Page 1

CR9000X Measurement and

Control System

Revision: 4/12

Copyright © 1995-2012

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

The CR9000X Measurement and Control System is warranted for thirty-six

(36) months subject to this limited warranty:

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

CR9000X Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

Quick Start.................................................................. QS-1

QS1. Setting Up....................................................................................... QS-2

QS1.1 Installing RTDAQ.................................................................. QS-2

QS1.2 Opening Enclosure................................................................. QS-2

QS1.3 Connecting the RS232 Port/ Card Installation....................... QS-2

QS1.4 Powering the Logger.............................................................. QS-3

QS1.5 Setting Up Serial Communications....................................... QS-3

QS1.6 Setting Up IP Communications ............................................. QS-9

QS2. Program Generator Basics ............................................................ QS-12

QS2.1 Program Generator Summary Window................................ QS-12

QS2.2 Program Generator Configuration Window......................... QS-13

QS2.3 Program Generator Scan Window ....................................... QS-14

QS2.4 Program Generator Output Table Window.......................... QS-15

QS2.5 Program Generator Special Configuration........................... QS-16

QS2.6 Program Generator: Save and Download ............................. QS-17

QS3. RealTime Monitoring ................................................................... QS-18

QS5. View Data..................................................................................... QS-20

QS6. Comparison of CR9032 and CR9031........................................... QS-21

Overview..................................................................... OV-1

OV1. Physical Description ......................................................................OV-2

OV1.1 Basic System .........................................................................OV-2

OV1.2 Measurement Modules ..........................................................OV-7

OV1.3 Communication Interfaces ..................................................OV-20

OV2. Memory and Programming Concepts ..........................................OV-20

OV2.1 Memory...............................................................................OV-20

OV2.2 Measurements, Processing, Data Storage............................OV-21

OV2.3 Data Tables..........................................................................OV-21

OV3. Commonly Used Peripherals .......................................................OV-22

OV4. Support Software .........................................................................OV-23

OV5. Specifications...............................................................................OV-27

1. Installation.................................................................1-1

1.1 Enclosure .............................................................................................. 1-1

1.1.1 Connecting Sensors..................................................................... 1-1

1.1.2 Quick Connectors ....................................................................... 1-1

1.1.3 Junction Boxes............................................................................ 1-2

1.2 System Power Requirements and Options............................................ 1-3

1.2.1 Power Supply and Charging Circuitry........................................ 1-3

1.2.2 Connecting to Vehicle Power Supply ......................................... 1-5

1.2.3 Solar Panels................................................................................. 1-6

1.2.4 External Battery Connection....................................................... 1-6

1.2.5 Safety Precautions....................................................................... 1-7

i

Page 6

CR9000X Table of Contents

2. Data Storage and Retrieval ..................................... 2-1

1.3 Humidity Effects and Control............................................................... 1-7

1.3.1 Desiccant..................................................................................... 1-7

1.3.2 Nitrogen Purging......................................................................... 1-7

1.4 Recommended Grounding Practices..................................................... 1-8

1.4.1 Protection from Lightning........................................................... 1-8

1.4.2 Operational Input Voltage Limits: Effect on Measurements....... 1-8

1.5 Use of Digital Control Ports for Switching Relays............................... 1-9

2.1 Memory/Data Storage in CR9000X...................................................... 2-1

2.1.1 Internal Flash Memory................................................................ 2-1

2.1.2 Internal Synchronous DRAM...................................................... 2-1

2.1.3 PCMCIA PC Card....................................................................... 2-1

2.2 Internal Data Format ............................................................................. 2-2

2.2.1 NAN and ±INF............................................................................ 2-3

2.3 Data Collection .....................................................................................2-5

2.3.1 The Collect Menu........................................................................ 2-5

2.3.2 Table Monitor Window Save to File........................................... 2-7

2.3.3 File Control Files Retrieval ......................................................... 2-7

2.3.4 Logger Files Retrieval Via PCMCIA PC Card ........................... 2-8

2.3.5 Converting File Format ................................................................ 2-9

2.4 Data Format on Computer................................................................... 2-10

2.4.1 Data File Header Information ...................................................2-10

2.4.2 TOA5 ASCII File Format .........................................................2-13

2.4.3 TOB1 Binary File Format ......................................................... 2-14

2.4.4 TOB3 Binary File Format ......................................................... 2-14

3. CR9000X Measurement Details .............................. 3-1

3.1 Measurements using the CR9041 A/D.................................................. 3-1

3.1.1 Analog Voltage Measurement Sequence ....................................3-1

3.1.2 Single Ended and Differential Voltage Measurements ............... 3-3

3.1.3 Signal Settling Time.................................................................... 3-8

3.1.4 Thermocouple Measurements ................................................... 3-10

3.1.5 Bridge Resistance Measurements.............................................. 3-18

3.1.6 Measurements Requiring AC Excitation................................... 3-20

3.1.7 Influence of Ground Loop on Measurements ...........................3-20

3.2 CR9058E Isolation Module Measurements ........................................ 3-21

3.2.1 CR9058E Supported Instructions.............................................. 3-22

3.2.2 CR9058E Sampling, Noise and Filtering.................................. 3-24

3.2.3 CR9058E; Hard Setting the Filter Order................................... 3-27

3.3 CR9052 Filter Module Measurements................................................ 3-30

3.4 Pulse Count Measurements................................................................. 3-35

3.4.1 CR9070 PulseCount Resolution................................................ 3-35

3.4.2 CR9071E PulseCount Resolution .............................................3-37

3.4.3 CR9071E TimerIO for Measuring Frequency Inputs................ 3-38

3.4.4 High Frequency Pulse Measurements ....................................... 3-38

4. CRBasic – Native Language Programming ........... 4-1

4.1 Introduction to Writing CR9000X Programs........................................ 4-1

4.1.1 ShortCut ......................................................................................4-1

4.1.2 Program Generator ...................................................................... 4-1

ii

Page 7

CR9000X Table of Contents

4.1.3 CRBasic Program Editor............................................................. 4-2

4.1.4 Programming CRBASIC's "Basics":........................................... 4-3

4.2 CRBasic Programming ......................................................................... 4-6

4.2.1 Fundamental elements of CRBASIC include: ............................ 4-6

4.2.2 Numerical Entries ....................................................................... 4-7

4.2.3 Programming Structure............................................................... 4-7

4.2.4 Declarations .............................................................................. 4-11

4.2.5 Constants................................................................................... 4-19

4.2.6 Flags.......................................................................................... 4-19

4.2.7 Parameter Types........................................................................ 4-20

4.2.8 Data Tables ............................................................................... 4-20

4.2.9 Measurement Timing and Processing....................................... 4-24

4.2.10 CRBasic Measurement Instructions........................................ 4-29

4.2.11 Expressions ............................................................................. 4-34

4.3 Program Access to Data Tables.......................................................... 4-39

5. Program Declarations ..............................................5-1

6. Data Table Declarations and Output Processing

Instructions ...........................................................6-1

6.1 Data Table Declaration ......................................................................... 6-1

6.2 Trigger Modifiers ................................................................................. 6-2

6.3 Export Data Instructions..................................................................... 6-11

6.4 Output Processing Instructions........................................................... 6-13

7. Measurement Instructions .......................................7-1

7.1 Voltage Measurements ......................................................................... 7-3

7.2 Thermocouple Measurements............................................................... 7-5

7.3 Resistive Bridge Measurements............................................................ 7-9

7.3.1 Electrical Bridge Circuits............................................................ 7-9

7.3.2 Bridge Excitation ........................................................................ 7-9

7.3.3 Half Bridges.............................................................................. 7-10

7.3.4 Full Bridges............................................................................... 7-13

7.4 Self Measurements.............................................................................. 7-15

7.5 Peripheral Devices.............................................................................. 7-16

7.6 Pulse/Timing/State Measurements....................................................... 7-36

7.7 Serial Sensors ..................................................................................... 7-42

7.8 CR9052DC & CR9052IEPE Filter Module........................................ 7-43

8. Processing and Math Instructions ..........................8-1

9. Datalogger Control ...................................................9-1

9.1 Program Structure/Control.................................................................... 9-1

9.2 Datalogger Status/Control .................................................................. 9-27

9.3 File Control......................................................................................... 9-53

10. Custom Keyboard Display Menus.......................10-1

iii

Page 8

CR9000X Table of Contents

11. String Functions .................................................. 11-1

Appendices

A. Keywords and Predefined Constants.................... A-1

B. Filter Module Available Scan Rates....................... B-1

C. PC/CF Card Information..........................................C-1

11.1 Expressions with Strings................................................................... 11-1

11.1.1 Constant Strings ...................................................................... 11-1

11.1.2 Add Strings ............................................................................. 11-1

11.1.3 Subtraction of Strings.............................................................. 11-1

11.1.4 String Conversion to/from Numeric........................................ 11-1

11.1.5 String Comparison Operators.................................................. 11-2

11.1.6 Sample () Type Conversions and other Output Processing

Instructions ..........................................................................11-2

11.2 String Manipulation Functions.......................................................... 11-2

D. Status Table .............................................................D-1

E. Glossary ................................................................... E-1

E.1 Terms....................................................................................................... 1

E.2 Concepts ................................................................................................ 11

E.2.1 Accuracy, Precision, and Resolution ........................................... 11

Index.........................................................................Index-1

iv

Page 9

Quick Start

QS-1

Page 10

Quick Start

p

y

QS1. Setting Up

QS1.1 Installing RTDAQ

QS1.2 Opening Enclosure

A CD with one licensed copy of RTDAQ is provided with every CR9000X.

Locate and install RTDAQ onto a computer with Windows 2000, XP, or

Vista. It is best to install RTDAQ in a sub folder called RTDAQ under a

CampbellSci directory in your root directory.

The CR9000XC and the

CR9000X with Environmental

Enclosure have air-tight seals. It

may be required to press the gas

relief valve on the side of the

enclosure to equalize the internal

and atmospheric pressures in

order to o

en the enclosure.

QS1.3 Connecting the RS232 Port/ Card Installation

A nine pin serial cable is supplied with your CR9000X. Plug one end into

your laptop COM port and the other to the CR9032 module's RS232 nine pin

communication port.

+12 G C1 C2 C3

SDM

CR9032 CPU

When using a Card, the process to remove it is to press

the "Card Removal" button and wait for the Card

Status Led to turn green.

CARD STATUS LED:

Not Lit: No card detected.

Red: Accessing the card

Yellow: Corrupt Card, Error

Green: Can safel

remove card

RS-232 CS I/O ETHERNET CARD PC-CARD

STATUS

CONTROL

Card Removal

Button

Card Status LED

Top of Card Faces Down

If you have either a Type II

Flash card or a compact flash

card, format it (CR9000X

accepts FAT16 or FAT32

formats) and install it into the

PC card slot, face down.

MADE IN USA

QS-2

Page 11

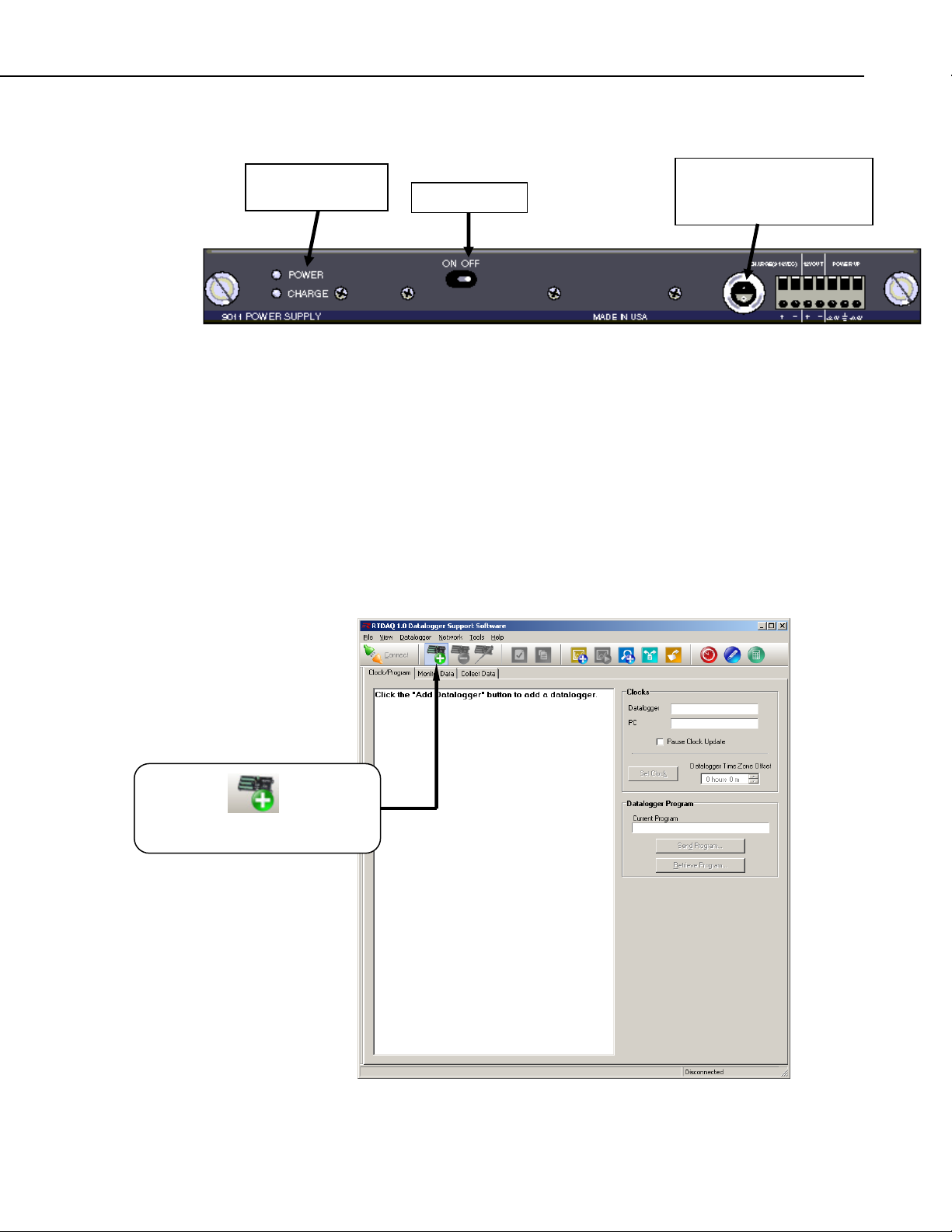

QS1.4 Powering the Logger

g

Quick Start

Power and Charge

LED Li

hts

On/Off Switch

A universal power adapter that can convert 120/240 AC to the required DC

voltage is supplied with the CR9000X(C). The adapter has a Limo

connector which mates with the CR9011 Power Supply module. Connect

the Limo connectors and plug the adapter into the AC wall outlet. The

Charge LED should turn red. You are now ready to power up the CR9000X

with the On/Off toggle switch.

