Page 1

CS

120A

and CS125

Visibility and Present

Weather Sensors

Revision

Copyright ©

Campbell Scientific, Inc.

: 01/2021

2013 – 2021

Page 2

About this manual

Some useful conversion factors:

Area: 1 in

Length: 1 in. (inch) = 25.4 mm

2

(square inch) = 645 mm2

1 ft (foot) = 304.8 mm

1 yard = 0.914 m

1 mile = 1.609 km

Mass:

Pressure: 1 psi (lb/in

Volume: 1 UK pint = 568.3 ml

1 oz. (ounce) = 28.35 g

1 lb (pound weight) = 0.454 kg

2

) = 68.95 mb

1 UK gallon = 4.546 litres

1 US gallon = 3.785 litres

Recycling information

At the end of this product’s life it should not be put in commercial or domestic refuse

but sent for recycling. Any batteries contained within the product or used during the

products life should be removed from the product and also be sent to an appropriate

recycling facility.

Campbell Scientific Ltd can advise on the recycling of the equipment and in some cases

arrange collection and the correct disposal of it, although charges may apply for some

items or territories.

For further advice or support, please contact Campbell Scientific Ltd, or your local agent.

Campbell Scientific Ltd, Campbell Park, 80 Hathern Road, Shepshed, Loughborough, LE12 9GX, UK

Tel: +44 (0) 1509 601141 Fax: +44 (0) 1509 270924

Email: support@campbellsci.co.uk

www.campbellsci.co.uk

Page 3

Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

1.1 General Safety........................................................................................... 2

1.2 Sensor Unit Safety .................................................................................... 2

1.3 Principle of operation ................................................................................ 3

1.4 Recommended Tools ................................................................................ 6

1.5 Quickstart .................................................................................................. 6

2. Measurement specification ........................................ 6

3. Technical specification ................................ .............. 7

3.1 Electrical specification .............................................................................. 7

3.2 Optical specification ................................................................................. 7

4. Communications specification .................................. 8

4.1 Communications electrical specifications ................................................. 8

4.2 Supported data rates and formats .............................................................. 8

5. Environmental specifications .................................... 9

6. Mechanical specifications .......................................... 9

6.1 Dimensions ............................................................................................... 9

6.2 Weights ................................................................................................... 10

6.3 Mounting................................................................................................. 10

7. Installation procedure .............................................. 10

7.1 Equipment grounding ............................................................................. 11

7.2 Mounting the sensor ................................ ................................ ................ 12

7.3 Optional Campbell Scientific Mount ...................................................... 14

8. Sensor internal connectors’ description ................ 17

8.1 Sensor recommended wiring using Campbell Scientific cables ............. 19

9. HygroVUE 5, HygroVUE 10 or CS215 T/RH Sensor

(CS125 only) ................................................................... 21

10. Functions of the internal switches ........................ 23

Page 4

ii

11. Message Formats: A breakdown of the different

default outputs of the sensor –

Basic/Partial/Full ............................................... 24

11.1 Visibility only messages ....................................................................... 25

11.2 Messages with SYNOP Present Weather Codes (CS125 only) .............. 26

11.3 Messages with METAR Present Weather Codes (CS125 only) ............. 27

11.4 Messages with Generic SYNOP Present Weather Codes (CS125 only) 28

11.5 Example sensor message outputs .......................................................... 33

11.6 Custom message format ........................................................................ 34

12. Interface methods – Device Configuration

Utility/Command line/Menu .................................. 36

12.1 Configuring a PC for talking to the sensor ........................................... 37

13. Definition of the variables that can be set by

the user on the sensor ........................................ 37

14. Command line mode............................................... 39

14.1 The SET Command .............................................................................. 40

14.1.1 Example of a SET Command ................................................... 40

14.2 The SETNC Command ......................................................................... 41

14.2.1 Example of a SETNC Command .............................................. 41

14.3 The MSGSET Command ...................................................................... 41

14.4 The GET Command .............................................................................. 43

14.5 The MSGGET Command ..................................................................... 45

14.6 The POLL Command – Polling the sensor ........................................... 46

14.7 The ACCRES Command – Resetting the accumulation value ............. 47

15. Entering the sensor menu system ........................ 47

16. Calibrating the sensor ............................................ 53

16.1 Visibility calibration ............................................................................. 53

16.2 Dirty window zero calibration .............................................................. 57

16.3 Internal temperature check (CS125) ..................................................... 57

17. Performing an operating system update .............. 58

18. Cleaning .................................................................. 60

19. Lubricating the enclosure screws ......................... 61

20. Desiccant ................................................................. 61

Addendum .................................................................Add-1

Page 5

iii

Appendices

A. Sensor Block Diagram ........................................... A-1

B. Example C code of the checksum CRC-16 ........... B-1

C. Present Weather Codes ........................................ C-1

D. A comparison of the two alternative visibility

calibrations ........................................................... D-1

Figures

1-1 Particles in the sample volume scatter light in all directions, including

into the detector ....................................................................................... 3

1-2 Signals from large, slow falling snowflakes and smaller, faster,

raindrops .................................................................................................. 4

1-3 Defining possible precipitation types based on wet bulb and dry

bulb temperatures ..................................................................................... 5

1-4 A typical size/speed map used by the CS125 present weather

algorithm ................................................................................................... 5

7-1 Airflow ................................................................................................... 11

7-2 Grounding boss ....................................................................................... 12

7-3 Mounting arrangement ........................................................................... 13

7-4 Mounting to a flat surface ....................................................................... 13

7-5 Use of band clamps ................................................................................ 14

7-6 Optical sensor mast ................................................................ ................. 15

7-7 Mounting footprint ................................................................................. 16

8-1 Connections ............................................................................................ 17

8-2 Communications and power connections ............................................... 19

8-3 Communications and power connector .................................................. 20

8-4 Configuration cable ................................................................................ 20

8-5 USB configuration cable ........................................................................ 20

9-1 Connection for the optional HygroVUE 5, HygroVUE 10 &

CS215 T/RH sensors .......................................................................... 22

10-1 Internal switches ................................................................................... 23

16-1 Calibration disk .................................................................................... 55

16-2 Mounting calibration disk ..................................................................... 56

17-1 Sensor DevConfig download instructions ............................................ 58

17-2 Sensor DevConfig screen when OS update is complete ....................... 59

Tables

10-1 Internal switch functions ..................................................................... 24

11-1 Summary of message IDs and descriptions ......................................... 30

11-2 Summary of system alarms and descriptions ....................................... 31

13-1 User definable settings and descriptions .............................................. 37

Page 6

1

CS120A and CS125 Visibility and Present

Weather Sensors

1. Introduction

The CS120A is a visibility sensor. The CS125 additionally detects and reports

present weather in the form of SYNOP, METAR or NWS codes. The CS125 has

the same specification for visibility measurement as the CS120A. It is possible to

upgrade a CS120A to a CS125, please contact Campbell Scientific for more

details.

The sensors are infra-red forward scatter visibility and present weather sensors for

automatic weather stations including road, marine and airport based stations.

They both use the well-established forward scatter system for visibility

measurement, utilising a 42º scatter angle. The CS125 uses high speed sampling

to reduce missed events and improves response to other suddenly changing

conditions.

The CS125 has a temperature sensor mounted in the cross arm used as part of the

process for identifying precipitation.

When an optional CS215 or HygroVUE temperature and RH sensor is connected,

the CS125 can distinguish wet and dry obscuration (for example mist and haze)

and make more precise discrimination between liquid and frozen precipitation.

Dew heaters are provided to keep the sensor optics clear of condensation and more

powerful hood heaters to prevent the build up of snow or ice.

This sensor is certified for Aviation use by the German Meteorological Service,

Deutscher Wetterdienst (DWD) (see Section 1.3 regarding the settings).

Page 7

CS120A and CS125 Visibility and Present Weather Sensors

2

1.1 General Safety

This manual provides important safety considerations for the installation,

operation and maintenance of the sensor. These safety considerations are

classified into three levels:

Warnings alert the installer or user to serious hazards.

Ignoring these warnings could result in injury or death

and/or irrevocable damage to the sensor unit.

