Page 1

INSTRUCTION MANUAL

COM220 Telephone Modem

Copyright © 1997- 2014

Campbell Scientific, Inc.

Revision: 7/14

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Precautions

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND

TRIPODS, TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES,

ANTENNAS, ETC. FAILURE TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS,

TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS

INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS.

CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE

EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design

limits. Be familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com or

by telephoning 435-227-9000 (USA). You are responsible for conformance with governing codes and regulations, including safety

regulations, and the integrity and location of structures or land to which towers, tripods, and any attachments are attached. Installation

sites should be evaluated and approved by a qualified engineer. If questions or concerns arise regarding installation, use, or

maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and qualified engineer or electrician.

General

• Prior to performing site or installation work, obtain required approvals and permits. Comply

with all governing structure-height regulations, such as those of the FAA in the USA.

• Use only qualified personnel for installation, use, and maintenance of tripods and towers, and

any attachments to tripods and towers. The use of licensed and qualified contractors is

highly recommended.

• Read all applicable instructions carefully and understand procedures thoroughly before

beginning work.

• Wear a hardhat and eye protection, and take other appropriate safety precautions while

working on or around tripods and towers.

• Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take

reasonable precautions to secure tripod and tower sites from trespassers.

• Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

• You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are

installing, constructing, using, or maintaining, or a tool, stake, or anchor, come in contact

with overhead or underground utility lines.

• Maintain a distance of at least one-and-one-half times structure height, or 20 feet, or the

distance required by applicable law, whichever is greater, between overhead utility lines and

the structure (tripod, tower, attachments, or tools).

• Prior to performing site or installation work, inform all utility companies and have all

underground utilities marked.

• Comply with all electrical codes. Electrical equipment and related grounding devices should

be installed by a licensed and qualified electrician.

Elevated Work and Weather

• Exercise extreme caution when performing elevated work.

• Use appropriate equipment and safety practices.

• During installation and maintenance, keep tower and tripod sites clear of un-trained or non-

essential personnel. Take precautions to prevent elevated tools and objects from dropping.

• Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

• Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks,

frayed cables, loose cable clamps, cable tightness, etc. and take necessary corrective actions.

• Periodically (at least yearly) check electrical ground connections.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS,

THE CUSTOMER ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR

MAINTENANCE OF TRIPODS, TOWERS, OR ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS,

ENCLOSURES, ANTENNAS, ETC.

Page 6

Page 7

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

1.1 General Description ............................................................................. 1

1.2 Computer Requirements ...................................................................... 3

2. Specifications ............................................................. 3

3. Installation ................................................................... 3

3.1 Connecting to Datalogger .................................................................... 3

3.2 Connecting to Earth Ground ................................................................ 5

3.3 LoggerNet Setup .................................................................................. 6

3.4 Telephone to MD485 or Telephone to RF Systems ............................. 7

3.5 Telephone Service ................................................................................ 7

3.6 Connecting to a Surge Protector .......................................................... 8

4. Modem Settings .......................................................... 9

5. Troubleshooting........................................................ 10

Appendices

Changing COM220 Settings ................................... A-1

A.

A.1 DIP Switch Settings ........................................................................ A-1

A.2 Hayes AT Commands ..................................................................... A-2

A.3 Downloading a New Operating System to the COM220 ................ A-6

A.4 Program Examples .......................................................................... A-7

A.4.1 ModemCallback Example (for CR1000) ................................. A-7

A.4.2 DialModem Example (for CR1000) ........................................ A-8

A.4.3 P97 Instruction (for CR10X) ................................................... A-9

A.4.4 Example Programs for Data Callbacks via a CR1000

Datalogger Router .............................................................. A-11

B. CS I/O Connection .................................................. B-1

B.1 CS I/O 9-Pin Connection ................................................................. B-1

C. Theory of Operation ................................................ C-1

C.1 Theory of Operation ......................................................................... C-1

D. FCC Warning to Users of Class B Computing

Devices .................................................................. D-1

E. IC Information ......................................................... E-1

i

Page 8

Table of Contents

Figures

Tables

1-1. COM220 DIP switches. Five screws and outer cover must be

removed for access to DIP switches. ............................................... 1

1-2. COM220 .............................................................................................. 2

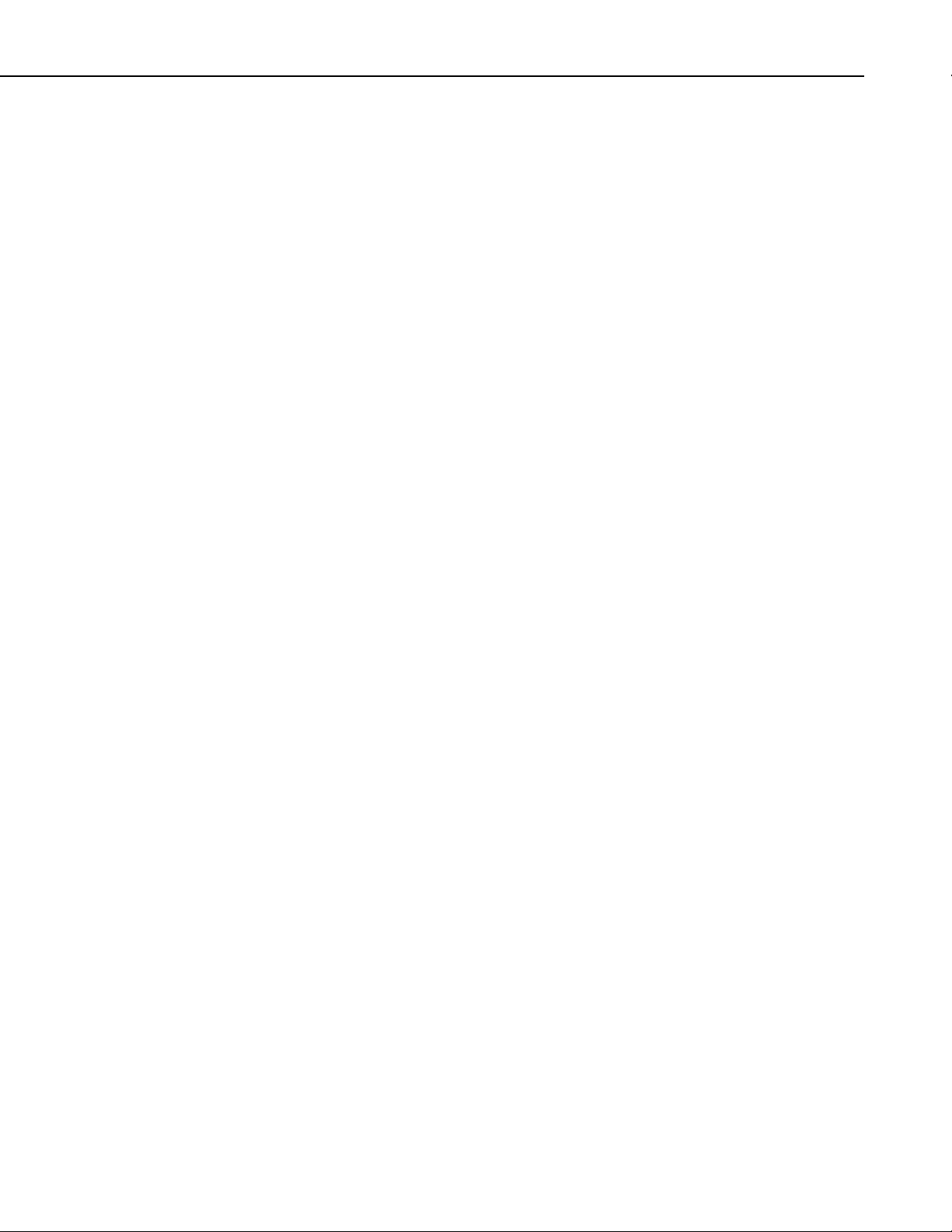

3-1. CR1000 and COM220 using remote telephone line ............................ 4

