Page 1

CNR4 Net Radiometer

Revision: 9/13

Copyright © 2000-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements...............................................1

3. Initial Inspection .........................................................1

3.1 Ships With............................................................................................1

4. Quickstart .................................................................... 2

4.1 Siting Considerations ...........................................................................2

4.2 Mounting..............................................................................................2

4.3 Use SCWin to Program Datalogger and Generate Wiring Diagram....4

5. Overview......................................................................7

6. Specifications .............................................................8

6.1 CNR4 Specifications..........................................................................10

6.2 Pyranometer Specifications................................................................10

6.3 Pyrgeometer Specifications................................................................11

6.4 Optional CNF4 Heater/Ventilator ......................................................12

6.4.1 CNF4 Specifications ...................................................................12

7. Operation...................................................................13

7.1 Using the CNR4 in the Four Separate Components Mode.................13

7.1.1 Measuring Short-wave Solar Radiation with Pyranometer.........13

7.1.2 Measuring Long-wave Far Infrared Radiation with

Pyrgeometer.............................................................................13

7.1.3 Measuring CNR4 Temperature with Thermistor ........................14

7.1.4 Calculation of Albedo .................................................................16

7.1.5 Calculation of Net Short-wave Radiation ...................................17

7.1.6 Calculation of Net Long-wave Radiation....................................17

7.1.7 Calculation of Net (Total) Radiation...........................................18

7.2 Wiring ................................................................................................18

7.3 Datalogger Programming...................................................................21

7.3.1 Sensor Sensitivity........................................................................21

7.3.2 Example Programs......................................................................21

7.3.2.1 Example 1, CR1000 Program Using Differential

Measurements...............................................................21

7.3.2.2 Example 2, CR3000 Program Using Differential

Measurements...............................................................24

7.3.2.3 Example 3, CR5000 Program Using Differential

Measurements...............................................................27

i

Page 6

Table of Contents

8. Troubleshooting........................................................30

8.1 Testing the Pyranometer.................................................................... 30

8.2 Testing the Pyrgeometer.................................................................... 31

8.3 Testing the Thermistor ...................................................................... 31

8.4 Testing the Pt-100 ............................................................................. 31

9. Maintenance and Recalibration ...............................32

9.1 Cleaning Windows and Domes ......................................................... 32

9.2 Recalibration ..................................................................................... 32

9.3 Replacing the Drying Cartridge......................................................... 32

9.4 Replacement Parts ............................................................................. 33

Appendices

CNR4 Performance and Measurements under

A.

Different Conditions .............................................A-1

B. CNF4 Heater/Ventilator ...........................................B-1

B.1 General Information ........................................................................ B-1

B.2 Attaching the Optional CNF4 Heater/Ventilator Unit to CNR4...... B-3

B.3 Wiring.............................................................................................. B-7

B.4 Example B, CR3000 Datalogger Program with Heater/

Ventilator Control ........................................................................ B-8

B.5 CNF4 Heater/Ventilator Maintenance........................................... B-11

B.5.1 Testing the Heater .................................................................. B-11

B.5.2 Testing the Ventilator............................................................. B-11

B.5.3 Replacing the Filter for the Ventilator.................................... B-11

C. CR3000 Program for Measuring Pt-100

Temperature Sensor............................................. C-1

Figures

4-1. Attaching the mounting rod to the CNR4 body................................... 2

4-2. Attaching the CNR4 onto the mounting rod (pn 26120) using

vertical pole or horizontal crossarm................................................. 3

6-1. The CNR4 net radiometer with cables and mounting rod, top view.... 9

6-2. The CNR4 net radiometer with CNF 4 heater/ventilator unit, top

view.................................................................................................. 9

7-1. The CNR4 sensor with SOLAR and TEMP cables........................... 18

7-2. The marks on the end of the CNR4: S for SOLAR cable, and T

for TEMP cable.............................................................................. 19

7-3. Labels on the pigtail end of the SOLAR cable.................................. 19

7-4. Labels on the pigtail end of the TEMP cable. ................................... 20

9-1. Replacing the drying cartridge .......................................................... 33

A-1. Different measurement conditions and signals................................ A-2

A-2. Partly cloudy day for the upward facing pyrgeometer..................... A-2

A-3. Clear day for the downward facing pyrgeometer ............................ A-3

B-1. CNF4 package contents................................................................... B-3

ii

Page 7

Tables

Table of Contents

B-2. Attaching the CNF4 to CNR4 using pan-head screws and

washers .........................................................................................B-4

B-3. Making sure the cables are clear from the edges..............................B-5

B-4. CNF4 solar shield and four flat-head screws ...................................B-5

B-5. Attaching the solar shield to CNF4 using four flat-head screws......B-6

B-6. Affixing the sensor label to CNF4 ...................................................B-6

B-7. Connecting the CNF4 power control cable and the mounting rod ...B-6

7-1. Resistance values versus CNR4’s thermistor temperature in °C........14

7–2. Resistance values versus CNR4’s Pt–100 temperature in °C.............16

7-3. Datalogger Connections for Differential Measurement .....................20

7-4. Datalogger Connections for Single-Ended Measurement ..................20

A-1. Typical output signals of CNR4 under different meteorological

conditions. Explanation can be found in the text......................... A-1

B-1. CR1000 and CR3000 Datalogger Connections for Differential

Measurement with Heater/Ventilator Control ..............................B-7

C-1. Datalogger Connections for Differential Measurement with

Pt-100 ...........................................................................................C-1

iii

Page 8

Table of Contents

iv

Page 9

CNR4 Net Radiometer

1. Introduction

The CNR4 is a research-grade net radiometer that measures the energy balance

between incoming and outgoing radiation. Our dataloggers measure the

CNR4’s output. This net radiometer offers a professional solution for

scientific-grade energy balance studies.

Before using the CNR4, please study:

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 4, Quickstart

2. Cautionary Statements

• Although the CNR4 is rugged, it is also a highly precise scientific

instrument and should be handled as such.

• Care should be taken when opening the shipping package to not damage or

cut the cable jacket. If damage to the cable is suspected, consult with a

Campbell Scientific applications engineer.

• Do not attempt to rotate the instrument using the sensor heads, or you may

damage the sensors; use the mounting rod only.

3. Initial Inspection

• Upon receipt of the CNR4, inspect the packaging and contents for damage.

File damage claims with the shipping company.

• The model number and cable length are printed on a label at the

connection end of the cable. Check this information against the shipping

documents to ensure the correct product and cable length are received.

• Refer to the Ships With list to ensure that parts are included (see Section

3.1, Ships With).

3.1 Ships With

(2) 26006 Drying Cartridges

(1) WRR Traceable Calibration Certificate for the pyranometers

(1) WRR Traceable Calibration Certificate for the pyregeometers

(1) Mounting Arm from original manufacturer

(1) Extra Calibration Stickers from original manufacturer

(1) ResourceDVD

1

Page 10

CNR4 Net Radiometer

4. Quickstart

4.1 Siting Considerations

Please review Section 7, Operation, for wiring and CRBasic programming.

Appendix B, CNF4 Heater/Ventilator, provides information about using the

CNF4 heater/ventilator.

1. Mount the sensor so no shadow will be cast on it at any time of day from

obstructions such as trees, buildings, or the mast or structure on which it is

mounted. If the instrument is h meters above the surface, 99% of the input

of the lower sensors comes from a circular area with a radius of 10h.

Shadows or surface disturbances with a radius < 0.1h will affect the

measurement by less than 1%.

2. To avoid shading effects and to promote spatial averaging, the CNR4

should be mounted at least 1.5 m above the ground surface. It is

recommended that the CNR4 be mounted to a separate vertical pipe at

least 25 ft from any other mounting structures.

3. Orient the sensor towards the nearest pole to avoid potential problems

from shading.