Cautions warn of potential hazards. Ignoring these cautions

could result in the sensor being damaged and data being lost.

Notes highlight useful information in the installation, use and

maintenance of this product. These should be followed carefully in

order to gain the maximum benefit from the use of this product.

1.2 Sensor Unit Safety

The sensor has been checked for safety before leaving the factory and

contains no internally replaceable or modifiable parts.

Do not modify the sensor unit. Such modifications will

lead to damage of the unit and could expose users to

dangerous light levels and voltages.

In unusual failure modes and environmental conditions

the sensor hood could become hot. In normal operation

they will be at ambient temperature or slightly above.

Ensure that the correct voltage supply is provided to the

sensor.

WARNING

CAUTION

NOTE

WARNING

WARNING

CAUTION

Page 8

Instruction Manual

3

1.3 Principle of operation

Figure 1-1. Particles in the sample volume scatter light in all directions,

including into the detector

The CS120A and CS125 comprise an emitter and detector aligned as in

Figure 1-1. The emitter produces a beam of near infra-red light pulsed at 1 kHz. A

detector has a field of view which overlaps the beam and is inclined at 42 degrees

to it. Light scattered by a particle (for example a fog droplet or particle of

precipitation) from the overlap or sample volume towards the detector is detected

by a photodiode and recorded as a signal. The size of the signal is therefore

proportional to the extinction of the emitted beam caused by scattering. The

scattering signal averaged over one second is used to calculate an extinction

coefficient or EXCO assuming the relationship between forward scatter and

EXCO is linear. Sixty one second averages are then themselves averaged to give a

one minute average EXCO. This is then converted to a value of Meteorological

Optical Range (MOR) using Koschmieder’s law:

MOR = 3/EXCO where MOR is in km and EXCO in units of km-1.

The CS125 calibration for visibility was derived by comparison with other high

grade, forward scatter sensors and has also been verified in a study by trained

meteorological observers. This is called the MOR calibration in this manual.

An alternative calibration, known as TMOR, is also available. This was derived

by following the ICAO procedure of calibrating the sensor against a

transmissometer. An empirical equation to convert from MOR to TMOR was

developed.

Page 9

CS120A and CS125 Visibility and Present Weather Sensors

4

This non-linear equation results in significantly higher visibility readings at lower

visibilities below 5000 metres. Further details of the calibration and graphs

comparing the two calibration options are given in Appendix D.

The TMOR calibration should be used for aviation applications as it is considered

to give more representative visibility values for a plane landing and viewing

landing lights. Use of the TMOR calibration is obligatory for use of this sensor on

German airfields.

The CS125 can be switched between outputting data using the original MOR or

the alternative TMOR calibration by using a configuration switch (See Section

10). Sensors made from early December 2020 leave the factory with this switch

set to ON to make the sensor output values according to the TMOR calibration.

The CS125 is capable of identifying weather type in addition to measuring

visibility. It does this by analysing the amplitude and width of spikes in the APD

signal corresponding to particles of precipitation passing through the sample

volume. The amplitude of the signal is a guide to the size of the particle and the

width, because it represents the time taken for the particle to fall through the

sample volume, is proportional to the fall speed, see Figure 1-2.

Figure 1-2. Signals from large, slow falling snowflakes and smaller, faster,

raindrops

The CS125 also has a temperature sensor. These three parameters, fall speed, size

and temperature are used to identify the type of particle. If an additional external

temperature and relative humidity probe is connected then a wet-bulb temperature

can be calculated. This provides useful additional information identifying particles

more accurately especially, between liquid and frozen around 0°C.

Figure 1-3 shows how these temperatures are used to define possible precipitation

types around 0°C.

Page 10

Instruction Manual

5

Figure 1-3. Defining possible precipitation types based on wet bulb and

dry bulb temperatures

The processing algorithm then works with several ‘maps’ such as Figure 1-4 to

identify each particle.

Figure 1-4. A typical size/speed map used by the CS125 present weather

algorithm

Page 11

CS120A and CS125 Visibility and Present Weather Sensors

6

1.4 Recommended Tools

The following installation tools are recommended:

10 mm open spanner/wrench (for grounding boss, must be open ended)

13 mm spanner/wrench

19 mm open spanner/wrench (for cable glands, must be open ended)

2 mm flat screwdriver

Number 2 cross head screwdriver

1.5 Quickstart

The sensor is shipped set to the following default communication RS-232, 8N1,

38400 baud, a sensor ID = 0 and set to transmit default messages, full format,

visibility only for the CS120A, SYNOP present weather full format for the

CS125, at 1 minute intervals (see Section 11).

To start using the CS120A or CS125, first connect a DC supply matching the

specification in Section 3.1 to the red and black wires on the ‘D-connector’ (see

Figure 8-3) and connect to a PC communications port with a terminal emulator set

to RS-232, 38400 baud, 8N1. After a couple of minutes, data messages will be

received. Typing ‘open 0’ will access the menu structure, see Section 15.

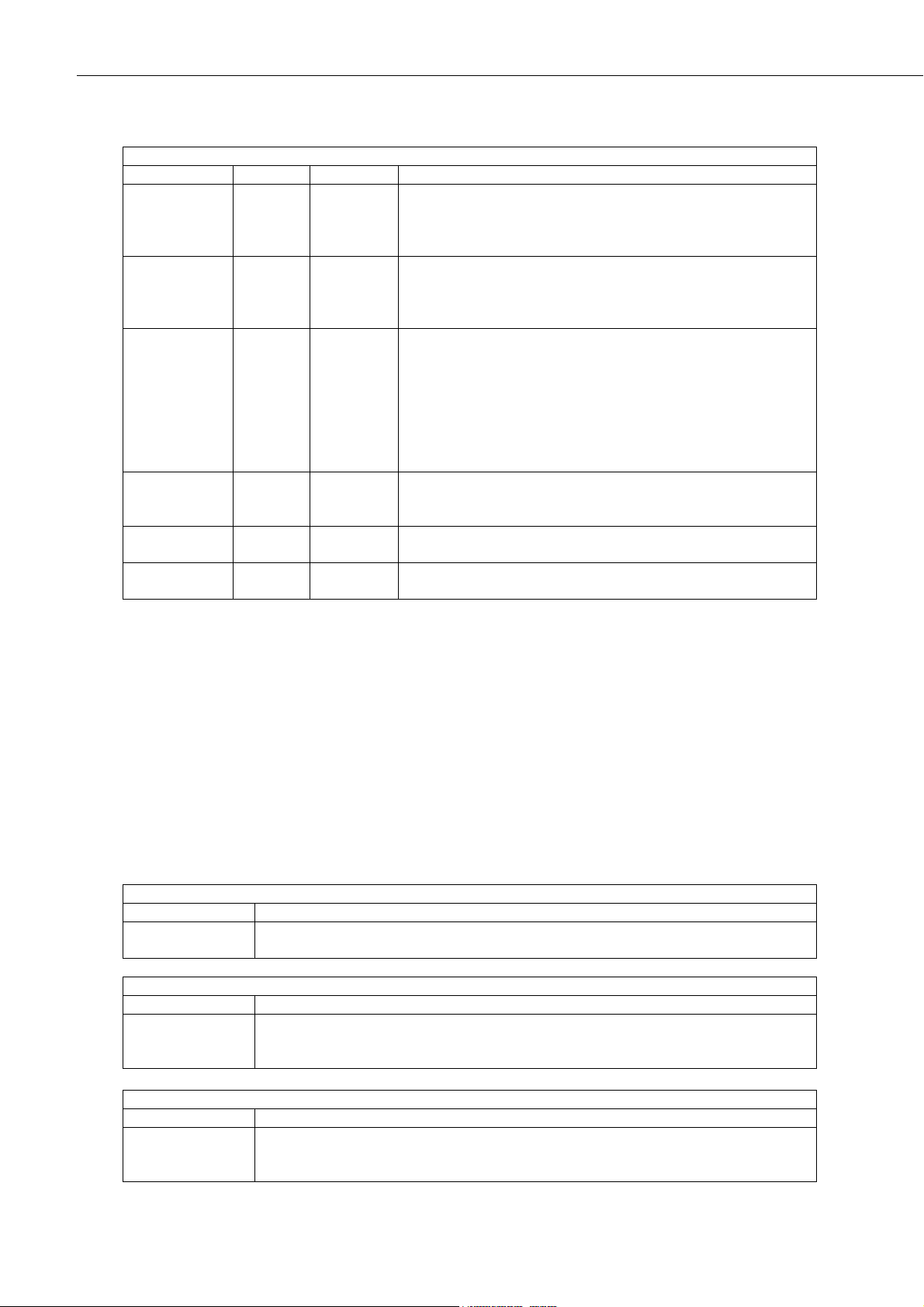

2. Measurement specification

Minimum

Value

Nominal

Value

Maximum

Value

Visibility characteristics

Reported visibility (metric)

