Page 1

A150 Desiccated Case

4/11

Copyright © 2011

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12) months

from date of shipment unless otherwise specified on the corresponding Campbell

invoice. Batteries, fine-wire thermocouples, desiccant, and other consumables have

no warranty. Campbell's obligation under this warranty is limited to repairing or

replacing (at Campbell's option) defective products, which shall be the sole and

exclusive remedy under this warranty. The customer shall assume all costs of

removing, reinstalling, and shipping defective products to Campbell. Campbell

will return such products by surface carrier prepaid within the continental United

States of America. To all other locations, Campbell will return such products best

way CIP (Port of Entry) INCOTERM

apply to any Campbell products which have been subjected to modification,

misuse, neglect, improper service, accidents of nature, or shipping damage. This

warranty is in lieu of all other warranties, expressed or implied. The warranty for

installation services performed by Campbell such as programming to customer

specifications, electrical connections to products manufactured by Campbell, and

product specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Campbell is not liable for any special, indirect, incidental, and/or consequential

damages.

Products may not be returned without prior authorization. The following contact

information is for US and International customers residing in countries served by

Campbell Scientific, Inc. directly. Affiliate companies handle repairs for customers

within their territories. Please visit www.campbellsci.com to determine which

Campbell Scientific company serves your country.

®

2010, prepaid. This warranty shall not

To obtain a Returned Materials Authorization (RMA), contact Campbell Scientific,

Inc., phone (435) 753-2342. After an applications engineer determines the nature

of the problem, an RMA number will be issued. Please write this number clearly

on the outside of the shipping container. Campbell Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material and

Decontamination” form and comply with the requirements specified in it. The form

is available from our website at

must be either emailed to repair@campbellsci.com

Campbell Scientific will not process any returns until we receive this form. If the

form is not received within three days of product receipt or is incomplete, the

product will be returned to the customer at the customer’s expense. Campbell

Scientific reserves the right to refuse service on products that were exposed to

contaminants that may cause health or safety concerns for our employees.

www.campbellsci.com/repair

or faxed to 435-750-9579.

. A completed form

Page 3

A150 Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Function........................................................................1

1.1 Typical Applications.................................................................................1

1.2 Compatibility ............................................................................................1

2. Physical Description ...................................................2

3. Specifications ..............................................................3

4. Sensor Hook-up and Example Diagrams...................3

4.1 #26972 with Stripped and Tinned Continuation Cable ............................4

4.2 #22018 PWENC Connector......................................................................4

4.3 #19520 CWS900 Connector.....................................................................5