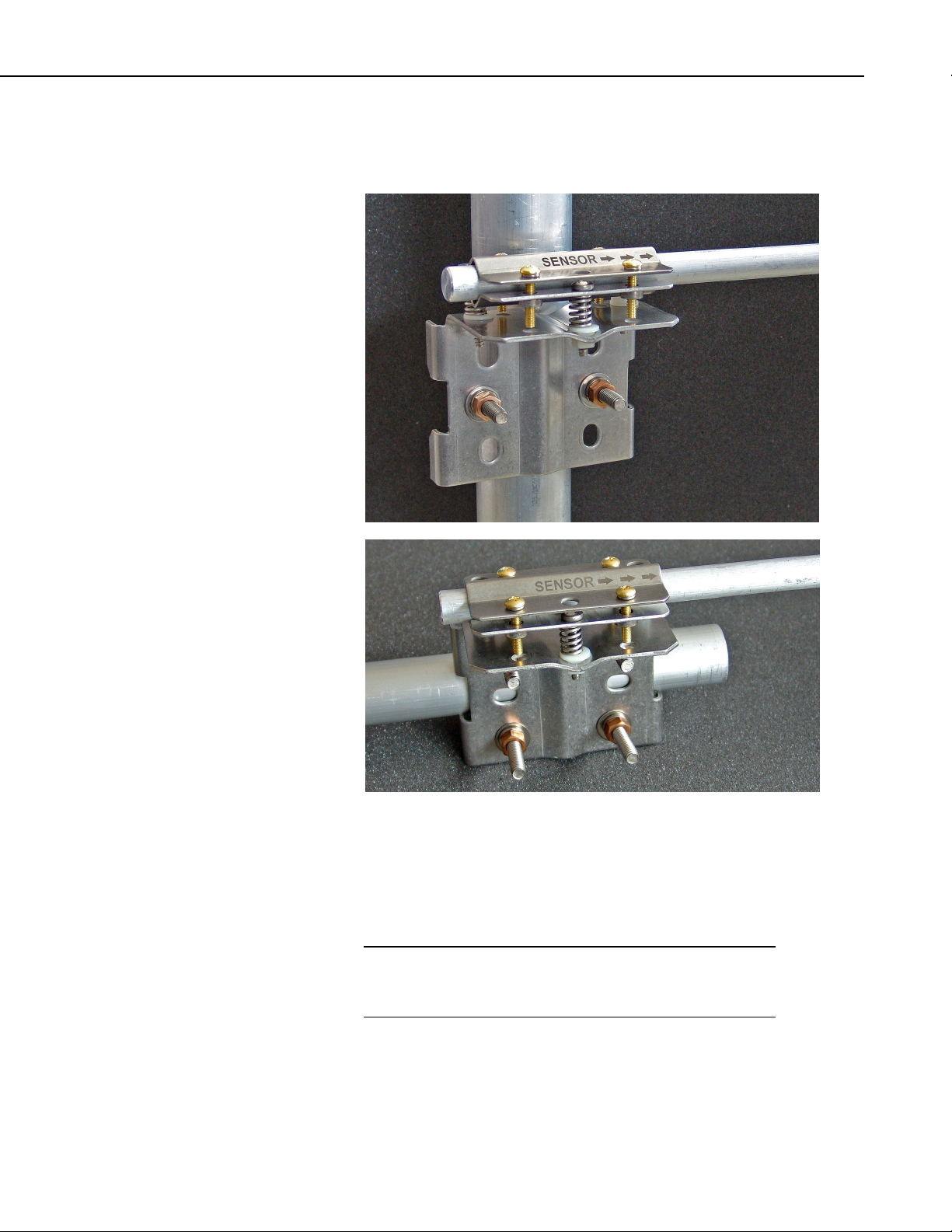

4.2 Mounting

A mounting bracket kit, pn 26120, is used to mount the CNR4 directly to a

vertical pipe, or to a CM202, CM203, CM204, or CM206 crossarm. Mount the

sensor as follows:

1. Attach the mounting rod to the CNR4 (see FIGURE 4-1).

FIGURE 4-1. Attaching the mounting rod to the CNR4 body

2

Page 11

CNR4 Net Radiometer

2. Attach the 26120 mounting bracket to the vertical mounting pipe, or

CM200-series crossarm using the provided U-bolt (see FIGURE 4-2).

CAUTION

FIGURE 4-2. Attaching the CNR4 onto the mounting rod

(pn 26120) using vertical pole or horizontal crossarm

3. Insert the sensor’s support arm into the mounting block of the mounting

bracket kit. Make sure the sensor points in the direction of the arrows that

appear after the word SENSOR on top of the bracket (see FIGURE 4-2).

Do not attempt to rotate the instrument using the sensor

heads, or you may damage the sensors; use the mounting

rod only.

4. Perform a coarse leveling of the sensor using the sensor’s bubble level.

5. Tighten the four screws on top of the mounting bracket to properly secure

the support arm so that it does not rotate (see FIGURE 4-2).

3

Page 12

CNR4 Net Radiometer

4.3 Use SCWin to Program Datalogger and Generate Wiring Diagram

6. Perform the fine leveling using the two spring-loaded leveling screws—

one on the front and the other on the back of the bracket.

7. Route the sensor cable to the instrument enclosure.

8. Use the UV-resistant cable ties included with the tripod or tower to secure

the cable to the vertical pipe or crossarm and tripod/tower.

The simplest method for programming the datalogger to measure the CNR4 is

to use Campbell Scientific’s SCWin Program Generator.

NOTE

The SCWin example provided here uses the thermistor to

provide the temperature correction.

1. Open Short Cut and click on New Program.

4

Page 13

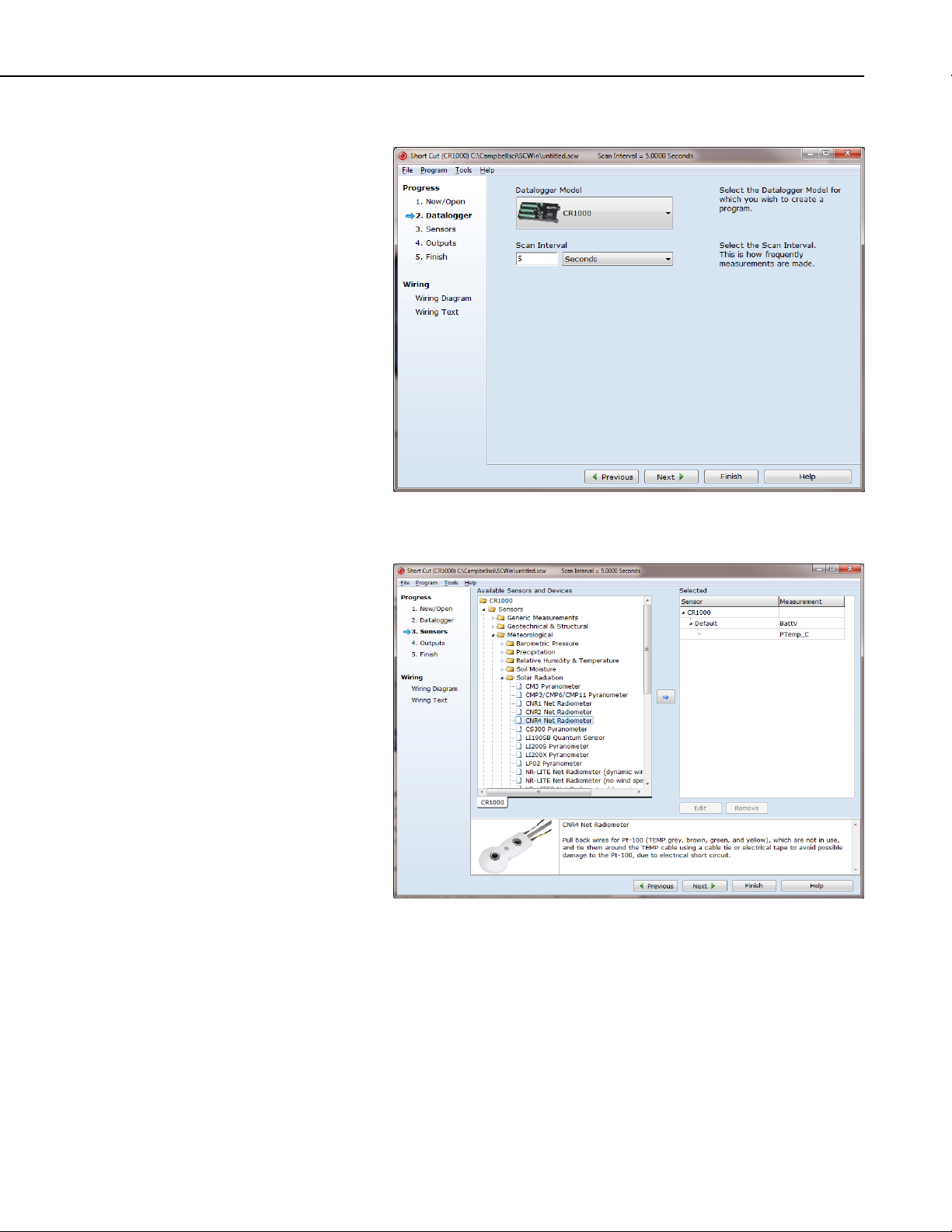

2. Select the datalogger and enter the scan interval.

CNR4 Net Radiometer

3. Select CNR4 Net Radiometer, and select the right arrow (in center of

screen) to add it to the list of sensors to be measured, and then select Next.

5

Page 14

CNR4 Net Radiometer

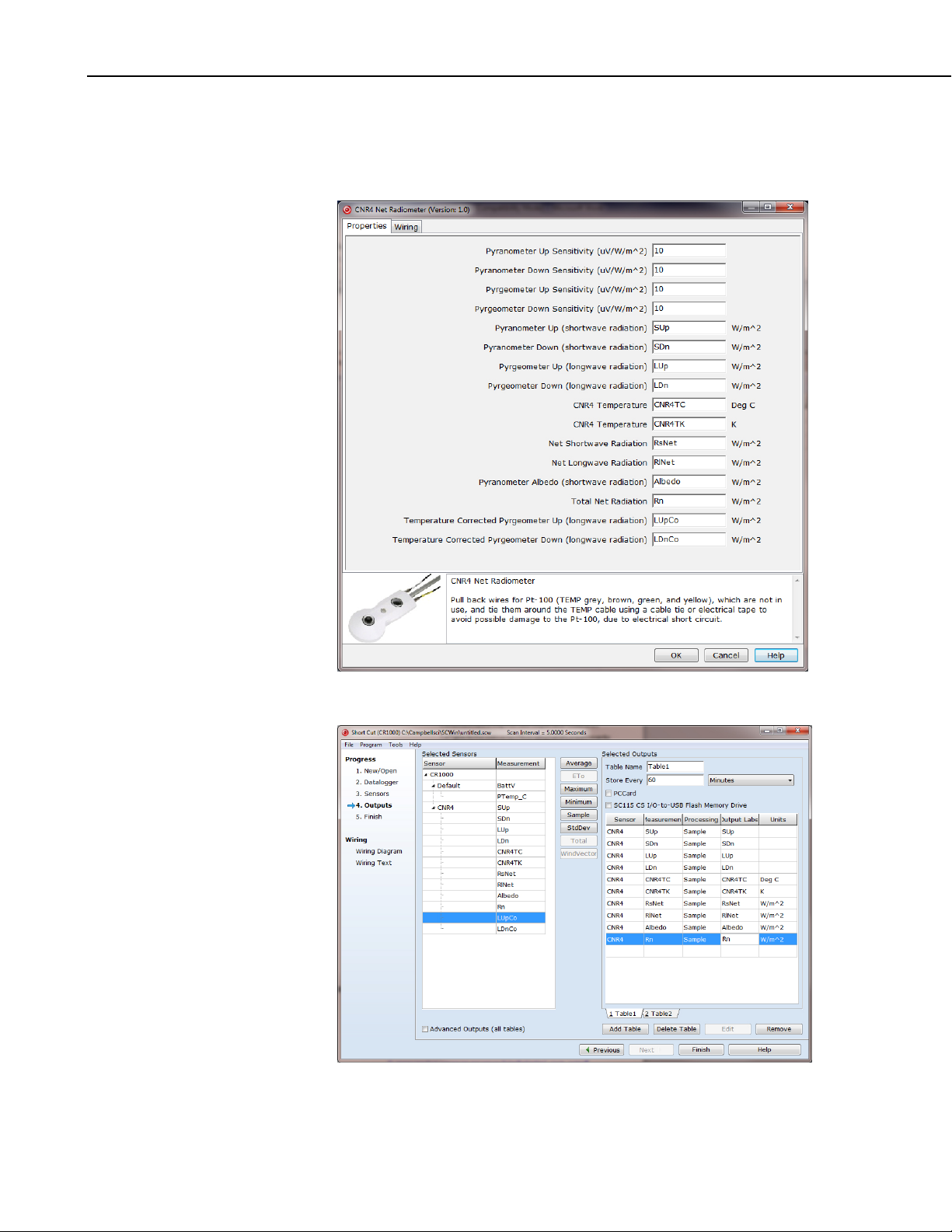

4. Enter the sensitivity values supplied on the manufacturer’s certificate of

calibration; these sensitivity values are unique to each sensor. The public

variables defaults can typically be used. After entering the information,

click on OK, and then select Next.

