Page 1

INSTRUCTION MANUAL

CPEC200 Closed-Path

Copyright © 2013- 2014

Campbell Scientific, Inc.

Eddy-Covariance System

Revision: 7/14

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning 435-227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is highly

recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact with

overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, or 20 feet, or the

distance required by applicable law, whichever is greater, between overhead utility lines and

the structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 6

Page 7

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 2

4. Overview ...................................................................... 2

4.1 System Components ............................................................................. 2

4.1.1 Standard Components ................................................................... 2

4.1.1.1 EC155 Gas Analyzer .......................................................... 2

4.1.1.2 EC100 Electronics .............................................................. 3

4.1.1.3 CPEC200 Enclosure ........................................................... 3

4.1.1.4 CPEC200 Pump Module .................................................... 4

4.1.2 Optional Components ................................................................... 4

4.1.2.1 CR3000 Datalogger ............................................................ 4

4.1.2.2 NL115 or CFM100 Storage Module .................................. 5

4.1.2.3 CPEC200 Valve Module .................................................... 6

4.1.2.4 CSAT3A Sonic Anemometer Head .................................... 6

4.1.2.5 Barometer ........................................................................... 7

4.1.2.6 Carrying Cases ................................................................... 7

4.1.2.7 Enclosure Mounting Options .............................................. 7

4.1.3 Common Accessories .................................................................... 8

4.1.4 Support Software ........................................................................ 10

4.1.5 Replacement Parts ....................................................................... 11

4.2 Theory of Operation ........................................................................... 13

4.2.1 EC155 Gas Analyzer ................................................................... 13

4.2.2 CSAT3A Sonic Anemometer Head ............................................ 14

4.2.3 Valve Module .............................................................................. 14

4.2.4 Pump Module .............................................................................. 16

4.3 Specifications ..................................................................................... 17

5. Installation ................................................................. 17

5.1 Mounting ............................................................................................ 18

5.1.1 Support Structure ........................................................................ 18

5.1.2 Mount Enclosures ....................................................................... 18

5.1.3 Install EC Sensors ....................................................................... 19

5.2 Plumbing ............................................................................................ 21

5.2.1 Pump Module .............................................................................. 21

5.2.2 Zero/Span .................................................................................... 22

5.3 Wiring ................................................................................................ 23

5.3.1 Ground Connections ................................................................... 23

5.3.2 EC Sensor Cables ........................................................................ 24

5.3.3 Pump Module Cable.................................................................... 27

5.3.4 Apply Power ............................................................................... 27

i

Page 8

Table of Contents

5.4 Configure the Program ...................................................................... 28

5.4.1 System Configuration Variables ................................................. 28

5.4.2 Compile Switches ....................................................................... 32

5.5 Verify Proper Operation .................................................................... 32

6. Zero and Span ........................................................... 33

6.1 Introduction ....................................................................................... 33

6.2 Automatic Zero and Span .................................................................. 34

6.3 Manual Zero and Span ....................................................................... 35

6.3.1 Manually starting the zero/span sequence .................................. 35

6.3.1.1 Temperature Control ........................................................ 35

6.3.1.2 Starting the sequence ....................................................... 36

6.3.1.3 Stopping the sequence ..................................................... 36

6.3.2 Full Manual Control of Zero and Span ....................................... 37

6.3.2.1 Getting Ready .................................................................. 37

6.3.2.2 Checking and Setting the Zero ........................................ 37

6.3.2.3 Checking and Setting the CO2 Span ................................ 38

6.3.2.4 Checking and Setting the H2O Span ................................ 38

6.3.2.5 Returning to Normal EC Mode ........................................ 39

7. Maintenance and Troubleshooting .......................... 39

7.1 Enclosure Desiccant .......................................................................... 40

7.2 EC155 Intake Filter ........................................................................... 40

7.3 EC155 Windows ................................................................................ 40

7.4 EC155 Chemical Bottles ................................................................... 41

8. Repair ......................................................................... 41

Appendices

CPEC200 Diagnostics ............................................. A-1

A.

A.1 Overview ......................................................................................... A-1

A.2 Status Text Variables ....................................................................... A-1

A.3 Status Boolean Variables ................................................................. A-6

A.4 CPEC200 Diagnostic Words ........................................................... A-8

B. Public Variables ...................................................... B-1

C. Output Variables ..................................................... C-1

D. Control Bits.............................................................. D-1

E. Using Swagelok® Fittings ....................................... E-1

E.1 Assembly .......................................................................................... E-1

E.2 Common Replacement Parts ............................................................ E-2

F. Installing the AC/DC Power Adapter Kit ............... F-1

ii

Page 9

Table of Contents

G. CPEC200 Scrub Module Installation, Operation

and Maintenance .................................................. G-1

G.1 Theory of Operation ........................................................................ G-1

G.2 Scrub Module Specifications .......................................................... G-2

G.3 Installation ....................................................................................... G-2

G.4 Maintenance .................................................................................... G-3

H. CPEC200 Pump Replacement ................................ H-1

H.1 Introduction ..................................................................................... H-1

H.2 Removal .......................................................................................... H-1

H.3 Installation ....................................................................................... H-4

Figures

4-1. EC155 closed-path CO2/H2O gas analyzer ......................................... 2

4-2. EC100 electronics module ................................................................... 3

4-3. CPEC200 system enclosure ................................................................. 3

4-4. CPEC200 pump module ....................................................................... 4

4-5. CR3000 datalogger ............................................................................... 5

4-6. NL115 (left) and CFM100 (right) ........................................................ 5

4-7. CFMC2G 2GB CompactFlash® memory card .................................... 5

4-8. CPEC200 valve module ....................................................................... 6

4-9. CSAT3A sonic anemometer head ........................................................ 7

4-10. CPEC200 scrub module ....................................................................... 9

4-11. 17752 USB memory card reader/writer ............................................. 10

4-12. Intake filter of EC155 ......................................................................... 11

4-13. Single desiccant pack ......................................................................... 11

4-14. Humidity indicator card ..................................................................... 12

4-15. Diaphragm pump used in CPEC200 .................................................. 12

4-16. EC155 gas analyzer ............................................................................ 13

4-17. CSAT3A sonic anemometer head ...................................................... 14

5-1. CPEC200 enclosure, pump module, and EC100 mounted to legs

of CM110-series tripod ................................................................... 19

5-2. CM210 mounting bracket on a tripod mast ........................................ 20

5-3. Mounting of EC155 and CSAT3A ..................................................... 20

5-4. Plumbing connections ........................................................................ 21

5-5. Connecting pump tube from EC155 analyzer to pump module ......... 22

5-6. Enclosure and tripod grounded to a copper-clad grounding rod ........ 24

5-7. EC155 electrical connections (mounting hardware not shown) ......... 24

5-8. Wiring of power and communications ............................................... 25

5-9. Wiring to EC100 electronics .............................................................. 26

5-10. Wiring to CPEC200 enclosure ........................................................... 26

E-1. Swagelok® insert .............................................................................. E-3

E-2. Front and back Swagelok® ferrules .................................................. E-3

E-3. Swagelok® plug ................................................................................ E-4

E-4. Swagelok® cap ................................................................................. E-4

F-1. Peripheral mounting kit installed in CPEC200 enclosure ................ F-1

F-2. Power supply in mounting bracket ................................................... F-2

F-3. Secured power supply in mounting bracket ..................................... F-2

F-4. Connections for the power supply in CPEC200 enclosure ............... F-3

F-5. Powered supply in CPEC200 enclosure ........................................... F-3

G-1. CPEC200 scrub module .................................................................. G-1

G-2. Scrub module interior ...................................................................... G-3

iii

Page 10

Table of Contents

Tables

G-3. Interior of CPEC200 scrub module with tubing and cover

removed ....................................................................................... G-4

G-4. Empty bottle showing the top (on the right with spring) and

bottom (left) caps ......................................................................... G-5

H-1. Four screws holding filter assembly inside CPEC200 pump

module enclosure ......................................................................... H-1

H-2. Upright filter unit in enclosure ........................................................ H-2

H-3. Location of #4 screws of pump assembly ........................................ H-2

H-4. Exposed CPEC200 pump assembly ................................................ H-3

H-5. Location of pump connector in CPEC200 pump electronics ........... H-3

H-6. Self-tapping screws attaching pump to metal box ........................... H-4

H-7. Location of cuts to remove pump assembly from tubing ................ H-4

H-8. Inlet and outlet tubing reconnected to pump ................................... H-5

H-9. Pump side with inlet and outlet tubing connected ........................... H-5

H-10. Proper positioning of CPEC200 in shell cover ................................ H-6

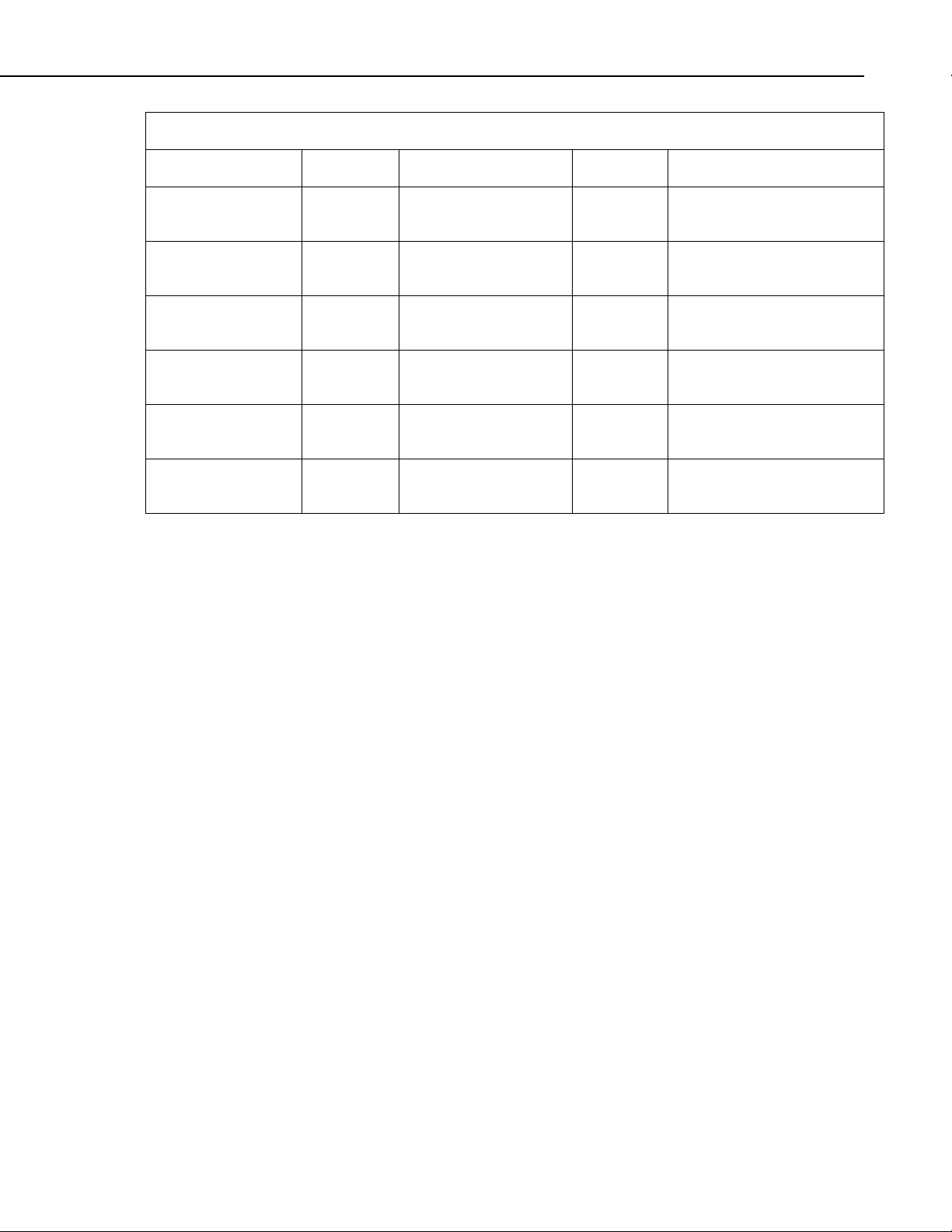

5-1. SDM Wiring ...................................................................................... 25

