Page 1

CS110 Electric Field Meter

Revision: 4/12

Copyright © 2005-2012

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell product manual. Batteries, fine-wire thermocouples, desiccant, and

other consumables have no warranty. Campbell's obligation under this

warranty is limited to repairing or replacing (at Campbell's option) defective

products, which shall be the sole and exclusive remedy under this warranty.

The customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any Campbell

products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages. In no event will CAMPBELL

SCIENTIFIC, INC. have liability in excess of the purchase price for the

CS110. CAMPBELL SCIENTIFIC, INC. does not warrant that the CS110 will

meet customer’s requirements or that its operation will be uninterrupted or

error-free. Atmospheric or local electric field conditions or different site

characteristics may cause false information, late data, or otherwise incomplete

or inaccurate data. Site correction and warning threshold levels are the

responsibility of the user. The user is responsible to set time since a threshold

was passed to clear an alarm, because these threshold levels may vary with

sensitivity to nature of risk (e.g., handling explosives) and cost of disruption

with an alarm (playing golf vs. fueling airplanes). The CS110 only measures

conditions that make lightning more likely. Just as with weather forecasts,

CS110 measurements only help assess the probability of lightning. Lightning

can occur causing personal injury, even death, or damage to property without

any warning from the CS110.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9579. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

CS110 Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. General Description.....................................................1

1.1 CS110 Introduction...................................................................................1

1.2 CR1000 Datalogger ..................................................................................2

1.3 Meteorological Inputs...............................................................................2

1.4 Communication and Data Storage ............................................................2

1.5 Digital I/O.................................................................................................3

1.6 Self-Check Features..................................................................................3

2. CS110 Specifications ..................................................4

3. CS110 Measurement Details....................................... 7

4. Site Requirements and Recommendations...............9

4.1 Power Requirements.................................................................................9

4.2 Campbell Scientific, Inc. Power Supplies ..............................................10

4.3 Communication Options.........................................................................10

4.4 Site Recommendations ...........................................................................11

5. Factory Calibration and Site Correction..................11

5.1 Factory Calibration .................................................................................11

5.2 Site Correction........................................................................................14

6. Lightning Warning ..................................................... 19

7. CRBasic Programming.............................................. 21

8. CS110 Measurement Instructions ............................ 25

8.1 CR1000 Measurement Overview............................................................25

8.2 Measuring Electric Field.........................................................................27

8.3 Measuring Electric Field Change ...........................................................27

8.4 Measuring Solar Radiation or Barometric Pressure................................27

8.5 Measuring Air Temperature and Relative Humidity ..............................28

8.6 Measuring Wind Speed and Direction....................................................28

8.7 Measuring Rainfall .................................................................................29

8.8 Measuring Internal Case Humidity.........................................................29

9. PC Software................................................................29

9.1 Quick Start..............................................................................................29

i

Page 6

CS110 Table of Contents

10. Maintenance .............................................................33

11. References................................................................40

Appendices

A. CS110 Measurement Status Codes ....................... A-1

B. CS110 Accessories ................................................. B-1

10.1 Checking Site Ground Integrity ........................................................... 33

10.2 Corrosion and Rust Inhibitors.............................................................. 33

10.3 Self-Check Features ............................................................................. 35

10.4 Cleaning the CS110 Electrode Head.................................................... 36

10.5 Changing Desiccant ............................................................................. 37

10.6 Checking Shutter/Encoder Alignment ................................................. 39

10.7 Re-Calibration...................................................................................... 40

B.1 Zero Field Cover Plate ........................................................................ B-1

B.2 Upward-Facing Site Calibration Kit.................................................... B-1

B.3 CR1000 Keyboard Display ................................................................. B-1

B.4 Miscellaneous Peripheral Modules...................................................... B-1

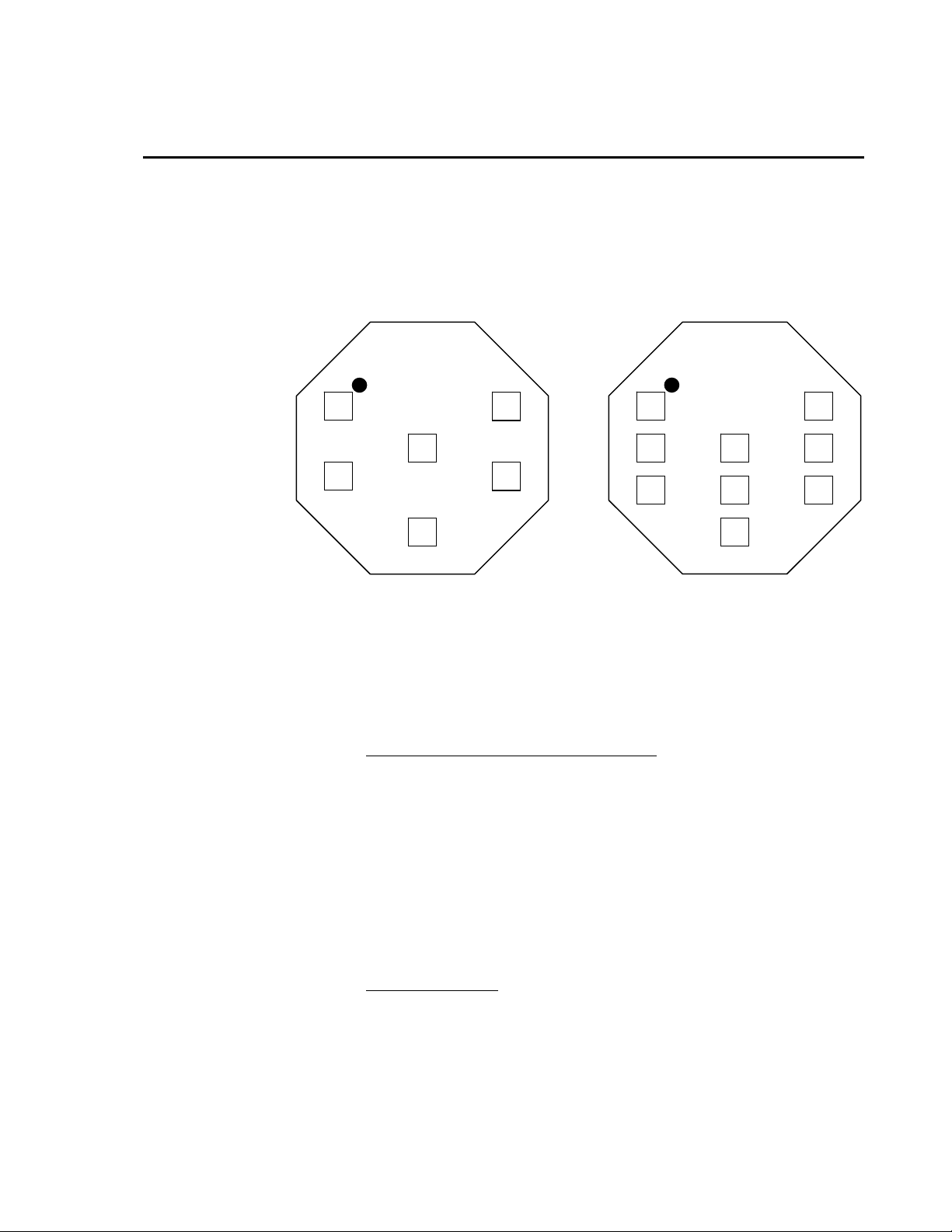

C. CS110 Connector Pin-outs .....................................C-1

D. Servicing the CS110................................................ D-1

D.1 Lid Gasket........................................................................................... D-1

D.2 Changing Out the CR1000.................................................................. D-1

D.3 Changing Out Motor Assembly .......................................................... D-2

D.4 Changing Out the CS110 Panel Board Assembly............................... D-2

D.5 Shutter/Encoder Alignment................................................................. D-3

D.6 Motor O-ring Seal ............................................................................... D-6

E. CS110 as a Slow Antenna....................................... E-1

E.1 Response of the CS110 Slow Antenna in the Frequency Domain .......E-1

E.2 Response of the CS110 Slow Antenna in the Time Domain................E-3

E.3 Programming ........................................................................................E-5

E.4 Calibration ............................................................................................E-6

F. Example CRBasic Programs .................................. F-1

G. CS110 2 Meter CM10 Tripod Site ...........................G-1

ii

Page 7

CS110 Table of Contents

H. Tripod CS110 and StrikeGuard Site....................... H-1

H.1 Tripod CS110 and StrikeGuard .......................................................... H-1

H.1.1 Installation of the Tripod CS110 and StrikeGuard site............. H-2

H.1.2 Determination of Csite .............................................................. H-7

