Page 1

CDM-VW300 Series

Dynamic Vibrating-Wire

Analyzers

Revision: 11/13

Campbell Scientific, Inc.

Copyright © 2013

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements............................................... 2

3. Initial Inspection .........................................................2

4. Overview......................................................................3

4.1 Channel Allocations .............................................................................3

4.2 Measurement Rates ..............................................................................4

4.3 Integrated Thermistor Measurement ....................................................4

4.4 Laboratory Mode..................................................................................5

4.5 Field Mode ...........................................................................................5

4.6 Data Uses .............................................................................................6

4.6.1 Static Measurements .....................................................................6

4.6.2 Dynamic Measurements................................................................6

4.6.3 Thermistor Measurements.............................................................6

4.6.4 Rainflow Histograms ....................................................................7

4.6.5 System Diagnostics .......................................................................7

5. Specifications .............................................................7

5.1 Features ................................................................................................7

5.2 Specifications .......................................................................................8

6. Installation.................................................................10

6.1 Laboratory-Mode Installation ............................................................11

6.1.1 Laboratory-Mode Installation Equipment...................................11

6.1.2 Laboratory-Mode Installation Procedure ....................................12

6.2 Field-Mode Installation ......................................................................18

6.2.1 Field-Mode Installation Equipment ............................................18

6.2.2 Field-Mode Installation Procedure..............................................18

7. System Operation .....................................................26

7.1 PC Based Tools..................................................................................26

7.1.1 Software and Driver Installation .................................................26

7.1.2 Using DVWTool.........................................................................27

7.1.2.1 Ensure Connection is Active ............................................27

7.1.2.2 DVWTool Settings Editor ................................................28

7.1.2.3 Button and Field Descriptions..........................................28

7.1.3 Using DevConfig ........................................................................29

7.1.3.1 Ensure Connection is Active ............................................29

7.1.3.2 DevConfig Settings Editor ...............................................30

i

Page 6

Table of Contents

7.2 Using the Datalogger......................................................................... 30

7.3 Using the SC-CPI Interface ............................................................... 31

7.4 Using Power Supplies........................................................................ 31

7.4.1 CDM-VW300 Series Analyzer Power ....................................... 31

7.4.2 Data-Acquisition System Power................................................. 32

7.5 Configuring the CDM-VW300 Analyzer .......................................... 32

7.5.1 Device Name.............................................................................. 34

7.5.2 CPI Bus Speed............................................................................ 34

7.5.3 Operating System Version.......................................................... 35

7.5.4 Operating System Date............................................................... 35

7.5.5 Analyzer Serial Number............................................................. 35

7.5.6 Display Rate ............................................................................... 35

7.5.7 Dynamic Sample Rate................................................................ 35

7.5.8 Device Type ............................................................................... 35

7.5.9 CPI Bus Address ........................................................................ 35

7.5.10 System Options .......................................................................... 35

7.5.11 Channels Enabled....................................................................... 36

7.5.12 Desired Resonant Amplitude...................................................... 36

7.5.13 Minimum- and Maximum Cut-Off Frequencies ........................ 36

7.5.14 Frequency-Output Format .......................................................... 36

7.5.15 Multipliers and Offsets ............................................................... 36

7.5.16 Steinhart-Hart Coefficients......................................................... 36

7.5.17 Rainflow-Histogram Output Configurations .............................. 36

7.6 Sensor Selection ................................................................................ 37

7.6.1 Frequency Considerations.......................................................... 37

7.6.2 Noise Performance ..................................................................... 37

7.7 System Connections .......................................................................... 37

7.7.1 CDM-VW300 to PC Connection ............................................... 38

7.7.2 CDM-VW300 to Sensor Connection.......................................... 38

7.7.3 CDM-VW300 to SC-CPI Connection ........................................ 40

7.7.4 CDM-VW300 to Power Connection .......................................... 42

7.7.5 Earth Ground Connections ......................................................... 44

7.7.6 Communication Connections ..................................................... 44

7.7.6.1 SC-CPI to CPI Bus Connection....................................... 44

7.7.6.2 Datalogger to SC-CPI Connection................................... 44

7.7.7 Maximum Number of Analyzers on a Datalogger ..................... 45

7.8 Operating System .............................................................................. 46

7.9 Power-Up Sequence .......................................................................... 46

7.10 CRBasic Programming ...................................................................... 47

7.10.1 Writing Programs ....................................................................... 47

7.10.2 Sending Programs to the Datalogger.......................................... 48

7.11 System Adjustments .......................................................................... 49

7.11.1 Frequency Range........................................................................ 49

7.12 System Validation ............................................................................. 49

7.12.1 Sensor Validation ....................................................................... 49

7.12.2 Monitoring System Performance................................................ 49

7.12.2.1 Monitoring with DVWTool Software.............................. 52

7.12.2.1.1 Fault Detection...................................................... 52

8. Troubleshooting........................................................53

8.1 Connections ....................................................................................... 53

8.2 Power................................................................................................. 53

8.3 Isolating Components ........................................................................ 53

8.4 Filtering Harmonics........................................................................... 54

8.5 Diagnostic Outputs............................................................................ 54

ii

Page 7

Table of Contents

8.5.1 Diagnostic Codes (Dynamic) ......................................................54

8.5.1.1 Description of Diagnostic Parameters ..............................55

8.5.1.2 Calculating Low- and High-Frequency Boundaries.........56

8.5.1.3 Using Diagnostic Parameters ...........................................57

8.5.1.4 Decoding the Diagnostic Code.........................................57

8.5.1.4.1 Excitation Strength ................................................57

8.5.1.4.2 Low-Amplitude Warning Flag ..............................57

8.5.1.4.3 High-Amplitude Warning Flag..............................58

8.5.1.4.4 Low-Frequency Warning Flag...............................58

8.5.1.4.5 High-Frequency Warning Flag..............................58

8.5.1.4.6 Interpreting the Diagnostic Code...........................58

8.5.2 Standard Deviation of Dynamic Output......................................59

8.6 Factory Default Reset.........................................................................59

9. Glossary ....................................................................60

10. References and Attributions....................................60

Appendices

Measurement Theory.............................................. A-1

A.

A.1 Dynamic Vibrating-Wire Measurements ........................................ A-1

A.1.1 Dynamic and Static Frequencies.............................................. A-2

B. SC-CPI Datalogger to CPI Interface....................... B-1

B.1 Introduction......................................................................................B-1

B.2 Quickstart.........................................................................................B-1

B.3 Overview..........................................................................................B-1

B.4 Specifications ...................................................................................B-3

C. CDM Devices and CPI Bus..................................... C-1

C.1 CDM Interconnection and Datalogger Connection..........................C-1

C.1.1 Power ........................................................................................C-1

C.1.2 Interconnect Cable ....................................................................C-1

C.1.3 Speed as a Function of Distance ...............................................C-2

C.1.4 CPI Grounding ..........................................................................C-3

C.1.6 Addressing ................................................................................C-3

C.2 Distributed Architecture...................................................................C-3

D. Digits Conversion ................................................... D-1

D.1 Example: Frequency to Digits to Displacement.............................. D-1

E. Calculating Measurement Error............................. E-1

E.1 Example Error Calculation: Geokon Strain Gage ............................ E-1

E.2 Example Error Calculation: DGSI Embedment Strain Gage ...........E-2

E.3 Example Error Calculation: DGSI Spot-Welded Strain Gage..........E-2

E.4 Example Error Calculation: Geokon 4420 Crack Meter .................. E-2

E.5 Example Error Calculation: DGSI Piezometer 52611099................E-3

iii

Page 8

Table of Contents

F. Thermistor Information........................................... F-1

F.1 Converting Resistance to Temperature.............................................F-1

F.1.1 Resistance Conversion Example – Geokon Sensor................... F-1

F.2 Accuracy and Resolution..................................................................F-1

G. CRBasic Program Library ......................................G-1

G.1 Dynamic Measurements .................................................................. G-1

G.1.1 20 Hz Measurement Example — One CDM-VW300, Two

Channels ............................................................................... G-1

G.1.2 20 Hz Measurement Example — One CDM-VW305, Eight

Channels ............................................................................... G-2

G.1.3 20 Hz Measurement Example — Three CDM-VW305s, 24

Channels ............................................................................... G-4

G.1.4 20 Hz Measurement Example — Six CDM-VW305s, 48

Channels ............................................................................... G-5

G.1.5 50 Hz Measurement Example — One CDM-VW300, Two

Channels ............................................................................... G-8

G.1.6 50 Hz Measurement Example — One CDM-VW305, Eight

Channels ............................................................................... G-9

G.1.7 50 Hz Measurement Example — Three CDM-VW305s, 24

Channels ............................................................................. G-11

G.1.8 50 Hz Measurement Example — One CDM-VW300, Two

Channels, Rainflow Histogram........................................... G-12

G.1.9 50 Hz Measurement Example — One CDM-VW305, Eight

Channels, Rainflow Histogram........................................... G-14

G.1.10 50 Hz Diagnostic Example — One CDM-VW300, Two

Geokon 4000 Sensors with FieldCal() ................................ G-15

G.1.11 50 Hz Measurement Example — One CDM-VW300, Two

Geokon 4000 Sensors with FieldCal() ................................ G-17

G.1.12 50 Hz Measurement Example — One CDM-VW300, Two

Geokon 4000 Sensors with FieldCal() and CardOut() to

CF .......................................................................................G-19

G.1.13 50 Hz Measurement Example — One CDM-VW300, Two

Geokon 4000 Sensors with FieldCal() and TableFile() to

CF .......................................................................................G-21

G.1.14 100 Hz Measurement Example — One CDM-VW300, Two

Channels ............................................................................. G-23

G.1.15 100 Hz Measurement Example — One CDM-VW305,

Eight Channels.................................................................... G-24

G.2 Static Measurements...................................................................... G-25

G.2.1 1 Hz Measurement Example — One CDM-VW300, Two

Channels ............................................................................. G-25

G.2.2 1 Hz Measurement Example — One CDM-VW305, Eight

Channels ............................................................................. G-26

Figures

4-1. Two-channel CDM-VW300 wiring panel........................................... 3

4-2. Eight-channel CDM-VW305 wiring panel.......................................... 4

4-3. Measurement speeds of the AVW200 and CDM-VW300 analyzers .. 4

4-4. Single-coil vibrating-wire sensor including coil and thermistor

outputs.............................................................................................. 5

4-5. Laboratory-mode measurement system diagram................................. 5

