Page 1

Revision: 12/2020

Copyright © 2020

Campbell Scientific, Inc.

Page 2

Table of contents

1. Introduction 1

2. Precautions 1

3. Initial inspection 3

4. Overview 3

4.1 Communications interface 4

5. Specifications 6

6. Installation 8

6.1 Connect to power source 10

6.1.1 Solar panel 10

6.1.2 DC power 11

6.2 Connect to battery 11

6.3 Connect to data logger 11

6.4 (Optional) Connect to data logger for SDI-12 or RS-232 communications 11

6.5 Turn on power source 12

6.6 Turn on CH201 12

6.7 (Optional) Configure using Device Configuration Utility 12

6.7.1 Battery families and capacity 15

7. Operation 19

7.1 Charging algorithm 19

7.2 Maximum power point tracking 20

7.3 Communications 21

7.3.1 SDI-12 communications 23

7.3.1.1 SDI-12 commands 24

7.3.1.2 CRBasic programming 25

7.3.2 RS-232 communications 25

7.3.2.1 RS-232 commands 27

7.3.2.2 CRBasic programming 29

7.4 LED indicators 29

Table of Contents - i

Page 3

8. References 30

Appendix A. Downloading an operating system 31

Table of Contents - ii

Page 4

1. Introduction

The CH201 is a charging regulator for an external rechargeable 12V VRLA, valve-regulated leadacid, battery, such as the BP12 or BP24 offered by Campbell Scientific. Charging power for this

charging regulator is typically supplied by an unregulated solar panel or AC-to-DC converter.

The CH201 is a smart charger that provides a programmable low voltage disconnect and two-step

constant voltage charging with temperature compensation for optimal charging and battery life.

A maximum power point tracking algorithm is incorporated for solar inputs to maximize available

solar charging resources.

The CH201 is a series regulator, which has the regulator placed, in series, between the charging

source and the load. As batteries become closer to fully charged, series regulators reduce the

current drawn from the charging source. The charging source may be completely unloaded if full

charge is reached. Charging source unloading is acceptable for solar panels and AC-to-DC

converters. For wind turbines, charging source unloading can cause free spinning. Consequently,

do not use series charging regulators, such as the CH201, to regulate wind-turbine outputs

without a method to load the turbine when the batteries require little or no charging current.

The CH201 has several safety features that protect the charging source, battery, charger, and load

devices. Both the DC In 1 and DC In 2 input terminals have polarity reversal protection and

programmable hardware current limits. The CH201 has a programmable maximum battery

charging current limit. A self-resettable, thermal fuse is in-series with the 12 VDC output

terminals to protect the charger from an output load fault. The CH201 includes battery reversal

protection, and ESD and surge protection are incorporated on all inputs and outputs.

2. Precautions

Only use the following battery cables with the CH201: pn34029, pn34031, pn34040, and

pn36589.

Overcharging VRLA batteries can produce excess hydrogen and oxygen gases, and the

accumulation of hydrogen gas can form an explosive mixture. Fortunately, hydrogen gas is

difficult to contain in anything but a metal or glass enclosure.

CH201 12V Charging Regulator 1

Page 5

DANGER:

Never house VRLA batteries in an enclosure that does not allow dispersion of emitted

hydrogen gas.

When using a current limiting power supply such as a AC-to-DC converter, change the input

current limit using the Device Configuration Utility to prevent the CH201 from pulling more

current than what is available, thus tripping current limit protection of the converter.

VRLA batteries can provide high-surge currents. A 4.6A solid-state circuit breaker protects the

12VDC output terminals, but there is no fusing for inadvertent bridging of the battery terminals.

DANGER:

Accidental shorting of battery terminals by metallic objects, such as watchbands, can cause

severe burns due to rapid heating and is also a fire hazard.

VRLA battery manufacturers state that “Heat Kills Batteries.” While the operating temperature

range is –40 to 60°C, optimum battery life occurs in the 5 to 35°C temperature range1. The

CH201 offers temperature compensation of the battery charging voltage based on a temperature

measurement inside the CH201 case. The CH201 internal temperature measurement only

accurately represents battery temperature for charge voltage compensation if the battery is next

to the CH201. To overcome temperature differences, use the CH201 serial interface to input an

independently measured battery temperature for improved charging temperature compensation.

With rechargeable batteries, a charge → discharge → recharge event is termed a cycle. Depth of

discharge can greatly affect the battery service life. For example, limiting the depth of discharge

to 50% instead of 100% (complete discharge) will double the number of useful cycles available

from the battery. VLRA batteries last longer with less (or more shallow) depth of discharge.

VRLA batteries self-discharge at approximately 3% of rated capacity per month at room

temperature1. A 3% of rated capacity per month self-discharge results in 100% discharge in

approximately 33 months for a battery stored at room temperature. The battery self-discharge

rate increases with higher storage temperatures.

WARNING:

Leaving a lead-acid battery in a discharged state for prolonged periods causes large sulfate

crystals (sulfation) that are detrimental to battery performance.

Every few months, recharge stored batteries to prevent irreversible sulfation due to prolonged

time in a discharged state.

1

Genesis Application Manual – Genesis NP and NPX Series US-NP-AM-002, June 2006.

CH201 12V Charging Regulator 2

Page 6

3. Initial inspection

Upon receipt of the CH201, inspect the packaging and contents for damage. File damage claims

with the shipping company.

