Page 1

INSTRUCTION MANUAL

CRS451/CRS456 Submersible

Copyright © 2013- 2014

Campbell Scientific, Inc.

Water-Level Recording Sensor

Revision: 1/14

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection and Handling Guidelines .............. 1

3.1 Ships With ............................................................................................ 2

4. Overview ...................................................................... 2

5. Specifications ............................................................. 2

6. Installation ................................................................... 4

6.1 Appropriate Depth ................................................................................ 4

6.2 Avoiding Freezing Conditions ............................................................. 5

6.3 Dislodge Bubbles ................................................................................. 5

6.4 Well Installation ................................................................................... 5

6.5 Other Installations ................................................................................ 6

6.6 Battery Voltage Reading ...................................................................... 6

6.7 Attaching Suspension Cable to CRS451/CRS456 ............................... 6

7. Programming .............................................................. 8

7.1 Settings ................................................................................................. 8

7.2 Connect to the CRS451/CR456 ............................................................ 8

7.3 Configure CRS45X for Measurements ................................................ 9

7.4 Compensating Measurements for Barometric Pressure ...................... 15

7.4.1 Using an Additional CRS45X ..................................................... 15

7.4.2 Using a Barometer ...................................................................... 15

8. Maintenance .............................................................. 20

8.1 Every Visit ......................................................................................... 20

8.2 Every Two to Three Years or on a Rotating Schedule ....................... 20

8.3 Battery Replacement .......................................................................... 21

9. Troubleshooting........................................................ 26

i

Page 6

Table of Contents

Appendices

Calibration Certificate ............................................. A-1

A.

B. Conversion to Units of Measurement ................... B-1

Table

B-1. Conversion Factors .......................................................................... B-1

ii

Page 7

CRS451/CRS456 Submersible

Water-Level Recording Sensor

1. Introduction

The CRS451 consists of a water-level and water-temperature sensor that has its

own time clock and memory to store the collected data, in a compact stainlesssteel case. This frees users to place the sensor in remote sites and let it collect

data for long periods of time. The CRS451/CRS456 supports standard timebased scanning and recording along with event-based recording based on water

level change (Delta) or logarithmic time sequence for pump and slug tests.

HydroSci software is included and supports test set up, data retrieval, and data

display.

The CRS451 has a 316L stainless-steel case that can be submerged in most

canals, wells, ponds, lakes, and streams. The CRS456 has a rugged titanium

case that allows it to be used in saltwater or other harsh environments.

Before using the CRS451/CRS456, please study:

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 6, Installation

2. Cautionary Statements

• The CRS451/CRS456 will be damaged if encased in frozen liquid (see

Section 6.2, Avoiding Freezing Conditions, for more information).

• Although the CRS451/CRS456 is a rugged and reliable device, it is also a

highly precise scientific instrument and should be handled as such.

• Dropping the instrument or allowing it to “free fall” down a well may

damage the transducer.

• Confirm the compatibility of the instrument to non-water environments

before installation.

• The CRS456 should be used in harsh water applications, including salt

water.

3. Initial Inspection and Handling Guidelines

• Upon receipt of the CRS451/CRS456, inspect the packaging for any signs

of shipping damage. File damage claims with the shipping company.

• Immediately check package contents against the shipping documentation

(see Section 3.1, Ships With). Contact Campbell Scientific with any

discrepancies.

1

Page 8

CRS451/CRS456 Submersible Water-Level Recording Sensor

• The model number and pressure range are etched on the housing. Check

this information against the shipping documentation to ensure that the

expected product was received.

3.1 Ships With

• 27555 USB 2.0 Cable Type A Male to Micro B Male, 6ft

• 29225 HydroSci Software on CD

4. Overview

The CRS451/CRS456, Submersible Water-Level Recording Sensor, provides

reliable, accurate pressure/level measurements that are fully temperature

compensated.

The 24 bit A/D has simultaneous 50/60 Hz rejection and automatic calibration

for each measurement. A number of additional advanced measurement

techniques are employed to harness the best possible performance available

from today’s state of the art pressure sensor technology. The CRS451/CRS456

reverts to a low power sleep state between measurements. A series of

measurements are performed yielding a temperature and pressure value. This

measurement cycle can be as fast as 1 second.

The design features a piezoresistive sensor housed in a 316L stainless steel

(CRS451) or titanium (CRS456) package to enhance reliability. The rugged

construction makes the CRS451/CRS456 suitable for water level measurement

in irrigation applications, water wells, lakes, streams, and tanks. The titanium

package of the CRS456 makes it ideal for salt water or other harsh

environments.

