Page 1

CM375 Portable 10-Meter Mast

Revision: 7/13

Copyright © 2009-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Overview......................................................................1

1.1 Specifications .......................................................................................1

1.2 Guy Duckbill Anchor Kits ...................................................................2

2. Tools List (for tripod, mast, enclosures, and

crossarms) ................................................................3

3. CM375 Installation ...................................................... 3

3.1 Site Selection........................................................................................3

3.2 Assembling Mast Sections ...................................................................4

3.3 Lightning Rod Assembly and Mounting Instrumentation..................12

3.4 Anchor Installation.............................................................................13

3.5 Raise, Plumb Mast and Final Cable Tensioning ................................18

4. Maintenance ..............................................................20

Figures

1-1. 21720 tote.............................................................................................1

3-1. Assembled CM375...............................................................................3

3-2. CM375 in opened tote..........................................................................4

3-3. Mast base, sections, and lightning rod kit ............................................4

3-4. Mast Section 1 oriented on base...........................................................5

3-5. Spike installation ..................................................................................6

3-6. Coupler installed in top of mast Section 1 ...........................................6

3-7. Bag containing hardware......................................................................7

3-8. Mast Section 2 and mast Section 3.......................................................7

3-9. Guy ring, mast Section 2 and mast Section 3.......................................8

3-10. 21663 bottom guy kit ...........................................................................8

3-11. Guy cable inserted into guy ring ..........................................................9

3-12. Mast Section 3 and guy ring/collar assembly.......................................9

3-13. Mast Section 4 ready to be installed in mast Section 3 ......................10

3-14. Mast Section 5....................................................................................10

3-15. 21661 guy kit .....................................................................................11

3-16. Mast Section 5 and guy ring/collar assembly.....................................11

3-17. Mast Section 6....................................................................................12

3-18. Lightning rod assembly......................................................................12

3-19. Installed lightning rod ........................................................................13

3-20. Tape measure in slot for South anchor...............................................13

3-21. 19282 duckbill anchor and cable assembly (left). The 25699 has

a threaded rod instead of the cable. The drive rod (right) is used

for both the 19282 and 25699. ........................................................14

3-22. Anchor driven into ground at 45° angle .............................................14

3-23. Locking anchor...................................................................................15

i

Page 6

Table of Contents

3-24. Tape measure in slot for Northeast anchor........................................ 15

3-25. Turnbuckle fastened to guy cable and anchor ................................... 16

3-26. Top and bottom guy cables fastened to an anchor............................. 16

3-27. Rope ratchet assists assembly............................................................ 17

3-28. Adjusting cable through wedge clamp .............................................. 17

3-29. Raising the mast ................................................................................ 18

3-30. Post level ensures vertical mast......................................................... 18

3-31. Adjusting turnbuckles........................................................................ 19

3-32. Guy cables with 100 lb of tension ..................................................... 19