4. Overview

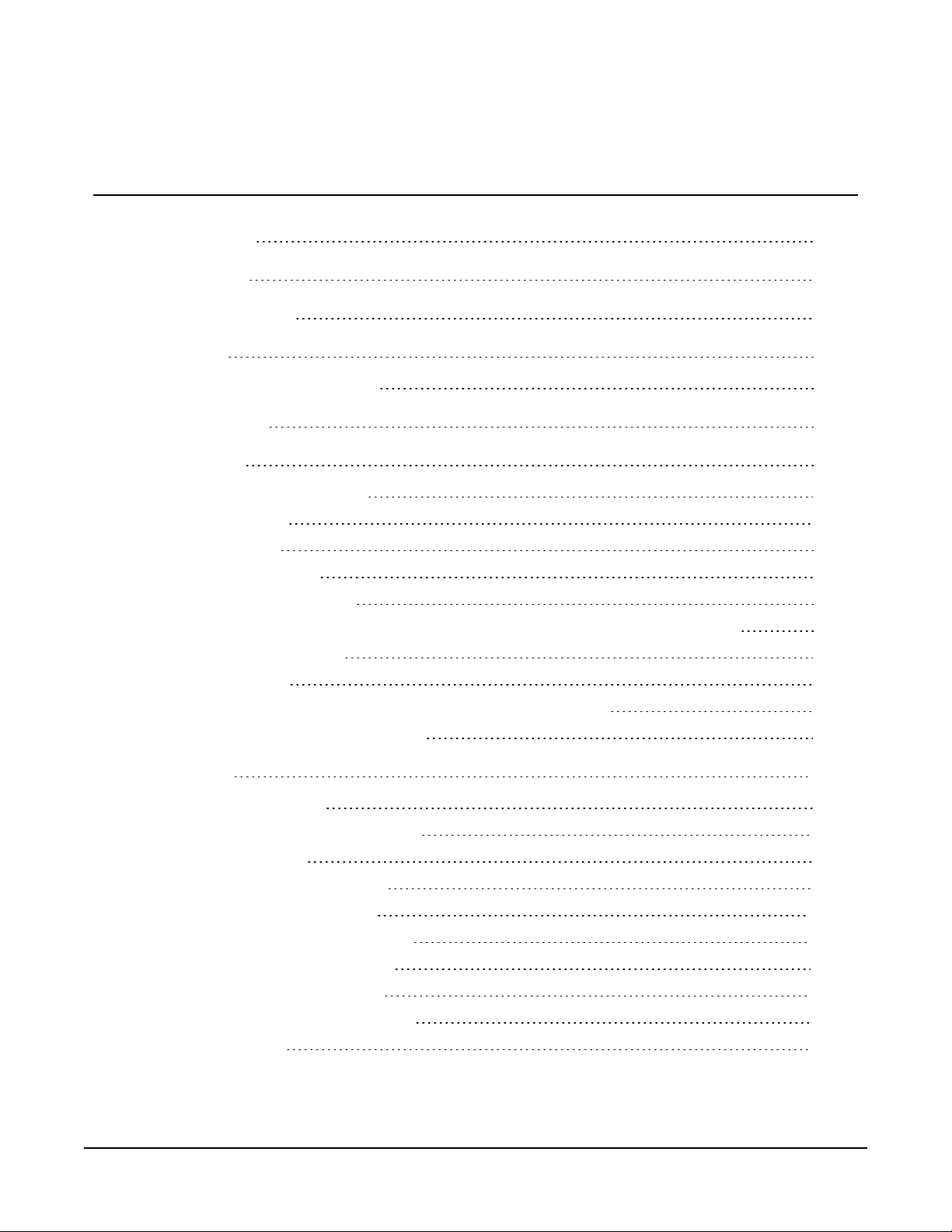

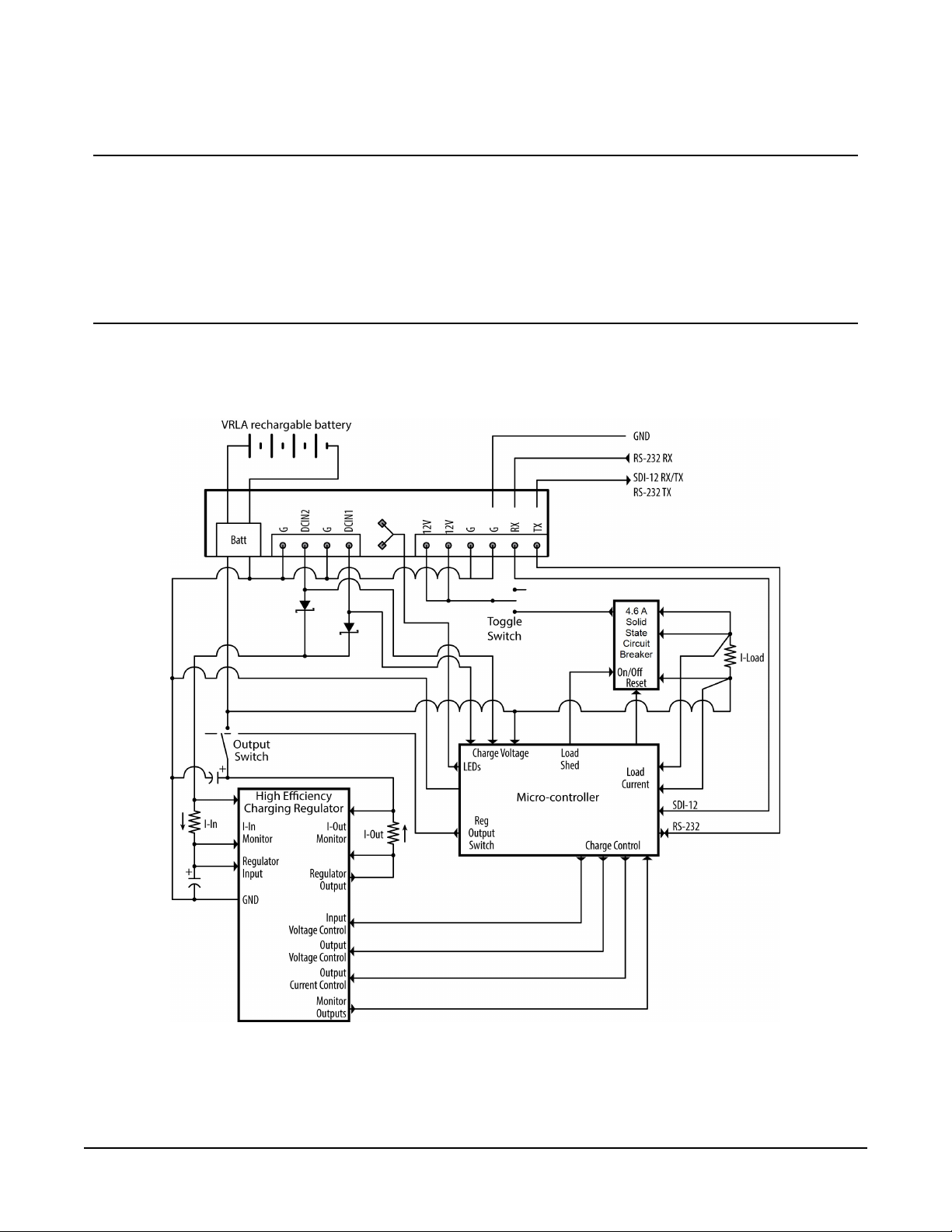

FIGURE 4-1 (p. 3) provides a simplified schematic of the CH201 charging regulator. See Table 5-1

(p. 7) for rechargeable batteries offered by Campbell Scientific.

FIGURE 4-1. CH201 schematic

CH201 12V Charging Regulator 3

Page 7

An unregulated solar panel or AC-to-DC converter typically supplies charging power to the

CH201. As shown in FIGURE 4-1 (p. 3), diodes connected to the two DCIn terminals provide input

reversal protection and isolation between power sources. DCIn terminals have a polarity that

must be followed. Connect the positive wires to the DCIn terminals, and connect the negative

wires to the G terminals. Reversed polarity inputs, however, will NOT damage the CH201. The

DCIn input terminals have an input current limit of approximately 10amps, making the CH201

well suited for 170watt or smaller solar panels. Higher powered solar panels may not damage the

CH201, but the additional power likely won't be fully used. Additionally, each input has a

programmable current limit. See (Optional) Configure using Device Configuration Utility (p. 12).

Internal diodes route power from the source with the highest input voltage. An AC-mainspowered application can use a solar panel for back-up if the AC-to-DC source has a higher

voltage than the solar panel. The solar power will be the primary supply and AC will be the

secondary supply if the solar panel has a higher output voltage than the AC-to-DC source.

The 12V output terminals are for powering a data logger and peripherals. A toggle switch

controls power to these output terminals. The total output current is limited by a 4.6A solid-state

circuit breaker.

