Page 1

CR5000 Measurement and

Control System

Revision: 11/06

Copyright © 2000-2006

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The CR5000 MEASUREMENT AND CONTROL SYSTEM is warranted

by CAMPBELL SCIENTIFIC, INC. to be free from defects in materials and

workmanship under normal use and service for thirty-six (36) months from

date of shipment unless specified otherwise. Batteries have no warranty.

CAMPBELL SCIENTIFIC, INC.'s obligation under this warranty is limited to

repairing or replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective

products. The customer shall assume all costs of removing, reinstalling, and

shipping defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country. To obtain a Returned Materials Authorization (RMA),

contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an

applications engineer determines the nature of the problem, an RMA number

will be issued. Please write this number clearly on the outside of the shipping

container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

CR5000 MEASUREMENT AND CONTROL SYSTEM

TABLE OF CONTENTS

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

PAGE

OV1. PHYSICAL DESCRIPTION

OV1.1 Measurement Inputs...........................................................................................................OV-1

OV1.2 Communication and Data Storage...................................................................................... OV-4

OV1.3 Power Supply and AC Adapter...........................................................................................OV-5

OV2. MEMORY AND PROGRAMMING CONCEPTS

OV2.1 Memory...............................................................................................................................OV-5

OV2.2 Measurements, Processing, Data Storage.........................................................................OV-5

OV2.3 Data Tables......................................................................................................................... OV-6

OV3. PC9000 APPLICATION SOFTWARE

OV3.1 Hardware and Software Requirements ..............................................................................OV-6

OV3.2 PC9000 Installation.............................................................................................................OV-6

OV3.3 PC9000 Software Overview................................................................................................ OV-7

OV4. KEYBOARD DISPLAY

OV4.1 Data Display...................................................................................................................... OV-12

OV4.2 Run/Stop Program............................................................................................................OV-16

OV4.3 File Display........................................................................................................................OV-17

OV4.4 Configure Display.............................................................................................................. OV-19

OV5. SPECIFICATIONS..........................................................................................................OV-20

1. INSTALLATION AND MAINTENANCE

1.1 Protection from the Environment........................................................................................... 1-1

1.2 Power Requirements ............................................................................................................. 1-1

1.3 CR5000 Power Supplies........................................................................................................ 1-2

1.4 Solar Panels........................................................................................................................... 1-4

1.5 Direct Battery Connection to the CR5000 Wiring Panel........................................................ 1-4

1.6 Vehicle Power Supply Connections....................................................................................... 1-4

1.7 CR5000 Grounding................................................................................................................ 1-6

1.8 Powering Sensors and Peripherals ....................................................................................... 1-9

1.9 Controlling Power to Sensors and Peripherals.................................................................... 1-10

1.10 Maintenance ........................................................................................................................ 1-12

2. DATA STORAGE AND RETRIEVAL

2.1 Data Storage in CR5000........................................................................................................ 2-1

2.2 Internal Data Format.............................................................................................................. 2-2

2.3 Data Collection....................................................................................................................... 2-3

2.4 Data Format on Computer................................................................................................... 2-10

i

Page 4

CR5000 TABLE OF CONTENTS

3. CR5000 MEASUREMENT DETAILS

3.1 Analog Voltage Measurement Sequence.............................................................................. 3-1

3.2 Single Ended and Differential Voltage Measurements.......................................................... 3-4

3.3 Signal Settling Time............................................................................................................... 3-5

3.4 Thermocouple Measurements............................................................................................... 3-7

3.5 Bridge Resistance Measurements.......................................................................................3-17

3.6 Measurements Requiring AC Excitation.............................................................................. 3-19

3.7 Pulse Count Measurements................................................................................................. 3-20

3.8 Self Calibration..................................................................................................................... 3-21

4. CRBASIC - NATIVE LANGUAGE PROGRAMMING

4.1 Format Introduction................................................................................................................4-1

4.2 Programming Sequence........................................................................................................4-2

4.3 Example Program .................................................................................................................. 4-4

4.4 Numerical Entries................................................................................................................... 4-7

4.5 Logical Expression Evaluation...............................................................................................4-7

4.6 Flags ......................................................................................................................................4-8

4.7 Parameter Types ................................................................................................................... 4-9

4.8 Program Access to Data Tables.......................................................................................... 4-10

5. PROGRAM DECLARATIONS ........................................................................................... 5-1

6. DATA TABLE DECLARATIONS AND OUTPUT PROCESSING INSTRUCTIONS

6.1 Data Table Declaration.......................................................................................................... 6-1

6.2 Trigger Modifiers.................................................................................................................... 6-2

6.3 Export Data Instructions......................................................................................................... 6-8

6.4 Output Processing Instructions............................................................................................ 6-11

7. MEASUREMENT INSTRUCTIONS

7.1 Voltage Measurements.......................................................................................................... 7-3

7.2 Thermocouple Measurements............................................................................................... 7-3

7.3 Half Bridges............................................................................................................................ 7-5

7.4 Full Bridges............................................................................................................................ 7-8

7.5 Current Excitation ................................................................................................................ 7-11

7.6 Excitation/Continuous Analog Output.................................................................................. 7-13

7.7 Self Measurements.............................................................................................................. 7-15

7.8 Digital I/O ............................................................................................................................. 7-19

7.9 Peripheral Devices...............................................................................................................7-29

8. PROCESSING AND MATH INSTRUCTIONS............................................................... 8-1

9. PROGRAM CONTROL INSTRUCTIONS....................................................................... 9-1

APPENDIX

A. CR5000 STATUS TABLE....................................................................................................A-1

INDEX ......................................................................................................................................... INDEX-1

ii

Page 5

CR5000 Overview

The CR5000 provides precision measurement capabilities in a rugged, battery-operated

package. The system makes measurements at a rate of up to 5,000 samples/second with

16-bit resolution. The CR5000 includes CPU, keyboard display, power supply, and analog

and digital inputs and outputs. The on-board, BASIC-like programming language includes

data processing and analysis routines. PC9000 Software provides program generation

and editing, data retrieval, and realtime monitoring.

19 20

17 18

15 16

13 14

11 12

910

56

34

12

SE

2

1

HL

HL

HL

DIFF

25 26

23 24

21 22

SE

12

11

H L

H L

H L

DIFF

VX1

VX3

VX2

VX4

G

C6

C5

C7

C8

G

CONTROL I/O

POWER

Logan, Utah

CR5000 MICROLOGGER

78

4

3

HL

27 28

14

13

HL

CAO1

CAO2

IX1

IX2

>2.0V

G

<0.8V

5V

5V

UP

7

6

5

HL

HL

HL

33 34

31 32

29 30

17

16

15

H L

HL

HL

CONTRO

IX3

IX4

IXR

P1

P1

C1C2C3

G

SDI-12

12V

G

SDM-C1

SDM-C2

SDM-C3

G

12V

POWER OUT

'

,

_

A B C

D E F

Hm

PgUp

1

2

G H I

J K L

M N O

Graph/

char

4

5

P R S

T U V

W X Y

End

PgDn

7

8

- + (

* / )

< = >

Del

Ins

ESC

0

SN:

3

6

9

HL

35 36

H L

G

8

18

L I/O

C4

SW-12

SW-12

CURSOR

ALPHA

SHIFT

Spc Cap

BKSPC

$ Q Z

ENTER

HL

37 38

H L

G

G

POWER IN

11 - 16 VDC

9

19

CAUTION

DC ONLY

12V

G

12V

MADE IN USA

10

HL

CS I/O

39 40

20

H L

RS-232

COMPUTER

(OPTICALLY ISOLATED)

GROUND

LUG

pc card

status

FIGURE OV1-1. CR5000 Measurement and Control System

OV1. Physical Description

Figure OV1-2 shows the CR5000 panel and the associated program

instructions. Unless otherwise noted, they are measurement instructions

(Section 7).

