cut and you

will be prompted to send the program just created to the datalogger.

9. If the sensor is connected to the datalogger, as shown in the wiring

diagram in step 6, check the output of the sensor in the datalogger support

software data display to make sure it is making reasonable measurements.

The CS470 and CS471 use the air bubble principle for measuring liquid level.

Generally, they measure ground or surface water level, but any liquid level can

be measured. Typical applications include agricultural water level/flow, water

wells, lakes, streams, and tanks. The CS470 and CS471 differ only in their

measurement accuracy.

Compressed air produced by a piston pump flows via a measuring tube into the

water to be measured. The pressure created in the measuring tube is directly

proportional to the water column above the bubble chamber. The

CS470/CS471 determines the barometric air and bubble pressure one after the

other. By taking the difference between the two signals, the CS470/CS471

calculates the height of the water level above the bubble chamber.

The CS470/CS471 contains a purge function. This clears the measuring tube

and the bubble chamber of any minor contamination by pumping a large

volume of air into the measuring tube.

By using an intelligent pump strategy, no air drying unit is necessary.

The CS470/CS471 has three communication options: SDI-12, 4 to 20 mA, or

RS-485 (SDI-12 protocol via a physical RS-485 interface). As an SDI-12

sensor, the CS470/CS471 is shipped with an address of 0.

The CS470 and CS471 are manufactured by OTT as model CBS.

6. Specifications

Features:

• Ideal for areas where submersed sensors can be damaged due to

corrosion, contamination, flood-related debris, lightning, or

vandalism

• Easy to maintain

• Robust pump design provides reliable operation

• Consistent accuracy ensured by drift-free measurements and offset

compensation using relative measurement

• Purge function clears the measuring tube and the bubble chamber of

contamination

5

Page 16

CS470/CS471 Compact Bubbler System

• Does not use pressurized nitrogen tank — requiring less frequent

• Existing tubes can be used

• Compatible with Campbell Scientific CRBasic dataloggers:

Power Requirements: 10 to 30 Vdc (typically supplied by the datalogger

Power Consumption: Quiescent current < 0.25 mA

Measurement/Communication Current:

Typical 320 mAh/day with 1 minute query interval

Typical 25 mAh/day with 15 min query interval

Measurement Time: 1 minute

Outputs: SDI-12 (version 1.3) 1200 Baud

4 to 20 mA

RS-484 (SDI-12 Protocol via RS-485 interface)

Measurement Ranges: 0 to 50 ft

attendance

CR200(X) series, CR800 series, CR1000, CR3000, and CR5000.

Also compatible with Edlog dataloggers: CR500, CR510, CR10(X),

and CR23X

7. Installation

Accuracy: CS470 Standard: ±0.02 ft

CS471 High Accuracy:

0 to 15 ft: ±0.01 ft

15 to 35 ft: ±0.065% of reading

35 to 50 ft: ±0.02 ft

Resolution: 0.003 ft/0.014 psi

Operating Temperature: –20 to 60 °C

Storage Temperature: –40 to 85 °C

Relative Humidity: 10 to 95% non-condensing

Measuring tube: 1/8 in. I.D, 3/8 in. O.D., 100.6 m (330 ft) maximum

length

Dimensions: 16.5 x 20.5 x 11.5 cm (6.5 x 8.1 x 4.5 in)

Weight: 1.5 kg (3.3 lb)

If you are programming your datalogger with Short Cut, skip Section 7.7,

Wiring, and Section 7.8, Programming. Short Cut does this work for you. See

Section 4, Quickstart, for a Short Cut tutorial.

6

Page 17

7.1 DIP Switch Settings

TABLE 7-1. Dip Switch Settings for

CS470/CS471 Compact Bubbler System

The default DIP switch settings are shown in TABLE 7-1. The default settings

support SDI-12 communications, which is the communication method typically

used by our dataloggers. The DIP switch settings need to be changed if using 4

to 20 mA communications (see Appendix C, 4 to 20 mA Operation).

SDI-12 Communications

SDI-12 Settings Switch Settings

1 ON

2 ON

3 OFF

4 NA

5 NA

6 NA

7 NA

8 NA

7.2 Installation/Water Depth Considerations

The CS470/CS471 and bubble chamber should be installed so that the tubing

has a continuous drop from the CS470/CS471 towards the bubble chamber.

Otherwise, moisture can collect in a hallow and potentially block the tubing

with the formation of drops.

The bubble chamber must be installed below the water at a fixed depth. The

maximum water depth is determined by the maximum tube length, which is

15.24 m (50 ft).

7

Page 18

CS470/CS471 Compact Bubbler System

For optimal measurement results, the bubble chamber should be horizontal and

aligned in the direction of water flow (maximum tolerance ±5°). The bubble

chamber has a ball-and-socket joint that adjusts to 15° in any direction.

