Page 1

AM25T Solid State Multiplexer

Revision: 1/10

Copyright © 1995-2010

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The AM25T SOLID STATE MULTIPLEXER is warranted by CAMPBELL

SCIENTIFIC, INC. to be free from defects in materials and workmanship

under normal use and service for twelve (12) months from date of shipment

unless specified otherwise. Batteries have no warranty. CAMPBELL

SCIENTIFIC, INC.'s obligation under this warranty is limited to repairing or

replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective products.

The customer shall assume all costs of removing, reinstalling, and shipping

defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to repair@campbellsci.com

435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed to

Page 3

AM25T Solid State Multiplexer

Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. General .........................................................................1

1.1 AM25T Specifications..............................................................................1

1.2 Physical Description.................................................................................2

1.3 Operation..................................................................................................3

2. Installation....................................................................4

3. Datalogger to AM25T Wiring.......................................5

4. Sensor to AM25T Wiring .............................................6

4.1 Thermocouple Measurement....................................................................6

4.2 Differential Analog Measurements...........................................................7

4.3 Mixed Sensor Types.................................................................................7

5. General Measurement Considerations......................8

6. Datalogger Programming............................................8

6.1 CRBasic Programming.............................................................................8

6.1.1 Example CRBasic Programs.........................................................11

6.1.1.1 CR1000 Example Program 1...............................................11

6.1.1.2 CR1000 Example Program 2...............................................12

6.2 Edlog Programming................................................................................ 13

6.2.1 Example CR10(X) Programs........................................................14

6.2.2 Example CR23X Program ............................................................18

Appendices

A. Single-Ended Measurements.................................A-1

A.1 Directions for Single-Ended Measurements....................................... A-1

A.2 Indexing with Loops........................................................................... A-5

B. Differences Between the AM25T, AM416, and

the AM32........................................................................B-1