Each battery family uses a unique charging algorithm to calculate the best charging voltage for

battery temperature. The algorithms use the charger temperature as the default temperature

source. If the charger and battery are in the same enclosure, the two temperatures will be similar.

If the battery will be in a separate enclosure, place a temperature sensor on or near the battery

and use the appropriate SDI-12 or RS-232 command to send this temperature to the module (see

Table 7-4 (p. 25) and Table 7-6 (p. 27)).

The CH201 has two LED indicators, the CHG (charge) LED and the CKBAT (check battery) LED.

Table 7-7 (p. 30) and Table 7-8 (p. 30) list the conditions and associated colors for the CHG and

CKBAT LEDs.

The CH201 communicates using a data logger or computer COM port. Data logger

communications can be done using SDI-12 or RS-232 as indicated in FIGURE 7-3 (p. 23) and

FIGURE 7-4 (p. 26). See Communications (p. 21) for details.

4.1 Communications interface

The CH201 can send data to the user to observe and manage power requirements and possible

problems. It can also be configured to work with a wide range of batteries and input power

supplies and test the existing battery system for possible shorting and sulfation problems.

The CH201 can be used without any configuration or communications. To take advantage of the

additional features of the CH201, however, the CH201 supports three kinds of communications:

CH201 12V Charging Regulator 4

Page 8

l Communications to a computer running Device Configuration Utility. This utility simplifies

configuration of the CH201 and allows for operating system updates. Device Configuration

Utility may be downloaded free of charge at www.campbellsci.com/downloads. See

(Optional) Configure using Device Configuration Utility (p. 12).

l SDI-12 communications as an SDI-12 sensor according to the SDI-12 standard

(www.SDI-12.org). See SDI-12 communications (p. 23) for an in depth explanation.

l RS-232 communications to a data logger or computer. See RS-232 communications (p. 25)

for an in-depth explanation.

SDI-12 data logger programming is usually simpler than RS-232 programming. Also, multiple

SDI-12 sensors can share a single data logger control or universal terminal if they have unique

SDI-12 addresses; RS-232 devices are limited to one device per terminal. The advantage of RS-232

is its speed can be faster than SDI-12.

All CH201 serial communications use three COM terminals, TX, RX, and G. The CH201 will detect

the mode of communications and will reconfigure itself accordingly.

FIGURE 4-2. CH201 COM terminals

CH201 12V Charging Regulator 5

Page 9

5. Specifications

Operational Temperaturea:

Dimensions:

SOLAR Terminals (Solar Panel

or Other DC Source)

b

Input Voltage Range:

Maximum Charging Current:

Power Out (+12 terminals)

Voltage:

Battery Charging

c

CYCLE Charging:

FLOAT Charging:

Measurements

Input Voltage:

–40 to 60 °C

11.40 x 10.08 x 3.38 cm (4.49 x 3.97 x 1.33 in)

15 to 50VDC

10 A

Unregulated 12 V from battery

4.6 A solid state circuit breaker. Self-resettable thermal.

Vbatt(T) = 14.70 V – (24 mV) • (T – 25 °C)

Vbatt(T) = 13.65 V – (18 mV) • (T – 25 °C)

±(1% of reading +15 mV)

Battery Voltage:

Load Currentd:

Battery Currentd:

Charger Temperature:

±(2% of reading +15 mV)

±(2% of reading +2 mA)

±(2% of reading +10 mA)

± 2 °C

Quiescent Current

No Charge Source Present:

No Battery Connected:

Compliance:

300 μA maximum

Typical 5 mA at 40 VDC

View the EU Declaration of Conformity at

www.campbellsci.com/CH201

a

VRLA battery manufacturers state that “heat kills batteries” and recommend operating batteries at temperatures

below 50 °C.

b

Battery voltages below 8.7 V may result in <3.0 A current limit because of fold-back current limit.

c

Two-step temperature compensated constant-voltage charging for valve-regulated lead-acid batteries. Cycle and

float charging voltage parameters are programmable with the default values listed.

d

Impulse-type changes in current may have an average current measurement error of ±(10% of reading + 2 mA).

CH201 12V Charging Regulator 6

Page 10

Table 5-1: Available Campbell Scientific battery packs

Operating

Battery Pack Model

Amp-Hour Capacity

Temperature Range

1

Battery Family

(Ah)

(ºC)

Charge: –15 to 50

BP7 7

EnerSys/Genesis

Discharge: –20 to 60

Charge: –15 to 50

BP12 12

EnerSys/Genesis

Discharge: –20 to 60

Charge: –15 to 50

BP24 24

EnerSys/Genesis

Discharge: –20 to 60

BP84 84 –40 to 71 Concorde Sun Xtender

1

Battery specifications are from the manufacturer. The CH201 contains charging algorithms that optimize battery

charging over the range of –40 to 60 °C. Battery usage outside of manufacturer specifications could have unknown

effects on the life of the battery.

WARNING:

Battery life is shortened if the battery is allowed to discharge below 11.5 VDC. Low voltage

disconnect can be set in the CH201. Default low voltage disconnect is 6 VDC.

Charging requirements and tips:

Campbell Scientific offers a variety of solar panels and AC-to-DC transformers to meet the power

requirements of a system installation.

l 10 A is the highest input current that the CH201 can fully use. Although a solar panel or

transformer with a higher output current won't damage the CH201, its power will not be

fully used. Peak voltage of the solar panel must be less than 50VDC.

l Solar panel specifications assume a 1 kilowatt per square meter illumination and a solar

panel temperature of 25°C (77°F).

l Individual solar panels may vary up to 10%.

l Solar panel output voltage increases as the panel temperature decreases. VRLA batteries

also have increased output voltage as the battery temperature decreases.

l Higher latitudes and less sun hours during winter months might require a larger solar panel

than what is required to keep the battery charged during the summer.

l Use the Device Configuration Utility to change the current limit settings of DC In 1 or

DCIn2 to accommodate the current limit of a charging source. For example, set the

CH201 12V Charging Regulator 7

Page 11

current limit to 1.67 A to avoid tripping the power supply when using a wall charger with a

1.67 A current limit.

DCIn terminals have a polarity that must be followed. Connect the positive wires to the DCIn

terminals, and connect the negative wires to the G terminals. Reversed polarity inputs, however,

will NOT damage the CH201.

6. Installation

The CH201 module is designed to handle extreme conditions and to transmit charging, load, and

battery voltage and current information directly to a data logger by using SDI-12 or RS-232

commands. The data logger program can use the CH201 data to calculate a power budget for the

system and remotely pinpoint power problems. SDI-12 or RS-232 connections are not required for

normal operation, and the module is ready to use out of the box.

The CH201 has mounting holes on one-inch centers for mounting to a standard Campbell

Scientific enclosure backplate—see the enclosure manual for mounting suggestions. See FIGURE

6-1 (p. 9) for a typical enclosure installation using a CH201.

NOTE:

By default, the CH201 module is programmed with a battery capacity of zero amp-hours (Ah).

This sets the charger to charge at a lower current rate. A battery capacity must be configured

into the CH201 to enable the more aggressive two-step constant voltage charging scheme.

See Battery families and capacity (p. 15) for making changes by using Device Configuration

Utility. A downloadable example program using SDI-12 to set the battery capacity is available

at www.campbellsci.com/downloads/ch201-program-examples.

