Page 1

4WFB120, 4WFB350, 4WFB1K

4 Wire Full Bridge Terminal

Input Modules

Revision: 5/07

Copyright © 1996-2007

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The 4WFB120, 4WFB350, 4WFB1K 4 WIRE FULL BRIDGE

TERMINAL INPUT MODULES are warranted by CAMPBELL

SCIENTIFIC, INC. to be free from defects in materials and workmanship

under normal use and service for twelve (12) months from date of shipment

unless specified otherwise. Batteries have no warranty. CAMPBELL

SCIENTIFIC, INC.'s obligation under this warranty is limited to repairing or

replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective products.

The customer shall assume all costs of removing, reinstalling, and shipping

defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

act information is for US and International customers residing in countries

cont

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country. To obtain a Returned Materials Authorization (RMA),

contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an

applications engineer determines the nature of the problem, an RMA number

will be issued. Please write this number clearly on the outside of the shipping

container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 W

Logan, Ut

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

est 1800 North

ah 84321-1784

Page 3

4WFB120, 4WFB350, 4WFB1K

Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Function........................................................................1

2. Specifications ..............................................................1

3. Measurement Concepts..............................................2

4. Wiring............................................................................3

5. Program Examples......................................................3

5.1 Edlog.........................................................................................................4

5.1.1 CR10(X)..........................................................................................4

5.1.2 21X .................................................................................................7

5.1.3 CR7...............................................................................................10

5.2 CRBasic..................................................................................................13

5.2.1 CR9000(X)....................................................................................14

6. Calculation of Strain..................................................15

Figures

1-1 Terminal Input Module ............................................................................1

2-1 Schematic.................................................................................................2

4-1 Wiring for Example Programs .................................................................3

6-1 Strain Gage in Full Bridge......................................................................15

Table

5-1 Input Locations Used in CR10(X), 21X, and CR7 Examples..................4

i

Page 4

This is a blank page.