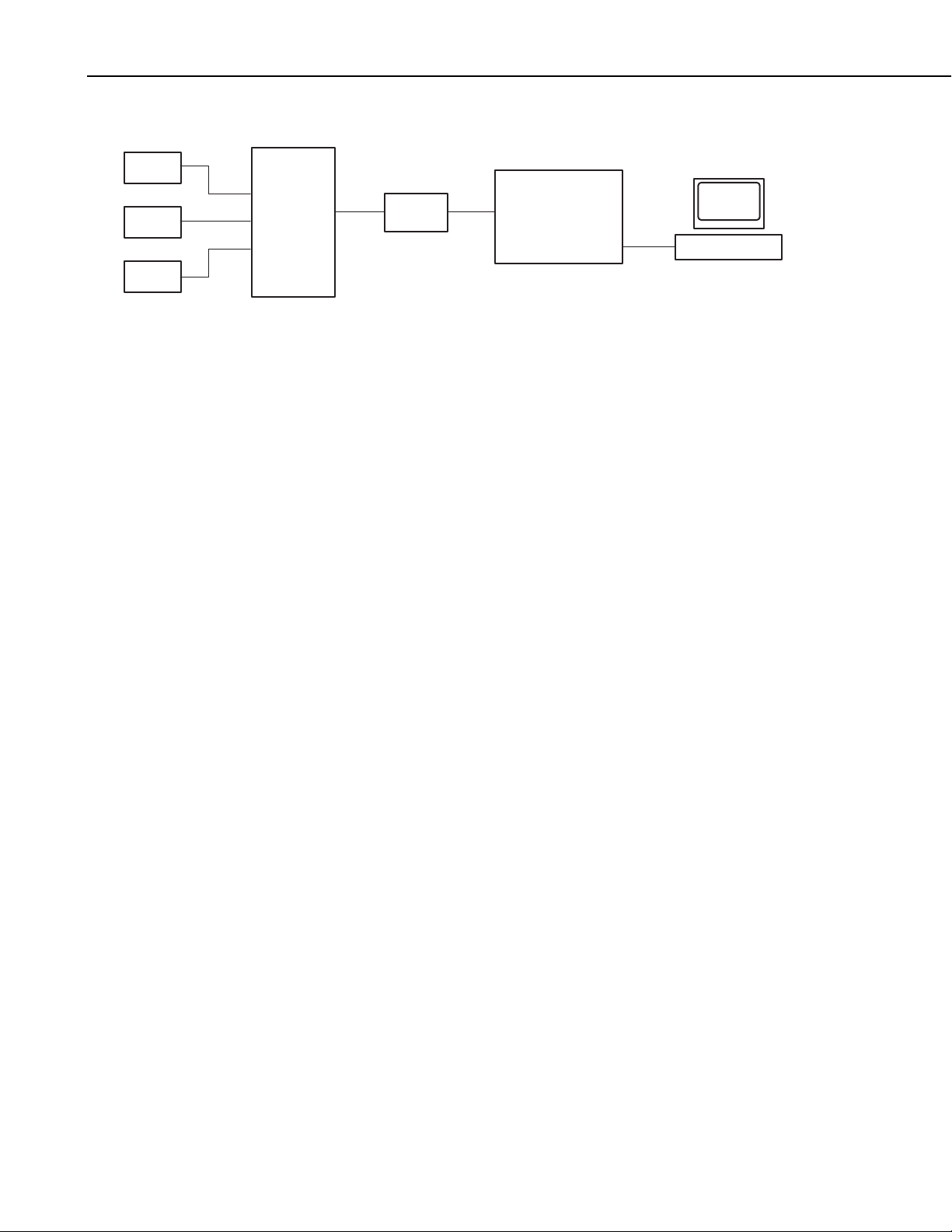

4-6. Field-mode data-acquisition system diagram ...................................... 6

iv

Page 9

Table of Contents

6-1. Laboratory-mode measurement system..............................................11

6-2. 12 Vdc power connection on the CDM-VW300................................12

6-3. USB receptacle on CDM-VW300 and Type-Micro-B connector

of USB cable...................................................................................13

6-4. Sensor connection on a CDM-VW305...............................................16

6-5. Three-wire vibrating-wire sensor connections ...................................16

6-6. Five-wire vibrating-wire sensor connections .....................................16

6-7. Field data-acquisition system.............................................................18

6-8. CPI communications links .................................................................21

6-9. Datalogger to SC-CPI connection ......................................................21

6-10. Connecting the CPI ports of the SC-CPI and CDM-VW300 .............22

6-11. Install CPI bus terminator ..................................................................22

6-12. Power connection ...............................................................................23

6-13. Earth ground connections...................................................................24

7-1. DVWTool Settings Editor and Data Display .....................................28

7-2. DevConfig Settings Editor .................................................................30

7-3. 12 Vdc power transformer for laboratory-mode installation..............31

7-4. USB port on the CDM-VW300..........................................................38

7-5. Three-wire vibrating-wire sensor leads..............................................38

7-6. Three-wire vibrating-wire sensor connection.....................................39

7-7. Five-wire, vibrating-wire sensors leads..............................................39

7-8. Five-wire vibrating-wire sensor connection.......................................40

7-9. SC-CPI and CDM-VW300 CPI ports with RJ45 cable marked

with yellow tape..............................................................................41

7-10. CPI terminator installed .....................................................................41

7-11. Multiple analyzers on a CPI bus ........................................................42

7-12. Installing 12 Vdc transformer on the CDM-VW300 ..........................43

7-13. Daisy-chaining 12 Vdc power input on the CDM-VW300 ................43

7-14. Earth ground connections...................................................................44

7-15. CR3000 and SC-CPI connections ......................................................45

7-16. LoggerNet connect screens showing frequencies from

CDM-VW300 .................................................................................50

7-17. RTDAQ screens showing frequencies in Public table.......................51

7-18. Dynamic Vibrating-Wire Tool Box Fault Indicators .........................52

A-1. Timing of dynamic vibrating-wire measurements .......................... A-2

B-1. Connection to the SC-CPI in DevConfig .........................................B-2

C-1. CPI pin assignments.........................................................................C-2

C-2. Long cable lengths of a distributed CPI bus.....................................C-4

D-1. Geokon Calibration Report of a Sensor without a Thermistor........ D-2

F-1. Temperature measurement error at three temperatures as a

function of lead length. Wire is 22 AWG with 16 ohms per

1000 feet. ...................................................................................... F-2

F-2. Temperature measurement error on a 1000 foot lead. Wire is

22 AWG with 16 ohms per 1000 feet........................................... F-3

F-3. Temperature measurement error on a 3000 foot lead. Wire is

22 AWG with 16 ohms per 1000 feet........................................... F-3

F-4. Temperature measurement error on a 5000 foot Lead. Wire is

22 AWG with 16 ohms per 1000 feet........................................... F-4

Tables

5-1. CDM-VW300 / Datalogger Compatibility...........................................8

5-2. CDM-VW300/305 Sensor Resonant Frequency Range (Hz)...............9

5-3. CDM-VW300/305 Effective Frequency Measurement Resolution4....9

6-1. CDM-VW300 Status LED States.......................................................17

6-2. DVWTool and CRBasic Settings.......................................................19

v

Page 10

Table of Contents

7-1. Summary of CDM-VW300 Configuration Settings.......................... 33

7-2. Relationship of Sample Rate and Sensor Frequency......................... 37

7-3. Number of Analyzers and Channels Supported by a Datalogger

Writing to CF Card ........................................................................ 45

7-4. CDM-VW300 Scan Rate / Datalogger Scan() Interval Pairings ....... 47

7-5. CDM-VW300 Channel-Status LED States ....................................... 49

8-1. Scan Rate and Boundary Resolution ................................................. 56

8-2. Diagnostic Code Ranges.................................................................... 58

C-1. Maximum Potential Speed as a Function of Distance1.................... C-2

vi

Page 11

CDM-VW300 Series Dynamic VibratingWire Analyzers

Configuring a dynamic vibrating-wire measurement system requires an

integrated system-wide approach. Please review this manual before

connecting hardware together or to the PC. The ResourceDVD, which ships

free of charge with most Campbell Scientific instrumentation orders, contains

the following tools that will help you configure a dynamic vibrating-wire

analyzer system:

• A copy of this manual

• DVWTool Dynamic Vibrating-Wire Toolbox software for CDM-

VW300 support

• DevConfig Device Configuration Utility software

• Required datalogger operating systems

Other support information and downloads are available at

www.campbellsci.com/cdm-vw300-support.

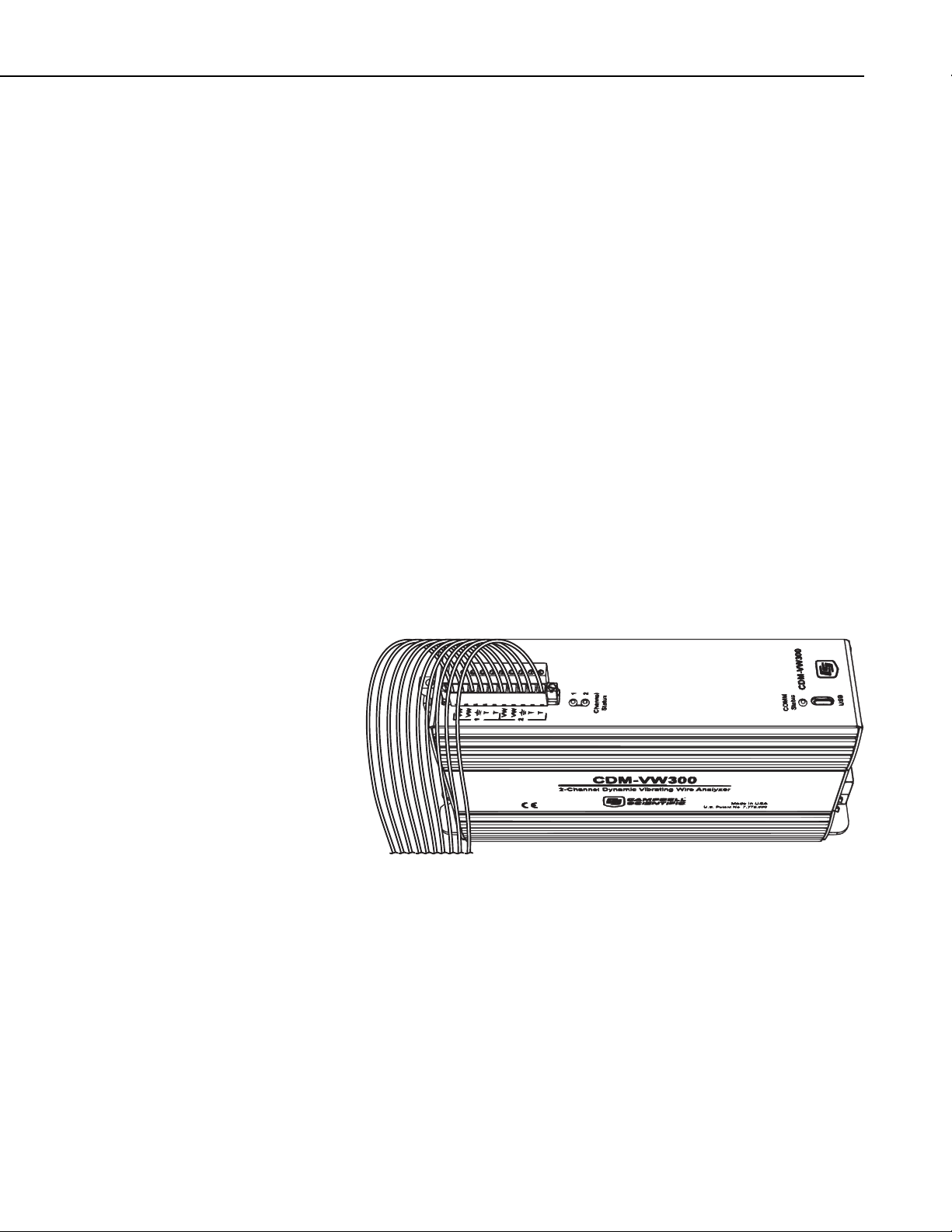

1. Introduction

Vibrating-wire sensors are commonly used in geotechnical or structural

monitoring applications to measure strain, load, tilt, inclination, temperature,

pressure, extension, and crack movement. CDM-VW300 Series Dynamic

Vibrating-Wire Analyzers facilitate sub-second measurement of vibrating-wire

sensors. These analyzers perform advanced excitation, spectral analysis, and

digital signal processing to obtain high-accuracy measurements. Data are

stored on a Campbell Scientific datalogger, which is normally used to control

the system in field installations.

The CDM-VW300 has two modes of operation:

• Laboratory mode

o Manual operation

o Does not require a datalogger

o Requires a PC

o Used in short-term evaluation

o Real-time data and metadata are monitored with PC

• Field mode

o Automated operation

o Requires a datalogger

o PC used only for setup and collection of data from datalogger

o Used in long-term monitoring applications

o Time-series data and metadata stored in datalogger memory

Two analyzer models are available in the CDM-VW300 series:

• CDM-VW300 (two channels)

• CDM-VW305 (eight channels)

1

Page 12

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

See TABLE 5-1, CDM / Datalogger Compatibility, in Section 5,

Specifications, for datalogger compatibility information.

Other than a few clearly noted exceptions, any discussion in this manual of the

CDM-VW300 also applies to the CDM-VW305.

