Page 1

INSTRUCTION MANUAL

Bowen Ratio Instrumentation

Revision: 9/05

Copyright (c) 1987-2005

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The BOWEN RATIO INSTRUMENTATION is warranted by CAMPBELL

SCIENTIFIC, INC. to be free from defects in materials and workmanship

under normal use and service for twelve (12) months from date of shipment

unless specified otherwise. Batteries have no warranty. CAMPBELL

SCIENTIFIC, INC.'s obligation under this warranty is limited to repairing or

replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective products.

The customer shall assume all costs of removing, reinstalling, and shipping

defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country. To obtain a Returned Materials Authorization (RMA),

contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an

applications engineer determines the nature of the problem, an RMA number

will be issued. Please write this number clearly on the outside of the shipping

container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

Bowen Ratio Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. System Overview......................................................1-1

1.1 Review of Theory................................................................................. 1-1

1.2 System Description............................................................................... 1-3

1.2.1 Water Vapor Measurement......................................................... 1-3

1.2.2 Air Temperature Measurement................................................... 1-4

1.2.3 Net Radiation and Soil Heat Flux............................................... 1-5

1.2.4 Power Supply.............................................................................. 1-5

2. Station Installation....................................................2-1

2.1 Sensor Height and Separation............................................................... 2-1

2.2 Soil Thermocouples and Heat Flux Plates............................................ 2-2

2.3 Wiring................................................................................................... 2-4

2.4 Battery Connections.............................................................................. 2-7

2.5 System Startup...................................................................................... 2-7

2.6 Routine Maintenance............................................................................ 2-7

2.7 Cleaning the DEW 10........................................................................... 2-8

3. Sample CR23X Program...........................................3-1

4. Calculating Fluxes Using SPLIT..............................4-1

4.1 Data Handling ........................................................................................ 4-1

4.2 Calculating Fluxes................................................................................ 4-1

Appendices

A. References...............................................................A-1

B. 023 Bowen Ratio (Pre July 1993)........................... B-1

Tables

1.2-1. Component Power Requirements..................................................... 1-5

2.3-1. CR23X/Sensor Connections for Example Program......................... 2-4

3-1. Sample CR23X Bowen Ratio Program Flow Chart............................ 3-2

3-2. Output From Example Bowen Ratio Program .................................... 3-5

4.2-1. Input Values for Flux Calculations .................................................. 4-3

i

Page 4

Bowen Ratio Table of Contents

Figures

1.2-1. Vapor Measurement System............................................................. 1-3

1.2-2. Thermocouple Configuration............................................................1-4

2-1. CSI Bowen Ratio System ....................................................................2-2

2.2-1. Placement of Thermocouples and Heat Flux Plates .........................2-3

2.2-2. TCAV Spatial Averaging Thermocouple Probe..............................2-4

2.3. A block diagram for the connections between the datalogger,

the BR relay driver and components, and the external battery................2-6

2.4-1. Terminal Strip Adapters for Connections to Battery........................2-7

2.7-1. DEW 10 Circuit Board.....................................................................2-9

B-1. 023 Bowen Ratio Vapor Measurement System with Three

Flowmeters............................................................................................. B-1

ii

Page 5

∂

∂

∂

∂

λρε∂

∂

(

(

Section 1. System Overview

1.1 Review of Theory

By analogy with molecular diffusion, the flux-gradient approach to vertical

transport of an entity from or to a surface assumes steady diffusion of the

entity along its mean vertical concentration gradient.

When working within a few meters of the surface, the water vapor and heat

flux densities, E and H, may be expressed as:

ρ

Ek

=

v

(1)

v

z

HCk

Here ρv is vapor density, ρ is air density, Cp is the specific heat of air, T is

temperature, z is vertical height, and k

vapor and heat, respectively. Air density and the specific heat of air should

account for the presence of water vapor, however, use of standard dry air

values usually causes negligible error. The eddy diffusivities are functions of

height. The vapor and temperature gradients reflect temporal and spatial

averages.

Applying the Universal Gas Law to Eq. (1), and using the latent heat of

vaporization, λ, the latent heat flux density, λ, can be written in terms of vapor

pressure (e).

Here P is atmospheric pressure and ε is the ratio of the molecular weight of

water to the molecular weight of dry air.

In practice, finite gradients are measured and an effective eddy diffusivity

assumed over the vertical gradient:

=ρ

L

=

e

T

pH

and kH are the eddy diffusivities for

v

Pez

(2)

z

k

v

(3)

ee

−

k

λρε

ρ

v

P

zz

()

TT

pH

zz

()

L

In general, k

equal. The ratio of H to L

surface into sensible and latent heat flux. This technique was first proposed by

Bowen (1926). The Bowen ratio, β, is obtained from Eq. (4) and Eq. (5).

and kH are not known but under specific conditions are assumed

v

=

e

HCk

=

is then used to partition the available energy at the

e

)

12

−

12

−

)

12

12

. (5)

−

(4)

1-1

Page 6

Section 1. System Overview

(

λ

−−−

=

−

where

βλε==

PC

ε is the psychrometric constant.

p

PC

H

L

e

−

TT

p

ee

()

)

12

12

(6)

−

The surface energy budget is given by,

where R

is net radiation for the surface and G is the total soil heat flux. The

n

sign convention used is R

RGHL

ne

positive into the surface and G, H, and Le positive

n

away from the surface. Substituting βL

e

0, (7)

for H in Eq. (7) and solving for Le

yields:

Measurements of R

=

e

, G, and T and e at two heights are then required to

n

. (8)

+1 β

RG

n

L

estimate sensible and latent heat flux.

