Page 1

4WFBS120, 4WFBS350, 4WFBS1K

4 Wire Full Bridge Terminal

Input Modules

Revision: 3/12

Copyright © 1996-2010

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

4WFBS120, 4WFBS350, 4WFBS1K

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Function........................................................................1

2. Specifications ..............................................................1

3. Measurement Concepts ..............................................2

4. Quarter Bridge Strain ..................................................4

4.1 Quarter Bridge Strain with 3 Wire Strain Element...................................4

4.1.1 Quarter Bridge Strain with 3 Wire Element Wiring .......................5

4.1.1.1 Quarter Bridge Strain with 3 Wire Element Wiring using

a multiplexer.......................................................................5

4.1.2 Quarter Bridge Strain with 3 Wire Element Calculations...............6

4.1.3 Quarter Bridge Strain with 3 Wire Program Examples ..................7

4.1.3.1 CRBasic Programming..........................................................7

4.1.3.2 Edlog ...................................................................................11

4.2 Quarter Bridge Strain with 2 Wire Element ...........................................17

4.2.1 Quarter Bridge Strain with 2 Wire Element Wiring .....................17

4.2.2 Two Wire ¼ Bridge use with Multiplexers and Equations...........18

4.3 Quarter Bridge Strain with Dummy Gage ..............................................18

4.3.1 Quarter Bridge Strain with Dummy Gauge Wiring Setup............20

4.3.2 Quarter Bridge Strain with Dummy Gauge Calculations..............21

4.3.3 Quarter Bridge Strain with Dummy Gauge Example Programs ...21

4.4 Quarter Bridge Strain Lead Resistance Compensation...........................21

4.4.1 Mathematical Lead Compensation for 3-Wire, ¼ Bridge Strain ..21

4.4.1.1 Mathematical Lead Compensation Circuit and Equations ..22

4.4.1.2 Mathematical Lead Compensation Programs......................23

4.4.2 Shunt Calibration Lead Compensation for 3-Wire, ¼ Bridge

Strain .........................................................................................30

4.4.2.1 Three Wire Gage Circuit with Shunt...................................30

4.4.2.2 Math for Shunt Calibration of 3-Wire, ¼ Bridge Strain

Circuits .............................................................................32

4.4.2.3 Example Programs for Shunt Calibration of 3-Wire,

¼ Bridge Strain Circuits...................................................34

4.4.3 Lead Compensation using Quarter Bridge Strain with 2 Wire

Element .....................................................................................35

4.5 Calculation of Strain for ¼ Bridge Circuits............................................37

i

Page 6

4WFBS120, 4WFBS350, 4WFBS1K Table of Contents

Figures

1-1. Terminal Input Module with CR1000 .................................................... 1

2-1. Schematic................................................................................................ 2

3-1. Strain definition ...................................................................................... 2

4.1-1. Three wire quarter bridge strain circuit ............................................... 4

4.1-2. 3-wire ¼ bridge strain wiring .............................................................. 5

4.1-3. 3-wire ¼ bridge strain with multiplexer wiring................................... 5

4.2-1. Two wire quarter bridge strain circuit ............................................... 17

4.2-2. Wiring for 2-wire gauges................................................................... 18

4.3-1. Quarter bridge strain circuit with dummy gauge............................... 19

4.3-2. ¼ bridge strain with remote dummy gauge ....................................... 20

4.3-3. ¼ bridge strain with dummy gauge at datalogger.............................. 20

4.4-1. Three wire ¼ bridge strain circuit...................................................... 22

4.4-2. Shunting remotely across active gauge.............................................. 31

4.4-3. Circuit for shunting across dummy resistor....................................... 31

4.4-4. Wiring for shunt across dummy resistor............................................ 32

4.4-5. Two wire quarter bridge strain circuit ............................................... 35

4.5-1. Strain gage in full bridge ................................................................... 37

Table

4-1. Input Locations Used in CR10(X), 21X, and CR7 Examples .............. 11

ii

Page 7

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

1. Function

The 4WFBS120, 4WFBS350, and 4WFBS1K Terminal Input Modules (TIM)

complete a full Wheatstone bridge for a single strain gage or other sensor that

acts as a single variable resistor. The difference between the three models is in

the resistor that matches the nominal resistance of a 120 ohm, 350 ohm, or

1000 ohm quarter bridge strain gage. It can also be used to complete the back

half of a Wheatstone bridge for use in a ¼ bridge strain circuit (1 active

element) using a dummy gage, or in a ½ bridge strain circuit (2 active

elements).

FIGURE 1-1. Terminal Input Module with CR1000

2. Specifications

2:1 Resistive Divider

Resistors:

Ratio tolerance @ 25 °C:

Ratio temperature coefficient:

Power rating per element:

Completion Resistor: 120, 350, or 1000 Ω

Tolerance @ 25 °C:

Temperature coefficient:

Power rating:

1 kΩ/1 kΩ

±0.01%

0.5 ppm/°C

(-55°C to 85°C)

0.1 W @ 70°C

±0.01%

±0.8 ppm °C

(-55°C to 85°C)

0.25 W @ 70°C

-1

1

Page 8

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

ε

(

)

