Page 1

CR7 MEASUREMENT AND CONTROL SYSTEM

INSTRUCTION MANUAL

REVISION: 7/97

COPYRIGHT (c) 1991-1997 CAMPBELL SCIENTIFIC, INC.

Page 2

This is a blank page.

Page 3

WARRANTY AND ASSISTANCE

The CR7 MEASUREMENT AND CONTROL SYSTEM is warranted by CAMPBELL SCIENTIFIC, INC. to

be free from defects in materials and workmanship under normal use and service for thirty-six (36)

months from date of shipment unless specified otherwise. Batteries have no warranty. CAMPBELL

SCIENTIFIC, INC.'s obligation under this warranty is limited to repairing or replacing (at CAMPBELL

SCIENTIFIC, INC.'s option) defective products. The customer shall assume all costs of removing,

reinstalling, and shipping defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC,

INC. will return such products by surface carrier prepaid. This warranty shall not apply to any CAMPBELL

SCIENTIFIC, INC. products which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability or fitness for a particular purpose. CAMPBELL SCIENTIFIC, INC. is not

liable for special, indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. To obtain a Returned Materials Authorization

(RMA), contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please write this number clearly on

the outside of the shipping container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Non-warranty products returned for repair should be accompanied by a purchase order to cover the repair.

815 W. 1800 N.

Logan, UT 84321-1784

USA

Phone (435) 753-2342

FAX (435) 750-9540

www.campbellsci.com

Campbell Scientific Canada Corp.

11564 -149th Street

Edmonton, Alberta T5M 1W7

CANADA

Phone (780) 454-2505

FAX (780) 454-2655

Campbell Scientific Ltd.

Campbell Park

80 Hathern Road

Shepshed, Loughborough

LE12 9GX, U.K.

Phone +44 (0) 1509 601141

FAX +44 (0) 1509 601091

Page 4

This is a blank page.

Page 5

CR7 OPERATOR'S MANUAL

TABLE OF CONTENTS

PAGE

WARRANTY AND ASSISTANCE

SELECTED OPERATING DETAILS..............................................................................................v

CAUTIONARY NOTES......................................................................................................................vi

OVERVIEW

OV1. PHYSICAL DESCRIPTION

OV1.1 700X Control Module ..........................................................................................................OV-1

OV1.2 720 I/O Module.................................................................................................................... OV-2

OV1.3 Enclosures and Connector Options .................................................................................... OV-2

OV2. MEMORY AND PROGRAMMING CONCEPTS

OV2.1 Internal Memory.................................................................................................................. OV-3

OV2.2 CR7 Instruction Types......................................................................................................... OV-6

OV2.3 Program Tables and the Execution and Output Intervals ................................................... OV-6

OV3. PROGRAMMING THE CR7

OV3.1 Functional Modes................................................................................................................ O V-8

OV3.2 Key Definition......................................................................................................................OV-8

OV3.3 Programming Sequence .....................................................................................................OV-8

OV3.4 Instruction Format............................................................................................................... OV-9

OV3.5 Entering a Program.............................................................................................................OV-9

OV4. PROGRAMMING EXAMPLE

OV4.1 Measurement.................................................................................................................... OV-10

OV4.2 Output ...............................................................................................................................OV-12

OV4.3 Editing an Existing Program.............................................................................................. OV-14

OV4.4 EDLOG Program Listing ...................................................................................................OV-14

OV5. DATA RETRIEVAL OPTIONS................................................................................ OV-15

OV6. SPECIFICATIONS...................................................................................................... OV-17

i

Page 6

TABLE OF CONTENTS

PROGRAMMING

1. FUNCTIONAL MODES

1.1 Program Tables - *1, *2, and *3 Modes ................................................................................. 1-1

1.2 Setting and Displaying the Clock - *5 Mode........................................................................... 1-2

1.3 Displaying and Altering Input Memory or Flags - *6 Mode..................................................... 1-2

1.4 Compiling and Logging Data - *0 Mode ................................................................................. 1-3

1.5 Memory Allocation - *A........................................................................................................... 1-4

1.6 Memory Testing and System Status - *B Mode ..................................................................... 1-5

1.7 *C Mode - Security................................................................................................................. 1-6

1.8 *D Mode - Save or Load Program.......................................................................................... 1-7

2. INTERNAL DATA STORAGE

2.1 Final Storage Areas, Output Arrays, and Memory Pointers................................................... 2-1

2.2 Data Output Format and Range Limits .................................................................................. 2-2

2.3 Displaying Stored Data on Keyboard/Display - *7 Mode........................................................ 2-3

3. INSTRUCTION SET BASICS

3.1 Parameter Data Types........................................................................................................... 3-1

3.2 Repetitions/Card Number....................................................................................................... 3-1

3.3 Entering Negative Numbers................................................................................................... 3-1

3.4 Indexing Input Locations ........................................................................................................ 3-2

3.5 Voltage Range and Overrange Detection .............................................................................. 3-2

3.6 Output Processing.................................................................................................................. 3-2

3.7 Use of Flags: Output and Program Control........................................................................... 3-3

3.8 Program Control Logical Constructions ................................................................................. 3-4

3.9 Instruction Memory and Execution Time................................................................................ 3-6

3.10 Error Codes............................................................................................................................ 3-9

DATA RETRIEVAL/COMMUNICATION

4. EXTERNAL STORAGE PERIPHERALS

4.1 On-Line Data Transfer - Instruction 96, *4 Mode ................................................................... 4-1

4.2 Manually Initiated Data Output - *9 Modes............................................................................. 4-2

4.3 Storage Module...................................................................................................................... 4-3

4.4 Printer Output Formats........................................................................................................... 4-4

5. TELECOMMUNICATIONS

5.1 Telecommunications Commands .......................................................................................... 5-1

5.2 Remote Programming of the CR7.......................................................................................... 5-3

6. 9 PIN SERIAL INPUT/OUTPUT

6.1 Pin Description....................................................................................................................... 6-1

6.2 Enabling Peripherals.............................................................................................................. 6-2

6.3 Interrupting Data Transfer to Storage Peripherals................................................................. 6-2

6.4 Telecommunications - Modem Peripherals............................................................................ 6-2

6.5 Interfacing with Computers, Terminals, and Printers............................................................. 6-2

ii

Page 7

TABLE OF CONTENTS

PROGRAMMING EXAMPLES

7. MEASUREMENT PROGRAMMING EXAMPLES

7.1 Single Ended Voltage-LI200S Silicon Pyranometer................................................................7-1

7.2 Differential Voltage Measurement...........................................................................................7-1

7.3 Thermocouple Temperatures Using 723-T Reference...........................................................7-2

7.4 Thermocouple Temperatures Using an External Reference Junction....................................7-2

7.5 Thermocouples for Differential Temperature Measurement...................................................7-3

7.6 Temperature with Calibrated Thermocouples.........................................................................7-4

7.7 107 Temperature Probe..........................................................................................................7-5

7.8 207 Temperature and RH Probe.............................................................................................7-5

7.9 Anemometer with Photochopper Output.................................................................................7-6

7.10 Tipping Bucket Raingage with Long Leads.............................................................................7-6

7.11 100 ohm PRT in 4 Wire Half-Bridge........................................................................................7-7

7.12 100 ohm PRT in 3 Wire Half-Bridge........................................................................................7-8

7.13 100 ohm PRT in 4 Wire Full-Bridge ........................................................................................7-9

7.14 Pressure Transducer-4 Wire Full-Bridge ..............................................................................7-10

7.15 Lysimeter-6 Wire Load Cell...................................................................................................7-11

7.16 227 Gypsum Soil Moisture Block ..........................................................................................7-13

7.17 Nonlinear Thermistor in Half Bridge (CSI Model 101)...........................................................7-14

8. PROCESSING AND PROGRAM CONTROL EXAMPLES

8.1 Computation of Running Average...........................................................................................8-1

8.2 Rainfall Intensity......................................................................................................................8-2

8.3 SUB 1 Minute Output Interval Synched to Real Time.............................................................8-3

8.4 Analog Output to Strip Chart...................................................................................................8-4

8.5 Converting 0-360 Wind Direction Output to 0-540 for Strip Chart...........................................8-5

8.6 Covariance Correlation Programming Example......................................................................8-6

INSTRUCTIONS

9. INPUT/OUTPUT INSTRUCTIONS.....................................................................................9-1

10. PROCESSING INSTRUCTIONS......................................................................................10-1

11. OUTPUT PROCESSING INSTRUCTIONS...................................................................11-1

12. PROGRAM CONTROL INSTRUCTIONS......................................................................12-1

MEASUREMENTS

13. CR7 MEASUREMENTS

13.1 Fast and Slow Measurement Sequence ...............................................................................13-1

13.2 Single-Ended and Differential Voltage Measurements .........................................................13-1

13.3 The Effect of Sensor Lead Length on the Signal Settling Time ............................................13-3

13.4 Thermocouple Measurements............................................................................................13-11

13.5 Bridge Resistance Measurements ......................................................................................13-15

13.6 Resistance Measurements Requiring AC Excitation ..........................................................13-19

13.7 Pulse Count Measurements................................................................................................13-20

iii

Page 8

TABLE OF CONTENTS

INSTALLATION

14. INSTALLATION

14.1 Environmental Enclosure, Connectors and Junction Boxes ................................................ 14-1

14.2 System Power Requirements and Options .......................................................................... 14-2

14.3 Humidity Effects and Control................................................................................................ 14-5

14.4 Recommended Grounding Practices................................................................................... 14-5

14.5 Use of Digital Control Ports for Switching Relays ................................................................ 14-6

15. I/O CARD ADDRESSING AND MULTIPLE I/0 MODULES

15.1 I/O Card Identification Number Decoding ............................................................................ 15-1

15.2 Use of Multiple I/O Modules................................................................................................. 15-4

APPENDICES

A. GLOSSARY..............................................................................................................................A-1

B. CR7 PROM SIGNATURES FOR SYSTEMS EQUIPPED WITH

STANDARD SOFTWARE....................................................................................................B-1

C. BINARY TELECOMMUNICATIONS

C.1 Telecommunications Command With Binary Responses......................................................C-1

C.2 Final Storage Format .............................................................................................................C-3

C.3 Generation of Signature.........................................................................................................C-4

D. CALIBRATION PROCEDURES

D.1 Voltage Reference Calibration Procedure..............................................................................D-1

D.2 Clock Calibration Procedure ..................................................................................................D-2

LIST OF TABLES.......................................................................................................................... LT-1

LIST OF FIGURES........................................................................................................................LF-1

INDEX ................................................................................................................................................... I-1

iv

Page 9

SELECTED OPERATING DETAILS

The channel numbering on the Analog Input

Card refers to differential measurements. Single

ended measurements assume the HI and LO

side of each differential channel are two

independent single ended channels, e.g., the HI

and LO side of differential channel 2 are single

ended channels 3 and 4 respectively.