CH201 12V Charging Regulator 8

Page 12

FIGURE 6-1. CH201 configured for SDI-12 communications

The installation section discusses the following:

6.1 Connect to power source 10

6.2 Connect to battery 11

6.3 Connect to data logger 11

6.4 (Optional) Connect to data logger for SDI-12 or RS-232 communications 11

6.5 Turn on power source 12

6.6 Turn on CH201 12

6.7 (Optional) Configure using Device Configuration Utility 12

CH201 12V Charging Regulator 9

Page 13

6.1 Connect to power source

DANGER:

Although the power supply and battery are low voltage, they can heat a metal ring,

watchband, or bracelet enough to burn skin or melt metal when shorted. Remove rings,

watches, or bracelets before hooking up power and connecting a battery.

Unlike the CH200, the CH201 has two DC inputs instead of one AC and one DC input. A solar

panel or AC-to-DC converter can connect to either input terminal. If both CH201 inputs are

connected to power sources, the power source with the highest voltage will supply power to the

CH201. Therefore, two solar panels can face different directions to allow the solar panel facing

the most direct sunlight to power the CH201.

Toggle the power supply switch to Off before connecting power to the CH201.

NOTE:

The switch on the CH201 only controls power going to the 12V terminals. The battery is

continuously charged regardless of the switch position when charging voltage is present.

6.1.1 Solar panel

WARNING:

To prevent sparking while wiring the solar panel, lay the solar panel face down on its packing

box or cover it with something to block the sunlight while wiring up the panel.

Connect the black (negative) wire from the solar panel to the G terminal that is adjacent to the

DCIn1 or DCIn2 terminal. Connect the red (positive) wire from an unregulated solar panel to

the DCIn1 or DCIn2 terminal. See FIGURE 6-2 (p. 10).

FIGURE 6-2. Voltage input connections on the CH201

CH201 12V Charging Regulator 10

Page 14

6.1.2 DC power

Double-check the input voltages coming in to the charger/regulator with a volt meter.

DC In 1 Input Voltage: 15 to 50VDC

DC In2 Input Voltage: 15 to 50VDC

WARNING:

Exceeding the maximum voltage will damage the CH201. Only one input is used at a time,

whichever has a higher voltage.

6.2 Connect to battery

Only use the following battery cables with the CH201: pn34029, pn34031, pn34040, and

pn36589. Connect the red wire to the positive battery post and the black wire to the negative

battery post. Inset the connector into the CH201 BAT port.

6.3 Connect to data logger

The CH201 comes with a 1-foot black wire attached to a G terminal block and a 1-foot red wire

attached to a 12V terminal block. The data logger includes a voltage input terminal connector.

The wires from the CH201 attach to this connector, which plugs into the PowerIn terminal on the

data logger. Attach the red wire from the CH201 to the 12V terminal on the connector; attach the

black wire to the G terminal, then plug the connector into the data logger.

6.4 (Optional) Connect to data logger for

SDI-12 or RS-232 communications

The TX, RX, and G terminals are used for communications. FIGURE 7-3 (p. 23) shows example

SDI-12 wiring and FIGURE 7-4 (p. 26) shows example RS-232 wiring.

NOTE:

Communications with the CH201 is required if the data logger is programmed to collect

information from the power supply. See Communications (p. 21) for more information.

CH201 12V Charging Regulator 11

Page 15

6.5 Turn on power source

Turn on the charging source power or uncover the solar panel. The green CHG LED should flash

every 4 to 5 seconds, which indicates correct incoming connections and adequate charging

voltage.

6.6 Turn on CH201

Toggle the switch on the CH201 supply to On. Check the voltage of the attached devices by using

a volt meter.

6.7 (Optional) Configure using Device

Configuration Utility

Using Campbell Scientific Device Configuration Utility is the easiest method to configure the

CH201 and the only method to update the operating system. If updating an operating system,

refer to Downloading an operating system (p. 31)

1. Select CH201 in the Device Type list on the left of the Device Configuration Utility window.

CH201 12V Charging Regulator 12

Page 16

2. Connect to the computer using an A200 device (see FIGURE 6-3 (p. 13)). Table 7-5 (p. 26)

and the bottom of the CH201 Device Configuration Utility screen show wiring to an A200.

FIGURE 6-3. Connecting the CH201 to a computer by using an A200

3. Select the appropriate Com Port.

4. Power the CH201 from the A200, battery, or DC power source on the DC In 1 or DC In 2

terminals.

CH201 12V Charging Regulator 13

Page 17

5. Click Connect to access the Settings Editor. The Settings Editor displays real-time values

(updated every second) and allows some settings to be changed.

6. To change a setting, select the field to be changed.

NOTE:

Although shown, the custom battery settings can only be changed if Custom is selected

for Battery Family.

7. Type a new value and press Enter. If the new value is not within an acceptable range, a red

message will appear to the right of the new value as shown in the following image.

Grayed-out fields cannot be changed. The bottom of the Settings Editor displays a

description of and information for the selected setting.

8. After changing settings, click Apply. If the CH201 accepts the settings, a configuration

summary will appear.

CH201 12V Charging Regulator 14

Page 18

9. Click Save to use the Read File option in the future to check settings or apply settings to

other CH201 regulators.

TIP:

Click the Factory Defaults button to revert to the factory default settings (read-only values are

not affected).

TIP:

Click the Read File button to restore settings based on a file that was created earlier.