ε

με

=

Δ

Δ

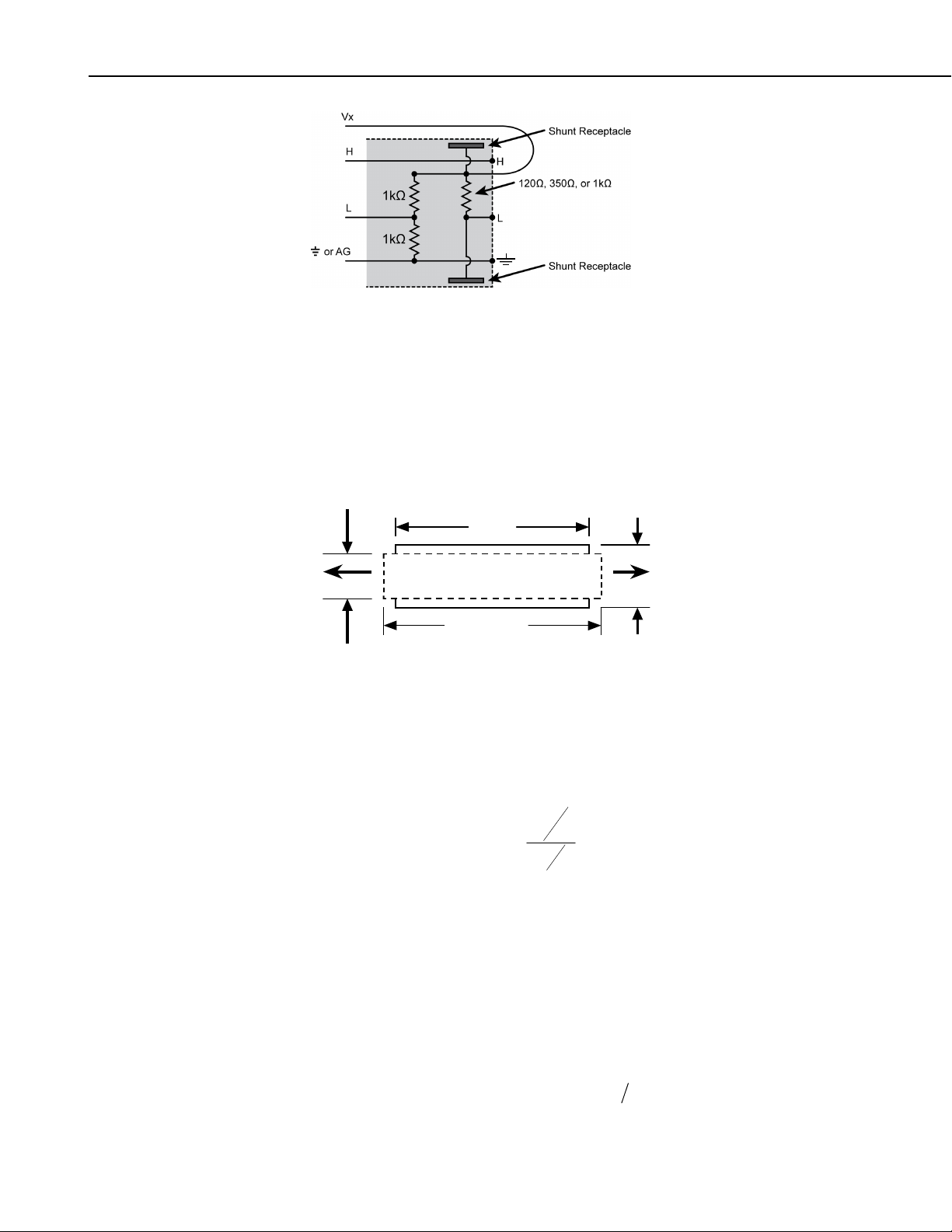

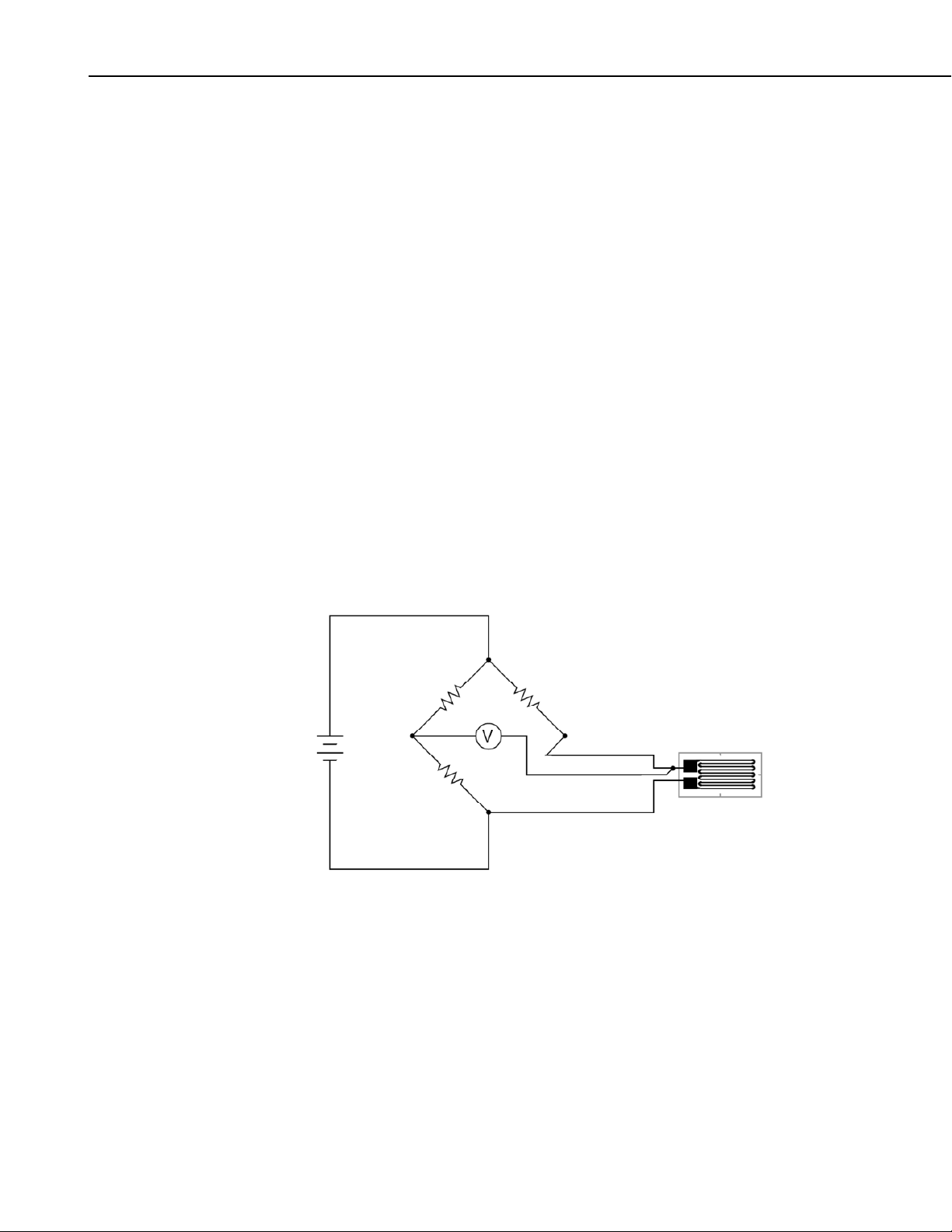

FIGURE 2-1. Schematic

3. Measurement Concepts

Measuring strain is measuring a change in length. Specifically, the unit strain

is the change in length divided by the unstrained length

()

and thus is dimensionless.

,

LL /Δ=

LT + ΔL

T

L

T

L

PP

L + ΔL

FIGURE 3-1. Strain definition

As the subject is elongated in the longitudinal direction, the material will be

narrowed or thinned down in the transverse direction. The ratio of the

transverse strain to the longitudinal strain is known as the Poisson ratio (

L

Δ

T

L

ν

=

3.1

This Poisson ratio is a known property for most materials and is used in some

half bridge strain and full bridge strain circuits.

T

L

Δ

L

ν).

2

Strain is typically reported in microstrain

expressed in parts per million, i.e.: a change in length divided by one millionth

of the length.

A metal foil strain gage is a resistive element that changes resistance as it is

stretched or compressed. The strain gage is bonded to the object in which

strain is measured. The gage factor,

resistance to the change in strain:

GF , is the ratio of the relative change in

GF R R l l

. Microstrain is strain

()

//

. For example, a

Page 9

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

μ

Δ

(

−

=

(

)

⋅

gage factor of 2 means that if the length changes by one micrometer per meter

of length

resistance. A more common method of portraying this equation is:

, the resistance will change by two micro-ohms per ohm of

()1

ε

=

ε

Or in terms of micro-strain:

με

=

Because the actual change in resistance is small, a full Wheatstone bridge

configuration is used to give the maximum resolution. The Wheatstone bridge

can be set up with 1 active gage (Quarter bridge strain circuit), two active

gages (Half bridge strain circuit), or 4 active gages (Full bridge strain circuit).

For each of these Wheatstone bridge circuits there are multiple configurations.

The 4WFBS module provides three resistors that can be used for three of the

arms of the Wheatstone Bridge (Figure 4-1). There are two 1000 ohm

precision resistors for the back plane of the Wheatstone bridge, and a resistor

matching the strain gage's resistance for the bridge arm opposite the gage. The

inputs of the 4WFBS are configured so that this matching resistor can be

bypassed if it is desired to utilize a dummy gauge, or to use two active gauges

(Half Bridge Strain circuit).

For Full Bridge Strain circuits, as all four arms of the Wheatstone bridge are

active gages, there is no need for completion resistors, and thus a 4WFBS

module is not required.

G

RGFR•

G

3.2

6

)

101

RΔ×

G

RGF •

G

3.3

The resistance of an installed gage will differ from the nominal value. In

addition, lead resistance imbalances can result in further unbalancing of the

bridge. A zero measurement can be made with the gage installed. This zero

measurement can be incorporated into the datalogger program such that

subsequent measurements can report strain relative to this zero basis point.

This removes the apparent strain resulting from the initial bridge imbalance.

Strain is calculated in terms of the result of the full bridge measurement. This

result is the measured bridge output voltage divided by the bridge excitation

voltage:

All of the various equations that are used to calculate strain use V

in the bridge measurement from the zero state:

The result of the zero measurement,

the calculation of future strain measurements. Alternatively, the zero reading

value can be left at 0 (zero measurement is neither recorded nor used).

It should be noted the actual result of the full bridge instruction (BrFull) is the

millivolts output per volt of excitation (

V

outex

V

/

.

VVVVV )/()/(

ZeroexoutStrainedexoutr

, can be stored and used in

VV /⋅

exout

Zero

1000 VV

out ex

). The StrainCalc

/

, the change

r

3.4

3

Page 10

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

function used in CRBasic uses this raw output as its input to calculate µstrain.

See Section 4.5 Calculation of Strain for ¼ Bridge Circuits for a detailed

derivation of the equations used.

4. Quarter Bridge Strain

A "quarter bridge strain circuit" is so named because an active strain gage is

used as one of the four resistive elements that make up a full Wheatstone

bridge. The other three arms of the bridge are composed of inactive elements.

There are various circuits that use a single active element, including 2-Wire

gauges, 3-Wire gauges, as well as a few circuits that utilize a dummy gauge for

the arm opposite the arm holding the active gage instead of a resistor, R

Figure 4.1.-1 (See Figures 4.3-1, 4.3-2, and 4.3-3). The 4WFBS TIM modules

can support all types of these ¼ Bridge Strain circuits.

4.1 Quarter Bridge Strain with 3 Wire Strain Element

A 3-wire quarter bridge strain circuit is shown in figure 4.1-1. Strain gages are

available in nominal resistances of 120, 350, and 1000 ohms. The

4WFBSXXX model must match the nominal resistance of the gage when using

the 3-Wire circuit (e.g., the 4WFBS120 is used with a 120 ohm strain gage).

D

in

In Figure 4.1-1, R

the Wheatstone bridge, as is done in the TIM design. R

element, is the complementary resistor that has a nominal resistance of the unstrained gage. The 4

R2=1 KΩ

Excite V

R

and R2 are 1000 ohm resistors making up the back plane of

1

, the third resistive

D

th

resistive element is the active strain gage.

R

D

R

= Gauge

4

=1 KΩ

1

L

-

+

3

L

2

L

1

FIGURE 4.1-1. Three wire quarter bridge strain circuit

The 3-Wire gage alleviates many of the issues of the 2-Wire gage. As can be

seen in Figure 4.1-1, lead wire L

has the completion resistor while lead wire L

gage. L

is tied back to the input channel of the datalogger that has an input

2

is in the arm of the Wheatstone bridge that

3

is in the arm that has the active

1

resistance greater than 1 Gohm, thus the current flow is negligible, negating

effects of L

’s resistance. This circuit nulls temperature induced resistance

2

changes in the leads as well as reduces the sensitivity effect that the wires have

on the gauge. See Section 4.4 for more on Lead resistance effects and methods

to compensate for them.