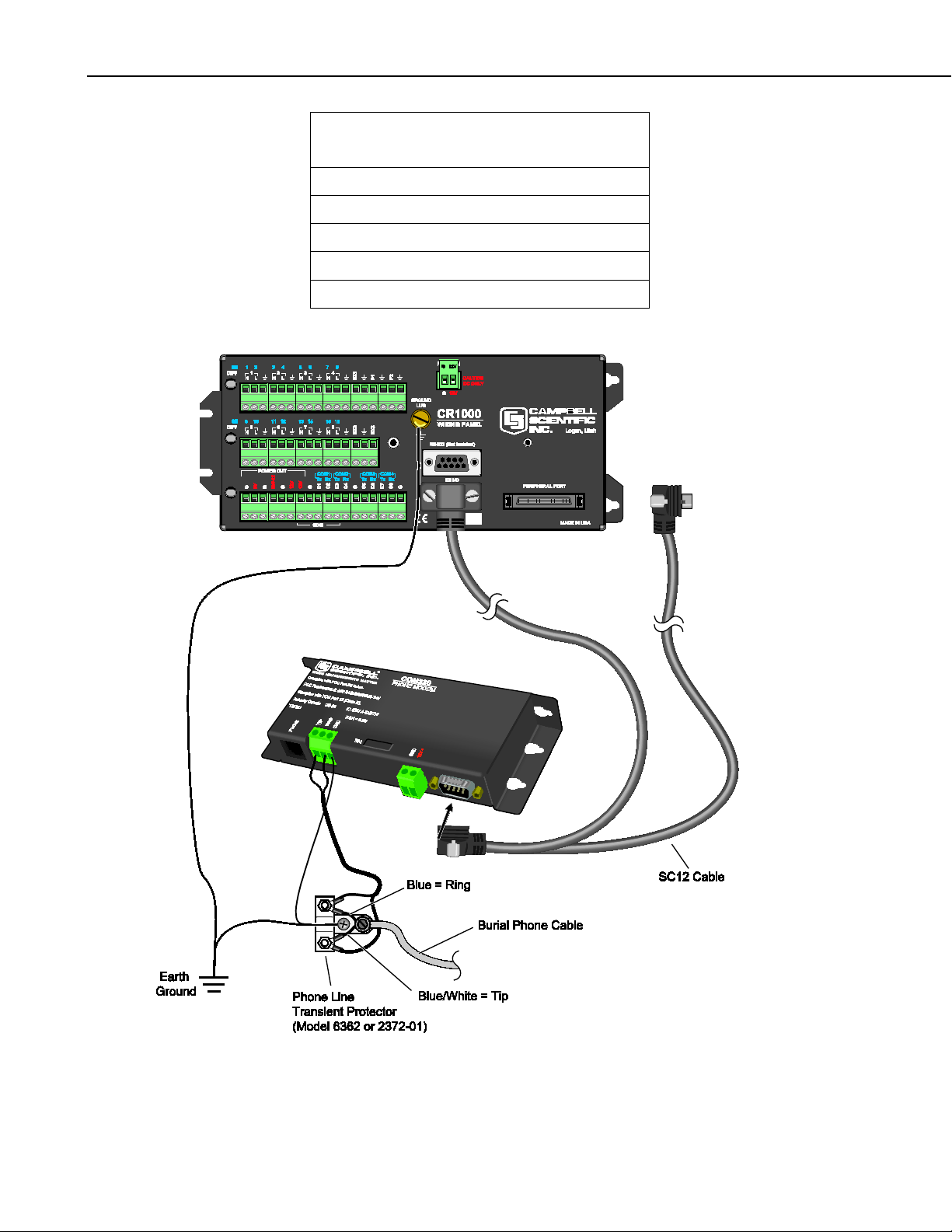

3-2. CR10X with CR10 wiring panel and COM220 using RJ11C

telephone jack .................................................................................. 5

3-3. Top view of surge-suppressor wiring .................................................. 8

3-4. Side view of surge-suppressor wiring ................................................. 9

A-1. COM220 to computer connection ................................................... A-3

A-2. Device Configuration screen ........................................................... A-4

A-3. Terminal Emulator screen in Device Configuration ........................ A-5

A-4. Send OS screen in Device Configuration ........................................ A-7

B-1. CS I/O pinout .................................................................................. B-1

1-1. Default DIP Switch Settings ................................................................ 2

3-1. Dataloggers that Require Direct 12-Vdc Connection to COM220 ...... 4

A-1. Selecting ME Baud Rates via DIP Switches 3 and 4 ....................... A-2

A-2. Maximum Datalogger ME Baud Rates ........................................... A-2

ii

Page 9

IMPORTANT

COM220 Telephone Modem

1. Introduction

1.1 General Description

The COM220 modem is a selectable-baud-rate modem employing the Hayes

AT command set. Its primary use is as a remote-site phone modem connected

to a CSI datalogger. The modem is powered and enabled by the batterypowered datalogger. When not active, the COM220 draws 100 to 120 µA from

the datalogger’s 12-Vdc output. During a call, it draws about 30 mA.

The COM220 is a replacement for the COM210. However, the COM220

supports both synchronous device communication (SDC) and modem enable

(ME) communication, as well as various ME baud rates (9600 to 115200). The

default setting for the COM220 at shipping is SDC7 (see Appendix A,

Changing COM220 Settings, for details).

The default settings ARE NOT compatible with dataloggers

that have non-PakBus operating systems (for example,

CR510, CR10X, CR23X, CR7, CR5000). However,

compatibility with non-PakBus dataloggers is easily

achieved by changing DIP switch settings (

you want to use the COM220 as a drop-in replacement for

the COM210, the COM220 settings should be changed to

modem enable (DIP switch 1 open) and 9600 baud (DIP

switches 3 and 4 open). Instructions for configuring the

COM220 are described in Appendix A

Settings.

, Changing COM220

FIGURE 1-1). If

FIGURE 1-1. COM220 DIP switches. Five screws and outer cover

must be removed for access to DIP switches.