6-1. Automatic Zero/Span Sequence ........................................................ 35

A-1. Summary CPEC200 diagnostic flags encoded in diag_cpec ........... A-9

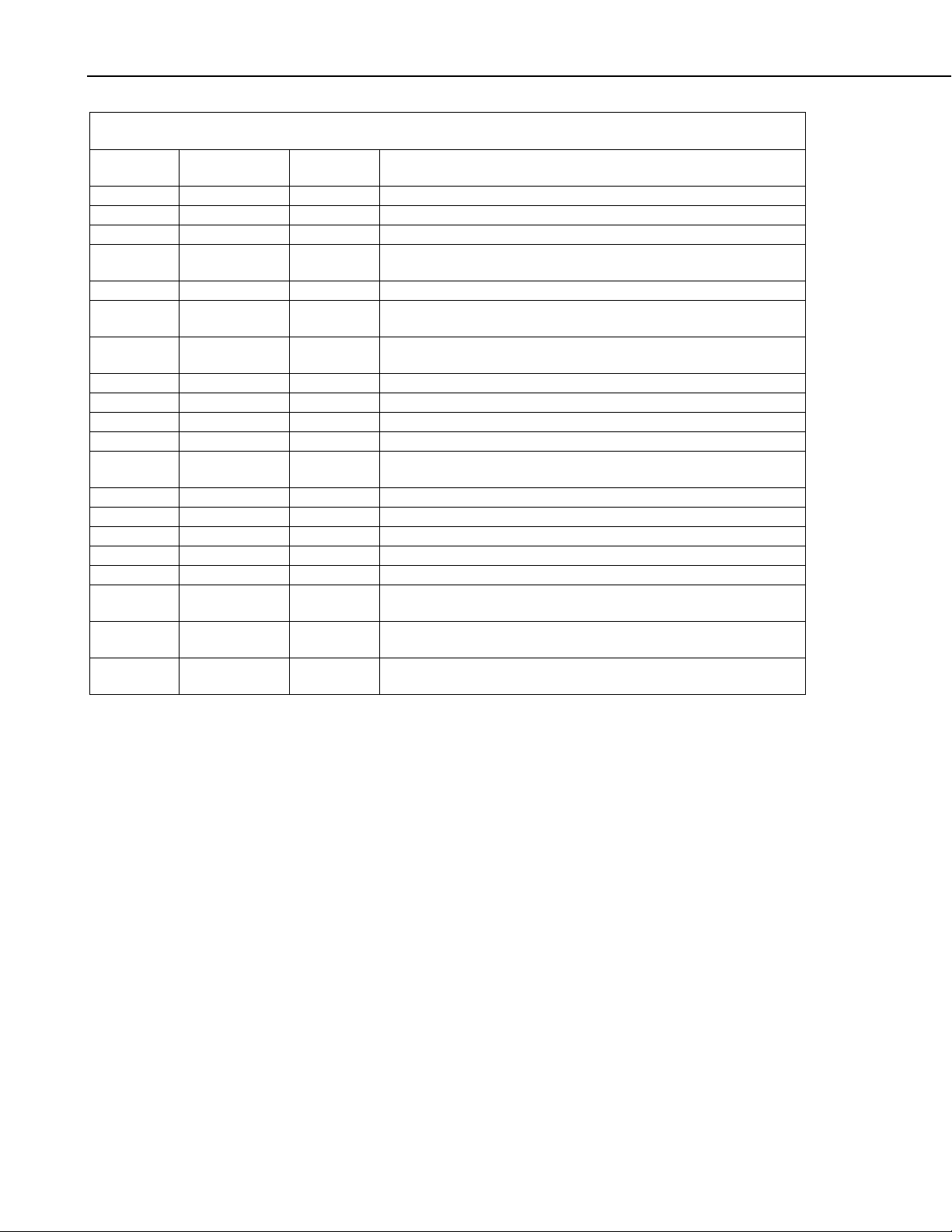

B-1. CPEC200 public variables ............................................................... B-1

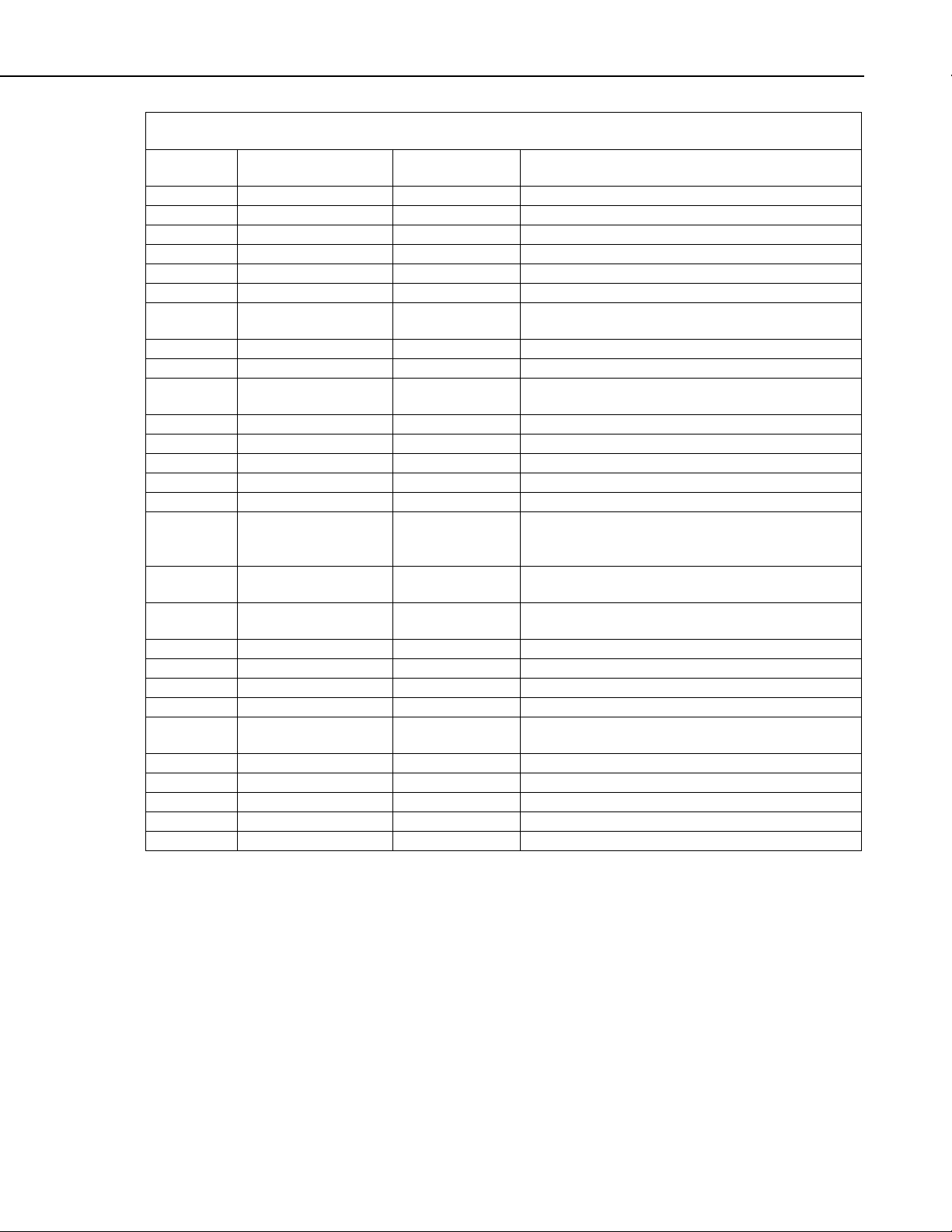

C-1. Values stored in table ts_data .......................................................... C-1

C-2. Values stored in table flux ............................................................... C-3

C-3. Values stored in table zero_ span .................................................... C-6

C-4. Values stored in table message_log ................................................. C-9

C-5. Values stored in table config_history ............................................ C-10