5. Choose the outputs and then select Finish.

6. In the Save As window, enter an appropriate file name and select Save.

6

Page 15

CNR4 Net Radiometer

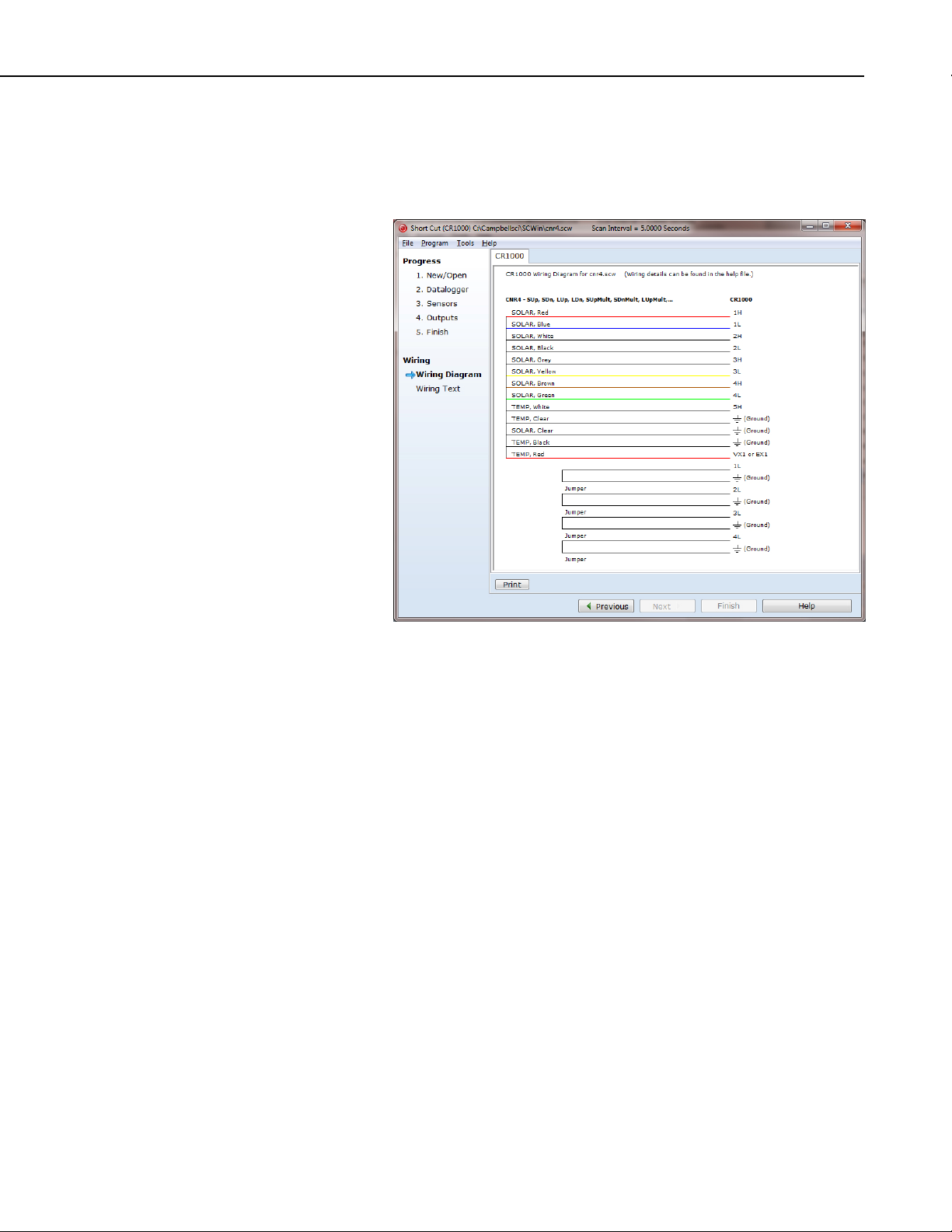

7. In the Confirm window, click Yes to download the program to the

datalogger.

8. Click on Wiring Diagram and wire according to the wiring diagram

generated by Short Cut.

5. Overview

The CNR4 Net Radiometer consists of a pyranometer pair, one facing upward,

the other facing downward, and a pyrgeometer pair in a similar configuration.

The pyranometer pair measures short-wave solar radiation, and the

pyrgeometer pair measures long-wave far infrared radiation. The upper longwave detector of CNR4 has a meniscus dome to ensure that water droplets roll

off easily while improving the field of view to nearly 180°, compared with a

150° for a flat window. All four sensors are integrated directly into the

instrument body, instead of separate modules mounted onto the housing. Each

sensor is calibrated individually for optimal accuracy.

Two temperature sensors, a thermistor and a Pt-100, are integrated with the

CNR4 body. The temperature sensor is used to provide information to correct

the infrared readings for the temperature of the instrument housing. Care has

been taken to place the long-wave sensors close to each other and close to the

temperature sensors. This ensures that the temperatures of the measurement

surfaces are the same and accurately known, improving the quality of the longwave measurements. A completion resistor is added in the pig tail end of the

thermistor cable providing an easy interface with dataloggers for half-bridge

measurement.

The CNR4 design is light weight and has an integrated solar shield that reduces

thermal effects on both the short-wave and the long-wave measurements. The

cables are made from Santoprene® jacket, which is intended for outdoor use,

7

Page 16

CNR4 Net Radiometer

and is resistant to a variety of pollutants and UV-radiation. The mounting rod

can be unscrewed for transport.

An optional ventilation unit with a heater, CNF4, is designed as an extension of

the solar shield and can be fitted to the CNR4 or retrofitted later. The

heater/ventilation unit is compact and provides efficient air-flow over the

domes and windows to minimize the formation of dew and to reduce the

frequency of cleaning. The integrated heater can be used to melt frost.

The CNR4 design is such that both the upward facing and the downwardfacing instruments measure the energy that is received from the whole

hemisphere (180° field of view). The output is expressed in W/m

spectral range that is measured is roughly from 0.3 to 42 μm. This spectral

range covers both the short-wave solar radiation, 0.3 to 2.8 μm, and the longwave far infrared radiation, 4.5 to 42 μm. The gap between these two produces

negligible errors.

The CNR4 is manufactured by Kipp & Zonen, but cabled for use with

Campbell Scientific dataloggers. Its cables can terminate in:

• Pigtails that connect directly to a Campbell Scientific datalogger

(cable termination option –PT).

• Connector that attaches to a prewired enclosure (cable termination

option –PW).

2

. The total

6. Specifications

Features:

Compatible Dataloggers: CR1000

CR3000

CR5000

• Research-grade performance

• Meniscus dome on upper long-wave detector allows water droplets to

easily roll off of it and increases field of view to nearly 180°

• Internal temperature sensors provide temperature compensation of

measurements

• Drying cartridge helps keep the electronics dry

• Compatible with the CNF4 ventilation unit with heater that reduces

formation of dew and melts frost

• Separate outputs of short-wave and long-wave infrared radiation for

better accuracy and more thorough quality assurance

• Solar shield reduces thermal effects on the sensors

8

Page 17

CNR4 Net Radiometer

The properties of the CNR4 are mainly determined by the properties of the

individual probes. Generally the accuracy of the CNR4 will be higher than that

of competitive net-radiometers, because the solar radiation measurement

performed by the pyranometer is accurate, and offers a traceable calibration.

Also the optionally integrated heater/ventilator unit improves the accuracy.

Due to the fact that the net short-wave radiation can be very intense, 1000

2

compared to a typical –100 W/m2 net long-wave radiation, the accuracy

W/m

of the short-wave radiation measurement is critical. Wind corrections, as

applied by less accurate competitive instruments are not necessary. The robust

materials used imply that the CNR4 will not suffer damages inflicted by birds.

FIGURE 6-1 and FIGURE 6-2 show the CNR4 with and without the CNF4

heater/ventilator. From a spectral point of view, the pyranometer and

pyrgeometer are complementary, and together they cover the full spectral

range.

FIGURE 6-1. The CNR4 net radiometer with cables and mounting rod,

top view

FIGURE 6-2. The CNR4 net radiometer with CNF 4 heater/ventilator

unit, top view

9

Page 18

CNR4 Net Radiometer

6.1 CNR4 Specifications

Sensor sensitivities:

Operating temperature:

Operating humidity:

Bubble level sensitivity:

Sensor type:

Receiver paint:

Desiccant:

Housing material:

Shock/vibration:

CE:

Environmental protection:

Requirements for data acquisition

Radiation components:

Thermistor:

Pt-100 temperature:

Cable length:

Weight

Sensor:

Heater/ventilator, CNF4

(optional):

Mounting rod:

Four probes with unique sensitivity

values. Please refer to the calibration

sheets or label on the bottom of the

sensor for the sensitivity values.

–40 to +80°C (–40 to 176°F)

0 to 100% RH

< 0.5°

Thermopile

Carbon Black

Silica gel (replaceable)

Anodized aluminum body

IEC 721-3-2-2m2

Complies with EC guideline

89/336/EEC 73/23/EEC

IP 67

4 differential or 4 single-ended analog

channels

1 voltage excitation and 1 singleended analog channel

1 current excitation and 1 differential

analog channel.