7.3 Mounting the CS470/CS471

The CS470/CS471 electronic box should be in a dry and dust-free location

such as a Campbell Scientific enclosure. It mounts to an enclosure backplate

using DIN rails (included with shipped material). With the supplied grommets

and screws, connect the top DIN rails horizontally to the back panel of a

Campbell Scientific enclosure (see FIGURE 7-1).

With the top DIN rails installed, first attach the CS470/CS471 on the upper

edge of the top DIN rail and then press the underside against the top DIN rail

until it clicks into place.

To dismount the CS470/CS471, first press one locking device downwards and

pull the CS470/CS471 slightly forwards at this point. Press the second locking

device downwards and remove the CS470/CS471 upwards from the top DIN

rail.

8

FIGURE 7-1. Securing the CS470/CS471 to a DIN Rail

Page 19

CS470/CS471 Compact Bubbler System

7.4 Connect Tubing to the CS470/CS471

1. Cut the bubble tube at a 90° angle with a sharp knife (not scissors).

2. Insert the tubing as far as possible into the tube fitting.

3. Rotate the nut until finger tight.

4. Tighten the nut with a wrench about one and one-quarter turns.

7.5 Bubble Chamber Installation

1. Install conduit (metal or plastic) from the CS470/CS471 to where the

bubble chamber will be located. There should be a continuous drop from

the CS470/CS471 to the bubble chamber (see FIGURE 7-2).

9

Page 20

CS470/CS471 Compact Bubbler System

10

FIGURE 7-2. Bubble Chamber Installation

2. Fasten the conduit in place

3. Attach an elbow or tee joint at the bubble chamber location. The elbow or

tee joint should terminate with a 2-inch NPT female threaded connection.

4. Route the tubing through the conduit.

5. Cut the tubing at a 90° angle with a sharp knife (not scissors).

6. Detach the NPT adapter from the bubble chamber by unscrewing the three

hexagonal screws of the bubble chamber’s flange (see FIGURE 7-3).

Page 21

CS470/CS471 Compact Bubbler System

NOTE

FIGURE 7-3. Connection of the Bubble Tube

7. Install the NPT adapter on the end of the elbow or tee joint.

8. Activate the CS470/CS471 while immersing the bubble chamber. The

CS470/CS471 needs to be activated, so that the piston pump is operating

during this procedure.

9. Insert the tubing as far as possible into the bubble chamber’s tube fitting

10. Rotate the nut until finger tight.

11. While holding the bubble chamber steady, tighten the nut with a wrench

about one and one-quarter turns.

12. Install the bubble chamber on the NPT adapter.

For optimal measurement results, the bubble chamber must be

adjusted to be horizontal and aligned in the direction of flow

(maximum tolerance ±5°). The 25502 bubble chamber has a balland-socket joint which allows for adjustments by 15° in any

direction.

7.6 Purging Function

On the front of the CS470/CS471, there is a pump membrane button (see

FIGURE 7-4). Pressing the button activates the purge function for as long as it

is pressed. The Status LED lights for approximately 2 seconds. With an

activated purge function, the sensor pumps a large amount of air through the

11

Page 22

CS470/CS471 Compact Bubbler System

NOTE

NOTE

measuring tube for the required time period. The purge function can also be

activated via an SDI-12 command.

Press the membrane button for at least one second as otherwise the

error is called and displayed at the Status LED.

FIGURE 7-4. Purge Button and Status LED

7.7 Wiring

All electrical connections are made using two screw terminal strips (supplied)

at terminal blocks A and B on the underside of the CS470/CS471 (see FIGURE

7-5).

Although the CS470/CS471 has three interfaces available, our dataloggers

typically use SDI-12, and, therefore, only the SDI-12 connections will be

addressed here (for information about 4 to 20 mA communication, see

Appendix C).

It is recommended to power down your system before wiring the

CS470/CS471. SDI-12 communication only requires a four-wire connection

(see TABLE 7-2). Use CABLE4CBL-L 4-conductor 22 AWG cable.

The shield wire plays an important role in noise emissions and

susceptibility as well as transient protection.

12

Page 23

CS470/CS471 Compact Bubbler System

TABLE 7-2. Datalogger Wiring

FIGURE 7-5. CS470/CS471 Screw Terminals

Terminal

Terminal

Number

Function

CR800, CR850,

CR1000, CR3000,

CR23X, CR10(X),

CR500, CR510

CR5000

CR200(X)

A 1 12 V power 12V 12V Battery+

A 4 Power Ground G G G

B 3 SDI-12 Data Odd Numbered

SDI-12 C1/SDI-12

Control Port

(C1, C3, …)

B 4 SDI-12 Ground G G G

13

Page 24

CS470/CS471 Compact Bubbler System

NOTE

7.8 Programming

Short Cut is the best source for up-to-date datalogger programming code.