Figures

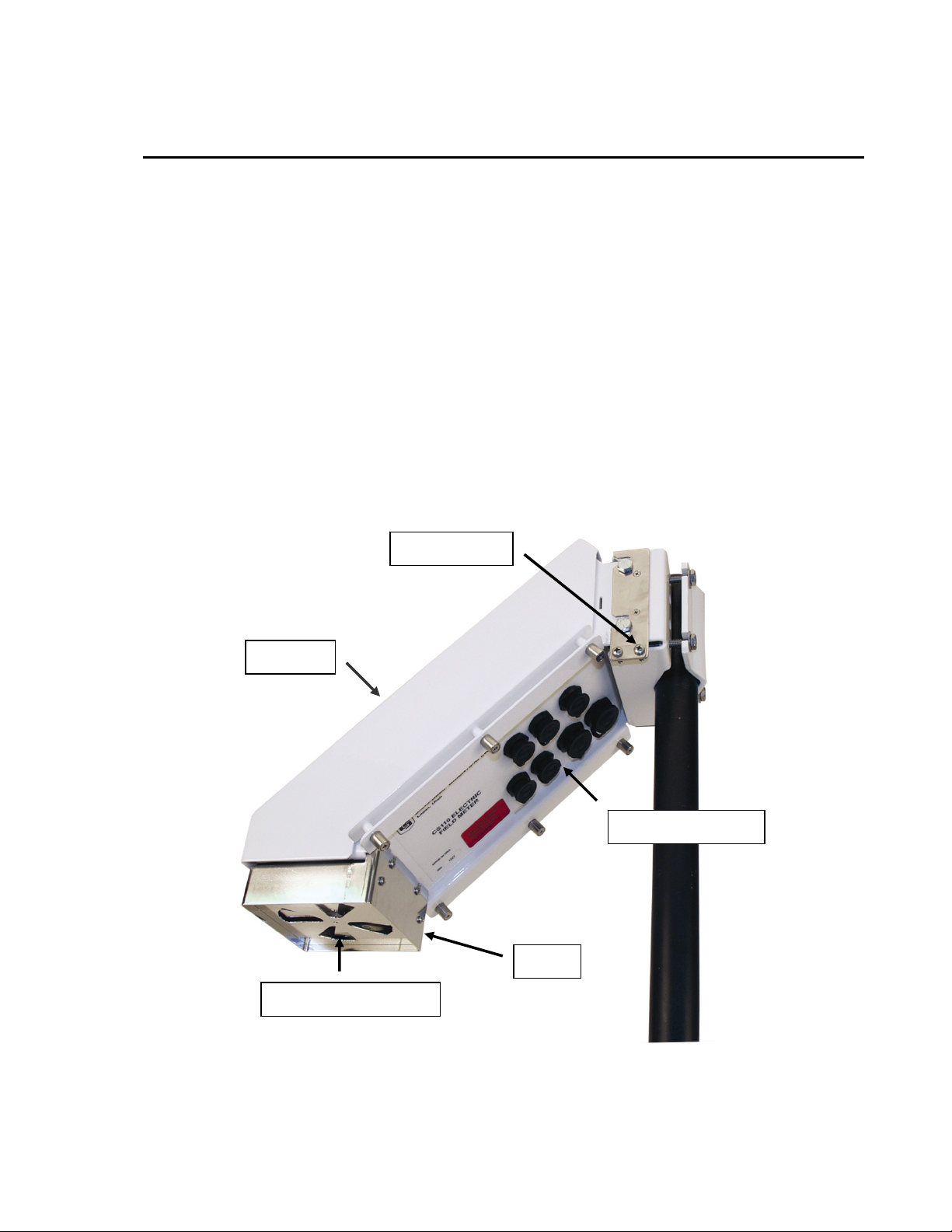

1. CS110 Electric Field Meter ........................................................................1

2. Charge amplifier circuitry of reciprocating electric field meter .................7

3. Charge amplifier output during an electric field measurement cycle .........8

4. CS110 average current consumption versus measurement interval..........10

5. Parallel-plate electric field meter calibration chamber ..............................12

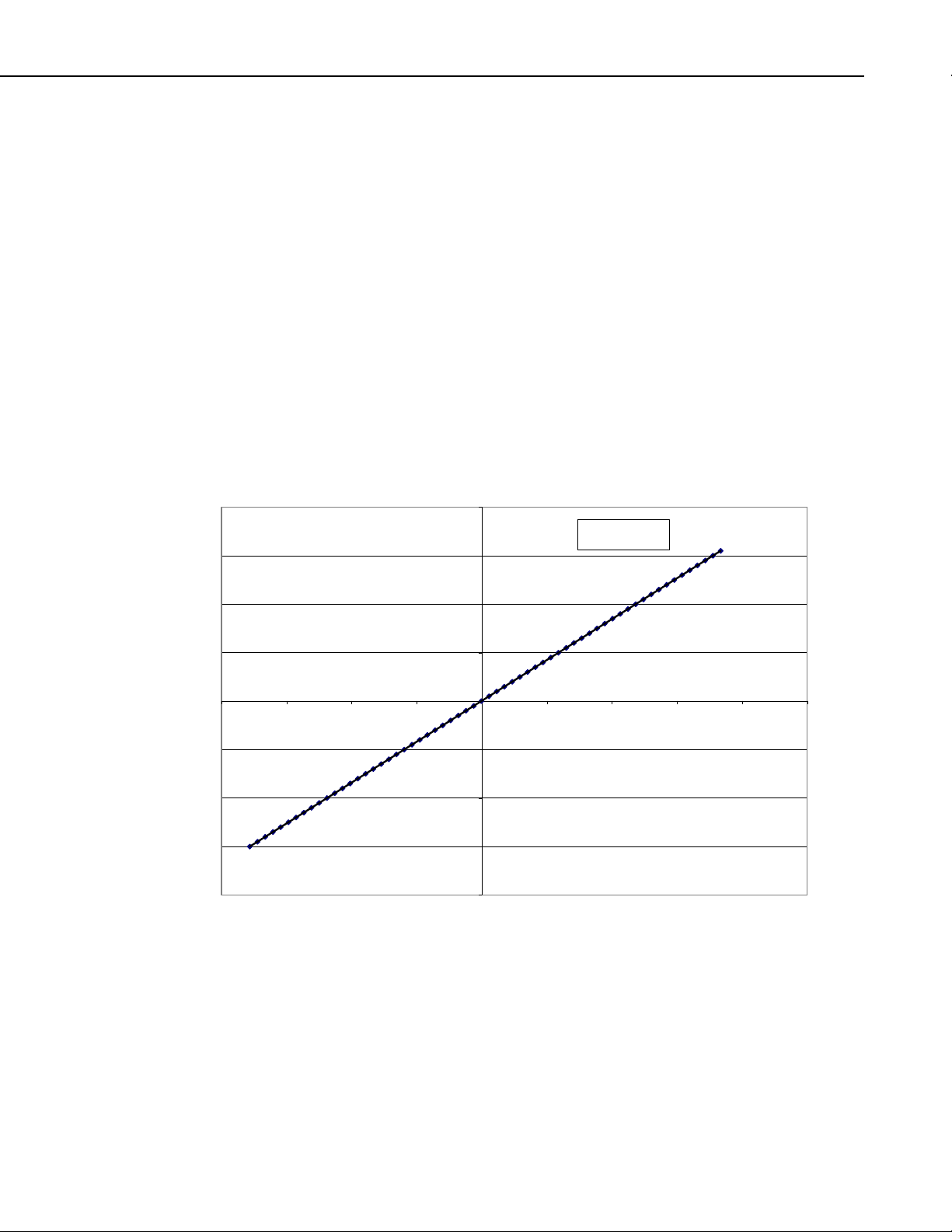

6. Factory calibration data for CS110 SN: 1026...........................................13

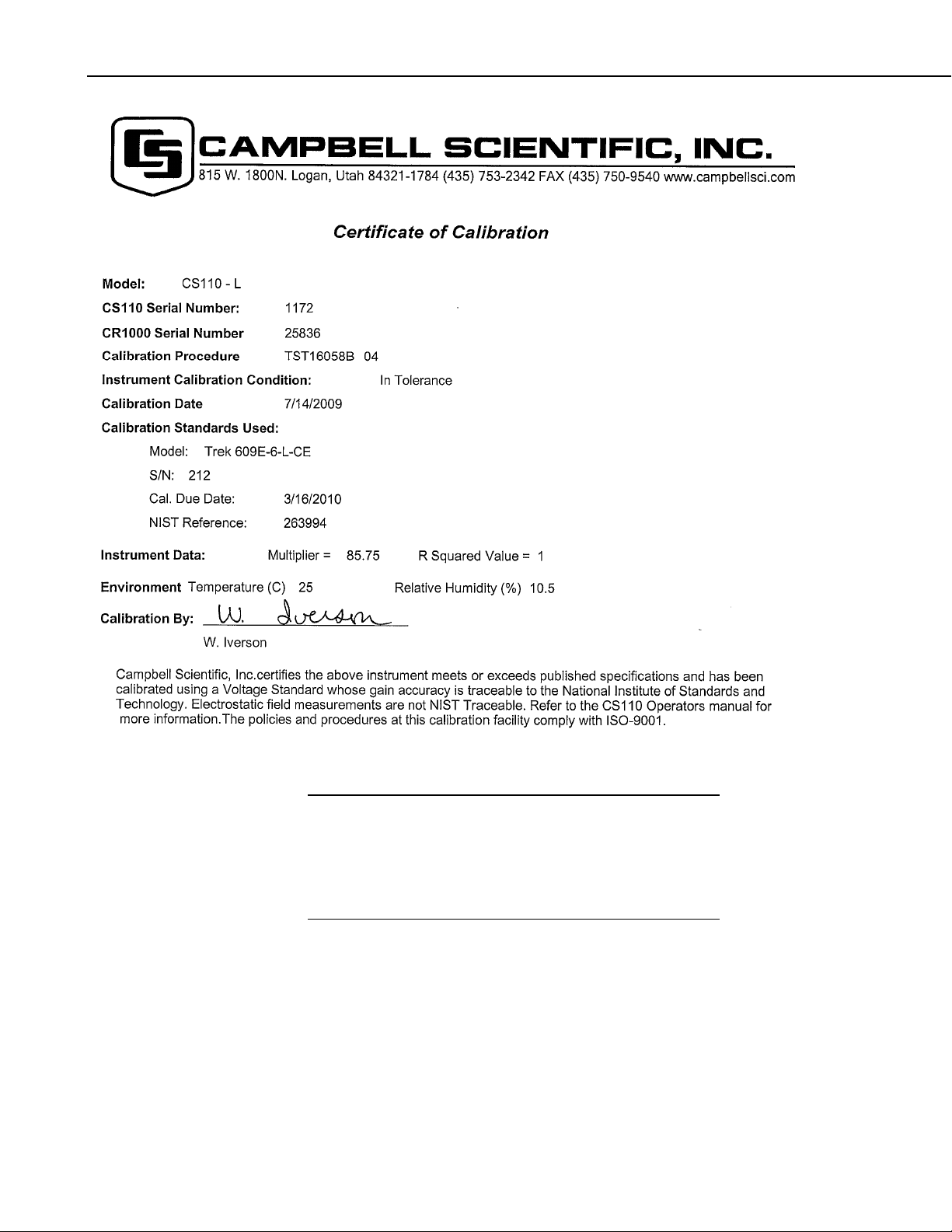

7. NIST calibration certificate ......................................................................14

8. CS110 2 Meter CM10 Tripod Site............................................................15

9. Campbell Scientific, Inc. electric field meter site correction facility........16

10. CS110 attached to upward-facing flush-mounted plate for site

correction ...........................................................................................17

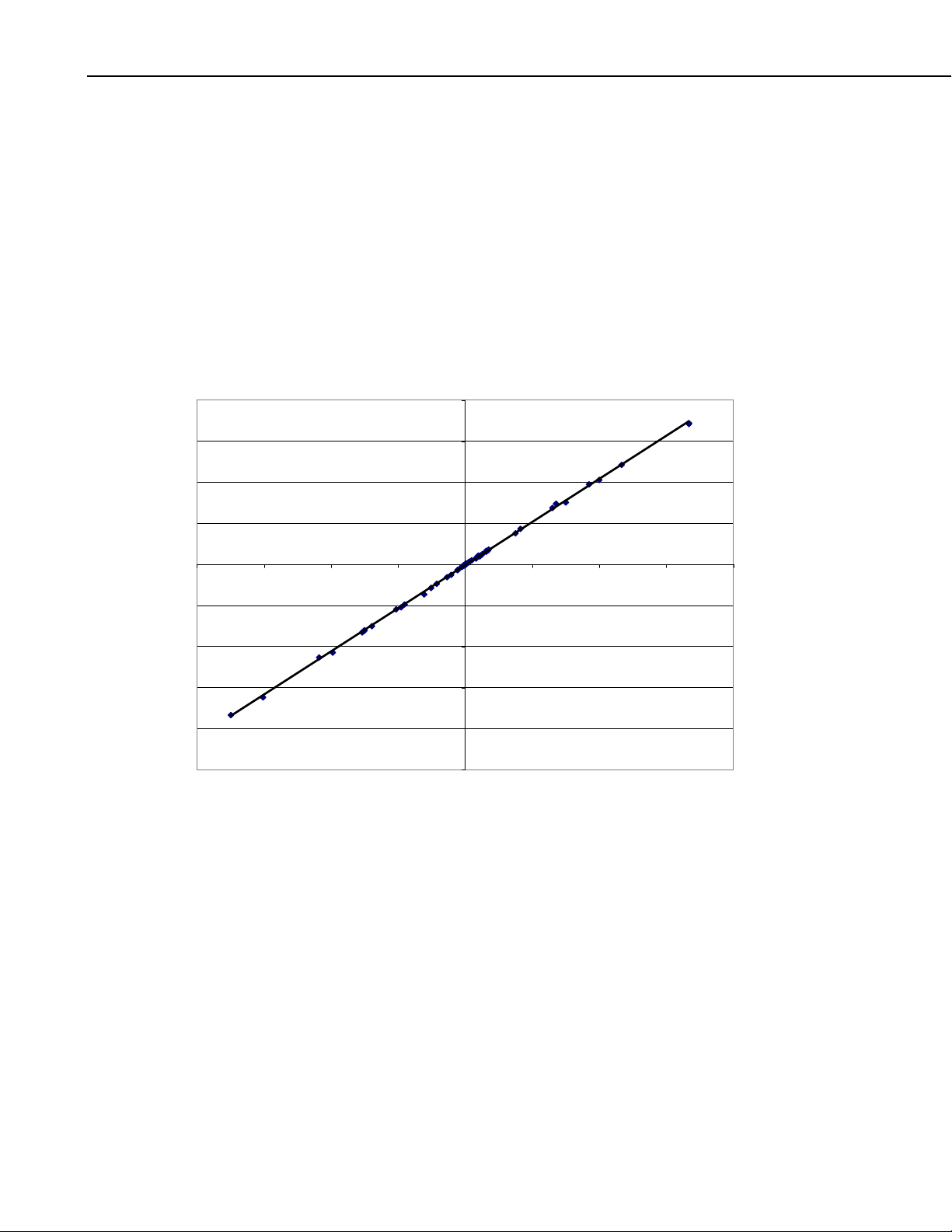

11. Site correction data for CS110 2 Meter CM10 Tripod Site....................18

12. Electric field measured with CS110 during local thunderstorm.............20

13. CS110 stator, shutter and sense electrode...............................................36

14. Inside of CS110 case illustrating bracket for holding desiccant.............38

D-1. Exploded View of CS110 Electric Field Meter................................. D-1

