Page 1

CMP6 -L, CMP11-L, and

CMP21-L Pyranometers

Revision: 9/13

Copyright © 2006-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements...............................................1

3. Initial Inspection .........................................................1

3.1 Ships With............................................................................................2

3.2 Calibration Certificate..........................................................................2

4. Quick Start................................................................... 2

4.1 Siting ....................................................................................................2

4.2 Mounting..............................................................................................3

4.3 Datalogger Programming / Wiring.......................................................5

5. Overview......................................................................6

5.1 Models..................................................................................................6

5.2 Construction.........................................................................................6

6. Specifications .............................................................7

6.1 Pyranometers........................................................................................7

6.2 CVF3 Ventilation Unit.........................................................................8

7. Installation...................................................................9

7.1 Mounting to a Tripod or Tower............................................................9

7.2 Wiring ................................................................................................11

7.2.1 CMP6, CMP11, and CMP21 Thermopile Schematic..................12

7.2.2 CMP6 and CMP11 Wiring..........................................................12

7.2.3 CMP21 Wiring............................................................................13

7.3 Programming......................................................................................14

7.3.1 Solar Radiation Measurements ...................................................14

7.3.1.1 Input Range ......................................................................15

7.3.1.2 Multiplier..........................................................................15

7.3.1.3 Offset................................................................................16

7.3.1.4 Output Format Considerations .........................................16

7.3.2 CMP21 Internal Thermistor Measurement .................................16

7.3.3 Example Programs......................................................................17

7.3.3.1 CR1000 Example Program for Measuring a CMP6.........17

7.3.3.2 CR1000 Example Program for Measuring a CMP11.......18

7.3.3.3 CR1000 Example Program for Measuring a CMP21.......19

7.3.3.4 CR10X Example Program for Measuring a CMP6..........20

i

Page 6

Table of Contents

8. Maintenance ..............................................................22

8.1 Cleaning Domes ................................................................................ 23

8.2 Changing the Desiccant..................................................................... 23

8.3 Check Sensor Output......................................................................... 24

8.4 Recalibration ..................................................................................... 24

9. Troubleshooting........................................................25

Appendix

A.

CVF3 Heater/Ventilator ...........................................A-1

A.1 General Information ........................................................................ A-1

A.2 Siting ............................................................................................... A-1

A.3 CVF3 Installation ............................................................................ A-2

A.4 Wiring.............................................................................................. A-4

A.5 CVF3 Heater/Ventilator Maintenance............................................. A-5

Figures

Tables

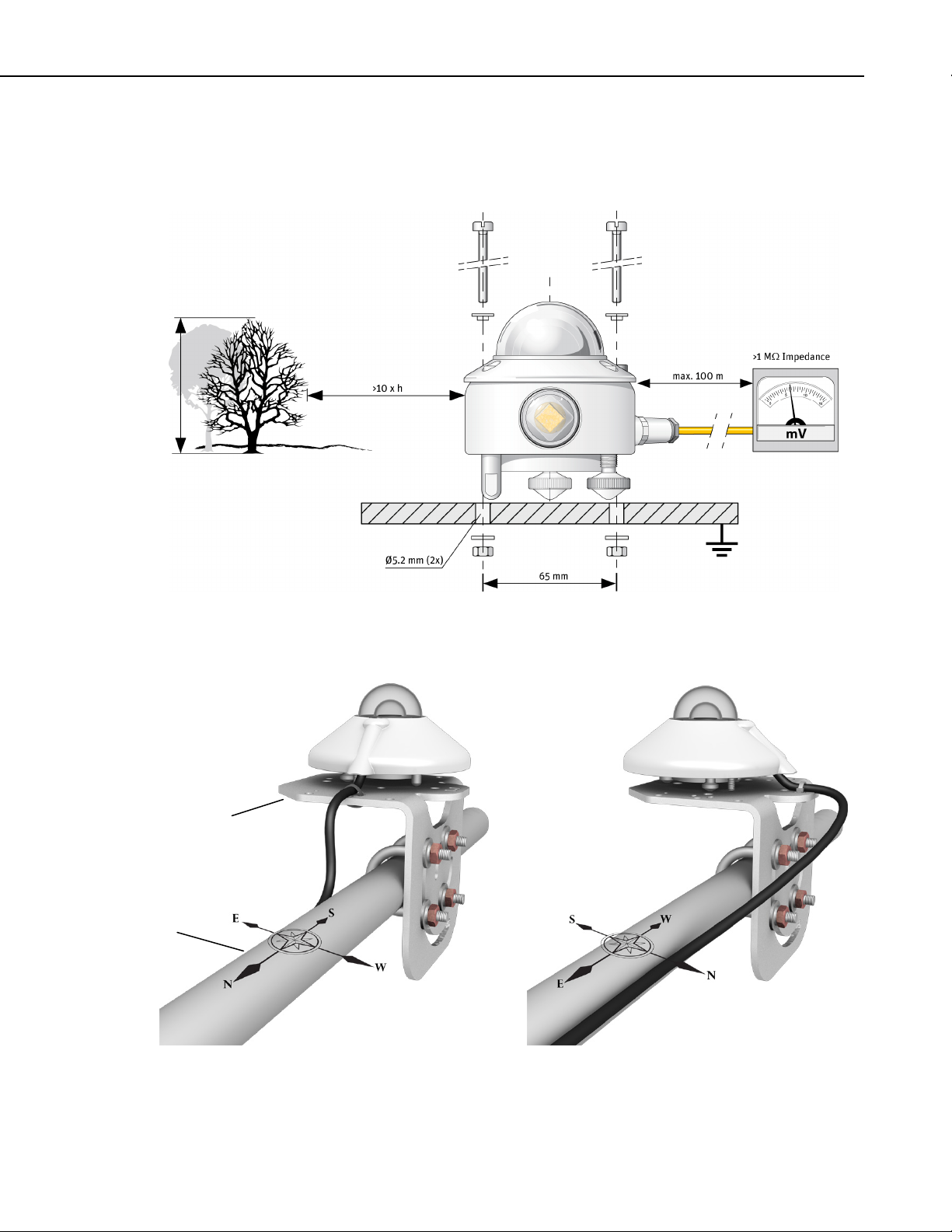

4-1. Pyranometer installation...................................................................... 3

4-2. Pyranometer mounted horizontally for the Northern Hemisphere

(left) and Southern Hemisphere (right)............................................ 3

4-3. Two views of a pyranometer mounted at an angle for the Northern

Hemisphere...................................................................................... 4