User defined

0.85 kg (1.89 lb) without cables

0.50 kg (1.11 lb) without cables

34.7 cm (13.67 in) length

1.6 cm (0.63 in) diameter

10

6.2 Pyranometer Specifications

* indicates ISO specifications.

Spectral range:

Sensitivity:

Response time*:

Non-linearity*:

Non-stability*:

Temperature dependence of

sensitivity*:

Tilt response*:

305 to 2800 nm (50% points)

10 to 20 µV/W/m

2

< 18 seconds (95% response)

< 1% (0 to 1000 W m

-2

irradiance)

< 1%

< 4% (–10° to +40°C)

< 1% at any angle with 1000 W/m

2

Page 19

CNR4 Net Radiometer

Directional error*:

Zero offset due to 0 to -200 W/m

2

IR net irradiance*:

Zero offset due to temperature

change*:

Operating temperature:

Field of view

Upper detector:

Lower detector:

Maximum solar irradiance:

Expected accuracy for daily totals:

Typical signal output for

atmospheric application:

Impedance:

Detector:

< 20 W/m

1000 W/m

< 15 W/m

< 3 W/m

< 1 W/m

2

at angle up to 80° with

2

2

2

(5 K/hr temperature change)

2

(with CNF4 installed)

–40°C to +80°C

180°

150° (due to lower solar shield to

prevent illumination at low zenith

angles)

2000 W/m

2

±10 %

0 to 15 mV

20 to 200 Ω, typically 50 Ω

Copper-constantan multi-junction

thermopile

Level accuracy:

Irradiance:

Spectral selectivity:

Uncertainty in daily total:

Instrument calibration:

6.3 Pyrgeometer Specifications

Spectral range:

Sensitivity:

Impedance:

Response time:

Non-linearity:

Temperature dependence of

sensitivity:

Tilt error:

1 degree

0 to 2000 W/m

2

< 3% (330 to 1500 nm spectral

interval)

< 5% (95% confidence level)

Indoors. Side by side against reference

CMP3 pyranometer according to ISO

9847:1992 annex A.3.1

4.5 to 42 μm (50% points)

2

5 to 15 μV/W/m

20 to 200 Ω (typically 50 Ω)

< 18 seconds (95% response)

2

< 1% (–250 to +250 W/m

irradiance)

< 4% (–10° to +40°C)

< 1% (deviation when tilted at any

angle off horizontal)

Zero offset due to temperature

change:

±4 W/m

2

(5 K/hr temperature change)

11

Page 20

CNR4 Net Radiometer

Field of view

Upper:

Lower:

Net-irradiance:

Non-stability:

Window heating offset:

Uncertainty in daily total:

Typical signal output for

atmospheric application:

Temperature sensors

Thermistor:

Pt-100:

Instrument calibration:

180 degrees

150 degrees

2

–250 to +250 W/m

< 1% (sensitivity change per year)

< 6 W/m

2

(1000 W/m

2

solar

irradiance)

< 10% (95% confidence level) indoor

calibration

±5 mV

10k Ω

DIN class A

Indoors, side by side against reference

CG(R) 3 pyrgeometer. On request

outdoors, side by side against

reference CG(R) 4 pyrgeometer

6.4 Optional CNF4 Heater/Ventilator

The purpose of the heater/ventilator is to prevent dew deposition on the

pyrgeometer and pyrgeometer window, thus enhancing the measurement

accuracy and reliability. Using the heater/ventilator will have negligible effect

on the pyranometer reading.

Generally, the errors caused by the heater/ventilator will be small relative to the

errors that would have been caused by water deposition.

6.4.1 CNF4 Specifications

Heater

Power consumption:

Ventilator

Power consumption:

Supply voltage:

Weight without cable:

Operating temperature:

10 W @ 12 Vdc (15 Ω)

5 W @ 12 Vdc

8 to 13.5 Vdc

0.5 kg (1.11 lb)

–40 to +80°C

12

Page 21

7. Operation

7.1 Using the CNR4 in the Four Separate Components Mode

7.1.1 Measuring Short-wave Solar Radiation with Pyranometer

CNR4 Net Radiometer

In the four separate components mode configuration (measuring two shortwave radiation signals and two long-wave signals), all signals are measured

separately. Calculation of net-radiation and albedo can be done online by the

datalogger, or offline by the user during post-processing, using the stored raw

data.

The two pyranometers will measure the short-wave radiation, both incoming

and reflected. The two pyrgeometers will measure the long-wave radiation.

For proper analysis of the pyrgeometer measurement results, they must be

temperature corrected using the temperature measurement performed by the

onboard thermistor or Pt-100 sensor.

The pyranometer generates an mV signal that is simply proportional to the

incoming short-wave radiation. The conversion factor between voltage, V, and

2

of solar irradiance E, is the calibration constant C or sensitivity

W/m

(Equation 7-1).

For each pyranometer,

E = V/C (7-1)

Measuring with a pyranometer can be done by connecting two pyranometer

wires to a datalogger. Incidental light results in a positive signal. The

pyranometer mounting plate and ambient air should be at the same

temperature. Conversion of the voltage to irradiance can be done according to

Equation 7-1, and is computed by the datalogger program.

With the upward-facing pyranometer, the global (solar) downwelling radiation

is measured. The downward-facing pyranometer measures the reflected

upwelling solar radiation. When calculating the net radiation, the upwelling

radiation must be subtracted from the downwelling radiation. See Section

7.1.5, Calculation of Net Short-wave Radiation.

7.1.2 Measuring Long-wave Far Infrared Radiation with Pyrgeometer

When using the pyrgeometer, you should realize the signal generated by the

pyrgeometer represents the exchange of long-wave far infrared (thermal)

radiation between the pyrgeometer and the object that it is facing. This implies

that the pyrgeometer will generate a positive voltage output, V, when it faces

an object that is hotter than its own sensor housing, and that it will give a

negative voltage signal when it faces an object that is colder. Therefore, when

estimating the far infrared radiation that is generated by the object facing the

pyrgeometer, usually the sky or the soil, you will have to take the pyrgeometer

temperature, T, into account. This is why the temperature sensors are

incorporated in the CNR4’s body near the pyrgeometer sensing element, and

has, therefore, the same temperature as the pyrgeometer sensor surface. The

calculation of the long-wave far infrared irradiance, E, is done according to

Equation 7-2.

13

Page 22

CNR4 Net Radiometer

For the pyrgeometer only

E = V/C + 5.67•10

-8•T4

In this equation, C is the sensitivity of the sensor.

NOTE

T is in Kelvin, and not in Celsius or Fahrenheit.

The downward-facing pyrgeometer measures the far infrared radiation that is

emitted by the ground. The upward-facing pyrgeometer measures the far

infrared radiation from the sky. As the sky is typically colder than the

instrument, one can expect negative voltage signals from the upward-facing

pyrgeometer. Equation 7-2 is used to calculate the far infrared irradiance of the

sky and of the ground.

7.1.3 Measuring CNR4 Temperature with Thermistor

The CNR4 has two temperature sensors built inside: thermistor and Pt-100;

both have identical accuracy. Using the thermistor is recommended when

using Campbell Scientific dataloggers. The thermistor has a greater resistance

(10 kΩ @ 25°C) than Pt-100 sensor (100 Ω @ 0°C), and the change in

resistance with respect to temperature, in absolute terms, is greater. Therefore,

the cable resistance can be neglected, and the thermistor can easily be

measured using Half-Bridge Measurement instruction on Campbell Scientific

dataloggers.

(7-2)

TABLE 7-1 shows the thermistor resistance values as a function of

temperature.

TABLE 7-1. Resistance values versus CNR4’s thermistor temperature in °C.

Temperature

[°C]

–30

–29

–28

–27

–26

–25

–24

–23

–22

–21

–20

–19

–18

–17

–16

–15

–14

Resistance

[Ω]

135200

127900

121100

114600

108600

102900

97490

92430

87660

83160

78910

74910

71130

67570

64200

61020

58010

Temperature

[°C]

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Resistance

[Ω]

29490

28150

26890

25690

24550

23460

22430

21450

20520

19630

18790

17980

17220

16490

15790

15130

14500

Temperature

[°C]

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

Resistance

[Ω]

8194

7880

7579

7291

7016

6752

6500

6258

6026

5805

5592

5389

5193

5006

4827

4655

4489

14

Page 23

CNR4 Net Radiometer

TABLE 7-1. Resistance values versus CNR4’s thermistor temperature in °C.

Temperature

[°C]

–13

–12

–11

–10

–9

–8

–7

–6

–5

–4

–3

–2

–1

Relatively small errors occur when the CNR4 is not in thermal equilibrium.

This happens for example when the heater is on, or when the sun is shining.

When the heater and ventilator are on, the largest expected deviation between

the real sensor temperature and the thermistor reading is 1 degree. This results

in a worst case error for the pyrgeometer of 5 W/m

the largest expected deviation between the real sensor temperature and the

thermistor reading is again 1 degree. This results in a worst case error for the

pyrgeometer of 5 W/m

Resistance

[Ω]

55170

52480

49940

47540

45270

43110

41070

39140

37310

35570

33930

32370

30890

Temperature

[°C]

17

18

19

20

21

22

23

24

25

26

27

28

29

2

.

Resistance

[Ω]

13900

13330

12790

12260

11770

11290

10840

10410

10000

9605

9227

8867

8523

Temperature

[°C]

47

48

49

50

51

52

53

54

55

56

57

58

59

2

. When the sun is shining,

Resistance

[Ω]

4331

4179

4033

3893

3758

3629

3504

3385

3270

3160

3054

2952

2854

The thermistor will not give a good indication of ambient air temperature; at

1000 W/m

2

solar radiation, and no wind, the instrument temperature will rise

approximately 5 degrees above the ambient temperature.

The offsets of both the pyranometers and the pyrgeometers might be larger

than 5 W/m

2

if large temperature gradients are forced on the instrument (larger

than 5 K/hr); for example, when rain hits the instrument. This occurrence can

be detected using the thermistor readout, and can be used for data filtering.