i

Page 4

AM25T Solid State Multiplexer Table of Contents

Figures

1. AM25T Thermocouple Multiplexer........................................................... 3

2. External Battery Connections .................................................................... 6

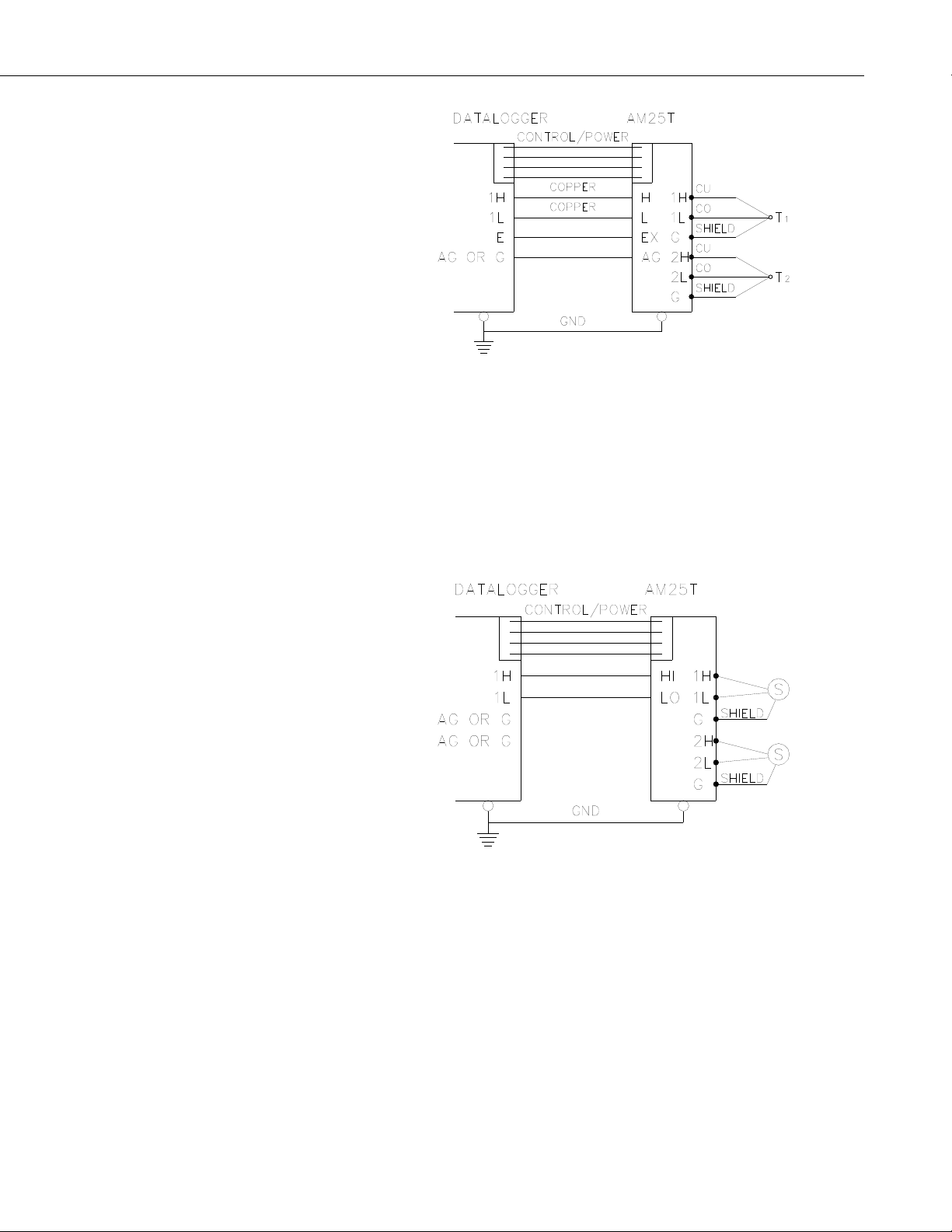

3. Differential Measurement of Type T Thermocouple................................. 7

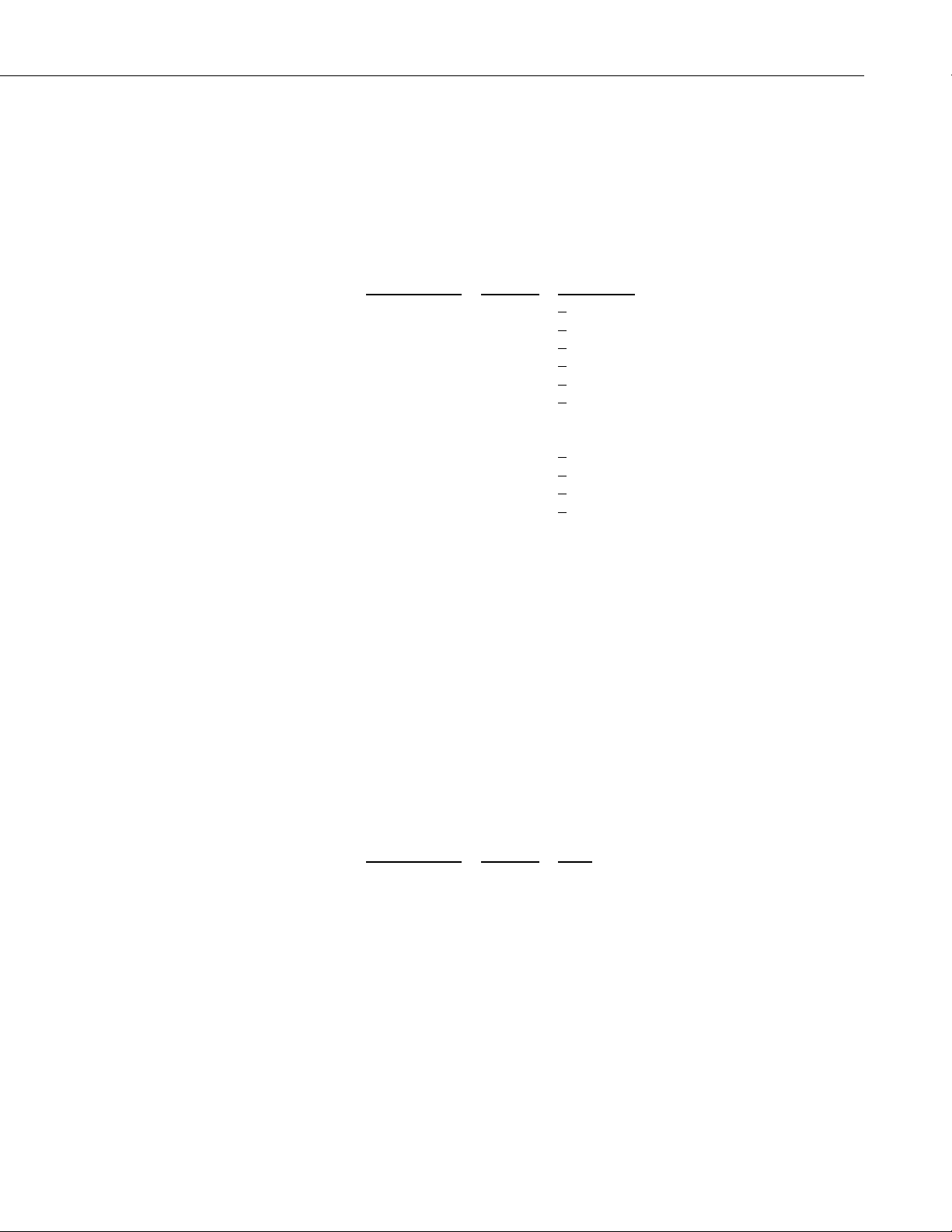

4. Differential Voltage Measurement............................................................. 7

A-1. Single-Ended Measurement of a Type T Thermocouple...................A-2

A-2. Single-Ended Measurement...............................................................A-5

Tables

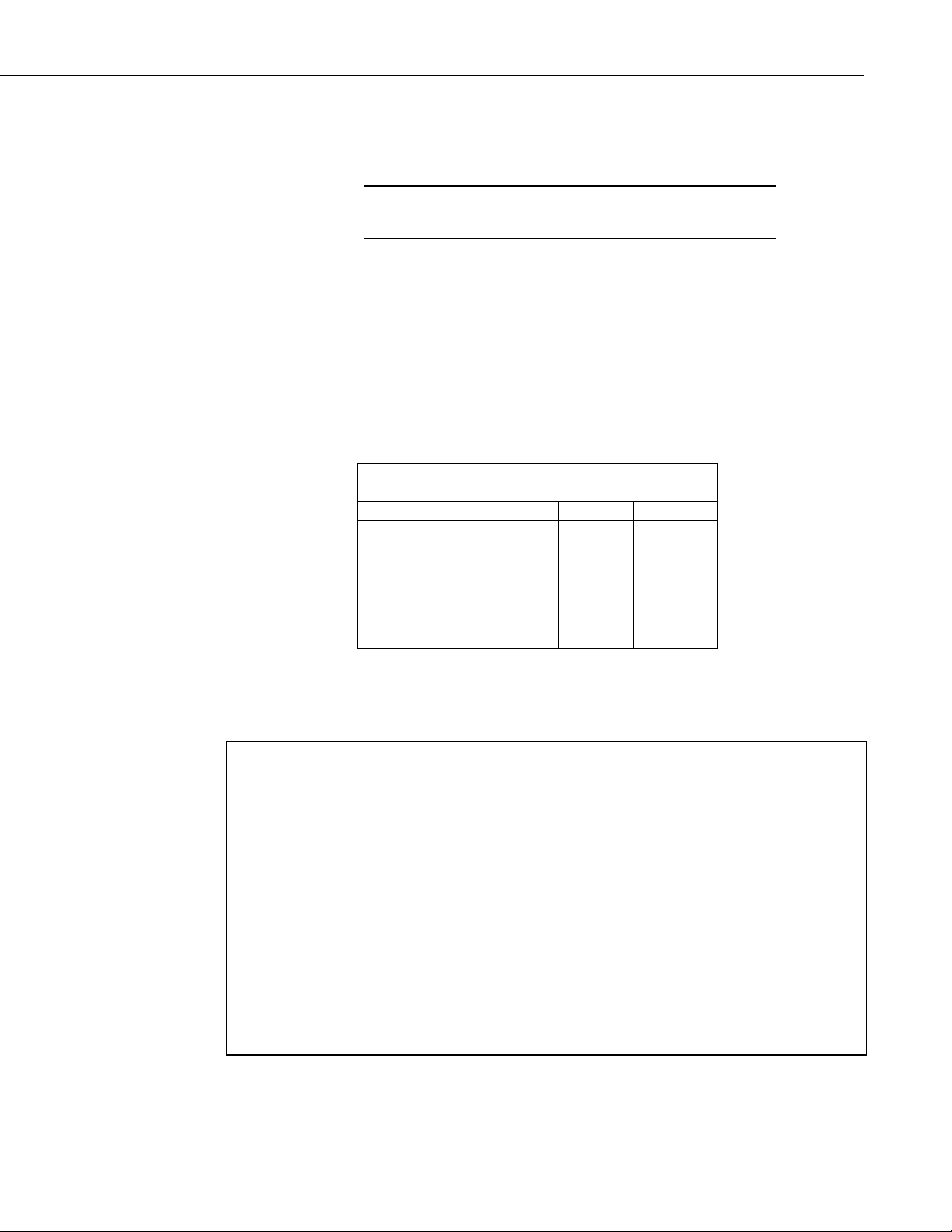

3-1. Datalogger to AM25T Wiring................................................................ 5

6-1. Wiring for CR1000 Example 1............................................................. 11

6-2. Wiring for CR1000 Example 2............................................................. 12

6-3. RTD Excitation Voltage and Measurement Range for AM25T

Multiplexers Prior to Serial Number 1839........................................ 14

6-4. Wiring for CR10(X) Examples............................................................. 14

6-5. Wiring for CR23X Example................................................................. 18

A-1. Values in Input Storage; Input Location Not Indexed.......................A-5

A-2. Values in Input Storage; with Input Location Index and without

Step Loop Index Instruction............................................................A-6

A-3. Values in Input Storage; with Input Location Index and Step

Loop Index Instruction....................................................................A-6

Program Examples

1. CR1000 Program Using One Instruction to Measure Both the

Reference Temperature and Thermocouples.....................................11

2. CR1000 Program that Uses Separate AM25T Instructions to

Measure the PRT and Thermocouples .............................................. 12

3. CR10(X) Program for Measuring 25 Type T Thermocouples or

Voltage Sensors Using a Differential Instruction.............................. 14

4. CR10(X) Program for Measuring 25 Type T Thermocouples with

the Differential Thermocouple Instruction and Long Lead

Length Compensation on the RTD Measurement............................. 16

5. CR23X Program for Measuring 25 Type T Thermocouples.................... 18

A-1. CR10 Program for Measuring 50 Type T Thermocouples or

Voltage Sensors Using a Single-Ended Instruction.........................A-2

A-2. 21X Program for Measuring 50 Type T Thermocouples or

Voltage Sensors Using Single-Ended Instruction ..........................A-3

A-3. Single-Ended Thermocouples, Input Location Not Indexed .............A-6

A-4. Measuring Single-Ended Thermocouples with the Input

Location Indexed and no Step Loop Index .....................................A-7

A-5. Measuring Single-Ended Thermocouples with the Input

Location Indexed and Step Loop Index .........................................A-7

ii

Page 5

AM25T Solid State Multiplexer

1. General

The AM25T Multiplexer increases the number of channels for measuring

thermocouples or voltage sensors with Campbell Scientific dataloggers. The

AM25T is positioned between the sensors and the datalogger. The datalogger

controls the AM25T's solid state relays, sequentially connecting each sensor to

the datalogger.

The AM25T is not suitable for resistive bridge measurements (high impedance

of the solid state relays) or multiplexing power (25 mA maximum switching

current).

A maximum of 25 thermocouples (differential voltage measurement) can be

multiplexed by an AM25T. Single-ended voltage measurements are not

recommended (Appendix A).

The AM25T must be used in a non-condensing environment. An enclosure is

required for field use. In applications where one or two multiplexers are

deployed in the field, the ENC12/14 can be used. The ENC16/18 can be used

to house several multiplexers at the same site.

