Page 1

Met One Rain Gage

Models 380 and 385

Revision: 2/08

Copyright © 1993-2008

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The MET ONE RAIN GAGE MODELS 380 AND 385 are warranted by

CAMPBELL SCIENTIFIC, INC. to be free from defects in materials and

workmanship under normal use and service for twelve (12) months from date

of shipment unless specified otherwise. Batteries have no warranty.

CAMPBELL SCIENTIFIC, INC.'s obligation under this warranty is limited to

repairing or replacing (at CAMPBELL SCIENTIFIC, INC.'s option) defective

products. The customer shall assume all costs of removing, reinstalling, and

shipping defective products to CAMPBELL SCIENTIFIC, INC. CAMPBELL

SCIENTIFIC, INC. will return such products by surface carrier prepaid. This

warranty shall not apply to any CAMPBELL SCIENTIFIC, INC. products

which have been subjected to modification, misuse, neglect, accidents of

nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. CAMPBELL SCIENTIFIC, INC. is not liable for special,

indirect, incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country. To obtain a Returned Materials Authorization (RMA),

contact CAMPBELL SCIENTIFIC, INC., phone (435) 753-2342. After an

applications engineer determines the nature of the problem, an RMA number

will be issued. Please write this number clearly on the outside of the shipping

container. CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

Met One Rain Gage Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Introduction..................................................................1

2. Specifications ..............................................................2

3. Installation....................................................................2

3.1 Siting.........................................................................................................2

3.2 Mounting ..................................................................................................3

3.3 Screen Removal........................................................................................3

4. Wiring............................................................................8

4.1 Heater Wiring...........................................................................................9

4.2 Wiring for Pulse Channel Input................................................................9

4.3 Wiring for Control Port Input...................................................................9

5. Datalogger Programming..........................................10

5.1 CR10X Programming.............................................................................10

5.1.1 CR200 Series Programming..........................................................11

5.1.2 CR1000 Programming..................................................................11

5.2 Control Port Programming .....................................................................12

5.2.1 CR1000 Programming..................................................................12

5.2.2 CR200 Series Programming..........................................................12

5.2.3 CR10X Programming ...................................................................13

6. Troubleshooting ........................................................14

6.1 Precipitation............................................................................................14

7. Maintenance and Calibration....................................14

7.1 Customer Calibration..............................................................................14

7.2 Factory Recalibration..............................................................................15

Figures

1-1. 385 Met One Rain and Snow Gage.........................................................1