ii

Page 7

CM375 Portable 10-Meter Mast

1. Overview

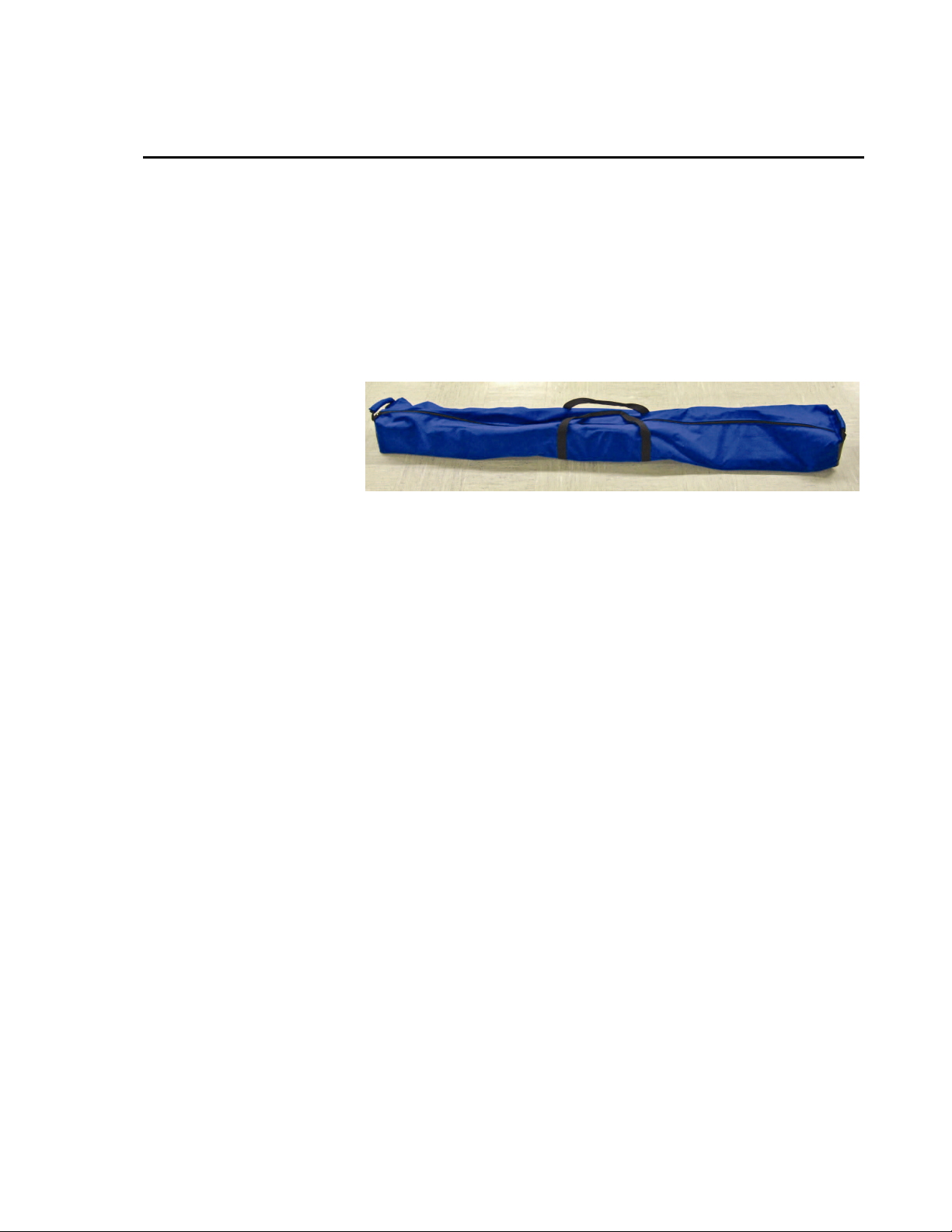

The CM375 is a corrosion-resistant 10 m (30 ft) mast for applications requiring a

tall yet portable instrument mount. It consists of six galvanized pipes, a stainlesssteel base, guy cables, 1 m crossarm and mount, and grounding kit. Duckbill

anchor kits (required) and a guy-wire tensioning kit (recommended) are ordered

separately. All of the components fit inside a 2 m (80 in) bag allowing the

CM375 to be carried from site to site (see FIGURE 1-1).

FIGURE 1-1. 21720 tote

1.1 Specifications

Weight: 30 kg (66 lb)

Mast: 9.2 m (30 ft) total length; consists of five

Main Mast Diameter: 48.26 mm (1.9 in)

Top Section Mast Diameter: 44.2 mm (1.74 in)

Base Radius: 6 m (20 ft) to each of three guy points, 120

Guy Configuration: Three guy cables at two levels; guyed at 3.6 m

Recommended Guy

Wire Pretension: 100 lb each; check and adjust guy wire tension

1.82 m (6 ft) and one 1 m (39 in) sections

degrees apart

(12 ft) and at 7.2 m (24 ft)

at least once a month, and after wind gusts

exceeding 50 mph

Maximum Weight of

Mounted Equipment: 34 kg (75 lb)