1.1 AM25T Specifications

POWER

Unregulated 9.6 V to 16 V; 12 VDC Nominal

CURRENT DRAIN

Quiescent: 0.5 mA

Active: 1.0 mA (typical)

ENABLE

Inactive: < 0.9 V

Active: 3.5 to 5.0 V (7 V max.)

CLOCK

The relays are advanced on the falling edge of the clock pulse (transition from

>3.5 V to <1.5 V; 7 V max.). The minimum clock pulse width is limited by

the datalogger.

Minimum ON time 50 microseconds

Minimum OFF time 60 microseconds

1

Page 6

AM25T Solid State Multiplexer

OPERATING TEMPERATURE

Standard: -40°C to +85°C

RTD accuracy ±0.4°C

OPERATING HUMIDITY

Noncondensing: 0 to 95%

DIMENSIONS

Length: 23.6 cm (9.3”)

Width: 5.10 cm (2.0")

Depth: 13.2 cm (5.2”)

WEIGHT

0.91 kg (2.0 lbs)

3.6 kg (8.0 lbs); Shipping

EXPANDABILITY (nominal)**

2 AM25Ts per CR800 or CR850

4 AM25Ts per CR1000

6 AM25Ts per CR23X

4 AM25Ts per CR10(X)

6 AM25Ts per 21X

7 AM25Ts per CR7 725 Card

MAXIMUM CABLE LENGTH

Multiplexers can be located up to 305 m (1000 ft) from the datalogger. When

lightning protection is required, do not exceed 152 m (500 ft) in cable length. The

spark gaps will not fire if the heavy ground wire is longer than 152 m (500 ft).

TYPICAL RELAY RESISTANCE

500 Ω

MAXIMUM SWITCHING CURRENT

25 mA; Switching currents greater than 25 mA will damage the relays and render

them unusable.

**Assumes sequential activation of multiplexers and that each datalogger channel

is uniquely dedicated. If your application requires additional multiplexing

capability, please consult CSI for application assistance.

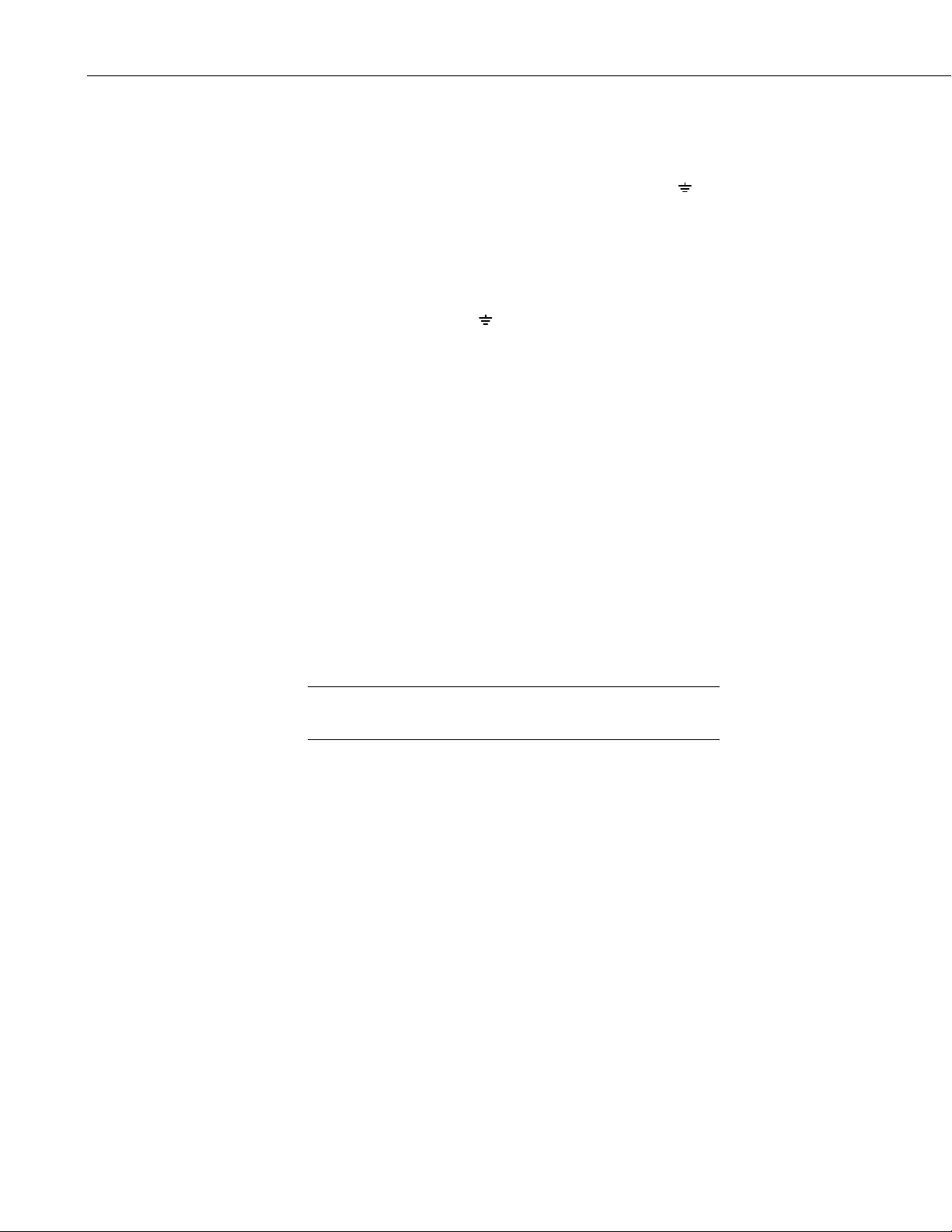

1.2 Physical Description

The AM25T is housed in an anodized aluminum case with a cover that will

help reduce temperature gradients across the AM25T's terminal strips

(Figure 1).

2

Page 7

AM25T

SOLID STATE THERMOCOUPLE

MULTIPLEXER

MADE IN USA

S / N

AM25T

SOLID STATE THERMOCOUPLE

MULTIPLEXER

LOGAN UTAH

Logan, Utah

AM25T Solid State Multiplexer

The terminal strips that run the length of the AM25T are for sensor

connections. All inputs are protected by spark gaps. All terminals accept

stripped and tinned lead wires up to 1.5 mm (0.059 inches) in diameter. A

strain-relief flange is located between the input terminals.

SOLID STATE THERMOCOUPLE

AM25T

MULTIPLEXER

MADE IN USA

RES

EX

CLK

13L

12L

12H

1H

HI

LO

AG

14H 14L13H

2H2L3H3L4H 4L 5H

1L+12

Logan, Utah

15H

16H 16L

15L

17H

18H

17L

FIGURE 1. AM25T Thermocouple Multiplexer

1.3 Operation

Measurement Terminals

Excitation Terminal

9L

AM25T

18L

19H 19L

5L

6H

SOLID STATE THERMOCOUPLE

MULTIPLEXER

20H 20L

8H

7L

6L

7H

MADE IN USA

21L

22H

21H

10H

11H

10L

9H

8L

23H

23L

22L

11L

S / N

1011

25H 25L

24L

24H

The AM25T is connected to the datalogger with eight insulated wires and a

large ground wire. These wires are used to power and control the multiplexer,

and connect the common analog inputs to the datalogger.

There are 25 differential channels on the AM25T. These channels are labeled

1H and 1L through 25H and 25L. The channels are sequentially connected and

reversed to the common channels HI and LO.

This terminal is used to excite the reference temperature (RTD) on the

AM25T. The excitation line is protected from transients with a transorb.

(Earlier versions of the AM25T, prior to 1839, used a zener diode for

protection. The diode limited the negative excitation voltage to -400 mV).

Power (12 V)

The AM25T requires a 9.6 to 16 VDC (12 VDC nominal) power supply.

In low current drain applications, it is convenient to power the AM25T from

the datalogger's battery. For power intensive operations, use a high Amp hour

12 VDC battery.

See Campbell Scientific’s application note on power supplies for information

on calculating the power requirements of your system.

3

Page 8

AM25T Solid State Multiplexer

Ground (GND)

Analog Ground (AG)

Reset (RES)

Each differential input channel has a ground terminal located next to it. The

ground terminal is common with the power ground and the ground lug on the

base. Connect the sensor shields to the ground terminals (

datalogger and multiplexer to a common earth ground via the grounding lug.

