Page 1

INSTRUCTION MANUAL

CS215 Temperature and

Copyright © 2005- 2014

Campbell Scientific, Inc.

Relative Humidity Probe

Revision: 8/14

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning (435) 227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is highly

recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact with

overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, 20 feet, or the distance

required by applicable law, whichever is greater, between overhead utility lines and the

structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 6

Page 7

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 1

4. Quickstart .................................................................... 2

5. Overview ...................................................................... 4

6. Specifications ............................................................. 4

6.1 Temperature Measurement................................................................... 5

6.2 Relative Humidity Measurement ......................................................... 5

7. Installation ................................................................... 5

7.1 Wiring to Datalogger ........................................................................... 6

7.2 Datalogger Programming ..................................................................... 6

7.2.1 CRBasic Programming ................................................................. 7

7.2.2 Edlog Programming ...................................................................... 7

7.3 Installation............................................................................................ 8

8. Operation ................................................................... 10

8.1 Sensor Measurements ........................................................................ 10

8.1.1 Measurements at Fast Scan Rates ............................................... 10

8.1.1.1 CRBasic Dataloggers ....................................................... 10

8.1.1.2 Edlog Dataloggers ............................................................ 11

8.1.2 Long Cables ................................................................................ 11

8.1.3 Power Conservation .................................................................... 12

8.2 Measuring Multiple SDI-12 Sensors .................................................. 12

9. Troubleshooting and Maintenance ......................... 12

9.1 Troubleshooting ................................................................................. 12

9.2 Maintenance ....................................................................................... 13

9.3 Calibration.......................................................................................... 13

9.4 Sensor Element Replacement ............................................................. 13

10. Attributions and References .................................... 16

i

Page 8

Table of Contents

Appendices

Importing Short Cut Code Into CRBasic Editor ... A-1

A.

A.1 Importing Short Cut Code into a Program Editor ............................ A-1

A.1.1 CRBasic Datalogger ................................................................. A-1

A.1.2 Edlog ........................................................................................ A-2

B. Example Programs .................................................. B-1

B.1 CRBasic Programs .......................................................................... B-1

B.1.1 Example CR200(X) Program ................................................... B-1

B.1.2 Example Program for CR800, CR850, CR1000, CR3000,

or CR5000 ............................................................................. B-2

B.2 Edlog Program................................................................................. B-3

C. Environmental Performance .................................. C-1

C.1 Tests to Defined Standards .............................................................. C-1

C.2 Exposure to Pollutants ..................................................................... C-1

C.3 Operating Range of RH Element ..................................................... C-2

C.4 Measurement Below 0 °C ............................................................... C-2

D. SDI-12 Sensor Support ........................................... D-1

D.1 SDI-12 Command Basics ................................................................ D-1

D.1.1 Address Query Command (?!) ................................................. D-2

D.1.2 Change Address Command (aAb!) .......................................... D-2

D.1.3 Send Identification Command (aI!) .......................................... D-2

D.1.4 Start Measurement Commands (aM!) ...................................... D-2

D.1.5 Aborting a Measurement Command ........................................ D-2

D.1.6 Send Data Command (aD!) ...................................................... D-2

D.2 SDI-12 Transparent Mode ............................................................... D-2

D.2.1 CR200(X) Series Datalogger Example .................................... D-3

D.2.2 CR1000 Datalogger Example ................................................... D-4

D.2.3 CR10X Datalogger Example .................................................... D-5

Figures

7-1. CS215 and 41303-5A Radiation Shield on a tripod mast .................... 9

7-2. CS215 and 41303-5A Radiation Shield on a CM200 Series

Crossarm .......................................................................................... 9

9-1. Correct fit of sensor element (side view)........................................... 15

9-2. Incorrect fit of sensor element (side view) ........................................ 16

C-1. Normal operating conditions of RH element ................................... C-2

D-1. CR200(X) example of using the SDI-12 transparent mode to

change the SDI-12 address from 0 to 1. ....................................... D-3

D-2. CR1000 example of using the SDI-12 transparent mode to

change the SDI-12 address from 3 to 1. Sensor is connected

to control port 1. ........................................................................... D-4

D-3. CR10X example of using the SDI-12 transparent mode to

change the SDI-12 address from 0 to 1. Sensor is connected

to control port 1. ........................................................................... D-5

ii

Page 9

Tables

Table of Contents

7-1. Datalogger Wiring................................................................................ 6

C-1. Environmental Tests ........................................................................ C-1

D-1. SDI-12 Command and Response Set .............................................. D-1

iii

Page 10

Table of Contents

iv

Page 11

CS215 Temperature and Relative

Humidity Probe

1. Introduction

The CS215 Temperature and Relative Humidity Probe is designed for general

meteorological and other data logging applications. It uses the SDI-12

communications protocol to communicate with any SDI-12 recorder,

simplifying installation and programming.

Before using the CS215, please study

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 4, Quickstart

2. Cautionary Statements

• READ AND UNDERSTAND the Precautions section at the front of this

manual.

• When opening the shipping package, do not damage or cut the cable

jacket. If damage to the cable is suspected, consult with a Campbell

Scientific application engineer.

• Although rugged, the CS215 should be handled as a precision scientific

instrument.

• Santoprene® rubber, which composes the black outer jacket of the CS215

cable, will support combustion in air. It is used because of its resistance to

temperature extremes, moisture, and UV degradation. It is rated as slow

burning when tested according to U.L. 94 H.B. and passes FMVSS302.

However, local fire codes may preclude its use inside buildings.

3. Initial Inspection

• Check the packaging and contents of the shipment. If damage occurred

during transport, immediately file a claim with the carrier. Contact

Campbell Scientific to facilitate repair or replacement.

• Check model information against the shipping documents to ensure the

expected products and the correct lengths of cable are received. Model

numbers are found on each product. On cables and cabled items, the

model number is usually found at the connection end of the cable. Report

any shortages immediately to Campbell Scientific.

