INSTRUCTION MANUAL

Use of the AVW1 and AVW4 with

Geokon Model 4500 Vibrating Wire

Piezometers and Pressure Transducers

Revision: 1/92

Copyright (c) 1987-1992

Campbell Scientific, Inc.

Warranty and Assistance

The AVW1 AND AVW4 are warranted by CAMPBELL SCIENTIFIC, INC.

to be free from defects in materials and workmanship under normal use and

service for twelve (12) months from date of shipment unless spec ified

otherwise. Batteries have no warranty. CAMPBELL SCIENTIFIC, INC.'s

obligation under this warranty is limited to repairing or replacing (at

CAMPBELL SCIENTIFIC, INC.'s option) defective products. The customer

shall assume all costs of removing, reinstalling, and shipping defective products

to CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. will

return such products by surface carrier prepaid. This warranty shall not apply

to any CAMPBELL SCIENTIFIC, INC. products which have been subjected to

modification, misuse, neglect, accidents of nature, or shipping damage. This

warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability or fitness for a particular purpose. CAMPBELL

SCIENTIFIC, INC. is not liable for special, indirect, incidental, or

consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle repairs

for custome rs within their territorie s. P lease visit www.ca m pbells ci.com to

determine which Campbell Scientific company serves your country. To obtain

a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

TABLE OF CONTENTS

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

PAGE

WARRANTY AND ASSISTANCE

1. GENERAL INFORMATION

1.1 Sensor Selection ..............................................................................................................................1-1

1.2 Sensor Care and Installation.............................................................................................. ..............1-1

2. TEMPERATURE MEASUREMENT

2.1 General.............................................................................................................................................2-1

2.2 Accuracy and Resolution..................................................................................................................2-1

2.3 Programming and Sensor Hook-up..................................................................................................2-6

3. VIBRATING WIRE MEASUREMENT

3.1 General.............................................................................................................................................3-1

3.2 Multiplier and Offset..........................................................................................................................3-1

3.3 Swept Frequency, Start and End......................................................................................................3-2

3.4 Resolution vs. "# of cycles" ..............................................................................................................3-3

3.5 Temperature Correction ...................................................................................................................3-3

3.6 Delay Between Measurements.........................................................................................................3-4

4. THE AVW1

4.1 General.............................................................................................................................................4-1

4.2 Sensor Hook Up...............................................................................................................................4-1

4.3 Well Monitoring Example..................................................................................................................4-1

5. THE AVW4

5.1 General.............................................................................................................................................5-1

5.2 Sensor Hook Up...............................................................................................................................5-2

5.3 Datalogger Programming .................................................................................................................5-2

6. THE AVW1 AND A MULTIPLEXER

Not yet available

APPENDIX A. PRESSURE CONVERSION CHART............................................... A-1

APPENDIX B. SCHEMATICS AND STUFFING CHARTS ......................................B-1

APPENDIX C. THEORY AND ADDITIONAL DETAILS

C.1 Swept Frequency Theory................................................................................................................C-1

C.2 Additional Theory on Multiplier and Offset......................................................................................C-1

I

TABLE OF CONTENTS

TABLES

2.2-1 Temperature vs. Thermistor Resistance, V, oC, and Linearization Error................................... 2-1

3.2-1 Calibration Data for Sensor 3998................................................................................................ 3-2

FIGURES

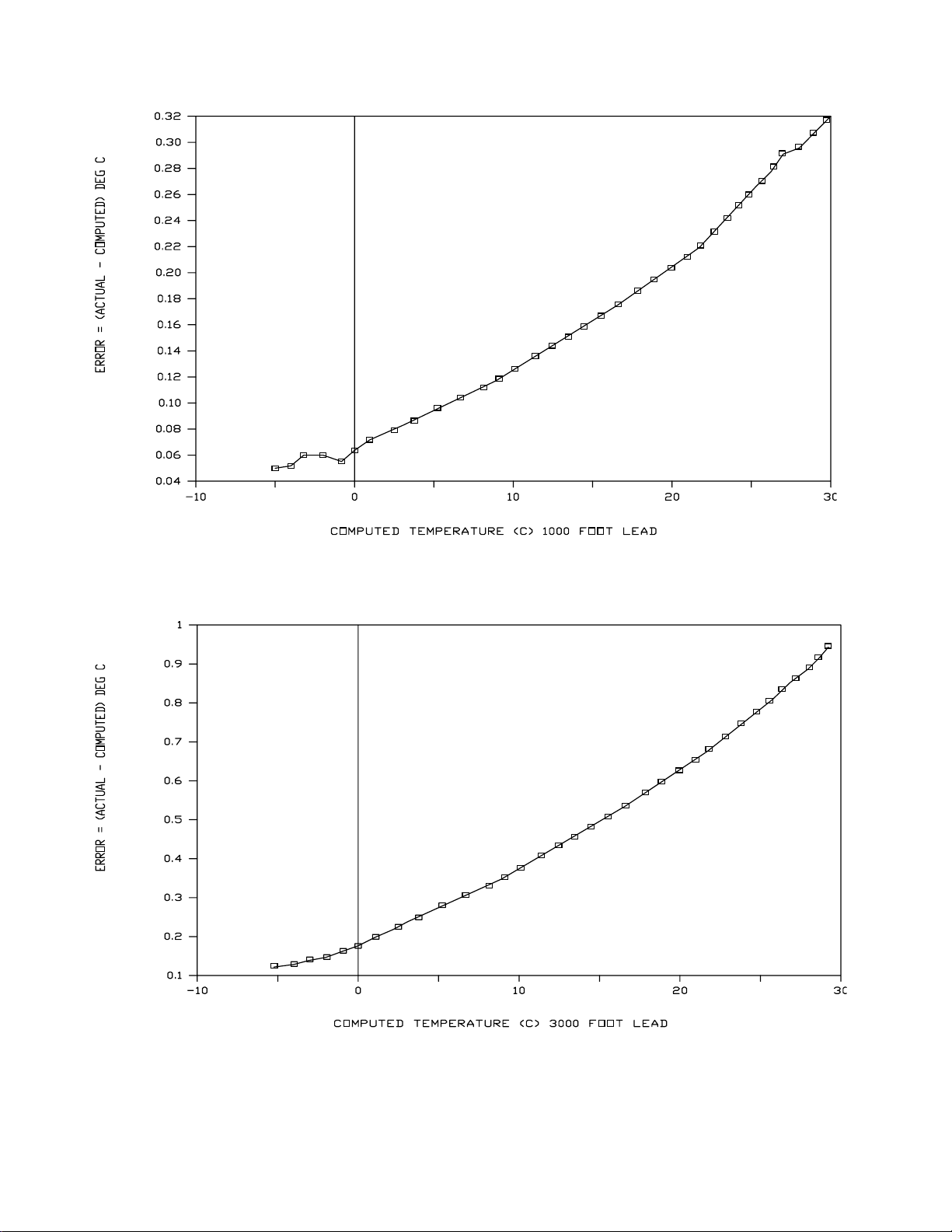

2.2-1 Temperature Measurement Error at Three Temperatures as a Function of Lead Length ......... 2-3