Page 5

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

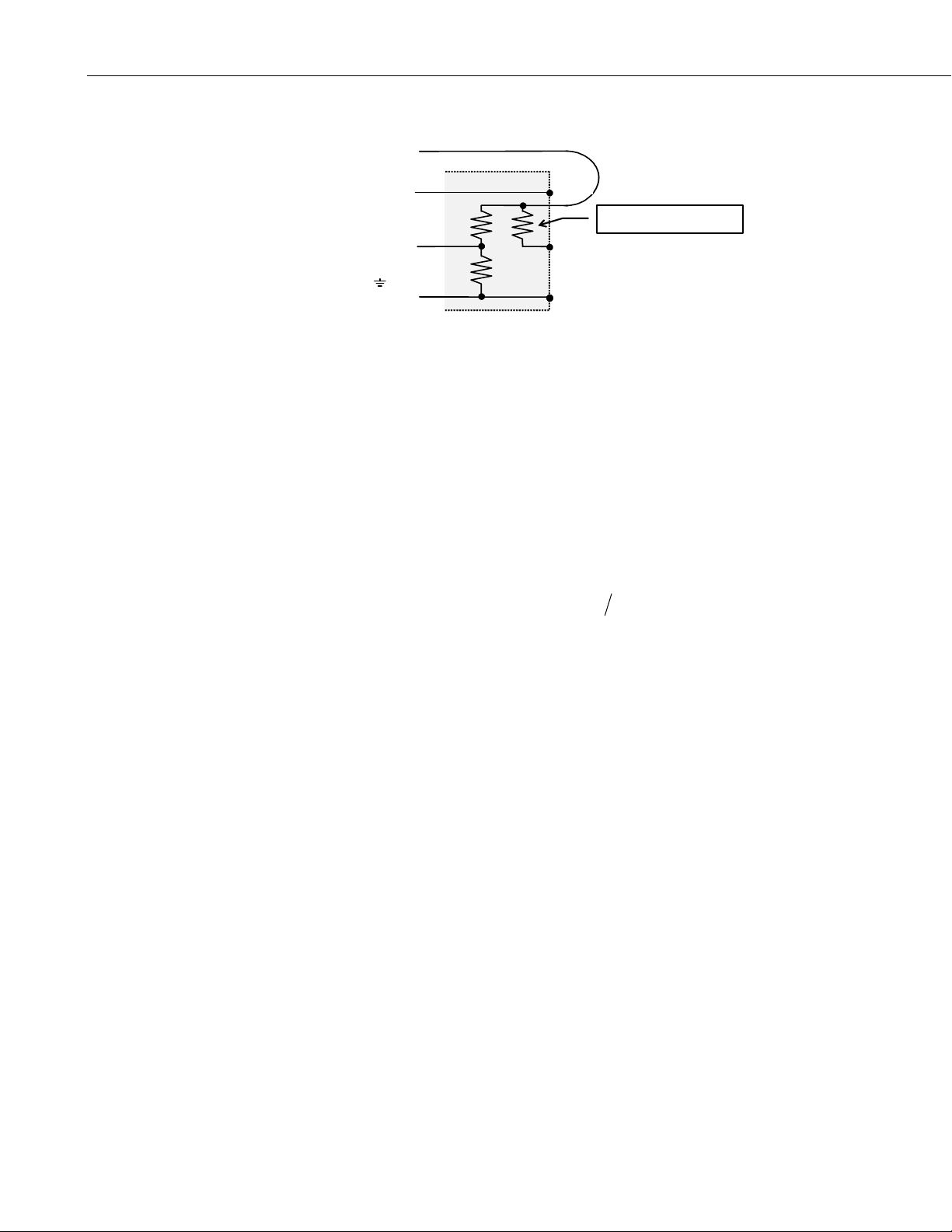

1. Function

Terminal input modules connect directly to the datalogger's input terminals to

provide completion resistors for resistive bridge measurements, voltage

dividers, and precision current shunts. The 4WFB120, 4WFB350, and

4WFB1K complete a full bridge for a strain gage or other sensor that acts as a

single variable resistor. The difference between the three models is in the

resistor that matches the nominal resistance of a 120 ohm, 350 ohm, or 1000

ohm quarter bridge strain gage.

H

L

G

H

L

AG

2. Specifications

2:1 Resistive Divider

Resistors

Ratio Tolerance @ 25 °C

Ratio Temperature

coefficient

Power rating 0.25 W

Completion Resistor: 120, 350, or 1000 Ω

Tolerance @ 25 °C

Temperature coefficient

0-60 °C

-55-125 °C

Power rating 0.25 W

H

L

AG

FIGURE 1-1. Terminal Input Module

1 kΩ/1 kΩ

±0.02%

2 ppm/°C

±0.01%

4 ppm/°C

8 ppm/°C

1

Page 6

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

ε

µ

=

∆

∆

µ

x

⋅

x

Vx

H

L

or AG

3. Measurement Concepts

Measuring strain is measuring a change in length. Specifically, the unit strain

()

is the change in length divided by the unstrained length

Strain is typically reported in microstrain

length by one millionth of the length.

A metal foil strain gage is a resistive element that changes resistance as it is

stretched or compressed. The strain gage is bonded to the object in which

strain is measured. The gage factor,

resistance for change in strain:

factor of 2 means that if the length changes by one micrometer per meter of

)

(1

ε

length

resistance.

, the resistance will change by two micro-ohms per ohm of

H

1kΩ

1kΩ

FIGURE 2-1. Schematic

H

L

G

()

GF , is the ratio of the relative change in

GF R R l l

120Ω, 350Ω, or 1kΩ

ε

=∆ll/

()

ε

; a microstrain is a change in

//

. For example, a gage

.

Because the actual change in resistance is so small, a full bridge configuration

is used to give the maximum resolution. A "quarter bridge" strain gage is so

named because the strain gage becomes one of the four resistors that make up a

full bridge. The 4WFBxxx module provides the other three resistors (Figure 4-

1). Quarter bridge strain gages are available in nominal unstrained resistances

of 120, 350, and 1000 ohms. The 4WFB model must match the resistance of

the gage (e.g., the 4WFB120 is used with a 120 ohm strain gage).

The resistance of an installed gage will differ from the nominal value. A zero

measurement can be made with the gage installed. This zero measurement can

be incorporated into the datalogger program; subsequent measurements can

report strain relative to the zero.