1

Page 12

CS215 Temperature and Relative Humidity Probe

4. Quickstart

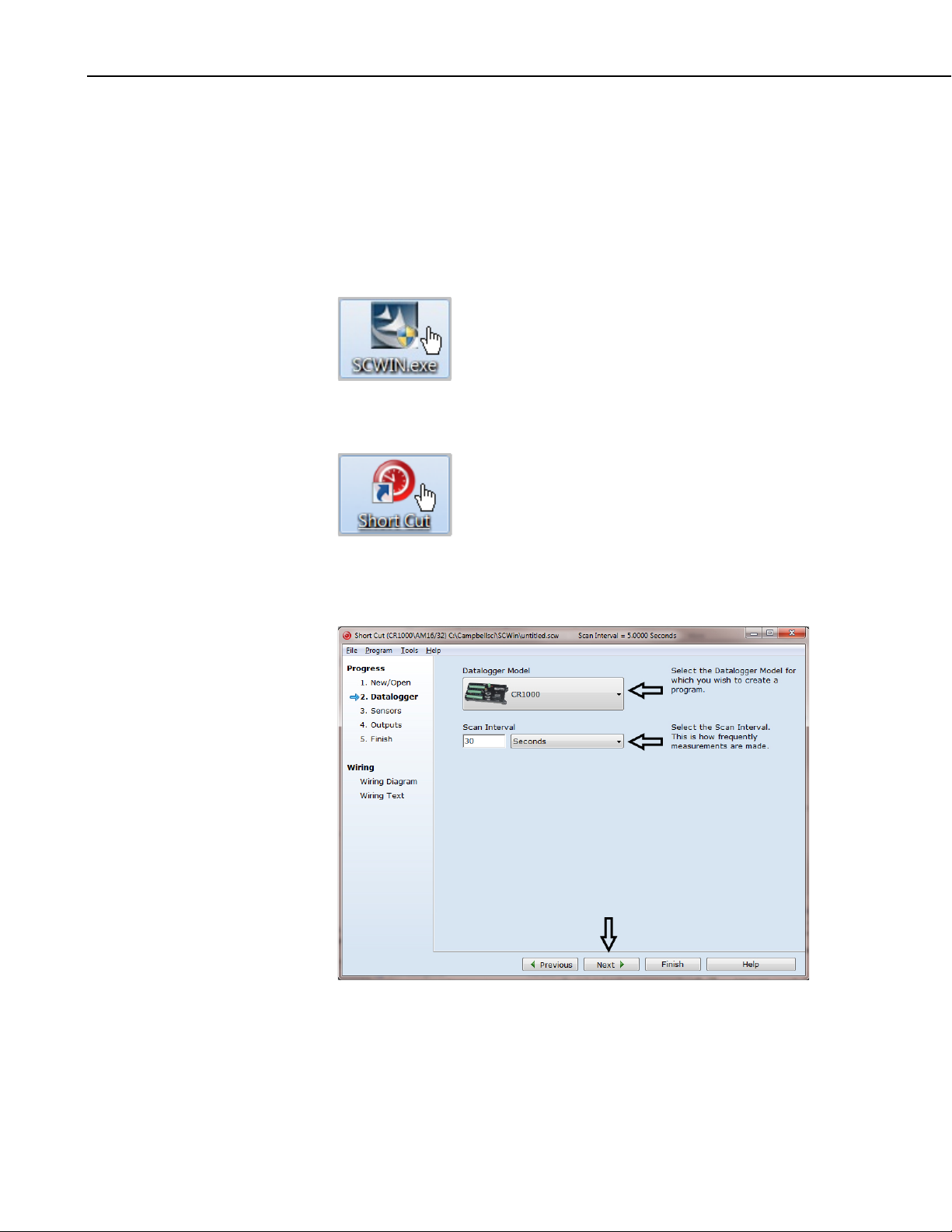

Short Cut is an easy way to program your datalogger to measure the CS215

sensor and assign datalogger wiring terminals. Use the following procedure to

get started.

1. Install Short Cut by clicking on the install file icon. Get the install file

from either www.campbellsci.com, the ResourceDVD, or find it in

installations of LoggerNet, PC200W, PC400, or RTDAQ software.

2. The Short Cut installation should place a shortcut icon on the desktop of

your computer. To open Short Cut, click on this icon.

3. When Short Cut opens, select New Program.

4. Select Datalogger Model and Scan Interval. Click Next.

2

Page 13

CS215 Temperature and Relative Humidity Probe

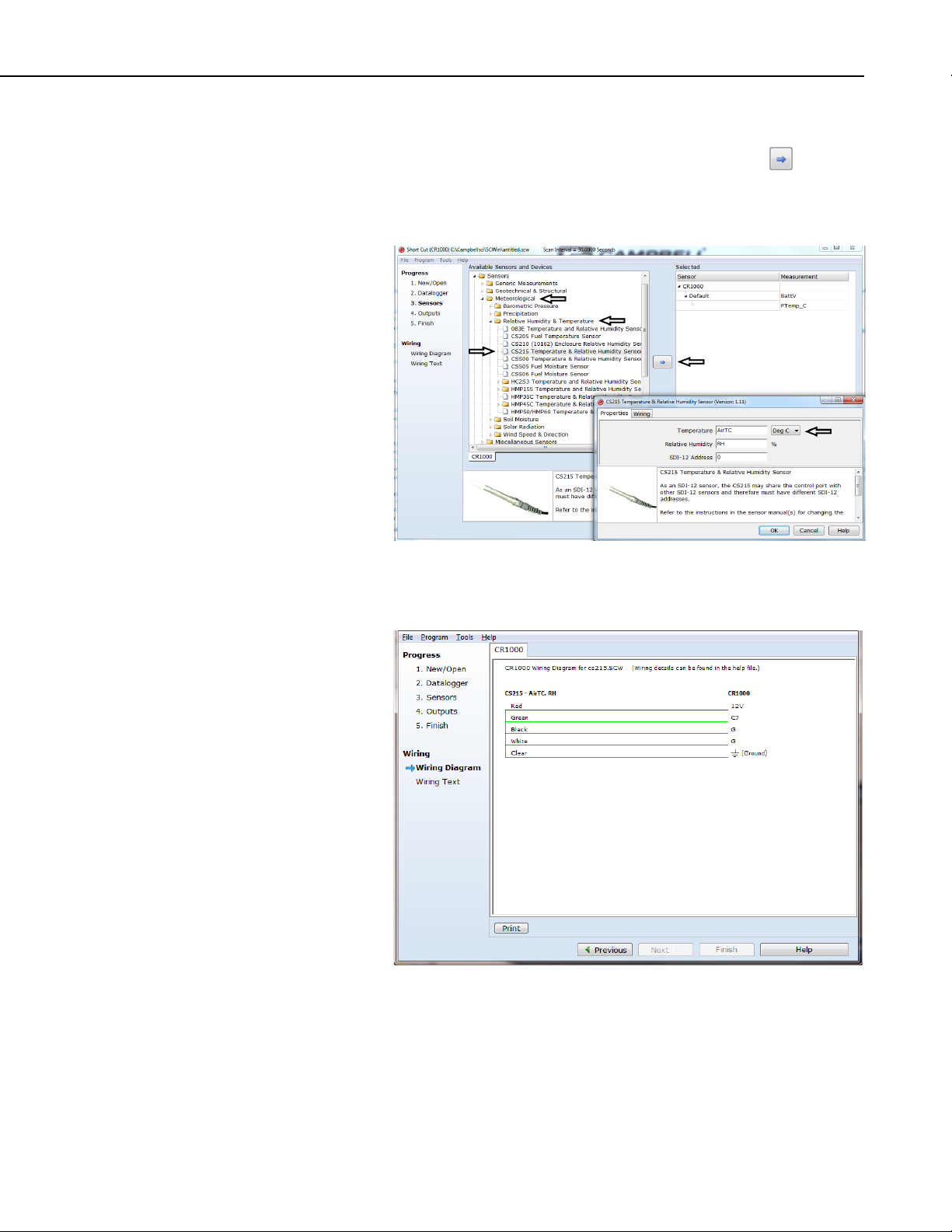

5. Under the Available Sensors and Devices list, select the Sensors |

Meteorological | Relative Humidity & Temperature folder. Select

CS215 Temperature & Relative Humidity Sensor. Click to move

the selection to the Selected device window. Data defaults to degree

Celsius. This can be changed by clicking the Deg C box and selecting

Deg F, for degrees Fahrenheit, or K for Kelvin.