2.2-2 Temperature Measurement Error on a 1000 Foot Lead............................................................. 2-4

2.2-3 Temperature Measurement Error on a 3000 Foot Lead............................................................. 2-4

2.2-4 Temperature Measurement Error on a 5000 Foot Lead............................................................. 2-5

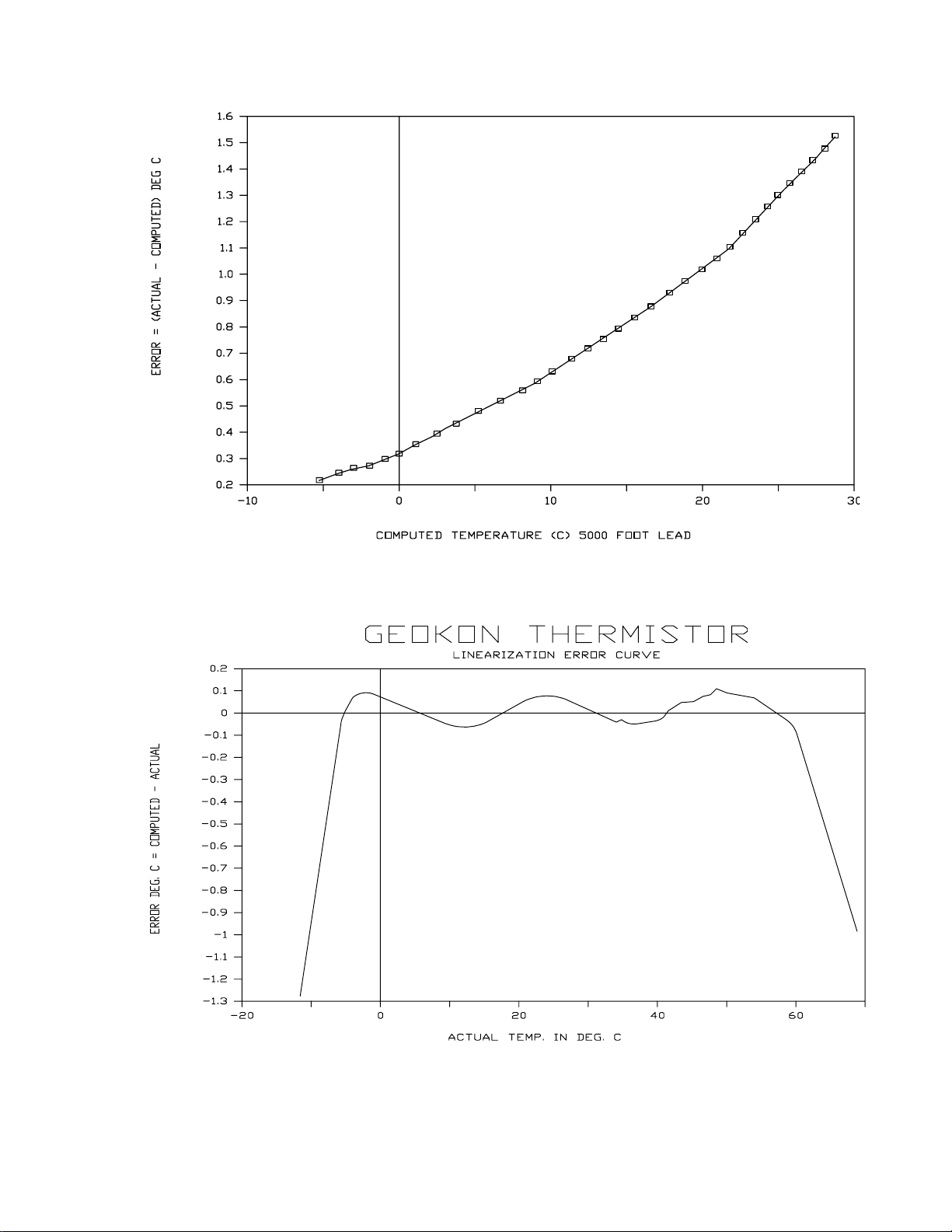

2.2-5 Thermistor Linearization Error .................................................................................................... 2-5

2.3-1 Direct Measurement of the Geokon Thermistor.......................................................................... 2-6

3.1-1 A Vibrating Wire Sensor.............................................................................................................. 3-1

4.1-1 The AVW1................................................................................................................................... 4-1

4.2-1 Hook up to AVW1 ....................................................................................................................... 4-1

4.3-1 Well Monitoring Example............................................................................................................ 4-2

5.1-1 The AVW4................................................................................................................................... 5-1

5.2-1 Hook up for AVW4...................................................................................................................... 5-2

A.1 Pressure Conversion Chart.........................................................................................................A-1

B.1-1 AVW1 Schematic........................................................................................................................B-1

B.1-2 AVW1 Stuffing Chart...................................................................................................................B-2

B.1-3 AVW4 Schematic........................................................................................................................B-3

B.1-4 AVW4 Schematic........................................................................................................................B-4

B.1-5 AVW4 Stuffing Chart...................................................................................................................B-5

II

USE OF THE AVW1 AND AVW4 WITH GEOKON MODEL 4500

VIBRATING WIRE PI EZOMETERS AND PRESSURE TRANSDUCERS

1. GENERAL INFORMATION

The CR10 is the only CSI datalogger that has

the capability of measuring the vibrating wire

pressure sensor in addition to the piezoresistive

type of strain gage sensor. The CR10 can

measure vibrating wire sensors with short leads

without the AVW1 or AVW4. However, the

AVW1 and AVW4 provide important signal

conditioning that 1) completes the thermistor

bridge for the measurement of the sensor's

temperature, 2) converts the swept frequency

excitation from 2.5 volts peak to peak to 12

volts peak to peak, 3) provides transformer

isolation and consequent noise reduction for the

vibrating wire signal, and 4) provides additional

transient protection for both the temperature

and vibrating wire circuits.

The AVW1 and AVW4 are designed and tested

over the environmental range from -25°C to

+50°C. CSI recommends that special

temperature testing be done at the factory if the

AVW's are to operate at temperatures outside

this range.