OV1.1 Measurement Inputs

OV1.1.1 Analog Inputs

There are 20 differential or 40 single-ended inputs for measuring voltages up

to ±5 V. A thermistor installed in the wiring panel can be used to measure the

reference temperature for thermocouple measurements, and a heavy copper

grounding bar and connectors combine with the case design to reduce

temperature gradients for accurate thermocouple measurements. Resolution on

the most sensitive range is 0.67 µV

OV-1

Page 6

CR5000 Overview

t

SWITCHED

VOLTAGE

EXCITATION

(VX)

Excite

BrFull

BrFull6w

BrHalf

BrHalf3W

BrHalf4W

12

1

HL

21

11

HL

VX1

34

2

HL

23 24

22

12

HL

VX2

VX3

SE

DIFF

SE

DIFF

CONTINUOUS ANALOG

OUTPUTS (CAO)

ExciteCAO

SWITCHED CURRENT

EXCITATION (IX)

ExciteI

Resistance

56

78

910

3

4

HL

HL

25 26

27 28

13

14

HL

HL

VX4

CAO1

CAO2

IX1

IX2

IX3

5

HL

29 30

15

HL

IX4

11 12

6

HL

31 32

16

HL

IXR

P1

P2

13 14

7

HL

33 34

17

HL

PULSE INPUTS

PulseCount

PulseCountRese

15 16

17 18

8

HL

HL

35 36

37 38

18

HL

HL

CONTROL I/O

C1C2C3

C4

CONTROL I/O

PortGet

PortSet

ReadIO

TimerIO

WriteIO

19 20

9

10

HL

39 40

19

20

HL

COMPUTER RS-232

CS I/O

(OPTICALLY ISOLATED)

ANALOG INPUTS

Voltage

VoltDiff

VoltSE

Thermocouple

TCDiff

TCSE

Bridge measurements

(use VX)

BrFull

BrFull6W

BrHalf

BrHalf3W

BrHalf4W

Others

Resistance

PanelTemp

PeriodAvg

AM25T

SIGNAL

GROUND (

FOR

Analog

Pulse

Excitation

CS I/O

DSP4 (Data Tables and Output)

),

GC5C6C7C8G>2.0VG>0.8V5V5VGSDI-12

CONTROL I/O POWER

Logan, U

CR5000 MICROLOGGER

POWER UP

PowerOff

(program

control)

UP

tah

SDI-12 12 V

SDM CONNECTIONS

CS7500

CSAT3

SDMINT8

SDMSpeed

SDMTrigger

12VGSDM-C1

SDM-C2

SDM-C3G12VGSW-12

POWER OUT

'

_

,

A B C

Hm

1

G H I

J K L

Graph/

char

4

P R S

T U V

End

7

- + (

Del

SN:

SW-12

G

CAUTION

DC ONLY

G12V

POWER IN

11 - 16 VDC

GROUND

LUG

pc card

status

RS-232

CHARGER INPUT

GROUND LUG

D E F

CURSOR

PgUp

M N O

W X Y

PgDn

< = >

ESC

3

6

9

ALPHA

SHIFT

Spc Cap

BKSPC

$ Q Z

ENTER

POWER IN

POWER GROUND (G),

FOR

5V

2

5

8

* / )

Ins

0

SW-12

12V

MADE IN USA

PCMCIA PC CARD

CardOut (Data Tables

and Output)

SWITCHED 12 VOLTS SW-12

PortSet

SW12

OV-2

FIGURE OV1-2. CR5000 Panel and Associated Instructions.

Page 7

OV1.1.2 Signal Grounds ( )

The Signal Grounds ( ) should be used as the reference for Single-ended

Analog inputs, Excitation returns, and sensor shield wires.

Signal returns from the CAO and Pulse channels should use the

located on the CAO and Pulse terminal strip to minimize current flow through

grounds on the analog terminal strips.

the

OV1.1.3 Power Grounds (G)

The Power Grounds (G) should be used as the returns for the 5V, SW12, 12V,

and C1-C8 outputs. Use of the G grounds for these outputs with potentially

large currents will minimize current flow through the analog section, which

can cause Single-ended voltage measurement errors.

OV1.1.4 Ground Lug

The large ground lug is used to connect a heavy gage wire to earth ground. A

good earth connection is necessary fix the ground potential of the datalogger

and to send to earth transients that come in on either the G or

are shunted to ground via the spark gaps protecting other inputs.

CR5000 Overview

terminals

terminals or

OV1.1.5 Power In

The G and 12V terminals on the unplugable Power In connector are for

connecting power from an external battery to the CR5000. These are the only

terminals that can be used to input battery power; the other 12V and SW-12V

terminals are out only. Power from this input will not charge internal CR5000

batteries. Power to charge the internal batteries (17-28 VDC or 18 VRMS AC)

must be connected to the charger input on the side of the LA battery back.

OV1.1.6 Switched 12 Volts SW-12

The SW-12 terminals provide an unregulated 12 volts that can be switched on

and off under program control.

OV1.1.7 Switched Voltage Excitation (VX)

Four switched excitation channels provide precision programmable voltages

within the ±5 Volt range for bridge measurements. Each analog output will

provide up to 50 mA between ±5 V.

OV1.1.8 Switched Current Excitation (IX)

Four Switched Current Excitation channels provide precision current

excitations programmable within ±2.5 mA for resistance or bridge

measurements.

OV1.1.9 Continuous Analog Outputs (CAO)

Two Continuous Analog Outputs (CAO) with individual outputs under

program control for proportional control (e.g., PID algorithm) and waveform

generation. Each analog output will provide up to 15 mA between ±5 V.

OV-3

Page 8

CR5000 Overview

OV1.1.10 Control I/O

OV1.1.11 Pulse Inputs

OV1.1.12 Power Up

There are 8 digital Input/Output channels (0 V low, 5 V high) for frequency

measurement, digital control, and triggering.

Two Pulse input channels can count pulses from high-level (5 V square wave),

switch closure, or low-level A/C signals.

The CR5000 allows shutting off power under program control. The Power Up

inputs allow an external signal to awaken the CR5000 from a powered down

state (PowerOff, Section 9). When the CR5000 is in this power off state the

ON Off switch is in the on position but the CR5000 is off. If the "<0.5 " input

is switched to ground or if the ">2" input has a voltage greater than 2 volts

applied, the CR5000 will awake, load and run the “run on power-up” program.

If the "< 0.5" input continues to be held at ground while the CR5000 is

powered on and goes through its 2-5 second initialization sequence, the

CR5000 will not run “run on power-up” program.

OV1.1.13 SDM Connections

The Synchronous Device for Measurement (SDM) connections C1,C2, and C3

along with the adjacent 12 volts and ground terminals are used to connect

SDM sensors and peripherals.

OV1.2 Communication and Data Storage

OV1.2.1 PCMCIA PC Card

One slot for a Type I/II/III PCMCIA card. The keyboard display is used to

check card status. The card must be powered down before removing it. The

card will be reactivated if not removed.

CAUTION

OV1.2.2 CS I/O

OV1.2.3 Computer RS-232

Removing a card while it is active can cause garbled data

and can actually damage the card. Do not switch off the

CR5000 power while the card is present and active.

A 9-pin serial I/O port supports CSI peripherals.

OV-4

RS-232 Port

Page 9

OV1.3 Power Supply and AC Adapter

The CR5000 has two base options the low profile without any power supply

and the lead acid battery power supply base. The low profile base requires an

external DC power source connected to the Power In terminal on the panel.

The battery base has a 7 amp hour battery with built in charging regulator and

includes an AC adapter for use where 120 VAC is available (18 VAC RMS

output). Charging power can also come from a 17-28 VDC input such as a

solar panel. The DCDC18R is available for stepping the voltage up from a

nominal 12 volt source (e.g., vehicle power supply) to the DC voltage required

for charging the internal battery.

OV2. Memory and Programming Concepts

OV2.1 Memory

The CR5000 has 2MB SRAM and 1MB Flash EEPROM. The operating

system and user programs are stored in the flash EEPROM. The memory that

is not used by the operating system and program is available for data storage.

The size of available memory may be seen in the status file. Additional data

storage is available by using a PCMCIA card in the built in card slot.

CR5000 Overview

OV2.2 Measurements, Processing, Data Storage

The CR5000 divides a program into two tasks. The measurement task

manipulates the measurement and control hardware on a rigidly timed

sequence. The processing task processes and stores the resulting

measurements and makes the decisions to actuate controls.

The measurement task stores raw Analog to Digital Converter (ADC) data

directly into memory. As soon as the data from a scan is in memory, the

processing task starts. There are at least two buffers allocated for this raw

ADC data (more under program control), thus the buffer from one scan can be

processed while the measurement task is filling another.

When a program is compiled, the measurement tasks are separated from the

processing tasks. When the program runs, the measurement tasks are

performed at a precise rate, ensuring that the measurement timing is exact and

invariant.

Processing Task: Measurement Task:

Digital I/O task

Read and writes to digital I/O ports

(ReadI/O, WriteI/O)

Processes measurements

Determines controls (port states) to set next scan

Stores data

Analog measurement and excitation sequence and

timing

Reads Pulse Counters

Reads Control Ports (GetPort)

Sets control ports (SetPort)

OV-5

Page 10

CR5000 Overview

OV2.3 Data Tables

The CR5000 can store individual measurements or it may use its extensive

processing capabilities to calculate averages, maxima, minima, histogams,

FFTs, etc., on periodic or conditional intervals. Data are stored in tables such

as listed in Table OV2-1. The values to output are selected when running the

program generator or when writing a datalogger program directly.