6. After selecting the sensor, click at the left of the screen on Wiring

Diagram to see how the sensor is to be wired to the datalogger. The

wiring diagram can be printed out now or after more sensors are added.

7. Select any other sensors you have, then finish the remaining Short Cut

steps to complete the program. The remaining steps are outlined in Short

Cut Help, which is accessed by clicking on Help | Contents |

Programming Steps.

3

Page 14

CS215 Temperature and Relative Humidity Probe

8. If LoggerNet, PC400, RTDAQ, or PC200W is running on your PC, and the

PC to datalogger connection is active, you can click Finish in Short Cut

and you will be prompted to send the program just created to the

datalogger.

9. If the sensor is connected to the datalogger, as shown in the wiring

diagram in step 6, check the output of the sensor in the datalogger support

software data display to make sure it is making reasonable measurements.

5. Overview

The CS215 probe uses a single chip element that incorporates both a

temperature and an RH sensor. Each element is individually calibrated with

the calibration corrections stored on the chip. The element is easily changed in

the field. The ability to replace the element in the field reduces downtime and

calibration costs.

Electronics within the CS215 control the measurement made by the sensor

element, apply temperature and linearization corrections to the readings, and

present the data via SDI-12 to a datalogger.

A sintered plastic filter minimizes the effects of dust and dirt on the sensor.

The filter is lightweight and hydrophobic, thereby diminishing its effect on the

time response of the sensor.

The probe housing is designed to withstand permanent exposure to all weather

and to fit into a range of radiation shields, including compact shields.

6. Specifications

Features:

Sensor Element: Sensirion SHT75

Supply Voltage: 6 to 16 Vdc

Current Consumption: Typically 120 µA quiescent

1.7 mA during measurement

Diameter: 12 mm at sensor tip, maximum 18 mm at cable end

• Accurate, stable measurements

• Field-changeable element allows on-site recalibration

• Individually calibrated sensor elements require no further adjustment

of the probe

• Low power consumption

• Digital SDI-12 output

• Compatible with Campbell Scientific CRBasic dataloggers:

CR200(X) series, CR800 series, CR1000, CR3000, and CR5000.

Also compatible with Edlog dataloggers: CR500, CR510, CR10(X),

and CR23X

4

Length: 180 mm, including cable strain relief

Housing Material: Anodized aluminum

Page 15

CS215 Temperature and Relative Humidity Probe

Filter Material: Sintered high-density polyethylene, average pore

size 13 µm

EMC Compliance: Tested and conforms to BS EN61326:2002

Calibration: Sensirion SHT75 sensor element is individually

calibrated during manufacture.

6.1 Temperature Measurement

Operating Range: –40 to +70 °C

Accuracy: ±0.3 °C at 25 °C

±0.4 °C over 5 to 40 °C

±0.9 °C over –40 to +70 °C

Response Time

with Filter: 120 s (63% response time in air moving at 1 m/s)

Default Units: Degrees Celsius

6.2 Relative Humidity Measurement

7. Installation

Operating Range: 0 to 100% RH (–20 to +60 °C; see Appendix C,

Environmental Performance)

Accuracy at 25°C: ±2% over 10 to 90%

±4% over 0 to 100%

Short-Term Hysteresis: <1% RH

Temperature

Dependence: Compensated to better than ±2% over –20 to 60 °C

Typical Long-Term

Stability: Better than ±1.0% per year

Response Time

with Filter: <10 s (63% response time in air moving at 1 m/s at

<85% RH)

Environmental

Performance: See Appendix C, Environmental Performance

If you are programming your datalogger with Short Cut, skip Section 7.1,

Wiring to Datalogger, and Section 7.2, Datalogger Programming. Short Cut

does this work for you. See Section 4, Quickstart, for a Short Cut tutorial.

5

Page 16

CS215 Temperature and Relative Humidity Probe

TABLE 7-1. Datalogger Wiring

NOTE

7.1 Wiring to Datalogger

Terminal Terminal

number

A 1 12 V

A 4 Power

B 3 SDI-12

B 4 SDI-12

To use more than one probe per datalogger, either connect the different probes

to different terminals on the datalogger or change the SDI-12 addresses of the

probes and wire them to the same terminal. Using the SDI-12 address reduces

the use of ports on the datalogger and allows probes to be connected in a

“daisy-chain” fashion which can minimize cable runs in some applications.

(See below for limits on the total cable length.)

The SDI-12 address of the CS215 can be set two ways:

Function CR800, CR850,

power

Ground

Data

Ground

CR1000, CR3000,

CR23X, CR10(X),

CR500, CR510

12V 12V Battery+

G G G

Odd Numbered

Control Port (C1,

C3, …)

G G G

CR5000

SDI-12 C1/SDI-12

CR200(X)

• By sending the required commands to the sensors via an SDI-12

recorder/datalogger that allows talk through to the sensor (see

Appendix D.2, SDI-12 Transparent Mode)

• By loading a program into the recorder that sends the required

commands

7.2 Datalogger Programming

Short Cut is the best source for up-to-date datalogger programming code.

Programming code is needed,

• when creating a program for a new datalogger installation

• when adding sensors to an existing datalogger program

If your data acquisition requirements are simple, you can probably create and

maintain a datalogger program exclusively with Short Cut. If your data

acquisition needs are more complex, the files that Short Cut creates are a great

source for programming code to start a new program or add to an existing

custom program.

Short Cut cannot edit programs after they are imported and edited

in CRBasic Editor.

6

Page 17

A Short Cut tutorial is available in Section 4, Quickstart. If you wish to import

Short Cut code into either Edlog or CRBasic Editor to create or add to a

customized program, follow the procedure in Appendix A.1, Importing Short

Cut Code into a Program Editor. Programming basics for CRBasic and Edlog

dataloggers are provided in the following sections. Complete program

examples for select dataloggers can be found in Appendix B, Example

Programs.

7.2.1 CRBasic Programming

The SDI12Recorder() measurement instruction programs CRBasic

dataloggers (CR200(X)-, and CR800-series, CR1000, CR3000, and CR5000)

to measure the CS215 sensor. This instruction sends a request to the sensor to

make a measurement and then retrieves the measurement from the sensor. See

Section 8.1, Sensor Measurements, for more information.

When using a CR200(X), the SDI12Recorder() instruction has the following

syntax:

SDI12Recorder(Destination,OutString,Multiplier,Offset)

For the other CRBasic dataloggers, the SDI12Recorder() instruction has the

following syntax:

CS215 Temperature and Relative Humidity Probe

SDI12Recorder(Destination, SDIPort, SDIAddress, “SDICommand”,

Multiplier, Offset)

For all of the CRBasic dataloggers, the Destination parameter must be an array

of length 2, with the first index for Air Temperature (in °C) and the second for

Relative Humidity (as a percent).