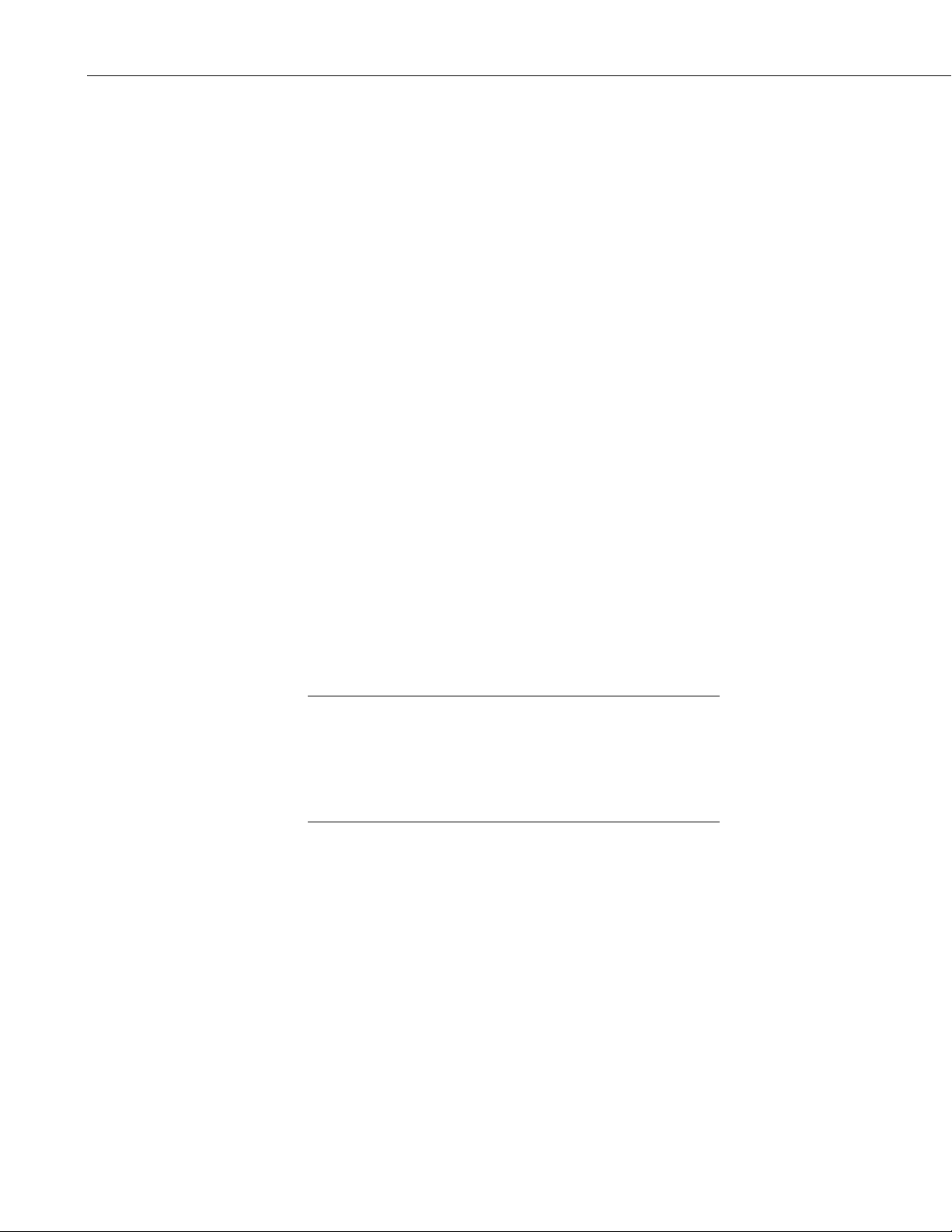

3-1. Typical Snow Gage Installation ..............................................................4

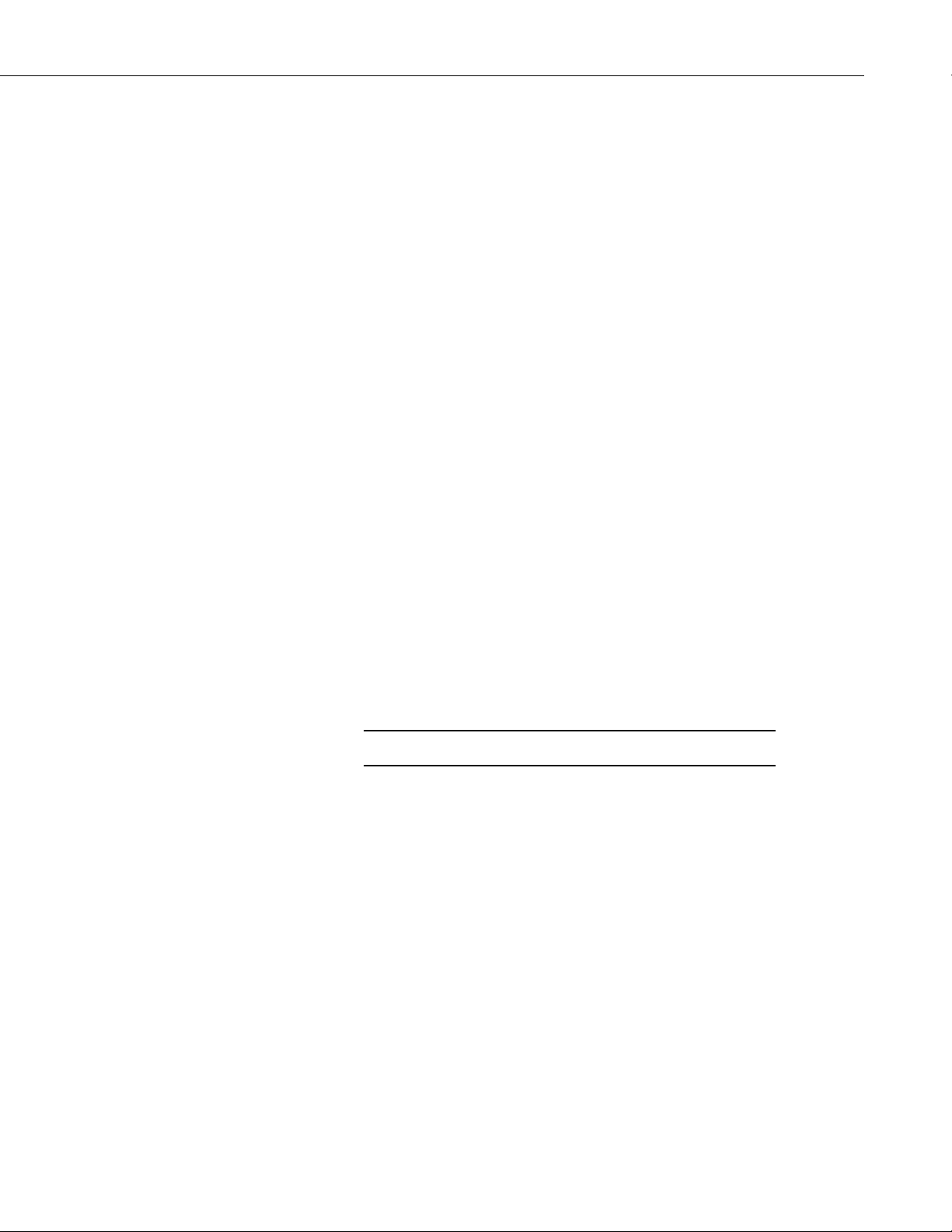

3-2. Pedestal Base Options.............................................................................5