Atmospheric pressure is also necessary, but seldom varies by more than a few

percent. It may be calculated for the site elevation, assuming a standard

atmosphere, or obtained from a nearby station and corrected for any elevation

difference (Wallace and Hobbes, 1977).

Eq. (6) shows that the sensitivity of β is directly related to the measured

gradients; a 1% error in a measurement results in a 1% error in β.

When the Bowen ratio approaches -1, the calculated fluxes approach infinity.

Fortunately, this situation usually occurs only at night when there is little

available energy, R

0.75), L

and H are assumed to be negligible and are not calculated. Ohmuna

e

- G. In practice, when β is close to -1 (e.g., -1.25 < β < -

n

(1982) describes an objective method for rejecting erroneous Bowen ratio data.

1-2

Page 7

Section 1. System Overview

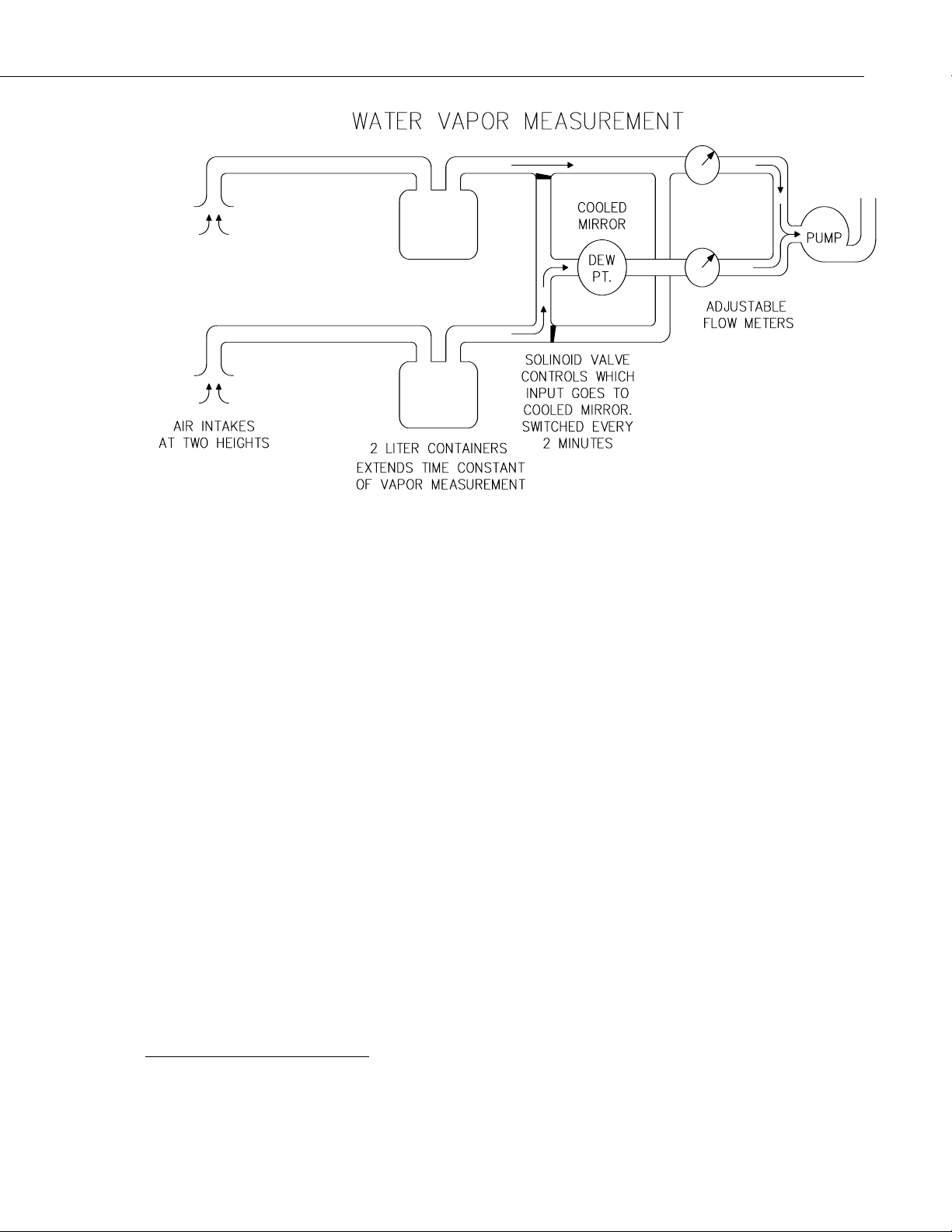

FIGURE 1.2-1. Vapor Measurement System

1.2 System Description

1.2.1 Water Vapor Measurement

It is common practice in Bowen ratio measurements to measure wet bulb

depression to develop the water vapor gradient. The position of the two

psychrometers is periodically reversed to cancel systematic sensor errors

(Suomi, 1957; Fuchs and Tanner, 1970).

In the Campbell Scientific system, vapor concentration is measured with a

single cooled mirror dew point hygrometer

multiple level gradient studies (Lemon, 1960). Air samples from two heights

are routed to the cooled mirror after passing through mixing volumes (Figure

1.2-1). The problems associated with wick wetting and water supply in

psychrometers are avoided and systematic sensor errors are eliminated.

Air is drawn from both heights continuously through inverted 25 mm filter

holders fitted with Teflon filters with a 1 µm pore size. The filter prevents dust

contamination in the lines and on the cooled mirror. It also prevents liquid

water from entering the system.

1

, using a technique developed for

A single low power DC pump aspirates the system. Manually adjustable

rotometers are used to adjust and match the flow rates. A flow rate of 0.4

liters/minute with 2 liter mixing chambers gives a 5 minute time constant.