Variations:

• Temperature reported as °C — set Multiplier to 1 and Offset to 0

• Temperature reported as °F — set Multiplier to 1.8 and Offset to 32

7.2.2 Edlog Programming

Edlog dataloggers read the CS215 using the SDI12 Recorder (P105)

instruction.

Please note that Edlog only allocates one input location for the SDI12

Recorder (P105) instruction. Two input locations are required for the SDI-12

M! command. The additional input location needs to be inserted manually

using the Input Location Editor. To get into the Input Location Editor, select

Edit/Input Labels or press the F5 key. Once in the Input Location Editor,

do the following:

1. Choose Edit/Insert Block.

2. After the Insert Block dialog box appears, type in a base name for the

input locations. Each input location will have the base name with an

underscore and a consecutive number.

3. In the Start Address field, type in the number of the first input location.

4. In the Number of InLocs field, type in 2 and select OK.

7

Page 18

CS215 Temperature and Relative Humidity Probe

7.3 Installation

Locate the sensor over an open, level area at least 9 m (EPA) in diameter. The

surface should be covered by short grass or the natural earth surface where

grass does not grow. Sensors should be located at a distance of at least four

times the height of any nearby obstruction and at least 30 m (EPA) from large

paved areas. Sensors should be protected from thermal radiation and

adequately ventilated. Protect the filter at the top of the sensor from exposure

to liquid water. The hydrophobic nature of the filter repels light rain, but

driving rain can force itself into the pore structure of the filter and take time to

dry out.

Standard measurement heights:

• 1.5 m (AASC)

• 1.25 – 2.0 m (WMO)

• 2.0 m (EPA)

See Section 10, Attributions and References, for a list of references that discuss

temperature and relative humidity sensors.

When used in the field, the CS215 must be housed in a radiation shield.

Typically, the 41303-5A six-plate solar radiation shield is used. The white

color reflects solar radiation, and the louvered construction allows air to pass

freely through, thereby keeping the probe at or near ambient temperature.

The 41303-5A attaches to a crossarm, mast, or user-supplied pipe with a 2.5 to

5.3 cm (1.0 to 2.1 inch) outer diameter.

A 41003-5 ten-plate solar radiation shield can also house the CS215 sensor by

using the 18.5 adapter (pn 6637). For this shield, tighten the sensor grip

around the probe where it best matches the size of the grip. (The probe will

also fit directly into most of the R.M. Young shields, where the probe enters

the shield from the top, pointing downwards.)

Both the 41303-5A and the 41003-5 solar radiation shields attach to a

crossarm, mast, or user-supplied pipe with a 2.5 to 5.3 cm (1.0 to 2.1 inch)

outer diameter.

Tools required for installing a radiation shield to a tripod or tower include:

• 1/2-inch open-end wrench

• small screwdriver provided with datalogger

• small Phillips screwdriver

• UV-resistant cable ties

• small pair of diagonal-cutting pliers

1. Loosen the plastic split collar at the base of the shield (reversing the

removable portion if necessary) and gently insert the probe.

2. Tighten the collar until it lightly grips the probe body.

8

3. Continue to push the probe up into the body of the shield until the step in

the tube stops it from going any further.

Page 19

CS215 Temperature and Relative Humidity Probe

41303-5A

CS215

Tripod or Tower Mast

41303-5A

CS215

Tripod or Tower Mast

CM200 Series Crossarm

4. Tighten the collar until it securely grips the probe.

5. Attach the radiation shield to the tripod mast, crossarm, or tower leg using

the supplied U-bolt. See FIGURE 7-1 and FIGURE 7-2 for examples of

shield mounting.

6. Route the cable to the datalogger, and secure the cable to the mounting

structure using cable ties.

FIGURE 7-1. CS215 and 41303-5A Radiation Shield on a tripod mast

FIGURE 7-2. CS215 and 41303-5A Radiation Shield on a

CM200 Series Crossarm

9

Page 20

CS215 Temperature and Relative Humidity Probe

NOTE

NOTE

8. Operation

8.1 Sensor Measurements

CRBasic instruction SDI12Recorder() measures the CS215 sensor using the

Start Measurement (aM!), Concurrent Measurement (aC!), or Continuous

Measurement (aR!) command. In all cases “a” is the address of the sensor and

“!” is the command terminator. The sensor returns two values: temperature in

degrees Celsius and relative humidity as a percentage (0 to 100).

A measurement is initiated with the aM! or aC! command. To these

commands, the sensor responds with the time until the measurement data are

available and the number of values to be returned when one or more

subsequent aD! commands are issued.

When using the aM! command, the datalogger waits the time specified by the

sensor, sends the aD! command, pauses its operation, and waits until either it

receives the data from the sensor or the sensor timeout expires. Because of the

delays this command requires, it is only recommended in measurement scans

of 10 seconds or more.

The aC! command follows the same pattern as the aM! command with the

exception that it does not require the datalogger to pause its operation until the

values are ready. Rather, the datalogger picks up the data with the aD!

command on the next pass through the program. Another measurement request

is then sent so that data are ready on the next scan.

An aR! command switches the sensor to automatically make measurements

and send data every 11 seconds, ±2 seconds, based on the sensor’s internal

clock. If measurements are requested at 2 seconds or faster, the sensor will

increase its measurement rate to approximately every 5 seconds. This

instruction usually takes less than 300 milliseconds to execute. The automatic

measurement mode can only be cancelled by powering down the sensor to reset

it.

See Appendix D, SDI-12 Sensor Support, for additional commands and details

of the SDI-12 protocol.

Only CS215 sensors with serial numbers after E1587 or those with

upgraded firmware support the aR! Command.

8.1.1 Measurements at Fast Scan Rates

8.1.1.1 CRBasic Dataloggers

Using the SlowSequence() function allows the SDI-12 instruction to run as a

background process, causing minimum interference to other measurements that

use the analog hardware. Measuring the sensor in a SlowSequence() section of

the program allows faster programs to run as the main scan.

For the CR5000, use a control port rather than the SDI-12 port to

allow the SDI12recorder instruction to run in the slow sequence.

10

Page 21

8.1.1.2 Edlog Dataloggers

The aM! command takes about 700 milliseconds in total to make a

measurement from the CS215. If it is included in the main program table

(table 1) the program will be delayed for this interval which will limit the

maximum scan rate for fast running programs.

For Edlog dataloggers, it is possible to put the SDI-12 instruction in table 2,

which allows table 1 to interrupt and pause the SDI-12 instruction letting it run

other instructions. However, table 1 cannot interrupt the instruction while

SDI-12 communications are taking place, only when datalogger is waiting for

the sensor to take the measurement. As the initiation of the sensor and also the

transfer of data from the sensor each take approximately 200 milliseconds this

limits the scan rate of table 1 to about 250 milliseconds, and only then if table 1

itself takes little time to execute.

The aC! concurrent measurement command can also be used where the sensor

measurement is initiated with one command and data is collected after a

minimum delay of one second or any time thereafter. With Campbell

Scientific dataloggers, this is done by using the SDI-12 recorder instruction

with the aC! command. The datalogger will return –99999 for the temperature

reading for the call of the instruction that initiates the measurement. At the

next call of the instruction, the datalogger will request the data and record the

correct temperature.