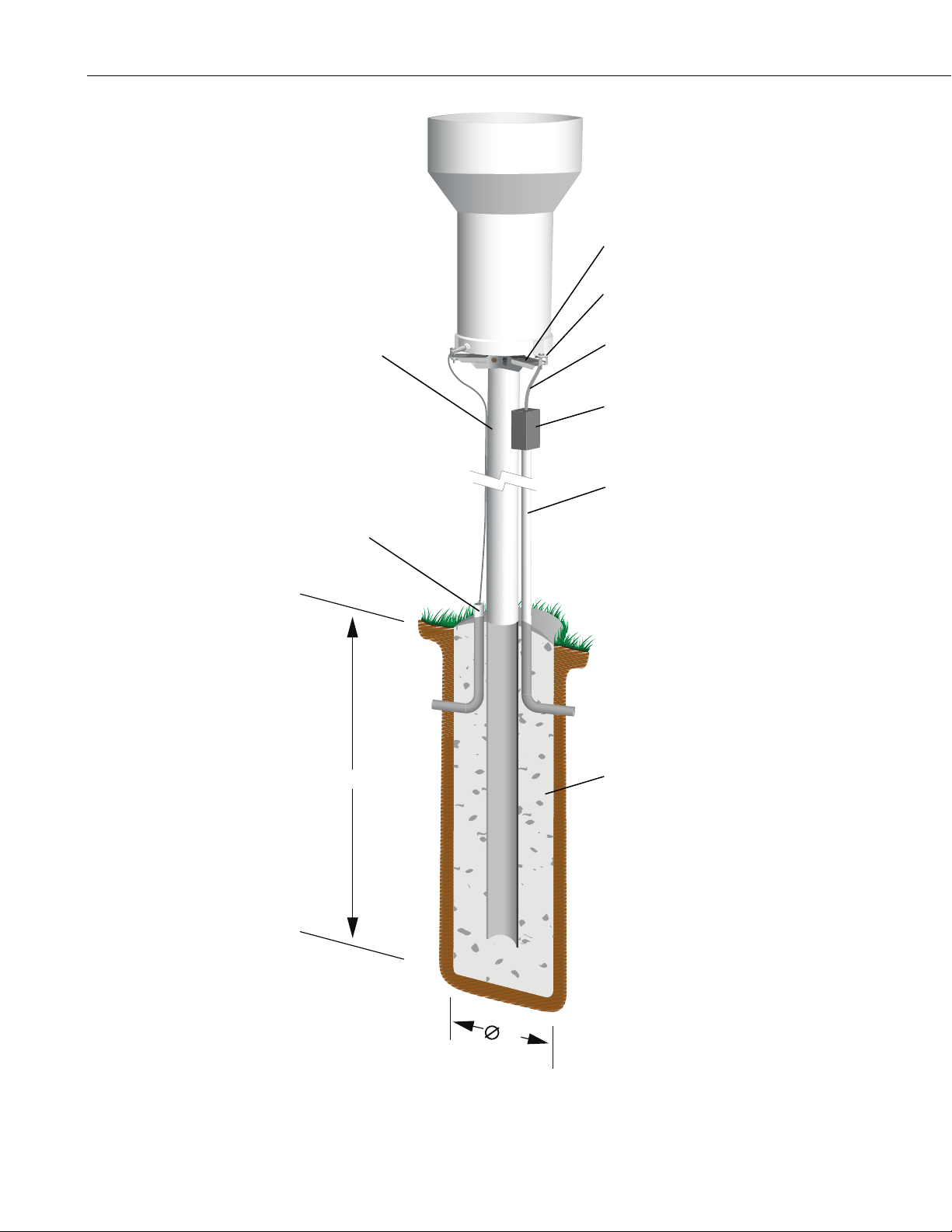

3-3. Connecting Signal Cable Leads ..............................................................6

3-4. Remove Screen if Snow is Anticipated...................................................7