The CRS451/CRS456 has three nose cone options. The weighted nose cone

makes the transducer easier to submerge to depth. The NPT option allows the

sensor to be mounted to a 1/4 inch fitting. The nose cones can be exchanged at

a later time.

Communicating with the CRS451/CRS456 requires a micro USB cable and

HydroSci software running on a computer with Windows XP or later.

Configurable settings can be changed using Campbell Scientific’s HydroSci

software utility.

5. Specifications

Features:

• Field replaceable batteries

• Campbell Scientific quality

2

• No additional datalogger, enclosure, and power supply; reduces

system costs and simplifies installation

• Free customer-friendly software for communication, configuration,

data collection

Page 9

CRS451/CRS456 Submersible Water-Level Recording Sensor

Pressure

(psig)

Pressure

(kPa)

Meters of

fresh water

Feet of

fresh water

0 to 7.25

0 to 50

0 to 5.1

0 to 16.7

0 to 14.5

0 to 100

0 to 10.2

0 to 33.4

0 to 29

0 to 200

0 to 20.4

0 to 67

0 to 72.5

0 to 500

0 to 50.9

0 to 167

0 to 145

0 to 1000

0 to 102

0 to 334.5

• Fast scan rate

• Large data storage capacity

• High accuracy

• Long battery life

• Data retrieval through sealed USB connector

Measurement Time: < 1 s typical

Output: micro USB

Internal Data

Collection Memory: 4 MB

HydroSci Supported

Operating Systems: Windows XP, Windows Vista, or Windows 7

Logging/Scanning Modes: Standard, Delta, Logarithmic

Power Requirements: Internal user-replaceable lithium battery

Battery Life: 5+ years when logging interval is once per

hour

Power Consumption

Quiescent Current: < 80 μA

Measurement/

Communication Current: 4 mA for 1 s measurement

Measurement Ranges

1

:

Accuracy

Pressure Reading

2

: 0.1% full-scale range TEB3

Temperature: ±0.2°C

Resolution: 0.0035% full-scale range

Overpressure: 2x pressure range

Dry Storage Temperature: –30° to 80°C

Operating Temperature: 0° to 60°C

3

Page 10

CRS451/CRS456 Submersible Water-Level Recording Sensor

CAUTION

Freezing conditions may damage the CRS451/CRS456

(see Section 6.2, Avoiding Freezing Conditions, for more

information).

Body Material

CRS451: 316L Stainless Steel

CRS456: Titanium

Element Material

CRS451: 316L Stainless Steel

CRS456: Hastelloy

®

Standard Cone Material: Delrin

®

Weighted and NPT Material: Stainless Steel

Dimensions

Length: 22.23 cm (8.75 in)

Diameter: 2.22 cm (0.875 in)

Weight: 230 g (0.51 lb)

1

The CRS451 is a sealed gage sensor and when not submerged will read

approximately 1 bar at sea level and less as elevation increases. The CRS451

is calibrated at 9 pressures starting at 0.6 bar up to full scale referenced to 1

bar. Points below 1 bar are used in the calibration for the benefit of those who

deploy this sensor at elevations above sea level.

2

The accuracy specification listed pertains to the level of accuracy that the

CRS451/CRS456 is able to measure pressure. If a barometric pressure sensor

is used to remove the component of atmospheric pressure from the pressure

reading provided by the CRS451/CRS456 while submerged in a column of

water vented to the atmosphere, the error of the barometric sensor must be

considered when calculating the resulting accuracy of the water level reading.

3

Total Error Band (TEB) includes the combined errors due to nonlinearity,

hysteresis, nonrepeatability, and thermal effects over the compensated

temperature range, per ISA S51.1.

6. Installation

6.1 Appropriate Depth

4

The CRS451/CRS456 is designed for water level measurements. Typical

applications include agricultural water level/flow, water wells, lakes, streams,

and tanks. If the device is to be installed in a liquid other than water or in

contaminated water, check the compatibility of the wetted material. The

CRS456 should be used in harsh water applications, including salt water.

The CRS451/CRS456 must be installed below the water at a fixed depth. This

depth should be chosen so that the water pressure will never exceed the

transducer’s pressure range (twice its pressure rating).

