Page 1

CS10-L and CS15-L

Current Transformers

Revision: 3/12

Copyright © 2001-2012

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

CS10-L and CS15-L Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. General Description.....................................................1

2. Specifications ..............................................................1

3. Installation....................................................................2

4. Wiring............................................................................3

5. Programming ...............................................................3

5.1 CR800, CR850, CR1000, or CR3000 Programming................................3

5.2 CR200(X)-series Dataloggers...................................................................4

5.3 CR510, CR10X, CR23X Dataloggers ......................................................6

5.4 21X, CR7 Dataloggers..............................................................................8

5.5 CR1000 with Multiplexer Sample Program ...........................................10

5.6 CR10X with Multiplexer Sample Program.............................................11

Appendix

A. Theory of Operation................................................ A-1

A.1 Typical Electrical Circuit.................................................................... A-1

A.2 Current Transformer Description........................................................ A-3

A.3 Converting a Milliamp Signal to a Millivolt Signal............................ A-4

A.4 Multiplier ............................................................................................ A-5

A.5 CS10/CS15 Comparison..................................................................... A-5

Figures

1. CS10-L Current Transformer .....................................................................1

2. AC load wire installed in CS10 (color of ac load wire can vary) ...............2

3. Graph of a CS15 waveform ........................................................................5

4. Graph of CS10 waveform using burst mode ..............................................7

5. Graph of a CS10 waveform using 90 samples of amperage.......................8

A-1. Generator schematic .......................................................................... A-1

A-2. Schematic of generator with current transformer .............................. A-2

A-3. Schematic of current transformer with the wire ................................ A-2

A-4. CS10 with the wire ............................................................................ A-3

A-5. Magnetic flux schematic.................................................................... A-3

A-6. Windings schematic........................................................................... A-4

A-7. CS10 schematic ................................................................................. A-5

A-8. Adding 1250 mV creates positive output .......................................... A-6

A-9. CS15 schematic ................................................................................. A-6

A-10. CS15 measurement range................................................................ A-7

