Page 1

CS100 Barometric

Pressure Sensor

Revision: 8/12

Copyright © 2002-2012

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements...............................................1

3. Initial Inspection .........................................................1

4. Quickstart .................................................................... 1

4.1 Step 1 — Mount Sensor to an Enclosure Backplate.............................1

4.2 Step 2 — Use SCWin Short Cut to Program Datalogger and

Generate Wiring Diagram.................................................................2

5. Overview......................................................................4

6. Specifications .............................................................6

6.1 Performance .........................................................................................6

6.1.1 Performance for “Standard” Range Option...................................6

6.1.2 Performance for “500 to 1100 mb” Range Option........................7

6.1.3 Performance for “800 to 1100 mb” Range Option........................7

6.2 Electrical ..............................................................................................7

6.3 Physical ................................................................................................7

7. Installation...................................................................8

7.1 Enclosure Considerations.....................................................................8

7.2 Wiring ..................................................................................................9

7.2.1 Datalogger Connection .................................................................9

7.2.2 5-pin Screw Terminal Plug Connector........................................10

7.3 Programming......................................................................................11

7.3.1 Conversion Factors .....................................................................11

7.3.2 Multipliers and Offsets for Different Measurement Range

Options ....................................................................................11

7.3.3 Program Examples ......................................................................12

7.3.3.1 CRBasic Example 1: CR1000 Program Using

Sequential Mode ...........................................................12

7.3.3.2 CRBasic Example 2: CR1000 Program Using

Pipeline Mode...............................................................13

7.3.3.3 Edlog Example — CR10X Program ................................14

7.3.4 Output Resolution .......................................................................15

7.4 Correcting Pressure to Sea Level .......................................................15

8. Maintenance and Calibration ...................................16

i

Page 6

Table of Contents

Figures

5-1. CS100 Barometric Pressure Sensor..................................................... 5

7-1. ENC100 is a very small enclosure that can house one CS100 ............ 8

7-2. CS100 as removed from the box ......................................................... 9

7-3. Connector key attached to 5-pin screw terminal plug connector....... 10

Tables

7-1. Signal and Ground Connectors for CS100 ........................................ 10

7-2. Conversion Factors for Alternative Pressure Units ........................... 11

7-3. Multipliers and Offsets...................................................................... 11

7-4. Wiring for Example Programs........................................................... 12

ii

Page 7

CS100 Barometric Pressure Sensor

1. Introduction

The CS100 measures barometric pressure for the range of 600 to 1100 mb.

This range equates to from below sea level (as in a mine) up to 12,000 feet

above sea level. Designed for use in environmental applications, the CS100 is

compatible with all Campbell Scientific dataloggers.

Before using the CS100, please study

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 4, Quickstart

More details are available in the remaining sections.

2. Cautionary Statements

• Warning: Failure to protect the sensor from condensation may result in

permanent damage.

• Warning: Improper wiring may damage the CS100 beyond repair.

• Care should be taken when opening the shipping package to not damage or

cut the cable jacket. If damage to the cable is suspected, consult with a

Campbell Scientific applications engineer.

• Although the CS100 is rugged, it should be handled as a precision

scientific instrument.

• The black outer jacket of the cable is Santoprene® rubber. This

compound was chosen for its resistance to temperature extremes, moisture,

and UV degradation. However, this jacket will support combustion in air.

It is rated as slow burning when tested according to U.L. 94 H.B. and will

pass FMVSS302. Local fire codes may preclude its use inside buildings.

3. Initial Inspection

• Upon receipt of the CS100, inspect the packaging and contents for

damage. File damage claims with the shipping company.

4. Quickstart

4.1 Step 1 — Mount Sensor to an Enclosure Backplate

The mounting holes for the sensor are one-inch-centered (three inches apart),

and will mount directly onto the holes on the backplates of the Campbell

Scientific enclosures. Mount the sensor with the pneumatic connector pointing

1

Page 8

CS100 Barometric Pressure Sensor

vertically downwards to prevent condensation collecting in the pressure cavity,

and also to ensure that water cannot enter the sensor.