CS215 Temperature and Relative Humidity Probe

8.1.2 Long Cables

Using the aC! command requires more detailed programming to ensure the

out-of-range values are not recorded as real temperatures. It also has similar

limitations to running the instruction in table 2 when trying to make other

measurements at a fast scan rate. This is because the program will still be

delayed by approximately 200 ms for both the initiation of the measurement

and the subsequent reading of data from the sensor. Using the aC! command

can be useful where predictable timing of the program is required (without the

complications of working out how different program tables will interrupt each

other).

Digital data transfer eliminates offset errors due to cable lengths. However,

digital communications can break down when cables are too long, resulting in

either no response from the sensor or corrupted readings. The original SDI-12

standard specifies the maximum total cable length to be 61 m (200 ft). To

ensure proper operation with long cables, follow these guidelines:

• Use low capacitance, low resistance, screened cable (as fitted by Campbell

Scientific) to reach distances of several hundred meters.

• Ensure that the power ground cable has low resistance and is connected to

the same ground reference as the datalogger control ports.

• Be aware that “daisy-chaining” sensors reduces the maximum cable length

roughly in proportion to the number of sensors connected in parallel.

11

Page 22

CS215 Temperature and Relative Humidity Probe

NOTE

8.1.3 Power Conservation

The CS215 draws less than 70 µA of current between measurements. In most

applications, this is insignificant compared to the datalogger and other power

uses, so the sensor can be permanently connected.

In low-power applications, battery power can be conserved by turning the 12 V

supply to the CS215 on just before the measurement (allowing a ‘warm-up’

time of at least 100 ms) and then turning it off afterwards. If available, the

switched 12 V output of the datalogger can be used.

8.2 Measuring Multiple SDI-12 Sensors

Up to ten CS215s or other SDI-12 sensors can be connected to a single

datalogger control port. Each SDI-12 device must have a unique SDI-12

address between 0 and 9.

9. Troubleshooting and Maintenance

All factory repairs and recalibrations require a returned material

authorization (RMA) and completion of the “Declaration of

Hazardous Material and Decontamination” form. Refer to the

Assistance page at the beginning of this manual for more

information.

9.1 Troubleshooting

Symptom: Temperature is reported as –9999 or NAN, and relative humidity is

reported as 0 or as an unchanging value.

Recheck wiring. Verify the green wire is connected to the control port

specified by the SDI12Recorder() instruction. Verify the red wire is

connected to a 12V terminal.

Check the voltage to the sensor with a digital voltage meter. If a switched 12V

terminal is used, temporarily connect the red wire to a 12V terminal (nonswitched) for test purposes.

Verify the probe’s SDI12 address matches the address entered for the

SDI12Recorder() instruction. The default address is 0. The address can be

verified or changed with the commands described in Appendix D, SDI-12

Sensor Support.

Remove the filter tip and verify that the sensing element has been installed

with the proper orientation as described in Section 9.4, Sensor Element

Replacement.

Symptom: Incorrect temperature or relative humidity is reported.

If using the SW12 terminal to power the sensor, verify the program is allowing

a warm-up time of at least 100 ms.

12

Check to see if the filter tip has been contaminated. Replace the filter tip (pn

18142), or clean with distilled water as needed.

Page 23

9.2 Maintenance

CAUTION

NOTE

The CS215 probe requires minimal maintenance.

• Check the radiation shield monthly to make sure it is free from dust and

• Clear the white filter on the end of the sensor of debris. If dirt or salt is

9.3 Calibration

The life of the humidity chip element is quoted as many years with a typical

drift of less than 1% per year when used in ‘clean’ environments. Because it

can be difficult to know what the sensor has been exposed to and because the

element is relatively inexpensive, we recommend replacing the sensor element

at the normal interval you would recalibrate similar probes, e.g. annually.

Replacing the element effectively brings the probe back to a factory calibration

state both for temperature and relative humidity.

CS215 Temperature and Relative Humidity Probe

debris.

engrained into the filter, it should be cleaned with distilled water or

replaced. Make sure the filter is connected firmly with your fingers — do

not over tighten.

If you wish to have an old element’s calibration checked in order to formally

record the probe’s pre-calibration state (pre-sensor replacement), you can

measure its performance by plugging it into another sensor.

9.4 Sensor Element Replacement

To replace the element:

1. Disconnect the sensor from the 12 V power supply.

2. Remove the filter by unscrewing it in a counter-clockwise direction when

looking towards the tip of the sensor.

The filter cap unscrews from the probe. Attempting to pull it

off will destroy it.

3. Wash your hands to avoid getting dirt or grease on the element.

It is virtually impossible to touch and damage the sensing elements

which are enclosed within the black molded plastic at the tip.

However, if dirt, salt, or grease are left on the plastic during the

process of handling the element, it may influence the

measurements made.

4. Identify the sensor element. FIGURE 9-1 shows a side-view of the end of

the probe and sensor element. Before removing the element, carefully

study the probe, note its orientation, and read the following description:

• The element plugs into the black plastic socket that protrudes by about

1 mm from the end of the metal body of the sensor.

13

Page 24

CS215 Temperature and Relative Humidity Probe

CAUTION

CAUTION

• There are eight holes in the socket, while the element only has four

pins.

• The element will work when fitted into either side of socket but must

be installed in one of the two possible orientations to work.

• The correct orientation is with the black molded tip of the element

(that contains the sensing components) mounted directly above the

center of the socket.

• FIGURE 9-1 shows the correct orientation, while FIGURE 9-2 shows

the incorrect orientation.

If the sensor is oriented incorrectly, it will not work. The

element will draw excessive power from the supply and may

be damaged if left powered in this state for more than a few

seconds.

5. Grasp the body of the sensor (this also ensures you are at the same

electrical potential as the element) and, holding the black tip of the

element between your fingertips, pull the element out of the socket. Store

the old element in electrostatic protective packaging if you wish to retain

it.

6. With the element removed, check for dirt and/or corrosion around the

socket. Clean any dirt away using a damp cloth to remove any salts that

might be there.

7. Unpack the replacement element, avoiding static discharges to the element

by making sure you touch the packaging before the element.

8. Either hold the element by the black top of the package (the other end to

the gold plated pins) or use a pair of fine nosed pliers or tweezers to grip

the sensor by the pins. Carefully match the pins to the socket in the end of

probe.

9. Confirm the correct orientation and gently push the pins into the socket

until they will not go in any further.

10. Before replacing the filter element and turning on power to the sensor,

double-check that the sensor is inserted in the correct orientation. Refer to

FIGURE 9-1.

11. Screw the filter back onto the end of the probe, making sure it clears the

sensor element. If the element appears too close to the filter, there is a fair

chance that it has been inserted in the incorrect orientation or that the legs

of the element have been bent. Screw the filter onto the thread and tighten

gently with your fingers.

14

Only tighten the filter approximately an eighth of a turn by

hand when the filter is fully screwed onto the thread. Overtightening the filter will damage it and cause problems in

inserting and removing the probe from some shields.