1

Page 10

COM220 Telephone Modem

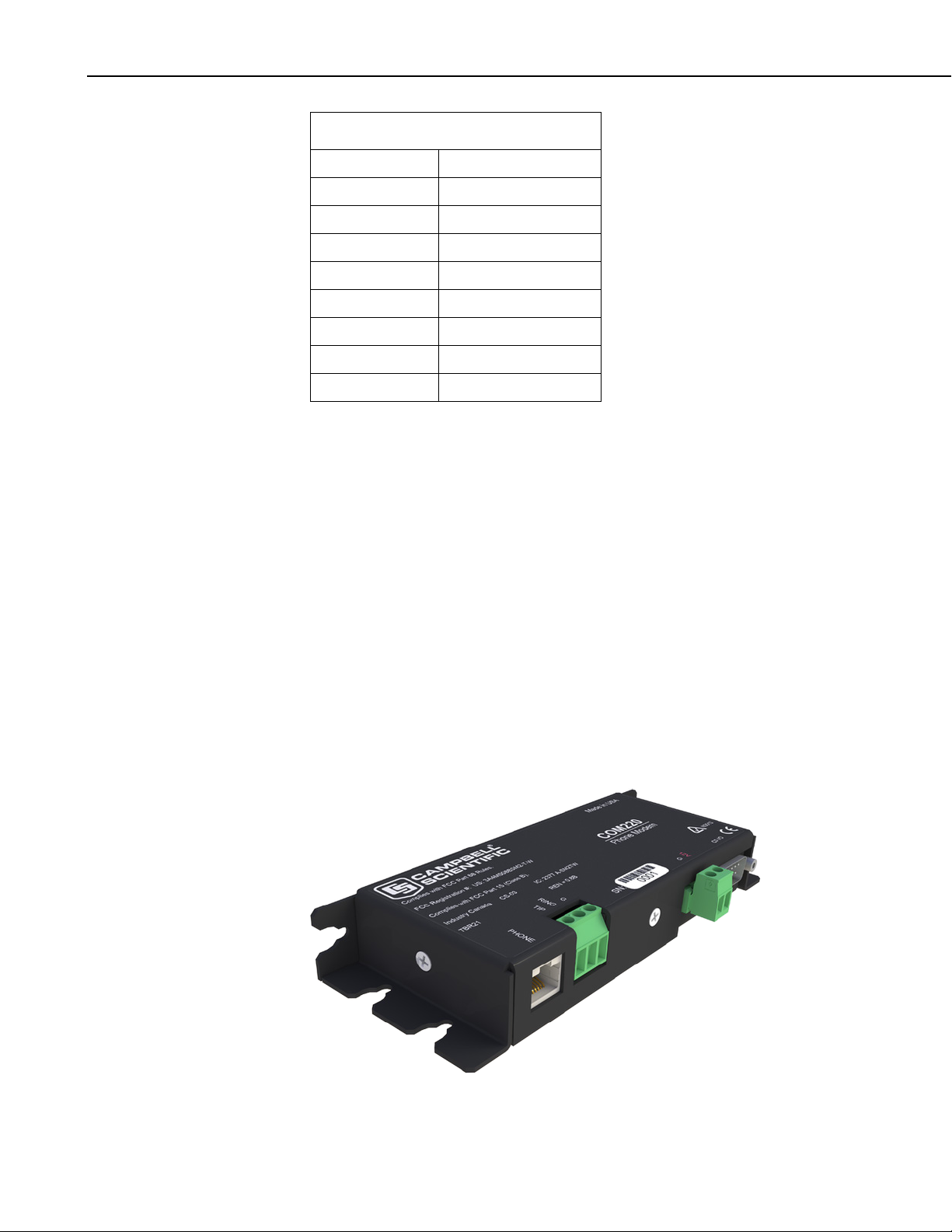

TABLE 1-1. Default DIP Switch Settings

DIP Switch Default Setting

1 Closed

2 Open

3 Closed

4 Closed

5 Open

6 Open

7 Open

8 Open

The COM220 is connected to a CSI datalogger by a 9-pin subminiature D

cable. This is the same 9-pin CS I/O interface common to all Campbell

Scientific dataloggers (except the CR200 series). This is not an RS-232

connection. Appendix B, CS I/O Connection, describes the CS I/O interface.

The COM220 can be used as an originate modem at the datalogger site. For

newer PakBus dataloggers (for example, CR800, CR1000, CR3000), use the

ModemCallback instruction or the DialSequence and DialModem instructions

to program the datalogger to originate a call to the computer. For non-PakBus

dataloggers (for example, CR510, CR10X, CR23X) and older PakBus

dataloggers (for example, CR10XPB, CR23XPB, CR510PB) use Instruction 97

to program the datalogger to originate a call to the computer. Refer to your

datalogger manual and LoggerNet Help files for detailed descriptions of these

instructions. In addition, Appendix A.4, Program Examples, includes sample

programs for the ModemCallback, DialModem, and P97 instructions.

The COM220 features a built-in speaker to allow monitoring of calling and

connection. See Appendix A.2, Hayes AT Commands, for the Hayes AT

commands that affect the speaker on/off and volume settings.

2

FIGURE 1-2. COM220

Page 11

1.2 Computer Requirements

A Hayes-compatible modem is used at the computer site with Campbell

Scientific computer software to call the datalogger attached to the COM220.

The computer’s modem must be configured to the proper settings using a set of

modem-initialization strings in the software program’s pick list.

2. Specifications

Standards: V.92, K56Flex, V.90, V.34, V.32bis, V32,

Registration: FCC US: 3A4M508BSM2-T-W

IC 2377 A-SM2TW

TBR21

Operating voltage: 12 Vdc

Current drain: 100 to 120 μA quiescent; 30 mA active

Communication rate between

datalogger and COM220: 9600, 38400, 57600, 115200 bps (selected

COM220 Telephone Modem

V23, V22bis, V22, V.21, B212, B103

by user)

3. Installation

3.1 Connecting to Datalogger

Operation: Full-duplex over standard, analog phone

lines

Operating temperature: –25° to +50°C std, –55° to +85°C optional

Dimensions: 16.5 x 2.5 x 6.6 cm (6.5 x 1.0 x 2.6 in)

Weight: 0.16 kg (0.35 lb)

The COM220 is designed to be used with standard, analog telephone lines. It

will not work with a digital telephone line. Connection to telephone companyprovided coin service (central office implemented systems) is prohibited.

Connection to party-line service is subject to state tariffs.

Connect the cable from the telephone RJ11C jack to the modem as shown in

FIGURE 3-2. If the telephone company has not installed surge protection in

the telephone line (no RJ11C jack), one must install surge protection (pn 6362

or 4330) and connect both the ring and tip terminal blocks as shown in

FIGURE 3-1.

Current Campbell Scientific dataloggers provide 12 Vdc to the COM220 from

the CS I/O port via the SC12 cable (FIGURE 1-2). Older dataloggers do not

provide 12 Vdc on their CS I/O port. When used with the older dataloggers

listed in TABLE 3-1, 12 Vdc and ground need to be connected via the green

power connector on the side of the COM220 (see FIGURE 3-2).