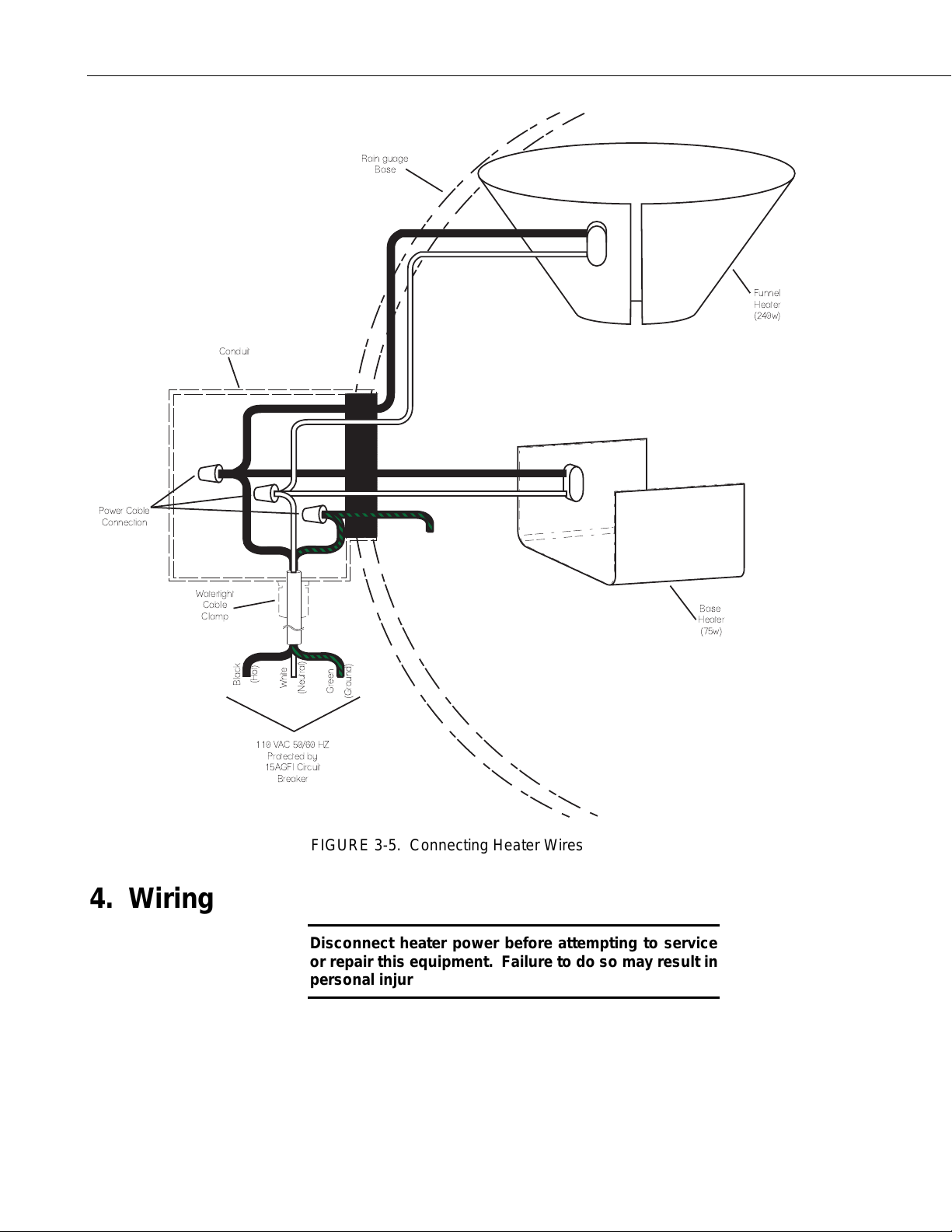

3-5. Connecting Heater Wires ........................................................................8

i

Page 4

Met One Rain Gage Table of Contents

Tables

4-1. Wiring for Pulse Channel Input.............................................................. 9

4-2. Wiring for Control Port Input................................................................. 9

7-1. Volume of Water for Recalibration...................................................... 15