When multiple measurements are specified in

one measurement instruction (through use of

the "Repetitions Parameter") the CR7 I/O

Module is capable of sequencing through 500

fast, single-ended measurements per second.

This specification is the MEASUREMENT

SPEED and should not be confused with

throughput which is the rate at which

measurements are made, converted to

engineering units and stored in Final memory.

With the 700X Control Module (6303 CPU

board), the maximum throughput rate for fast,

single-ended measurements is approximately

310 measurements per second (1 second

execution: Instruction 1 entered 4 times, 3 times

with 99 repetitions, once with 11 repetitions).

Data is stored in Final Memory only by Output

Processing Instructions and only when the

Output Flag is set.

The default case for data stored in Final

Memory is low resolution (4 characters). High

resolution values (5 characters) must be

specified through use of Instruction 78. All data

contained in Input Memory is displayed (*6) as

HIGH RESOLUTION (5 characters) but the

default case for all data stored in Final Memory

is LOW RESOLUTION unless high resolution is

specified through use of Instruction 78.

Floating Point Format - The computations

performed in the CR7 use floating point

arithmetic. CSI's 4 byte floating point numbers

contain a 23 bit binary mantissa and a 6 bit

binary exponent. The largest and smallest

numbers that can be stored and processed are

9 x 1018 and 1 x 10

The computations performed in the CR7 are

done in floating point arithmetic. Internally, the

number is stored and processed as a binary

number with a 23 bit binary mantissa and a 6 bit

binary exponent. The largest and smallest

numbers that can be stored and processed are

9 x 1018 and 1 x 10

of the mantissa limits the resolution of the

arithmetic to 1 part in 223 binary (1.3 x 10

decimal).

Time is stored with data in Final Memory only if

specifically requested through use of the Real

Time Instruction 77.

Data in Final Storage can be erased without

altering the program by using the *A Mode to

repartition memory. The simplest method is to

re-enter the current allocation for Input Storage

(32 locations is the default allocation). All

memory can be erased and the CR7 completely

reset by entering 1744 for the number of bytes

left in Program Memory.

On-line (as opposed to a manually initiated

dump) data transfer to peripherals (printer,

storage module, etc.) occurs only if enabled

through use of the *4 Mode or Instruction 96.

Data transfer to cassette tape is no longer

supported.

-19

, respectively.

-19

respectively. The size

9

v

Page 10

CAUTIONARY NOTES

The typical current drain for the CR7 is

approximately 100 mA while executing and 8-10

mA quiescent. Do not allow the lead-acid

batteries (2.5 Ahr) to drop below 11.76 V as

irreversible battery damage may result.

An external battery connected to the I/O Module

+12V and ground terminals continues to power

the CR7 system even though the CR7 power

switch is off. Reverse polarity protection is NOT

provided on this connection so exercise

extreme care if connecting external power

supplies.

Damage will occur to the analog input channel

circuitry if voltages in excess of +16V are

applied for a sustained period.

A POTENTIALLY DANGEROUS situation can

result due to hydrogen gas build up if the CR7 is

housed in a gas tight enclosure and the internal

lead acid batteries are shorted or overcharged.

Hydrogen concentration levels may occur which

are capable of causing injury or equipment

damage if ignited.

vi

Page 11

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

The CR7 Measurement and Control System combines precision measurement with processing and

control capability in a battery operated system.

Campbell Scientific, Inc. provides three documents to aid in understanding and operating the CR7:

1. This Overview

2. The CR7 Operator's Manual

3. The CR7 Prompt Sheet

This Overview introduces the concepts required to take advantage of the CR7's capabilities. Hands-on

programming examples start in Section OV4. Working with a CR7 will help the learning process, so

don't just read the examples, turn on the CR7 and do them. If you want to start this minute, go ahead

and try the examples, then come back and read the rest of the Overview.

The sections of the Operator's Manual which should be read to complete a basic understanding of the

CR7 operation are the Programming Sections 1-3, the portions of the data retrieval Sections 4 and 5

appropriate to the method(s) you are using (see OV5), and Section 14 which covers installation and

maintenance.

Section 6 covers the details of serial communications. Sections 7 and 8 contain programming examples.

Sections 9-12 have detailed descriptions of the programming instructions, and Section 13 goes into

detail on the CR7 measurement procedures.

The Prompt Sheet is an abbreviated description of the programming instructions. Once familiar with the

CR7, it is possible to program it using only the Prompt Sheet as a reference, consulting the manual if

further detail is needed.

Read the Selected Operating Details and Cautionary Notes at the front of the Manual before using the

CR7.

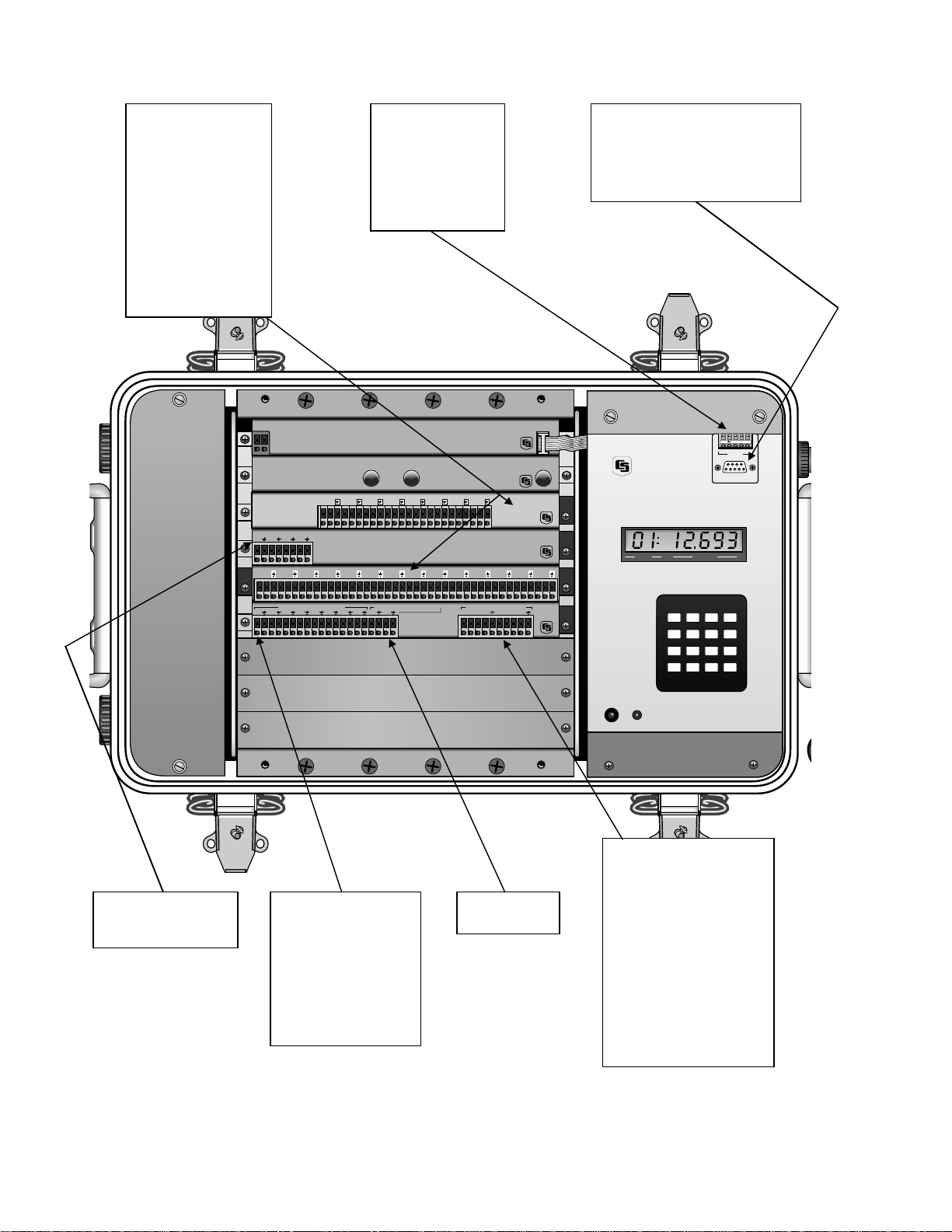

OV1. PHYSICAL DESCRIPTION

The CR7 features a modular, multiple

processor design that provides precision

measurement and control capability in a rugged,

battery operated system. Control Module

functions include real-time task initiation,

measurement processing, data storage,

telecommunications, and keyboard/display

interaction. The I/O Module performs all analog

and pulse signal measurement functions as well

as the analog and digital control output

functions. The I/O Module contains its own

processor card, a precision analog interface

card, and seven card slots which can

accommodate any combination of I/O Cards.

Sensor leads are connected to the I/O cards via

screw terminals.

A maximum of four I/O modules, separated by

up to 1,000 feet, may be connected to a single

Control Module in applications that require

distributed measurement capability.