3

Page 12

COM220 Telephone Modem

TABLE 3-1. Dataloggers that Require Direct

12-Vdc Connection to COM220

CR10(X) with silver wiring panel

CR10(X) with black CR10 wiring panel (pn 8032)

21X(L) — serial number 13,442 or lower

CR500 serial number 1764 or lower

CR7, CR700X — serial number 2778 or lower

FIGURE 3-1. CR1000 and COM220 using remote telephone line

4

Page 13

COM220 Telephone Modem

CAUTION

14-AWG Ground Wire

Red

(+12V)

FIGURE 3-2. CR10X with CR10 wiring panel and COM220 using

RJ11C telephone jack

3.2 Connecting to Earth Ground

Connect the green 14-AWG grounding wire (provided with the COM220) to

the ground terminal (GND) on the COM220 and to the enclosure’s earth

ground connection. If the site does not have a grounded enclosure, connect the

ground wire directly to an earth ground connection. The datalogger ground

should also be tied to the earth ground (see FIGURE 3-1 and FIGURE 3-2).

The modem must be grounded for its transient protection to

work.

5

Page 14

COM220 Telephone Modem

3.3 LoggerNet Setup

• In the LoggerNet Setup Screen, press Add Root and choose ComPort.

From the ComPort, select Communications, and Add a PhoneBase, a

PhoneRemote, a PakBusPort (if your datalogger is a PakBus datalogger),

and your datalogger.

• Click on the ComPort in your network map, and select the correct

ComPort Connection for your modem.

• Click on the PhoneBase in your network map. Select your PC modem

from the drop-down list or add it using the Edit Modem Database dialog

box. Set the Maximum Baud Rate appropriate for your modem and

datalogger.

• Click on the PhoneModem in your network map. Enter the COM220’s

analog phone number.

6

• If your datalogger is a PakBus datalogger, click on the datalogger in your

network map. Enter the PakBus Address of your datalogger.

Page 15

COM220 Telephone Modem

NOTE

• Press Apply to save your changes.

3.4 Telephone to MD485 or Telephone to RF Systems

Telephone-to-MD485 or telephone-to-radio configurations can be utilized for

communicating with multiple dataloggers through one telephone line. For

telephone-to-MD485 or telephone-to-radio communications (with no

datalogger router), the COM220 should be set for ME mode. The COM220

and MD485 should be set to the same baud rate. When using a PakBus

network with a datalogger configured as a router, the COM220 can be set for

SDC7 and the radio for SDC8, or vice versa. Contact a Campbell Scientific

application engineer for more information. In addition, Appendix A.4.4,

Example Programs for Data-Callbacks via a CR1000 Datalogger Router,

includes example programs for both a router datalogger and a remote

datalogger communicating by telephone to MD485 or telephone to radio.

3.5 Telephone Service

If you have any questions about your telephone line, such as how many pieces

of equipment you can connect to it, the telephone company will provide this

information upon request. If the telephone company requests information

concerning the equipment which you have connected to your telephone line,

the FCC registration number and the ringer equivalence number (REN) of the

COM220 are listed on its label. Additional technical information from the

FCC and IC on the COM220 is available in Appendix D, FCC Warning to

Users of Class B Computing Devices, and Appendix E, IC Information,

respectively.

If the telephone company does not provide phone-line surge

protection, a Campbell Scientific surge suppressor should be used.

Refer to Section

information.

3.6, Connecting to a Surge Protector, for more

7

Page 16

COM220 Telephone Modem

NOTE

CAUTION

3.6 Connecting to a Surge Protector

Campbell Scientific offers two surge protectors (pn 4330 and 6362). The 4330

and 6362 are essentially the same, except that the 6362 has hardware for

mounting to an enclosure backplate.

The 4330 is also known as the 2374-01.

The 4330 and 6362 have a protector element for each line that consists of a

heavy-duty rated, two-element gas tube, an external, backup gap assembly, and

a switch-grade shorting mechanism. The gas tubes (tip and ring) are sealed in

a fire-resistant plastic body. DC breakdown at 100 V/sec is 300 to 500 V; DC

extinguishing at 52 V, 135 V, and 150 V is less than 150 ms.

FIGURE 3-3 and FIGURE 3-4 show the wiring for connecting the surge

suppressor. Color coding of wires may vary. The important consideration is to

follow tip all the way through and ring all the way through. Getting wires

crossed typically does not damage anything. The phone line just will not work

until the wires are straightened out.

Phone wires are live, typically with low voltage (24 Vdc).

While not harmful in most situations, Campbell Scientific

recommends installing the surge protector in dry weather

only by technicians with a healthy heart.

8

FIGURE 3-3. Top view of surge-suppressor wiring

Page 17

COM220 Telephone Modem

IMPORTANT

FIGURE 3-4. Side view of surge-suppressor wiring

4. Modem Settings

The COM220 is shipped from the factory with default settings that support

PakBus dataloggers (such as the CR800, CR1000, CR3000, and CR10XPB).

The modem comes configured for synchronous device communication (SDC7),

and, if using a PakBus datalogger, can answer a call as soon as a call is

detected.

Default settings must be changed if using a non-PakBus datalogger.

The default settings ARE NOT compatible with dataloggers

that have non-PakBus operating systems (such as the

CR510, CR10X, CR23X, CR7, and CR5000). However,

compatibility with non-PakBus dataloggers is easily

achieved by changing DIP-switch settings (

you want to use the COM220 as a drop-in replacement for

the COM210, the COM220 settings should be changed to

modem enable (DIP switch 1 open) and 9600 baud (DIP

switches 3 and 4 open). Instructions for configuring the

COM220 are described in Appendix A

Settings.

You can modify the following COM220 settings with DIP switches:

1) Communication mode (SDC or ME)

2) ME baud rate

FIGURE 1-1). If

, Changing COM200

Additional changes (see examples below) may be modified with Hayes AT

commands. Appendix A.2, Hayes AT Commands, describes the procedures

and commands required to effect the changes described in this section.

9

Page 18

COM220 Telephone Modem

Some of the AT command settings that may be changed are:

Disable auto-answer: This option is used only when the modem is not to

answer a call. For example, the COM220 is connected to a telephone line that

is to be used partly for voice communication. In this situation, it is best to have

the datalogger call the computer.

Speaker on/off and volume: Default settings have the speaker on only during

call establishment and set to a low volume. The speaker may be turned

completely off in order to limit the current drain during the connection or so

you cannot/do not hear the speaker. It is also possible to set the speaker

volume higher if you want to hear the speaker better than the default, lowvolume setting.

th

Answer on X

and you only want it to answer after a specified number of rings. For example,

the COM220 is sharing a line with people at an office. It can be programmed

to only answer after the third ring. If the PC calls when the office is closed and

no one answers the phone after three rings, the datalogger will pick it up.