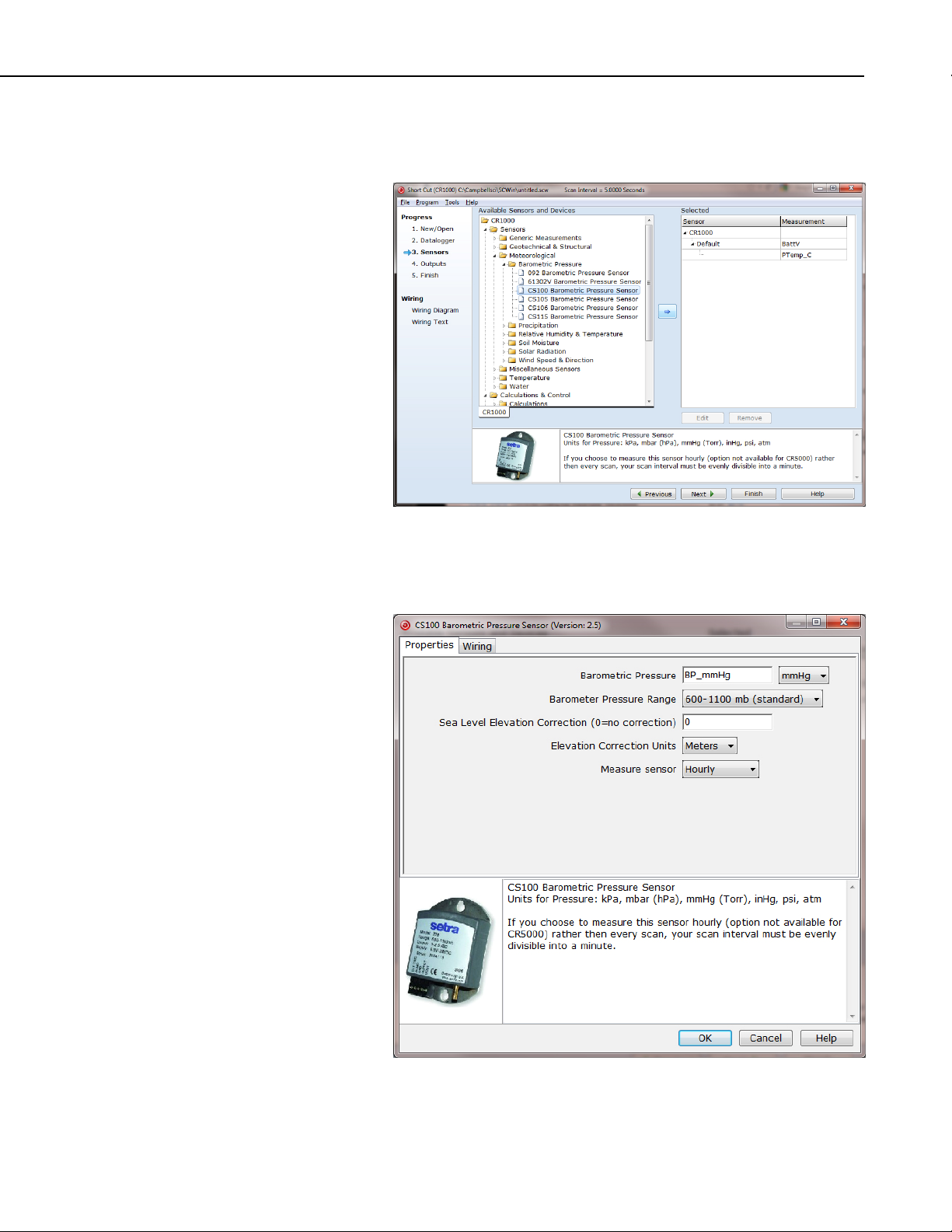

4.2 Step 2 — Use SCWin Short Cut to Program Datalogger and Generate Wiring Diagram

The simplest method for programming the datalogger to measure the CS100 is

to use Campbell Scientific's SCWin Short Cut Program Generator.