ii

Page 5

Met One Rain Gage Models 380 and 385

1. Introduction

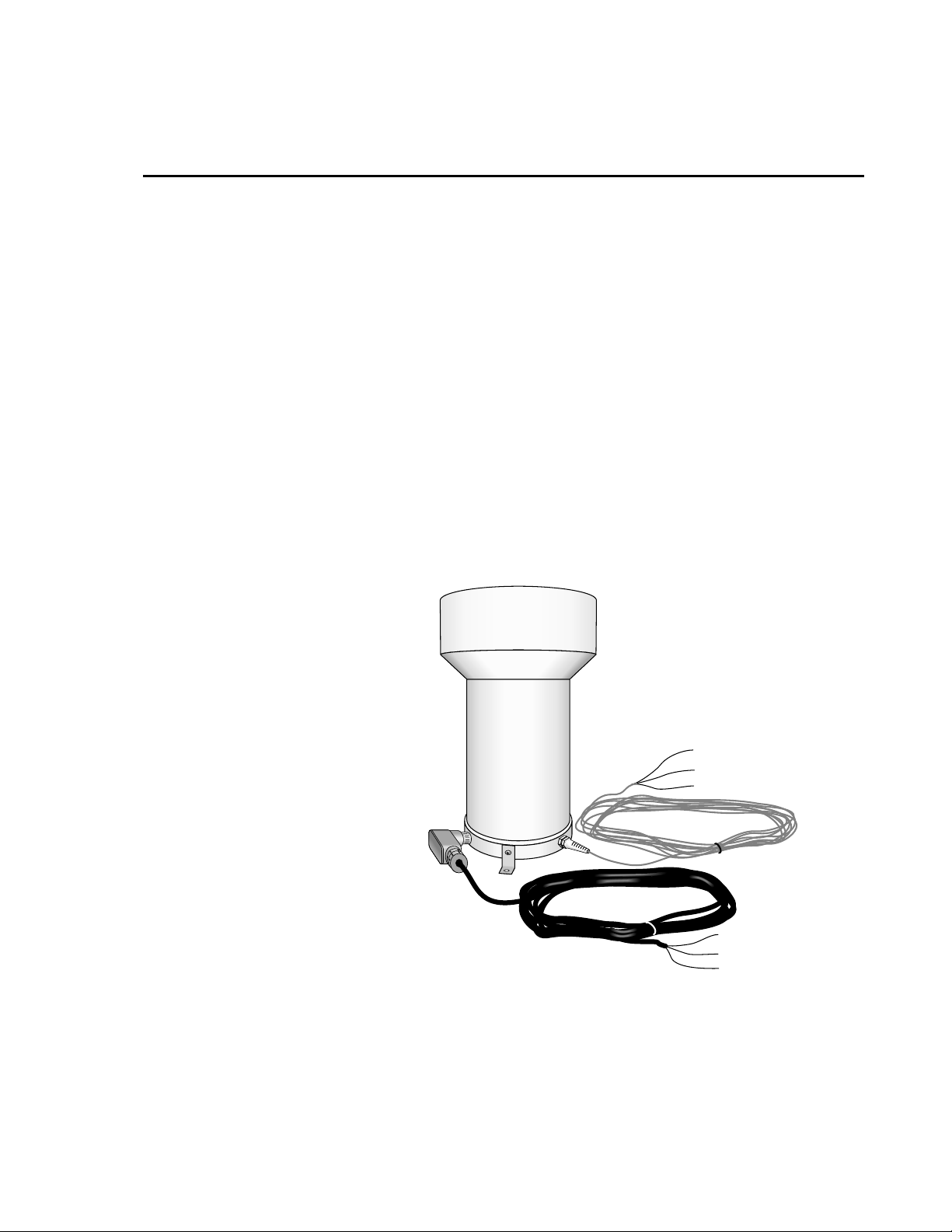

Met One's tipping bucket rain or snow gage is used to measure rain or snow

water equivalent on a continuous basis. The Model 380 rain gage is intended

to measure rainfall during above freezing conditions. The Model 385 AC

heated rain gage provides year round measurement of either rain or snow. In

the standard versions Model 380/385, precipitation is measured in increments

of 0.01 inches.

The Model 380 rain gage works by collecting rainfall in the 12 inch collection

funnel and metering the rain into the tipping bucket assembly. When 0.01

inches of rainfall are collected, the tipping bucket assembly tips and activates a

mercury switch. The switch closure is recorded by the datalogger pulse

channel. When the bucket tips, the water drains out the screened base of the

gage. In the case of the Model 385 heated rain gage, snowfall is captured in

the collection funnel and melted by the heater element. After melting, the

snow water is metered into the tipping bucket assembly for measurement of the

snow water equivalent.

FIGURE 1-1. 385 Met One Rain and Snow Gage

The 385 ships with:

(1) Calibration Sheet

(1) Instruction Manual

1

Page 6

Met One Rain Gage Models 380 and 385

2. Specifications

MODEL 380/385 RAIN GAGE

Funnel: 12 inch (30.5 cm)

Accuracy: ±0.5% < 0.5"(1.27 cm)/hr rate

±2.0% < 3.0"(7.62 cm)/hr rate

Resolution:

380/385 0.01 inch

Environmental Conditions:

Temperature: 0°C to +50°C

Humidity: 0 to 100%

Dimensions:

Weight: 7 pounds (3.2 kg) w/ 50 ft. signal cable

Height: 14" (35.5 cm)

Diameter: 12" (30.5 cm)

MODEL 385

Specifications same as Model 380 unless listed below.

NOTE

3. Installation

3.1 Siting

Environmental Conditions:

Temperature: -20°C to +50°C

Humidity: 0 to 100%

Weight: 12.2 pounds (5.57 kg) w/ 50' power/signal cable

Heater Power Specification:

Voltage: 115 VAC (50/60 Hz)

Current: 5 amps maximum

Heater: 300 W Cartridge Element

The black outer jacket of the cable is Santoprene

compound was chosen for its resistance to temperature extremes,

moisture, and UV degradation. However, this jacket will

support combustion in air. It is rated as slow burning when

tested according to U.L. 94 H.B. and will pass FMVSS302.

Local fire codes may preclude its use inside buildings.