4

Page 11

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

A

A

X

4

4.1.1 Quarter Bridge Strain with 3 Wire Element Wiring

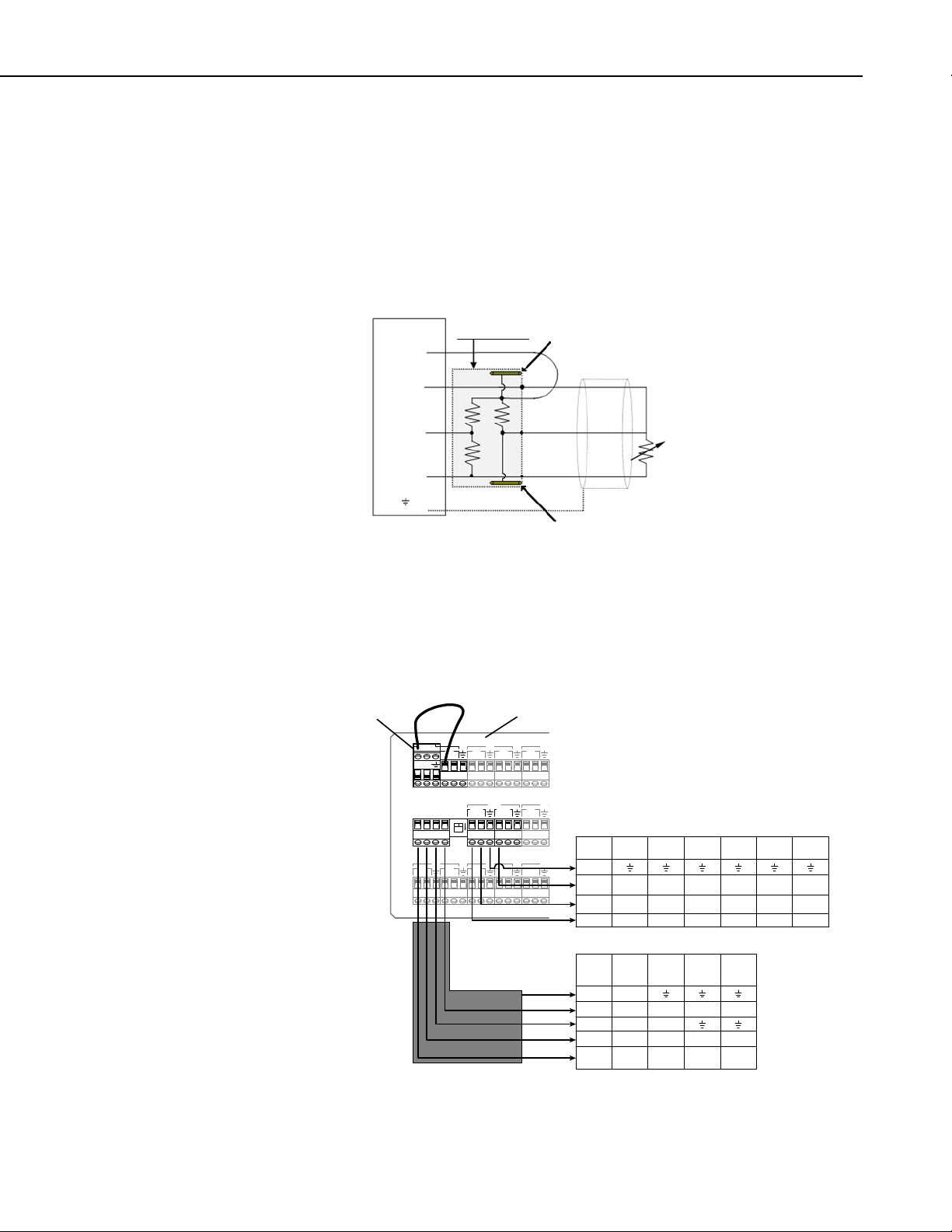

Figure 4.1-2 illustrates the wiring of the strain gage to the 4WFBS module and

the wiring of the module to the datalogger. It is important that the gage be

wired as shown, and that the leads to the L and G terminals be the same length,

diameter, and wire type. It is preferable to use a twisted pair for these two

wires so that they will undergo the same temperature and electromagnetic field

variations. With this configuration, changes in wire resistance due to

temperature occur equally in both arms of the bridge with negligible effect on

the output from the bridge.

Datalogger

VX or E

4WFBSXXX TIM

Shunt Receptacl e

H

R

2

R

=1KΩ R

D

L

1

=1KΩ

ctive Gauge

G

or G

Shunt Receptacle

FIGURE 4.1-2. 3-wire ¼ bridge strain wiring

4.1.1.1 Quarter Bridge Strain with 3 Wire Element Wiring using a multiplexer

When using a mechanical relay multiplexer such as the AM16/32B, the

4WFBS module should normally be placed on the face of the multiplexer

similar as shown in Figure 4.1-3.

WFBS

2 345

H L H LH LHL

HLG

AM16/32B Relay Multiplexer

23

COM

ODD EVEN

H LHL H L

4X16

GND

CLK

RES

12V

N

1

O

2X32

11

21

LHLHLHLHL

H

12

22

23 24

7

13

13

25

Cable Shield

CR10X

AG

E1–E3

1L

1H

CR800

CR850

12 V

C1–C4

C1–C4

CR1000

EX1–EX3 or

VX1–VX3

1L

1H

CR23X

CR5000

12 V

G

C1–C8

C1–C8

CR3000

CR5000

VX1–VX4

1L

1H

21X

+12 V

EXCIT 1–4

C1–C6

21X

EXCITATION

1–4

1L

1H

CR7

12 V

EXCITATION

725 Card

Control

CR23X

EX1–EX4

1L

1H

CR10X

CR1000

CR3000

G

G

12 V

G

G

C1–C8

C1–C8

CR7

SWITCHED

ANALOG OUT

1L

1H

CR800

CR850

EX1–EX2 or

VX10VX2

1L

1H

FIGURE 4.1-3. 3-wire ¼ bridge strain with multiplexer wiring

5

Page 12

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

(

⋅

=

−

V

Although this requires a 4WFBS module for each strain gage, it is important

because placing relays internal a Wheatstone bridge strain system is

discouraged. Any change in resistance of the multiplexer’s relay contacts

would result in a corresponding change in the bridge’s output voltage.

Changes in contact resistance can be induced by temperature fluctuations,

oxidation, environmental conditions, and normal wear of contact surfaces. The

specification for the relays that are used in our multiplexers state that initial

contact resistance will be less than 100 milliohms (AM16/32B). There is not a

specification for change in contact resistance for the relays because there are so

many variables that affect contact resistance. Test reports exist for various test

conditions that show contact resistance changing over time by 10 to 20 milliOhms. These tests were performed using static test temperatures, so it is safe

to assume that real world conditions would result in larger resistance shifts.

When strain gauges are used in the Wheatstone bridge, small changes in

contact resistance result in large apparent strains. To understand the error that

can be introduced from allowing the relay contacts to be internal of the

Wheatstone bridge, let us assume that the two relays carrying the current from

the strain gage vary by 20 milliohms (40 milliohm total variance or ΔR

mΩ ). Inserting this into equation 3.3, using a 120 ohm strain gage with a gage

factor of 2 results in an apparent strain of about 167 με.

= 40

G

6

με

167

=

)

1202

Ω×× 04.0101

Ω×

4.1.2 Quarter Bridge Strain with 3 Wire Element Calculations

As noted in Section 3, in real life applications the Wheatstone bridge starts out

unbalanced. The strain gauge is never perfectly at its nominal resistance even

prior to installation. The installation process can lead to even more deviation

from this nominal state. In addition, lead resistance can cause an initial

apparent strain reading. To remove this initial offset, a zero measurement can

be made with the gauge installed. This zero measurement can be incorporated

into the datalogger program and subsequent measurements can report strain

relative to this zero basis point.

Strain is calculated in terms of the result of the full bridge measurement. This

result is the measured bridge output voltage divided by the bridge excitation

voltage

V

out ex

millivolts output per volt of excitation,

measurement,

strain measurements. The change in the full bridge measurement from the zero

state, V

, is used in the calculation of the strain.

r

. (The actual result of the full bridge instruction is the

V

/

1000⋅V

1000

VV

out ex

VVV V V

r out ex out ex

can be stored and used to calculate future

/

0

(/)( /)

out

0

) The result of the zero

/ V

ex

4.1.1

Using V

4.1.2

from equation 4.1.1, the strain is calculated using equation 4.1.2.

r

ε

=

GF V

r

()

−412

r

The calculations are covered in more detail in Section 4.5.

6

Page 13

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

4.1.3 Quarter Bridge Strain with 3 Wire Program Examples

This section is broken out into CRBasic programs and EDLOG programs.

These programs are only to be used as examples. Besides adding additional

measurement instructions, the programs will need to have the scan and data

storage intervals altered for actual applications. Refer to the datalogger’s

manuals and/or the CRBasic Editor’s help files for detailed information on the

program instructions used as well as additional program examples.

4.1.3.1 CRBasic Programming

Dataloggers that use CRBasic include our CR800, CR850, CR1000, CR3000,

CR5000, and CR9000(X). CRBasic uses the StrainCalc Instruction for

calculating strain from the output of different full bridge configurations:

StrainCalc(Dest,Reps,Source,BrZero,BrConfig,GageFactor,PoissonRatio)

Source is the variable holding the current result from the full bridge

measurement

BrZero is the zero measurement; this parameter uses the results of a previous

full bridge measurement instruction when the gage is at the zero condition

(multiplier=1, offset=0, mV/V) directly.

BRCode for the Bridge Configuration used with the 4WFBS module should be

set to -1 for a quarter bridge strain circuit.

Enter the actual gage factor in the GageFactor parameter.

Enter 0 for the Poisson ratio parameter, which is not used with ¼ Bridge strain

circuits.

Example Program 4.1. CR9000X ¼ bridge Strain with 3 reps

This example program measures the output from the Wheatstone bridge using

the BrFull instruction. The output from this instruction is input into the

StrainCalc instruction in order to calculate the raw µstrain value. This

program does not use a zero offset reading. See Example Program 4.2 for an

example that performs a zero calibration.

' Program name: STRAIN.C9X

Public StrainMvperV(3) : Units StrainMvperV = mV_per_V 'Raw Strain dimensioned source

Public Strain(3) : Units Strain = uStrain ‘uStrain dimensioned source

Public GF(3) 'Dimensioned gauge factor

DataTable(STRAIN,True,-1) 'Trigger, auto size

DataInterval(0,0,0,100) 'Synchronous, 100 lapses, autosize

CardOut(0,-1) 'PC card , size Auto

Sample (3,Strain(),IEEE4) '3 Reps, uStrain, Resolution

Sample (3,StrainMvperV(),IEEE4) ‘3Reps,Stain mVolt/Volt, Resolution

EndTable 'End of table STRAIN

BeginProg 'Program begins here

GF(1) = 2.1 : GF(2) = 2.2 : GF(3) = 2.3 'Initialize gauge factors for Strain( )

7

Page 14

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

Scan(10,mSec,100,0) 'Scan once every 10 mSecs, non-burst

BrFull(StrainMvperV(),3,mV50,4,1,5,7,1,5000,True,True,70,100,1,0)

StrainCalc(Strain(),3,StrainMvperV(),0,-1,GF(),0) 'Strain calculation

CallTable STRAIN

Next Scan 'Loop up for the next scan

SlowSequence 'Slow sequence Scan to perform temperature

Scan(1,Sec,0,0) ' compensation on DAQ

Calibrate 'Corrects ADC offset and gain

BiasComp 'Corrects ADC bias current

Next Scan

EndProg 'Program ends here

Example Program 4.2. CR9000X ¼ bridge Strain with 3 reps and zero offset

This example program starts out with Example Program 4.1 and adds

instructions (highlighted) to perform a zero calibration. As all strain circuits

have a zero or initial imbalance that is related to the circuit rather than the

member undergoing strain, a zero reading is often used to offset or remove this

apparent strain. Again, see the manual and CRBasic editor’s Help file for

more in-depth discussion on the instructions.

The FieldCalStrain instruction takes care of the underlying math for the

zeroing using equation 4.1.2.

The LoadFieldCal instruction facilitates the reloading of the calibration

factors when the logger is powered up. In addition, the programmer should

create a DataTable (we have called this DataTable Calib in the example) to

store the calibration factors each time a calibration is done.

The NewFieldCal is a Boolean flag variable that is only high during the Scan

that a calibration has been completed. It is used in the DataTable instruction’s

trigger parameter to trigger the table to record a record.

The SampleFieldCal output instruction is used to inform the logger to store all

of the calibration factors that are controlled using the FieldCalStrain

instruction.