The analog ground (AG) terminal is the ground reference for the AM25T

reference temperature measurement. AG ground is not common with the other

ground terminals labeled (

datalogger ground as shown in Table 3-1.

A control port is used to operate the RES channel. The AM25T is reset and

activated by applying and holding 5 VDC to the RES channel. Once the

AM25T is activated, the AM25T reference temperature can be immediately

measured. The AM25T enters its quiescent state when the RES channel is set

to 0 VDC.

). Terminal AG must be connected to

). Always tie the

Clock (CLK)

NOTE

2. Installation

Pulsing the CLK channel sequentially advances the relays. A control port is

used to operate the CLK channel.

The first CLK pulse advances the relays to the reference temperature excitation

channel. The second CLK pulse advances the relays and connects HI and LO to

1H and 1L on the multiplexer.

Two clock pulses are required to advance to the next adjacent

sensor input channel on the AM25T.

The fourth CLK pulse advances the relays and connects HI and LO to 2H and

2L. The sixth CLK pulse advance the relays and connects HI and LO to 3H

and 3L. This sequence is continued for the remaining input channels.

The standard AM25T may be operated in a non-condensing environment. An

enclosure is required for field use.

Campbell Scientific’s ENC12/14 and ENC16/18 enclosures offer a degree of

protection against dust, spraying water, oil, falling dirt, or dripping non-corrosive

liquids. The enclosures contain plates for multiplexer mounting and conduit

bushings for cable entry. These enclosures are rain tight but not waterproof.

4

The enclosure lids have water resistant gaskets. Electricians putty is shipped

with the enclosures to seal around the cable entry to reduce the moisture

entering the enclosure. Desiccant should be kept in the enclosure and

exchanged regularly or as indicated by the humidity indicator.

Page 9

U-bolts are used to attach the enclosures to a 1.25" NPT pipe. The enclosure

may also be lag-bolted to a wall or similar flat surface.

Fasten the AM25T to the enclosure backplate. Securely fasten the leads to the

strain relief flange running between the AM25T terminal strips and install the

cover to reduce temperature gradients during thermocouple measurements.

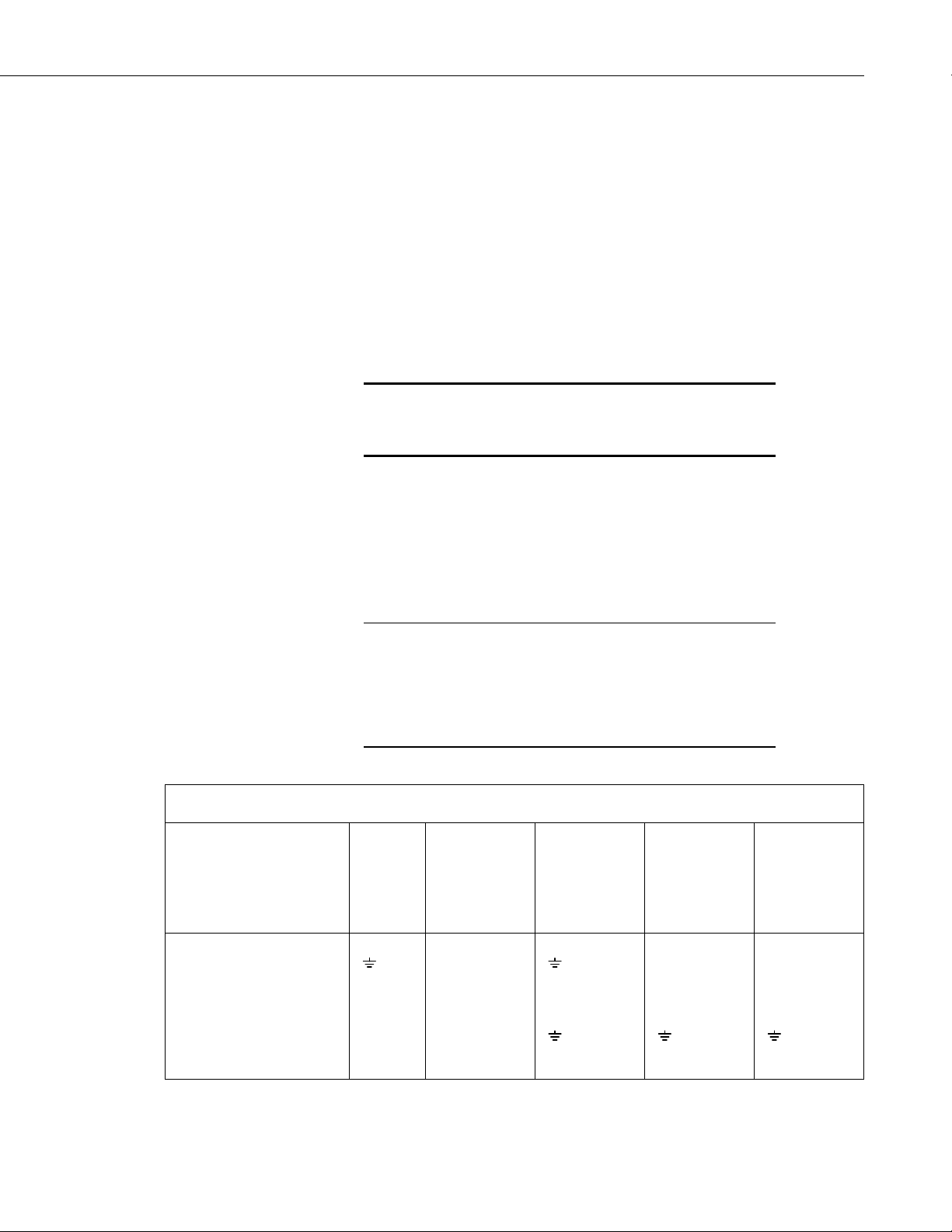

3. Datalogger to AM25T Wiring

When powering the AM25T from the same battery as the datalogger, connect

the datalogger to the AM25T as shown in Table 3-1. Two CABLE4CBL-L

cables typically carry control, power, and measurement signals between the

AM25T and the datalogger.

AM25T Solid State Multiplexer

WARNING

Caution

Function

+12V Power 12 V 12 V 12 V 12 V 12 V

Power and Shield Ground

Clock CLK Control Port Control Port Control Port Control Port

Reset RES Control Port Control Port Control Port Control Port

RTD Excitation EX Excitation Excitation Excitation Excitation

Analog Ground AG AG

Common High HI Diff. Chan. H Diff. Chan. H Diff. Chan. H Diff. Chan. H

Common Low LO Diff. Chan. L Diff. Chan. L Diff. Chan. L Diff. Chan. L

Do not reverse the polarity of the +12 Volt and Ground

leads. Damage to the multiplexer, sensors, and

datalogger will occur.

A separate battery can be used to power the AM25T. A separate battery might

be used when the AM25T is installed some distance from the datalogger.

Ground must be connected between the datalogger and the AM25T (Figure 2).

When leads in excess of 152 m (500 feet) are used to connect the datalogger to

the AM25T, it may be necessary to compensate for the drop in RTD excitation

voltage (program example 4).

All AM25T inputs are spark gap protected. To ensure that

the spark gaps fire, the large ground wire between the

AM25T and datalogger must not be greater than 152 m

(500 ft). In applications where lightning protection is not

required, limit the cable length between the AM25T and

datalogger to 305 m (1000 ft).

TABLE 3-1. Datalogger to AM25T Wiring

AM25T

CR10(X)

G

21X/CR7

CR23X

G G

CR800,

CR850,

CR1000,

CR3000,

CR5000,

CR9000X

5

Page 10

AM25T Solid State Multiplexer

FIGURE 2. External Battery Connections

4. Sensor to AM25T Wiring

This section and the examples describe differential voltage measurements of

thermocouples. It is possible to make single-ended measurements with the

AM25T, however they are more likely to have problems (Appendix A).

Shield wires are connected to the ground terminal next to the measurement

channel and left unattached at the sensor.

AM25T

4.1 Thermocouple Measurement

An internal reference RTD is located in the AM25T. This reference

temperature does not require an additional datalogger input to measure the

reference. The RTD is located in the center of the multiplexer on the strain

relief flange.