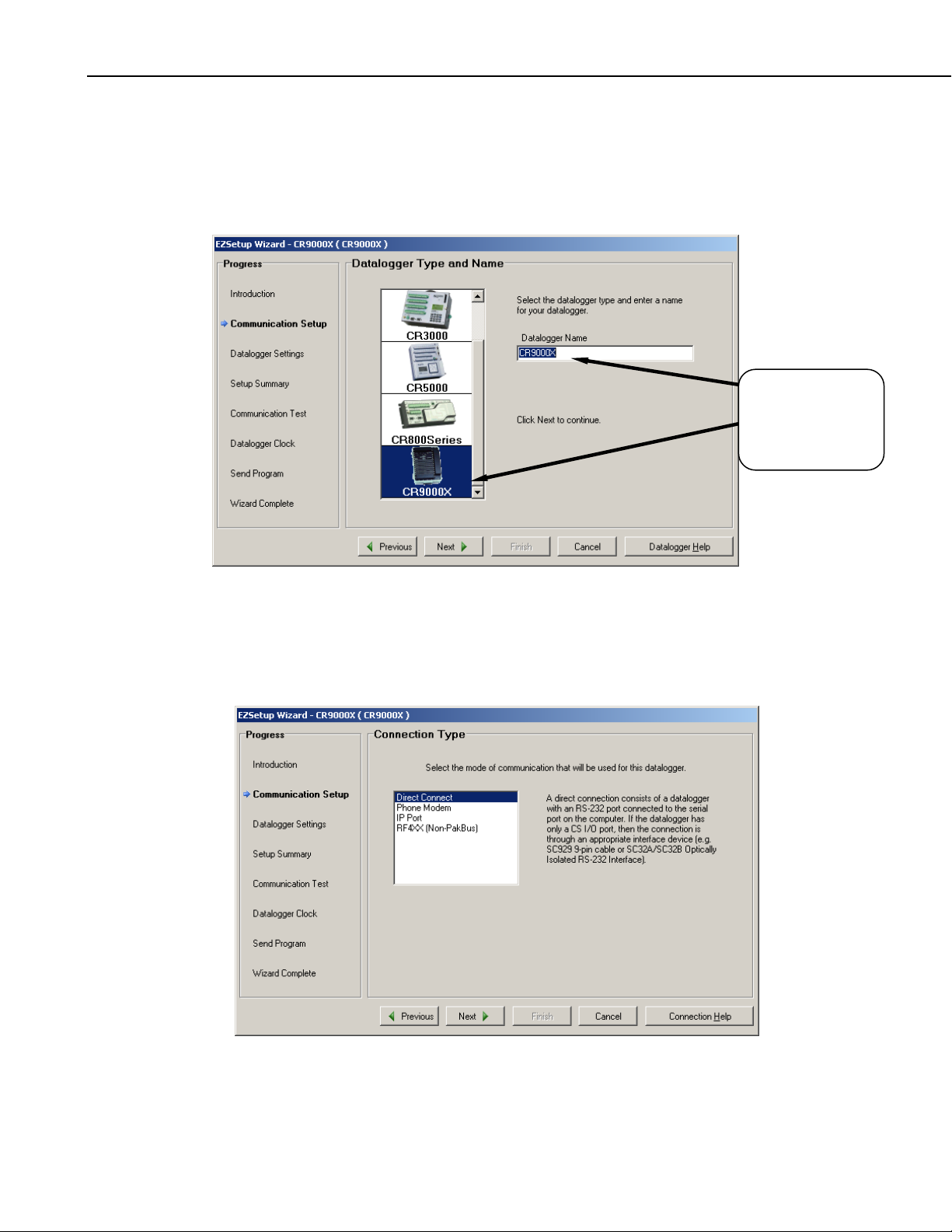

QS1.5 Setting Up Serial Communications

Connect a straight through RS-232 cable from your computers serial port to

the RS-232 port on the CR9032. Start up RTDAQ. You should see the

Window shown below. Click on the Icon with a data logger + sign to start

the Wizard to set up a new CR9000X.

Limo connector for

connection to universal AC

power adapter.

Click on to set up

a CR9000X

datalogger.

QS-3

Page 12

Quick Start

The wizard will prompt you sequentially through the settings required for

your RS232 communication set-up. In this window, scroll down through

the logger types and select the CR9000X. You can enter a descriptive

name for the datalogger set-up. It should be noted that this name is used

solely for the software and does not affect the "Station Name" internal of

the logger.

Select the

CR9000X and

enter a name for

the logger set-up.

Click on Next.

Select "Direct Connect" for your communication mode.

QS-4

Page 13

Quick Start

y

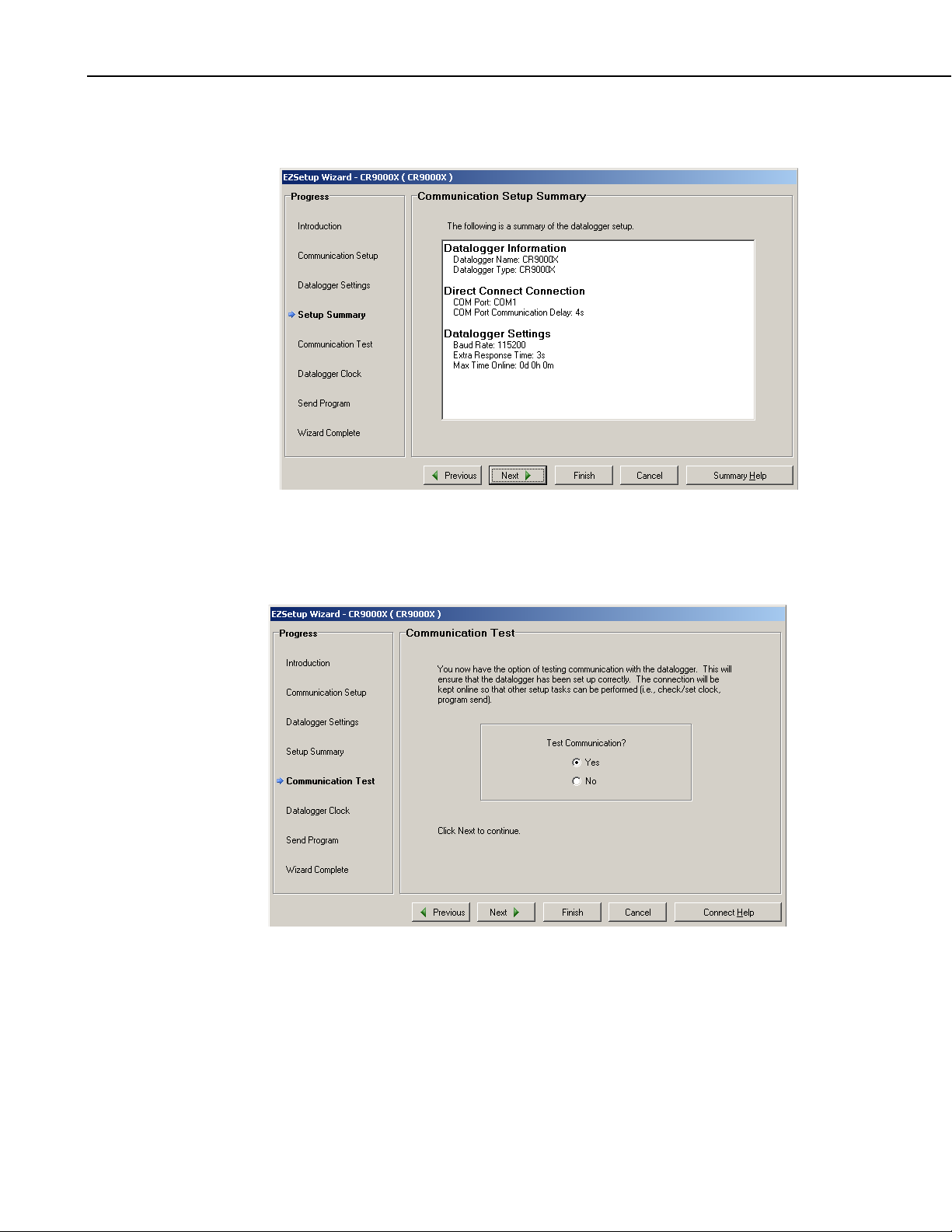

Select the computer COM Port that you will be using to communicate

with the logger. Only COM ports which are recognized and made

available by the PC's operating system will be listed.

Enter 4 seconds for the Com Port Communication Delay. Click "Next".

Select the

COM Port

from the pull

down list, and

enter 4 seconds

for the Port

Comm Dela

.

Select the desired

Baud Rate

Enter 3 for the

Extra Response

Time

Enter 0 for the

Max Time Online.

Enter the Baud Rate supported by your computer, up to 115200 baud.

Enter 3 or 4 seconds for the Extra Response Time and 0 for the Max

Time On-Line. Click on "Next".

QS-5

Page 14

Quick Start

This next window has a Synopsis of your selected options. Verify that it

has the requisite settings and click on "Next".

You will now have the option to Test your Communications link. If you

are connected to a logger, select "Yes", and click on "Next". If you are not

connected to a logger, click on "Finish".

QS-6

Page 15

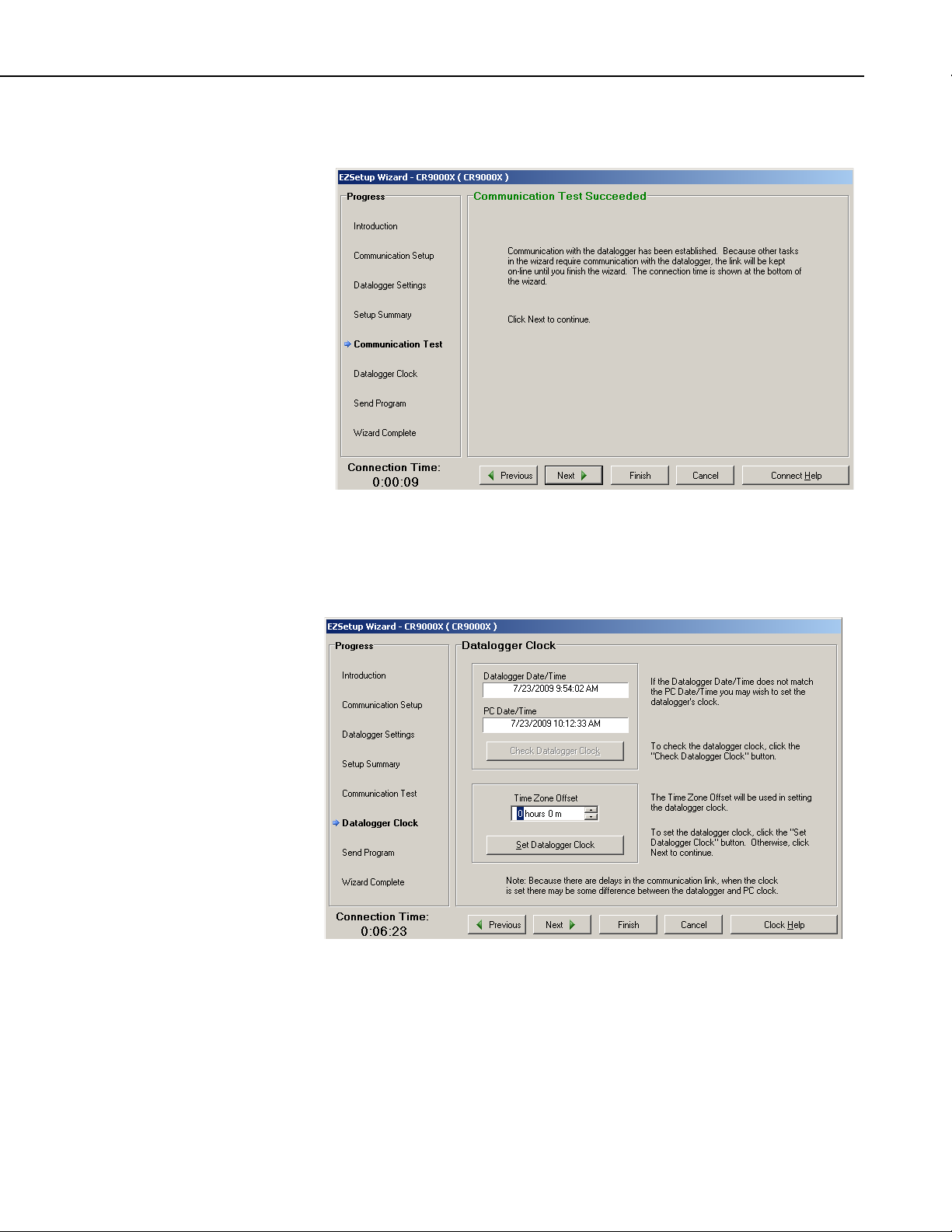

Quick Start

If you have set up the communication link correctly, you should see this

screen. Click on "Next".

The next window is for setting your logger's clock. You have the option to

enter an offset to account for a Time Zone difference between what your

PC is set to and the time zone where the logger will be located. Click on

"Set Datalogger Clock" and then "Next".