Table OV2-1. Typical Data Table

TOA4 StnName Temp

TIMESTAMP RECORD RefTemp_Avg TC_Avg(1) TC_Avg(2) TC_Avg(3) TC_Avg(4) TC_Avg(5) TC_Avg(6)

TS RN degC degC degC degC degC degC degC

Avg Avg Avg Avg Avg Avg Avg

1995-02-16 15:15:04.61 278822 31.08 24.23 25.12 26.8 24.14 24.47 23.76

1995-02-16 15:15:04.62 278823 31.07 24.23 25.13 26.82 24.15 24.45 23.8

1995-02-16 15:15:04.63 278824 31.07 24.2 25.09 26.8 24.11 24.45 23.75

1995-02-16 15:15:04.64 278825 31.07 24.21 25.1 26.77 24.13 24.39 23.76

OV3. PC9000 Application Software

PC9000 is a Windows™ application for use with the CR5000. The software

supports CR5000 program generation, real-time display of datalogger

measurements, graphing, and retrieval of data files.

OV3.1 Hardware and Software Requirements

The following computer resources are necessary:

• IBM PC, Portable or Desktop

• 8 Meg of Ram

• VGA Monitor

• Windows 95 or newer

• 30 Meg of Hard Drive Space for software

• 40 Meg of Hard Drive Space for data

• RS232 Serial Port

OV-6

The following computer resources are recommended:

• 16 Meg of Ram

• 33 MHz 486 or faster

• Mouse

OV3.2 PC9000 Installation

To install the PC9000 Software:

• Start Microsoft Windows

• Insert diskette 1 (marked 1 of 2) in a disk drive.

• From the Program Manager, select F

• Type (disk drive):\setup and press Enter e.g. a:\setup<Enter>

• The setup routine will prompt for disk 2.

ile menu and choose Run

Page 11

You may use the default directory of PC9000 or install the software in a

different directory. The directory will be created for you.

To abort the installation, type Ctrl-C or Break at any time.

OV3.3 PC9000 Software Overview

This overview points out the main PC9000 functions and where to find them.

PC9000 has extensive on-line help to guide the user in its operation, run

PC9000 to get the details. A CR5000 is not necessary to try out the

programming and real time display options; a demo uses canned data for

viewing. Without a CR5000, there are no communications with the

datalogger; operations such as downloading programs and retrieving data will

not function.

Figures OV3-1 and OV3-2 show the main PC9000 menus. The primary

functions of PC9000 are accessed from the File, Comm, Realtime, and

Analysis selections on the main menu (Figure OV3-1).

CR5000 Overview

OV-7

Page 12

CR5000 Overview

File Edit Realtime Analysis Tools Collect Display Windows Help

CommLink

Alarms List . . .

ield Monitor . . .

F

Virtual M

Virtual O

-Y Plotter . . .

X

istogram . . .

H

Fast Fourier T

Level Crossing Histogram . . .

et/Set Variable . . .

G

Display Data Graph 1 . . .

Display Data Graph 2

ID2000 . . . Ctrl + I

eter . . .

'Scope . . .

ransform . . .

Select S

Select P

Logger C

Logger Status . . .

D

ownload . . .

Save and Download

Logger F

Di

agnostics

Data Retrieval . . .

cheduled Data Retrieval . . .

S

eries Linked Station . . .

arallel Linked Station . . .

lock . . .

iles . . .

. . .

Realtime Display

& Graphing

Display Data in Tables Collected From CR5000.

Graphing requires no special processing of the data

and provides rapid feedback to the operator.

Collect data from CR5000

PC to CR5000

communications.

CR9000 Program Generator

000 Program Generator

CR5

CR9000 Program Editor . . .

CR5000 Program Editor . . .

Open W

Open Data Table I

Open D

Convert Binary to ASCII File . . .

P

Printer Setup . . .

D

File Manager . . .

E

Exit PC9000

iring Diagram . . .

ata File . . .

rint . . .

OS Shell . . .

xplorer . . .

nfo File . . .

Menu-driven Program Generation.

Direct Editing of Program

View/Edit Wiring Diagram & DataTable

Information (Created by Program Generator)

View Data Collected from CR5000

OV3-1. PC9000 Primary Functions

OV-8

Page 13

CR5000 Overview

File Edit Realtime Analysis Tools Collect Display Windows Help

Undo Ctrl + Z

Date & Time

Select All

Strip Remarks and Spaces Ctrl + S

Cut Ctrl + X

Copy Ctrl + C

Paste Ctrl + V

Delete

Delete Line Ctrl + Y

Wrap Text Ctrl + W

Go To Line . . .

Find Ctrl + F

Replace Ctrl + R

OV3-2. PC9000 Editing, Help, and User Preferences

Editing Options for

Active Windows

Colors . . .

Fonts . . .

Defaults . . .

Change fonts

and/or Colors for

Active Windows.

Tile Horizontal . . .

Tile Vertical . . .

Cascade . . .

Arrange Icons . . .

ork Area Setup . . .

W

List of Windows

PC9000 Help Contents . . .

earch PC9000 Help . . .

S

CRBasic Help Contents . . .

Search CR

Obtaining Technical Support . . .

A

bout PC9000 . . .

Software Versions . . .

Basic Help . . .

OV3.3.1 File

OV3.3.2 Edit

Program Generator

Guides the user through a series of menus to configure the measurement types:

thermocouple, voltage, bridge, pulse counting, frequency, and others. Creates

a CR5000 program, wiring diagram, output table, description, and

configuration file.

Program Editor

Create programs directly or edit those created by the program generator or

retrieved from the CR5000. Provides context-sensitive help for the CR5000's

BASIC-like language.

REALTIME

Virtual Meter

Updates up to five displays simultaneously. Choices include analog meter,

horizontal and vertical bars, independent scaling/offset, multiple alarms, and

rapid on-site calibration of sensors

OV-9

Page 14

CR5000 Overview

OV3.3.3 Analysis

OV3.3.4 Tools

OV3.3.5 Collect

Virtual Oscilloscope

Displays up to six channels. Time base variable from milliseconds to hours.

X-Y Plotter

Allows comparison of any two measurements in real time.

Data Graphing

Displays up to 16 fields simultaneously as strip charts or two multi-charts with

up to 8 traces each. Includes 2D/3D bars, line, log/linear, area, and scatter.

Line statistics available for max/min, best fit, mean, and standard deviation.

Handles files of unlimited size. Historical graphing requires no special

processing of the data and provides rapid feedback to the operator.

Control and Communications

Supports PC to CR5000 communications: clock read/set, status read, program

download, and program retrieval.

OV3.3.6 Display

OV3.3.7 Windows

OV3.3.8 Help

Collect data from CR5000 data tables

Configure the font and color scheme in an active window.

Size and arrange windows.

On-line help for PC9000 software.

OV-10

Page 15

OV4. Keyboard Display

CR5000 Overview

Power Up Screen

Press any key

CAMPBELL

SCIENTIFIC

CR5000 Datalogger

06/18/2000, 18:24:35

CPU: TRIG.CR5

Running.

for Main Menu

(except < >)

Data

Run/Stop Program

File

Status

Configure, Settings

Adjust contrast with < >

< lighter darker >

Real Time Tables

Real Time Custom

Final Storage Data

Reset Data Tables

Graph Setup

New

Edit

Copy

Delete

Run Options

Directory

Format

ROM Version : xxxx

OS Version : xxxx

OS Date : xxxx

OS Signature

Serial Number

Rev Board

Station Name : xxxx

Program Name : xxxxx

StartTime : xxxxx

Run Signature

DLD Signature

Battery : xxxx

Set Time/Date

Settings

Display

OV-11

Page 16

CR5000 Overview

OV4.1 Data Display

Data

Run/Stop Program

File

Status

Configure, Settings

Curs or to Data

and Press

Enter

Real Time Tables

Real Time Custom

Final Storage Data

Reset Data Table

Graph Setup

List of Data Tables created by

active program

List of Data Tables created by

active program

List of Data Tables created by

active program

OV-12

All Tables

List of Data Tables created by

active program

Graph Type: Scope

Scaler: Manual

Upper: 0.000000

Lower: 0.000000

Display Val Off

Display Max Off

Display Mi n Off

Page 17

OV4.1.1 Real Time Tables

List of Data Tables created by

active program. For Example,

Table1

Temps

Public

Cursor to desired

Table and press

Enter

Tref : 23.0234

TCTemp(1) : 19.6243

TCTemp(2) : 19.3429

TCTemp(3) : 21.2003

TCTemp(3) :

Flag(1) : -1.0000

Flag(2) : 0.00000

Flag(3) : 0.00000

Flag(4) : 0.00000

Public Table values

can be changed.

