INSTRUCTION MANUAL

AL200 ALERT2 Encoder,

Copyright © 2013- 2014

Campbell Scientific, Inc.

Modulator, and Sensor Interface

4/14

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 1

4. Quickstart .................................................................... 2

4.1 Stand-Alone Mode ............................................................................... 2

4.1.1 Physical Setup ............................................................................... 2

4.1.2 Configuring the AL200 ................................................................. 2

4.2 Datalogger Peripheral Mode ................................................................ 3

4.2.1 Physical Setup ............................................................................... 3

4.2.2 Configuring the AL200 ................................................................. 3

5. Overview ...................................................................... 4

6. Specifications ............................................................. 5

7. Installation ................................................................... 8

7.1 Configuring the AL200 ........................................................................ 8

7.1.1 Stand-alone Device ....................................................................... 9

7.1.2 Datalogger Peripheral ................................................................. 12

7.2 Mounting in an Enclosure .................................................................. 14

7.3 Grounding .......................................................................................... 14

7.4 Wiring ................................................................................................ 14

8. Operation ................................................................... 14

9. Maintenance .............................................................. 15

10. Troubleshooting........................................................ 16

11. Repair ......................................................................... 16

Appendices

Glossary .................................................................. A-1

A.

B. Cables and Connector Pin Descriptions .............. B-1

B.1 CS I/O .............................................................................................. B-1

B.2 RS-232 ............................................................................................. B-1

i

Table of Contents

B.3 USB ................................................................................................. B-2

B.4 Power ............................................................................................... B-2

B.5 Analog Radio Interface .................................................................... B-2

B.6 Sensor I/O Interface ......................................................................... B-3

B.7 GPS Input ........................................................................................ B-3

C. LED Indicators ......................................................... C-1

D. AL200 Settings ........................................................ D-1

E. AL200 USB Driver Installation Instructions .......... E-1

F. Updating the Operating System of the AL200 ...... F-1

G. List of Recommended Sensor IDs ......................... G-1

H. Calculating Multipliers and Offsets ....................... H-1

Figure

Tables

5-1. AL200 .................................................................................................. 5

6-1. AL200 dimensions .............................................................................. 6

B-1. CS I/O Pin Description .................................................................... B-1

B-2. RS-232 Pin Description ................................................................... B-1

B-3. USB Pin Description ....................................................................... B-2

B-4. Power Input Pin Description ........................................................... B-2

B-5. Radio Interface Pin Description ...................................................... B-3

B-6. Sensor I/O Pin Description .............................................................. B-3

B-7. GPS Input Pin Description .............................................................. B-3

C-1. GPS LED State Descriptions ........................................................... C-1

C-2. Serial LED State Descriptions ......................................................... C-1

C-3. Radio LED State Descriptions ......................................................... C-1

G-1. Recommended Sensor IDs .............................................................. G-1

ii

AL200 ALERT2 Encoder, Modulator, and

Sensor Interface

1. Introduction

The AL200 is an encoder, modulator, and sensor interface designed for use

both as a stand-alone device and as a peripheral to a Campbell Scientific

datalogger or third party Data Collection Platform (DCP). This device uses the

Automated Local Evaluation Real Time Protocol version 2 (ALERT2) and can

operate as both a remote ALERT2 transmitter and as an ALERT to ALERT2

concentrator and repeater.

For more information on the ALERT2 protocol, refer to the National

Hydrologic Warning Council’s ALERT2 Technical Working Group website:

http://www.hydrologicwarning.org/content.aspx?page_id=22&club_id=61721

8&module_id=83216.

2. Cautionary Statements

• GPS input gain, antenna gain less conductor losses, should not exceed 25

dBm.

• If protecting GPS input with coaxial surge protector, ensure that the

protector does NOT block DC voltages.

• Ensure maximum protection against electrical transients/surges. Install

coaxial surge protection on all antenna runs. Keep RS-232 and CS I/O

connections short.

• The AL200 is NOT powered over CS I/O.

• When powered over USB, the AL200 will not power up either the radio or

attached sensors.

• The device driver for the AL200 must be installed on your computer

before you can connect to the AL200 via USB. See Appendix E, AL200

USB Driver Installation Instructions, for instructions on installing the

device driver.

• Device Configuration Utility 2.05 or higher is required to configure the

AL200. The latest Device Configuration Utility can be downloaded from

our website, www.campbellsci.com/downloads.

3. Initial Inspection

Inspect the AL200 for any obvious signs of damage upon receipt. For each

AL200, the following items should be accounted for:

• QTY 1, AL200

• QTY 1, 2-pin mating screw terminal connector (pn 7843)

• QTY 2, 5-pin mating screw terminal connectors (pn 28750)

1

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

NOTE

• QTY 4, mounting grommets (pn 6044)

• QTY 4, mounting screws (pn 505)

• QTY 1, Micro-B USB cable (pn 27555)

4. Quickstart

There are two basic modes of operation for the AL200. For simplicity, these

will be referred to as stand-alone and datalogger peripheral modes.

4.1 Stand-Alone Mode

4.1.1 Physical Setup

• Attach a GPS antenna to the GPS SMA connector located on the side of

the AL200.

• Attach the desired sensors to the appropriate channels on the sensor input

connector.

4.1.2 Configuring the AL200

The device driver for the AL200 must be installed on your

computer before you can connect to the AL200 via USB. See

Appendix E, AL200 USB Driver Installation Instructions, for

instructions on installing the device driver.

1. Connect the supplied USB cable between a USB port on your computer

and the USB port on the AL200. The AL200 will be powered over the

USB for configuration only. The AL200 will not turn on an attached radio

and transmit while powered over the USB port.

2. Open Device Configuration Utility.

3. Under Device Type, select AL200.

4. Click the browse button next to Communication Port and select the port

associated with the AL200.

5. Click OK.

6. Click Connect.

7. Specify the settings on each tab as described below.

• Main

Set Operation Mode to Sensor Input Enabled (CS I/O Disabled),

ALERT Concentration on RS-232.

• ComPort

Leave all settings as defaults.

2

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

NOTE

NOTE

• ALERT2

Configure settings to match your ALERT2 network.

• Radio Settings

Default settings will work for Campbell Scientific’s RF320 series

radios. (Campbell Scientific’s RF320 series is the Ritron DTX-L

series. For other radios, check with the manufacturer for the

necessary radio settings.)

• GPS Settings

Leave all settings as defaults.

• Sensor Input Settings

Configure settings to enable or disable the inputs you wish to use with

the AL200.

8. Click the Apply button located at the bottom of the window. It is a good

idea to save the configuration file for later reference.