QS-7

Page 16

Quick Start

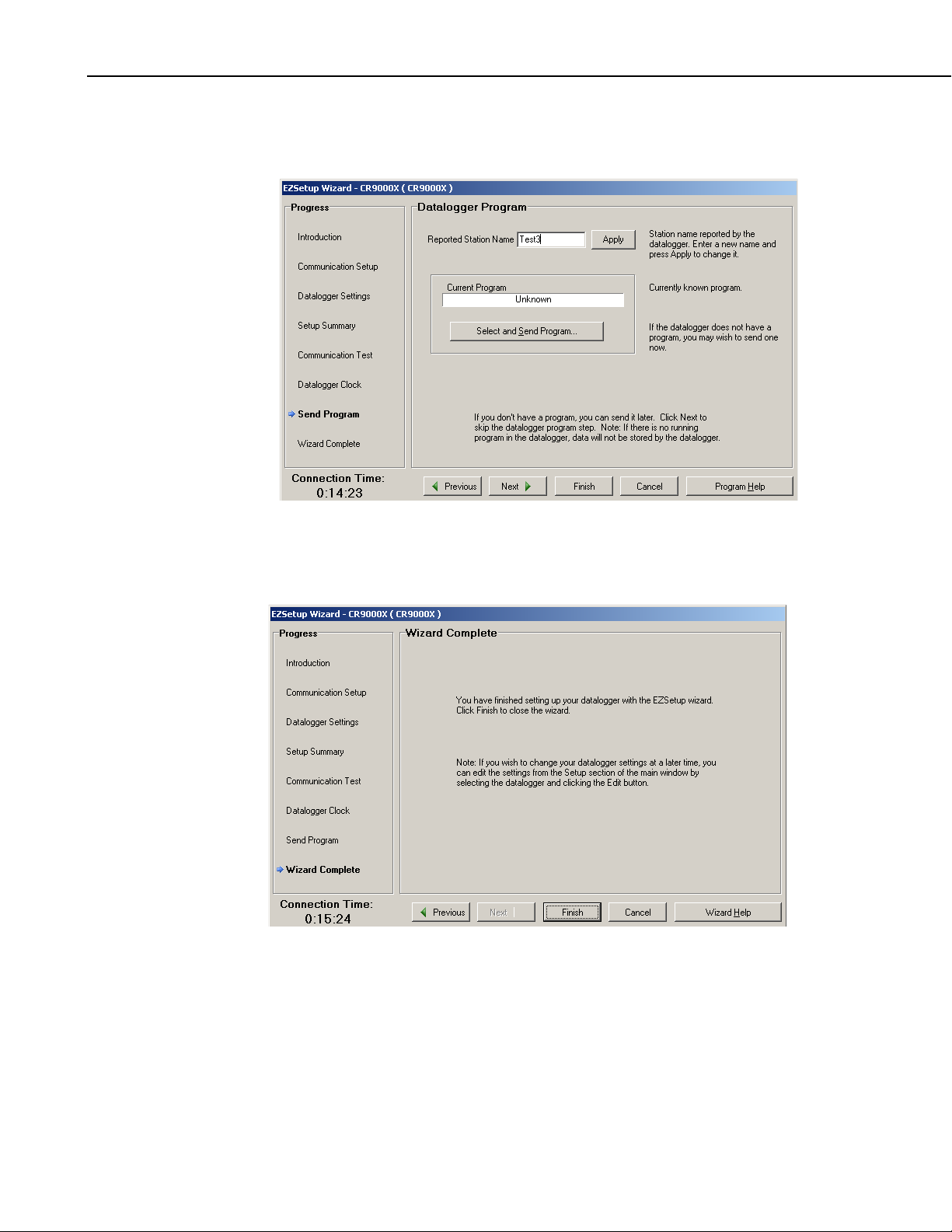

In this next window, the Station Name internal of the logger (Status Table)

is shown and can be modified if desired. A program can also be sent to the

logger if desired. For now, click on "Next".

You are now finished setting up your communication link. Click on

"Finish" and you will be prompted to stay connected to the logger. Click

on "Yes".

QS-8

Page 17

QS1.6 Setting Up IP Communications

b

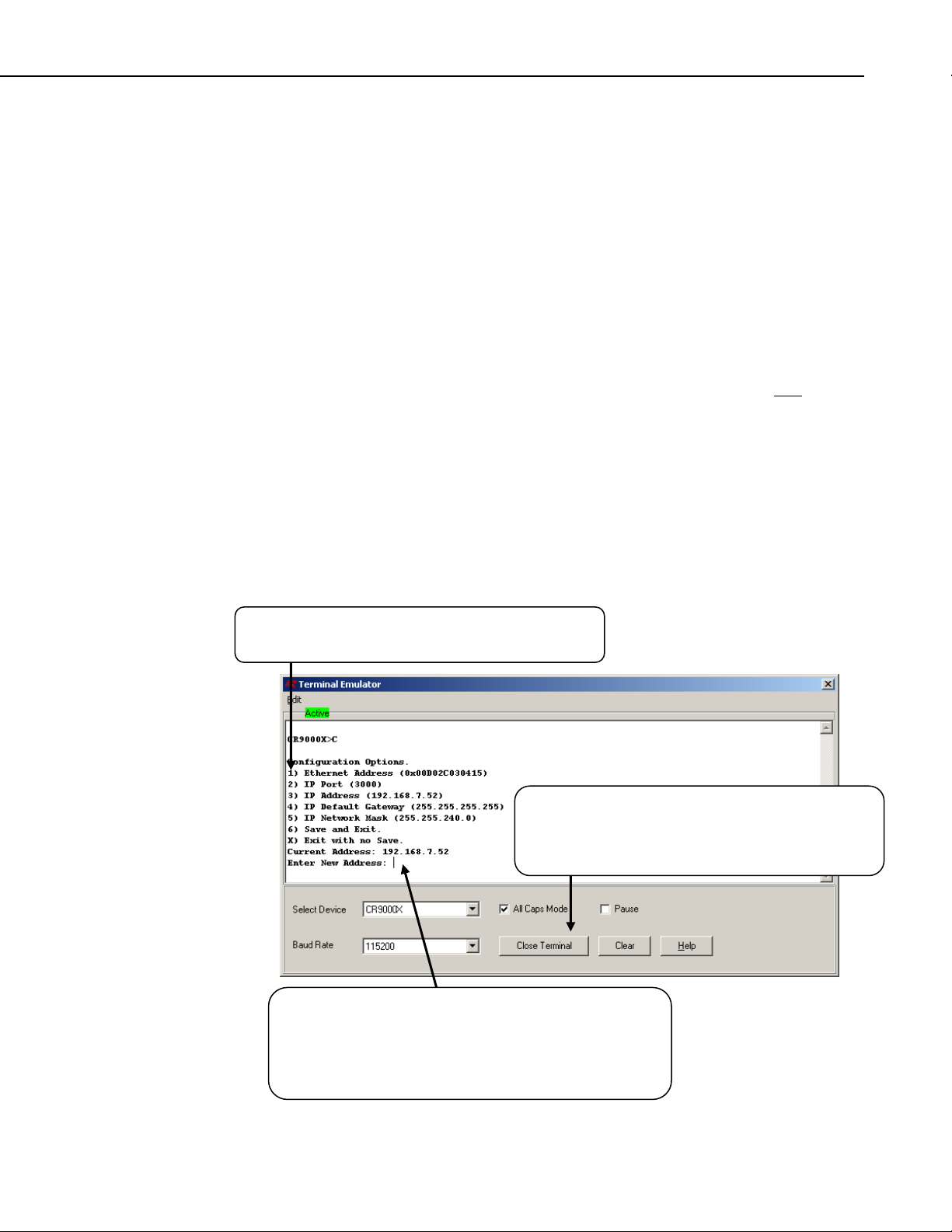

Once serial communications has been established, the CR9000X's IP can be

set. First you have to be connected to the CR9000X through the RS232

port. Next go into RTDAQ's Terminal Mode window

(Datalogger/Terminal Emulator). Click on "Open Terminal" in the "I/O

Port" section and then press <enter> recursively until the "CR9000X"

prompt appears. Press C and <enter>. If you delay for too long, you may

need to press <enter> to re-invoke the CR9000X prompt. The CR9000X's

IP port settings will be shown. To change any of the settings, type in the

associated number, enter the new setting and press <enter>. Once

complete, type in 6 (Save and Exit). Press <enter> until you get the

CR9000X prompt and type in C and <enter> to verify new settings.

For communications across a LAN, or through the Internet, a straight CAT

5 Ethernet cable should be used. For hooking up directly to your PC's

Ethernet port, a CAT 5 Ethernet crossover cable is required.

After the CR9000X's IP settings have been set, you will need to add another

logger communication station, this time setting it up for IP communications

instead of serial communications. Before RTDAQ will allow you to set up

another station, it will be necessary to "Disconnect" from the Serial

Connected Logger (station that we just created). To start, press the Icon

with a data logger + sign to start the Station set-up wizard again. This time

select "IP Port" for the Communication Mode. Once you have setup the IP

station, if communication is still not established, read the section QS1.6.1,

"IP Port Set-up Tips".

Quick Start

To change a setting, type in the associated number and

press <enter>.

First, click on "Open Terminal". Next press <enter>

until the CR9000X prompt is returned. Type in "C"

and <enter> and the CR9000X's I/P port setting will

e returned.

In this example, a 3 (IP Address) was typed in. The

CR9000X responded with the its current IP address and the

software is waiting for a new IP address to be entered.

After changes are made and entered, enter 6 and hit

<enter> to "Save" the new values to the logger.

QS-9

Page 18

Quick Start

QS1.6.1 IP Port Setup Tips

If you are hooking up one or more CR9000Xs on to a Local Area

Network, we recommend that you obtain from your IT department a

value for the SubNet mask and a fixed range of IP addresses for the(se)

CR9000X(s). This will ensure that you are operating within the

requirements set by your IT department, and should eliminate conflicts with

other Ethernet devices on your LAN. No two devices may share an IP

address.

Many Networks are configured to provide dynamic IP addressing (every

time you log onto the Network, your PC is assigned a new IP address). If

your computer is set-up for Dynamic IP addressing, when it is booted up

without being connected to your LAN, its IP address will be set to

000.000.000.000. This setting disables the IP port and network routing for

your computer; i.e. you will not be able to communicate with the

CR9000X. If the computer is booted while connected to the LAN and

receives an IP address, this address should remain in effect until the

computer is rebooted. You can determine whether or not your PC is set-up

for Dynamic Addressing, as well as the current IP address and Subnet Mask

settings for the computer, by going to your Control Panel: Control

Panel/Network Connections/Local Area Network/Properties/ scroll to

Internet Protocol and click on Properties. If "Obtain an IP address

automatically" is clicked on, then your PC is set-up for Dynamic IP

addressing. If the PC was booted up without being connected to the LAN,

remove this selection and enter a IP address and mask.

See Section QS1.6.1.1 Subnet Mask and IP Settings for more on IP

Address and Mask settings.

It should be noted that the CR9000X requires a static IP address. If the

CR9000X will be hooked up to a LAN, this static IP address should be

provided by the IT department. Although the CR9000X may have left

the manufacturer with an IP address and Subnet Mask, these values should

be changed for communications on your LAN.

If you are communicating with the CR9000X using a computer that is never

hooked up to a Network, you can easily choose the Mask and IP addresses

for the CR9000X and the PC. The same mask should be used for both the

CR9000X and the PC. An example of a good Mask setting is

255.255.255.0. Using this Mask setting, the first three bytes of the PC's and

the CR9000X's IP addresses would need to be set to identical values while

the fourth byte could be set to anything from 0 to 255 (example: PC IP

address set to 223.240.0.1 and the CR9000X set to 223.240.0.2). After

changing the computer's IP port settings, you will need to re-boot before the

new settings will be activated. The PC's and CR9000X's IP addresses

cannot be identical.

QS-10

Page 19

QS1.6.1.1 Subnet Mask and IP Settings

The SubNet Mask is a decimal equivalent of a 4-byte binary address. For

any bit set high in the computer's Mask, the corresponding bit in the IP

addresses, for devices that will be communicating with each other, must be

identical.

Example: A PC's SubNet Mask is set to 255.255.240 (binary representation:

is 11111111.11111111.11110000.00000000). For two devices to

communicate, the first two bytes of their IP addresses must be identical.

The first 4 bits of the third byte must also match. So if the third byte for the

PC's IP address is set to 192 (11000000), then any other device that is to

communicate with this PC would need to have the third byte set to

1100XXXX (first 4 bits identical). For this example, a third byte of

11000001 (193) or 11000011 (195) would work. Even 11000000 (192)

would work as long as the fourth byte is not identical for the two devices.

As the PC's Mask fourth byte is all zeros, none of its bits for the two

devices' IP addresses need to match.

It should be remembered that two devices on a network, or that will be

communicating with each other, should not have identical IP addresses. So

for the Subnet Mask of 255.255.240.0, one example of a good pair of IP

addresses is 128.255.192.1 and 128.255.192.2.

Quick Start

If the PC has a fixed IP address, set the CR9000X's Mask to the value of

the PC's SubNet mask, and use the above to determine the CR9000X's IP

address. Example, the PC mask is 255.255.255.0, and its IP address is

192.168.240.3. Valid IP address for the logger would be

192.168.240.XXXX, with XXXX ranging from 0 to 255 with the exception

of 3 (cannot be identical).

If you are using a computer that will be hooked up to a Network, then your

IT people should provide you information on what values you should use

for the SubNet mask and the IP address.

QS-11

Page 20

Quick Start

QS2. Program Generator Basics

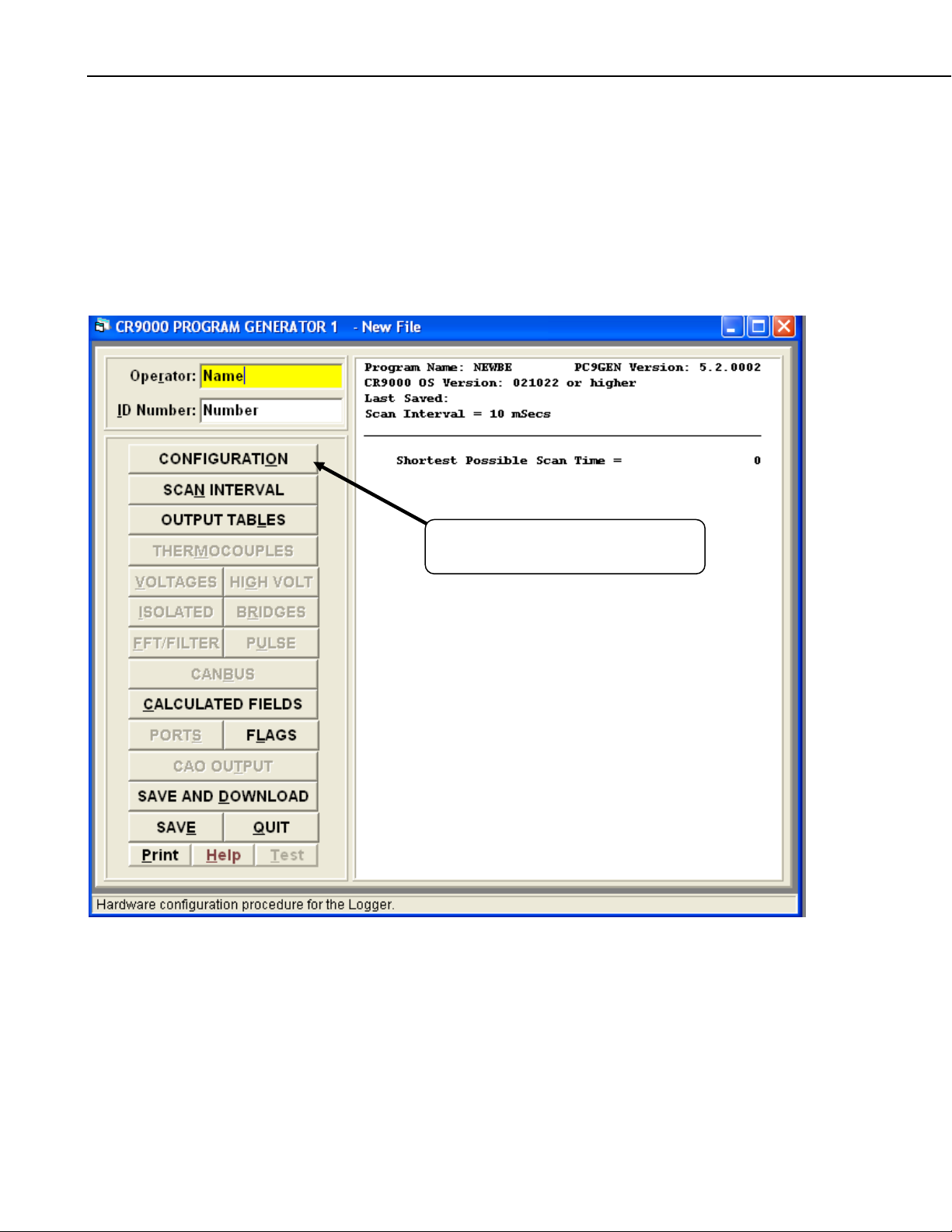

QS2.1 Program Generator Summary Window

Access RTDAQ's Program Generator for the CR9000X using the green

calculator ICON at the right of the main tool bar. If a CR5000 Program

Generator window is invoked, click on File/New/CR9000X.