Program name: STRAIN0.C9X

'

Public StrainMvperV(3) : Units StrainMvperV = mV_per_V 'Raw Strain dimensioned source

Public Strain(3) : Units Strain = uStrain ‘uStrain dimensioned source

Public GF(3) 'Dimensioned gauge factor

Public ZeromV_V(3), ZeroStrain(3)

Public ZReps, ZIndex, ModeVar

DataTable(STRAIN,True,-1) 'Trigger, auto size

DataInterval(0,0,0,100) 'Synchronous, 100 lapses, autosize

CardOut(0,-1) 'PC card , size Auto

Sample (3,Strain(),IEEE4) '3 Reps, uStrain, Resolution

Sample (3,StrainMvperV(),IEEE4) ‘3Reps,Stain mVolt/Volt, Resolution

EndTable 'End of table STRAIN

DataTable (Calib,NewFieldCal,10) ‘Table for calibration factors from zeroing

SampleFieldCal ‘User should collect these to his computer

EndTable ‘for future reference

8

Page 15

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

BeginProg 'Program begins here

GF(1) = 2.1 : GF(2) = 2.2 : GF(3) = 2.3 'Initialize gauge factors for Strain( )

ZReps = 3 : ZIndex = 1 ‘initialize cal reps and index pointer

LoadFieldCal(True) ‘Load prior calibration factors

Scan(10,mSec,100,0) 'Scan once every 10 mSecs, non-burst

FieldCalStrain(10,StrainMvperV(),ZReps,0,ZeromV_V(),ModeVar,0,ZIndex,1,0,Strain())

BrFull(StrainMvperV(),3,mV50,4,1,5,7,1,5000,True,True,70,100,1,0)

StrainCalc(Strain(),3,StrainMvperV(),ZeromV_V(),-1,GF(),0) 'Strain calculation

CallTable STRAIN

CallTable Calib

Next Scan 'Loop up for the next scan

SlowSequence 'Slow sequence Scan to perform

Scan(1,Sec,0,0) 'temperature compensation on the DAQ

Calibrate 'Corrects ADC offset and gain

BiasComp 'Corrects ADC bias current

Next Scan

EndProg 'Program ends here

Example Program 4.3. CR1000 ¼ Bridge Strain with 3 reps and zero offset

This example program performs the same tasks as Example Program 4.2, only

it is a CR1000 program instead of a CR9000X program. There are slight

differences such as range codes and the fact that the CR1000 does not have a

Slot parameter for its measurement instructions. This program is more similar

to what a CR800, CR3000, or a CR5000 program would look like than the

CR9000X program.

Program name: STRAIN0.CR1

'

Public StrainMvperV(3) : Units StrainMvperV = mV_per_V 'Raw Strain dimensioned source

Public Strain(3) : Units Strain = uStrain ‘uStrain dimensioned source

Public GF(3) 'Dimensioned gauge factor

Public ZeromV_V(3), ZeroStrain(3)

Public ZReps, ZIndex, ModeVar

DataTable(STRAIN,True,-1) 'Trigger, auto size

DataInterval(0,0,0,100) 'Synchronous, 100 lapses, autosize

CardOut(0,-1) 'PC card , size Auto

Sample (3,Strain(),IEEE4) '3 Reps, uStrain, Resolution

Sample (3,StrainMvperV(),IEEE4) ‘3Reps,Stain mVolt/Volt, Resolution

EndTable 'End of table STRAIN

DataTable (Calib,NewFieldCal,10) ‘Table for calibration factors from zeroing

SampleFieldCal ‘User should collect these to his computer

EndTable ‘for future reference

BeginProg 'Program begins here

GF(1) = 2.1 : GF(2) = 2.2 : GF(3) = 2.3 'Initialize gauge factors for Strain( )

ZReps = 3 : ZIndex = 1 ‘initialize cal reps and index pointer

LoadFieldCal(True) ‘Load prior calibration factors

Scan(100,mSec,100,0) 'Scan once every 10 mSecs, non-burst

FieldCalStrain(10,StrainMvperV(),ZReps,0,ZeromV_V(),ModeVar,0,ZIndex,1,0,Strain())

BrFull(StrainMvperV(),3,mV7_5,1,1,3,2500,True,True,450,500,1,0)

StrainCalc(Strain(),3,StrainMvperV(),ZeromV_V(),-1,GF(),0) 'Strain calculation

CallTable STRAIN

CallTable Calib

Next Scan 'Loop up for the next scan

9

Page 16

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

Example Program 4.3. CR1000 ¼ Bridge Strain using an AM16/32B

Multiplexer with 16 reps and zero offset

This example program has 16 strain gages multiplexed through an AM16/32

Multiplexer and uses FieldCalStrain for zeroing.

Program name: QuarterStrain with Zero and Mux.CR1

'

' This is only an example program and should be used only for help in creating a usable program

' ----------------------------------------------- WIRING ---------------------------------------------------------' CR1000 to AM16/32 Multiplexer Control

' C1 (Control Port 1) Res (Reset)

' C2 (Control Port 2) Clk (Clock)

' G GND (Ground)

' 12V 12V

' CR1000 to AM16/32 Common TIMs to AM16/32 Banks

' Diff 1H to Common Even Hi Blk Wire to Bank Odd Lo

' Diff 1L to Common Even Lo TIM H to Bank Even Hi

' EX1 to Common Odd Lo Tim L to Bank Even Lo

' AG to Common Gnd Tim AG to Bank Even AG

'\\\\\\\\\\\\\\\\\\\\\\\DECLARE VARIABLES and CONSTANTS ///////////////////////

Const REPS = 16 'Strain gage sensor count

Public MVpV(REPS) : Units MVpV = mV_V 'mV per Volt output from Bridge Measurement

Public STRAIN(REPS) : Units STRAIN = uStrain 'Variable where uS is stored,

Const BATCH_GF = 2.1 : Public GF(REPS) 'Batch Gage Factor

Public mV_VZero(REPS) : Units mV_VZero = mV_V 'Variable for Zero mV per V reading

Public CalReps, ZeroMode, ZeroStartIdx, ZeroCalAvgs 'Used by wizard for zeroing

Public CalFileLoaded As Boolean

Dim I

'\\\\IF DESIRED (NOT REQUIRED): GIVE STRAIN VARIABLES UNIQUE ALIAS NAMES ////////

Alias STRAIN(1) = Strain1 : Alias STRAIN(2) = Strain2 : Alias STRAIN(3) = Strain3

Alias STRAIN(4) = Strain4 : Alias STRAIN(5) = Strain5 : Alias STRAIN(6) = Strain6

Alias STRAIN(7) = Strain7 : Alias STRAIN(8) = Strain8 : Alias STRAIN(9) = Strain9

Alias STRAIN(10) = Strain10 : Alias STRAIN(11) = Strain11 : Alias STRAIN(12) = Strain12

Alias STRAIN(13) = Strain13 : Alias STRAIN(14) = Strain14 : Alias STRAIN(15) = Strain15

Alias STRAIN(16) = Strain16

'\\\\\\\\\\\\\\\\\\\\\\\\ OUTPUT SECTION ////////////////////////

' Table STRAIN stores uStrain and raw mV per Volt measurements to the PC Card

DataTable(STRAIN,True,-1) 'Trigger, auto size

DataInterval(0,0,0,100) 'Synchronous, 100 lapses

CardOut(0,-1) 'PC card , Autosize

Sample (REPS,STRAIN(),IEEE4) 'Sample uStrain

Sample (Reps,mVpV(),IEEE4) 'Sample raw mV per Volt values

EndTable 'End of table

' Table CalHist uses SampleFieldCal which stores all of the Calibration constants

' When a calibration function is complete, user should always collect this Table as a record

DataTable(CalHist,NewFieldCal,50)

SampleFieldCal

EndTable

'\\\\\\\\\\\\\\\\\\\\\\\\MAIN PROGRAM SECTION ////////////////////////

BeginProg 'Program begins here

For I = 1 To REPS ' For the 16 gages

GF(I) = BATCH_GF 'Assign default gauge factor (2.1) to GF array elements

Next I 'Loop back up until complete

CalFileLoaded = LoadFieldCal(1) 'Load the Cal constants if program signature matches

10

Page 17

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

Scan(1,Sec,10,0) 'Scan once a Second

PortSet (1 ,1 ) 'Turn on AM16/32 using C1

I = 1

Delay (0,150,mSec) 'required Delay for AM16/32 multiplexer

SubScan (0,0,16)

PulsePort (2,10000) 'Pulse port C2 hi and low to clock the multiplexer

BrFull(MVpV(I),1,mV7_5C,1,VX1,1,2500,True,True,250,500,1,0) 'Full Bridge measurement

StrainCalc(Strain(I),1,MVpV(I),mV_VZero(I),-1,GF(I),0) 'Strain calculation

I = I + 1 'Increment I

NextSubScan

PortSet (1 ,0 ) 'Turn on AM16/32 using C1

FieldCalStrain(10,MVpV(),CalReps,0,mV_VZero(),ZeroMode,0,ZeroStartIdx,ZeroCalAvgs,0,STRAIN())

CallTable CalHist

CallTable STRAIN

Next Scan 'Loop up for the next scan

EndProg 'Program ends here

4.1.3.2 Edlog

The following examples for the CR10(X), 21X, and CR7 all have subroutines

that measures the unstrained "zero" output of the strain gage. The examples

calculate strain using equation 4.1.2 for a strain gage with a GF=2. These are

just examples. Besides adding additional measurement instructions, the

programs will probably need to have the scan and data storage intervals altered

for actual applications. The instructions in the subroutine will also need to be

modified for the actual gage factor.

Dataloggers that use Edlog include CR510, CR10(X), 21X, and CR7. The

Edlog instruction that is used to measure strain gages is Instruction 6 – Full

Bridge.

The Input Locations assignments used in CR10(X), 21X, and CR7 Examples

are listed in Table 4-1.

