Page 1

USER GUIDE

CS125

Present Weather Sensor

Issued: 3.6.14

Copyright © 2013-14 Campbell Scientific Ltd.

CSL 1000

Page 2

Page 3

Guarantee

This equipment is guaranteed against defects in materials and workmanship.

This guarantee applies for twelve months from date of delivery. We will

repair or replace products which prove to be defective during the guarantee

period provided they are returned to us prepaid. T he guarantee will not apply

to:

• Equipment which has been modified or altered in any way without the

written permission of Campbell Scientific

• Batteries

• Any product which has been subjected to misuse, neglect, acts of God or

damage in transit.

Campbell Scientific will return guaranteed equipment by surface carrier

prepaid. Campbell Scientific will not reimburse the claimant for costs incurred

in removing and/or reinstalling equipment. This guarantee and the Company’s

obligation thereunder is in lieu of all other guarantees, expressed or implied,

including those of suitability and fitness for a particular purpose. Campbell

Scientific is not liable for consequential damage.

Please inform us before returning equipment and obtain a Repair Reference

Number whether the repair is under guarantee or not. Please state the faults as

clearly as possible, and if the product is out of the guarantee period it should

be accompanied by a purchase order. Quotations for repairs can be given on

request. It is the policy of Campbell Scientific to protect the health of its

employees and provide a safe working environment, in support of this policy a

“Declaration of Hazardous Material and Decontamination” form will be

issued for completion.

When returning equipment, the Repair Reference Num ber must be clearly

marked on the outside of the package. Complete the “Declaration of

Hazardous Material and Decontamination” form and ensure a completed copy

is returned with your goods. Please note your Repair may not be processed if

you do not include a copy of this form and Campbell Scientific Ltd reserves

the right to return goods at the customers’ expense.

Note that goods sent air freight are subject to Customs clearance fees which

Campbell Scientific will charge to customers. In many cases, these charges are

greater than the cost of the repair.

Campbell Scientific Ltd,

Campbell Park, 80 Hathern Road,

Shepshed, Loughborough, LE12 9GX, UK

Tel: +44 (0) 1509 601141

Fax: +44 (0) 1509 601091

Email: support@campbellsci.co.uk

www.campbellsci.co.uk

Page 4

Page 5

PLEASE READ FIRST

About this manual

Some useful conversion factors:

2

Area: 1 in

Length: 1 in. (inch) = 25.4 mm

1 ft (foot) = 304.8 mm

1 yard = 0.914 m

1 mile = 1.609 km

(square inch) = 645 mm2

Mass: 1 oz. (ounce) = 28.35 g

1 lb (pound weight) = 0.454 kg

Pressure: 1 psi (lb/in

Volume: 1 UK pint = 568.3 ml

1 UK gallon = 4.546 litres

1 US gallon = 3.785 litres

2

) = 68.95 mb

Recycling information

At the end of this product’s life it should not be put in commercial or domestic refuse

but sent for recycling. Any batteries contained within the product or used during the

products life should be removed from the product and also be sent to an appropriate

recycling facility.

Campbell Scientific Ltd can advise on the recycling of the equipment and in some cases

arrange collection and the correct disposal of it, although charges may apply for some

items or territories.

For further advice or support, please contact Campbell Scientific Ltd, or your local agent.

Campbell Scientific Ltd, Campbell Park, 80 Hathern Road, Shepshed, Loughborough, LE12 9GX, UK

Tel: +44 (0) 1509 601141 Fax: +44 (0) 1509 601091

Email: support@campbellsci.co.uk

www.campbellsci.co.uk

Page 6

Page 7

Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

1.1 Version Information .................................................................................. 1

1.2 General Safety .......................................................................................... 2

1.3 Sensor Unit Safety .................................................................................... 2

2. Technical specification .............................................. 3

3. Electrical specification ............................................... 3

4. Supported data rates for RS232 and RS485 ............. 4

5. Environmental specifications .................................... 5

6. Mechanical specifications .......................................... 5

7. Installation procedure ................................................ 5

7.1 Equipment grounding ............................................................................... 7

7.2 Mounting the CS125 ................................................................ ................. 7

7.3 Optional Campbell Scientific Mount ........................................................ 9

8. CS125 internal connectors’ description .................. 11

8.1 CS125 recommended wiring using Campbell Scientific cables ............. 13

9. CS215 T/RH Sensor .................................................. 14

10. Functions of the internal switches ........................ 15

11. Message Formats: A breakdown of the different

default outputs of the CS125 –

Basic/Partial/Full ............................................... 16

2

11.1 Visibility only messages (CS120 emulation) ........................................ 17

11.2 Messages with SYNOP Present Weather Codes ................................ ... 18

11.3 Messages with METAR Present Weather Codes .................................. 19

11.4 Example CS125 message outputs ......................................................... 22

11.5 SYNOP Codes produced by the CS125 ................................................ 23

11.6 METAR Codes produced by the CS125 ............................................... 24

Page 8

12. Interface methods – Device Configuration

Utility/Command Line/Menu ................................. 24

12.1 Configuring a PC for talking to the CS125 ........................................... 25

13. Definition of the variables that can be set by

the user on the CS125 ......................................... 25

14. Command line mode .............................................. 27

14.1 The SET command ............................................................................... 28

14.1.1 Example of a SET Command .................................................... 29

14.2 The SETNC Command ......................................................................... 29

14.2.1 Example of a SETNC Command .............................................. 29

14.3 The GET command ............................................................................... 29

14.4 The POLL command – Polling the CS125 ........................................... 31

15. Entering the CS125 menu system ......................... 32

16. Calibrating the CS125 ............................................. 36

Appendices

17. Performing a firmware update ............................... 39

18. Cleaning .................................................................. 40

19. Lubricating the enclosure screws ......................... 41

20. Desiccant ................................................................. 41

A. CS125 Block Diagram ............................................ A-1

B. Example C code of the CCITT CRC ....................... B-1

C. Example CRBasic programs ................................ C -1

3

Page 9

CS125 Present Weather Sensor

Manual Version

Revisions

1.0

None

1. Introduction

The CS125 is an infrared forward scatter present weather sensor for automatic

weather stations including road, marine and airport based stations. The CS125

uses the well-established forward scatter system for visibility measurement,

utilising a 42º scatter angle. The CS125 uses high speed sampling to reduce

missed events such as rain and hail and improves response to other suddenly

changing conditions. When an optional CS215 temperature and RH sensor is

connected, the CS125 can distinguish wet and dry obscuration (for example mist

and haze) and make more precise discrimination between liquid and frozen

precipitation.

1.1 Version Information

1

Page 10

CS125 Present Weather Sensor

WARNING

CAUTION

NOTE

WARNING

WARNING

CAUTION

1.2 General Safety

1.3 Sensor Unit Safety

This manual provides important safety considerations for the installation,

operation and maintenance of the CS125. These safety considerations are

classified into three levels:

Warnings alert the installer or user to serious hazards.

Ignoring these warnings could result in injury or death

and/or irrevocable damage to the sensor unit.

Cautions warn of potential hazards. Ignoring these cautions

could result in the sensor being damaged and data being lost.

Notes highlight useful information in the installation, use and

maintenance of this product. These should be followed carefully in

order to gain the maximum benefit from the use of this product.

The CS125 sensor has been checked for safety before leaving the factory and

contains no internally replaceable or modifiable parts.

Do not modify the CS125 unit. Such modifications will

lead to damage of the unit and could expose users to

dangerous light levels and voltages.

In unusual failure modes and environmental conditions

the sensor hood could become hot. In normal operation

they will be at ambient temperature or slightly above.

Ensure that the correct voltage supply is provided to the

sensor.