OV1.1 700X CONTROL MODULE

Contains the CPU card, with 24K of system

PROM and 40K of RAM; the serial interface

card for peripheral communication and

connection of up to four I/O Modules; and the

keyboard display card. Two slots are present

for optional RAM expansion. The system's 2.5

Ahr lead-acid batteries and AC charging

circuitry are also contained in this module.

The CS I/O 9-pin port provides connection to

data storage peripherals, such as the

SM192/716 Storage Module, and provides

serial communication to computer or modem

devices for data transfer or remote

programming (Section 6). This 9 pin port does

NOT have the same pin configuration as the

OV-1

Page 12

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

RS232 9 pin serial ports used on many

computers.

The SDM terminals adjacent to the serial port

allow connection to Synchronous Device for

Measurement (SDM) peripherals. These

peripherals include the SDM-INT8 Interval

Timer, the SDM-SW8A Switch Closure Module,

the SDM-CD16AC AC/DC Controller, and the

SDM-OBDII Engine Controller Interface.

709 512K MEMORY CARD: This card

provides RAM storage for an additional 262,126

Final Data values. Only one 709 card may be

installed.

OV1.2 720 I/O MODULE

The processor card provides regulated power

for analog and digital functions from the

unregulated 12 volt supply. The analog

interface card contains a 16-bit A/D-D/A

converter, and a precision voltage reference.

The standard I/O Module contains slots for 7 I/O

Cards; the expanded Model 720XL contains 14

slots. All input and output connections to the

I/O module are transient protected with spark

gaps.

voltage with respect to the CR7 ground. Singleended channels are numbered sequentially,

e.g., the HI and LOW sides of differential

channels 2 are single-ended channels 3 and 4,

respectively (Section 13.2).

724 PULSE COUNTER CARD: Provides 4

pulse counting channels for switch closures, low

level AC cycles, or high frequency pulse signals.

725 EXCITATION CARD: There are 8

switched analog excitation channels. These

supply programmable excitation voltages for

resistive bridge measurements. The excitation

channels are only switched on during the

measurement. Only one is on at a time.

The two Continuous Analog Output (CAO)

channels supply continuous output voltages,

under program control, for use with strip charts,

X-Y plotters, or proportional controllers.

The 8 Digital Control Ports (0 or 5 volt states)

allow on-off control of external devices. These

control ports have a very limited current output

(5mA) and are used to switch solid state

devices which in turn provide power to relay

coils (Section 14.4).

The +12 volt and ground terminals provide a

direct connection to the CR7 power supply.

723 ANALOG INPUT CARD: Contains 14

differential or 28 single ended inputs. Input

ground terminals connect to a heavy copper

bar, which reduces single ended measurement

offsets to less than 5µV.

723-T ANALOG INPUT CARD WITH RTD:

Identical to the 723 Card except that a platinum

resistance thermometer is mounted in the

center of the terminal strip. The PRT provides a

reference junction temperature for

thermocouple measurement. The PRT

measurement is accurate to ±0.1oC over a

range of -40oC to +60oC.

The numbering on the terminals refers to the

differential channels; i.e., the voltage on the HI

input is measured with respect to the voltage on

the Low input. When making single-ended

measurements either the HI or the Low channel

may be used independently to measure the

726 50 VOLT ANALOG INPUT CARD:

Provides 8 differential or 16 single ended inputs

for full scale DC ranges of ±50 V and ±15V.

Resolution is 1.66 millivolts on the ±50 V and

0.5 millivolts on the ±15 V range. The common

mode range is ±50 volts.

OV1.3 ENCLOSURES AND CONNECTOR

OPTIONS

ENC-7L ALUMINUM FRAME FOR

LABORATORY ENVIRONMENTS: 17" x 12" x

6"; provides a housing for benchtop use or a

frame for attachment to a wall or a NEMA type

enclosure.

ENC-7F ENVIRONMENTALLY SEALED

FIBERGLASS ENCLOSURE: 20" x 13" x 10";

housing for harsh environments. Sensor leads

enter via two ports fitted with 0.75" conduit

bushings, and plugged with removable

stoppers. The 1.040" hole size accommodates

#14 shell size circular connectors.

OV-2

Page 13

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

CR7

RELIEF VALVE

N

TTO

U

SS B

E

E

R

CAUTION

PR

SE

FO

A

E

B

C

G

IN

K

C

LO

N

U

FIGURE OV1-1. CR7 Measurement and Control System

OV2. MEMORY AND PROGRAMMING

CONCEPTS

The CR7 must be programmed before it will

make any measurements. A program consists

of a group of instructions entered into a program

table. The program table is given an execution

interval which determines how frequently that

table is executed. When the table is executed,

the instructions are executed in sequence from

beginning to end. After executing the table, the

CR7 waits the remainder of the execution

interval and then executes the table again

starting at the beginning.

The interval at which the table is executed will

generally determine the interval at which the

sensors are measured. The interval at which

data are stored is separate and may range from

samples every execution interval to processed

summaries output hourly, daily, or on longer or

irregular intervals.