Thermal gradients between the AM25T's sensor input terminals and the RTD

cause errors in thermocouple readings. For example, a one degree gradient

between input terminals and the RTD will result in a one degree measurement

error. The central aluminum (strain relief) bar and the cover are designed to

reduce gradients.

Heat conduction along the thermocouple wire, into the terminal strips, can be

reduced by coiling some excess lead wire inside the enclosure.

The datalogger manual contains a thorough discussion on thermocouple

measurements and error analysis. Consult the datalogger manual for more

details.

For a differential voltage measurement of a thermocouple, wire the high side of

the thermocouple to the high side of a differential input channel and the low

side of the thermocouple to the low side of the channel. Thermocouples that

follow the U.S. industry standards use red insulation on the low side of the

thermocouple. Wire one thermocouple per differential input channel

(Figure 3).

6

Page 11

FIGURE 3. Differential Measurement of Type T Thermocouple

4.2 Differential Analog Measurements

Connect one differential sensor to a differential AM25T input channel.

Connect the sensor shields to the ground terminals next to the input channel.

Up to 25 differential sensors may be measured by one differential channel on

the datalogger (Figure 4).

AM25T Solid State Multiplexer

4.3 Mixed Sensor Types

Different sensors may be mixed on the AM25T. Additional loops and

measurement instructions will be required.

FIGURE 4. Differential Voltage Measurement

7

Page 12

AM25T Solid State Multiplexer

5. General Measurement Considerations

Cables have additional capacitance that increases the time required for a signal

to settle its true value. To reduce settling time, Campbell Scientific

recommends use of Teflon, polyethylene, or polypropylene insulation around

individual conductors. Do not use PVC as conductor insulation. PVC may be

used as a cable jacket.

With long lead lengths, a delay within the measurement instruction will allow

the capacitance of the lead wires to discharge before the measurement is made.

Consult the Measurement Section of your datalogger manual for more

information.

6. Datalogger Programming

The datalogger is programmed using either CRBasic or Edlog. Dataloggers

that use CRBasic include our CR800, CR850, CR1000, CR3000, CR5000, and

CR9000(X). Dataloggers that use Edlog include our CR10(X), 21X, CR23X,

and CR7. Both CRBasic and Edlog are included in PC400 and LoggerNet.

6.1 CRBasic Programming

In CRBasic, the AM25T instruction is used to control the AM25 T Multiplexer

with the datalogger. The instruction will automatically measure the PRT

incorporated in the AM25T and use it as a reference temperature for

thermocouple measurements.

Syntax

AM25T (Dest, Reps, Range, AM25TChan, DiffChan, TCType, TRef, ClkPort,

ResPort, ExChan, RevDiff, SettlingTime, Integ, Mult, Offset)

Datalogger

8

The AM25T instruction has the following parameters:

Dest: The Dest parameter is a variable in which to store the results of the

measurement.

Reps: The Reps parameter is the number of times the measurement should be

made. Measurements are made on consecutive channels. If the Reps parameter

Page 13

AM25T Solid State Multiplexer

is greater than 1, the Dest parameter must be a variable array. If 0 is entered,

the only measurement that is made is the reference temperature measurement.

Range: The Range parameter is the expected voltage range of the input from

the sensor. An alphanumeric or the numeric code can be entered.

The range code options depend on the datalogger used. For example, the range

codes for the CR1000 are as follows:

Alphanumeric

mV5000 0 +

mV2500 1 +

mV250 2 +

mV25 3 +

mV7_5 4 +

mV2_5 5 +

Numeric Description

5000 mV

2500 mV

250 mV

25 mV

7.5 mV

2.5 mV

autorange 6 mV2_5 to mV5000; datalogger tests for and

uses most suitable range

mV250C 20 +

mV25C 30 +

mV7_5C 40 +

mV2_5C 50 +

250 mV, checks for open input

25 mV, checks for open input

7.5 mV, checks for open input

2.5 mV, checks for open input

autorangeC 60 mV2_5 to mV5000; datalogger tests for and

uses most suitable range, checks for open input

Refer to the CRBasic help for range code options available for your

datalogger.

AM25TChan: The AM25TChan parameter specifies the starting input channel

for the multiplexer. If the Reps parameter is greater than 1, the additional

measurements will be made on sequential channels. If the channel is entered as

a negative number, all reps occur on the same channel.

DiffChan: The DiffChan argument is the number of the differential channel to

which the first AM25T is connected.

TCType: The TCType argument is used to identify the type of thermocouple

being measured. An alphanumeric or numeric code can be entered. Entering a

-1 records a voltage, in millivolts, instead of a thermocouple temperature.

Alphanumeric

Numeric Type

mV -1 Outputs a voltage, in millivolts

TypeT 0 Copper Constantan

TypeE 1 Chromel Constantan

TypeK 2 Chromel Alumel

TypeJ 3 Iron Constantan

TypeB 4 Platinum Rhodium

TypeR 5 Platinum Rhodium

TypeS 6 Platinum Rhodium

TRef: The TRef argument is the name of the variable which holds the result of

the reference temperature measurement.

9

Page 14

AM25T Solid State Multiplexer

ClkPort: The ClkPort argument is the control port that will be used to clo ck

the AM25T. One clock port may be used with several AM25Ts. A numeric

code is entered for this argument:

Description

Code

1 Control Port 1

2 Control Port 2

3 Control Port 3

4 Control Port 4

5 Control Port 5

6 Control Port 6

7 Control Port 7

8 Control Port 8

ResPort: The ResPort argument is the control port that will be used to enable

and reset the AM25T. Each AM25T must have a unique Reset port. A numeric

code is entered for this argument; refer to ClkPort above.

ExChan: The ExChan argument is the excitation channel that will b e used to

provide switched excitation for the PRT reference temperature measurement.

An alphanumeric or numeric code can be entered:

Alphanumeric

Numeric Description

0 0 Temperature not measured

VX1 1 Excitation channel 1

VX2 2 Excitation channel 2

VX3 3 Excitation channel 3

RevDiff: A constant is entered for the RevDiff parameter to determine whether

the inputs are reversed and a second measurement made. This function will

remove any voltage offset errors due to the datalogger measurement circuitry,

including common mode errors. Enabling this parameter will double

measurement time. False (or 0) = Do not make second measurement; True (or

1) = Reverse inputs and make second measurement.

SettlingTime: The SettlingTime parameter is the amount of time to delay after

setting up a measurement and before making the measurement. Refer to the

table below for default SettlingTimes.

Range Integration Settling Time

Entry

0 All 250 μs 450 μs (default)

0 All _50Hz 3 ms (default)

0 All _60Hz 3 ms (default)

100 All All μs entered

>

Integ: The Integ parameter is the amount of time, in microseconds, to integrate

a signal for the channel being measured.

10

Option Description

250 Performs a 250 microsecond integration.

_60Hz Performs a 16.667 millisecond integration; filters 60 Hz noise.

_50Hz Performs a 20 millisecond integration; filters 50 Hz noise.

Page 15

AM25T Solid State Multiplexer

Mult, Offset: The Mult and Offset parameters are each a constant, variable,

array, or expression by which to scale the results of the measurement. With a

multiplier (mult) of 1 and an offset of 0, the output is in degrees Celsius.

NOTE

The AM25T instruction must NOT be placed in a conditional

statement when running in pipeline mode.

6.1.1 Example CRBasic Programs

Both CRBasic example programs are written for CR1000 dataloggers. Other

CRBasic dataloggers are programmed similarly.

6.1.1.1 CR1000 Example Program 1

In this example, 25 type T thermocouples are connected to the AM25T. One

AM25T instruction will measure the AM25T’s PRT and the thermocouples.

Table 6-1 shows the wiring used with the example.