2

Page 11

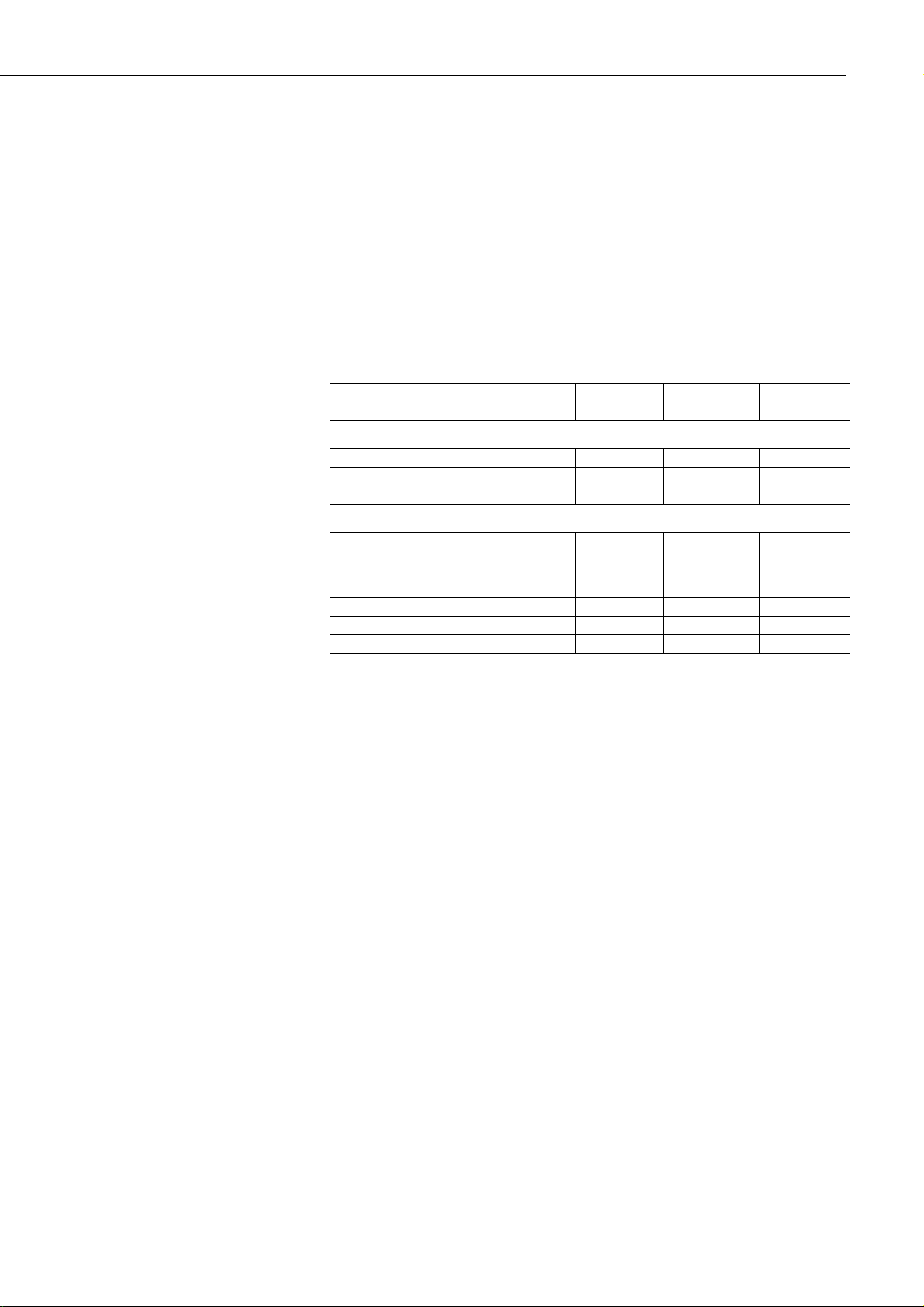

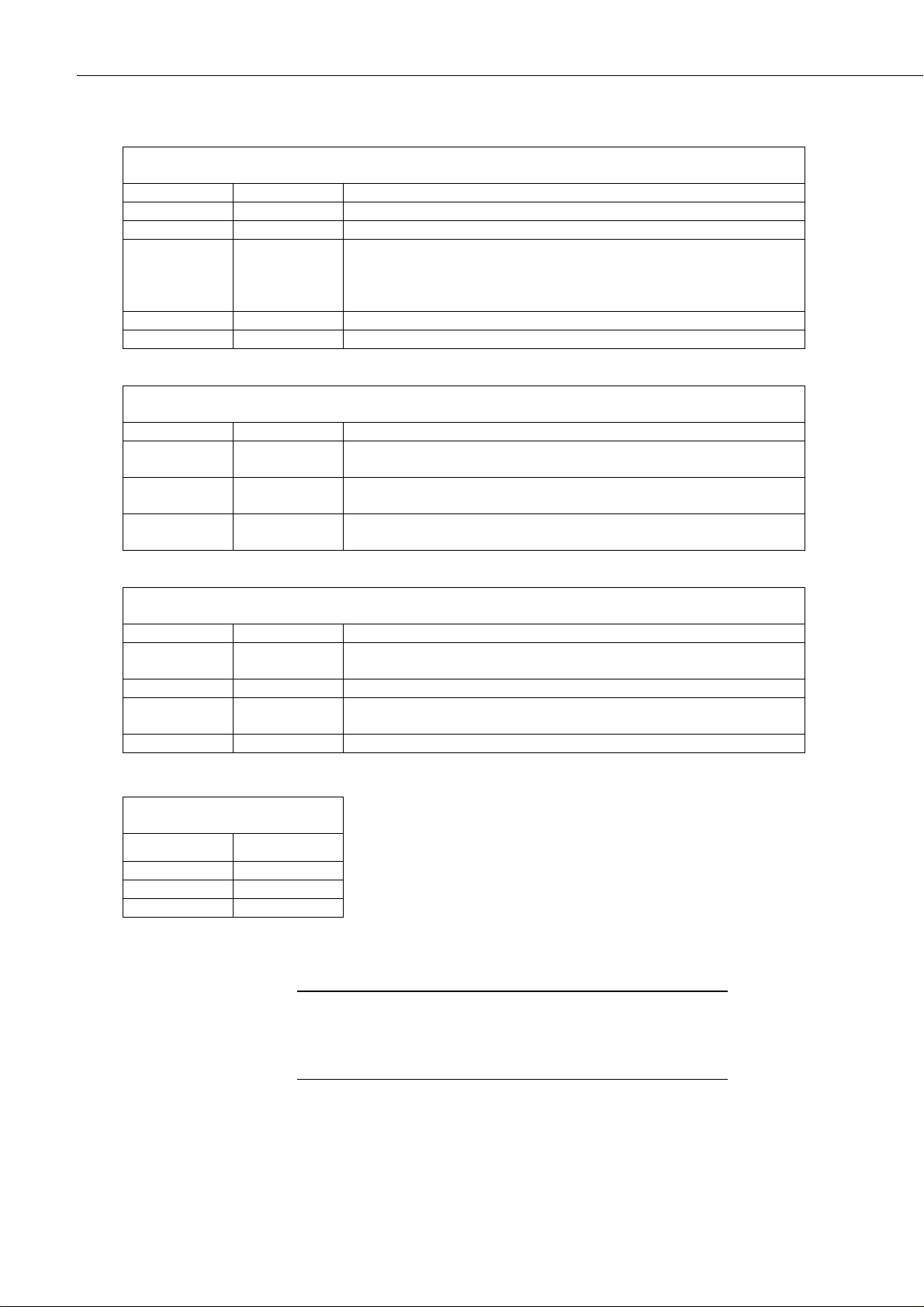

2. Technical specification

Minimum

Value

Nominal

Value

Maximum

Value

Main power supply for DSP and dew heaters

Power supply, +12V connection (DC

only)

9V

12V

28V

(1)

Current consumption sampling

continuously with dew heaters active

(at 12V DC)

-

200mA

248mA

Current consumption sampling

continuously with dew heaters

disabled (at 12V DC)

-

110mA

151mA

Current consumption without any

sampling occurring and dew heaters

disabled (at 12V DC)

-

21mA

30mA

Active power consumption with dew

heaters and RS232 communications

interface active

(2,3)

(at 12V DC)

-

200mA

250mA

Hood heater power supply

Hood heater voltage (AC or DC)

-

24V

(3)

30V

(4)

Hood heater wattage (at 24V AC or

DC)

-

60W

(5)

-

RS232 Communications

RS232 input threshold Low

0.8V

1.5V

-

RS232 input threshold High

-

2.0V

2.4V

RS232 input absolute maximum

-15V

-

+15V

RS232 input resistance

12K

-

-

RS232 output voltage low

- - 0.4V

User Guide

Visibility characteristics

Reported Visibility (metric) 12 metres - 32,000

Reported Visibility (imperial) 39 feet - 104,985

Visibility accuracy up to 10,000m - +/-10%

Visibility accuracy up to 20,000m - +/-20%

Weather characteristics

Precipitation Sensitivity

Optical characteristics

LED centre wavelength - 850nm

LED spectral bandwidth - +/-35nm

Pulse characteristics

Light pulse rate - 1KHz

3. Electrical specification

Minimum

Value

-

Nominal

Value

0.05 mm/h

Maximum

Value

metres

feet

-

-

-

-

-

-

3

Page 12

CS125 Present Weather Sensor

RS232 output voltage high (into

3K)

4.4V - -

RS485 Communications

RS485 input threshold voltage

-0.2V

-

+0.2V

RS485 output (Unloaded)

- - 5V

RS485 output (Load 50)

2V - -

Maximum voltage at any terminal

(6)

-7V

-

+7V

User alarm outputs

User output high level (at 85ºC)

3.8V - -

User output high level (at 25ºC )

4.13V - -

User output low (All temperatures)

0.25V

-

0.55V

User output current

- - 32mA

CAUTION

(1) If a CS215 is being used the supply voltage should not exceed 16V.

(2) The RS232 communications interface will automatically turn itself off when not transmitting.

(3) If hood heaters are not being used ensure `Hood heater override’ (details in Section 13) is set to

off.

(4) It is recommended that the hood heaters are run at 24V AC/DC. It’s possible to run the heaters at

any voltage below 24V but the heaters will generate proportionally less heat reducing their ability to

prevent ice build-up.

(5) Each hood takes 30W, 60W is the total for both hoods on the sensor together.

(6) The ground of the CS125 and the earth of any RS485 equipment cannot be further apart than this

voltage. A 100 resistor can be used to connect the CS125 RS485 earth to other equipment. This will

reduce any parasitic currents and bring the two earths closer together if a direct connection cannot be

made.

If a CS215 is being used the supply voltage should not

exceed 16V.

4. Supported data rates for RS232 and RS485

Serial setting 8N1

Supported data rates

1200 bps

2400 bps

9600 bps

19200 bps

38400 bps - default

57600 bps

115200 bps

4

Page 13

Supported formats

Minimum

Value

Nominal

Value

Maximum

Value

Sensor temperature ranges

Operating temperature

-25°C

-

+60°C

Extended operating temperature

-40°C

-

+70°C

(1)

Storage temperature

-40°C

-

+85°C

Sensor humidity ranges

Operating humidity range

0%

-

100%

Sensor heater thresholds

Dew heater Turn On

-

<35°C

-

Dew heater Turn Off

-

>40°C

-

Hood heater Turn On

-

<5°C

-

Hood heater Turn Off

-

>15°C

-

RS232 (Full duplex only), default

RS485 (Half duplex)

8 bit data bytes

1 stop bit

Parity checking is not supported as most communication protocols used by

the CS125 have built in checksums as well as checks that communications

have been understood

5. Environmental specifications

User Guide

(1) Extended temperature ranges are only guaranteed if the sensor has been tested by Campbell

Scientific and verified within this temperature range. Some degradation of absolute accuracy can be

expected at the extremes of the extended ranges.