1.1 SENSOR SELECTION

The vibrating wire sensors may be purchased

as either vented or sealed sensors. The vented

sensors have a small hollow "vent tube" that

connects the hollow chamber behind the

diaphragm to the atmosphere. The vent tube

allows the barometric pressure to act on both

sides of the diaphragm equally which removes

the barometric pressure from the reading. A

pressure reading with out a barometric pressure

component is referred to as "gage" pressure. A

pressure reading with a barometric pressure

component is referred to as "absolute"

pressure. One disadvantage of the vented

sensor is that the cable, which contains the vent

tube, is more expensive than the cable for the

unvented sensor. For this reason, it may be

more economical to buy unvented sensors and

use an extra one as a barometer to remove the

barometric pressure. A second small

disadvantage of the vented sensors is that they

require the use of desiccant, which must be

changed periodically, to dry the air entering the

vent tube.

The vibrating wire pressure sensor has a good

reputation for long term stability. The sensor

utilizes a change in the frequency of a vibrating

wire to sense pressure. Two measurements

are usually made on a vibrating wire sensor.

The first is the measurement of the temperature

of the probe to compensate for changes in its

temperature. The second is the measurement

of the frequency of the vibrating wire.

This manual covers the use of the CR10 and

AVW1 or AVW4 with Geokon's Model 4500

vibrating wire sensor series. Sections 2 and 3

of this manual cover the temperature and

vibrating wire measurements respectively.

Sections 4 and 5 give detail concerning the use

of the AVW1 and AVW4.

Geokon includes a calibration sheet and

instruction manual with each sensor or group of

sensors they sell. Geokon's manual should be

consulted for information on sensor selection

and installation. Geokon's address and phone

number are: 48 Spencer Street, Lebanon, NH

03766, (603) 448-1562.

1.2 SENSOR CARE AND INSTALLATION

The moisture trap of the vented models should

be kept closed until readings are to be taken.

DO NOT FORGET to remove the screw that

plugs the moisture trap when readings are to be

taken.

The large diameter diaphragm used in the low

pressure sensor requires special care when

handling. Avoid bumping or jarring the sensor.

Orientation of the 4500 series sensors will affect

the zero reading. Readings should be taken

with the sensor in the same orientation at all

times. When installing the 4500 series sensors,

certain steps should be followed to obtain

proper zero readings.

The cavity between the sintered filter cap and

the diaphragm should be filled with clean water

without any air bubbles.

In most cases the sensor is made to output

water height or pressure relative to a measured

level. In this case the pressure sensor should

1-1

AVW1/AVW4

be placed at the desired level and allowed to

come to temperature equilibrium with its

surroundings (5 minutes or more). The

multiplier determined in equation 3.2-2 should

be entered and 0.0 should be entered for the

offset. After the temperature and the reading

has stabilized, determine the value that would

have to be added to the reading to obtain the

measured level. Enter this value as the offset.

In some cases there is no measured reference.

In order to obtain the correct offset under these

conditions, lower the sensor to a point just

above the water level and wait 5 minutes. Use

the multiplier, an offset of 0.0, and the

temperature correction function determined in

Sections 3.2 and 3.5 to obtain a reading.

Record the reading. Solve equation 3.2-3 for

the new offset by plugging in the "reading" in the

place of the "[Gage Factor * Zero Reading]" and

the "Barometric Pressure" from an accurate

barometer or a reference sensor in the place of

"Po" unless it is a vented sensor then use 0 in

the place of "Po". Enter the new offset.

1-2

SECTION 2. TEMPERATURE MEASUREMENT

2.1 GENERAL

The vibrating wire probe includes a thermistor

which is used to measure the temperature of

the probe. Probe temperature is used to correct

errors in the vibrating wire measurement

caused by changes in the temperature of the

probe. The temperature correction is most

important when the temperature of the medium

the probe is measuring is changing (e.g. water

temperature in a river or shallow lake). When

concerned with the absolute reading, it is also

important to make the temperature correction if

the medium temperature differs from the

calibration temperature. In a deep well where

the water temperature does not change, the

error due to temperature can be removed by

allowing the sensor to come to thermal

equilibrium and adjusting the sensor reading to

read the correct depth by means of an offset.