TABLE 4-1. Input Locations Used in

CR10(X), 21X, and CR7 Examples

Addr Name

1 mVperV

2 mVperV_0

3 Vr

4 uStrain

5 Count

6 GF

7 _4e6

8 Mult

9 1_2Vr

10 Vr_1_2Vr

11

Page 18

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

Example Program 4.4. CR10X ¼ Bridge Strain with 1 rep and zero offset

;{CR10X}

*Table 1 Program

01: 1 Execution Interval (seconds)

1: If Flag/Port (P91) ;On the first execution (Flag 1 is low)

1: 21 Do if Flag 1 is Low ;or when user sets Flag 1 low

2: 1 Call Subroutine 1 ;call the zeroing subroutine

2: Full Bridge (P6) ;Measure the strain gage

1: 1 Reps

2: 22 ± 7.5 mV 60 Hz Rejection Range

3: 1 DIFF Channel

4: 1 Excite all reps withExchan 1

5: 2500 mV Excitation

6: 1 Loc [ mVperV ]

7: 1 Mult

8: 0 Offset

3: X-Y (P35) ;Subtract zero reading from the

1: 1 X Loc [ mVperV ] ;measurement

2: 2 Y Loc [ mVperV_0 ]

3: 3 Z Loc [ Vr ]

4: X*F (P37) ;Change Vr from mV/V to V/V

1: 3 Loc [ Vr ]

2: 0.001

3: 3 Loc [ Vr ]

;The following instructions calculate microstrain

5: Z=X*F (P37)

1: 3 X Loc [ Vr ]

2: -2 F

3: 9 Z Loc [ 1_2Vr ]

6: Z=Z+1 (P32)

1: 9 Z Loc [ 1_2Vr ]

7: Z=X/Y (P38)

1: 3 X Loc [ Vr ]

2: 9 Y Loc [ 1_2Vr ]

3: 10 Loc [ Vr_1_2Vr ]

8: Z=X*Y (P36)

1: 10 X Loc [ Vr_1_2Vr ]

2: 8 Y Loc [ Mult ]

3: 4 Z Loc [ uStrain ]

; Output Section : This example outputs an average of the 1 second readings ;once per minute.

09: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1 Interval (same units as above)

3: 10 Set Output Flag High

10: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 1 Array ID ;Set Array ID = 1 for measurement data

11: Real Time (P77)

1: 1110 Year,Day,Hour/Minute

12

Page 19

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

12: Average (P71)

1: 1 Reps

2: 4 Loc [ uStrain ]

*Table 2 Program

2: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

1: Beginning of Subroutine (P85) ;Subroutine to measure "zero"

1: 1 Subroutine 1

2: Do (P86) ;This prevents calling subroutine

1: 11 Set Flag 1 High ;until user sets flag 1 low again.

3: Z=F (P30) ;Set counter use for average to 0

1: 0 F

2: 0 Exponent of 10

3: 5 Z Loc [ Count ]

4: Z=F (P30) ;load 4 million (4*uS/S) into input location

1: 4 F

2: 6 Exponent of 10

3: 7 Z Loc [ _4e6 ]

5: Z=F (P30) ;Load Gage Factor into input location

1: 2 F ;Enter the actual Gage Factor here

2: 0 Exponent of 10

3: 6 Z Loc [ GF ]

6: Z=X/Y (P38) ;calculate multiplier to use with strain

1: 7 X Loc [ _4e6 ] ;calculation

2: 6 Y Loc [ GF ]

3: 8 Z Loc [ Mult ]

7: Beginning of Loop (P87) ;Loop through 5 times to obtain average

1: 0 Delay ;zero reading

2: 5 Loop Count

8: Z=Z+1 (P32) ;Increment Counter used to determine

1: 5 Z Loc [ Count ] ;when to output

9: Full Bridge (P6) ;Measure Strain Gage

1: 1 Reps

2: 22 ± 7.5 mV 60 Hz Rejection Range

3: 1 DIFF Channel

4: 1 Excite all reps withExchan 1

5: 2500 mV Excitation

6: 1 Loc [ mVperV ]

7: 1 Mult

8: 0 Offset

10: IF (X<=>F) (P89) ;Check for last pass through loop

1: 5 X Loc [ Count ] ;to set output flag

2: 3 >=

3: 5 F

4: 10 Set Output Flag High

11: Set Active Storage Area (P80) ;Direct averaged "zero" reading

1: 3 Input Storage Area ;to input storage

2: 2 Array ID or Loc [ mVperV_0 ]

13

Page 20

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

12: Average (P71)

1: 1 Reps

2: 1 Loc [ mVperV ]

13: If Flag/Port (P91) ;When average is calculated,

1: 10 Do if Output Flag is High (Flag 0) ;also send it to Final Storage

2: 10 Set Output Flag High

14: Set Active Storage Area (P80) ;Direct Output to Final Storage

1: 1 Final Storage Area 1

2: 11 Array ID ;set Array ID = 11 for zero data

15: Real Time (P77)

1: 110 Day,Hour/Minute

16: Sample (P70)

1: 1 Reps

2: 2 Loc [ mVperV_0 ]

17: End (P95)

18: End (P95)

End Program

Example Program 4.5. 21X ¼ Bridge Strain with 1 rep and zero offset

;{21X}

*Table 1 Program

01: 1 Execution Interval (seconds)

;Other measurements could be inserted here or before the Output section

1: If Flag/Port (P91) ;On the first execution (Flag 1 is low)

1: 21 Do if Flag 1 is Low ;or when user sets Flag 1 low

2: 1 Call Subroutine 1 ;call the zeroing subroutine

2: Full Bridge (P6) ;Measure the strain gage

1: 1 Reps

2: 2 ± 15 mV Slow Range

3: 1 DIFF Channel

4: 1 Excite all reps withExchan 1

5: 5000 mV Excitation

6: 1 Loc [ mVperV ]

7: 1 Mult

8: 0 Offset

3: Z=X-Y (P35) ;Subtract zero reading from the

1: 1 X Loc [ mVperV ] ;measurement

2: 2 Y Loc [ mVperV_0 ]

3: 3 Z Loc [ Vr ]

4: Z=X*F (P37) ;Change Vr from mV/V to V/V

1: 3 X Loc [ Vr ]

2: 0.001 F

3: 3 Z Loc [ Vr ]

14

Page 21

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

;The following instructions calculate microstrain

5: Z=X*F (P37)

1: 3 X Loc [ Vr ]

2: -2 F

3: 9 Z Loc [ 1_2Vr ]

6: Z=Z+1 (P32)

1: 9 Z Loc [ 1_2Vr ]

7: Z=X/Y (P38)

1: 3 X Loc [ Vr ]

2: 9 Y Loc [ 1_2Vr ]

3: 10 Z Loc [ Vr_1_2Vr ]

8: Z=X*Y (P36)

1: 10 X Loc [ Vr_1_2Vr ]

2: 8 Y Loc [ Mult ]

3: 4 Z Loc [ uStrain ]

;Output Section

;This example outputs an average of the 1 second readings

;once per minute.

9: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1 Interval (same units as above)

3: 10 Set Output Flag High

10: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 1 Array ID ;Set Array ID = 1 for measurement data

11: Real Time (P77)

1: 1110 Year,Day,Hour/Minute

12: Average (P71)

1: 1 Reps

2: 4 Loc [ uStrain ]

*Table 2 Program

01: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

1: Beginning of Subroutine (P85) ;Subroutine to measure "zero"

1: 1 Subroutine 1

2: Do (P86) ;This prevents calling subroutine

1: 11 Set Flag 1 High ;until user sets flag 1 low again.

3: Z=F (P30) ;Set counter use for average to 0

1: 0 F

2: 5 Z Loc [ count ]

4: Z=F (P30) ;load 4000 into

1: 4000 F ;input location

2: 7 Z Loc [ 4e6 ]

5: Z=X*F (P37) ;Multiply by 1000 to get (4*uS/S)

1: 7 X Loc [ 4e6 ]

2: 1000 F

3: 7 Z Loc [ 4e6 ]

15

Page 22

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

6: Z=F (P30) ;Load Gage Factor into input location

1: 2 F ;Enter the actual Gage Factor here

2: 6 Z Loc [ GF ]

7: Z=X/Y (P38) ;calculate multiplier to use with strain

1: 7 X Loc [ 4e6 ] ;calculation

2: 6 Y Loc [ GF ]

3: 8 Z Loc [ Mult ]

8: Beginning of Loop (P87) ;Loop through 5 times to obtain average

1: 0 Delay ;zero reading

2: 5 Loop Count

9: Z=Z+1 (P32) ;Increment Counter used to determine

1: 5 Z Loc [ count ] ;when to output

10: Full Bridge (P6) ;Measure Strain Gage

1: 1 Reps

2: 2 ± 15 mV Slow Range

3: 1 DIFF Channel

4: 1 Excite all reps withExchan 1

5: 5000 mV Excitation

6: 1 Loc [ mVperV ]

7: 1 Mult

8: 0 Offset

11: IF (X<=>F) (P89) ;Check for last pass through loop

1: 5 X Loc [ count ] ;to set output flag

2: 3 >=

3: 5 F

4: 10 Set Output Flag High

12: Set Active Storage Area (P80) ;Direct averaged "zero" reading

1: 3 Input Storage ;to input storage

2: 2 Array ID or Loc [ mVperV_0 ]

13: Average (P71)

1: 1 Reps

2: 1 Loc [ mVperV ]

14: If Flag/Port (P91) ;When average is calculated,

1: 10 Do if Output Flag is High (Flag 0) ;also send it to Final Storage

2: 10 Set Output Flag High

15: Set Active Storage Area (P80) ;Direct Output to Final Storage

1: 1 Final Storage

2: 11 Array ID ;set Array ID = 11 for zero data

16: Real Time (P77)

1: 110 Day,Hour/Minute

17: Sample (P70)

1: 1 Reps

2: 2 Loc [ mVperV_0 ]

18: End (P95)

19: End (P95)

End Program

16

Page 23

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

4.2 Quarter Bridge Strain with 2 Wire Element

NOTE

Although a two wire gage can be used with the 4WFBS TIM,

due to the issues outlined in Section 4.4.3, it is not

recommended. An exception may be applications with short

leads in a stable temperature environment.

A 2-wire quarter bridge strain circuit is shown in figure 4.2-1.

R

D

R

=Gauge

+

4

Excite V

R

=1KΩ

2

R1=1KΩ

-

FIGURE 4.2-1. Two wire quarter bridge strain circuit

In this circuit, R1 and R2 are 1000 ohm resistors making up the back plane of

the Wheatstone bridge, as is done in the TIM design. R

resistor, or Dummy Resistor, that has a nominal resistance of the un-strained

gage. The 4

th

resistive element is the active strain gage. Strain gages are

available in nominal resistances of 120, 350, and 1000 ohms. The 4WFBS

model must match the nominal resistance of the gage (e.g., the 4WFBS120 is

used with a 120 ohm strain gage).

As can be seen in Figure 4.2-1, both sensor leads are in the same arm of the

Wheatstone bridge. Not only does this affect the sensitivity of the gage, the

output from this circuit will include temperature induced line resistance errors.

See Section 4.4.3, Lead Compensation using ¼ Bridge Strain with 2 Wire

Element for more information on issues with using 2 wire gages.