The thermistor measurement is calculated by the datalogger, using the Half-

Bridge Measurement instruction, which requires one voltage excitation and

one single-ended analog channel.

Alternatively, you can use the Pt-100 to make the temperature measurement.

In order to make the temperature measurement, using the Pt-100 sensor, you

will need one current excitation channel, and one differential analog channel.

TABLE 7–2 shows the Pt-100 resistance values as a function of temperature.

Please refer to Appendix C, CR3000 Program for Measuring Pt-100

Temperature Sensor, for a sample program to measure Pt-100.

15

Page 24

CNR4 Net Radiometer

TABLE 7–2. Resistance values versus CNR4’s Pt–100 temperature in °C.

Temperature

[°C]

–30

–29

–28

–27

–26

–25

–24

–23

–22

–21

–20

–19

–18

–17

–16

–15

–14

–13

–12

–11

–10

–9

–8

–7

–6

–5

–4

–3

–2

–1

Resistance

[Ω]

88.22

88.62

89.01

89.40

89.80

90.19

90.59

90.98

91.37

91.77

92.16

92.55

92.95

93.34

93.73

94.12

94.52

94.91

95.30

95.69

96.09

96.48

96.87

97.26

97.65

98.04

98.44

98.83

99.22

99.61

Temperature

[°C]

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Resistance

[Ω]

100.00

100.39

100.78

101.17

101.56

101.95

102.34

102.73

103.12

103.51

103.90

104.29

104.68

105.07

105.46

105.85

106.24

106.63

107.02

107.40

107.79

108.18

108.57

108.96

109.35

109.73

110.12

110.51

110.90

111.28

Temperature

[°C]

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

Resistance

[Ω]

111.67

112.06

112.45

112.83

113.22

113.61

113.99

114.38

114.77

115.15

115.54

115.93

116.31

116.70

117.08

117.47

117.85

118.24

118.62

119.01

119.40

119.78

120.16

120.55

120.93

121.32

121.70

122.09

122.47

122.86

16

7.1.4 Calculation of Albedo

Albedo is the ratio of reflected short-wave radiation to incoming short-wave

radiation. This unitless value ranges between 0 and 1. Typical values are 0.9

for snow, and 0.3 for grassland. To determine the albedo, the measured values

of the two pyranometers are used. Do not use the measured values when the

solar elevation is lower than 10 degrees above the horizon. Errors in the

measurements at these elevations are likely and yield unreliable results. This is

due to deviations in the directional response of the pyranometers.

Albedo = (E lower Pyranometer) / (E upper Pyranometer) (7-3)

In the equation above, E is calculated according to the Equation 7-1.

Page 25

Albedo will always be smaller than 1. Checking this can be used as a tool for

quality assurance of your data. If you know the approximate albedo at your

site, the calculation of albedo can also serve as a tool for quality control of your

measured data at a specific site.

7.1.5 Calculation of Net Short-wave Radiation

The net short-wave solar radiation is equal to the incoming (downwelling)

short-wave radiation minus the reflected (upwelling) short-wave radiation.

Net Short-wave Radiation = (E upper Pyranometer)

– (E lower Pyranometer) (7-4)

In the equation above, E is calculated according to Equation 7-1.

Net short-wave solar radiation will always be positive. This can be used as a

tool for quality assurance of your measured data.

7.1.6 Calculation of Net Long-wave Radiation

The net long-wave far infrared radiation is the part that contributes to heating

or cooling of the earth’s surface. In practice, usually the net long-wave far

infrared radiation will be negative.

CNR4 Net Radiometer

Net Long-wave Radiation = (E upper Pyrgeometer)

– (E lower Pyrgeometer) (7-5)

In the equation above, E is calculated according to Equation 7-2. According to

Equation 7-5 above, the terms that contain the sensor body temperature, T,

cancel each other. Therefore, if one is only interested in the net long-wave

radiation, instead of separate upper and lower components of the long-wave

radiation, the CNR4 temperature measurement is not required.

The E measured with the pyrgeometer actually represents the irradiance of the

sky (for upward-facing pyrgeometer) or the ground (for downward-facing

pyrgeometer). Assuming that these two, ground and sky, behave like perfect

blackbodies, theoretically, one can calculate an effective “sky temperature” and

an effective “ground temperature”.

4/1

rPyrgeometeupper E

⎡

eTemperaturSky

=

⎢

⎣

⎡

eTemperatur Ground

=

⎢

⎣

−

1067.5

⋅

1067.5

⋅

⎤

(7-6)

⎥

8

⎦

4/1

rPyrgeometelower E

⎤

⎥

8

−

⎦

(7-7)

As a rule of thumb, for ambient temperatures of about 20 degrees Celsius, one

can say that one degree of temperature difference between two objects results

in a 5 W/m

2

exchange of radiative energy (infinite objects):

1 degree of temperature difference = 5 W/m

2

(rule of thumb)

17

Page 26

CNR4 Net Radiometer

7.1.7 Calculation of Net (Total) Radiation

In the four separate components mode, net radiation, Rn, can be calculated

using the individual sensor measurement results:

7.2 Wiring

R

+ {(E upper Pyrgeometer) - (E lower Pyrgeometer)} (7-8)

Where E upper/lower pyranometers are calculated according to Equation 7-1,

and E upper/lower pyrgeometers are calculated according to Equation 7-2. The

terms with T cancel each other out.

The CNR4 has two outputs for short-wave radiation, two outputs for long-wave

radiation, thermistor output, and Pt-100 temperature sensor output. In addition,

if a user chooses to attach the optional CNF4 heater/ventilator unit, it will have

power wires for heater and ventilator. All wiring diagrams shown in this

manual and the sample programs will use the thermistor for the temperature

measurement of the CNR4. The wiring diagrams for the thermistor in this

manual is applicable only if the CNR4 and the cables were purchased from

Campbell Scientific, Inc.

The CNR4 comes with two sets of cables labelled SOLAR and TEMP, as

shown in FIGURE 7-1. FIGURE 7-2 shows the marks by the connecting ports

at the sensor’s end for the cable connection: S and T for SOLAR and TEMP

cables, respectively. The two cables, SOLAR and TEMP, have identical

connectors, and care should be used to ensure that the correct cables are

connected to the correct ports of the sensor.

= {(E upper Pyranometer) - (E lower Pyranometer)}

n

18

FIGURE 7-1. The CNR4 sensor with SOLAR and TEMP cables

Page 27

CNR4 Net Radiometer

FIGURE 7-2. The marks on the end of the CNR4: S for SOLAR cable,

and T for TEMP cable

NOTE

The measurement details for Pt-100 sensor, including the wiring diagram and

sample program, are explained in Appendix C, CR3000 Program for

Measuring Pt-100 Temperature Sensor.

The four radiation outputs can be measured using differential or single-ended

inputs on the datalogger. A differential voltage measurement is recommended

because it has better noise rejection than a single-ended measurement.

When differential inputs are used, jumper the low side of the

input to AG or to keep the signal in common mode range.

TABLE 7-3 and TABLE 7-4 show the wiring instructions for the differential

measurement and single-ended measurement connections to the datalogger,

respectively. The cables have the white band at the pigtail end of the cable

with the color keys. See FIGURE 7-3 and FIGURE 7-4 below for the labels on

the cable for both the SOLAR and TEMP cables.

FIGURE 7-3. Labels on the pigtail end of the SOLAR cable

19

Page 28

CNR4 Net Radiometer

FIGURE 7-4. Labels on the pigtail end of the TEMP cable.

TABLE 7-3. Datalogger Connections for Differential Measurement

Function Wire Color CR1000 CR3000/CR5000

Pyranometer Up Signal Red Differential Input (H) Differential Input (H)

Pyranometer Up R rential Input (L) eference *Blue Differential Input (L) Diffe

Pyranometer Down Signal White Differential Input (H) Differential Input (H)

Pyranome eference Differ t (L) Dter Down R *Black ential Inpu ifferential Input (L)

Pyrgeometer Up Signal Grey Differential Input (H) Differential Input (H)

Pyrgeometer Up Reference * Yellow Differential Input (L) Differential Input (L)

Pyrgeometer Down Signal Brown Differential Input (H) Differential Input (H)

Pyrgeometer Down Reference *Green Differential Input (L) Differential Input (L)

Shield Clear

Thermistor Signal White Single-Ended Input Single-Ended Input

Thermistor Voltage Excitation Red V V oltage Excitation (VX) oltage Excitation (VX)

Thermistor Signal Reference Black

Sh ld Clear ie

*Jumper to with user supplied wire.

. Datalo onnections for Single nded Measurement TABLE 7-4 gger C -E

Function Wire Color CR1000 CR3000/CR5000

Pyranometer Up Signal Red Single-Ended Input Single-Ended Input

Pyranometer Up Reference Blue

Pyranometer Down Signal White Single-Ended Input Single-Ended Input

Pyranome eference ter Down R Black

Pyrgeometer Up Signal Grey Single-Ended Input Single-Ended Input

Pyrgeometer Up Reference Yellow

Pyrgeometer Down Signal Brown Single-Ended Input Single-Ended Input

Pyrgeometer Down Reference Green

Shield Clear

Thermistor Signal White Single-Ended Input Single-Ended Input

Thermistor Voltage Excitation Red Voltage Excitation (VX) Voltage Excitation (VX)

Thermistor Signal Reference Black

Shield Clear

*P , brown, nd yello and t

ull b (grey

ack wires for Pt-100 green, a w e,

c l tape to possible o e

able using a cable tie or electrica

avoid

), which are not in us ie P

damage to the Pt-100, due t

them around the TEM

lectrical short circuit.

20

Page 29

CNR4 Net Radiometer

7.3 Datalogger Pro ming

The CNR4 outputs four voltages that typically range from 0 to 15 mV for the

pyranometers, and ± 5 mV for the pyrgeometers. A differential voltage

measurement is recommended because it has better noise rejection than a

single-ended measurement. If differential channels are not available, singleended measurements can be used. The acce

measurement can be determin

ended and differential measurements made under the same conditions.