TABLE 6-1. Wiring for CR1000 Example 1

Function AM25T CR1000

+12V Power 12 V 12 V

Power and Shield Ground Gnd Gnd

Clock CLK C5

Reset RES C4

RTD Excitation EX EX1

Common High HI 1H

Common Low LO 1L

Example 1. CR1000 Program Using One Instruction to Measure Both the Reference

Temperature and Thermocouples

‘Declare Public Variables

Public Tref

Public TC (25)

‘Define Data Tables

DataTable (Dat15sec,1,-1)

DataInterval (0,15,Sec,10)

Sample (1,Tref,IEEE4)

Sample (25,TC(1),IEEE4)

EndTable

DataTable (Dat5min,1,-1)

DataInterval (0,5,Min,10)

Average (1,Tref,IEEE4,False)

Average (25,TC(1),IEEE4,False)

EndTable

11

Page 16

AM25T Solid State Multiplexer

‘Main Program

BeginProg

Scan (1,Sec,0,0)

AM25T (TC(),25,mV2_5C,1,1,TypeT,Tref,5,4,Vx1,True,0,250,1.0,0)

CallTable Dat15sec

CallTable Dat5min

NextScan

EndProg

6.1.1.2 CR1000 Example Program 2

In this example, one AM25T instruction is used to measure the on-board PRT,

and another AM25T instruction is used to measure ten type T thermocouples.

Table 6-2 provides the wiring for the example.

TABLE 6-2. Wiring for CR1000 Example 2

Function AM25T CR1000

+12 Power 12 V 12 V

Power and Shield Ground Gnd Gnd

Clock CLK 2

Reset RES 1

RTD Excitation EX EX1

Common High HI 1H

Common Low LO 1L

Example 2. CR1000 Program that Uses Separate AM25T Instructions to Measure the PRT

and Thermocouples

'Declare Variables and Units

Public Batt_Volt

Public RTemp_C

Public Temp_C(10)

Units Batt_Volt=Volts

Units RTemp_C=Deg C

Units Temp_C=Deg C

'Define Data Tables

DataTable(Table1,True,-1)

DataInterval(0,60,Min,0)

Sample(10,Temp_C(),FP2)

EndTable

'Main Program

BeginProg

Scan(30,Sec,1,0)

'Default Datalogger Battery Voltage measurement Batt_Volt:

Battery(Batt_Volt)

12

Page 17

AM25T Solid State Multiplexer

'Only the Reference Temperature is measured and stored in RTemp_C.

'To do this, enter 0 for the REP value

AM25T(RTemp_C,0,mV2_5C,1,1,TypeT,RTemp_C,2,1,1,True,0,250,1,0)

'Ten Type T (copper-constantan) are measured on the AM25T.

'Thermocouple measurements are stored in the Temp_C() variable

AM25T(Temp_C(1),10,mV2_5C,1,1,TypeT,RTemp_C,2,1,0,True,0,_60Hz,1,0)

'Call Data Tables and Store Data

CallTable(Table1)

NextScan

EndProg

6.2 Edlog Programming

The CR23X uses Instruction 134 for measuring the AM25T. Other Edlog

dataloggers use a program that contains a loop in which the multiplexer is

advanced to the next channel and the datalogger makes a measurement.

An outline of the looping datalogger program appears below. Steps two

through seven are used to measure the reference temperature for

thermocouples and could be skipped for voltage measurements.

1. Turn on the AM25T

2. Measure the output of the RTD full bridge

3. Find the resistance of the RTD

4. Calculate the reference temperature

5. Pulse the CLK line once (long lead length compensation only)

6. Measure the excitation at the full bridge (long lead length compensation

only)

7. Reset the AM25T by pulsing the RES line (long lead length compensation

only)

8. Loop through the measurements

a) Pulse the CLK line twice

b) Measure the sensor

c) Convert the engineering units

d) Go to a) until all the sensors have been measured

9. Turn off the AM25T

Earlier versions of the AM25T had a zener diode for transient protection on the

RTD excitation. This diode limited the negative excitation to -400 mV.

Instruction 6 used to measure the RTD uses both a positive and negative

excitation voltage. Table 6-3 lists recommended excitation voltages and

measurement ranges to use with these early multiplexers. The newer

multiplexers will work with the excitation voltages in Table 6-3, bu t the higher

excitations used in the example programs provide more immunity to noise.

AM25T multiplexers starting with serial number 1839 allow an excitation

voltage up to ± 5000 mV.

13

Page 18

AM25T Solid State Multiplexer

TABLE 6-3. RTD Excitation Voltage and Measurement Range for AM25T

Datalogger Temperature Range Excitation voltage Vs Range Vx Range

21X -40 to 85°C

CR10(X) -40 to 85°C

CR7 -40 to 85°C 350 mV

6.2.1 Example CR10(X) Programs

Multiplexers Prior to Serial Number 1839

250 mV

-24 to 65°C

-11 to 52°C

The two example CR10(X) programs in this section cover measuring

thermocouples and low level voltage sensors with the differential measurement

instruction. The 21X and CR7 are programmed similarly.

Input locations within the measurement loops must be indexed (--), see

Instruction 87 in the datalogger manual. To index a location, using Edlog ver

6.0 or greater, move the cursor to the Input location label and press “F4”. To

index a location with the datalogger keyboard, press the “C” key when

entering the location number and before the “A” key is pressed.

350 mV

350 mV

250 mV

± 5 mV

± 5 mV

± 7.5 mV

± 2.5 mV

± 15 mV ± 500 mV

± 500 mV

± 500 mV

± 2500 mV

± 250 mV

TABLE 6-4. Wiring for CR10(X) Examples

Function AM25T CR10(X)

+12V Power 12 V 12 V

Power and Shield Ground

Clock CLK C1

Reset RES C2

RTD Excitation EX E1

Analog Ground AG AG

Common High HI 1H

Common Low LO 1L

Example 3. CR10(X) Program for Measuring 25 Type T Thermocouples or Voltage Sensors

Using a Differential Instruction

*Table 1 Program

01: 10 Execution Interval (seconds)

01: Set Port(s) (P20) ;Configure Control Ports for 1 millisecond pulse

1: 9999 C8..C5 = nc/nc/nc/nc

2: 9933 C4..C1 = nc/nc/1ms/1ms

02: Do (P86) ;Turn On AM25T

1: 42 Set Port 2 High

G

14

Page 19

AM25T Solid State Multiplexer

03: Full Bridge (P6) ;Measure the output of the reference temp. full bridge

1: 1 Reps

2: 23 25 mV 60 Hz Rejection Range ;See Table 6-1 for older AM25T multiplexers

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 1200 mV Excitation ;See Table 6-1 for older AM25T multiplexers

6: 1 Loc [ RefTemp_C ]

7: -0.001 Mult

8: 0.09707 Offset

04: BR Transform Rf[X/(1-X)] (P59) ;Calculate RTD resistance R/R0

1: 1 Reps

2: 1 Loc [ RefTemp_C ]

3: 10.025 Multiplier (Rf)

05: Temperature RTD (P16) ;Calcula te reference temperature

1: 1 Reps

2: 1 R/R0 Loc [ RefTemp_C ]

3: 1 Loc [ RefTemp_C ]

4: 1.0 Mult

5: 0.0 Offset

06: Beginning of Loop (P87) ;Loop through thermocouple channels

1: 0 Delay

2: 25 Loop Count

07: Do (P86) ;Clock the AM25T twice

1: 71 Pulse Port 1

08: Do (P86)

1: 71 Pulse Port 1

09: Thermocouple Temp (DIFF) (P14) ;Measure the connected thermocouple

1: 1 Reps

2: 21 2.5 mV 60 Hz Rejection Range

3: 1 DIFF Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp (Deg. C) Loc [ RefTemp_C ]

6: 2-- Loc [ TC_1 ]

7: 1.0 Mult

8: 0.0 Offset

10: End (P95) ;End loop

11: Do (P86) ;Turn off AM25T

1: 52 Set Port 2 Low

15

Page 20

AM25T Solid State Multiplexer

Example 4. CR10(X) Program for Measuring 25 Type T Thermocouples with the Differential

Thermocouple Instruction and Long Lead Length Compensation on the RTD Measurement

*Table 1 Program

01: 10 Execution Interval (seconds)

01: Set Port(s) (P20) ;Configure Control Ports for 1 millisecond pulse

1: 9999 C8..C5 = nc/nc/nc/nc

2: 9933 C4..C1 = nc/nc/1ms/1ms

02: Do (P86)