This Summary window will be shown.

Click on Configuration to enter your

Loggers configuration.

QS-12

Page 21

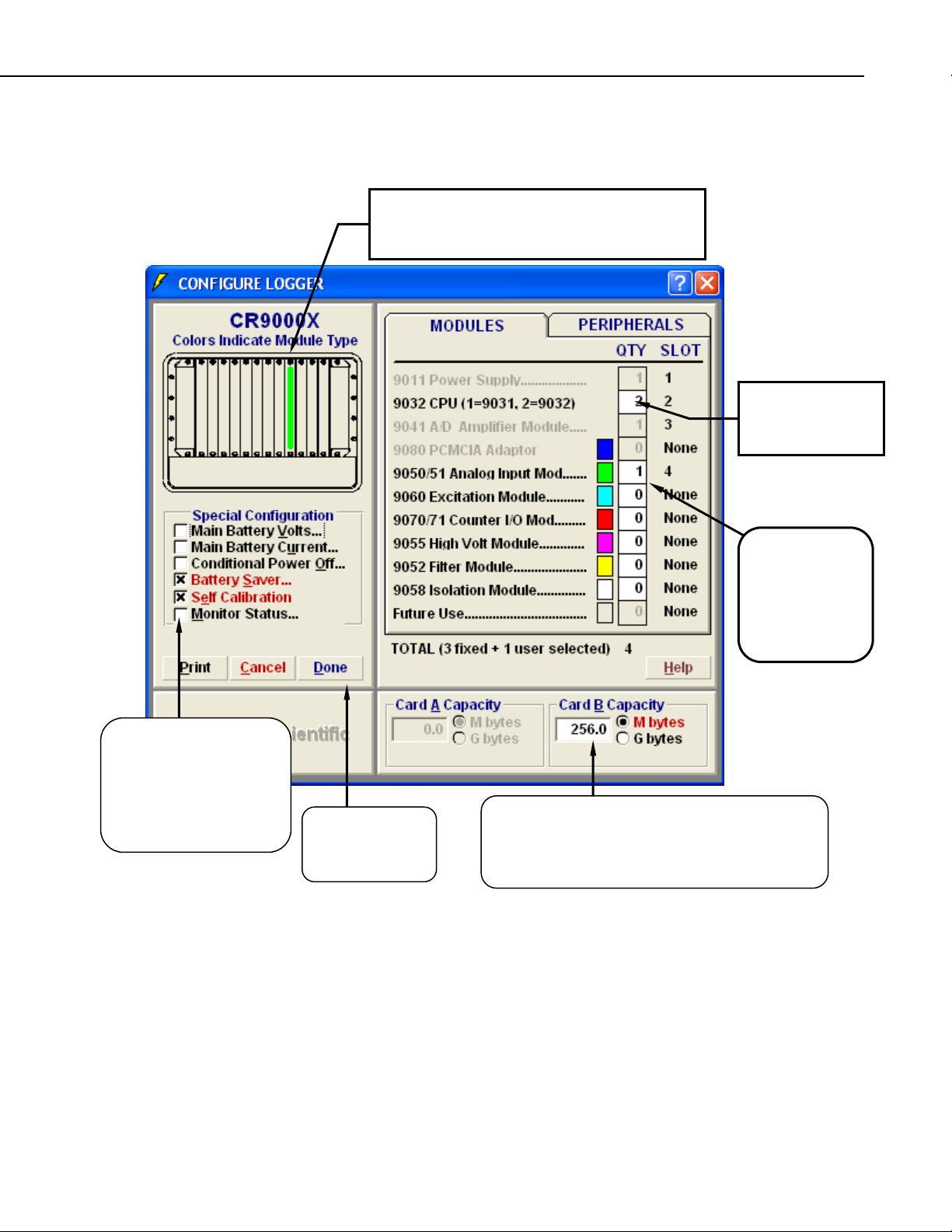

QS2.2 Program Generator Configuration Window

(

Colors match the colors of the module names to

the right. The modules must be inserted into the

Quick Start

Enter a 2 for the

CPU Type

CR9032 CPU).

When checked, these

boxes create the code to

perform special

functions. We will be

selecting some of these

later.

Click on Done

to save your

selections.

Enter the number

and type of

modules that you

will be using in

your CR9000X.

Enter the size of the PCMCIA memory card used in

the CR9032 module's PC card slot. This value will

be used to estimate the amount of remaining

memory in the Output Tables window.

QS-13

Page 22

Quick Start

QS2.3 Program Generator Scan Window

SCAN RATE

The values entered here set the scan rate of the program which determines how often the

measurements are made. You may use the scroll bar to set the time value or type the numeric time

value directly into the Scan Interval box. Enter 10 in the Scan Interval box and select mSeconds for

the units. This will create a program that scans 100 times a second.

Enter 100 for the number of Scans

to Buffer. This sets the number

of scans that processing can la

measurements without having

skipped scans (loss of data). The

number of Scans to Buffer is

limited by the available memory

Click on Done

to save your

selections.

g

QS-14

Page 23

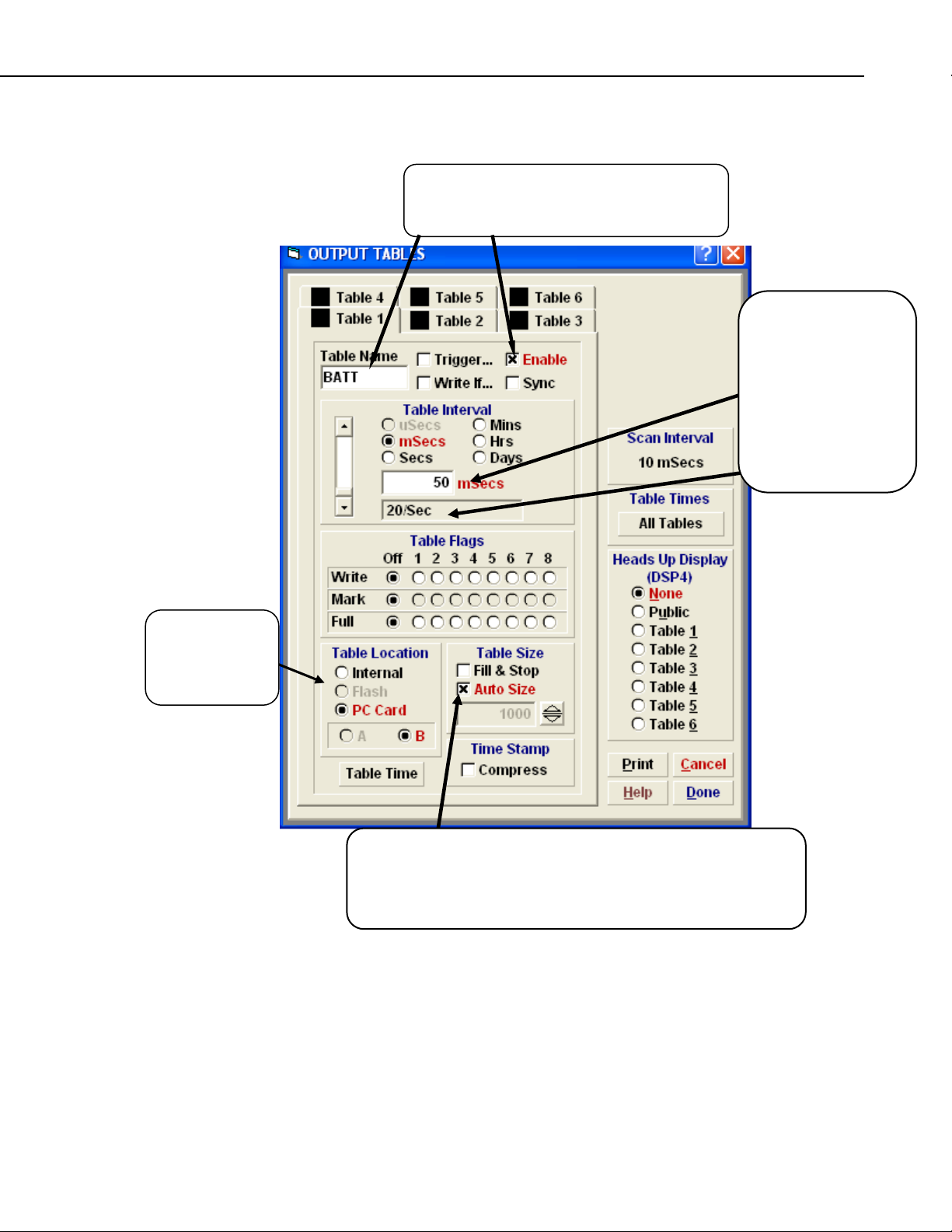

QS2.4 Program Generator Output Table Window

Click on Enable to set-up a Data Table. Click

in the Table Name box and enter a name for

your Data Table (up to 8 characters).

Quick Start

Each table interval is

independently set or

Synchronized to the

program scan interval.

Select mSecs and

enter 50 in the

numeric box (output

to the Table at a rate

of 20 Hz).

Select the

media where

the DataTable

is to be stored

Check the Auto Size box. This will cause the CR9000X to allocate

the largest possible table size for the media selected at compile time.

Specified table sizes will be allocated first, then memory for the

auto-size tables will be allocated to fill at nearly the same time.

Output tables are the data bases created by the CR9000X. They may either

reside within the CR9000X memory or on PCMCIA cards, and may be

accessed with the real-time capabilities of the RTDAQ software. The

Program Generator allows you to create and configure up to 6 tables. Click

on Done after the Data Table is set up.

QS-15

Page 24

Quick Start

QS2.5 Program Generator Special Configuration

Click on Main

Battery Volts and

Main Battery

Current to invoke

the output dialogue

box.

Next we will go back into the Configuration window to enable the

monitoring of the CR9000X's battery.

Click on Done after

setting up the Battery

measurements.

Click on Public

and Average.

QS-16

Page 25

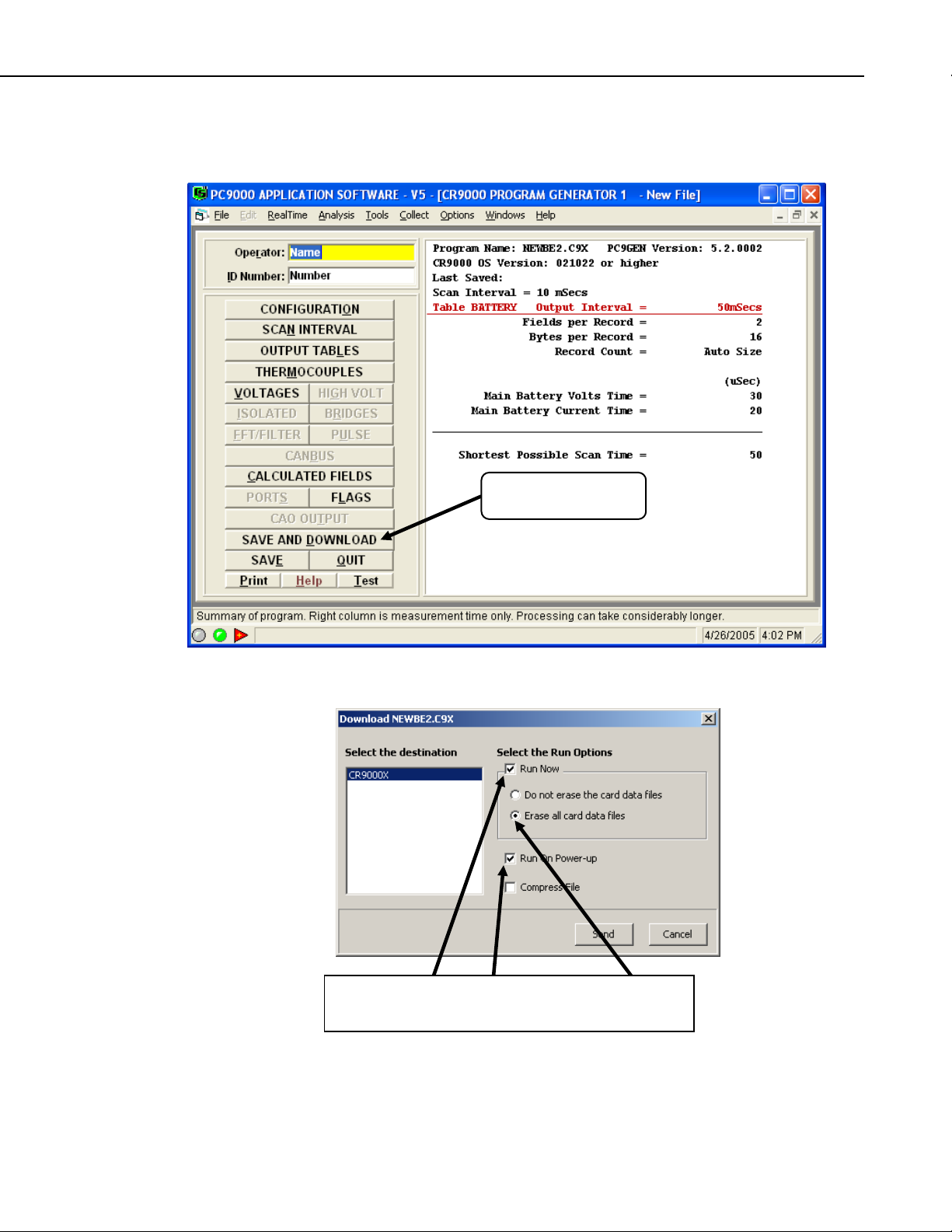

QS2.6 Program Generator: Save and Download

Now we are ready to download the program into the CR9000X.

Click on

Save and Send.

Quick Start

Select a name for the program and "Save" it to a directory on your

computer.

Click on Run Now, Run On Power Up, and Erase all

card data files. Then Click Send.