6. Mechanical specifications

Main body including base mount

Height: 447 mm

Width: 640 mm

Depth: 245 mm

Sensor weight: 3 Kg

Sensor mounting: Bracket mounts on a vertical pole 32-52.5 mm diameter. The

mounting bracket has cut-outs for band clamps for larger

diameter masts.

Shipping weight: 6 Kg (including packing box)

7. Installation procedure

The CS125 measures environmental variables and is designed to be located in

harsh weather conditions. However there are a few considerations to take into

account if accurate and representative data from a site are to be obtained.

5

Page 14

CS125 Present Weather Sensor

NOTE

Receiver

Transmitter

The descriptions in this section are not exhaustive. Please refer to

meteorological publications for further information on locating

weather instruments

The CS125 should be sited in a position representative of local weather conditions

and not of a specific microclimate (unless the analysis of microclimate weather is

being sought).

The CS125 has good resistance to background light but it is a good idea to avoid

locations where the transmitter is pointing at a light scattering or reflecting

surface. Ideally the receiver should point north in the northern hemisphere and

south in the southern hemisphere but this is not critical if the field of view does

not include a bright and scattering surface.

To give non-microclimatic measurements the CS125 should be sited away from

possible physical obstructions that could affect the fall of precipitation. The

CS125 should also be positioned away from sources of heat, electrical interference

and in such a position as to not have direct light on the sensor lenses. Whenever

possible, the CS125 should be located away from windbreaks.

Several zones have been identified upwind and downwind of a windbreak in

which the airflow is unrepresentative of the general speed and direction. Eddies

are generated in the lee of the windbreak and air is displaced upwind of it. The

height and depth of these affected zones varies with the height and to some extent

the density of the obstacle.

Generally, a structure disturbs the airflow in an upwind direction for a distance of

about twice the height of the structure, and in a downwind direction for a distance

of about six times the height. The airflow is also affected to a vertical distance of

about twice the height of the structure. Ideally, therefore, the CS125 should be

located outside this zone of influence in order to obtain representative values for

the region.

In order to reduce the service frequency with the unit, the CS125 should be placed

away from sources of contamination, in the case of roadside monitoring; larger

mounting poles can be used. More regular maintenance will be required when the

instrument is placed in areas where contamination is unavoidable or where

measurements may be safety critical.

The WMO recommend a sample volume height of 1.5 m. However, for

applications such as aviation or road visibility other heights may be appropriate.

6

Page 15

NOTE

NOTE

If operating a CS125 indoors it is likely that there will be sources of

light and/or reflections that will create false readings and erratic

results.

If carrying out simple checks, blocking a lens or the sample volume

will simulate an INCREASE in visibility not a decrease.

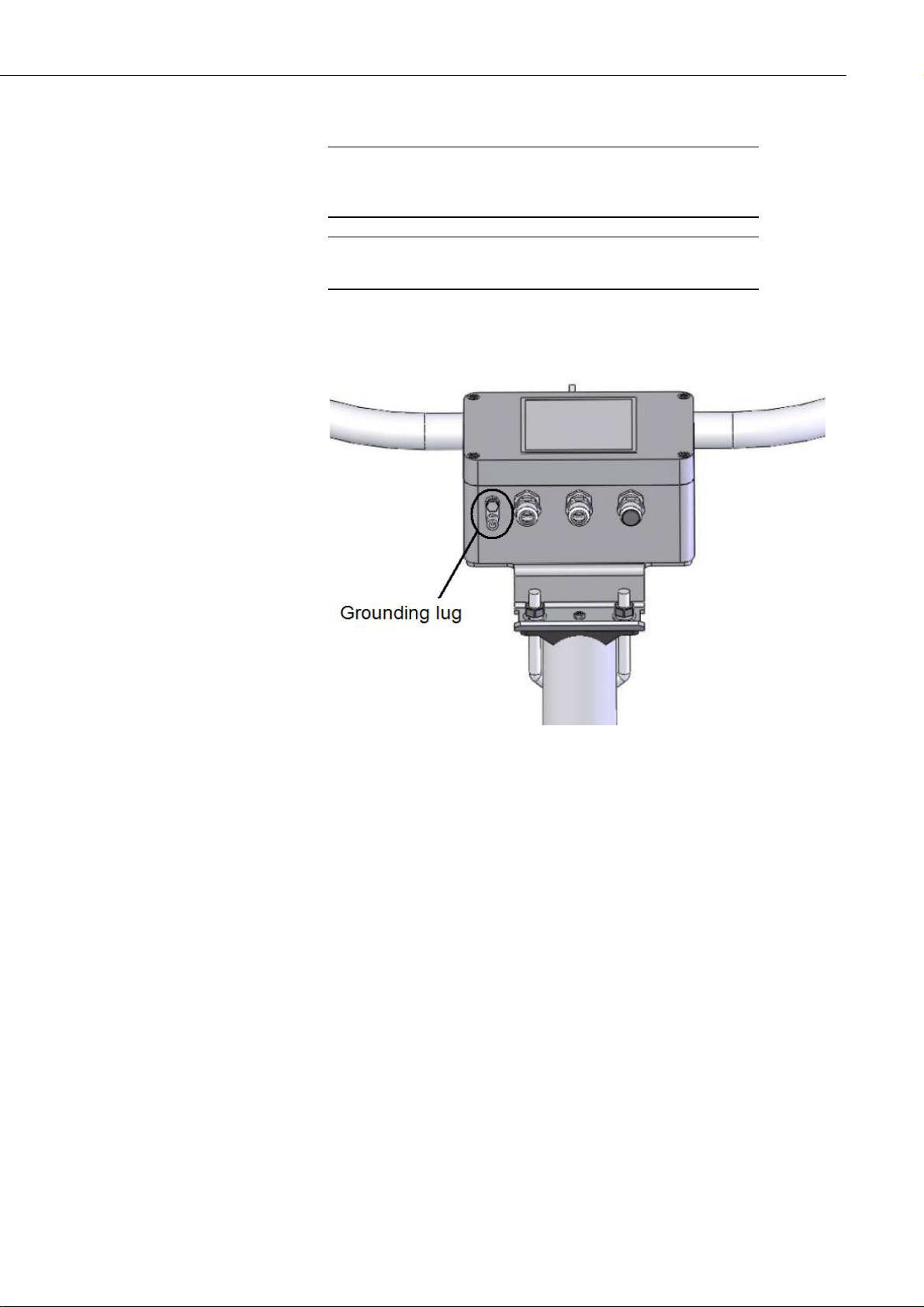

7.1 Equipment grounding

User Guide

The CS125 must be properly grounded by taking a ground wire with a minimum

cross sectional area of 6 mm2 and maximum length of 5 m from the brass

grounding lug in the lower face of the electronics enclosure to an adequate

grounding point. The pole and foundations of a pole mounted installation will

provide some basic lightning protection and protection against radio frequency

interference and should also be correctly grounded.

7.2 Mounting the CS125

A pole mounting kit is supplied with the CS125. To mount the CS125 onto a pole:

1. Offer up the DSP plate to the pole and present the `V’ bolts from the other side

as shown.

2. Clamp the pole between the DSP plate and brackets by tightening using the

nuts and washers provided.

3. If a power supply enclosure has been supplied with the sensor it can be

mounted on the pole, near its base using the brackets supplied with the

enclosure. Alternatively the power supply can be mounted elsewhere, e.g. on a

wall at some distance from the sensor. The power supply enclosure should be

7

Page 16

CS125 Present Weather Sensor

CAUTION

CAUTION

mounted away from the sensor head to avoid wind flow disturbance or rain

drops bouncing back up into the sensor’s sensing volume.

Take care not to overtighten the nuts on the bolts, as it may

be possible to distort and/or damage the brackets or DSP

plate by doing so, and/or the nuts may seize up. Only tighten

the nuts to a degree necessary to hold the CS125 firmly in

place.

Where the CS125 is to be mounted onto another type of mast, please refer to

the manual for that mast for mounting details.

Ensure that the CS125 is mounted according to the figure

below. Do not reposition, once fixings are tightened, by

forcing the arms of the unit as this can cause damage.

Slots are provided to allow band clamps to be used with larger diameter masts.