i

Page 6

Page 7

CS10-L and CS15-L Current Transformers

1. General Description

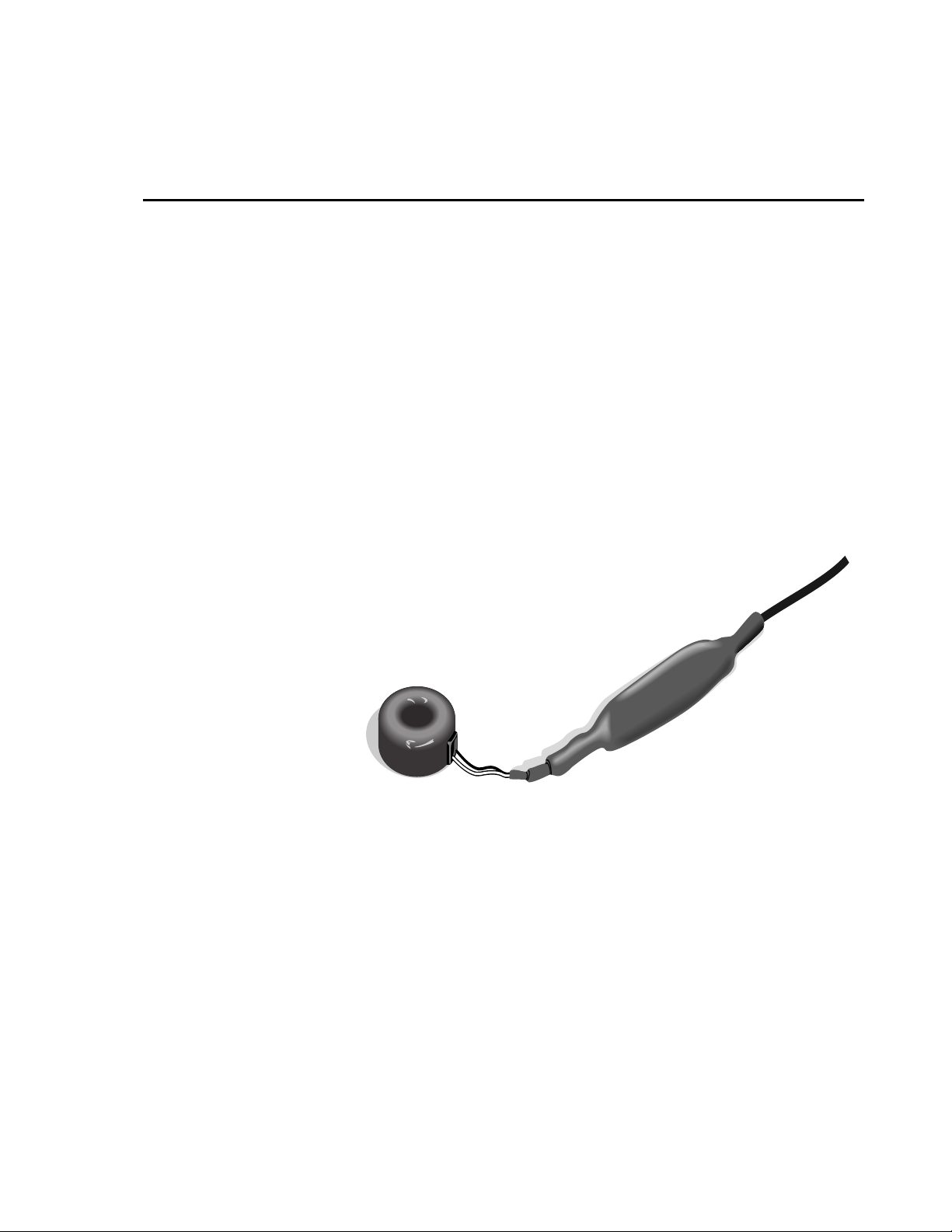

Campbell Scientific’s CS10 and CS15 detect and measure the ac current along

an electrical wire using the magnetic field that is generated by that current.

The CS10 or the CS15 do not have direct electrical connection to the system.

These sensors output a millivolt signal allowing them to be directly connected

to our dataloggers.

The CS10 is compatible with our CR800, CR850, CR1000, CR3000, CR510,

CR10(X), and CR23X dataloggers. It uses CR Magnetic’s CR8459 Current

Transducer to measure the approximate current over a range of 0 to 200 A.

The CS15 was developed specifically for our CR200(X)-series dataloggers. It

is a modified version of the CS10 that measures the approximate current over

the range of 0 to 125 A. Both sensors are recommended for measurements that

do not require high accuracy.

FIGURE 1. CS10-L Current Transformer

2. Specifications

Example Applications:

• Motor or generator load conditions

• Efficiency studies

• Intermittent fault detection

• Rough submetering

1

Page 8

CS10-L and CS15-L Current Transformers

Specifications

Measurement Ranges: 0.15 to 200 A (CS10)

0.15 to 125 A (CS15)

Frequency: 50 and 60 Hz

Insulation Resistance: 100 M ohm @ 500 VDC

High Potential: 2000 volts

Rated Current: 200 A (CS10), 125 A (CS15)

Storage Temperature: -25ºC to 70ºC

Operating Temperature: -25ºC to 55ºC

Case Material: Polypropylene Resin

Construction: Epoxy Encapsulated

Accuracy with 10 ohm

burden max. (resistive): typically ±5 percent of actual value with

provided multiplier

Dimensions: Outer diameter: 1.89” (4.8 cm)

Inner diameter: 0.75” (1.9 cm)

Height: 0.67” (1.7 cm)

3. Installation

Place one AC load wire through the hole of the CS10-L or CS15-L (see Figure

2).

2

FIGURE 2. AC load wire installed in CS10 (color of ac load wire can

vary)