4-4. Pyranometer mounted at an angle for the Southern Hemisphere......... 4

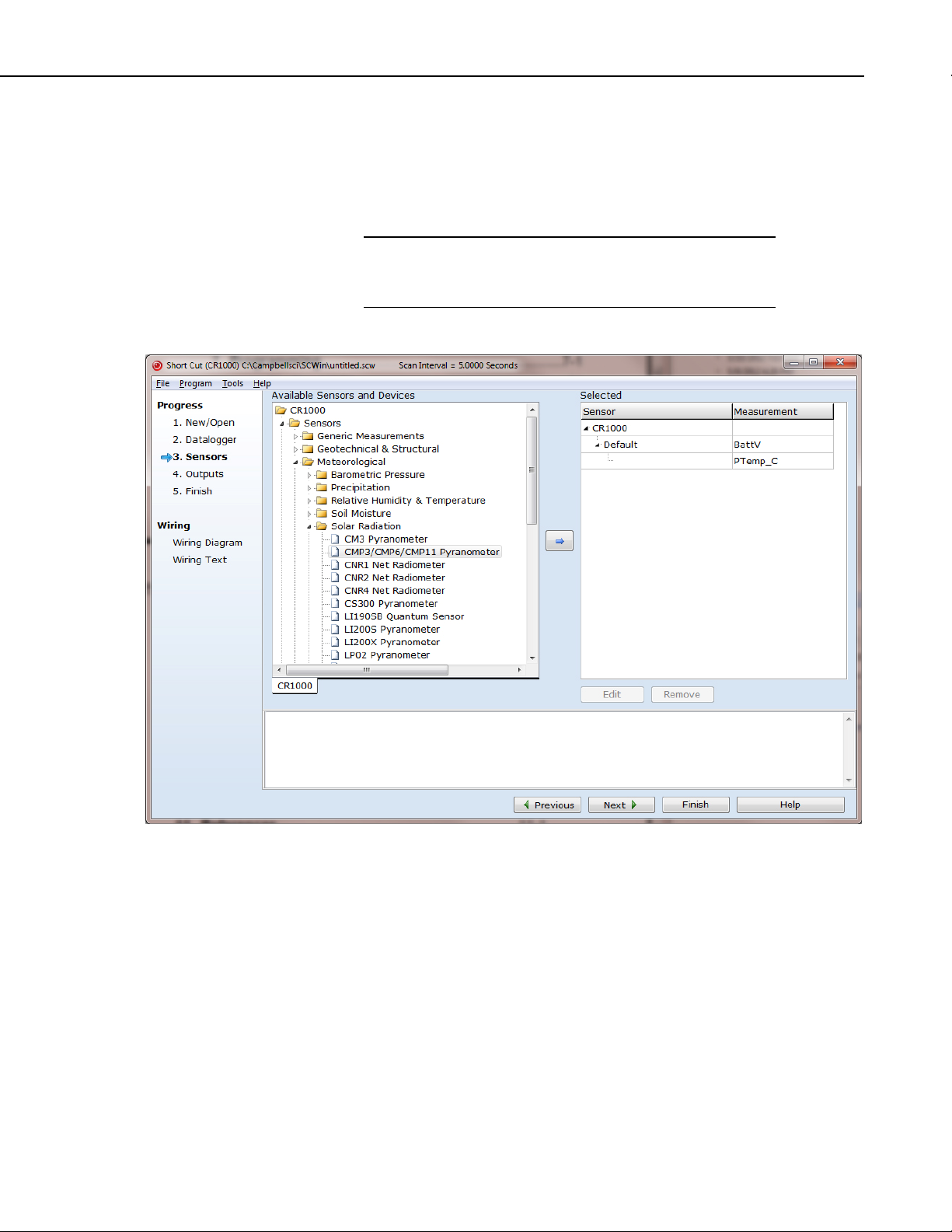

4-5. SCWin Short Cut Program Generator ................................................. 5

6-1. Dimensions of the CMP6, CMP11, and CMP21................................. 8

6-2. Dimensions of the CVF3..................................................................... 8

7-1. CM245 bracket with 2.125” u-bolts positioned to mount the

pyranometer horizontally on a crossarm.......................................... 9

7-2. CM245 bracket with 1.5” u-bolts positioned to mount pyranometer

at a 40° angle on a vertical pipe..................................................... 10

7-3. Exploded view of the pyranometer mounting.................................... 11

7-4. CMP6, CMP11, and CMP21 thermopile detector schematic ............ 12

8-1. Reading is reduced if dome is not dry or clean.................................. 23

8-2. Changing the desiccant...................................................................... 24

A-1. Transparent view of CVF3 shows air flow...................................... A-1

A-2. Pyranometer mounted to the CVF3 ................................................. A-2

A-3. CVF3 installed onsite ...................................................................... A-3

A-4. Fastening cover on CVF3................................................................ A-4

A-5. CVF3 filter replacement.................................................................. A-5

6-1. CMP-series Specifications................................................................... 7

7-1. CMP6 and CMP11 Differential Connections to Campbell

Scientific Dataloggers.................................................................... 12

7-2. CMP6 and CMP11 Single-Ended Connections to Campbell

Scientific Dataloggers.................................................................... 13

7-3. CMP21 Differential Connections to Campbell Scientific

Dataloggers .................................................................................... 13

ii

Page 7

Table of Contents

7-4. CMP21 Single-Ended Connections to Campbell Scientific

Dataloggers.....................................................................................14

7-5. Multipliers Required for Flux Density and Total Fluxes ...................15

7-6. CR1000 Wiring for CMP6 Example Program ...................................17

7-7. CR1000 Wiring for CMP11 Example Program .................................18

7-8. CR1000 Wiring for CMP21 Example Program .................................19

7-9. CR10X Wiring for CMP6 Example Program ....................................21

A-1. CVF3 Wiring................................................................................... A-4

iii

Page 8

Table of Contents

iv

Page 9

CMP6-L, CMP11-L, and CMP21-L

Pyranometers

1. Introduction

CMP-series pyranometers are designed for continuous outdoor monitoring of

solar radiation intensity. A flat spectral sensitivity from 285 to 2800 nm

enables accurate measurements in natural sunlight, under plant canopies, and in

green houses or buildings. When inverted, these pyranometers can measure

reflected solar radiation. Uses include monitoring global horizontal irradiance

(GHI) and plane of array irradiance (POA). Diffuse sky radiation can also be

measured with the use of a shade mechanism.

CMP-series pyranometers are manufactured by Kipp & Zonen, and cabled by

Campbell Scientific.

Before using these pyranometers, please study:

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 4, Quick Start

More details are available in the remaining sections.