Programming code is needed,

• when creating a program for a new datalogger installation

• when adding sensors to an existing datalogger program

If your data acquisition requirements are simple, you can probably create and

maintain a datalogger program exclusively with Short Cut. If your data

acquisition needs are more complex, the files that Short Cut creates are a great

source for programming code to start a new program or add to an existing

custom program.

Short Cut cannot edit programs after they are imported and edited

in CRBasic Editor.

A Short Cut tutorial is available in Section 4, Quickstart. If you wish to import

Short Cut code into either Edlog or CRBasic Editor to create or add to a

customized program, follow the procedure in Appendix A.1, Importing Short

Cut Code into a Program Editor. Programming basics for CRBasic and Edlog

dataloggers are provided in the following sections. Complete program

examples for select dataloggers can be found in Appendix B, Example

Programs.

7.8.1 CRBasic Programming

The SDI12Recorder() measurement instruction programs CRBasic

dataloggers (CR200(X) series, CR800 series, CR1000, CR3000, and CR5000)

to measure the CS470/CS471 sensor. This instruction sends a request to the

sensor to make a measurement and then retrieves the measurement from the

sensor. See Section 8.1, SDI-12 Commands, for more information.

When using a CR200(X), the SDI12Recorder() instruction has the following

syntax:

SDI12Recorder(Destination,OutString,Multiplier,Offset)

For the other CRBasic dataloggers, the SDI12Recorder() instruction has the

following syntax:

SDI12Recorder(Destination, SDIPort, SDIAddress, “SDICommand”,

Multiplier, Offset)

7.8.2 Edlog Programming

Edlog dataloggers read the CS470/CS471 using the SDI-12 Recorder (P105)

instruction.

Please note that Edlog only allocates one input location for the SDI-12

Recorder (P105) instruction. Seven input locations are required for the SDI12 M! command. The additional input locations need to be inserted manually

using the Input Location Editor. To get into the Input Location Editor, select

Edit/Input Labels or press the F5 key. Once in the Input Location Editor,

do the following:

14

Page 25

1. Choose Edit/Insert Block.

NOTE

NOTE

2. After the Insert Block dialog box appears, type in a base name for the

input locations. Each input location will have the base name with an

underscore and a consecutive number.

3. In the Start Address field, type in the number of the first input location.

4. In the Number of InLocs field, type in 7 and select OK.

8. Operation

8.1 SDI-12 Commands

This section briefly describes using the SDI-12 commands.

Additional SDI-12 information is available at Appendix D,

SDI-12 Sensor Support, www.sdi-12.org, or

www.youtube.com/user/CampbellScientific

CRBasic instruction SDI12Recorder() measures the CS470/CS471 sensor

using the Start Measurement (aM!) command. The “a” is the address of the

sensor and “!” is the command terminator. The sensor returns the following

seven values.

CS470/CS471 Compact Bubbler System

.

1. Level [m]; resolution: 0.001 m

2. Level [cm]; resolution: 1 cm

3. Level [ft]; resolution: 0.01 ft

4. Pressure [mbar]; resolution: 0.01 mbar

5. Pressure [psi]; resolution: 0.001 psi

6. Temperature [°C]; resolution: 0.1 °C

7. Status

A measurement is initiated with the aM! command. To this command, the

sensor responds with the time until the measurement data are available and the

number of values to be returned when one or more subsequent aD! commands

are issued.

8.2 Measurements at Fast Scan Rates

Using the SlowSequence() function allows the SDI-12 instruction to run as a

background process, causing minimum interference to other measurements that

use the analog hardware. Measuring the sensor in a SlowSequence() section of

the program allows faster programs to run as the main scan.

For the CR5000, use a control port rather than the SDI-12 port to

allow the SDI12recorder instruction to run in the slow sequence.

8.3 Long Cables

Digital data transfer eliminates offset errors due to cable lengths. However,

digital communications can break down when cables are too long, resulting in

either no response from the sensor or corrupted readings. The original SDI-12

standard specifies the maximum total cable length to be 61 meters (200 feet).

To ensure proper operation with long cables, follow these guidelines:

15

Page 26

CS470/CS471 Compact Bubbler System

• Use low capacitance, low resistance, screened cable (as fitted by Campbell

Scientific) to reach distances of several hundred meters.

• Ensure that the power ground cable has low resistance and is connected to

the same ground reference as the datalogger control ports.

• Be aware that “daisy-chaining” sensors reduces the maximum cable length

roughly in proportion to the number of sensors connected in parallel.

8.4 Measuring Multiple SDI-12 Sensors

Up to ten CS470/CS471 sensors or other SDI-12 sensors can be connected to a

single datalogger control port. Each SDI-12 device must have a unique SDI-12

address of 0 and 9, A to Z, or a to z. See Appendix D, SDI-12 Sensor Support,

for more information.