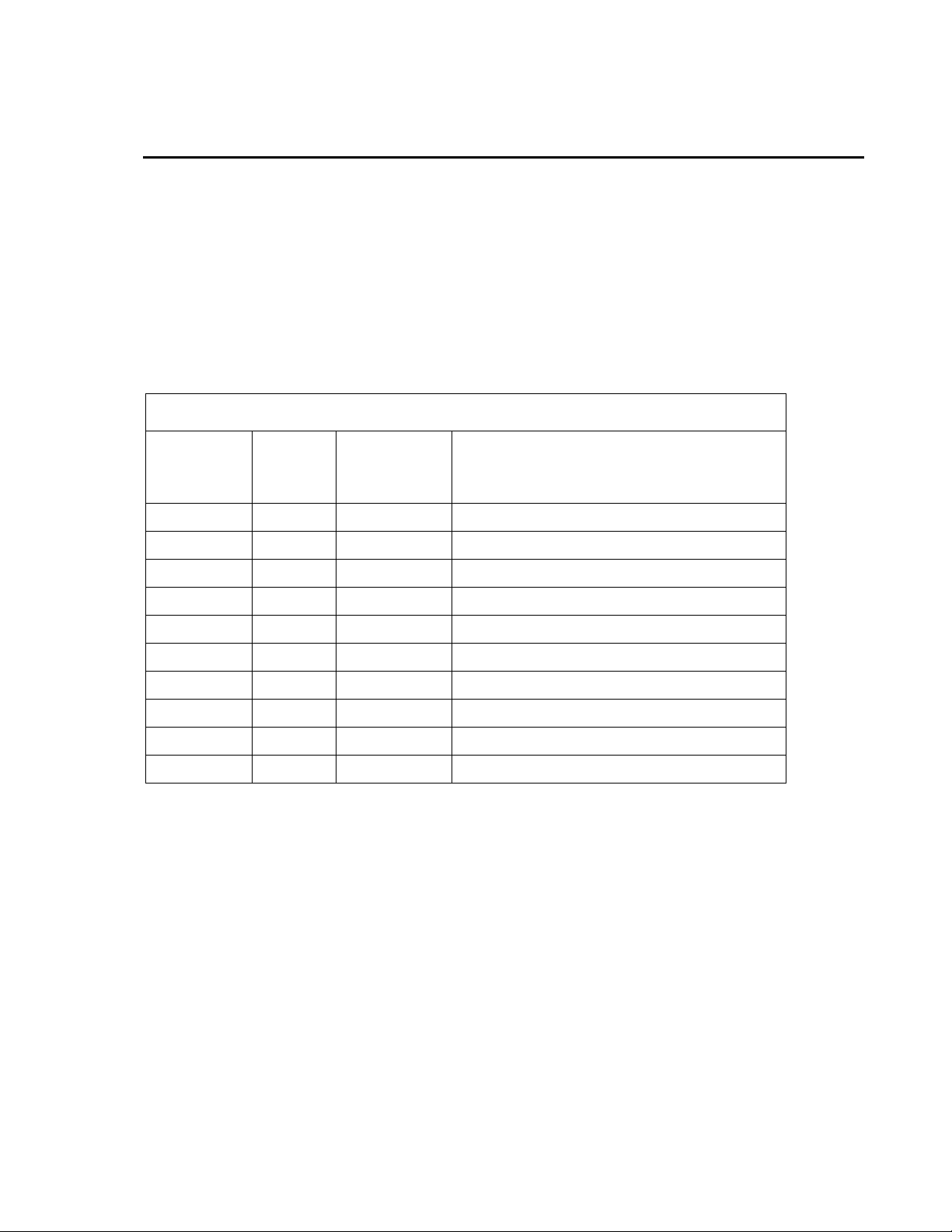

D-1. CPEC200 temperature control bits encoded in ControlBits ............ D-1

E-1. Available plastic tubing sizes, construction, and usage

guidelines ...................................................................................... E-2

E-2. Dimensions and part numbers for Swagelok® inserts ....................... E-3

E-3. Dimensions and part numbers for Swagelok® ferrules ..................... E-3

E-4. Dimensions and part numbers for Swagelok® plugs ........................ E-4

E-5. Dimensions and part numbers for Swagelok® caps .......................... E-4

iv

Page 11

NOTE

CPEC200 Closed-Path Eddy-Covariance

System

1. Introduction

The CPEC200 is a closed-path, eddy-covariance (EC) flux system used for

long-term monitoring of atmosphere–biosphere exchanges of carbon dioxide,

water vapor, heat, and momentum. This complete, turn-key system includes a

closed-path gas analyzer (EC155), a sonic anemometer head (CSAT3A),

datalogger (CR3000), sample pump, and optional valve module for automated

zero and span.

Before using the CPEC200, please study:

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 5, Installation

Operational instructions critical to the preservation of the system are found

throughout this manual. Before using the CPEC200, please study the entire

manual. Further information pertaining to the CPEC200 can be found in the

Campbell Scientific publications EC155 CO

Analyzer Manual, available at www.campbellsci.com.

and H2O Closed-Path Gas

2

Other manuals that may be helpful include:

• CR3000 Micrologger Operator’s Manual

• CFM100 CompactFlash® Module Instruction Manual

• NL115 Ethernet and CompactFlash® Module Instruction Manual

• Application Note 3SM-F, PC/CF Card Information

• LoggerNet Instruction Manual

• ENC10/12, ENC12/14, ENC14/16, ENC16/18 Instruction Manual

• CM106 Tripod Instruction Manual

• Tripod Installation Manual Models CM110, CM115, CM120

• CSAT3 Three Dimensional Sonic Anemometer Manual

This user manual applies specifically to version 2.0 of the

CPEC200 CRBasic program.

2. Cautionary Statements

• WARNING:

o Do not connect or disconnect the EC155 gas analyzer head or the

CSAT3A sonic anemometer head from the EC100 electronics

while the EC100 is powered. Doing so can result in

unpredictable performance of the system or damage to the

instrument head.

o Grounding electrical components in the measurement system is

critical. Proper earth (chassis) grounding will ensure maximum

electrostatic discharge (ESD) protection and higher measurement

accuracy.

o Use care when connecting and disconnecting tube fittings to

avoid introducing dust or other contaminants.

1

Page 12

CPEC200 Closed-Path Eddy-Covariance System

3. Initial Inspection

Upon receipt of the CPEC200, inspect the packaging and contents for damage.

File damage claims with the shipping company.

Model numbers are found on each product. On cables, the model number is

usually found at the connection end of the cable. Check this information

against the enclosed shipping documents to verify the expected products and

the correct lengths of cable are included.

4. Overview

The CPEC200 is a closed-path EC flux system used for long-term monitoring

of atmosphere–biosphere exchanges of carbon dioxide, water vapor, heat, and

momentum.

4.1 System Components

o Do not overtighten the tube fittings. Consult Appendix E, Using

Swagelok

o The CPEC200 power source should be designed thoughtfully to

ensure uninterrupted power. If needed, contact a Campbell

Scientific applications engineer for assistance.

o Retain all spare caps and plugs as these are required when

shipping or storing the CPEC200 system.

®

Fittings, for information on proper connection.

The CPEC200 consists of several components, some of which are optional.

Some additional accessories are required to complete a fully functioning

CPEC200 system and are described and illustrated in the sections that follow.

4.1.1 Standard Components

Standard with the CPEC200 are the CPEC200 system enclosure, EC155 gas

analyzer, EC100 electronics, and CPEC200 pump module.

4.1.1.1 EC155 Gas Analyzer

The EC155 is a closed-path, infrared CO

integrated electronics (EC100 electronics) with the CSAT3A sonic

anemometer head. For detailed information and specifications, see the EC155

manual at www.campbellsci.com. The EC155, as shown in FIGURE 4-1, is an

included part of the CPEC200 system.

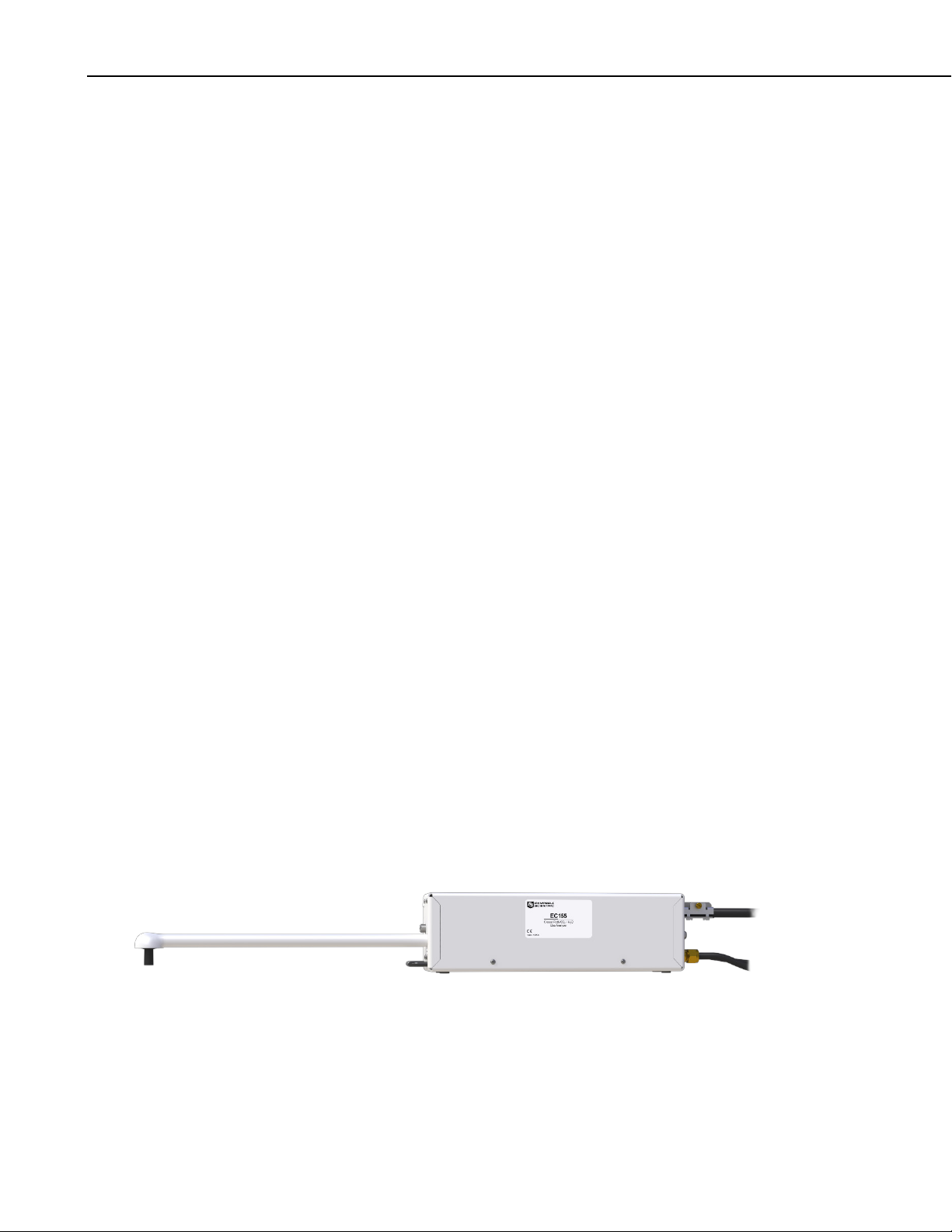

FIGURE 4-1. EC155 closed-path CO2/H2O gas analyzer

O gas analyzer. It shares

2/H2

2

Page 13

4.1.1.2 EC100 Electronics

The EC100 electronics module (FIGURE 4-2) controls the EC155 and

CSAT3A. It is housed in its own enclosure and must be mounted within 3 m

of the sensors.

CPEC200 Closed-Path Eddy-Covariance System

FIGURE 4-2. EC100 electronics module

4.1.1.3 CPEC200 Enclosure

The CPEC200 enclosure (FIGURE 4-3) houses the CR3000 datalogger, control

electronics, the optional valve module, and communications and power

terminals. Several options for mounting to a tower, tripod, or large diameter

pole can be specified when ordering the system.

FIGURE 4-3. CPEC200 system enclosure

3

Page 14

CPEC200 Closed-Path Eddy-Covariance System

4.1.1.4 CPEC200 Pump Module

The pump module (FIGURE 4-4) uses a small, low-power diaphragm pump to

draw air through the EC155 sample cell. The pumping speed is automatically

controlled to maintain the volumetric flow at the setpoint (3 to 7 LPM). The

pump module is temperature controlled to keep the pump in its operating

temperature range of 0°C to 55°C. The pump module includes a large-capacity

filter to protect the pump from contamination and dampen pressure fluctuations

in the sample cell that are caused by the pump.