1: 42 Set Port 2 High ;Turn On AM25T

03: Full Bridge (P6) ;Measure the output of the reference temp. full bridge, Vs

1: 1 Reps

2: 23 25 mV 60 Hz Rejection Range ;See Table 6-1 for older AM25T multiplexers

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 1200 mV Excitation ;See Table 6-1 for older AM25T multiplexers

6: 27 Loc [ Vs ]

7: 1 Mult

8: 0 Offset

04: Do (P86) ;Clock to advance to measure excitation

1: 71 Pulse Port 1

05: Full Bridge (P6) ;Measure the Excitation at the full bridge, Vx

1: 1 Reps

2: 25 2500 mV 60 Hz Rejection Range ;See Table 6-1 for older AM25T multiplexers

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 1200 mV Excitation ;See Table 6-1 for older AM25T multiplexers

6: 28 Loc [ Vx ]

7: .001 Mult

8: 0 Offset

06: Z=X/Y (P38) ;Calculate Vs/Vx

1: 27 X Loc [ Vs ]

2: 28 Y Loc [ Vx ]

3: 1 Z Loc [ RefTemp_C ]

07: Z=X*F (P37)

1: 1 X Loc [ RefTemp_C ]

2: -0.001 F

3: 1 Z Loc [ RefTemp_C ]

08: Z=X+F (P34)

1: 1 X Loc [ RefTemp_C ]

2: .09707 F

3: 1 Z Loc [ RefTemp_C ]

16

Page 21

AM25T Solid State Multiplexer

09: BR Transform Rf[X/(1-X)] (P59) ;Calculate RTD resistance R/R0

1: 1 Reps

2: 1 Loc [ RefTemp_C ]

3: 10.025 Multiplier (Rf)

10: Temperature RTD (P16) ;Calcula te reference temperature

1: 1 Reps

2: 1 R/R0 Loc [ RefTemp_C ]

3: 1 Loc [ RefTemp_C ]

4: 1.0 Mult

5: 0.0 Offset

11: Do (P86) ;Reset multiplexer

1: 72 Pulse Port 2

12: Beginning of Loop (P87) ;Loop through thermocouple channels

1: 0 Delay

2: 25 Loop Count

13: Do (P86) ;Clock the AM25T twice

1: 71 Pulse Port 1

14: Do (P86)

1: 71 Pulse Port 1

15: Thermocouple Temp (DIFF) (P14) ;Measure the connected thermocouple

1: 1 Reps

2: 21 2.5 mV 60 Hz Rejection Range

3: 1 DIFF Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp (Deg. C) Loc [ RefTemp_C ]

6: 2-- Loc [ TC_1 ]

7: 1.0 Mult

8: 0.0 Offset

16: End (P95) ;End loop

17: Do (P86) ;Turn off AM25T

1: 52 Set Port 2 Low

17

Page 22

AM25T Solid State Multiplexer

6.2.2 Example CR23X Program

Example 5. CR23X Program for Measuring 25 Type T Thermocouples

The CR23X uses Instruction 134 for measuring thermocouples or voltages

with the AM25T. Example 5 is a portion of a datalogger program that uses the

instruction to measure 25 type T thermocouples. Instruction 134 automatically

compensates for long lead lengths.

TABLE 6-5. Wiring for CR23X Example

Function AM25T CR23X

+12V Power 12 V 12 V

Power and Shield Ground

Clock CLK C1

Reset RES C2

RTD Excitation EX E1

Analog Ground AG

Common High HI 1H

Common Low LO 1L

G

;{CR23X}

;

*Table 1 Program

01: 1 Execution Interval (seconds)

01: AM25TMultiplexer (P134)

1: 25 Reps

2: 21 10 mV, 60 Hz Reject, Slow Range

3: 1 AM25T Channel

4: 1 DIFF Channel

5: 21 Exchan 1, 60 Hz Reject

6: 1 Clock Control

7: 2 Reset Control

8: 1 Type T (Copper-Constantan)

9: 1 Ref Temp (Deg. C) Loc [ RefTemp ]

10: 2 Loc [ TC_1 ]

11: 1.0 Mult

12: 0.0 Offset

18

Page 23

Appendix A. Single-Ended Measurements

Single-ended measurements with the AM25T are not recommended. This is not due to any

problem with the AM25T. Single-ended measurements have some problems that

differential measurements avoid. The problems with single-ended measurements are:

• Reduced noise rejection.

• Ground reference and Ground Loops.

A differential voltage measurement measures the voltage difference between two inputs.

Current is not allowed to flow through either input. A single-ended voltage measurement

measures the voltage of an input with respect to datalogger ground. Current can flow to

ground if there is a voltage potential to drive it. When current is flowing, the voltage will

change along the current path. For example, if a thermocouple’s measurement junction is

in electrical contact with a point on a car that is at +1 millivolt with respect to datalogger

ground, that voltage will be added to the thermocouple’s output, about a 2.5 degree error

on a copper-constantan thermocouple. Likewise, current flowing through the datalogger’s

ground can cause the ground reference to vary slightly along the terminal strip.

Despite the shortcomings, single-ended voltage measurements are possible with the

AM25T.

A.1 Directions for Single-Ended Measurements

If single-ended measurements are required, take the following precautions.

1. Use only shielded wire (this advice is just as pertinent for differential

measurements). Tie the sensor shields to the datalogger earth ground

through the multiplexer’s ground terminals.

2. Electrically insulate the measurement junctions of thermocouples. This

must be done to avoid errors caused by different ground potentials.

3. With a CR10(X), connect the AM25T ground to analog ground (AG)

instead of ground (G). Make sure any other power returns are connected

to ground (G).

CAUTION

When making single-ended measurements with a 21X,

power the AM25T, and any other peripherals, with a

separate power supply. Connect a single wire between a

21X ground and the negative terminal of the external

battery.

A-1

Page 24

Appendix A. Single-Ended Measurements

A.1.1 Thermocouple Measurements

Wire the high side of each thermocouple into an input terminal. The low side

of each thermocouple is wired into the adjacent ground terminal (Figure A-1).

FIGURE A-1. Single-ended Measurement of a Type T Thermocouple

Example A-1. CR10 Program for Measuring 50 Type T Thermocouples or Voltage Sensors

Using a Single-Ended Instruction

*Table 1 Program

01: 10 Execution Interval (seconds)

01: Set Port(s) (P20) ;Configure Control Ports for 1 millisecond pulse

1: 9999 C8..C5 = nc/nc/nc/nc

2: 9933 C4..C1 = nc/nc/1ms/1ms

02: Do (P86) ;Turn On AM25T

1: 42 Set Port 2 High

03: Full Bridge (P6) ;Measure the output of the reference temp. full bridge

1: 1 Reps

2: 24 250 mV 60 Hz Rejection Range ;See Table 6-1 for older AM25T multiplexers

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 1200 mV Excitation ;See Table 6-1 for older AM25T multiplexers

6: 1 Loc [ RefTemp_C ]

7: -0.001 Mult

8: 0.09707 Offset

04: BR Transform Rf[X/(1-X)] (P59) ;Calculate RTD resistance R/R0

1: 1 Reps

2: 1 Loc [ RefTemp_C ]

3: 10.025 Multiplier (Rf)

A-2

Page 25

Appendix A. Single-Ended Measurements

05: Temperature RTD (P16) ;Calcula te reference temperature

1: 1 Reps

2: 1 R/R0 Loc [ RefTemp_C ]

3: 1 Loc [ RefTemp_C ]

4: 1.0 Mult

5: 0.0 Offset

06: Beginning of Loop (P87) ;Loop through thermocouple channels

1: 0 Delay

2: 25 Loop Count

07: Step Loop Index (P90) ;Set index to advance 2 locations/loop

1: 2 Step

08: Do (P86) ;Clock the AM25T twice

1: 71 Pulse Port 1

09: Do (P86)

1: 71 Pulse Port 1

10: Thermocouple Temp (SE) (P13) ;Measure the connected thermocouple

1: 2 Reps

2: 21 2.5 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp (Deg. C) Loc [ RefTemp_C ]

6: 2-- Loc [ TC_1 ]

7: 1.0 Mult

8: 0.0 Offset

11: End (P95) ;End loop

12: Do (P86) ;Turn off AM25T

1: 52 Set Port 2 Low

Example A-2. 21X Program for Measuring 50 Type T Thermocouples or Voltage Sensors