4.2.1 Quarter Bridge Strain with 2 Wire Element Wiring

To use a two wire element strain gauge with the 4WFBS TIM requires a

jumper wire be placed between the H and L terminal of the TIM module as

shown in Figure 4.2-2.

is the complementary

D

17

Page 24

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

(

)

(

με

=

−

με

με

×

Datalogger

Vx

H

L

or AG

or G

Shield

R

R

H

H

Jumper Wire

RD

2

L

1

G

Gauge

FIGURE 4.2-2. Wiring for 2-wire gauges

4.2.2 Two Wire ¼ Bridge use with Multiplexers and Equations

The equations to resolve the strain, programming of the logger, and methods of

using with multiplexers are the same as those covered in Section 4.1 for the 3Wire Strain gauge. The only variance is the wiring of the gage to the TIM.

4.3 Quarter Bridge Strain with Dummy Gage

An undesirable property of strain gauges is that of resistance change with

changes in temperature. This is true even for the self-temperature

compensating strain gages on the market today. Supplied with each package of

strain gages are graphs and equations for the variance in the output of the strain

gage due to thermal changes (referred to as thermal output or apparent strain)

and for the variation of the gage factor with temperature. These graphs are

based on the assumption that the gages are mounted on a material with the

given thermal coefficient of expansion (TCE). The TCE value is included in

the gage type nomenclature. Following are some typical equations supplied.

µε

Equation 4.3.1 is used to calculate the thermal output variance (

) with the

TO

result in μStrain. Equation 4.3.2 is used to determine the change in the gauge

factor (GF) due to temperature changes. Both are based on temperature in

degrees Celsius (T).

−−

93.325.305.015.195.2 TETETT

με

4.3.1

TO

4

−

−+−+−=

GFTEGFGF 2440.1

−×+=

rawrawadj

4.3.2

47342

As an example, let us assume we use a gauge with a GF of 2.00 in a test that

started at 24°C and 0

1000 μStrain. The thermal output strain,

μStrain. The error in the gage factor would be 0.364% with a resultant GF

μStrain, and ended at 50°C and a recorded strain value of

µε

, at 50°C would be -29.3

TO

of

adj

2.007. The corrected strain would be 967 μStrain:

18

cor

)

007.2/000.23.291000

4.3.3

The uncorrected value had an error of approximately 3.3%. And if the ending

strain would have been 100 μStrain instead of 1000 μStrain, the error would

have been around 30%.

Page 25

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

Ω

Another temperature induced error in a quarter bridge strain circuit is due to

the Temperature Coefficient of Resistance (TCR) of the completion resistor in

the arm opposite the strain gauge. The 4WFBS TIMs use a high quality

resistor having a TCR of 0.8ppm/°C to minimize these errors. For our example

above, this could lead to an error in the reading of approximately 10 μStrain,

assuming that the datalogger experiences the same level of temperature

variation. This error could be additive or subtractive to the other errors as the

resistor manufacturer does not specify the polarity of the change in resistance,

only the absolute magnitude.

These errors, with exception to the completion resistor’s TCR, can be

mathematically compensated for to some degree. It should be remembered that

the curves and equations given are the average for the given batch of gages and

are only applicable when mounting on the specified material. An alternative

approach to eliminate the errors is to either use a dummy gage, from the same

batch mounted on identical material, or to use a half or full bridge strain

circuit.

Dummy gauges can be used to compensate for these false apparent strain

readings. A strain gauge that is mounted on a coupon that is not undergoing

mechanical stress and is used as the resistive element for the Wheatstone

bridge arm opposite the active gage is referred to as a “Dummy Gauge”. This

non-active gauge in the other arm of the Wheatstone bridge is referred to as a

“dummy gauge” because it is not subjected to “load induced” strains.

With the two opposing gauges experiencing the same temperature conditions,

the temperature effects on the active gage will be nullified by the equivalent

temperature effects on the dummy gauge. Figure 4.3.1 depicts a Quarter Bridge

Strain circuit with a Dummy gauge.

L3

L

R2=1 KΩ

R =1 K

1

3

L2

-

+

L

1

Dummy Gauge

Active Gauge

FIGURE 4.3-1. Quarter bridge strain circuit with dummy gauge

It should be noted that the coupon on which the dummy gauge is mounted can

still be subjected to temperature induced strains. This can be used to null

temperature induced strains in the monitored member if the dummy gauge is

mounted to a coupon made up of material having the same Temperature

Coefficient of Resistance (TCR) as the member that the active gauge is

mounted to. Conversely, the dummy gage could be mounted to a coupon with

a negligible TCR allowing for the monitoring of temperature induced stresses.

19

Page 26

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

The 4WFBS modules can support quarter bridge strain circuits using either the

completion resistor built into the TIM, or a user supplied “dummy” strain

gauge, for the Wheatstone Bridge arm's resistive element opposite of the active

strain gauge in the bridge. Wiring circuits using a dummy gage are covered in

Section 4.3.1.

4.3.1 Quarter Bridge Strain with Dummy Gauge Wiring Setup

Figure 4.3-2 illustrates the wiring of the strain gage with a dummy gage to the

4WFBS module, as well as the wiring of the module to the datalogger. This

shows the dummy gauge out at the remote site along with the active gage. This

is the best setup to achieve the best compensation for the apparent strain and

gauge factor variance due to temperature fluctuations, as it will be easier to

keep the temperature of the two gages equivalent.

FIGURE 4.3-2. ¼ bridge strain with remote dummy gauge

Figure 4.3-3 illustrates the wiring of the strain gage to the 4WFBS module with

the Dummy gauge at the logger location. Apparent strain errors could result

because of temperature variances between the two gauges with this setup. This

circuit is still utilized in some applications for ease of Shunt calibration (can

shunt across Dummy gage at logger location rather than at the remote gauge

location). Also an existing, standard 3-wire ¼ Bridge strain circuit can easily

be transformed into this circuit. If large temperature variances will exist

between the active gage and the dummy gage located at the datalogger, using

the 4WFBS completion resistor can result in lower temperature induced errors.

20

FIGURE 4.3-3. ¼ bridge strain with dummy gauge at datalogger

Page 27

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

With either circuit, one lead leg, L

the Wheatstone bridge. It is important that the gage be wired such, and that

these two leads be the same length, diameter and wire type. It is preferable to

use a twisted pair for these two wires so that they will undergo the same

temperature and electromagnetic field variations. With this configuration,

changes in wire resistance due to temperature occur equally in both arms of the

bridge with negligible effect on the output from the bridge.

or L3, is in one of the two opposing arms of

1

4.3.2 Quarter Bridge Strain with Dummy Gauge Calculations

The calculations for this bridge setup are the same as for the 3-Wire Quarter

Bridge circuit. See Section 4.1.2 Quarter Bridge Strain with3 Wire Element

Calculations for details.

4.3.3 Quarter Bridge Strain with Dummy Gauge Example Programs

The programming for this bridge setup is the same as for the 3-Wire Quarter

Bridge circuit. See Section 4.1.3 Quarter Bridge Strain with3 Wire Program

Examples for details.

4.4 Quarter Bridge Strain Lead Resistance Compensation

When using quarter bridge strain (full bridge with one active element) with

long lead lengths, errors can be introduced due to the resistance of the leads.

This section covers both mathematical and Shunt Calibration methods used to

rectify these errors. The techniques covered in the section can be used with

circuits using a 4WFBS’s completion resistor or a dummy gauge for the

resistive element in the third arm of the Wheatstone Bridge (arm opposite of

active gauge). The only difference is that when using a dummy gauge, the

4WFBS module’s gold shunt receptacles cannot be used. These receptacles are

connected to the dummy resistor supplied by the 4WFBS module.

One potential error with long leads is due to the leads' resistance change from

temperature fluctuations. When using a three wire strain gauge, wired as

depicted in Figure 4.1-2 3-Wire ¼ Bridge Strain Wiring, with the three leads

all the same length and laid out together (all three experience the same

temperature swings), the leads' resistance changes are self compensating. It is

preferable to use a twisted pair for the two wires (L and G) carrying the current

so that they definitely undergo the same temperature and electromagnetic field

variations. With this configuration, changes in wire resistance due to

temperature occur equally in both arms of the bridge with negligible effect on

the output from the bridge.

Another error that is introduced when using long leads, is a sensitivity

reduction of the system. There are two methods to rectify this error. The first

is mathematical. The second is to perform a shunt calibration. Sections 4.4.1

and 4.4.2 cover these methods for ¼ Bridge Strain circuits.

4.4.1 Mathematical Lead Compensation for 3-Wire, ¼ Bridge Strain

The same equations pertain whether a completion (dummy) resistor or a

dummy gauge is used to complete the third arm of the Wheatstone Bridge. So

the material in this section is relevant for wiring setups shown in Figures 4.1-2,

4.3-2, and 4.3-3. The math and the programs used would be identical for all

three of these circuits.

21

Page 28

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

4.4.1.1 Mathematical Lead Compensation Circuit and Equations

If the lead resistance is known, the sensitivity error can be mathematically

corrected for by multiplying the output by a simple factor (1+R

is the nominal resistance of one of the lead legs and R

is the resistance of the

G

strain gauge. The Gauge Factor can be multiplied by the inverse of this value,

/(RG+ RL), to derive an adjusted Gauge Factor.