Page 25

CS215 Temperature and Relative Humidity Probe

Sensor

connector

sticking out of

the end of the

tube

Gold pins

Sensing

Element

Sensing part of

the element.

Print ing on this

side.

Center line of

the sensor

body and

socket

Thread for the

filt er

Gold colored

side o f t he tip

FIGURE 9-1. Correct fit of sensor element (side view)

15

Page 26

CS215 Temperature and Relative Humidity Probe

Sensing part of

element NOT on

the center line

Center line o f the

sensor body

FIGURE 9-2. Incorrect fit of sensor element (side view)

10. Attributions and References

AASC, 1985: The State Climatologist (1985) Publication of the American

Association of State Climatologists: Heights and Exposure Standards for

Sensors on Automated Weather Stations, v. 9, No. 4 October, 1985.

(www.stateclimate.org/publications/state-climatologist/NOAA-NCYSCBOOKS-SC77097/00000029.pdf)

EPA, 2008: Quality Assurance Handbook for Air Pollution Measurement

Systems, Vol. IV, Meteorological Measurements, Ver. 2.0, EPA-454/B-08002 (revised 2008). Office of Air Quality Planning and Standards,

Research Triangle Park, NC 27711.

Goff, J. A. and S. Gratch, 1946: Low-pressure properties of water from -160°

to 212°F, Trans. Amer. Soc. Heat. Vent. Eng., 51, 125-164.

Lowe, P. R., 1977: An approximating polynomial for the computation of

saturation vapor pressure, J. Appl. Meteor., 16, 100-103.

16

Page 27

CS215 Temperature and Relative Humidity Probe

Meyer, S. J. and K. G. Hubbard, 1992: Nonfederal Automated Weather

Stations and Networks in the United States and Canada: A Preliminary

Survey, Bulletin Am. Meteor. Soc., 73, No. 4, 449-457.

Weiss, A., 1977: Algorithms for the calculation of moist air properties on a

hand calculator, Amer. Soc. Ag. Eng., 20, 1133-1136.

WMO, 2008. Guide to Meteorological Instruments and Methods of

Observation. World Meteorological Organization No. 8, 7th edition,

Geneva, Switzerland.

17

Page 28

CS215 Temperature and Relative Humidity Probe

18

Page 29

NOTE

Appendix A. Importing Short Cut Code Into CRBasic Editor

This tutorial shows:

• How to import a Short Cut program into a program editor for

additional refinement

• How to import a wiring diagram from Short Cut into the comments of

a custom program

A.1 Importing Short Cut Code into a Program Editor

Short Cut creates files that can be imported into either CRBasic Editor or

Edlog program editor. These files normally reside in the

C:\campbellsci\SCWin folder and have the following extensions:

• .DEF (wiring and memory usage information)

• .CR1 (CR1000 datalogger code)

• .CR8 (CR800 datalogger code)

• .CR3 (CR3000 datalogger code)

• .CR7 (CR7 datalogger code)

• .DLD (contain code for CR10(X), CR23X, CR500, CR510, 21X, or

CR7(X) dataloggers)

The following procedures show how to import these files for editing.

A.1.1 CRBasic Datalogger

Use the following procedure to import Short Cut code into CRBasic Editor

(CR200(X), CR1000, CR800, CR3000, CR5000 dataloggers).

1. Create the Short Cut program following the procedure in Section 4,

Quickstart. Finish the program and exit Short Cut. Make note of the file

name used when saving the Short Cut program.

2. Open CRBasic Editor.

3. Click File | Open. Assuming the default paths were used when Short Cut

was installed, navigate to C:\CampbellSci\SCWin folder. The file of

interest has a “.CR1”, “.CR8”, “.CR3”, or “.CR5” extension, for CR1000,

CR800, CR3000, or CR5000 dataloggers, respectively. Select the file and

click Open.

4. Immediately save the file in a folder different from \Campbellsci\SCWin,

or save the file with a different file name.

Once the file is edited with CRBasic Editor, Short Cut can no

longer be used to edit the datalogger program. Change the name

of the program file or move it, or Short Cut may overwrite it next

time it is used.

A-1

Page 30

Appendix A. Importing Short Cut Code Into CRBasic Editor

NOTE

5. The program can now be edited, saved, and sent to the datalogger.

6. Import wiring information to the program by opening the associated .DEF

file. Copy and paste the section beginning with heading “-Wiring for

CRXXX–” into the CRBasic program, usually at the head of the file.

After pasting, edit the information such that a ' character (single quotation

mark) begins each line. This character instructs the datalogger compiler to

ignore the line when compiling the datalogger code.

A.1.2 Edlog

Use the following procedure to import Short Cut code into the Edlog program

editor (CR10(X), CR500, CR510, and CR23X dataloggers).

1. Create the Short Cut program following the procedure in Section 4,

Quickstart. Finish the program and exit Short Cut. Make note of the file

name used when saving the Short Cut program.

2. Open Edlog.

3. Click File | Document DLD File. Assuming the default paths were used

when Short Cut was installed, navigate to C:\CampbellSci\SCWin folder.

The file of interest has a “.DLD” extension. Select the file and click

Open. The .dld file, which is a type of ASCII machine code, is imported,

documented, and, when saved, given a “.CSI” extension.

4. Immediately save the file in a folder different from \Campbellsci\SCWin,

or save the file with a different file name.

Once the file is edited with Edlog, Short Cut can no longer be used

to edit the program. Change the name of the program file or move

it, or Short Cut may overwrite it.

5. The program can now be edited, saved, and sent to the datalogger.

6. Import wiring information to the program by opening the associated .DEF

file. Copy and paste the section beginning with heading “-Wiring for

CRXXX–” into the Edlog program, usually at the head of the file. After

pasting, edit the information such that a ; (semicolon) begins each line,

which instructs the datalogger compiler to ignore the line when compiling

the datalogger code.

A-2

Page 31

Appendix B. Example Programs

B.1 CRBasic Programs

B.1.1 Example CR200(X) Program

This example program shows the measurement of a single CS215 and can be

used directly with CR200(X) series dataloggers.

'CR200(X) Series Datalogger

'Program measures one CS215 sensor every 30 seconds and stores the average

'temperature and a sample of relative humidity every 10 minutes.

'Wiring Diagram

'==============

'CS215

' Wire

' Color Function CR200(X)

' ----- -------- ------' Red Power (12V) Battery +

' Green SDI-12 signal C1/SDI-12

' Black Power ground G

' White Power ground G

' Clear Shield AG*

'*AG = Analog Ground (represented by ground symbol on CR200 wiring panel

'Declare the variable array for the measurement

Public TRHData(2)

Alias TRHData(1)=AirTC

Alias TRHData(2)=RH

Units AirTC=Deg C

Units RH=%

'Define a data table for ten-minute data

DataTable(TenMin,True,-1)

DataInterval(0,10,Min)

Average(1,AirTC,False)

Sample(1,RH)

EndTable

'Main Program

BeginProg

Scan (30,Sec) 'Scan every 30 seconds

'CS215 Temperature & Relative Humidity Sensor measurements 'AirTC' and 'RH'

SDI12Recorder(TRHData(),"0M!",1,0)

'Call Data Tables and Store Data

CallTable TenMin

NextScan

EndProg

B-1

Page 32

Appendix B. Example Programs

B.1.2 Example Program for CR800, CR850, CR1000, CR3000,

or CR5000

'Program measures one CS215 sensor every 5 seconds and stores the average

'temperature and a sample of relative humidity every 10 minutes.