2. Cautionary Statements

• CMP-series pyranometers are rugged, but they should be handled as

precision scientific instruments.

• Care should be taken when opening the shipping package to not damage or

cut the cable jacket. If damage to the cable is suspected, consult with a

Campbell Scientific applications engineer.

3. Initial Inspection

Check the contents of the shipment. If there is a shortage (see Section 3.1,

Ships With), contact Campbell Scientific. If any damage has occurred during

transport, immediately file a claim with the carrier and contact Campbell

Scientific to facilitate repair or replacement.

The model number and cable length are printed on a label at the connection end

of the cable. Check this information against the shipping documents to ensure

the correct product and cable length are received.

1

Page 10

CMP6-L, CMP11-L, and CMP21-L Pyranometers

3.1 Ships With

(2) Bolts for mounting from original mfg

(1) Instruction Manual from original mfg

(1) Sun Shield from original mfg

(2) Nylon washers from original mfg

3.2 Calibration Certificate

Each pyranometer is shipped with an instruction manual provided by Kipp &

Zonen that contains information concerning its construction, spectral

sensitivity, cosine response, and a simple sensor check out procedure. Included

with the sensor and manual is a calibration certificate with the sensor

sensitivity value and serial number.

NOTE

4. Quick Start

NOTE

4.1 Siting

Cross check this serial number against the serial number on your

pyranometer to ensure that the given sensitivity value

corresponds to your sensor.

Appendix A, CVF3 Heater/Ventilator, provides the installation

procedure for the CVF3 ventilation unit.

The pyranometer is usually installed horizontally for global horizontal

measurements. However, the pyranometer can be installed at any angle for

POA measurements and in the inverted position for reflected measurements. In

all cases it will measure the solar flux incident on the sensor surface.

Site the pyranometer to allow easy access for maintenance while ideally

avoiding any obstructions above the plane of the sensing element. It is

important to mount the pyranometer such that a shadow will not be cast on it at

any time.

If this is not possible, try to choose a site where any obstruction over the

azimuth range between earliest sunrise and latest sunset has an elevation not

exceeding 5°. Diffuse solar radiation is less influenced by obstructions near

the horizon. For instance, an obstruction with an elevation of 5° over the

whole azimuth range of 360° decreases the downward diffuse solar radiation

by only 0.8%.

2

The sensor should be mounted with the cable pointing towards the nearest

magnetic pole (e.g., in the Northern Hemisphere point the cable toward the

North Pole); see FIGURE 4-1 through FIGURE 4-4.

Page 11

4.2 Mounting

CMP6-L, CMP11-L, and CMP21-L Pyranometers

See Section 7.1, Mounting to a Tripod Tower, for more information.

CM245 Adjustable

Angle Mounting

Stand

CM2XX-Series

Crossarm

FIGURE 4-1. Pyranometer installation

FIGURE 4-2. Pyranometer mounted horizontally for the Northern

Hemisphere (left) and Southern Hemisphere (right)

3

Page 12

CMP6-L, CMP11-L, and CMP21-L Pyranometers

FIGURE 4-3. Two views of a pyranometer mounted at an angle for the

Northern Hemisphere

4

FIGURE 4-4. Pyranometer mounted at an angle for the Southern

Hemisphere

Page 13

CMP6-L, CMP11-L, and CMP21-L Pyranometers

4.3 Datalogger Programming / Wiring

The simplest method for programming the datalogger to measure a CMP6 or

CMP11 is to use Campbell Scientific's SCWin Short Cut Program Generator

(see FIGURE 4-5). Wire the pyranometer according to the wiring diagram

generated by Short Cut.

NOTE

The CMP21 is not included in Short Cut. Refer to Section 7,

Installation, for wiring and programming information if not

using Short Cut.

FIGURE 4-5. SCWin Short Cut Program Generator

5

Page 14

CMP6-L, CMP11-L, and CMP21-L Pyranometers

5. Overview

5.1 Models

CMP-series models differ in accuracy and performance. See Section 6,

Specifications. The CMP21 also includes an internal thermistor allowing

individually optimized compensation of the measurements. The –L portion of

the model number indicates that the pyranometer has a user-specified cable

length. The pyranometers have several cable termination options. Their cables

can terminate in:

• Pigtails that connect directly to a Campbell Scientific datalogger

(cable termination option –PT).

• Connector that attaches to a prewired enclosure (cable termination

option –PW).

• Connector that attaches to a CWS900 Wireless Sensor Interface (cable

termination option –CWS). The CWS900 enables the pyranometer to

be used in a wireless sensor network. Please note that this option is

not available for the CMP21.

5.2 Construction

The pyranometers consist of a thermopile sensor, housing, two glass domes,

and cable. The thermopile is coated with a black absorbent coating. The paint

absorbs the radiation and converts it to heat. The resultant temperature

difference is converted to a voltage by the copper-constantan thermopile. The

thermopile is encapsulated in the housing in such a way that it has a field of

view of 180 degrees and the angular characteristics needed to fulfill the cosine

response requirements.

6

Page 15

CMP6-L, CMP11-L, and CMP21-L Pyranometers

6. Specifications

6.1 Pyranometers

TABLE 6-1. CMP-series Specifications

Specification CMP6 CMP11 CMP21

ISO Classification First Class Secondary Standard

Maximum irradiance

2000 W•m

Spectral range

(50% points)

Response time (95 %) <18 s <5 s

Expected daily

uncertainty

Zero offset due to thermal

radiation

(200 W•m

–2

)

<15 W•m

Zero offset due to

temperature change

–1

(5 K•hr

)

<4 W•m

Non-stability

(change/year)

Non-linearity

(0 to 1000 W•m

–2

)

Directional error

(up to 80° with 1000

–2

W•m

beam)

<20 W•m

Tilt error

(at 1000 W•m

–2

)

Level accuracy 0.1°

Operating temperature –40° to 80°C

Temperature dependence

of sensitivity

Sensitivity

Typical signal output for

atmospheric applications

<4% (–10° to +40°C) <1% (–10° to +40°C) <1% (–20° to +50°C)

5 to 20 µV / W•m

0 to 20 mV 0 to 15 mV

Weight

Impedance* 20 to 200 Ω 10 to 100 Ω

* Impedance is defined as the total electrical impedance at the radiometer output connector fitted to the housing. It

arises from the electrical resistance in the thermal junctions, wires, and passive electronics within the radiometer.