QS-17

Page 26

Quick Start

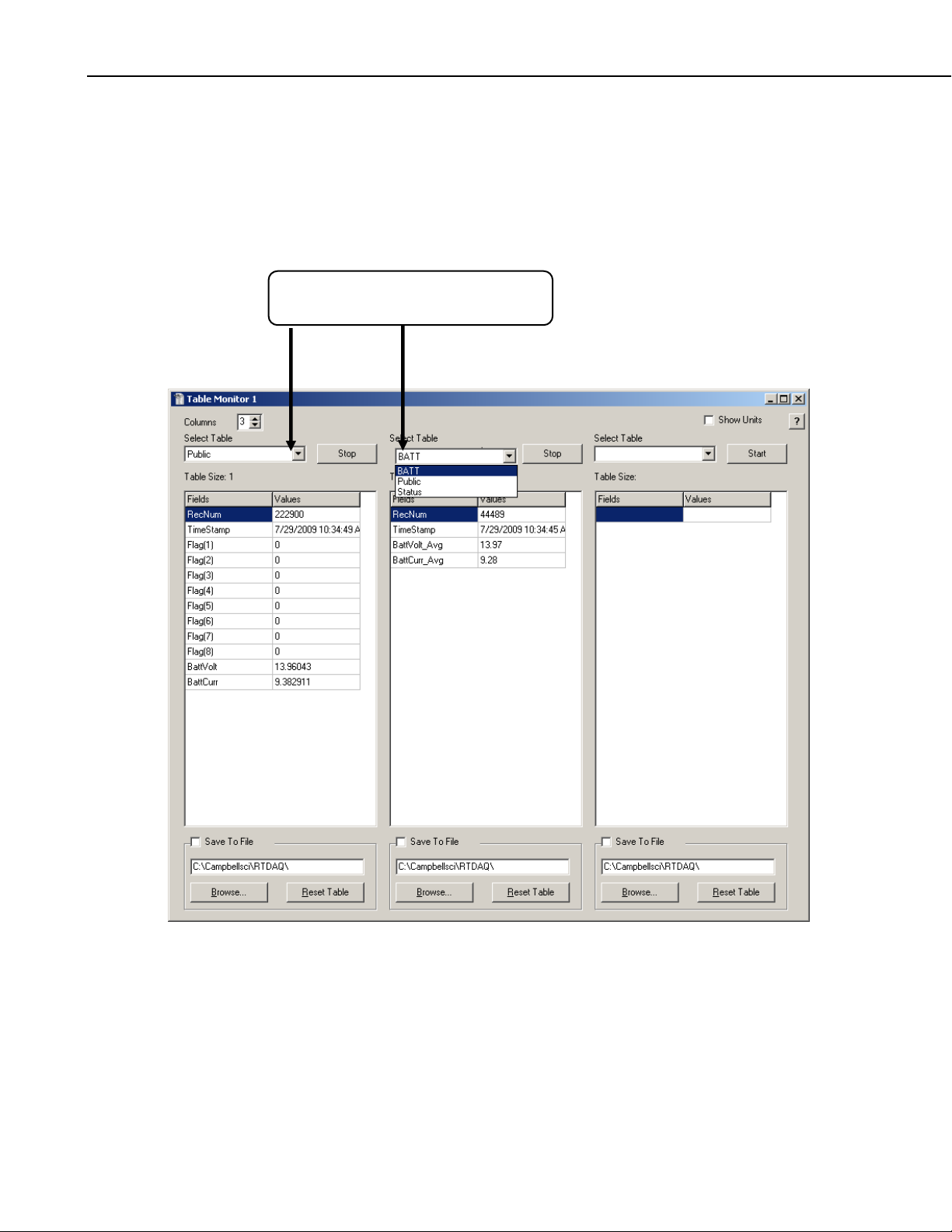

QS3. RealTime Monitoring

The Table Monitor window can be accessed from RTDAQ's "Monitor

Data" tab. From the Icons available, select Table Monitor. Up to three

Tables can be displayed on a single instance of a Table Monitor window.

Simply select the Table(s) to monitor from the pull down list.

Select Public and Batt from the pull

down list of available Data Tables.

QS-18

Page 27

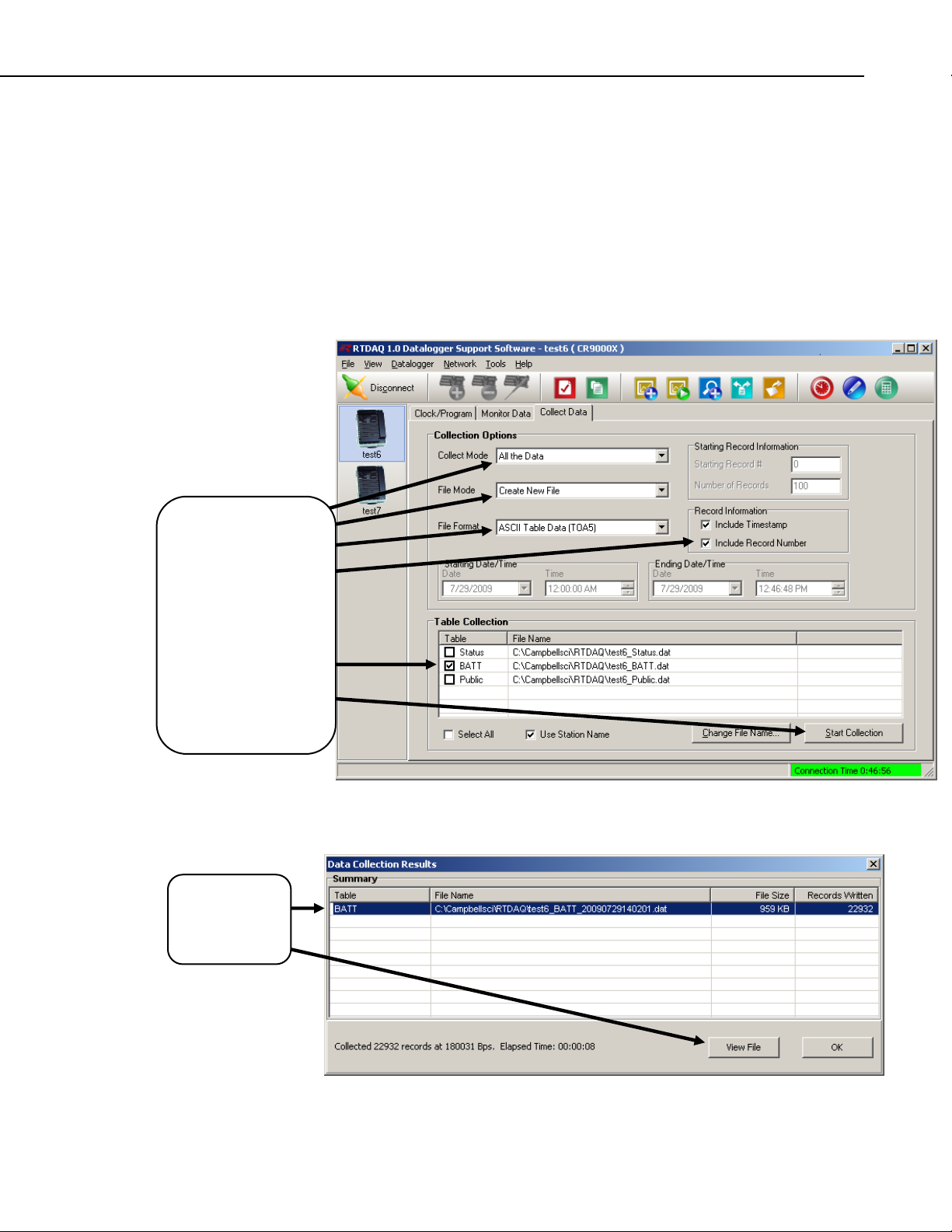

QS4. Data Collection

The Collect window can be accessed from RTDAQ's Collect Data tab.

There are options for setting-up the collection mode, the file mode, and file

format for the data collection process. The file name and path can also be

set here. The default path and name would be:

C:\CampbellSci\RTDAQ\LoggerName_TableName.dat; where

LoggerName = The name user defined name in RTDAQ's network

TableName = The name of the data table in the logger.

Quick Start

map.

Select

All the Data,

Create New File and

AS

CII Data

w/ Time Stamps and

Record Numbers.

Click off Select All,

select the Batt Data

Table from the list

and then click

Start Collectio

Highlight

Batt, and then

click on

ViewFile.

on

n.

Once the collection is complete, a Data Collection Results window will

appear. Highlight the Table Batt and click on View File.

QS-19

Page 28

Quick Start

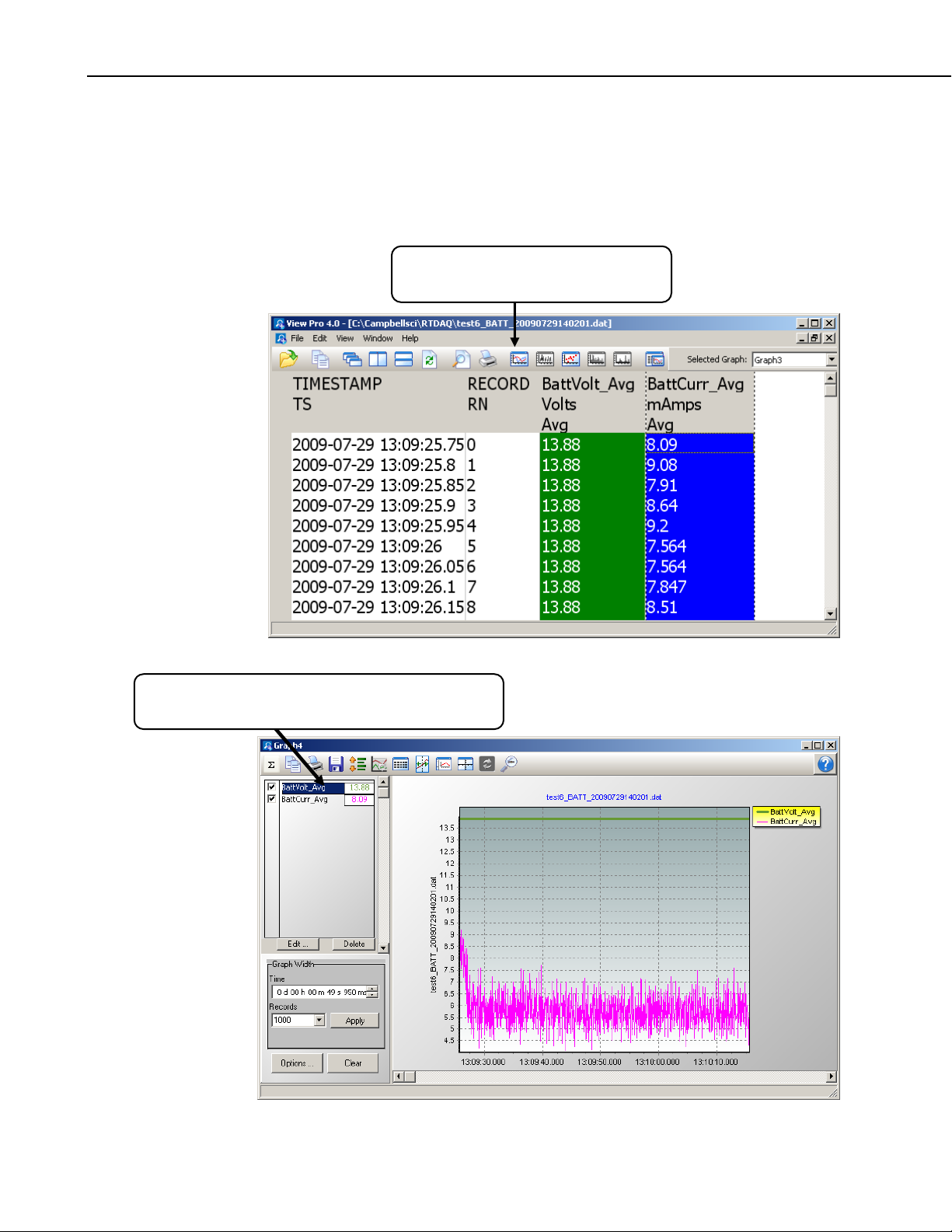

QS5. View Data

The ViewPro utlitity can also be accessed from RTDAQ's main toolbar:

Tools\ViewPro. ViewPro includes a full set of graphing capabilities.

Select one or two columns and click on the Line Graph Icon.

Highlight BattVolt & BattCurr columns

and click on the Line Graph icon.

Right click on trace name and select "Edit Selection"

to change trace properties and set up the X axis.