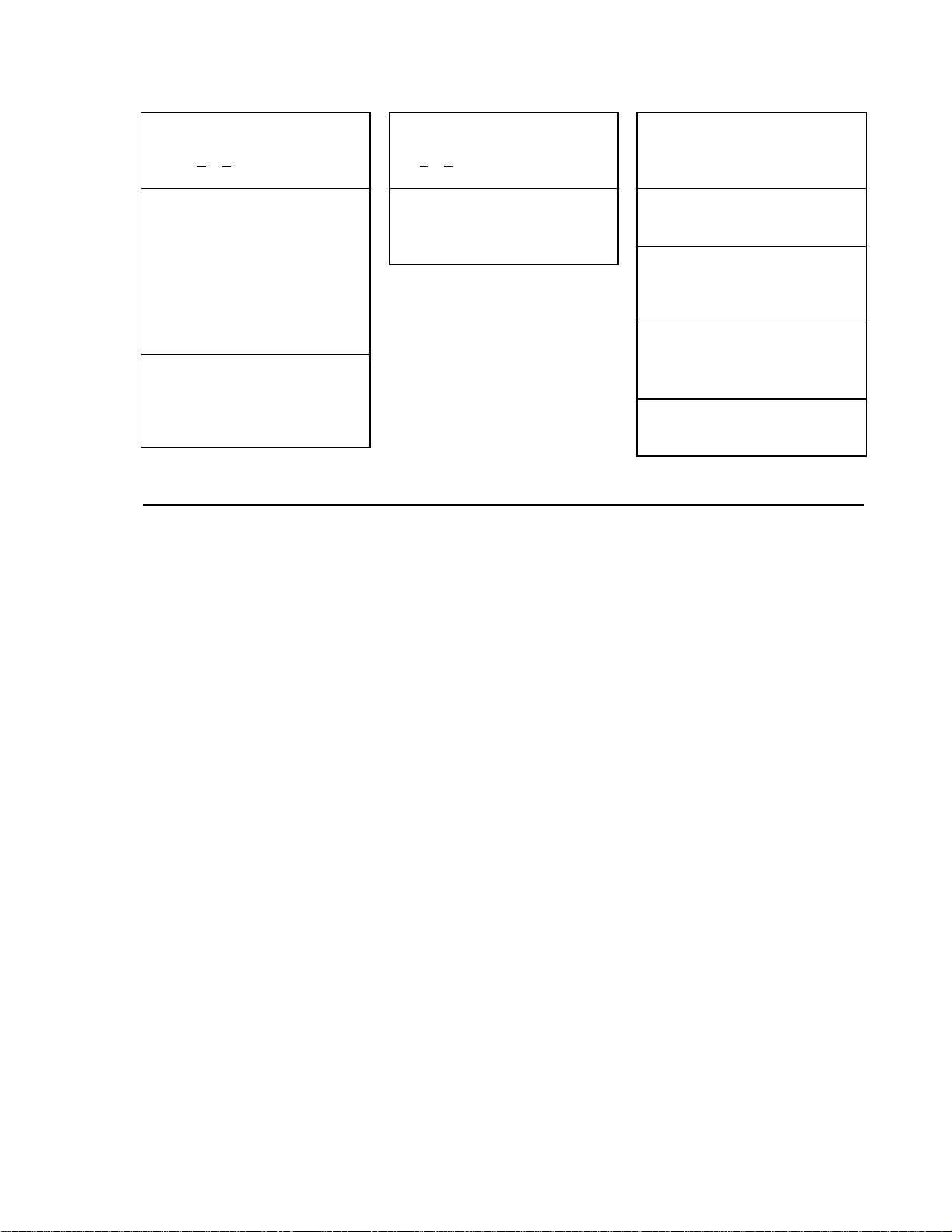

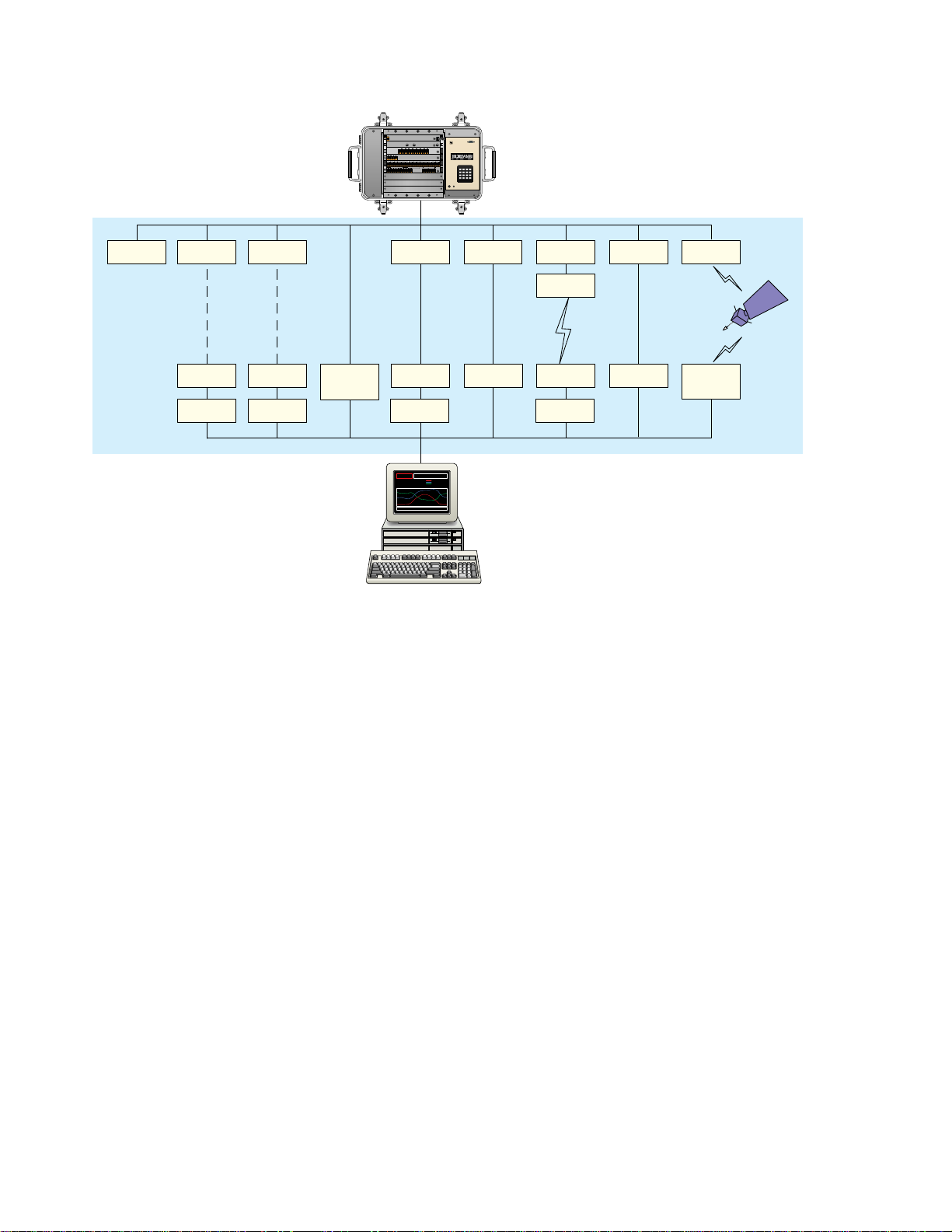

Figure OV2-1 represents the measurement,

processing, and data storage sequence in the

CR7 and shows the types of instructions used

to accomplish these tasks.

OV2.1 INTERNAL MEMORY

The CR7 has 40,960 bytes of Random Access

Memory (RAM), divided into five areas. The

five areas of RAM are:

1. Input Storage - Input Storage holds the

results of measurements or calculations.

The *6 Mode is used to view Input Storage

locations to check current sensor readings

or calculated values. Input Storage defaults

to 28 locations. Additional locations can be

assigned using the *A Mode.

2. Intermediate Storage - Certain Processing

Instructions and most of the Output

Processing Instructions maintain

intermediate results in Intermediate

Storage. Intermediate storage is

automatically accessed by the Instructions

and cannot be accessed by the user. The

default allocation is 64 locations. The

number of locations can be changed using

the *A Mode.

OV-3

Page 14

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

ANALOG IPUTS

Input/Output Inst ruc tions

1. Volt (SE)

2. Volt (DIFF)

4. Ex-Del-Se

5. AC Half Br

6. Full Br

7. 3W Half Br

9. Full Br-Mex

11. Temp (107)

12. RH-(07)

13. Temp-TC SE

14. Temp-TC DIFF

17. Temp-Panel

+12

RTD

SDM PORTS

101 SDM-INT8

102 SDM-SW8

103 SDM-AO4

104 SDM-CD16

113 SDM-SIO4

115 Set SDM Clock

118 SDM-OBDII

720 I/O MODULE

ANALOG INTERFACE

H

726

50 VOLT INPUT

1234

H H H H

123456 7891011121314

HL HL HL HL HL HL HL HL HL HL HL HL HL HL

L1H L2H L3H L4H L5H L6H L7H L

724 PULSE COUNTER

MADE IN USA

8

CS I/O PORT

Telecommunications

Program Control Instructions

96 (Storage Module, Printer)

97 Initiate Telecommunications

98 Print Character

700X CONTROL MODULE

CAMPBELL

SCIENTIFIC

LOGAN, UTAH

INC.

1

CR7 MEASUREMENT & CONTROL SYSTEM

2

I. D.

3

DATA

C3C2C1

+12

SDM

SERIAL I/O

PULSE INPUTS

Input/Output Inst ruc tions

3. Pulse

SWITCHED ANALOG OUT

1 2 3 4 5 6 7 8 1 2

EXCITATION OUTPUTS

Input/Output Inst ruc tions

4. Ex-Del-Se

5. AC Half Br

6. Full Br

7. 3W Half Br

9. Full Br-Mex

11. Temp (107)

12. RH (207)

22. Excit-Del

CONTINUOUS ANALOG OUT

725

EXCITATION

DIGITAL CONTROL OUT

1234 5678

CAO

21ANALOG OUT

4

ON

OFF

AUX.

POWER

CONTROL PORTS

Input/Output Inst ruc tions

20 Set Port

Program Control Instructions

83 If Case < F

86 Do

88 If x < = > y

89 If x < = > f

91 If flag, port

92 If Time

Command Codes:

4x Set port x high

5x Set port x low

6x Toggle port x

7x Puls e port x

123A

456B

789C

0#D

*

MADE IN USA

OV-4

FIGURE OV1-2. CR7 Wiring Panel and Associated Programming Instructions

Page 15

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

INPUT/OUTPUT

INSTRUCTIONS

Specify the conversion of a sensor signal

to a data value and store it in Input

Storage. Programmable entries specify:

(1) the measurement type

(2) the number of channels to measure

(3) the input voltage range

(4) the Input Storage Location

(5) the sensor calibration constants

used to convert the sensor output to

engineering units

I/O Instructions also control analog

outputs and digital control ports.

INPUT STORAGE

Holds the results of measurements or

calculations in user specified locations.

The value in a location is written over

each time a new measurement or

calculation stores data to the locations.

PROCESSING INSTRUCTIONS

Perform calculations with values in Input

Storage. Results are returned to Input

Storage. Arithmetic, transcendental and

polynomial functions are included.

OUTPUT PROCESSING

INSTRUCTIONS

Perform calculations over time on the

values updated in Input Storage.

Summaries for Final Storage are

generated when a Program Control

Instruction sets the Output Flag in

response to time or events. Results

may be redirected to Input Storage for

further processing. Examples include

sums, averages, max/min, standard

deviation, histograms, etc.

Output Flag set high

FINAL STORAGE

Final results from OUTPUT

PROCESSING INSTRUCTIONS are

stored here for on-line or interrogated

transfer to external devices (Figure

OV5.1-1). When memory is full, new

data overwrites the oldest data.

FIGURE OV2-1. Instruction Types and Storage Areas

INTERMEDIATE STORAGE

Provides temporary storage for

intermediate calculations required by the

OUTPUT PROCESSING INSTRUCTIONS;

for example, sums, cross products,

comparative values, etc.

OV-5

Page 16

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

3. Final Storage - Final, processed values are

stored here for transfer to printer, solid state

Storage Module or for retrieval via

telecommunication links. Values are stored

in Final Storage only by the Output

Processing Instructions and only when the

Output Flag is set in the users program.

The 18,336 locations allocated to Final

Storage at power up is reduced if Input or

Intermediate Storage is increased.

4. System Memory - used for overhead tasks

such as compiling programs, transferring

data, etc. The user cannot access this

memory.

5. Program Memory - available for user

programs entered in Program Tables 1 and

2, and Subroutine Table 3. (Sections OV3,

1.1)

The use of the Input, Intermediate, and Final

Storage in the measurement and data

processing sequence is shown in Figure OV2-1.

While the total size of these three areas

remains constant, memory may be reallocated

between the areas to accommodate different

measurement and processing needs (*A Mode,

Section 1.5). The size of system and program

memory are fixed.

3. OUTPUT PROCESSING INSTRUCTIONS

(69-82, Section 11) are the only

instructions which store data in Final

Storage (destination). Input Storage

(source) values are processed over time to

obtain averages, maxima, minima, etc.

There are two types of processing done by

Output Instructions: Intermediate and Final.

Intermediate processing normally takes

place each time the instruction is executed.

For example, when the Average Instruction

is executed, it adds the values from the

input locations being averaged to running

totals in Intermediate Storage. It also keeps

track of the number of samples.

Final processing occurs only when the

Output Flag is high. The Output Processing

Instructions check the Output Flag. If the

flag is high, final values are calculated and

output. With the Average, accumulated

totals are divided by the number of samples

and the resulting averages sent to Final

Storage. Intermediate locations are zeroed

and the process starts over. The Output

Flag, Flag 0, is set high by a Program

Control Instruction which must precede the

Output Processing Instructions in the user

entered program.

OV2.2 CR7 INSTRUCTION TYPES

Figure OV2.1 illustrates the use of the three

different instruction types which act on data.

The fourth type, Program Control, is used to

control output times and vary program

execution. Instructions are identified by

numbers.

1. INPUT/OUTPUT INSTRUCTIONS (126,101-104, Section 9) control the terminal

strip inputs and outputs (the sensor is the

source, Figure OV1-2), storing the results in

Input Storage (destination). Multiplier and

offset parameters allow conversion of linear

signals into engineering units. The Control

Ports and Continuous Analog Outputs are

also addressed with I/O Instructions.

2. PROCESSING INSTRUCTIONS (30-66,

Section 10) perform numerical operations

on values located in Input Storage (source)

and store the results back in Input Storage

(destination). These instructions can be

used to develop high level algorithms to

process measurements prior to Output

Processing (Section 10).