The rain or snow gage should be mounted in a relatively level spot which is

representative of the surrounding area. The lip of the funnel should be

horizontal and at least 30 inches above the ground. Install the snow gage high

enough to prevent burial by snow during the winter months. The ground

surface around the rain gage should be natural vegetation or gravel. The gage

should not be installed over a paved or concrete surface. Refer to Figure 3-1

for an illustration of gage installation.

®

rubber. This

2

Page 7

3.2 Mounting

Met One Rain Gage Models 380 and 385

The rain or snow gage should be placed away from objects that obstruct wind.

The minimum distance should be 2 times the height of the obstruction or more.

The rain or snow gage is designed to mount on a flat surface. Three equally

spaced adjustable mounting legs are provided. The mounting legs are predrilled for 1/4" bolts on a 9.66" diameter bolt circle. A mounting bracket is

available from Campbell Scientific (CM240) to install either the rain or snow

gage. The mounting bracket provides additional adjustment for leveling the

rain or snow gage. The CM240 base helps level the rain gage, ensuring a more

accurate measurement. The base may be attached to a CM300-Series

Mounting Pole or to a user-supplied 1.5 IPS (1.9” OD, unthreaded) pipe. The

pipe should be long enough to place the gage's orifice at a one-meter height.

The pole or pipe can be placed directly into a concrete foundation, attached to

a concrete foundation using J-bolts, or self-supporting with legs (see Figure 3-

2). A concrete pad is recommended. A typical snow gage installation is

illustrated in Figure 3-1.

Loosen the three screws and lift the housing assembly from the base. Adjust

the three slotted feet on the base of the rain gage and/or the three nuts on the

CM240 to level the gage.

Remove the rubber shipping band securing the stainless steel tipping bucket

assembly. Verify the bucket tips freely and that all the adjusting screws are

tight. Replace the housing assembly and tighten the three screws to secure the

housing to the base. Level the rain gage after mounting it.

3.3 Screen Removal

If snowfall is anticipated, remove the primary screen from funnel, as shown in

Figure 3-3.

NOTE

Remember to replace primary screen after a snowfall event.

3

Page 8

Met One Rain Gage Models 380 and 385

CM240 Mounting Bracket

Level Adjustments

1.5” IPS Pipe

User-Supplied 1” Conduit

for Signal Cable

24”

Power Cable

User-Supplied AC Power

Termination Box

User-Supplied AC Power

and Conduit for Heated

Snow Gage

User-Supplied

Concrete Pad

4

8”

FIGURE 3-1. Typical Snow Gage Installation

Page 9

Met One Rain Gage Models 380 and 385

3.5”

1.5”

24”

FIGURE 3-2. Pedestal Base Options

14”

5

Page 10

Met One Rain Gage Models 380 and 385

A

P/N 2196 (2) Plcs.

WHITE

BLACK

6”

3/8”

Heat Shrink (2) Plcs.

Cut Shield Off Flush to Jacket

P/N 9661

8”

3/8”

Clear Heat Shrink

WHITE

SHIELD

BLACK

8”

3/8”

Heat Shrink (2) Plcs.

P/N 7805 Beldon #1934B

2”

3/8”

BLACK

WHITE

GREEN

TTACH WHITE OF (SIGNAL CABLE) TO PIN 3

FIGURE 3-3. Connecting Signal Cable Leads

6

Page 11

Remove Primary

Screen

if Snow is

Anticipated

Met One Rain Gage Models 380 and 385

FIGURE 3-4. Remove Screen if Snow is Anticipated

7

Page 12

Met One Rain Gage Models 380 and 385

!

4. Wiring

WARNING

"

%% &' () *

+

%'$,

"

$

#

$

FIGURE 3-5. Connecting Heater Wires

Disconnect heater power before attempting to service

or repair this equipment. Failure to do so may result in

personal injury or death due to electrocution.

The BLACK (Signal) lead connects to a pulse channel. The WHITE (Power

Ground) connects to ground channel. The CLEAR (shield) lead connects to

ground channel. Refer to Table 4-1 for the wiring of your datalogger. The

purpose of the shield wire is to drain any charges built up in the cable due to

transients etc.

8

Page 13

4.1 Heater Wiring

Attach the power plug supplied with the Model 385 by following the

instructions supplied with the plug. The electric heated snow gage requires

115VAC (50/60hz), 5 amps maximum, to operate the heater. (If supplying

your own signal or power cable, refer to Figure 3-4 for an illustration of cable

installation.) The heater should be unplugged during warmer months to

prevent evaporation during low rainfall and to minimize wear and tear on the

heater element.

Met One Rain Gage Models 380 and 385

NOTE

The heater thermostat is factory set and requires no field

adjustment.

4.2 Wiring for Pulse Channel Input

Connections to Campbell Scientific dataloggers are given in Table 4-1. When

Short Cut for Windows software is used to create the datalogger program, the

sensor should be wired to the channels shown on the wiring diagram created

by Short Cut.