9. Maintenance

Never open the CS470/CS471 housing! There are no adjustments or control

elements inside the housing!

The CS470/CS471 itself is maintenance free. The manufacturer recommends

checking the measuring tube and bubble chamber at regular intervals and

cleaning as required. For every visit, you should do the following:

• Collect data.

• Visually inspect wiring and physical conditions.

• Check battery condition (inspect physical appearance and use a keyboard

display or laptop to view the battery voltage).

• Check all sensor readings; adjust level offsets if necessary.

• Check recent data.

• Check the bubble chamber quarterly for sand buildup and weed

infiltration. For light sand buildup, clean the bubble chamber using the

purge function, and for heavier buildup or weed infiltration, clean the

bubble chamber carefully manually (do not change the position of the

bubble chamber).

• Activate the purge function by pressing the membrane button. Pump and

check whether air bubbles rise out of the bubble chamber. If not, check

whether the bubble chamber is blocked, and/or whether the measuring tube

is leaking or blocked.

After 15 years of operation, test the measuring tube for tightness/pressure

resistance; repeat this test roughly every two years thereafter.

16

Page 27

9.1 Replacing Tubing

TABLE 10-1. Status LED

1. Untighten the nut securing the tubing to the hose connection.

2. Pull out tubing.

3. Untighten the nut securing the tubing to the bubble chamber.

4. Pull out tubing.

5. Follow procedures provided in Sections 7.4, Connect Tubing to the

CS470/CS471, and 7.5, Bubble Chamber Installation, to reconnect the

tubing.

10. Troubleshooting

10.1 Status LED

For the display of any error states that may occur, the CS470/CS471 has a

Status LED on the front of the device.

The following error states can arise:

CS470/CS471 Compact Bubbler System

1 x flash level too low (< 5 cm)

2 x flash level too high (range exceeded)

3 x flash power supply too low

4 x flash pump motor overloaded

5 x flash watchdog error

6 x flash data memory defective

7 x flash data bus defective

8 x flash analog converter defective

9 x flash measuring cell defective

The CS470/CS471 shows an error state when it arises and for approximately 2

minutes after pressing the pump membrane button.

The defective error states signify hardware problems that can only be rectified

by the CS470/CS471 manufacturer repair center. The watchdog error error

state means that the CS470/CS471 has been restarted. No intervention is

necessary.

17

Page 28

CS470/CS471 Compact Bubbler System

NOTE

Any error states arising can be displayed as follows:

Press pump membrane button briefly (< 1 sec). The LED lights

st

once for a longer period as confirmation, then pauses. 1

nd

state arising, then pause. 2

error state arising, then pause. LED

error

lights continue until all error states arising have flashed. The

CS470/CS471 repeats all error states arising for approximately

two minutes.

The most common causes for erroneous data include:

• poor sensor connections to the datalogger

• damaged cables

• damaged transducers

Problem:

Unit will not respond when attempting serial communications.

Suggestion:

Check the power and signal lines to ensure proper connection to the datalogger.

Check the datalogger program to ensure that the same port the SDI-12 data line

is connected to is specified in the measurement instruction.

18

Page 29

NOTE

Appendix A. Importing Short Cut Code

This tutorial shows:

• How to import a Short Cut program into a program editor for

additional refinement.

• How to import a wiring diagram from Short Cut into the comments of

a custom program.

A.1 Importing Short Cut Code into a Program Editor

Short Cut creates files that can be imported into either CRBasic Editor or

Edlog program editor. These files normally reside in the

C:\campbellsci\SCWin folder and have the following extensions:

• .DEF (wiring and memory usage information)

• .CR2 (CR200(X) datalogger code)

• .CR1 (CR1000 datalogger code)

• .CR8 (CR800 datalogger code)

• .CR3 (CR3000 datalogger code)

• .CR5 (CR5000 datalogger code)

• .DLD (contain code for CR10(X), CR23X, CR500, or CR510

dataloggers)

The following procedures show how to import these files for editing.

A.1.1 CRBasic Datalogger

Use the following procedure to import Short Cut code into CRBasic Editor

(CR200(X), CR1000, CR800, CR3000, CR5000 dataloggers).

1. Create the Short Cut program following the procedure in Section 4,

Quickstart. Finish the program and exit Short Cut. Make note of the file

name used when saving the Short Cut program.

2. Open CRBasic Editor.

3. Click File | Open. Assuming the default paths were used when Short Cut

was installed, navigate to C:\CampbellSci\SCWin folder. The file of

interest has a “.CR2”, “.CR1”, “.CR8”, “.CR3, or “.CR5” extension, for

CR200(X), CR1000, CR800, CR3000, or CR5000 dataloggers,

respectively. Select the file and click Open.

4. Immediately save the file in a folder different from \Campbellsci\SCWin,

or save the file with a different file name.