Page 9

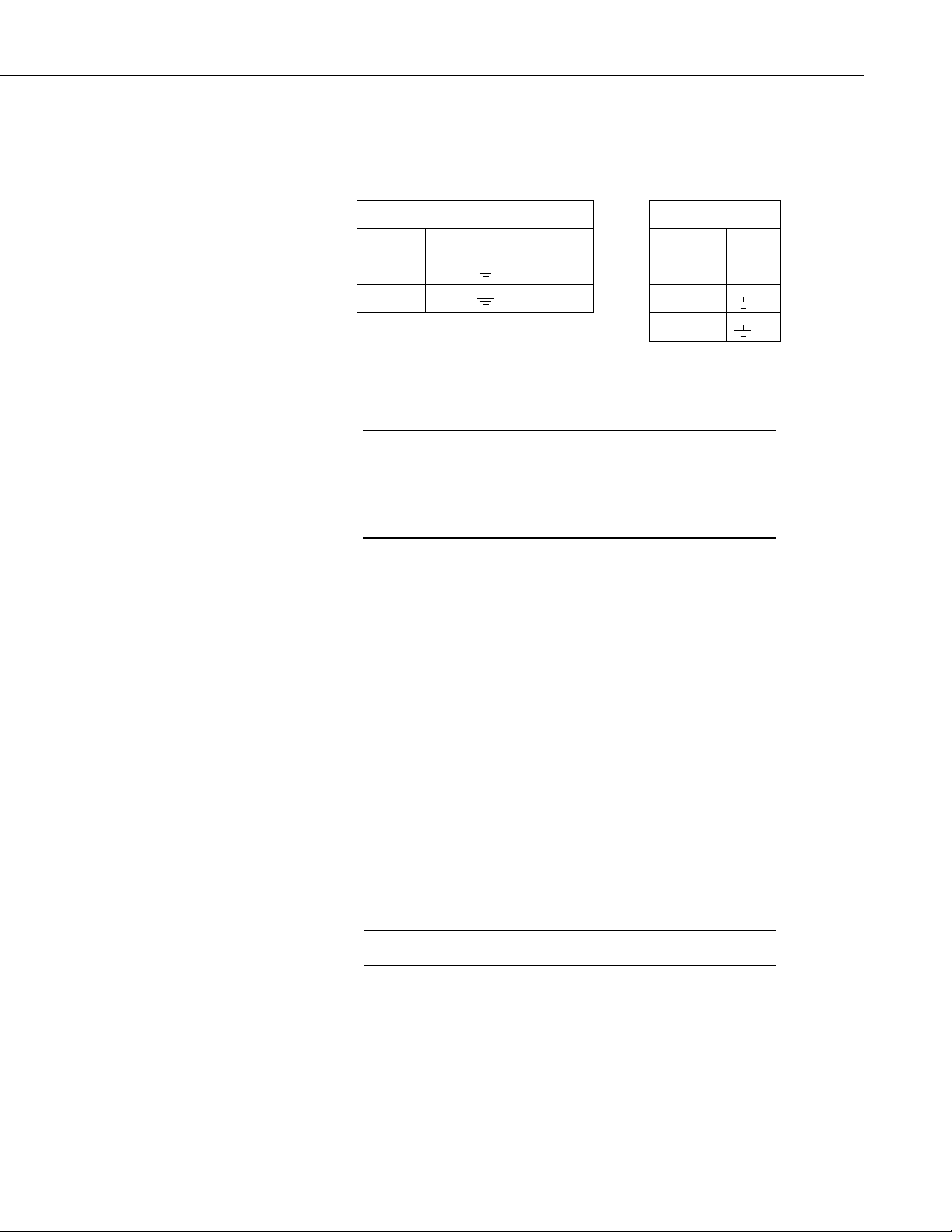

4. Wiring

CS10-L and CS15-L Current Transformers

The CS10-L and CS15-L use a single-ended analog channel as follows.

5. Programming

NOTE

CS10-L

White Single-Ended Channel Red EX

Black AG or White SE

Shield AG or Black

Shield

SCWIN users: This manual was written primarily for those

whose needs are not met by SCWin. Your procedure is much

simpler: just add the CS10-L or CS15 (in the Miscellaneous

Sensors folder), save your program, and follow the wiring shown

in Step 2 of SCWin.

The datalogger is programmed using either CRBasic or Edlog. Dataloggers

that use CRBasic include our CR200(X)-series, CR800, CR850, CR1000, and

CR3000. Dataloggers that use Edlog include our CR510, CR10(X), and

CR23X. In CRBasic, the VoltSE instruction is used to measure the sensor. In

Edlog, a P1 instruction is used.

CS15-L

In order to monitor the amperage of an alternating current circuit, the program

must take many samples from the CS10-L or CS15-L sensor to capture the

waveform over a specified time, and then calculate the average energy under

the curve. There are many methods to do this, depending on the datalogger,

the untapped programming capacity, and other factors.

5.1 CR800, CR850, CR1000, or CR3000 Programming

With these dataloggers, the best method for monitoring amperage is to make

millivolt burst measurements, and then calculate RMS. The millivolt burst

measurements are made by using the VoltSE instruction with multiple reps on

the same channel (i.e., negative value for channel number). The SpaDevSpa

instruction calculates RMS.

NOTE

Program must be run in the pipeline mode.

It is important to get complete cycles. If you make 100 measurements during a

0.1 second time period, you’ll get five complete cycles for a 50 Hz waveform

or six complete cycles for a 60 Hz waveform.