Using a Single-ended Instruction

*Table 1 Program

01: 10 Execution Interval (seconds)

01: Do (P86) ;Turn On AM25T

1: 42 Set Port 2 High

02: Full Bridge (P6) ;Measure the output of the reference temp. full bridge

1: 1 Reps

2: 3 50 mV Slow Range ;See Table 6-1 for older AM25T multiplexers

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 2400 mV Excitation ;See Table 6-1 for older AM25T multiplexers

6: 1 Loc [ RefTemp_C ]

7: -0.001 Mult

8: 0.09707 Offset

A-3

Page 26

Appendix A. Single-Ended Measurements

03: BR Transform Rf[X/(1-X)] (P59) ;Calculate RTD resistance R/R0

1: 1 Reps

2: 1 Loc [ RefTemp_C ]

3: 10.025 Multiplier (Rf)

04: Temperature RTD (P16) ;Calcula te reference temperature

1: 1 Reps

2: 1 R/R0 Loc [ RefTemp_C ]

3: 1 Loc [ RefTemp_C ]

4: 1.0 Mult

5: 0.0 Offset

05: Beginning of Loop (P87) ;Loop through thermocouple channels

1: 0 Delay

2: 25 Loop Count

06: Step Loop Index (P90) ;Set index to advance 2 locations/loop

1: 2 Step

07: Do (P86) ;Clock the AM25T twice

1: 41 Set Port 1 High ;Setting high then low is faster than pulsing w/21X

08: Do (P86)

1: 51 Set Port 1 Low

09: Do (P86)

1: 41 Set Port 1 High

10: Do (P86)

1: 51 Set Port 1 Low

11: Thermocouple Temp (SE) (P13) ;Measure the connected thermocouples

1: 2 Reps

2: 1 5 mV Slow Range

3: 1 SE Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp (Deg. C) Loc [ RefTemp_C ]

6: 2-- Loc [ TC_1 ]

7: 1.0 Mult

8: 0.0 Offset

12: End (P95) ;End of loop

13: Do (P86) ;Turn off AM25T

1: 52 Set Port 2 Low

A-4

A.1.2 Single-Ended Voltage Measurement

Connect two single-end sensors to the differential AM25T input channel.

Connect the sensor shields to the ground terminals next to the input channel. Up

to 50 single-ended voltage sensors may be measured by two single-ended

datalogger channels (Figure A-2).

Page 27

FIGURE A-2. Single-Ended Measurement

A.2 Indexing with Loops

When a multiplexer is measured with a measurement instruction within a loop, the

input locations in which to store measurements must be indexed to the loop

counter so the measurement is stored in the next input location each pass through

the loop. When more than one repetition is used on the measurement instruction,

as in examples A-1 and A-2, Instruction 90 is used to set the increment of the loop

index. With Instruction 90 correctly used, each measurement will occupy its own

input location, without being overwritten by subsequent passes through the loop.

Appendix A. Single-Ended Measurements

NOTE

Take the following measurement case. Six Type T thermocouples are measured

with a CR10 and AM25T. The thermocouples are wired into the AM25T as

shown in Figure A-1. Instruction 13, with two repetitions, is u sed to measure the

thermocouples inside a loop. With a Loop Count of three and no indexing on the

thermocouple location (Example A-3), the measurements would be stored in

Input Storage as shown in Table A-1.

Note that after the third pass through the loop, only the last two measurements

are in Input Storage. The temperatures for TC_1 through TC_4 have been

overwritten.

The multiplexer control instructions are not included in the

example program fragment.

TABLE A-1. Values in Input Storage; Input Location Not Indexed

Pass 18 19 20 21 22 23

First TC_1 TC_2

Second TC_3 TC_4

Third TC_5 TC_6

When the Input Location is indexed (see Instruction 87 in the datalogger

manual), the Loop Index counter is added to the specified input location, each

pass through the loop, to determine where the measurement is stored. By

default, the index advances by one with each pass through the loop. Simply

indexing a measurement instruction’s Input Location works, when the

A-5

Page 28

Appendix A. Single-Ended Measurements

instruction has one repetition. If the instruction has two repetitions, then every

other Input Location will be over written. This effect is illustrated in Table A-

2. The program fragment in Example A-4 generated this effect.

NOTE

NOTE

The multiplexer control instructions are not included in the

example program fragment.

TABLE A-2. Values in Input Storage; with Input Location Index and

without Step Loop Index Instruction

Pass 18 19 20 21 22 23

First TC_1 TC_2

Second TC_3 TC_4

Third TC_5 TC_6

By adding Instruction 90 (Step Loop Index) with a value of two, the

measurements will be stored sequential in Input Storage. See Table A-3 and

the program fragment in Example A-5.

The multiplexer control instructions are not included in the

example program fragment.

TABLE A-3. Values in Input Storage; with Input Location Index and

Step Loop Index Instruction

Pass 18 19 20 21 22 23

First TC_1 TC_2

Second TC_3 TC_4

Third TC_5 TC_6

A-6

Example A-3. Single Ended Thermocouples, Input Location Not Indexed

01: Beginning of Loop (P87)

1: 0 Delay

2: 6 Loop Count

02: Thermocouple Temp (SE) (P13)

1: 2 Reps

2: 21 2.5 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp (Deg. C) Loc [ RefTemp ]

6: 18 Loc [ TC_1 ]

7: 1.0 Mult

8: 0.0 Offset

03: End (P95)

Page 29

Appendix A. Single-Ended Measurements

Example A-4. Measuring Single Ended Thermocouples with the Input Location Indexed and

no Step Loop Index

01: Beginning of Loop (P87)

1: 0 Delay

2: 6Loop Count

02: Thermocouple Temp (SE) (P13)

1: 2 Reps

2: 21 2.5 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp (Deg. C) Loc [ RefTemp ]

6: 18-- Loc [ TC_1 ]

7: 1.0 Mult

8: 0.0 Offset

03: End (P95)

Example A-5. Measuring Single Ended Thermocouples with the Input Location Indexed and

Step Loop Index

01: Beginning of Loop (P87)

1: 0 Delay

2: 6 Loop Count

02: Step Loop Index (P90)

1: 2 Step

03: Thermocouple Temp (SE) (P13)

1: 2 Reps

2: 21 2.5 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 1 Type T (Copper-Constantan)

5: 1 Ref Temp (Deg. C) Loc [ RefTemp ]

6: 18-- Loc [ TC_1 ]

7: 1.0 Mult

8: 0.0 Offset

04: End (P95)

A-7

Page 30

Appendix A. Single-Ended Measurements

A-8

Page 31

Appendix B. Differences Between the AM25T, AM416, and the AM32

The AM25T differs from Campbell Scientific's AM416 and AM32

multiplexers in the following ways:

1. The AM25T cannot be used to multiplex power and is not suitable for

bridge measurements because of the high impedance of the solid state

relays.

2. The AM25T switches 25 sets of 2 lines at time, (HI and LO) (2 x 25),

unlike the AM416 which switches 16 sets of 4 lines at a time (4 x 16).

The AM32 switches 32 sets of 2 lines at a time (2 x 32).

3. The AM25T has a built-in temperature reference RTD for thermocouple

measurements. It is 1000 Ohm RTD and has a temperature specification

of

+/-0.2°C an α of 0.00385.

4. The AM25T is packaged in an aluminum case that will decrease

temperature gradients across the multiplexer terminal strip. It has a large

aluminum bar through the center of the unit for temperature stabilization

and sensor cable strain relief.

5. The AM25T is smaller than the AM416 and AM32. It is packaged in a

vertical manner for a smaller footprint and requires less space for

mounting.

6. The AM25T has a ground path back to the datalogger for spark gap firing

and sensors shields via the grounding lug on the side. The AM25T

contains terminals and circuitry for sensor shield wires. This circuitry

allows sensor shield wires to be routed through the multiplexer and

grounded at the datalogger.

7. The AM25T contains spark gaps on all inputs and like the AM416

contains diodes between shields and power ground for transient

protection.

B-1

Page 32

Appendix B. Differences Between the AM25T, AM416, and the AM32

B-2

Page 33

Page 34

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...