Strain is calculated in terms of the result of the full bridge measurement. This

result is the measured bridge output voltage divided by the bridge excitation

VV

/

voltage

millivolts output per volt of excitation,

measurement,

measurements. Strain is calculated from the change in the bridge

measurement,

outex

. (The actual result of the full bridge instruction is the

1000

VV

/

is stored and used to calculate future strain

0

out e

1000⋅VV

/

out e

) The result of the zero

2

Page 7

r

x

x

=

−

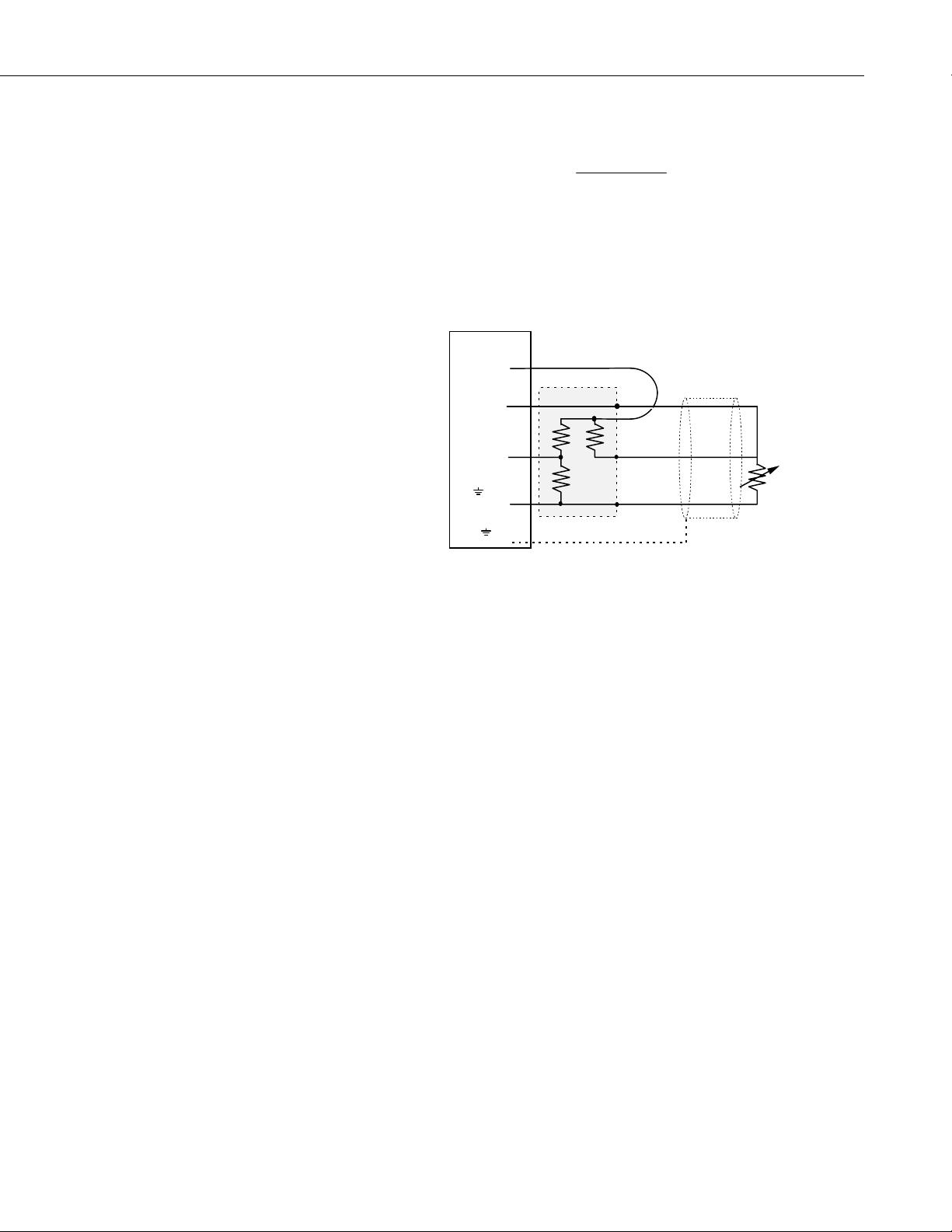

4. Wiring

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

VVV VV

(/)( /0)

out e

ε

=

GF V

out e

V

r

−412

()

r

: 3.1.

3.2.

The calculations are covered in more detail in section 6.

Datalogger

Vx

Figure 4-1 illustrates the wiring of the strain gage to the 4WFB module and the

wiring of the module to the datalogger. It is important that the gage be wired

as shown with the wire from H connected at the gage, and that the leads to the

L and G terminals be the same length, diameter, and wire type. With this

configuration, changes in wire resistance due to temperature occur equally in

both arms of the bridge with negligible effect on the output from the bridge.