Cursor to value and

press Enter to edit

value.

CR5000 Overview

Tref : 23.0234

TCTemp(1) : 19.6243

TCTemp(2) : 19.3429

TCTemp(3) : 21.2003

TCTemp(3)

2

Flag(1) : -1.0000

Flag(2) : 0.00000

Flag(3) : 0.00000

Flag(4) : 0.00000

Press Graph/ Char

for Graph of

selected field

30.0 22.35

_____

___ ____

__

20.00

New values are displayed as they

are stored.

Scaler Manual

Press Ins for

Graph Setup

Upper: 30.000000

Lower: 20.000000

Display Val On

Display Max On

Display Min On

Graph Type Roll

OV-13

Page 18

CR5000 Overview

)

OV4.1.2 Setting up Real Time Custom Display

List of Data Tables created by

active program. For Example,

Table1

Temps

Public

Cursor to desired

Table and Press

Enter

Tref

TCTemp(1)

TCTemp(2)

TCTemp(3)

TCTemp(3

Flag(1)

Flag(2)

Flag(3)

Flag(4)

Cursor to position for next value

and Press Enter

Cursor to desired

Field and Press

Enter

TCTemp(3) : 24.9496

New values are displayed as they

are stored.

:

:

:

:

:

:

:

OV-14

Page 19

OV4.1.3 Final Storage Tables

_

List of Data Tables created by

active program. For Example:

Table1

Temps

CR5000 Overview

Cursor to desired

Table and Press

Enter

Use Hm (oldest), End (newest),

PgUp (older) , PgDn (newer),

←, →, ↑

, and ↓ to move around

in data table.

TimeStamp Record Tref TC(1) TC(2) TC(3)

"2000-01-03 00:12:38" 0 21.934 22.8419

"2000-01-03 00:12:39" 1 24.1242 21.8619 21.9173 22.8364

"2000-01-03 00:12:40" 2 24.1242 21.8786 21.9229 22.8364

"2000-01-03 00:12:41" 3

"2000-01-03 00:12:42" 4

"2000-01-03 00:12:43" 5

"2000-01-03 00:12:44" 6

"2000-01-03 00:12:45" 7

"2000-01-03 00:12:46" 8

5 :2000-01-03 00:12:43

Tref TC(1)

24.1242 : 21.8786

24.1242 : 21.8786

24.1242 : 21.8675

21.8675

24.1242 : 21.8675

24.1242 : 21.8675

24.1242 : 21.8398

21.9173 22.8419

21.9173 22.8253

21.9118 22.8364

21.9173 22.8087

21.9173 22.8142

21.9395 22.8253

"2000-01-03 00:12:47" 9 24.1242 21.8176 21.9118 22.8308

"2000-01-03 00:12:48" 10 24.1242 21.8342 21.945 22.8364

"2000-01-03 00:12:49" 11 24.1242 21.8453 21.9506 22.8364

Press Ins for Jump To screen.

Go to Record:

Press Graph/ Char for

Graph of selected field.

←, →

Use

, PgUp, PgDn

to move cursor and

window of data graphed.

5

press Ins to edit

Table Size:

1000

Current Record:

759

30.0 21.87

______

______ _______

____ ___ ____

__

20.00

Press Ins for

Graph Setup

Scaler Manual

Upper: 30.000000

Lower: 20.000000

Display Val On

Display Max On

Display Min On

Graph Type Roll

OV-15

Page 20

CR5000 Overview

OV4.2 Run/Stop Program

PCCard Display

Data

Run/Stop Program

File

Status

Configure, S e ttin g s

Cursor to

PCCard and

Press Enter

Remove Card

Forma t Card

Table Status

Card Status

CPU:

List of Programs

No Prog ra m

CRD:

List of Programs

You may now

remov e the Card.

CR500 0 close s ta ble s first.

All Card Data

Will be Lost!

Proceed?

Yes

No

List of Data Ta b les on card

created by active program

PC Card Status:

Battery OK

5Volt Card

WP Disabled

OV-16

Page 21

OV4.3 File Display

Data

Run/Stop Program

File

Status

Configure, Settings

Curs o r to

File and

Press Enter

New

Edit

Copy

Delete

Run Options

Directory

Format

CR5000 Overview

New F i le Name:

CPU: .CR5

CRD: .CR5

CPU:

CRD:

Copy

From

To

Execute

List of files on

CPU or Card.

CPU: Program

No Program

CRD: Program

CPU:

All programs and other files

will be lost!

Proceed?

Yes List of Programs

No

OV-17

Page 22

CR5000 Overview

D

p

)

p

OV4.3.1 File: Edit

List of Program files on CPU: or

CRD: For Example:

CPU:

TCTEMP.CR5 0

RACE.CR5 0

Cursor to desired Program

and Press Enter

The Program Editor in PC9000 is recommended for writing and editing

datalogger programs. Changes in the field can be made with the keyboard

display.

Save Changes?

Yes

No

ESC

CR5000

' TCTemp.CR5

Public TREF,TC(3),FLAG(8)

D ataTable (Temps,1,1000)

Sample (1,TREF,IEEE4)

Sample (3,TC(),IEEE4)

Edit Directly or Cursor to first

character of line and Press

Enter

ENTER

Edit Instruction

Blank Line

Create Block

DataTable (Temps,1,1000)

DataTable (Temps,1,1000

Sample (1,TREF,IEEE4)

Sample (3,TC(),IEEE4)

EndTable

Press Ins

Edit Instruction parameters with

Cursor down to

highlight desired

block and press

Enter

INSERT

Instruction

Function

Blank Line

Block

Insert Off

arameter names and some pick lists:

DataTable

TableName

> Temps

TrigVar

1

Size

1000

Insert blank line

Block Commands

Copy

Cut

Delete

BeginProg

Scan(1,sec,3,0)

To insert a block created by this

operation, cursor to desired place in

rogram and press Ins.

OV-18

Page 23

OV4.4 Configure Display

Data

Run/Stop Program

File

Status

Configure, Settings

Cursor to

Configure,

Settings and

Press Enter

Set Tim e /Date

Settings

Display

CR5000 Overview

05/24/2000, 15:10:40

Year 2000

Month 5

Day 24

Hour 15

Minute 10

Set

Cancel

Security Enable

RS-23 2 Time Out: No

CR5000 Off

Light Dark

<- * ->

Enter Passwords:

Level 1:

Level 2:

Level 3:

click

Enter

Num

Password

Turn off dis play

Back Light

Contrast Adjust

Display Time O ut: No, Ye s (if yes)

Time out (min) 1

OV-19

Page 24

CR5000 Overview

OV5. Specifications

Electrical specifications are valid over a -25° to +50°C range unless otherwise specified;testing over -40° to +85°C available as

an option, excludes batteries. Non-condensing environment required. Yearly calibrations are recommended to maintain electrical specifications.

PROGRAM EXECUTION RATE

The CR5000 can measure one channel and store the

result in 500 µs; all 40 SE* channels can be measured

in 8 ms (5 kHz aggregate rate).

ANALOG INPUTS

DESCRIPTION: 20 DF* or 40 SE, individually

configured. Channel expansion provided through

AM16/32, AM416, and AM25T Multiplexers.

RANGES, RESOLUTION, AND TYPICAL INPUT

NOISE: Basic Resolution (Basic Res) is the A/D

resolution of a single conversion. Resolution of

DFM* with input reversal is half the Basic Res.

Noise values are for DFM with input reversal;noise

is greater with SEM.*

Input Basic 0 Int. 250 µs Int. 20/16.7 ms Int.

Rng (mV) Res (µV) (µV RMS) (µV RMS) (µV RMS)

±5000 167 70 60 30

±1000 33.3 30 12 6

±200 6.67 8 2.4 1.2

±50 1.67 3.0 0.8 0.3

±20 0.67 1.8 0.5 0.2

ACCURACY

MINIMUM TIME BETWEEN MEASUREMENTS:

COMMON MODE RANGE: ±5 V

DC COMMON MODE REJECTION: >100 dB with

NORMAL MODE REJECTION: 70 dB @ 60 Hz

SUSTAINED INPUT VOLTAGE WITHOUT DAMAGE:

INPUT CURRENT: ±2 nA typ., ±10 nA max. @ 50°C

INPUT RESISTANCE: 20 GΩ typical

ACCURACY OF INTERNAL THERMOCOUPLE

REFERENCE JUNCTION:

†

:

±(0.05% of Reading + Offset) 0° to 40°C

±(0.075% of Reading + Offset) -25° to 50°C

±(0.10% of Reading + Offset) -40° to 85°C

Offset for DFM w/input reversal =

Offset for DFM w/o input reversal =

Offset for SEM = 2Basic Res + 10 µV

Zero Integration: 125 µs

250 µs Integration: 475 µs

16.7 ms Integration: 19.9 ms

20 ms Integration: 23.2 ms

input reversal (>80 dB without input reversal)

when using 60 Hz rejection

±16 Vdc

±0.25°C, 0° to 40°C

±0.5°C, -25° to 50°C

±0.7°C, -40° to 85°C

Basic Res +1 µV

2Basic Res + 2 µV

ANALOG OUTPUTS

DESCRIPTION: 4 switched voltage; 4 switched cur-

rent; 2 continuous voltage; switched outputs active

only during measurements, one at a time.