Additionally, one voltage excitation channel and one single-ended analog

channel are required to make the temperature measurement of the sensor bod

using the thermistor.

7.3.1 Sensor Sens

The CNR4 comes with four different sensor sensitivity values for four sepa

probes. The CNR4 sensor comes with two copies of its ‘Certificate of

Calibration’ by the ma

sensitivity values for four individual probes: one copy for pyranometers, and

another cop

also shown

attach the CNF4 heater/ventilator unit to the CNR4, the label showing the

serial number and sensitivity values will be covered. After attaching the

heater/ventilator, affix the extra label to the bottom of the CNF4 in a visible

location. The extra label containing the serial number and sensitivity values is

supplied with the purchase of the CNR4. Please refer to Appendix B, CNF4

Heater/Ventilator, for more details.

gram

itivity

nufacturer. They show the sensor serial number and

y for pyrgeometers. The serial number and sensitivity values are

on a label affixed to the bottom of the sensor. If you choose to

ptability of a single-ended

ed by simply comparing the results of single-

y,

rate

CNF4

7.3.2 Example Pro

7.3.2.1 Example 1, CR

2

The sensor sensitivity is in μV/(W/m

2

)/mV to be used as a multiplier parameter inside the datalogger program

(W/m

To convert the units, divide the sensor sensitivity value into 1000. For

example, if the sensitivity is 7.30 μV/(W/m

136.99 (W/m

2

)/mV.

). This needs to be converted into

2

), the multiplier is 1000/7.3 =

grams

1000 Program Using Differential Measurements

Example 1 requires fo

outputs, one excitation channel, and one single-ended channel to measure the

thermistor. T

online proce

table called cnr4_data once every 60 minutes. It also stor

data from CNR4 to data table called cnr4_ts.

Minimum battery voltage

Sample datalogger panel temperature

Average short-wave radiation (pyranometer up)

Average short-wave radiation (pyranometer down)

Average long-wave radiation (pyrge

Average long-wave radiation (pyrgeometer down)

Average CNR4 thermistor

Average CNR4 thermistor temperature

Average corrected long-wave radiation (pyrgeom

Average corrected long-wave radiation (pyrgeometer do

he program measures the sensors every 1 second, performs the

ssing of the data, and stores the following processed data to a data

ur differential channels to measure the four radiation

es the raw time-series

ometer up)

temperature (degrees C)

(Kelvin)

eter up)

wn)

.

21

Page 30

CNR4 Net Radiometer

'CR1000 Series Dat logger a

'

'CNR4 program

'This program meas er ures CNR4 four-component net radiomet

'This program also NR4 measures the thermistor inside the C

'

'User must enter the sensitivity values for all four probes in the program and save/compile

'prior to downloading it to the datalogger.

'Search for the text string "unique" to find places to enter the sensitivity values.

'

'Wiring Instructions

'

'ANALOG CHANNELS

'1H CNR4 Pyranometer Upper signal (red)

'1L CNR4 Pyranometer Upper signal reference (blue)

'gnd jumper to 1L

'

'2H CNR4 Pyranometer Lower signal (white)

'2L CNR4 Pyranometer Lower signal reference (black)

'gnd jumper to 2L

'

'3H CNR4 Pyrgeometer Upper signal (grey)

'3L CNR4 Pyrgeometer Upper signal reference (yellow)

'gnd jumper to 3L

'

'4H CNR4 Pyrgeometer Lower signal (brown)

'4L CNR4 Pyrgeometer Lower signal reference (green)

'gnd jumper to 4L

' CNR4 shield (clear)

'

'

'

'8H

'8L CNR4 thermistor signal (white)

'gnd CNR4 thermistor signal reference (black)

' CNR4 thermistor shield (clear)

'

'VOLTAGE EXCITATION

'

'EX2 CNR4 thermistor voltage excitation (red)

'

'CNR4 sensor

Public logger_temp, batt_volt

Public cnr4(4)

Alias cnr4(1) = short_up

Alias cnr4(2) = short_dn

Alias cnr4(3) = long_up

Alias cnr4(4) = long_dn

Public cnr4_T_C 'CNR4 thermistor temperature in Celcius

Public cnr4_T_K 'CNR4 thermistor temperature in Kelvin

Public long_up_corr 'Downwelling long-wave radiation with temperature correction

Public long_dn_corr 'Upwelling long-wave radiation with temperature correction

Public Rs_net 'short-wave net radiation

Public Rl_net 'long-wave net radiation

Public albedo 'Albedo

Public Rn 'total net radiation

Average short-wave net radiation

Average long-wave net radiation

Average albedo

Average net radiation

22

Page 31

CNR4 Net Radiometer

Units logger_temp = d gC e

Units batt_volt s = volt

Units short_up = W/m^2

Units short_dn = W/m^2

Units long_up = W/m^2

Units long_dn = W/m^2

Units cnr4_T_C = deg_C

Units cnr4_T_K = K

Units long_up_corr = W/m^2

Units long_dn_corr = W/m^2

Units Rs_net = W/m^2

Units Rl_net = W/m^2

Units albedo = W/m^2

Units Rn = W/m^2

Dim Rs, Vs_Vx

'CNR4 sensitivities: refer to the Certificate of Calibration from Kipp & Zonen for sensitivity values

'for each probes, and enter them below.

Const pyranometer_up_sensitivity = 15.35 'unique sensitivity for upper pyranometer

'(microV/W/m^2)

Const pyranometer_dn_sensitivity = 15.41 'unique sensitivity for lower pyranometer

'(microV/W/m^2)

Const pyrgeometer_up_sensitivity = 8.50 'unique sensitivity for upper pyrgeometer

'(microV/W/m^2)

Const pyrgeometer_dn_sensitivity = 7.09 'unique sensitivity for lower pyrgeometer

'(microV/W/m^2)

'CNR4 multipliers

Public cnr4_mult(4)

Const pyranometer_up_mult = 1000/pyranometer_up_sensitivity '(W/m^2/mV)

Const pyranometer_dn_mult = 1000/pyranometer_dn_sensitivity '(W/m^2/mV)

Const pyrgeometer_up_mult = 1000/pyrgeometer_up_sensitivity '(W/m^2/mV)

Const pyrgeometer_dn_mult = 1000/pyrgeometer_dn_sensitivity '(W/m^2/mV)

DataTable (cnr4_data,True,-1)

DataInterval (0,60,Min,10)

CardOut (1,-1)

Minimum (1,batt_volt,FP2,0,False)

Sample (1,logger_temp,FP2)

Average (4,cnr4(1),IEEE4,False)

Average (1,cnr4_T_C,IEEE4,False)

Average (1,cnr4_T_K,IEEE4,False)

Average (1,long_up_corr,IEEE4,False)

Average (1,long_dn_corr,IEEE4,False)

Average (1,Rs_net,IEEE4,False)

Average (1,Rl_net,IEEE4,False)

Average (1,albedo,IEEE4,False)

Average (1,Rn,IEEE4,False)

EndTable

DataTable (cnr4_ts,True,-1)

DataInterval (0,1,Sec,10)

CardOut (1,-1)

Sample (4,cnr4(1),IEEE4)

Sample (1,cnr4_T_K,IEEE4)

EndTable

BeginProg

'Load the multiplier values for the CNR4

cnr4_mult(1) = pyranometer_up_mult

cnr4_mult(2) = pyranometer_dn_mult

cnr4_mult(3) = pyrgeometer_up_mult

cnr4_mult(4) = pyrgeometer_dn_mult

23

Page 32

CNR4 Net Radiometer

Scan (1,Sec,3,0)

PanelTemp (logger_temp,250)

Battery (batt_volt)

'CNR4 radiation measurements

VoltDiff (cnr4(),4,mV20C,1,True ,0,_60Hz,cnr4_mult(),0)

'CNR4 thermistor measurement

BrHalf (Vs_Vx,1,mV2500,16,Vx2,1,2500,True ,0,250,1.0,0)

Rs = 1000*(Vs_Vx/(1-Vs_Vx))

cnr4_T_C = 1/(1.0295e-3+2.391e-4*LN(Rs)+1.568e-7*(LN(Rs))^3)-273.15

'Convert CNR4 temperature to Kelvin

cnr4_T_K = cnr4_T_C+273.15

'Correct the long-wave radiation values from pyrgeometers

long_up_corr = long_up+5.67e-8*cnr4_T_K^4

long_dn_corr = long_dn+5.67e-8*cnr4_T_K^4

'Compute short-wave net radiation

Rs_net = short_up - short_dn

'Compute long-wave net radiation

Rl_net = long_up - long_dn

'Compute albedo

albedo = short_dn/short_up

'Compute net radiation

Rn = Rs_net + Rl_net

CallTable cnr4_data

CallTable cnr4_ts

NextScan

EndProg

7.3. ing Differential Measurements

2.2 Example 2, CR3000 Program Us

Example 2 requires fo

outputs and one excitation

the thermistor. The progra

the online processin

data table called cn

series data from CN

ur differential channels to measure the four radiation

channel and one single-ended channel to measure

m measures the sensors every 1 second, performs

g of the data and stores the following processed data to a

r4_data once every 60 minutes. It also stores the raw time-

R4 to data table called cnr4_ts.

Minimum battery voltage

Sam

Ave

Ave

Ave

Aver

ple datalogger panel temperature

rage short-wave radiation (pyranometer up)

rage short-wave radiation (pyranometer down)

rage long-wave radiation (pyrgeometer up)

age long-wave radiation (pyrgeometer down)

Average CNR4 thermistor temperature (degrees C)

Average CNR4 thermistor temperature (Kelvin)

Average corrected long-w

Average corrected long-w

Average short-wave net ra

Average long-wave net ra

ave radiation (pyrgeometer up)

ave radiation (pyrgeometer down)

diation

diation

Average albedo

Average net radiation

24

Page 33

CNR4 Net Radiometer

'CR3000 Series Datalogger

'

'CNR4 program

'This program measures CNR4 four-component net radiometer

'This program also measures the thermistor inside the CNR4

'

'User must enter the sensitivity values for all four probes in the program and save/compile

'prior to downloading it to the datalogger.