The AL200 will suppress event-triggered transmissions while

connected to Device Configuration Utility. During this time the

Test Button may be used to trigger a data transmission.

4.2 Datalogger Peripheral Mode

Out of the box, the AL200 is configured for ALERT2 on CS I/O, ALERT

Concentration on RS-232 (datalogger peripheral mode). In this mode, the

AL200 will receive ALERT protocol packets on the RS-232 port from an

external device and retransmit them as ALERT2 packets using the ALERT

concentration protocol. The AL200 will also receive ALERT2 IND layer

packets on the CS I/O port and retransmit them as ALERT2 packets.

4.2.1 Physical Setup

Attach a GPS antenna to the GPS SMA connector located on the side of the

AL200.

4.2.2 Configuring the AL200

The device driver for the AL200 must be installed on your

computer before you can connect to the AL200 via USB. See

Appendix E, AL200 USB Driver Installation Instructions, for

instructions on installing the device driver.

1. Connect the supplied USB cable between a USB port on your computer

and the USB port on the AL200. The AL200 will be powered over the

USB for configuration only. The AL200 will not turn on an attached radio

and transmit while powered over the USB port.

2. Open Device Configuration Utility.

3

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

3. Under Device Type, select AL200.

4. Click the browse button next to Communication Port and select the port

associated with the AL200.

5. Click OK.

6. Click Connect.

7. Specify the settings on each tab as described below.

• Main

Set the Operation Mode to ALERT2 on CS I/O, ALERT

Concentration on RS-232.

• ComPort

Leave all settings as defaults.

• ALERT2

Configure settings to match your ALERT2 network.

5. Overview

• Radio Settings

Default settings will work for Campbell Scientific’s RF320 series

radios. (Campbell Scientific’s RF320 series uses the Ritron DTX-L

series.) For other radios, check with the manufacturer for necessary

radio settings.

• GPS Settings

Leave all settings as defaults.

• Sensor Input Settings

Leave all settings as defaults.

The AL200 ALERT2 Encoder, Modulator, and Sensor Interface is designed for

use in radio networks using the ALERT2 protocol. The AL200 can be

configured to operate as a stand-alone device or as a datalogger peripheral. In

stand-alone mode, the AL200 will measure sensors, perform calculations, and

if appropriate, transmit the data during a designated time slot. In datalogger

peripheral mode, the AL200 will receive data from a datalogger, such as the

CR800 or CR1000, or other device and transmit this data during a designated

time slot. In both modes, the AL200 will receive ALERT data on one of the

serial ports, then concentrate and retransmit the data via the ALERT2 protocol.

4

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

FIGURE 5-1. AL200

The AL200 includes a CS I/O port and an RS-232 port for serial

communications. A USB device port is used for configuring the AL200,

viewing real time sensor data, and diagnostics. An SMA female connector is

provided for connecting a GPS antenna, and a removable screw terminal allows

for the easy connection of an analog radio. Removable screw terminals are

also used for supplying power to the AL200 and connecting sensors. Lastly,

there is a copper ground lug for attaching an earth ground.

6. Specifications

Operating Temperature

Standard –40° to +60°C

Power

9-18 Vdc

Current Drain @ 12 Vdc

Idle: 1.5 mA

GPS Fix: 40 mA

Transmit: 35 mA (not including radio or attached sensors)

Reverse polarity protected

Removable screw terminal connector, 0.15” pitch

Weight

206 g (7.3oz)

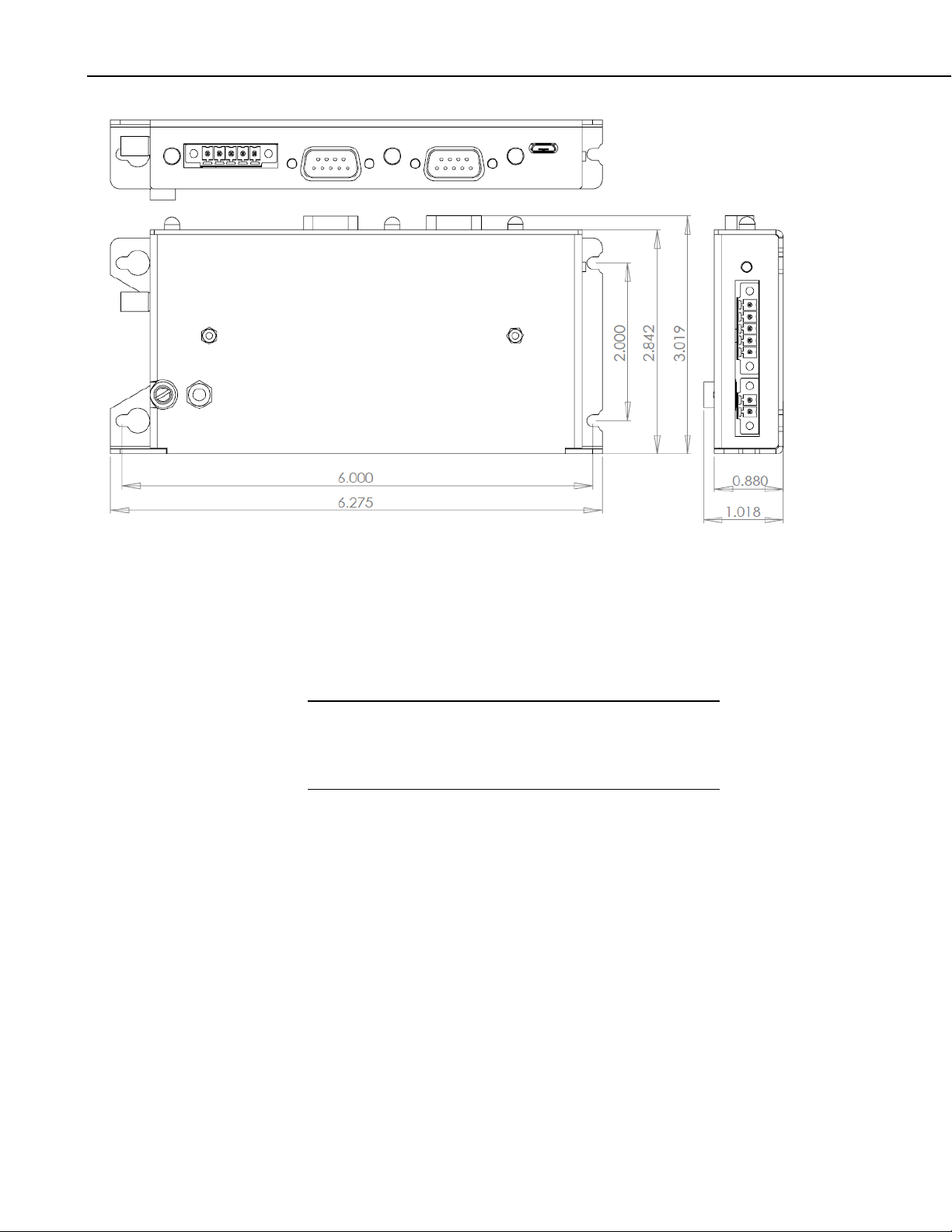

Dimensions

159.385 x 76.683 x 25.857 mm (6.275 x 3.019 x 1.018 in)

5

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

NOTE

FIGURE 6-1. AL200 dimensions

Configuration

This device is designed to easily be configured through the graphical

interface, Device Configuration Utility. When used as a stand-alone

device, no programming is required.