1. Open Short Cut and click on New Program.

2. Select a datalogger and scan interval.

2

Page 9

CS100 Barometric Pressure Sensor

3. Select CS100 Barometric Pressure Sensor then click the right arrow in

the middle of the page to add the sensor to the list of sensors to be

measured.

4. Define the name of the public variables. Variable defaults to BP_mmHg

that holds the barometric pressure measurements. Select the desired units

of measure, pressure range, sea level elevation correction, elevation

correction units, and whether the sensor should be measured hourly.

3

Page 10

CS100 Barometric Pressure Sensor

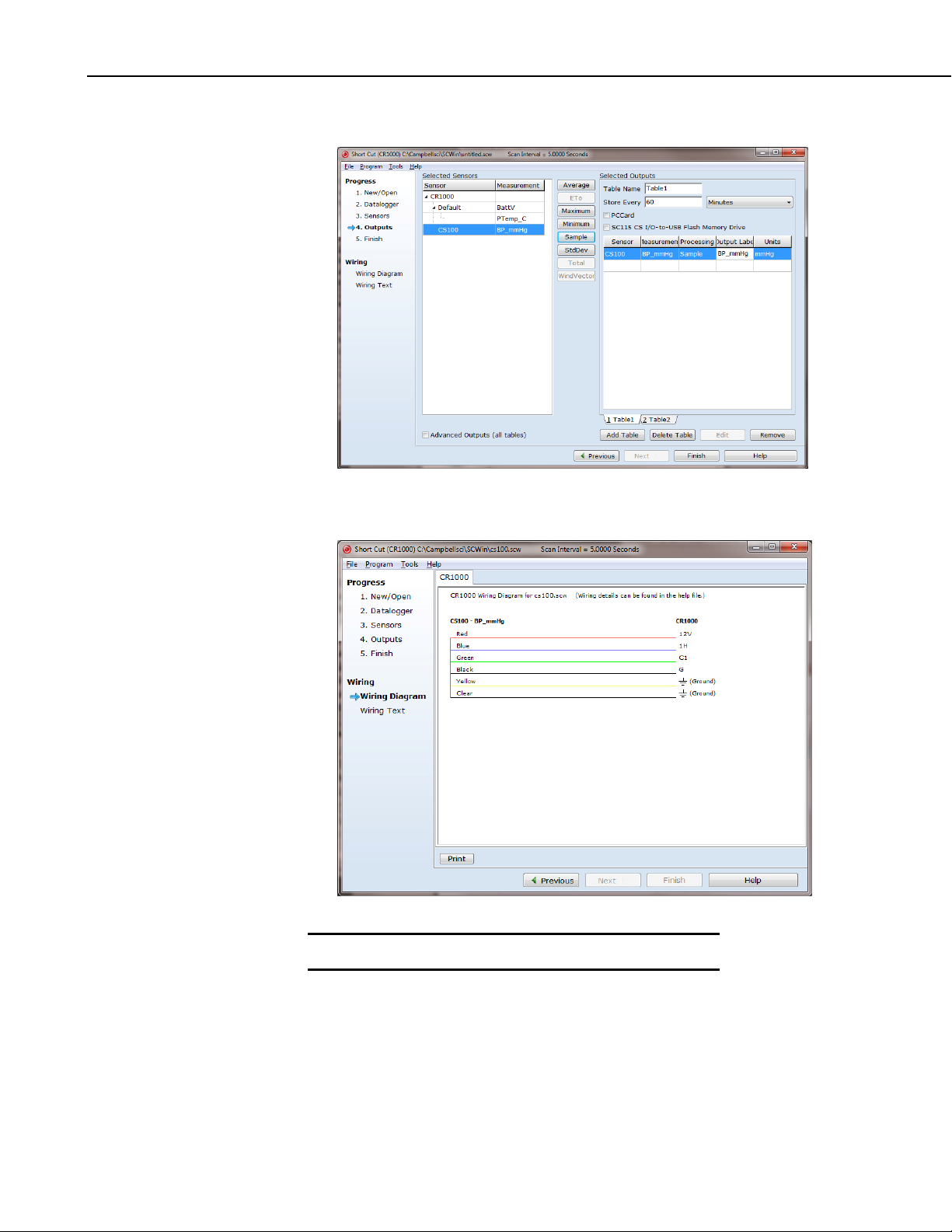

5. Choose the outputs for the barometric pressure and then select finish.

6. Remove the yellow warning label from the pigtails and wire according to

the wiring diagram generated by SCWin Short Cut.