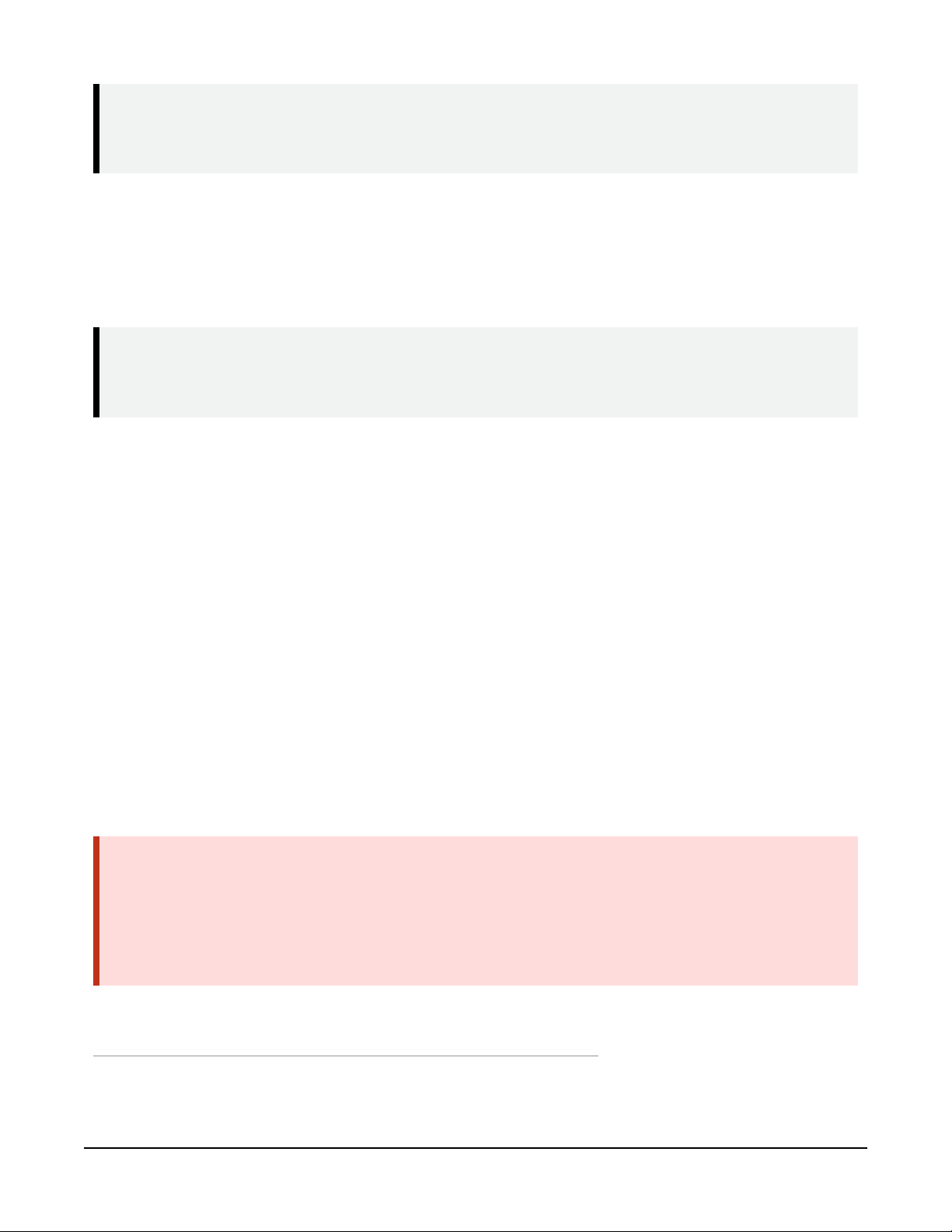

6.7.1 Battery families and capacity

The CH201 has built-in charging algorithms for the EnerSys/Genesis NP series of batteries

(Campbell Scientific models BP7, BP12, and BP24), EnerSys/Cyclon Series, Concorde Sun Xtender

(BP84), or it can use custom algorithms entered by the user. The CH201 uses a second order

polynomial to make the correct battery charging adjustments for known battery families and

charging cycles. See FIGURE 6-4 (p. 16).

CH201 12V Charging Regulator 15

Page 19

FIGURE 6-4. Battery family list

Set the Battery Family to match the battery family being used. The default settings are Battery

Capacity of zero (0) and Battery Family of EnerSys/Genesis NP Series. Setting the Battery Capacity

to zero (0) forces the charger to only float charge the battery. Battery Capacity must be changed

to allow cycle charging. Table 6-1 (p. 17) shows the default settings for each battery family. The

settings are based on the following equation:

V

charge

(T) = C0+ C1(T-25°C) + C2(T-25°C)

2

Where:

T = Battery temperature in ° C.

C2= 0 for linear charge voltage vs. temperature relation.

CH201 12V Charging Regulator 16

Page 20

Table 6-1: Battery specifications

(V)

1

0

Float C

(mV/°C)

1

Float C

(mV/°C)

Minimum

2

2

Voltage (V)

Battery

family

Cycle C

1

(V)

0

Cycle C

(mV/°C)

1

Cycle C

(mV/°C)

2

2

Float C

EnerSys/

Genesis

NP Series 14.70 –24 0 13.65 –18 0 12.5

EnerSys/

Cyclon Family

Cyclon Series 14.70 –24 0.24 13.65 –24 0.24 13.2

Concorde

14.31 –24 0.24 13.29 –24 0.24 13.0

Sun Xtender

Custom

User

Settable

1

C0values are at 25 °C

User set

Default =

14.70

User set

Default =

–24

User set

Default =

0

User set

Default =

13.65

User set

Default =

–18

User set

Default =

0

User set

Default =

12.5

NOTE:

Consider changing the Custom Battery default settings. See your battery manufacturer

specifications for correct charging information.

The CH201 is designed to charge lead-acid batteries only. Lead-acid batteries come in three

styles. The first two styles are valve-regulated lead-acid (VRLA) batteries. VRLA batteries are

considered maintenance free because they do not require the addition of water to the cells. They

also vent less gas than flooded lead-acid batteries.

l Absorbed Glass Mat (AGM) maintenance-free battery. This style of battery has the

electrolyte (acid) absorbed and trapped in a glass fiber mat, which is sandwiched between

lead plates. This battery is sealed. No water or acid can be added and the design allows the

battery to be mounted in any position. This style battery is also called starved-electrolyte.

l Gel Cell maintenance-free battery. This battery has the electrolyte (acid) mixed with silica

dust to form an immobilized gel, which is sandwiched between lead plates. This battery is

sealed. No water or acid can be added. This type of battery can be sensitive to how it is

mounted. See manufacturer for details.

CH201 12V Charging Regulator 17

Page 21

l Flooded-Cell batteries. These are commonly used in automobiles. Deep-cycle marine

batteries are usually flooded-cell batteries. These batteries use a liquid electrolyte and

require the addition of water over time. They can only be mounted upright.

Different battery families and sometimes different manufacturers of the same battery style require

different charging algorithms. For example, Campbell Scientific sells VRLA AGM style batteries

from two different manufacturers — EnerSys/Genesis (BP7, BP12, and BP24) and Concorde

(BP84) — yet both batteries require a different charging algorithm. The charging algorithm

applied depends on the battery temperature and whether the battery is cycle charged (fast

charged) or float charged. Each manufacturer has a recommended charging algorithm for cycle

charging or float charging the battery. Cycle charging puts a higher voltage across the battery for

a short time, forcing the battery to take in more current and charge faster. Cycle charging is

recommended for systems running on solar panels so the maximum amount of current is moved

into the battery as quickly as possible. Battery amp-hour capacity must be known when cycle

charging to switch over to float charging at the correct point in the charging cycle, eliminating

overcharging and damaging the battery. Float charging puts a lower voltage across the battery

and is amp-hour independent.

FIGURE 6-5. Device Configuration Utility Advanced Settings tab

When using a charger with current limiting feature, use the Device Configuration Utility to

change the current limit in the CH201 to be slightly lower so that it doesn't trip the current limit

feature of the charge source (see FIGURE 6-5 (p. 18)).

CH201 12V Charging Regulator 18

Page 22

7. Operation

This section covers the following:

7.1 Charging algorithm 19

7.2 Maximum power point tracking 20

7.3 Communications 21

7.3.1 SDI-12 communications 23

7.3.2 RS-232 communications 25

7.4 LED indicators 29

7.1 Charging algorithm

The CH201 uses a two-step constant voltage charging algorithm, which is the preferred method

for rapidly charging VRLA batteries1from a solar panel. If the CH201 is powered solely from a

continuous power supply, bypass the two-step charging and use continuous, unaggressive

charging by using the battery capacity setting of zero (default value). When powered from a solar

panel, the battery charge deficit (Qloss) is compared to the specified battery capacity to

determine if aggressive cycle charging is necessary. Cycle charging is used if Qloss is determined

to be greater than 20% of the battery capacity. Upon detection that the battery is near full

charge, the constant voltage charging level is reduced from the aggressive cycle charging voltage

to the non-aggressive float-charge voltage to prevent overcharging and unwanted gassing of the

battery.