D-2. CS110 Motor Assembly .................................................................... D-5

E-1. CS110 slow antenna frequency response............................................ E-2

E-2. KSC electric field and CS110 slow antenna data................................E-3

E-3. KSC electric field change and CS110 slow antenna data ................... E-4

G-1. CS110 2 Meter CM10 Tripod Site .................................................... G-1

G-2. CS110 on CM10 Tripod Mast ........................................................... G-3

G-3. Earth Grounding ................................................................................ G-4

G-4. Determination of Csite ...................................................................... G-5

H-1. Tripod CS110 and StrikeGuard......................................................... H-1

H-2. CS110 and StrikeGuard on Tripod Mast ........................................... H-3

H-3. Grounding the CS110 Grounding Strap ............................................ H-4

H-4. Grounding the Tripod and Battery .................................................... H-5

H-5. Connections for Combined System ................................................... H-6

H-6. Determination of Csite ...................................................................... H-7

iii

Page 8

CS110 Table of Contents

iv

Page 9

CS110 Electric Field Meter

1. General Description

1.1 CS110 Introduction

Case Lid

Atmospheric electric fields have been measured for decades by electric field

meters nicknamed “field mills”. Traditional field mills employ a spinning

meters nicknamed “field mills”. Traditional field mills employ a spinning

metal rotor (vane) electrically connected to Earth ground, placed between the

metal rotor (vane) electrically connected to Earth ground, placed between the

external field and stationary metal sense electrodes. The grounded spinning

external field and stationary metal sense electrodes. The grounded spinning

rotor alternately shields and exposes the sense electrodes from the electric field

rotor alternately shields and exposes the sense electrodes from the electric field

to be measured, resulting in a modulation of the induced charge on the sense

to be measured, resulting in a modulation of the induced charge on the sense

electrodes. Typically, a pair of charge amplifiers converts the modulated

electrodes. Typically, a pair of charge amplifiers converts the modulated

charge into AC voltages that are synchronously rectified and filtered to form a

charge into AC voltages that are synchronously rectified and filtered to form a

low-frequency voltage proportional to the low-frequency (≤10 Hz) electric

low-frequency voltage proportional to the low-frequency (≤10 Hz) electric

field.

field.

Ground Strap

easured for decades by electric field

Reciprocating Shutter

FIGURE 1. CS110 Electric Field Meter

Sealed Connectors

Stator

1

Page 10

CS110 Electric Field Meter

1.2 CR1000 Datalogger

1.3 Meteorological Inputs

Unlike traditional rotating vane field mills, the CS110 uses a reciprocating

shutter. A stepper motor opens and then closes the reciprocating shutter by 45°

during measurements. The reciprocating shutter is electrically connected to

ground potential by a flexible stainless-steel strap operated below its fatigue

limit, resulting in an ultra-reliable electrical ground connection. The CS110

offers improved dc error performance, as compared with traditional rotating

vane field mills, by utilizing a zero field (closed shutter) reference for each

measurement. Power consumption is also reduced (< 1 Watt for 1

measurement per second) in the CS110 by de-energizing the motor coils in

between measurements.

The CS110 contains an embedded CR1000 datalogger, which provides

measurement and control functions, data processing and storage, a user

interface language (CRBasic™), and flexible communications options.

LoggerNet™ PC software (purchased separately) provides versatile networking

and data collection capabilities. For more details on the CR1000 datalogger

see the CR1000 Measurement and Control System Operator’s Manual.

The CS110 interfaces to various meteorological sensors resulting in an

automated weather station that includes atmospheric electric field. Wind speed

and direction, air temperature and relative humidity, rainfall, solar radiation or

barometric pressure sensors interface directly to the CS110. Measurement

details of the various sensors are given in section 7.

1.4 Communication and Data Storage

The circular RS-232 connector on the underside of the CS110 can be used to

interface directly to RS-232 devices (DTE or DCE), utilizing the CS110

RS-232 cable (CS110CBL1-L).

The circular CS I/O connector on the underside of the CS110 can be used to

interface directly to various Campbell Scientific, Inc. peripherals, utilizing the

CS110 CS I/O cable (CS110CBL2-L). Examples of CS I/O peripherals include

the CR1000 Keyboard Display and the COM220 phone modem.

The DB9 end of CS110 RS-232 cable and CS110 CS I/O cable won’t fit through

the conduit used on some enclosures, whereas the smaller circular end that

connects to the CS110 will.

The embedded CR1000 will have either 2 MB (PN: 18292) or 4 MB (PN:

18293) of battery-backed SRAM and 16K Flash EEPROM. The operating

system and user programs are stored in Flash EEPROM. Memory not used by

the operating system and user program is available for data storage. The size

of available memory can be seen in the Status Table discussed in Appendix B

of the CR1000 manual.

2

Page 11

1.5 Digital I/O

Three general purpose 0 to 5 V digital I/O lines are available on the CS110

Power cable (CS110CBL3-L) that attaches to the circular power connector on

the underside of the CS110. The blue, yellow, and green wires connect to

control ports C1, C2, and C3 respectively. Using CRBasic, these digital I/O

lines can be used to conditionally turn on alarms, provide an interrupt or pulsed

signal to be measured by the CS110, or as a serial communication port.

1.6 Self-Check Features

The CS110 has been designed to provide reliable electric field measurements

and to minimize and simplify maintenance. The CS110 incorporates extensive

self-checking for each measurement in an effort to identify measurement

problems and reduce or eliminate scheduled maintenance. The status code

returned from each electric field measurement reports on instrument health

along with any measurement problems as described in Appendix A.

For example, insulator leakage current is measured during each electric field

measurement, indicating the cleanliness of electrode insulators. A leakage

current compensation circuit for the charge amplifier input is incorporated in

the CS110 to minimize the effects of insulator leakage current on measured

results (Patent pending). A status code indicating excessive leakage current is

returned if the measured input leakage current exceeds the compensation range

due to insulator cleanliness problems.

CS110 Electric Field Meter

A relative humidity sensor is included inside the CS110 case to provide

information on when case desiccant should be changed. The CS110 also

provides measurement of the battery input voltage in order to monitor the input

power to the instrument. Section 7 discusses CS110 electric field measurement

details. CS110 maintenance details are discussed in Section 10.

3

Page 12

CS110 Electric Field Meter

2. CS110 Specifications

Electric Field Measurement Performance:

Parallel-Plate Configuration

Accuracy

Measurement

3

(V m-1)

Range

±1% of reading + 60 V m

Resolution

(V m-1)

Sensitivity

(µV/V m

1

)

-1

offset1

Noise

-

(V m

-1

RMS)

±(0 to 21,000) 3 12 4.0

±(21,000 to 212,000) 30 118 18.0

2 m CM10 Tripod Configuration2

Accuracy

Measurement

3

(V m-1)

Range

±5% of reading + 8 V m

Resolution

(V m-1)

Sensitivity

(µV/V m

1

)

-1

offset1

Noise

-

(V m

-1

RMS)

±(0 to 2,200) 0.32 1.2 0.42

±(2,200 to 22,300) 3.2 13 1.9

1

Typical offset for clean electrodes is ≤ |30 V m-1| for the

parallel-plate configuration, which is reduced by the field

enhancement factor for typical inverted and elevated mounting

configurations.

4

2

Field enhancement due to typical inverted and elevated

mounting requires additional site correction, estimated at ±5%

accuracy when done in appropriate high field conditions.

Practical outdoor CS110 electric field measurement accuracy is

estimated at ±5% of reading + 8 V m

-1

for the CS110 2 Meter

CM10 Tripod Site.

3

The CS110 incorporates automatic gain ranging between two

input ranges. The measurement is first tried on the lowest input

range. If the signal is too large for the lowest range, the larger

range is used.

Standard Mounting: 2 m height on a CM10 tripod mast

Site Correction: Site correction factors available for several standard

mounting configurations

Page 13

CS110 Electric Field Meter

Sample

(Measurement) Rate: Programmable sample rate up to 5 samples per

second, variable sample rates possible. Variable

example: sample every 10 seconds until field

exceeds threshold then sample once a second until

field returns to normal.

Power Requirements: 11 to 16 Vdc; peak-current demand is 750 mA

during motor operation.

7 mA @ 12 V = 0.08 W average power

consumption at 1 sample per 10 seconds

60 mA @ 12 V = 0.7 W average power

consumption at 1 sample per second

120 mA @ 12 V = 1.4 W average power

consumption at 2 samples per second

300 mA @ 12 V = 3.6 W average power

consumption at 5 samples per second

Communication: 1 RS-232 port; 1 CS I/O port used to interface with

our peripherals such as a COM320 Voice Modem;

digital control ports 1, 2, and 3 for alarm, SDI-12

communications, or asynchronous communications

Baud Rates: Selectable from 300 to 115,200 bps

ASCII Protocol: One start bit, one stop bit, eight data bits, no parity

Lightning Protection: Multi-stage transient protection on all extenal

interfaces

CE Compliance: Standards to which conformity is declared—BS

EN61326:2002

Connectors/

Compatible Sensors: Connector Label Compatible Sensors

1

Temp/RH: HC2S3-L, HMP60-L (choose the -C cable

termination option for these sensors)

Wind: 05103-LC, 05106-LC, 05305-LC, 034B-LC,

03001-LC

Solar: LI200X-LC pyranometer, CS100 barometer or

CS106 barometer (the barometer attaches to the

CS110 via the 17640 cable; they must be housed in

a separate enclosure such as the ENC100)

Rain: CS700-LC, TB4-LC, TE525-LC, TE525WS-LC,

1

One sensor per connector

Programmability: CRBasic

TE525MM-LC

TM

programming allows the selection of

sample rate, data processing and storage options

and setting output ports based on alarm conditions.

LoggerNet

TM

includes the CRBasic editor and

compiler.

5

Page 14

CS110 Electric Field Meter

Rugged Construction: Ultra-reliable metallic ground connection to

reciprocating shutter (no wiping contact), brushless

stepper motor, powder-coated aluminum case,

Teflon insulators, and electro-polished 316L

stainless steel used for corrosion protection of

critical exposed metallic parts

Easy Maintenance: The stator is easily removed for cleaning (proper

cleaning does not invalidate calibration).

Instrument self-checking allows maintenance to be

performed on an as needed basis. The self-checking

also monitors internal humidity, insulator

cleanliness, and power supply voltage, and verifies

that CS110 components such as the charge

amplifier and shutter open/close are functioning

properly.