WARNING

5. Overview

4

Improper wiring may damage the CS100 beyond repair.

The CS100 is a capacitive pressure transducer that uses the Setra's electrical

capacitor technology for barometric pressure measurements over the 600 to

1100 millibar range. The transducer’s compact and rugged polyester housing

with stainless blackplate contains two closely-spaced, parallel, electrically-

Page 11

CS100 Barometric Pressure Sensor

isolated metallic surfaces. One of the surfaces is essentially a diaphragm

constructed of a Setra’s proprietary compound of fused glass and ceramic

(Setraceram™) or a low-hysteresis material, such as 17-4 PH SS. The

diaphragm is capable of detecting a slight change in the applied pressure,

which is then converted to an analog voltage signal by Setra’s custom

Application Specific Integrated Circuit (ASIC). The analog signal generated

by the barometer can be directly measured by a Campbell Scientific datalogger.

The CS100 is supplied in the triggered mode, in which the datalogger switches

12 VDC power to the barometer before the measurement. The datalogger then

powers down the barometer after the measurements to conserve power.

Other measurement range options such as 500 to 1100 millibar, and 800 to

1100 millibar are also available. Please contact Campbell Scientific, Inc. for

ordering these special versions.

Campbell Scientific offers the CS100-QD, a version of the CS100 that includes

a connector for use with a RAWS-F or RAWS-P weather station (refer to the

RAWS-F and RAWS-P manuals for more information).

If the CS100 and datalogger will be housed in different enclosures, the

CABLE5CBL-L should be used instead of the cable that is shipped with the

CS100. The CABLE5CBL-L can terminate in:

• Pigtails that connect directly to a Campbell Scientific datalogger

(option –PT).

• Connector that attaches to a prewired enclosure (option –PW). Refer

to www.campbellsci.com/prewired-enclosures for more information.

FIGURE 5-1. CS100 Barometric Pressure Sensor

5

Page 12

CS100 Barometric Pressure Sensor

6. Specifications

Features:

Compatibility

Dataloggers: CR200(X) series

CR800 series

CR1000

CR3000

CR5000

CR9000(X)

CR7X

CR510

CR10(X)

CR23X

21X

• Integral switching circuit limits power consumption to measurement

cycle

• Compatible with all Campbell Scientific dataloggers (including the

CR200(X) series)

• Calibration NIST traceable

• Meets CE conformance standards

6.1 Performance

6.1.1 Performance for “Standard” Range Option

Measurement Range: 600 mb to 1100 mb (hPa)

Operating Temperature Range: -40° to +60°C (-40° to +140°F)

Storage Temperature Range: -60° to +120°C (-76° to +248°F)

Proof Pressure: 1500 mb

Burst Pressure: 2000 mb

Humidity Range: non-condensing (up to 95% RH)

Media Compatibility: non-corrosive, non-condensing air or gas

Resolution: 0.01 mb

Total Accuracy

±1.0 mb @ 0° to +40°C

±1.5 mb @ -20° to +50°C

±2.0 mb @ -40° to +60°C

Linearity: ±0.4 mb

Hysteresis: ±0.05 mb

Repeatability: ±0.03 mb

Long-term Stability: ±0.1 mb per year

1

The root sum squared (RSS) of end point non-linearity, hysteresis, non-

repeatability and calibration uncertainty.