If the battery capacity is left at the default value of zero, Qloss always equals 0, which disables

cycle charging. Consequently, CH201 users must enter the battery capacity in the Device

Configuration Utility to enable the aggressive cycle charging capability of the two-step constant

voltage charging algorithm that is optimal for charging from solar panels.

Discharged VRLA batteries can initially accept large charging currents, often resulting in the

charger being unable to initially maintain a constant voltage because of current limiting by the

charge source or the charger itself. As a result, a typical two-step constant voltage charging cycle

usually consists of three distinct stages; a current limited charge stage, a constant cycle voltage

charge stage, and a constant float voltage charge stage (see FIGURE 7-1 (p. 20)). The current

limited stage and/or the constant cycle charge voltage stage may not occur if the battery size is

CH201 12V Charging Regulator 19

Page 23

small relative to the current capability of the charge source, or if the battery is near full charge at

the beginning of a charge cycle.

Normally, cycle charging terminates and float charging begins when Qloss has been reduced to

zero. An exception occurs if, during cycle charging the battery, charge current is reduced to

below C/100, where C is the user-entered battery capacity. This condition indicates the charger is

trying to aggressively cycle charge a fully charged battery, perhaps because a new fully charged

battery was swapped in to replace an old battery that suffered from a significant Qloss. During

cycle charging, if the battery charge current falls below C/100, cycle charging is terminated and

Qloss is zeroed.

FIGURE 7-1. Two-step constant voltage battery charging

7.2 Maximum power point tracking

FIGURE 7-2 (p. 21) shows the current and power versus voltage for a 70W solar panel. The graph

shows the maximum power point of operation for the solar panel. Adjusting the load on the solar

panel so it operates at this maximum power point is referred to as maximum power point

tracking (MPPT). MPPT is beneficial when insufficient power is available from the charge source,

which is the case during current limited charging. The noisy charging current and voltage

observed in FIGURE 7-1 (p. 20) during the initial current limited charging stage is due to the

MPPT algorithm of the CH201 searching for the maximum power point of the associated solar

panel.

CH201 12V Charging Regulator 20

Page 24

FIGURE 7-2. 70 W solar panel I – V and power characteristics

7.3 Communications

SDI-12 or RS-232 communications can be used to monitor the status of the battery, charging

source, and charging regulator. Table 7-1 (p. 22) lists the measurements available for both

communications modes.

CH201 12V Charging Regulator 21

Page 25

Table 7-1: CH201 measurements

Measurement Units

Battery voltage V

Battery current A

Load current A

DC In 1 voltage V

DC In 2 voltage V

Temperature °C

Charge state

Charge source

Check battery

SDI-12 Response

RS-232 Response/

DI-12 Meaning

–1 “REGULATOR FAULT”

0 “NO CHARGE”

1 “CURRENT LIMITED”

2 “CYCLE CHARGING”

3 “FLOAT CHARGING”

RS-232 Response/

SDI-12 Response

SDI-12 Meaning

0 “NONE”

1 "DC In 1"

2 “DC In 2”

0 = normal

1 = check battery (battery voltage less

than 10.5 V or battery is open circuit)

Target battery voltage V

Input voltage at maximum power V

Battery capacity Ah

Qloss Ah

The information from the regulator can also be used to calculate power usage by the battery and

the system. Measuring and storing power usage is useful to determine system power

requirements (power budget) and to help identify devices using too much power. A

CH201 12V Charging Regulator 22

Page 26

downloadable example program that monitors power usage is available at

www.campbellsci.com/downloads/ch201-program-examples.

7.3.1 SDI-12 communications

SDI-12 is a serial communications standard specifically designed for reading measurements from

multiple measurement sensors to data recorders, including Campbell Scientific data loggers.

Additional information about the SDI-12 protocol is available at www.SDI-12.org website and the

SDI-12 Sensors | Transparent Mode and SDI-12 Sensors | Watch or Sniffer Mode videos.

To communicate with the CH201 using SDI-12, connect the CH201 to the data logger as shown in

Table 7-2 (p. 23).

Table 7-2: Wiring for SDI-12 communications

CH201 connection CH201 terminal function Data logger connection

TX SDI-12 transmit and receive

G Ground ⏚ (analog ground)

1

U and C terminals are automatically configured by the measurement instruction.

C or U1configured for SDI-12

FIGURE 7-3. CH201 connected to a CR1000X via SDI-12

CH201 12V Charging Regulator 23

Page 27

If multiple SDI-12 devices are connected to a data logger, Campbell Scientific recommends using

separate terminals when possible. However, multiple SDI-12 devices can connect to the same

data logger control or U terminal. Each must have a unique SDI-12 address. Valid addresses are 0

through 9, a through z, and A through Z. The CH201 has a default SDI-12 address of 0. The SDI-12

address can be changed by using Device Configuration Utility or an SDI-12 command (aAb!).

For the CR6 and CR1000X data loggers, triggering conflicts may occur when a companion

terminal is used for a triggering instruction such as TimerInput(), PulseCount(), or

WaitDigTrig(). For example, if the CH201 is connected to C3 on a CR1000X, C4 cannot be

used in the TimerInput(), PulseCount(), or WaitDigTrig() instructions.

7.3.1.1 SDI-12 commands

Table 7-3: SDI-12 commands and responses

SDI-12 command

aM!, aMC!

aM1!, aMC1!

aM2!, aMC2!

1

a is the sensor address.

1

Values returned

1. Battery voltage

2. Battery current

3. Load current

4. DC In 1 voltage

5. DC In 2 voltage

6. Temperature

7. Charge state

8. Charge source

9. Check battery

1. Charge state

2. charge source

3. check battery

1. Target battery voltage

2. Input voltage at maximum

3. Battery capacity, Qloss

CH201 12V Charging Regulator 24

Page 28

Table 7-4: SDI-12 extended commands and responses

SDI-12 Command Description Response

Overrides the internal temperature

aXTnn.nn!

Where:

a = CH201 SDI-12 address

nn.nn = temperature in °C

aXTR!

Where:

a = CH201 SDI-12 address

measurement for 15 minutes (or until

canceled by a temperature restore

command). Useful for entering the

temperature of a remote battery.

Temperature range is –40.00 to

100.00°C.

Restore temperature measurement to

internal CH201 measurement.

aOK

aOK

aXCnn.n!

Where:

a = CH201 SDI-12 address

nn.n = battery capacity in Ah

aXRQ!

Where:

a = CH201 SDI-12 address

Downloadable example programs using these extended commands are available at

www.campbellsci.com/downloads/ch201-program-examples.

Enter battery capacity in Ah. Used to

charge the battery correctly. Must be

aOK

non-zero to use the quicker dual-rate

charging scheme.

Sets Qloss to zero. If not used, the

CH201 will automatically set Qloss to

aOK

zero after trying to cycle charge a

battery for eight hours or more.