3

Page 10

CS10-L and CS15-L Current Transformers

CAUTION

'CR1000 program to measure rms current

PipeLineMode 'must be pipeline mode

Const num_samples = 100 '100 Samples @ 1000 micro sec = 0.1 second (5 @ 50Hz or 6 @ 60 Hz).

Public Amps 'the line current

Public Amp_mult

Dim i_sig (num_samples) 'to hold the burst measurements, each 100 samples long

PreserveVariables 'to store values between power cycles

DataTable (AmpTable,True,-1)

DataInterval (0,1,Min,10)

Maximum (1,Amps,IEEE4,False,False)

Average (1,Amps,FP2,False)

EndTable

BeginProg

Amp_mult = 0.2 '0.2 multiplier for the CS10-L

Scan (250, mSec, 10, 0)

VoltSe (i_sig (1), num_samples, mV2500,-1, True, 1000, 0, 1.0, 0)

StdDevSpa (Amps, num_samples, i_sig (1))

Amps = Amps * Amp_mult 'put in amps

CallTable (AmpTable)

NextScan

EndProg

Do not average the waveform or use 60 Hz (or 50 Hz)

rejection. Under these circumstances, the amperage value

will always be zero.

Below is an example CR1000 program. In the program, a multiplier of 0.2 is

applied to the RMS value; see Section A.4 for more information.

4

5.2 CR200(X)-series Dataloggers

The CS15 is manufactured specifically for the CR200(X)-series dataloggers. It

has an extra wire and requires an ExciteV instruction in the program. The

voltage excitation creates a positive reference output that the CR200(X)-series

can measure.

The recommended programming method for CR200(X)-series dataloggers

(where the scan interval is limited to once per second) is to place the VoltSE

instruction within a loop. The first CR200(X) example program has a loop that

samples 25 times, and the second CR200(X) example program has a loop that

samples 30 times. A 25-sample loop produces almost two cycles of a 60 Hz

wave form, and a 30-sample loop produces almost two cycles of a 50 Hz wave

form (see Figure 3). The average energy under the curve is calculated using

the RMSSpa instruction. A multiplier of 0.2 is applied to the RMS value; see

Section A.4 for more information.

Page 11

CS10-L and CS15-L Current Transformers

25 Samples of Amperage on CR200(X) Datalogger (60 Hz)

or 30 Samples of Amperage on CR200(X) Datalogger (50 Hz)

80

60

40

20

0

mV

1 3 5 7 9 11 13 15 17 19 21 23 25

-20

-40

-60

-80

Instanteneous Amps

FIGURE 3. Graph of a CS15 waveform

CR200(X) Program for 60 Hz

CS15-L waveform

'CR200(X) Series Datalogger

' Program name: CS15-LManual.cr2

'date: 4 Mar 2009

'program author: Brad Maxfield

Const Samples = 25 ' 25 samples for 2 waves of 60 Hz.

'Const Samples = 30 ' 30 samples for 2 waves of 50 Hz.

Public Crnt_A

Public mV(Samples)

Dim Counter

'Define Data Tables

DataTable (Test,1,-1)

DataInterval (0,1,min)

Average (1,Crnt_A,False)

Maximum (1,Crnt_A,False,0)

EndTable

'Main Program

BeginProg

Scan (1,Sec)

ExciteV (Ex1,mV2500)

For Counter = 1 To Samples

VoltSe (mV(Counter),1,1,1.0,-1250)

Next

ExciteV (Ex1,mV0)

RMSSpa (Crnt_A,(Samples-0),mV(1))

Crnt_A=Crnt_A*0.2 ' Multiplier for sensor

If Crnt_A<0.15 Then ' Eliminate noise below 0.15 amps.

Crnt_A = 0

EndIf

5

Page 12

CS10-L and CS15-L Current Transformers

CallTable Test

NextScan

EndProg

CR200(X) Program for 50 Hz

' CR200(X) Series Datalogger

' Program name: CS15-LManual.cr2

' date: 4 Mar 2009

' program author: Brad Maxfield

Const Samples = 30 ' 30 samples for 2 waves of 50 Hz.

'Const Samples = 25 ' 25 samples for 2 waves of 60 Hz.