5. Program Examples

The following examples for the CR10(X), 21X, CR7, and CR9000(X) all have

a subroutine that measures the unstrained "zero" output of the strain gage. The

examples calculate strain using equation 3.2 for a strain gage with a GF=2.

These are just examples. Besides adding additional measurement instructions,

the programs will probably need to have the scan and d ata storage intervals

altered for actual applications. The instructions in the subroutine will also

need to be modified for the actual gage factor.

H

H

L

G

or AG

or G

H

L

Shield

FIGURE 4-1. Wiring for Example Programs

This zeroing subroutine is called automatically when the progr am is first

executed. The user can call the subroutine by setting Flag 1 low using the

datalogger support software or the *6 mode with the keyboard display. The

"zero" reading is then used during normal measurements for the strain

calculations.

3

Page 8

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

5.1 Edlog

Dataloggers that use Edlog include CR510, CR10(X), 21X, and CR7. The

Edlog instruction that measures strain gages is Instruction 6 – Full Bridge.

The Input Locations assignments used in CR10(X), 21X, and CR7 Examples

are listed in Table 5-1.

TABLE 5-1. Input

Locations Used in

CR10(X), 21X, and CR7

Examples

Addr Name

1 mVperV

2 mVperV_0

3 Vr

4 uStrain

5 Count

6 GF

7 _4e6

8 Mult

9 1_2Vr

10 Vr_1_2Vr

5.1.1 CR10(X)

;{CR10X}

;

*Table 1 Program

01: 1 Execution Interval (seconds)

;Other measurements could be inserted here or before the Output section

1: If Flag/Port (P91) ;On the first execution (Flag 1 is low)

1: 21 Do if Flag 1 is Low ;or when user sets Flag 1 low

2: 1 Call Subroutine 1 ;call the zeroing subroutine

2: Full Bridge (P6) ;Measure the strain gage

1: 1 Reps

2: 22 ± 7.5 mV 60 Hz Rejection Range

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 2500 mV Excitation

6: 1 Loc [ mVperV ]

7: 1 Mult

8: 0 Offset

4

Page 9

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

3: X-Y (P35) ;Subtract zero reading from the

1: 1 X Loc [ mVperV ] ;measurement

2: 2 Y Loc [ mVperV_0 ]

3: 3 Z Loc [ Vr ]

4: X*F (P37) ;Change Vr from mV/V to V/V

1: 3 Loc [ Vr ]

2: 0.001

3: 3 Loc [ Vr ]

;The following instructions calculate microstrain

5: Z=X*F (P37)

1: 3 X Loc [ Vr ]

2: -2 F

3: 9 Z Loc [ 1_2Vr ]

6: Z=Z+1 (P32)

1: 9 Z Loc [ 1_2Vr ]

7: Z=X/Y (P38)

1: 3 X Loc [ Vr ]

2: 9 Y Loc [ 1_2Vr ]

3: 10 Loc [ Vr_1_2Vr ]

8: Z=X*Y (P36)

1: 10 X Loc [ Vr_1_2Vr ]

2: 8 Y Loc [ Mult ]

3: 4 Z Loc [ uStrain ]

;Output Section

;This example outputs an average of the 1 second readings

;once per minute.

09: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1 Interval (same units as above)

3: 10 Set Output Flag High

10: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 1 Array ID ;Set Array ID = 1 for measurement data

11: Real Time (P77)

1: 1110 Year,Day,Hour/Minute

12: Average (P71)

1: 1 Reps

2: 4 Loc [ uStrain ]

*Table 2 Program

2: 0.0000 Execution Interval (seconds)

5

Page 10

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

*Table 3 Subroutines

1: Beginning of Subroutine (P85) ;Subroutine to measure "zero"

1: 1 Subroutine 1

2: Do (P86) ;This prevents calling subroutine

1: 11 Set Flag 1 High ;until user sets flag 1 low again.