Change telephone system types: Change from the Bell 212A (U.S. and

Canada) system to a CCITT V.32 (foreign, 9600 baud) or CCITT V.22

(foreign, 1200 baud) system. This does not mean that the COM220 is tested

and approved for all foreign countries.

ring: This option is used when the modem is sharing a line

CCITT is an international consultative committee that sets international

communications-usage standards. V.32 and V.22 are CCITT standards that the

COM220 meets.

5. Troubleshooting

When the Campbell Scientific software cannot establish a link to a remote

datalogger that is connected to a COM220, check the following:

1) Verify that the modem initialization settings on your computer are correct

for your specific calling modem (that is, the modem attached to your

computer). See the calling modem’s software manual and/or help screens

for more information.

2) If using a non-PakBus datalogger (such as the CR510, CR10X, CR23X,

CR7, and CR5000), verify that DIP switch 1 on the COM220 is in the

open (modem enable) position. For PakBus dataloggers (such as the

CR800, CR850, CR1000, CR3000, CR10XPB, 23XPB, etc.), DIP switch 1

can be in either position, but closed (SDC7) is preferred. See Appendix

A.1, DIP Switch Settings, for details.

3) If the COM220 is set for modem enable (DIP switch 1 open), verify that

the ME baud rate selected (DIP switches 3 and 4) agrees with related

communication instructions in the datalogger program. Instructions for

setting the COM220’s ME baud rate are found in Appendix A.1, DIP

Switch Settings.

10

4) If the COM220 is set for modem enable (DIP switch 1 open) and you are

unable to connect to the datalogger, try setting the datalogger ME baud

rate, BaudrateME, to a negative number (for example, –9600) in order to

Page 19

COM220 Telephone Modem

enable auto-bauding in the datalogger. If the datalogger BaudrateME is

positive (due to an earlier program instruction or Status table

configuration), the datalogger will be unable to communicate with the

COM220 unless baud rates happen to match. A good rule of thumb is to

keep baud rates negative (–) in programs and when configuring the

Status table to allow datalogger auto-bauding.

5) If unable to connect to a datalogger via the COM220, make sure that the

datalogger is not beaconing to the same port for which the COM220 is

configured (that is, if the COM220 is configured for SDC7 and the

datalogger’s BeaconSDC7 is set to something other than 0, a connection

cannot be established).

6) If the COM220 is in modem enable mode, verify that the COM220 is the

only modem-enable device connected to the datalogger. Other common

Campbell Scientific modem-enable devices are the SC32B, some RF

modems, the MD485, the RF401, the SC932A, and the PDA-to-CS I/O

connector.

7) If the COM220 is in SDC mode (the default is SDC7, with DIP switch 1

closed and DIP switch 2 open), verify that any other SDC devices attached

to the datalogger are using a different SDC address (that is, if the COM220

is configured for SDC7, another SDC device attached to the datalogger

must use SDC8).

8) Verify that no other software application is currently using the same COM

port on the computer. Even if a program is minimized in windows, it may

put a lock on a COM port. Some notebook computers do not

automatically activate the COM ports. Verify that the COM port you are

using is activated.

9) Use the Low Level Log in the Campbell Scientific software, LoggerNet,

[Status Monitor | Tools | Log Tool | View | View I/O (Low Level Log)] to

see connection progress while a link is being established. Assuming the

above items are OK, the Low-Level Log will display “ATDT#######”,

where ####### is the phone number entered in LoggerNet Setup’s Phone

Remote device for the datalogger you are trying to call. The modem

attached to the computer will respond back to the computer with result

codes showing how the call is progressing. These responses should

include “RING” and “CONNECT ####” where #### is the negotiated

modem-to-modem connection baud rate. The maximum baud rate setting

in Setup’s PakBusPort [LoggerNet | Setup | PakBusPort (in the device

map)] device may limit the baud rate selected by the modems since it

defaults to 9600. You can sometimes achieve a higher connection baud

rate by raising the PakBusPort’s maximum baud rate.

10) Can you attach an analog telephone to the line and make a call out? If not,

contact your local telephone company. If you can make a call out but the

connection is poor or faint, contact your local telephone company.

11) Verify the COM220 is receiving 12 Vdc. If the COM220 is receiving 12

Vdc from a separate power supply instead of the datalogger, verify that the

ground of the separate power supply is connected to the datalogger’s

ground.

12) Verify the datalogger is turned on.

11

Page 20

COM220 Telephone Modem

To comply with FCC rules and regulations, all repairs on the COM220 modem

must be performed by Campbell Scientific, Inc. or an authorized agent of

Campbell Scientific, Inc. For assistance in installation or troubleshooting or

for repairs, contact Campbell Scientific:

Campbell Scientific, Inc.

815 West 1800 North

Logan, Utah 84321-1784

Telephone: (435) 227-9000

Fax: (435) 227-9001

Website: www.campbellsci.com

12

Page 21

CAUTION

IMPORTANT

Appendix A. Changing COM220 Settings

Changing any of the modem’s settings may result in

communication problems. After changing the settings, try

the modem locally before installing it at a remote location.

To speed problem resolution when contacting Campbell

Scientific for support, please inform us of any modemsettings changes that have been made.

A.1 DIP Switch Settings

The following COM220 settings are changed by opening or closing DIP

switches:

1) Communication mode, either synchronous device communication (SDC) or

modem enable (ME)

2) ME baud rate

To change DIP switch settings, the outer cover must first be removed by

unscrewing and removing the five Philips head screws on the cover.

It is necessary to cycle power to the COM220 for changes

to the DIP switch settings to take effect. This is done by

removing the 9-pin connector for about 5 s. As with other

devices, if you leave the power off for too short a time, you

may get unexpected results.

DIP Switches 1 and 2: SDC or ME

The COM220 supports synchronous device communication (SDC) and modem

enable (ME) communication. Switch 1 selects between SDC and ME. If

switch 1 is open, ME mode is selected. If switch 1 is closed and switch 2 is

open (default), SDC7 is selected. If both switch 1 and 2 are closed, SDC8 is

selected. SDC is not supported by non-PakBus operating systems (such as the

CR10X, CR23X, CR7, and CR510). Hence, to connect with these older

dataloggers, switch 1 must be open (that is, modem enable selected).

DIP Switches 3 and 4: ME Baud Rates

DIP switches 3 and 4 only have effect when the COM220 is in modem enable

mode. If the COM220 is in ME mode, switches 3 and 4 select the baud-rate

setting between the COM220 and the datalogger as follows:

A-1

Page 22

Appendix A. Changing COM220 Settings

TABLE A-1. Selecting ME

TABLE A-2. Maximum Datalogger ME Baud Rates

Baud Rates via DIP Switches 3 and 4

ME Baud Rate Switch 3 Switch 4

9600 Open Open

38400 Open Closed

57600 Closed Open

115200 Closed Closed

Please note that older dataloggers (such as the CR10X, CR23X, and CR510)

cannot support the highest COM220 ME baud rates. TABLE A-2 lists

maximum datalogger baud rates.