TABLE 4-1. Wiring for Pulse Channel Input

Color

Black Signal Pulse Channel Pulse Channel Pulse Channel P_SW

White Signal Return

Clear Shield

Dataloggers listed in Table 4-2 have the capability of counting switch closures

on some of their control ports. When a control port is used, the return from the

rain gage must be connected to +5 volts on the datalogger.

Description

CR800

CR1000

CR3000

CR5000

CR500

CR510,

CR10(X),

G

G

21X,

CR7,

CR23X

CR200

Series

4.3 Wiring for Control Port Input

TABLE 4-2. Wiring for Control Port Input

Color

Black Signal Control Port C2/P3 Control Port Control Port

White Signal Return 5 V 5 V 5 V 5 V

Clear Shield

The CR10 does not support the use of control port inputs with the Pulse Count

instruction; use Short Cut or see Example 8.5 in the CR10 operator’s manual.

Description

CR800

CR1000

CR3000

CR500,

CR510

CR10(X)

G

CR23X

9

Page 14

Met One Rain Gage Models 380 and 385

5. Datalogger Programming

5.1 CR10X Programming

This section is for users who write their own programs. A datalogger program

to measure this sensor can be created using Campbell Scientific’s Short Cut

Program Builder software. You do not need to read this section to use Short

Cut.

The Model 385 rain gage is measured using the Pulse Count instruction

configured for a switch closure. In all dataloggers, a multiplier of 0.01

converts the output to inches and a multiplier of 0.254 converts the output to

millimeters.

The following example program uses a pulse channel to read the output from

the rain gage and will work with CR500, CR510, CR10(X), 21X or CR23X.

The CR7 is similar but has an additional parameter in the Pulse Count

instruction to specify the slot that the Pulse Card is in.

Input Location Labels:

1. Rain (in)

*Table 1 Program

01: 10 Sec. Execution Interval

1: Pulse (P3)

1: 1 Rep

2: 1 Pulse Input Channel

3: 2 Switch Closure

4: 1 Loc [:Rain (in)]

5: 0.01 Mult

6: 0 Offset

2: If time is (P92)

1: 0 minutes into a

2: 60 minute interval

3: 10 Set high Flag 0

3: Real Time (P77)

1: 110 Day,Hour-Minute

4: Totalize (P72)

1: 1 Repetitions

2: 1 Starting Input Location

5: End Table 1

10

Output Instruction 72, Totalize, is used in the output section of the program to

output the total rainfall over the output interval. This section should be

executed every scan and not placed in a subroutine or conditional statement.

Page 15

Met One Rain Gage Models 380 and 385

5.1.1 CR200 Series Programming

'CR200 Series

'Example program showing measurement of a 380/385 sensor every 10 seconds.

'Declare Public Variables and Units

Public Rain_in

Units Rain_in=inch

'Define Data Tables

DataTable(Table1,True,-1) 'As an example store the data every 60 minutes.

DataInterval(0,60,Min)

Totalize(1,Rain_in,False)

EndTable

'Main Program

BeginProg

Scan(10,Sec)

'MetOne 380/385 Rain Gauge measurement Rain_in:

PulseCount(Rain_in,P_SW,2,0,0.01,0)

'Call Data Tables and Store Data

CallTable(Table1)

NextScan

EndProg

5.1.2 CR1000 Programming

‘CR1000

‘Example program showing measurement of a 380/385 sensor every 10 seconds.

‘Declare Variables and Units

Public Rain_in

Units Rain_in=inch

‘Define Data Tables

DataTable (Table1,True,-1)

DataInterval (0,60,Min,10) ‘As an example store the data every 60 minutes.

Totalize (1,Rain_in,FP2,False)

EndTable

‘Main Program

Begin Prog

Scan (10,Sec,1,0)

‘MetOne 380/385 Rain Gauge measurement Rain_in:

PulseCount (Rain_in,1,1,2,0,0.01,0)

‘Call Data Tables and Store Data

CallTable (Table1)

NextScan

End Prog

11

Page 16

Met One Rain Gage Models 380 and 385

‘Main Program

BeginProg

Scan(10,Sec,1,0)

‘Default Datalogger Battery Voltage measurement Batt_Volt:

Battery(Batt_Volt)

‘MetOne 380/385 Rain Gauge measurement Rain_in:

PulseCount(Rain_in,1,1,2,0,0.01,0)

‘Call Data Tables and Store Data

CallTable(Table1)

CallTable(Table2)

NextScan

EndProg

5.2 Control Port Programming

The following examples measure a 380 and 385 rain gage using a control port

on a datalogger. Wire the sensor as shown in Table 4-2.