3: Z=F (P30) ;Set counter use for average to 0

1: 0 F

2: 0 Exponent of 10

3: 5 Z Loc [ Count ]

4: Z=F (P30) ;load 4 million (4*uS/S) into input location

1: 4 F

2: 6 Exponent of 10

3: 7 Z Loc [ _4e6 ]

5: Z=F (P30) ;Load Gage Factor into input location

1: 2 F ;Enter the actual Gage Factor here

2: 0 Exponent of 10

3: 6 Z Loc [ GF ]

6: Z=X/Y (P38) ;calculate multiplier to use with strain

1: 7 X Loc [ _4e6 ] ;calculation

2: 6 Y Loc [ GF ]

3: 8 Z Loc [ Mult ]

7: Beginning of Loop (P87) ;Loop through 5 times to obtain average

1: 0 Delay ;zero reading

2: 5 Loop Count

8: Z=Z+1 (P32) ;Increment Counter used to determine

1: 5 Z Loc [ Count ] ;when to output

9: Full Bridge (P6) ;Measure Strain Gage

1: 1 Reps

2: 22 ± 7.5 mV 60 Hz Rejection Range

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 2500 mV Excitation

6: 1 Loc [ mVperV ]

7: 1 Mult

8: 0 Offset

10: IF (X<=>F) (P89) ;Check for last pass through loop

1: 5 X Loc [ Count ] ;to set output flag

2: 3 >=

3: 5 F

4: 10 Set Output Flag High

6

Page 11

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

11: Set Active Storage Area (P80) ;Direct averaged "zero" reading

1: 3 Input Storage Area ;to input storage

2: 2 Array ID or Loc [ mVperV_0 ]

12: Average (P71)

1: 1 Reps

2: 1 Loc [ mVperV ]

13: If Flag/Port (P91) ;When average is calculated,

1: 10 Do if Output Flag is High (Flag 0) ;also send it to Final Storage

2: 10 Set Output Flag High

14: Set Active Storage Area (P80) ;Direct Output to Final Storage

1: 1 Final Storage Area 1

2: 11 Array ID ;set Array ID = 11 for zero data

15: Real Time (P77)

1: 110 Day,Hour/Minute

16: Sample (P70)

1: 1 Reps

2: 2 Loc [ mVperV_0 ]

17: End (P95)

18: End (P95)

End Program

5.1.2 21X

;{21X}

*Table 1 Program

01: 1 Execution Interval (seconds)

;Other measurements could be inserted here or before the Output section

1: If Flag/Port (P91) ;On the first execution (Flag 1 is low)

1: 21 Do if Flag 1 is Low ;or when user sets Flag 1 low

2: 1 Call Subroutine 1 ;call the zeroing subroutine

2: Full Bridge (P6) ;Measure the strain gage

1: 1 Reps

2: 2 ± 15 mV Slow Range

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 5000 mV Excitation

6: 1 Loc [ mVperV ]

7: 1 Mult

8: 0 Offset

7

Page 12

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

3: Z=X-Y (P35) ;Subtract zero reading from the

1: 1 X Loc [ mVperV ] ;measurement

2: 2 Y Loc [ mVperV_0 ]

3: 3 Z Loc [ Vr ]

4: Z=X*F (P37) ;Change Vr from mV/V to V/V

1: 3 X Loc [ Vr ]

2: 0.001 F

3: 3 Z Loc [ Vr ]

;The following instructions calculate microstrain

5: Z=X*F (P37)

1: 3 X Loc [ Vr ]

2: -2 F

3: 9 Z Loc [ 1_2Vr ]

6: Z=Z+1 (P32)

1: 9 Z Loc [ 1_2Vr ]

7: Z=X/Y (P38)

1: 3 X Loc [ Vr ]

2: 9 Y Loc [ 1_2Vr ]

3: 10 Z Loc [ Vr_1_2Vr ]

8: Z=X*Y (P36)

1: 10 X Loc [ Vr_1_2Vr ]

2: 8 Y Loc [ Mult ]

3: 4 Z Loc [ uStrain ]

;Output Section

;This example outputs an average of the 1 second readings

;once per minute.

9: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1 Interval (same units as above)

3: 10 Set Output Flag High

10: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 1 Array ID ;Set Array ID = 1 for measurement data

11: Real Time (P77)

1: 1110 Year,Day,Hour/Minute

12: Average (P71)

1: 1 Reps

2: 4 Loc [ uStrain ]

*Table 2 Program

01: 0.0000 Execution Interval (seconds)

8

Page 13

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

*Table 3 Subroutines

1: Beginning of Subroutine (P85) ;Subroutine to measure "zero"

1: 1 Subroutine 1

2: Do (P86) ;This prevents calling subroutine

1: 11 Set Flag 1 High ;until user sets flag 1 low again.