FIGURE 4-4. CPEC200 pump module

4.1.2 Optional Components

4.1.2.1 CR3000 Datalogger

The CR3000 datalogger (FIGURE 4-5) is housed in the CPEC200 enclosure.

The CR3000 executes and stores measurements from all sensors. It calculates

online flux measurements, and stores both raw and processed data. Although

the CR3000 is a required component, the CPEC200 can be purchased without

the CR3000. However, the user must supply a CR3000 with the low-profile

base option.

4

Page 15

FIGURE 4-5. CR3000 datalogger

4.1.2.2 NL115 or CFM100 Storage Module

The datalogger saves data onto a CompactFlash® (CF) memory card (FIGURE

4-7) via an optional NL115 or CFM100 card module (FIGURE 4-6). Either

module will provide data storage. The NL115 has the added capabilities that

are available with the Ethernet interface.

CPEC200 Closed-Path Eddy-Covariance System

FIGURE 4-6. NL115 (left) and CFM100 (right)

The CPEC200 can be ordered with either of the storage modules factory

installed. If the CPEC200 is ordered without a storage module, the user must

provide one. The CF card (FIGURE 4-7) can be ordered separately from

www.campbellsci.com. For details, see the CFM100 CompactFlash® Module

Instruction Manual or the NL115 Ethernet and CompactFlash® Module

Instruction Manual, and the Application Note 3SM-F, PC/CF Card

Information. All manuals are available at www.campbellsci.com.

FIGURE 4-7. CFMC2G 2GB CompactFlash® memory card

5

Page 16

CPEC200 Closed-Path Eddy-Covariance System

NOTE

4.1.2.3 CPEC200 Valve Module

The optional CPEC200 valve module (FIGURE 4-8) is housed in the CPEC200

enclosure and is used to automate zero and CO

perform a field zero and field CO

span requires a dewpoint generator and cannot be automated because the

dewpoint generator is a laboratory instrument. Therefore, H

performed manually.

The CPEC200 valve module is available in two versions, one with three valves

(pn 27559) and another with six valves (pn 26578). The valve module is

normally ordered as a factory-installed option of the CPEC200, but the module

can also be ordered separately and installed by the user.

span checks, and automatically

2

span on a user-defined interval. Field H2O

2

O spans must be

2

FIGURE 4-8. CPEC200 valve module

4.1.2.4 CSAT3A Sonic Anemometer Head

The CSAT3A (FIGURE 4-9) is Campbell’s 3D sonic anemometer sensor head.

It shares integrated electronics (EC100 electronics) with the EC155 gas

analyzer. For detailed information and specifications, see the CSAT3 manual.

Campbell’s standalone sonic anemometer, the CSAT3, has its own

electronics box, whereas the CSAT3A shares the EC100

electronics with the EC155 gas analyzer. The measurement

specifications for the CSAT3 and CSAT3A are the same.

6

Page 17

4.1.2.5 Barometer

CPEC200 Closed-Path Eddy-Covariance System

FIGURE 4-9. CSAT3A sonic anemometer head

4.1.2.6 Carrying Cases

The EC100 is always configured with an EC100 basic barometer. However, an

EC100 enhanced barometer is available as an option. The decision to upgrade

to the enhanced barometer is largely dependent on the specific site and

environmental constraints for a given site. In general, the enhanced barometer

provides overall greater accuracy, but may not be a necessary upgrade for

many applications.

Unlike open-path systems, the accuracy of the CPEC200 system is influenced

by the sample cell pressure. The EC155 sample cell pressure is measured by a

differential pressure sensor that measures the sample cell pressure relative to

barometric pressure (as measured by the EC100 barometer). The accuracy of

the sample cell pressure measurement is the sum of the accuracy of the

barometer in the EC100 and the differential pressure sensor in the EC155.

The measurement rate is likewise affected by both the sample cell pressure and

the specific barometric pressure of the barometer – either basic or enhanced.

The differential pressure sensor is always measured at 10 Hz, while the basic

barometer is measured at 10 Hz and the enhanced barometer is measured at 1

Hz.

For greater detail, see Section 4.3, Specifications, of this manual or consult a

Campbell Scientific applications engineer for specific sites and applications.

The EC155 and the CSAT3A may be ordered with optional carrying cases. If

the carrying cases are not ordered, the sensors are shipped in cardboard boxes.

4.1.2.7 Enclosure Mounting Options

The CPEC200 system enclosure and the CPEC200 pump module can be

configured with one of several mounting options. The CPEC system enclosure

is similar to the Campbell Scientific ENC16/18 enclosure, and the CPEC200

7

Page 18

CPEC200 Closed-Path Eddy-Covariance System

NOTE

NOTE

pump module is similar to the ENC10/12 enclosure. The same mounting

options are available and outlined below:

• Triangular tower (UT10, UT20, or UT30)

• Tripod mast 3.8 cm (1.5 in) to 4.8cm (1.9 in) diameter

• Tripod leg (CM106 or CM106K tripod only)

• Large pole 10.2 cm (4.0 in) to 25.4 cm (10.0 in) diameter

• No mounting bracket

Consult the ENC10/12, ENC12/14, ENC14/16, ENC16/18 Instruction Manual,

available at www.campbellsci.com, for details on mounting bracket options.

4.1.3 Common Accessories

There are several items that may be required to complete the installation, but

are not included in the CPEC200. Some of the more common accessories are:

System Power Cable: Two power cables are required for the CPEC200; one

for the main CPEC200 system and one for the EC100 electronics.

The preferred power cable, CABLEPCBL-L, consists of a twisted red/black

pair of wire gauge (AWG) 16 within a rugged Santoprene™ jacket. It is cut to

the specified length and the end is finished for easy installation.

The “-L” designation after certain parts designates a cable or tube

length in feet. The length is specified by the user at the time of

order.

SDM Cable: An SDM communication cable is required to connect the EC100

to the CPEC200 system enclosure. The preferred SDM cable is CABLE4CBLL. This cable consists of four conductors with a shield and drain wire, and a

rugged Santoprene™ jacket. It is cut to the specified length and the end is

finished for easy installation.

Pump Tube: A tube must be used to connect the EC155 to the pump module.

If the EC155 is within 50 ft of the pump module, 3/8-in OD tubing, such as pn

26506, is recommended. For longer distances (up to 500 ft), a larger 1/2-in OD

tube (pn 25539) is recommended to minimize pressure drop in the tube. Preswaged pump tube assemblies, such as pn 26504-L, 3/8-in OD, or pn 26503-L,

1/2-in OD, are available for this purpose.

The fittings on the EC155 and the pump module are sized for 3/8in OD tubing. A reducer is required at each end for the larger

tubing size. These reducers are supplied as part of the pre-swaged

tube assembly.

Zero/span tubes: Tubes must be used to connect the EC155 and the zero and

span cylinders to the valve module. Bulk tubing may be cut to length and

CO

2

installed onsite using pn 15702 or its equivalent. This tubing has a 1/4-in OD

to fit the Swagelok

®

fittings on the EC155 and the valve module. The tubing

has an aluminum core to minimize diffusion through the tubing wall and a UVresistant, black, high-density polyethylene jacket. Maximum tubing length

available is a 500-ft roll.

8

Page 19

CPEC200 Closed-Path Eddy-Covariance System

Minimize the length of these tubes to reduce the amount of equilibration time

required after the zero or CO

span cylinder is selected. One long tube is

2

required to connect the valve module to the EC155, and two short tubes are

required to connect the zero and CO

span cylinders to the valve module. Pre-

2

swaged tube assemblies (pn 21823-L) are available for this purpose.

CPEC200 Scrub Module: The CPEC200 scrub module (pn 27423) provides

a source of zero air and is used for zeroing the EC155. It consists of a pump

and a three-stage molecular sieve and connects to the CPEC200 system

enclosure. The scrub module (shown in FIGURE 4-10) eliminates the need for

a cylinder of zero air. A cylinder of known CO

is still required. The module

2

reduces the need for one of the two cylinders for zero/span and is useful in

locations where transporting and replacing cylinders is inconvenient.

Additional information regarding installation and maintenance of the CPEC200

scrub module can be found in Appendix G, CPEC200 Scrub Module

Installation, Operation and Maintenance.

FIGURE 4-10. CPEC200 scrub module

AC/DC Power Adapter Kit: An AC/DC adapter kit (pn 28549) can be

configured within the CPEC200 system enclosure with a peripheral mounting

kit (pn 16987). This configuration allows the CPEC200 to be powered from

AC mains power. See Appendix F, Installing the AC/DC Power Adapter Kit,

for more information.

CF Card: The CPEC200 stores data on a CompactFlash® memory card.

There are two types of CF cards available today: industrial grade and standard

or commercial grade. Industrial grade PC/CF cards are certified to a higher

standard in that they are designed to operate over a wider temperature range,

offer better vibration and shock resistance, and have faster read/write times

than their commercial counterparts. Campbell Scientific recommends the use

of industrial-grade cards, such as the CFMC2G or CFMC16G (FIGURE 4-7)

9

Page 20

CPEC200 Closed-Path Eddy-Covariance System

available from Campbell Scientific. For more details about this card, see

Application Note 3SM-F, PC/CF Card Information, available from

www.campbellsci.com.

USB Memory Card Reader/Writer: The USB memory card reader/writer

(pn 17752) is shown in FIGURE 4-11. It is a single-slot, high-speed

reader/writer that allows a computer to read a memory card. When used with

Campbell Scientific equipment, the 17752 typically reads data stored on

CompactFlash® cards, but it can read many different types of memory cards.

FIGURE 4-11. 17752 USB memory card reader/writer

4.1.4 Support Software

There are several software products available for interfacing a PC to the

CPEC200’s datalogger.

PC200W: PC200W is a free, starter software package that provides basic

tools such as clock set, program download, monitor data, retrieve data, etc.

PC200W supports direct connections between PC and datalogger but has no

telecommunications or scheduled data-collection support.

PC400: PC400 is a mid-level software package that supports a variety of

telecommunication options, manual data collection, data display, and includes

a full-featured CRBasic program editor. PC400 does not support combined

communication options (for example, phone-to-RF), PakBus® routing, or

scheduled data collection.

LoggerNet: LoggerNet is a full-featured software package that supports

programming, communication, and data collection and display. LoggerNet

consists of a server application and several client applications integrated into a

single product. This package is recommended for applications that require

telecommunications support, scheduled data retrieval, or for large datalogger

networks.

LoggerLink Mobile Apps: The LoggerLink Mobile Apps allows an iOS or

Android device to communicate with an IP-enabled datalogger such as the

CR3000. The apps support field maintenance tasks such as viewing and

collecting data, setting the clock, and downloading programs.