8

Page 17

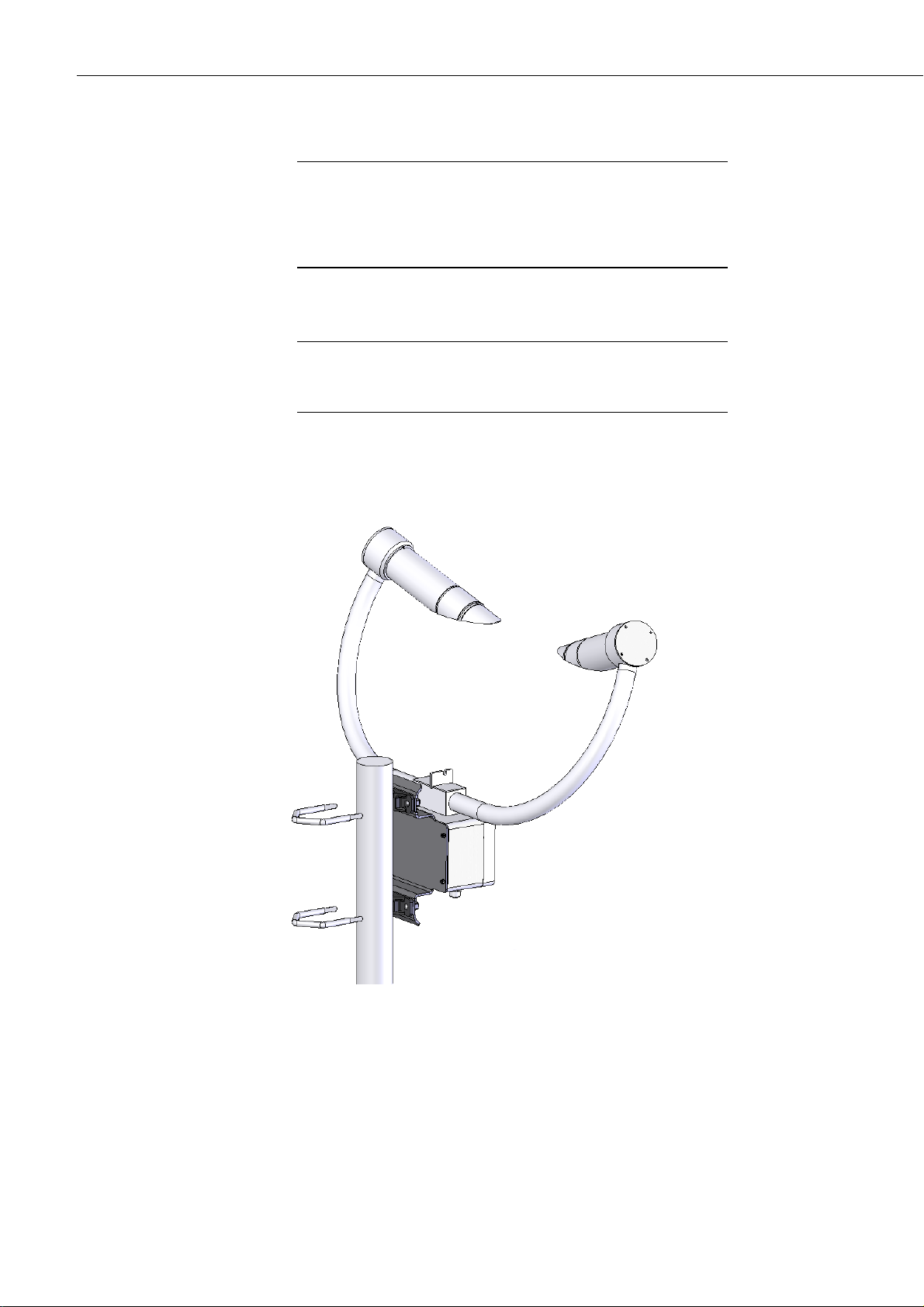

7.3 Optional Campbell Scientific Mount

A Campbell Scientific `optical sensor mount’, part number 009354, is available.

This will put the sample volume at about 1.5 m in compliance with the WMO

`Guide to Meteorological Instruments and Methods of Observation’, 7

Section 9.3.4.

User Guide

th

Edition,

If one is to be used, follow the installation instructions below.

The mount should be installed on a concrete foundation. If one does not already

exist then a concrete foundation should be constructed at least 600 mm square and

600 mm deep. Ensure the ground consistency is not too loose and will be able to

support the mount and concrete foundation.

9

Page 18

CS125 Present Weather Sensor

Drill four 12 mm diameter holes using the mount base as a template or following

the drawing below to a depth of 77 mm.

Clean the holes of all debris.

Place washers and nuts on the ends of the wedge anchors supplied (to protect the

threads during installation).

Hammer the wedge anchors into the holes until the start of the threads are below

the surface.

Tighten the nuts until about 25 mm of thread protrudes above the surface.

Remove the washers and nuts from the protruding length screw. Then lower the

mount into place.

Finally secure the mount with the washers and nuts.

If the surface is not level and flat it may be necessary to add washers under the

base on one or more of the foundation screws.

10

Page 19

8. CS125 internal connectors’ description

CAUTION

CAUTION

The CS125 has three standard IP66 rated glands. The first gland is by default used

by the power/communications line. This comprises the +12V/24V for the main

electronics, and the serial communications wires. The CS125 is supplied with 5 m

cable already connected.

The second gland is used for the 24 V feeds for the hood heaters fitted with a 5 m

cable.

The third gland is spare.

If the power cable is incorrectly wired to the CS125 then

irrevocable damage can be done to the unit.

10 m is the longest length of the cable type supplied

recommended. In particular, additional RS485 communication

should be twisted pair. Please contact Campbell Scientific if

you wish to use a longer length of cable.

User Guide

A configuration cable, part number 010817, is available from Campbell Scientific

that plugs directly into connector B, in place of the normal connector and cable.

The configuration cable is fitted with a 9-way D connector for use with a PC serial

port or USB to serial adaptor.

11

Page 20

CS125 Present Weather Sensor

Connector A

Five way connector

Pin number

Description

Notes

Pin 1

+12V

Main electronics 12V supply input (also supports 24V DC)

Pin 2

0V

Auxiliary Electronics 0V. Common with the main electronics 0V.

Pin 3

Hood low

Hood heater –V input, this input is totally separate to the main

electronics 0V within the sensor so can be connected to a separate

power supply. However, this pin should not be more than 5V

different from the main electronics 0V.

Pin 4

0V

Auxiliary Electronics 0V. Common with the main electronics 0V.

Pin 5

Hood high

Hood heater +V input (Normally 24V)

Connector B

Three way connector

Pin number

Description

Notes

Pin 1

0V

0V connection for serial communications. This connection is

common with the main electronics 0V (Connector A, pin 2).

Pin 2

Receive

RS232 receive line. Also, acts as the Y transmit line in RS485 half

duplex mode and the A receive line

Pin 3

Transmit

RS232 transmit line. Also, acts as the Z transmit line in RS485 half

duplex mode and the B receive line

Connector C – USER ALARMS

Four way connector

Pin number

Description

Notes

Pin 1

0V

0V connection for user alarms. This connection is common with the

main electronics 0V (Connector A, Pin 2).

Pin 2

User 2

Output for user alarm 2

Pin 3

0V

0V connection for user alarms. This connection is common with the

main electronics 0V (Connector A, Pin 2).

Pin 4

User 1

Output for user alarm 1

CS215 Connector

Three way connector

Pin number

Description

Pin 1

+12V

Pin 2

SDI-12

Pin 3

0V

NOTE

To use these connections it is necessary to either use the cable gland

taking the hood heater power or, if the hood heater is also required,

to use different cables to those supplied. Please contact Campbell

Scientific if you need any advice on choice of cable.

12

Page 21

User Guide

8.1 CS125 recommended wiring using Campbell Scientific cables

(this cable is supplied already connected as standard)

The CS125 is provided pre-wired with a default 5 m power and communications

cable which is terminated at one end with a 9 pin D-connector (DB9). The Dconnector can be connected directly to a PC or to a datalogger such as the

Campbell Scientific CR1000 using a suitable interconnecting cable such as the

SC110. If another type of connection is required then the D-connector should be

removed.

13

Page 22

CS125 Present Weather Sensor

9. CS215 T/RH Sensor

A CS215 temperature and RH sensor can be connected to the CS125. This is

recommended as it will improve the performance of the CS125 in identifying

precipitation and allows it to, for example, distinguish between mist and haze.

Precipitation identification at temperatures close to freezing will be much

improved by a CS215 and its use is highly recommended in regions where

temperatures close to 0°C are common if information on precipitation type is

important. It also allows RH information to be included in data messages.

If a CS215 is connected then the temperature used for assessment of precipitation

type and included in data messages will come from the CS215 instead of the

temperature sensor mounted in the cross arm.

The connections for the CS215 are shown below. The CS215 itself can be

mounted in a Met20 screen on the same mast as the CS125. The screen can be

mounted on the top section of an OSM1 optical mast below a CS125.

WMO – No. 8, 2.1.4.1 recommends temperature measurement at a height of

between 1.2 and 2.0 m above ground. The screen should be below the height of

the CS125 electronics box.

14

Page 23

User Guide

IMPORTANT

10. Functions of the internal switches

The CS125 is equipped with four switches located within the main enclosure.

These switches perform certain functions at power up, their functions are detailed

below.

The switches are only read during the power up sequence of the

CS125. This means that if the switches are pressed whilst the

CS125 is running nothing will happen, the sensor will need to be

power cycled leaving at least 10 seconds with the sensor off for any

of their functions to be performed.

15

Page 24

CS125 Present Weather Sensor

Internal switch functions

Switch

number

Function

4

Reserved for future use

3

When switched to the ON position this switch temporarily sets the

CS125 communications port to a default RS232 communication state

(38400 bps). This is useful during field tests or maintenance when

the CS125 has been remotely configured for RS485 mode or a baud

rate your PC does not support. This change is temporary and will not

be stored to flash.

Once this switch is returned to its OFF position and the CS125 is

power cycled the CS125 will return to its previous communications

settings.

2

Reserved for future use, set to OFF.

1

When switched to the ON position this switch will reset the CS125 to

its factory default values. This reset will affect all communication

setting and will replace the user calibration settings with the factory

defaults. This will take immediate effect upon power up.

NOTE

11. Message Formats: A breakdown of the different default outputs of the CS125 – Basic/Partial/Full

The CS125 has three different standard message formats available to the user.

These three outputs are named Basic, Partial and Full. All parameters are space

delimited with a unique start and end character allowing easy storage into any

logger (see Section 15 on how to set default outputs). The SYNOP Full Format

message is the default message.

STX and ETX are hexadecimal command characters.