1

Page 8

CM375 Portable 10-Meter Mast

Maximum Allowable

Wind Gust

i

: 136 kmh–1 (85 mph)

The wind gust value assumes:

• Proper installation

• Proper anchoring:

o Adequate soil (guy anchors/base support)

o Guy anchors at 20-ft from base with 120 degrees of separation

o Proper guy tension (100 lb each)

• No ice buildup

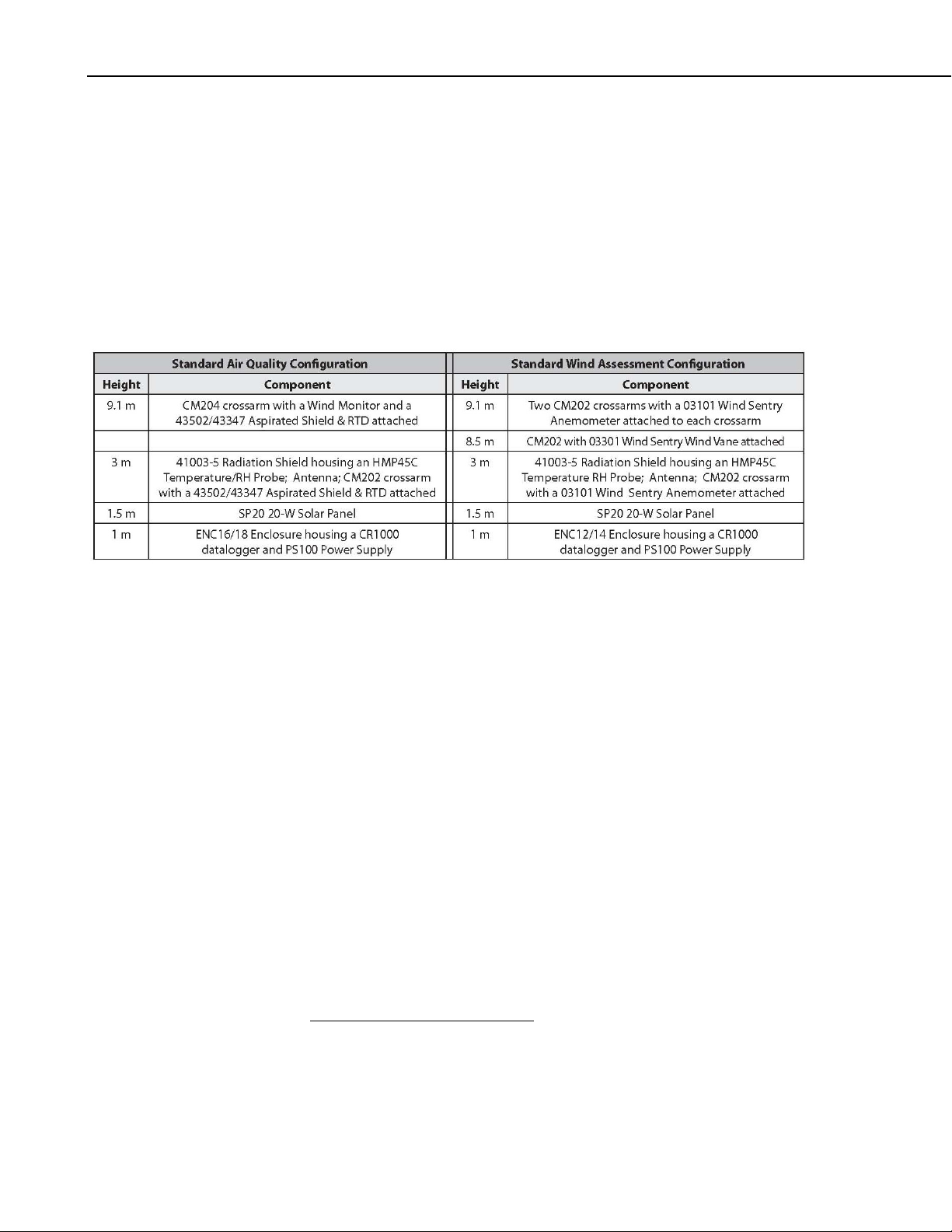

• Standard air quality or wind assessment configuration (see Table

below)