2.2 ACCURACY AND RESOLUTION

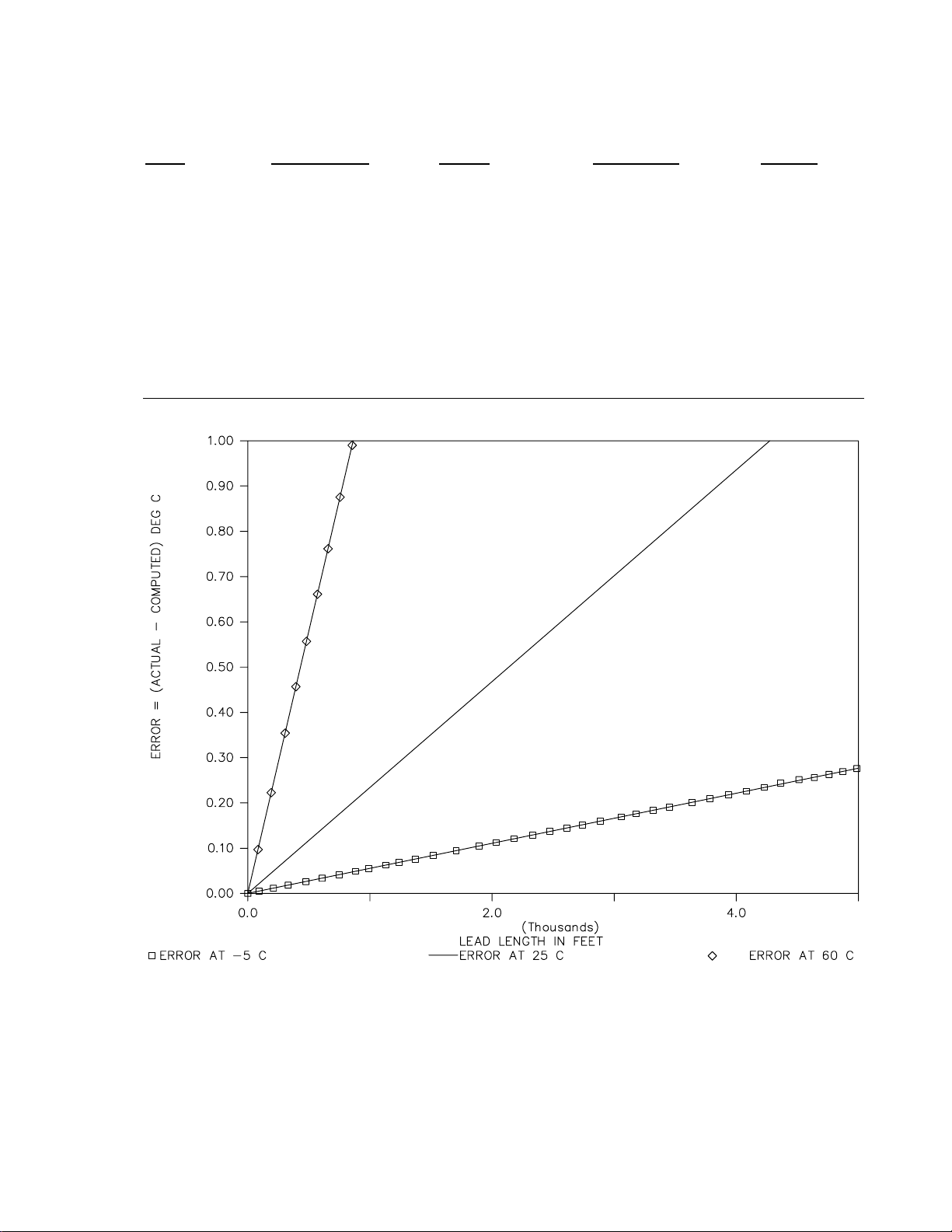

The accuracy of the temperature measurement

is a function of the following factors listed in

decreasing importance: 1) the thermistor's

interchangeability, 2) the resistance of the wire,

3) the linearization error, 4) the precision of the

bridge resistors, 5) the accuracy of the

datalogger's voltage measurement, and 6) the

temperature coefficient of the bridge resistors.

The interchangeability of the thermistor is

o

C although a thermistor with ±0.2oC

±0.5

interchangeability is an option. The error due to

wire resistance is normally less than ±0.5

(see Figure 2.2-1 through 2.2-4). The

linearization error is ±0.15

over the range from -5 to +60

ο

C (see Figure 2.2-5)

o

C. The precision

of the bridge resistors (±0.1%) results in a

o

tolerance of ±0.03

C. The accuracy of the

datalogger's voltage measurement (±0.015%)

o

results in a tolerance of ±0.01

C. The

temperature coefficient of the bridge resistors

o

(10 ppm/

±0.0003

C) results in a tolerance of

oC/o

C.

Errors four, five, and six mentioned above are

o

all less than ±0.03

C each and can probably be

ignored. The wire resistance is primarily an

offset error and its affect on the pressure

measurement is removed by the initial

calibration. Errors caused by the change in wire

resistance due to temperature, thermistor

interchangeability, and the linearization error are

not removed by the initial calibration.

Ignoring the offset errors, the remaining

temperature accuracy is expected to be about

o

C. The temperature correction for the

±0.7

vibrating wire measurement is typically less than

o

0.05 psi/

C. A ±0.7oC temperature error would

result in a 0.035 psi (±1.0 inch H2O) error on a

50 psi Full Scale range.

The thermistor, Dale Electronics part number

1C3001-B3 is the standard with an

o

interchangeability of ±0.5

C. The optional

thermistor, Dale Electronics part number

1C3001-C3 has an inter-changeability of

o

C. Both of the above thermistors have the

±0.2

same resistance vs. temperature relationship as

o

C

the YSI thermistor number 44005.

The following table shows the relationship

between temperature and resistance, volts,

CR10 output, and linearization error.

o

TABLE 2.2-1. Temperature vs. Thermistor Resistance, V,

C, and Linearization Error

SENSOR

TEMP RESISTANCE, VOLTS CR10 ERROR

o

C OHMS OUT OUTPUT,oC

o

C

-5 12700 0.668449 -5.09136 -0.09136

-4 12050 0.692520 -4.02248 -0.02248

-3 11440 0.716743 -2.98315 0.016846

-2 10860 0.741399 -1.95557 0.044427

-1 10310 0.766400 -0.93843 0.061560

2-1

AVW1/AVW4

SENSOR

TEMP RESISTANCE, VOLTS CR10 ERROR

o

C OHMS OUT OUTPUT,oC

o

C

0 9796 0.791339 0.057084 0.057084

1 9310 0.816459 1.045822 0.045822

2 8851 0.841694 2.029469 0.029469

3 8417 0.867031 3.011520 0.011520

4 8006 0.892474 3.995450 -0.00454

5 7618 0.917902 4.979594 -0.02040

6 7252 0.943253 5.963992 -0.03600

7 6905 0.968616 6.954119 -0.04588

8 6576 0.993956 7.950259 -0.04974

9 6265 1.019160 8.949209 -0.05079

10 5971 1.044190 9.950388 -0.04961

11 5692 1.069107 10.95688 -0.04311

12 5427 1.093900 11.96879 -0.03120

13 5177 1.118368 12.97814 -0.02185

14 4939 1.142700 13.99297 -0.00702

15 4714 1.166697 15.00510 0.005100

16 4500 1.190476 16.01954 0.019545

17 4297 1.213945 17.03265 0.032652

18 4105 1.237011 18.04042 0.040421

19 3922 1.259826 19.04982 0.049822

20 3748 1.282314 20.05785 0.057855

21 3583 1.304393 21.06127 0.061275

22 3426 1.326119 22.06310 0.063105

23 3277 1.347418 23.06048 0.060484

24 3135 1.368363 24.05747 0.057474

25 3000 1.388888 25.05167 0.051679

26 287 1.408926 26.04042 0.040428

27 2750 1.428571 27.02901 0.029014

28 2633 1.447932 28.02396 0.023968

29 2523 1.466619 29.00577 0.005777

30 2417 1.485089 29.99901 -0.00098

31 2317 1.502945 30.98300 -0.01699

32 2221 1.520496 31.97513 -0.02486

33 2130 1.537515 32.96311 -0.03688

34 2042 1.554339 33.96711 -0.03288

35 1959 1.570549 34.96239 -0.03760

36 1880 1.586294 35.95767 -0.04232

37 1805 1.601537 36.95011 -0.04988

38 1733 1.616448 37.95060 -0.04939

39 1664 1.631002 38.95742 -0.04257

40 1598 1.645169 39.96844 -0.03155

41 1535 1.658925 40.98115 -0.01884

42 1475 1.672240 41.99263 -0.00736

43 1418 1.685090 42.99951 -0.00048

44 1363 1.697677 44.01695 0.016954

45 1310 1.709986 45.04335 0.043350

46 1260 1.721763 46.05610 0.056109

47 1212 1.733222 47.07191 0.071918

48 1167 1.744104 48.06568 0.065681

2-2

AVW1/AVW4

SENSOR

TEMP RESISTANCE, VOLTS CR10 ERROR

o

C OHMS OUT OUTPUT,oC

o

C

49 1123 1.754878 49.07873 0.078734

50 1081 1.765287 50.08636 0.086361

51 1040 1.775568 51.11067 0.110677

52 1002 1.785204 52.09809 0.098095

53 965 1.794687 53.09674 0.096746

54 929.6 1.803855 54.08849 0.088499

55 895.8 1.812697 55.07032 0.070322

56 863.3 1.821281 56.04819 0.048193

57 832.2 1.829571 57.01651 0.016519

58 802.3 1.837613 57.97896 -0.02103

59 773.7 1.845372 58.92977 -0.07022

60 746.3 1.852867 59.86962 -0.13037

FIGURE 2.2-1. Temperature Measurement Error at Three Temperatures as a Function of Lead

Length. Wire is 22 AWG with 16 ohms per 1000 feet.