Once the file is edited with CRBasic Editor, Short Cut can no

longer be used to edit the datalogger program. Change the name

of the program file or move it, or Short Cut may overwrite it next

time it is used.

5. The program can now be edited, saved, and sent to the datalogger.

A-1

Page 30

Appendix A. Importing Short Cut Code

NOTE

6. Import wiring information to the program by opening the associated .DEF

file. Copy and paste the section beginning with heading “-Wiring for

CRXXX–” into the CRBasic program, usually at the head of the file.

After pasting, edit the information such that a ' character (single quotation

mark) begins each line. This character instructs the datalogger compiler to

ignore the line when compiling the datalogger code.

A.1.2 Edlog

Use the following procedure to import Short Cut code into the Edlog program

editor (CR10(X), CR500, CR510, and CR23X dataloggers).

1. Create the Short Cut program following the procedure in Section 4,

Quickstart. Finish the program and exit Short Cut. Make note of the file

name used when saving the Short Cut program.

2. Open Edlog.

3. Click File | Document DLD File. Assuming the default paths were used

when Short Cut was installed, navigate to C:\CampbellSci\SCWin folder.

The file of interest has a “.DLD” extension. Select the file and click

Open. The .dld file, which is a type of ASCII machine code, is imported,

documented, and, when saved, given a “.CSI” extension.

4. Immediately save the file in a folder different from \Campbellsci\SCWin,

or save the file with a different file name.

Once the file is edited with Edlog, Short Cut can no longer be used

to edit the program. Change the name of the program file or move

it, or Short Cut may overwrite it.

5. The program can now be edited, saved, and sent to the datalogger.

6. Import wiring information to the program by opening the associated .DEF

file. Copy and paste the section beginning with heading “-Wiring for

CRXXX–” into the Edlog program, usually at the head of the file. After

pasting, edit the information such that a ; (semicolon) begins each line,

which instructs the datalogger compiler to ignore the line when compiling

the datalogger code.

A-2

Page 31

Appendix B. Example Programs

B.1 CRBasic Programs

B.1.1 Example CR200(X) Program

'CR200 Series

'Declare the variable for the water level measurement

Public CS470(7)

'Rename the variable names

Alias CS470(1)=Level_m

Alias CS470(2)=Level_cm

Alias CS470(3)=Level_ft

Alias CS470(4)=Pressure_mbar

Alias CS470(5)=Pressure_psi

Alias CS470(6)=Temperature_C

Alias CS470(7)=Status

'Define a data table for 60 minute maximum and minimums

DataTable(Hourly,True,-1)

DataInterval(0,60,Min)

Maximum(1,Level_ft,0,0)

Minimum(1,Level_ft,0,0)

Maximum(1,Temp_C,0,0)

Minimum(1,Temp_C,0,0)

EndTable

'Read sensor every 60 seconds

BeginProg

Scan(60,sec)

'Code for SDI-12 measurements:

SDI12Recorder(CS470,0M!,1,0)

'Call the data table:

CallTable(Hourly)

NextScan

EndProg

B-1

Page 32

Appendix B. Example Programs

B.1.2 Example CR1000 Program

'CR1000 Series Datalogger

'Declare the variable for the water level measurement

Public CS470(7)

'Rename the variable names

Alias CS470(1)=Level_m

Alias CS470(2)=Level_cm

Alias CS470(3)=Level_ft

Alias CS470(4)=Pressure_mbar

Alias CS470(5)=Pressure_psi

Alias CS470(6)=Temperature_C

Alias CS470(7)=Status

'Define a data table for 60 minute maximum and minimums

DataTable(Hourly,True,-1)

DataInterval(0,60,Min,10)

Maximum(1,Level_ft,FP2,0,0)

Minimum(1,Level_ft,FP2,0,0)

Maximum(1,Temperature_C,FP2,0,0)

Minimum(1,Temperature_C,FP2,0,0)

EndTable

'Read sensor every 60 seconds

BeginProg

Scan(60,sec,1,0)

'Code for SDI-12 measurements:

SDI12Recorder(CS470,”0”,”M!”,1,0)

'Call the data table:

CallTable(Hourly)

NextScan

EndProg

B-2

Page 33

B.2 Edlog Program

NOTE

Below is a portion of a CR10X program that measures the CS470/CS471.

The instructions below do not store data in final storage.

Instruction 92, Instruction 77 and processing instructions such as

Instruction 70 are required to store the data permanently.

;{CR10X}

;

*Table 1 Program

01: 60 Execution Interval (seconds)

1: SDI-12 Recorder (P105)

1: 0 SDI-12 Address

2: 0 Start Measurement (aM0!)