RANGE: Voltage (current) outputs programmable

between ±5 V (±2.5 mA)

RESOLUTION: 1.2 mV (0.6 µA) for voltage (current)

outputs

ACCURACY: ±10 mV (±10 µA) for voltage (current)

outputs

CURRENT SOURCING: 50 mA for switched voltage;

15 mA for continuous

CURRENT SINKING: 50 mA for switched voltage;

5 mA for continuous (15 mA w/selectable option)

COMPLIANCE VOLTAGE: ±5 V for switched current

excitation

RESISTANCE MEASUREMENTS

Provides voltage ratio measurements of 4- and 6-wire

full bridges, and 2-, 3-, 4-wire half bridges. Direct

resistance measurements available with current excitation. Dual-polarity excitation is recommended.

VOLTAGE RATIO ACCURACY

excitation reversal and an excitation voltage of at

least 2000 mV.

±(0.04% Reading + Basic Res/4) 0° to 40°C

±(0.05% Reading + Basic Res/4) -25° to 50°C

±(0.06% Reading + Basic Res/4) -40° to 85°C

ACCURACY

†

WITH CURRENT EXCITATION:

Assumes input and excitation reversal, and an

excitation current, I

±(0.075% Reading + Basic Res/2I

±(0.10% Reading + Basic Res/2I

±(0.12% Reading + Basic Res/2I

†

: Assumes input and

, of at least 1 mA.

x

x

x

) 0° to 40°C

x

) -25° to 50°C

) -40° to 85°C

PERIOD AVERAGING MEASUREMENTS

DESCRIPTION: The average period for a single

cycle is determined by measuring the duration of a

specified number of cycles. Any of the 40 SE

analog inputs can be used; signal attenuation and

ac coupling may be required.

INPUT FREQUENCY RANGE:

Input Signal (peak to peak) Min. Max.

Rng (mV) Min. Max.

±5000 600 mV 10 V 2.5 µs 200 kHz

±1000 100 mV 2.0 V 5.0 µs 100 kHz

±200 4 mV 2.0 V 25 µs 20 kHz

1

Maximum signals must be centered around

datalogger ground.

RESOLUTION: 70 ns/number of cycles measured

ACCURACY: ±(0.03% of Reading + Resolution)

1

Pulse W. Freq

PULSE COUNTERS

DESCRIPTION: Two 16-bit inputs selectable for switch

closure, high frequency pulse, or low-level ac.

MAXIMUM COUNT: 4 x 10

SWITCH CLOSURE MODE:

Minimum Switch Closed Time: 5 ms

Minimum Switch Open Time: 6 ms

Maximum Bounce Time: 1 ms open without

being counted.

HIGH FREQUENCY PULSE MODE:

Maximum Input Frequency: 400 kHz

Maximum Input Voltage: ±20 V

Voltage Thresholds: Count upon transition

from below 1.5 V to above 3.5 V at low frequen-

cies. Larger input transitions are required at high

frequencies because of 1.2 µs time constant filter.

LOW LEVEL AC MODE:

Internal ac coupling removes dc offsets up to

±0.5 V .

Input Hysteresis: 15 mV

Maximum ac Input Voltage: ±20 V

Minimum ac Input Voltage (sine wave):

(mV RMS) Range (Hz)

20 1.0 to 1000

200 0.5 to 10,000

1000 0.3 to 16,000

9

counts per scan

DIGITAL I/O PORTS

DESCRIPTION: 8 por ts selectable as binar y inputs or

control outputs.

OUTPUT VOLTAGES (no load):high 5.0 V ±0.1 V;

low < 0.1 V

OUTPUT RESISTANCE: 330 Ω

INPUT STATE: high 3.0 to 5.3 V; low -0.3 to 0.8 V

INPUT RESISTANCE: 100 kΩ

EMI and ESD PROTECTION

The CR5000 is encased in metal and incorporates

EMI filtering on all inputs and outputs. Gas discharge

tubes provide robust ESD protection on all terminal

block inputs and outputs. The following European

standards apply.

EMC tested and conforms to BS EN61326:1998.

Details of performance criteria applied are available

upon request.

Warning: This is a Class A product. In a domestic

environment this product may cause radio interference

in which case the user may be required to correct the

interference at the user’s own expense.

CPU AND INTERFACE

PROCESSOR: Hitachi SH7034

MEMORY: Battery-backed SRAM provides 2 Mbytes

for data and operating system use with

128 kbytes reserved for program storage.

Expanded data storage with PCMCIA type I,

type II, or type III card.

DISPLAY: 8-line-by-21 character alphanumeric or

128 x 64 pixel graphic LCD display w/backlight.

SERIAL INTERFACES: Optically isolated RS-232

9-pin interface for computer or modem. CSI/O

9-pin interface for peripherals such as CSI

modems.

BAUD RATES: Selectable from 1,200 to 115,200 bps.

ASCII protocol is eight data bits, one start bit, one

stop bit, no parity.

CLOCK ACCURACY: ±1 minute per month

SYSTEM POWER REQUIREMENTS

VOLTAGE:11 to 16 Vdc

TYPICAL CURRENT DRAIN: 400 µA software power

off; 1.5 mA sleep mode; 4.5 mA at 1 Hz (200 mA

at 5 kHz) sample rate.

INTERNAL BATTERIES: 7 Ahr rechargeable base

(optional); 1650 mAhr lithium batter y for clock and

SRAM backup, 10 years of service typical, less at

high temperatures.

EXTERNAL BATTERIES: 11 to 16 Vdc; reverse

polarity protected.

PHYSICAL SPECIFICATIONS

SIZE: 9.8” x 8.3” x 4.5” (24.7 cm x 21.0 cm x 11.4 cm)

WEIGHT: 4.5 lbs (2.0 kg) with low-profile base;

Terminal strips extend 0.4” (1.0 cm).

12.2 lbs (5.5 kg) with rechargeable base

WARRANTY

Three years against defects in materials and

workmanship.

*SE(M): Single-Ended (Measurement)

*DF(M): Differential (Measurement)

†

Sensor and measurement noise not included.

We recommend that you confirm system

configuration and critical specifications with

Campbell Scientific before purchase.

OV-20

Page 25

Section 1. Installation and Maintenance

1.1 Protection from the Environment

The normal environmental variables of concern are temperature and moisture.

The standard CR5000 is designed to operate reliably from -25 to +50°C (-40°C

to +85°C, optional) in noncondensing humidity. When humidity tolerances are

exceeded, damage to IC chips, microprocessor failure, and/or measurement

inaccuracies due to condensation on the various PC board runners may result.

Effective humidity control is the responsibility of the user.

The CR5000 is not hermetically sealed. Two half unit packets of DESI PAK

desiccant are located by the batteries. A dry package weighs approximately 19

grams and will absorb a maximum of six grams of water at 40% humidity and

11 grams at 80%. Desiccant packets can be dried out by placing the packets in

an oven at 120°C for 16 hours (desiccant only, not the CR5000).

Campbell Scientific offers two enclosures for housing a CR5000 and

peripherals. The fiberglass enclosures are classified as NEMA 4X (water-tight,

dust-tight, corrosion-resistant, indoor and outdoor use). A 1.25" diameter

entry/exit port is located at the bottom of the enclosure for routing cables and

wires. The enclosure door can be fastened with the hasp for easy access, or

with the two supplied screws for more p e r m anent applications. The white

plastic inserts at the corners of the enclosure must be removed to insert the

screws. Both enclosures are white for reflecting solar radiation, thus reducing

the internal enclosure temperature.

The Model ENC 12/14 fiberglass enclosure houses the CR5000 and one or

more peripherals. Inside dimensions of the ENC 12/14 are 14"x12"x5.5",

outside dimensions are 18"x13.5"x8.13" (with brackets); weight is 11.16 lbs.

The Model ENC 16/18 fiberglass enclosure houses the CR5000 and several

peripherals. Inside dimensions of the ENC 16/18 are 18"x16"x8¾", outside

dimensions are 18½"x18¾"x10½" (with brackets); weight is 18 lbs.

1.2 Power Requirements

The CR5000 operates at a nominal 12 VDC. Below 11.0 V or above 16 volts

the CR5000 does not operate properly.