3: Z=F (P30) ;Set counter use for average to 0

1: 0 F

2: 5 Z Loc [ count ]

4: Z=F (P30) ;load 4000 into

1: 4000 F ;input location

2: 7 Z Loc [ 4e6 ]

5: Z=X*F (P37) ;Multiply by 1000 to get (4*uS/S)

1: 7 X Loc [ 4e6 ]

2: 1000 F

3: 7 Z Loc [ 4e6 ]

6: Z=F (P30) ;Load Gage Factor into input location

1: 2 F ;Enter the actual Gage Factor here

2: 6 Z Loc [ GF ]

7: Z=X/Y (P38) ;calculate multiplier to use with strain

1: 7 X Loc [ 4e6 ] ;calculation

2: 6 Y Loc [ GF ]

3: 8 Z Loc [ Mult ]

8: Beginning of Loop (P87) ;Loop through 5 times to obtain average

1: 0 Delay ;zero reading

2: 5 Loop Count

9: Z=Z+1 (P32) ;Increment Counter used to determine

1: 5 Z Loc [ count ] ;when to output

10: Full Bridge (P6) ;Measure Strain Gage

1: 1 Reps

2: 2 ± 15 mV Slow Range

3: 1 DIFF Channel

4: 1 Excite all reps w/Exchan 1

5: 5000 mV Excitation

6: 1 Loc [ mVperV ]

7: 1 Mult

8: 0 Offset

11: IF (X<=>F) (P89) ;Check for last pass through loop

1: 5 X Loc [ count ] ;to set output flag

2: 3 >=

3: 5 F

4: 10 Set Output Flag High

9

Page 14

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

12: Set Active Storage Area (P80) ;Direct averaged "zero" reading

1: 3 Input Storage ;to input storage

2: 2 Array ID or Loc [ mVperV_0 ]

13: Average (P71)

1: 1 Reps

2: 1 Loc [ mVperV ]

14: If Flag/Port (P91) ;When average is calculated,

1: 10 Do if Output Flag is High (Flag 0) ;also send it to Final Storage

2: 10 Set Output Flag High

15: Set Active Storage Area (P80) ;Direct Output to Final Storage

1: 1 Final Storage

2: 11 Array ID ;set Array ID = 11 for zero data

16: Real Time (P77)

1: 110 Day,Hour/Minute

17: Sample (P70)

1: 1 Reps

2: 2 Loc [ mVperV_0 ]

18: End (P95)

19: End (P95)

End Program

5.1.3 CR7

;{CR7}

*Table 1 Program

01: 1.0000 Execution Interval (seconds)

;Other measurements could be inserted here or before the Output section

1: If Flag/Port (P91) ;On the first execution (Flag 1 is low)

1: 21 Do if Flag 1 is Low ;or when user sets Flag 1 low

2: 1 Call Subroutine 1 ;call the zeroing subroutine

2: Full Bridge (P6) ;Measure the strain gage

1: 1 Reps

2: 3 ±15 mV Slow Range

3: 1 In Card

4: 1 DIFF Channel

5: 1 Ex Card

6: 1 Ex Channel

7: 1 Meas/Ex

8: 5000 mV Excitation

9: 1 Loc [ mVperV ]

10: 1 Mult

11: 0 Offset

10

Page 15

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

3: Z=X-Y (P35) ;Subtract zero reading from the

1: 1 X Loc [ mVperV ] ;measurement

2: 2 Y Loc [ mVperV_0 ]

3: 3 Z LOC [ Vr ]

4: Z=X*F (P37) ;Change Vr from mV/V to V/V

1: 3 X Loc [ Vr ]

2: 0.001 F

3: 3 Z Loc [ Vr ]

;The following instructions calculate microstrain

5: Z=X*F (P37)

1: 3 X Loc [ Vr ]

2: -2 F

3: 9 Z LOC [ 1_2Vr ]

6: Z=Z+1 (P32)

1: 9 Z LOC [ 1_2Vr ]

7: Z=X/Y (P38)

1: 3 X Loc [ Vr ]

2: 9 Y Loc [ 1_2Vr ]

3: 10 Z LOC [ Vr_1_2Vr ]

8: Z=X*Y (P36)

1: 10 X Loc [ Vr_1_2Vr ]

2: 8 Y Loc [ Mult ]

3: 4 Z LOC [ uStrain ]

;Output Section

;This example outputs an average of the 1 second readings

;once per minute.