Operating

Temperature Range: -25° to 50°C standard, -40° to +85°C optional

RH Range: 0 to 100% RH

Dimensions: 15.2 x 15.2 x 43.2 cm (6 x 6 x 17 in)

Mounting: Vertical pipe 1.91 to 6.35 cm OD (0.75 to 2.5 in)

Weight: 4 kg (9 lb)

6

Page 15

3. CS110 Measurement Details

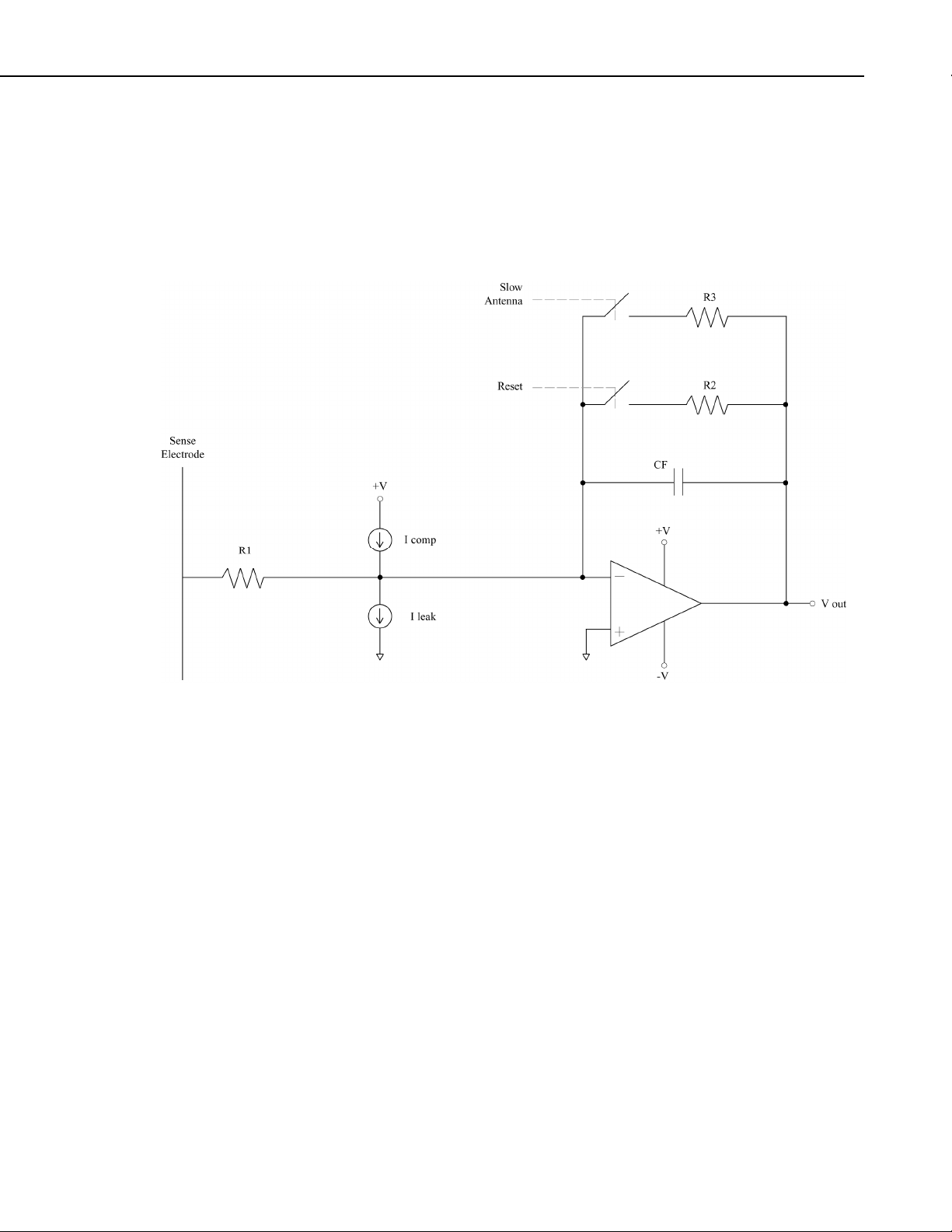

The charge amplifier circuitry of the reciprocating electric field meter is

depicted in Figure 2. Induced charge on the sense electrode results in the

operational amplifier placing charge on the feedback capacitor C in order to

restore the sense electrode to virtual ground.

CS110 Electric Field Meter

FIGURE 2. Charge amplifier circuitry of reciprocating electric field

meter

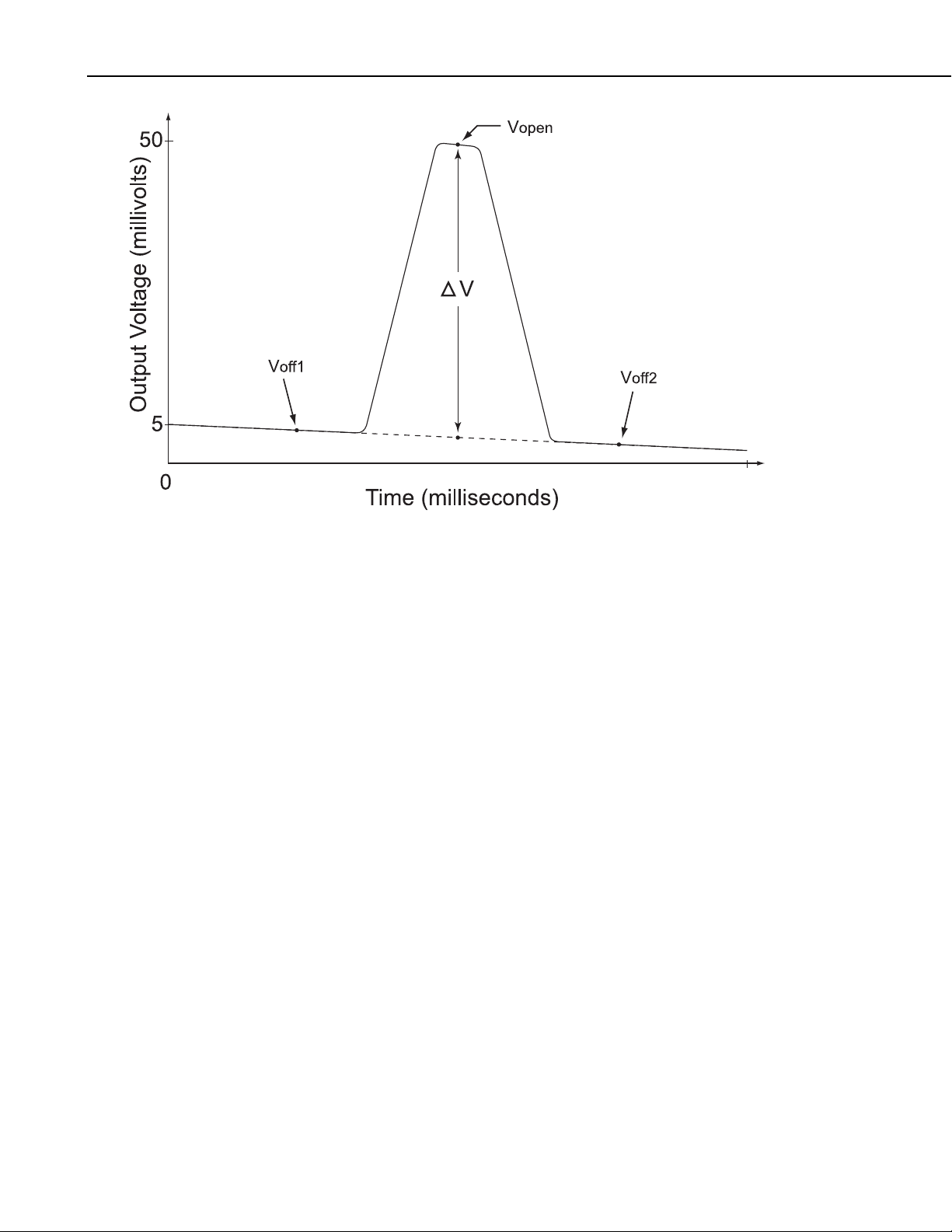

The charge amplifier output during a measurement cycle of the reciprocating

electric field meter is illustrated in Figure 3.

7

Page 16

CS110 Electric Field Meter

160

FIGURE 3. Charge amplifier output during an electric field

measurement cycle

Offset voltages Voff1 and Voff2 are zero field reference measurements made

when the shutter is closed, and utilized to accurately estimate voltage ΔV when

the shutter is completely open. Electronic offset voltages, surface potentials

between various metallic parts and leakage currents on the charge amplifier input

result in non-zero values of Voff1 and Voff2. An electronic reset of the charge

amplifier is performed prior to the measure of Voff1 to keep the charge amplifier

output near zero volts when the shutter closed. The measured electric field E, as

determined from the charge amplifier output is as follows:

E = k⋅ΔV = k⋅[Vopen – (Voff1 + Voff2)/2] (eq. 1)

Where k is a constant determined by electrode geometry and electronic gain.

The resulting algorithm effectively eliminates measurement error sources that vary

slowly with respect to the time between zero field reference measurements, which

is approximately 140 ms. Measurement noise due to 50 or 60 Hz AC power can

be suppressed by utilizing the 50 Hz or 60 Hz noise rejection measurement

capability of the datalogger.

Current source Ileak in Figure 2 represents leakage currents across the Teflon

insulators supporting the sense electrode, along with the input bias current of the

operational amplifier. Deleterious effects of Ileak are compensated for in the

determination of ΔV as given in (eq. 1). However, it is desirable to minimize the

difference between Voff1 and Voff2 in order to preserve dynamic range for large

magnitude Vopen voltages. Hence a leakage-current compensation circuit is

utilized to generate the current Icomp, illustrated in Figure 2, such that Icomp =

Ileak. The leakage-current compensation algorithm determines Icomp for the

present measurement based on Ileak from the previous measurement, which is

determined as follows:

8

Page 17

CS110 Electric Field Meter

Ileak = Cf·(Voff1 – Voff2)/ΔT + Icomp (eq. 2)

Where Cf is the value of feedback capacitor used in the charge amplifier, and

Icomp is the leakage current compensation value implemented during the

measurement.

This charge amplifier input leakage current increases with degradation of

insulation of the sense electrode insulators due to moisture or other surface

contamination. Consequently, the measurement and reporting of Ileak is useful in

determining if or when insulators should be cleaned.

The reciprocating motion of the CS110 electric field meter is limited to

approximately 5 Hz, which is adequate for lightning hazard warning, where 1

minute averaged data is often used. For applications desiring > 5 Hz, the CS110

reciprocating electric field meter can be configured as a slow antenna

(MacGorman and Rust 1998). The shutter would typically be left open

indefinitely in slow antenna mode and resistor R3, depicted in Figure 2, is

switched in parallel with Cf providing a 66 ms decay time constant for the

charge amplifier. In the slow antenna mode, the charge amplifier has a highpass filter frequency response with the lower cutoff frequency defined as f

(2⋅π⋅R⋅C)

the charge amplifier output can be sampled by the datalogger as fast as every

20 ms (50 Hz), using 250 μs integration durations for the analog integrator.

Voltage measurements using the 250 μs integration duration for an analog

integrator, result in an upper 3 dB bandwidth of 1.8 kHz. Detailed information

regarding the slow antenna mode of the CS110 is given in Appendix E and

Section 8.3.