Public Crnt_A

Public mV(Samples)

Dim Counter

'Define Data Tables

DataTable (Test,1,-1)

DataInterval (0,1,min)

Average (1,Crnt_A,False)

Maximum (1,Crnt_A,False,0)

EndTable

'Main Program

BeginProg

Scan (1,Sec)

ExciteV (Ex1,mV2500)

For Counter = 1 To Samples

VoltSe (mV(Counter),1,1,1.0,-1250)

Next

ExciteV (Ex1,mV0)

RMSSpa (Crnt_A,(Samples-0),mV(1))

Crnt_A=Crnt_A*0.2 ' Multiplier for sensor

If Crnt_A<0.15 Then ' Eliminate noise below 0.15 amps.

Crnt_A = 0

EndIf

CallTable Test

NextScan

EndProg

6

5.3 CR510, CR10X, CR23X Dataloggers

With these dataloggers, the best method for monitoring amperage is to make

millivolt burst measurements using Instruction 23 and then calculate RMS

using Instruction 82. For Instruction 23, the entry for parameter 4 needs to be

0001. This triggers on the first channel, triggers immediately, stores data in

input locations, and makes single-ended measurements.

Page 13

CS10-L and CS15-L Current Transformers

Remember that it is important to get complete cycles. For Instruction 23, if

parameters 5 and 6 are 2.0 and 0.05, respectively, then you get five complete

cycles for a 50-Hz waveform, and six complete cycles for a 60-Hz waveform

(see Figure 4). The multiplier for the CS10 is 0.2; see Section A.4 for more

information.

Six Cycles at 60 Hz Burst CR10X

I Instanteneous

FIGURE 4. Graph of CS10 waveform using burst mode

The following CR10X program generates the waveforms shown in Figure 4.

NOTE

The instructions listed below do not store data in final storage.

P92, P77, and output processing instructions such as P70 are

required to store the data permanently.

; Parameter 2 should be 2500 mV for 50-200 amps

; should be 250 mV for 5-49 amps

; should be 25 mV for 0-4.9 amps

; Parameter 5 should be 2.0 msec for 50 Hz or 60 Hz

; Parameter 6 should be 0.05 thousand scans for 50 Hz or 60 Hz

; if parameter 5 & 6 are 2.0 and 0.05, then you have 5 complete cycles at 50 Hz

; or 6 complete cycles at 60 Hz.

;

1: Burst Measurement (P23)

1: 1 Input Channels per Scan ; Should always be 1

2: 15 2500 mV Fast Range ; Change according to expected Amperage

3: 1 In Chan ; Change according to Wiring

4: 0001 Trig/Trig/Dest/Meas Options ; Should always be 0001

5: 2.0 Time per Scan (msec) ; Must be 2.0

6: .05 Scans (in thousands) ; Must be 0.05 (for 50 measurements * 2.0 msec = 100 mS)

7: 0 Samples before Trigger ; Should always be 0

8: 0.0 mV Limit ; Should always be 0

9: 0000 mV Excitation ; Should always be 0

10: 4 Loc [ Amps_1 ] ; First location of Block (array)

11: .2 Multiplier ; Match Multiplier of CT:0.2 for CS10-L with 10 ohm shunt

12: 0.0 Offset

2: Z=F x 10^n (P30)

1: 0.0 F

2: 00 n, Exponent of 10

3: 1 Z Loc [ Counter ]

7

Page 14

CS10-L and CS15-L Current Transformers

; This part of the program will calculate the RMS Amperage

; Standard Deviation in this part of the code works mathematically the same

; as RMS calculation, and it is easier to program this way. The RMS

; value is calculated and stored back into an input location for further

; processing if needed.

3: Beginning of Loop (P87)

1: 0 Delay

2: 50 Loop Count

4: Z=Z+1 (P32)

1: 1 Z Loc [ Counter ]

5: If (X<=>F) (P89)

1: 1 X Loc [ Counter ]

2: 1 =

3: 50 F

4: 10 Set Output Flag High (Flag 0)

6: Set Active Storage Area (P80)

1: 3 Input Storage Area

2: 2 Loc [ BurstAmps ]

7: Standard Deviation (P82)^3012

1: 1 Reps

2: 4 -- Sample Loc [ Amps_1 ]

8: End (P95)

5.4 21X, CR7 Dataloggers

Some Edlog dataloggers such as the 21X and CR7 do not have a burst mode.

For those dataloggers, you can use a “Loop Measurement Method” similar to

the method used with the CR200(X). This method is also an option for our

CR510, CR10X, and CR23X, but only three measurements per period will be

made. Figure 5 shows a graph produced by a CR10X program with a loop that

samples 90 times. A portion of this program is shown below.