1

: ±0.5 mb @ 20°C

6

Page 13

CS100 Barometric Pressure Sensor

6.1.2 Performance for “500 to 1100 mb” Range Option

Measurement Range: 500 to 1100 mb

Total Accuracy

2

: ±0.6 mb @ 20°C

±1.2 mb @ 0° to +40°C

±2.0 mb @ -20° to +50°C

±2.5 mb @ -40° to +60°C

Linearity: ±0.5 mb

Hysteresis: ±0.06 mb

Repeatability: ±0.04 mb

6.1.3 Performance for “800 to 1100 mb” Range Option

Measurement Range: 800 to 1100 mb

Total Accuracy

±0.6 mb @ 0° to +40°C

±1.0 mb @ -20° to +50°C

±1.5 mb @ -40° to +60°C

Linearity: ±0.25 mb

Hysteresis: ±0.03 mb

Repeatability: ±0.02 mb

3

: ±0.3 mb @ 20°C

6.2 Electrical

Supply Voltage: 9.5 to 28 Vdc

Current Consumption: 3 mA nominal (operating mode)

1 µA quiescent (sleep mode)

Signal Output: 0 to 2.5 Vdc

Warm-up Time: <1 s from shutdown mode

Response Time: <100 ms

6.3 Physical

NOTE

Dimensions (Main Box): 9.1 x 6.1 x 2.5 cm (3.6 x 2.4 x 1.0 in)

Weight: 135 g (4.8 oz)

Mounting Hole Centers: 7.62 cm (3 in)

Pressure Connector: 1/8 in ID barbed fitting

®

The black outer jacket of the cable is Santoprene

rubber. This

compound was chosen for its resistance to temperature extremes,

moisture, and UV degradation. However, this jacket will support

combustion in air. It is rated as slow burning when tested

according to U.L. 94 H.B. and will pass FMVSS302. Local fire

codes may preclude its use inside building.

2

The root sum squared (RSS) of end point non-linearity, hysteresis, non-

repeatability and calibration uncertainty.

3

The root sum squared (RSS) of end point non-linearity, hysteresis, non-

repeatability and calibration uncertainty.

7

Page 14

CS100 Barometric Pressure Sensor

7. Installation

7.1 Enclosure Considerations

To prevent condensation, install the sensor in an environmentally protected

enclosure, complete with desiccant, which should be changed at regular

intervals.

CAUTION

Failure to protect the sensor from condensation may result

in permanent damage.

The CS100 is typically mounted in a Campbell Scientific enclosure next to the

datalogger. Campbell Scientific also offers the ENC100 for situations where it

is desirable to house the CS100 in its own enclosure. The ENC100 is a 6.7-in.

x 5.5-in. x 3.7-in. enclosure that includes a compression fitting for cable entry,

a vent for equalization with the atmosphere, a backplate for mounting the

CS100, and hardware for mounting the ENC100 to a tripod, tower, or pole (see

FIGURE 7-1).

8

FIGURE 7-1. ENC100 is a very small enclosure that can house one

CS100

Page 15

CS100 Barometric Pressure Sensor

Remember that for the sensor to detect the external ambient pressure, the

enclosure must vent to the atmosphere (i.e., not be hermetically sealed).

Enclosures purchased from Campbell Scientific properly vent to the

atmosphere.

NOTE

For user-supplied enclosures, it may be necessary to make a vent

hole on the outer wall. In this situation, do not make the hole on

one of the vertical side walls, as wind blowing around it can

cause transient changes in pressure.

7.2 Wiring

7.2.1 Datalogger Connection

Before connecting the barometer to the datalogger, a yellow warning label

must be removed from the pigtails (see FIGURE 7-2). The warning label

reminds the user of the importance of properly connecting the barometer to the

datalogger. Proper wiring is shown in TABLE 7-1.

Yellow Warning Label

FIGURE 7-2. CS100 as removed from the box

9

Page 16

CS100 Barometric Pressure Sensor

TABLE 7-1. Signal and Ground Connectors for CS100

Wire

Blue VOUT S.E. Input High Side of Diff Input

Yellow AGND

Black GND

Green EXT TRIG

Red SUPPLY 12 VDC 12 VDC

Shield Shield

CS100 Terminal

WARNING

Single-Ended Measurement

AG (CR10(X), CR500, CR510)

(Other Dataloggers)

(21X, CR7, CR9000(X))

G (Other Dataloggers)

Control port (use to turn power

on/off)

G (CR10(X), CR500, CR510)

(Other Dataloggers)

Improper wiring may damage the CS100 beyond repair.