1.2 Guy Duckbill Anchor Kits

A choice of duckbill anchor kits is offered for the CM375. The 19282 Guy

Duckbill Standard Anchor Kit is adequate for most sandy and loamy soils.

Clay soils and other soils with higher corrosive properties will require the

25699 Guy Duckbill Heavy Duty Anchor Kit. These corrosive soils, also

known as aggressive soils, have one or more of the following properties:

• High electrical conductivity (>0.33 dS m

• High acidity (pH <5)

• High chloride concentration (>1000 ppm)

• High sulfate concentration (>500 ppm)

• Poor aeration

Both the 19282 and 25699 have one drive rod. The 19282 also has four

duckbill anchors with a cable attached to each of them; at the end of the cable

is a loop for connecting the guy wires. The 25699 has a threaded rod attached

to each of the four duckbill anchors instead of the cable; at the end of the

threaded rod is a metal ring for connecting the guy wires.

i

The amount of wind gust that this mount can withstand is affected by quality

of anchoring and installation, guy wire tension, soil type, guy angle, and the

number, type, and location of instruments fastened to the CM375.

–1

)

2

Page 9

CM375 Portable 10-Meter Mast

2. Tools List (for tripod, mast, enclosures, and crossarms)

1/2-in. and 7/16-in. open end wrenches

adjustable wrench

Phillips head screw drivers (medium, small)

Straight bit screwdrivers (large, medium)

12-in. torpedo level

side-cut pliers

pencil

tape measure

compass and site declination angle

shovel

sledge hammer (for driving ground rod and stakes)

step ladder

3. CM375 Installation

3.1 Site Selection

Select a site free from overhead power lines, and 30 m (100 ft) in any direction

from trees, buildings, and other obstructions (see FIGURE 3-1).

FIGURE 3-1. Assembled CM375

3

Page 10

CM375 Portable 10-Meter Mast

3.2 Assembling Mast Sections .2 Assembling Mast Sections

Step 1: Remove mast sections and other bundled hardware from tote; unzip

Step 1: Remove mast sections and other bundled hardware from tote; unzip

and loosen straps (see FIGURE 3-2).

and loosen straps (see FIGURE 3-2).

NOTE

Sections are numbered for sequential assembly (see FIGURE 3-3). Sections are numbered for sequential assembly (see FIGURE 3-3).

FIGURE 3-2. CM375 in opened tote

4

Base

FIGURE 3-3. Mast base, sections, and lightning rod kit

Page 11

CM375 Portable 10-Meter Mast

Step 2: Place Section 1 at deployment location with base oriented, as shown in

FIGURE 3-4 and mast pointing NORTH.

NOTE

A compass is included in the optional “Tensioning Kit” for your

use.

NORTH

WARNING

FIGURE 3-4. Mast Section 1 oriented on base

Step 3: Use spikes provided (3 each) to anchor base to site (see FIGURE 3-5).

Always maintain a safe distance between the mast and

any overhead power lines. Contact local utilities prior

to assembling the mast to locate any buried utility

lines in the area the mast is to be installed.

5

Page 12

CM375 Portable 10-Meter Mast

Spikes

FIGURE 3-5. Spike installation

Step 4: Insert the Section 2 coupler into the top of Section 1 (see FIGURE

3-6).