'Wiring Diagram

'==============

'CS215

' Wire

' Color Function CR1000

' ----- -------- ------' Red Power (12V) 12V

' Green SDI-12 signal C3

' Black Power ground G

' White Power ground G

' Clear Shield AG*

'Declare the variable array for the measurement

Public TRHData(2)

Alias TRHData(1)=AirTC

Alias TRHData(2)=RH

Units AirTC=Deg C

Units RH=%

'Define Data Tables

DataTable(TenMin,True,-1)

DataInterval(0,10,Min,10)

Average(1,AirTC,FP2,False)

Sample(1,RH,FP2)

EndTable

'Main Program

BeginProg

'Main Scan

Scan(5,Sec,1,0)

'CS215 Temperature & Relative Humidity Sensor measurements 'AirTC' and 'RH'

SDI12Recorder(TRHData(),7,"0","M!",1,0)

'Call Data Tables and Store Data

CallTable(TenMin)

NextScan

EndProg

This program can be used directly with CR800 series, CR1000, CR3000, and

CR5000 dataloggers.

B-2

Page 33

B.2 Edlog Program

The following example is written for the CR10(X). Programs for the CR500,

CR510, and CR23X would be similar. The program below shows a simple

example reading a sensor which has been set up with address 0 (the default)

and connected to control port 1.

;{CR10X}

;Example program for a CS215 sensor on control port 1

;Measures every minute and stores some summary statistics

;once per hour

*Table 1 Program

01: 60 Execution Interval (seconds)

;Measure the sensor on control port 1

;Note you have to manually assign the labels in the Inloc Editor

;to make sure two locations are free.

1: SDI-12 Recorder (P105)

1: 0000 SDI-12 Address

2: 00 SDI-12 Command

3: 1 Port

4: 1 Loc [ Temp ]

5: 1. 0 Mult

6: 0.0 Offset

;Now store some statistics.

2: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

3: Real Time (P77)

1: 111 Day,Hour/Minute,Seconds (midnight = 0000)

4: Average (P71)

1: 1 Reps

2: 1 Loc [ Temp ]

5: Sample (P70)

1: 1 Reps

2: 2 Loc [ RH ]

*Table 2 Program

02: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

End Program

Appendix B. Example Programs

B-3

Page 34

Appendix B. Example Programs

B-4

Page 35

TABLE C-1. Environmental Tests

Appendix C. Environmental Performance

This appendix details tests and limitations of the sensor when exposed to extremes of the

environment.

C.1 Tests to Defined Standards

The sensor element has been tested by the manufacturer and found to comply

with various environmental test standards as shown in the table below:

Environment Norm Results

Temperature Cycles

HAST Pressure

Cooker

Salt Atmosphere

Condensing Air

Freezing Cycles Fully

Submerged

Various Automotive

Chemicals

Cigarette Smoke

N.B. The temperature sensor passed all tests without any detectable drift. Package and

electronics also passed 100%

C.2 Exposure to Pollutants

All capacitive sensors are susceptible to pollutants to some degree. The vapors

may interfere with the polymer layers used in the structure of the sensing

element. The diffusion of chemicals into the polymer may cause temporary or

even permanent shifts in both offset and sensitivity.

JESD22-A104-B

–40/+125 °C, 1000

cycles

JESD22-A110-B 2.3bar

125 °C 85%RH

DIN-50021SS Within

– Within

–20/+90 °C, 100cycles,

30min dwell time

DIN 72300-5 Within

Equivalent to 15 years in

a mid-size car

Within

Specifications

Reversible shift by

+2% RH

Specifications

Specifications

Reversible shift by

+2% RH

Specifications

Within

Specifications

After low levels of exposure, in a clean environment the contaminants will

slowly outgas and the sensor recovers. High levels of pollutants may cause

permanent damage to the sensing polymer.

As a general rule, the sensor will not be damaged by levels of chemicals which

are not too dangerous to human health (see TABLE C-1), so damage is not

normally a problem in outdoor applications. Avoid exposing the sensor to

chemicals at higher concentrations.

C-1

Page 36

Appendix C. Environmental Performance

C.3 Operating Range of RH Element

The RH sensor is specified to work over the entire humidity range of 0 to

100% RH for the temperature range –20 to +60 °C. It will give readings over

an extended range as shown in FIGURE C-1 (although the electronics of the

CS215 probe are not specified to operate beyond +70 °C).

When used outside the range of normal conditions or when subject to

prolonged periods of condensation or freezing, the sensor calibration may be

temporarily altered, normally resulting in a change of <+3% RH. Upon

returning to normal conditions, the calibration will settle back to the “standard”

calibration over the course of several days. In laboratory conditions, it is

possible to speed up this process by a reconditioning process, as follows: 80-90

°C at < 5 %RH for 24h (baking) followed by 20 to 30 °C at > 74 %RH for 48h

(re-hydration).

FIGURE C-1. Normal operating conditions of RH element

C.4 Measurement Below 0 °C

The CS215 provides a humidity reading that is referenced to the saturated

water vapor pressure above liquid water, even at temperatures below 0 °C,

where ice might form. This is the common way to express relative humidity

and is as defined by the World Meteorological Organization. If an RH value is

required to be referenced to ice, the CS215 readings will need to be corrected.

One consequence of using water as the reference is that the maximum humidity

that will normally be output by the sensor for temperatures below freezing is as

follows:

100% RH at 0 °C

95% RH at –5 °C

91% RH at –10 °C

87% RH at –15 °C

82% RH at –20 °C

78% RH at –25 °C

75% RH at –30 °C

In practical terms this means that, for instance, at –20 °C the air is effectively

fully saturated when the sensor outputs 82% RH.

C-2

Page 37

TABLE D-1. SDI-12 Command and Response Set

Appendix D. SDI-12 Sensor Support

D.1 SDI-12 Command Basics

SDI-12 commands have three components:

Sensor address (a) – a single character, and is the first character of the

command. The default address of zero (0) can be used unless multiple sensors

are connected to the same port.

Command body (e.g., M1) – an upper case letter (the “command”) followed by

alphanumeric qualifiers.

Command termination (!) – an exclamation mark.

An active sensor responds to each command. Responses have several standard

forms and terminate with <CR><LF> (carriage return – line feed). Standard

SDI-12 commands supported by the CS215 are listed in TABLE D-1.

Name Command Response

Acknowledge

Active

Send

Identification

Change

Address

Address

Query

Start

Measurement

Send Data aD0! a<values><CR><LF>

Start

verification

a! a<CR><LF>

aI! allccccccccmmmmmmvvvxxx...xx<CR><LF>

aAb! b<CR><LF>

?! a<CR><LF>

aM! atttn<CR><LF>

aV! atttn

D-1

Page 38

Appendix D. SDI-12 Sensor Support

D.1.1 Address Query Command (?!)