QS-20

Page 29

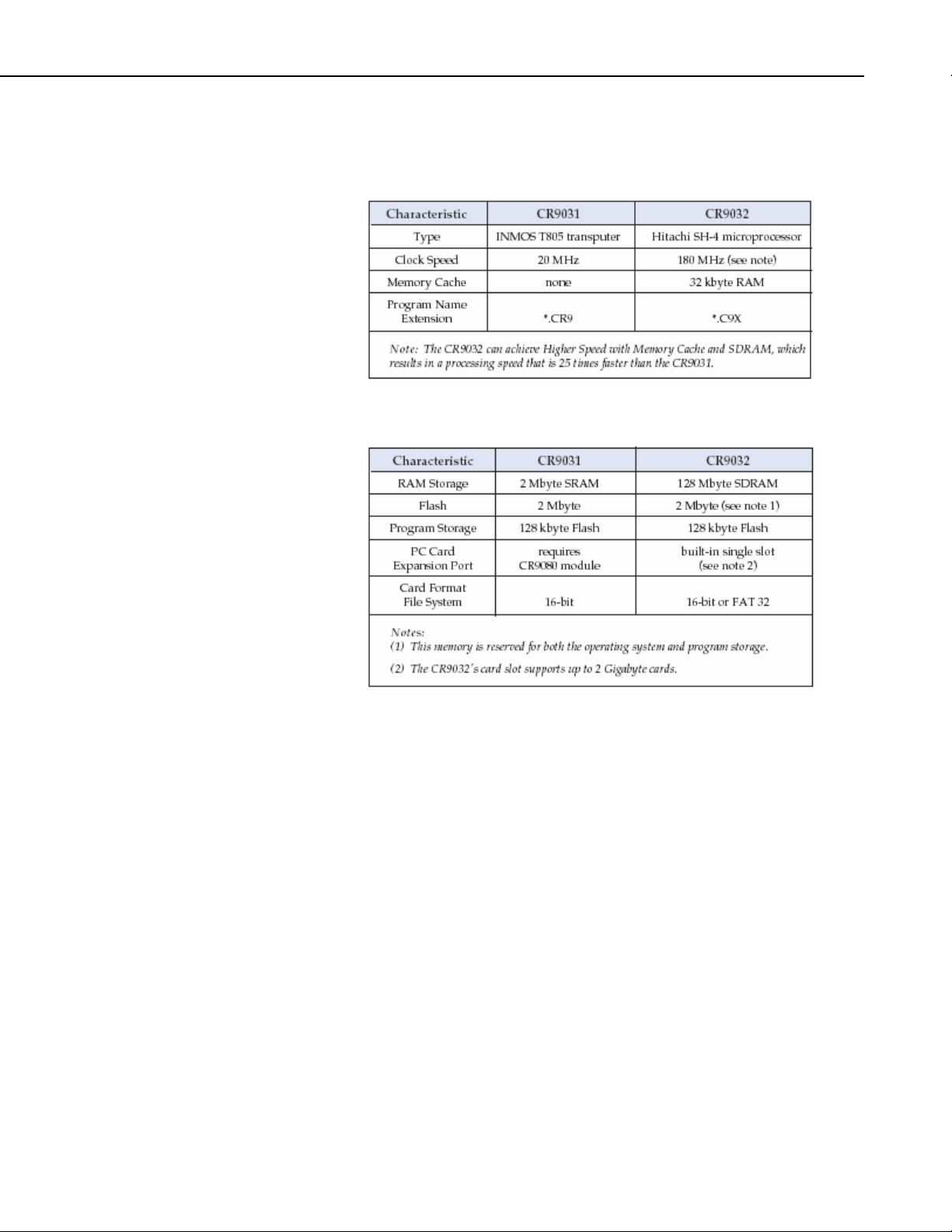

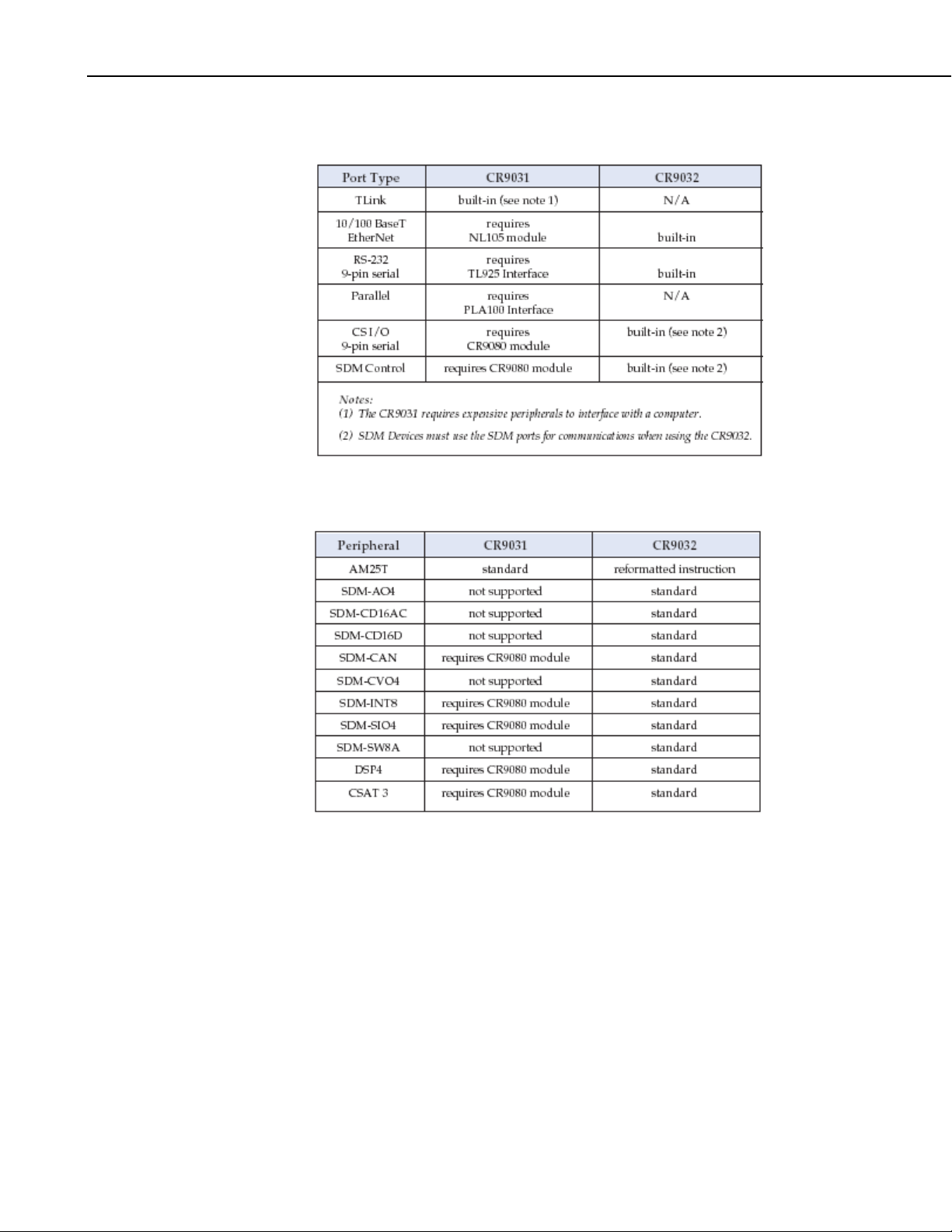

QS6. Comparison of CR9032 and CR9031

Processor

Memory

Quick Start

QS-21

Page 30

Quick Start

Communication Ports

Peripheral Compatibility

QS-22

Page 31

PC-Card LED Indicator Status

Instruction Set

The CR9031 and CR9032 have similar instruction sets, and many existing

CR9000 programs will function properly without modifications. The

CR9032 includes additional instructions that support capabilities not

provided in the CR9031. Also, some of the CR9031’s instructions have

been modified or removed, and programs containing those instructions will

need to be revised.

Quick Start

New Instructions

QS-23

Page 32

Quick Start

Modified or Removed Instructions

Existing CR9000 programs that include one or more of the following

instructions will need to be revised if the CR9000 is upgraded to a

CR9000X (i.e., the CR9031 module is replaced with the CR9032).

QS-24

Page 33

Overview

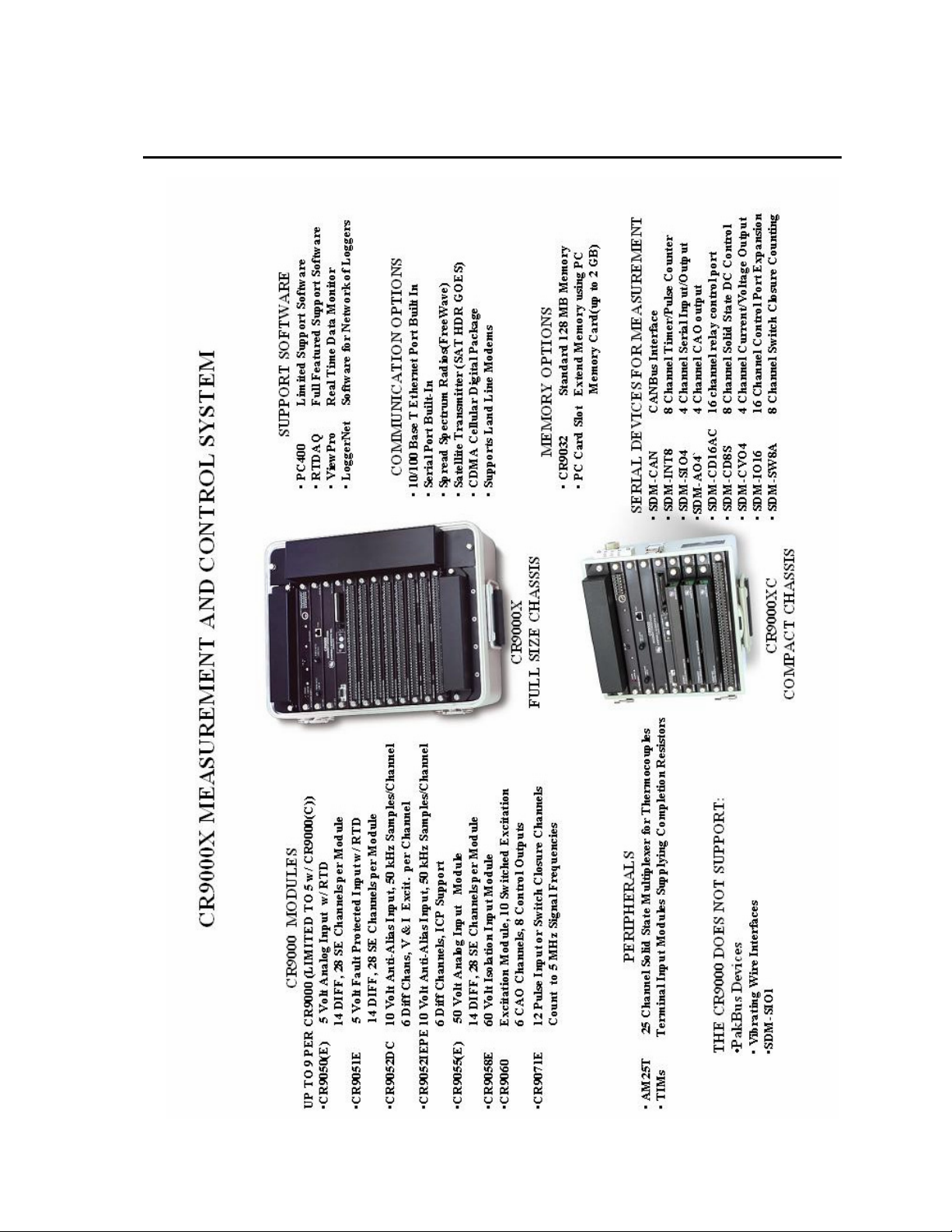

The CR9000X is a modular, multi-processor system that provides precision measurement

capabilities in a rugged,stand-alone, battery-operated package. The system makes

measurements at a rate of up to 100 K samples/second with 16-bit resolution. The

CR9000X Base System includes CPU, power supply, and A/D modules. Up to nine I/O

modules are inserted in the CR9000X, or up to five I/O modules are inserted into the

CR9000XC, to configure a system for specific applications. The on-board, BASIC-like

programming language includes data processing and analysis routines. RTDAQ

Windows

realtime monitoring. LoggerNet software can be used for multiple station applications

requiring modem communications and/or where schedule data collection to a PC is

required.

™

Software provides program generation and editing, data retrieval, and

CR9000

AC ADAPTOR

FIGURE OV1-1. CR9000X Measurement and Control System

OV-1

Page 34

Overview

OV1. Physical Description

OV1.1 Basic System

The basic CR9000X system includes a CR9011 Power supply module, a

CR9032 CPU module, and a CR9041 A/D module. These are installed into a

mother board in an enclosure. Also included in all CR9000X base systems is a

battery, and a wall charger.

There are two sizes of base systems to choose from. The CR9000XC compact

version comes in an aluminum enclosure and can accommodate up to 5

measurement modules. The CR9000X full size chassis can be configured with

a lab enclosure or a fiberglass environmental enclosure and can accommodate

up to 9 measurement modules.

The CR9000XC includes a 7 AHr lithium battery. The CR9000X full size

logger includes two 7 AHr batteries. It is recommended to keep these

batteries from reaching a state of deep discharge (10.5 V) which can damage

the cells.

CR9011 Power Supply Module and AC Adapter

POWER

CHARGE

9011 POWER SUPPLY

ON OFF

MADE IN USA

FIGURE OV1-4. CR9011

The CR9011 Power Supply Module provides regulated power to the CR9000X

from either the internal battery modules or from the 9 to 18 VDC (fuse and

diode protected) charge inputs. It also regulates battery charging (up to 2

amps) from power supplied by the AC adapter, a DC input, or other external

sources. The AC adapter may be used where AC power is available (100 - 240

volts) to provide power to the CR9000X and charge its batteries.

High Current Demand Applications

A DC source with voltage in the range of 9 to 18 VDC will charge the internal

lead acid batteries and power the CR9000X provided sufficient current is

available and the system is set-up to use 3 amps or less. If the CR9000X

system configuration requires greater than 3 amps, consult a CSI applications

engineer for information about the CR9011 Power Supply High-Current

modification.

CHARGE(9-18VDC)

12VOUT POWER UP

>2.0V

<0.8V

OV-2

LEDs There are 2 LEDs: Power and Charge. The Power LED is red if

the logger is powered up. The Charge LED is red to indicate the

presence of a charging source for the batteries.

On/Off The ON/Off toggle switch is used to manually power up and down

the logger. It should be noted that if the toggle switch is in the ON

position, but the Power LED is dark, it could either mean that there

Page 35

Overview

is no power available, the logger has been shut down through

software control or that the internal fuse is blown.

Charge There are two connections, in parallel, for hooking up a 9 to 18

VDC charging source. These connections are fuse and diode

protected. The CR9011's 12VOUT supply is current limited to 300

mA. If a peripheral requires more current, the CR9032 SDM 12

volt out can source up to 1.85 amps.

>2.0V The CR9011 has a relay that allows shutting off power under

program control. The Power Up inputs allow an external signal to

awaken the CR9000X from a powered down state (see the

PowerOff topic in Section 9 9.2 Data Logger Status/ Control).

When the CR9000X is in this "Power Off" state, the On/Off switch

is in the ON position but the internal relay is open and the power

LED is not lit. If the ">2" input has a voltage greater than 2 volts

applied to it (most common usage is 12 Volts), the CR9000X will

awake, load the program in memory and run.

<0.8V If the <0.8 input is shorted to ground during the CR9000X's 2 to 5

second initialization during power-up, any program set to Run On

Powerup will be disabled. This is useful if a program is in some

endless loop and communications cannot be established. Can also

be used to wake up a logger that has been shut down through

software control.

In addition to regulating and supplying power to the logger, the CR9011 keeps

track of the date and time. If the CR9000X system's CR9011 module is

swapped out, the Date/Time will need to be reset. The clock is powered off the

main 12 volt batteries. In addition, there are two backup power sources for the

clock, a lithium battery and a super capacitor, both located on the CR9011

board.

The run time attributes (Run Now, Run on Powerup ..) of the program files are

also stored on the CR9011. If the CR9011 in the system is swapped out for

a different CR9011, the run time attribute settings will no longer be valid

and will need to be reset by the user.

MEASUREMENTS:

Battery (voltage and current)

CONTROL:

PowerOff

Program Run Attributes

ClockSet

See Section 1.2 System Power Requirements and Options for additional

details.

OV-3

Page 36

Overview

CR9032 CPU Module

SDM

CR9032 CPU

+12 G C1 C2 C3

RS-232 CS I/O ETHERNET CARD PC-CARD

STATUS

CONTROL

Top of Card Faces Down

FIGURE OV1-2. CR9032

The CR9032 CPU Module provides system control, processing, and

communication. The CR9032 CPU module is the main processor for the

datalogger as well as memory for program storage and buffering data. The

main processor is a 180 MHz Hitachi SH-4 microprocessor. The module has

128 MB SDRAM and 2 MB Flash EEPROM. 128 KB of the Flash memory is

reserved for program storage.

MADE IN USA

NOTE

The 128 MB of SDRAM is not battery backed and that data that

is stored there will be lost when the logger is powered down or

experiences a watchdog reset.

CRITICAL DATA SHOULD BE STORED ON THE

PCMCIA CARD.

The CR9032 CPU Module provides the following:

SDM Ports C1 through C3 are used for communication with SDM (Synchronous Device

for Measurements) peripherals such as the SDM-CAN or SDM-SIO4. The

SDM 12 volt supply is current limited to 1.85 amps and can be used to power

other peripherals besides SDM devices.