-1

= 2.4 Hz. In this mode the instrument is a field change meter and

3dB

=

4. Site Requirements and Recommendations

4.1 Power Requirements

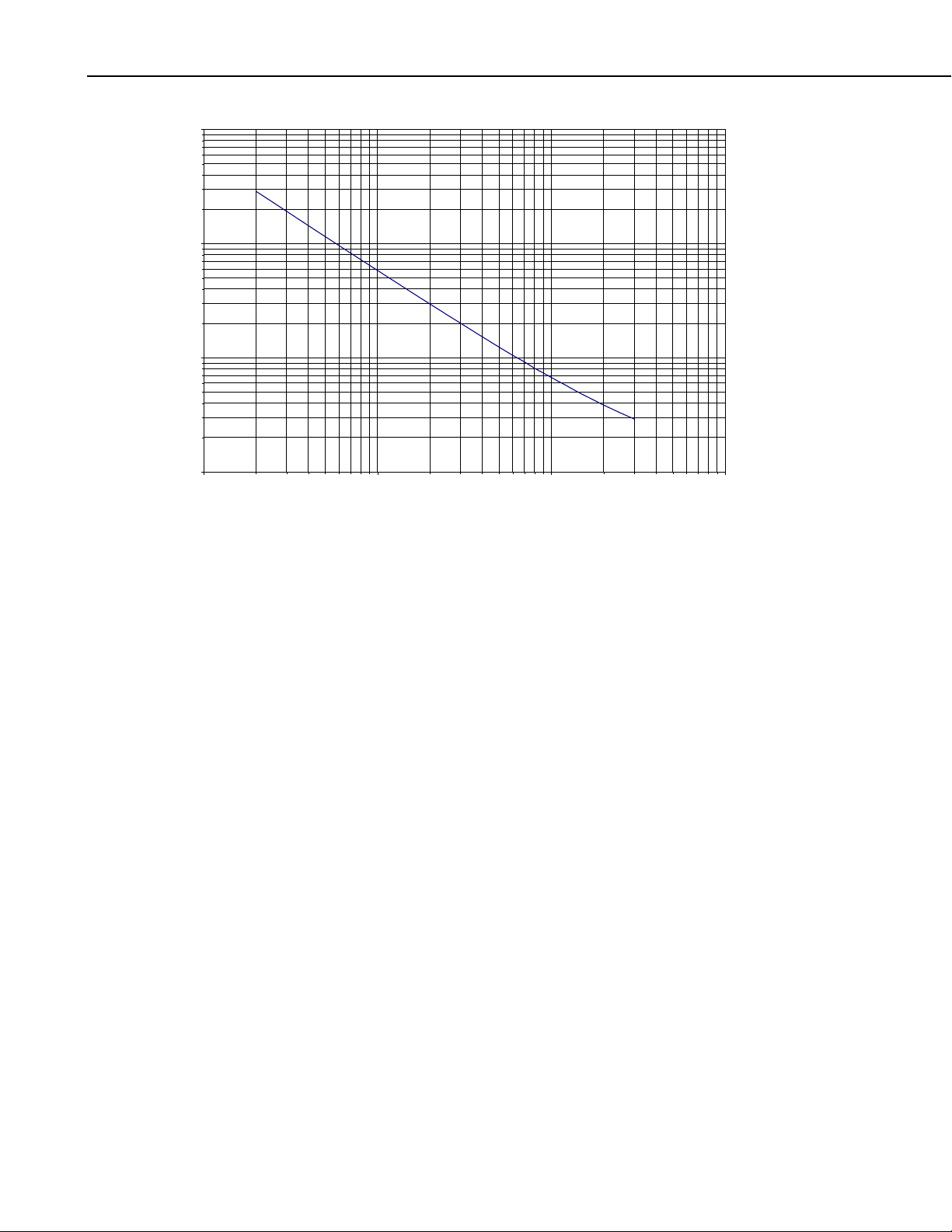

Field mills typically consume many watts of power because their motors are

operated continuously. In the reciprocating approach, the stepper motor is

powered off much of the time, resulting in low power consumption. The

current required by the CS110 powered from 12 V DC is shown in Figure 4.

As depicted in the figure, the average electric field meter current is a function

of the desired measurement rate, which is user-controlled by means of the

datalogger program, making economical remote solar power feasible. Variable

sample rates based on measured results can also be implemented to conserve

power in solar powered applications. For example, the datalogger can be

programmed to measure electric field at a 10-second rate during fair weather

conditions, and then automatically switch to 1-second measurements during

threatening conditions. An example variable sample rate program is given in

Appendix F. Figure 4 does not include the current required for peripheral

devices necessary to communicate with the CS110 site. Like the stepper

motor, communication devices that are turned off when not needed, can offer

low average power consumption.

9

Page 18

CS110 Electric Field Meter

1000

100

10

Average Current (mA) @ 12 V

1

0.1 1 10 100

Measurement Interval (Seconds)

FIGURE 4. CS110 average current consumption versus measurement

interval

The CS110 requires 11 V to 16 Vdc with a peak current demand of 750 mA

during motor operation. The CS110 Power Cable (pn 16965) is used to

connect the dc power supply to the CS110. The recommended maximum

length on the CS110 Power Cable (CS110CBL3-L) is 50 feet. The CS110 is

protected against accidental reversal of the positive and ground leads from the

dc power supply. Transient protection is also included on the power supply

inputs. DC input voltages in excess of 18 V may damage the CS110.

4.2 Campbell Scientific, Inc. Power Supplies

The PS100 provides a 12 Vdc, 7.0 Ahr rechargeable power supply for the

CS110 and peripherals. The CH100 is a charging regulator for 12 V

rechargeable batteries that is commonly used with the larger 12 amp hour

(BP12) and 24 amp hour (BP24) Battery Packs. The rechargeable battery can

be trickle-charged from an ac power wall charger. The PN: 9591 wall charger

accepts 110 Vac while the PN: 14014 accepts 90 to 264 Vac. Charging power

can also come from a 17 – 28 VDC input such as a solar panel. Depending on

power requirements, 10 watt or 20 watt solar panels (SP10 or SP20) are

available.

4.3 Communication Options

10

The circular RS-232 connector on the underside of the CS110 can be used to

interface directly to RS-232 devices (DB-9), utilizing the CS110 RS-232 cable

(CS110CBL1-L).

The circular CS I/O connector on the underside of the CS110 can be used to

interface directly to various Campbell Scientific, Inc. peripherals, utilizing the

Page 19

CS110 CS I/O cable (CS110CBL2-L). Examples of CS I/O peripherals include

the CR1000 Keyboard Display and the COM220 phone modem.

The CS110 also offers SDI-12 communication or SDM (Synchronous Device

for Measurement) control capability utilizing the CR1000 control ports

available through the CS110 POWER CABLE (CS110CBL3-L).

4.4 Site Recommendations

Many factors can distort and/or change the electric field at a given sight. For

example, vegetation growth can reduce the effective height of an elevated

instrument above the ground and can created unwanted space-charge due to

corona discharge. Gravel rings or concrete pads around a given site are

recommended to prevent changes in effective instrument height due to

vegetation growth. Electric field meters used for lightning warning at Kennedy

Space Center use a 25-foot radius gravel ring around each electric field meter

[LPLWS].

Animals and people within the vicinity of an electric field meter can

significantly alter the measurements. Fencing off a given site may be best for

some applications. However, installing a small metal fence around an electric

field meter site may result in corruption of measurements at large electric fields

because of corona discharge from sharp metal points on the fence.

CS110 Electric Field Meter

Aerosols, dust, and automobile exhaust should be considered when selecting an

electric field meter site, as they can affect the local electric field.

In theory, the effects of tall nearby objects can be accounted for in site

correction. Yet, because of possible corona current along with general field

distortion, it is recommended that electric field meter sites should not be

located near tall objects. Kennedy Space Center site requirements stipulate

having no objects protruding higher than 18° above the horizon, as seen from

the ground at the electric field meter location [LPLWS]. Roof mounted

electric field measurements are practical if a site correction can be done to

account for field distortions.

Also a good Earth ground connection to the CS110 and associated mounting

hardware is necessary to make a given site appear as a vertical extension of the

Earth ground. It is recommended that the integrity of this Earth Ground

connection be checked periodically by verifying that the resistance of the stator

to Earth Ground rod is <1 Ω.

Although the list of factors that can impair electric field measurements is long,

experience has shown that useful electric field measurements can be made by

paying careful attention to the above mentioned details.

5. Factory Calibration and Site Correction

5.1 Factory Calibration

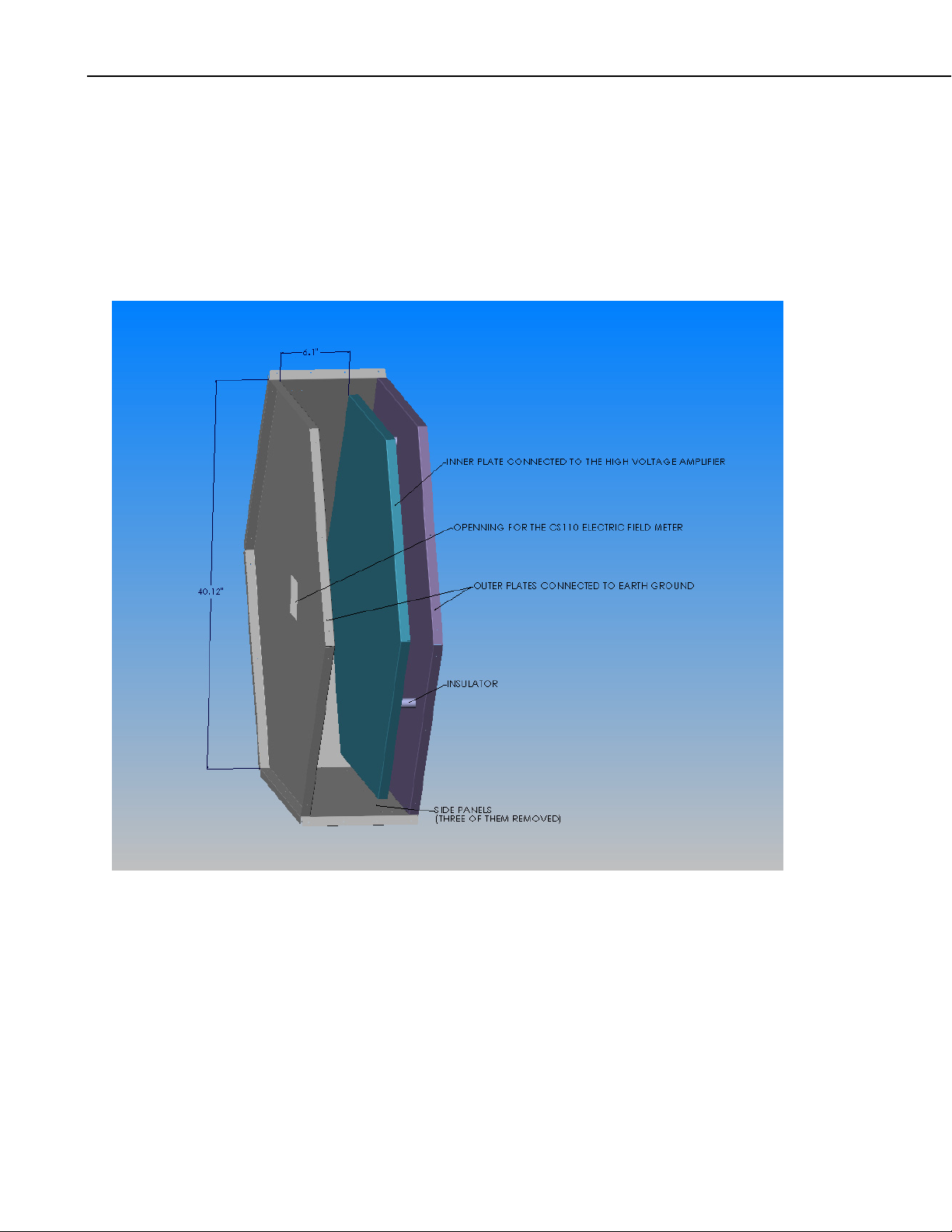

Electric field meters are typically factory calibrated using a parallel plate

method, where a uniform electric field is developed by applying a known

voltage between parallel conductive plates. The large hexagonal parallel plate

electric field calibrator illustrated in Figure 5 is used for factory calibration of

the CS110 Electric Field Meter. The large physical size was incorporated to

11

Page 20

CS110 Electric Field Meter

minimize non-ideal fringing effects. Sharp corners were avoided in order to

prevent corona discharge. All metal parts of the calibrator are manufactured

from stainless steel, and the inside surfaces are polished to reduce the surface

charges in order to provide a stable zero electric field. All outer surfaces are

electrically connected and tied to Earth ground while the insulated inner plate

is driven by a high voltage amplifier. The high-voltage amplifier is calibrated

out-of-house yearly against a reference that is traceable to the National Institute

of Standards and Technology (NIST).