Command ?! requests the address of the connected sensor. The sensor replies

to the query with the address, a.

D.1.2 Change Address Command (aAb!)

Sensor address is changed with command aAb!, where a is the current address

and b is the new address. For example, to change an address from 0 to 2, the

command is 0A2!. The sensor responds with the new address b, which in this

case is 2.

D.1.3 Send Identification Command (aI!)

Sensor identifiers are requested by issuing command aI!. The reply is defined

by the sensor manufacturer, but usually includes the sensor address, SDI-12

version, manufacturer’s name, and sensor model information. Serial number or

other sensor specific information may also be included.

D.1.4 Start Measurement Commands (aM!)

A measurement is initiated with M! commands. The response to each

command has the form atttnn, where

a = sensor address

ttt = time, in seconds, until measurement data are available

nn = the number of values to be returned when one or more subsequent D!

commands are issued.

D.1.5 Aborting a Measurement Command

A measurement command (M!) is aborted when any other valid command is

sent to the sensor.

D.1.6 Send Data Command (aD!)

This command requests data from the sensor. It is normally issued

automatically by the datalogger after measurement commands aM!. In

transparent mode, the user asserts this command to obtain data.

D.2 SDI-12 Transparent Mode

System operators can manually interrogate and enter settings in probes using

transparent mode. Transparent mode is useful in troubleshooting SDI-12

systems because it allows direct communication with probes. Datalogger

security may need to be unlocked before transparent mode can be activated.

D-2

Transparent mode is entered while the PC is in telecommunications with the

datalogger through a terminal emulator program. It is easily accessed through

Campbell Scientific datalogger support software, but is also accessible with

terminal emulator programs such as Windows HyperTerminal. Datalogger

keyboards and displays cannot be used.

Page 39

Appendix D. SDI-12 Sensor Support

The terminal emulator is accessed by navigating to the Datalogger menu in

PC200W, the Tools menu in PC400, or the Datalogger menu in the LoggerNet

Connect screen.

The following examples show how to use LoggerNet software to enter

transparent mode and change the SDI-12 address of the sensor. The same steps

are used to enter transparent mode with PC200W and PC400 software after

accessing the terminal emulator as previously described.

D.2.1 CR200(X) Series Datalogger Example

1. Connect a single CS215 to the CR200(X) (see TABLE 7-1).

2. In the LoggerNet Connect screen navigate to the Datalogger menu and

select Terminal Emulator. The terminal emulator window will open. In

the Select Device menu, located in the lower left-hand side of the window,

select the CR200Series station.

3. Click on the Open Terminal button.

4. Press the <enter> key until the datalogger responds with the CR2XX>

prompt. At the CR2XX> prompt, make sure the All Caps Mode box is

checked and enter the command SDI12 <enter>. The response SDI12>

indicates that the sensor is ready to accept SDI-12 commands.

5. To query the sensor for its current SDI-12 address, key in ?! <enter> and

the sensor will respond with its SDI-12 address. If no characters are typed

within 60 seconds, then the mode is exited. In that case, simply enter the

command SDI12 again and press <enter>.

6. To change the SDI-12 address, key in aAb! <enter>, where a is the current

address from the above step and b is the new address (see FIGURE D-1).

The sensor will change its address and the datalogger will respond with the

new address. To exit SDI-12 transparent mode, select the Close Terminal

button.

FIGURE D-1. CR200(X) example of using the SDI-12 transparent

mode to change the SDI-12 address from 0 to 1.

D-3

Page 40

Appendix D. SDI-12 Sensor Support

D.2.2 CR1000 Datalogger Example

1. Connect a CS215 to the CR1000 (see TABLE 7-1).

2. In the LoggerNet Connect screen navigate to the Datalogger menu and

3. Click on the Open Terminal button.

4. Press the <enter> key until the datalogger responds with the CR1000>

5. To query the sensor for its current SDI-12 address, key in ?! <enter> and

select Terminal Emulator. The terminal emulator window will open. In

the Select Device menu, located in the lower left-hand side of the window,

select the CR1000 station.

prompt. At the CR1000> prompt, make sure the All Caps Mode box is

checked and enter the command SDI12 <enter>. At the Enter Cx Port 1,

3, 5, or 7 prompt, key in the control port number where the sensor is

connected and press <enter>. The response Entering SDI12 Terminal

indicates that the sensor is ready to accept SDI-12 commands.

the sensor will respond with its SDI-12 address. If no characters are typed

within 60 seconds, then the mode is exited. In that case, simply enter the

command SDI12 again, press <enter>, and key in the correct control port

number when prompted.

6. To change the SDI-12 address, key in aAb! <enter>, where a is the current

address from the above step and b is the new address (see FIGURE D-2).

The sensor will change its address and the datalogger will respond with the

new address. To exit SDI-12 transparent mode, select the Close Terminal

button.

FIGURE D-2. CR1000 example of using the SDI-12 transparent mode

to change the SDI-12 address from 3 to 1. Sensor is connected to

control port 1.

D-4

Page 41

D.2.3 CR10X Datalogger Example

1. Connect CS215 to the CR10(X) (see TABLE 7-1).

2. Download a datalogger program that contains the SDI-12 Recorder

(P105) instruction with valid entries for each parameter. Make sure that

parameter 3 of the P105 instruction matches the control port number

where the sensor is connected.

3. In the LoggerNet Connect screen navigate to the Datalogger menu and

select Terminal Emulator. The terminal emulator window will open. In

the Select Device menu, located in the lower left-hand side of the window,

select the CR10X station.

4. Click on the Open Terminal button.

5. Press the <enter> key until the datalogger responds with the * prompt.

6. To activate the SDI-12 Transparent Mode on control port p, enter pX

<enter>. For this example, key in 1X <enter>. The datalogger will

respond with entering SDI-12. If any invalid SDI-12 command is issued,

the datalogger will exit the SDI-12 Transparent Mode.

Appendix D. SDI-12 Sensor Support

7. To query the sensor for its current SDI-12 address, enter the command ?!.

The sensor will respond with the current SDI-12 address.

8. To change the SDI-12 address, enter the command aAb!; where a is the

current address from the above step and b is the new address. The sensor

will change its address and the datalogger will exit the SDI-12 Transparent

Mode.

9. Activate the SDI-12 Transparent Mode on Control Port 1 again by entering

1X <enter>. Verify the new SDI-12 address by entering the ?! command.

The sensor will respond with the new address.

10. To exit the SDI-12 Transparent Mode, enter *.

FIGURE D-3. CR10X example of using the SDI-12 transparent mode to

change the SDI-12 address from 0 to 1. Sensor is connected to

control port 1.

D-5

Page 42

Appendix D. SDI-12 Sensor Support

D-6

Page 43

Page 44

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific (Beijing) Co., Ltd.

8B16, Floor 8 Tower B, Hanwei Plaza

7 Guanghua Road

Chaoyang, Beijing 100004

P.R. CHINA

www.campbellsci.com • info@campbellsci.com.cn

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Loading...

Loading...