The device driver for the AL200 must be installed on your

computer before you can connect to the AL200 via USB. See

Appendix E, AL200 USB Driver Installation Instructions, for

instructions on installing the device driver.

When used as a datalogger peripheral, the same Device Configuration

Utility software is used to configure the AL200. Additional steps will be

required to program the datalogger to interface with the AL200.

USB

Micro-B receptacle

Can power AL200 during configuration; not suitable for operational

current draws

Requires FTDI Virtual COM Port (VCP) driver installation

6

CS I/O Port

SDC 7, 8, 10, 11

ALERT2 or ALERT-concentration

AL200 is NOT powered over CS I/O

Multiplexed with integrated sensor I/O

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

RS-232 Port

DCE

Configurable baud rates, parity, stop bits, and timeout

ElA/TIA-232 and V.28/V.24 Signaling

± 15kV ESD protection

Test Button

The test button located in the lower left hand corner of the AL200 serves

two functions. Pressing it for three to six seconds will trigger a test

transmission containing the latest data available to the AL200. Pressing

the button for longer than 6 seconds will cause the AL200 to generate a

test tone and sustain it for 5 seconds. If the AL200 has been configured as

a datalogger peripheral, only the test tone functionality is active.

Analog Radio Interface

Removable screw terminal connector, 0.15” pitch

Transmit only

Transmit Audio (Tx), 100 – 1000 mV peak-to-peak, software adjustable

Switched Voltage (SW12V), switched supply voltage, 1.8 A at +70°C

Sensor I/O

Removable screw terminal connector, 0.15” pitch

Switch closure (P1)

Internally pulled up to 5 V

16-bit counter

3.3 ms time constant for debounce

5 ms minimum closed time, 6 ms minimum open time

Single-ended analog (SE1)

16-bit Adc

0-5 Vdc

± 12 mV accuracy

80 µV resolution

50 dB rejection at 60 Hz

Software configurable as millivolt or milliamp input

Precision 100 Ω current sense resistor when configured for

milliamp input

Digital I/O (C1)

Software configurable as status (high/low) or SDI-12 input

Status Low 0 to 1.4 Vdc, High 3.5 to 5.0 Vdc

SDI-12 limited to 1 address, 1 value

Transient voltage surge (TVS) and gas discharge tube (GDT)

protected

7

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

NOTE

Switched Voltage (SW12V)

Voltage supply switched on prior to operational sensor scan

Thermal fuse hold current = 900 mA @ 20°C, 630 mA @ 50°C,

450 mA @ 70°C

GPS

SMA Female

50 Ω input impedance

Active antenna design, 3.3 Vdc

25 dBm maximum input

Integrated SAW filtering and jam resistance

1 second time-to-fix during normal operation

35 second time-to-fix on power up or reboot

13 min for leap second, once per day auto

PPS ± 1 usec to full UTC second

Receive sensitivity –161 dBm

Timekeeping

GPS disciplined to ± 1 µS

Drift ± 170 ms per day with 40°C temperature change (w/o GPS sync)

7. Installation

7.1 Configuring the AL200

Compliance

RoHs

CE

IEC61000-4 ESD

The AL200 is configured via the USB port using the Device Configuration

Utility.

It is important to have an understanding of the network that the AL200 will be

used in. There are many settings that are used to configure when and how the

AL200 will report data in the time division multiple access (TDMA) scheme.

Incorrect settings can cause channel contention and may result in lost data.

The device driver for the AL200 must be installed on your

computer before you can connect to the AL200 via USB. See

Appendix E, AL200 USB Driver Installation Instructions, for

instructions on installing the device driver.

1. Connect the supplied USB cable between a USB port on your computer

and the USB port on the AL200. The AL200 will be powered over the

USB for configuration only. The AL200 will not turn on an attached radio

and transmit while powered over the USB port.

8

2. Open Device Configuration Utility.

3. Under Device Type, select AL200.

NOTE

4. Click the browse button next to Communication Port and select the port

associated with the AL200.

5. Click OK.

6. Click Connect.

7. Specify the settings on each tab as described below for the desired mode.

When a value is shown in parentheses next to a setting, it is the

default values that should work in most cases. Do not change

these values, unless you are certain a change is required.

7.1.1 Stand-alone Device

Main

• Set the Operation Mode to Sensor Input Enabled (CS I/O

Disabled), ALERT Concentration on RS-232.

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

ComPort

These settings have no effect in stand-alone mode.

ALERT2

These settings will be unique to a particular station and to your network.

• Set the Station Source Address – This is a station ID number that

must be unique within the network. This is an integer between 0 and

65,501. A database of source addresses can be found at

www.alert2.org.

• Set the Frame Length – This is the total amount of time that all of the

stations in the network will report in. This is an integer with a

resolution of 500 ms between 500 and 43,200,000 (12 hours).

• Set the Slot Length – This is the maximum amount of time within the

frame that the station can report. It is an integer value between 500

and a maximum of the Frame Length.

• Set the Slot Offset – This is the amount of time into the frame that the

slot will occupy. For example, if your frame is 120,000 ms (2

minutes) and your slot offset is 60,000 ms, the slot time will begin 1

minute after the beginning of the frame.

• Set the Hop Limit – (None) – This is the maximum number of times a

remote transmission can be retransmitted by repeaters.

• Set the Path Service Enabled – (No) – When enabled, each device

that repeats a remote transmission will add its source address to the

9

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

packet. This makes it possible to trace the path that a packet took

from its beginning to its destination.

Radio Settings

The default radio settings have been chosen to work well with Campbell

Scientific’s RF320 series (Ritron DTX-L series) radios. If using a different

type of radio, consult the manufacturer and apply the changes to the following

settings.

• Set the Radio Power Up Mode – (On Only With Data to TX) – This

determines when the radio will be powered on.