–2

4000 W•m–2

285 to 2800 nm

<5% <2%

–2

<7 W•m–2

–2

<2 W•m–2

<1 % <0.5%

<1% <0.2%

–2

<10 W•m–2

<1% <0.2%

–2

7 to 14 µV / W•m–2

0.6 kg (1.3 lb) without cable;

0.9 kg (2 lb) with 10 m (33 ft) cable

7

Page 16

CMP6-L, CMP11-L, and CMP21-L Pyranometers

FIGURE 6-1. Dimensions of the CMP6, CMP11, and CMP21

6.2 CVF3 Ventilation Unit

Compatible Pyanometers: CMP6, CMP11, CMP21

Power supply: 12 Vdc, 1.3 A (with 10 W Heater)

Operating temperature range: –40° to 70°C

Ventilation power: 5 W continuously

Heating power: 5 W and 10 W

Heater induced offset: <1 W•m

Weight without cable: 1.6 kg (3.5 lb)

–2

(with CMP11 Pyranometer)

8

FIGURE 6-2. Dimensions of the CVF3

Page 17

7. Installation

7.1 Mounting to a Tripod or Tower

CMP6-L, CMP11-L, and CMP21-L Pyranometers

Tools required for installation on a tripod or tower:

Small and medium Phillips screwdrivers

5/16”, 1/2” open end wrenches

5/32” Allen wrench

Tape measure

UV-resistant wire ties

Side-cut pliers

Compass

Step ladder

The pyranometers include a bubble level and two leveling screws, which allow

them to be leveled horizontally without using a leveling base. They mount to a

mast, crossarm, or pole (1.0 in. to 2.1 in. outer diameter) via the CM245

Mounting Stand.

NOTE

If using a CFV3 Ventilation Unit, a different mounting stand, the

27084, is required. Refer to Appendix A, CVF3

Heater/Ventilator, for more information.

The CM245 includes slots that allow it to be adjusted to any angle from

horizontal to vertical. If mounting the pyranometer at an angle, ensure that the

crossarm is leveled horizontally before placing the bracket at its proper angle.

Angle positions are included on the bracket label (see FIGURE 7-1 and

FIGURE 7-2).

Pyranometer

mounts here

First

2.125”

u-bolt

First

Second

2.125”

u-bolt

FIGURE 7-1. CM245 bracket with 2.125” u-bolts positioned to mount

the pyranometer horizontally on a crossarm

2.125”

u-bolt

90

Second

2.125”

u-bolt

9

Page 18

CMP6-L, CMP11-L, and CMP21-L Pyranometers

First

1.5”

u-bolt

40

Second

1.5”

u-bolt

FIGURE 7-2. CM245 bracket with 1.5” u-bolts positioned to mount

pyranometer at a 40° angle on a vertical pipe

Do the following to level the pyranometer horizontally (see FIGURE 7-3):

1. Attach the mounting stand to the crossarm.

2. Loosely mount the pyranometer on the mounting stand. Do not fully

tighten the two mounting screws.

3. Turn the leveling screws as required to bring the bubble of the level within

the ring.

4. Tighten the mounting screws to secure the assembly in its final position.

Check that the pyranometer is still correctly leveled and adjust as necessary.

5. Attach the white plastic sun screen to the pyranometer.

10

Page 19

Mounting screws

d

N

Levelling screw

CMP6-L, CMP11-L, and CMP21-L Pyranometers

Sun shield

ylon washers

Bubble level

Pyranometer

mounting st45an

7.2 Wiring

NOTE

CM2

Crossarm

FIGURE 7-3. Exploded view of the pyranometer mounting

Short Cut users should wire the sensor according to the wiring

diagram generated by Short Cut.

The cable of the CMP6 and CMP11 has two conductors and a shield. The

cable of the CMP21 has five conductors and a shield. The additional

conductors on the CMP21’s cable are for connecting its internal thermistor. A

schematic for the CMP6, CMP11, and the thermopile of the CMP21 is

provided in Section 7.2.1, CMP6, CMP11, and CMP21 Thermopile Schematic.

Wiring for the CMP6 and CMP11 is described in Section 7.2.2, CMP6 and

CMP11 Wiring, wiring for the CMP21 is described in Section 7.2.3, CMP21

Wiring.

11

Page 20

CMP6-L, CMP11-L, and CMP21-L Pyranometers

7.2.1 CMP6, CMP11, and CMP21 Thermopile Schematic

A schematic diagram of a CMP6, CMP11, or CMP21 thermopile is shown in

FIGURE 7-4.

W hite(+)

Red

Black (-)

Blue

Black

Shield

FIGURE 7-4. CMP6, CMP11, and CMP21 thermopile detector

schematic

7.2.2 CMP6 and CMP11 Wiring

NOTE

A CMP6 or CMP11 purchased from Campbell Scientific has

different wiring than a pyranometer purchased directly from

Kipp & Zonen.

The pyranometer is measured using either differential analog channels or

single-ended analog channels.

A differential voltage measurement is recommended because it has better noise

rejection than a single-ended measurement.

Connections to Campbell Scientific dataloggers for a differential measurement

are given in TABLE 7-1. A user-supplied jumper wire should be connected

between the low side of the differential input and ground (AG or

) to keep

the signal in common mode range.

Connections to Campbell Scientific dataloggers for a single-ended

measurement are given in TABLE 7-2.

TABLE 7-1. CMP6 and CMP11 Differential Connections to Campbell Scientific Dataloggers

Color

Description

CR9000(X), CR5000,

CR3000, CR1000,

CR800

CR510, CR500,

CR10(X)

21X, CR7, CR23X

White Signal (+) DIFF Analog High DIFF Analog High DIFF Analog High

Black Signal (–) *DIFF Analog Low *DIFF Analog Low *DIFF Analog Low

Shield Shield

* Jumper to AG or

with user supplied 26 AWG or larger wire.

G

12

Page 21

CMP6-L, CMP11-L, and CMP21-L Pyranometers

TABLE 7-2. CMP6 and CMP11 Single-Ended Connections to Campbell Scientific Dataloggers

Color

Description

CR9000(X), CR5000,

CR3000, CR1000,

CR800

CR510, CR500,

CR10(X)

21X, CR7, CR23X

White Signal (+) SE Analog SE Analog SE Analog

Black Signal (–)

Clear Shield

AG

G

7.2.3 CMP21 Wiring

NOTE

A CMP21 purchased from Campbell Scientific has different

wiring than a CMP21 purchased directly from Kipp & Zonen.

The CMP21’s pyranometer can be measured using either differential analog

channels or single-ended analog channels. A differential voltage measurement

is recommended because it has better noise rejection than a single-ended

measurement. If a differential channel is not available, a single-ended

measurement can be used.