Datalogger

Differential Measurement

Low Side of Diff. Input

(21X, CR7, CR9000(X))

G (Other Dataloggers)

Control port (use to turn power

on/off)

G (CR10(X), CR500, CR510)

(Other Dataloggers)

Datalogger

7.2.2 5-pin Screw Terminal Plug Connector

The datalogger connects to the CS100 via a 5-pin screw terminal plug

connector. This connector is removable and may be replaced. The

replacement connector may come with a connector key attached to it to ensure

that the connector is plugged into the CS100 right side up (see FIGURE 7-3).

When the connector is right side up, it will easily plug into the barometer.

10

WARNING

FIGURE 7-3. Connector key attached to 5-pin screw terminal plug

connector

A 5-pin screw terminal that is plugged in upside down

will damage the sensor—perhaps beyond repair.

Page 17

7.3 Programming

The CS100 sensor is measured using the singled-ended voltage measurement

instruction (VoltSE() in CRBasic and Instruction 1 in Edlog).

Atmospheric pressure changes little with time. In most weather station

applications measuring pressure once an hour is adequate.

7.3.1 Conversion Factors

In the example programs, the pressure is reported in millibars (mb). To report

pressure in different units, multiply the measured pressure by the appropriate

conversion factor using the P37 (Z=X*F) instruction for CR500, CR510,

CR10(X), CR23X, 21X, and CR7, or by adding an expression for CR200(X),

CR800, CR850, CR1000, CR3000, CR5000, and CR9000(X) dataloggers. See

TABLE 7-2 below for conversion factors.

TABLE 7-2. Conversion Factors for

Alternative Pressure Units

To Find Multiply by

hPa 1.0

kPa 0.1

mm of Hg 0.75006

in of Hg 0.02953

Psi 0.0145

Atm 0.00099

Torr 0.75006

CS100 Barometric Pressure Sensor

7.3.2 Multipliers and Offsets for Different Measurement Range Options

Please refer to the table below for proper multipliers and offsets.

TABLE 7-3. Multipliers and Offsets

Range Options Multiplier Offset

600 to 1100 mb

(Standard range)

500 to 1100 mb 0.24 500

800 to 1100 mb 0.12 800

0.2 600

11

Page 18

CS100 Barometric Pressure Sensor

7.3.3 Program Examples

The CS100 wiring instructions for the example programs are shown in TABLE

7-4 below.

Wire Color Description CR10(X) CR1000

Blue VOUT – Pressure Signal Out SE6 SE15

Red SUPPLY – 12 Vdc Power In 12V 12V

Black GND – Power Ground G G

Yellow AGND – Signal Ground AG

Green ETX. TRIG. – External Trigger C8 C4

Clear Shield G G

7.3.3.1 CRBasic Example 1: CR1000 Program Using Sequential Mode

This CR1000 program uses the sequential mode, which is the simplest mode

and can be used for most meteorological applications. Although the example is

for the CR1000, other CRBasic dataloggers, such as the CR200(X), CR800,

CR850, CR3000, and CR9000(X) are programmed similarly. In the example,

the CR1000 measures the CS100 once an hour. To do this, the CR1000 uses a

control port to turn on the CS100 one minute before the top of the hour. On the

hour, the datalogger measures the CS100, and then turns the CS100 off.