7.3.1.2 CRBasic programming

The CRBasic instruction SDI12Recorder() is used to program a data logger to communicate

with the CH201 using SDI-12. Refer to the CRBasic help for information about this instruction.

Downloadable SDI-12 example programs are available at

www.campbellsci.com/downloads/ch201-program-examples.

7.3.2 RS-232 communications

The CH201 can use RS-232 to communicate directly with a Campbell Scientific data logger, or it

can communicate with a computer through an A200 module. The following table shows the

wiring for both connections.

CH201 12V Charging Regulator 25

Page 29

Table 7-5: Wiring for RS-232 communications

CH201 connection

TX Transmit

RX Receive

COM G Ground G G

DC In 1 or DC In2 12 VDC No connection +12Vdc

CH201

Data logger connection A200 connection

terminal function

C (even) (RX terminal

RX

of a COM port pair)

C (odd) (TX terminal

TX

of a COM port pair)

FIGURE 7-4. CH201 connected to a CR1000X via RS-232

RS-232 settings are as follows:

Bits per second:

Data bits:

Parity: None

Stop bits: 1

Flow control:

9600

8

None

CH201 12V Charging Regulator 26

Page 30

7.3.2.1 RS-232 commands

An RS-232 host initiates communication by sending an ASCII command string CH201(n)x

terminated with <CR> (carriage return, 0x0D in hexadecimal format), where n = command

number and x = command value.

The CH201 response string begins with an asterisk (*), followed by the comma-delimited data

strings and a checksum <CRC>. The string is terminated with <CR><LF> (carriage return 0x13,

line feed 0x10). Responses are numerical values with decimal points except for Charge State and

Charge Source, which appear as ASCII strings.

Table 7-6: RS-232 commands and responses

RS-232 command and response Description

Command:

CH201(0)0<CR>

Response:

*,

nnnn,nnnn,…,<CRC><CR><LF>

Where

nnnn = comma-delimited values and

strings

Read CH201 status.

Values Returned:

Battery voltage, battery current, load current, DC In 1

voltage, DC In 2 voltage, temperature, target battery

voltage, maximum power input voltage setting, battery

capacity, Qloss, charge state, charge source, check

battery

Command:

CH201(1)nn.nn<CR>

Where

nn.nn = temperature in °C

Response:

*Battery Temperature =

nnnn,<CRC><CR><LF>

Where

nnnn = set temperature

Command:

CH201(2)0<CR>

Response:

*OK<CRC><CR><LF>

Overrides the internal temperature measurement for 15

minutes (or until canceled by a temperature restore

command). Useful for entering the temperature of a

remote battery. Temperature range is –40.00 to

100.00°C.

Restore temperature measurement to internal CH201

measurement.

CH201 12V Charging Regulator 27

Page 31

Table 7-6: RS-232 commands and responses

RS-232 command and response Description

Command:

CH201(3)nnn.nn<CR>

Where

nnn.nn = battery capacity in Ah

Response:

*Battery capacity =

nnn.nn<CRC><CR><LF>

Command:

CH201(4)nnn.nn<CR>

Where

nnn.nn = battery charge deficit in Ah

Response:

*Qloss = nnn.nn

<CRC><CR><LF>

RS-232 command and response example:

Transmit: CH201(0)0<CR>

Receive:

*,14.726,0.0514,0.0017,23.045,0.2922,25.03,14.699,18.45,7.00,2.99

126,CYCLE CHARGING,DC In 1,0,<CRC><CR><LF>

Enter battery capacity in Ah. Used to charge the battery

correctly. Must be non-zero to use the quicker dual-rate

charging scheme.

Sets Qloss to zero. If not used, the CH201 will

automatically set Qloss to zero after trying to cycle

charge a battery for eight hours or more.

These values indicate the following:

Battery Voltage (V) = 14.726

Battery Current (A) = 0.0514

Load Current (A) = 0.0017

DC In 1 Voltage (V) = 23.045

DC In 2 Voltage (V) = 0.2922

Temperature (°C) = 25.03

Target Battery Voltage (V) = 14.699

Maximum Power Input Voltage (V) = 18.45

Battery Capacity (Ah) = 7.00

Qloss (Ah) = 2.99126

CH201 12V Charging Regulator 28

Page 32

Charge State = CYCLE CHARGING

Charge Source = DC In 1

Check Battery = 0

7.3.2.2 CRBasic programming

Use the SerialOut() and SerialInRecord() CRBasic instructions to program a data

logger to communicate with the CH201 using RS-232. To separate the numerical values, use

SplitStr().

The data logger can decipher the two-character checksum by using the CRBasic instruction

CheckSum(). Set the ChkSumType parameter to 5. A correct checksum will produce a result

of zero. A non-zero result indicates a transmission error(s) occurred.

The normal communication mode is SDI-12. Therefore, when the host first sends RS-232

characters, the first character might be missed. Avoid this by initiating RS-232 communication

with two backspace characters <BS> (0x08) as shown in the following example subroutine:

'Subroutine sends two backspace characters to the CH201 to

'wake it up and switch over to RS-232 mode.

Sub WAKEUP

SerialOut (COMPRT,CHR(&H08),"",1,3)

SerialOut (COMPRT,CHR(&H08),"",1,3)

EndSub

Downloadable example programs are available at www.campbellsci.com/downloads/ch201-

program-examples.

7.4 LED indicators

The CH201 has two LED indicators, the CHG (charge) LED and the CKBAT (check battery) LED.

Table 7-7 (p. 30) and Table 7-8 (p. 30) list the conditions and associated colors for the CHG and

CKBAT LEDs.

CH201 12V Charging Regulator 29

Page 33

Table 7-7: CHG LED

Condition Color/state

No valid charge source Off

Valid charge source and charging battery Flashing green

Valid charge source but battery discharging Flashing orange

Regulator fault detected Flashing red

Waiting for new operating system

(Downloading an operating system (p. 31))

Transferring operating system Solid green

Table 7-8: CK BAT LED

Condition Color/state

Battery voltage > 11.5 V Off

10.5 V ≤ battery voltage ≤ 11.5 V Flashing orange

Battery fault detected OR battery voltage < 10.5 V Flashing red

Solid red

8. References

1 – Genesis Application Manual – Genesis NP and NPX Series US-NP-AM-002, June 2006.

CH201 12V Charging Regulator 30

Page 34

Appendix A. Downloading an operating system

Although rarely needed, the operating system is easily updated by using the Device

Configuration Utility and the RS-232 interface cable (sold separately).

1. Download the latest CH201 operating system from www.campbellsci.com/ch201 to your

computer. This download is an executable file that automatically installs itself into the

correct folders. Run the file on the computer that will be used to connect to the CH201.

2. Connect the CH201 to power then connect it to the computer.

3. Open Device Configuration Utility.

4. Select CH201 from the Device Type list on the left of the Device Configuration Utility

window.

5. Select the Send OS tab.

6. Click Start and the Select the operating system to send dialog window appears.

7. Navigate to the CH201_[version number].a43 operating system file and click Open.

8. The CHG LED changes from red to green, indicating the module is receiving a new

operating system. The process will take a few minutes.

CAUTION:

DO NOT disconnect from the CH201 during this process.