1

Model Dew-10, General Eastern Corp. Watertown, MA

1-3

Page 8

Section 1. System Overview

A datalogger is used to measure all sensors and control the valve that switches

the air stream through the cooled mirror.

The resolution of the dewpoint temperature measurement is ±0.003°C over a

±35°C range. The limitation is the stability of the Dew-10, approx imately

0.05°C, yielding better than ±0.01 kPa vapor pressure resolution over most of

the environmental range.

Every 2 minutes the air drawn through the cooled mirror is switched from one

height to the other with the valve. Forty seconds is allowed for the mirror to

stabilize on the new dewpoint temperature and 1 minute and 20 seconds worth

of measurements for an individual level are obtained for each 2 minutes cycle.

The dewpoint temperature is measured every second and the vapor pressure is

calculated by the datalogger using the equation described by Lowe (1976).

The average vapor pressure at each height is calculated every 20 minutes.

CR23X

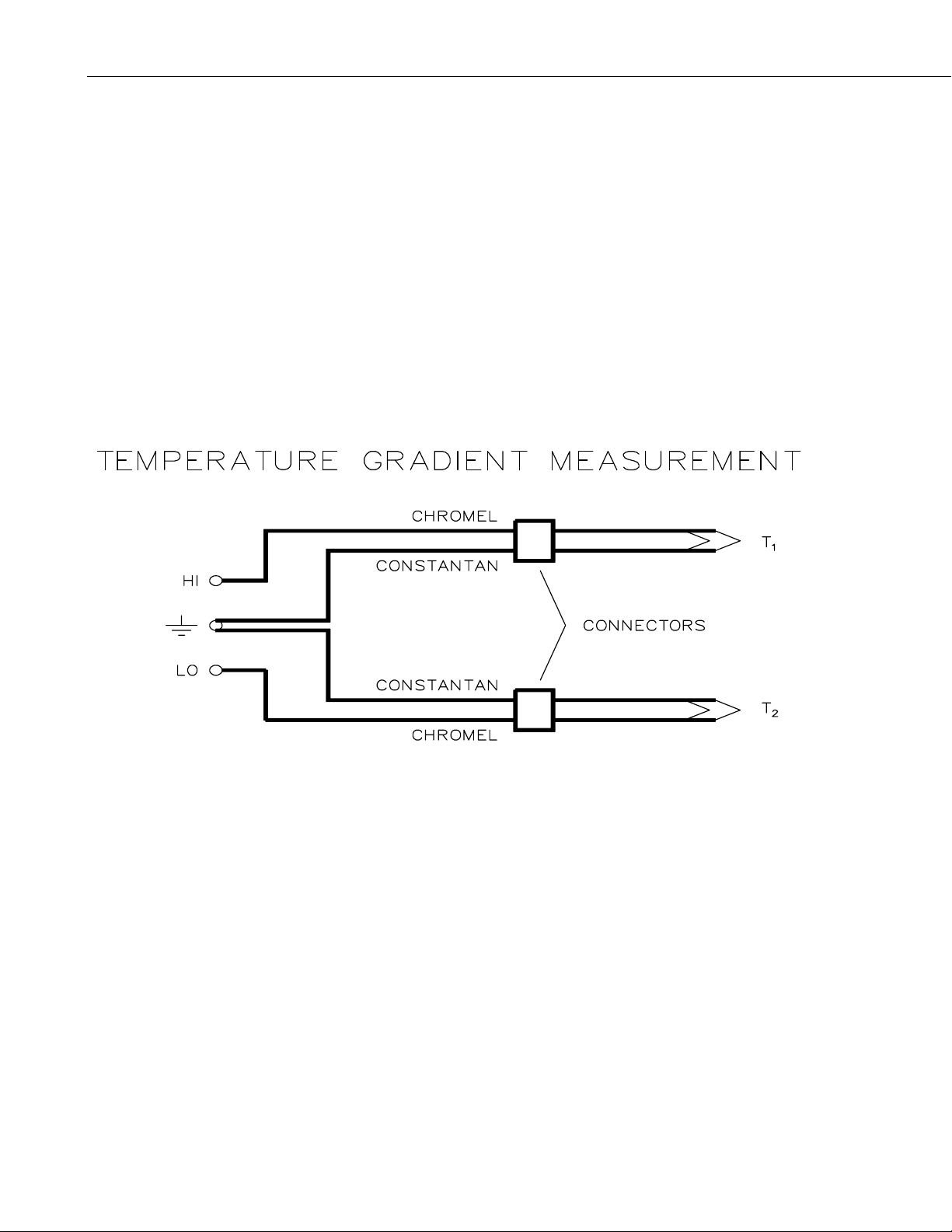

FIGURE 1.2-2. Thermocouple Configuration

1.2.2 Air Temperature Measurement

Air temperature is measured at two heights with chromel–constantan

thermocouples wired as in Figure 1.2-2. The differential voltage is due to the

difference in temperature between T

error. The datalogger resolution is 0.006°C with 0.1 µV rms noise.

The thermocouples are not aspirated. Attempts to aspirate the TCs with the air

from the vapor measurement system were not successful. Testing under 1000

-2

W m

solar radiation, with several radiation shield designs and aspiration rates

of up to 80 cm s

to radiation from the shield/ducting.

Calculations indicate that a 25 µm (0.001 in) diameter TC experiences less

than 0.2°C and 0.1°C heating at 0.1 m s

under 1000 W m

-1

(1 l min-1), showed a significant increase in temperature due

-2

solar radiation (Tanner, 1979). More importantly, error in

and T2 and has no inherent sensor offset

1

-1

and 1 m s-1 wind speeds, respectively,

1-4

Page 9

the gradient measurement is due only to the difference in the radiative heating

of the two TC junctions and their physical symmetry minimizes this.