Datalogger Max Baud Rate

CR10X, CR510, CR7, CR21X 9600

CR23X 38400

CR5000 57600

CR800, CR1000, CR3000 115200

DIP Switches 5, 6, and 7: Not used

DIP Switch 8: Configuration Mode

Closing DIP switch 8 (and cycling power to the COM220) places the COM220

in configuration mode. The COM220 can be configured using an SC532 or

SC532A with a 12-Vac adapter (pn 15966) and Device Configuration Utility

version 1.6 or newer and Hayes AT commands (see below).

A.2 Hayes AT Commands

To configure the COM220 with Hayes AT commands, you will need the

Campbell Scientific Device Configuration Utility version 1.6 or newer and an

SC532 or SC532A device. An SC12 cable must be connected to the peripheral

port on the SC532 or SC532A and the CS I/O port on the COM220. Another

cable should connect the RS232 port (if using an SC532 device) or the PC port

(if using an SC532A device) to one of your computer’s serial ports. If using an

SC532A device, power will be provided to the modem by the SC532A with a

12-Vac adapter (FIGURE A-1). However, if using the older SC532, you must

apply 12 V to the COM220 via the green connector.

A-2

Page 23

Appendix A. Changing COM220 Settings

FIGURE A-1. COM220 to computer connection

To configure the COM220 with Hayes AT commands, follow these steps:

1) Close DIP switch 8 on the COM220 (power to the COM220 must be

cycled for about 5 sec before changes to DIP-switch settings are effective).

2) You must use an SC532A with a 12-Vac adapter or an SC532 interface to

communicate with the modem. Connect the PC port (called RS232 on the

SC532) to a serial port on your computer via an RS232 cable. Leave the

COM220 modem disconnected for now.

3) Run Device Configuration Utility version 1.6 or newer.

4) Select COM220 from the Device Configuration Utility menu (FIGURE

A-2).

5) Make sure the appropriate serial port is selected on the left panel of the

Device Configuration Utility window and click on the connect button.

6) Once you have clicked on the connect button, connect the peripheral port

on the SC532 or SC532A to the CS I/O port on the modem with an SC12

cable. If using an SC532, you will also have to apply 12 V to the

COM220 via a green connector attached to a power supply. If using an

SC532A device, power will be provided to the modem by the SC532A.

A-3

Page 24

Appendix A. Changing COM220 Settings

NOTE

You must click on the connect button BEFORE applying power

to the COM220.

7) Follow the instructions that appear in the terminal emulator screen

(FIGURE A-3).

8) Be sure to save all new commands before exiting (by entering 5 and

pressing Enter).

9) When finished, return DIP switch 8 on the COM220 to its open position.

A-4

FIGURE A-2. Device Configuration screen

Page 25

Appendix A. Changing COM220 Settings

NOTE

FIGURE A-3. Terminal Emulator screen in Device Configuration

HAYES AT COMMAND SUMMARY:

This manual does not attempt to be a primer on the Hayes AT command set.

The commands are, therefore, only summarized below. For most applications,

these commands will not need to be used. Except as noted, all commands

should begin with an “AT” and end with a carriage return (press the Enter key).

There are no “O” as in Oscar commands, only “0” as in Zero commands. For

example, to change the default number of rings from 1 to 3, the command is:

ATS0=2 (the default is 1 ring as the MPU sends ATS0=1 by default to the

modem module).

To turn the speaker off, the command is ATM0.

For command changes to be effective, you MUST press Enter

after typing the command and you MUST press 5 to save the new

command before disconnecting or exiting set up.

COMMANDS TO CHANGE DEFAULT MODES:

B1 (default) CCITT V.32 (9600 baud), Bell 212A (1200 baud), and Bell

103 (300 baud)

B0 CCITT V.32 (9600 baud), CCITT V.22 (1200 baud), and

CCITT V.21 (300 baud)

L0 Lowest speaker volume

L1 (default) Low speaker volume

L2 Medium speaker volume

L3 High speaker volume

A-5

Page 26

Appendix A. Changing COM220 Settings

CAUTION

NOTE

M0 Speaker always off

M1 (default) Speaker on during call establishment

M2 Speak on during entire call session

S0=0 Disable Auto Answer

S0=1 (default) Answer on second ring

S0=2 Answer on third ring

S0=n Answer on (n + 1) ring.

When doing datalogger-to-datalogger communications with

the COM220, if more than six rings are specified, the

datalogger may time out before the modem answers;

communication will never be established! Be sure to try the

setup locally before installing at a remote location.

A.3 Downloading a New Operating System to the

COM220

To download a new operating system to the COM220, follow these steps:

1) You must use an SC532 or an SC532A interface to communicate with the

modem. Connect the PC port (called RS232 on the SC532) to a serial port

on your computer via an RS232 cable. Leave the modem disconnected for

now.

2) Make sure that you have the appropriate serial port selected in the left

panel of the Device Configuration Utility window.

3) Click the Start button.

4) In the resulting file-open dialogue box that appears, select the file that

should be sent as the modem’s operating system. Do not attempt to load

any operating system other than that designed for the COM220

modem.

5) Once you have pressed OK in the file-open dialogue box, connect the

peripheral port on the SC532 or SC532A to the CS I/O port on the modem

with an SC12 cable. If using an SC532, you will also have to apply 12 V

to the COM220 via a green connector attached to a power supply. If using

an SC532A device, power will be provided to the modem by the 12-V

adapter connected to the SC532A.

You must highlight/select the operating system file to be sent

BEFORE applying power to the COM220.

A-6

6) The program should now send the operating system to the modem.

Interrupting this process may corrupt the modem operating system.

Page 27

Appendix A. Changing COM220 Settings

FIGURE A-4. Send OS screen in Device Configuration

A.4 Program Examples

A.4.1 ModemCallback Example (for CR1000)

The ModemCallBack instruction is available in the CR1000 with operating

system std.12 or greater, in the CR3000 with operating system std.05 or

greater, and in the CR800 or CR850 with operating system std.03 or greater.

The following program uses the ModemCallBack instruction to call LoggerNet

every 2 minutes. The ModemCallBack instruction assumes that LoggerNet

resides at the phone number and that callback is enabled in LoggerNet Setup,

both for the comport and for the datalogger.

Public PTemp, batt_volt, Count, Result as Long

Const Abort = 0 ' False

DataTable (Test5,1,-1)

DataInterval (0,0,Sec,10)

Sample (1,batt_volt,FP2)

Minimum (1,batt_volt,FP2,0,False)

Maximum (1,batt_volt,FP2,False,False)

Sample (1,PTemp,FP2)

Minimum (1,PTemp,FP2,0,False)

Maximum (1,PTemp,FP2,False,False)

Sample (1,Count,FP2)

EndTable

BeginProg

Scan (2,Min,3,0)

Count = Count + 1

PanelTemp (PTemp,250)

Battery (Batt_volt)

ModemCallBack(Result,ComSDC7,9600,0,"5551212","",40,60,Abort)

CallTable Test5

NextScan

End Program

A-7

Page 28

Appendix A. Changing COM220 Settings

NOTE

A.4.2 DialModem Example (for CR1000)

The program below does 2-min callbacks via the COM220 configured for

SDC7. DialModem is set equal to a variable, so that the success/failure result

can be used by the EndDialSequence instruction. If the call fails, the link will

be terminated at the EndDialSequence instruction. If the call is successful, the

device will be kept online until the SendVariables command is completed.