10

Page 21

4.1.5 Replacement Parts

Intake Filter: The EC155 intake filter (FIGURE 4-12) will become clogged

over time and must be replaced. The default replacement part is pn 26072. It is

a 2.5-cm (1.0-in) diameter, sintered stainless steel disk filter with a 20 µm pore

size encased in a molded Santoprene™ shell. An alternative 40 µm filter (pn

28698) is also available. Use a 40 µm filter if the default 20 µm filter clogs

long before the EC155 optical windows become dirty.

FIGURE 4-12. Intake filter of EC155

Sonic Wicks: A sonic wicks spares kit (pn 28902) is used to replace the wicks

on the CSAT3A. The kit includes three top wicks, three bottom wicks, an

installation tool, and adhesive.

CPEC200 Closed-Path Eddy-Covariance System

Silica Desiccant Bags: Silica desiccant bags (FIGURE 4-13) are used to

desiccate the CPEC200 system enclosure and should be periodically replaced.

A single four-unit silica desiccant bag is pn 4905. These can be purchased in

quantities of 20 as pn 6714.

FIGURE 4-13. Single desiccant pack

Humidity Indicator Card: The replacement humidity indicator card

(FIGURE 4-14) provides a visual reference of humidity level inside the

enclosure. A single replacement card is pn 28878.

11

Page 22

CPEC200 Closed-Path Eddy-Covariance System

FIGURE 4-14. Humidity indicator card

EC155 Replacement Chemical Bottles: The EC155 has two small bottles

filled with chemicals to remove CO

sensor head. If replacement bottles are needed, two bottles are included with

pn 26511.

and water vapor from the inside of the

2

Diaphragm Pump: The pump module for the CPEC200 includes a small

double-head diaphragm pump with a brushless DC motor. The pump includes

a speed-control input and a tachometer to measure actual pumping speed. It is

mounted in an insulated, temperature-controlled box inside the CPEC200

system enclosure. If the pump fails, the replacement pump (FIGURE 4-15) is

available as pn 26402. The part includes the connector for easy installation.

See Appendix H, CPEC200 Pump Replacement, for instructions on replacing

the pump.

12

FIGURE 4-15. Diaphragm pump used in CPEC200

Page 23

4.2 Theory of Operation

The CPEC200 is used for long-term monitoring of atmosphere–biosphere

exchanges of carbon dioxide, water vapor, heat, and momentum. This

complete, turn-key system includes a closed-path gas analyzer (EC155), a

sonic anemometer head (CSAT3A), datalogger (CR3000), sample pump, and

an optional valve module for automated zero and span.

4.2.1 EC155 Gas Analyzer

The EC155 (FIGURE 4-16) is Campbell Scientific’s closed-path, mid-infrared

absorption gas analyzer that measures molar mixing ratios of carbon dioxide

and water vapor. More information about the operation of the EC155 can be

found in the manual, EC155 CO

www.campbellsci.com.

CPEC200 Closed-Path Eddy-Covariance System

and H2O Closed-path Gas Analyzer at

2

FIGURE 4-16. EC155 gas analyzer

13

Page 24

CPEC200 Closed-Path Eddy-Covariance System

4.2.2 CSAT3A Sonic Anemometer Head

The CSAT3A, as shown in FIGURE 4-17, is an ultrasonic anemometer sensor

head for measuring wind speed in three dimensions. It shares integrated

electronics, the EC100 electronics, with the EC155 gas analyzer. It is similar

to the sensor head for the CSAT3 sonic anemometer, with the primary

difference being that the CSAT3 can be used as a standalone anemometer

because it includes independent electronics. The CSAT3A uses three

nonorthogonal pairs of transducers to sense the wind velocity vector. Each pair

of transducers transmits and receives ultrasonic pulses to determine the time of

flight, which is directly related to the speed of sound and the wind speed along

the line between the pair of transducers. The CSAT3A transforms the results

into orthogonal wind components u

head.

The CSAT3A also determines the speed of sound for each transducer pair.

These measurements are averaged and converted to sonic virtual temperature

) based on the relationship between speed of sound and air temperature. For

(T

s

more detailed information and specifications, see the CSAT3 manual.

, uy, and uz, referenced to the anemometer

x

14

FIGURE 4-17. CSAT3A sonic anemometer head

4.2.3 Valve Module

The optional valve module, shown in FIGURE 4-8, is housed in the CPEC200

enclosure and is used to automate zero and CO

perform a zero and CO

Section 4.1.2.3, CPEC200 Valve Module, H

generator and cannot be automated.

The CPEC200 valve module is available in two versions, one with three valves

(pn 27559) and another with six valves (pn 26578). The valve module is

normally ordered as a factory-installed option, but can also be ordered

separately and installed by the user.

span checks, and automatically

2

span on a user-defined interval. As described in

2

O span requires a dewpoint

2

Page 25

CPEC200 Closed-Path Eddy-Covariance System

For the three-valve version, the inputs are:

• Zero

• CO

• H

Span 1

2

O Span

2

For the six-valve version, the inputs are:

• Zero

• CO

• CO

• CO

• CO

• H

Span 1

2

Span 2

2

Span 3

2

Span 4

2

O Span

2

The CPEC200’s zero and CO

that they flow only when selected. This allows the zero and CO

span inlets are not bypass equipped, meaning

2

span tanks to

2

be continuously connected for automatic, unattended operation.

The H

O Span input is bypassed (vented to the atmosphere through the H2O

2

Span Bypass outlet) when it is not selected, so it permits flow all the time.

This allows a dewpoint generator to be connected directly to the H

O Span

2

inlet. The dewpoint generator’s internal pump can push flow into the valve

module even when the H

caused by pressurization inside the dewpoint generator. When the H

O Span valve is not selected, minimizing errors

2

O Span

2

valve is selected, the dewpoint generator pushes moist air through the valve

module to the EC155.

The CPEC200 pushes the zero/span flow backward through the EC155 sample

cell and exhausts it through the intake tube to the atmosphere. Flow through

the intake tube causes the sample-cell pressure to rise slightly above ambient

pressure. The CPEC200 infers the flow rate from this pressure rise. The

EC155 has a differential pressure sensor to measure this pressure rise directly,

but its accuracy is affected by a small offset drift. The accuracy of this

differential pressure measurement can be improved by stopping all flow

through the EC155, allowing the pressure in the sample cell to equilibrate with

ambient pressure, and measuring the differential pressure offset. This offset is

then subtracted from subsequent measurements used to control the flow.

Because the pressure sensor offset can change over time, this offset is

measured at the beginning of every zero/span cycle. This step requires at least

10 seconds to complete; 5 seconds for the pressure to equilibrate, and 5

seconds to average and store the differential pressure measurement.

Either of the CPEC200 valve modules have a proportional control valve to

actively control the flow of zero and span gas to the EC155. The CPEC200

program adjusts public variable valveControl between 0 (closed) and 1 (fully

open) as needed for the measured flow valve_flow to reach the desired flow, as

indicated by CAL_FLOW_SETPT. The default value for

CAL_FLOW_SETPT is 1.0 LPM. This flow is adequate for lower

measurement heights (allowing a shorter tube between the valve module and

the EC155), but setting a higher flow rate may be required with long zero/span

delivery tubes used on tall towers. The proportional valve is opened fully

during an H

O span operation to prevent pressurizing the dewpoint generator.

2

15

Page 26

CPEC200 Closed-Path Eddy-Covariance System

The CPEC200 valve module includes a heater and a fan to keep the valves

within their operating range of 0°C to 60°C. The valve heater turns on/off at

2°C. The valve fan turns on at 50°C and stays on until the valve temperature

drops to 48°C. To conserve power, temperature control is active just prior to

and during the time when valves are in use. If the valves cannot be maintained

within the temperature range, the valves are disabled. The valve module

temperature control can be manually activated so that manual zero/span can be

performed by the station operator on site or remotely. If starting from the

minimum ambient temperature (–30°C), the valves may take as much as 15

min to warm up to the operating range of 0°C to 60°C.

4.2.4 Pump Module

The CPEC200 pump module pulls air through the system and exhausts it

through the Exhaust fitting on the bottom of the enclosure. It uses a small

double-head diaphragm pump with a brushless DC motor. This pump includes

a speed control input and a tachometer to measure the actual pumping speed. It

is mounted in an insulated, temperature-controlled box located inside the

weather-tight fiberglass enclosure. The pump module includes a large filter

cartridge to dampen the pressure fluctuations from the pump and to protect the

pump from particulates or debris.

If the pump fails, the replacement pump is available as pn 26402 (see Section

4.1.5, Replacement Parts). See Appendix H, CPEC200 Pump Replacement,

for instructions on replacing the pump. The filter cartridge in the pump module

is unlikely to clog over the lifetime of the CPEC200 system.

The following sections describe operating parameters of the pump.

Pump Speed: The pump tachometer is measured, converted to volumetric

flow rate, and reported in public variable pump_flow. The CPEC200 sets the

value of public variable pump_control to a value between 0 (off) and 1 (full

speed) to adjust the pump’s speed as needed to match pump_flow to the

setpoint flow PUMP_SETPT. PUMP_SETPT is a system configuration

variable (see Section 5.4.1, System Configuration Variables).

Pump Inlet Pressure: The measured inlet pressure of the pump is reported in

public variable pump_press. This pressure will normally be slightly lower (~1

kPa) than the EC155 sample cell pressure due to the pressure drop in the pump

tube.

Pump Temperature: The temperature of the pump module is reported in

public variable pump_tmpr. The operating range of the pump is 0°C to 55°C.

If the pump temperature is outside this range, the CPEC200 will disable the

pump. The pump module has a heater (drawing 8 W while operational) that

turns on if the pump temperature falls below 2°C. If the CPEC200 is started at

cold temperature, it may take up to 50 minutes to warm the pump module

(from –30°C to 0°C). When it reaches 2°C the heater will cycle on/off as

needed to maintain this temperature.

The pump module has a fan (drawing 0.7 W while operational) that turns on if

the pump temperature rises above 50°C. The fan will stay on until the pump

temperature falls below 45°C.

16

Page 27

The outlet of the pump connects the Exhaust fitting on the bottom of the pump

module enclosure. This fitting has a screen to prevent insects or debris from

entering when the pump is off.

4.3 Specifications

System

Operating temperature: –30° to +50°C

Input voltage: 10.5 to 16.0 Vdc

Power: 12 W (typical), 35 W (max, at cold startup)

System enclosure

Dimensions: 52.1 x 44.5 x 29.7 cm (20.5 x 17.5 x 11.7 in)

Weight basic system: 11.6 kg (25.5 lb)

CR3000: 1.6 kg (3.7 lb)

CFM100/NL115: 0.2 kg (0.4 lb)

Three-valve module: 1.5 kg (3.3 lb)

Six-valve module: 1.9 kg (4.2 lb)

Pump module

Cable length: 3.0 m (10 ft)

Inlet connection: 3/8-in Swagelok

Pressure sensor range: 15 to 115 kPa

Pumping speed: 3 to 9 LPM (automatically controlled at the

Dimensions: 35.6 x 29.2 x 13.5 cm (14.0 x 11.5 x 5.3 in)

Weight w/ out mounting: 5.4 kg (11.8 lb)

CPEC200 Closed-Path Eddy-Covariance System

®

set-point, typically 7 LPM)

5. Installation

Valve module

Flow rate: 1 to 5 LPM (automatically controlled at the

set-point, typically 1 LPM)

Inlets

Three-valve module: Zero, CO

Six-valve module: Zero, CO

Outlets: Analyzer and H

Connections: 1/4-in Swagelok

span, and H2O span

2

spans 1 through 4, and H2O span

2

O bypass

2

®

Dimensions: 14.0 x 12.7 x 14.0 cm (5.5 x 5.0 x 5.5 in.)