3: 1 Port ;this is where the SDI-12 signal wire is connected

4: 1 Loc[Level_m ]

5: 1.0 Mult

6: 0.0 Offset

*Table 2 Program

02: 0.000 Execution Interval (seconds)

*Table 3 Subroutines

End Program

After this command is executed, the input location with the datalogger called

“Level-m” holds the measured value for Level, reported in meters. The result

may be further processed with the datalogger or stored to final storage

memory. Note that Port 1 specifies that the SDI-12 data line is to be connected

to the Port C1. Using the Inloc editor, allocate seven locations to allow for the

entire string of variables that will be provided by the CS470/CS471.

Appendix B. Example Programs

B-3

Page 34

Appendix B. Example Programs

B-4

Page 35

Appendix C. 4 to 20 mA Operation

The load resistance connected to the CS470/CS471 must not exceed a specific

maximum value. This value depends on the level of the supply voltage of the

CS470/CS471. If the load resistance is greater, the output current can no

longer be evaluated. Smaller load resistances are allowed.

• Read off the maximum load resistance for your power supply from

FIGURE C-1.

Example: Power supply 18 volt max. load resistance 450 Ohm.

The CS470/CS471 delivers an output current corresponding to the measured

value for a load resistance of up to 450 Ohm.

• Dimension the connected electrical circuit accordingly. Check the input

resistance of the connected peripheral.

FIGURE C-1. Diagram to determine the maximum load resistance as a

function of the power supply.

C-1

Page 36

Appendix C. 4 to 20 mA Operation

C.1 Setting Operating Parameters using DIP

Switches

The following 4 to 20 mA operating parameters can be set with DIP switches.

DIP switches 1, 2, and 3 are reserved for the SDI-12 interface.

Setting measurement type to level or depth

• Level Measurement – Set DIP Switch 4 to the OFF position.

• Depth Measurement – Set DIP Switch 4 to the ON position.

Scaling the measurement

With DIPS 5 and 6 you can scale the available measuring range to a smaller

range. Where the whole measuring range is not required, this has the

advantage of increasing the resolution.

• 50 ft (not scaled) – DIPS 5 and 6 to the ON position.

• 25 ft – DIP 5 to the OFF position, DIP 6 to the ON position.

• 12 ft – DIP 5 to the ON position, DIP 6 to the OFF position.

• 6 ft – DIPS 5 and 6 to the OFF position.

Setting the measurement system

Use DIP 7 to set the engineering units of the measurement.

• Metric – DIP 7 to OFF.

• Imperial – DIP 7 to ON.

Setting measurement type

Use DIP 8 to set water level or pressure units.

• Water Level – DIP 8 to OFF.

• Pressure – DIP 8 to ON.

C-2

Page 37

TABLE D-1. CS470/CS471 SDI-12 Command and Response Set

Appendix D. SDI-12 Sensor Support

D.1 SDI-12 Command Basics

SDI-12 commands have three components:

Sensor address (a) – a single character, and is the first character of the

command. The default address of zero (0) can be used unless multiple sensors

are connected to the same port.

Command body (e.g., M1) – an upper case letter (the “command”) followed by

alphanumeric qualifiers.

Command termination (!) – an exclamation mark.

An active sensor responds to each command. Responses have several standard

forms and terminate with <CR><LF> (carriage return – line feed). Standard

SDI-12 commands supported by the CS470/CS471 are listed in TABLE D-1.

Appendix D.3 provides advanced commands.

Name Command Response

Acknowledge

Active

Send

Identification

Change

Address

Address

Query

Start

Measurement

Send Data aD0! a<values><CR><LF>

Start

Verification

a! a<CR><LF>

aI! allccccccccmmmmmmvvvxxx...xx<CR><LF>

aAb! b<CR><LF>

?! a<CR><LF>

aM! atttn<CR><LF>

aV! atttn

D.1.1 Address Query Command (?!)

Command ?! requests the address of the connected sensor. The sensor replies

to the query with the address, a.

D.1.2 Change Address Command (aAb!)

Sensor address is changed with command aAb!, where a is the current address

and b is the new address. For example, to change an address from 0 to 2, the

command is 0A2!. The sensor responds with the new address b, which in this

case is 2.

D-1

Page 38

Appendix D. SDI-12 Sensor Support

D.1.3 Send Identification Command (aI!)

Sensor identifiers are requested by issuing command aI!. The reply is defined

by the sensor manufacturer, but usually includes the sensor address, SDI-12

version, manufacturer’s name, and sensor model information. Serial number or

other sensor specific information may also be included.

An example of a response from the aI! command is:

13OTT HACH CBS107

Where:

SDI-12 version =1.3

Manufacturer = OTT HACH

Sensor model = CBS

Sensor serial number = 107

D.1.4 Start Measurement Commands (aM!)

A measurement is initiated with M! commands. The response to each

command has the form atttnn, where

a = sensor address

ttt = time, in seconds, until measurement data are available

nn = the number of values to be returned when one or more subsequent D!

commands are issued.