TABLE 7-4. Wiring for Example Programs

'CR1000

'Declare Variables and Units

Public BattV

Public PTemp_C

Public BP_mmHg

Units BattV=Volts

Units PTemp_C=Deg C

Units BP_mmHg=mmHg

'Define Data Tables

DataTable(Table1,True,-1)

DataInterval(0,60,Min,10)

Sample(1,BP_mmHg,FP2)

EndTable

DataTable(Table2,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

EndTable

'Main Program

BeginProg

'Main Scan

Scan(5,Sec,1,0)

'Default Datalogger Battery Voltage measurement 'BattV'

Battery(BattV)

'Default Wiring Panel Temperature measurement 'PTemp_C'

PanelTemp(PTemp_C,_60Hz)

'CS100 Barometric Pressure Sensor measurement 'BP_mmHg'

If IfTime(59,60,Min) Then PortSet(4,1)

If IfTime(0,60,Min) Then

VoltSE(BP_mmHg,1,mV2500,15,1,0,_60Hz,0.2,600)

BP_mmHg=BP_mmHg*0.75006

PortSet(4,0)

12

Page 19

CS100 Barometric Pressure Sensor

EndIf

'Call Data Tables and Store Data

CallTable(Table1)

CallTable(Table2)

NextScan

EndProg

7.3.3.2 CRBasic Example 2: CR1000 Program Using Pipeline Mode

Although this example is for the CR1000, other CRBasic dataloggers, such as

the CR200(X), CR800, CR850, CR3000, and CR9000(X) are programmed

similarly. In the example, the CR1000 measures the CS100 once an hour in a

program that runs at 1 Hz. In order to keep the CR1000 running in a pipeline

mode, the measurement instruction is placed outside the “If” statement. The

measurement is made every scan, and the measured value is first written into a

temporary variable called "CS100_temp". Once the CS100 is turned on one

minute before the hour, the CS100 starts to make the correct pressure

measurements. At the top of the hour, the correct value is copied into the

current variable called "pressure", and the sensor is turned off immediately.

'CR1000 Datalogger

Public CS100_temp

Public pressure

Units pressure = mbar

DataTable (met_data,True,-1)

DataInterval (0,60,min,10)

Sample (1,pressure,IEEE4)

EndTable

BeginProg

Scan (1,sec,3,0)

'Measurement is made every scan outside the “If” statement

VoltSE (CS100_temp,1,mV2500,15,False,200,250,0.2,600)

'Turn on CS100 one minute before the hour

If (IfTime (59,60,min)) Then WriteIO (&b1000,&b1000)

'Copy the correct value to a current variable called “pressure” at the top of the

hour

'Turn off CS100 after measurement

If (IfTime (0,60,min)) Then

pressure = CS100_temp

WriteIO (&b1000,&b0)

EndIf

CallTable met_data

NextScan

EndProg

13

Page 20

CS100 Barometric Pressure Sensor

7.3.3.3 Edlog Example — CR10X Program

Although this example is for a CR10X, other Edlog dataloggers, such as the

CR510, CR23X, CR7, and 21X are programmed similarly. In the example, the

CR10X datalogger turns on the CS100 one minute before the top of the hour

using a control port. On the hour, the datalogger measures the CS100, and then

it turns the CS100 off.

;{CR10X}

;

*Table 1 Program

01: 1 Execution Interval (seconds)

;Turn on CS100 one minute before the hour

;

1: If time is (P92)

1: 59 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 48* Set Port 8* High

;Measure CS100 at the top of the hour

;

2: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 30 Then Do

3: Volt (SE) (P1)

1: 1 Reps

2: 15 2500 mV Fast Range

3: 6 SE Channel

4: 1 Loc [ P_mb ]

5: 0.2 Multiplier

6: 600 Offset

;Turn off CS100

;

4: Do (P86)

1: 58* Set Port 8* Low

5: End (P95)

6: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

7: Real Time (P77)

1: 0110 Day,Hour/Minute (midnight = 0000)

;Store in high resolution mode to retain 0.01mb resolution

;

8: Resolution (P78)

1: 1 High Resolution

14

Page 21

CS100 Barometric Pressure Sensor

⎧

9: Sample (P70)

1: 1 Reps

2: 1* Loc [ P_mb ]

*Table 2 Program

02: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

End Program

-Input Locations1 P_mb

* Proper entries will vary with program and datalogger channel, and input location assignments.