Before using the CDM-VW300, please study

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

Detailed installation, operation, and troubleshooting information can be found

in the remaining sections.

2. Cautionary Statements

• CAUTION — Do not connect power to the system until it is completely

assembled.

• IMPORTANT — Do not connect the CDM-VW300 analyzer or SC-CPI

interface to a PC until AFTER installing DVWTool or DevConfig on the

PC. Consult Section 7.1.1, Software and Driver Installation, for more

information.

• All references to DVWTool mean Dynamic Vibrating-Wire Tool Box

software version 1.0 or later. DVWTool is available on current versions of

the ResourceDVD that ships with CDM-VW300 series analyzers. All

references to DevConfig mean Device Configuration Utility software

version 2.04 or later. DevConfig is available from the these three sources:

3. Initial Inspection

• CDM-VW300 series analyzers ship with,

o 1 each pn 29389 CDM Parts Kit

o 1 each ResourceDVD, which contains DVWTool and current

• Upon receipt of the CDM-VW300, inspect the packaging and contents for

damage. File damage claims with the shipping company.

• Thoroughly check all packaging material for product that may be

concealed inside it. Check model and part numbers, and product

descriptions against the shipping documents. Model or part numbers are

found on each product. Cable numbers are normally found at the end of

the cable that connects to the measurement device. Check that expected

cable lengths were received. Contact Campbell Scientific immediately

concerning any discrepancies.

o ResourceDVD shipped with CDM-VW300 series analyzers

o www.campbellsci.com/downloads (no charge)

o Installations of LoggerNet, PC400, PC200W, or RTDAQ

software. Check the Help | About screen in DevConfig for

the version number.

DevConfig software.

2

Page 13

4. Overview

4.1 Channel Allocations

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Single-coil vibrating-wire sensors are preferred in many applications because

they are stabile, accurate, and durable. CDM-VW300 Series Dynamic

Vibrating-Wire Analyzers make accurate high-speed measurements of the

resonant frequencies of these sensors at sub-second intervals using advanced

excitation and signal processing techniques, including spectral analysis.

Resonant frequency data are passed with diagnostics to a Campbell Scientific

datalogger. Applications include characterization of events that require rapid

measurements and data storage, and measurement of sensor signals too weak to

be measured with other instrumentation. See Appendix A, Measurement

Theory, for more information.

Dynamic vibrating-wire measurements require a complete system of

instrumentation. This manual focuses on the use of CDM-VW300 series

analyzers, but it also gives basic guidance on system configuration.

As illustrated in FIGURE 4-1, the CDM-VW300 simultaneously measures two

vibrating-wire sensors. FIGURE 4-2 shows that the CDM-VW305 has the

capacity to measure eight sensors. When more than eight channels are needed,

multiple devices are attached to the same datalogger through the CPI bus. See

Section 7.7.7, Maximum Number of Analyzers on a Datalogger, and Appendix

C, CDM Devices and CPI Bus, for details on connecting multiple analyzers to

a CPI bus.

FIGURE 4-1. Two-channel CDM-VW300 wiring panel

3

Page 14

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

FIGURE 4-2. Eight-channel CDM-VW305 wiring panel

4.2 Measurement Rates

CDM-VW300 analyzers use patented techniques to measure sensors at rates

from 1 to 333.3 Hz. Systems that exclusively require rates slower than 1 Hz

should use a Campbell Scientific AVW200-Series Vibrating-Wire Spectrum

Analyzer.

4

FIGURE 4-3. Measurement speeds of the AVW200 and CDM-VW300

analyzers

4.3 Integrated Thermistor Measurement

Many vibrating-wire sensors include an integrated thermistor to allow for

temperature compensation of the vibrating-wire measurement. The CDMVW300 supports thermistor measurements and the associated temperature

compensation required in some applications.

Page 15

Vibrating Wire

Thermistor

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Stainless Steel Housing

4-Conductor Cable

Two Thermistor

Outputs

Diaphragm

Filter

Plucking and Pickup Coils

FIGURE 4-4. Single-coil vibrating-wire sensor including coil and

thermistor outputs

4.4 Laboratory Mode

Laboratory mode allows for examination and validation of specific

measurements types without a datalogger, such as might occur before field

deployment. As shown in FIGURE 4-5, a connection is made from the CDMVW300 to a personal computer using a USB cable. Campbell Scientific

DVWTool software on the PC enables observation of sensor outputs and

configuration of the CDM-VW300 to measure sensors. Specific procedures

can be found in Section 6.1.2, Laboratory-Mode Installation Procedure.

Vibrating-Wire

Sensors

CDM-

VW300

Two Coil Outputs

Internal Bulkhead Seal

PC

DVWTool

4.5 Field Mode

FIGURE 4-5. Laboratory-mode measurement system diagram

Field mode is used for long-term measurement and data acquisition. As shown

in FIGURE 4-6, a connection is made from the CDM-VW300 to a Campbell

Scientific datalogger through the SC-CPI interface. A Campbell Scientific

datalogger with a customized CRBasic program configures, controls, and

collects data from the CDM-VW300. Specific installation procedures are

found in Section 6.2.2, Field-Mode Installation Procedure.

5

Page 16

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Vibrating-Wire

Sensors

CDM-

VW300

FIGURE 4-6. Field-mode data-acquisition system diagram

4.6 Data Uses

Users should consult authoritative sources concerning the use of vibrating-wire

data in structural analysis applications. Following is a short introduction to the

use of data made available by CDM-VW300 series analyzers.

4.6.1 Static Measurements

Each sensor is measured for a static frequency once per second. The static

frequency is used to obtain a result with finer spectral bin resolution than that

which can be achieved at the dynamic measurement rates. This measurement

can be helpful in detecting the rare case, for example, in which a noise

frequency very near the resonant frequency affects dynamic sampling

measurements.

SC-CPI

CR3000

Datalogger

PC

LoggerNet

4.6.2 Dynamic Measurements

Each analyzer can be configured in a 20, 50, 100, 200, or 333.3 Hz sampling

mode. By capturing multiple readings each second from a vibrating-wire

sensor, rapid changes or events can be captured and evaluated. Due to the

Nyquist sampling theorem, only responses equal to or less than half of the

sampling frequency can be detected and characterized. Event-based data

capture techniques programmed into the controlling datalogger can be helpful

to ensure useful data are captured under the right event conditions. In this way,

storage and retrieval of less-useful data are avoided.

4.6.3 Thermistor Measurements

Each vibrating-wire sensor input channel has inputs for the thermistor that is

usually built into a vibrating-wire sensor. The temperature measurement is

normally used to correct the frequency measurement for temperature changes.

A 24-bit measurement circuit ensures high-accuracy resistance measurements,

which are converted to temperature. Guidance about the impact of temperature

on the vibrating wire is usually provided by the manufacturer in documentation

provided with each individual sensor. Contact the sensor manufacturer if more

information is required.

6

Page 17

4.6.4 Rainflow Histograms

Rainflow histograms are 3-D representations of the rainflow counting

algorithm of Matsuiski and Endo (1968). Rainflow histograms can be used to

monitor fatigue levels of structures under stress, such as components of a largescale transportation bridge. The histograms are calculated by the CDMVW300 analyzer to ease the processing burden required of the controlling

datalogger.

CRBasic Help topic for the Rainflow() instruction has more information about

rainflow histograms.

4.6.5 System Diagnostics

Several diagnostic values will help you scrutinize basic CDM-VW300

measurements. Excitation level and low / high frequency or amplitude

warnings are provided for each dynamic measurement. A standard deviation is

provided once each second.

Excitation level is bounded by setting the amplitude at which the wire in the

sensor is to be maintained. That figure is reported so that excitation levels can

be monitored. If the analyzer-sensor system experiences a low amplitude, high

amplitude, low-frequency, or high frequency condition, that information is also

provided.

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Once each second, a standard deviation of a dynamic measurement is provided.

Unexplained changes in the standard deviation from baseline levels may

indicate noise or other interference.

5. Specifications

5.1 Features

• Measurement of standard, single-coil circuit, vibrating-wire sensors

• Dynamic-sampling rates of 20 to 333.3 Hz

• On-board frequency-output conversion

• Two (CDM-VW300) or eight (CDM-VW305), simultaneously-sampled

• Time synchronization of multiple modules using one datalogger

• Thermistor input for each vibrating-wire channel measured at 1 Hz

• On-board temperature conversion

• Rainflow-histogram compilation

• Superior noise immunity and effective measurement resolution (precision)

• Continuous resonant vibration in the sensor

channels per module

• Spectral analysis method protected under U.S. patent no. 7,779,690. An

additional U.S. patent that relates to the dynamic vibrating-wire

measurement technique is pending.

7

Page 18

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

5.2 Specifications

Electrical specifications are valid from –25 to 50 °C unless otherwise specified.

Non-condensing environment required. Specifications are subject to change.

Compatibility:

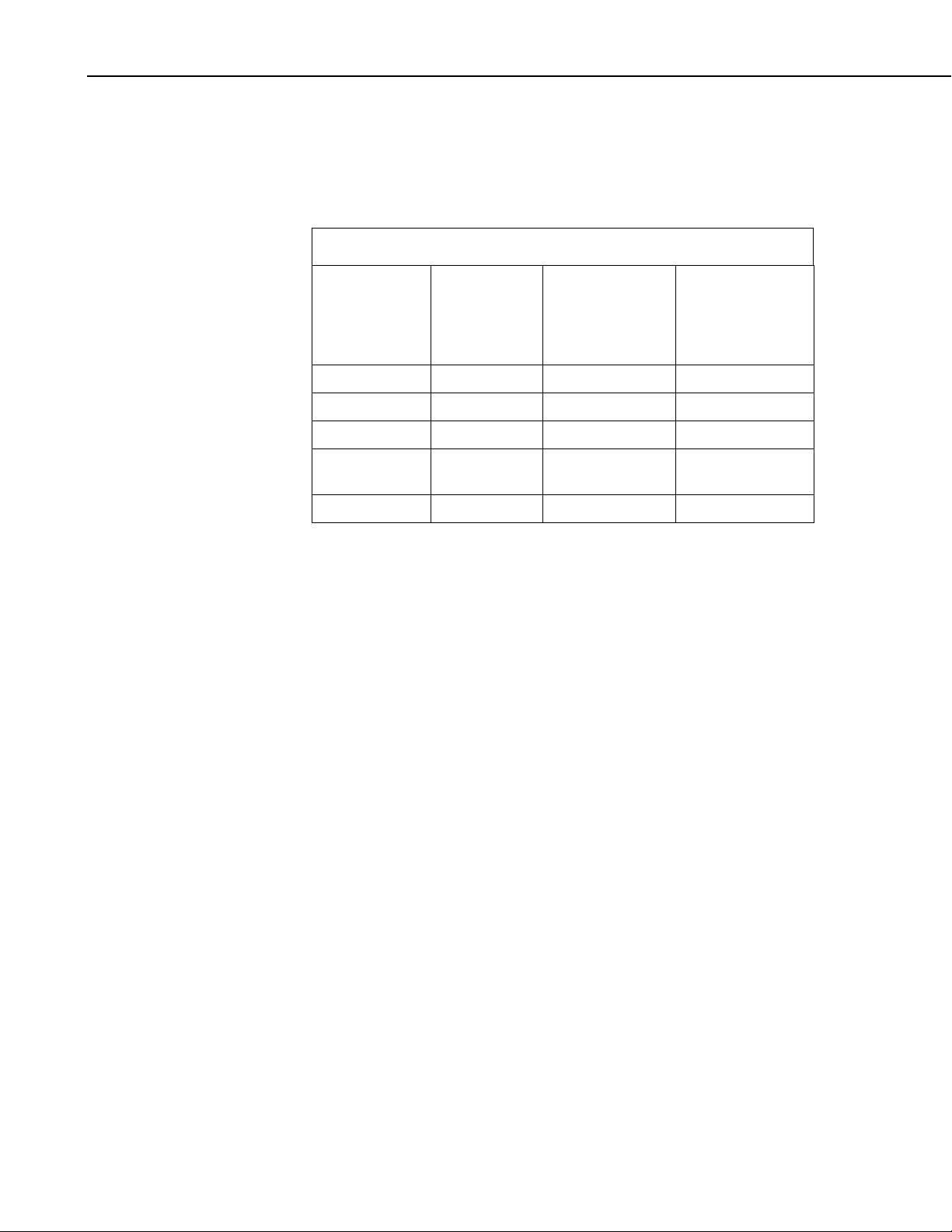

TABLE 5-1. CDM-VW300 / Datalogger Compatibility

Maximum CDM-

VW305 Analyzers

Datalogger

Connect with

SC-CPI

1

Module

Maximum

Measurement

Rate (Hz)

at Max Rate /

Maximum

Channels

CR3000 * 1002 1/8

– – 50 3/24

– – 20 6/48

CR800 /

CR1000

* 50

1/8

– – 20 4/32

Frequency measurement:

A vibrating-wire circuit is excited and

measured through the same coil

connection. Sinusoidal excitation

persists for a few cycles of the wire

oscillation. The wire is maintained in a

continuously vibrating state. Excitation

voltage varies automatically to maintain

the desired return signal strength.