5. Installation....................................................................6

Figures

5.1 Mounting ..................................................................................................6

5.2 Wiring.......................................................................................................6

1. A150 Desiccated Case ................................................................................1

2. A150 Interior ..............................................................................................2

3. CWS900 Connector Pin-Out ......................................................................3

4. A150 with Continuation Cable ...................................................................4

5. A150 with PWENC Connector...................................................................4

6. Anemometer Wired to an A150..................................................................5

7. A150 with CWS900 Connector..................................................................5

8. A150 Wired for CS450 Pressure Sensor and CWS900 Connector ............5

i

Page 4

Page 5

A150 Desiccated Case

1. Function

1.1 Typical Applications

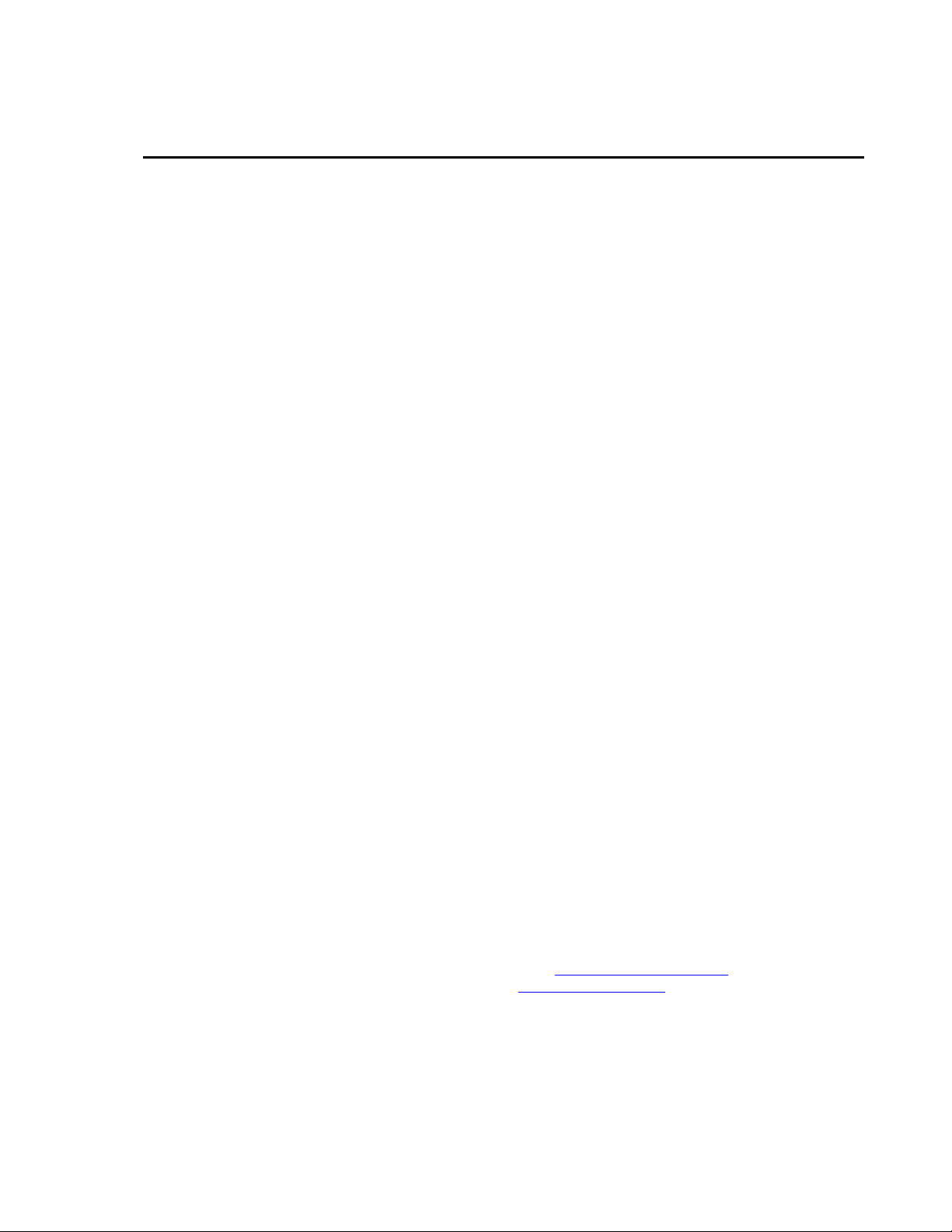

The A150 desiccated case is a small, self-contained junction box that allows a

sensor to be connected to a continuation cable, a PWENC connector, or a

CWS900 wireless sensor connector. Utilizing the A150, a sensor may be

incorporated into a wireless sensor network or may be attached to a prewired

enclosure.

Lid

Cable Gland

Chassis

The A150 allows the CS450 and CS455 pressure transducers to be used

without the need to run a ventilation tube all the way to a datalogger enclosure.

The sensor cable with a ventilation tube terminates at the A150, which contains

a small vent and desiccant, while a second cable without a ventilation tube

completes the connection to the datalogger.

The A150 provides a way for a sensor to be included in a wireless sensor

network. The sensor is attached to the A150 junction box, and a second cable

attaches the A150 to a CWS900 wireless sensor interface. This allows the

sensor more flexibility and range than it would have if it were wired directly to

a datalogger.

1.2 Compatibility

As a junction box, the A150 is compatible with most sensors using six wires or

less. Sensors with multiple ground wires can use the included 5-position lever

nut to combine the grounds into a single wire connection.