5 metres

-

75,000

metres

Reported visibility (imperial)

16 feet

-

46 miles

Visibility accuracy calibration

against factory calibration disk**

-

+/- 2%

-

Visibility accuracy up to 600 m

-

+/-8%

-

Visibility accuracy up to 10,000 m

-

+/-10%

-

Visibility accuracy up to 15,000 m

-

+/-15%

-

Visibility accuracy above 15,000 m

-

+/-20%

-

Precipitation characteristics, water equivalent (CS125 only)

Reported accumulation range

0 – 999.9 mm

Accumulation accuracy

+/-15%

Accumulation resolution

0.1 mm

Reported intensity range (up to *)

0 - 999.99 mm/hr

Intensity accuracy**

+/-15%

Intensity resolution

0.01 mm/hr

*The maximum intensity reported is dependent on the mixture of precipitation falling.

**Please refer to Section 1.3 regarding the calibration options for the sensor.

Page 12

Instruction Manual

7

3. Technical specification

3.1 Electrical specification

Minimum

Value

Nominal

Value

Maximum

Value

Main power supply for DSP and dew heaters

Power supply, (DC only)

7V

12V

30V

(1)

Current consumption sampling

continuously with dew heaters ON and

RS-232 communications active

(2, 3)

(at 12V DC)

-

200 mA

248 mA

Current consumption sampling

continuously with dew heaters disabled

(at 12V DC)

-

110 mA

151 mA

Current consumption without any

sampling occurring and dew heaters

disabled (at 12V DC)

-

21 mA

30 mA

Hood heater power supply

Hood heater voltage (AC or DC)

-

24V

(3)

30V

(4)

Hood heater wattage (at 24V AC or

DC)

-

60W

(5)

-

User alarm outputs

User output high level (at 85ºC)

3.8V - -

User output high level (at 25ºC )

4.13V - -

User output low (All temperatures)

0.25V - 0.55V

User output current

- - 32 mA

(1) If a CS215 or HygroVUE probe is being used with a CS125 the supply voltage should not exceed

28V.

(2) The RS-232 communications interface will automatically turn itself off when not transmitting.

(3) If hood heaters are not being used ensure ‘Hood heater override’ (details in Section 13) is set to

off.

(4) It is recommended that the hood heaters are run at 24V AC/DC. It is possible to run the heaters at

any voltage below 24V but the heaters will generate proportionally less heat reducing their ability

to prevent ice build-up.

(5) Each hood takes 30W, 60W is the total for both hoods on the sensor together.

If a CS215 or HygroVUE probe is being used the supply

voltage should not exceed 28V.

3.2 Optical specification

Minimum

Value

Nominal

Value

Maximum

Value

Optical characteristics

LED centre wavelength

-

850 nm

-

LED spectral bandwidth

-

+/-35 nm

-

Pulse characteristics

CAUTION

Page 13

CS120A and CS125 Visibility and Present Weather Sensors

8

Light pulse rate

-

1KHz

-

4. Communications specification

4.1 Communications electrical specifications

Minimum

Value

Nominal

Value

Maximum

Value

RS-232 Communications

(1)

RS-232 input threshold Low

0.8V

1.5V

-

RS-232 input threshold High

-

2.0V

2.4V

RS-232 input absolute maximum

-15V

-

+15V

RS-232 input resistance

12K

-

-

RS-232 output voltage low

- - 0.4V

RS-232 output voltage high (into

3K)

4.4V - -

RS-485 Communications

RS-485 input threshold voltage

-0.2V

-

+0.2V

RS-485 output (Unloaded)

- - 5V

RS-485 output (Load 50)

2V - -

Maximum voltage at any terminal

(2)

-7V

-

+7V

(1) The RS-232 communications interface will automatically turn itself off when not transmitting.

(2) The ground of the sensor and the ground of any RS-485 equipment cannot be further apart than

this voltage. The sensor ground (pin 1) on connector B, see page 18, can be connected to the

ground of the host equipment. This will reduce any parasitic currents.

4.2 Supported data rates and formats

Serial setting 8N1

Supported data rates

• 1200 bps

• 2400 bps

• 9600 bps

• 19200 bps

• 38400 bps - default

• 57600 bps

• 115200 bps

Supported formats

• RS-232 (Full duplex only), default

• RS-485 (Half duplex)

• 8 bit data bytes

• 1 stop bit

• Parity checking is not supported as most communication protocols used by

the CS125 have built in checksums as well as checks that communications

have been understood.

Page 14

Instruction Manual

9

5. Environmental specifications

Minimum

Value

Nominal

Value

Maximum

Value

Sensor temperature ranges

Operating temperature

-25°C

-

+60°C

Extended operating temperature

-40°C

-

+70°C

(1)

Storage temperature

-40°C

-

+85°C

Sensor humidity ranges

Operating humidity range

0%

-

100%

Sensor heater thresholds

Dew heater Turn On

-

<35°C

-

Dew heater Turn Off

-

>40°C

-

Hood heater Turn On

-

<15°C

-

Hood heater Turn Off

-

>25°C

-

(1) Extended temperature ranges are only guaranteed if the sensor has been tested by Campbell

Scientific and verified within this temperature range. Some degradation of absolute accuracy can

be expected at the extremes of the extended ranges.

6. Mechanical specifications

6.1 Dimensions

Page 15

CS120A and CS125 Visibility and Present Weather Sensors

10

6.2 Weights

Sensor weight: 3 Kg

Shipping weight: 6 Kg (including packing box)

6.3 Mounting

Sensor mounting: Bracket mounts on a vertical pole 32-52.5 mm diameter. The

mounting bracket has cut-outs for band clamps for larger

diameter masts.

7. Installation procedure

The sensor measures environmental variables and is designed to be located in

harsh weather conditions. However, there are a few considerations to take into

account if accurate and representative data from a site are to be obtained.

The descriptions in this section are not exhaustive. Please refer to

meteorological publications for further information on locating

weather instruments

The sensor should be sited in a position representative of local weather conditions

and not of a specific microclimate (unless the analysis of microclimate weather is

being sought).

The sensor has good resistance to background light but it is a good idea to avoid

locations where the transmitter is pointing at a light scattering or reflecting

surface. Ideally, the receiver should point north in the northern hemisphere or

south in the southern hemisphere but this is not critical. This is because it is more

important to make sure the receiver is not pointing towards any possible sources

or reflected light in its field of view, for instance nearby sensors or enclosures

mounted below it on a mast. Where those objects cannot be moved, pointing the

sensor away from North/South is acceptable. Failure to do this can result in the

sensor reporting a DC light saturation error when there is bright sunlight.

To give non-microclimatic measurements the sensor should be sited away from

possible physical obstructions that could affect the fall of precipitation. The sensor

should also be positioned away from sources of heat, electrical interference and in

such a position as to not have direct light on the sensor lenses. Whenever possible,

the sensor should be located away from windbreaks.

Several zones have been identified upwind and downwind of a windbreak in

which the airflow is unrepresentative of the general speed and direction. Eddies

are generated in the lee of the windbreak and air is displaced upwind of it. The

height and depth of these affected zones varies with the height and to some extent

the density of the obstacle.

Generally, a structure disturbs the airflow in an upwind direction for a distance of

about twice the height of the structure, and in a downwind direction for a distance

of about six times the height. The airflow is also affected to a vertical distance of

about twice the height of the structure. Ideally, therefore, the sensor should be

located outside this zone of influence in order to obtain representative values for

the region.