Dynamic measurement

20, 50, 100, 200

3

, and 333.33 Hz

rates:

8

Accuracy:

Input resistance:

Excitation voltage

Range:

Resolution:

±(0.005% of reading + effective

measurement resolution)

5 k

0 to ±3 V (6 V peak-to-peak)

26 mV

Page 19

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Sensor resonant frequency

range:

Sensor Resonant Frequency Range (Hz)

TABLE 5-2. CDM-VW300/305

Sample Rate

20 290 6000

50 290 6000

100 580 6000

2003 1150 6000

333.33 2300 6000

Effective resolution (precision):

TABLE 5-3. CDM-VW300/305

Effective Frequency Measurement Resolution

Sample Rate (Hz) Noise Level (Hz RMS)5

1 0.005

20 0.008

50 0.015

100 0.035

2003 0.11

333.33 0.45

Minimum Sensor

Frequency

Maximum Sensor

Frequency

4

Sustained input voltage without

damage:

Temperature measurement:

Accuracy:

Resolution:

Bridge resistor:

Excitation voltage:

Measurement rate:

–0.5 to 7.1 V

Temperature measurement is

available for sensors so equipped.

Excitation and half-bridge

measurement circuits are integrated

into the CDM-VW300 and CDMVW305 analyzers.

6

0.15% of reading

0.002 RMS @ 5 k thermistor

resistance

4.99 k 0.1%

1.5 V

1 Hz

9

Page 20

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Operating temperature

Standard:

Extended:

Power requirement

Voltage:

Typical current drain

CDM-VW300:

CDM-VW305:

Output

CPI:

USB:

–25° to 50°C

–55° to 85°C

9.6 to 32 Vdc

115 mA @ 12 Vdc

190 mA @ 12 Vdc

Connects to datalogger. Baud rate

selectable from 50 kbps to 1 Mbps.

Cable length varies depending on

baud rate, number of nodes, cable

quality, and noise environment.

2500 ft maximum.

Connects to PC. USB 2.0 full speed.

Provided for configuration, updates,

and communication with DVWTool

software. The USB port does not

support collection of time-series

data.

6. Installation

Weight:

Dimensions:

Mounting:

< 1 kg, < 2 lb

20.3 x 12.7 x 5.1 cm (8 x 5 x 2 in)

One-inch grid. Optional DIN rail

mounting is available using

Campbell Scientific pn 29388.

1

SC-CPI module connects to terminals C1, C2, C3 (not SDM-C1, SDM-C2, SDM-C3).

2

CR3000 is the recommended datalogger.

3

These rates available only on PC with fast processor using USB cable in lab mode.

4

The effective resolution (precision) of the output is limited by noise and varies with the sample

rate.

5

Typical values for a 2.5 kHz resonant sensor.

6

Thermistor accuracy and resistance of the wire should be considered as additional errors.

The CDM-VW300 system is designed for use with a PC or as part of a field

data-acquisition system using a Campbell Scientific CR3000 datalogger.

When sensors are sampled at slower rates equal to or less than 50 Hz, a

CR1000 or CR800 datalogger can be used.

Pre-configure and test the system before taking it to the field. Issues that are

unresolved before placing instrumentation in the field will usually be more

10

Page 21

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

difficult to resolve. Data-acquisition systems, from the sensors to the

telecommunications equipment, are complex. Campbell Scientific equipment

and software are among the best available, but the integration process can be

demanding and involves trial and error; contingencies should be developed to

address possible problems. Do the bulk of the integration work in a

comfortable and dry location that has a communications link with Campbell

Scientific during regular business hours. If you are experienced with field

deployments, set aside at least a full day for pre-configuration work.

Otherwise, set aside three to seven days for system development before

travelling to the field.

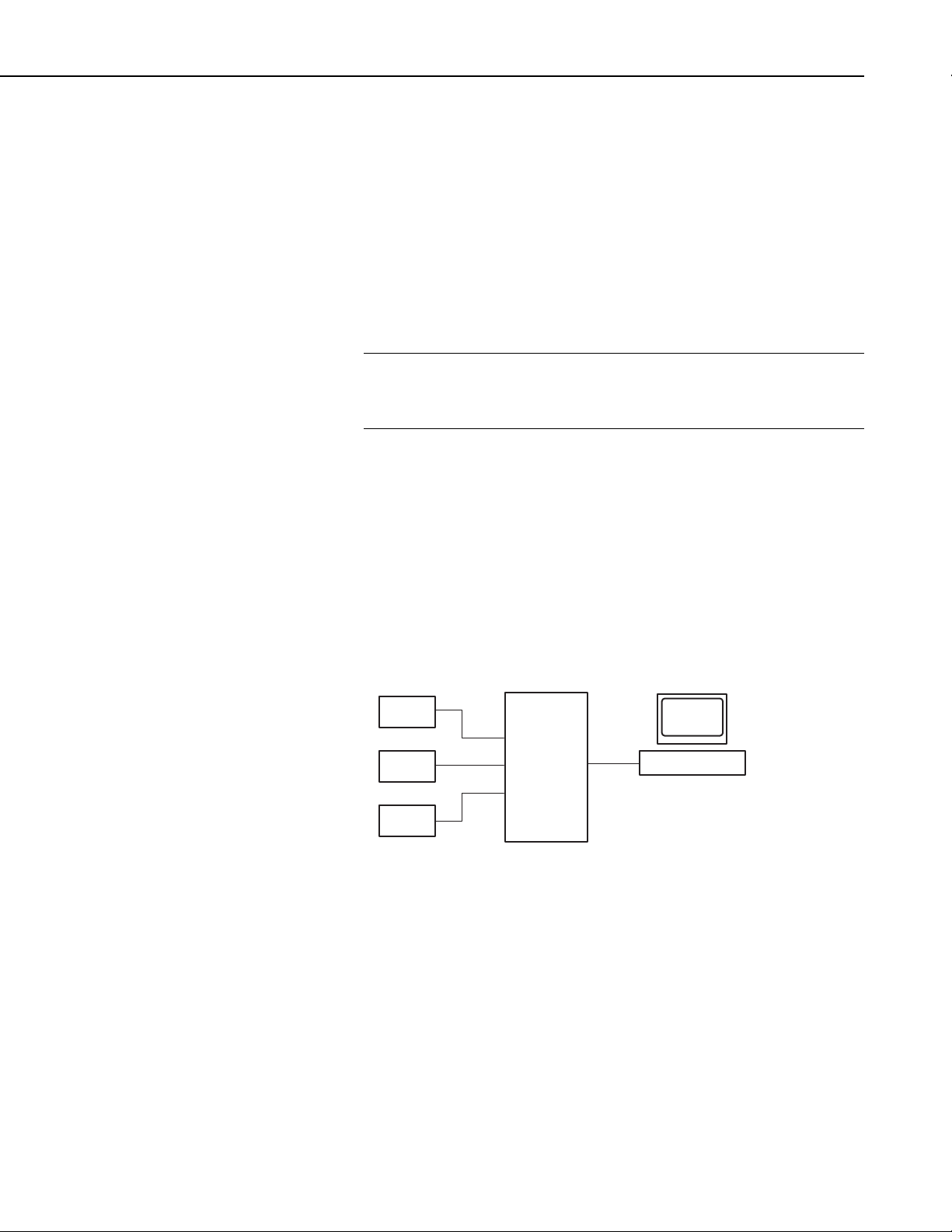

6.1 Laboratory-Mode Installation

IMPORTANT — Do not connect the CDM-VW300 analyzer or SC-CPI

interface to a PC until AFTER installing DVWTool 1.0 or later or DevConfig

2.04 or later. Consult Section 7.1.1, Software and Driver Installation, for more

information.

Laboratory mode allows for easy examination and validation of measurements.

To ensure a successful field deployment, perform this procedure before

stepping through the field-mode installation procedure of Section 6.2, Field-

Mode Installation.

As illustrated in the following figure, a connection is made directly between

the CDM-VW300 and a PC via USB cable. No datalogger is required.

DVWTool support software is used to configure, communicate with, and obtain

sensor readings from the CDM-VW300.

Vibrating-Wire

Sensors

CDM-

VW300

FIGURE 6-1. Laboratory-mode measurement system

6.1.1 Laboratory-Mode Installation Equipment

The following equipment is used in a laboratory-mode installation:

• Vibrating-wire sensors

• CDM-VW300 measurement module

• PC

• DVWTool software

PC

DVWTool

11

Page 22

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

r

p

6.1.2 Laboratory-Mode Installation Procedure .1.2 Laboratory-Mode Installation Procedure

The following procedure sets up the measurement system in laboratory mode: The following procedure sets up the measurement system in laboratory mode:

1. Install DVWTool software on the PC. Do this before connecting the CDM-

1. Install DVWTool software on the PC. Do this before connecting the CDM-

VW300 to the PC. DVWTool installation automatically installs drivers for

VW300 to the PC. DVWTool installation automatically installs drivers for

the CDM-VW300 USB connection.

the CDM-VW300 USB connection.

Reference Section 7.1.1, Software and Driver Installation.

Reference Section 7.1.1, Software and Driver Installation.