9: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 1 Interval (same units as above)

3: 10 Set Output Flag High

10: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 1 Array ID ;Set Array ID = 1 for measurement data

11: Real Time (P77)

1: 1110 Year,Day,Hour/Minute

12: Average (P71)

1: 1 Reps

2: 4 Loc [ uStrain ]

11

Page 16

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

*Table 2 Program

01: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

1: Beginning of Subroutine (P85) ;Subroutine to measure "zero"

1: 1 Subroutine 1

2: Do (P86) ;This prevents calling subroutine

1: 11 Set Flag 1 High ;until user sets flag 1 low again.

3: Z=F (P30) ;Set counter use for average to 0

1: 0 F

2: 5 Z LOC [ Count ]

4: Z=F (P30) ;load 4000 into

1: 4000 F ;input location

2: 7 Z LOC [ 4e6 ]

5: Z=X*F (P37) ;Multiply by 1000 to get (4*uS/S)

1: 7 X Loc [ 4e6 ]

2: 1000 F

3: 7 Z LOC [ 4e6 ]

6: Z=F (P30) ;Load Gage Factor into input location

1: 2 F ;Enter the actual Gage Factor here

2: 6 Z LOC [ GF ]

7: Z=X/Y (P38) ;calculate multiplier to use with strain

1: 7 X Loc [ 4e6 ] ;calculation

2: 6 Y Loc [ GF ]

3: 8 Z LOC [ Mult ]

8: Beginning of Loop (P87) ;Loop through 5 times to obtain average

1: 0 Delay ;zero reading

2: 5 Loop Count

9: Z=Z+1 (P32) ;Increment Counter used to determine

1: 5 Z Loc [ Count ] ;when to output

10: Full Bridge (P6) ;Measure Strain Gage

1: 1 Reps

2: 3 ± 15 mV Slow Range

3: 1 In Card

4: 1 DIFF Channel

5: 1 Ex Card

6: 1 Ex Channel

7: 1 Meas/Ex

8: 5000 mV Excitation

9: 1 Loc [ mVperV ]

10: 1 Mult

11: 0 Offset

12

Page 17

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

11: IF (X<=>F) (P89) ;Check for last pass through loop

1: 5 X Loc [ Count ] ;to set output flag

2: 3 >=

3: 5 F

4: 10 Set Output Flag High

12: Set Active Storage Area (P80) ;Direct averaged "zero" reading

1: 3 Input Storage ;to input storage

2: 2 Array ID or Loc [ mVperV_0 ]

13: Average (P71)

1: 1 Reps

2: 1 Loc [ mVperV ]

14: If Flag/Port (P91) ;When average is calculated,

1: 10 Do if Output Flag is High (Flag 0) ;also send it to Final Storage

2: 10 Set Output Flag High

15: Set Active Storage Area (P80) ;Direct Output to Final Storage

1: 1 Final Storage

2: 11 Array ID ;set Array ID = 11 for zero data

16: Real Time (P77)

1: 110 Day,Hour/Minute

17: Sample (P70)

1: 1 Reps

2: 2 Loc [ mVperV_0 ]

18: End (P95)

19: End (P95)

End Program

5.2 CRBasic

Dataloggers that use CRBasic include our CR800, CR850, CR1000, CR3000,

CR5000, and CR9000(X). CRBasic uses the StrainCalc Instruction for

calculating strain from the output of different full bridge configurations:

StrainCalc(Dest,Reps,Source,BrZero,BrConfig,GageFactor,PoissonRatio)

Source is the variable holding the current measurement, BrZero is the zero

measurement; this instruction uses the results of the full bridge measurement

instruction (multiplier=1, offset=0, mV/V) directly. The code for the Bridge

Configuration used with the 4WFB module is -1. Enter the actual gage factor

for GageFactor. Enter 0 for the Poisson ratio parameter which is not used with

this bridge configuration.

13

Page 18

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

5.2.1 CR9000(X)

This example program is slightly different in operation than the examples for

the other dataloggers. Data are only output to data table STRAINS when the

user sets Flag(1). Every measurement is output (rather than averages like in

the other examples) while Flag(1) is high.