NOTE

Page 16

Instruction Manual

11

Figure 7-1. Airflow

In order to reduce the service frequency with the unit, the sensor should be placed

away from sources of contamination, in the case of roadside monitoring; larger

mounting poles can be used. More regular maintenance will be required when the

instrument is placed in areas where contamination is unavoidable or where

measurements may be safety critical.

The WMO recommend a sample volume height of 1.5 m. However, for

applications such as aviation or road visibility other heights may be appropriate.

If operating a sensor indoors it is likely that there will be sources of

light and/or reflections that will create false readings and erratic

results.

If carrying out simple checks, blocking a lens or the sample volume

will simulate an INCREASE in visibility not a decrease.

7.1 Equipment grounding

The sensor must be properly grounded. It is sufficient to ground the mounting

bracket and if the sensor is connected to a grounded metal mast, and in electrical

contact with it, then this will be sufficient. Otherwise, the mounting bracket

should be earthed and a grounding boss is supplied to allow this.

A ground wire with a minimum cross section of 6 mm2 and maximum length of

5 m should be used.

The pole and foundations of a pole mounted installation will provide some basic

lightning protection and protection against radio frequency interference and

should also be correctly grounded.

NOTE

NOTE

Page 17

CS120A and CS125 Visibility and Present Weather Sensors

12

Figure 7-2. Grounding boss

7.2 Mounting the sensor

A quick release pole mounting kit is supplied with the sensor.

If a power supply enclosure has been supplied with the sensor it can be mounted

on the pole, near its base using the brackets supplied with the enclosure.

Alternatively the power supply can be mounted elsewhere, e.g. on a wall at some

distance from the sensor. The power supply enclosure should be mounted away

from the sensor head to avoid wind flow disturbance or rain drops bouncing back

up into the sensor’s sensing volume.

Take care not to overtighten the nuts on the bolts, as it may

be possible to distort and/or damage the brackets or DSP

plate by doing so, and/or the nuts may seize up. Only tighten

the nuts to a degree necessary to hold the sensor firmly in

place.

Where the sensor is to be mounted onto another type of mast, please refer to the

manual for that mast for mounting details.

Ensure that the sensor is mounted according to the following

figure. Do not reposition, once fixings are tightened, by

forcing the arms of the unit as this can cause damage.

CAUTION

CAUTION

Page 18

Instruction Manual

13

Do not remove the mounting plate as this will compromise

resistance to water ingress.

Figure 7-3. Mounting arrangement

If you need to mount the sensor to a flat surface, remove the plastic formers from

the mounting brackets and use the holes as shown in Figure 7-4.

If mounting to a flat surface ensure that there is no obstruction to

airflow through the sample volume.

Figure 7-4. Mounting to a flat surface

CAUTION

NOTE

Page 19

CS120A and CS125 Visibility and Present Weather Sensors

14

Slots are provided to allow band clamps to be used with larger diameter masts, see

Figure 7-5.

Figure 7-5. Use of band clamps

7.3 Optional Campbell Scientific Mount

A Campbell Scientific ‘optical sensor mount’ is available. This will put the

sample volume at about 1.5 m in compliance with the WMO ‘Guide to

Meteorological Instruments and Methods of Observation’, 7th Edition, Section

9.3.4.

Page 20

Instruction Manual

15

Figure 7-6. Optical sensor mast

If one is to be used, use the following installation instructions.

Install the mount on a concrete foundation. If one does not already exist then a

concrete foundation should be constructed at least 600 mm square and 600 mm

deep. Ensure the ground consistency is not too loose and will be able to support

the mount and concrete foundation.

Page 21

CS120A and CS125 Visibility and Present Weather Sensors

16

Drill four 12 mm diameter holes using the mount base as a template or using the

following in Figure 7-7 to a depth of 77 mm.

Figure 7-7. Mounting footprint

Clean the holes of all debris.

Place washers and nuts on the ends of the wedge anchors supplied (to protect the

threads during installation).

Hammer the wedge anchors into the holes until the start of the threads are below

the surface.

Tighten the nuts until about 25 mm of thread protrudes above the surface.

Remove the washers and nuts from the protruding length screw. Then lower the

mount into place.

Finally secure the mount with the washers and nuts.

If the surface is not level and flat it may be necessary to add washers under the

base on one or more of the foundation screws.

Page 22

Instruction Manual

17

8. Sensor internal connectors’ description

The sensor has four standard IP66 rated glands. The first gland is by default used

by the power/communications line. This comprises the 7-30 V for the main

electronics, and the serial communications wires. The sensor is supplied with 5 m

cable already connected.

The second gland is used for the 24 V feeds for the hood heaters fitted with a 5 m

cable.

Glands 3 and 4 are spare. If user alarms are connected they usually use gland 3

and if a CS215 or HygroVUE probe is fitted this usually uses gland 4.

If you need to run cables through the cable glands follow these guidelines. If a

torque wrench is available use a torque of 2.5 Nm (do not over tighten).

Otherwise tighten with fingers as tight as possible and then add a further ¾ turn

with a 19 mm spanner (do not over tighten).

The glands are suitable for cables between 5 and 9 mm diameter.

If the power cable is incorrectly wired to the sensor then

damage can be done to the unit.

10 m is the longest length of the cable type supplied

recommended. In particular, additional RS-485

communication should be twisted pair. Please contact

Campbell Scientific if you wish to use a longer length of cable.

Figure 8-1. Connections

CAUTION

CAUTION

Page 23

CS120A and CS125 Visibility and Present Weather Sensors

18

Connector A - Five way connector

Pin number

Description

Notes

Pin 1

+ve supply

Main electronics +ve supply input

Pin 2

0V

Auxiliary Electronics 0V. Common with the main electronics 0V.

Pin 3

Hood low

This is for the hood heater power supply. If the hood heater supply is

DC it should be the negative connection and if it is AC it should be

the ‘neutral’ or ‘ground’ connection if there is one.

Pin 4

0V

Auxiliary Electronics 0V. Common with the main electronics 0V.

Pin 5

Hood high

This is for the hood heater power supply. If the hood heater supply is

DC it should be the positive connection.

To avoid damage to noise filters on the hood heater inputs if

the heater voltage is DC the –ve connection should be made

to pin 3 and the +ve to pin 5. If the heater voltage is AC with a

ground or neutral wire then this should be connected to pin 3.

Pin 3 should not be more than 5 volts from the main

electronics 0V.

Connector B - Three way connector

Pin number

Description

Notes

Pin 1

0V

0V connection for serial communications. This connection is

common with the main electronics 0V (Connector A, pin 2).

Pin 2

Receive

RS-232 receive line, RXD, B/D+ for RS-485 half duplex

Pin 3

Transmit

RS-232 transmit line, TXD, A/D− for RS-485 half duplex

It may be necessary to use a 120 ohm termination resistor to reduce signal

distortion when using RS-485 for cable runs over about 500 m and baud rates

above 38400. It should be connected between pins 2 and 3.

Connector C - Four way connector

Pin number

Description

Notes

Pin 1

0V

0V connection for user alarms. This connection is common with the

main electronics 0V (Connector A, Pin 2).

Pin 2

User 2

Output for user alarm 2

Pin 3

0V

0V connection for user alarms. This connection is common with the

main electronics 0V (Connector A, Pin 2).

Pin 4

User 1

Output for user alarm 1

CS125 only

Pin number

Description

Pin 1

+12V

Pin 2

SDI-12

Pin 3

0V

To use these connections it is necessary to either use the cable gland

taking the hood heater power or, if the hood heater is also required,

to use different cables to those supplied. Please contact Campbell

Scientific if you need any advice on choice of cable.

CAUTION

NOTE

Page 24

Instruction Manual

19

8.1 Sensor recommended wiring using Campbell Scientific cables (this cable is supplied already connected as standard)

The sensor is provided pre-wired with a default 5 m power and communications

cable which is terminated at one end with a 9 pin D-connector (DB9). The

D-connector can be connected directly to a PC or to a datalogger such as the

Campbell Scientific CR1000 using a suitable interconnecting cable such as the

SC110. If another type of connection is required then the D-connector should be

removed.