D.1.5 Aborting a Measurement Command

A measurement command (M!) is aborted when any other valid command is

sent to the sensor.

D.1.6 Send Data Command (aDv!)

This command requests data from the sensor. It is normally issued

automatically by the datalogger after measurement commands aMv!. In

transparent mode, the user asserts this command to obtain data. If the expected

number of data values are not returned in response to an aD0! command, the

datalogger issues aD1!. TABLE D-2 shows the values returned when using the

send data command.

D-2

Page 39

Appendix D. SDI-12 Sensor Support

TABLE D-2. Send Data Return Values

SDI-12

Command

D! 7 Level [m], Level [cm], Level [ft],

D0! 1 Level [m]; resolution: 0.001 m

D1! 1 Level [cm]; resolution: 1 cm

D2! 1 Level [ft]; resolution: 0.01 ft

D3! 1 Pressure [mbar]; resolution: 0.01 mbar

D4! 1 Pressure [psi]; resolution: 0.001 psi

D5! 1 Temperature [°C]; resolution: 0.1 °C

D6! 1 Status

Number of

Values

Returned

D.2 SDI-12 Transparent Mode

System operators can manually interrogate and enter settings in probes using

transparent mode. Transparent mode is useful in troubleshooting SDI-12

systems because it allows direct communication with probes. Datalogger

security may need to be unlocked before transparent mode can be activated.

Values Returned

Pressure [mbar], Pressure [psi],

Temperature [°C], Status

Transparent mode is entered while the PC is in telecommunications with the

datalogger through a terminal emulator program. It is easily accessed through

Campbell Scientific datalogger support software, but is also accessible with

terminal emulator programs such as Windows HyperTerminal. Datalogger

keyboards and displays cannot be used.

The terminal emulator is accessed by navigating to the Datalogger menu in

PC200W, the Tools menu in PC400, or the Datalogger menu in the Connect

screen of LoggerNet.

The following examples show how to use LoggerNet software to enter

transparent mode and change the SDI-12 address of a CS470/CS471 sensor.

The same steps are used to enter transparent mode with PC200W and PC400

software after accessing the terminal emulator as previously described.

D.2.1 CR200(X) Series Datalogger Example

1. Connect a single CS470/CS471 to the CR200(X) (see TABLE 7-2)

2. In the LoggerNet Connect screen, navigate to the Datalogger menu and

select Terminal Emulator. The terminal emulator window will open. In

the Select Device menu, located in the lower left-hand side of the window,

select the CR200Series station.

3. Click on the Open Terminal button.

D-3

Page 40

Appendix D. SDI-12 Sensor Support

4. Press the <enter> key until the datalogger responds with the CR2XX>

5. To query the C470/CS471 for its current SDI-12 address, key in ?! <enter>

6. To change the SDI-12 address, key in aAb! <enter>, where a is the current

prompt. At the CR2XX> prompt, make sure the All Caps Mode box is

checked and enter the command SDI12 <enter>. The response SDI12>

indicates that the C470/CS471 is ready to accept SDI-12 commands.

and the C470/CS471 will respond with its SDI-12 address. If no

characters are typed within 60 seconds, then the mode is exited. In that

case, simply enter the command SDI12 again and press <enter>.

address from the above step and b is the new address (see FIGURE D-1).

The C470/CS471 will change its address and the datalogger will respond

with the new address. To exit SDI-12 transparent mode, select the Close

Terminal button.

FIGURE D-1. CR200(X) example of using the SDI-12 transparent

mode to change the SDI-12 address from 0 to 1.

D.2.2 CR1000 Datalogger Example

1. Connect a CS470/CS471 to the CR1000 (see TABLE 7-2).

2. In the LoggerNet Connect screen navigate to the Datalogger menu

and select Terminal Emulator. The terminal emulator window will

open. In the Select Device menu, located in the lower left-hand side

of the window, select the CR1000 station.

3. Click on the Open Terminal button.

4. Press the <enter> key until the datalogger responds with the CR1000>

prompt. At the CR1000> prompt, make sure the All Caps Mode box

is checked and enter the command SDI12 <enter>. At the Enter Cx

Port 1, 3, 5, or 7 prompt, key in the control port number where the

CS470/CS471 is connected and press <enter>. The response Entering

SDI12 Terminal indicates that the CS470/CS471 is ready to accept

SDI-12 commands.

5. To query the CS470/CS471 for its current SDI-12 address, key in ?!

<enter> and the CS470/CS471 will respond with its SDI-12 address.

If no characters are typed within 60 seconds, then the mode is exited.

D-4

Page 41

Appendix D. SDI-12 Sensor Support

In that case, simply enter the command SDI12 again, press <enter>,

and key in the correct control port number when prompted.

6. To change the SDI-12 address, key in aAb! <enter>, where a is the

current address from the above step and b is the new address (see

FIGURE D-2). The C470/CS471 will change its address and the

datalogger will respond with the new address. To exit SDI-12

transparent mode, select the Close Terminal button.