7.3.4 Output Resolution

When storing the values from the CS100 to a data table or to a datalogger’s

final storage location, care must be taken to choose suitable scaling of the

reading, or to store the value with adequate resolution to avoid losing useful

resolution of the pressure measurement. The default resolution (low

resolution) for Campbell Scientific dataloggers is limited to a maximum of four

digits. Even then, the maximum digit value that can be displayed is 6999 for

Edlog dataloggers, and 7999 for the CRBasic dataloggers. If you use this

option with barometric data scaled in millibars (hPa), a reading above

799.9 mb for CRBasic dataloggers or 699.9 mb for Edlog dataloggers will lose

one digit of resolution, e.g. at 900 mb, the resolution is limited to 1 mb.

To retain 0.01 mb resolution, you either need to deduct a fixed offset from the

reading before it is stored to avoid exceeding the 799.9 for CRBasic

dataloggers or 699.9 for Edlog dataloggers threshold, or output the barometric

reading in high resolution format. This can be done by using the IEEE4 format

for the CR800, CR850, CR1000, CR3000, CR5000, and CR9000(X)

dataloggers or using the Resolution (P78) instruction for our Edlog

dataloggers. The default data output format for CR200(X) series datalogger is

IEEE4.

7.4 Correcting Pressure to Sea Level

The weather service, most airports, radio stations, and television stations adjust

the atmospheric pressure to a common reference (sea level). Equation 1 can be

used to find the difference in pressure between the sea level and the site. That

value (dP) is then added to the offset (600 mb in our example programs) in the

measurement instruction. U. S. Standard Atmosphere and dry air were

assumed when Equation 1 was derived (Wallace, J. M. and P. V. Hobbes,

1977: Atmospheric Science: An Introductory Survey, Academic Press,

pp. 59-61).

⎪

⎛

1013 25 1 1

dPE=−−

⎨

.

⎜

⎝

⎪

⎩

44307 69231

.

5.25328

⎞

⎟

⎠

⎫

⎪

⎬

(1)

⎪

⎭

15

Page 22

CS100 Barometric Pressure Sensor

The value dP is in millibars and the site elevation, E, is in meters. Add dP

value to the offset in the measurement instruction.

Use Equation (2) to convert feet to meters.

Eft

Em

()

The corrections involved can be significant: e.g. at 1000mb and 20°C,

barometric pressure will decrease by 1.1mb for every 10 meter increase in

altitude.

()

.=3281

(2)

ft m

8. Maintenance and Calibration

Since the sensor is semi-sealed, minimum maintenance is required:

1. Visually inspect the cable connection to ensure it is clean and dry.

2. Visually inspect the casing for damage.

3. Ensure that the pneumatic connection and pipe are secure and undamaged.

CAUTION

The external case can be cleaned with a damp, lint-free cloth and a mild

detergent solution.

Contact Campbell Scientific, Inc. (435-227-9000) for an RMA number before

returning the sensor for recalibration. You may also return the unit directly to

Setra for recalibration.

Should you lose the five terminal connector (p/n 16004), the replacement part

can be purchased from Campbell Scientific, Inc. Contact Campbell Scientific,

Inc. to purchase the part.

The CS100 is sensitive to static when the backplate is

removed. To avoid damage, take adequate anti-static

measures when handling.

16

Page 23

Page 24

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

Garbutt Post Shop QLD 4814

www.campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

www.campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

www.campbellsci.cc

Campbell Scientific Ltd. (CSL)

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

www.campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

www.campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or interna tional representative.

• info@campbellsci.com

PO Box 2450

• cleroux@csafrica.co.za

PO Box 8108

AUSTRALIA

• info@campbellsci.com.au

• suporte@campbellsci.com.br

CANADA

• dataloggers@campbellsci.ca

COSTA RICA

• info@campbellsci.cc

Campbell Park

80 Hathern Road

• sales@campbellsci.co.uk

92160 ANTONY

FRANCE

• info@campbellsci.fr

08024 Barcelona

SPAIN

• info@campbellsci.es

Loading...

Loading...