Figure 8-2. Communications and power connections

Page 25

CS120A and CS125 Visibility and Present Weather Sensors

20

Figure 8-3. Communications and power connector

Two types of configuration cable are available from Campbell Scientific that plug

directly into connector B in place of the normal connector and cable. One has a

RS-232 or RS-485 output according to how the CS120A/CS125 is configured

(Figure 8-4) and one has a USB output (Figure 8-5).

If the lid is removed, take care not to overtighten the fixing screws.

A small gap should remain between the lid and box.

Figure 8-4. Configuration cable

Figure 8-5. USB configuration cable

NOTE

Page 26

Instruction Manual

21

9. HygroVUE 5, HygroVUE 10 or CS215 T/RH Sensor (CS125 only)

The CS125 has a temperature sensor mounted in the crossarm that is used in

determining precipitation type.

A HygroVUE 5, HygroVUE 10 or CS215 temperature and RH sensor can be

connected to a CS125. This is recommended as it will improve the performance of

the CS125 in identifying precipitation and allows it to, for example, distinguish

between mist and haze. Precipitation identification at temperatures close to

freezing will be much improved by a CS215 and its use is highly recommended in

regions where temperatures close to 0°C are common if information on

precipitation type is important. It also allows RH information to be included in

data messages.

If a HygroVUE 5, HygroVUE 10 or CS215 is connected then the temperature

used for assessment of precipitation type and included in data messages will come

from the HygroVUE 5, HygroVUE 10 or CS215 instead of the temperature sensor

mounted in the cross arm.

The connections for the HygroVUE 5, HygroVUE 10 or CS215 are shown in

Figure 9-1. The HygroVUE 5 can be mounted in the Rad 6, the HygroVUE 10 in

the Rad 10E, or CS215 itself can be mounted in a Met20 screen on the same mast

as the CS125. The screen can be mounted on the top section of an OSM1 optical

mast below a CS125.

WMO – No. 8, 2.1.4.1 recommends temperature measurement at a height of

between 1.2 and 2.0 m above ground. The screen should be below the height of

the CS125 electronics box.

Page 27

CS120A and CS125 Visibility and Present Weather Sensors

22

Connections for temperature

and RH sensor

Figure 9-1. Connection for the optional HygroVUE 5, HygroVUE 10 and

CS215 T/RH sensors

CS215 WIRING

COLOUR

FUNCTION

PIN

Red

+12V

1

Green

SDI-12

2

Black

Power Ground

3

Clear

Shield

3

White

Power Ground

3 or NC

HYGROVUE 5 & HYGROVUE 10

WIRING

COLOUR

FUNCTION

PIN

Brown

+12V

1

White

SDI-12

2

Black

Power Ground

3

Clear

Shield

3

Page 28

Instruction Manual

23

10. Functions of the internal switches

The sensor is equipped with four switches located within the main enclosure.

These switches perform certain functions at power up, their functions are detailed

in Figure 10-1.

The switches are only read during the power up sequence of the

sensor. This means that if the switches are pressed whilst the sensor

is running nothing will happen, the sensor will need to be power

cycled leaving at least 10 seconds with the sensor off for any of

their functions to be performed.

Figure 10-1. Internal switches

IMPORTANT

Page 29

CS120A and CS125 Visibility and Present Weather Sensors

24

Table 10-1. Internal switch functions

Switch number

Function

4

When switched ON the sensor uses the TMOR

calibration and OFF it uses the MOR calibration.

Please refer to Section 1.3 for a description of

these two calibration options.

3

When switched to the ON position and the sensor

is power cycled this switch temporarily sets the

sensor communications port to a default RS-232

communication state at 38400 baud. This is useful

during field tests or maintenance when the sensor

has been remotely configured for RS-485 mode or

a baud rate your PC does not support. This change

is temporary and will not be stored to flash.

However, if the menu system is accessed and a

‘Save and exit’ command is performed these new

data rate settings will be committed to flash.

Once this switch is returned to its OFF position

and the sensor is power cycled the sensor will

return to its previous communications settings.

2

Reserved for future use, set to OFF.

1

When switched to the ON position this switch

will reset the sensor to its factory default values.

This reset will affect all communication settings.

This will take immediate effect upon power up.

NOTE: To use this the power supply must be

stable. Do not leave this switch set permanently.

If the lid is removed take care not to overtighten the screws when it

is replaced. A small gap should remain between the lid and box.

11. Message Formats: A breakdown of the different default outputs of the sensor – Basic/Partial/Full

The sensor has twelve different message formats available to the user. All

parameters are space delimited with a unique start and end character allowing easy

storage into any logger (see Section 15 on how to set default outputs). The

SYNOP Full Format message is the default message for the CS125 and the Full

Format Visibility only message is the default for the CS120A. These can be

selected from the Message – Sub 3 menu.

NOTE

CS125 MESSAGE - SUB 3

Set the message output format. Current format is: FULL SYNOP

- Basic = 0

- Partial = 1

- Full = 2

- Basic SYNOP = 3

- Partial SYNOP = 4

- Full SYNOP = 5

- Basic METAR = 6

- Partial METAR = 7

- Full METAR = 8

- Generic Basic SYNOP = 9

- Generic Partial SYNOP = 10

- Generic Full SYNOP = 11

- Custom output = 12

->

Page 30

Instruction Manual

25

STX and ETX are hexadecimal command characters.

Refer to Appendix B for the checksum algorithm.

11.1 Visibility only messages

Basic Format, Visibility Only

STX

Message ID Sensor ID System

status Visibility distance

Visibility units

Checksum (CCITT) ETX

Carriage return Line feed

0x02

0

M or F

XXXX

0x03

0x0D

0x0A

0 0 0 19837 M FC92 (Example message, visibility units = metres)

In the following example messages the shown message intervals are

12 seconds and visibility units are in metres unless otherwise

indicated.

Partial Format, Visibility Only

STX

Message

ID

Sensor ID System status Message interval Visibility distan

ce

Visibility units

User alarms Checksum (CCITT) ETX

Carriage return Line feed

0x02

1

M or F

0 0

XXXX

0x03

0x0D

0x0A

1 0 0 12 20405 M 0 0 EF07 (Example message)

NOTE

NOTE

NOTE

Page 31

CS120A and CS125 Visibility and Present Weather Sensors

26

Full Format, Visibility Only (Default message for CS120A)

STX

Message ID

Sensor ID

System status Message interval Visibi

lity

distance

Visibility units Averaging duration User

alarms

System

alarms 10 charac

ters

Checksum (CCITT) ETX

Carriage return Line feed

0x02

2

M or F

0 0

0 0 0 0 0…

XXXX

0x03

0x0D

0x0A

2 0 0 12 68218 F 1 0 0 0 0 0 0 0 0 0 0 0 0 D378 (Example with Visibility Units = Feet)

2 0 0 12 21793 M 1 0 0 0 0 0 0 0 0 0 0 0 0 CB0F (Example with Visibility Units = Metres)

11.2 Messages with SYNOP Present Weather Codes (CS125 only)

SYNOP Present Weather Basic Format

STX

Message ID Sensor ID System status Visibility distance

Visibility units

SYNOP Code Checksum (CCITT) ETX

Carriage return Line feed

0x02

3

M or F

0-99

XXXX

0x03

0x0D

0x0A

3 0 0 20428 M 0 20B8 (Example message)

SYNOP Present Weather Partial Format

STX

Message ID Sensor ID System status Message interval Visibility distance

Visibility units

User a

larms

Particle

count

(minute)

Intensi

ty (mm/h)

SYNOP Code Tempera

ture (deg C)

Relative humidity* Checksum (CCITT) ETX

Carriage return Line feed

0x02

4

M or F

0 0

0-99

XXXX

0x03

0x0D

0x0A

4 0 0 12 21157 M 0 0 0 0.00 0 24.1 -99 5A55 (Example message)

Page 32

Instruction Manual

27

SYNOP Present Weather Full Format (Default message for CS125)