Weight

Three-valve module: 1.5 kg (3.3 lb)

Six-valve module: 1.9 kg (4.2 lb)

EC155 and CSAT3A Specifications: see the user manual: EC155 CO

O Closed-path Gas Analyzer Manual and CSAT3 Three Dimensional Sonic

H

2

and

2

Anemometer Manual

The following tools are required to install the CPEC200 system in the field.

Additional tools may be required for a user-supplied tripod or tower.

• 9/16-in, open-end wrench

• 1/2-in, open-end wrench

• 11/16-in, open-end wrench

• Adjustable wrench

17

Page 28

CPEC200 Closed-Path Eddy-Covariance System

NOTE

• Small, flat-tip screwdriver (included with EC100 and CPEC200)

• Large, flat-tip screwdriver (included with EC100)

• Sledgehammer (to drive grounding rod into the ground)

• 3/16-in hex-key wrench (included with CM250 leveling mount)

5.1 Mounting

5.1.1 Support Structure

The CPEC200 system has four major components that must be mounted to a

user-provided support structure. The support structure itself is not included in

the CPEC200 so that it can be tailored to specific needs, but several options are

available. Contact a Campbell Scientific applications engineer for more

information on site-specific mounting options.

EC sensors (EC155 and CSAT3A): Mounted on a horizontal round pipe of

3.33 cm (1.31 in) outer diameter, such as the CM20X crossarm.

EC100 electronics: Mounted within 3.0 m (10 ft) of the EC sensors. The

EC100 mounting bracket will accommodate a pipe at any orientation, with

outer diameter from 2.5 cm to 4.8 cm (1.0 in to 1.9 in).

CPEC200 enclosure: Mounted where it can be accessed easily to retrieve data

from the CF cards on the datalogger. The CPEC200 enclosure is similar to the

ENC16/18, with the same mounting options (tower, tripod, leg, or pole).

CPEC200 pump module: Mounted within 3.0 m (10 ft) of the CPEC200

enclosure. The pump module enclosure is similar to the ENC10/12, with the

same mounting options (tower, tripod, leg, or pole).

Consult the ENC10/12, ENC12/14, ENC14/16, ENC16/18 Instruction Manual,

available at www.campbellsci.com, for details on mounting bracket options.

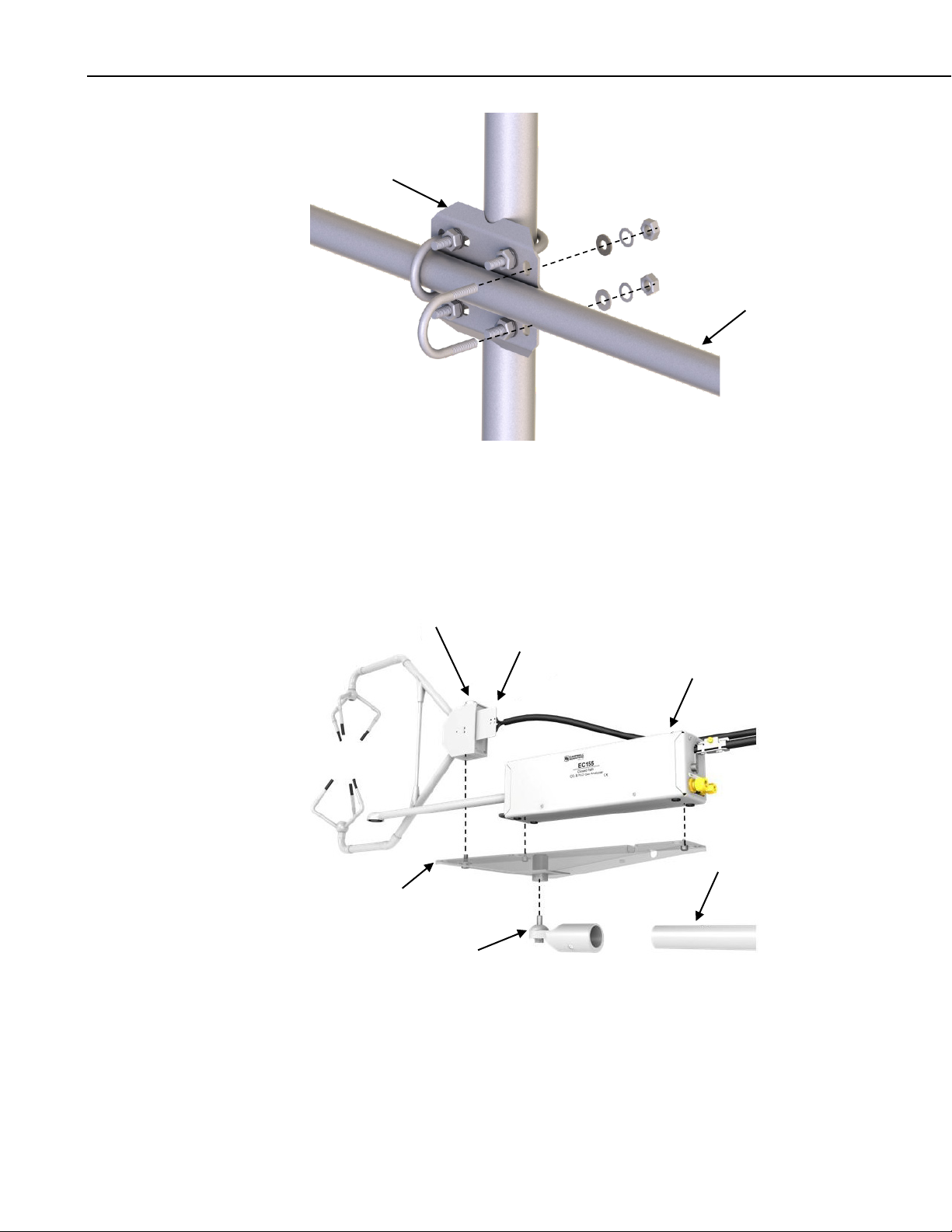

The following sections describe a typical application using a CM110 tripod and

CM202 crossarm. The CPEC200 enclosure and the CPEC200 pump module

are shown with the leg-mount options. The CM110 tripod and the leg

mounting options, shown in FIGURE 5-1, are ideal for a low EC measurement

height to minimize wind disturbance.

5.1.2 Mount Enclosures

Mount the EC100 electronics within 3.0 m (10 ft) of the EC sensors (this

measurement corresponds to the length of the cables on the EC155 and the

CSAT3A).

The EC100 should be mounted vertically to prevent water ingress

from precipitation.

The mounting bracket will accommodate a horizontal, vertical, or angled pipe

from 2.5 cm to 4.8 cm (1.0 in to 1.9 in) diameter. See the EC155 user manual

for details on configuring the EC100 mounting bracket. The EC100 electronics

are shown mounted on one leg of a CM110 tripod in FIGURE 5-1.

18

Mount the CPEC200 enclosure and the CPEC200 pump module within 3.0 m

(10 ft) distance. The enclosure and pump module are shown mounted back-to-

Page 29

CPEC200 Closed-Path Eddy-Covariance System

CPEC200 Enclosure

Pump Module

EC100

Electronics

back on the leg of a CM110 tripod in FIGURE 5-1, but they may also be

mounted on a vertical pipe, triangular tower, or large-diameter pole, depending

on the site requirements and the mounting options ordered.

FIGURE 5-1. CPEC200 enclosure, pump module, and EC100 mounted

to legs of CM110-series tripod

For the EC100 and the system enclosure, open the sealed bag containing the

desiccant packs and humidity card. Place two of the desiccant packs and the

humidity indicator card in the mesh pocket in the enclosure door. Reseal the

remaining two desiccant packs in the bag to use later.

5.1.3 Install EC Sensors

Install a horizontal mounting crossarm at the height desired for the EC

measurement. This crossarm must be within ±15 degrees of horizontal to level

the sonic anemometer. Point the crossarm into the predominant wind direction

to minimize wind disturbance caused by wind flowing past the mounting

structure and EC sensors. The outer diameter of the crossarm should be 3.3 cm

(1.3 in). The CM202 crossarm is shown in FIGURE 5-2.

19

Page 30

CPEC200 Closed-Path Eddy-Covariance System

CM202 Crossarm

CM210 Crossarm-to-

Leveling

Bubble

CSAT3A Sonic

Anemometer Head

EC155

Gas Analyzer

CM20X

Crossarm

CM250 Leveling

Mount

Mounting

Platform

Pole Bracket

FIGURE 5-2. CM210 mounting bracket on a tripod mast

The EC155 gas analyzer and CSAT3A sonic anemometer head are mounted on

the end of the crossarm using the CM250 leveling mount and the CPEC200

mounting platform, as shown in FIGURE 5-3. Adjust the tilt of the mounting

platform to level the CSAT3A. For more details see instructions in the EC155

and H2O Closed-path Gas Analyzer manual.