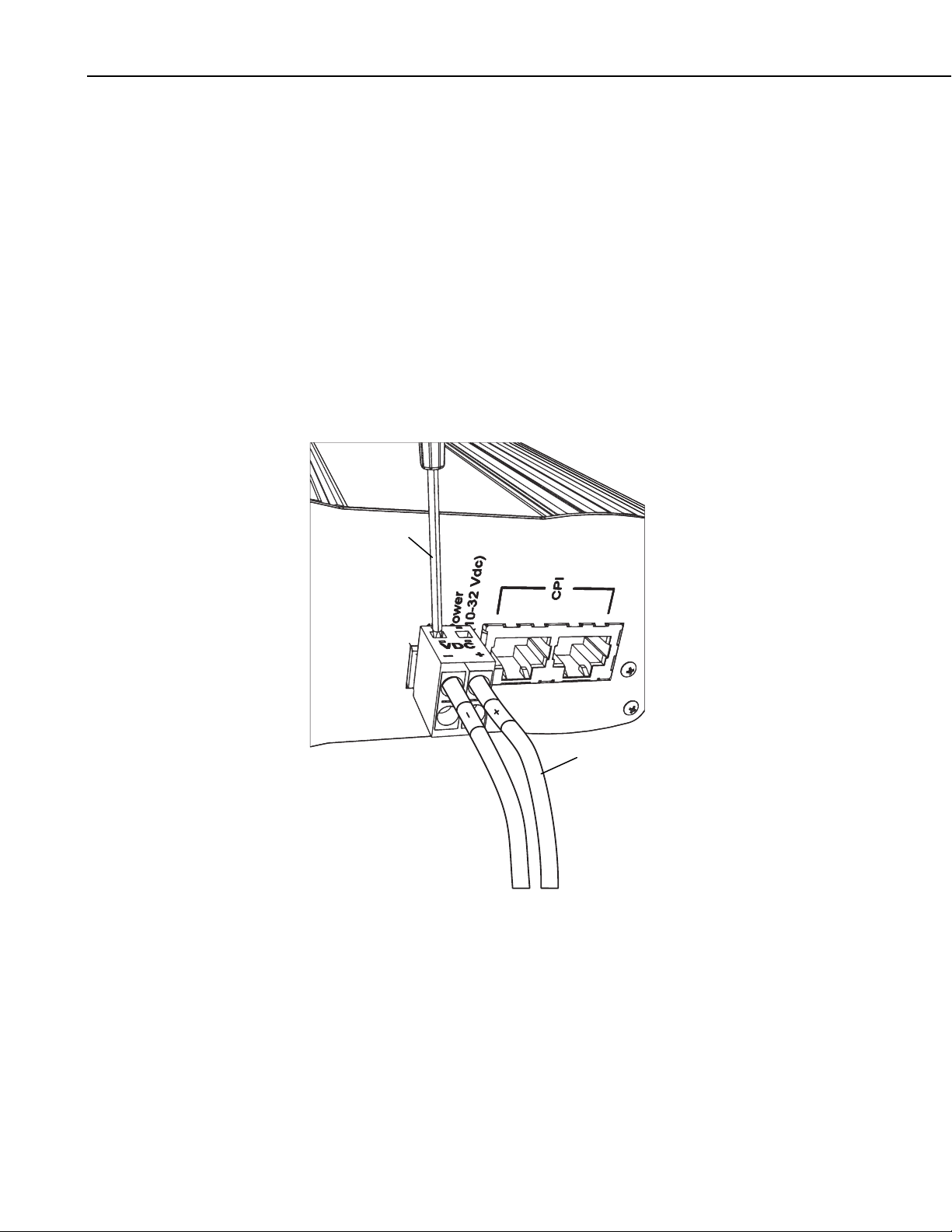

2. Connect 12 Vdc power to the CDM-VW300 as shown in FIGURE 6-2.

2. Connect 12 Vdc power to the CDM-VW300 as shown in FIGURE 6-2.

Reference Section 7.4, Using Power Supplies.

Reference Section 7.4, Using Power Supplies.

Campbell Scientific pn 29796, a 24 Vdc, 1670 mA wall charger, is

Campbell Scientific pn 29796, a 24 Vdc, 1670 mA wall charger, is

recommended.

recommended.

Insert small

screwdriver

en gates.

to o

Leads from

pn 13947

transforme

FIGURE 6-2. 12 Vdc power connection on the CDM-VW300

3. Connect a type-A male to type-micro-B male USB cable (Campbell

Scientific pn 27555, supplied with the analyzer) between the CDMVW300 and the PC as shown in FIGURE 6-3.

Reference Section 7.7.1, CDM-VW300 to PC Connection.

12

Page 23

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

FIGURE 6-3. USB receptacle on CDM-VW300 and Type-Micro-B

connector of USB cable

With the driver installed (step 1) and the power connected and live (step

2), connecting the USB cable will start an automatic process that creates a

new communication (COM) port for the CDM-VW300 on the PC. Watch

the Windows® system tray to see that the PC completes the process. Once

complete, a new port will appear as an available communication port in

DVWTool.

4. Test to see that DVWTool can access the USB connection.

Reference Section 7.1.2, Using DVWTool.

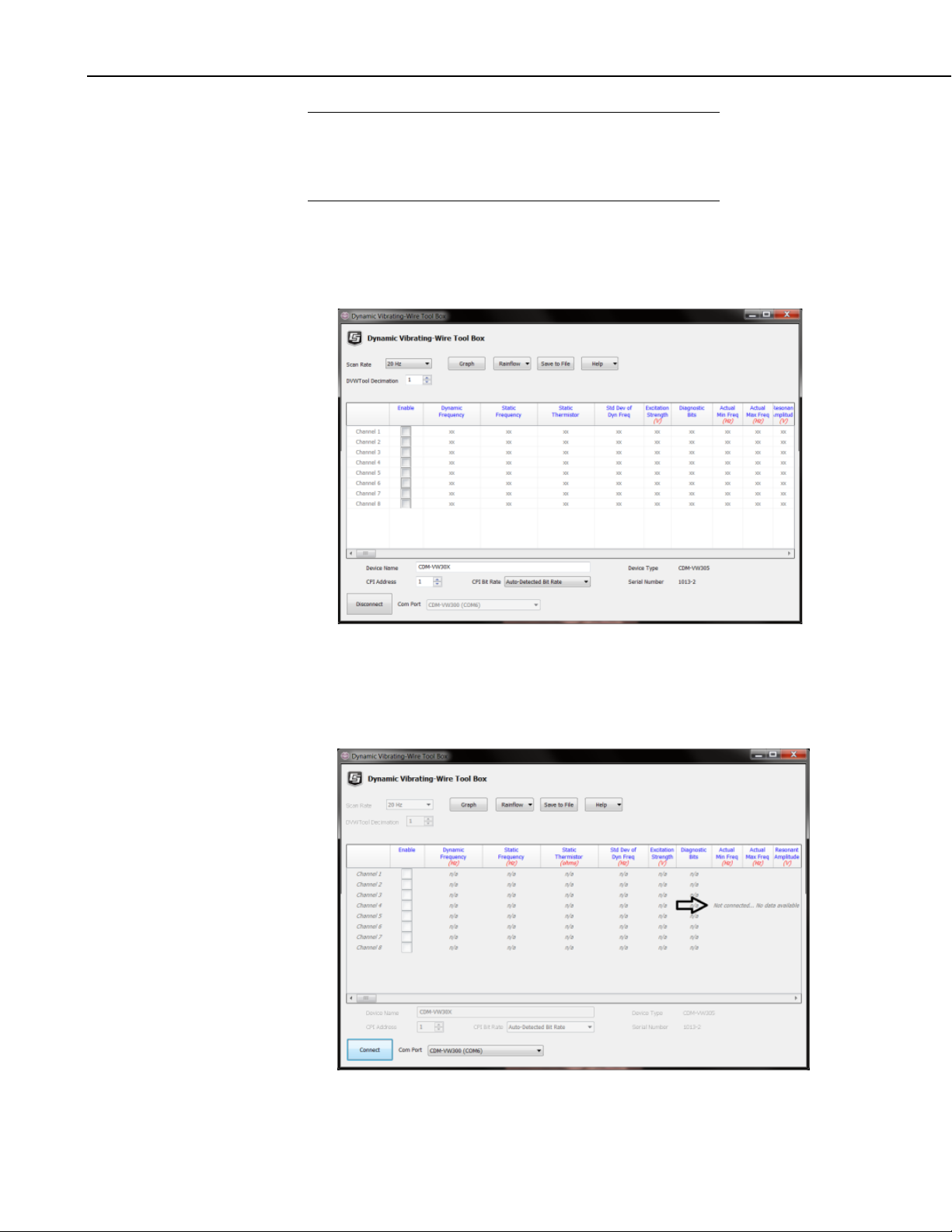

Run DVWTool. Select CDM-VW300 from the Com Port drop-down list

as indicated in the following figure.

13

Page 24

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

NOTE

If COM port CDM-VW300 does not appear, there is a problem

with the installation of the device driver or the creation of the

COM port. See Section 7.1.1, Software and Driver Installation,

for remedial steps.

Press Connect in the lower left of the DVWTool window. If DVWTool

connects with the CDM-VW300, the channel list on the DVWTool

interface becomes available and the button at lower left reads Disconnect

as shown in the following figure.

Notice that the fields Device Type, Serial Number, Device Name, and

CPI address are active and populated in the lower portion of the

DVWTool window. Otherwise, the channel list remains dimmed and the

notice Not connected... No data available is displayed at the right of the

channel list, as shown in the following figure.

14

Page 25

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

5. Check the operating system version of the CDM-VW300.

Reference Section 7.8, Operating System.

Operating systems are occasionally updated. To ensure the CDM-VW300

has the latest, search through www.campbellsci.com/downloads for the

most recent release. Compare the version information on the website with

the version shown in the DVWTool Help | About screen, which is sampled

in the following figure.

6. If DVWTool is running, click Disconnect. Remove the 12 Vdc power

from the CDM-VW300.

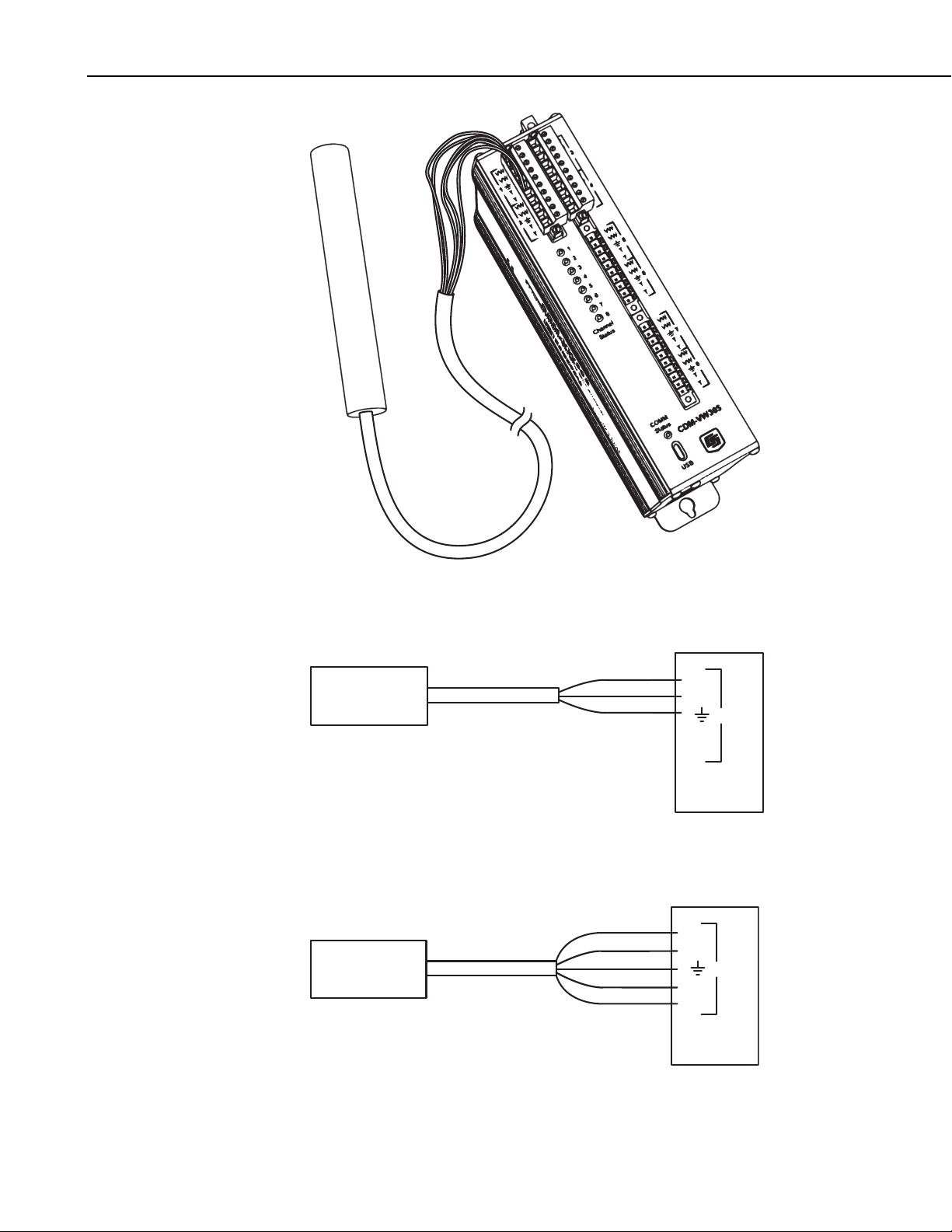

7. Connect the vibrating-wire sensors to the CDM-VW300 as shown in the

following figures.