STX

Message ID Sensor ID System status Message in

terval

Visibili

ty distance

Visibility units

Averaging durat

ion

User alarms

System alarms 12 characters

Particle count (minute) Intensity (mm/h) SYNO

P Code

Temperatu

re (deg C)

Relative humidity* Checksum (CCIT

T)

ETX

Carriage Return Line feed

0x02

5

M or F

0 0

0 0 0 0 0…

0-99

XXXX

0x03

0x0D

0x0A

5 0 0 12 20880 M 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0.00 0 24.1 -99 CAFA (Example message)

11.3 Messages with METAR Present Weather Codes (CS125 only)

METAR Present Weather Basic Format

STX

Message ID Sensor

ID

System status Visibility distance

Visibil

ity

units

METAR Code Checksum (CCITT) ETX

Carriage return Line feed

0x02

6

M or F

XXXX

0x03

0x0D

0x0A

6 0 0 20573 M NSW 291A (Example message)

METAR Present Weather Partial Format

STX

Message ID Sensor ID

System status Message interval Visibility distance Visibility

units

User alarms Particle

count (minute)

Intensity (mm/h) SYNOP

Code

METAR Code Temperature (deg C) Relative hu

midity*

Check

sum

(CCITT) ETX

Carriage

return

Line fe

ed

0x02

7

M or F

0 0

XXXX

0x03

0x0D

0x0A

7 0 0 12 20673 M 0 0 0 0.00 0 NSW 24.2 -99 BD78 (Example message)

Page 33

CS120A and CS125 Visibility and Present Weather Sensors

28

METAR Present Weather Full format

STX

Message ID Sensor ID System status Message inter

val

Visibility distance Visibility units

Averaging duration User alarms

System alarms 12 characters Particle count (minute) Intensity (mm/h) SYNOP Code METAR Code Temperature (

deg C)

Relative h

umidity

*

Checksu

m (CCITT)

ETX

Carriage Return Line feed

0x02

8

M or F

0 0

0 0 0 0 0…

XXXX

0x03

0x0D

0x0A

8 0 0 12 20504 M 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0.00 0 NSW 24.2 -99 40A2 (Example message)

Relative humidity is only available if a CS215 or HygroVUE probe

temperature and RH sensor is attached. If not this field is “-99”.

11.4 Messages with Generic SYNOP Present Weather Codes

(CS125 only)

These messages include simplified, generic present weather codes such as 70 for

snow which may be required for some data collection systems.

Generic SYNOP Present Weather Basic format

STX

Message ID Sensor ID System status Visibility

distance

Visibility

units

Gener

ic SYNOP code

SYNOP code METAR code Checksum

(CCITT)

ETX

Carriage

return

Line feed

0x02

9

M or F

XXXX

0x03

0x0D

0x0A

9 0 0 20481 M 0 0 NSW 73DF (Example message)

*NOTE

Page 34

Instruction Manual

29

Generic SYNOP Present Weather Partial format

STX

Message ID Sensor ID System status Message

interval

Visibility

distance

Visibility units

User alarms Particle count (minute)

Intensity (mm/h) Generic SYNOP code SYNOP code METAR code Temperature (deg

C)

Relative hu

midity (%)

Checksum(CC

ITT)

ETX

Carriage

Return

Line feed

0x02

10

M or F

0 0

XXXX

0x03

0x0D

0x0A

10 0 0 12 20909 M 0 0 0 0.00 0 0 NSW 24.2 -99 AB02 (Example message)

Generic SYNOP Present Weather Full format

STX

Message

ID

Sensor ID System status Message

interval

Visibility

distance

Visibility un

its

Averaging

duration

User alarms

System alarms

Particle count (minut

e)

Intensity (mm/h) Generic SYNOP

code

SYNOP code METAR code Temp

erature (deg

C)

Relative humidity (%) Checksum(CCITT) ETX

Carriage

Return

Line feed

0x02

11

M or F

0 0

0 0 0 0

0…

XXXX

0x03

0x0D

0x0A

11 0 0 12 21342 M 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0.00 0 0 NSW 24.3 -99 9AD6 (Example message)

Page 35

CS120A and CS125 Visibility and Present Weather Sensors

30

Table 11-1. Summary of message IDs and descriptions

Message ID break down

ID

Definition

0

Basic format. Contains only distance and system information

1

Partial format. Contains user alarm outputs

2

Full format. Contains all system alarms codes

3*

Basic SYNOP present weather format

4*

Partial SYNOP present weather format

5*

Full SYNOP present weather format

6*

Basic METAR present weather format

7*

Partial METAR present weather format

8*

Full METAR present weather format

9*

Generic Basic SYNOP present weather format

10*

Generic Partial SYNOP present weather format

11*

Generic Full SYNOP present weather format

12

Custom output

*CS125 only

Sensor ID break down

ID

Definition

0-9

Unit number defined by the user to aid identification of data. Zero by default.

Useful for RS-485 networks. Operates as an address in RS-485 mode

System status break down

(1)

Status level

Definition

0

No fault

1

Possible degraded performance

2

Degraded performance

3

Maintenance required

(1) System status break down reflects the highest level of severity of any active alarm.

Message interval

Time

Definition

1-3600

The amount of time, in seconds, between outputs in continuous mode

Visibility distance break down

ID

Definition

0-75,000 metres

Current visibility distance being detected by the sensor

Visibility units break down

ID

Definition

M

Metres

F

Feet

Averaging duration break down (see note)

ID

Definition

1

One minute average

10

Ten minute average

Page 36

Instruction Manual

31

In accordance with WMO requirements the sensor produces

visibility measurement that are either one or ten minute rolling

averages that are updated at the chosen output interval or when the

sensor is polled. Those averages are not direct averages of MOR

measurements but are averages of extinction coefficient and that

average is then used to calculate the MOR for that period. As the

relationship between extinction coefficient and MOR is not linear it

is possible to see quite rapid changes in MOR that might not be

expected if the result was a rolling average of MOR. Please consider

this, especially when testing the sensor with artificial obscurants or

using the calibration disc.

User alarms

ID

Range

Definition

1

0-1

Visibility either less or greater than a user specified threshold

2

0-1

Visibility either less or greater than a user specified threshold

Table 11-2. Summary of system alarms and descriptions

System alarms break down

Alarm

Range

Severity

Definition

Emitter failure

(emitter hoods

main LED

output power

level)

0-2

0

3

3

0 = Everything is within normal parameters

1 = Light output level too low

2 = Light output level too high

Emitter lens

dirty

(1)

0-3

0

3

1

2

0 = OK. The reported attenuation is below 10%

1 = Reported window signal value is out of range (>30%)

Possible sensor fault or hood could be blocked

2 = Slight dirt build up (10% signal attenuation or higher)

3 = High level of dirt build up (>20%)

Emitter

temperature

0-3

0

1

1

3

0 = Temperature is within operating conditions

1 = Too low. Less than -40°C

2 = Too high. Over 80°C

3 = No sensor detected or below -54°C

Detector lens

dirty

(1)

0-3

0

3

1

2

0 = OK. The reported attenuation is below 10%

1 = Reported window signal value is out of range (>30%)

Possible sensor fault or hood could be blocked

2 = Slight dirt build up (10% signal attenuation or higher)

3 = High level of dirt build up (>20%)

Detector

temperature

0-3

0

1

1

2

0 = Temperature is within operating conditions

1 = Too low. Less than -40°C

2 = Too high. Over 80°C

3 = No sensor detected or below -54°C

Detector DC

saturation

level (amount

of background

light seen by

the detector

hood)

(1)

0-1

0

2

0 = Within limits

1 = Saturated. The sensor may not be able to perform visibility

readings in some circumstances. Possibly due to high level of

reflections into the detector.

NOTE

Page 37

CS120A and CS125 Visibility and Present Weather Sensors

32

System alarms break down

Alarm

Range

Severity

Definition

Hood

temperature

0-3

0

1

1

2

0 = Temperature is within operating conditions

1 = Too low. Less than -40°C

2 = Too high. Over 80°C

3 = No sensor detected or below -56°C

External

temperature

(CS125 only)

0-3

0

1

1

2

0 = Temperature is within operating conditions

1 = Too low. Less than -40°C

2 = Too high. Over 80°C

3 = No sensor detected or below -54°C

Signature

error

0-4

0

3

2

2

3

0 = No fault

1 = OS signature error at power up

2 = User memory signature did not match when last read

3 = User memory fault at power up. Secondary copy was

reinstated to correct error.