4. PROGRAM CONTROL INSTRUCTIONS

(85-98, Section 12) are used for logic

decisions and conditional statements. They

can set flags, compare values or times,

execute loops, call subroutines,

conditionally execute portions of the

program, etc.

OV2.3 PROGRAM TABLES AND THE

EXECUTION AND OUTPUT INTERVALS

Programs are entered in Tables 1 and 2.

Subroutines, called from Tables 1 and 2, are

entered in Subroutine Table 3. The size of each

table is flexible, limited only by the total amount

of program memory. If Table 1 is the only table

programmed, the entire program memory is

available for Table 1.

Table 1 and Table 2 have independent

execution intervals, entered in units of seconds

with an allowable range of 0.0125 to 6553

seconds. Intervals shorter than 0.1 seconds are

allowed only in Table 1. Subroutine Table 3 has

no execution interval; subroutines are only

executed when called from Table 1 or 2.

OV-6

Page 17

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

Table 1.

Execute every x sec.

0.0125 < x < 6553

Instructions are executed

sequentially in the order they

are entered in the table. One

complete pass through the table

is made each execution interval

unless program control

instructions are used to loop or

branch execution.

Normal Order:

MEASURE

PROCESS

CHECK OUTPUT COND.

OUTPUT PROCESSING

FIGURE OV2-2. Program and Subroutine Tables

OV2.3.1 THE EXECUTION INTERVAL

The execution interval specifies how often the

program in the table is executed, which is

usually determined by how often the sensors

are to be measured. Unless two different

measurement rates are needed, use only one

table. A program table is executed sequentially

starting with the first instruction in the table and

proceeding to the end of the table.

Each instruction in the table requires a finite

time to execute. If the execution interval is less

than the time required to process the table, the

CR7 overruns the execution interval, finishes

processing the table and waits for the next

execution interval before initiating the table.

When an overrun occurs, decimal points are

shown on either side of the G on the display in

the LOG mode (*0). Overruns and table priority

are discussed in Section 1.1.

Table 2.

Execute every y sec.

0.1 < y < 6553

Table 2 is used if there is a

need to measure and process

data on a separate interval from

that in Table 1.

Table 3.

Subroutines

A subroutine is executed only

when called from Table 1 or 2.

Subroutine Label

Instructions

End

Subroutine Label

Instructions

End

Subroutine Label

Instructions

End

OV2.3.2 THE OUTPUT INTERVAL

The interval at which output occurs is

independent from the execution interval, other

than the fact that it must occur when the table is

executed (i.e., a table cannot have a 10 minute

execution interval and output every 15 minutes).

A single program table can have many different

output intervals and conditions, each with a unique

data set (output array). Program Control

Instructions are used to set the Output Flag which

determines when output occurs. The Output

Processing Instructions which follow the instruction

setting the Output Flag determine the data output

and its sequence. Each additional output array is

created by another Program Control Instruction

setting the Output Flag high in response to an

output condition, followed by Output Processing

Instructions defining the data set to output.

OV3. PROGRAMMING THE CR7

A program is created by keying it directly into

the datalogger or on a PC using the PC208 or

PC208W Datalogger Support Software program

EDLOG. This manual describes direct

interaction with the CR7. Work through the

direct programming examples in this overview

before using EDLOG and you will have the

basics of CR7 operation as well as an

appreciation for the help provided by the

software. Section OV3.5 describes options for

loading the program into the CR7.

OV-7

Page 18

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

OV3.1 FUNCTIONAL MODES

User interaction with the CR7 is broken into

different functional MODES, (e.g., programming

the measurements and output, setting time,

manually initiating a block data transfer to

Storage Module, etc.). The modes are referred

to as Star (*) Modes since they are accessed by

first keying *, then the mode number or letter.

Table OV3.1 lists the CR7 Modes.

TABLE OV3-1. * Mode Summary

Key Mode

*0 LOG data and indicate active Tables

*1 Program Table 1

*2 Program Table 2

*3 Program Table 3, subroutines only

*4 Enable/disable printer output

*5 Display/set real time clock

*6 Display/alter Input Storage data, toggle

flags

*7 Display Final Storage data

*8 Final Storage data transfer to cassette

tape

*9 Final Storage data transfer to printer

*A Memory allocation/reset

*B Signature test/PROM version

*C Security

*D Save/load Program

TABLE OV3-2. Key Description/Editing

Functions

Key Action

0-9 Key numeric entries into display

* Enter Mode (followed by Mode Number)

A Enter/Advance

B Back up

C Change the sign of a number or index

an input location to loop counter

D Enter the decimal point

# Clear the rightmost digit keyed into the

display

#A Advance to next instruction in program

table (*1, *2, *3) or to next output array

in Final Storage (*7)

#B Back up to previous instruction in

program table or to previous output

array in Final Storage

#D Delete entire instruction

OV3.3 PROGRAMMING SEQUENCE

In routine applications, sensor signals are

measured, processed over some time interval,

and the results are stored in Final Storage. A

generalized programming sequence is:

1. Enter the execution interval, determined by

the desired sensor scan rate.

OV3.2 KEY DEFINITION

Keys and key sequences have specific

functions when using the CR7 keyboard or a

terminal/computer in the remote keyboard state

(Section 5). Table OV3.2 lists these functions.

In some cases, the exact action of a key

depends on the mode the CR7 is in and is

described with the mode in the manual.

2. Enter the Input/Output Instructions required

to measure the sensors.

3. Enter any Processing Instructions required

to get the data ready for Output Processing.

4. Enter a Program Control Instruction to test

the output condition and Set the Output

Flag when the condition is met. For

example, use Instruction 92 to output based

on time, 86 to output each time the table is

executed, and 88 or 89 to compare input

values. This instruction must precede the

Output Processing Instructions.

5. Enter the Output Processing Instructions to

store processed data in Final Storage. The

order in which the data are stored is

determined by the order of the Output

Processing Instructions in the table.

6. Repeat steps 4 and 5 for output on different

intervals or conditions.

OV-8

Page 19

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

OV3.4 INSTRUCTION FORMAT

Instructions are identified by an instruction

number. Each instruction has a number of

parameters that give the CR7 the information it

needs to execute the instruction.

The CR7 Prompt Sheet has the instruction

numbers in red, with the parameters briefly

listed in columns following the description.

Some parameters are footnoted with further

description under the "Instruction Option Codes"

heading.

For example, Instruction 73 stores the

maximum value that occurred in an Input

Storage Location over the output interval. The

instruction has three parameters (1)

REPetitionS, the number of sequential Input

Storage locations on which to find maxima, (2)

TIME, an option of storing the time of

occurrence with the maximum value, and (3)

LOC the first Input Storage Location operated

on by the Maximum Instruction. The codes for

the TIME parameter are listed in the "Instruction

Option Codes".

The repetitions parameter specifies how many

times an instruction's function is to be repeated.

For example, four 107 thermistor probes, wired

to single-ended channels 1 through 4, are

measured using a single Instruction 11, Temp107, with four repetitions. Parameter 2

specifies the input channel of the first thermistor

(channel 1) and parameter 4 specifies the Input

Storage Location in which to store

measurements from the first thermistor. If

Location 5 were used, the temperature of the

thermistor on channel 1 would be stored in Input

Location 5, the temperature from channel 2 in

Input Location 6, etc.

Detailed descriptions of the instructions are

given in Sections 9-12.

OV3.5 ENTERING A PROGRAM

Programs are entered into the CR7 in one of

four ways:

1. Keyed in using the CR7 keyboard.

b. Stored/loaded from SM192/716 Storage

Module

3. Loaded from Storage Module or internal

PROM (special software) upon power-up.

A program is created by keying it directly into

the datalogger as described in the following

Section, or on a PC using the PC208

Datalogger Support Software.

PC208 Software programs are used to develop

and send programs to the CR7. Program files

developed can be downloaded directly to the

CR7 via direct wire, telephone, or Radio

Frequency (RF).

Programs on disk can be copied to a Storage

Module. Using the *D Mode to save or load a

program from a Storage Module is described in

Section 1.8.

If the SM192/716 Storage Module is connected

when the CR7 is powered-up, the CR7 will

automatically load program number 8, provided

that a program 8 is loaded in the Storage

Module (Section 1.8).

It is also possible (with special software) to

create a PROM (Programmable Read Only

Memory) that contains a datalogger program.

With this PROM installed in the datalogger, the

program will automatically be loaded and run

when the datalogger is powered-up, requiring

only that the clock be set.

OV4. PROGRAMMING EXAMPLE

The best way to become acquainted with the

CR7 is to program it and make some

measurements. If your CR7 contains either a

723 or 723-T Analog Input card, a short

copper-constantan thermocouple (TC) should

be connected to channel 5. In this example, you

will program the CR7 to sample the

thermocouple temperature. If you have not

purchased the 723-T with a Resistive

Temperature Device (RTD) to measure the TC

reference junction temperature, a "dummy"

reference temperature will be used.

2. Loaded from a pre-recorded listing using

the *D Mode. There are two types of

storage/input:

a. Stored on disk/sent from computer

(PC208 software).

OV-9

Page 20

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

Tables OV3-1 and OV3-2 summarize the

Keyboard Commands and Control Modes used

to program the CR7, monitor Input and Final

Storage and control data output to peripherals.

The instructions, and their associated

parameters, are the CR7's programming steps

and are used to build the CR7's program. It is

not necessary to understand all the commands

to proceed with this programming exercise. It is

helpful to find the example's instructions on the

CR7 Prompt Sheet provided with this manual.

As you become familiar with programming the

CR7, you will find that the Prompt Sheet or the

PC208 program EDLOG has all the information

you need to write your program. By following

along on the Prompt Sheet as you proceed with

this exercise, you will learn how to use it to write

your own programs.