Mounting Bracket

FIGURE 1. A150 Desiccated Case

1

Page 6

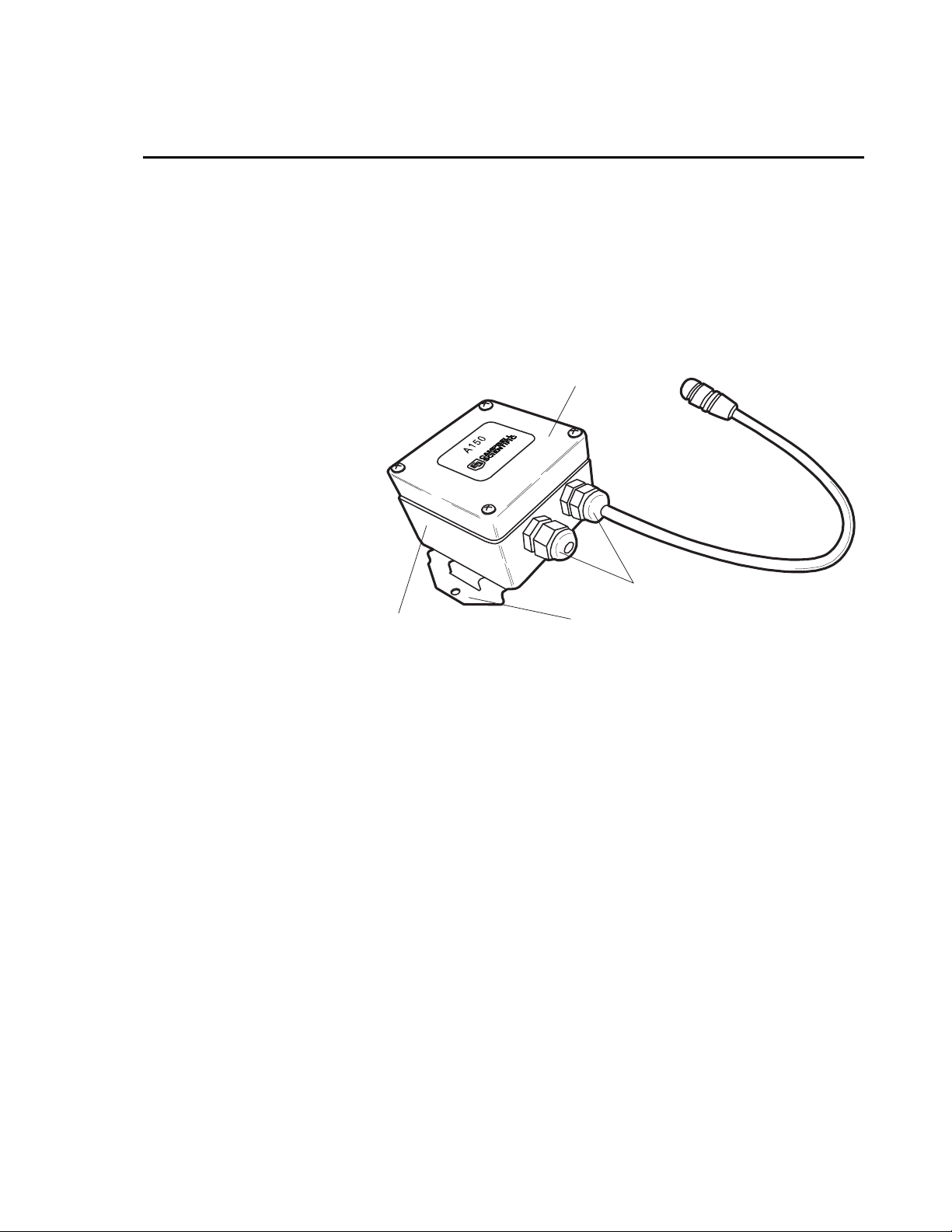

A150 Desiccated Case

T

NOTE

erminal Block

It is not recommended to insert more than one wire into each

connection on the terminal block. If it is necessary to combine

wires, use the 5-position lever nut to combine the wires, and then

insert the lead wire from the lever nut into the terminal block.

When used with a CWS900, the sensor can be used with sensors measuring

analog voltages, frequency, and pulse. The CWS900 can also provide

excitation voltage to a sensor through the A150.

Wire to Datalogger

or CWS900

Lever Nut

Vent

FIGURE 2. A150 Interior

2. Physical Description

The A150 has an 80 mm x 82 mm x 55 mm chassis. Four screws secure the lid

to the rest of the unit. A terminal block is mounted inside the chassis. A small

vent is located on the bottom of the chassis. The vent is protected by a GORE

filter, which prevents moisture and contaminants from entering the unit while

equalizing the interior air pressure to the current atmospheric pressure.

A mounting bracket is attached to the bottom of the chassis. The bracket is

used to fasten the A150 inside an enclosure or, with the included Velcro

to another location of the user’s choosing.

®

strap,

®

2

Page 7

A150 Desiccated Case

3. Specifications

Dimensions: 80 mm x 82 mm x 55 mm (3.15" x 3.228" x 2.171")

Temperature Range: -30ºC to +65ºC

Internal Protection Rating: IP 66 (International Standard IEC 60529)

Terminal Block Wire Gauges: 28–12

5-wire Lever Nut Wire Gauges: 28–12 (replacement part number 27373)

Cable Gland Min/Max Cable Diameter: 4.6 mm/7.9 mm (0.181"/0.312")

Desiccant Bag (1/2 Unit) Replacement Part Number: 905

®

Velcro

Humidity Indicator Card Replacement Part Number: 6571

Strap Replacement Part Number: 5487

4. Sensor Hook-up and Example Diagrams

There are three options available when ordering the A150. The first option

includes a stripped and tinned continuation cable. The length of this cable is

specified when ordering the A150.