32 cycles 60 Hz 90 samples in loop on CR10X

FIGURE 5. Graph of a CS10 waveform using 90 samples of amperage

I instant eneous

8

Page 15

CS10-L and CS15-L Current Transformers

NOTE

The instructions listed below do not store data in final storage.

P92, P77, and output processing instructions such as P70 are

required to store the data permanently.

3: Beginning of Loop (P87)

1: 0 Delay

2: 90 Loop Count

4: Z=Z+1 (P32)

1: 4 Z Loc [ Counter ]

5: Volt (SE) (P1)

1: 1 Reps

2: 14 250 mV Fast Range

3: 1 SE Channel

4: 57 -- Loc [ LoopAmp_1 ]

5: .2 Multiplier

6: 0.0 Offset

6: If (X<=>F) (P89)

1: 4 X Loc [ Counter ]

2: 1 =

3: 90 F

4: 10 Set Output Flag High (Flag 0)

7: Z=X (P31)

1: 57 -- X Loc [ LoopAmp_1 ]

2: 3 Z Loc [ Sensor ]

8: Set Active Storage Area (P80)

1: 3 Input Storage Area

2: 2 Loc [ Amp ]

9: Standard Deviation (P82)^12989

1: 1 Reps

2: 3 Sample Loc [ Sensor ]

10: End (P95)

The above CR10X program may provide an adequate waveform because the

program makes more than two measurements per period and samples many

periods. However, if the datalogger’s Burst Measurement Instruction is used

with specific settings, the program will make more measurements per cycle

assuring that complete periods for both 50 and 60 Hz (5 at 50 Hz and 6 at 60

Hz) will be monitored (see Figure 4).

9

Page 16

CS10-L and CS15-L Current Transformers

5.5 CR1000 with Multiplexer Sample Program

This program uses the CR1000 and an AM16/32-series multiplexer to read 32

CS10-L current transformers.

'CR1000 program to measure rms current

PipeLineMode 'must be pipeline mode

Const num_samples = 100 '6 waveforms for 60 Hz, 5 waveforms for 50 Hz

Const NumSensors=32 'Number of Sensors on the Mux MUX in 2X32 Mode *****

'Sensor wired to Low on each of the 32 channels.

'Odd Low on Mux wired to SE2 on Datalogger

Public Amps(NumSensors), i, Batt_Volt 'the line current

Public Amp_mult, TempAmps

Dim i_sig (num_samples) 'to hold the burst measurements, each 100 samples long

PreserveVariables 'to store values between power cycles

DataTable (AmpTable,True,-1)

DataInterval (0,1,Min,10)

Maximum (NumSensors,Amps,IEEE4,False,False)

Average (NumSensors,Amps,FP2,False)

EndTable

BeginProg

Amp_mult = 0.2 '0.2 multiplier for the CS10-L/CS15-L

Scan (10,Sec,0,0)

Battery (Batt_volt)

'Turn AM16/32 Multiplexor On

PortSet(4,1)

i=0

SubScan(0,uSec,NumSensors)

'Switch to next AM16/32 Multiplexer Channel

PulsePort(5,10000)

i=i+1

VoltSe (i_sig (1), num_samples, mV2500,-2, True, 1000, 0, 1.0, 0)

StdDevSpa (Amps(i), num_samples, i_sig (1))

Amps(i) = Amps(i) * Amp_mult 'put in amps

If Amps(i) <= 0.15 Then Amps(i) = 0

NextSubScan

'Turn AM16/32 Multiplexer Off

PortSet(4,0)

CallTable (AmpTable)

NextScan

EndProg

10

Page 17

CS10-L and CS15-L Current Transformers

5.6 CR10X with Multiplexer Sample Program

This program uses the CR10X and an AM16/32-series multiplexer to read 32

CS10-L current transformers.

;{CR10X}

; Example program for CS10-L

;

; Program to test the CS10-L or CS15-L sensor on a CR10X datalogger

; and AM1632 Multiplexer.

;

*Table 1 Program

01: 30 Execution Interval (seconds)

; Turn on the multiplexer

1: Do (P86)

1: 41 Set Port 1 High

2: Excitation with Delay (P22)

1: 1 Ex Channel

2: 0 Delay W/Ex (0.01 sec units)

3: 15 Delay After Ex (0.01 sec units)

4: 0 mV Excitation

3: Beginning of Loop (P87)

1: 0000 Delay

2: 32 Loop Count

; Clock multiplexer to next channel

4: Do (P86)

1: 72 Pulse Port 2

5: Excitation with Delay (P22)

1: 1 Ex Channel

2: 0 Delay W/Ex (0.01 sec units)

3: 1 Delay After Ex (0.01 sec units)

4: 0 mV Excitation

6: Do (P86)

1: 1 Call Subroutine 1

; This part of the program will calculate the RMS Amperage

; Standard Deviation in this part of the code works mathematically the same

; as RMS calculation, and it is easier to program this way. The RMS

; value is calculated and stored back into an input location for further

; processing if needed.