Conversely, contamination of only one junction can cause larger errors.

Applying temperature gradients to the TC connectors was found to cause

offsets. The connector mounts were designed with radiation shields and

thermal conductors to minimize gradients.

The prototype systems used two sets of TCs on each system, one 25 µm and

one 76 µm diameter. It was hypothesized that the 25 µm diameter would

suffer less from radiation loading and the 76 µm would be less prone to

breakage. The current design uses a single set of TCs (76 µm standard) with

two parallel junctions at each height as a back up against breakage.

1.2.3 Net Radiation and Soil Heat Flux

Net radiation and soil heat flux are averaged over the same time period as the

vapor pressure and temperature differences.

To measure soil heat flux, heat flux plates are buried in the soil at a fixed depth

of between 5 to 10 cm to reduce errors due to vapor transport of heat.

Typically the plates are buried at a depth of 8 cm. The average temperature of

the soil layer above the plate is measured using 4 parallel thermocouples. The

heat flux at the surface is then calculated by adding the heat flux measured by

the plate to the energy stored in the soil layer. The storage term is calculated

by multiplying the change in soil temperature over the averaging perio d by the

soil heat capacity.

Section 1. System Overview

1.2.4 Power Supply

The current requirements of the components of the Bowen ratio system are

given in Table 1.2-1.

Component Current at 12 VDC

Cooled Mirror 150 - 500 mA

Pump 60 mA

CR23X 5 mA

A 20 watt solar panel (SP20R) and a 70 amp-hour battery are capable of

providing a continuous current of 300 - 350 mA. The solar panel is necessary

if the system is to be used for periods longer than 2-3 days. The datalogger

can control power to the cooled mirror and pump, and can shut down the

system if the battery voltage is low or if measurements are not needed at night.

TABLE 1.2-1. Component Power

Requirements

1-5

Page 10

Section 1. System Overview

This is a blank page.

1-6

Page 11

Section 2. Station Installation

Figure 2-1 shows the typical Bowen ratio installation on the CM10 tripod. The 023A

enclosure, mounting arms, and SP20R solar panel all mount to the tripod mast (1 1/4 in.

pipe, inside diameter) with U-bolts. The size of the tripod allows the heights of the arms to

be adjusted from 0.5 to 3 meters. The mounting arms should be oriented due south to

avoid partial shading of the thermocouples.

The net radiometer is mounted on a separate stake (not provided by Campbell Scientific) so

that the tripod is not a significant portion of its field of view. It should be positioned so

that it is never shaded by the tripod or mounting arms and should be mounted so that it

points south.

2.1 Sensor Height and Separation

There are several factors which must be balanced against each other when

determining the height at which to mount the support arms for the temperature

and air intakes. The differences in temperature and moisture increase with

height, so the resolution on the measurements of the temperature and vapor

gradient will improve the farther apart the arms are.

The upper mounting arm must be low enough that it is not sampling air that is

coming from a different environment upwind. The air that the sensors see

must be representative of the soil/vegetation that is being measured. As a rule

of thumb, the surface being measured should extend a distance upwind that is

at least 100 times the height of the sensors. The following references discuss

fetch requirements in detail: Brutsaert (1982); Dyer and Pruitt (1962); Gash

(1986); Schuepp et al. (1990); and Shuttleworth (1992).

The lower mounting arm needs to be higher than the surrounding vegetation so

that the air it is sampling is representative of the bulk crop surface, and not a

smaller scale effect that might be seen in a row crop if the sensors were down

between rows.

2-1

Page 12

Section 2. Station Installation

Q7-BR

(system)

FIGURE 2-1. CSI Bowen Ratio System

2.2 Soil Thermocouples and Heat Flux Plates

The soil thermocouples and heat flux plates are typically installed as shown in

Figure 2.2-1. The TCAV parallels four thermocouples together to provide the

average temperature, as shown in Figure 2.2-2). It is constructed so two

thermocouples can be used to obtain the average temperature of the soil layer

above one heat flux plate and the other two above the second plate. The

thermocouple pairs may be up to two meters apart.

The location of the two heat flux plates/ thermocouples should be chosen to be

representative of the area under study. If the ground cover is extremely varied,

it may be necessary to have additional sensors to provide a valid average.

Use a shovel to cut a vertical slice in the soil and remove the soil to one side of

the cut. Try to keep the soil that is removed intact so that it can be replaced

with as little disruption as possible.

The sensors are installed in the undisturbed face. The depths are measured

from the top of the soil. A horizontal cut is made with a knife to install the

heat flux plate, and the stainless steel tubes on the ends of the thermocouple are

pressed in, keeping the tubes horizontal. When removing the thermocouples,

grip the tubing, not the thermocouple wire.

2-2

Page 13

Section 2. Station Installation

To minimize thermal conduction down the sensor lead wires, they should be

buried for a short distance back from the sensor. In particular, do not run the

leads directly to the surface, but wrap them around the edge of the hole,

keeping the leads at the same level as the sensor for as long as possible. Once

the sensors are installed, backfill the hole.

Install the CS616 as shown in Figure 2.2-1. See the CS616 manual (Section 5)

for detailed installation instructions.

Up to 1 m

2.5 cm

2 cm

6 cm

Partial emplacement of HFT3 and TCAV sensors

is shown for illustration purposes. All sensors

must be completely inserted into the soil face

before the hole is backfilled.