• Set the Radio Warm Up – (750) – This is the amount of time, in

milliseconds, that power will be applied to the external radio prior to

data transmission.

• Set the Carrier Only Time – (10) – This is the amount of time, in

milliseconds, that radio will be fed an unmodulated carrier.

• Set the AGC Time – (25) – This is the amount of time, in

milliseconds, that the radio will be fed a tone-modulated carrier.

• Set the Tail Time – (5) – This is the amount of time, in milliseconds,

an unmodulated carrier will be transmitted following data

transmission.

• Set the Modulation Voltage – (390) – This is the peak-to-peak

voltage level of the modulated signal that will be fed to the radio.

Value is expressed in millivolts.

• Set the Modulation Polarity – (Normal) – This is the polarity of the

modulated signal fed to the radio.

GPS Settings

• Last GPS Fix – This is the data and time of the last successful GPS

fix obtained by the AL200.

• Set the GPS Power On Interval – (30) – This is how often the GPS

receiver will be powered on and an attempt to get a GPS fix will be

made. Value is expressed in minutes.

• Set the GPS On Max – (5) – This is the maximum amount of time, in

minutes, that the GPS receiver will be powered on without a GPS fix

being obtained.

Sensor Input Settings

10

• Set the Self Report Interval – (43,200,000 (12 hours)) – This is how

often the AL200 will transmit non-event triggered data. Value is

expressed in seconds.

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

• Set the Sensor Scan Interval – This is how often the AL200 will

power up and measure attached and enabled sensors. Value is

expressed in seconds.

• Set the SW12 Warm Up Time – This is the amount of time in

seconds that the AL200 will wait after powering up attached sensors

before making a measurement.

• Set the P1 Mode – Enable or disable the pulse count channel

depending on whether or not it is being used.

• Set the SE1 Mode – Set to Millivolt if using a sensor that has a single

ended voltage output. Set to Milliamp if sensor has a single ended

current output or 4-20 mA loop output.

• Set the SE1 ALERT2 Sensor ID – This is the sensor ID of the sensor

connected to the SE1 channel. See Appendix G, List of

Recommended Sensor IDs, for a list of recommended sensor ID

values.

• Set the SE1 Multiplier – This is a sensor specific value that along

with the SE1 Offset will be used to convert the analog output of a

sensor to an engineering unit. See Appendix H, Calculating

Multipliers and Offsets, for how to calculate multipliers and offsets.

• Set the SE1 Offset – This is a sensor specific value that along with the

SE1 Multiplier will be used to convert the analog output of a sensor to

an engineering unit. See Appendix H, Calculating Multipliers and

Offsets, for how to calculate multipliers and offsets.

• Set the SE1 Tx Change – This is the threshold which a calculated

value for the SE1 measurement must exceed in order to trigger a data

transmission.

• Set the C1 Mode – Set to Status to configure C1 to read a dry contact

(commonly a float switch). Set to SDI-12 to configure for use with an

SDI-12 type sensor.

• Set the C1 ALERT2 Sensor ID – This is the sensor ID of the sensor

connected to the C1 channel. See Appendix G, List of Recommended

Sensor IDs, for a list of recommended sensor ID values.

• Set the SDI-12 Command – This is the measurement command that

will be sent to the attached SDI-12 sensor. The format is xM!, where

x is the SDI-12 address.

• Set the SDI-12 Value to Send – If the attached SDI-12 sensor returns

more than one value, select which value will be used.

• Set the SDI-12 Multiplier – (1) – This is a sensor specific value that

along with the SDI-12 Offset will be used to convert the analog output

of a sensor to an engineering unit. See Appendix H, Calculating

Multipliers and Offsets, for how to calculate multipliers and offsets.

(Note that most SDI-12 sensors do not require a multiplier or offset

except for unit conversion.)

11

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

• Set the SDI-12 Offset – (0) – This is a sensor specific value that along

with the SE1 Multiplier will be used to convert the analog output of a

sensor to an engineering unit. See Appendix H, Calculating

Multipliers and Offsets, for how to calculate multipliers and offsets.

(Note that most SDI-12 sensors do not require a multiplier or offset

except to convert units of measure.)

• Set the SDI-12 Tx Change – This is the threshold which a calculated

value for the SDI-12 measurement must exceed in order to trigger a

data transmission.

Sensor Data Monitoring

• Set the Configuration Sensor Scan Interval – This is the interval on

which sensors will be read only while you are connected to the AL200

with the Device Configuration Utility software.

After configuring the AL200 settings, click the Apply button at the bottom of

the screen to send the changes to the device. It is a good idea to save the

configuration file for later reference.

7.1.2 Datalogger Peripheral

Main

• Set the Operation Mode to either ALERT2 on CS I/O, ALERT

Concentration on RS-232 or ALERT Concentration on CS I/O,

ALERT2 on RS-232 depending on what type of device the AL200

will be connected to.

ComPort

• If the AL200 is connected to a Campbell Scientific datalogger, select

the appropriate SDC address. When using the CS I/O port, it is not

necessary to configure the RS-232 related settings.

• If the AL200 is connected to an RS-232 device, configure the RS-232

Baud Rate, RS-232 Parity, and RS-232 Stop Bits to match the

device.

ALERT2

These settings will be unique to a particular station and to your network.

• Set the Station Source Address – This is a station ID number that

must be unique within the network. This is an integer between 0 and

65,501. A database of source addresses can be found at

www.alert2.org.

12

• Set the Frame Length – This is the total amount of time that all of the

stations in the network will report in. This is an integer with a

resolution of 500 ms between 500 and 43,200,000 (12 hours).

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

• Set the Slot Length – This is the maximum amount of time within the

frame that the station can report during. It is an integer value between

500 and a maximum of the Frame Length.

• Set the Slot Offset – This is the amount of time into the frame that the

slot will occupy. For example, if your frame is 120,000 ms (2

minutes) and your slot offset is 60,000 ms, the slot time will begin 1

minute after the beginning of the frame.

• Set the Hop Limit – (None) – This is the maximum number of times a

remote transmission can be retransmitted by repeaters.

• Set the Path Service Enabled – (No) – When enabled each device

that repeats a remote transmission will add its source address to the

packet. This makes it possible to trace the path that a packet took

from its beginning to its destination.

Radio Settings

The default radio settings have been chosen to work well with Campbell

Scientific’s RF320 series (Ritron DTX-L series) radios. If using a different

type of radio, consult the manufacturer and apply the changes to the following

settings.

• Set the Radio Power Up Mode – (On Only With Data to TX) – This

determines when the radio will be powered on.