Page 11

CRS451/CRS456 Submersible Water-Level Recording Sensor

CAUTION

CAUTION

CAUTION

The output reading will not be correct, and the transducer

can be damaged if pressure is twice its pressure rating.

Pressure can be converted to feet of fresh water using the following simple

equation:

1 psi = 2.31 feet of water

For example, the maximum depth with a pressure range of 0 to 7.25 psig is

16.748 feet of water.

6.2 Avoiding Freezing Conditions

Expansion of water due to freezing will irreparably damage the

CRS451/CRS456. The CRS451/CRS456 can be safely deployed in freezing

conditions if the sensor is placed below the frost line. In a lake or channel of

moving water, often the sensor can be placed deep enough to avoid freezing.

In shallow conditions, where the water body is at risk of freezing solid, placing

the sensor in a stilling well that extends below the frost line will protect the

sensor from freezing water.

6.3 Dislodge Bubbles

While submersing the CSR451/CRS456, air bubbles may become trapped

inside the nose cone, causing small, offset errors until the bubbles dissolve.

Dislodge these bubbles by gently shaking the CRS451/CRS456 while under

water.

Hitting the instrument against the well casing or other solid

surface could damage the CRS451/CRS456.

If the bubbles are not removed by rotation and shaking

underwater (or bleeding out the air in a closed system), the

CRS451/CRS456 reading will drift lower by the distance of

the gap as the air is slowly dissolved into the water over

time.

6.4 Well Installation

Braided stainless steel cable (pn 29221-L) is used to lower the instrument to an

appropriate depth and to suspend the CRS451/CRS456 in a well.

With long drops, it may be necessary to use the weighted nose cone (option

–WN).

For surface installations the instrument’s body can be strapped with tie wraps

or tape. Campbell Scientific offers cable ties (pn 7421) to secure the cable. If

installing in a well, fasten the cable to the well head.

5

Page 12

CRS451/CRS456 Submersible Water-Level Recording Sensor

6.5 Other Installations

The CRS451/CRS456 can be installed in any position; however, when it leaves

the factory it is tested in the vertical position. There will be an offset error if

not installed vertically; contact Campbell Scientific for more information.

Strapping the transducer body with tie wraps or tape will not hurt it.

6.6 Battery Voltage Reading

The voltage of the lithium ion battery used in the CRS451/CRS456 will

abruptly decrease at the end of the battery’s useful life, which makes predicting

remaining battery life difficult by measuring battery voltage alone. Knowing

the energy consumption of the CRS451/CRS456 while in operation, HydroSci

displays a predicted remaining battery life by combining an estimate of the

energy consumed based on the totalized measurements since new and direct

battery measurements. For this reason, if the battery is removed from the

CRS451/CRS456 anytime during deployment and then replaced, HydroSci will

assume a fresh battery was added to the device and the estimated remaining

battery life will be overstated.

For similar reasons, if the operating system is upgraded or sent to the

CRS451/CRS456, the estimated remaining battery life will also be exaggerated

by HydroSci.

6.7 Attaching Suspension Cable to CRS451/CRS456

Attach the split ring to the CRS451 cap.

6

Page 13

CRS451/CRS456 Submersible Water-Level Recording Sensor

7

Page 14

CRS451/CRS456 Submersible Water-Level Recording Sensor

CAUTION

7. Programming

Communicating with the CRS451/CRS456 requires a micro USB cable and

HydroSci software running on a computer with Windows XP or later.

The CRS451/CRS456 is configured using the HydroSci software provided with

the unit. A DVD containing HydroSci is shipped with the CRS451/CRS456.

If you are using an XP computer, please have the driver disc

in the CD/DVD drive before plugging in the USB cord. A

driver will need to be installed before the computer can

connect with the sensor.

7.1 Settings

Before connecting to the CRS451/CR456, you can change the sensor name or

the appearance of HydroSci screens by clicking on Settings at the upper right

portion of the HydroSci screen.

7.2 Connect to the CRS451/CR456

1. Select CRS45X from the left margin.

2. Select appropriate COM Port.

3. Click Connect button.

8

Page 15

CRS451/CRS456 Submersible Water-Level Recording Sensor

NOTE

7.3 Configure CRS45X for Measurements

1. Click Configuration.

2. Select Create New Configuration button located at lower left of screen.

3. Select the type of measurements you want to make.

a) Barometer Pressure Reference should be selected if you want to use

CR45X sensor as a barometer to compensate for changes in

barometric pressure.