12

FIGURE 5. Parallel-plate electric field meter calibration chamber

Each CS110 is factory calibrated in the parallel plate calibration fixture

depicted in Figure 5. A linear fit of the calibration data results in a calibration

equation in slope-intercept form expressed as

E = M

The multiplier M

parallel_plate

is a function of the CS110 electrode dimensions and

parallel_plate

⋅V + O

parallel_plate

the feedback capacitor in the charge amplifier. The offset term O

(eq. 3).

parallel_plate

is

due to unwanted surface charges residing on non-conductive deposits on the

electrodes. The electric field offset of an instrument varies over time because

Page 21

CS110 Electric Field Meter

of variations in surface cleanliness along with charging and discharging

processes. Polished 316-L stainless-steel is used for critical electrode surfaces

on the CS110 to minimize unwanted surface charges. CS110s with clean

electrodes have been found to display electric field offsets <⏐30 V/m⏐, which

has negligible effect on the determination of M

parallel_plate

because of the ±15

kV/m range of electric fields used during factory calibration. Neglecting

O

parallel_plate

results in the simplified parallel-plate calibration equation

E = M

parallel_plate

The estimated measurement accuracy of M

⋅V (eq. 4).

parallel_plate

for the CS110 calibrated in

the parallel plate electric field calibrator illustrated in Figure 5 is ± 1 %. The

electric field offset of the CS110 can be measured by covering the stator with a

clean Zero Electric Field Cover (PN: 17642). If the resulting zero field reading

with the zero field cover exceeds an absolute value of 60 V/m then cleaning of

electrodes in the CS110 is suggested. The factory calibration data for a typical

CS110 factory calibration and resulting determination of M

parallel_plate

= 84.32

V/m⋅mV (Volts/meter⋅millivolt) is illustrated in Figure 6.

20000

y = 84.324x + 26.258

2

= 1

15000

10000

5000

0

-200 -150 -100 -50 0 50 100 150 200 250

R

Applied Electric Field (V/m)

-5000

-10000

-15000

-20000

Charge Amplifier Output Voltage (mV)

FIGURE 6. Factory calibration data for CS110 SN: 1026

13

Page 22

CS110 Electric Field Meter

14

FIGURE 7. NIST calibration certificate

NOTE

Careful removal and replacement of the stator on the CS110 does

not invalidate the factory derived M

However, switching stators with another unit or accidentally

bending the stator, shutter or sense electrodes invalidates the

factory parallel-plate calibration because of possible electrode

dimensional changes.

5.2 Site Correction

As previously mentioned, each CS110 is factory calibrated in a parallel plate

calibration fixture resulting in calibration equation 4. However, when

monitoring the Earth’s electric field, equation 4 is valid only if the instrument

aperture is mounted flush with the Earth’s surface and upward-facing. Yet for

permanent outdoor measurements of electric field, a flush-mounted and

upward-facing orientation is problematic because of dirt, bird droppings, rain,

etc., collecting on the sense electrodes and fouling the measurement.

parallel_plate

of a given unit.

Page 23

CS110 Electric Field Meter

Consequently, a downward facing and elevated configuration as illustrated in

Figure 8 is recommended for long-term field applications.

FIGURE 8. CS110 2 Meter CM10 Tripod Site

Inverting the CS110 reduces the effective gain while elevating it’s height

above ground enhances the gain, with respect to an ideal upward-facing flushmounted geometry. It should be mentioned that this gain enhancement reduces

the effect of unwanted electrical field offsets. A site correction factor C

necessary to correct M

parallel_plate

[McGorman and Rust]. The corrected multiplier M

M

In equation 5, M

site, whereas C

parallel_plate

is unique for each given site, yet independent of the

site

particular CS110 used at the site. C

for non flush-mounted configurations

becomes as follows:

corrected

= C

corrected

site⋅Mparallel_plate

is unique for each CS110, yet independent of a given

is typically determined by using a flush-

site

is

site

(Eq. 5).

mounted upward-facing unit in the vicinity of the site needing correction.

Campbell Scientific, Inc. developed the site correction facility illustrated in

Figure 9 to determine C

for various site configurations.

site

15

Page 24

CS110 Electric Field Meter

FIGURE 9. Campbell Scientific, Inc. electric field meter site correction

facility

16

Page 25

CS110 Electric Field Meter

An upward-facing calibration kit (PN: 17579) was developed to hold the

CS110 in a flush-mounted upward-facing position, as illustrated in Figure 10.

NOTE

FIGURE 10. CS110 attached to upward-facing flush-mounted plate for

site correction

Both the upward-facing and the inverted and elevated unit need

to be electrically connected to Earth potential. This can best be

accomplished by a grounding rod and wire connected to ground

lugs provided on both the upward-facing plate and on the

mounting bracket on the standard CS110.

Ideally, site correction should be done in the absence of precipitation, and

during the presence of slowly varying electric fields of bipolar polarity and

magnitudes large enough to make instrument offset errors negligible. These

conditions may be infrequent in practice, making site correction using a flushmounted upward-facing unit somewhat challenging. Falling precipitation

along with blowing dirt can result in questionable measurements by an

exposed, upward-facing unit. Cleaning of the electrodes of an upward-facing

unit is recommended after it has been exposed to blowing dust and/or falling

precipitation. The measurement of meteorological parameters such as rainfall,

along with the averaging and data storage capability of the CS110 can be

17

Page 26

CS110 Electric Field Meter

utilized to autonomously measure, process and store data to aid in site

correction.

Campbell Scientific, Inc. has performed a site correction on the CS110 2 Meter

CM10 Tripod Site described in Appendix G. The collected data between the

upward-facing unit and a downward facing CS110 2 Meter CM10 Tripod Site

is illustrated in Fig 10. A best-fit line computed from the data resulted in C

site

= 0.105 ± 4%, which is valid for users at other sites who use the same site

dimensions on level terrain clear of vegetation. Dimensional details of the 2

meter standard meteorological site are described in Appendix F.

10/02/05 Site Correction of CS110 2 Meter CM10 Tripod Site

-80000 -60000 -40000 -20000 0 20000 40000 60000 80000

Mparallel_plate = 87.6 volt/meter*millivolt

10/02/05 Site Correction of CS110 2 Meter CM10 Tripod Site

Results indicate Csite = 0.105.

Results indicate Csite = 0.105.

8000

y = 0.1051x - 35.664

6000

4000

2000

0

-2000

-4000

-6000

2

= 0.9996

R

Mparallel_plate = 87.6 volt/meter*millivolt

Electric Field (volt/meter for Upward Facing CS110 SN:1022

Electric Field (volt/meter) for Upward Facing CS110 SN:1022

Uncorrected (Csite = 1) Electric Field (volt/meter) for 2 Meter Mounted CS110 on CM10

Uncorrected (Csite = 1) Electric Field (volt/meter) for 2 Meter Mounted CS110 on CM10

Tripod. SN: 1023 (Mparallel_Plate = 81.77 volt/meter*millivolt)

Tripod. SN: 1023 Mparallel_Plate = 81.77 volt/meter*millivolt

-8000

-10000

18

FIGURE 11. Site correction data for CS110 2 Meter CM10 Tripod Site

The user is responsible for determining if a CS110 site is representative of

the CS110 2 Meter CM10 Tripod Site, and if not, for determining the

appropriate site correction.

The atmospheric electric field at the Earth’s surface during fair weather

conditions is on the order of –100 V/m; the negative sign indicating that the

electrostatic force on a positive charge is directed downward to the Earth’s

surface [McGorman and Rust],[Rakov and Uman]. Ballpark site corrections are

sometimes computed in fair weather conditions by assuming a -100 V/m fair

weather field. The accuracy of a fair weather site correction is questionable

because local conditions may result in a fair weather field significantly different

(>100%) from –100 V/m. Also, the unknown electric field offset may be

significant when calibrating at –100 V/m. This offset can be measured by

Page 27

covering the stator with a clean Zero Electric Field Cover (PN: 17642). Fair

weather field site correction is not recommended for lightning warning

applications because of the relatively poor accuracy in determining Csite.

6. Lightning Warning

Lightning warning devices fall into two classes: lightning detectors and electric

field monitors. Stand-alone lightning detectors provide warning based on

nearby discharges, but give no warning until a detectable discharge occurs.

Electric field monitors measure the atmospheric electric field, indicating the

presence of nearby electrified clouds capable of producing lightning

discharges. Consequently, electric field monitors can give warning at the

beginning of storms prior to hazardous discharges. Both lightning detectors

and electric field monitors are employed in high-risk applications.

Lightning safety guidelines based on human observations exist and should

not be ignored simply because of the presence of sensitive electronic

instrumentation. The NOAA 30/30 rule suggests seeking shelter if thunder is

heard within 30 seconds of a lightning flash (approximately 6 miles), and

remaining in a sheltered area for 30 minutes after the last lightning or thunder

before resuming outdoor activities [NOAA].

CS110 Electric Field Meter

It should be noted that no method of lightning warning completely

eliminates the risks associated with lightning. As mentioned, lightning

detectors give no warning until a detectable discharge has occurred.

Atmospheric electric field yields warning prior to the “first strike” for storms

developing overhead, along with some indication of the end of a thunderstorm.

Yet there are occurrences of cloud-to-ground lightning discharges striking the

ground several miles away from the electrified cloud where the discharge

initiated [NOAA]. Electric field monitors may give no practical warning in

these instances because the electric field in the vicinity of the strike point may

not indicate hazardous levels until milliseconds before the strike.

Consequently, while lightning warning systems can greatly reduce the

probability of death or injury from lightning discharges, they cannot

reduce this probability to zero.

19

Page 28

CS110 Electric Field Meter

9000

8000

7000

6000

5000

4000

3000

2000

1000

0

Electric Field (volt/meter)

5:34:00 5:40:00 5:46:00 5:52:00 5:58:00 6:04:00 6:10:00 6:16:00 6:22:00 6:28:00 6:34:00 6:40:00 6:46:00

-1000

-2000

-3000

-4000

-5000

August 2, 2005 Thunderstorm at Logan, Utah

Mountain Standard Time (1 sample per second)

FIGURE 12. Electric field measured with CS110 during local

thunderstorm

Figure 12 illustrates the atmospheric electric field monitored by a CS110

during a local thunderstorm. As illustrated in Figure 12, the atmospheric

electric field changes dramatically from fair weather conditions (≈ -100 V/m)

during the course of this thunderstorm. The abrupt electric field change

observed at approximately 6:12 am was due to a hazardous cloud-to-ground

lightning discharge. A lightning hazard warning algorithm would ideally issue

an alarm, or perhaps various caution/alarm levels, during the critical front-end

portion of the storm illustrated in Figure 12, as the electric field is seen to

deviate from a typical fair weather field and approach levels capable of

producing hazardous lightning discharges. There is no universal hazard alarm

level based on atmospheric electric field, although two levels that have been

used are ≥ ⏐1000 V/m⏐ [LPLWS] and ≥ ⏐2000⏐ V/m [NAVSEA]. Obviously

the lower the level used the more risk reduction available, at the expense of

increased down time for operations suspended for lightning hazard warning.

Campbell Scientific, Inc. is not liable for the reliability and performance of

the warning algorithms implemented by users of our equipment. While

lightning warning systems can greatly reduce the probability of death or

injury from lightning discharges, they cannot reduce this probability to

zero.

As previously mentioned, both lightning detection and electric field

monitoring are used for lightning warning systems in high-risk

applications. Lightning detectors with serial digital outputs can be

interfaced to the CS110 resulting in both lightning detection and electric

field monitoring for a given site. The CS I/O port, along with the three

general purpose 0 to 5 V digital I/O ports (C1 - blue, C2 - yellow and C3 green) available on the CS110 Power cable (CS110CBL3-L) can be used

for a serial digital interface. Control ports C1, C2 and C3 can also be used

to conditionally control warning and alarm indicators.