• Set the Radio Warm Up – (750) – This is the amount of time, in

milliseconds, that power will be applied to the external radio prior to

data transmission.

• Set the Carrier Only Time – (10) – This is the amount of time, in

milliseconds, that radio will be fed an unmodulated carrier.

• Set the AGC Time – (25) – This is the amount of time, in

milliseconds, that the radio will be fed a tone-modulated carrier.

• Set the Tail Time – (5) – This is the amount of time, in milliseconds,

an unmodulated carrier will be transmitted following data

transmission.

• Set the Modulation Voltage – (390) – This is the peak-to-peak

voltage level of the modulated signal that will be fed to the radio.

Value is expressed in millivolts.

• Set the Modulation Polarity – (Normal) – This is the polarity of the

modulated signal fed to the radio.

GPS Settings

• Last GPS Fix – This is the data and time of the last successful GPS

fix obtained by the AL200.

13

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

• Set the GPS Power On Interval – (30) – This is how often the GPS

receiver will be powered on and an attempt to get a GPS fix will be

made. Value is expressed in minutes.

• Set the GPS On Max – (5) – This is the maximum amount of time, in

minutes, that the GPS receiver will be powered on without a GPS fix

being obtained.

Sensor Input Settings

These settings have no effect in datalogger peripheral mode.

Sensor Data Monitoring

These values are not updated when the AL200 is configured as a datalogger

peripheral.

After configuring the AL200 settings, click the Apply button at the bottom of

the screen to send the changes to the device. It is a good idea to save the

configuration file for later reference.

7.2 Mounting in an Enclosure

7.3 Grounding

7.4 Wiring

8. Operation

When used in outdoor applications, the AL200 should be installed in a

desiccated, weatherproof enclosure. The AL200 can either be flat- or edgemounted to a panel using the supplied plastic grommets and 6-32 screws.

The ground lug should be connected to a good earth ground using 12 AWG

stranded wire. This will help protect the AL200 from electrical surges and

provide a good reference for analog measurements.

Connect the transmit, power, and ground lines (Push to Talk and Frequency

Select lines are optional) from your analog radio to the SW12V, Tx and G

terminals of the radio connector. The AL200 should be mounted as close as

possible to the radio in order to avoid long cable runs between the two devices.

Connect the sensor leads to the appropriate sensor inputs. Depending on site

conditions, additional surge protection for the sensor cables may be required.

If using the AL200 as a datalogger peripheral, connect either the CS I/O or RS232 port to the datalogger using the supplied SC12 cable.

14

The AL200 uses the ALERT2 protocol as developed by the ALERT2

Technical Working Group (TWG) and is designed for use as an ALERT2

transmitter or ALERT to ALERT2 concentrator and repeater. For more

information on the ALERT2 protocol, visit the National Hydrologic Warning

Council’s website: www.hydrologicwarning.org.

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

Under normal operation, the AL200 will obtain a GPS fix and measure sensors

based on its configuration. When the sensors are measured and an event

threshold has been exceeded, the AL200 will wait until its designated time slot

and then power up the radio and transmit the data to a repeater or base receiver.

• Concentrated ALERT data is retransmitted using the ALERT

concentration protocol.

• Event-driven rainfall data is transmitted as a tipping bucket rain gauge

report with a sensor ID of zero (0).

• Other event-driven sensor data is transmitted as a general sensor

report. If events for multiple sensors are detected in the same frame,

then multiple general sensors reports will be transmitted.

• A scheduled self-report is transmitted as a multi-sensor report.

If a GPS fix cannot be obtained and the AL200’s internal clock cannot be

disciplined, the device will transmit data during random slot times throughout

the frame interval in an attempt to not continuously interfere with adjacent time

slots.

9. Maintenance

When connected to the AL200 with the Device Configuration Utility, the

AL200 will power up and measure the attached sensors on the Configuration

Sensor Scan Interval located on the Sensor Data Monitoring tab, but

transmissions will be suppressed.

It is a good idea to periodically check the sensor inputs against known values to

ensure that the device is still within the specified accuracy ranges. Connecting

to the AL200 with a USB cable will force the AL200 to measure the attached

sensors on the Configuration Sensor Scan Interval. This will allow the user

to quickly see how sensors respond to changes. Upon disconnecting from the

device, the AL200 will resume its Sensor Scan Interval.

Pressing the test button for three to six seconds will trigger a test transmission

containing the latest data available to the AL200. Pressing the button for

longer than six seconds will cause the AL200 to generate a test tone and sustain

it for five seconds. This test tone can be used to check the forward and

reflected power of the radio.

Consult your sensor and radio manufacturer’s manuals for recommended

maintenance of these devices.

15

AL200 ALERT2 Encoder, Modulator, and Sensor Interface

10. Troubleshooting

Problem Possible Causes

The AL200 will not transmit eventtriggered data.

The Test Button is not initiating a

data transmission.

The AL200 is reporting incorrect

values.

The radio LED is always red. • The AL200 has been configured to

• The AL200 is currently connected

to Device Configuration Utility and

data transmissions are being

suppressed.

• The event threshold is not properly

set.

• The AL200 is not currently

measuring a level that exceeds the

event threshold.

• The AL200 has not obtained an

initial GPS fix.

• The AL200 has not obtained an

initial GPS fix.

• The AL200 has been configured as

a datalogger peripheral and the test

button functionality has been

disabled.

• The applied multipliers and offsets

are not correct.

• There is an issue with the attached

sensor or sensor wiring.

keep the radio always on.

11. Repair

The GPS LED is on longer than the

maximum allowed on time.

The AL200 is designed to give years of trouble-free service with reasonable

care. However, if factory repair is needed, first contact a Campbell Scientific

application engineer to obtain an RMA (Return Materials Authorization)

number. An RMA number and product-safety documents are required prior to

any repair shipments being accepted at Campbell Scientific. See the

Assistance statement at the beginning of this manual for more information.

• The GPS module is attempting to

obtain leap second information and

may be on for up to 13 minutes.

16

Appendix A. Glossary

ALERT

Automated Local Evaluation in Real Time. A communication protocol

developed in the early 1970’s for the efficient reporting of real-time rainfall

data over radio telemetry networks.

ALERT2

Successor of the ALERT communication protocol. A layered protocol suite

designed for the primary purpose of real-time and coordinated communication

of data over a radio telemetry network.

IND

Intelligent Network Device. A device that implements the AirLink and MANT

protocols for the transmission, repeating, or receipt of ALERT2 data.

MANT

ALERT2 Network and Transport layer providing the required services to

transport application and network control data.