4 = User memory fault at power up. No secondary copy was

found to reinstate. Factory defaults have been reinstated.

System will need re-calibrating

Flash read

error

0-1

0

3

0 = No errors

1 = One or more errors reading user variables from flash

occurred

Flash write

error

0-1

0

3

0 = No errors

1 = One or more errors writing user variables to flash occurred

Particle limit

(CS125 only)

0-1

0

1

0 = No errors

1 = More particles detected than can be processed

(1)

With operating system 14 onwards, to avoid short term appearance of alarms caused by transient

events, such as insects or raindrops on the lens, the condition which triggers an increase in alarm level

must persist for 15 minutes before the alarm is set.

Errors are checked every 10 seconds and the next message output is updated with

the following exceptions:

Signature error is checked and reset at power up.

Flash read and write errors are checked when flash memory is updated, for

example when changes are made through the memory structure. They are also

reset on power up.

Particle limit is checked every minute and reset when read.

Particle count*

Range

Definition

0-7200

Value represented by an integer number of the current number of particle per minute.

(-99 indicates either an error or that the sensor has been powered less than one minute)

Intensity value*

Range

Definition

0 - 999.99

Value represented by a single precision value of the last minutes rainfall intensity in

mm/hr (-99 indicates either an error or that the sensor has been powered up less than

one minute)

SYNOP code*

Range

Definition

See Appendix C

SYNOP weather code for the last minute as defined by the WMO code table 4680.

(-1 indicates either an error or that the sensor has been powered up less than one

minute)

Page 38

Instruction Manual

33

Generic SYNOP code*

Range

Definition

See Appendix C

SYNOP weather code for the last three minutes as defined by the WMO code table

4680 simplified to give generic codes. (-1 indicates either an error or that the sensor

has been powered up for less than one minute)

METAR code*

Range

Definition

See Appendix C

METAR weather code for the last minute as defined by the WMO code table 4678.

External temperature*

Range

Definition

-40.0 - +80.0°C

External temperature in degrees Celsius

Relative humidity*

Range

Definition

0 - 100

External relative humidity in %RH (-99 indicates either a fault or no CS215 or

HygroVUE T/RH sensor is connected)

*CS125 only, see Appendix C.

11.5 Example sensor message outputs

Full format, visibility only (CS120A default)

2 0 0 10 9622 M 1 0 0 0 0 0 0 0 0 0 0 0 0 46AA

SYNOP present weather full format (CS125 default)

5 0 0 10 112 M 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 6 0.14 52 24.0 -99 9190

METAR present weather full format

8 9 0 60 6682 M 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 54 4.5 63 +RA 20.2 91 ABCD

Where:

9 is the sensor id

60 is the message interval (60 seconds)

6682 is the visibility in metres

M is the visibility units (metres)

54 is particle count

4.5 is intensity (4.5 mm/hr)

63 is the SYNOP code (heavy rain)

+RA is the METAR code (heavy rain)

20.2 is the temperature (20.2 deg. C)

91 is the RH (91%)

ABCD is the checksum

Page 39

CS120A and CS125 Visibility and Present Weather Sensors

34

11.6 Custom message format

Once a custom message has been formatted it can be output by selecting option 12

from the message - sub 3 menu.

The custom message format allows the CS120A/CS125 message to be modified to

meet particular requirements. The custom message contains a fixed basic set of

variables and up to 16 additional fields.

The custom message output is only available on OS7 and above.

The custom message is as follows:

Custom format

STX

Message ID Unit ID System status

Message

interv

al

Visibility

distance

Visibility

units

Up to 16

custom f

ields

Checksum

EOT

0x02

12

M or F

X X X …

XXXX

0x04

There are two ways to configure the custom message. The first is through the user

menu system. The second is through the use of logger commands. These logger

commands are MSGSET and MSGGET.

To configure the message using the user menu you will need to enter the sensor

menu system, see the following and Section 15. Entering the sensor menu system.

Return to the message menu 1 and select option 7. You will now be presented

with the list of options shown below:

NOTE

CS125 MESSAGE - SUB 3

Set the message output format. Current format is: FULL SYNOP

- Basic = 0

- Partial = 1

- Full = 2

- Basic SYNOP = 3

- Partial SYNOP = 4

- Full SYNOP = 5

- Basic METAR = 6

- Partial METAR = 7

- Full METAR = 8

- Generic Basic SYNOP = 9

- Generic Partial SYNOP = 10

- Generic Full SYNOP = 11

- Custom output = 12

->

Page 40

Instruction Manual

35

12 0 0 1 0 92 M1 000000000000 2 0 3 0 92 135 88EF

Menu 1: The message output menu

This will take you to message sub 4 so that the parameters required can be

selected from the available options to configure the message output format;

Enter the number of a custom message field you wish to use and type return. The

screen will update with a 1 next to the chosen field. Repeat for each field you

want then exit the menu. The changes take effect after selecting “Exit and Save”

from the main menu.

Example

In the following example selecting options 1, 3, 4, 10, 15 and 17 puts averaging

duration, system alarms, dirty windows values, SYNOP code, 10 minute average

visibility, and 1 sec visibility into the custom message.

This would give the following output:

Above the custom fields are “1 000000000000 2 0 30 92 135”. The averaging

duration is 1 minute, no system alarms are set, the emitter is reading 2%

contamination, the detector is reading 0% contamination, the SYNOP code is 30,

the 10 minute average visibility is 92 m and the 1 sec reading is 135 m.

CS125 MESSAGE - SUB 4

Configure the message output format:

1 - Averaging duration = 0

2 - User alarms = 0

3 - System alarms = 0

4 - Dirty windows values = 0

5 - Sensor serial number = 0

6 - Particle count = 0

7 - Intensity = 0

8 - Accumulation = 0

9 - Generic SYNOP = 0

10 - SYNOP code = 0

11 - METAR code = 0

12 - NWS code = 0

13 - Temperature (Degrees C) = 0

14 - Humidity (%) = 0

15 - 10 minute ave. vis. = 0

16 - Special 1 = 0

17 - One second vis = 0

18 - Past SYNOP = 0

19 - EXCO = 0

Or, choose 0 to exit when done.

->0

CS125 MESSAGE - MENU 1

ID 0

S/N E1007

(1) Set message format: FULL METAR

(2) Toggle units: METRES

(3) Toggle polled or continuous mode: CONTINUOUS

(4) Set continuous mode message-interval: 1 second(s)

(5) Toggle output averaging period: 1 minute(s)

(6) Sampling interval: 1 second(s)

(7) Configure custom message format

(9) Refresh

(0) Return to main menu

Page 41

CS120A and CS125 Visibility and Present Weather Sensors

36

The following describes the number of values output.

List of custom output values

Field

Description

Number of

values output

1

Averaging duration

1

2

User alarms

2

3

System alarms

12 4 Dirty windows values, as percentages, emitter followed by detector

2

5

Sensor serial number

1

6

Particle count

(1)

, particles in the previous minute

1 7 Intensity

(1)

, mm/hr

1

8

Accumulation

(1),(2)

1

9

Generic SYNOP

(1)

1

10

SYNOP code

(1)

1

11

METAR code

(1)

1

12

NWS code

(1)

1

13

Temperature (degrees C)

(1)

1

14

Humidity (%)

(1)(3)

1

15

Visibility averaged over the last 10 minutes

1

16

Special 1 (reserved)

1

17

One second visibility

(4)

1

18

Past SYNOP

1

19

EXCO

1

(1) These options are only available with a CS125.

(2) This increments to 999.99 mm before resetting to zero. It may be reset to zero at any time with the ACCRES command.

(3) Only outputs a valid value when a CS215/HygroVUE temperature and humidity probe is connected.

(4) The 1 second visibility output is provided ffor special applicationsand research purposes only. This output will have increased noise

levels especially at high visibilities.