CO

2

20

FIGURE 5-3. Mounting of EC155 and CSAT3A

Page 31

5.2 Plumbing

NOTE

Zero Air Tubing

Pump Tubing

Pump Module Cable

CO2 Span Gas

Tubing

Analyzer Tubing

CPEC200 Closed-Path Eddy-Covariance System

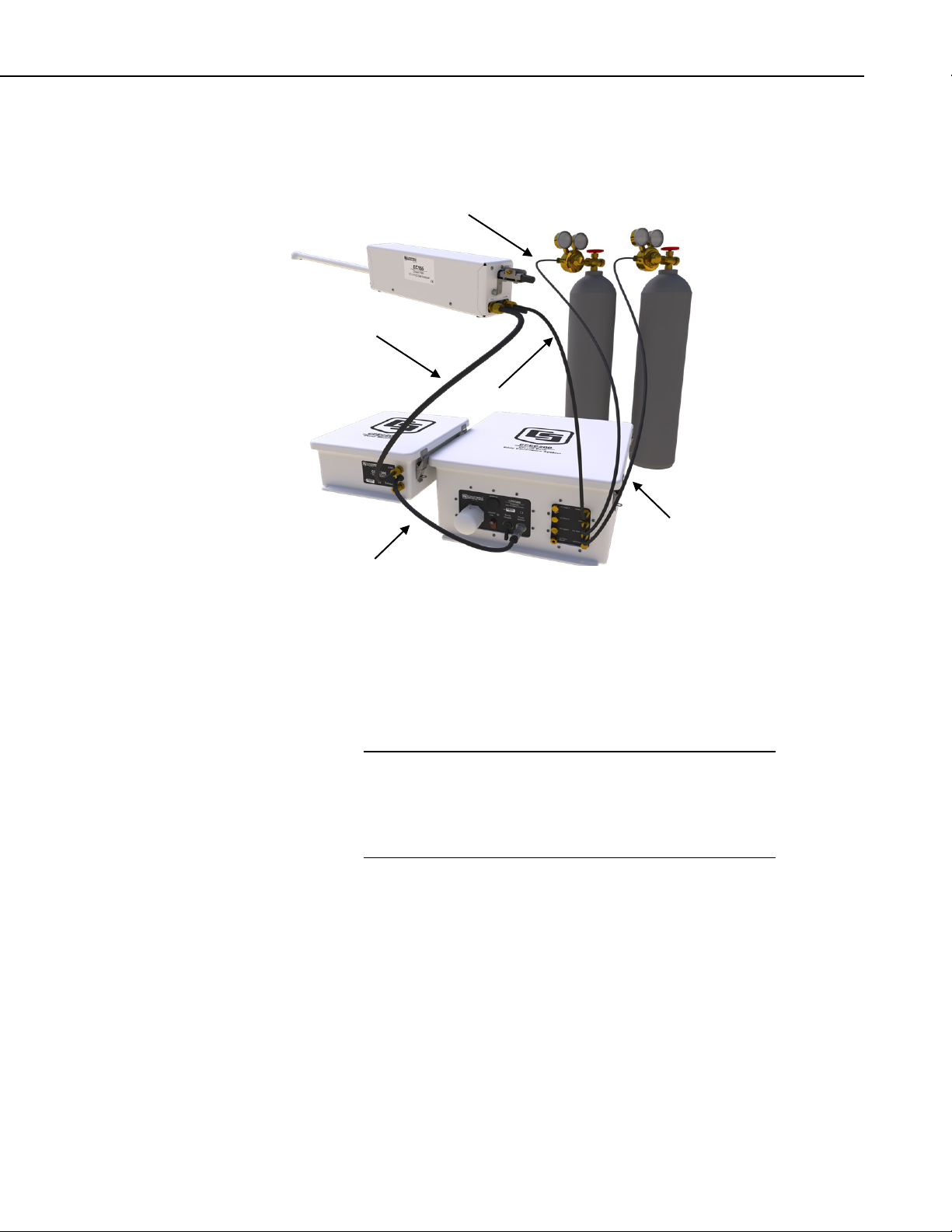

FIGURE 5-4 shows the basic plumbing configuration of a CPEC200 including

the cylinders required for zero and span operations.

FIGURE 5-4. Plumbing connections

5.2.1 Pump Module

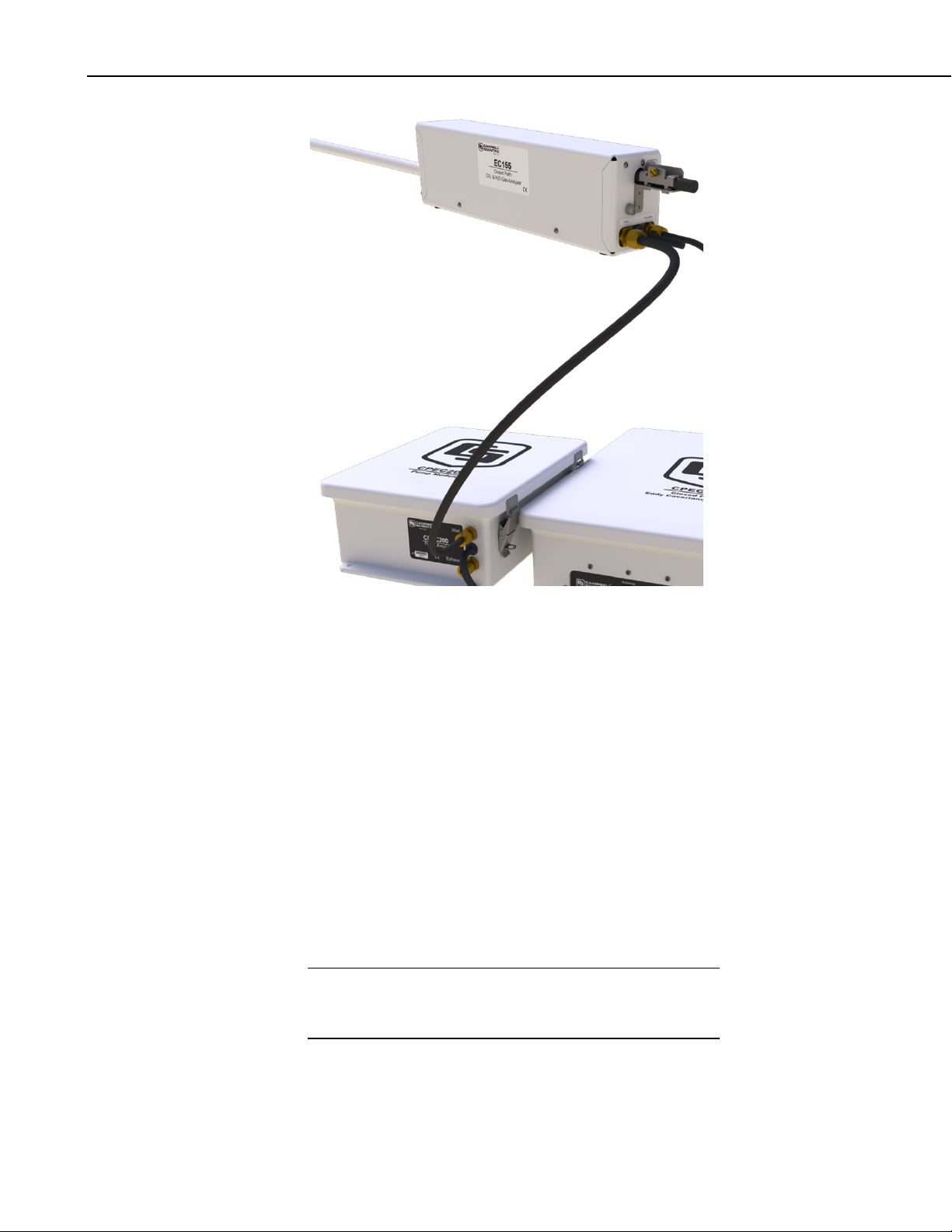

Connect the EC155 to the pump module, see FIGURE 5-5. If the EC155 is

within 15 m (50 ft) of the pump module, 3/8-in OD tubing, such as pn 26506,

is recommended. For longer distances of up to 150 m (500 ft), a 1/2-in OD

tube (pn 25539) is recommended to minimize pressure drop in the tube.

The fittings on the EC155 and the pump module are sized for 3/8in OD tubing. A reducer is required at each end for the larger

tubing size. Campbell Scientific supplies pre-swaged pump tube

assemblies pn 26503-L (1/2-in OD), with reducers at each end for

this purpose.

Connect one end of the pump tube to the fitting labeled Pump on the back of

the EC155 analyzer. Connect the other end to the fitting labeled Inlet on the

CPEC200 pump module as shown in FIGURE 5-5.

21

Page 32

CPEC200 Closed-Path Eddy-Covariance System

NOTE

5.2.2 Zero/Span

FIGURE 5-5. Connecting pump tube from EC155 analyzer to pump

module

The CPEC200 can perform automated zero (CO2 and H2O) and CO2 span of

the EC155. In most cases the user must supply cylinders of zero air and CO

2

span gas with appropriate regulators. If the user has chosen the optional

CPEC200 scrub module, then no cylinder of zero air is required. The rest of

this section assumes the use of cylinders of compressed gas, but see Appendix

G, CPEC Scrub Module Installation, Operation and Maintenance, for details

on the scrub module. Install cylinders in close proximity to the CPEC200

system enclosure. Each cylinder must have a pressure regulator to control the

outlet pressure at 10 psig and must have a 1/4-in Swagelok

®

fitting on the

outlet. Connect regulators to the valve module inlets using 1/4-in OD tubing,

such as pn 15702, or pre-swaged tube assemblies (pn 21823-L). Minimize the

length of these tubes to reduce the equilibration time after the zero or CO

®

cylinder is selected. Refer to Appendix E, Using Swagelok

®

information on installing and replacing Swagelok

fittings.

Fittings, for

span

2

Flow meters and needle valves are not needed because the

CPEC200 valve module has a proportional-control valve to

actively control the flow of zero and span gas to the EC155.

22

Page 33

CPEC200 Closed-Path Eddy-Covariance System

NOTE

NOTE

NOTE

NOTE

Make sure there are no leaks in the regulators or the connections

to the valve module. For automatic operation, the tank shutoff

valves are left continuously open. A plumbing leak could cause

the contents of the tank to be lost.

When inlets are not in use, replace the Swagelok® plugs to keep

the system clean.

Connect the valve module’s Analyzer outlet to the Zero/Span fitting on back

of the EC155 analyzer. Similar tubing (pn 15702) or pre-swaged tube

assembly (pn 21823-L) is recommended for this connection. The length of this

tube should also be minimized to reduce equilibration time.

5.3 Wiring

If the CPEC200 has been configured with the six-valve module, additional CO

span cylinders may be connected to the additional CO

Span inlets on the valve

2

module.

Open the shutoff valves on the cylinders and set the pressure regulators for

10 ± 5 psig delivery pressure.

If you inadvertently adjust the pressure too high, you may need to

slightly loosen the tube fitting to bleed off the excess pressure.

Retighten the fitting when the proper setting is reached.

The H2O Span inlet is bypass equipped, allowing continuous flow. This inlet

can be connected directly to the output of a dewpoint generator. The bypass on

this inlet will avoid pressurizing the dewpoint generator.

Some systems, such as the AP200 CO2/H2O Atmospheric Profile

system, require a tee in the connection from the dewpoint

generator to bleed off excess flow and avoid pressurizing the

dewpoint generator. Do not use a tee to connect a dewpoint

generator to the CPEC200.

2

5.3.1 Ground Connections

The CPEC200 system enclosure and the EC100 electronics must be earth

grounded as illustrated in FIGURE 5-6. Ground the tripod and enclosures by

attaching heavy gage grounding wire (12 AWG minimum) to the grounding

lug found on the bottom of each enclosure. The other end of the wire should

be connected to earth ground through a grounding rod. For more details on

grounding, see the grounding section of the CR3000 Micrologger Operator’s

Manual.

23

Page 34

CPEC200 Closed-Path Eddy-Covariance System

EC155

EC155 Sample-cell Cable

CSAT3A Cable

FIGURE 5-6. Enclosure and tripod grounded to a copper-clad

grounding rod

5.3.2 EC Sensor Cables

Ensure the EC100 is not powered. Connect the EC155 gas analyzer head,

EC155 sample cell, and CSAT3A sonic anemometer head to the EC100

electronics. FIGURE 5-7 shows the electrical connections described in this

section. For more details see the EC155 CO

and H2O Closed-Path Gas

2

Analyzer Manual.