For data callbacks to occur, Callback Enable must be selected

in LoggerNet Setup both for the comport and for the

datalogger.

'Replace DialModem phone number with your PC's phone number

Public batt_volt, Result

Public PTemp, TCvalue_F, dummy

Public RespStrng, DialSuccess, AccumDialFails as LONG

DataTable (DC1,1,1000)

DataInterval (0,0,Sec,10)

Sample (1,PTemp,FP2)

Sample (1,TCvalue_F,FP2)

Sample (1,DialSuccess,FP2)

EndTable

DialSequence (4094) 'Establishes a phone connection if there isn't one already.

DialSuccess =DialModem (ComSDC7,-115200,"5551212","") ' " Param 2 baud rate setting

affects sdc bit rate." Param 4 allows OS to accept any listed modem response.

If DialSuccess = 0 then AccumDialFails = AccumDialFails + 1

EndDialSequence (DialSuccess) ' -1 = success, 0 = failure of response to match Param 4

BeginProg

Scan (2,Min,3,0)

PanelTemp (PTemp,250)

Battery (Batt_volt)

dummy = 0

TCDiff (TCvalue_F,1,mV2_5C,1,TypeT,PTemp,True ,0,250,1.8,32)

SendVariables (Result,ComSDC7,4094,4094,0000,3500,"Public","Callback",dummy,1)

'Establishes static route to LN

'35 sec timeout allows time to dial/train

CallTable DC1

NextScan

EndProg

A-8

Page 29

Appendix A. Changing COM220 Settings

CAUTION

The COM220 can return several possible responses once

connected (each terminating in a carriage return):

“1” CONNECT

“5” CONNECT1200

“10” CONNECT2400

“13” CONNECT9600

“18” CONNECT4800

“20” CONNECT7200

“21” CONNECT12000

“25” CONNECT14400

Hence, to work with the COM220, the user must put in a

NULL string, or else the DialModem will fail unless, by

chance, it returns the specific string the user entered.

Therefore, it is highly recommended to use the “” string for

the connect string, unless the user is using some other

modem that he knows has a different response string than

those listed above.

A.4.3 P97 Instruction (for CR10X)

Instruction 97 is a Program Control instruction that makes the following types

of calls:

• Datalogger calls a computer to send data.

• Datalogger calls a voice phone using our voice-synthesized modem.

• Datalogger calls a remote datalogger to retrieve its input locations.

Instruction 97 has the following parameters:

• Parameter 1 — Modem/Baud Rate Codes

• Parameter 2 — Flag No. to Disable P97

• Parameter 3 — Call Time Limit (seconds)

• Parameter 4 — Seconds Before Fast Attempts

• Parameter 5 — Fast Attempts

• Parameter 6 — Minutes Before Slow Attempts

• Parameter 7 — Failure Location

• Parameter 8 — Callback ID

A-9

Page 30

Appendix A. Changing COM220 Settings

IMPORTANT

Do not put Instruction 97 inside a loop or conditional

statement; it must be executed each time the table is run.

In the example below, the program does two minute data callbacks via the

COM220 phone modem. Edit instruction 13 with your PC’s (LoggerNet’s)

phone number. Remember to set switch 1 open for modem enable mode, and

switches 3 and 4 open for 9600 baud. The callback ID in this example is 222.

The callback ID is a user-specified number and must also be entered in

LoggerNet Setup for callbacks to work.

*Table 1 Program

01: 5 Execution Interval (seconds)

; Prevent callback when program Compiled

1: If Flag/Port (P91)

1: 28 Do if Flag 8 is Low

2: 30 Then Do

2: Do (P86)

1: 15 Set Flag 5 High

3: Do (P86)

1: 18 Set Flag 8 High

4: End (P95)

5: Batt Voltage (P10)

1: 1 Loc [ BatVolt ] ;measure battery voltage

6: Internal Temperature (P17)

1: 2 Loc [ TEMP_PANL ] ;measure panel temperature

7: If time is (P92) ;final storage every 10 seconds

1: 0 -- Minutes (Seconds --) into a

2: 10 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

8: Real Time (P77)

1: 111 Day,Hour/Minute,Seconds (midnight = 0000) ;place a time stamp

9: Sample (P70)

1: 1 Reps

2: 1 Loc [ BatVolt ] ;sample battery voltage

10: Sample (P70)

1: 1 Reps

2: 2 Loc [ Temp_PANL] ;sample panel temperature

11: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 2 Interval (same units as above)

3: 25 Set Flag 5 Low

12: Initiate Telecommunications (P97)

1: 22 Phone Modem/9600 Baud ;set baud rate/modem

2: 5 Disabled when User Flag 5 is High

3: 45 Seconds Call Time Limit

4: 0 Seconds Before Fast Retry

5: 0 Fast Retries

6: 0 Minutes Before Slow Retry

7: 3 Failures Loc [ Failures ]

8: 222 Callback ID ;must also enter callback ID in LoggerNet Setup

A-10

Page 31

Appendix A. Changing COM220 Settings

13: Extended Parameters (P63) ;7-digit phone number

1: 5 Option

2: 5 Option

3: 5 Option

4: 1 Option

5: 2 Option

6: 1 Option

7: 2 Option

8: 13 Option ;13 is the termination character; always place after phone number

End Program

A.4.4 Example Programs for Data Callbacks via a CR1000

Datalogger Router

To do data callbacks via a datalogger router with COM220 and RF401s or

MD485s, they must all be configured to communicate with one another. In

addition, two programs are necessary: one for the datalogger router and one for

the remote datalogger. Below are example programs for a datalogger router

and a remote datalogger. For these examples, the COM220 is configured for

SDC7 and the router datalogger has the following settings (you can enter these

settings via the datalogger keypad or from the LoggerNet status table):

PakBusAddress = 2, IsRouter = 1 or True, and BeaconSDC8 = 30, enabling the

router to discover the remote. The remote datalogger’s PakBusAddress = 1. In

addition, the RF401s or MD485s are set for CSDC8 (see the RF401 or MD485

manual for directions on configuring these devices).

Program for CR1000 Router:

'Router program for data callback via router w/ phone link to LoggerNet

'Phone to MD485 or RF401 w/ DL at Base

'Router PakBus Address = 2, IsRouter = 1, BeaconSDC8 = 30 to discover Remote DL

which has PBA = 1

'Router COM220 = SDC7; Base RF401 CSDC8; Remote RF401 CSDC8.