12. Interface methods – Device Configuration Utility/Command line/Menu

The sensor can be set up and controlled in one of three ways.

The first method is by using Campbell Scientific’s Device Configuration Utility

Software (DevConfig) which is included with each delivery on the manuals/

resource disk. This software allows an easy menu driven interface for configuring

the sensor on any Microsoft™ based personal computer. All settings can be

accessed using this program.

The program includes online help instructions that describe its general use with

the sensor and also how to load an operating system.

The Device Configurator can also be used as a terminal emulator to use the builtin menu system of the sensor and to access its calibration menu.

The second method is by using the command line interface where discrete

commands are sent without response from the sensor. This would be the preferred

Page 42

Instruction Manual

37

method of setting up a sensor if it was connected to a logger for instance. The

configuration setting commands can be sent via a logger to the sensor removing

the need for a local PC to set up the unit.

The third method is by using the simple menu interface built into the sensor

communicating via RS-232 or RS-485, using a terminal emulator program. This

menu system gives access to the more common settings.

All three of these methods use the sensor’s serial connector B to communicate

with the sensor. This can be via the normal communications cable or a

configuration cable as described in Section 8.1.

12.1 Configuring a PC for talking to the sensor

The following describes the procedure for setting up communications using a

terminal emulator program. The terminal emulators built into many Campbell

Scientific software products can also be used.

The following settings should then be used by default:

Bits per second: 38400

Data bits: 8

Parity: none

Stop bits: 1

Flow control: none

Ensure that if the baud rate of the unit has been adjusted and then the

corresponding bits per second value is entered in the port settings of the terminal

emulator. The sensor should now be ready to accept commands.

It is possible to set the sensor into the default communication state via one of the

internal switches on the sensor main board. See Section 9.

13. Definition of the variables that can be set by the user on the sensor

Both DevConfig and the command line interface can access all the user

configurable variables within the sensor. The following lists the acceptable range

and the identification number for these variables along with a short description.

Table 13-1. User definable settings and descriptions

ID

Name

Range

Description

Factory

default

1

Sensor ID

0-9

Separate ID used as an extra identifier for a

particular sensor on a network.

0

2

User Alarm 1 Enabled

0-1

User alarm one activation state

0 = Alarm one disabled

1 = Alarm one enabled

0

3

User Alarm 1 Active

0-1

0 = Check if distance is less than ‘User alarm 1

Distance’

1 = Check if distance is greater than ‘User alarm

1 Distance’

0

Page 43

CS120A and CS125 Visibility and Present Weather Sensors

38

Table 13-1. User definable settings and descriptions

ID

Name

Range

Description

Factory

default

4

User Alarm 1 Distance

060000

Distance value that alarm one will trigger against.

This value will correspond to metres or feet

depending upon which is selected in ‘Visibility

Unit’

10000

5

User Alarm 2 Enabled

0-1

User alarm two activation state

0 = Alarm two disabled

1 = Alarm two enabled

0

6

User Alarm 2 Active

0-1

0 = Check if distance is less than ‘User alarm 2

Distance’

1 = Check if distance is greater than ‘User alarm 2

Distance’

0

7

User Alarm 2 Distance

060000

Distance value that alarm one will trigger against.

This value will correspond to metres or feet

depending upon which is selected in ‘Visibility

Unit’

10000

8

Baud rate

0-6

Baud rate for the main RS-232/RS-485 interface

0 = 115200 bps

1 = 57600 bps

2 = 38400 bps

3 = 19200 bps

4 = 9600 bps

5 = 2400 bps

6 = 1200 bps

2

9

Serial number

-

Internal serial number for the sensor.

(Read only)

-

10

Visibility Unit

M or F

Unit the visibility value will be presented as

M = metres

F = feet

M

11

Message Interval

1-3600

Interval in seconds between outputs in continuous

mode. This value has no effect if polled mode has

been selected in ‘Measurement mode’

60

12

Measurement mode

0-1

Selects polled or continuous modes.

In continuous mode the sensor will output a string

in the format as set by ‘Message Format’ at

regular intervals as defined by ‘Continuous

Interval’.

0 = Continuous mode

1 = Polled mode

0

13

Message Format

0-12

Output message

0, 1 and 2 = Basic, partial or full visibility

messages

3, 4 and 5 = Basic, partial or full SYNOP

messages

6, 7 and 8 = Basic, partial or full METAR

messages

9, 10 and 11 = Generic basic, partial or full

SYNOP messages

12 = Custom message

5

14

Serial port protocol

0-1

Selects the physical serial interface

0 = RS-232 mode

1 = RS-485 mode

0

15

Averaging period

1 or 10

The period of time that the visibility measurement

is averaged over. Either one minute or ten.

1

Page 44

Instruction Manual

39

ID

Name

Range

Description

Factory

default

16

Sample timing

1-60

Used to define the time interval between sampling

the volume. It is recommended that this value is

left at one except when very low power demands

are needed. Note that 1s sample timing is needed

for present weather measurement. For example:

1 = Sample every second

2 = Sample one second in every two

3 = Sample one second in every three etc.

1

17

Dew heater override

0-1

0 = Allow the sensor to automatically control the

dew heaters

1 = Turn the dew heaters off

0

18

Hood heater override

(1)

0-1

0 = Allow the sensor to automatically control the

hood heaters

1 = Turn the hood heaters off

0

19

Dirty window

compensation

0-1

0 = No compensation applied

1 = Compensation for dirt on lenses applied.

The sensor will compensate for up to 10% signal

loss due to dirt per lens.

0

20

Use CRC-16

0-1

0 = Disable command line CRC-16 checking

(2)

1 = Enable command line CRC-16 checking

Note: this does not affect communications via

DevConfig or terminal emulator.

0

21

Sensor power down

voltage

7-30

PSU Input voltage level below which the sensor

will enter low power mode. This is usually used to

protect batteries.

7.0

22

Relative humidity

(3)

threshold

1-99

Threshold at which the sensor will define

obscuration as liquid or dry if a CS215 is fitted.

80%

(1) Hood heater override needs to be set to ‘1’ (off) when either no hood heaters are installed or

the hood heaters have no power connected to them. This will save power as the relay is not

enabled at low temperatures in this mode.

(2) If disabled the sensor does not check the validity of received data against the checksum sent.

It is, however, recommended that checksum checking is enabled to remove any chance of the

sensor being configured incorrectly by accident.

(3) CS125 only.

14. Command line mode

The command line interface is broken down into three major commands. These

are GET, SET and POLL. The GET command is used to request all current user

settable values from the sensor. The SET commands sets user settable values and

the POLL command is used to request the current visibility and/or alarm

conditions from the sensor.

The sensor can be configured to expect any commands sent to it to include a valid

checksum. For simple commands, e.g. GET and POLL, fixed value checksums

can be used (see the downloadable example programs at:

www.campbellsci.com/downloads/cs125-example-programs or

www.campbellsci.com/downloads/cs120a-example-programs ).

For more complex SET commands the checksum needs to be calculated (see

Appendix B). The use of the checksum is disabled by default. It is recommended

that the checksum functionality is enabled where possible, especially when long

cable runs are used, or in electronically noisy environments.

Page 45

CS120A and CS125 Visibility and Present Weather Sensors

40

14.1 The SET Command

The set command is used to configure the sensor via the command line. The SET

command is a single space delimited string that can be sent from any data logger

or PC equipped with serial communications. The SET command and the ‘Device

Configuration Utility’ software access identical settings within the sensor, please

refer to the ‘Device Configuration Utility’ section of this document for a more

detailed breakdown of the setting available here. This command is used to change

the default power up state of the sensor. See Section 14.2 if a setting is going to be

changed on a regular basis e.g. heater controls.

See Section 12 for more information on the values used by the ‘SET’ command.

SET transmitted data

Example

Description

0x02

(1)

STX ^ B

(2)

SET

SET

:

Delimiting character

Current Sensor ID

:

Delimiting character

Sensor ID (may be a new ID)

User Alarm 1 Set

User Alarm 1 Active

User Alarm 1 Distance

User Alarm 2 Set

User Alarm 2 Active

User Alarm 2 Distance