FIGURE 2.2-1. Placement of Thermocouples and Heat Flux Plates

Ground Surface

8 cm

2-3

Page 14

Section 2. Station Installation

HI (PURPLE)

LO (RED)

24 GAUGE

CHROMEL

CONSTANTAN

STAINLESS STEEL

TUBE

40 GAUGE CHROMEL

CONSTANTAN

2.3 Wiring

FIGURE 2.2-2. TCAV Spatial Averaging Thermocouple Probe

Table 2.3-1 lists the connections to the CR23X for the standard Bowen ratio

sensors measured by the example program. Because the air temperature

measurements are so critical, the air temperature thermocouples are connected

to differential channel 4 (the channel that is closest to the reference

temperature thermistor). The input terminal strip cover for the CR23X must be

installed once all connections have been made and verified (Section 13.4 of

CR23X manual).

TABLE 2.3-1. CR23X/Sensor Connections for Example

Program

CHANNEL SENSOR COLOR

1H Q7.1 RED

1L Q7.1 BLACK

SHIELD CLEAR

2H HYGROMETER PRT GREEN

2L HYGROMETER PRT WHITE

HYGROMETER PRT BLACK

3H TCAV PURPLE

3L TCAV RED

TCAV CLEAR

4H UPPER 0.003 TC - CHROMEL PURPLE

4L LOWER 0.003 TC - CHROMEL PURPLE

2-4

Page 15

Section 2. Station Installation

UPPER/LOWER TCs - CONSTANTAN RED/RED

TC SHIELD CLEAR/CLEAR

5H HFT#1 BLACK

5L HFT#2 WHITE/WHITE

HFT#1 AND HFT#2 CLEAR/CLEAR

6H WIND SENTRY RED

6L CS615 GREEN

WIND SENTRY WHITE/CLEAR

CS615 BLACK/CLEA

R

EX1 HYGROMETER EXCITATION RED

EX2 WIND SENTRY BLACK

GND HYGROMETER CLEAR

C1 PULSE FOR LOWER AIR INTAKE GREEN

C2 PULSE FOR UPPER AIR INTAKE WHITE

C3

PULSE TO TURN ON POWER TO

BLACK

MIRROR AND PUMP (FLAG 6)

C4

PULSE TO TURN OFF POWER TO

RED

MIRROR AND PUMP (FLAG 7)

C7 CS615 (TURN UNIT ON) ORANGE

G GROUND WIRE CLEAR

PULSE

1 WIND SENTRY BLACK

WIND SENTRY WHITE/CLEAR

2 CS615 GREEN

CS615 BLACK/CLEA

R

+12 V CS615 RED

2-5

Page 16

Section 2. Station Installation

CR23X

2-6

FIGURE 2.3. A Block Diagram for the Connections between

the Datalogger, the BR Relay Driver and Components,

and the External Battery.

Page 17

2.4 Battery Connections

Two terminal strip adapters for the battery posts (P/N 4386) are provided with

the 023A (Figure 2.4-1). These terminal strips will mount to the wing nut

battery posts on most deep cycle lead acid batteries.

FIGURE 2.4-1. Terminal Strip Adapters for Connections to Battery

The SP20R solar panel, BR relay driver, and CR23X each have a separate

power cable. Once the system is installed, these power cables are then

connected to the external battery (red to positive, black to negative). The

CR23X power cable is shipped in the 023A enclosure and must be connected

to the +12 V (red from power cable) and ground (black from power cable)

terminals on the CR23X wiring panel.

Section 2. Station Installation

2.5 System Startup

To bring the Bowen ratio system on-line, turn on the datalogger, set the

datalogger time, download the program, and set flag 6 high to activate the

hygrometer and pump.

2.6 Routine Maintenance

Change air intake filters 1-2 weeks

Clean mirror and adjust bias 1-2 weeks

Clean thermocouples as needed

Clean Radiometer domes as needed

Filters are Teflon, 25 mm diameter with a 1 µm pore size, i.e., Nuclepore

130610 or Gelman 66154

To write an array to Final Storage, while replacing filters and cleaning

thermocouples, set flag 4 high. Set flag 4 low when maintenance is complete.

The time that the site maintenance bean and ended will be written into Final

Storage.

Before removing the filters, turn the pump/mirror off by setting flag 7 high.

Install the clean filters with the glossy, textured side down. Be sure to remove

any protective paper from the filter. Remove all debris from the fine wire

2-7

Page 18

Section 2. Station Installation

thermocouples. A camel-hair brush and tweezers can be used to clean the

thermocouples. To turn the hygrometer and pump on, set flag 6 high.

The thermocouples can also be dipped in a mild acid to dissolve spider webs.

For example, muratic acid (hydrochloric acid) is available in most hardware

stores. Rinse the thermocouples thoroughly with distilled water after dipping.

2.7 Cleaning the DEW 10

Mirror cleaning and optical bias adjustment are important periodic

maintenance functions. Adjustment of the optical bias determines the

thickness of the dew layer on which the system reaches its control point.

Proper adjustment of the bias is essential. The DEW 10 will not control on an

excessively thick dew layer, whereas controlling on a thin layer requires more

frequent mirror cleaning.

CAUTION

Gently spin the cotton swab to clean the mirror. Use a

dabbing motion to dry the mirror. Using excessive force to

clean the mirror will scratch it.

1. Write time that site maintenance began by setting flag 4 high.

2. Shut off the thermoelectric cooler by sliding switch S1 toward the nearest

end of the card, out of the operate position (OP) and into the balance

position (BAL).

3. Remove the DEW 10 connector from the circuit board (Figure 2.7-1).

Pull firmly on the DEW 10 until it slides out of the mirror block.