A single-ended channel and a voltage excitation channel are used to measure

the CMP21’s internal thermistor.

Connections to Campbell Scientific dataloggers for a differential measurement

are given in TABLE 7-3. A user-supplied jumper wire should be connected

between the low side of the differential input and ground (AG or

) to keep

the signal in common mode range. Connections to Campbell Scientific

dataloggers for a single-ended measurement are given in TABLE 7-4.

TABLE 7-3. CMP21 Differential Connections to Campbell Scientific Dataloggers

Wire Color

Wire Label/

Description

CR9000(X),

CR5000, CR3000,

CR1000, CR800

CR510, CR500,

CR10(X)

21X, CR7, CR23X

White Pyranometer Sig DIFF Analog High DIFF Analog High DIFF Analog High

Blue Pyranometer Ref *DIFF Analog Low *DIFF Analog Low *DIFF Analog Low

Yellow Thermistor Volt Excite VX or EX E EX

Black Thermistor Sig Single-ended analog Single-ended analog Single-ended analog

Brown Thermistor Ref

Clear Shield

* Jumper to AG or

with user-supplied wire.

AG

G

13

Page 22

CMP6-L, CMP11-L, and CMP21-L Pyranometers

TABLE 7-4. CMP21 Single-Ended Connections to Campbell Scientific Dataloggers

Wire Color

Wire Label/

Description

CR9000(X),

CR5000, CR3000,

CR1000, CR800

CR510, CR500,

CR10(X)

21X, CR7, CR23X

White Pyranometer Sig Single-ended analog Single-ended analog Single-ended analog

Blue Pyranometer Ref

AG

Yellow Thermistor Volt Excite VX or EX E EX

Black Thermistor Sig Single-ended analog Single-ended analog Single-ended analog

Brown Thermistor Ref

Clear Shield

AG

G

7.3 Programming

NOTE

This section is for users who write their own datalogger

programs. You do not need to read this section if using our Short

Cut Program Generator, or connecting the pyranometer to a

prewired enclosure or CWS900 Wireless Sensor Interface. Our

prewired enclosures include a datalogger program. Refer to the

Wireless Sensor Manual for programming information if using a

CMP6 or CMP11 with a CWS900.

7.3.1 Solar Radiation Measurements

CAUTION

Solar radiation can be reported as an average flux density (W•m–2) or daily

total flux density (MJ•m

7-5. Programming examples are given for both average and daily total solar

radiation.

The pyranometers output a low level voltage ranging from 0 to a maximum of

up to 20 mV, in natural light, depending on the calibration factor and radiation

level.

This voltage output is measured using either a differential voltage instruction

(VoltDiff() in CRBasic or Instruction 2 (P2) in Edlog) or a single-ended

voltage instruction (VoltSE() in CRBasic or Instruction 1 (P1) in Edlog).

Nearby AC power lines, electric pumps, or motors can be a

source of electrical noise. If the sensor or datalogger is

located in an electrically noisy environment, the

measurement should be made with the 60 or 50 Hz

rejection integration option as shown in the example

programs.

–2

). The appropriate multipliers are listed in TABLE

14

Page 23

7.3.1.1 Input Range

CMP6-L, CMP11-L, and CMP21-L Pyranometers

The output voltage is usually between 5 and 20 mV per 1000 W•m

–2

. When

estimating the maximum likely value of sensor output a maximum value of

–2

solar radiation of 1100 W•m

horizontal surface. Plane of array irradiances can exceed 1500 W•m

can be used for field measurements on a

–2

.

Select the input range as follows:

7.3.1.2 Multiplier

1. Estimate the maximum expected input voltage by multiplying the

–2)

maximum expected irradiance (in W•m

–2

). Divide the answer by 1000 to give the maximum in millivolt

W•m

by the calibration factor (in µV /

units.

2. Select the smallest input range which is greater than the maximum

expected input voltage. Normally the 50 mV range for the CR3000,

CR5000, CR9000(X), CR7, and CR23X and the 25 mV or 250 mV range

for the CR800, CR850, CR1000, CR510, and CR10(X) will be suitable.

The exact range will depend on the sensitivity of your individual sensor

and the maximum expected reading. With some dataloggers an autorange

option can be used if measurement time is not critical.

The parameter code for the input range also specifies the measurement

integration time. The slow or 60 Hz rejection integration gives a more noisefree reading. The 250 µs (CRBasic) or a fast (Edlog) integration takes less

power and allows for faster throughput.

The multiplier converts the millivolt reading to engineering units. The

sensitivity value supplied by the manufacturer gives the output of the sensor as

–2

µV (micro-volts) / W•m

. As the datalogger voltage measurement

instructions give a default output in mV, the following equation should be used

–2

to calculate the multiplier to give the readings in W•m

:

m = 1000/c

Where,

m = multiplier

c = sensor output in µV / W•m

–2

Other units can be used by adjusting the multiplier as shown in TABLE 7-5.

TABLE 7-5. Multipliers Required for Flux Density and Total Fluxes

Units Multiplier Output Processing

W•m–2

MJ•m–2

kJ•m–2

cal•cm–2

cal • cm

–2

• min–1

W • hr • m–2

M Average

M * t * 0.000001 Totalize

M *

t * 0.001

Totalize

M * t * 0.0239 * 0.001 Totalize

M * 1.434 * 0.001 Average

t / 3600 Totalize

M = calibration factor with units of W•m–2 / mV

t = datalogger program execution interval in seconds

15

Page 24

CMP6-L, CMP11-L, and CMP21-L Pyranometers

7.3.1.3 Offset

The offset will normally be fixed at zero as the sensor should output no

significant signal in dark conditions. In practice, because of the nature of

thermopile detector sensors, there will be some offset in dark conditions;

sometimes this offset can give negative light readings. This offset varies with

several factors (e.g., rate of change of sensor temperature), so it cannot be

removed with a fixed offset. Some users may wish to remove small negative

readings by including code after the measurement instructions that sets

negative readings to zero.

7.3.1.4 Output Format Considerations

Over-ranging may be an issue if the measurement values are totalized. Overranging can be prevented when using CRBasic by storing the data in the IEEE4

format.

When using Edlog, the largest number the datalogger can store in final storage

is 6999 in low resolution mode (FP2) and 99999 in high resolution mode (if

available). The following example shows how over-ranging can be a problem

for Edlog dataloggers.

Example

Assume that daily total flux is desired, and that the Edlog datalogger scan rate

is 1 second. With a multiplier that converts the readings to units of kJ•m

an average irradiance of 0.5 kW•m

will be exceeded in less than four hours.