The CR5000 is diode protected against accidental reversal of the positive and

ground leads from the battery. Input voltages in excess of 18 V may damage

the CR5000 and/or power supply. A transzorb provides transient protection by

limiting voltage at approximately 20 V.

System operating time for the batteries can be determined by dividing the battery

capacity (amp-hours) by the average system current drain. The CR5000

typically draws 1.5 mA in the sleep state (with display off), 4.5 mA with a 1 Hz

sample rate, and 200 mA with a 5 kHz sample rate.

1-1

Page 26

Section 1. Installation and Maintenance

1.3 CR5000 Power Supplies

The CR5000 may be purchased with either a rechargeable lead acid battery or

with a low profile case without a battery.

While the CR5000 has a wide operating temperature range (-40 to +85°C

optional), the lead acid battery base is limited to -40 to +60°C. Exceeding this

range will degrade battery capacity and lifetime and could also cause

permanent damage.

1.3.1 CR5000 Lead Acid Battery BASE

Temperature range: -40° to +60°C

Charging voltage: 17 to 24 VDC or 18 V RMS AC

NOTE

In normal operation a charging source should be connected to

the base at all times. The CR5000 stops measuring at ~11 V.

Battery life is shortened when discharged below 10.5 V.

The CR5000 includes a 12 V, 7.0 amp-hour lead acid battery, an AC

transformer (18 V RMS AC), and a temperature compensated charging circuit

with a charge indicating LED (Light Emitting Dio de). An AC transformer or

solar panel should be connected to the base at all times. The charging source

powers the CR5000 while float charging the lead acid batteries. The internal

lead acid battery powers the datalogger if the charging source is interrupted.

The lead acid battery specifications are given in Table 1.3-1.

The leads from the charging source connect to a wiring terminal plug on the

side of the base. Polarity of the leads to the connector does not matter. A

transzorb provides transient protection to the charging circuit. A sustained

input voltage in excess of 40V will cause the transzorb to limit voltage.

The red light (LED) on the base is on during charging with 17 to 24 VDC or

18 V RMS AC. The switch turns power to the CR5000 on or off. Battery

charging still occurs when the switch is o ff.

Should the lead acid batteries require replacement, consult Figure 1.3-1 for

wiring.

1-2

Page 27

Section 1. Installation and Maintenance

LEAD ACID BATTERY REPLACEMENT

6V 7AH

LEAD ACID

BATTERY

++

6V 7AH

LEAD ACID

BATTERY

RED

BLACK

WHITE

--

FIGURE 1.3-1. Lead Acid Battery Wiring

Monitor the power supply using datalogger Instruction “Battery”. Incorporate

this instruction into data acquisition programs to keep track of the state of the

power supply. If the system voltage level consistently decreases through time,

some element(s) of the charging system has failed. Battery measures the

voltage at the CR5000 electronics, not the voltage of the lead acid battery. The

measured voltage will normally be about 0.3 V less than the voltage at the

internal or external 12 V input. This voltage drop is on account of a Schottkey

diode. External power sources must be disconnected from the CR5000 to

measure the actual lead acid battery voltage.

TABLE 1.3-1. CR5000 Rechargeable Battery and AC Transformer

Specifications

Lead Acid Battery

Battery Type Yuasa NP7-6

Float Life @ 25oC 3 years minimum

Capacity 7.0 amp-hour

Shelf Life, full charge 6 months

Charge Time (AC Source) 40 hr full charge, 20 hr 95% charge

Operating temperature -40°C to 60°C

AC Transformer

Input: 120 VAC, 60 Hz

Isolated Output: 18 VAC 1.2 Amp

There are inherent hazards associated with the use of sealed lead acid batteries.

Under normal operation, lead acid batteries generate a small amount of

hydrogen gas. This gaseous by-product is generally insignificant because the

hydrogen dissipates naturally before build-up to an explosive level (4%)

occurs. However, if the batteries are shorted or overcharging takes place,

hydrogen gas may be generated at a rate sufficient to create a hazard.

Campbell Scientific recommends:

1. A CR5000 equipped with standard lead acid batteries should NEVER be

used in applications requiring INTRINSICALLY SAFE equipment.

2. A lead acid battery should not be housed in a gas-tight enclosure.

1-3

Page 28

Section 1. Installation and Maintenance

1.3.2 Low Profile CR5000

The low profile CR5000 option is not supplied with a battery base. See

Section 1.5 and 1.6 for external power connection considerations.

1.4 Solar Panels

Auxiliary photovoltaic power sources may be used to maintain charge on lead

acid batteries.

When selecting a solar panel, a rule-of-thumb is that on a stormy overcast day

the panel should provide enough charge to meet the system current drain

(assume 10% of average annual global radiation, kW/m

information, if available, could strongly influence the solar panel selection.

For example, local effects such as mountain shadows, fog from valley

inversion, snow, ice, leaves, birds, etc. shading the panel should be considered.

Guidelines are available from the Solar e x Corporation for solar panel selection

called "DESIGN AIDS FOR SMALL PV POWER SYSTEMS". It provid e s a

method for calculating solar panel size based on general site location and

system power requirements. If you need help in determining your system

power requirements contact Campbell Scientific's Marketing Department.

2

). Specific site

1.5 Direct Battery Connection to the CR5000 Wiring Panel

Any clean, battery backed 11 to 16 VDC supply may be connected to the 12 V

and G connector terminals on the front panel. When connecting external

power to the CR5000, first, remove the green power connector from the

CR5000 front panel. Insert the positive 12 V lead into the right-most terminal

of the green connector. Insert the ground lead in the left terminal. Double

check polarity before plugging the green connector into the panel.

Diode protection exists so that an external battery can be connected to the green

G and 12 V power input connector, without loading or charging the internal

batteries. The CR5000 will draw current from the source with the largest

voltage. When power is connected through the front panel, switch control on

the standard CR5000 power supplies is by-passed (Figure 1.7-1).

1.6 Vehicle Power Supply Connections

1.6.1 CR5000 with Battery Base

The best way to power a CR5000 with battery base from a vehicle’s 12 V

power system is to use the DCDC18R to input the power to the CR5000’s

charger input (Figure 1.6-1). With this configuration the CR5000’s batteries

are charged when the vehicle power is available. When the vehicle’s voltage is

too low or off, the CR5000 is powered from its internal batteries.

1-4

Page 29

Section 1. Installation and Maintenance

19 20

17 18

15 16

13 14

11 12

910

12

SE

2

1

HL

HL

DIFF

3

HL

4

HL

5

HL

6

HL

HL

8

7

HL

78

56

34

9

HL

10

HL

23 24

21 22

SE

12

11

H L

H L

DIFF

VX1

VX3

VX2

VX4

G

C6

C5

C7

C8

G

CONTROL I/O

Logan tah

CR5000

easurement and Control System

25 26

13

H L

POWER

UP

CAO1

>2.0V

G

CAO2

<0.8V

27 28

HL

IX1

5V

ROND

CS I/O

RS-232

COPTER

(OPTICALLY ISOLATED)

L

pc card

status

DCDC1R

BOOST REGULATOR

V in

V out

(11-16)

V

G 18V G

MADE IN

USA

29 30

16

15

14

H L

HL

IX2

IX3

IX4

IXR

P1

5V

G

SDI-12

12V

G

SDM-C1

SDM-C2

A B C

m

1

L

raph

char

4

P R S

T V

End

-

Del

ns

SN

2

5

0

P1

SDM-C3

17

H L

CONTROL I/O

C1C2C3

G

12V

POWER OUT

D E

Pgp

3

N O

6

W

PgDn

ESC

18

H L

G

SW-12

CRSOR

ST

Spc Cap

BSPC

ENTER

ALPA

C4

SW-12

19

HL

G

12V

POWER N

11 - 16 VDC

CATON

DC ONL

12V

ADE N SA

H L

20

39 40

37 38

35 36

33 34

31 32

FIGURE 1.6-1. CR5000 with DCDC18R

It is also possible to use the vehicle's 12 V power system as the primary supply

for a CR5000 with a battery base (Figure 1.6-2). When a vehicle’s starting

motor is engaged, the system voltage drops considerably below the 11 volts

needed for uninterrupted datalogger function. Diodes in the CR5000 in series

with the 12 V Power In connector allow the battery base to supply the needed

voltage during motor start. The diodes also prevent the separate power

systems of the CR5000 and vehicle from attempting to charge each other.

Because this configuration does not charge the CR5000 batteries, it is not

recommended.