5.2.1 CR1000 Programming

'CR1000

'Declare Public Variables and Units

Public Rain_in

Units Rain_in=inch

DataTable (Rain,True,-1)

DataInterval (0,60,Min,0)

Totalize (1,Rain_in,FP2,0)

EndTable

'Main Program

BeginProg

Scan (1,Sec,1,0)

PulseCount (Rain_in,1,18,2,0,.01,0) ; Black wire connect to C8

CallTable (Rain)

NextScan

EndProg

12

5.2.2 CR200 Series Programming

'CR200

'A 20 kOhm pull up resistor is required to read a switch closure on C1 or C2

'as a Pulse Counter. The 20 kOhm resistor uses the battery voltage.

'Declare Public Variables and Units

Public Rain_in

Units Rain_in=inch

Page 17

Met One Rain Gage Models 380 and 385

'Define Data Tables

DataTable(Table1,True,-1) 'As an example store the data every 60 minutes.

DataInterval(0,60,Min)

Totalize(1,Rain_in,False)

EndTable

'Main Program

BeginProg

Scan(10,Sec)

'MetOne 380/385 Rain Gauge measurement Rain_in:

PulseCount(Rain_in,C2,2,0,0.01,0) ; Black wire connect to C2

'Call Data Tables and Store Data

CallTable(Table1)

NextScan

EndProg

5.2.3 CR10X Programming

;{CR10X}

;

*Table 1 Program

01: 1 Execution Interval (seconds)

1: Pulse (P3)

1: 1 Reps

2: 8 Control Port 8 (switch closure only) ; Black wire connect to C8

3: 2 Switch Closure, All Counts

4: 1 Loc [ Rain_inch ]

5: .01 Multiplier

6: 0 Offset

2: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

3: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 101 Array ID

4: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

5: Totalize (P72)

1: 1 Reps

2: 1 Loc [ Rain_inch ]

*Table 2 Program

02: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

End Program

13

Page 18

Met One Rain Gage Models 380 and 385

6. Troubleshooting

6.1 Precipitation

Symptom: No precipitation

1. Check that the sensor is wired to the Pulse Channel specified by the Pulse

Count instruction.

2. Verify that the Co nfiguration Code (Switch Closure), and Multiplier and

Offset parameters for the Pulse Count instruction are correct for the

datalogger type.

3. Disconnect the sensor from the datalogger and use an ohm meter to do a

continuity check of the switch. The resistance measured at the terminal

block on the inside of the bucket between the black and white leads

should vary from infinite (switch open) when the bucket is tipped, to less

than an ohm when the bucket is balanced.

7. Maintenance and Calibration

During each site visit, check for and remove any debris, insects, sediment, etc.

from the collection funnel, debris screens, or tipping bucket assembly. Verify

the tipping bucket assembly moves freely, and that the datalogger records 0.01

in for each bucket tip.

7.1 Customer Calibration

The sensor is factory calibrated; recalibration is not required unless damage

has occurred or the adjustment screws have loosened. Nevertheless, the

following calibration check is recommended once every 12 months:

a. Remove the housing assembly from the base by loosening the three

screws and lifting upward on the housing.

b. Check bubble level to verify sensor is level.

c. Pour water through the inner funnel to wet the two bucket surfaces.

Using a graduated cylinder, slowly pour the appropriate amount of

water (refer to Table 7-1) through the inner funnel to the tipping

bucket, which should tip once. Repeat for the other bucket. If both

buckets tip when filled with the appropriate amount of water (refer to

Table 7-1), the sensor is properly calibrated and no additional

adjustment is needed. If either bucket fails to tip, recalibrate as

follows:

14

1. Release the lock nuts on the cup adjustments.

2. Move the adjustment screws down to a position that would place the

bucket far out of calibration.

Page 19

Met One Rain Gage Models 380 and 385

3. Pour the appropriate amount of water (see Table 7-1) into the inner funnel

(i.e. 18.52 ml for 0.01 inches of rain / tip):

Conversion Factors:

3

Tip to in

3

in

: 113.04 in2 (catch orifice area) x increment in inches.

to ml: multiply by 16.3881.

ml to ounces: multiply by 0.03382.

4. Turn the cup adjustment screw, opposite the full bucket, up until the

bucket assembly tips. Tighten the lock nut.

5. Repeat steps 3 and 4 for the opposite bucket.

6. Repeat steps 1-5 to ensure proper calibration.

7. Reinstall the housing assembly and tighten the three screws.

TABLE 7-1. Volume of Water

for Recalibration

Tip Increment in3 ml ounces

0.01 in 1.130 18.52 0.63

7.2 Factory Recalibration

Factory recalibration is available from either Campbell Scientific Incorporated

or Met One Instruments. Please call and request an RMA number prior to

returning any equipment to Campbell Scientific Incorporated

15

Page 20

Met One Rain Gage Models 380 and 385

16

Page 21

This is a blank page.

Page 22

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

cleroux@csafrica.co.za

Campbell Scientific Australi

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

info@campbellsci.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

a Pty. Ltd. (CSA)

Loading...

Loading...