The second option includes a PWENC connector, allowing the A150 to be

attached to prewired enclosures.

The third option includes a connector to attach the A150 to the CWS900

wireless sensor interface. The CWS900 completes the connection to the

datalogger through a wireless sensor network.

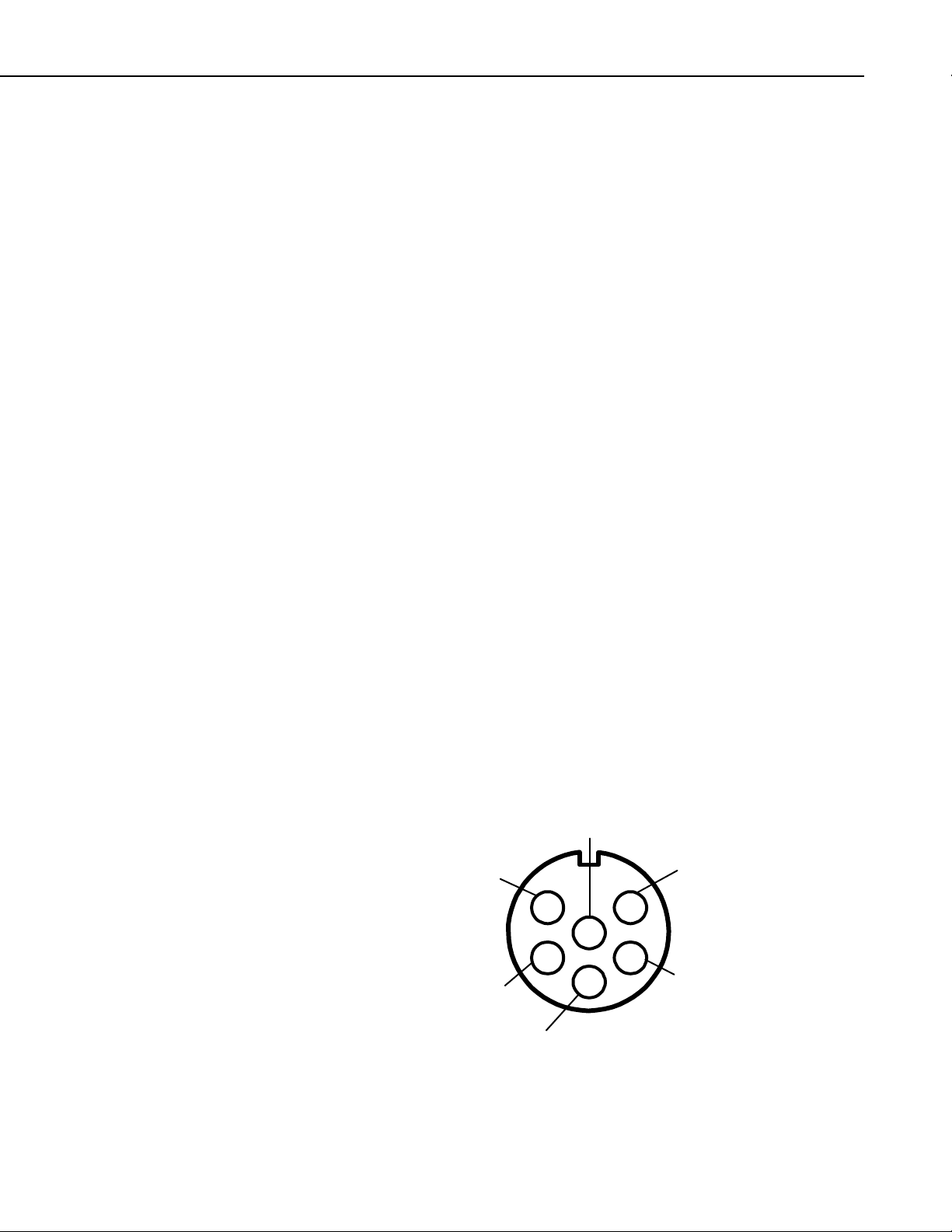

Figure 3 shows the pin-out of the CWS900 connector. Take care that the

sensor wires attached to the A150 correspond to the correct pins as shown in

the diagram.