CR5000

Panel

+12V

G

FIGURE 1.6-2. Alternate Connect on to Vehicle Power Supply

1-5

Page 30

Section 1. Installation and Maintenance

1.6.2 CR5000 with Low Profile Base (No Battery)

If a CR5000 without batteries is to be powered from the 12 Volts of a motor

vehicle, a second 12 V supply is required. When the starting motor of a

vehicle with a 12 V electrical system is engaged, the voltage drops

considerably below 11 V, which would cause the CR5000 to stop measurement

every time the vehicle is started. The second 12 V supply prevents this

malfunction. Figure 1.6-3 shows connecting the two supplies to a CR5000

without a battery base. The diodes allows the vehicle to power the CR5000

without the second supply attempting to power the vehicle.

CR5000

Panel

+12V

G

FIGURE 1.6-3. Connecting CR5000 without Battery Base to Vehicle

1.7 CR5000 GROUNDING

Grounding of the CR5000 and its peripheral devices and sensors is critical in

all applications. Proper grounding will ensure the maximum ESD

(electrostatic discharge) protection and higher measurement accuracy.

1.7.1 ESD Protection

An ESD (electrostatic discharge) can originate from several sources. However,

the most common, and by far potentially the most destructive, are primary and

secondary lightning strikes. Primary lightning strikes hit the datalogger or

sensors directly. Secondary strikes induce a voltage in power lines or sensor

wires.

The primary devices for protection against ESD are gas-discharge tubes

(GDT). All critical inputs and outputs on the CR5000 are protected with GDTs

or transient voltage suppression diodes. The GDTs fire at 150 V to allow

current to be diverted to the earth ground lug. To be effective, the earth

ground lug must be properly connected to earth (chassis) ground. As shown in

Figure 1.7-1, the power ground and signal ground are independent lines until

joined inside the CR5000.

Power Supply

1-6

Page 31

Section 1. Installation and Maintenance

Tie analog signal

shields and returns to

grounds (

) located in

analog input terminal

strips.

Analog Grounds

Excitation, CAO,

Pulse Counter Grounds ( )

Power Grounds (G)

Tie CAO and pulse-counter returns into grounds ( ) in CAO and pulse-counter

terminal strip. Large excitation return currents may also be tied into this ground

in order to minimize induced single-ended offset voltages in half bridge

measurements.

Tie 5 V, SW-12, 12 V and C1-C8

returns into power grounds (G).

12

34

56

78

910

11 12

13 14

15 16

17 18

G

3

6

9

HL

37 38

19

HL

POWER IN

11 - 16 V

CURSOR

ALPA

SIT

Spc Cap

BSPC

ENTER

19 20

HL

39 40

HL

CAUTION

DC ONL

G 12V

DC

5A Thermal fuse

1.5k E20A

10

20

GROUND

LUG

CS IO

COPUTER RS-232

(OPTICALL ISOLATED)

Batteries

pc card

status

On/Off

SE

1

2

HL

DIFF

SE

21

22

11

DIFF

HL

VX1

VX2

GC5C6C7C8G>2.0VG>0.8V5V5VGSDI-12

CONTROL I/O POWER

Logan Utah

3

HL

HL

Ground Plane

23 24

25 26

12

13

HL

HL

VX3

VX4

CAO1

CAO2

UP

CR5000 ICROLOGGER

4

HL

27 28

14

HL

IX1

IX2

IX3

To CR5000

Electronics

5

HL

29 30

15

HL

IX4

6

HL

31 32

16

HL

IXR

P1

12VGSDM-C1

7

HL

33 34

17

HL

CONTROL I/O

P2C1C2C3C4

SDM-C2

SDM-C3G12VGSW-12

POWER UP

SW12

Control

1.85A

Thermal fuse

A B C

m

1

G I

L

Graph

char

4

10µf

T U V

P R S

End

7

)

- (

Ins

Del

HL

35 36

HL

2

5

0

8

18

SW-12

0.9A

Thermal

fuse

D E

PgUp

N O

W

PgDn

ESC

Star Ground at

Ground Lug

1.85A

Thermal fuse

External

Power Input

SN

ADE IN USA

FIGURE 1.7-1. Schematic of CR5000 Grounds

The 9-pin serial I/O ports on the CR5000 are another path for transients to

enter and damage the CR5000. Communications devices such a telephone or

short-haul modem lines should have spark gap protection. Spark gap

protection is often an option with these products, so it should always be

requested when ordering. The spark gaps for these devices must be connected

to either the CR5000 earth ground lug, the enclosure ground, or to the earth

(chassis) ground.

1-7

Page 32

Section 1. Installation and Maintenance

A good earth (chassis) ground will minimize damage to the datalogger and

sensors by providing a low resistance path around the system to a point of low

potential. Campbell Scientific recommends that all dataloggers be earth

(chassis) grounded. All components of the system (dataloggers, sensors,

external power supplies, mounts, housings, etc.) should be referenced to one

common earth (chassis) ground.

In the field, at a minimum, a proper earth ground will consist of a 6 to 8 foot

copper sheathed grounding rod driven into the earth and connected to the

CR5000 Ground Lug with a 12 AWG wire. In low conductive substrates, such

as sand, very dry soil, ice, or rock, a single ground rod will probably not

provide an adequate earth ground. For these situations, consult the literature

on lightning protection or contact a qualified lightning protection consultant.

An excellent source of information on lightning protection can be located via

the web at http://www.polyphaser.com.

In vehicle applications, the earth ground lug should be firmly attached to the

vehicle chassis with 12 AWG wire or larger.

In laboratory applications, locating a stable earth ground is not always obvious.

In older buildings, new cover plates on old AC sockets may indicate that a

safety ground exists when in fact the socket is not grounded. If a safety ground

does exist, it is good practice to verify that it carries no current. If the integrity

of the AC power ground is in doubt, also ground the system through the

buildings, plumbing or another connection to earth ground.

1.7.2 Effect of Grounding on Measurements: Common Mode Range

The common mode range is the voltage range, relative to the CR5000 ground,

within which both inputs of a differential measurement must lie in order for the

differential measurement to be made correctly. Common mode range for the

CR5000 is ±5.0 V. For example, if the high side of a differential input is at 2 V

and the low side is at 0.5 V relative to CR5000 ground, a measurement made on

the ±5.0 V range would indicate a signal of 1.5 V. However, if the high input

changed to 6 V, the common mode range is exceeded and the measurement may

be in error.

Common mode range may be exceeded when the CR5000 is measuring the

output from a sensor which has its own grounded power supply and the low

side of the signal is referenced to the sensors power supply ground. If the

CR5000 ground and the sensor ground are at sufficiently different potentials,

the signal will exceed the common mode rang e. To solve this problem, the

sensor power ground and the CR5000 ground should be connected, creating

one ground for the system.

In a laboratory application, where more than one AC socket may be used to

power various sensors, it is not safe to assume that the power grounds are at the

same potential. To be safe, the ground of all the AC sockets in use should be

tied together with a 12 AWG wire.

1-8

Page 33

Section 1. Installation and Maintenance

1.7.3 Effect of Grounding on Single-Ended Measurements

Low-level single-ended voltage measurements can be problematic because of

ground potential fluctuations. The grounding scheme in the CR5000 has been

designed to eliminate ground potential fluctuations due to changing return

currents from 12 V, SW-12, 5 V, and the control ports. This is accomplished

by utilizing separate signal grounds (

advantage of this design, observe the following grounding rule:

) and power grounds (G). To take

NOTE

Always connect a device’s ground next to the active terminal

associated with that ground.

Examples:

1. Connect 5 Volt, 12 Volt, and control grounds to G terminals.

2. Connect excitation grounds to the closest

terminal block.

3. Connect the low side of single-ended sensors to the nearest

the analog input terminal blocks.

4. Connect shield wires to the nearest

terminal blocks.

If offset problems occur because of shield or ground leads with large current

flow, tying the problem leads into the

and pulse-counter channels should help. Problem leads can also be tied

directly to the ground lug to minimize induced single-ended offset voltages.

terminal on the analog input

terminals next to the excitation, CAO,

1.8 Powering Sensors and Peripherals

terminal on the excitation

terminal on

The CR5000 is a convenient source of power for sensors and peripherals

requiring a continuous or semi-continuous 5 VDC or 12 VDC source. The

CR5000 has 2 continuous 12 Volt (12V) supply terminals, 2 switched 12 Volt

(SW-12) supply terminals, and 2 continuous 5 Volt (5V) supply terminals.

Voltage on the 12V and SW-12 terminals will change with the CR5000 supply

voltage. The 5V terminal is regulated and will always remain near 5 Volts

(±4%)so long as the CR5000 supply voltage remains above 11 Volts. The 5V

terminal is not suitable for resistive bridge sensor excitation. Table 1.8-1

shows the current limits of the 12 Volt and 5 Volt ports. Table 1.8-2 shows

current requirements for several CSI peripherals. Other devices normally have

current requirements listed in their specifications. Current drain of all

peripherals and sensors combined should not exceed current sourcing limits of

the CR5000.