9. When the operating system has been successfully sent, the green LED turns off and Device

Configuration Utility will bring up a window showing the new operating system was

successfully sent.

CH201 12V Charging Regulator 31

Page 35

FIGURE A-1. Downloading a new operating system

CH201 12V Charging Regulator 32

Page 36

Limited warranty

Products manufactured by Campbell Scientific are warranted by Campbell Scientific to be free

from defects in materials and workmanship under normal use and service for twelve months from

the date of shipment unless otherwise specified on the corresponding product webpage. See

Product Details on the Ordering Information pages at www.campbellsci.com. Other

manufacturer's products, that are resold by Campbell Scientific, are warranted only to the limits

extended by the original manufacturer.

Refer to www.campbellsci.com/terms#warranty for more information.

CAMPBELL SCIENTIFIC EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Campbell Scientific hereby

disclaims, to the fullest extent allowed by applicable law, any and all warranties and conditions

with respect to the Products, whether express, implied or statutory, other than those expressly

provided herein.

Page 37

Assistance

Products may not be returned without prior authorization.

Products shipped to Campbell Scientific require a Returned Materials Authorization (RMA) or

Repair Reference number and must be clean and uncontaminated by harmful substances, such as

hazardous materials, chemicals, insects, and pests. Please complete the required forms prior to

shipping equipment.

Campbell Scientific regional offices handle repairs for customers within their territories. Please

see the back page for the Global Sales and Support Network or visit

www.campbellsci.com/contact to determine which Campbell Scientific office serves your country.

To obtain a Returned Materials Authorization or Repair Reference number, contact your

CAMPBELL SCIENTIFIC regional office. Please write the issued number clearly on the outside of

the shipping container and ship as directed.

For all returns, the customer must provide a “Statement of Product Cleanliness and

Decontamination” or “Declaration of Hazardous Material and Decontamination” form and

comply with the requirements specified in it. The form is available from your CAMPBELL

SCIENTIFIC regional office. Campbell Scientific is unable to process any returns until we receive

this statement. If the statement is not received within three days of product receipt or is

incomplete, the product will be returned to the customer at the customer’s expense. Campbell

Scientific reserves the right to refuse service on products that were exposed to contaminants that

may cause health or safety concerns for our employees.

Page 38

Safety

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND TRIPODS,

TOWERS, AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC. FAILURE

TO PROPERLY AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS, TOWERS, AND ATTACHMENTS, AND

FAILURE TO HEED WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE.

TAKE ALL REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS. CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR

POLICY) FOR PROCEDURES AND REQUIRED PROTECTIVE EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design limits. Be

familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com. You are responsible

for conformance with governing codes and regulations, including safety regulations, and the integrity and location of structures or land to

which towers, tripods, and any attachments are attached. Installation sites should be evaluated and approved by a qualified engineer. If

questions or concerns arise regarding installation, use, or maintenance of tripods, towers, attachments, or electrical connections, consult

with a licensed and qualified engineer or electrician.

General

l Protect from over-voltage.

l Protect electrical equipment from water.

l Protect from electrostatic discharge (ESD).

l Protect from lightning.

l Prior to performing site or installation work, obtain required approvals and permits. Comply with all governing structure-height

regulations.

l Use only qualified personnel for installation, use, and maintenance of tripods and towers, and any attachments to tripods and

towers. The use of licensed and qualified contractors is highly recommended.

l Read all applicable instructions carefully and understand procedures thoroughly before beginning work.

l Wear a hardhat and eye protection, and take other appropriate safety precautions while working on or around tripods and towers.

l Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take reasonable precautions to secure tripod

and tower sites from trespassers.

l Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

l You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are installing, constructing, using, or

maintaining, or a tool, stake, or anchor, come in contact with overhead or underground utility lines.

l Maintain a distance of at least one-and-one-half times structure height, 6 meters (20 feet), or the distance required by applicable

law, whichever is greater, between overhead utility lines and the structure (tripod, tower, attachments, or tools).

l Prior to performing site or installation work, inform all utility companies and have all underground utilities marked.

l Comply with all electrical codes. Electrical equipment and related grounding devices should be installed by a licensed and qualified

electrician.

l Only use power sources approved for use in the country of installation to power Campbell Scientific devices.

Elevated Work and Weather

l Exercise extreme caution when performing elevated work.

l Use appropriate equipment and safety practices.

l During installation and maintenance, keep tower and tripod sites clear of un-trained or non-essential personnel. Take precautions to

prevent elevated tools and objects from dropping.

l Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

l Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks, frayed cables, loose cable clamps, cable

tightness, etc. and take necessary corrective actions.

l Periodically (at least yearly) check electrical ground connections.

Internal Battery

l Be aware of fire, explosion, and severe-burn hazards.

l Misuse or improper installation of the internal lithium battery can cause severe injury.

l Do not recharge, disassemble, heat above 100 °C (212 °F), solder directly to the cell, incinerate, or expose contents to water. Dispose

of spent batteries properly.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS, THE CUSTOMER

ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR MAINTENANCE OF TRIPODS, TOWERS, OR

ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC.

Page 39

Campbell Scientific regional offices

Australia

Location:

Phone:

Email:

Website:

Brazil

Location:

Phone:

Email:

Website:

Canada

Location:

Phone:

Email:

Website:

China

Location:

Phone:

Email:

Website:

Garbutt, QLD Australia

61.7.4401.7700

info@campbellsci.com.au

www.campbellsci.com.au

São Paulo, SP Brazil

11.3732.3399

vendas@campbellsci.com.br

www.campbellsci.com.br

Edmonton, AB Canada

780.454.2505

data loggers@campbellsci.ca

www.campbellsci.ca

Beijing, P. R. China

86.10.6561.0080

info@campbellsci.com.cn

www.campbellsci.com.cn

France

Location:

Phone:

Email:

Website:

Vincennes, France

0033.0.1.56.45.15.20

info@campbellsci.fr

www.campbellsci.fr

Germany

Location:

Phone:

Email:

Website:

Bremen, Germany

49.0.421.460974.0

info@campbellsci.de

www.campbellsci.de

India

Location:

Phone:

Email:

Website:

New Delhi, DL India

91.11.46500481.482

info@campbellsci.in

www.campbellsci.in

South Africa

Location:

Phone:

Email:

Website:

Stellenbosch, South Africa

27.21.8809960

sales@campbellsci.co.za

www.campbellsci.co.za

Thailand

Location:

Phone:

Email:

Website:

UK

Location:

Phone:

Email:

Website:

USA

Location:

Phone:

Email:

Website:

Bangkok, Thailand

66.2.719.3399

info@campbellsci.asia

www.campbellsci.asia

Shepshed, Loughborough, UK

44.0.1509.601141

sales@campbellsci.co.uk

www.campbellsci.co.uk

Logan, UT USA

435.227.9120

info@campbellsci.com

www.campbellsci.com

Costa Rica

Location:

Phone:

Email:

Website:

San Pedro, Costa Rica

506.2280.1564

info@campbellsci.cc

www.campbellsci.cc

Spain

Location:

Phone:

Email:

Website:

Barcelona, Spain

34.93.2323938

info@campbellsci.es

www.campbellsci.es

Loading...

Loading...