7: Do (P86)

1: 2 Call Subroutine 2

11

Page 18

CS10-L and CS15-L Current Transformers

8: Step Loop Index (P90)

1: 2 Step

9: Z=X (P31)

1: 2 X Loc [ BurstAmps ]

2: 4 -- Z Loc [ CS10_1 ]

10: Do (P86)

1: 3 Call Subroutine 3

11: Z=X (P31)

1: 3 X Loc [ Burst_A2 ]

2: 5 -- Z Loc [ CS10_2 ]

12: End (P95)

13: Do (P86)

1: 51 Set Port 1 Low

; This part of the program will store a one minute average of the amperage.

14: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

15: Set Active Storage Area (P80)^17815

1: 1 Final Storage Area 1

2: 60 Array ID

16: Real Time (P77)^10331

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

17: Average (P71)^5143

1: 64 Reps

2: 4 Loc [ CS10_1 ]

*Table 2 Program

02: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

;

; Parameter 2 should be 2500 mV for 50-200 amps

; should be 250 mV for 5-49 amps

; should be 25 mV for 0-4.9 amps

; Parameter 5 should be 2.0 msec for 50 Hz or 60 Hz

; Parameter 6 should be 0.05 thousand scans for 50 Hz or 60 Hz

; if parameter 5 & 6 are 2.0 and 0.05, then you have 5 complete cycles at 50 Hz

; or 6 complete cycles at 60 Hz.

1: Beginning of Subroutine (P85)

1: 1 Subroutine 1

12

Page 19

CS10-L and CS15-L Current Transformers

2: Burst Measurement (P23)

1: 1 Input Channels per Scan

2: 15 2500 mV Fast Range

3: 1 In Chan

4: 0001 Trig/Trig/Dest/Meas Options

5: 2.0 Time per Scan (msec)

6: .05 Scans (in thousands)

7: 0 Samples before Trigger

8: 0.0 mV Limit

9: 0000 mV Excitation

10: 71 Loc [ Amps_1 ]

11: .2 Multiplier

12: 0.0 Offset

3: Burst Measurement (P23)

1: 1 Input Channels per Scan

2: 15 2500 mV Fast Range

3: 2 In Chan

4: 0001 Trig/Trig/Dest/Meas Options

5: 2.0 Time per Scan (msec)

6: .05 Scans (in thousands)

7: 0 Samples before Trigger

8: 0.0 mV Limit

9: 0000 mV Excitation

10: 123 Loc [ AmpsII_1 ]

11: .2 Multiplier

12: 0.0 Offset

4: End (P95)

5: Beginning of Subroutine (P85)

1: 2 Subroutine 2

6: Z=F x 10^n (P30)

1: 0.0 F

2: 00 n, Exponent of 10

3: 1 Z Loc [ Counter ]

7: Beginning of Loop (P87)

1: 0 Delay

2: 50 Loop Count

8: Z=Z+1 (P32)

1: 1 Z Loc [ Counter ]

9: If (X<=>F) (P89)

1: 1 X Loc [ Counter ]

2: 1 =

3: 50 F

4: 10 Set Output Flag High (Flag 0)

10: Set Active Storage Area (P80)

1: 3 Input Storage Area

2: 2 Loc [ BurstAmps ]

13

Page 20

CS10-L and CS15-L Current Transformers

11: Standard Deviation (P82)^13110

1: 1 Reps

2: 71 -- Sample Loc [ Amps_1 ]

12: End (P95)

13: End (P95)

14: Beginning of Subroutine (P85)

1: 3 Subroutine 3

15: Z=F x 10^n (P30)

1: 0.0 F

2: 00 n, Exponent of 10

3: 1 Z Loc [ Counter ]

16: Beginning of Loop (P87)

1: 0 Delay

2: 50 Loop Count

17: Z=Z+1 (P32)

1: 1 Z Loc [ Counter ]

18: If (X<=>F) (P89)

1: 1 X Loc [ Counter ]