PDU

Protocol Data Unit. Data payload with control header used for exchange

between protocol layers. Sometimes generalized as “packet”.

SDC

Synchronous Device Communications. A Campbell Scientific addressable,

synchronous communications protocol. The protocol allows multiple

peripherals to be connected to the same communication bus as long as each

peripheral has a unique SDC address.

A-1

Appendix A. Glossary

A-2

TABLE B-1. CS I/O Pin Description

TABLE B-2. RS-232 Pin Description

1

N/C

3

RXD

5

SIGNAL GND

7

CTS

9

N/C

Appendix B. Cables and Connector Pin Descriptions

B.1 CS I/O

CS I/O is an interface unique to Campbell Scientific products. CS I/O uses

TTL signaling. CS I/O devices are connected using a 9-pin, straight-through,

male to female cable with all 9 pins connected. Use of the supplied SC12 cable

(pn 16675) is recommended.

Pin Datalogger Function, DB9 Female AL200 Function, DB9 Male

1 5 VDC N/C

2 SIGNAL GND SIGNAL GND

3 RING RING

4 RXD TXD

5 ME ME

6 SDE SDE

7 CLK/HS CLK/HS

8 12 VDC N/C

9 TXD RXD

B.2 RS-232

RS-232 is used for asynchronous serial communication. It is a standard

EIA/TIA-232 DB9 socket female DCE interface. A DB9 male to male null

modem cable (pn 18663) is used to connect the AL200 to a Campbell

Scientific datalogger’s RS-232 port.

Pin AL200 Function, DCE, DB9 Female

2 TXD

4 N/C

6 N/C

8 RTS

B-1

Appendix B. Cables and Connector Pin Descriptions

TABLE B-3. USB Pin Description

TABLE B-4. Power Input Pin Description

B.3 USB

The USB interface is a standard Micro-B configuration. A USB A to Micro-B

cable is supplied (pn 27555). Connection to a PC requires installation of the

FTDI Virtual COM Port (VCP) device driver.

Pin Function

1 VBUS, 5 Vdc

2 Data -

3 Data +

4 Not used, Grounded Internally

5 GND

B.4 Power

Input power is supplied via a 2-pin screw terminal. A mating connector is

supplied (pn 7843).

Pin Function

G Supply Ground

12V Supply Voltage

B.5 Analog Radio Interface

The analog radio interface is a 5-pin screw terminal. A mating connector is

supplied (pn 28750).

B-2

TABLE B-5. Radio Interface Pin Description

Pin Function

TABLE B-6. Sensor I/O Pin Description

TABLE B-7. GPS Input Pin Description

Freq. Select Frequency Select. Accommodate frequency selection during

SW12V Switchable radio power supply

PTT Push-to-talk. Grounded during transmission.

G Ground

TX Transmit audio output

B.6 Sensor I/O Interface

The sensor I/O interface is a 5-pin screw terminal. A mating connector is

supplied (pn 28750).

Appendix B. Cables and Connector Pin Descriptions

operation by grounding selected pin on radio interface.

B.7 GPS Input

Pin Function

SE1 Analog voltage / current input

SW12V Switchable sensor power supply

P1 Switch closure input. Internally tied high to 5V.

G Ground

C1 Digital I/O for high/low status or SDI-12

The GPS input is a threaded SMA female connector.

Pin Function

Center Conductor Socket RF Input, biased by 3.3 V for use with active

antennas

Shield RF ground

B-3

Appendix B. Cables and Connector Pin Descriptions

B-4

TABLE C-1. GPS LED State Descriptions

TABLE C-2. Serial LED State Descriptions

TABLE C-3. Radio LED State Descriptions

Appendix C. LED Indicators

The GPS LED is next to the GPS antenna connection. It can be used for

monitoring GPS power up and acquisition of a good satellite lock / fix.

State Description

Off GPS module in “hibernate state”

Green GPS lock acquired (will only flash momentarily before turning off)

Red GPS module on, No GPS Lock (or downloading almanac/leap

second information)

The Serial LED is located between the RS-232 and CS I/O interfaces. It can be

used for monitoring communication events on those ports.

State Description

Off Neither interface is currently transferring data

Green RS-232 activity, Internal U0 activity

Red CS I/O activity, Internal U1 activity

The Radio LED is located between the CS I/O and USB interfaces. It can be

used for monitoring the power and communication state of the radio interface.

State Description

Off Radio interface not currently in use

Green PTT applied, Transmitting

Red Power applied to radio, SW12V high

*When the radio is both powered on and transmitting, the red and green

LEDs will appear orange.

Under normal operation, the LED sequence should be as follows from

powering up the device through a data transmission:

a. GPS LED is red immediately after power, then flashes green

indicating that the AL200 has a GPS fix.

C-1

Appendix C. LED Indicators

b. The GPS light remains red for up 13 minutes as the AL200 downloads

leap second information from the satellite.

c. The Serial LED flashes green or red indicating that the AL200 has

been sent data from a datalogger, or data is being internally

transferred from the sensor inputs to memory.

d. The Radio LED is red briefly while the radio is powered up and

allowed to warm up. If the radio is set to always on, this LED will

constantly be red.

e. The Radio LED flashes orange (actually green and red lights, but is

orange in appearance) indicating that the AL200 is transmitting data.

C-2

Appendix D. AL200 Settings

Operation Mode The AL200 supports ALERT2 and ALERT-concentration processing. Each process

can service one physical connection on the AL200 at a time. Those connections are

the CS I/O, RS-232, and direct-sensor inputs. The CS I/O port and sensor inputs are

multiplexed, so their use is mutually exclusive.

• ALERT2 on CS I/O, ALERT Concentration on RS-232

In this mode, the AL200 will accept ALERT2 on the CS I/O port and

ALERT packets on the RS-232 port.

• Sensor Input Enabled (CS I/O Disabled), ALERT Concentration on

RS-232

In this mode, the AL200 will measure attached sensors and receive serial

ALERT packets on the RS-232 port.

• ALERT Concentration on CS I/O, ALERT2 on RS-232

In this mode, the AL200 will accept ALERT on the CS I/O port and

ALERT2 on the RS-232 port.

OS Version The version of the operating system currently running on this device. Updates can be

found on Campbell Scientific’s website, www.campbellsci.com/downloads.

CS I/O SDC Address Synchronous Device for Communication (SDC) address that this device should use

while communicating over CS I/O. Communication speed (bit rate) is controlled by

the datalogger.

RS-232 Baud Rate The baud rate used for communication over RS-232.

RS-232 Parity Parity bit usage during communication over RS-232.

RS-232 Stop Bits The number of stop bits sent after each character during communication over RS-

232.