R

G

) where RL

L/RG

⎞

R

g

⎟

⎟

RR

+

Lg

⎠⎝

4.4.1

The adjusted Gauge Factor, GF

derive the µ

Strain. The proof used to derive this adjusted Gauge Factor is

⎛

GFGF

⎜

×=

rawadj

⎜

, would be used in the StrainCalc function to

adj

shown below:

R2= 1K

Excite

R1= 1K

Ω

-

Ω

R

D

R

+

L

R

L

R

L

FIGURE 4.4-1. Three wire ¼ bridge strain circuit

R4=Gauge

22

Balanced Bridge Condition

⎞

⎛

E

O

⎟

⎜

⎜

E

4.4.2

⎝

=

⎟

I

⎠

BAL

RR

+

LG

RRRR

+++

DLG

R

1

−

RR

+

L

21

Strained Bridge Condition

⎞

⎛

E

O

⎟

⎜

⎜

E

⎝

=

⎟

I

⎠

STR

Change in Bridge Output (V

⎞

⎛

⎞

⎛

E

O

⎟

⎜

V

=

R

⎟

⎜

E

I

⎠

⎝

STR

E

O

⎟

⎜

−

⎟

⎜

E

I

⎠

⎝

BAL

)

R

=

RRR

Δ++

GLG

RRRRR

Δ++++

LDLG

RRR

Δ++

GLG

GLD

R

1

−

RR

+

G

RR2RR

Δ+++

G

21

4.4.3

RR

+

−

LG

2RRR

++

LGD

4.4.4

Page 29

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

Assume R

D

= R

G

RRR

Δ++

V

=

R

GLG

−

R2R2R

Δ++

GL

G

RR

+

LG

2R2R

+

LG

4.4.5

Simplify

RRRR Δ+Δ

V =

R

()()

Solve for ΔR

4.4.7

G/RG

Δ

R

4V

G

R

=

()

Use the Gauge Factor to calculate micro-strain

6

×

10

4V

=

με

4.4.8

R

()

2V-1GF

R

GLGG

2R+2RR2R+2R Δ+

L

GGLG

⎛

+

RR

⎜

⎜

⎝

LG

R2V-1R

GRG

⎛

⎜

⎜

⎝

⎛

+

⎜

⎜

R

G

⎝

⎞

⎟

⎟

⎠

με

RR

4.4.6

6

⎞

×Δ

R

10

=

G

⎞

LG

⎟

⎟

⎠

⎟

⎟

×

GFR

⎠

4.4.1.2 Mathematical Lead Compensation Programs

Example Program 4.6. CR9000X ¼ Bridge Strain with zero offset and Lead

Compensation

This program starts with Example Program 4.2 and adds instructions to

mathematically compensate for the leads resistances effects on the Gauge

Factor (sensitivity effect). Added instructions are highlighted.

Program name: StrainSH.C9X

'

Public StrainMvperV(3) : Units StrainMvperV = mV_per_V 'Raw Strain dimensioned source

Public Strain(3) : Units Strain = uStrain ‘uStrain dimensioned source

Dim GF(3) 'Dimensioned gauge factor

Public ZeromV_V(3), ZeroStrain(3)

Public ZReps, ZIndex, ModeVar

Public Leadlength(3), Lead_R(3),GF_Adjusted(3),

Public I, LeadRper100ft, Gauge_R

DataTable(STRAIN,True,-1) 'Trigger, auto size

DataInterval(0,0,0,100) 'Synchronous, 100 lapses, autosize

CardOut(0,-1) 'PC card , size Auto

Sample (3,Strain(),IEEE4) '3 Reps, uStrain, Resolution

Sample (3,StrainMvperV(),IEEE4) ‘3Reps,Stain mVolt/Volt, Resolution

EndTable 'End of table STRAIN

DataTable (Calib,NewFieldCal,10) ‘Table for calibration factors from zeroing

SampleFieldCal ‘User should collect these to his computer

EndTable ‘for future reference

23

Page 30

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

BeginProg 'Program begins here

GF(1) = 2.1 : GF(2) = 2.2 : GF(3) = 2.3 'Initialize gauge factors for Strain( )

LeadLength(1) = 1.25 ' load lead lengths (100s of feet)

LeadLength(2) = 1.50

LeadLength(3) = 2.00

LeadRper100ft = 2.5 '24 gauge copper wire lead R is 0.025 ohms/ft

Gauge_R = 350 ' Load Strain gauge Resistance

For I = 1 To 3 ' Loop through calculate the adjusted gauge factors

Lead_R(I) = LeadLength(I) * LeadRper100ft

GF_Adjusted(I) = GF(I) * (Gauge_R/(Gauge_R + Lead_R(I)))

Next I

ZReps = 3 : ZIndex = 1 ‘initialize cal reps and index pointer

LoadFieldCal(True) ‘Load prior calibration factors

Scan(10,mSec,100,0) 'Scan once every 10 mSecs, non-burst

FieldCalStrain(10,StrainMvperV(),ZReps,0,ZeromV_V(),ModeVar,0,ZIndex,1,0,Strain())

BrFull(StrainMvperV(),3,mV50,4,1,5,7,1,5000,True,True,70,100,1,0)

StrainCalc(Strain(),3,StrainMvperV(),ZeromV_V(),-1,GF(),0) 'Strain calculation

CallTable STRAIN

CallTable Calib

Next Scan 'Loop up for the next scan

SlowSequence 'Slow sequence Scan to perform temperature

Scan(1,Sec,0,0) ' compensation on DAQ

Calibrate 'Corrects ADC offset and gain

BiasComp 'Corrects ADC bias current

Next Scan

EndProg 'Program ends here

24

Page 31

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

Example Program 4.7. CR10X ¼ Bridge Strain with 16 reps, using

multiplexer with zero offset and Lead Compensation Calculations using

Lead resistance

Input Locations Used in CR10(X)Program Example X.X

Addr Name Addr Name Addr Name Addr Name

1 mVPerVG01 36 AdjGF01 70 LeadFt01 102 GF01

2 mVPerVG02 37 AdjGF02 71 LeadFt02 103 GF02

3 mVPerVG03 38 AdjGF03 72 LeadFt03 104 GF03

4 mVPerVG04 39 AdjGF04 73 LeadFt04 105 GF04

5 mVPerVG05 40 AdjGF05 74 LeadFt05 106 GF05

6 mVPerVG06 41 AdjGF06 75 LeadFt06 107 GF06

7 mVPerVG07 42 AdjGF07 76 LeadFt07 108 GF07

8 mVPerVG08 43 AdjGF08 77 LeadFt08 109 GF08

9 mVPerVG09 44 AdjGF09 78 LeadFt09 110 GF09

10 mVPerVG10 45 AdjGF10 79 LeadFt10 111 GF10

11 mVPerVG11 46 AdjGF11 80 LeadFt11 112 GF11

12 mVPerVG12 47 AdjGF12 81 LeadFt12 113 GF12

13 mVPerVG13 48 AdjGF13 82 LeadFt13 114 GF13

14 mVPerVG14 49 AdjGF14 83 LeadFt14 115 GF14

15 mVPerVG15 50 AdjGF15 84 LeadFt15 116 GF15

16 mVPerVG16 51 AdjGF16 85 LeadFt16 117 GF16

17 mVPerVZ01 52 uStrain01 86 OhmLead01 118 G01Ohms

18 mVPerVZ02 53 uStrain02 87 OhmLead02 119 G02Ohms

19 mVPerVZ03 54 uStrain03 88 OhmLead03 120 G03Ohms

20 mVPerVZ04 55 uStrain04 89 OhmLead04 121 G04Ohms

21 mVPerVZ05 56 uStrain05 90 OhmLead05 122 G05Ohms

22 mVPerVZ06 57 uStrain06 91 OhmLead06 123 G06Ohms

23 mVPerVZ07 58 uStrain07 92 OhmLead07 124 G07Ohms

24 mVPerVZ08 59 uStrain08 93 OhmLead08 125 G08Ohms

25 mVPerVZ09 60 uStrain09 94 OhmLead09 126 G09Ohms

26 mVPerVZ10 61 uStrain10 95 OhmLead10 127 G10Ohms

27 mVPerVZ11 62 uStrain11 96 OhmLead11 128 G11Ohms

28 mVPerVZ12 63 uStrain12 97 OhmLead12 129 G12Ohms

29 mVPerVZ13 64 uStrain13 98 OhmLead13 130 G13Ohms

30 mVPerVZ14 65 uStrain14 99 OhmLead14 131 G14Ohms

31 mVPerVZ15 66 uStrain15 100 OhmLead15 132 G15Ohms

32 mVPerVZ16 67 uStrain16 101 OhmLead16 133 G16Ohms

33 VR_1 68 Number4e3 134 GAndLOhms

34 One_2Vr 69 LeadOhms 135 AdjFactor

35 Vr_1_2Vr 136

25

Page 32

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

;{CR10X}

;16SGMux.CSI

;This program calculates the strain for 16 quarter strain bridges using4 wire bridge completion modules.

; It takes into account the sensitivity changes due to lead length resistance.

;(1) Sensors:

; 16 strain gauges multiplexed through an AM416

;(2) DataInfo:

; Strain gauges will be measured every 5 seconds.

; Only measurement at top of minute will be stored.

;(3) SubroutineDescrptions:

; Subroutine01: Measures the zero offset strain reading, sets the gauge factor.

; Subroutine02: Outputs processed values to FinalStorage

;(4) Wiring:

; (a) Mux01:

; 10x_12V To AM416_12V 10x_GND To AM416_GND

; 10x_C3 To AM416_ResetEnable 10x_C4 To AM416_Clock

; 10x_H4 To AM416_ComH1 10x_L4 To AM416_ComL1

; 10x_E2 To AM416_ComH2 10x_AG To AM416_ComL2

; First bank example:

; SG+ To H1 SG- To L1

; SGExcite To H2 SGGnd To L2

*Table 1 Program

01: 5 Execution Interval (seconds)

;Loop through the strain gages using the AM416:

1: Do (P86)

1: 43 Set Port 3 High ; Reset and Enable the AM416.

2: Beginning of Loop (P87)

1: 0 Delay

2: 16 Loop Count

3: Do (P86)

1: 74 Pulse Port 4 ; Clock forward to the next bank on the AM416.

4: Excitation with Delay (P22) ; Delay to allow relay connection to settle.

1: 2 Ex Channel

2: 0 Delay WITHEx (units = 0.01 sec)

3: 5 Delay After Ex (units = 0.01 sec)

4: 0 mV Excitation

5: Full Bridge (P6)

1: 1 Reps

2: 2 7.5 mV Slow Range

3: 4 DIFF Channel

4: 2 Excite all reps withExchan 2

5: 2500 mV Excitation

6: 1 -- Loc [ mVPerVG01 ]

7: 1.0 Mult

8: 0.0 Offset

6: End (P95)

7: Do (86)

1: 53 Set Port 3 Low ; Deactivate the AM416.

;..

8: If Flag/Port (P91) ; If first time through then call zero routine.

1: 21 Do if Flag 1 is Low

2: 1 Call Subroutine 1

9: Beginning of Loop (P87) ; This Loop calculates uStrain values:

1: 0 Delay

2: 16 Loop Count

10: Step Loop Index (P90)

1: 1 Step

26

Page 33

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

11: Z=X-Y (P35) ; Subtract zeroed value from measurement.