2-3

AVW1/AVW4

FIGURE 2.2-2. Temperature Measurement Error on a 1000 foot Lead. Wire is 22 AWG with 16

ohms per 1000 feet.

FIGURE 2.2-3. Temperature Measurement Error on a 3000 foot Lead. Wire is 22 AWG with 16

ohms per 1000 feet.

2-4

AVW1/AVW4

FIGURE 2.2-4. Temperature Measurement Error on a 5000 foot Lead. Wire is 22 AWG with 16

ohms per 1000 feet.

FIGURE 2.2-5. Thermistor Linearization Error

2-5

AVW1/AVW4

2.3 PROGRAMMING AND SENSOR HOOK-UP

Measure the thermistor with Instruction 4 using

a measurement range of 2500 mV fast, an

excitation voltage of 2500 mV, a delay of 1, and

a multiplier of 0.001. The resulting value is

linearized with Instruction 55 using the following

coefficients: C0 = -104.78, C1 = 378.11, C2 = -

611.59, C3 = 544.27, C4 = -240.91, C5 =

43.089. The output is in degrees Celsius and

o

covers the range from -5

C to +60oC. Due to

the small current requirement, up to 118

thermistors could theoretically be powered by

one excitation channel.

When measuring the Geokon temperature

through CSI's AVW1 or AVW4, see Sections 4

or 5 respectively for hook up information.

NOTE: This manual covers AVW1's with

serial number 1093 and up plus serial

numbers 1002, 1034, 1040A, 1041, 1042,

1051, 1052, 1055, 1057, 1058, 1059, 1069,

1071, 1073, 1076, 1080, 1084, 1086, 1087,

1088, 1088A, 1089A, 1090A, 1091A, and

1092A. This manual also covers AVW4s

with serial number 1045 and up plus serial

numbers 1034 and 1038. These serial

numbers mark a change in circuitry that

changes the excitation voltage for the

temperature measurement from -2500 mV

(before) to +2500 mV (after). The multiplier

also changed from -.001 (before) to +.001

(after). The values of the resistors in

locations B4 and C4 for the AVW1 and

locations D4 and E4 for the AVW4 were

changed to the values shown in the current

schematics.

When measuring the Geokon temperature

directly with the CR10, connect the leads and

bridge completion resistors as shown in Figure

2.3-1.

FIGURE 2.3-1. Direct Measurement of the

Geokon Thermistor

2-6

SECTION 3. VIBRATI NG WIRE MEASUREMENT

FIGURE 3.1-1. A Vibrating Wire Sensor

3.1 GENERAL

Figure 3.1-1 illustrates how an increase in

pressure on the diaphragm decreases the

tension on the wire attached to the diaphragm.

A decrease in the wire tension decreases the

resonant frequency in the same way that

loosening a string on a guitar decreases it's

frequency. Therefore, the resonant frequency

of the vibrating wire sensor decreases with

increasing pressure.

The Vibrating Wire Measurement Instruction

excites the "plucking" and "pickup" coils shown

in the above figure with a "swept" frequency. A

"swept" frequency is a group of different

frequencies that are sent one right after another

starting with the lowest frequency and ending

with the highest. The lowest and highest

frequencies are entered by the user in units of

hundreds of Hz. The CR10 requires 150 ms to

"sweep" through all of the frequencies. This

"swept" frequency causes the wire to vibrate at

each of the individual frequencies. Ideally, all of

the frequencies except the one matching the

resonant frequency of the wire will die out in a

very short time. The wire will vibrate with the

resonant frequency for a relatively long period of

time and as it does so it will cut the lines of flux

in the "plucking" and "pickup" coils inducing the

same frequency on the lines to the CR10. After

waiting for the non resonant frequencies to die

out (20 ms) the CR10 accurately measures how

much time it takes to receive a user specified

number of cycles. Knowing the length of time

and the number of cycles, the CR10 then

computes the square of the frequency

2

expressed in units of kHz

(= 1/T2 where T is the

period in milliseconds).

3.2 MULTIPLIER & OFFSET

The 50 psi vibrating wire pressure sensor used

in this example is the Geokon Model 4500SV-

50. It is vented to the atmosphere so it will not

be affected by changes in barometric pressure.

Each sensor is individually calibrated and has a

unique set of calibration coefficients. A

calibration sheet contains the Model Number,

Serial Number, Gage Factor (psi/digit),

Temperature Coefficient (psi/

(digits), zero Period (microseconds), calibration

o

Temperature (

C) and calibration Barometric

Pressure (inches Hg). A Geokon "digit" is

defined as the square of the frequency in kHz

multiplied by 1000 (1 digit = 0.001 kHz

2)

. The calibration coefficients for the sensor

Hz

with serial number 3998 are given below:

o

C), Zero Reading

2

= 1000

3-1

AVW1/AVW4

TABLE 3.2-1. Calibration Data for Sensor 3998

Gage Factor Temp. Coeff. Zero Rdg. Period Temp. Baro.

(psi/digit) (psi/oC)

(digit) (usecond) (oC) (in Hg)

0.0151 -0.0698 9431 325.6 24 29.51

The equation to change the CR10's output into

pressure (psi) exerted on the sensor is given

below:

3.3 SWEPT FREQUENCY, START AND END

The AVW1 and AVW4 were not designed for

P = [M * X] + B 3.2-1

where P is the pressure in psi and X is the

2

result of measurement Instruction 28 in kHz

2

where T is the period in milliseconds). The

1/T

( =

multiplier (M) and offset (B) are determined by

equations 3.2-2 and 3.2-3.

use below 1000 Hz.