16

Page 25

STX

Message

ID

Sensor ID

System

status

Visibility

distance

Visibility

units

Checksum

(CCITT)

EXT

Carriage

return

Line feed

0x02

0

M or F

XXXX

0x03

0x0D

0x0A

STX

Message ID

Sensor ID

System status

Message

interval

Visibility

distance

Visibility

units

User alarms

Checksum

(CCITT)

EXT

Carriage

return

Line feed

0x02

1

M or F

0 0

XXXX

0x03

0x0D

0x0A

STX

Message

ID

Sensor ID

System

status

Message

interval

Visibility

distance

Visibility

units Averaging

duration

User

alarms System

alarms

10 characters

Checksum

(CCITT)

EXT

Carriage

return

Line feed

0x02

2

M or F

0 0

0 0 0 0 0…

XXXX

0x03

0x0D

0x0A

NOTE

11.1 Visibility Only messages (CS120 emulation)

Basic Format, Visibility Only

Partial Format, Visibility Only

User Guide

Refer to Appendix B for the checksum algorithm.

Full Format, Visibility Only

17

Page 26

CS125 Present Weather Sensor

STX

Message ID

Sensor ID

System status

Visibility

distance

Visibility

units

SYNOP Code

Checksum

(CCITT)

EXT

Carriage

return

Line feed

0x02

3

M or F

00-99

XXXX

0x03

0x0D

0x0A

STX

Message ID

Sensor ID

System status

Message

interval

Visibility

distance

Visibility

units

User alarms

Particle count (minute)

Intensity (mm/h)

SYNOP Code

Temperature (deg C)

Relative humidity*

Checksum

(CCITT)

EXT

Carriage

return

Line feed

0x02

4

M or F

0 0

00-99

XXXX

0x03

0x0D

0x0A

STX

Message ID

Sensor ID

System status

Message interval

Visibility distance

Visibility units Averaging duration

User alarms System alarms

12 characters Particle count (minute)

Intensity (mm/h)

SYNOP Code

Temperature (deg C)

Relative humidity*

Checksum

(CCITT)

EXT

Carriage Return

Line feed

0x02

5

M or F

0 0

0 0 0 0 0…

00-99

XXXX

0x03

0x0D

0x0A

11.2 Messages with SYNOP Present Weather Codes

SYNOP Present Weather Basic Format

SYNOP Present Weather Partial Format

SYNOP Present Weather Full Format

18

Page 27

11.3 Messages with METAR Present Weather Codes

STX

Message ID

Sensor ID

System status

Visibility

distance

Visibility

units

METAR Code

Checksum

(CCITT)

EXT

Carriage

return

Line feed

0x02

6

M or F

XXXX

0x03

0x0D

0x0A

STX

Message ID

Sensor ID

System status

Message interval

Visibility distance

Visibility units

User alarms

Particle count (minute)

Intensity (mm/h)

SYNOP Code

METAR Code

Temperature (deg C)

Relative humidity*

Checksum

(CCITT)

EXT

Carriage return

Line feed

0x02

7

M or F

0 0

XXXX

0x03

0x0D

0x0A

STX

Message ID

Sensor ID

System status

Message interval

Visibility distance

Visibility units Averaging duration

User alarms System alarms

12 characters

Particle count (minute)

Intensity (mm/h)

SYNOP Code

METAR Code

Temperature (deg C)

Relative humidity*

Checksum (CCITT)

EXT

Carriage Return

Line feed

0x02

8

M or F

0 0

0 0 0 0 0…

XXXX

0x03

0x0D

0x0A

METAR Present Weather Basic Format

METAR Present Weather Partial Format

User Guide

METAR Present Weather Full format

*Note: relative humidity is only available if a CS215 temperature and RH sensor is attached. If not this field is “-99”.

19

Page 28

CS125 Present Weather Sensor

Message ID break down

Id

Definition

0

Basic format. Contains only distance and system information

1

Partial format. Contains user alarm outputs

2

Full format. Contains all system alarms codes

3

Basic SYNOP present weather format

4

Partial SYNOP present weather format

5

Full SYNOP present weather format

6

Basic METAR present weather format

7

Partial METAR present weather format

8

Full METAR present weather format

Sensor ID break down

ID

Definition

0-9

Unit number defined by the user to aid identification of data. Zero by default.

Useful for RS485 networks. Operates as an address in RS485 mode

System status break down

(1)

Status level

Definition

0

No fault

1

Possible degraded performance

2

Degraded performance

3

Maintenance required

Message interval

Time

Definition

1-3600

The amount of time, in seconds, between outputs in continuous mode

Visibility distance break down

ID

Definition

0-32,000 metres

Current visibility distance being detected by the sensor

Visibility units break down

ID

Definition

M

Metres

F

Feet

Averaging duration break down (see note below)

ID

Definition

1

One minute average

10

Ten minute average

(1) System status break down reflects the highest level of severity of any active alarm.

Note: In accordance with WMO requirements the CS125 produces visibility measurement that are either one or ten

minute rolling averages that are updated at the chosen output interval or when the sensor is polled. Those averages are

not direct averages of MOR measurements but are averages of extinction coefficient and that average is then used to

calculate the MOR for that period. As the relationship between extinction coefficient and MOR is not linear it is

possible to see quite rapid changes in MOR that might not be expected if the result was a rolling average of MOR.

Please consider this, especially when testing the sensor with artificial obscurants or using the calibration disc.

20

Page 29

User Guide

User alarms

ID

Range

Definition

1

0-1

Visibility either less or greater than a user specified threshold

2

0-1

Visibility either less or greater than a user specified threshold

System alarms break down

Alarm

Range

Severity

(2)

Definition

Emitter failure

0-2

(1)

3

The emitter hoods main LED output power level.

0 = Everything is within normal parameters

1 = Light output level too low

2 = Light output level too high

Emitter lens

dirty

0-3

1

0 = OK. The reported attenuation is below 10%.

1 = Reported window signal value is too low (Possible sensor

fault)

2 = Slight dirt build up (10% signal attenuation or higher)

3 = High level of dirt build up (The hood could be blocked)

Emitter

temperature

0-3

1 or 2

0 = Temperature is within operating conditions

1 = Too low. Less than -40°C.

2 = Too high. Over 80°C.

3 = No sensor detected or below -54°C (Severity 2)

Detector lens

dirty

0-3

1

0 = OK. The reported attenuation is below 10%.

1 = Reported window signal value is too low (Possible sensor

fault)

2 = Slight dirt build up (10% signal attenuation or higher)

3 = High level of dirt build up (The hood could be blocked)

Detector

temperature

0-3

1 or 2

0 = Temperature is within operating conditions.

1 = Too low. Less than -40°C.

2 = Too high. Over 80°C.

3 = No sensor detected or below -54°C (Severity 2)

Detector DC

saturation

level

0-1

1

The amount of background light as seen by the detector hood.

0 = Within limits

1 = Saturated. The CS125 no longer has enough head room to

perform visibility readings in most circumstances.

Hood

temperature

0-3

1 or 2

0 = Temperature is within operating conditions.

1 = Too low. Less than -40°C.

2 = Too high. Over 80°C.

3 = No sensor detected or below -56°C (Severity 2)

External

temperature

0-3

1 or 2

0 = Temperature is within operating conditions.

1 = Too low. Less than -40°C.

2 = Too high. Over 80°C.

3 = No sensor detected or below -54°C (Severity 2)

Signature

error

0-1

3

0 = Signature of entire flash matches the stored version

1 = Signature does not match previous readings

Flash read

error

0-1

3

0 = No errors

1 = One or more errors reading user variables from flash

occurred

Flash write

error

0-1

3

0 = No errors

1 = One or more errors writing user variables to flash occurred

Particle limit

0-1

1

0 = No errors

1 = More particles detected than can be processed.

(1)

The emitter power level reporting too high will cause the CS125 to shut down and go into low power mode.

(2)

The severity of the alarm. The higher the number the more serious the error is considered to be.

21

Page 30

CS125 Present Weather Sensor

Particle count

Range

Definition

0-7200

Value represented by an integer number of the current number of particle per minute.

(-99 indicates either an error or that the sensor has been powered less than one minute)

Intensity value

Range

Definition

0-100.0

Value represented by a single precision value of the last hours rainfall intensity in

millimetres (-99 indicates either an error or that the sensor has been powered up less

than minute)

SYNOP code

Range

Definition

See section 10.2

SYNOP weather code for the last minute as defined by the WMO code table 4680.

(-1 indicates either an error or that the sensor has been powered up less than a minute)

METAR code

Range

Definition

See section 10.3

METAR weather code for the last minute as defined by the WMO code table 4678.

External temperature

Range

Definition

-40.0 - +80.0°C

External temperature in degrees Celsius

Relative humidity

Range

Definition

0 - 100

External relative humidity in %RH (-99 indicates either a fault or no CS215 T/RH

sensor is connected)

11.4 Example CS125 message outputs

Basic format (visibility only)

0 9 0 6682 M ABCD

SYNOP present weather partial format

4 9 0 60 6682 M 0 0 54 4.5 63 20.2 91 ABCD

METAR present weather full format

8 9 0 60 6682 M 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 54 4.5 63 +RA 20.2 91 ABCD

Where:

9 is the sensor id

60 is the message interval (60 seconds)

6682 is the visibility in metres

M is the visibility units (metres)

54 is particle count

4.5 is intensity (4.5 mm/hr)

63 is the SYNOP code (heavy rain)

+RA is the METAR code (heavy rain)

20.2 is the temperature (20.2 deg. C)

91 is the RH (91%)

ABCD is the checksum

22

Page 31

11.5 SYNOP Codes produced by the CS125

The following SYNOP codes from WMO table 4680 can be output by the CS125.