Solution 1 – Change the multiplier in the instruction to (m * 0.001). This will

totalize MJ•m

Solution 2 – Record the average flux density and later multiply the result by the

number of seconds in the output interval to arrive at total flux.

Solution 3 – Record the total flux using the high resolution format. The draw

back to high resolution is that it requires four bytes of memory per data point,

consuming twice as much memory as low resolution. Instruction 78 is used to

switch to high resolution in the Edlog dataloggers.

–2

instead of kJ•m–2.

–2

, the maximum low resolution output limit

7.3.2 CMP21 Internal Thermistor Measurement

The thermistor is measured using a half bridge measurement instruction

(BrHalf instruction in CRBasic or Instruction 5 (P5) in Edlog). The value

provided by the half bridge instruction needs to be converted to resistance and

then converted to temperature.

The following equation is used to convert to resistance:

–2

and

16

=

⎜

⎝

⎛

⎜

1000Res.

⎞

V

x

⎟

⎟

V1

−

x

⎠

Page 25

CMP6-L, CMP11-L, and CMP21-L Pyranometers

Where,

Vx = the value provided by the half bridge instruction

In CRBasic, the conversion to resistance is entered as a mathematical

expression. In Edlog, Instruction P59 (Bridge Transform) does the conversion.

The Steinhart-Hart equation is used to convert resistance to temperature. The

Steinhart-Hart equation for converting resistance to degree Celsius is as

follows:

Temperature = 1/[A + B*LN(resistance) + C*(LN(resistance))^3] - 273.15

Where A, B, and C are coefficients for the Steinhart-Hart equation.

The coefficients for the Steinhart-Hart equation are specific to the thermistor

contained in your CMP21. A calibration certificate that lists these coefficients

is shipped with each CMP21 pyranometer.

In CRBasic, the Steinhart-Hart equation is entered as a mathematical

expression. Edlog dataloggers can use Instruction P200 (requires a newer

datalogger operating system).

7.3.3 Example Programs

7.3.3.1 CR1000 Example Program for Measuring a CMP6

Although this example is for the CR1000, other CRBasic dataloggers are

programmed similarly. The following program measures the CMP6 every

second and converts the millivolt output to W•m

14.33 µV / W•m

program outputs the average and standard deviation of the flux (W•m

measurements.

Wiring for this example is given in TABLE 7-6.

TABLE 7-6. CR1000 Wiring for CMP6 Example Program

Wire Color Description CR1000 Jumper*

White Solar Signal (+) 1H

Black Solar Signal (–) 1L

Clear Shield

* Jumper 1L to

–2

is used for the example program. Every 10 minutes, the

with user-supplied 26 AWG or larger wire.

–2

. A sensor calibration of

–2

)

17

Page 26

CMP6-L, CMP11-L, and CMP21-L Pyranometers

'CR1000 Series Datalogger

Public PTemp

Public Batt_Volt

Public CMP6_Irr

Units CMP6_Irr = W/m2

DataTable (TenMin,1,-1)

DataInterval (0,1,Min,4)

Minimum (1,Batt_Volt,FP2,0,False)

Sample (1,PTemp,FP2)

Average (1,CMP6_Irr,FP2,False)

StdDev (1,CMP6_Irr,FP2,False)

EndTable

BeginProg

Scan (1,Sec,0,0)

'Measure the Battery Voltage and Panel Temperature

PanelTemp (PTemp,250)

Battery (Batt_Volt)

'Measure the CMP6

VoltDiff (CMP6_Irr,1,mV25C,1,True ,10000,_60Hz,1000/14.33,0)

CallTable TenMin

NextScan

EndProg

7.3.3.2 CR1000 Example Program for Measuring a CMP11

Although this example is for the CR1000, other CRBasic dataloggers are

programmed similarly. The following program measures the CMP11 every

second and converts the millivolt output to W•m

8.55 µV / W•m

–2

is used for the example program. Every 10 minutes, the

program outputs the average and standard deviation of the flux (W•m

measurements.

Wiring for this example is given in TABLE 7-7.

TABLE 7-7. CR1000 Wiring for CMP11 Example Program

Wire Color Description CR1000 Jumper*

White Solar Signal (+) 2H

Black Solar Signal (–) 2L

Clear Shield

* Jumper 2L to

with user-supplied 26 AWG or larger wire.

–2

. A sensor calibration of

–2

)

18

Page 27

CMP6-L, CMP11-L, and CMP21-L Pyranometers

'CR1000 Series Datalogger

Public PTemp

Public Batt_Volt

Public CMP11_Irr

Units CMP11_Irr = W/m2

DataTable (TenMin,1,-1)

DataInterval (0,1,Min,4)

Minimum (1,Batt_Volt,FP2,0,False)

Sample (1,PTemp,FP2)

Average (1,CMP11_Irr,FP2,False)

StdDev (1,CMP11_Irr,FP2,False)

EndTable

BeginProg

Scan (1,Sec,0,0)

'Measure the Battery Voltage and Panel Temperature

PanelTemp (PTemp,250)

Battery (Batt_Volt)

'Measure the CMP11

VoltDiff (CMP11_Irr,1,mV25C,2,True ,10000,_60Hz,1000/8.55,0)

CallTable TenMin

NextScan

EndProg

7.3.3.3 CR1000 Example Program for Measuring a CMP21

Although this example is for the CR1000, other CRBasic dataloggers are

programmed similarly. The following program measures the CMP21 every

second. It converts the pyranometer’s millivolt output to W•m

pyranometer calibration of 8.65 µV / W•m

The resistance of the internal thermistor is converted to degree Celsius and then

to Kelvin. Every 10 minutes, the program outputs the average and standard

deviation of the flux (W•m

–2

) measurements and temperature measurements.

Wiring for this example is given in TABLE 7-8.

TABLE 7-8. CR1000 Wiring for CMP21 Example Program

Wire Color Description CR1000 Jumper*

White Solar Signal (+) 3H

Blue Solar Signal (–) 3L

Yellow Voltage Excitation VX1

Black Temp Signal 15 SE

Brown Signal Reference

Clear Shield

* Jumper 3L to with user-supplied 26 AWG or larger wire.

–2

–2

is used for the example program.