OV4.1 MEASUREMENT

To make a thermocouple temperature

measurement, the CR7 must know the

temperature of the reference junction. The CR7

takes the reference temperature, converts it to

the equivalent TC voltage, adds the measured

TC voltage and converts the sum to

temperature through a polynomial fit to the TC

output curve. In this example, the reference

junction is at the Analog Input Card. Its

temperature is measured with Instruction 17,

Panel Temperature. If you have an Analog

Input Card with RTD, check to see which

number is assigned to it. A tag labeled RTD is

on the left hand side and the card number is on

the right hand side of the Analog Input Card. If

the RTD card is not card 1, you must enter the

correct card number as Parameter 1 of

Instruction 17. If you do not have an Analog

Input Card with RTD, you will omit Instruction 17

from the Program and enter a "dummy"

reference temperature after the Program is

compiled.

The thermocouple temperature measurement is

made using Instruction 14 (differential voltage

measurement of TC) on differential channel 5.

When using a copper-constantan

thermocouple, the copper lead is connected to

the high input of a differential channel and the

constantan lead is connected to the low side.

The channel numbering printed on the Analog

Input Cards refers only to differential channels.

Either the high or low side of a differential

channel may be used for single ended

measurements. (Each side is counted when

assigning single ended channel numbers; e.g.,

the high side of differential channel 8 is single

ended channel 15 and the low side is single

ended channel 16).

The first parameter in Instruction 14 is the

number of times to repeat the measurement: 1

is entered because only one thermocouple is

measured. If more thermocouple

measurements were desired, the copper leads

would be connected to the high sides of

consecutive differential channels, the

constantan leads to the low sides and the

number of repetitions entered in Parameter 1

would equal the number of thermocouples.

Parameter 2 is the voltage range to use when

making the measurement. The output of a

copper-constantan thermocouple is

approximately 40 microvolts per oC difference

in temperature between the two junctions. The

+5000 uV scale will provide a range of +5000/40

= +125 oC (i.e., this scale will not overrange as

long as the measuring junction is within 125 oC

of the panel temperature). The resolution of the

+5000 uV range is 166 nV or 0.004 oC.

Parameter 3 is the Input Card number and

Parameter 4 is the channel on which to make

the first measurement. If more than one

thermocouple is measured, the CR7 will

automatically advance through the channels

and on to the next card if necessary. Similarly,

Parameter 7 is the Input Storage Location in

which to store the first measurement; e.g., if

there are five repetitions and the first

measurement is stored in location 3, the final

measurement will be stored in location 7.

Parameter 6 is the Input Storage location in

which the reference temperature is stored, and

Parameters 8 and 9 are the multiplier and offset

to apply to the temperature value. A multiplier of

1 and an offset of 0 give the result in oC, a

multiplier of 1.8 and an offset of 32 give the

result in oF.

Now that you have some idea of what you are

telling the CR7 by entering the parameters, we

will proceed with programming the CR7.

OV-10

Page 21

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

TABLE OV4-1. Thermocouple Measurement Programming Example

TURN ON THE POWER SWITCH AND PROCEED AS FOLLOWS:

Display

ID:Data Key

HELLO 01

00:00

01:0.0000

01:P00

01:00

02:0000

02:P00

01:00

02:00

03:00

04:00

05:00

06:0000

07:0000

08: 0.0000

09: 0.0000

03:P00

17

14

Display

ID:Data Key Description

:0064

1

01:00

2

01:2

-------Users without RTD omit next Instruction------

01:P17

1

01:1

1

02:1

-------Users without RTD continue here-------

Instruction Location Number will be 1 less (i.e., 01:P00)

02:P14

1

01:1

2

02:2

1

03:1

5

04:5

1

05:1

1

06:1

2

07:2

1

08:1

09:0.0000

*

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

*

The number after "HELLO" will count up as memory

is checked. If you have a 512K Memory Card, this

can take a long time; key # to abort the test. The

result of the CPU board memory check is then

displayed (Sect. 1.5)

Enter Program Table 1, advance to Execution

Interval

Enter 2 second Execution Interval advance to first

instruction

Measure Panel Temp., advance to first Parameter

RTD in input card #1, if RTD card other than #1,

enter correct card #

Store temp in location 1

TC temp., differential meas.

1 repetition

Range code (5000uV, slow)

Input card #1

Input channel of 1st TC

TC type (copper-constantan)

Reference temp. is in location 1

Store TC temp. in location 2

Multiplier of 1

No offset entered (offset=0), advance to next

instruction

Exit Table 1

00:00

The CR7 is now programmed to measure the thermocouple temperature and to store the result in Input

Storage Location 2. The colon between the ID and Data fields blinks each time Table 1 is executed,

every 2 seconds in this example. If you do not have an RTD, the "reference temperature" is 0.0 and the

value stored in Location 2 is the difference in temperature between the panel and the thermocouple. The

*6 Mode can be used to monitor the values in the Input Storage and to change the value of the dummy

reference temperature.

0

:LOG 1

Enter *0 Mode, compile table

OV-11

Page 22

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

TABLE OV4-2. Using *6 Mode to Observe Example TC Measurements

(User with Model 723-T RTD Card)

Display

ID:Data Key

:LOG 1

00:00

Display

ID:Data Key

:LOG 1

:0.0000

00:00

*6

TABLE OV4-3. Using *6 Mode to Observe Example TC Measurements

*6

20

Display

ID:Data Key Description

06:0000

01:21.234

02:22.433

01:21.199

0

:LOG 1

(User with Model 723 Card, No RTD)

Display

ID:Data Key Description

06:0000

01:0.0000

02:2.9533

01:0.0000

:20

01:20.000

02:22.866

0

:LOG 1

A

A

B

*

A

A

B

C

A

A

*

Enter *6 Mode, advance to first location

Panel temp is 21.234 oC, advance to location 2

TC temp is 22.433 oC, backup to location 1

Panel temp is now 21.199 oC

Return to *0 Mode

Enter *6 Mode, advance to first location

Reference temp is 0.0oC, advance to location 2

TC "temp" is 2.9533 C, backup to location 1

Setup to change stored value

Store 20 in location 1

Advance to location 2

The TC temp in location 2 using a reference

temperature of 20

Return to *0 Mode

o

You can advance through Input Storage by

keying in the advance command, A, or backup

by keying in the backup command, B. The Input

Location you are observing is shown on the left

in the display ID field. The temperature data

stored in the Input locations are updated every 2

seconds, each time Table 1 is executed. Verify

this by changing the temperature of the

thermocouple (hold it in your fingers) while

monitoring the proper Input Location.

It is possible to go directly to a specific Input

Storage location by entering the *6 Mode and

keying in the desired location before keying A.

A similar utility is available in other Modes.

OV4.2 OUTPUT

In the following example instructions are

appended to Table 1 to output the time and the

average temperatures to Final Storage every 5

minutes.

OV-12

Page 23

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

TABLE OV4-4. Example Programming to Obtain Five Minute Averages

Display

ID:Data Key

00:00

01:00

03:P00

01:0000

02:0000

03:00

04:P00

01:0000

05:P00

01:00

02:0000

06:P00

00:00

05:00

05:0000

05:00:21

13:24:01

: LOG 1

92

10

77

10

71

85

11

1324

Display

ID:Data Key Description

1

3

0

5

2

1

5

: LOG 1

01:00

01:3

03:P92

01:0

02:5

03:10

04:P77

:10

05:P71

01:2

02:1

:00:21:32

05:85

05:11

05:13:24

*

A

A

A

A

A

A

A

A

A

A

*

A

A

A

A

*0

Program Table 1

Advance to 3rd Instruction location (Key in 2 if

Instruction 17 was not entered, Instruction Location

Number will be 1 less than shown in table)

Enter If Time Instruction

Enter 0 minutes into interval

Enter 5 minute time interval

Set output Flag 0

Enter Output Time Instruction

Code for HR:MIN

Enter Average Instruction

2 repetitions

Location of 1st input data to be averaged

Exit Table 1

Enter *5 Mode to set clock (the clock will be running)

Enter Year

Enter Julian day (January 11 assumed in this

example)

Enter Hours:Minutes (24 hour time, 1:24 PM

assumed in this example)

Exit *5 Mode, compile Table 1, commence logging

data

The CR7 is now programmed to sample the panel and thermocouple temperatures every 2 seconds and

to output the time and the average temperatures to Final Storage every 5 minutes. Each Output Array

sent to Final Storage will consist of 4 data values. The first value will be an output identifier which gives

the number of the Table which caused the output, and the instruction location number of the instruction

which set the output flag. The second value will be the time, and the third and fourth values will be the

average temperatures of the I/O Module and the thermocouple. Values stored in Final Storage can be

viewed using the *7 Mode. Table 1.2-5 shows an example of the use of the *7 Mode, it is assumed that

the CR7 has been logging data for 8 minutes since the time was set in the previous example.

OV-13

Page 24

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

TABLE OV4-5. Using *7 Mode to View Values in Final Storage

Display

ID:Data Key

:LOG 1

00:00

01:0103.

02:1325.

03:22.57

04:23.43

01:0103.

02:1330.

03:22.61

00:00

OV4.3 EDITING AN EXISTING PROGRAM

When editing an existing program in the CR7,

entering a new instruction inserts the

instruction; entering a new value for an

instruction parameter replaces the previous

value.

To insert an instruction, enter the program table

and advance to the position where the

instruction is to be inserted (i.e., P in the data

portion of the display), key in the instruction

number, and then key A. The new instruction

will be inserted at that point in the table,

advance through and enter the parameters.

The Instruction that was at that point and all

instructions following it will be pushed down to

follow the inserted instruction.

An instruction is deleted by advancing to the

instruction number (P in display) and keying #D

(Table OV3-2).

To change the value entered for a parameter,

advance to parameter and key in the correct

value then key A. Note that the new value is not

entered until A is keyed.