00 No significant weather observed

04 Haze or smoke, or dust in suspension in the air, visibility equal to, or greater

than, 1 km

05 Haze or smoke, or dust in suspension in the air, visibility less than 1 km

Note: Codes 04 and 05 will only be returned if a CS215 is present to provide

relative humidity, otherwise they will default to mist (10) or fog (20, 30 or 35).

10 Mist

Code figures 20–26 are used to report precipitation, fog (or ice fog) or

thunderstorm at the station during the preceding hour but not at the time of

observation.

20 Fog

21 PRECIPITATION

22 Drizzle (not freezing) or snow grains

23 Rain (not freezing)

24 Snow

25 Freezing drizzle or freezing rain

30 FOG

35 Fog, depositing rime

40 PRECIPITATION

51 Drizzle, not freezing, slight

52 Drizzle, not freezing, moderate

53 Drizzle, not freezing, heavy

54 Drizzle, freezing, slight

55 Drizzle, freezing, moderate

56 Drizzle, freezing, heavy

57 Drizzle and rain, slight

58 Drizzle and rain, moderate or heavy

61 Rain, not freezing, slight

62 Rain, not freezing, moderate

63 Rain, not freezing, heavy

64 Rain, freezing, slight

65 Rain, freezing, moderate

66 Rain, freezing, heavy

67 Rain (or drizzle) and snow, slight

68 Rain (or drizzle) and snow, moderate or heavy

71 Snow, slight

72 Snow, moderate

73 Snow, heavy

User Guide

23

Page 32

CS125 Present Weather Sensor

11.6 METAR Codes produced by the CS125

The following METAR codes from WMO table 4678 can be output by the CS125.

UP Unidentified precipitation

HZ Haze

BR Mist

FG Fog

DZ Drizzle

RA Rain

SN Snow

SG Snow grains

PL Ice pellets

Notes:

HZ will only be reported if a CS215 is connected to allow relative humidity

information to be available.

FZ (freezing) may be added as a descriptor in front of BR, FG, DZ and RZ

Intensity qualifiers, ‘-‘ for light, ‘+’ for heavy, may be added in front of DZ, RA,

SN, SG and PL

Combinations, for example RASN for rain and snow can be reported.

12. Interface methods – Device Configuration Utility/Command line/Menu

The CS125 can be setup and controlled in one of three ways.

The first method is by using Campbell Scientific’s Device Configuration Utility

Software (DevConfig) which is included with each delivery on the manuals/

resource disk. This software allows an easy menu driven interface for configuring

the CS125 on any Microsoft™ based personal computer. All settings can be

accessed using this program.

The program includes online help instructions that describe its general use with

the CS125 and also how to load an operating system.

The Device Configurator can also be used as a terminal emulator to use the builtin menu system of the CS125 and to access its calibration menu.

The second method is by using the command line interface where discrete

commands are sent without response from the sensor. This would be the preferred

method of setting up a CS125 if it was connected to a logger for instance. The

configuration setting commands can be sent via a logger to the CS125 removing

the need for a local PC to set up the unit.

The third method is by using the simple menu interface built into the CS125

communicating via RS232 or RS485, using a terminal emulator program. This

menu system gives access to the more common settings.

24

All three of these methods use the CS125s serial port A to communicate with the

sensor. Configuration cable part number 010817, described in section 8.1 can be

used.

Page 33

12.1 Configuring a PC for talking to the CS125

Described below is the procedure for setting up communications using a terminal

emulator program. The terminal emulators built into many Campbell Scientific

software products can also be used.

The following settings should then be used by default:

Bits per second: 38400

Data bits: 8

Parity: none

Stop bits: 1

Flow control: none

Ensure that if the baud rate of the unit has been adjusted and then the

corresponding bits per second value is entered in the port settings of the terminal

emulator. The CS125 should now be ready to accept commands.

It is possible to set the CS125 into the default communication state via one of the

internal switches on the CS125 main board. See section 9.

User Guide

13. Definition of the variables that can be set by the user on the CS125

Both DevConfig and the command line interface can access all the user

configurable variables within the CS125. The acceptable range and the

identification number for these variables are listed below along with a short

description.

25

Page 34

CS125 Present Weather Sensor

ID

Name

Range

Description

Factory

default

1

Sensor ID

0-9

Separate ID used as an extra identifier for a

particular CS125 on a network.

0

2

User Alarm 1 Enabled

0-1

User alarm one activation state

0 = Alarm one disabled

1 = Alarm one enabled

0

3

User Alarm 1 Active

0-1

0 = Check if distance is less than ‘User alarm 1

Distance’

1 = Check if distance is greater than ‘User alarm 1

Distance’

0

4

User alarm 1 Distance

060000

Distance value that alarm one will trigger against.

This value will correspond to metres or feet

depending upon which is selected in ‘Visibility

Unit’

10000

5

User Alarm 2 Enabled

0-1

User alarm two activation state

0 = Alarm two disabled

1 = Alarm two enabled

0

6

User Alarm 2 Active

0-1

0 = Check if distance is less than ‘User alarm 2

Distance’

1 = Check if distance is greater than ‘User alarm 2

Distance’

0

7

User alarm 2 Distance

060000

Distance value that alarm one will trigger against.

This value will correspond to metres or feet

depending upon which is selected in ‘Visibility

Unit’

10000

8

Baud rate

0-6

Baud rate for the main RS232/RS485 interface

0 = 115200 bps

1 = 57600 bps

2 = 38400 bps

3 = 19200 bps

4 = 9600 bps

5 = 2400 bps

6 = 1200 bps

2

9

Serial Number

032000

Internal serial number for the CS125.

(Read only)

-

10

Visibility Unit

M or F

Unit the visibility value will be presented as.

M = metres

F = feet

M

11

Message Interval

1-3600

Interval in seconds between outputs in continuous

mode. This value has no effect if polled mode has

been selected in ‘Measurement mode’

60

12

Measurement mode

0-1

Selects polled or continuous modes.

In continuous mode the sensor will output a string

in the format as set by ‘Message Format’ at regular

intervals as defined by ‘Continuous Interval’.

0 = Continuous mode

1 = Polled mode

0

13

Message Format

0-8

Level of detail outputted by polled or continuous

modes

0, 1 and 2 = Basic, partial or full visibility

messages

3, 4 and 5 = Basic, partial or full SYNOP messages

6, 7 and 8 = Basic, partial or full METAR

messages

2

26

Page 35

User Guide

14

Serial port protocol

0-1

Selects the physical serial interface

0 = RS232 mode

1 = RS485 mode

0

15

Averaging period

1 or 10

The period of time that the visibility value should

be averaged over. Either one minute or ten.

1

16

Sample timing

1-60

Used to define the time interval between sampling

the volume. It is recommended that this value is

left at one except when very low power demands

are needed. For example:

1 = Sample every second

2 = Sample one second in every two

3 = Sample one second in every three etc.

1

17

Dew heater override

0-1

0 = Allow the CS125 to automatically control the

dew heaters

1 = Turn the dew heaters off

0

18

Hood heater override

(1)

0-1

0 = Allow the CS125 to automatically control the

hood heaters

1 = Turn the hood heaters off

0

19

Dirty window

compensation

0-1

0 = No compensation applied

1 = Compensation for dirt on lenses applied.

The CS125 will compensate for up to 10% signal

loss due to dirt per lens.

0

20

Use CRC

0-1

0 = Disable command line CRC checking

(2)

1 = Enable command line CRC checking

Note: this does not affect communications via

DevConfig or terminal emulator.

0

21

Sensor power down

voltage

7-30

PSU Input voltage level below which the CS125

will enter low power mode. This is usually used to

protect batteries.

7.0

22

Relative humidity

threshold

1-99

Threshold at which the CS125 will define

obscuration as liquid or dry if a CS215 is fitted.

80%

(1) Hood heater override needs to be set to `1’ (off) when either no hood heaters are installed or

the hood heaters have no power connected to them. This will save power as the relay is not

enabled at low temperatures in this mode.

(2) If disabled the sensor does not check the validity of received data against the checksum sent.

It is, however, recommended that checksum checking is enabled to remove any chance of the

CS125 being configured incorrectly by accident.

14. Command line mode

The command line interface is broken down into three major commands. These

are GET, SET and POLL. The GET command is used to request all current user

settable values from the CS125. The SET commands sets user settable values and

the POLL command is used to request the current visibility and/or alarm

conditions from the sensor.

The CS125 can be configured to expect any commands sent to it to include a valid

checksum. For simple commands, e.g. GET and POLL, fixed value checksums

can be used (see the example programs). For more complex SET commands the

checksum needs to be calculated (see Appendix B). The use of the checksum is

disabled by default. It is recommended that the checksum functionality is enabled

where possible, especially when long cable runs are used, or in electronically

noisy environments.

27

Page 36

CS125 Present Weather Sensor

SET transmitted data

Example

Description

0x02

(1)

STX ^B

(2)

:

Delimiting character

SET

SET

:

Delimiting character

0

Address based on Sensor ID

:

Delimiting character

Sensor ID

User Alarm 1 Set

User Alarm 1 Active

User Alarm 1 Distance

User Alarm 2 Set

User Alarm 2 Active

User Alarm 2 Distance

Serial Baud Rate

Sensor serial number (read only)

Visibility Units

Message interval

Polling Or Continuous modes

Message Format (Basic/Partial/Full)

RS232 or RS485 serial communications enabled

Averaging Period

Sample timing

Dew heater override

Hood heater override

Dirty window compensation

CRC checking on received commands

Sensor power down voltage

Relative humidity threshold

:

Delimiting character

XXXX

Checksum (use the valid CCITT checksum)

:

Delimiting character

0x03

(1)

ETX ^C

(2)

0x0D

(1)

Carriage return

0x0A

Line feed

14.1 The SET command

The set command is used to configure the CS125 via the command line. The SET

command is a single space delimited string that can be sent from any data logger

or PC equipped with an RS232 or RS485 port. The SET command and the

‘Device Configuration Utility’ software access identical settings within the

CS125, please refer to the ‘Device Configuration Utility’ section of this document

for a more detailed breakdown of the setting available here. This command is used

to change the default power up state of the sensor. See Section 14.2 if a setting is

going to be changed on a regular basis e.g. heater controls.