NORTH

6

FIGURE 3-6. Coupler installed in top of mast Section 1

Page 13

CM375 Portable 10-Meter Mast

Step 5: Secure joint with 2 flat washers, 2 lock washers and 2 bolts from the

hardware bag (see FIGURE 3-7).

NOTE

FIGURE 3-7. Bag containing hardware

Step 6: Assemble Section 3 to the top of Section 2 (see FIGURE 3-8).

The BLACK tape around Section 2 is a reference (11 foot level)

for optional sensor mounts.

Section 2

Collar

FIGURE 3-8. Mast Section 2 and mast Section 3

Step 7: Remove the collars from Section 3 and place next to the mounting

holes in Section 2 (see FIGURE 3-8 and FIGURE 3-9).

7

Page 14

CM375 Portable 10-Meter Mast

Section 2

FIGURE 3-9. Guy ring, mast Section 2 and mast Section 3

Step 8: Remove guy ring from bottom guy kit, pn 21663 (see FIGURE 3-9 and

FIGURE 3-10).

Collar

Guy Ring

Section 3

Collar

8

FIGURE 3-10. 21663 bottom guy kit

Page 15

CM375 Portable 10-Meter Mast

Step 9: Place ball end of each guy cable into its slot in the guy ring and place

guy ring onto coupler of Section 3 (see FIGURE 3-11).

FIGURE 3-11. Guy cable inserted into guy ring

NOTE

Only one of the three cable ends is shown.

Step 10: Slide coupler into Section 2 mast and assemble collars, as shown in

FIGURE 3-12.

FIGURE 3-12. Mast Section 3 and guy ring/collar assembly

9

Page 16

CM375 Portable 10-Meter Mast

Step 11: Slide coupler end of Section 4 into the top of Section 3, and secure

with remaining components from hardware bag (see FIGURE 3-13).

Section 3

Coupler

FIGURE 3-13. Mast Section 4 ready to be installed in mast Section 3

Step 12: Remove collars from Section 5 (see FIGURE 3-14).

FIGURE 3-14. Mast Section 5

Collar

Collar

10

Page 17

CM375 Portable 10-Meter Mast

Step 13: Remove the guy collar from the 21661 guy kit (FIGURE 3-15).

FIGURE 3-15. 21661 guy kit

Step 14: Place the guy cable ball ends into the guy ring, and then slide the guy

ring onto the bottom end of Section 5 oriented as shown in FIGURE 3-16.

Align the holes in Section 4 and Section 5, and reassemble the collars.

FIGURE 3-16. Mast Section 5 and guy ring/collar assembly

11

Page 18

CM375 Portable 10-Meter Mast

Step 15: Remove the hardware from Section 6. Insert Section 6 into the top of

Section 5 and secure with hardware (FIGURE 3-17).

FIGURE 3-17. Mast Section 6

3.3 Lightning Rod Assembly and Mounting Instrumentation

Step 1: Fit lightning rod assembly (from pn 21660) to top of Section 6 mast

(see FIGURE 3-18).

12

FIGURE 3-18. Lightning rod assembly

Step 2: Place clamp onto top of mast Section 6 and tighten (see FIGURE

3-19).

Step 3: Insert rod into clamp and tighten (see FIGURE 3-19).

Page 19

CM375 Portable 10-Meter Mast

FIGURE 3-19. Installed lightning rod

Step 4: Assemble enclosures, sensors and tie cables to mast, as required.

3.4 Anchor Installation

FIGURE 3-20. Tape measure in slot for South anchor

Step 1: For the South anchor, place tape measure into slot in base centering

tape within notch on edge of base. Measure to 20 ft (see FIGURE 3-20).

Step 2: At 20 ft, install the duckbill anchor with drive rod (see FIGURE 3-21).

The anchor needs to be driven into the ground at a 45° angle (see FIGURE

3-22). Drive anchor until the loop or metal ring is several inches above the

ground.