4. Locate the mirror, it is circular in shape and only the edge can be seen

when looking straight into the mirror cavity. The mirror is mounted on a

45° angle within the mirror cavity.

Gently clean the mirror with a cotton swab and the blue cleaning solution.

Remove any excess cleaning fluid by gently dabbing with a clean dry

swab.

Wait at least 2 minutes before continuing to the next step. This will allow

sufficient evaporation of the moisture from the mirror.

5. Place the DEW 10 back into the chilled mirror block and reconnect it to

the circuit board.

2-8

To aid in reinsertin g the DEW 10 into the mirror block, twist the DEW 10

1/8 of a turn while firmly pushing it into the mirror block. Be sure the

mirror cavity is parallel to the flow through the mirror block, i.e., vertical.

6. Use a small screwdriver to turn the potentiometer, R34, located on the top

edge of the circuit board (Figure 2.6-1).

If the LED is on, turn the screw counter clockwise until the red LED turns

off.

Page 19

Section 2. Station Installation

If the LED is not already on, turn the potentiometer clockwise until it

turns on and then counter clockwise until it goes off.

Now, slowly turn the potentiometer clockwise until the LED comes on

again.

7. Return the switch to its normal operating position. The LED will turn off

several seconds after the switch is moved to the normal operating

position.

8. Set flag 4 low to write the time that site maintenance ended.

Cleaning the mirror with a cotton swab does not result in a surface condition

like the one reached after evaporation of a dew layer. Therefore, a more

appropriate bias adjustment is reached with a mirror surface on which a dew

layer has been formed and then evaporated.

By adding two steps to the above procedure, a more appropriate bias

adjustment can be made and the period between required mirror cleaning can

be further extended. These additional steps are:

9. Allow the system to run under normal operation for 8 to 24 hours, after

completing steps 1 through 8.

10. Now repeat step 1, 2, and 6 through 8.

FIGURE 2.7-1. DEW 10 Circuit Board

2-9

Page 20

Section 2. Station Installation

This is a blank page.

2-10

Page 21

Section 3. Sample CR23X Program

The example program is available on the Campbell Scientific FTP site,

ftp://ftp.campbellsci.com/pub/outgoing/files/br_023a.exe. The example

program measures the standard Bowen ratio inputs: vapor pressure and air

temperature gradients, net radiation, and soil heat flux (flux at 8 cm and change

in temperature of the soil layer above). If additional measurements are to be

made or if a different installation is to be used, the program will have to be

altered. Note that even if this exact installation is used, the correct calibratio n

(multiplier and offset) must be entered for the net radiometer and soil heat flux

plates.

Table 3-1 is a flow chart of the example program and Table 3-2 lists the output

generated by the program.

Power to the pump and cooled mirror is switched on and off by the datalogger.

This can be under manual control by setting a flag in the *6 Mode (flag 6 to

turn on, flag 7 to turn off), or automatically by the program if the battery

voltage drops below 11.5 volts (subroutine 2).

3-1

Page 22

Section 3. Sample CR23X Program

TABLE 3-1. Sample CR23X Bowen Ratio Program Flow Chart

Subtract Upper TC Temp. from the Lower TC Temp.

Yes

Yes

Set Flag 0 (Output)

Yes

Set Flag 0 (Output)

[process]

Yes

Set Flag 9

(Disable Intermediate Processing)

Yes

Set Flag 9

(Disable Intermediate Processing)

[process]

Yes

Set Flag 9

(Disable Intermediate Processing)

Yes

Set Flag 9

(Disable Intermediate Processing)

[process]

Table 1

1 Second Execution Interval

Measure Panel Temperature

Measure Lower Thermocouple (Single Ended)

Measure Upper Thermocouple (Differential)

Measure RTD on Cooled Mirror

Calculate RTD R/Ro

Calculate RTD Temperature

Calculate Vapor Pressure

Flag 5 Set?

20 Minute Interval ?

Flag 4 Set ?

Set Flag 5

Day, Hour:Minute (smpl)

Panel Temperature (smpl)

Lower Temperature (avg)

Temperature Gradient (avg)

Flag 2 Set ?

Flag 1 Set ?

Upper Dew Point (avg)

Upper Vapor Pressure (avg)

Reset Flag 9

Flag 2 Reset ?

Flag 1 Set ?

Lower Dew Point (avg)

Lower Vapor Pressure (avg)

No

No

No

No

No

No

No

3-2

Page 23

Section 3. Sample CR23X Program

Table 2

10 Second Excitation Interval

40 Second Interval ?

Yes

Reset Flag 1

Flag 5 Set ?

Yes

Yes

Flag 4 Reset

?

No

Call Subroutine 1

2 Minute Interval ?

Yes

Set Flag 1

Yes

Set Port 2 High

Set Flag 2

4 Minute

Interval ?

No

Set Port 1 High

Reset Flag 2

Delay 0.01 Seconds

Set Port 1 Low

Set Port 2 Low

Measure Battery Voltage

Measure Net Radiation

Yes

Call Subroutine 3

(wind speed correction on

positive radiation)

Net Radiation Positive ?

Call Subroutine 4

(wind speed correction on

negative radiation)

Measure 2 Soil Heat Flux Plates

Measure Soil Temperature (Layer Average)

Scale Heat Flux Measurements

Wind Speed Wind Direction

Yes

Ten Minutes Into Interval ?

Measure CS615

Last 10 Minutes of a 20

Minute Interval ?

Yes

Compute Average Soil Temperature

20 Minute Interval ?

Yes

Calculate 10 Minute Soil Temp. (avg)

Calculate Change from Previous Soil Temp.