OV4.4 EDLOG PROGRAM LISTING

The examples in the rest of this manual use

program listings generated by EDLOG, the

datalogger Program Editor for the PC

(PC208(W) Software). The EDLOG listing does

not show the CR7 display or the "A" keystrokes

used to enter data. The EDLOG listing for the

previous example is given in Table OV4-6.

Display

ID:Data Key Description

7007:9.0000

:LOG 1

*

A

Enter *7 Mode. The DSP is at Final Storage location 9,

advance to first data value

A

Output identifier: users who did not enter Instruction 17 will

see 01: 0102 because the output flag is set by the second

instruction in Table 1

A

Time

A

Average panel temp for readings between 1:24 and 1:25 P.M.

A

Average thermocouple temp.

A

Output identifier

A

Time

*

Average panel temp for readings between 1:25 and 1:30 P.M.

Enter *0 Mode

TABLE OV4-6. EDLOG Listing of Example

Program

* 1 Table 1 Programs

01: 2 Sec. Execution Interval

01: P17 Panel Temperature

01: 1 IN Card

02: 1 Loc :

02: P14 Thermocouple Temp (DIFF)

01: 1 Rep

02: 2 5000 uV slow Range

03: 1 IN Card

04: 5 IN Chan

05: 1 Type T (Copper-Constantan)

06: 1 Ref Temp Loc

07: 2 Loc [:TC Temp ]

08: 1 Mult

09: 0 Offset

03: P92 If time is

01: 0 minutes into a

02: 5 minute interval

03: 10 Set high Flag 0 (output)

04: P77 Real Time

01: 10 Hour-Minute

05: P71 Average

01: 2 Reps

02: 1 Loc

OV-14

Page 25

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

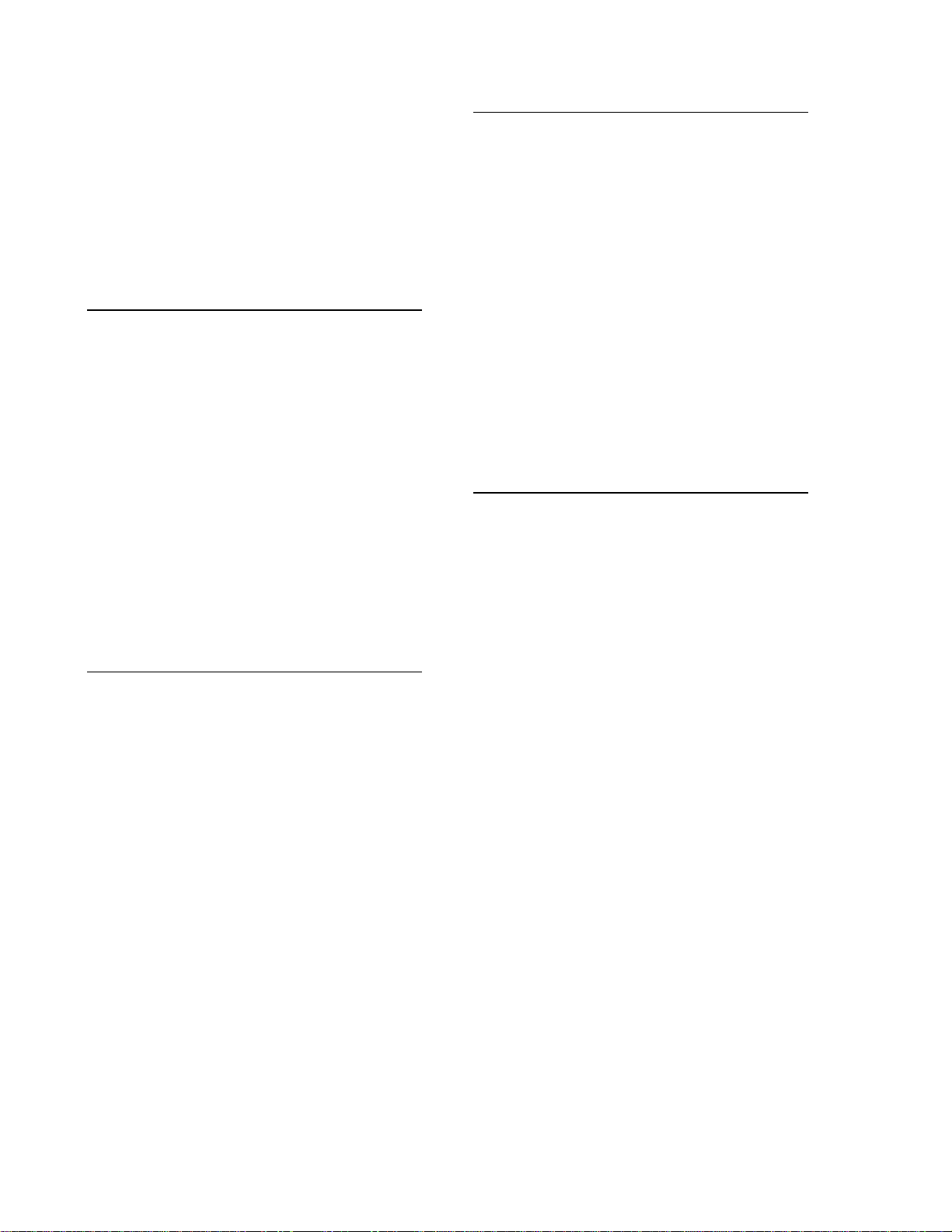

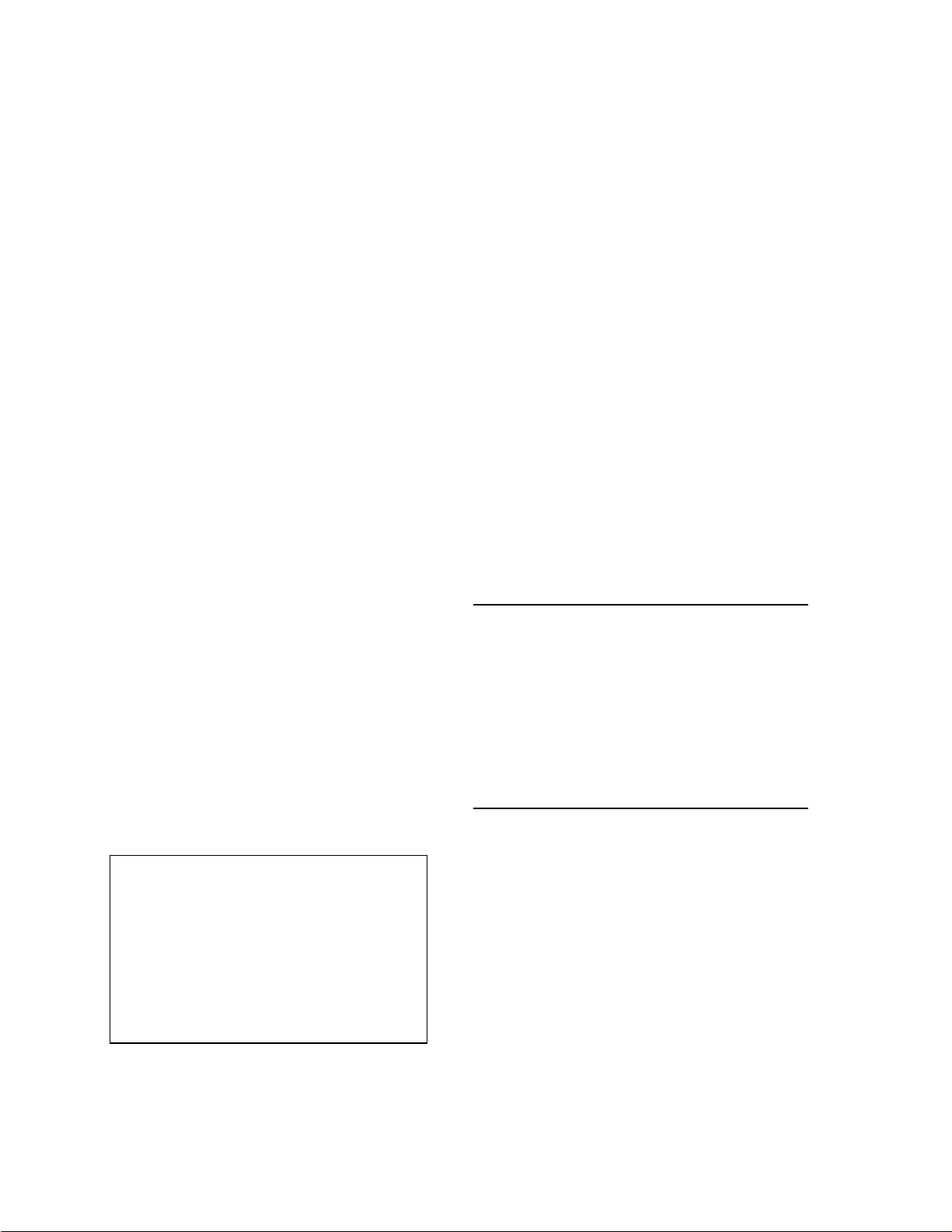

OV5. DATA RETRIEVAL OPTIONS

There are several options for data storage and

retrieval. These options are covered in detail in

Sections 2, 4, and 5. Figure OV5-1

summarizes the various possible methods.

Regardless of the method used, there are three

general approaches to retrieving data from a

datalogger.

1. On-line output of Final Storage data to a

peripheral storage device. On a regular

schedule, that storage device is brought

back to the office/lab where the data is

transferred to the computer. Another

storage device is usually taken into the field

and exchanged for the one which is

retrieved so that data collection can

continue uninterrupted.

2. Bring a storage device to the datalogger

and transfer all the data that has

accumulated in Final Storage since the last

visit.

3. Retrieve the data over some form of

telecommunications link, that is, Radio

Frequency (RF), telephone, short haul

modem, multi-drop interface, or satellite.

The PC208 software automates this

process.