'Search for the text string "unique" to find places to enter the sensitivity values.

'

'Wiring Instructions

'

'ANALOG CHANNELS

'1H CNR4 Pyranometer Upper signal (red)

'1L CNR4 Pyranometer Upper signal reference (blue)

'gnd jumper to 1L

'

'2H CNR4 Pyranometer Lower signal (white)

'2L CNR4 Pyranometer Lower signal reference (black)

'gnd jumnper to 2L

'

'3H CNR4 Pyrgeometer Upper signal (grey)

'3L CNR4 Pyrgeometer Upper signal reference (yellow)

'gnd jumper to 3L

'

'4H CNR4 Pyrgeometer Lower signal (brown)

'4L CNR4 Pyrgeometer Lower signal reference (green)

'gnd jumper to 4L

' CNR4 shield (clear)

'

'

'8H

'8L CNR4 thermistor signal (white)

'gnd CNR4 thermistor signal reference (black)

' CNR4 thermistor shield (clear)

'

'VOLTAGE EXCITATION

'

'VX1 CNR4 thermistor voltage excitation (red)

'

'CNR4 sensor

Public logger_temp, batt_volt

Public cnr4(4)

Alias cnr4(1) = short_up

Alias cnr4(2) = short_dn

Alias cnr4(3) = long_up

Alias cnr4(4) = lo g_dn n

Public cnr4_T_C 'CNR ius 4 thermistor temperature in Celc

Public cnr4_T_K 'CNR4 thermistor temperature in Kelvin

Public long_up_cor 'Dow re correction r nwelling long-wave radiation with temperatu

Public long_dn_cor 'Upw ection r elling long-wave radiation with temperature corr

Public Rs_net 'short-wave net radiation

Public Rl_net 'long-wave net radiation

Public albedo 'Albedo

Public Rn 'total net radiation

Units logger_temp degC =

Units batt_volt = olts v

Units short_up = W m^2 /

Units short_dn = W m^2 /

Units long_up = W/m^2

Units long_dn = W/m^2

Units cnr4_T_C = deg_C

Units cnr4_T_K = K

25

Page 34

CNR4 Net Radiometer

Units long_up_corr = W/m^2

Units long_dn_corr = W/m^2

Units Rs_net = W/m^2

Units Rl_net = W/m^2

Units albedo = W/m^2

Units Rn = W/m^2

Dim Rs, Vs_Vx

'CNR4 sensitivities: refer to the Certificate of Calibration from Kipp & Zonen for sensitivity values

'for each probes, and enter them below.

Const pyranometer_up_sensitivity = 15.35 'unique sensitivity for upper pyranometer

'(microV/W/m^2)

Const pyranometer_dn_sensitivity = 15.41 'unique sensitivity for lower pyranometer

'(microV/W/m^2)

Const pyrgeometer_up_sensitivity = 8.50 'unique sensitivity for upper pyrgeometer

'(microV/W/m^2)

Const pyrgeometer_dn_sensitivity = 7.09 'unique sensitivity for lower pyrgeometer

'(microV/W/m^2)

'CNR4 multipliers

Public cnr4_mult(4)

Const pyranometer_up_mult = 1000/pyranometer_up_sensitivity '(W/m^2/mV)

Const pyranometer_dn_mult = 1000/pyranometer_dn_sensitivity '(W/m^2/mV)

Const pyrgeometer_up_mult = 1000/pyrgeometer_up_sensitivity '(W/m^2/mV)

Const pyrgeometer_dn_mult = 1000/pyrgeometer_dn_sensitivity '(W/m^2/mV)

DataTable (cnr4_data,True,-1)

DataInterval (0,60,Min,10)

CardOut (1,-1)

Minimum (1,batt_volt,FP2,0,False)

Sample (1,logger_temp,FP2)

Average (4,cnr4(1),IEEE4,False)

Average (1,cnr4_T_C,IEEE4,False)

Average (1,cnr4_T_K,IEEE4,False)

Average (1,long_up_corr,IEEE4,False)

Average (1,long_dn_corr,IEEE4,False)

Average (1,Rs_net,IEEE4,False)

Average (1,Rl_net,IEEE4,False)

Average (1,albedo,IEEE4,False)

Average (1,Rn,IEEE4,False)

EndTable

DataTable (cnr4_ts,True,-1)

DataInterval (0,1,Sec,10)

CardOut (1,-1)

Sample (4,cnr4(1),IEEE4)

Sample (1,cnr4_T_K,IEEE4)

EndTable

BeginProg

'Load the multiplie alues for the CNR4 r v

cnr4_mu 1) = pyranometer_up_mult lt(

cnr4_mult 2) = pyranometer_dn_mult (

cnr4_mult 3) = pyrgeometer_up_mult (

cnr 4) = pyrgeometer_dn_mult 4_mult(

Scan (1,Sec,3,0)

PanelTe temp,250) mp (logger_

Battery (batt_volt)

'CNR4 radiation measurements

VoltDiff (cnr4(),4,mV20C,1,True ,0,_60Hz,cnr4_mult(),0)

26

Page 35

CNR4 Net Radiometer

'CNR4 thermistor measurement

BrHalf (Vs_Vx,1,mv5000,16,Vx1,1,2500,True ,0,250,1.0,0)

Rs = 1000*(Vs_Vx/(1-Vs_Vx))

cnr4_T_C = 1/(1.0295e-3+2.391e-4*LN(Rs)+1.568e-7*(LN(Rs))^3)-273.15

'Convert CNR4 temperature to Kelvin

cnr4_T_K = cnr4_T_C+273.15

'Correct the long-wave radiation values from pyrgeometers

long_up_corr = long_up+5.67e-8*cnr4_T_K^4

long_dn_corr = long_dn+5.67e-8*cnr4_T_K^4

'Compute short-wave net radiation

Rs_net = short_up - short_dn

'Compute long-wave net radiation

Rl_net = long_up - long_dn

'Compute albedo

albedo = short_dn/short_up

'Compute net radiation

Rn = Rs_net + Rl_net

CallTable cnr4_data

CallTable cnr4_ts

NextScan

EndProg

7.3. m Using Differential Measurements

2.3 Example 3, CR5000 Progra

ur differential channels to measure the four radiation

n channel, and one single-ended channel to measure the

easures the sensors every 1 second, performs the

a, and stores the following processed data to a data

ta once every 60 minutes. It also stores the raw time-series

data table called cnr4_ts.

NOTE

Example 3 requires fo

outputs, one excitatio

thermistor. The program m

online processing of the dat

table called cnr4_da

data from CNR4 to

The variables for the CR5000 datalogger can be up to 16

characters in length. However, if the variable is processed in the

output table by an

be truncate

underscore a

output type other than Sample, the name will

d in the datalogger to 12 characters, plus an

nd a 3 digit suffix indicating the output type (for

example, _avg, _max).

Minimum battery voltage

Sample datalogger panel temperature

Average short-wave radia

Average short-wave radia

Average

Average long-wave radiation (pyrgeometer up)

long-wave radiation (pyrgeometer down)

Average CNR4 thermistor temperature (degrees C)

tion (pyranometer up)

tion (pyranometer down)

Average CNR4 thermistor temperature (Kelvin)

Average corrected long-wave radiation (pyrgeometer up)

Average corrected long-wave radiation (pyrgeometer dow

Average short-wave net radiation

Average long-wave net radiation

Average albedo

Average net radiation

n)

27

Page 36

CNR4 Net Radiometer

'CR5000 Series Datalogger

'

'CNR4 program

'This program measures CNR4 four-component net radiometer

'This program also measures the thermistor inside the CNR4

'

'User must enter the sensitivity values for all four probes in the program and save/compile

'prior to downloading it to the datalogger.

'Search for the text string "unique" to find places to enter the sensitivity values.

'

'Wiring Instructions

'

'ANALOG CHANNELS

'1H CNR4 Pyranometer Upper signal (red)

'1L CNR4 Pyranometer Upper signal reference (blue)

'gnd jumper to 1L

'

'2H CNR4 Pyranometer Lower signal (white)

'2L CNR4 Pyranometer Lower signal reference (black)

'gnd jumnper to 2L

'

'3H CNR4 Pyrgeometer Upper signal (grey)

'3L CNR4 Pyrgeometer Upper signal reference (yellow)

'gnd jumper to 3L

'

'4H CNR4 Pyrgeometer Lower signal (brown)

'4L CNR4 Pyrgeometer Lower signal reference (green)

'gnd jumper to L 4

' CNR4 shield (clear)

'

'

'8H

'8L CNR4 thermistor signal (white)

'gnd CNR4 thermistor signal reference (black)

' CNR4 thermistor shield (clear)

'

'VOLTAGE EXCITATION

'

'VX1 CNR4 thermistor voltage excitation (red)

'

'CNR4 sensor

Public logger_temp, batt_volt

Public cnr4(4)

Alias cnr4(1) = short_up

Alias cnr4(2) = short_dn

Alias cnr4(3) = long_up

Alias cnr4(4) = long_dn

Public cnr4_T_C 'CNR ius 4 thermistor temperature in Celc

Public cnr4_T_K 'CNR4 thermistor temperature in Kelvin

Public long_up_cor 'Dow e correction r nwelling long-wave radiation with temperatur

Public long_dn_cor 'Upw correction r elling long-wave radiation with temperature

Public Rs_net 'short-wave net radiation

Public Rl_net 'long-wave net radiation

Public albedo 'Albedo

Public Rn 'total net radiation

Units logger_temp degC =

Units batt_volt = olts v

Units short_up = W m^2 /

Units short_dn = W m^2 /

Units long_up = W/m^2

Units long_dn = W/m^2

Units cnr4_T_C = deg_C

28

Page 37

CNR4 Net Radiometer

Units cnr4_T_K = K

Units long_up_corr = W/m^2

Units long_dn_corr = W/m^2

Units Rs_net = W/m^2

Units Rl_net = W/m^2

Units albedo = W/m^2

Units Rn = W/m^2

Dim Rs, Vs_Vx

'CNR4 sensitivities: refer to the Certificate of Calibration from Kipp & Zonen for sensitivity values

'for each probes, and enter them below.