Reference Section 7.7.2, CDM-VW300 to Sensor Connection.

15

Page 26

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

FIGURE 6-4. Sensor connection on a CDM-VW305

Coil

Coil

Ground

VW

VW

T

T

CDM-VW300

FIGURE 6-5. Three-wire vibrating-wire sensor connections

Coil

Coil

Ground

Thermistor

Thermistor

VW

VW

T

T

1

1

16

CDM-VW300

FIGURE 6-6. Five-wire vibrating-wire sensor connections

Page 27

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

8. Reconnect 12 Vdc power to the CDM-VW300.

9. Confirm sensor operation.

Reference Section 7.12.1, Sensor Validation.

Two status LED lights are provided on the CDM-VW300 for each sensor

connection. Eight are provided on the CDM-VW305. The following table

lists LED functions and interpretations:

TABLE 6-1. CDM-VW300 Status LED States

Green or red flash at three-second

Channel is activated.

interval

Green flash Response received from sensor.

Red flash Diagnostic flags indicate there may

be a problem.

No flash, unlit Channel is not activated.

10. Ensure that frequency readings can be obtained from the sensors.

Reference Section 7.12.2.1, Monitoring with DVWTool Software.

Click Connect on the DVWTool window. Check the box associated with

each channel to which a sensor is connected. If all sensor systems are

operational, the DVWTool main window will appear much as it does in the

following figure:

a. Frequency reading of each sensor will correspond to the

frequency range specified by the sensor manufacturer.

b. No faults are indicated. If faults are indicated (Diagnostic Bits

does not equal 0x00, measurement results are in red type, or cells

17

Page 28

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

are shaded red), consult Section 7.12.2.1, Monitoring with

DVWTool Software, for troubleshooting help.

6.2 Field-Mode Installation

IMPORTANT — Do not connect the CDM-VW300 analyzer or SC-CPI

interface to a PC until AFTER installing DVWTool 1.0 or later or DevConfig

2.04 or later. Consult Section 7.1.1, Software and Driver Installation, for more

information.

A simple field-mode configuration, using one CDM-VW300, is covered in this

section. Additional details concerning field-mode configuration and daisychaining power and RJ45 connections are discussed in Section 7, System

Operation. Capacity of the power supply is a critical element of field

installations. Most field-mode installations will require continuous ac power or

large solar panels and batteries.

6.2.1 Field-Mode Installation Equipment

The following components are used in a field-mode installation:

• Vibrating-wire sensors

• CDM-VW300 measurement modules

• SC-CPI interface

• Datalogger

• Datalogger power supply

• Personal computer (PC)

• DVWTool analyzer software

• Datalogger support software (LoggerNet, PC400, or RTDAQ)

6.2.2 Field-Mode Installation Procedure

FIGURE 6-7 illustrates the final form of a simplified field-mode installation.

With reference to this figure, work through the following procedure. Reference

Section 7.7, System Connections, for more information.

Vibrating-Wire

Sensors

CDM-

VW300

12V G

RJ-45 to

RJ-45

FIGURE 6-7. Field data-acquisition system

SC-CPI

12 Vdc and G

Connection

pn 29526

Cable

C1

C2

C3

12V

G

C1

C2

C3

12V

G

Power In

G 12V

CR3000

Datalogger

G 12V

PC

LoggerNet

12 Vdc

Ground

Power Supply

18

Page 29

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Procedure:

1. Install DVWTool before connecting the SC-CPI or CDM-VW300 to the

PC. Reference Section 7.1.1, Software and Driver Installation.

2. Before proceeding, follow the procedure outlined in Section 6.1,

Laboratory-Mode Installation for all sensors connected to the CDMVW300. Record settings determined in DVWTool for later use in the

CRBasic program. The following work sheet (TABLE 6-2) lists DVWTool

settings and corresponding CRBasic instruction settings, and provides a

place to record settings for one sensor. Copy and fill in this worksheet for

each sensor to be connected.