. A

19

Page 28

CMP6-L, CMP11-L, and CMP21-L Pyranometers

'CR1000 Series Datalogger

Public PTemp

Public Batt_Volt

Public CMP21_Irr

Public CMP21_T_C

Public CMP21_T_K

Dim Rs,Vs_Vx

Units CMP21_Irr = W/m2

Units CMP21_T_C = Degrees C

Units CMP21_T_K = Degrees K

DataTable (TenMin,1,-1)

DataInterval (0,1,Min,8)

Minimum (1,Batt_Volt,FP2,0,False)

Sample (1,PTemp,FP2)

Average (1,CMP21_Irr,FP2,False)

StdDev (1,CMP21_Irr,FP2,False)

Average (1,CMP21_T_C,FP2,False)

StdDev (1,CMP21_T_C,FP2,False)

Average (1,CMP21_T_K,FP2,False)

StdDev (1,CMP21_T_K,FP2,False)

EndTable

BeginProg

Scan (1,Sec,0,0)

‘Measure the Battery Voltage and Panel Temperature

PanelTemp (PTemp,250)

Battery (Batt_Volt)

‘Measure the CMP21 pyranometer

VoltDiff (CMP21_Irr,1,mV25C,3,True,10000,_60Hz,1000/8.65,0)

'CMP21 Thermistor Measurement

BrHalf (Vs_Vx,1,mV5000,15,Vx1,1,2500,True ,0,250,1.0,0)

Rs = 1000*(Vs_Vx/(1-Vs_Vx))

CMP21_T_C = 1/(1.0295e-3+2.391e-4*LN(Rs)+1.568e-7*(LN(Rs))^3)-273.15

'Convert CMP21 temp to Kelvin.

CMP21_T_K = CMP21_T_C+273.15

CallTable TenMin

NextScan

EndProg

20

7.3.3.4 CR10X Example Program for Measuring a CMP6

The following program uses a CR10X to measure a CMP6 every 10 seconds

and convert the mV output to W•m

14.33 µV / W•m

hourly average flux (W•m

–2

is used for this example program. The program outputs an

–2

–2

and MJ•m–2. A sensor calibration of

), and a daily total flux density (MJ•m–2).

Page 29

CMP6-L, CMP11-L, and CMP21-L Pyranometers

Wiring for the example is given in TABLE 7-9.

TABLE 7-9. CR10X Wiring for CMP6 Example Program

Wire Color Description CR10X Jumper*

White Solar Signal (+) 1H

Black Solar Signal (–) 1L

Clear Shield AG

* Jumper 1L to AG terminal on CR10X with user-supplied 26 AWG or larger

wire.

;{CR10X}

*Table 1 Program

01: 10.0000 Execution Interval (seconds)

; CMP6 measurement in W/m2

1: Volt (Diff) (P2)

1: 1 Reps

2: 23 25 mV 60 Hz Rejection Range ;use the 50 mV range for the CR7, 21X and CR23X

3: 1 DIFF Channel ;use the 250 mV range for the CR10X if

4: 3 Loc [ Solar_Wm2 ] ;calibration factor is > 25 µV/Wm-2

5: 69.7837 Multiplier ;1000/14.33

6: 0 Offset

; Set negative values to zero

2: If (X<=>F) (P89)

1: 3 X Loc [ Solar_Wm2 ]

2: 4 <

3: 0 F

4: 30 Then Do

3: Z=F x 10^n (P30)

1: 0 F

2: 0 n, Exponent of 10

3: 3 Z Loc [ Solar_Wm2 ]

4: End (P95)

; Calculate units in MJ, where MJ = m * t * 0.000001.

; m = Solar_Wm2 from above, and t = 10 (scan interval).

5: Z=X*F (P37)

1: 3 X Loc [ Solar_Wm2 ]

2: .00001 F

3: 4 Z Loc [ Solar_MJ ]

6: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

21

Page 30

CMP6-L, CMP11-L, and CMP21-L Pyranometers

7: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 101 Array ID

8: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

9: Average (P71)

1: 1 Reps

2: 3 Loc [ Solar_Wm2 ]

10: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1440 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

11: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 102 Array ID

12: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

13: Resolution (P78)

1: 1 High Resolution

14: Totalize (P72)

1: 1 Reps

2: 4 Loc [ Solar_MJ ]

15: Resolution (P78)

1: 0 Low Resolution

8. Maintenance

At regular intervals, physically inspect the pyranometer to ensure that:

• Dome is free of dirt, condensation, and ice (see Section 8.1, Cleaning

• Desiccant granules are orange and opaque (see Section 8.2, Changing the

• Mounting is secure.

• Pyranometer is level (if mounted horizontally).

• Cables are in good condition.

22

Domes).

Desiccant).

Page 31

8.1 Cleaning Domes

Clean the outer dome at regular intervals (e.g., every week or so). Remove any

accumulated dust, condensation, or ice from the dome and pyranometer body

using a soft cloth dampened with water or alcohol (see FIGURE 8-1).

FIGURE 8-1. Reading is reduced if dome is not dry or clean

8.2 Changing the Desiccant

A desiccant-filled drying cartridge prevents dew from forming on the inner

sides of the domes; Campbell Scientific part number 27052 is the replacement

desiccant for this cartridge. The optional CVF3 Heater/Ventilator Unit is also

available to keep the pyranometer dome free from ice and dew (see Appendix

A, CVF3 Heater/Ventilator). In some applications, the CVF3 may also reduce

the deposition of dust on the pyranometer dome, and therefore reduce the

cleaning interval frequency.

CMP6-L, CMP11-L, and CMP21-L Pyranometers

The silica gel desiccant granules in the drying cartridge should be orange and

opaque. Replace the desiccant granules when they become translucent

(normally after several months). Refill packs of desiccant are shipped with the

pyranometer and can be purchased from Campbell Scientific. The drying

cartridge uses the content of one refill pack. FIGURE 8-2 shows the

replacement process.

When changing the desiccant, ensure that:

• The surfaces touching the rubber o-ring are clean. Dirt, in combination

with water, can cause corrosion, harming it.

• The rubber o-ring is coated with silicon grease or petroleum jelly. The

grease coating improves the o-ring’s seal.

• The drying cartridge is tightly threaded into the pyranometer’s body.

23

Page 32

CMP6-L, CMP11-L, and CMP21-L Pyranometers

FIGURE 8-2. Changing the desiccant

8.3 Check Sensor Output

It is also important to check the data returned from the sensor as it will show

the first indication of a fault. When doing this you should be aware of several

expected phenomena that can cause strange measurements. In particular on

clear, windless nights the outer dome temperature of horizontally placed

pyranometers can fall as low as the dew point temperature of the air, due to

infrared radiation exchange with the cold sky. (The effective sky temperature

can be 30°C lower than the ground temperature, which results in an infra-red

emission of –150 W

be precipitated on the top of the outer dome and can stay there for several hours

in the morning. An ice cap on the dome is a strong diffuser and can increase

the pyranometer signal by up to 50% in the first hours after sunrise.