1: 1 -- X Loc [ mVPerVG01 ]

2: 17 -- Y Loc [ mVPerVZ01 ]

3: 33 Z Loc [ Vr_1 ]

12: Z=X*F (P37)

1: 33 X Loc [ Vr_1 ]

2: -2 F

3: 34 Z Loc [ One_2Vr ]

13: Z=X+F (P34)

1: 34 X Loc [ One_2Vr ]

2: 1000 F

3: 34 Z Loc [ One_2Vr ]

14: Z=X/Y (P38)

1: 33 X Loc [ Vr_1 ]

2: 34 Y Loc [ One_2Vr ]

3: 35 Z Loc [ Vr_1_2Vr ]

15: Z=X/Y (P38)

1: 35 X Loc [ Vr_1_2Vr ]

2: 36 -- Y Loc [ AdjGF01 ]

3: 52 -- Z Loc [ uStrain01 ]

16: Z=X*Y (P36)

1: 52 -- X Loc [ uStrain01 ]

2: 68 Y Loc [ Number4e3 ]

3: 52 -- Z Loc [ uStrain01 ]

17: End (P95)

18: If Flag/Port (P91)

1: 12 Do if Flag 2 is High

2: 30 Then Do

19: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1 Interval (same units as above)

3: 2 Call Subroutine 2 ; Outputs data to FinalStorage.

20: End (P95)

*Table 2 Program

02: 0

*Table 3 Subroutines

1: Beginning of Subroutine (P85) ; Measures ZeroOffset strain reading and sets GF

1: 1 Subroutine 1

2: Do (P86) ; Setup so Subroutine does not get called again.

1: 11 Set Flag 1 High

3: Z=F (P30) ; Lead Length Resistance per 100 feet.

1: 2.5 F ; 0.025 Ohms/Foot for 24 gauge copper stranded wire.

2: 0 Exponent of 10

3: 69 Z Loc [ LeadOhms ]

4: Bulk Load (P65) ; Load lead length of the gages in 100s of feet:

1: 3.0 F ; Gage01

2: 4.4 F ; Gage02

3: 8 F ; Gage03

4: 12 F ; Gage04

5: 14 F ; Gage05

6: 19 F ; Gage06

7: 15 F ; Gage07

8: 13 F ; Gage08

9: 70 Loc [ LeadFt01 ]

27

Page 34

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

5: Bulk Load (P65)

1: 5 F ; Gage09

2: 9 F ; Gage10

3: 12 F ; Gage11

4: 4 F ; Gage12

5: 8 F ; Gage13

6: 2 F ; Gage14

7: 8 F ; Gage15

8: 9 F ; Gage16

9: 78 Loc [ LeadFt09 ]

6: Beginning of Loop (P87) ; Calculate lead length resistance:

1: 0 Delay

2: 16 Loop Count

7: Z=X*Y (P36)

1: 70 -- X Loc [ LeadFt01 ]

2: 69 Y Loc [ LeadOhms ]

3: 86 -- Z Loc [ OhmLead01 ]

8: End (P95)

9: Bulk Load (P65) ; Load strain gauge Gage Factors:

1: 2.095 F ; Gauge01

2: 2.095 F ; Gauge02

3: 2.095 F ; Gauge03

4: 2.095 F ; Gauge04

5: 2.095 F ; Gauge05

6: 2.095 F ; Gauge06

7: 2.095 F ; Gauge07

8: 2.095 F ; Gauge08

9: 102 Loc [ GF01 ]

10: Bulk Load (P65)

1: 2.095 F ; Gauge09

2: 2.095 F ; Gauge10

3: 2.095 F ; Gauge11

4: 2.095 F ; Gauge12

5: 2.095 F ; Gauge13

6: 2.095 F ; Gauge14

7: 2.095 F ; Gauge15

8: 2.095 F ; Gauge16

9: 110 Loc [ GF09 ]

; Load strain gauge resistance values:

11: Bulk Load (P65)

1: 350 F ; Gage01

2: 350 F ; Gage02

3: 350 F ; Gage03

4: 350 F ; Gage04

5: 350 F ; Gage05

6: 350 F ; Gage06

7: 350 F ; Gage07

8: 350 F ; Gage08

9: 118 Loc [ G01Ohms ]

12: Bulk Load (P65)

1: 350 F ; Gage09

2: 350 F ; Gage10

3: 350 F ; Gage11

4: 350 F ; Gage12

5: 350 F ; Gage13

6: 350 F ; Gage14

28

Page 35

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

7: 350 F ; Gage15

8: 350 F ; Gage16

9: 126 Loc [ G09Ohms ]

13: Z=F (P30) ; Load in the large number, 4000.0

1: 4 F

2: 3 Exponent of 10

3: 68 Z Loc [ Number4e3 ]

14: Beginning of Loop (P87) ; Loop through the strain gages using the AM416:

1: 0 Delay

2: 16 Loop Count

15: Z=X+Y (P33) ; Calculate GOhms+LeadOhms

1: 118 -- X Loc [ G01Ohms ]

2: 86 -- Y Loc [ OhmLead01 ]

3: 134 Z Loc [ GAndLOhms ]

16: Z=X/Y (P38) ; Calculate RG/(RG + RL)

1: 118 -- X Loc [ G01Ohms ]

2: 134 Y Loc [ GAndLOhms ]

3: 135 Z Loc [ AdjFactor ]

17: Z=X*Y (P36) ; Calculate adjusted Gauge Factor, GF*[RG/(RG + RL)]

1: 135 X Loc [ AdjFactor ]

2: 102 -- Y Loc [ GF01 ]

3: 36 -- Z Loc [ AdjGF01 ]

18: Z=X (P31) ; Load last gauge measurements.

1: 1 -- X Loc [ mVPerVG01 ]

2: 17 -- Z Loc [ mVPerVZ01 ]

19: End (P95)

;..

20: Do (P86) ; Store zero measurement values and adjusted GF.

1: 10 Set Output Flag High (Flag 0)

21: Set Active Storage Area (P80)^15754

1: 1 Final Storage Area 1

2: 311 Array ID

22: Real Time (P77)^19880

1: 1111 Year,Day,Hour/Minute,Seconds (midnight = 0000)

23: Sample (P70)^22627

1: 16 Reps

2: 17 Loc [ mVPerVZ01 ]

24: Sample (P70)^11346

1: 16 Reps

2: 36 Loc [ AdjGF01 ]

25: Do (P86)

1: 20 Set Output Flag Low (Flag 0)

26: End (P95)

;

27: Beginning of Subroutine (P85) ; Output data to FinalStorage.

1: 2 Subroutine 2

28: Do (P86)

1: 10 Set Output Flag High (Flag 0)

29: Set Active Storage Area (P80)^28949

1: 1 Final Storage Area 1

2: 321 Array ID

30: Real Time (P77)^16027

1: 1111 Year,Day,Hour/Minute,Seconds (midnight = 0000)

29

Page 36

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

31: Sample (P70)^16425

1: 16 Reps

2: 52 Loc [ uStrain01 ]

32: Do (P86)

1: 20 Set Output Flag Low (Flag 0)

33: End (P95)

End Program

4.4.2 Shunt Calibration Lead Compensation for 3-Wire, ¼ Bridge Strain

NOTE

Although the following may seem complicated, the process of

performing a Shunt calibration is simple when using the

Calibration Wizard utility found in CSI’s software packages.

Another method to compensate for sensitivity errors, and to calibrate the

system (adjust system scaling), is to do a shunt calibration. This entails

shunting a resistor across one of the arms of the bridge. The premise of a shunt

calibration is that the shunted arm undergoes a reduction in resistance creating

a simulated strain. The difference in strain reported by the system is checked

against the actual simulated strain. Variance between the reported strain and

the simulated strain can be corrected through adjusting the strain gauge’s Gage

Factor (GF).

4.4.2.1 Three Wire Gage Circuit with Shunt

There are two methods for performing a shunt calibration on a 3-Wire ¼ bridge

strain circuit. The first is to shunt across the active gage remotely, and the

second is to shunt across the Dummy resistor or Dummy Gage (dependant on

which is employed in the circuit) back at the datalogger.

For either shunt method, the Dummy resistor should be a 0.02% precision or

better resistor to insure that its resistance is the nominal resistance of the active

gauge. In addition it should have a low Temperature Coefficient of Resistance

(TCR) to limit the errors introduced by the change in its resistance due to

temperature variations. The Shunt resistor should also have a precision of

0.02% or better and a low TCR.

30

4.4.2.1.1 Three Wire Gage Circuit with Remote Shunt across the Active Gage

A 3-wire quarter bridge strain circuit with a Shunt calibration resistor ready to

shunt across the arm that holds the strain gauge is shown in figure 4.4-2.

Page 37

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

A

i

R

R2= 1K

R1= 1K

Ω

+

-

Ω

D

R

L

R

L

Gauge

R

L

R

S

FIGURE 4.4-2. Shunting remotely across active gauge

represents the line resistances. RD is the resistor in the arm next to the active

R

L

gage which has a resistance equal to the nominal resistance of the Strain gauge

and is referred to as the Dummy Resistor. R

is the Shunt resistor. This setup

s

is the classical method for shunting a 3-wire ¼ bridge strain circuit.

4.4.2.1.2 Three Wire Gage Circuit with Shunt across the Dummy Resistor

Shunting across the active gauge is frequently impractical due to inaccessibility

or protective coatings across the gage and leads, which precludes getting an

electrical contact across the gauge. For these types of applications it is more

convenient to place a shunt resistor across the Wheatstone bridge arm that

holds the dummy resistor, R

. Figure 4.4-3 shows a 3-wire ¼ Bridge strain

D

circuit for shunting across the dummy resistor.

R

S

R

R2= 1K

R2= 1K

Ω

Ω

D

R

L

R

L

R

L

Gauge

ct

ve

FIGURE 4.4-3. Circuit for shunting across dummy resistor

31

Page 38

4WFBS120, 4WFBS350, 4WFBS1K 4 Wire Full Bridge Terminal Input Modules (TIM)

A

A

X

Δ

−

NOTE

It should be noted that a shunt resistor should not be connected

across the active gauge’s leads back at the completion portion of

the Wheatstone Bridge, as this would not correctly account for

the leads resistances. If performing a shunt back at the

instrumentation location, it must be done across the Dummy

Resistor as shown in figure 4.4-3.

The 4WFBS TIM modules include 2 gold plated, shunt pin receptacles to

facilitate easy access to the internal dummy resistor. These receptacles, which

accept 0.015 to 0.025 inch diameter pins, are depicted in figure 4.4-4.

Datalogger

VX or E

or G

H

L

G