In general, the starting frequency of the swept

frequency for this sensor should be just a bit

lower than the frequency at the Full Scale

pressure of the sensor. A rough rule of thumb

would put the starting frequency at two thirds

that of the ending frequency. Almost always the

M = -1000(digits/kHz

2

) * Gage Factor 3.2-2

starting frequency should not be lower than half

of the ending frequency.

where M is the multiplier in psi/(kHz

Gage Factor is found on the Calibration Sheet

in psi/digit.

B = Po + [Gage Factor * Zero Reading] 3.2-3

where B is the offset in psi and Po is the

pressure in psi at the time of calibration. For

2

) and the

Start Freq. < ([Full Scale Pressure - (Gage

Factor * Zero

Reading)]/M)0.5 * 1000 Hz/kHz 3.3-1

Start Freq. < ([50psi - (0.0151psi/digit *

9431digits)]/

vibrating wire sensors not vented to the

atmosphere, Po is the barometric pressure

[-15.1psi/kHz

2])0.5

* 1000 Hz/kHz

["Baro."(in Hg) * 0.49116 (psi/in Hg)] at the time

of calibration. For the vented sensors, Po is 0

Start Freq. < 2474 Hz or 24 hundred Hz

psi. The Gage Factor (psi/digit) and Zero

Reading (digits) are found on the Calibration

Sheet.

In general, the ending frequency of the swept

frequency for this sensor should be just a bit

higher than the frequency at Zero Pressure.

Example: Using sensor number 3998, the

multiplier, offset, and equation for pressure

would be:

End Freq. > ([Zero Pressure - (Gage Factor *

Zero Reading)]/M)

0.5

2

M = (-1000 digits/kHz

M = -15.1 psi/(kHz

) * 0.0151 psi/digit

2

)

B = 0.0 psi + (0.0151 psi/digit * 9431 digits)

B = 142.4 psi

P = [-15.1 psi/(kHz

2

) * X (kHz2)] + 142.4 psi

3-2

* 1000 Hz/kHz 3.3-2

End Freq. > ([0.0psi - (0.0151psi/digit *

9431digits)]/

[-15.1psi/kHz

2])0.5

* 1000 Hz/kHz

End Freq. > 3071 Hz or 31 hundred Hz

AVW1/AVW4

Some additional information concerning the

swept frequency may be found in Appendix C.

NOTE: Please remember that sealed (or

absolute) sensors calibrated near sea level

will read negative at higher elevations due

to the decrease in barometric pressure with

increasing elevation. In most cases the

solution is to load the sensor with extra

external pressure to cause it to operate in

its calibrated range. For example, a sealed

0 to 5 psi sensor used at 10,000 feet

elevation would have to be placed under

10.6 feet of water (4.6 psi) in order to read 0

psi. This is because the barometric

pressure at 10,000 feet is about 4.6 psi

lower than at sea level.

3.4 RESOLUTION VS. "# OF CYCLES"

CSI and Geokon recommend that the number

of cycles measured be between 200 and 500.

Five hundred cycles would probably be the

optimum for most applications. The

measurement of more than 500 cycles is not

recommended without testing. Some sensors,

for example, will not vibrate a full 1000 cycles at

all pressures in their pressure range.

For the sake of this discussion we will define the

resolution of the vibrating wire measurement as

plus or minus three standard deviations (±3 SD)

of the vibrating wire measurement. The

standard deviation of the measurement in psi is

given by the following equation:

3

SD = (2*M*C)/(N*T

where M is the multiplier computed in 3.2-2. "C"

is 0.00015 ms which is the typical standard

deviation of a time interval measurement on the

CR10 using a 4 mV peak to peak signal with no

external noise. "N" is the number of cycles

timed to determine the period (T) in ms of the

signal being measured.

The standard deviation is greater when the

period is shorter. The period is shortest at zero

pressure so the "Period" at zero pressure given

in Table 3.2-1 is used for the example below:

)3.4-1

2

SD = (2*-15.1psi/(kHz

(500 * (325.6us/1000us/ms)

) * 0.00015ms)

3

SD = 0.00026246 psi

RESOLUTION = ±

0.00078738

psi

Resolution improves as the number of cycles

measured increases but it worsens as the

signal level decreases and as the noise

increases. The optimum resolution is obtained

when the number of cycles measured covers

one time constant (τ) of the decay of the signal.

Number of cycles = (τ/T)

where T is the period of the signal in

milliseconds and τ is the time in milliseconds

required for the signal to decay from its initial

peak to peak value to (0.368 * initial peak to

peak value). An oscilloscope is required to

measure the time constant. The time constants

of the Geokon sensors we have measured are

typically between one third second and one

second.

The amount of time required to make one

repetition of the vibrating wire measurement is

given below:

150. ms to sweep the frequency

20. ms delay

(1.5cycles + #cycles measured) * period of the

signal in ms

3.5 TEMPERATURE CORRECTION

The equation used to remove errors caused by

changes in the sensor's temperature is found

below:

Pt = P + (TEMP. COEFF.)*(T - To) 3.5-1

where Pt(psi) is the temperature corrected

pressure. P(psi) is the uncorrected pressure

from equation 1. T(

temperature of the sensor. To(

"Temp." on the Calibration Sheet which is the

temperature of the sensor at the time of

calibration. TEMP. COEFF.(psi/

found on the Calibration Sheet. It is important

to note that the "TEMP. COEFF." can be either

positive or negative.

o

C) is the current

o

C) is the

o

C) is also

3-3

AVW1/AVW4

Example: Using sensor number 3998 and

assuming a sensor temperature of 15

corrected pressure would be:

o

Pt = P psi + (-0.0698 psi/

= P psi + 0.6282 psi

C)*(15oC - 24oC)

3.6 DELAY BETWEEN MEASUREMENTS

The vibrating wire sensor should not be excited

more often than once every five time constants

if high resolution is important. If more than one

repetition is specified the "delay before

excitation applied" parameter can be used to

ensure the proper amount of delay between

excitations. Excitation of the sensor while the

wire is still vibrating can cause the signals to

add or subtract (in phase or out of phase)

causing the wire to vibrate excessively hard or

almost not at all.

o

C, the

If two back to back measurements are required

they can be done one of two ways. With the

AVW4 the repetitions parameter must be set to

2--. The "--" instructs the CR10 to excite both

sensors, delay 20 ms, measure the first sensor,

and then measure the second sensor. There is

no delay or re-application of the excitation

between the measurements. Back to back

measurements require that the sum of the

number of cycles measured on each sensor not

exceed the time constant of the last sensor or

the signal may have become too week to be

measured. (e.g., two sensors measured

separately, each having a time constant equal

to 700 cycles would have to be measured back

to back with a maximum of 350 cycles.) Back

to back measurements with two AVW1s and

two excitation channels can be done simply by

entering Instruction 28 twice, once for the first

sensor and once for the second. In this case

the second AVW1 measurement will begin 170

milliseconds after the first one ended.