8.4 Recalibration

The calibration of the pyranometer may drift with time and exposure to

radiation. Recalibration every two years is recommended. The sensor should

be returned to Campbell Scientific for recalibration. A Returned Materials

Authorization (RMA) is required (refer to the Assistance page for more

information).

–2

•m

). If this happens, dew, glazed frost or hoar frost can

24

Page 33

9. Troubleshooting

Symptom: NAN, –9999, or radiation values around 0

1. Check that the sensor is wired to the differential channel specified by the

measurement instruction.

2. Verify that the range code is correct for the datalogger type.

CMP6-L, CMP11-L, and CMP21-L Pyranometers

3. Measure the impedance across the red and blue sensor wires. This should

be around 100 ohms plus the cable resistance (typically 0.1 ohm•m

the resistance is very low, there may be a short circuit (check the wiring).

Resistances somewhat lower than expected could be due to water ingress

into the sensor or enclosure connectors. If the resistance is infinite, there

is a broken connection (check the wiring).

4. Disconnect the sensor cable and check the voltage output from the sensor.

With the sensor located 8” below a 60 W incandescent light bulb the

voltage should be approximately 2.5 mV. No voltage indicates a problem

with the sensor.

Symptom: sensor signal is unrealistically high or low

1. Check that the right calibration factor has been properly entered into the

datalogger program. Please note that each sensor has its own individual

calibration factor.

2. Check the condition of the sensor cable.

Symptom: sensor signal shows unexpected variations

1. Check for the presence of strong sources of electromagnetic radiation

(radar, radio, etc.).

–1

). If

2. Check the condition and the connection of the sensor shield wire.

3. Check the condition of the sensor cable.

25

Page 34

CMP6-L, CMP11-L, and CMP21-L Pyranometers

26

Page 35

Appendix A. CVF3 Heater/Ventilator

A.1 General Information

The CVF3 consists of a ventilation unit and heaters. The ventilation unit uses a

fan and inlet filter to draw clean air over the pyranometer’s domes. The fan

runs continuously to reduce dust and dirt settling, to dissipate rain drops, and to

stabilize the dome temperature.

The CVF3 has both a 5 W and a 10 W heater. The 5 W heater raises the

temperature of the dome slightly above ambient temperature to prevent the

formation of dew and frost. The 10 W heater is used for more extreme

climates to melt snow and ice.

The 10 W heater’s current drain is approximately 850 mA at 12 Vdc, and the

5 W heater’s current drain is approximately 420 mA at 12 Vdc. The ventilator

draws an additional 5 W of power at 12 Vdc. These power requirements are

large compared to most Campbell Scientific products. Because of this, the

CVF3 should be connected to the 21326 Power Net 5 A Power Supply and the

7321 Crydom Relay.

A.2 Siting

The Crydom relay allows the heater power to be controlled by the datalogger

program and thus reducing power consumption. For example, the datalogger

program can turn on the heater only when the light level falls below 20 W/m

or, if a measurement of air humidity is available, when the dew point of the air

falls to within 1ºC of the sensor body temperature.

Siting information provided in Section 4.1, Siting, is pertinent when using the

CVF3 heater/ventilation. Additionally, the area directly under the CVF3’s

120-mm diameter hole needs to be free from snow, leaves, or other

obstructions that could inhibit the air flow (see FIGURE A-1).

2

FIGURE A-1. Transparent view of CVF3 shows air flow

A-1

Page 36

Appendix A. CVF3 Heater/Ventilator

A.3 CVF3 Installation

The CVF3 heater/ventilator unit includes the heater/ventilator unit, white

cover, cable, and mounting hardware.

Tools required for mounting to a tripod or tower are:

• Small and medium Phillips screwdrivers

• 5/16”, 1/2” open end wrenches

• 5/32” Allen wrench

• Tape measure

• UV-resistant wire ties

• Side-cut pliers

• Compass

• Step ladder

To install, do the following:

1. Remove leveling screws from the pyranometer.

2. Fit the pyranometer in the upper plate of the CVF3 (see FIGURE A-2).

3. Use the counter sink screws, nylon rings, and nuts to secure the upper plate

of the CVF3 with the lower portion of the unit (see FIGURE A-2).

Nylon Ring

A-2

FIGURE A-2. Pyranometer mounted to the CVF3

Page 37

Appendix A. CVF3 Heater/Ventilator

4. Loosely mount the pyranometer on the 27084 mounting stand. Do not

fully tighten the two mounting screws.

5. Turn the CVF3’s leveling screws bringing the bubble of the pyranometer’s

level within the ring (see FIGURE A-3).

FIGURE A-3. CVF3 installed onsite

6. Tighten the mounting screws to secure the assembly in its final position.

Check that the pyranometer is still correctly leveled and adjust as

necessary.

7. Use the cover’s screws to fasten the white cover to the pyranometer (see

FIGURE A-4).

A-3

Page 38

Appendix A. CVF3 Heater/Ventilator

FIGURE A-4. Fastening cover on CVF3

A.4 Wiring

8. Attach the power cable to the CVF3 connector.

Wiring of the CVF3 is shown in TABLE A-1. Refer to Section 7.2, Wiring, for

information about wiring the pyranometer.

TABLE A-1. CVF3 Wiring

Wire Color Description Connection

Red Ventilator Power +12V on 21326 Power Supply

Brown Ventilator Power +12V on 21326 Power Supply

Blue Ventilator Ground G on 21326 Power Supply

Black Ventilator Ground G on 21326 Power Supply

Gray Ventilator Ground G on 21326 Power Supply

Green 5 W Heater Power +12V on 21326 Power Supply

White 5 W Heater Power +12V on 21326 Power Supply

Clear Shield

Yellow 5 V Tacho Output Control port on datalogger

on 21326 Power Supply

A-4

Page 39

Appendix A. CVF3 Heater/Ventilator

A.5 CVF3 Heater/Ventilator Maintenance

1. Refer to Section 8, Maintenance, for the pyranometer’s maintenance.

2. Inspect the area directly under the 120 mm diameter hole in the mounting

plate to ensure that it is free from leaves, snow, or other obstructions that

can inhibit air flow.

3. Unclip the CVF3’s filter cover and check the filters (see FIGURE A-5).

4. Replace filters as needed.

FIGURE A-5. CVF3 filter replacement

A-5

Page 40

Appendix A. CVF3 Heater/Ventilator

A-6

Page 41

Page 42

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...