2: 1 =

3: 50 F

4: 10 Set Output Flag High (Flag 0)

19: Set Active Storage Area (P80)

1: 3 Input Storage Area

2: 3 Loc [ Burst_A2 ]

20: Standard Deviation (P82)^6732

1: 1 Reps

2: 123 -- Sample Loc [ AmpsII_1 ]

21: End (P95)

22: End (P95)

End Program

14

Page 21

Appendix A. Theory of Operation

A.1 Typical Electrical Circuit

An example of a typical electrical circuit is a generator that provides energy in

the form of a 60-Hz sine wave. The energy is carried from the point of

generation to the point of consumption via two wires. The generator creates an

electrical load that lights up the light bulb (see Figure A-1).

FIGURE A-1. Generator schematic

If we want to know the consumption (amps) of the load, we need a way to

measure what is passing through the wires.

We can add a sensor into the circuit to measure the amperage going through

the circuit (see Figures A-2 through Figure A-4). This sensor is called a CT or

Current Transformer. Our CS10 and CS15 are current transformers.

A-1

Page 22

Appendix A. Theory of Operation

FIGURE A-2. Schematic of generator with current transformer

A-2

FIGURE A-3. Schematic of current transformer with the wire

Page 23

FIGURE A-4. CS10 with the wire

Appendix A. Theory of Operation

A.2 Current Transformer Description

A current transformer is a special kind of transformer that transfers energy

from one side to another through magnetic fluxes (see Figure A-5).

FIGURE A-5. Magnetic flux schematic

The formula for a transformer is as follows (Equation A):

i

* n1 = i2 * n2 Equation A

1

Where i = amps and n = number of turns or windings

And where n

is the primary winding and n2 is the secondary

1

A-3

Page 24

Appendix A. Theory of Operation

With the current transformer, the primary coils or windings are minimized to

avoid removing power out of the circuit, but still have a signal large enough to

measure (see Figure A-6).

FIGURE A-6. Windings schematic

A tiny bit of the current is transferred to the secondary coil.

We can find the current induced on the secondary windings by solving for i

i

= i1 * n1/n2 Equation B

2

:

2

For Example: The CS10 current transducer has an n2 value of 2000 windings.

If 20 amps pass through the primary winding, the following amperage is

produced on the secondary winding:

= 20 * (1/2000) = 0.01 amp on secondary winding

i

2

A.3 Converting a Milliamp Signal to a Millivolt Signal

After the current is transformed from one level to another level, we need to

convert the amperage signal into a voltage signal so that the datalogger can

measure it.

Use Ohm’s Law (Equation C) to convert amperage to voltage:

E = I * R (E=Volts, I = Amps, R = Ohms) Equation C

For Example: Using our previous example:

E = 0.01 amps * R

A-4

The CS10-L contains a 10-ohm burden (shunt) resistor. Therefore E is:

E = 0.01 amps * 10 ohms = 0.1 volts (or 100 mV)

From these calculations, we can determine if we want slightly better resolution

on the measurement. We can lower the Range Code to 250 mV for some

dataloggers.

Page 25

A.4 Multiplier

Appendix A. Theory of Operation

Use Equation D to calculate the multiplier.

m=C*n

Where, C = a correction constant

If we assume a correction constant of 1, then we can solve for the equation

from the above information.

m = 1 * 2000/1 * (1/10) * (1/1000) = 0.2 multiplier

*(1/R)*(1 V/1000 mV) Equation D

2/n1

A.5 CS10/CS15 Comparison

The CS10 consists of a CR Magnectic’s CR8459 Current Transducer with a

10-ohm burden resistor incorporated into its cable (see Figure A-7). The

resistor allows most of our dataloggers to measure it.

CS10-L

FIGURE A-7. CS10 schematic

The CS15, a modified version of the CS10, was developed specifically for the

CR200(X)-series dataloggers. CR200(X)-series dataloggers require special

treatment because they cannot measure negative values; range is only 0 to

2500 mV (see Figure A-9). To create positive reference, the CS15-L uses

Voltage Excitation to shift the measurement range (see Figures A-8 through A-

10).

A-5

Page 26

Appendix A. Theory of Operation

1250 mV

FIGURE A-8. Adding 1250 mV creates positive output

0 mV

A-6

FIGURE A-9. CS15 schematic

Page 27

Appendix A. Theory of Operation

FIGURE A-10. CS15 measurement range

A-7

Page 28

Appendix A. Theory of Operation

A-8

Page 29

Page 30

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...