Time To Next Slot Time (seconds) until the next transmission slot.

Station Source Address ALERT2 station source address. Each station in an ALERT2 network should have a

unique source address.

Destination Address The source address of device that packets are directed to.

Add Destination Address Controls if Destination Address will be added to the packet header. A setting of No

will disable the Destination Address settings control.

Frame Length The total amount of time that all of the stations in the network will report within.

The value is expressed in milliseconds with a resolution of 500 ms. It is an integer

between 500 and 43,200,000 (12 hours). The value must be evenly divisible into 12

hours, that is (43200000 / Frame Length = Whole Number) or (43200000 MOD

Frame Length = 0).

Slot Length The maximum amount of time this device can transmit within a single frame. The

value is expressed in milliseconds with a resolution of 500 ms. It is an integer value

between 500 and a maximum of the Frame Length.

Slot Offset The offset, from the beginning of the frame, for the transmission slot. The value is

expressed in milliseconds with a resolution of 500 ms. The value cannot exceed

(Frame Length - 500 ms).

D-1

Appendix D. AL200 Settings

Hop Limit The maximum number of times a packet, originating from this device, will be

repeated (hop) before being discarded. None (7) disables the limiting of hops.

Example: if this station requires 1 repeater hop to reach the base station receiver, the

hop limit should be set to a minimum of 1.

Path Service Enabled Request that each device that forwards data originating from this station add its

source address to the packet header. Enabling this option allows a receiver to know

the path that the packet took through the network.

Radio Power Up Mode The setting controls when the attached radio is powered up. The radio can be

powered up every frame, continuously, or only when data is available for

transmission. For maximum power savings, set to On Only With Data to Tx. The

radio will only power up if the AL200 has data to be transmitted. For maximum

responsiveness, set to On Every Frame or On Continuously. If On Every Frame,

the radio will be turned on for a minimum of Radio Warm Up milliseconds every

frame.

Radio Warm Up The amount of time power should be applied to the radio prior to the start of the

transmission slot. Power will be applied according to the Radio Power Up Mode.

The value is expressed in milliseconds with a resolution of 10 ms.

Carrier Only Time Amount of unmodulated carrier used in Airlink preamble. The value is expressed in

milliseconds.

AGC Time Amount of tone-modulated carrier used in Airlink preamble. The value is expressed

in milliseconds.

Tail Time Amount of unmodulated carrier to follow transmitted frame. The value is expressed

in milliseconds.

Modulation Voltage This setting controls the modulation voltage. The value is expressed in millivolts,

peak-to-peak. Settings do not take effect until applied.

Modulation Polarity Depending on the radio used the audio AirLink modulation signal may need to be

inverted. For Midland and Ritron radios, set this to Normal.

Last GPS Fix The last time that the device successfully acquired a GPS fix. The time is shown in

UTC. Remember that you may need to correct for your time zone offset when trying

to understand this value in context of the local time.

GPS Power On Interval Time between GPS fix attempts. The value is expressed in minutes.

GPS On Max The maximum time the GPS will remain on while trying to obtain a fix. The value is

expressed in minutes.

Self Report Interval Controls the frequency at which sensor data should be reported, without being

triggered by an event. Value is expressed in seconds.

Sensor Scan Interval Controls the interval at which sensors, with the exception of P1, will be read during

normal operation. Value is expressed in seconds.

SW12 Warm Up Time Controls the amount of time SW12V should be on before reading sensor inputs, with

the exception of P1. A setting of –1 means SW12V will be left on continuously. A

setting of 0 means SW12V will not be enabled before measurement. Value is

expressed in seconds.

P1 Mode Enables the P1 terminal input. The P1 input is most commonly used for measuring

switch closures, like those commonly produced by a tipping bucket rain gage. An

ALERT2 sensor ID of 0 will be used for tipping bucket and general sensor reports for

this input.

D-2

Appendix D. AL200 Settings

For example, if the sensor returned 4 values, and the 3rd value needs to

SE1 Mode Sets the operation mode for the SE1 terminal input. SE1 is used for measuring

millivolt or milliamp input signals, like those commonly produced by a pressure

transducing level sensor.

SE1 ALERT2 Sensor ID The ALERT2 sensor ID that will be used to identify a SE1 general sensor report.

The ID cannot be set to 0 or 8. 0 is reserved for reporting P1 input. 8 is reserved for

reporting battery.

SE1 Multiplier Multiplier to apply to SE1 measurement before evaluation and transmission.

Example: Water Level = SE1 measurement • SE1 Multiplier + SE1 Offset.

SE1 Offset Offset to apply to SE1 measurement before evaluation and transmission. Example:

Water Level = SE1 measurement • SE1 Multiplier + SE1 Offset.

SE1 Tx Change Amount of change in reading required to trigger Tx of reading. Reading = SE1

measurement • SE1 Multiplier + SE1 Offset.

C1 Mode Sets the operation mode for the C1 terminal input. C1 is used for measuring status

(high/low) or SDI-12 inputs, like those produced by a float switch or pressure

transducing level sensor, respectively.

C1 ALERT2 Sensor ID The ALERT2 sensor ID that will be used to identify a C1 general sensor report. The

ID cannot be set to 0 or 8. 0 is reserved for reporting P1 input. 8 is reserved for

reporting battery.

SDI-12 Command SDI-12 command to be sent to the attached sensor.

SDI-12 Value to Send Selects which value returned by the SDI-12 sensor to use for evaluation and

transmission.

be used, this setting should be 3.

SDI-12 Multiplier Multiplier to apply to the SDI-12 measurement before evaluation. Example: Water

Level = SDI-12 measurement • SDI-12 Multiplier + SDI-12 Offset.

SDI-12 Offset Offset to apply to the SDI-12 measurement before evaluation. Example: Water Level

= SDI-12 measurement • SDI-12 Multiplier + SDI-12 Offset.

SDI-12 Tx Change Amount of change in the reading required to trigger Tx of reading. Reading = SDI-

12 measurement • SDI-12 Multiplier + SDI-12 Offset.

Configuration Sensor

Scan Interval

Controls the interval at which sensors, with the exception of P1, will be read while

connected with Device Configuration Utility. Value is expressed in seconds. This

setting does not take effect until settings are applied.

Battery Battery / supply voltage (volts). While connected via Device Configuration Utility,

the battery voltage will be measured every Configuration Sensor Scan Interval.

The measured value will be queried and displayed here at a regular refresh interval.

P1 Total If the P1 input is enabled, the total number of counts since the device was last

powered up or reset will be displayed here. The measured value will be queried and

displayed here at a regular refresh interval.