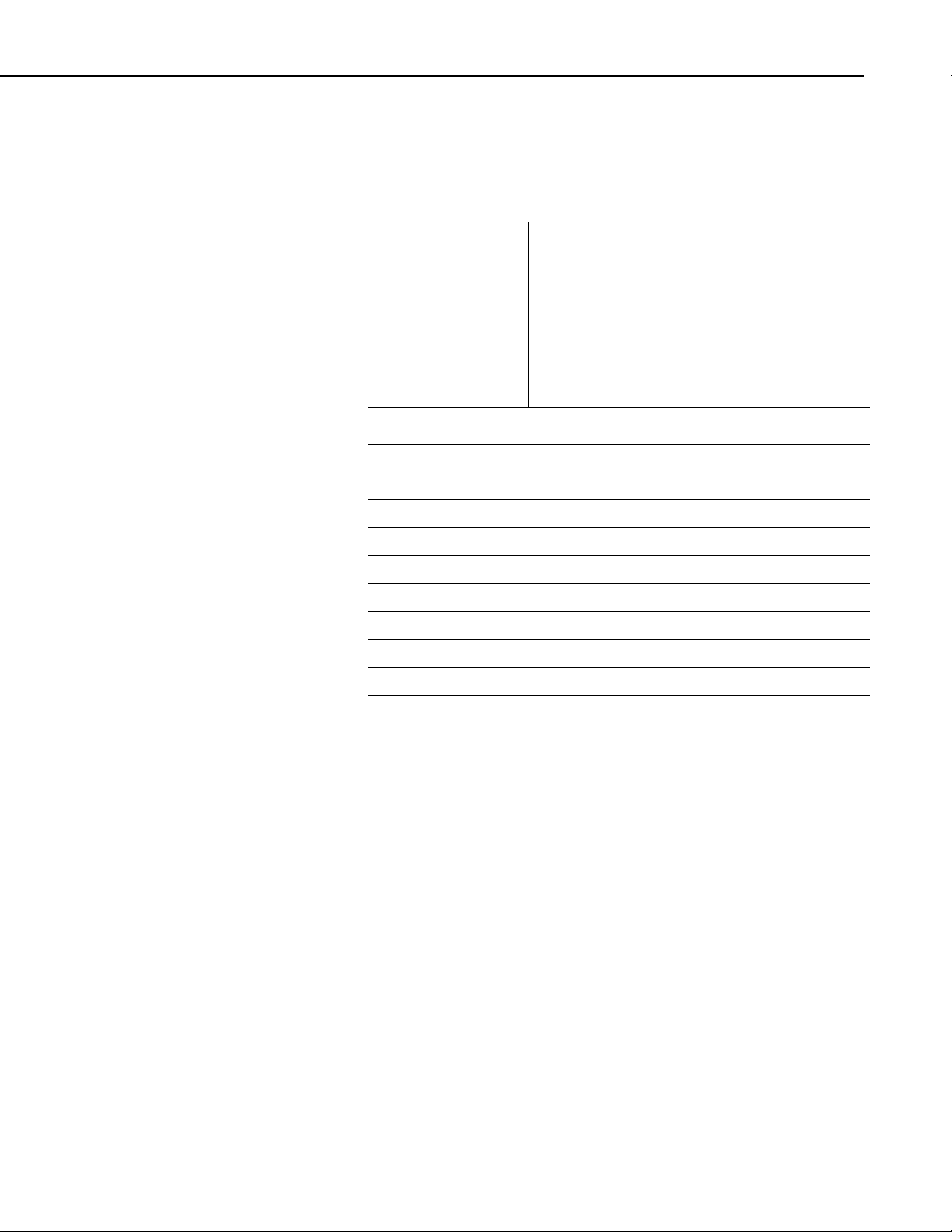

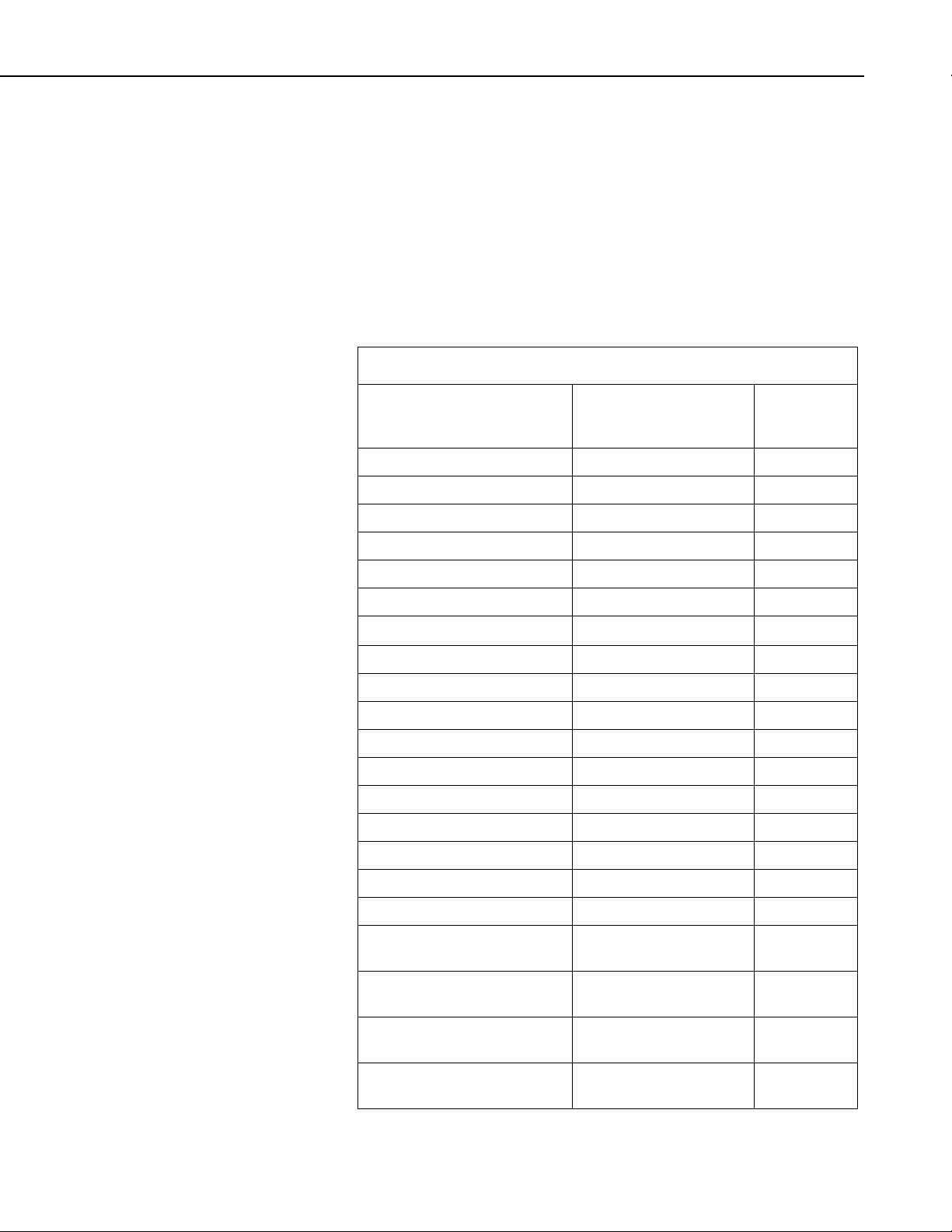

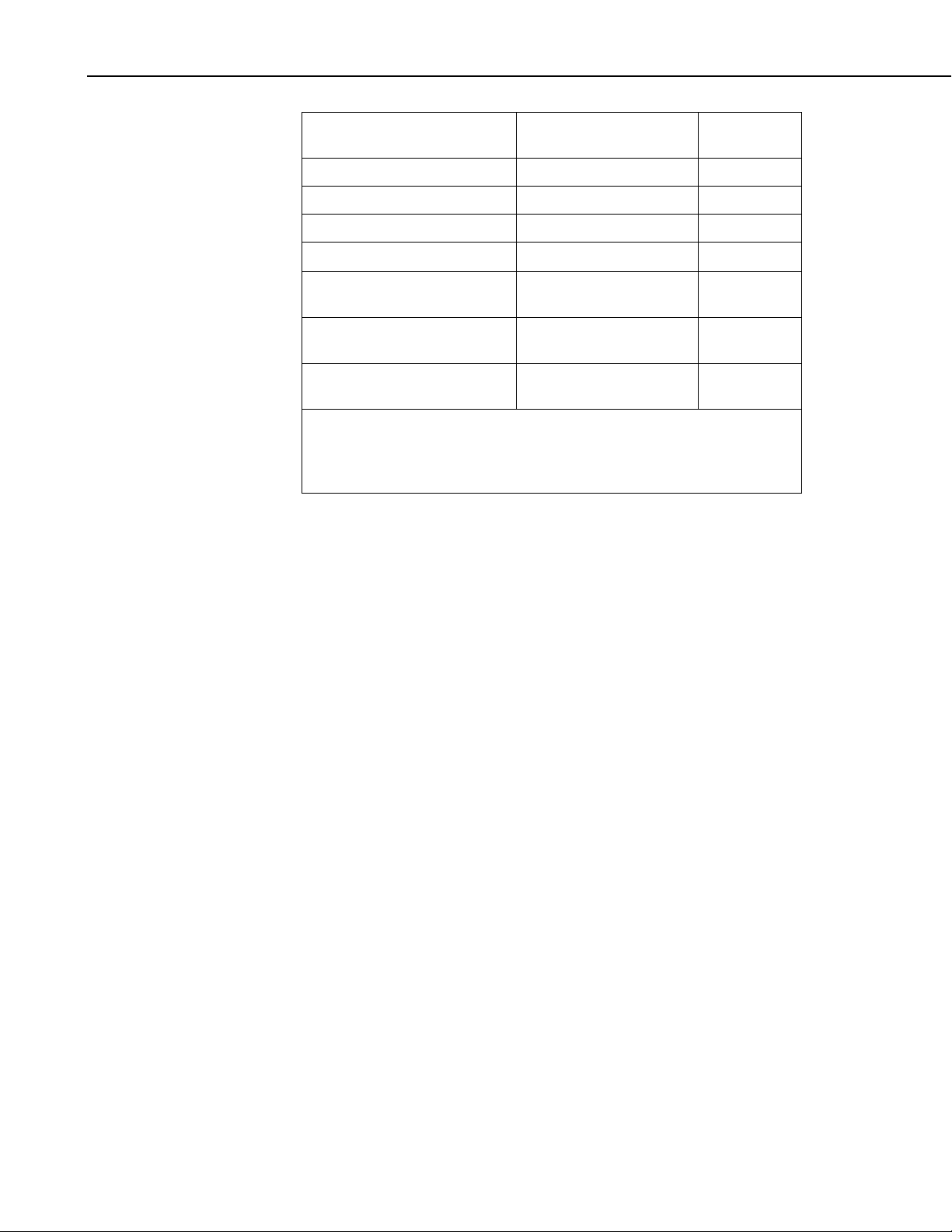

TABLE 6-2. DVWTool and CRBasic Settings

Corresponding CRBasic

Instructions and

DVWTool Setting

Device Name No corresponding setting

Parameters Setting

Scan Rate1 Interval

No corresponding setting

No corresponding setting

No corresponding setting

Device Type (auto-detected) DeviceType

CPI Address CPIAddress

No corresponding setting

Channel X Enable check box

Resonant Amplitude (V) ResonAmp

Minimum Frequency (Hz) LowFreq

Maximum Frequency (Hz) HighFreq

Output Format (Hz or Hz2)

Multiplier Mult

Offset Offset

Steinhart-Hart Thermistor

Coeff A

Scan()

1

Units = msec

Buffer = 500

Count = 0

CDM_VW300Config()

SysOptions

ChanEnable

ChanOptions

SteinA

Steinhart-Hart Thermistor

Coeff B

Steinhart-Hart Thermistor

Coeff C

Rainflow | Number of Mean

Bins

SteinB

SteinC

RF_MeanBins

19

Page 30

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Rainflow | Number of Amp

Bins

Rainflow | Low Limit

Rainflow | High Limit

Rainflow | Minimum Change

Rainflow | Rainflow Form |

RF_AmpBins

RF_LowLim

RF_HighLim

RF_Hyst

RF_Form

A

reset list

Rainflow | Rainflow Form |

B

total list

Rainflow | Rainflow Form |

C

form list

1

Scan rate is automatically set based on the datalogger CRBasic Scan() instruction

Interval parameter. Set the Interval parameter such that the desired CDM-VW300

scan rate is achieved. Relationship between Scan Rate and Interval is:

CRBasic Scan() instruction Interval = (1 / DVWTool Scan Rate) * 1000

3. When the laboratory-mode installation has been performed on all sensors,

click Disconnect in the DVWTool window. Disconnect or turn off power

to the CDM-VW300.

4. Assemble the datalogger and power supply using FIGURE 6-7, Field data-

acquisition system, as a guide. Do not turn power on until the system is

completely assembled.

5. A reliable data-acquisition system requires a reliable power supply. CDM-

VW300 analyzers consume more power than do many Campbell Scientific

products, so the power supplies often used with other data-acquisition

systems may not be adequate. Consult Section 7.4, Using Power Supplies,

for sizing guidance. For large systems, consult with a Campbell Scientific

application engineer.

6. The following figure illustrates the connections between the datalogger,

SC-CPI interface, and CDM-VW300. With this figure as a reference,

work through the following procedure.

20

Page 31

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

SC-CPI to CDM-VW300

CPI to CPI

(RJ-45 to RJ-45)

SC-CPI to Datalogger

12V to 12V

G to G

C1 to C1

C2 to C2

C3 to C3

CPI Bus

Terminator

NOTE

FIGURE 6-8. CPI communications links

a. Connect the SC-CPI to the datalogger. Reference FIGURE 6-9,

Datalogger to SC-CPI Connection.

CR3000, CR1000, and CR800 dataloggers require that a SC-CPI

interface the datalogger to the CDM-VW300. Connect 12V, G, C1,

C2, and C3 from the SC-CPI to the corresponding 12V, G, C1, C2,

and C3 ports of the datalogger.

SC-CPI module connects to terminals C1, C2, C3 (not SDM-C1,

SDM-C2, SDM-C3).

FIGURE 6-9. Datalogger to SC-CPI connection

b. As shown in FIGURE 6-10, connect the CDM-VW300 to the SC-CPI.

Reference Section 7.7.3, CDM-VW300 to SC-CPI Connection, and

Appendix B, SC-CPI Datalogger to CPI Interface.

21

Page 32

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Use the RJ45 CPI cable between the CPI ports of the CDM-VW300

and the SC-CPI interface. Use the yellow tape included in the CPI

Network Kit (pn 29370) to differentiate a cable used for CPI bus

communications from cables used for Ethernet communications.

FIGURE 6-10. Connecting the CPI ports of the SC-CPI and CDM-

Connect SC-CPI to CDM-VW300:

RJ-45 to RJ-45

VW300

c. As shown in FIGURE 6-11, place a CPI terminator in the remaining

open CPI port of the CDM-VW300 unless more CDM-VW300

devices will be daisy-chained.

22

FIGURE 6-11. Install CPI bus terminator

Page 33

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

7. As shown in FIGURE 6-12, connect power leads to the CDM-VW300.

Do not turn power on until the system is fully assembled.

Connect dc power to the Power connector on the side of the CDMVW300. Voltages from 10 to 32 Vdc may be used. Do not connect ac

power directly to the CDM-VW300. A convenient power source is the

combination of 12V and G terminals on the face of the datalogger.

FIGURE 6-12. Power connection

8. As shown in FIGURE 6-13, connect earth grounds.

Ground lugs are provided for tying the CDM-VW300 and datalogger to

earth ground with large gage wire. 14 AWG wire or larger is

recommended. Reference Section 7.7.5, Earth Ground Connections.

23

Page 34

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

FIGURE 6-13. Earth ground connections

9. Write or obtain a CRBasic program for the datalogger. Reference Section

7.10, CRBasic Programming, and Appendix G, CRBasic Program

Library.

CDM-VW300 and CDM-VW305 programs use the following CRBasic

instructions:

CDM_VW300Config()

CDM_VW300Dynamic()

CDM_VW300Static()

The CRBasic program must be enabled specifically for the CDM-VW300

or the CDM-VW305. Programs enabled for a CDM-VW300 use a

DeviceType argument of 0 in the CDM_VW300Config() instruction.

Programs enabled for a CDM-VW305 use a DeviceType of 1. Check that

other settings recorded in step 2 are integrated into the CRBasic program.

24

NOTE

Do not attempt to use a program written for the CDM-VW300

when using a CDM-VW305. Configurations for a particular

analyzer are deeply rooted in the CRBasic program. Simply

changing the DeviceType argument will not make all the

necessary changes.

Page 35

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

The following figure points out essential elements of the CRBasic program

for a datalogger controlling a CDM-VW300.

To simply confirm that readings can be obtained, one of the following

example programs can be used. These programs measure only basic

frequency:

• Appendix G.1.1, 20 Hz Measurement Example – One CDM-

VW300, Two Channels

• Appendix G.1.2, 20 Hz Measurement Example – One CDM-

VW305, Eight Channels

10. Send the CRBasic program to the datalogger using the program Send

command in the datalogger support software (RTDAQ, LoggerNet, or

PC400).

11. Monitor the operation of the system.

Reference Section 7.12.2, Monitoring System Performance.

Using the datalogger support software, monitor the datalogger Public table

as indicated in the following figure. In the Public table, frequency data

can be displayed that correspond to the channels selected for measurement.

The following figure shows Public table variables Freq(1), Diag(1),

StaticFreq(1), Therm(1), DynStdDev(1) as active with frequency data

from one sensor. The sensor is connected to channel 1 of the CDMVW305.

25

Page 36

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

A clean display of data, as shown in the previous figure, is obtained by

deactivating all but channel 1 in the CRBasic program. If channels 2 through 8

had not been deactivated, erroneous, but perhaps seemingly-real, data would be

displayed. Channels 2 through 8 are deactivated by setting line 24 in the

CRBasic example in Appendix G.1.2, 20 Hz Measurement Example – One

CDM-VW305, Eight Channels, to the following:

Dim Enable(8) As Long = { 1, 0, 0, 0, 0, 0, 0, 0}

If proper frequencies are shown, the datalogger has successfully communicated

with the CDM-VW300 via the SC-CPI device and obtained data. A permanent

data collection program for field operation can now be loaded.

7. System Operation

IMPORTANT — Do not connect the CDM-VW300 analyzer or SC-CPI

interface to a PC until AFTER installing DVWTool 1.0 or later or DevConfig

2.04 or later. Consult Section 7.1.1, Software and Driver Installation, for more

information.

7.1 PC Based Tools

All PC software is for use on Windows® XP, Windows® Vista, Windows® 7, or

Windows

7.1.1 Software and Driver Installation

USB communication between the PC and the CDM-VW300 analyzer, and

between the PC and the SC-CPI interface, require that USB drivers be installed

on the PC. For driver installation to work seamlessly, the drivers must be

installed before making the physical USB connections. These drivers are

installed automatically when DVWTool 1.0 software or DevConfig 2.04

software or later are installed.

®

8 operating systems.

26

• If the physical USB connection is attempted before the installation of

the drivers, a non-functional placeholder definition is created in the

Windows

from becoming active during subsequent driver installs and device

connections via USB. The following procedure should correct this

condition:

®

USB device list. This placeholder prevents that device

Page 37

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

1. Install either DVWTool 1.0 or later or DevConfig 2.04 or

later.

2. Connect the device to the computer with the USB cable.

3. Open the Windows

®

Device Manager. In Windows® 7, this

is done by choosing Control Panel | Hardware and Sound,

and then clicking on the Device Manager icon found in the

Devices and Printers section.