FIGURE D-2. CR1000 example of using the SDI-12 transparent mode

to change the SDI-12 address from 3 to 1. Sensor is connected to

control port 1.

D.2.3 CR10X Datalogger Example

1. Connect a CS470/CS471 to the CR10(X) (see TABLE 7-2).

2. Download a datalogger program that contains the SDI-12 Recorder (P105)

instruction with valid entries for each parameter. Make sure that

parameter 3 of the P105 instruction matches the control port number where

the CS470/CS471 is connected.

3. In the LoggerNet Connect screen navigate to the Datalogger menu and

select Terminal Emulator. The terminal emulator window will open. In

the Select Device menu, located in the lower left-hand side of the window,

select the CR10X station.

4. Click on the Open Terminal button.

5. Press the <enter> key until the datalogger responds with the * prompt.

6. To activate the SDI-12 Transparent Mode on control port p, enter pX

<enter>. For this example, key in 1X <enter>. The datalogger will

respond with entering SDI-12. If any invalid SDI-12 command is issued,

the datalogger will exit the SDI-12 Transparent Mode.

D-5

Page 42

Appendix D. SDI-12 Sensor Support

7. To query the CS470/CS471 for its current SDI-12 address, enter the

8. To change the SDI-12 address, enter the command aAb!; where a is the

9. Activate the SDI-12 Transparent Mode on Control Port 1 again by entering

10. To exit the SDI-12 Transparent Mode, enter *.

command ?!. The CS470/CS471 will respond with the current SDI-12

address.

current address from the above step and b is the new address. The

CS470/CS471 will change its address and the datalogger will exit the SDI12 Transparent Mode.

1X <enter>. Verify the new SDI-12 address by entering the ?! command.

The CS470/CS471 will respond with the new address.

FIGURE D-3. CR10X example of using the SDI-12 transparent mode to

change the SDI-12 address from 0 to 1. Sensor is connected to

control port 1.

D-6

Page 43

Appendix D. SDI-12 Sensor Support

TABLE D-3. Advanced SDI-12 Commands

constant nalgravitatio

LocaldensityWater

C4

at

pressure

OmH

level

Water

2

80665.91

∗∗°=

D.3 Advanced SDI-12 Commands

All advanced SDI-12 commands begin with O (the letter not zero).

Command Response Description

aOXP<value>! aOXP<value><CR><LF> Activate purge function.

The parameter <value> represents the setting

defined as follows:

0 = purge function deactivated

1 = purge function activated

aOXG<value>! or aOXG! a<value><CR><LF> Set/query value for local gravitational constant.

Format: cb.aaaaaa

c: Polarity (+ or -)

bb: Number before the decimal point

aaaaaa: Number after the decimal point

(max. 6 digits)

default setting: +9.80665

aOXT<value>! or aOXT! a<value><CR><LF> Set/query value for local water temperature.

Format: cb.aaaaaa

c: Polarity (+ or -)

bb: Number before the decimal point

aaaaaa: Number after the decimal point

(max. 6 digits)

default setting: +3.98

The CS470/CS471 either produces a value proportional to the pressure, or an

actual water level compensated for the relative density of the water (using the

default settings).

The correct water level measurement is calculated according to the following

formula:

Where: water density = -6.017777e

-6 t2

+ 0.0000408 t + 0.999841 and

t = temperature in °C

The CS470/CS471 can calculate the water density at any time using the value

for the local water temperature. You can enter the value for the local

gravitational constant using the command aOXG<value>! and the value for

the local temperature using the command aOXT<value>!.

Calculation of the correct value for the local gravitational constant

The gravitational acceleration at the earth’s surface varies between 9.78036

2

m/s

at the equator and 9.83208 m/s2 at the poles. Also, it decreases by

D-7

Page 44

Appendix D. SDI-12 Sensor Support

0.003086 m/s2 for each kilometer above sea level. With the following formula

2

the local gravitational constant g in m/s

g = 9.780356 * (1 + 0.0052885 sin

can be calculated:

2

-0.0000059 sin2 2) -0.003086 h

where is the degrees of latitude and h the height above sea level in km.

th

(Jursa, A.S., Ed., Handbook of Geophysics and the Space Environment, 4

ed.,

Air Force Geophysics Laboratory, 1985, pp. 14-17).

Example: At a height above mean sea level of 0.669 km and a latitude of

2

47.71°, a gravitational constant of 9.80659 m/s

results.

D-8

Page 45

Page 46

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific (Beijing) Co., Ltd.

8B16, Floor 8 Tower B, Hanwei Plaza

7 Guanghua Road

Chaoyang, Beijing 100004

P.R. CHINA

www.campbellsci.com • info@campbellsci.com.cn

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Loading...

Loading...