See Section 12 for more information on the values used by the `SET’ command.

(1) These values are shown in hexadecimal format not ASCII.

(2) As entered on a keypad.

28

Page 37

14.1.1 Example of a SET Command

GET transmitted data

Example

Description

0x02

(1)

STX (^B)

(2)

GET

GET

:

Delimiting character

0

Address based on Sensor ID

:

Delimiting character

0

Reserved for future use, zero default

:

Delimiting character

XXXX

Checksum

:

Delimiting character

0x03

(1)

ETX (^C)

(2)

0x0D

(1)

Carriage return

0x0A

Line feed

SETNC:0:0 1 1 1000 1 0 15000 2 0 M 60 1 2 0 1 1 0 0 0 1 7 80 :XXXX:

SET:0:0 1 1 1000 1 0 15000 2 0 M 60 1 2 0 1 1 0 0 0 1 7 :68A3:

GET:0:0:XXXX:

14.2 The SETNC Command

The format of the SETNC command is nearly exactly the same as the SET

command. The only functional difference is that the SETNC command does not

commit the values set into flash memory. This means that the next time the

CS125 is power cycled it will revert back to its previous settings. This command

should be used when a setting in the sensor is changed regularly, e.g. heater

functions, as this command avoids the risk of wearing out the flash storage

memory. Note: this includes communication data rates as well.

14.2.1 Example of a SETNC Command

User Guide

14.3 The GET Command

The GET command retrieves settings data from the CS125, including message

format data and user alarm settings amongst others. This command does not

retrieve visibility or environmental information from the CS125. To retrieve

visibility data refer to the POLL command.

The GET request

(1) These values are shown in hexadecimal format not ASCII.

(2) As entered on a keypad

Example of a GET command

29

Page 38

CS125 Present Weather Sensor

GET returned data

Example

Description

0x02

(1)

STX

Sensor ID

User Alarm 1 Set

User Alarm 1 Active

User Alarm 1 Distance

User Alarm 2 Set

User Alarm 2 Active

User Alarm 2 Distance

Serial Baud Rate

Sensor serial number (read only)

Visibility Units

Message interval

Polling Or Continuous modes

Message Format (Basic/Partial/Full)

RS232 or RS485 serial communications enabled

Averaging Period

Sample timing

Dew heater override

Hood heater override

Dirty window compensation

CRC checking on received commands

Sensor power down voltage 7.0

Relative humidity threshold

:

Delimiting character

XXXX

Checksum

:

Delimiting character

0x04

(1)

EOT

0x0D

(1)

Carriage return

0x0A

Line feed

Example data returned by the GET command – See Section 12 for more

information on values returned by the `GET’ command

(1) These values are shown in hexadecimal format not ASCII.

Example of a GET returned data

0 0 0 10000 0 0 10000 2 1009 M 30 0 2 1 1 1 0 0 0 1 11.5 D4FD

Explanation: -

Sensor ID = 0

User Alarm 1 not set

User Alarm 1 not active

User Alarm 1 distance = 10000 metres

User Alarm 2 not set

User Alarm 2 not active

30

Page 39

User Guide

POLL transmitted data

Example

Description

0x02

(1)

STX, ^B

(2)

POLL

POLL

:

Delimiting character

0

Address based on Sensor ID

:

Delimiting character

0

Reserved for future use, zero default

:

Delimiting character

XXXX

Checksum

(3)

:

Delimiting character

0x03

(1)

ETX, ^C

(2)

0x0D

(1)

Carriage return

0x0A

Line feed

User Alarm 2 distance = 10000 metres

Serial baud rate 2 (=38400Bd)

Serial number = 1009

Visibility Units = M

Continuous mode output interval = 30 seconds

Polling mode = 0 (continuous mode)

Message format = 2 (full message)

RS232 or RS485 serial communications = 1 ( RS485)

Averaging period = 1 minute

Sample timing = 1 sample per second

Dew heater override = 0 (CS125 will automatically control the dew heaters)

Hood heater override = 0 (CS125 will automatically control the hood heaters)

Dirty window compensation = 0 (dirty window compensation off)

CRC checking on received commands = 1 (CRC checking enabled)

Sensor power down voltage = 11.5V

Checksum = D4FD

14.4 The POLL command – Polling the CS125

The POLL command requests the current visibility and/or alarm conditions from

the CS125. The output format of this command depends on how the CS125 is

configured using the SET command or the menu interfaces.

The POLL request

(1) These values are shown in hexadecimal format not ASCII.

(2) As entered on a keypad.

(3) Not case sensitive.

31

Page 40

CS125 Present Weather Sensor

NOTE

NOTE

POLL:0:0:XXXX:

WELCOME TO THE CAMPBELL SCIENTIFIC LTD CS125 SETUP

MENU

ID 0

S/N 1003

(1) Message output menu

(2) User alarm menu

(3) Calibrate CS125

(4) Communications setup

(5) System configuration

(9) Exit and save

(0) Exit and don't save

->

Example of a POLL request

The maximum response time to a poll command is 100 ms.

If the setting to check the checksum on received commands is enabled the

checksum varies with the Sensor ID value.

15. Entering the CS125 menu system

The user can enter the menu system by typing ‘open id’ into their terminal

program then pressing the return key on their keyboard. The id corresponds to the

sensor ID number. The Sensor ID number can be in the range of 0 to 9. The

factory default is 0.

The ‘open 0’ command is not normally echoed.

The terminal menu only gives access to more common settings.

The following text should now be displayed:

The displayed options are accessed simply by typing the corresponding number

then pressing return. No changes will take effect until you `save and exit’. The

exception to this is the calibration menu, but you will be informed before any

changes are made.

32

The displayed options are accessed simply by typing the corresponding number

then pressing return. No changes will take effect until you `Exit and Save’. The

exception to this is the calibration menu, but you will be informed before any

changes are made.

Typing `1’ opens the message menu containing settings relating to the CS125’s

outputs.

Page 41

User Guide

CS125 ALARM - MENU 2

ID 0

S/N 1009

(1) Toggle user alarm one: DISABLED

(2) Toggle alarm one threshold: LESS THAN

(3) Set new user alarm one activation point: 10000 m

(4) Toggle user alarm two: DISABLED

(5) Toggle alarm two threshold: LESS THAN

(6) Set new user alarm two activation point: 10000 m

(9) Refresh

(0) Return to main menu

->

CS125 CALIBRATION - MENU 3

ID 0

S/N 1003

(1) Perform calibration

(2) Restore the factory calibration

(3) Perform dirty windows zero offset calibration

(4) Restore dirty windows factory calibration

(9) Refresh

(0) Return to main menu

->

CS125 MESSAGE - MENU 1

ID 0

S/N 1009

(1) Toggle message format:FULL

(2) Toggle units:METRES

(3) Toggle polled or continuous mode:CONTINUOUS

(4) Set continuous mode output interval:6 second(s)

(5) Toggle output averaging period: 1 minute(s)

(6) Sampling interval:1 second(s)

(9) Refresh

(0) Return to main menu

Menu 1: The message output menu

For example, typing `2’ will toggle the units through the options `METRES’ and

`FEET’ and typing `4’ will allow the message interval to be entered.

Option (2) allows the User Alarms to be set, again by toggling through options or

changing values.

Menu 2: The user alarm menu

Menu 2: The user alarm menu. Sub menu 2: Alarm two activation level

(Option 6)

Option (3) is the calibration menu

Menu 3: The calibration menu

33

Page 42

CS125 Present Weather Sensor

NOTE

CS125 INFORMATION - MENU 4

ID 0

S/N 1003

OS version: 007646v1

Alarm Value

- Last visibility reading: - 3258M

- Overall system status: 0 No faults

- Emitter dirty window alarm: 0 0%

- Emitter internal temperature: 0 38.4

- Detector dirty window alarm: 0 0%

- Detector internal temperature: 0 31.0

- Detector DC light saturation: 0 -

- Hood heater temperature: 0 25.6

- CS125 Calibrator Serial No: - 1000

- CS125 Calibrator Constant: - 30.5

- Calibration value Fac offset: - -0.026

- Calibration value Fac scale: - 0.02682

- Calibration value Cal offset: - -0.026

- Calibration value Cal scale: - 0.02682

- Signature fault: 0 -

- Flash write errors: 0 0

- Flash read errors: 0 0

- Supply voltage: <7.0V 11.3V

- Aux supply voltages: +5V=5.0 -5V=-5.1

+6V=5.9

- External temperature: 0 26.4

- Present weather mode enabled

(8) Get debug

(9) Refresh

(0) Return to main menu

->

Consult the ‘calibration’ section of this manual for information on how to

calibrate the CS125 present weather sensor.

Once a calibration is finished changes are immediate, but factory

calibrations can be restored if needed using Option `(2)’ in the

calibration menu. The disk constants however remain as the last

disk used.

Option (4) gives the systems information menu containing useful information such

as temperature and system alarms.