See Section 7.4.2

from a nearby barometer to correct for the barometric pressure.

b) Disable: To preserve battery between deployments always configure

the sensor for storage after use.

, Using a Barometer, if using the measurements

9

Page 16

CRS451/CRS456 Submersible Water-Level Recording Sensor

4. Add offset to relate water level measurements to a known datum or

reference point. (Aquifer test start at level 0.)

a) This step is optional and not required.

b) This offset takes effect at the Start Time—which is set in a subsequent

screen—so it is necessary that this sensor be in its permanent

measurement position before the Start Time, otherwise the offset

correction will not be correct.

10

5. Select a Start and Stop Time.

a) Select a time in the future when measurements should begin.

Selecting a time in the past will force the sensor to begin making

measurements immediately at the indicated frequency. If an offset

calculation was selected in the previous screen, the sensor will not

make correct measurements. If an offset calculation is needed, a Start

Time must be selected far enough in the future that the sensor can be

properly placed in its measurement position before measurements

begin.

Page 17

CRS451/CRS456 Submersible Water-Level Recording Sensor

b) If desired, select time in future when measurements should cease.

c) Select the rate at which measurements will be made. This does not

configure the senor for data storage, only the rate at which

measurements are made.

11

Page 18

CRS451/CRS456 Submersible Water-Level Recording Sensor

6. Select and Name Data Tables for Datalogging.

a) Up to four different Data Tables can archive data at independent

intervals with any combination of elements (samples, averages,

maximum, etc).

b) Contents of the Data Table are selected in the next screen.

12

Page 19

CRS451/CRS456 Submersible Water-Level Recording Sensor

7. Select which data, in which format and unit of measurement, is to be

included in each of the data tables selected in the previous screen.

13

Page 20

CRS451/CRS456 Submersible Water-Level Recording Sensor

8. Once the Data Tables have been configured, the configuration process is

finished and the Finish button can be selected.

9. Once the configuration is complete, it must be copied to the CRS451

before it will take effect. Click on Apply Configuration to CRS45X to

start this process.

Before sending the configuration file to the CRS45X, HydroSci may provide a

warning that your start and stop times may need adjusting. If the Start Time is

in the past, the CRS45X will immediately begin logging data but any offset

you may have applied will not be effective. Also, if the Stop Time is in the

past, no data will be logged.

14

Save data if you have not already done so. Archived data is purged from the

CRS45X when a new configuration file is copied so you will want to collect

any data before sending the configuration file.

This option allows you to save the configuration file for future reference or for

easy use in other similarly deployed sensors.

The CRS451 is calibrated to pressure units in psi. TABLE B-1 contains the

conversion factors used to convert psi to depth of water.

Page 21

CRS451/CRS456 Submersible Water-Level Recording Sensor

7.4 Compensating Measurements for Barometric Pressure

The CRS45X pressure transducer is unvented; therefore it is monitoring sealed

gage pressure and should be corrected for barometric pressure.

7.4.1 Using an Additional CRS45X

One simple way to complete this correction is to deploy an additional CRS45X

as a reference sensor. For this method, in the Select Field Application window,

choose Barometer Pressure Reference (see Section 7.3, Configure CRS45X for

Measurements).

7.4.2 Using a Barometer

The barometric pressure data from a nearby Campbell Scientific weather

station or other Campbell Scientific monitoring platform can also be used to

compensate for barometric pressure. The Data tab is used to process and

merge the data file from the test sensor with the data file from the barometric

reference sensor. The procedure for doing this follows:

1. Press the browse button next to the Collected Data File field to browse to

the data files retrieved from the CRS45X.

15

Page 22

CRS451/CRS456 Submersible Water-Level Recording Sensor

2. Select a data file you wish to be corrected by barometric pressure values.

a) The Field Application Used to Produce Collected Measurement

Data information will be shown based on the collected data file

selected.

3. Press the browse button next to the Barometric Pressure Reference Data

File field to browse the data files from the barometric reference sensor.

16

Page 23

CRS451/CRS456 Submersible Water-Level Recording Sensor

4. Select a data file you wish to use as the barometric pressure reference data

file.

a) Use the drop-down list to select the Barometric Pressure Reference

Column in the data file.

The reference column must be a measurement of pressure or level. If

from a nearby Campbell Scientific weather station, note that the

reference column must have units associated with it. The units can be

any pressure or level units as defined in HydroSci and they must

match exactly the HydroSci abbreviation as shown here.