RS232 The Datalogger RS-232 port can function as either a DCE (Data

Communication Equipment such as a modem) or DTE (Data Terminal

Equipment such as a computer) device. For the Datalogger RS-232 port to

function as a DTE device, a null modem cable is required. The most common

use of the Datalogger's RS-232 port is a connection to a computer DTE device.

A standard DB9-to-DB9 cable can connect the computer DTE device to the

Datalogger DCE device. Pins 1, 4, 6 and 9 function differently than a standard

DCE device. This is to accommodate a connection to a modem or other DCE

device via a null modem. Pin configuration for the CR9000X RS-232 9-pin

port is listed in TABLE OV1-1.

TABLE OV1-1. Datalogger RS-232 Pin-Out

OV-4

PIN

1 DCD DTR (tied to pin 6) O* Data Terminal Ready

2 TXD TXD O Asynchronous data Transmit

3 RXD RXD I Asynchronous data Receive

4 DTR N/A X* Not Connected

5 GND GND GND Ground

6 DSR DTR O* Data Terminal Ready

7 CTS CTS I Clear to send

8 RTS RTS O Request to send

9 RI RI I* Ring

DCE

Function

Logger

Function

I/O

Description

Page 37

Overview

* Different pin function compared to a standard DCE device. These pins will

accommodate a connection to modem or other DCE devices via a null modem

cable.

I/O Descriptors: O = Signal Out of the CR1000 to a RS-232 device;

I = Signal Into the CR1000 from a RS-232 device,

X = Signal has no connection (floating)

CS I/O CSI 9 Pin port for communications with CSI's peripherals (such as the DSP4).

Table OV1-2 lists the pin configuration for the CR9000X CS I/O port.

TABLE C-1. CS I/O Pin Description

O = Signal Out of the CR9000X to a peripheral.

I = Signal Into the CR9000X from a peripheral.

PIN ABR I/O Description

1 5 V O 5V: Sources 5 VDC, used to power peripherals.

2 SG Signal Ground: Provides a power return for pin 1 (5V),

and is used as a reference for voltage levels.

3 RING I Ring: Raised by a peripheral to put the CR9000X in the

telecommunications mode.

4 RXD I Receive Data: Serial data transmitted by a peripheral are

received on pin 4.

5 ME O Modem Enable: Raised when the CR9000X determines

that a modem raised the ring line.

6 SDE O Synchronous Device Enable: Used to address

Synchronous Devices (SDs), and can be used as an enable

line for printers.

7 CLK/HS I/O Clock/Handshake: Used with the SDE and TXD lines to

address and transfer data to SDs. When not used as a

clock, pin 7 can be used as a handshake line (during printer

output, high enables, low disables).

8 +12 VDC

9 TXD O Transmit Data: Serial data are transmitted from the

CR9000X to peripherals on pin 9; logic low marking (0V)

logic high spacing (5V) standard asynchronous ASCII, 8

data bits, no parity, 1 start bit, 1 stop bit, 300, 1200, 2400,

4800, 9600, 19,200, 38,400, 115,200 baud (user

selectable).

Ethernet Supports 10BaseT or 100baseT communications. An Ethernet crossover

cable is required for hooking up directly to a computer.

There are two LEDs on the Ethernet port. The LED on the lower left of the

port indicates communication speed. If hooked into a 10BaseT link it will be

dark, if hooked into a 100BaseT link it will be lit green.The LED on the lower

right of the port indicates communication traffic. If communications is active,

it should be flashing yellow.

PC Card The CR9000X has a built in PCMCIA card slot that can support cards up to 2

GB in size with a status LED and control button. Removing a card while it is

active can corrupt the data and potentially damage the card. Press Card

removal button and wait for LED to turn green before removing Card. Do not

switch off the power (CR9011 Module) while the cards are present and active

OV-5

Page 38

Overview

(Press card button prior to flipping the power switch). If the logger is powered

off using software control (PowerOff instruction), the data buffered in the CPU

is flushed to the card and the Logger is shut down properly.

NOTE

DO NOT POWER DOWN LOGGER WHILE PCMCIA CARD

IS ACTIVE.

LED code description:

Dark: No card detected or formatted card present without errors

Yellow: Either no card or corrupt card with program trying to access the card

Red: Accessing the card

Green: Can safely remove the card

Only Industrial grade PC cards should be used. They can operate over a wider

temperature range, have better vibration and shock resistance, have faster

read/write times, and can withstand more write cycles than the commercial

grade cards. It should be remembered that a system is only as good as its

weakest link. Do not buy a cheap memory card to store data for a test whose

results are important.

See Appendix C PC/CF Card Information for details on selecting memory card.

Up to a total of 30 data tables, each capable of storing data at different rates,

can be created between the CPU's SDRAM and the PC Card. Data Tables

created on the PC cards will also have a buffer table created in SDRAM. The

size of this buffer can either be manually or auto allocated.

MEASUREMENTS/INSTRUCTIONS THAT DIRECTLY UTLIZE THE

CPU HARDWARE OR COMMUNICATIONS OPTION:

CardOut Output Data to PC Card

CS7500 Open Path CO2/H20 Sensor

CSAT3 CSI Sonic Anemometer

DSP4 DSP4 Heads up Display

SDMA04 Analog Voltage Output Peripheral

SDMCANBus CANBus Interface Peripheral

SDMCD16AC I/O Port Peripheral used for controlling relays

SDMCVO4 Analog Current and Voltage Output Peripheral

SDMINT8 Interval Timer Peripheral

SDMIO16 Control Port Expansion device

SDMSIO4 Serial Input/Output Peripheral

SDMSW8A Switch Closure Measurement Peripheral

CR9041 A D

OV-6

CR9041 A/D and Amplifier Module

CR9000X

MEASUREMENT & CONTROL SYSTEM

LOGAN, UTAH

FIGURE OV1-3. CR9041

The CR9041 A/D and Amplifier Module provides signal conditioning and 16

bit, 100 kHz A/D conversions.

MADE IN USA

Page 39

OV1.2 Measurement Modules

CR9050(E) Analog Input Module

1

3

5

7

9

SE

2

4

6

1

2

H

DIF

H

L

3

H

L

8

4

H

L

L

11

10

5

H

12

6

H

L

L

Overview

13

15

17

19

21

23

25

14

16

18

20

22

7

8

9

10

H

H

H

L

L

H

L

11

H

L

24

12

H

L

L

27

26

13

H

28

14

H

L

L

9050 ANALOG INPUT W RTD

MADE IN USA

FIGURE OV1-5. CR9050

The only difference between a CR9050 and a CR9050E is that the CR9050E is

an "Easy Connect" module type, and includes a CR9050EC. Both the

CR9050E and the CR9051E use the same CR9050EC Easy Connect module

(See Figure OV1-6). The CR9050E typically remains in the CR9000(X)

chassis while each CR9050EC remains connected to the sensors. This allows

one CR9000(X) system to be moved from location to location and be quickly

connected to the sensors on-site.

The CR9050(E) Analog Input Module has 14 differential inputs for measuring

voltages up to ±5 V. Each differential input can be, independently, configured

as two Single Ended inputs. Next to each differential channel, is an analog

ground input. All analog grounds on all CR9050(E), CR9051E, CR9055(E),

CR9060, CR9070, and CR9071E modules in a CR9000X chassis are common.

Diff. Channel H

Differential Channel 1 through 14

Diff. Channel L

.

Sensor

Sensor wired up as a Differential (DIF) input

Each differential analog input can, independently, be setup as 2 single-ended

inputs.

S.E. Channel

Single Ended Channel 1 through 28

Sensor

Ground

Sensor wired up as a Single Ended (SE) input

All inputs on the CR9050(E), CR9051E, and CR9055(E) modules are

multiplexed through the single 16 bit A/D on the CR9041 A/D module. The

maximum aggregate throughput for all channels on all modules is 100,000

samples per second. Resolution on the most sensitive range is 1.6 μV.

OV-7

Page 40

Overview

Full Scale Maximum

Range Resolution Throughput

± 5000 mV 158 uV 100 KHz

± 1000 mV 32 uV 100 KHz

± 200 mV 6.3 uV 100 KHz

± 50 mV 1.6 uV 50 KHz

The CR9050(E) operational input voltage limits are ± 5 volts with reference to

datalogger ground. Voltages exceeding ±9 V with reference to datalogger

ground may cause errors on other channels. When the logger is powered off,

the CR9050(E)'s input impedance drops drastically.

The CR9050(E) contains an on-board PRT, located at the top center of the

module, which provides the reference temperature for thermocouple

measurements. A heavy copper grounding bar and connectors combined with

the aluminum case help to reduce temperature gradients for accurate

thermocouple measurements. If the logger is in an environment that is

experiencing rapid temperature fluctuations, it is recommended that the

CR9000X be insulated to reduce the temperature gradient along the copper bar.

This is true for all modules used to measure thermocouples.

CR9050 SUPPORTED MEASUREMENT INSTRUCTIONS:

Voltage

VoltDiff Differential Voltage

VoltSe Single-Ended Voltage

TCDiff Differential Thermocouple

TCSE Single Ended Thermocouple

NOTE

Bridge measurements (also requires CR9060 Excitation Module)

BrFull Full Bridge

BrFull6W 6 Wire Full Bridge

BrHalf Half Bridge

BrHalf3W 3 Wire Half Bridge

BrHalf4W 4 Wire Half Bridge

Self measurements (reference PRT for thermocouple measurements)

ModuleTemp Module Temperature

See Section 3.1 Measurements using the CR9041 A/D for measurement details.

See Section 7 Measurement Instructions for Instruction details.

The CR9051E is recommended over the CR9050E for

applications where fault voltages beyond ±9 V could come in

contact with the inputs, or when the CR9000X could be powered

off while still connected to sensors that have power applied to

them.

OV-8

Page 41

CR9051E Fault Protected 5 V Analog Input Module

Overview

FIGURE OV1-6. CR9051E with CR9050EC

The number of channels are the same as for the CR9050(E) Analog Input

Module. This module includes an Easy Connect (CR9050EC) that can quickly

be removed from the CR9000X chassis. The CR9050EC contains the PRT that

is used to provide the reference temperature for thermocouple measurements.

All inputs on the CR9050(E), CR9051E, and CR9055(E) modules are

multiplexed through the single 16 bit A/D on the CR9041 A/D module. The

maximum aggregate throughput for all channels on all modules is 100,000

samples per second. Resolution on the most sensitive range is 1.6 μV.

Full Scale Maximum

Range Resolution Throughput

± 5000 mV 158 uV 100 KHz

± 1000 mV 32 uV 100 KHz

± 200 mV 6.3 uV 50 KHz

± 50 mV 1.6 uV 50 KHz

Although the measurable voltage range with respect to data logger ground is

±5 V, the same as the CR9050, the CR9051E's input channels are faultprotected so as to permit over-voltages between +50 V and –40 V without

corruption of measurements on other input channels.

Another difference from the CR9050(E) module is that the CR9051E's input

channels become open switches when the CR9000X is powered off.

The CR9051E supports the same instruction set as the CR9050.

See Section 3.1 Measurements using the CR9041 A/D for measurement details.

See Section 7 Measurement Instructions for Instruction details.

OV-9

Page 42

Overview

CR9052DC Anti-Alias Filter Module with DC Excitation

CR9052EC

CR9052DC MADE IN USA

FILTER MODULE CONNECTOR DC EXCITATION MADE IN USA

FIGURE OV1-7. CR9052DC with CR9052EC

The CR9052DC is a high-performance Fast Fourier Transform (FFT) spectrum

analyzer and anti-alias Finite Impulse Response filter module. Each

CR9052DC includes one CR9052EC. Additional CR9052ECs can be

purchased separately. The CR9052DC typically remains in the CR9000(X)

chassis while each CR9052EC remains connected to sensors. This allows one

CR9000(X) system to be moved from location to location and be quickly

connected to the sensors on-site.

NOTE

The module includes six anti-aliased, differential analog measurement

channels, each channel having its own programmable gain amplifier, presampling analog filter, and 16 bit sigma-delta analog to digital converter. \

The Differential channels cannot be configured as two Single

Ended inputs.

The CR9052DC can burst measurements to its on-board, 8-million sample

buffer at 50,000 measurements per second per channel. Using the FFT

spectrum analyzer mode, the module's DSP can provide real-time spectra from

"seamless", anti-aliased, 50-kHz, 2048-point time-series snapshots for each of

its six analog input channels. The decimated data can be downloaded to an

appropriate PC card at an aggregate rate of 300,000 measurements per second.

It has differential input ranges from ±20 mV to ±5 V and operational input

voltage limits of -5 to +15 VDC. Inputs outside of this range will return either

erroneous measurements or NAN.

Inputs outside of the range of -40VDC to +50VDC can compromise the

integrity of the measurements for all of the inputs on this and other modules in

the CR9000X chassis, as well as possibly damaging the system and creating

communication problems between the logger and PC.

Each input channel has both regulated constant voltage excitation (VEX) and

regulated constant current excitation (IEX) channels. These can be used for

ratiometric bridge measurements. The corresponding Current Return (IRTN)

or Voltage Return (VRTN) must be used for the input of the ground side of

OV-10

Page 43

Overview

the bridge. See figure OV1-8 for an example of how to wire up a full

Wheatstone bridge using the VEX output and VRTN return channels.

V

EEEXXX

V

IN+

V

IN-

V

RTN

FIGURE OV1-8. Wiring a Wheatstone bridge

Channel Description

V

Regulated DC voltage output. Can be set to 5 VDC or 10 VDC

EX

and can source up to 85 mA. Must use the V

input for the

RTN

voltage return.

I

Regulated 10 mA DC current output. Has a compliance voltage

EX

of 12 Volts. Must use the I

V

High side of the differential voltage input for measurement.

IN+

V

Low side of the differential voltage input for measurement.

IN-

V

Return, or ground plane, for VEX

RTN

I

Return, or ground plane, for IEX

RTN

input for the voltage return.

RTN

System analog ground. Same reference ground as grounds on the

CR9050 and CR9060. Used mainly for shield drain.

It should be noted that the raw value returned from the VoltFilt measurement

is in millivolts. This is true even when measuring an electrical bridge that is

excited using one of the excitation options supplied by the CR9052DC

module. If it is desired to have a ratio-metric value returned (mVolts per

Volt), the applicable multiplier will need to be applied.

For example, if 5 volts were used to excite the Wheatstone bridge depicted in

Figure OV1-8, a multiplier of 0.2 (1/5) would need to be applied to have a

ratio-metric value returned.

The CR9052DC supports Hanning, Hamming, Blackman, and Kaiser-

Bessel windowing. Windowing may be shut off if desired. The CR9052DC

can also implement A, B, or C spectral weighting for all spectral output

modes as defined in the IEC 60651 international standard. It also supports 1/N

octave analysis (such as the 1.3 octave analysis) for acoustic applications.