SE1 Raw Reading If SE1 is enabled, the SE1 reading without SE1 Multiplier and SE1 Offset applied.

While connected via Device Configuration Utility, SE1 will be measured every

Configuration Sensor Scan Interval. The measured value will be queried and

displayed here at a regular refresh interval.

SE1 Scaled Reading If SE1 is enabled, the SE1 reading, with SE1 Multiplier and SE1 Offset applied.

While connected via Device Configuration Utility, SE1 will be measured every

Configuration Sensor Scan Interval. The measured value will be queried and

displayed here at a regular refresh interval.

D-3

Appendix D. AL200 Settings

SE1 Transmitted Last three transmitted readings for SE1 (T0, T1, T2). The list will be queried and

displayed here at a regular refresh interval. While connected via Device

Configuration Utility, automated reporting/transmission is disabled. Press and hold

the test button for 3 to 5 seconds to force a transmission while connected.

C1 Raw Reading If C1 input is enabled, this will be either a) the control port state or b) the value for

SDI-12 without SDI-12 Multiplier and SDI-12 Offset applied, during the last sensor

scan. While connected via Device Configuration Utility, C1 will be measured every

Configuration Sensor Scan Interval. The measured value will be queried and

displayed here at a regular refresh interval.

C1 Scaled Reading If C1 input is enabled, this will be either a) the control port state or b) the value for

SDI-12 with SDI-12 Multiplier and SDI-12 Offset applied, during the last sensor

scan. While connected via Device Configuration Utility, C1 will be measured every

Configuration Sensor Scan Interval. The measured value will be queried and

displayed here at a regular refresh interval.

C1 Transmitted If C1 input is enabled, this will be either a) the control port state or b) the value for

SDI-12 for the last three transmitted readings of C1 (T0, T1, T2). The list will be

queried and displayed here at a regular refresh interval. While connected via Device

Configuration Utility, automated reporting/transmission is disabled. Press and hold

the test button for 3 to 5 seconds to force a transmission while connected.

D-4

Appendix E. AL200 USB Driver Installation Instructions

When plugging the AL200 into your Windows XP or Vista PC for the first

time, it may be necessary to install the FTDI Virtual COM Port (VCP) driver.

This is not required when using Windows 7 or 8.

Visit www.ftdichip.com/Drivers/VCP and select the appropriate file based on

your computer’s operating system. Download the zip file to your PC and

extract the files to a directory of your choosing. Select and open the executable

file and proceed through the install wizard. After the drivers finish installing,

you should see a confirmation screen indicating that the drivers were installed

or updated successfully. You will then need to restart your computer to apply

the changes.

E-1

Appendix E. AL200 USB Driver Installation Instructions

E-2

Appendix F. Updating the Operating System of the AL200

Whenever a new operating system is released for the AL200, it will be

available from our website, www.campbellsci.com/downloads.

Follow these steps to send the new OS to the AL200:

1. Connect a USB cable between one of your computer’s USB ports and the

USB port on the AL200.

2. Open DevConfig.

3. Select the AL200 under Device Type.

4. Select the appropriate Communication Port.

5. Go to the Send OS tab.

6. Press the Start button.

7. In the resulting dialog box, select the file that should be sent to the device

as an operating system (this file should have a .hex extension) and press

the OK button.

8. The operating system will be sent to the AL200.

9. Do not remove power while an OS download is in process.

F-1

Appendix F. Updating the Operating System of the AL200

F-2

TABLE G-1. Recommended Sensor IDs

Appendix G. List of Recommended Sensor IDs

ID Sensor Type

0 Rain

1 Air Temperature

2 Relative Humidity

3 Barometric Pressure

4 Wind Speed

5 Wind Direction

6 Peak Wind Speed

7 Stage

8 Battery Voltage

*As recommended in the ALERT2 Application Layer Protocol Specification

document, Version 1.2.

G-1

Appendix G. List of Recommend Sensor IDs

G-2

1X2

X

1Y

2Y

Multiplier

−

−

=

mVper psi 0060.0

)7.4974(30)3.

124987(

030

Multiplier =

=

−

−

=

( )

mVper psi 074.03.12•0060.00Offset −=−=

Appendix H. Calculating Multipliers and Offsets

Unlike ALERT which could only represent measurement values between 0 and

2047, ALERT2 has the ability to represent a much larger range of floating

point numbers. It is no longer necessary to scale a reading to a unit-less

number less than 2047. Instead, with ALERT2, you can transmit values in

engineering units with a high degree of resolution. The simplified example

below demonstrates how to calculate the multiplier and offset that are needed

to convert a pressure transducer’s output, 0-5 volts, to feet of water.

For this example we will use a pressure transducer that has a 0 to 30 psi range

and a 0 to 5 volts output. From the manufacturer supplied calibration report it

is known that the sensor outputs 0.0123 volts at 0 psi and 4.987 volts at 30 psi

(12.3 and 4987 millivolts respectively).

The relationship between the sensor’s output in millivolts and pressure is

defined by the equation of a line (assuming linearity), Y = mX + b, where Y is

pressure, m is the calculated multiplier, X is the sensor’s output in millivolts,

and b is the calculated offset.

Y = mX + b

OR

Pressure = Multiplier • Sensor Output + Offset

The multiplier is determined by dividing the sensor’s measurement ranges by

the sensor’s range of output. For this example the multiplier will be:

OR

The offset is determined by entering the multiplier into the pressure equation

and solving for the offset using a known pressure and sensor output.

Offset = Pressure – (Multiplier • Sensor Output)

OR

H-1

Appendix H. Calculating Multipliers and Offsets

Now, we can calculate pressure based on the reading we get from the sensor.

For example, you measure the sensor’s output as 2543.210 mV. Pressure

would be determined by:

Pressure = (0.0060 • 2543.210) + (–0.074) = 15.263 psi

To determine water depth, simply multiply the pressure value by the

appropriate conversion factor.

For fresh water this is:

1 psi = 2.308 ft.

For salt water this is:

1 psi = 2.250 ft.

For the above example (assuming fresh water):

Depth of Water = Pressure • 2.308

Depth of Water = 15.263 • 2.308 = 35.226 ft.

These calculations can easily be performed using many spreadsheet programs

by plotting the sensor’s measurement range versus the sensor’s output range.

The equation of the trendline contains the multiplier and offset.

H-2

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific (Beijing) Co., Ltd.

8B16, Floor 8 Tower B, Hanwei Plaza

7 Guanghua Road

Chaoyang, Beijing 100004

P.R. CHINA

www.campbellsci.com • info@campbellsci.com.cn

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Loading...

Loading...