The following pressure and level units are defined in HydroSci:

HydroSci Abbreviation Units of Measure

mm millimeter

m meter

ft feet

in inch

mb millibar

bar bar

kPa kilopascal

psia psi absolute

17

Page 24

CRS451/CRS456 Submersible Water-Level Recording Sensor

5. Press the browse button next to the Corrected Data File field to indicate

where the corrected data file should be stored.

Rename the file as applicable.

6. After completing all of the fields, press the Build Corrected Data File

button.

7. Once the corrected data file has been built, press the View Corrected

Data File button to open the file in View.

The View Data button at the bottom of the screen can also be used to open

View.

18

Page 25

CRS451/CRS456 Submersible Water-Level Recording Sensor

In View, use the File | Open menu item to browse to any data file you

would like to view.

To select the data values to be graphed, click on the column heading(s) in

the data file with a single mouse click. The selection will be highlighted

and will automatically be added to the graph.

Multiple columns can be added by holding the Ctrl key and dragging the

mouse pointer over the column headings.

To see the graph, press the Graph button. The graph will then appear on a

new screen.

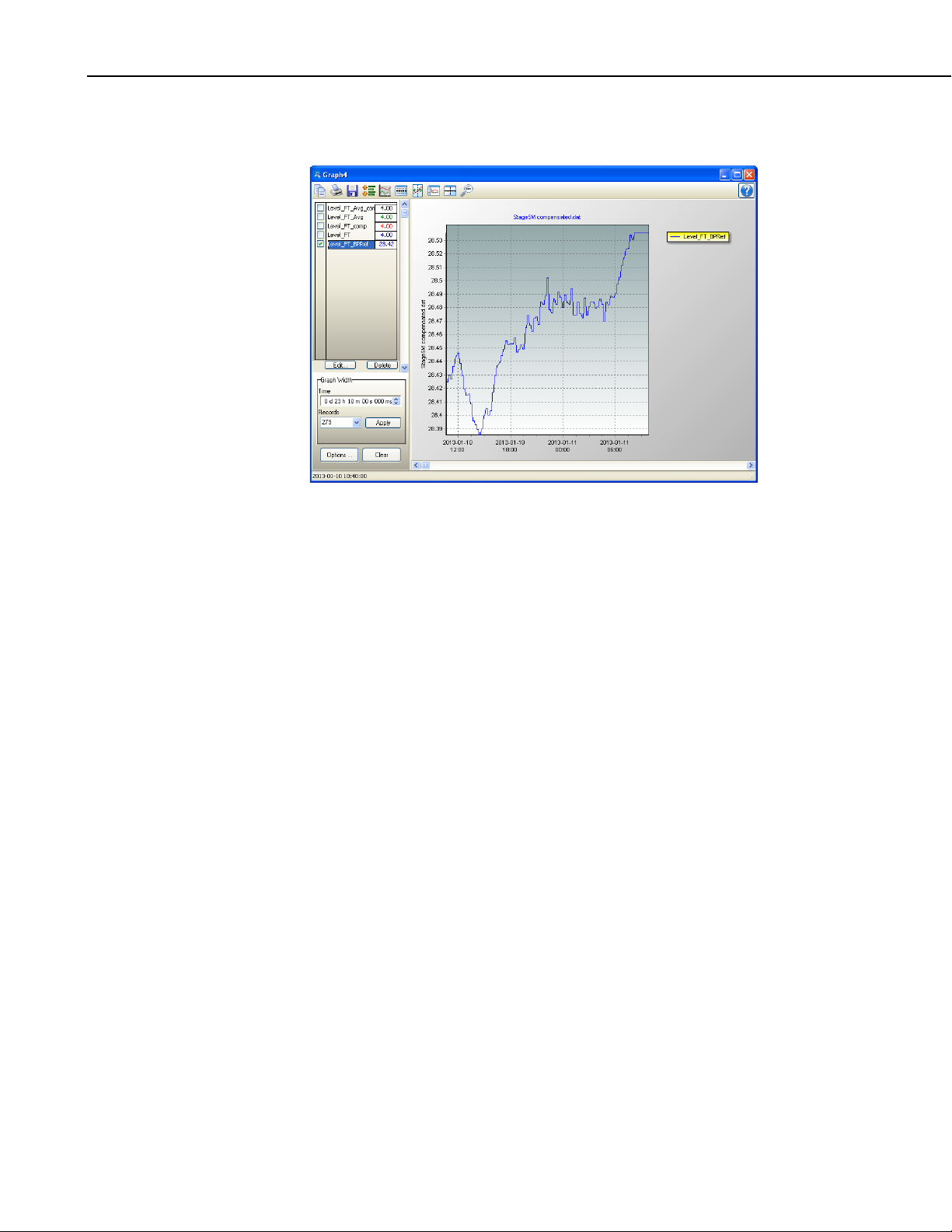

An example of the measured data and the barometric pressure

compensated data is shown here.