4. Find the placeholder device (CDM-VW300 or SC-CPI)

identified with a super-imposed exclamation point in a

yellow bubble box. Right-click on the device. Select Scan

for hardware changes or Update Driver Software....

5. The driver will be found and the disabled placeholder will be

overridden.

®

• If USB drivers are installed on Windows

8:

The installation of the USB drivers can fail silently on the Windows

8 platform under certain circumstances. This problem is indicated by

the absence of the CDM-VW300 COM port from the list of available

COM ports associated with the Connect button in the main screen of

DVWTool.

To correct this problem, connect the device to the computer with the

USB cable. Open the Windows

®

Device Manager. Find the

placeholder device (CDM-VW300 or SC-CPI) identified with a

super-imposed exclamation point in a yellow bubble box. Right-click

on the device. Select Update Driver Software....

®

7.1.2 Using DVWTool

The Dynamic Vibrating-Wire Tool Box (DVWTool) is a software package that

enables a PC to communicate with the CDM-VW300 via USB, configure

CDM-VW300 settings, and display the output of attached sensors. No

datalogger is required. Data are output in the main window table, on a line

graph, and in a rainflow histogram.

Users of the CDM-VW300 should become familiar with the function and

operation of DVWTool. Detailed information about this software can be found

in the DVWTool Help system.

7.1.2.1 Ensure Connection is Active

The installation of DevConfig 2.04 or later or DVWTool 1.0 or later

automatically installs the drivers required to make a connection between the

CDM-VW300 and the PC. Do not connect a USB cable between your CDMVW300 and the PC until after DevConfig or DVWTool has been installed.

Before starting DVWTool , ensure that the CDM-VW300 analyzer is connected

to the PC via USB cable. After opening DVWTool, choose the CDM-VW300

port from the Com Port dropdown list, as indicated in FIGURE 7-1. Click the

Connect button.

27

Page 38

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

FIGURE 7-1. DVWTool Settings Editor and Data Display

NOTE

If CDM-VW300 does not appear in the available selections for

Com Port, there is a problem with the installation of the device

driver or the creation of the COM port. See Section 7.1.1,

Software and Driver Installation, for remedial steps.

7.1.2.2 DVWTool Settings Editor

See TABLE 7-1, Summary of CDM-VW300 Configuration Settings, for a

listing of settings that can be viewed and edited with DVWTool.

7.1.2.3 Button and Field Descriptions

Enable — select each checkbox to turn on the respective channel.

Dynamic Frequency is the resonant frequency of the vibrating-wire sensor

sampled at the specified scan rate. This is the primary output of the attached

analyzer. If the Output Format field is set to Freq then this field represents

the resonant frequency of the vibrating-wire sensor. If the Output Format

field is set to Freq

format, the resulting number is modified by the Multiplier and Offset fields

before being output to this field.

Static Frequency (Hz or Hz

Dynamic Frequency field in all respects except for the slower rate at which it

is computed.

2

, this is the square of the resonant frequency. In either

2

) represents the same information as the

28

Static Thermistor (ohms) is a measure of the resistance across the thermistor

inputs. It is measured once per second. If the Steinhart-Hart Thermistor

Coefficients (A, B, and C) are entered for the channel, then they are used to

convert the measured resistance to degrees Celsius.

Page 39

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

2

Standard Deviation of Dynamic Frequency (Hz or Hz

) is the standard

deviation of the Dynamic Frequency field computed on one-second data. It is

output once per second. It is computed after the Output Format, Multiplier,

and Offset have been applied.

Resonant Amplitude (V) sets the desired amplitude of the steady-state signal

response from the sensor.

Excitation Strength (V) is the peak-to-peak amplitude of the excitation

waveform that is required to produce the desired response amplitude. An

increase in the Scan Rate corresponds to a decrease in the excitation strength

needed.

Diagnostic Bits provides information on the operation of the module and can

indicate conditions during which the data may be suspect.

The Minimum Frequency (Hz) and Maximum Frequency (Hz) are the

bounds in which the resonant frequency of the sensor is expected to fall during

its operation. Signal frequencies measured outside of this range are not

included in the spectral analysis, except as noted in Section 8.5.1.1,

Description of Diagnostic Parameters.

Graph button brings up a graphical display of the frequency output of the

sensors.

Pressing the Rainflow button and selecting a channel brings up a rainflow

histogram of the frequency output of the sensor on that channel.

7.1.3 Using DevConfig

The Device Configuration Utility (DevConfig) is a software package that

enables a PC to communicate with many Campbell Scientific products. It

communicates with the CDM-VW300 via USB to configure settings and

display the output of attached sensors. No datalogger is required. Data are

output to the main window in tabular form.

Users of the CDM-VW300 should become familiar with the function and

operation of DevConfig. Detailed information about this software can be found

in the DevConfig Help system and the LoggerNet software manual, which is

available at www.campbellsci.com.

7.1.3.1 Ensure Connection is Active

The installation of DevConfig 2.04 or later or DVWTool 1.0 or later

automatically installs the drivers required to make a connection between the

CDM-VW300 and the PC. Do not connect a USB cable between your CDMVW300 and the PC until after DevConfig or DVWTool has been installed.

Before starting DevConfig, ensure that the CDM-VW300 analyzer is connected

to the PC via USB cable. After opening DevConfig, choose the CDM-VW300

port from the Communication Port dropdown list as indicated in FIGURE

7-2. Click the Connect button.

29

Page 40

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

FIGURE 7-2. DevConfig Settings Editor

Details about using DevConfig can be found in DevConfig Help or in the

LoggerNet datalogger support software manual, which is available at

www.campbellsci.com.

NOTE

7.1.3.2 DevConfig Settings Editor

If a COM port CDM-VW300 does not appear in the available

selections for Communications Port, then there is a problem

with the installation of the device driver or the creation of the

COM port. See Section 7.1.1, Software and Driver Installation,

for remedial steps.

See TABLE 7-1, Summary of CDM-VW300 Configuration Settings, for a

listing of settings that can be viewed and edited with DevConfig.

7.2 Using the Datalogger

Outputs from the CDM-VW300 are captured by a CR3000, CR1000, or CR800

datalogger via the SC-CPI communications interface. A custom CRBasic

program written to capture and store device outputs is loaded into the

datalogger.

30

Page 41

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Write or obtain a CRBasic program for the datalogger. Reference Section

7.10, CRBasic Programming. Example programs are available in Appendix G,

CRBasic Program Library, and at www.campbellsci.com/cdm-vw300-support.

7.3 Using the SC-CPI Interface

See Appendix B, SC-CPI Datalogger to CPI Interface.

7.4 Using Power Supplies

See Section 7.7.4, CDM-VW300 to Power Connection, for instructions and

precautions when connecting power.

7.4.1 CDM-VW300 Series Analyzer Power

The purchase of a CDM-VW300 series analyzer does not include a power

supply. A 12 Vdc power source must be specifically ordered or provided by

other means. Power supplies providing 9.6 to 32 Vdc, with a 200 mA or

greater current rating, can be used. Transformer pn 29796, which is illustrated

in FIGURE 7-3, is a 24 Vdc, 1.67 A wall charger. It can be purchased from

Campbell Scientific. Alternatively, if an adequate power supply used with a

Campbell Scientific datalogger is available, power for the CDM-VW300 series

analyzer can be drawn from the datalogger wiring panel.

NOTE

FIGURE 7-3. 12 Vdc power transformer for laboratory-mode installation

The transformer sometimes used to provide charging power to a

Campbell Scientific PS100 power supply, or to a CR3000

datalogger with a battery base (Campbell Scientific pn 9591),

does not

have the correct power output for the CDM-VW300.

31

Page 42

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

7.4.2 Data-Acquisition System Power

Power supply requirements will vary depending on system configuration and

location. The following power supplies are typically adequate to power a dataacquisition system consisting of one datalogger, one CDM-VW300, and the

SC-CPI interface:

• PS100 connected to ac

• PS200 connected to ac

• CR3000 rechargeable base connected to ac

NOTE

CR3000 with alkaline base is NOT an adequate power supply

and will fail shortly after deployment.

A solar powered system requires careful planning including a power budget.

For example, to power a data-acquisition system consisting of a CR3000

datalogger, an SC-CPI interface, and a CDM-VW300 series analyzer, the

following battery and solar panel specifications are required to operate the

system year-round in a remote installation in northern Utah using standard

silicon cell solar panels, lead-acid rechargeable batteries, and industry accepted

reserve margins:

• CDM-VW300, two channels enabled

o 60 watts of solar panel capacity

o 91 ampere-hours of battery reserve

• CDM-VW305, eight channels enabled

o 84 watts of solar panel capacity

o 130 ampere-hours of battery reserve.

Many applications will require the use of several analyzers. A carefully

considered power budget in these applications is essential to ensuring system

reliability and data continuity. Contact a Campbell Scientific application

engineer for assistance in configuring an adequate power supply.

32

7.5 Configuring the CDM-VW300 Analyzer

CDM-VW300 series analyzers must be configured by the user before sensor

measurement will be successful. Configuration can be done using DVWTool or

DevConfig software or a datalogger CRBasic program. See Section 7.1, PC

Based Tools, for more information about the software. See Section 7.10,

CRBasic Programming, for more information about using the datalogger.

IMPORTANT — Do not connect the CDM-VW300 analyzer or SC-CPI

interface to a PC until AFTER installing DVWTool 1.0 or later or DevConfig

2.04 or later. Consult Section 7.1.1, Software and Driver Installation, for more

information.

Page 43

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

If using software to configure the analyzer, which is recommended, physically

connect the CDM-VW300 to the PC with a USB cable. See Section 7.7.1,

CDM-VW300 to PC Connection, for assistance in making this connection.

Check that the software is pointing to the correct communications port.

TABLE 7-1, summarizes the configuration settings. Each configuration setting

is discussed in the following sections.

TABLE 7-1. Summary of CDM-VW300 Configuration Settings

DVWTool PC Software

Setting Description

Device name

CPI bus speed (kbps)

Operating system

version

Operating system date ncs

Analyzer serial

number

Display rate

Dynamic sample rate

Device type

CPI bus address

Device Name Device Name

CPI Bit Rate CPI Bit Rate CPISpeed()

ncs

Serial Number Board Serial Number

DVWTool Decimation

Scan Rate Scan Rate Hz

Device Type

CPI Address

Setting Name

1

DevConfig PC Software

Setting Name

OS Version

OS Date

DevConfig Output

Decimation

Device Type

CPI Address

CRBasic Datalogger

Instructions /

Parameters

ncs

ncs

ncs

ncs

ncs

Scan()

Interval = (1/DVWTool

Scan Rate * 1000)

CDM_VW300Config()

DeviceType

CDM_VW300Config()

CPIAddress

System options ncs ncs

Channels enabled

Desired resonant

amplitude

Minimum cut-off

frequency

Maximum cut-off

frequency

Frequency-output

format

Enable

Resonant Amplitude (V)

Minimum Frequency (Hz)

Maximum Frequency (Hz)

Output Format (Hz or

Hz

Channel X Enable

RMS Amplitude Set

Point

Low Freq. bound

High Freq. bound

2

)

Output Format

CDM_VW300Config()

SysOptions

CDM_VW300Config()

ChanEnable

CDM_VW300Config()

ResonAmp

CDM_VW300Config()

LowFreq

CDM_VW300Config()

HighFreq

CDM_VW300Config()

ChanOptions

33

Page 44

CDM-VW300 Series Dynamic Vibrating-Wire Analyzers

Setting Description

DVWTool PC Software

Setting Name

DevConfig PC Software

Setting Name

CRBasic Datalogger

Instructions /

Parameters

Multiplier

Offset

Steinhart-Hart

coefficients

Rainflow-histogram

output configuration

Rainflow | Low Limit

Rainflow | High Limit

Multiplier

Offset

Steinhart-Hart

Thermistor Coeff A

Steinhart-Hart

Thermistor Coeff B