20

Page 29

A network or array of electric field meters improves lightning warning

because of a wider area of coverage along with measurement redundancy.

The PackBus

datalogger embedded in the CS110 provides for extensive networking

capability.

TM

communication protocol capability of the CR1000

7. CRBasic Programming

The CR1000 uses a programming language that has similarities to structured

BASIC, hence the name CRBasic. Within CRBasic there are special

instructions for making various measurements and for defining tables of output

data. Measured results are assigned variable names. Mathematical operations

are written out much as they would be algebraically. Conditional statements

based on measured results provide users with extensive capability for

measurement and control applications. See Section 8 for details on individual

instructions. Appendix F contains some example CRBasic programs for the

CS110. A simple example CRBasic program illustrating some of the general

concepts follows:

'Comments can be inserted in CRBasic utilizing a single quote (').

'Simple CS110 program that measures panel (case) temperature, internal case

'relative humidity, battery voltage and electric field.(CS110_Simple.cr1).

'Updated last by Jody Swenson on 7/12/04.

const Mult = 85 'Define constant to be used in the program.

Public panel_temp 'Define variables to be used in the program.

Public internal_RH

Public battery_volt

Public E_field

Public leakage_cur

Public status

DataTable(Tab1,1,500) 'User defined table called Tab1 of size 500 records.

DataInterval(0,60,sec,10) 'Output data to the table processed every 60 seconds.

Average (1,panel_temp,ieee4,0) 'Average panel temperature over interval.

Average (1,internal_RH,ieee4,0) 'Average internal case RH.

Average (1,battery_volt,ieee4,0) 'Use 4 byte ieee4 format for wide dynamic range.

Average(1,E_field,ieee4,0)

StdDev (1,E_field,ieee4,0)

Average (1,leakage_cur,ieee4,0)

Maximum (1,status,ieee4,0,False)

EndTable

BeginProg

Scan(1,sec,0,0) 'Scan loop occurring every second.

PanelTemp (panel_temp,250) 'Measure temperature on CS110 panel board.

VoltDiff (internal_RH,1,mV2500,5,True ,0,250,0.1,0)

Battery (battery_volt) 'Measure CS110 battery voltage.

CS110(E_field,leakage_cur,status,_60Hz,Mult,0) 'CS110 electric field measurement.

CallTable Tab1 'Call data table Tab1 every scan.

NextScan

EndProg

CS110 Electric Field Meter

21

Page 30

CS110 Electric Field Meter

Public variables are defined and available for viewing in the Public table,

which is a data table automatically set up by the CR1000. The Public table

keeps only the current value of each of the defined variables.

In the example program, the DataTable instruction is used to define the data

table Tab1. A record in a table consists of the data from all output processing

instructions, along with a record number and time stamp data. Using -1 for last

parameter in DataTable results in the automatic allocation of all available

table storage area. The DataInterval instruction following the DataTable

instruction defines the interval at which new values are determined and written

into the table, which is every 60 seconds in the above example. Once a table is

full the CR1000 writes new values over the top of old values starting with the

oldest data in the table. Data can be collected manually or automatically on a

scheduled collection interval by means of LoggerNet PC software.

The Sample output processing instruction simply outputs the current variable

value at the appropriate time to the data table. The Average and StdDev output

processing instructions accumulate all measured values over the associated

data interval and then compute the average and standard deviation,

respectively, at the appropriate time. Several other processing instructions exist

for the CR1000 as described in the CR1000 Measurement and Control System

Operator’s Manual.

The Scan and NextScan instructions set up a loop based on the scan interval.

PanelTemp, VoltDiff, Battery, and CS110 are measurement instructions that

return the temperature inside the CS110 case, relative humidity inside the

CS110 case, the voltage being provided to the CS110 to power the instrument

and the measured electric field, respectively. These and other measurement

instructions are discussed more fully in Section 7 on CS110 Measurement

Instructions. The CallTable instruction sends data to the output processing

instructions associated with a given table.

A more involved program that incorporates site correction multiplier, rainfall,

wind speed and direction, solar radiation, relative humidity and air

temperature, along with electric field follows:

'CS110 efield and weather station program.(CS110_WStation.cr1).

'Measures rainfall, wind speed and direction, solar radiation,

'relative humidity and air temperature and electric field.

'Updated last by Jody Swenson on 11/15/05 for Error_Count.

const Mparallel_plate = 85

const Csite = 0.10

const Mcorrected = Mparallel_plate*Csite 'Mcorrected is what goes into CS110 instruction.

Public E_field

Units E_field=volts/m

Public battery_volt

Public leakage_cur

Units leakage_cur=nA

Public status

Public panel_temp

Units panel_temp=DegC

Public rain_fall

Units rain_fall=inch

Public wind_speed

22

Page 31

CS110 Electric Field Meter

Units wind_speed=mph

Public wind_dir

Units wind_dir=deg

Public solar_rad

Units solar_rad=W/m2

Public air_temp

Units air_temp=DegF

Public RH

Units RH=%

Public internal_RH

Units internal_RH=%

Public E_status(16) 'E_field status array.

Public k 'Index for E_status array.

Public meas_error 'Disable variable for slow table.

Public Error_Count 'Keep track of total errors measurements.

DataTable(Tabslow,1,-1) '-1 to auto-allocate all available memory.

DataInterval(0,60,sec,10) 'Averaged 60 second output data.

Average(1,E_field,ieee4,meas_error)

Sample (1,status,FP2) 'Use 2-byte floating point for non-critical numbers.

Sample (1,Error_Count,FP2)

Totalize (16,E_status,FP2,0) 'Look at Efield status array over interval.

Average (1,leakage_cur,FP2,0)

Average(1,panel_temp,FP2,0)

Totalize (1,rain_fall,FP2,0)

WindVector (1,wind_speed,wind_dir,FP2,False,0,0,0)

Average (1,solar_rad,FP2,0)

Average(1,air_temp,FP2,0)

Average (1,RH,FP2,0)

Average (1,battery_volt,FP2,0)

Average (1,internal_RH,FP2,0)

EndTable

DataTable(Tabfast,1,-1) '-1 to auto-allocate all available memory.

Sample(1,E_field,ieee4)

Sample (1,status,FP2)

Sample (1,leakage_cur,FP2)

Sample (1,rain_fall,FP2)

Sample (1,wind_speed,FP2)

Sample (1,wind_dir,FP2)

Sample (1,solar_rad,FP2)

Sample (1,air_temp,FP2)

Sample (1,RH,FP2)

Sample (1,battery_volt,FP2)

EndTable

BeginProg

Error_Count = Tabslow.Error_Count(1,1) 'Retrieve ErrorCount from Tab60sec in case of watchdog.

if (Error_Count = NAN) Then

Error_Count = 0

EndIf

23

Page 32

CS110 Electric Field Meter

Scan(1,sec,0,0)

for k = 1 to 16 'Initialize status array.

E_status(k) = 0

next

PanelTemp (panel_temp,250)

Battery (battery_volt)

VoltDiff (internal_RH,1,mV2500,5,True ,0,250,0.1,0)

PulseCount (rain_fall,1,2,2,0,0.01,0) 'TE525 tipping bucket 0.01 inches per tip

PulseCount (wind_speed,1,1 ,1,1,0.2192,0) 'Mult for 05103 Wind Monitor.

BrHalf (wind_dir,1,mV2500,4,Vx2,1,2500,False,450,250,355,0) 'Mult. for 05103 Wind Monitor.

VoltDiff (solar_rad,1,mV7_5,3,True,450,250,200,0)

meas_error = 0 'Initialize disable variable for Efield average in slow table.

SW12 (1 ) 'Apply 12 V to warm-up Temp and RH probe at least 150 ms.

CS110(E_field,leakage_cur,status,_60Hz,Mcorrected,0)

VoltSe (RH,1,mV2500,1,1,0,250,0.1,0)

VoltSe (air_temp,1,mV2500,2,1,0,250,.18,-40)

SW12 (0) 'Turn off power to Temp and RH probe.

if RH > 100 and RH < 108 then

RH = 100

EndIf

If E_field = NAN Then 'Not-A-Number because of measurement problem.

meas_error = 1 'Disable output to slow table if efield = NAN.

EndIf

E_status(status) = 1 'Set appropriate element in status array.

If status > 6 Then

Error_Count = Error_Count + 1 'Increment Error_Count.

EndIf

CallTable Tabfast

CallTable Tabslow

NextScan

EndProg

This program incorporates two different user-defined data tables, Tabfast and

Tabslow. Tabfast contains 1 second measurements, while Tabslow contains 1

minute averaged data. Under certain error conditions the CS110 returns NAN

(Not-A-Number) for measured electric field rather than a questionable electric

field measurement. For example, the CS110 will detect if the shutter cannot be

properly closed at the completion of a measurement due to an obstruction. If

the shutter cannot properly close then the CS110 will return NAN for the

electric field measurement along with a status value indicating that the motor

could not properly close the shutter. The various CS110 status codes are

described in Appendix A.

The above program utilizes the array E_status(16) to store the various status

codes returned from a given measurement. The Totalize instruction in

Tabslow computes the total number of occurrences for each array value during

the output interval. Consequently, the array E_status returns the total number

of occurrences of each status code during the associated 1 minute output

interval. As given in Appendix A, status codes 1, 2, and 3 are associated with

good electric field measurements, whereas each of the higher codes indicates a

concerning condition such as low-battery voltage or too much leakage current

on the electrode insulators.

There are times when it is desirable to exclude a measured result from an

output processing instruction such as Average. This can be conveniently

24

Page 33

CS110 Electric Field Meter

accomplished using a disable variable (DisableVar) associated with

appropriate output processing instructions. The last parameter of the Average

instruction is the DisableVar and will exclude the current measured value

when DisableVar is not equal to zero. In order to prevent a single NAN

electric field result from corrupting measurements over the entire output

interval, the variable meas_error is used to disable writing NAN results to the

Average(1,E_field,ieee4,meas_error) instruction in TabSlow.

It is also sometimes desirable to keep a count of total measurement errors,

which is accomplished in the above program by the variable Error_Count. The

last stored value of Error_Count is retrieved from final storage at the beginning

of the program and Error_Count is incremented once during a scan each time

status >6 from the CS110 instruction. The Error_Count can be zeroed by

means of LoggerNet by accessing the Public variable Error_Count in the

Numeric display available in the Connect Screen.

Appendix F contains more example CS110 programs that users may find

beneficial in various applications. A more detailed description of CRBasic is

contained in the CR1000 Measurement and Control System Operator’s

Manual.

8. CS110 Measurement Instructions

8.1 CR1000 Measurement Overview

The CR1000 datalogger can perform many different measurement tasks as

defined by measurement instructions in CRBasic. A brief explanation of

CS110 measurement instructions is given followed by some specific examples.

Further measurement instructions and measurement details are provided in the

CR1000 Measurement and Control System Operator’s Manual.

The CR1000 differential voltage measurement (VoltDiff) instruction is given

as follows:

VoltDiff(Dest,Reps,Range,DiffChan,RevDiff,Settling Time,Integ,Mult,Offset)

where Dest is the destination variable of the result. Reps is the number of

times to repeat a given measurement on successive channels, Range is one of

±5000 mV, ±2500 mV, ±250 mV, ±25 m, ±7.5 mV, or ±2.5 mV input voltage

ranges available on the CR1000. DiffChan is the appropriate differential input

channel (1 – 8). RevDiff is a true or false parameter to determine whether or

not to perform two successive differential measurements with reversed input

polarity, in order to reduce low-frequency measurement errors. Settling Time

is a parameter allowing extra input settling time for “slow” settling sensors.

Integ is a parameter indicating the length of time to perform an analog

integration during the measurement, with options of 250 μs, _50Hz and _60Hz.

Integration times for _50Hz and _60Hz are 20 ms and 16.67 ms, respectively

for cancellation of unwanted 50 Hz and 60 Hz noise. Mult provides for scaling

within the measurement instruction, while Offset provides for the

incorporation of offsets.