3-4

SECTION 4. THE AVW1

4.1 GENERAL

The AVW1 contains circuitry needed to

interface Geokon's 4500 series vibrating wire

sensor to the CR10. The AVW1 is designed to

interface one vibrating wire sensor (temperature

and pressure) to two single ended CR10

channels. The AVW1 has no quiescent current

drain. The current drain during the very short

(2.4 ms) temperature measurement is .4 mA or

lower. The current drain during the vibrating

wire measurement (170 ms to 500 ms) is 32

mA. The AVW1 is 2.5 inches long by 2.5

inches wide by 1.4 inches high. The silk

screening for the AVW1 is shown below.

4.2 SENSOR HOOK UP

FIGURE 4.1-1. The AVW1

FIGURE 4.2-1. Hook up to AVW1

4.3 WELL MONITORING EXAMPLE

In this example the vibrating wire sensor is used

to monitor the Distance from the lip of the well

to the water surface in a 150 foot well. The

water level is expected to stay within 40 to 80

feet of the lip so the 50 psi pressure sensor is

placed approximately 100 feet below the lip of

the well. The same sensor used in Section 3.2

for the computation of the multiplier etc. (serial

number 3998) will be used again in this

example.

In the example program that follows the depth

of water above the vibrating wire sensor is

measured in psi and then converted into feet of

4-1

AVW1/AVW4

water. The water depth above the sensor is

referred to as the "Reading" in the following

equation. The Reading decreases with

increasing "Distance" from lip of well to water

surface so the Distance is computed by

subtracting the Reading from the Offset as

shown in the above figure and the following

equation.

Distance = Offset - Reading

feet (of head above the sensor). Solving the

above equation for the Offset, one obtains:

Offset = Initial Distance + Initial Reading

= 47.23 feet + 54.832 feet

= 102.062 feet

The following is a sample program that

measures the temperature and frequency of the

vibrating wire sensor and stores the

o

temperature (

C), pressure (psi), temperature

corrected pressure (psi), correction factor (psi),

temperature corrected pressure (feet of H2O),

and Distance from the lip to the water surface

(feet) in Input Locations 1-6 respectively. This

example assumes the sensor has been

connected as shown in Figure 4.2-1.

Program: AVW & CR10 USED TO MEASURE

1 GEOKON VIBRATING WIRE SENSOR.

* 1 Table 1 Programs

01: 10 Sec. Execution Interval

01: P4 Excite,Delay,Volt(SE)

01: 1 Rep

02: 15 2500 mV fast Range

03: 1 IN Chan

04: 1 Excite all reps w/EXchan 1

05: 1 Delay (units .01sec)

06: 2500 mV Excitation

07: 1 Loc [:TEMP C]

08: .001 Mult

09: 0.0000 Offset

02: P55 Polynomial

01: 1 Rep

02: 1 X Loc TEMP C

03: 1 F(X) Loc [:TEMP C]

04: -104.78 C0

05: 378.11 C1

06: -611.59 C2

07: 544.27 C3

08: -240.91 C4

09: 43.089 C5

FIGURE 4.3-1. Well Monitoring Example

The "Initial Distance" to the water surface is

measured with a chalked line to be 47.23 feet

below the lip. The "Initial Reading" is 54.832

4-2

AVW1/AVW4

03: P28 Vibrating Wire (SE)

01: 1 Rep

02: 2 IN Chan

03: 1 Excite all reps w/EXchan 1

04: 24 Starting Freq. (units=100 Hz)

05: 31 End Freq. (units=100 Hz)

06: 500 No. of Cycles

07: 0000 Rep delay (units=.01sec)

08: 2 Loc [:PRESS psi]

09: -15.1 Mult

10: 142.4 Offset

04: P34 Z=X+F

01: 1 X Loc TEMP C

02: -24 F calibration "Temp." in C

03: 4 Z Loc [:(T-To)*C]

05: P37 Z=X*F

01: 4 X Loc (T-To)*C

02: -.0698 F "Temp. Coeff."

03: 4 Z Loc [:(T-To)*C]

06: P33 Z=X+Y

01: 2 X Loc PRESS psi

02: 4 Y Loc (T-To)*C]

03: 3 Z Loc [:Pt psi]

07: P37 Z=X*F Converts psi to

negative ft H20

01: 3 X Loc Pt psi

02: -2.3067 F

03: 5 Z Loc [:-Pt FEET H20]

08: P34 Z=X+F Adds the Offset to the

negative of the Reading to

obtain the Distance from lip of

the well to water surface.

01: 5 X Loc -Pt FEET H20

02: 102.06 F OFFSET

03: 6 Z Loc [:DISTANCE FEET]

09: P End Table 1

First 99 Input Location Labels:

1:TEMP C

2:PRESS psi

3:Pt psi

4:(T-To)*C

5:Pt Ft H20

6:DISTAN FT

4-3

AVW1/AVW4

This is a blank page.

4-4

SECTION 5. THE AVW4

5.1 GENERAL

The AVW4 contains circuitry needed to

interface Geokon's 4500 series vibrating wire

sensor to the CR10. The AVW4 is designed to

interface four vibrating wire sensors

(temperature and pressure) to eight single

ended CR10 channels. The AVW4 has no

quiescent current drain. The current drain

during the very short (2.4 ms) temperature

measurement is .4 mA per channel or lower.

The current drain during each vibrating wire

measurement (170 ms to 500 ms) is 32 mA.

The AVW4 is 6.7 inches long by 2.9 inches wide

by 1.4 inches high.

FIGURE 5.1-1. The AVW4

5-1

AVW1/AVW4

5.2 SENSOR HOOK UP

FIGURE 5.2-1. Hook up for AVW4

5.3 DATALOGGER PROGRAMMING

The following is a sample program that

measures four sealed Geokon sensors and

stores the temperature, pressure, pressure

corrected for temperature, and barometric

corrected pressure in psi in Input Locations 1..4,

5..8, 9..12, and 10..12 respectively. The

example utilizes the calibration data given

previously from sensor number 3998. The first

sensor measures barometric pressure only and

is used to remove atmospheric pressure

changes from the readings on the other three

sensors. This example assumes the sensors

have been connected as shown in the sensor

hookup diagram.

5-2

Program: AVW4 & CR10 USED TO MEASURE

4 GEOKON SENSORS. THE FIRST SENSOR

SERVES AS A BAROMETER AND IS

SUBTRACTED FROM THE OTHER THREE

TO MEASURE THREE WATER PRESSURES

IN PSI EVERY FIVE MINUTES.