Menu 4: The system information menu

34

If either of the dirty window alarms are set it is recommended you follow the

cleaning section of this manual (Section 18).

If there is a flash error or signature error it is recommended that you contact

Campbell Scientific.

Page 43

User Guide

NOTE

CS125 COMMUNICATIONS - MENU 5

ID 0

S/N 1009

(1) Set sensor ID

(2) Set RS232/RS485 baud rate:38400

(3) Toggle RS232/RS485 modes:RS232

(9) Refresh

(0) Return to main menu

->

CS125 CONFIGURATION - MENU 6

ID 0

S/N 1003

(1) Dew heater override: AUTOMATIC

(2) Hood heater override: AUTOMATIC

(3) Dirty window compensation: NO COMPENSATION

(4) Command line CRC Checking: DO NOT CHECK

(5) Sensor power down voltage: 7.0V

(6) RH threshold: 80%

(9) Refresh

(0) Return to main menu

->

The sensor power down voltage shown before the supply voltage is only available

if the sensor is running firmware version 4 or later and only functional for sensors

with serial number greater than E1029.

Menu 5: The communication menu

The communications menu is used to set baud rates and the mode of operation

(RS232/RS485).

No change will take effect until you `exit and save’.

Menu 6: Configuration

This menu sets dew and hood heaters to automatic or off, dirty window

compensation and CRC checking. In addition it allows the sensor power down

voltage to be set. If set this will shut down the CS125 before the battery voltage

has fallen low enough to damage a back-up battery. The RH threshold can also be

set from this menu. This applies if a CS215 sensor is attached and defined the

level of RH below which obscuration is deemed to be dry (that is haze, SYNOP

04 or 05, METAR HZ) rather than wet (mist, SYNOP 10, METAR BR or fog,

SYNOP 30 etc. METAR FG).

35

Page 44

CS125 Present Weather Sensor

CS125 CALIBRATION - MENU 3

ID 0

S/N 1009

(1) Perform calibration

(2) Restore the factory calibration

(9) Refresh

(0) Return to main menu

CAMPBELL SCIENTIFIC LTD CS125 menu exited.

Menu 9 and 0: Exiting the menu system

Options `9’ and `0’ exit from the menu system. Note that typing `0’ will lose all

changes made including communications settings.

16. Calibrating the CS125

The CS125 can be checked and adjusted using the optional CS125 calibrator part

number 010816. The calibration must be run using the onboard menu system. If

you have Campbell Scientific’s Device configuration program a terminal

emulation screen is provided in the CS125 screens to let you access this function.

To perform the calibration you will need a CS125 calibrator disk and a computer

with a standard serial port compatible with the CS125. If your CS125 is not

currently configured for RS232 communications you can set the internal switch,

switch three, to temporarily set the sensor to RS232 mode 38400bps. If the sensor

is already set in RS232 mode it should not be necessary to change any internal

switches. (See Section 10 for more information on the CS125 internal switches.)

The test should ideally be performed in the following conditions:

Ambient temperature should be 20ºC +/-10ºC

The local visibility should be approximately 10,000 metres or higher.

The system is self-regulating. However, it is recommended that the CS125 is

calibrated at least every two years.

The calibration is performed from menu item 3 on the main terminal screen.

Please refer to the menu section (Section 13) of this manual for further

information on how to access this menu.

Once you have selected menu item 3 you should be presented with the following

screen.

Select option 1 to start the calibration. You will then be asked to confirm that you

would like to perform a calibration. Please note, once you have entered yes at this

point you will not be able to exit until the test is complete. However, power

cycling the unit at this point will have no adverse effect on the sensor.

36

Page 45

User Guide

CS120/125 calibrator serial

number and coefficients will

be within this area.

NOTE

Starting calibration.

Input the CS125 calibrator serial number ->12345

Is 12345 correct? (Y/N)?

Input the CS125 calibrator constant ->10000

Is 10000 correct? (Y/N)?

Place one calibration bung into each hood, then

press any key.

Do you want to perform a calibration Y/N?

Once you have started the tests you will be asked for the CS125 calibrator serial

number and coefficient with a confirmation at each step giving you the chance to

correct typing mistakes.

When asked for confirmation you do not need to press return after

you type ‘y’.

When you have entered the calibrator information the sensor will wait for you to

place the foam bungs into the sensor hoods. The bungs are designed to block all

light from the outside reaching inside the head. Place one bung into each hood. If

either of the bungs are damaged or appear to have any gaps around the edge please

contact Campbell Scientific.

37

Page 46

CS125 Present Weather Sensor

NOTE

Starting dark level calibration.

This test will take approximately two minutes

Dark level test complete. Please remove the

bungs.

Now place the CS125 calibrator into the sampling

volume.

Press any key once this is done.

This part of the test will take approximately two minutes. Every ten seconds a dot

should appear indicating that the test is progressing as normal.

Remove the bungs once the sensor instructs you to. Place the CS125 calibrator

into the volume by fastening it to the central mounting point.

At this stage it is advisable to clean the lenses. Refer to Section 18

`Cleaning’ for more information. A simple visual check may be

enough to confirm the lenses are clean.

38

Page 47

User Guide

Starting light level calibration.

This test will take approximately two minutes.

Calibration is now complete.

Saving user settings

Press any key to exit.

This part of the test will take approximately two minutes. Every ten seconds a dot

should appear indicating that the test is progressing as normal.

Once the second stage of the test has been completed the new calibration constants

will be saved automatically. All calibration constants including both the user and

the factory setting can be viewed from menu item 4 from the main menu once the

test is completed.

17. Performing a firmware update

Firmware updates for the CS125 present weather sensor are performed using

Campbell Scientifics Device Configuration Utility (DevConfig) software. Please

refer to the help built into the DevConfig software for full instructions on how to

update the CS125 firmware.

39

Page 48

CS125 Present Weather Sensor

NOTE

CAUTION

NOTE

18. Cleaning

The CS125 present weather sensor is a robust instrument that will provide years of

uninterrupted weather monitoring. Calibration of the instrument is carried out at

the factory and can be redone easily on site with the optional CS125 calibrator or

carried out by Campbell Scientific if required. Only general cleaning of the lenses

is required to keep the sensor working efficiently.

Cleaning of the CS125 will be required from time to time to ensure that the lenses

are free from contaminants. The frequency of required cleaning depends on the

exposure of the instrument to such contaminants. This will vary depending on the

site location. The CS125 is capable of self diagnosing dirty lenses and will

indicate in its output when the lenses are contaminated to such a degree that its

visibility measurements may be affected.

A lower level of contamination than is detected by the dirty window

alarms, can affect the visibility measurements. The sensor can be

configured to attempt to make a correction for contamination

although the accuracy of that correction depends on the `type of

dirt’.

We suggest 6 monthly intervals for locations not prone to contaminants and

monthly intervals for those prone to contamination (roadside or airport use). In

some cases more frequent cleaning may be required where there are high levels of

contaminants and high dependency on the instrument output.

If the lenses require cleaning, it is very important that only a

proper lens cloth or lens tissue be used. The use of

inappropriate materials to clean the lenses can permanently

damage or reduce the effectiveness of the lenses leading to

errors in measurement of precipitation and visibility.

It is advisable to use an air duster to blow any loose dust and dirt from the lenses

as a first step. Using a lint free lens cloth or lens tissue impregnated with a small

amount of isopropyl alcohol solvent clean the lens surface by dragging the cloth

across the lens surface being careful not to apply excessive pressure.

Excessive pressure may lead to some types of contaminant scratching the lens

surface. Over time such scratches can lead to reduced sensor accuracy.

Spiders webs and certain `fluffy’ seeds which get lodged in the

optical path can lead to the sensor permanently giving low readings

as they can emulate precipitation. Cleaning the contamination away

with a duster will return the sensor to normal operation.

40

If spiders are a persistent problem, using some carefully applied

insecticide can deter them.

Page 49

19. Lubricating the enclosure screws

CAUTION

The CS125 enclosure screws should be lubricated with a suitable anti-seize grease

(often copper loaded) to protect the threads from corrosion. This should be

reapplied when resealing the enclosure at regular intervals, normally after

replacing the desiccant. This is of particular importance if using the sensor in

corrosive or salt laden atmospheres.

20. Desiccant

Two bags of desiccant are supplied. One is inside the enclosure, the other is

separate and sealed in a plastic bag. Desiccant use depends on your application but

for use in typical temperature conditions one bag is sufficient for a twelve month

period. The desiccant should be placed inside the enclosure taking care that it is

not trapped between the lid and the enclosure when the lid is replaced.

The second bag of desiccant should be kept in the plastic shipping bag as a

replacement for when the initial bag needs to be dried out. The bags can be rotated

in this way many times. Desiccant bags can be dried out by the following method:

1. Arrange the bags on a wire tray in a single layer to allow for adequate air flow

around the bags during the drying process. The oven’s inside temperature

should be room or ambient temperature (25°C - 30°C). A convection,

circulating, forced air type oven is recommended for this regeneration

process. Seal failures may occur if any other type of heating unit or appliance

is used.

User Guide

2. When placed in a forced air, circulating air, or convection oven, allow a

minimum of 4 to 5 cm of air space between the top of the bags and the next

metal tray above the bags. If placed in a radiating exposed infrared element

type oven, shield the bags from direct exposure to the heating element, giving

the closest bags a minimum of 40 cm clearance from the heat shield.

Excessive surface film temperature due to infrared radiation will cause the

Tyvek material to melt and/or the seals to fail. Seal failure may also occur if

the temperature is allowed to increase rapidly. This is due to the fact that the

water vapour is not given sufficient time to diffuse through the Tyvek

material, thus creating internal pressure within the bag, resulting in a seal