25

Page 34

CS110 Electric Field Meter

Single-ended voltage measurements are referenced to ground, rather than the

low side of a differential input. The VoltSE single-ended measurement

instruction is quite similar to the VoltDiff instruction and is given as follows:

VoltSe (Dest,Reps,Range,SEChan,MeasOff,Settling Time,Integ,Mult,Offset)

An internal ground reference is utilized in single-ended measurements. Singleended offset errors are reduced in single-ended measurements by measuring the

voltage on the internal ground reference. The MeasOff parameter in the

VoltSe instruction determines if this internal ground reference is measured at

the beginning of every VoltSe instruction (MeasOff = True) or whether a

single-ended offset voltage measure is performed as part of an on-going

instrument self-calibration routine occurring in background (MeasOff = False).

Another general purpose voltage measurement instruction is the BrHalf

instruction, which provides voltage excitation for a simple resistive divider

(half of a 4-element Wheatstone bridge), and then measures the resulting

voltage.

A BrHalf instruction follows:

BrHalf (Dest,Reps,Range,SEChan,ExChan,MeasPEx,ExmV,RevEx,Settling

Time,Integ,Mult,Offset)

Most parameters of the BrHalf instruction are common to the VoltDiff and

VoltSE instructions, and so only the differences will be discussed. The

ExChan parameter determines which one of the three CR1000 voltage

excitation outputs are used to excite the half-bridge. MeasPEx determines how

many successive channels are excited by the same excitation channel in

successive Reps. ExmV determines the excitation voltage which can range

from –2500 mV to +2500 mV. RevEx is a true/false parameter and if true then

the polarity of the excitation is reversed during the measurement and a second

measurement taken. Like input reversal on differential measurements,

excitation reversal is an error canceling technique for reducing low-frequency

measurement errors such as offset voltages.

The Battery instruction is used to measure the input voltage of the power

supply to the CS110 and follows:

Battery (Dest)

The PanelTemp instruction is used to measure the temperature of a thermistor

located within the CS110 case and follows:

PanelTemp (Dest,Integ)

The PulseCount instruction is used to count the pulses generated from sensors,

such as an anemometer or switch closures from a tipping bucket rain gauge,

and has the following parameters.

26

PulseCount(Dest,Reps,PChan,PConfig,POption,Mult,Offset)

PChan is the number pulse channel (1 or 2) used for the measurement.

PConfig is a code (0-2) for three different types of pulse-count inputs; High-

frequency = 0, low-level AC = 1, and switch closure = 2. POption is a code to

Page 35

determine if results are returned as counts for a given interval (POption = 0),

or as frequency = counts/(scan interval in seconds) (POption = 1).

8.2 Measuring Electric Field

The CS110 instruction is used to perform the electric field measurement of the

CS110 and follows:

CS110(Dest,Leakage,Status,Integ,Mult,Offset)

Leakage is a variable containing the measured leakage current in nano amps

(nA) on the charge amplifier input during the CS110 electric field

measurement. A perfect unit is 0 nA. Actual units deviate from perfection

such that some have small (<< 1 nA) positive leakage current and some have

small negative leakage current. Status is a variable containing numeric codes

indicating various status conditions occurring during the measurement, as

defined in Appendix A. Integ is a parameter indicating the length of time to

perform an analog integration during the measurement, with options of 250 μs,

_50Hz and _60Hz. Integration times for _50Hz and _60Hz are 20 ms and

16.67 ms, respectively for cancellation of unwanted 50 Hz and 60 Hz noise.

Mult provides for convenient scaling within the measurement instruction, and

Offset provides for convenient incorporation of offsets. The CS110 instruction

measures the electric field utilizing the ±250 mV range. If the result is NAN,

the instruction re-measures utilizing the ±2500 mV input voltage range.

CS110 Electric Field Meter

8.3 Measuring Electric Field Change

CS110Shutter(Status,Move)

Status is a variable containing the following subset of measurement status

codes given in Appendix A: status codes 1, 4, 7, 8, 9, 10, 11, 14, 15, and 16.

Move is a variable set to 1 to open the shutter and set to 0 for the

CS110Shutter instruction to close the shutter.

The CS110Shutter instruction can be utilized along with a Delay instruction to

visually verify the fully opened and fully closed positioning of the CS110

shutter, as described in Appendix D on Servicing the CS110. The

CS110Shutter instruction can also be used to implement a Slow Antenna

electric field measurement as described in Appendix E. The CS110 panel

board contains circuitry to switch in a parallel 200 MΩ resistor with the 330 pf

feedback capacitor in the charge amplifier during execution of an open shutter

CS110Shutter instruction. This results in a charge amplifier with a 66 ms time

constant implemented as a slow antenna that can be utilized to measure

changes in electric field at rates much faster than the 5 Hz maximum rate of the

CS110 electric field measurement instruction. In the slow antenna mode the

CS110 becomes a field-change meter, meaning that the useful data becomes

the differences between the VoltDiff measurements rather than the absolute

value of each VoltDiff measurement.

8.4 Measuring Solar Radiation or Barometric Pressure

Circular connector labeled SOLAR RADIATION on the CS110 can be used

to connect up an LI200X solar radiation sensor. Alternately, a special cable,

the CS110-L BAROMETRIC PRESSURE SENSOR CABLE (17460), can be

27

Page 36

CS110 Electric Field Meter

‘Measure LI200X.

VoltDiff (solar_rad,1,mV7_5,3,True,450,250,200,0)

‘Measure CS106 - “continuous” or “always on” mode = jumper installed

VoltDiff (Barom_pres,1,mV2500,3,True,450,250,0.24,500)

‘Measure CS100 every hour – “triggered” mode = on/off. Trigger or turn on by setting control port

4 (C4=green wire) high.

Scan (1,Sec,0,0)

If Iftime(3599,3600,sec) then PortSet (4,1 )

VoltDiff (Barom_pres,1,mV2500,3,True,450,250,0.2,600)

If Iftime(0,3600,sec) then PortSet (4,0 )

NextScan

purchased and connected to the SOLAR RADIATION connector to interface

to either the CS100 or the CS106 barometric pressure sensor. Examples of

instructions to measure the LI200X solar radiation sensor or the barometric

pressure sensors are given below.

8.5 Measuring Air Temperature and Relative Humidity

Circular connector labeled TEMP/RH can be used to connect up an HC2S3

temperature and relative humidity sensor. Example CRBasic instructions to

measure the HC2S3 Temperature and RH are given below.

SW12 (1 ) ‘Apply switched 12 V power to the probe.

Delay (0,3,sec) ‘Warm up probe before measurements.

VoltSe (air_temp,1,mV2500,2,1,0,250,.18,-40) ‘Single-ended air temp. measure.

VoltSe (RH,1,mV2500,1,1,0,250,0.1,0) ‘Single-ended relative humidity.

SW12 (0) ‘Turn off power to the probe.

if RH > 100 and RH < 103 then

RH = 100

Endif

8.6 Measuring Wind Speed and Direction

Circular connector labeled WIND can be used to connect up various wind

sensors, including the 05103 Wind Monitor, 034B Met One Wind Sensor, and

03001 Wind Sentry. Example CRBasic instructions to measure the 05103

Wind Monitor are given below.

PulseCount (wind_speed,1,1 ,1,1,0.2192,0) 'Wind Speed.

BrHalf (wind_dir,1,mV2500,4,Vx2,1,2500,False,450,250,355,0) 'Wind Direction.

28

Page 37

CS110 Electric Field Meter

8.7 Measuring Rainfall

Circular connector labeled RAIN can be used to connect up a rain gauge using

a switch closure such as the CS700 or the TE525MM tipping bucket rain

gauges. Example CRBasic instruction to measure the TE525 is given below.

PulseCount(rain_fall,1,2,2,0,0.01,0) 'TE525 tipping bucket 0.01 inches per tip

8.8 Measuring Internal Case Humidity

In order to determine when to change desiccant within a CS110 case, a relative

humidity sensor is contained inside the case. The following CRBasic

instruction provides internal humidity data to the variable Internal_RH, which

can then be monitored in real-time and/or included in an output table.

VoltDiff(Internal_RH,1,mV2500,5,True,0,250,0.1,0) 'Internal humidity

measure.

Changing of CS110 desiccant is recommended for internal relative humidity

values ≥ 80%.

9. PC Software

9.1 Quick Start

Campbell Scientific offers two datalogger support software packages for PC

computers that can be used with the CS110 and its embedded CR1000

datalogger. The PC400 package is less expensive than the full featured

LoggerNet package but PC400 does not support combined communication

options (e.g., phone-to-RF), PakBus routing, or scheduled data collection.

LoggerNet software is recommended for applications that require these

capabilities.

The CS110’s embedded CR1000 datalogger is only supported in LoggerNet

version 3.0 and higher or PC400 version 1.0 and higher. Upgrades to earlier

versions of LoggerNet or PC208W are available for approximately half the list

price.

The following overview describes connecting a PC running LoggerNet to the

CS110 and viewing electric field data. The full capabilities of LoggerNet and

PC400 are covered in their respective manuals.

Connect the CS110’s RS232 port to the PC, and apply 12 Vdc power to the

CS110. Due to a factory installed CR1000 program the shutter should begin to

open/close about 30 seconds after power is turned on.

The CR1000 uses a Campbell Scientific communication protocol called

PakBus. Each CR1000 datalogger in a network connecting to the LoggerNet

PC should have a unique PakBus address. Each CS110 is shipped with a

PakBus address of 1.

The following three screen captures show the settings for each of the three

links in the path from COM Port 1 on the PC to the CS110 with the factory

29

Page 38

CS110 Electric Field Meter

default PakBus address of 1. Use LoggerNet Tool Bar’s “Setup” button or “EZ

Setup” button to create the PC to CS110 communication path shown below:

30

Page 39

CS110 Electric Field Meter

Remember to click on the “Apply” button to cause the settings to take effect.

The “Apply” button is grayed out once it has been executed.

Once this is done, switch to the “Connect” button on the LoggerNet Tool Bar,

select the CS110, and select “Connect”.

31

Page 40

CS110 Electric Field Meter

If the connection is made and the stations time shows up in the window, you

can then select the “Numeric:” button and add the desired public variables to

see electric field readings updated every measurement interval.

If you have changed the CR1000’s PakBus address and subsequently forgotten

it, you can download from http://www.campbellsci.com/downloads at no cost,

a software package named Device Configuration Utility that will discover the

PakBus address. Run the software and set it up with device type set to

CR1000, specify the correct COM port, and select “Connect” and the software

will discover the PakBus address for you.

If necessary, this software is also used to send a new operating system (OS) to

the CR1000.

The following screen captures show the Device Configuration software.

32

Page 41

CS110 Electric Field Meter

10. Maintenance

10.1 Checking Site Ground Integrity

10.2 Corrosion and Rust Inhibitors

The CS110 electric field meter needs to be electrically connected to Earth

ground for valid measurements. It is recommended that the integrity of this

Earth Ground connection be checked periodically by verifying that the

resistance of the stator to Earth Ground rod is <1 Ω.

In corrosive environments, metal friction points (set screws, bolts, etc.) and

electrical connections to earth ground can be protected with the use of a rust

inhibitor. Sanchem makes such an inhibitor and some information on their

products may be found at http://www.sanchem.com/ox.html. Following is an

excerpt from their web site:

“NO-OX-ID A-SPECIAL is a soft, wax based rust preventive and lubricant

that contains an active rust inhibitor and small amount of solvent for ease of

application. This corrosion resistant coating can be applied by spray or brush

application. NO-OX-ID A-SPECIAL controls corrosion by leaving a thick,

semi-transparent, non-drying barrier coating that retains its anti-rust properties

indefinitely.

NO-OX-ID A-SPECIAL is the electrical contact grease of choice in new