13

Page 20

CM375 Portable 10-Meter Mast

d

WARNING

Anchor

Cable

Always maintain a safe distance between the mast and

any overhead power lines. Contact local utilities prior

to assembling the mast to locate any buried utility

lines in the area the mast is to be installed.

Ro

Anchor

FIGURE 3-21. 19282 duckbill anchor and cable assembly (left). The

25699 has a threaded rod instead of the cable. The drive rod (right)

is used for both the 19282 and 25699.

45°

FIGURE 3-22. Anchor driven into ground at 45° angle

14

Page 21

Anchor

CM375 Portable 10-Meter Mast

Step 3: With a rod through the loop or metal ring, pull up on the cable or

threaded rod until the anchor rotates and locks (see FIGURE 3-23).

FIGURE 3-23. Locking anchor

Step 4: Fill-in the hole around the cable or threaded rod with loose dirt and

tamp firm.

Step 5: Repeat process for the NE (FIGURE 3-24) and NW anchors.

NE

FIGURE 3-24. Tape measure in slot for Northeast anchor

15

Page 22

CM375 Portable 10-Meter Mast

r

Step 6: Attach guy wires to anchors by first opening the turnbuckle to the

widest setting. Attach turnbuckle to wedge end of the guy cable, and then

attach the other end of the turnbuckle to an anchor (see FIGURE 3-25).

NOTE

Open turnbuckle to widest setting.

Guy Cable Wedge

Ancho

FIGURE 3-25. Turnbuckle fastened to guy cable and anchor

Step 7: If using rope ratchet to assist assembly, set to 7 feet and attach to

tension clamp on cable and to anchor end. Do this for both NE and NW

anchors and top and bottom guy cables (see FIGURE 3-26 and FIGURE 3-27).

Do not connect the SOUTH cables at this time.

FIGURE 3-26. Top and bottom guy cables fastened to an anchor

16

Page 23

CM375 Portable 10-Meter Mast

NOTE

FIGURE 3-27. Rope ratchet assists assembly

Step 8: Course adjustments to cable length are made by loosening screw

clamp and then releasing wedge with a blade screwdriver (see FIGURE 3-28).

This allows the cable to be adjusted through the wedge clamp.

Retighten screw when adjustment is complete.

FIGURE 3-28. Adjusting cable through wedge clamp

17

Page 24

CM375 Portable 10-Meter Mast

3.5 Raise, Plumb Mast and Final Cable Tensioning

Step 1: With NW and NE cables attached to anchors have one person lift mast,

while another person pulls on the SOUTH cables to bring mast to an upright

position (see FIGURE 3-29). If using rope ratchets, adjust them to allow

further steps.

FIGURE 3-29. Raising the mast

Step 2: Attach SOUTH cables to anchor. While first person holds mast and

uses a post level (available at most hardware stores or online), the second

person adjusts each of the bottom guy cable wedge clamps, maintaining level

in all directions (see FIGURE 3-30). The rope ratchet can be used to

temporarily remove the load from the wedge assembly during wedge

adjustments.

18

FIGURE 3-30. Post level ensures vertical mast

Page 25

CM375 Portable 10-Meter Mast

Step 3: Repeat process with the top guy cables to establish a straight mast.

Step 4: Apply further tensioning using the turnbuckles (see FIGURE 3-31).

FIGURE 3-31. Adjusting turnbuckles

Step 5: Adjust each cable turnbuckle to maintain plumb and increase cable

tension. A deflection of 3 inches when using a 4.4 pound (20 Newton)

perpendicular force, 68 inches from the duckbill anchor loop equates to 100

pounds of tension in the cables (see FIGURE 3-32).

FIGURE 3-32. Guy cables with 100 lb of tension

19

Page 26

CM375 Portable 10-Meter Mast

Step 6: After tensioning the top guy cables, recheck the bottom guy cables.

Adjust, as necessary.

4. Maintenance

Check and adjust guy cable tension at least once a month, and after wind gusts

exceeding 50 mph.

20

Page 27

Page 28

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...