CR9052DC SUPPORTED MEASUREMENT INSTRUCTIONSS:

VoltFilt Differential Filter Measurement

FFTFilt Differential FFT Measurement

See Section 3.3 CR9052 Filter Module Measurements for measurement details.

See Section 7 Measurement Instructions for Instruction details.

OV-11

Page 44

Overview

CR9052IEPE Anti-Alias Filter Module

CR9052IEPE

SHORT

OPEN

CH 1

SHORT

OPEN

CH 2

SHORT

OPEN

CH 3

SHORT

OPEN

CH 4

SHORT

OPEN

CH 5

SHORT

OPEN

CH 6

FIGURE OV1-9. CR9052IEPE

The The CR9052IEPE module allows direct connection of Internal Electronics

Piezo-Electric (IEPE) accelerometers and microphones to CR9000X

dataloggers. A CR9052IEPE has six channels. Each channel has a BNC

connector, an open circuit indicator LED, and a short circuit indicator LED

which can indicate if the channel is over-or under-driven. Each channel has a

built-in constant current source, which is software programmable to 0, 2, 4, or

6 mA.

OPEN LED input Resistance code description:

Programmed Current Level

2 mA

4 mA 6mA

Red (Open): > 15 KOhm > 7.8 KOhm > 5.2 KOhm

Green(connected): < 15 KOhm < 7.7 KOhm < 5.2 KOhm

SHORT LED input Resistance code description:

Programmed Current Level

2 mA

4 mA 6mA

Red (Short): < 1 KOhm < 500 Ohm < 300 Ohm

Green(connected): > 1 KOhm > 500 Ohm > 300 Ohm

MADE IN USA

OV-12

The CR9052IEPE can burst measurements to its on-board, 8-million sample

buffer at 50,000 measurements per second per channel. Using the FFT

spectrum analyzer mode, the module's DSP can provide real-time spectra from

"seamless", anti-aliased, 50-kHz, 2048-point time-series snapshots for each of

its six analog input channels. The decimated data can be downloaded to an

appropriate PC card at an aggregate rate of 300,000 measurements per second.

MEASUREMENTS:

VoltFilt Differential Filter Measurement

FFTFilt Differential FFT Measurement

The CR9052IEPE module measurements have two programmable time

constants available: 5 seconds and 0.5 seconds.

See Section 3.3 CR9052 Filter Module Measurements for measurement details.

See Section 7 Measurement Instructions for Instruction details.

Page 45

CR9055(E) 50-Volt Analog Input Module

1

3

5

7

9

11

SE

2

4

6

8

1

2

3

H

H

DIF

L

H

L

4

H

L

10

5

H

L

L

13

12

6

H

14

7

H

L

L

Overview

15

17

19

21

23

25

16

18

20

22

8

9

10

H

H

L

H

L

11

H

L

24

12

H

L

L

27

26

13

H

28

14

H

L

L

9055 50V ANALOG INPUT

MADE IN USA

FIGURE OV1-10. CR9055

The only difference between a CR9055 and a CR9055E is that the CR9055E is

an "Easy Connect" module type, and includes a CR9055EC (See Figure OV1-

6). The CR9055E typically remains in the CR9000(X) chassis while each

CR9055EC remains connected to the sensors. This allows one CR9000(X)

system to be moved from location to location and be quickly connected to the

sensors on-site.

The CR9055(E) 50-Volt Analog Input Module has 14 differential or 28 singleended inputs for measuring voltages up to ±50 V. Resolution on the most

sensitive range is 16 μV. The CR9055 has an operational input voltage limit

range of ±50 V.

Full Scale Maximum

Range Resolution Throughput

± 50.0 V 1580 uV 50 KHz

± 10.0 V 320 uV 50 KHz

± 2.0 V 63 uV 25 KHz

± 0.5 V 16 uV 25 KHz

All inputs on the CR9050(E) and CR9051E modules are multiplexed through

the single 16 bit A/D on the CR9041 A/D module. The maximum aggregate

throughput for all channels on all modules is 100,000 samples per second. The

higher range codes are simply accomplished through the use of a voltage

divider network.

NOTE

CR9055(E) SUPPORTED MEASUREMENT INSTRUCTIONS:

VoltDiff Differential Voltage

VoltSe Single-Ended Voltage

TCDiff Differential Thermocouple

TCSE Single Ended Thermocouple

Normally thermocouple measurements would be made on the CR9050 Analog

Input Module (±5 Volt) because of its greater resolution, however they can be

made with the CR9055(E) using the 0.5 V range if the ±50 V operational

voltage range is necessary and a CR9058E Isolation module is not available.

The 16 μV resolution corresponds to about 0.41 degrees C resolution for the

measurement.

As the CR9055(E) does not have a PRT for measuring the

reference temperature for the thermocouple measurement, either

an adjacent CR9050 or CR9051E module's reference

temperature can be used. If there are temperature gradients in

the chassis, this will lead to additional measurement errors.

OV-13

Page 46

Overview

CR9058E Isolation Module

CR9058EC

CR9058E 60V ISOLATED ANALOG INPUT MODULE W/RTD MADE IN USA

60V ISOLATED ANALOG INPUT CONNECTOR FOR CR9058E MADE IN USA

FIGURE OV1-9. CR9058E with CR9058EC

The CR9058E is a 10-channel, differential input isolation module. One

CR9058EC Easy Connector Module is included with the CR9058E; additional

CR9058ECs can be purchased as accessories. The CR9058E typically remains

in the CR9000(X) chassis while the CR9058EC remains connected to sensors.

This allows one CR9000(X) system to be moved from location to location and

be quickly connected to the sensors on-site.

Next to each channel is an isolated ground. The CR9058E ten input channels

cannot be configured as Single Ended inputs. Each channel has a 24-bit A/D

converter which supplies input isolation for up to ±60 VDC continuous

operational voltage conditions. Inputs with voltages greater than 469 VDC

with respect to data logger ground can damage the logger. The full-scale

ranges available are ±60 VDC, ±20 VDC, and ±2 VDC with a resolution to 2

μVolts. Due to its superb signal to noise ratio, and good resolution, an

accurate thermocouple measurement can be made on the 2 Volt range code.

The measurement speed for the CR9058E is lower than the other CR9000X

modules, but this is somewhat offset by the fact that all of the channels are

sampled simultaneously:

Full Scale Maximum Maximum

Range Resolution Throughput

± 60 V 300 uV 650 Hz

± 10 V 100 uV 650 Hz

± 2 V 10 uV 650 Hz

CR9058E SUPPORTED MEASUREMENT INTRUCTIONS:

ModuleTemp Module Temperature

VoltDiff Differential Voltage

VoltSe Single-Ended Voltage

See Section 3.2 CR9058E Isolation Module Measurements for measurement details.

See Section 7 Measurement Instructions for Instruction details.

OV-14

Page 47

Overview

CR9060 Excitation Module

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 1 3 6 82457

9060 EXCITATION C.A.O. SWITCHED EXCITATION DIGITAL CONTROL OUTPUT

FIGURE OV1-11. CR9060

The CR9060 is the Excitation Module for the CR9000X Measurement and

Control System. The CR9060 module has 6 Continuous Analog Outputs

(CAO), 10 Switched Excitation, and 8 Control Ports.

: The CR9060 Excitation Module has six continuous analog outputs with

CAOs

individual digital-to-analog converters for PID Algorithm, waveform

generation, and excitation for bridge measurements. The six CAOs can be

controlled independently, or can be turned on simultaneously.

Switched Excitation

: The CR9060 also has ten switched excitation channels

that provide precision voltages for bridge measurements. Only 1 switched

excitation is active at a time, where all 6 of the CAOs can be turned on

simultaneously. The advantage of using switched excitation is that it requires

less power and it reduces, or eliminates, self-heating sensor errors, as the on

time of the excitation is limited.

The ten switched and six continuous analogue output excitation channels can

be set to any value within the range of ±5 VDC with a compliance current of

50 mA. Again, only one switched excitation can be on at a time.

Control Ports

: The CR9060 also has 8 built in control ports (output only).

These can be set to TTL levels (0 Volts or 5 Volts). These ports can be used to

activate external relays, or simply to toggle the state of LEDs for monitoring

purposes. The output resistance of these ports is 100 ohms, so the current drive

is rather limited.

MADE

IN USA

CR9060 Supported measurement Instructions

BrFull Requires CR9050(1) Full Bridge

BrFull6W Requires CR9050(1) 6 Wire Full Bridge

BrHalf Requires CR9050(1) Half Bridge

BrHalf3W Requires CR9050(1) 3 Wire Half Bridge

BrHalf4W Requires CR9050(1) 4 Wire Half Bridge

CR9060 Supported control Instructions

Excite Sets a CAO or Switched Excite Channel

PortSet Sets the logic level of a Single Control Port

WriteIO Sets the logic level of a group of Control Ports

See Section 3.1.5 Bridge Resistance Measurements for measurement details.

See Section 7 Measurement Instructions for Measurement Instruction details.

See Section 9.2 Data Logger Status/Control for Control Instruction details.

OV-15

Page 48

Overview

CR9070 Counter - Timer / Digital I/O Module — Obsolete

1 2

45 78 9 10 12 13 15 16 1 2 3 4 5 6 7 8 9 10 11 12

3 6 11 14

9070 COUNTER & DIGITAL I O

Digital I/O

DIGITAL I/O

LOW LEVEL AC SWITCH CLOSURRE

FIGURE OV1-12. 9070

The CR9070 has been replaced by the CR9071E, which provides better overvoltage protection, increased channel-to-channel cross-talk isolation, interval

(edge) timing with 40 nanosecond resolution, and a Wait Digital Trigger

function.

The CR9070 Pulse Module has 16 Digital I/O channels and 12 Pulse channels

with 16 bit accumulators. The CR9070 is used for Pulse measurements, as

well as state monitoring and control.

CHANNEL DESCRIPTION

The CR9070 has 16 Digital I/O ports selectable, under program control, as

binary inputs or control outputs. These ports have multiple function capability

including: edge timing, TTL signal period or frequency measurements, device

driven interrupts, and, as shown in Figure OV1-13, state monitoring and

control (i.e.: turning on/off devices and monitoring whether the device is On or

Off). The Edge Timing resolution is limited to the logger's Scan Interval.

MADE IN USA

Digital I/O Ports Used to Control/Monitor Pump

C1 - Used as input to monitor pump status.

C2 - Used as output to switch power to a pump via a solid state relay.

FIGURE OV1-13. Control and monitoring of a device using digital I/O

ports

OV-16

Page 49

Overview

Pulse Counting

The CR9070 has 12 Pulse input channels with 16 bit counters. These channels

count on the rising edge of the input signal and can be configured to output

Counts or Signal Frequency. The maximum input voltage allowed on these

channels is

interval (e.g., a PulseCount instruction in a 1 second scan has a frequency

resolution of 1 Hz, a 0.5 second scan gives a resolution of 2 Hz, and a 1 ms

scan gives a resolution of 1000 Hz). The resolution can be increased through

using the running average parameter of the PulseCount instruction. The

resultant measurement will bounce around by the resolution.

These twelve channels are further segmented based on the input signal's

characteristics.

Channels 1-8:

± 20 volts. The resolution of the frequency measurement is 1/scan

The first 8 Pulse input channels can be configured as Low

Level AC inputs to count the frequency of low level AC

signals from such sensors as a magnetic pickups. The

minimum input voltage that can be counted is 20 mV RMS

with a max frequency of 10 KHz. With input amplitudes

greater than 50 mV RMS, up to 20 KHz signals can be read.

The maximum allowable input voltage for this or the high

frequency mode is 20 VDC.

Channels 1 through 8 can also be configured to measure

"High Frequency" pulses, which are signals that have

transitions from below 1.5 volts to above 3.5 volts. High

Level Frequency input up to 5 MHz can be measured. If

possible, it is preferable to place Low Level measurement

inputs and high frequency measurement inputs on opposite

ends of the module to eliminate the possible of crosstalk.

Channels 9-12:

CR9070 SUPPORTED MEASUREMENT/CONTROL INSTRUCTIONS:

PulseCount Count Pulses or Frequency

ReadI/O Read State of I/O Channels

TimerIO Interval and Timing Measurements

WriteI/O Set State of I/O Channels

See Section 3.4 Pulse Count Measurements for measurement details.

See Section 7 Measurement Instructions for Measurement Instruction details.

See Section 9.2 Data Logger Status/ Control for Control Instruction details.

The last 4 Pulse channels (9-12) can be configured as Switch

Closure inputs. The dry contact switch should be connected

between the Pulse port and ground. When the switch is open,

the port is pulled to 5 volts through a 100 kohm pull up

resistor. Maximum frequency : 100 Hz.

Channels 9 through 12 can also be configured to measure

"High Frequency" pulses, which are signals that have

transitions from below 1.5 volts to above 3.5 volts. High

Level Frequency input up to 5 MHz can be measured.

OV-17

Page 50

Overview

CR9071E Counter and Digital I/O Module

CR9071EC

CR9071E COUNTER MADE IN USA

COUNTER & DIGITAL I/O MADE IN USA

FIGURE OV1-13. CR9071E

The CR9071E is an "Easy Connect" module type, and includes a CR9071EC

(See Figure OV1-6). The CR9071E typically remains in the CR9000(X)

chassis while each CR9071EC remains connected to the sensors. This allows

one CR9000(X) system to be moved from location to location and be quickly

connected to the sensors on-site.

This module is the direct replacement module for the CR9070. It has improved

resolution, channel isolation, over-voltage input protection, as well as new

functionality.

The CR9071E Pulse Module has 16 Digital I/O channels and 12 Pulse

channels with 32 bit accumulators. The CR9071 is used for Pulse

measurements, as well as state monitoring and control.

Digital I/O

CHANNEL DESCRIPTION

The CR9071E has 16 Digital I/O ports selectable, under program control, as

binary inputs or control outputs. These ports have multiple function capability

including: edge timing, TTL signal period or frequency measurements, device

driven interrupts, and, as shown in Figure OV1-13, state monitoring and

control (i.e.: turning on/off devices and monitoring whether the device is On or

Off). The Edge Timing resolution is 40 nanoseconds.

Digital I/O Ports Used to Control/Monitor Pump

OV-18

C1 - Used as input to monitor pump status.

C2 - Used as output to switch power to a pump via a solid state relay.

FIGURE OV1-13. Control and monitoring of a device using digital I/O

ports

Page 51

Overview

Pulse Counting

The CR9071E has 12 Pulse input channels with 32 bit counters. These

channels count on the falling edge of the input signal and can be configured to

output in Counts or Signal Frequency. The maximum input voltage allowed on

these channels is

40 nanoseconds.

These twelve channels are further segmented based on the input signal's

characteristics.

Channels 1-8:

± 20 volts. The resolution of the frequency measurement is

The first 8 Pulse input channels can be configured as Low

Level AC inputs to count the frequency of low level AC

signals from such sensors as a magnetic pickups. The