Const pyra_up_sensitiv = 15.35 'unique sensitivity for upper pyranometer (microV/W/m^2)

Const pyra_dn_sensitiv = 15.41 'unique sensitivity for lower pyranometer (microV/W/m^2)

Const pyrg_up_sensitiv = 8.50 'unique sensitivity for upper pyrgeometer (microV/W/m^2)

Const pyrg_dn_sensitiv = 7.09 'unique sensitivity for lower pyrgeometer (microV/W/m^2)

'CNR4 multipliers

Public cnr4_mult(4)

Const pyra_up_mult = 1000/pyra_up_sensitiv '(W/m^2/mV)

Const pyra_dn_mult = 1000/pyra_dn_sensitiv '(W/m^2/mV)

Const pyrg_up_mult = 1000/pyrg_up_sensitiv '(W/m^2/mV)

Const pyrg_dn_mult = 1000/pyrg_dn_sensitiv '(W/m^2/mV)

DataTable (cnr4_dat,True,-1)

DataInterval (0,60,Min,10)

CardOut (1,-1)

Minimum (1,batt_volt,FP2,0,False)

Sample (1,logger_temp,FP2)

Average (4,cnr4(1),IEEE4,False)

Average (1,cnr4_T_C,IEEE4,False)

Average (1,cnr4_T_K,IEEE4,False)

Average (1,long_up_corr,IEEE4,False)

Average (1,long_dn_corr,IEEE4,False)

Average (1,Rs_net,IEEE4,False)

Average (1,Rl_net,IEEE4,False)

Average (1,albedo,IEEE4,False)

Average (1,Rn,IEEE4,False)

EndTable

DataTable (cnr4_ts,True,-1)

DataInterval (0,1,Sec,10)

CardOut (1,-1)

Sample (4,cnr4(1),IEEE4)

Sample (1,cnr4_T_K,IEEE4)

EndTable

BeginProg

'Load the multiplier values for the CNR4

cnr4_mult(1) = pyra_up_mult

cnr4_mult(2) = pyra_dn_mult

cnr4_mult(3) = pyrg_up_mult

cnr4_mu 4) = pyrg_dn_mult lt(

Scan (1,Sec,3,0)

PanelTemp (logger_temp,250)

Battery (ba ) tt_volt

'CNR4 radiation ements measur

Volt (),4,mV20C,1,True ,0,_60Diff (cnr4 Hz,cnr4_mult(),0)

'CNR4 thermistor measurement

BrHalf (Vs_Vx,1,mv5000,21,Vx1,1,2500,True ,0,250,1.0,0)

Rs = 1000*(Vs_Vx/(1-Vs_Vx))

cnr4_T_C = 1/(1.0295e-3+2.391e-4*LN(Rs)+1.568e-7*(LN(Rs))^3)-273.15

29

Page 38

CNR4 Net Radiometer

'Convert CNR4 temperature to Kelvin

cnr4_T_K = cnr4_T_C+273.15

'Correct the long-wave radiation values from pyrgeometers

long_up_corr = long_up+5.67e-8*cnr4_T_K^4

long_dn_corr = long_dn+5.67e-8*cnr4_T_K^4

'Compute short-wave net radiation

Rs_net = short_up - short_dn

'Compute long-wave net radiation

Rl_net = long_up - long_dn

'Compute albedo

albedo = short_dn/short_up

'Compute net radiation

Rn = Rs_net + Rl_net

CallTable cnr4_dat

CallTable cnr4_ts

NextScan

EndProg

8. Tr

8.1

oubleshooting

If there is no indicatio

following “upside-down te

be performed both outdoor

source for both shortpreferably work wi

above horizon) and

irradiance, and prefe

1. Measur

measure

e the radiation outputs in the normal position. Record the

d values when the signals have stabilized, i.e. after about three

minutes.

2. Rotate t

he instrument 180 degrees, so that the upper and the lower sensors

are now in the reverse orientation as to the previous position.

3. Measure the radiation out

when the radiometers

4. The computed net rad

magnitude but only differing in sign. In a rough test like this, deviations

of ± 10 % can be tolerated. If deviations greater than this are encountered,

additional tes

Testing the Pyranometer

wave and long-wave radiation. Outdoors, one should

th a solar elevation of more than 45 degrees (45 degrees

under stable conditions (no large changes in solar

rably no clouds).

ting is warranted.

n as to what may be the problem, start performing the

st”, which is a rough test for a first diagnosis. It can

s and indoors. Indoors, a lamp can be used as a

puts once more. Record the measured values

have stabilized.

iation values in rotated position should be equal in

30

As a first test,

indicated in the specifications. Zero, or infinite resistan

check the sensor impedance. It should have a nominal value as

ce, indicates a failure in

hardware connection.

Before starting the second test measurement, let the pyranometer rest for at

least five minutes to let it regain its thermal equilibrium. For testing, set a

Page 39

CNR4 Net Radiometer

voltmeter to its most sensitive range setting. Darken the sensor. The signal

should read zero; this response ca

from zero are possible; this is caused by the therm

the pyranometer with your hand. This thermal effe

deliberately heating the pyranometer with your hand. If

within specifications, proceed with the third test.

n take up to one minute. Small deviations

al effects, such as touching

ct can be demonstrated by

the zero offset is

In the third test, the sensor sho

positive reading. S

scale output of the pyranome

voltmeter. The range can be estimated on theoretical considerations. When the

maximum expected radiation is 1500

outdoor daylight conditions

2

, the e

W/m

22.5 mV. One can calculate the radiation intensity by dividing the

pyra ut as m the voltmeter ex ) nom

your

eter outp easured by (for ample, 22.5 mV by

sor sensitivity (15 μV/W/m

nthe se

pyranometer is probably operating correctly.

et the voltmeter range in such a way that the expected full-

xpected output range of the pyranometer is equal to 22500 μV, or

8.2 Testing the Pyrgeometer

It is assumed that the zero offset is no more than a few watts per square meter

(see second tes

The CNR4 body and the ambient air should be at the same temperature. Let

the pyrgeometer rest for at least five minutes to regain its thermal equilibrium.

Set the voltmeter to its most sensitive range. To test if the pyrgeometer is

working properly, put your hand in front of the pyrgeometer. The thermal

radiation from your hand will cause the pyrgeometer to generate a positive

voltage when the surface temperature of your hand is higher than the

pyrgeometer temperature. The pyrgeometer will generate a negative vo

the hand is colder. The signal is proportiona

the rule of thumb in Section 7.1.6, Calculation of Net Long-wave Radia

The

radiation emitted by the hand can be calculated by dividing the

pyrg tput by the sensor’s sensitivity value, and subsequently

eometer ou

correcting for the temperature, according to Equation 5-2. If there are still no

lt

fau s found, your pyrgeometer is probably operating correctly.

t in Section 8.1, Testing the Pyranometer).

uld be exposed to light. The signal should be a

ter is within the full-scale input range of the

2

, which is roughly equal to normal

W/m

, and the sensitivity of the pyranometer is 15 μV per

2

). If no faults are found up to this point,

ltage if

l to the temperature difference (see

tion).

8.3 Testing th

e Thermistor

Usin between the black and white wires

g a multimeter, measure the resistance

h

of t e thermistor, and compare the value with the resistance values listed in

TAB

LE 7-1. The resistance should be around 10 k Ω at 25 °C, and the cable

resist

ance should add about 0.026 Ω per each foot of cable. When in doubt, the

Pt-1 e checked as well for reference.

00 resistance (temperature) can b

8.4 Testing the Pt-100

Using a multimeter, measure the resistance between the two opposite wires of

the Pt-100 (gray-yellow, gray-brown, green-yellow, green-brown), and

compare the measured

The resistance should be above 100 Ω at 0°C, and the cable resistance should

add about 0.026 Ω per each foot of cable. When in doub,t the thermistor

resistance (temperature) can be checked as well for reference.

value with the resistance values listed in TABLE 7–2.

31

Page 40

CNR4 Net Radiometer

9. Maintenance

9.1 Cleaning W

9.2 Recalibrat

and Recalibration

The CNR4 is weatherproof, and is intended for a continuous outdoor use. The

materials used in the pyranometer and the pyrgeometer are robust and require

little maintenance. For optimal results, however, proper care must be take

indows and Domes

The radiometer readings can be reduced if domes and windows are not clean.

The site operator should check the windows and domes of the CNR4 regularly,

and clean them as needed. Use distilled water or alcohol as cleaning solution,

being careful not to scratch the windows and domes during cleaning.

ion

For quality assurance of the measured data, the manufacturer recommends th

CNR4 be recalibrated on a regular schedule by an a

calibration facility.

The CNR4 should be reca

check the sensor calibration by letting a higher standard run parallel to it over a

two-day period and, then, comparing the results. For comparison of

pyranometers, one should use a clear day. For comparison

one should compare the nighttime results. If the deviations are greater than

6%, the sensor should be recalibrated.

librated every two years. Alternatively, one can

uthorized Kipp & Zonen

of pyrgeometers,

n.

e

9.3 Replacing

Please contact Campbell Scientific to obtain an RMA number for recalibration.

the Drying Cartridge

The CNR4 has a drying cartridge inside the sensor to help keep the electronics

dry. The manufacturer recommends replacing the drying cartridge every 6 to

12 months. The three screws holding the white solar shield and the six

holding the aluminium base plate need to be removed to access the drying

cartridge, as shown in FIGURE 9-1. Make sure that the black rubber gasket is

put in place properly before the base plate is put back to keep the

sealed. The CNR4 comes with two spare drying cartridges. Additional drying

cartridges, pn 26006, c

an be purchased from Campbell Scientific.

screws

compartment

32

Page 41

t

Drying Cartridge

Rubber Gaske

FIGURE 9-1. Replacing the drying cartridge

CNR4 Net Radiometer

9.4 Replaceme

nt Parts

The following is the list of replacement

(heater/ventilator) available from Campbell Scientific.

CSI Part

Number

CNR4CBL1-L Replacement CNR4 Solar Cable

CNR4CBL2-L Replacement CNR4 Temperature Cable