Analyzer Cable

24

FIGURE 5-7. EC155 electrical connections (mounting hardware not

shown)

Page 35

CPEC200 Closed-Path Eddy-Covariance System

TABLE 5-1. SDM Wiring

NOTE

NOTE

Wire the SDM communications cable (CABLE4CBL-L) between the EC100

and the CPEC200 enclosure as shown in FIGURE 5-8, FIGURE 5-9, and

FIGURE 5-10. TABLE 5-1 shows the color scheme of the SDM wires.

Description Wire Color EC100 CPEC200

SDM Data Green SDM-C1 SDM-C1

SDM Clock White SDM-C2 SDM-C2

SDM Enable Red SDM-C3 SDM-C3

Digital Ground Black Ground Ground

Shield Clear Ground Ground

To bring cables into the CPEC200 enclosure, remove the cap from

the cable feedthrough by loosening the thumbscrew and twisting

the cap while pulling it off.

To connect a wire to the DIN rail terminal blocks of the CPEC200

enclosure, insert a small screwdriver into the square hole to open

the spring-loaded contacts. Insert the wire into the corresponding

round hole and then remove the screwdriver. Gently tug the wire

to confirm it is secure.

Ensure the CPEC200 enclosure is not powered, and wire the power cable

(CABLEPCBL-L) from the EC100 electronics to the CPEC200 enclosure as

shown in FIGURE 5-8, FIGURE 5-9, and FIGURE 5-10.

Secure the SDM and power cables in the EC100 with a cable tie.

FIGURE 5-8. Wiring of power and communications

25

Page 36

CPEC200 Closed-Path Eddy-Covariance System

EC100 Power

Cable

EC100 SDM

Cable

Power Cable

to EC100

Power Cable to

+12Vdc

Power Supply (off)

SDM Cable to EC100

FIGURE 5-9. Wiring to EC100 electronics

26

FIGURE 5-10. Wiring to CPEC200 enclosure

Page 37

5.3.3 Pump Module Cable

NOTE

CAUTION

NOTE

NOTE

Ensure the CPEC200 system is not powered, and connect the pump module

cable to the bottom of the CPEC200 system enclosure.

5.3.4 Apply Power

The CPEC200 requires a 10.5 to 16.0 Vdc power source. Its average power

consumption is 12 W typical but will be slightly higher at cold temperatures,

especially at startup in cold weather. In typical remote applications the power

will be supplied from a user-provided 12 Vdc battery system charged with

solar panels. If AC mains power is available it may be convenient to use the

AC/DC power adapter (see Appendix F, Installing the AC/DC Power Adapter

Kit) for details.

Before applying power, verify all of the tubes and cables have

been connected according to the instructions above.

To reduce the risk of shorting the power supply, especially

when using batteries, connect the power cable to the

CPEC200 first and then connect the other end to the power

source. Carefully design any DC power source to ensure

uninterrupted power. If needed, contact a Campbell

Scientific applications engineer for assistance.

CPEC200 Closed-Path Eddy-Covariance System

Connect a power cable (CABLEPCBL-L) from the CPEC200 power terminals,

as shown in FIGURE 5-10, to a user-supplied, 12 Vdc power supply.

Relieve strain on the cables in the CPEC200, by using a cable tie to secure the

cables to the cable-tie loop on the plate next to the CPEC200 DIN rail.

Replace the cap on the CPEC200 enclosure feedthrough. Gently bend the

cables back as you slide the cap on and rotate the cap to minimize the space

around the cables. Tighten the thumbscrew to further relieve strain on the

cable. This will also minimize air infiltration and extend the life of the

enclosure desiccant packs.

In very humid conditions it may be helpful to seal the cable

feedthrough with plumber’s putty.

The CPEC200 stores energy in a capacitor to provide backup

power in the event power is interrupted. The capacitor will power

the datalogger for a few seconds allowing it to finish writing data

to the CF card and close the file to prevent loss of data or damage

to the CF card. Do not attach additional sensors or other devices

that are powered from the datalogger without consulting a

Campbell Scientific applications engineer.

27

Page 38

CPEC200 Closed-Path Eddy-Covariance System

NOTE

5.4 Configure the Program

A CR3000 datalogger program Cpec200_vx_x.cr3 is included with the

CPEC200 system. If the CPEC200 was ordered with the CR3000 factory

installed, the CPEC200 is shipped with the program installed. A copy of the

program is found on the CPEC200 Support CD (pn 26857) or can be

downloaded from www.campbellsci.com.

The CPEC200 program uses both constants and variables to customize the

behavior of the system for a particular installation. Constants are used for

parameters that must be determined when the program is compiled and

variables are used otherwise.

Constants are most easily modified using the CRBasic Editor, which is part of

the PC400 and LoggerNet datalogger support software packages. They may

also be edited with a simple text editor and uploaded to the datalogger using

PC200W, which may be downloaded from www.campbellsci.com. The

CPEC200 uses some constants as “compile switches” to define the state of the

system during compilation.

Variables may be edited while the program is running using either a keyboard

display or a PC connected through PC200W, PC400, or LoggerNet. Variables

that define the operational configuration of the system are defined as system

configuration variables. Any changes to these variables are automatically

saved in nonvolatile memory.

Modifications to the CPEC200 program (for example, to measure

additional sensors) are not recommended without first consulting

a Campbell Scientific applications engineer.

5.4.1 System Configuration Variables

Several special variables are used to configure the CPEC200. These variables

are included at the end of TABLE B-1 in Appendix B, Public Variables, and

are distinguished by all capital letters. They may be edited directly in the

public table or with the keypad display on the datalogger.

These variables are stored in the sys_conf_var.dat file so their values will be

saved and recalled if the program is recompiled. They are intended to be set

when a new system is installed but may be edited at any time. When a system

configuration variable is changed, the CPEC200 will write a message to the

message_log table and save the new values in sys_conf_var.dat. It will also

add a record to the config_history table. This section gives a brief description

of each of these variables and refers the reader to the appropriate section of the

user manual if a lengthy discussion is required.

BATT_LOWLIMIT:

If the supply voltage BattVolt falls below this value, the CPEC200 will set

BattVolt_OK = False and shut down as much of the system as possible until

the voltage recovers. BATT_LOWLIMIT must be 10.0 V to 15.0 V. The

default value for BATT_LOWLIMT is 10.0 V, which corresponds to 10.3 V

at the input terminal. This power-down feature is to protect the battery from

deep discharge cycles. The user should set BATT_LOWLIMIT as

appropriate to protect the battery. If AC main power and an AC/DC adapter

are used, the limit may be left at 10.0 V.

28

Page 39

CPEC200 Closed-Path Eddy-Covariance System

NOTE

NOTE

BATT_DEADBAND:

This variable, along with BATT_LOWLIMIT, determines when the

CPEC200 will restart after an automatic power shutdown. The CPEC200 will

not restart until the supply voltage BattVolt reaches at least

BATT_LOWLIMIT + BATT_DEADBAND. The purpose of the deadband

function (the gap between the shutdown voltage and the turn-on voltage) is to

protect the CPEC200 from repeated power cycles when the battery voltage is

very near the limit. BATT_DEADBAND must be between 0 and 10.0 V. The

default is 1.0 V.

SONIC_AZIMUTH:

The variable SONIC_AZIMUTH specifies the angle in degrees between true

north and the direction that the sonic anemometer is pointing. For example, if

the sonic anemometer is pointing due east, set SONIC_AZIMUTH to 90°. If

the sonic anemometer is pointing southwest, enter 225°, and so on.

SONIC_AZIMUTH is used to calculate wnd_dir_compass.

BANDWIDTH:

The CPEC200 program configures the EC155 bandwidth according to system

configuration variable BANDWIDTH. This variable may be set to any of the

valid settings: 5, 10, 12 (12.5 Hz), 20, or 25. The CPEC200 program will save

the updated setting in the configuration file, configure the EC100 electronics

and update the lag time.

The IRGA data will be invalid for up to one second after changing

the bandwidth as the EC100’s digital filter is reinitialized for the

new bandwidth setting.

The default setting is 20 (20 Hz bandwidth), which preserves all of the highfrequency fluctuations in the CO

and H2O measurements. If the raw time

2

series are processed to give spectra, the user generally should set

BANDWIDTH to 5 (5 Hz). This will filter the IRGA data to avoid aliased

response.

For more information, see the EC155 CO

and H2O Closed-Path Gas Analyzer

2

Manual available at www.campbellsci.com.

AMB_PRESS_NOMINAL:

This is a backup for when the differential pressure sensor is not used. If

USE_DIFF_PRESS = False, then the value entered here is used for the

ambient pressure in flux calculations. Otherwise the EC100 barometer (basic

or enhanced) is used, and this variable is ignored. See Section 4.1.2.5,

Barometer, for more discussion on the interaction between the EC100

barometer and the differential pressure sensor.

The EC100 always includes the EC100 basic barometer, but it

may be ordered with the optional EC100 enhanced barometer. The

EC100 is configured at the factory to use the enhanced barometer,

if ordered. Normally, the user will not have to change this setting.

If there is a need to check or change this setting, see the EC155

user manual.

29

Page 40

CPEC200 Closed-Path Eddy-Covariance System

PUMP_SETPT:

Variable PUMP_SETPT determines the volumetric flow rate at which the

pump will draw the air sample through the EC155 sample cell.

PUMP_SETPT must be 3 to 9. The default setting is 7.0 LPM. In tall tower

applications where decreased frequency response is acceptable, lowering the

flow rate may be desirable as it will prolong the life of the intake filter. This

may be particularly applicable if the site is dusty or if accessing instruments on

the tower is difficult. Decreasing the flow by a factor of two will generally

lead to a four-fold increase in filter lifetime.

CAL_INTERVAL:

This variable determines how often (given in minutes) the calibration

(zero/span) sequence will be run. It is ignored if CHECK_ZERO = False.

The minimum time is the output interval (30 min). The maximum time is

1,440 min, or once per day. The default is 1,440.

CAL_TIMEOFFSET:

This variable determines when the calibration (zero/span) sequence is started

within the CAL_INTERVAL time. If CAL_TIMEOFFSET = 0, the

calibration sequence will start at the start of the CAL_INTERVAL. Setting

this variable to a non-zero value will delay the start of the zero/span sequence

by the set number of minutes. CAL_TIMEOFFSET may be set to any value

from zero to CAL_INTERVAL. The default is 59, which will start the

zero/span sequence 59 minutes past midnight. This avoids starting the

zero/span sequence at midnight, when the datalogger has the extra processing

tasks associated with closing and opening files for the ts_data table. It starts

the sequence one minute before the end of an averaging period. The sequence

is generally longer than one minute, so the EC samples that are lost to the

zero/span sequence are split between two consecutive flux output intervals.

ZERO_TIME:

Determines the time (given in seconds) for the zero gas to flow while checking

the zero. ZERO_TIME must be 20 to 300. The default is 60, which should be

adequate for low measurement heights. For taller towers, increase the time as