'LoggerNet PakBusPort has PBA = 4094

' PC-pcMODEM --------COM220sdc7-CR1000(2)-RF401sdc8~~~~~~~~~~~RF401sdc8-CR1000(1)

Public PanelTemperature, BatteryVoltage, DialSuccess

Public Flag(10) AS BOOLEAN

SequentialMode

DataTable (TestA,1,-1)

DataInterval (0,2,Sec,10)

Minimum (1,BatteryVoltage,FP2,0,False)

Sample (1,PanelTemperature,FP2)

EndTable

DialSequence (4094)

StaticRoute(ComSDC8,4094,4094) ' So router discovers LoggerNet server

DialSuccess = DialModem (ComSDC8,9600,"5551212","")

' Param 4 = "" allows CR1000 to accept all possible COM220 responses

' DialSuccess: -1 means successful, 0 means failure.

EndDialSequence (DialSuccess)

BeginProg

Scan (2,Sec,0,0)

PanelTemp (PanelTemperature,250)

Battery (BatteryVoltage)

CallTable TestA

NextScan

EndProg

A-11

Page 32

Appendix A. Changing COM220 Settings

Remote datalogger program for CR1000:

'Remote program for 2-min data callbacks via DL router with RF401 or MD485 link and

COM220 link

'Datalogger router PakBusAdddress = 2

'LoggerNet server PakBusAddress = 4094

'Replace DialModem phone number with your PC's phone number

Public batt_volt, Result

Public PTemp, TCvalue_F, dummy

Public RespStrng, DialSuccess

DataTable (DC1,1,1000)

DataInterval (0,0,Sec,10)

Sample (1,PTemp,FP2)

Sample (1,TCvalue_F,FP2)

Sample (1,DialSuccess,FP2)

EndTable

BeginProg

Scan (2,Min,3,0)

PanelTemp (PTemp,250)

Battery (Batt_volt)

dummy = 0

TCDiff (TCvalue_F,1,mV2_5C,1,TypeT,PTemp,True ,0,250,1.8,32)

SendVariables(Result,ComSDC7,2,4094,0000,3500,"Public","Callback",dummy,1)

'35-s timeout allows time for phone modems to dial/train

CallTable DC1

NextScan

EndProg

A-12

Page 33

Appendix B. CS I/O Connection

B.1 CS I/O 9-Pin Connection

The pinout of the connector is shown in FIGURE B-1. The direction of the

signal relative to the modem is shown in parentheses. Unless specified

otherwise, all levels are 0 V for logic low, 5 V for logic high.

FIGURE B-1. CS I/O pinout

1. (input) +5 Vdc supply. Used to power internal line drivers for ‘Ring’ and

‘RX Data’ output signals.

2. (input) Ground

3. (output) Ring — A logic high signifies a ring signal has been detected.

4. (output) RX Data — Serial data from COM220

5. (input) Modem Enable — A logic high internally switches power to the

modem. A logic low internally shuts off power to the modem.

6. (input) Serial Device Enable — A logic high disables communication with

the modem without removing power or changing the modem's mode.

7. (input) SDC clock

8. (input) +12 Vdc supply

9. (input) TX Data — Serial data to COM220

B-1

Page 34

Appendix B. CS I/O Connection

B-2

Page 35

Appendix C. Theory of Operation

C.1 Theory of Operation

The COM220 modem is used to transmit data over bandwidth-limited channels

such as telephone lines by modulating audio tones. The COM220 uses various

modulation schemes including FSK (Frequency Shift Keying), TCM (Trellis

Coded Modulation), QAM (Quadrature Amplitude Modulation), and DPSK

(Differential Phase Shift Keying).

The telephone company gives a 40- to 150-VRMS, 20-Hz signal on the

telephone lines to signify a ring, which is typically on for two seconds and off

for four seconds. The COM220 is supplied with 12 V from the datalogger’s

CS I/O connector or from the COM220’s external power connector. The 12 V

is then regulated to +5 V to give power to the ring detect circuitry. The ring

detection circuitry is continuously powered but draws less than 2 µA. The ring

signal is passed on to the datalogger through an opto-coupler. The datalogger

responds to a “ring” by raising the modem-enable line, which internally

switches the regulated +5 V supply to the rest of the modem’s circuitry.

The modem then answers and remains off-hook until it loses the carrier or the

datalogger lowers the modem-enable line. The datalogger lowers the modemenable line by remote command or after 40 s in the absence of a command.

When the modem-enable line goes low, the COM220 internally removes the +5

V from the modem circuitry, dropping power to the off-hook relay and thus

placing the telephone line on-hook. The COM220’s ring detect circuitry is still

powered at this time.

To reject noise common to telephone lines and to satisfy registration

requirements, the modem circuitry is electrically isolated from the telephone

lines by using an opto-isolator and a coupling transformer.

C-1

Page 36

Appendix C. Theory of Operation

C-2

Page 37

WARNING

Appendix D. FCC Warning to Users of Class B Computing Devices

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

interference to radio communications. It has been

tested and found to comply with the limits for a Class B

computing device pursuant to Subpart J of Part 15 of

FCC Rules, which are designed to provide reasonable

protection against such interference when operated in

a COMMERCIAL ENVIRONMENT. Operation of this

equipment in a residential area may cause interference

to radio and television reception. The operator must

take whatever measures are necessary to correct the

interference.

D-1

Page 38

Appendix D. FCC Warning to Users of Class B Computing Devices

D-2

Page 39

NOTE

Appendix E. IC Information

Industry Canada (IC) was formerly known as DOC.

CP-01, Issue 8, Part I

Section 14.1

“NOTICE: The Industry Canada label identifies certified equipment. This

certification means that the equipment meets certain telecommunications

network protective, operational and safety requirements as prescribed in the

appropriate Terminal Equipment Technical Requirements document(s). The

Department does not guarantee the equipment will operate to the user’s

satisfaction.

“Before installing this equipment, users should ensure that it is permissible to

be connected to the facilities of the local telecommunications company. The

equipment must also be installed using an acceptable method of connection.

The customer should be aware that compliance with the above conditions may

not prevent degradation of service in some situations.

“Repairs to certified equipment should be coordinated by a representative

designated by the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the telecommunications

company cause to request the user to disconnect the equipment.

“Users should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines and internal metallic water

pipe system, if present, are connected together. This precaution may be

particularly important in rural areas.

“CAUTION: Users should not attempt to make such connections themselves,

but should contact the appropriate electric-inspection authority, or electrician,

as appropriate.”

CP-01, Issue 8, Part I

Section 14.2

“NOTICE: The Ringer Equivalence Number (REN) assigned to each terminal

device provides an indication of the maximum number of terminals allowed to

be connected to a telephone interface. The termination on an interface may

consist of any combination of devices subject only to the requirement that the

sum of the Ringer Equivalence Numbers of all the devices does not exceed 5.”

E-1

Page 40

Appendix E. IC Information

E-2

Page 41

Page 42

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific (Beijing) Co., Ltd.

8B16, Floor 8 Tower B, Hanwei Plaza

7 Guanghua Road

Chaoyang, Beijing 100004

P.R. CHINA

www.campbellsci.com • info@campbellsci.com.cn

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Loading...

Loading...