The original data are shown in blue and the compensated data are shown in

red.

19

Page 26

CRS451/CRS456 Submersible Water-Level Recording Sensor

The barometric pressure sensor data are shown below, also in blue.

8. Maintenance

Campbell Scientific recommends that the CRS451/CRS456 be factory

recalibrated every 24 months. Before a CRS451/CRS456 is sent to Campbell

Scientific, the customer must get an RMA (returned material authorization)

number and fill out the Declaration of Hazardous Material and

Decontamination form.

8.1 Every Visit

• Collect data.

• Visually inspect the physical conditions.

• Check battery condition by using a laptop and HydroSci software to view

• Check all readings; adjust offsets if necessary.

• Check recent data.

8.2 Every Two to Three Years or on a Rotating Schedule

• Send the CRS451/CRS456 in for inspection and calibration.

the battery voltage (see Section 6.6, Battery Voltage Reading). The

battery replacement procedure is provided in Section 8.3, Battery

Replacement.

20

Page 27

CRS451/CRS456 Submersible Water-Level Recording Sensor

New Battery

Screwdriver

8.3 Battery Replacement

Remove the set screws on the cap end of the CRS451.

21

Page 28

CRS451/CRS456 Submersible Water-Level Recording Sensor

Gently pull the end out of the housing.

Unplug the connecter.

22

Page 29

CRS451/CRS456 Submersible Water-Level Recording Sensor

Gently pull the battery out the end.

Disconnect the battery.

Remove the battery.

Slide in the new battery.

Plug in the new battery.

23

Page 30

CRS451/CRS456 Submersible Water-Level Recording Sensor

Slide the battery into the housing.

24

Reconnect the cable.

Page 31

CRS451/CRS456 Submersible Water-Level Recording Sensor

NOTE

Gently slide the end piece with its O-rings into the housing.

Nicking the O-ring could result in a leak.

Line up the holes and insert the set screw. Do not over tighten the set screw.

25

Page 32

CRS451/CRS456 Submersible Water-Level Recording Sensor

9. Troubleshooting

The most common causes for erroneous pressure transducer data include:

• Low battery

• Damaged CRS451/CRS456

Water damage

Damage to diaphragm due to excessive pressure

• Atmospheric pressure not subtracted from pressure reading

Problem:

Unit will not respond when attempting USB communications.

Suggestion:

Replace battery.

Correct COM Port used for communication not selected in HydroSci.

26

Page 33

Appendix A. Calibration Certificate

Each CRS451/CRS456 has been calibrated to meet printed accuracy

specification at multiple temperature and pressure ranges. If additional

verification is required, a Calibration Certificate can be purchased for each

CRS451/CRS456 Water-Level Recording Sensor.

The Instrument Data Report provides a list of the pressure and temperature at

which the sensor was tested.

Pressure [kPa] is the pressure applied (listed in kilopascals) to the sensor.

Temperature [°C] is the temperature inside the test chamber at the time of

testing. Pressure After [kPa] represents the resulting measurement output by

the CRS451/CRS456 at the given pressure and temperature. Finally,

Deviation After [%F.S.] provides the difference between the actual pressure

applied to the sensor and the pressure measurement output by the sensor. This

value is listed as a percentage of the full scale range of the sensor.

When a CRS451/CRS456 is returned to Campbell Scientific for calibration, the

sensor will be returned with an Instrument Data Report. This report will

include values in the Pressure Before [kPa] column. These values represent

the measured pressure the sensor returns at the specified pressure and

temperature, BEFORE calibration.

A-1

Page 34

Appendix A. Calibration Certificate

A-2

Page 35

TABLE B-1. Conversion Factors

Appendix B. Conversion to Units of Measurement

Unit of Measurement Factor of Conversion

Feet 2.3066587369

Inches 27.679904843

Meters 0.1019716213

Millimeters 101.9716213

B-1

Page 36

Appendix B. Conversion to Units of Measurement

B-2

Page 37

Page 38

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...