[output process]

Day, Hour:Minute

Net Radiation (avg)

2 Soil Heat Flux Plates (avg)

Soil Temp. 10 min. avg. (smpl)

Change in Soil Temp. (smpl)

CS615 mSec Soil Water Content

Soil Water Content Corrected for Temp.

Battery (avg)

Call Subroutine 2 (battery check)

No

No

No

No

No

No

No

3-3

Page 24

Section 3. Sample CR23X Program

Turn the cooled mirror and pump on/off in response to a user flag or battery voltage

Yes

Set Port 3 High

(Turn on Pump and Mirror)

Yes

Set Port 4 High

(Turn off Pump and Mirror)

Yes

Flag 3 Reset ?

Yes

Set Port 4 High

Delay 0.01 Seconds

Set Port 4 Low

Set Flag 3

[output process]

Day, Hour:Minute

Battery Voltage (smpl)

Apply positive wind speed correction to positive Net Radiation

Apply negative wind speed correction to negative Net Radiation

Subroutine 1

Output the time processing is re-enabled

Reset Flag 5 (Re-enable Output)

[output process]

Day, Hour:Minute

Subroutine 2

Flag 6 Set ?

Reset Flag 6

Flag 7 Set ?

Reset Flag 7

Battery Volts < 11.5 ?

No

Yes

Flag 3 Reset ?

Yes

Set Port 3 High

Delay 0.01 Seconds

Set Port 3 Low

[output process]

Day, Hour:Minute

Battery Voltage (smpl)

Subroutine 3

Positive net radiation

Subroutine 4

Negative net radiation

Battery Voltage

Reset Flag 3

No

No

No

≥ 12

No

No

3-4

Page 25

Section 3. Sample CR23X Program

TABLE 3-2. Output From Example Bowen Ratio Program

01: 110 20 minute Bowen ratio data

02: Day

03: hhmm

04: Avg Reference Temperature

05: Avg T low

06: Avg dT

07: Avg DP low

08: Avg VP low

09: Avg DP high

10: Avg VP high

01: 237 20 minute Bowen ratio data

02: Day

03: hhmm

04: Avg RN

05: Avg soil heat flux #1

06: Avg soil heat flux #2

07: Avg soil temp (Last 10 min)

08: Change from previous soil temp

09: Avg wind speed

10: Avg wind direction

11: Standard deviation of wind direction

12: CS615 period

13: Volumetric soil water content

14: Volumeric soil water content corrected for temperature

15: Avg battery voltage

01: 302 Beginning of site maintenance

02: Day

03: hhmm

01: 303 End of site maintenance

02: Day

03: hhmm

01: 317 Pump and cooled mirror shut off due to low battery

02: Day

03: hhmm

04: Batt volts

01: 328 Pump and cooled mirror turned on, batt recharged

02: Day

03: hhmm

04: Batt volts

3-5

Page 26

Section 3. Sample CR23X Program

This is a blank page.

3-6

Page 27

Section 4. Calculating Fluxes Using SPLIT

SPLIT (LoggerNet software) can be used to calculate the fluxes from the Bowen ratio

measurements. This section describes these calculations on the data output from the

example datalogger program. It requires two passes with SPLIT to compute the fluxes.

The first pass operates on the raw data files generated by the datalogger. The definitions

of points in this data is given in Table 3-2 which is the Output from the sample program.

The output file from this first pass (RAWBOW.PRN) is defined in the parameter file

RAWBOW.PAR. The fluxes are then calculated by SPLIT with the parameter file

CALCBOW.PAR.

The example SPLIT parameter files: SERVICE.PAR, SHUTDOWN.PAR, RAWBOW.PAR,

and CALCBOW.PAR are on the Campbell Scientific, Inc. FTP site,

ftp://ftp.campbellsci.com/pub/outgoing/files/br_023a.exe.

4.1 Data Handling

Before calculating the surface fluxes, first Quality Control the raw data. Use

the SPLIT parameter files SERVICE.PAR and SHUTDOWN.PAR to

determine when the station was down for service or when it shut itself down

because of low battery voltage.

Next, combine the air temperature and vapor pressure gradients with net

radiation, soil heat flux, soil temperature, wind speed, and wind direction,

using the SPLIT parameter file RAWBOW.PAR.

This parameter file assumes that the data files from the datalogger were saved

on disk under the name BOWEN.DAT. It creates a file with the raw data

necessary to calculate fluxes RAWBOW.PRN.

Plot the data in RAWBOW.PRN, check the temperature and vapor pressure

gradient, soil heat flux and temperature, and net radiation for anomalous

readings. Check the wind speed and direction data to determine if the fetch

conditions are adequate.

4.2 Calculating Fluxes

Once the necessary data is in one file the fluxes can be calculated. The

constants and parameters necessary for calculating the fluxes are listed in

Table 4.2-1.

Most of the calculations in CALCBOW.PAR are explained in the overview in

Section 1. The method used to calculate the heat storage term and hence soil heat

flux at the surface is explained below.

The soil heat flux at the surface is calculated by adding the measured flux at a fixed

depth, d, to the energy stored in the layer above the heat flux plates. The specific

4-1

Page 28

Section 4. Calculating Fluxes Using SPLIT

(

∆

heat of the soil and the change in soil temperature, ∆T

, over the output interval, t,

s

are required to calculate the stored energy.

The heat capacity of the soil is calculated by adding the specific heat of the dry

soil to that of the soil water. The values used for specific heat of dry soil and

water are on a mass basis. The heat capacity of the moist is given by:

CCCC C

where C

of water, C

is the heat capacity of moist soil, ρb is bulk density, ρw is the density

S

is the heat capacity of a dry mineral soil, θm is soil water content

d

on a mass basis, θ

=+ =+ρθ ρθρ (9)

sbdmw bdvww

is soil water content on a volume basis, and Cw is the heat

v

)

ρ

w

θ

m

θ

= (10)

v

ρ

b

capacity of water.