* 1 Table 1 Programs

01: 300 Sec. Execution Interval

01: P4 Excite,Delay,Volt(SE)

01: 4 Reps

02: 15 2500 mV fast Range

03: 1 IN Chan

04: 1 Excite all reps w/EXchan 1

05: 1 Delay (units .01sec)

06: 2500 mV Excitation

07: 1 Loc [:TEMP C #1]

08: .001 Mult

09: 0.0000 Offset

AVW1/AVW4

02: P55 Polynomial

01: 4 Reps

02: 1 X Loc TEMP C #1

03: 1 F(X) Loc [:TEMP C #1]

04: -104.78 C0

05: 378.11 C1

06: -611.59 C2

07: 544.27 C3

08: -240.91 C4

09: 43.089 C5

03: P28 Vibrating Wire (SE)

01: 4 Reps

02: 5 IN Chan

03: 1 Excite all reps w/EXchan 1

04: 24 Starting Freq. (units=100 Hz)

05: 31 End Freq. (units=100 Hz)

06: 500 No. of Cycles

07: 500 Rep delay (units=.01sec) 5

SEC DELAY BETWEEN

MEASUREMENTS

08: 5 Loc [:P psi #1]

09: 1 Mult

10: 0 Offset

04: P53 Scaling Array (A*loc +B)

APPLY MULT & OFFSET

01: 5 Start Loc [:P psi #1]

02: -15.1 A1

03: 142.4 B1

04: -15.1 A2

05: 142.4 B2

06: -15.1 A3

07: 142.4 B3

08: -15.1 A4

09: 142.4 B4

07: P34 Z=X+F ASSUMES

CALIBRATION TEMP. = 24

01: 1-- X Loc TEMP C #1

02: -24 F

03: 17-- Z Loc [:T-To*C #1]

08: P36 Z=X*Y

01: 13-- X Loc Cpsi/C #1

02: 17-- Y Loc T-To*C #1

03: 17-- Z Loc [:T-To*C #1]

09: P33 Z=X+Y

01: 5-- X Loc psi #1

02: 17-- Y Loc T-To*C #1

03: 9-- Z Loc [:Pt psi #1]

10: P95 End

FOLLOWING THREE INSTRUCTIONS

SUBTRACT THE BAROMETRIC PRESSURE

FROM THE THREE WATER PRESSURES

11: P35 Z=X-Y

01: 10 X Loc Ptb psi #2

02: 9 Y Loc Pt psi #1

03: 10 Z Loc [:Ptb psi #2]

12: P35 Z=X-Y

01: 11 X Loc Ptb psi #3

02: 9 Y Loc Pt psi #1

03: 11 Z Loc [:Ptb psi #3]

13: P35 Z=X-Y

01: 12 X Loc Ptb psi #4

02: 9 Y Loc Pt psi #1

03: 12 Z Loc [:Ptb psi #4]

o

C

05: P53 Scaling Array (A*loc +B)

LOADS TEMP. COEFF.

01: 13 Start Loc [:Cpsi/C #1]

02: 0 A1

03: -.0698 B1

04: 0 A2

05: -.0698 B2

06: 0 A3

07: -.0698 B3

08: 0 A4

09: -.0698 B4

06: P87 Beginning of Loop

TEMPERATURE

CORRECTION

01: 00 Delay

02: 4 Loop Count

First 99 Input Location Labels:

1:TEMP C #1 11:Ptbpsi #3

2:TEMP C #2 12:Ptbpsi #4

3:TEMP C #3 13:Cpsi/C #1

4:TEMP C #4 14:Cpsi/C #2

5:P psi #1 15:Cpsi/C #3

6:P psi #2 16:Cpsi/C #4

7:P psi #3 17:T-To*C #1

8:P psi #4 18:T-To*C #2

9:Pt psi #1 19:T-To*C #3

10:Ptbpsi #2 20:T-To*C #42

5-3

AVW1/AVW4

This is a blank page.

5-4

APPENDIX A. PRESSURE CONVERSION CHART

A-1

This is a blank page.

APPENDIX B. SCHEMATICS AND STUFFING CHARTS FOR

AVW1 AND AVW4

B-1

APPENDIX B. SCHEMATICS AND STUFFING CHARTS FOR AVW1 AND AVW4

B-2

APPENDIX B. SCHEMATICS AND STUFFING CHARTS FOR AVW1 AND AVW4

B-3

APPENDIX B. SCHEMATICS AND STUFFING CHARTS FOR AVW1 AND AVW4

B-4

APPENDIX B. SCHEMATICS AND STUFFING CHARTS FOR AVW1 AND AVW4

B-5

APPENDIX B. SCHEMATICS AND STUFFING CHARTS FOR AVW1 AND AVW4

This is a blank page.

B-6

APPENDIX C. THEORY AND ADDITIONAL DETAILS

C.1 SWEPT FREQUENCY THEORY

Example: f2 = 31 hundred Hz

f1 = 24 hundred Hz

X = (30*f1*f2)/(f2-f1)

= 3189

where f1 and a f2 are the starting and ending

frequencies in hundreds of Hz respectively.

One clock cycle (CC) occurs every 813.8 ns or

at a rate of 1.2288 mHz.

Rule #1: 65535 > X > 256

the 256 constraint is somehow due to an 8 bit

constraint. The 65535 constraint is some limit

where the swept frequency can no longer be

done in exactly 15 ms.

The minimum increment in frequency is 1 clock

cycle.

How many times do we have to change the half

period by 1 clock cycle to cover the frequency

range?

1/(F1 * 2) = 1/(2400 * 2) =

.208333 ms = half period

1/(F2 * 2) = 1/(3100 * 2) =

.161290 ms = half period

Change in half period =

.208333 - .161290 = .047043 ms

# of clock cycle increments to cover the

.047043 ms half period range is:

= (.047043 ms/.0008138 ms) =

57.81 freq. increments

How much time is there between frequency

increments to cover the frequency range in 15

ms?

time = 15 ms/58 frequency increments =

.2586 ms/freq. incr.

C.2 ADDITIONAL THEORY ON

MULTIPLIER AND OFFSET

The result (X) of Instruction #28 is:

X = 1/((t ms)2) =

1,000,000/((t s)2

where t is the period in milliseconds. Since

frequency (f) is the inverse of period, this can

also be expressed as:

X = (f kHz)2 =

[(f Hz)2]/1,000,000

C-1

This is a blank page.

This is a bla nk page.

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

sales@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringo wa Cent ra l

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda . (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...