1-9

Page 34

Section 1. Installation and Maintenance

Make certain that the primary source of power for the CR5000 can sustain the

current drain for the period of time required. Contact a CSI applications

engineer for help in determining a power budget for applications that approach

the limits of a given power supply’s capabilities. Be particularly cautious

about any application using solar panels and cellular telephone or radio,

applications requiring long periods of time between site visits, or applications

at extreme temperatures.

Table 1.8-1 Current Sourcing Limits

Terminals Current Source Limit

SW12 < 900 mA @ 20°C

< 729 mA @ 40°C

< 630 mA @ 50°C

< 567 mA @ 60°C

< 400 mA @ 80°C

12V + SW12 < 1.85 A @ 20°C

< 1.50 A @ 40°C

< 1.30 A @ 50°C

< 1.17 A @ 60°C

< 0.85 A @ 80°C

5V + CSI/O < 200 mA

TABLE 1.8-2. Typical Current Drain for Some CR5000 Peripherals

Typical Current Drain (mA)

Peripheral Quiescent Active

AM25T .5 1

COM100 .5 1.8

COM200 Phone Modem 0.0012 140

SDM-INT8 0.4 6.5

1.9 Controlling Power to Sensors and Peripherals

Controlling power to an external device is a common function of the CR5000.

Many devices can conveniently be controlled with the SW-12 (Switched 12

Volt) terminals on the CR5000. Table 1.8-1 shows the current available from

SW-12 port.

Applications requiring more control channels or greater power sourcing

capacity can usually be satisfied with the use of Campbell Scientific’s

A21REL-12 Four Channel Relay Driver, A6REL-12 Six Channel Relay

Driver, SDM-CD16AC 16 Channel AC/DC Relay Module, or by using the

control (C1-C8) ports as described in Section 1.9.1

1-10

Page 35

Section 1. Installation and Maintenance

1.9.1 Use of Digital I/O Ports for Switching Relays

Each of the eight digital I/O ports can be configured as an output port and set

low or high (0 V low, 5 V high) using the PortSet or WriteIO instructions. A

digital output port is normally used to operate an external relay driver circuit

because the port itself has a limited drive capability (2 .0 mA minimum at 3.5

V).

Figure 1.9-1 shows a typical relay driver circuit in conjunction with a coil

driven relay which may be used to switch external power to some device. In

this example, when the control port is set high, 12 V from the datalogger passes

through the relay coil, closing the relay which completes the power circuit to a

fan, turning the fan on.

In other applications it may be desirable to simply switch power to a device

without going through a relay. Figure 1.9-2 illustrates a circuit for switching

external power to a device without going through a relay. If the peripheral to be

powered draws in excess of 75 mA at room temperature (limit of the 2N2907A

medium power transistor), the use of a relay (Figure 1.9-1) would be required.

Other control port activated circuits are possible for applications with greater

current/voltage demands than shown in Figures 1.9-1 and 2. For more

information contact a Campbell Scientific applications engineer.

FIGURE 1.9-1. Relay Driver Circuit with Relay

1-11

Page 36

Section 1. Installation and Maintenance

FIGURE 1.9-2. Power Switching without Relay

1.10 Maintenance

The CR5000 power supplies require a minimum of routine maintenance.

When not in use, the rechargeable supply should be stored in a cool, dry

environment with the AC charger active.

1.10.1 Desiccant

The CR5000 is shipped with desiccant to reduce humidity. Desiccant should

be changed periodically. To prevent corrosion in uncontrolled or condensing

atmospheres, the CR5000 must be placed inside a weather tight instrument

enclosure with desiccant. Do not completely seal the enclosure if lead acid

batteries are present. Hydrogen gas generated by the batteries may build up to

an explosive concentration.

1.10.2 Replacing the Internal Battery

CAUTION

Misuse of the lithium battery or installing it improperly can

cause severe injury. Fire, explosion, and severe burn

hazard! Do not recharge, disass emble, heat above 100°C

(212°F), solder directly to the cell, incinerate, nor expose

contents to water.

The CR5000 contains a lithium battery that operates the clock and SRAM

when the CR5000 is not powered. The CR5000 does not draw any power from

the lithium battery while it is powered by a 12 VDC supply. In a CR5000

stored at room temperature, the lithium battery should last approximately 10

years (less at temperature extremes). Where the CR5000 is powered most or

all of the time the lithium cell should last much longer.

1-12

Page 37

Section 1. Installation and Maintenance

While powered from an external source, the CR5000 measures the voltage of

the lithium battery daily. This voltage is displayed in the status table (Section

1.6) A new battery will have approximately 3.6 volts. The CR5000 Status

Table has a “Lithium Battery” field. This field is either “ True” (battery is

good) or “False” (replace battery). If the lithium cell is removed or allowed to

discharge below the safe level, the CR5000 will still operate correctly while

powered. Without the lithium battery, the clock will reset and data will be lost

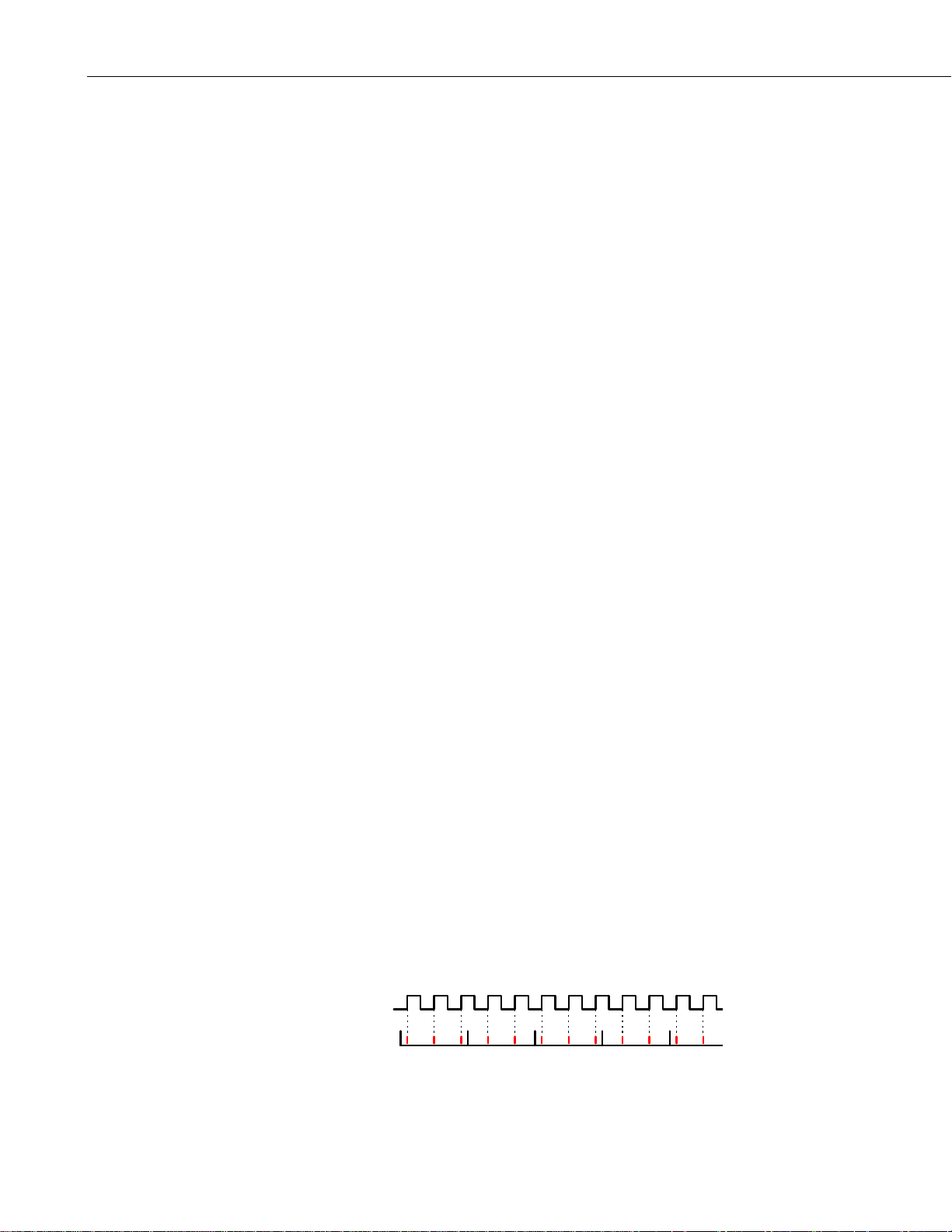

when power is removed.