This calculation requires site specific inputs for bulk density, mass basis soil

water content or volume basis soil water content, and the specific heat of the

dry soil. Bulk density and mass basis soil water content can be found by

sampling (Klute, 1986). The volumetric soil water content is measured by the

CS615 soil water content reflectometer. The value used for the heat capacity

of dry soil in the example SPLIT parameter file is a reasonable value for most

mineral soils (Hanks and Ashcroft, 1980).

The storage term is then given by Eq. (3).

TCd

ss

S

=

(11)

t

Atmospheric pressure is a site-specific input. Pressure can be measured at the

site or obtained from a local meteorological station. An estimate of pressure

can be calculated for the site using a standard atmosphere with the following

equation:

P

⎡

=−

101325 1

.. (12)

⎢

⎣

E

44307 69231

5.25328

⎤

⎥

⎦

where P is in kPa and the elevation, E, is in meters (Wallace and Hobbs, 1977).

4-2

Page 29

Section 4. Calculating Fluxes Using SPLIT

TABLE 4.2-1. Input Values for Flux Calculations

VARIB. VALUE UNITS DESCRIPTION

CP 1.01 kJ/(kg K) Specific heat of air

CW 4190.0 J/(kg K) Specific heat of water

CS* 840.0 J/(kg K)

Specific heat of dry soil (estimate)

EW** 2450.0 kJ/kg Latent heat of vaporization at 20°C

P* 87.18 kPa Atmospheric pressure, measure or

calculate for elevation

T** 1200 s Output interval

D** 0.08 m Depth to flux plates

BD* 1200 kg/m3

Soil bulk density, must be

measured for site

W vol-H2O/bulk

vol-soil

Soil water content, volume basis,

measured by the CS615

F W/m2 Soil heat flux measured at 8 cm.

S W/m2 Heat stored, calculated from soil

heat capacity and measured change

in temperature

G W/m2 Soil heat flux at surface (F+S)

RN W/m2 Net radiation, measured

BR — Bowen ratio

LE W/m2 Latent heat flux

H W/m2 Sensible heat Flux

0.622 Molecular weight of

water/molecular weight of air.

* These values are for a particular site. Correct values must be entered for the

site under study.

** These values may need to change if the program or installation is changed.

4-3

Page 30

Section 4. Calculating Fluxes Using SPLIT

This is a blank page.

4-4

Page 31

Appendix A. References

Bowen, I. S., 1926: The ratio of heat losses by conduction and by evaporation

from any water surface. Phys. Rev., 27, 779-787.

Brutsaert, W., 1982: Evaporation into the Atmosphere. D. Reidel Publishing

Co., 300 pp.

Dyer, A. J., and W. O. Pruitt, 1962: Eddy flux measurements over a small

irrigated area. J. Appl. Meteor., 1, 471-473.

Fuchs, M. and C. B. Tanner, 1970: Error analysis of bowen ratios measured

by differential psychrometer. Ag. Meteor., 7, 329-334.

Gash, J. H. C., 1986: A note on estimating the effect of a limited fetch on

micrometeorological evaporation measurements. Bound.-Layer Meteor.,

35, 409-413.

Hanks, R. J., and G. L. Ashcroft, 1980: Applied Soil Physics: Soil Water and

Temperature Application. Springer-Verlag, 159 pp.

Klute, A., 1986: Method of Soil Analysis. No. 9, Part 1, Sections 13 and 21,

American Society of Agronomy, Inc., Soil Science Society of America,

Inc.

Lemon, E. R., 1960: Photosynthesis under field conditions: II. An

aerodynamic method for determining the turbulent carbon dioxide

exchange between the atmosphere and a corn field. Agron. J., 52, 697-

703.

Lowe, P. R., 1976: An approximating polynomial for computation of

saturation vapor pressure. J. Appl. Meteor., 16, 100-103.

Ohmura, A., 1982: Objective criteria for rejecting data for bowen ratio flux

calculations. J. Appl. Meteor., 21, 595-598.

Schuepp, P. H., M. Y. Leclerc, J. I. MacPherson, and R. L. Desjardins, 1990:

Footprint prediction of scalar fluxes from analytical solutions of the

diffusion equation. Bound.-Layer Meteor., 50, 355-373.

Shuttleworth, W. J., 1992: Evaporation (Chapter 4), Handbook of Hydrology,

Maidment, Ed., Mc Graw-Hill, 4.1-4.53.

Suomi, V. E., 1957: Double-psychrometer lift apparatus, Exploring the

Atmosphere’s First Mile, Pergamon, 183-187.

Tanner, C. B., 1960: Energy balance in approach to evapotranspiration from

crops, Soil Sci. Soc. Am. Proc., 24, 1-9.

Tanner, C. B., 1979: Temperature: Critique I. Controlled Environmental

Guidelines for Plant Research, T. W. Tibbits and T. T. Kozolowski, Eds.,

Academic Press, 117-130.

A-1

Page 32

Appendix A. References

Wallace, J. M., and P. V. Hobbes, 1977: Atmospheric Science: An

Introductory Survey. Academic Press, 350 pp.

A-2

Page 33

Appendix B. 023 Bowen Ratio (Pre July

1993)

FIGURE B-1. 023 Bowen Ratio Vapor Measurement System with Three Flowmeters

B-1

Page 34

This is a blank page.

Page 35

This is a bla nk page.

Page 36

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

sales@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringo wa Cent ra l

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda . (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...