Pin 6

SE2 or DIFF L

Pin 1 SE3

Pin 2 Pulse

Pin 5

SE1 or DIFF H

Pin 4 EX

(2.5V, 3.3V, or 5V)

Pin 3 Ground

FIGURE 3. CWS900 Connector Pin-Out

3

Page 8

A150 Desiccated Case

4.1 #26972 with Stripped and Tinned Continuation Cable

Figure 4 shows the A150 terminal block with a 26972 continuation wire

attached. This configuration allows a CS450 or other sensor to be attached to

the A150 while the pigtail wire completes the connection to the datalogger.

WHITE

BLUE

GREEN

RED

BLACK

BLACK

CLEAR

FIGURE 4. A150 with Continuation Cable

NOTE

Wire colors may vary between different sensors. It is up to the

installer to take into account any mismatched wire colors

between the sensor and pigtail wire when connecting wires to the

A150.

4.2 #22018 PWENC Connector

Figure 5 shows the A150 terminal block with a PWENC connector attached.

This configuration allows a CS450 or other sensor to be attached to the A150

while the PWENC connector completes the connection to a pre-wired

enclosure.

#26972 Cable w/ Tinned Wire Ends

4

BLACK

NOTE

WHITE

BLUE

GREEN

RED

BLACK

CLEAR

#26972 Cable

(Pin #)

1

2

3

#22018

PWENC Connector

4

5

6

FIGURE 5. A150 with PWENC Connector

When using the A150 to wire a sensor to a PWENC connector,

ensure the wiring inside the pre-wired enclosure corresponds

with the wiring from the sensor.

Figure 6 gives an example of an anemometer wired to an A150. Note that the

green wire in the PWENC connector must be connected to a datalogger’s pulse

input inside the enclosure for the signal to be measured.

Page 9

A150 Desiccated Case

W

A

r

Anemometer

BLACK Signal Pulse

HITE Signal Reference

CLEAR Shield

4.3 #19520 CWS900 Connector

WHITE

BLUE

GREEN

RED

BLACK

CLEAR

#26972 Cable

(Pin #)

1

2

3

#22018

PWENC Connector

4

5

6

FIGURE 6. Anemometer Wired to an A150

Figure 7 shows the A150 terminal block with a CWS900 attached. This

configuration allows a CS450 or other sensor to be attached to the A150 while

the CWS900 wireless sensor interface completes the connection to the wireless

sensor network.

WHITE

BLUE

GREEN

RED

BLACK

BLACK

CLEAR

#26972 C able

56(Pin #)

2

1

#19520

CWS900 Connector

4

3

Sensor RX (In)

Sensor T X (Ou t)

Power

Power GND

Digital GND

Shield

Ven t

FIGURE 7. A150 with CWS900 Connector

Figure 8 shows a CS450 connected to an A150. Note how multiple grounds

are combined into a single lead wire using the lever nut.

CS450

BLUE

WHITE

RED

BLACK

YELLOW

CLEAR

TUBE

N.C.

BLACK

N.C.

150Pressure Senso

WHITE

BLUE

GREEN

RED

BLACK

CLEAR

Terminates in A150 Enclosure

#26972 Cable

(Pin #)

5

2

1

#19520

CWS900 Connector

4

3

6

FIGURE 8. A150 Wired for CS450 Pressure Sensor and CWS900 Connector

5

Page 10

A150 Desiccated Case

5. Installation

5.1 Mounting

5.2 Wiring

The A150 provides two options for mounting. The first is to use the Velcro®

strap included with the A150. This allows the A150 to be secured to a small

mast, fencepost or other location where it is not possible to use mounting

screws.

The second option is to use the mounting bracket on the back of the A150.

This bracket allows the A150 to be mounted inside an enclosure or to another

flat surface, using two screws through the bracket to secure the A150.

To wire a sensor to the A150, route the sensor cable through the cable gland

and attach each wire to the terminal block adjacent to the corresponding wire to

the datalogger or CWS900. Use the lever nut to combine multiple ground

wires into a single wire connection. Consult the documentation included with

the sensor, or contact a Campbell Scientific Applications Engineer, for the

correct placement of each wire.

Once all wires are attached, tighten the wire gland to prevent water or

contaminants from entering the A150. Place a desiccant pack, included with

the A150, inside the chassis. Also place the humidity indicator card inside the

A150, and then secure the lid in place with the four captured screws.

6

Page 11

Page 12

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...