Regardless of which method is used, the

retrieval of data from the datalogger does NOT

erase those data from Final Storage. The data

remain in the ring memory until:

• they are written over by new data

(Section 2.1)

• memory is reallocated (Section 1.5)

• the power to the datalogger is turned

off.

Table OV5-1 lists the instructions used with the

various methods of data retrieval.

TABLE OV5-1. Data Retrie val Methods and Related Instructions

Storage Printer, other Telecommunications

Module Serial Device

Inst. 96, Inst. 96, 98 Inst. 97

*4 *4

*9 *9 (Telecommunications Commands)

*D *D

TABLE OV5-2. Data Retrieval Sections in Manual

Topic Section in Manual

Instr. 96 4.1, 12

Instr. 97 12

*4 4.1

*8 4.2

*9 4.2

*D 1.8

Storage Module 4.3

Telecommunications 5

(RF, Phone, Short Haul, SC32A)

OV-15

Page 26

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

+12

720 I/O MODULE

ANALOG INTERFACE

H

726

50 VOLT INPUT

1234

H H H H

1 2 3 4 5 6 7 8 9 10 11 12 13 14

HL HL HL HLHL HL HLHL HLHL HLHL HL HL

RTD

SWITCHED ANALOG OUT

1 2 3 4 5 6 7 8 1 2

L1HL2HL3HL4HL5HL6HL7HL

724 PULSE COUNTER

CONTINUOUS ANALOG OUT

725

EXCITATION

700X CONTROL MODULE

MADE IN USA

CAMPBELL

SCIENTIFIC

LOGAN, UTAH

INC.

SERIAL I/O

8

1

CR7 MEASUREMENT & CONTROL SYSTEM

2

I. D.

DATA

3

DIGITAL CONTROL OUT

1234 5678

4

123A

456B

789C

0#D

*

ON

AUX.

POWER

OFF

MADE IN USA

Display

Storage

Module

Storage

Module

RS-232

Interface

Card Storage

Module

Multidrop

Modem

Shorthaul

Modem

RF Modem Phone

Transceiver

Card Storage

Module

RS-232

Interface

Direct

RS-232

Interface

Multidrop

Modem

RS-232

Interface

Logger Time 00:03:54

= Graph enter/exit

G

= Re-scale

R

Flags

= Incr. auto exponent

+

Ports

= Decr. auto exponent

-

H=Help

100

200

300

400

500

600

700

800

900

Shorthaul

Modem

V = View save to file

F1. . F8 = Toggle flags

P1. . P6 = Toggle ports

C = Collect data

SOLAR

1:

TEMP C

2:

RH %

3:

Scale = Auto

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

2200

2300

Transceiver

RF Base

Station

FIGURE OV5-1. Data Retrieval Hardware Options

Modem

Phone

Modem

Satellite

Interface

Satellite

Ground

Station

OV-16

Page 27

OV6. SPECIFICATIONS

Electrical specifications are valid for over a -25° to +50°C range unless otherwise specified.

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

Analog Inputs

(723T or 723 Card specifications below;

726 ±50 V Card specifications discussed in

System Description

Voltage Measurement Types: Single-ended or

differential.

Range and Resolution: Ranges are software

selectable on any input channel.

Full Scale Resolution

Input Range (mV) Differential Single-ended

±5000 166 µV 333 µV

±1500 50 µV 100 µV

±500 16.6 µV 33.3 µV

±150 5 µV10µV

±50 1.66 µV 3.33 µV

±15 500 nV 1000 nV

±5 166 nV 333 nV

±1.5 50 nV 100 nV

Accuracy of Voltage Measurements:

Differential: ±0.02% FSR (±0.01%, 0-40°C)

(e.g. ±0.02% FSR = ±2.0 mV for ±5 V range)

Positive single-ended: ±0.02% FSR

(±0.01%, 0-40°C) ±5 µV

Negative single-ended: ±0.03% FSR

(±0.015%, 0-40°C) ±5 µV

Input Sample Rates: Fast A/D conversions are

integrated over 250 µs. Slow A/D conversions

are integrated over 16.67 ms for 60 Hz AC

rejection or optionally, 20.0 ms for 50 Hz AC

rejection. Differential measurements include

two conversions, one with reversed input polarity, to reduce thermal offset and common mode

errors. The following intervals do not include

the self-calibration measurement which occurs

once per instruction.

Fast Single-ended 2.9 350

Fast Differential 4.7 250

Slow Single-ended 22.0 43

Slow Differential 43.0 30

Fast Differential (TC) 7.9 250

Common Mode Range: ±5 V

Common Mode Rejection: > 140 dB (DC to 100 Hz)

Normal Mode Rejection: 70 dB (60 Hz with

slow differential measurement)

Input Current: 100 pA max

Input Current Noise: 9 pA RMS (slow differential)

Input Resistance: 2.5 GΩ typical

Sustained Input Voltage without Damage:

≤ ±16 VDC

)

Input sample Typical input

rates noise

ms/channel nV/RMS

Pulse Counters

(724 Card)

Pulse Counters per Card: 4

Maximum Counts per Interval: 32,767 (with

overrange detection)

Modes: Programmable modes are switch

closure, high frequency pulse, and low level AC.

Switch Closure Mode

Minimum Switch Closed Time:1 ms

Minimum Switch Open Time:4 ms

Maximum Bounce Time:1.4 ms open without

being counted.

High Frequency Pulse Mode

Minimum Pulse Width: 2 µs

Maximum Input Frequency: 250 kHz

Voltage Thresholds: The count is incremented

when the input voltage changes from below

1.5 V to above 3.5 V.

Maximum Input Voltage: ±20 V

Low Level AC Mode

This mode is used for counting the frequency

of low voltage, sine wave signals.

Input Hysteresis: 11 mV

Maximum AC Input Voltage (RMS): 20 V

Frequency Range:

Minimum AC Input Voltage Range (Hz)

(mV RMS)

15 1 to 100

25 1 to 1,000

50 1 to 3,000

160 1 to 10,000

Digital Control Outputs

(725 Card)

Each card includes 8 digital control outputs.

Output Voltages (no load):

High: 5.0 V ±0.1 V

Low: < 0.1 V

Output Resistance: 400 Ω

Analog Outputs

(725 Card)

Each card contains 8 switched and 2 continuous

analog outputs.

Switched: Provides a precision voltage for

resistance measurement, then switches off

(high impedance). Only one switched output

can be active at a time.

Continuous: A preset voltage is held until

updated. Voltage degrades 0.17 mV every 7

seconds. All continuous analog outputs (and

digital control ports) can be active simultaneously.

Range: ±5 V

Resolution: 166 µV

Accuracy: Same as voltage measurements.

Output Current: 25 mA at ±5 V, 50 mA at ±2 V

Resistance and Conductivity

Measurements

(Combination of 723 and 725 Cards)

Accuracy: ±0.01% of full scale bridge output

provided the matching bridge resistors are not

the limiting factor.

Measurement Types: 6-wire and 4-wire full

bridge, 4-wire, 3-wire, and 2-wire half bridges.

High accuracy, low impedance bridge

measurements are made ratiometrically with

dual polarity measurements of excitation and

output to eliminate thermal emfs. AC resistance and conductivity measurements use a

750 µs excitation pulse with the signal integration occurring over the last 250 µs. An equal

duration pulse of opposite polarity is applied

for ionic depolarization.

Transient Protection

All input and output connections to the I/O

Module are protected using spark gaps that

are rated to 10,000 A. The spark gaps are

connected directly to a heavy copper bar on

each input card with no more than 2 inches of

20 AWG copper wire.

Control Module

Processor: Hitachi 6303

Memory: 24K ROM; 40K RAM, 709 Card

provides an additional 512K RAM.

Data Storage: 18.8K values, standard;280K

values, expanded.

Display: 8 digit LCD (0.5” digits).

Peripheral Interface: 9-pin, D-type connector

on the Control Module panel for connection to

storage module, card storage module,

multidrop interface, modem, printer, or RS-232

adapter. Baud rates selectable at 300, 1200,

9600, and 76,800.

I/O Module Interface: Optically isolated current

loops allow connection of up to 4 I/O Modules.

I/O Modules can be separated from the Control

Module by up to 1,000 feet.

Clock Accuracy: ±1 minute per month.

Maximum Program Execution Rate: System

tasks can be initiated in sync with real-time up

to 80 Hz.

System Power Requirements

Voltage: 9.6 to 15 VDC

Typical Current Drain: 3.5 - 6 mA (minimum

system) quiescent, 16 mA during processing,

100 mA during analog measurement.

Internal Batteries: Sealed rechargeable with

2.5 Ahr capacity per charge.

Charging Circuit: Requires DC or rectified AC

voltage from 15 to 25 V. Thermal compensation is included to optimize charging voltage

according to ambient temperature.

External Batteries: Any 12 V external battery

can be a primary power source; internal batteries provide a backup while the external

batteries are changed.

Operation from AC Sources: An AC operated

battery charger is included with the enclosure

to maintain full charge on the batteries where

AC power is available. In the event of power

failure, the internal batteries will keep the

system operational for up to 5 days in most

applications.

Physical Specifications

Size: ENC 7L 17” x 12” x 6”

Weight: ~40 lbs (ENC 7F with 700X, 720, &

ENC 7F 20” x 13” x 10”

ENC 7XL 19” x 19” x 10”

seven I/O cards).

Warranty

Three years against defects in materials and

workmanship.

OV-17

Page 28

CR7 MEASUREMENT AND CONTROL SYSTEM OVERVIEW

This is a blank page.

OV-18

Page 29

SECTION 1. FUNCTIONAL MODES

1.1 PROGRAM TABLES - *1, *2, AND *3 MODES

Data acquisition and processing functions are

controlled by instructions contained in program

tables. Programming can be separated into two

tables, each having its own programmable

execution interval. A third table is available for

programming subroutines which may be called

by instructions in Tables 1 or 2 or by a special

interrupt. The *1 and *2 Modes are used to