' Program name: STRAIN.DLD

Public Count, ZStrain, StMeas, Strain, Flag(8) 'Declare all variables as public

'Data Table STRAINS samples every measurement when user Sets Flag(1) High

DataTable(STRAINS,Flag(1),-1)

DataInterval(0,0,0,100) 'Interval = Scan, 100 lapses

Sample (1,Strain,Ieee4)

EndTable

'DataTable ZERO_1 stores the "zero" measurements

DataTable(ZERO_1,Count>99,100) 'Trigger on Count 100

Average(1,ZStrain,IEEE4,0)

EndTable

'Subroutine to measure Zero, Called when user sets Flag(2)low

Sub Zero

Count = 0 'Reset Count

Scan(10,mSec,0,100) 'Scan 100 times

BrFull(ZStrain,1,mV50,5,1,6,7,1,5000,1,0,0,100,1,0)

Count = Count + 1 'Increment Counter used By DataTable

CallTable ZERO_1 'Zero_1 outputs on last scan (Count=100)

Next Scan

ZStrain = ZERO_1.ZStrain_Avg(1,1) 'Set ZStrain = averaged value

Flag(1) = True

End Sub

BeginProg

Scan(10,mSec,0,0) 'Scan 10(mSecs)

If Not Flag(2) Then Zero

BrFull(StMeas,1,mV50,5,1,6,7,1,5000,1,0,0,100,1,0)

StrainCalc(Strain,1,StMeas,ZStrain,-1,2,0)

CallTable STRAINS 'Strains outputs only when Flag(1)=True

Next Scan

EndProg

14

Page 19

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

⎛

⎞

R

∆

R

R

+

∆

6. Calculation of Strain

Vx

H

R1

L

R2

or AG

FIGURE 6-1. Strain Gage in Full Bridge

Figure 6-1 is the diagram of the strain gage in the full bridge configuration

provided by the terminal input module. The result of the datalogger's full

bridge measurement when a multiplier of 1 and an offset of 0 is used is the

measured bridge output in millivolts divided by the excitation in volts (1000

mV=1V):

Vout

1000 1000

⋅=⋅+−

Vin

The result is output in the units of millivolts output per volt o f excitation

because the output voltage is small relative to the excitation voltage; these

units allow the result to be a larger number easier for the datalogger to display

and store (see data format discussion in the datalogger manual). The output is

a ratio because: 1) the datalogger's ratiometric measurement technique allows

this ratio to be more accurate than the measurement of the output voltage

(errors in the excitation and measured output cancel). 2) This ratio can be used

directly in the calculation of strain.

H

H

R3

L

Rg

G

R

g

⎜

RRRRR

⎝

3

g

2

+

12

6.3.

⎟

⎠

When strain is calculated the direct ratio of the voltages (volts per volt not

millivolts per volt) will be used:

Vout

=

Vin

If the previous equation is taken as the result when the gage is unstrained, then

when the gage is strained it will change resistance by

the bridge output is:

Vout

Vin

=

strained

g

RRRRR

+

3

g

gg

RR RRRR

++

gg

3

−

12

∆

2

6.4.

+

R

. The equation for

g

2

−

12

6.5.

+

15

Page 20

4WFB120, 4WFB350, 4WFB1K 4 Wire Full Bridge Terminal Input Modules

r

+

∆

=

⋅

⋅

∆∆∆∆∆

(

∆

∆

Subtracting the unstrained (zero) result from the strained result gives

Vout

⎛

⎞

⎜

V

=

r

=

The terminal input module is selected so that

:

R

3

V

=

r

Solving for strain:

⎟

⎝

⎠

Vin

strained unstrained

RR R RR

()()

++ ⋅ +

gg g

33

++ ⋅ +

()()424

RR R RR

gg g gg

Vout

⎛

⎜

−

⎝

Vin

RR

⋅

∆

g

3

∆

RR

gg

42

42

⎞

⎟

⎠

=

+=

∆∆

RRV

ggr

+=

RV RV R

gr gr g

∆∆

RR

gg

=

RR RRRR

++

gggg

3

RR

RR

gg

2

+

RRRRRR

gggggg

)

R

g

−

∆

. Substituting R for

g3

=

+

3

+

2

V

:

6.6.

g

6.7.

∆

42

412

Strain is calculated by dividing equation 6.8 by the gage factor. The units are

converted to microstrain by multiplying by 10

µε

=−

RV R RV

RV R V

=

∆∆

gr g gr

=−

∆

gr g r

4

−

12VV

410

GF V

()

R

r

r

6

⋅

−

12

()

g

=

V

r

6.8.

R

g

6

uS/S.

6

10

=

GF R

r

⋅

R

g

6.9.

g

16

Page 21

This is a blank page.

Page 22

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...