Page 1

Model 237 Leaf Wetness Sensor

Revision: 7/10

Copyright © 1988-2010

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The 237 LEAF WETNESS SENSOR is warranted by Campbell Scientific,

Inc. to be free from defects in materials and workmanship under normal use

and service for twelve (12) months from date of shipment unless specified

otherwise. Batteries have no warranty. Campbell Scientific, Inc.'s obligation

under this warranty is limited to repairing or replacing (at Campbell Scientific,

Inc.'s option) defective products. The customer shall assume all costs of

removing, reinstalling, and shipping defective products to Campbell Scientific,

Inc. Campbell Scientific, Inc. will return such products by surface carrier

prepaid. This warranty shall not apply to any Campbell Scientific, Inc.

products which have been subjected to modification, misuse, neglect, accidents

of nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. Campbell Scientific, Inc. is not liable for special, indirect,

incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact Campbell

Scientific, Inc., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to repair@campbellsci.com

435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed to

Page 3

237 Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Introduction..................................................................1

1.1 Specifications............................................................................................1

2. Wiring............................................................................ 1

3. Programming ...............................................................2

3.1 Measurement of Vs / Vx...........................................................................2

3.2 Calculating Sensor Resistance..................................................................2

3.3 Interpreting Resistance Values .................................................................3

3.4 Calculating Wet Time Fraction.................................................................3

4. Programming Examples.............................................. 4

4.1 CR1000 Program Example.......................................................................4

4.2 CR200(X) Programming ..........................................................................4

4.3 CR10(X) Programming Example .............................................................5

5. Plant Pathology Application ....................................... 6

5.1 Sensor Preparation....................................................................................6

5.2 Plant Pathology Application Programming ..............................................7

5.3 Sensor Deployment...................................................................................7

5.4 Calibration ................................................................................................7

6. References ...................................................................8

Figures

1. 237 Sensor Schematic.................................................................................1

2. Mounting the 237 Sensor............................................................................7

Tables

1. Connections to Campbell Scientific Dataloggers .......................................1

2. Measurement Instructions, Parameters, Results .........................................2

3. 237 Resistance Interpretations....................................................................3

i

Page 4

Page 5

Model 237 Leaf Wetness Sensor

1. Introduction

The 237 Leaf Wetness Sensor is a simple resistive grid configured in a 3-wire

half-bridge. The circuit is completed when water bridges two inter-digitate

electrodes. Response is non-linear with a rapid decrease in resistance relative

to an increase in wetness. The simplicity of the sensor lends it to various

applications, means of preparation, and data interpretations.

1.1 Specifications

Temperature Range: Operational 0° to 100°C; Survival -40° to 150°C

Sensor may crack if temperature drops below -40°C

Dimensions: 2.75" W x 3.0" L x 0.25" D (7.1 x 7.6 x 0.64 cm)

Weight: 3 oz per 10' cable (91 g per 3.1 m cable)

2. Wiring

Figure 1 is a circuit schematic of the 237. Table 1 describes wiring to

Campbell Scientific dataloggers.

FIGURE 1. 237 Sensor Schematic

TABLE 1. Connections to Campbell Scientific Dataloggers

CR200(X)

CR800

Color Description

Black Excitation

Resistance

Red

Purple

Clear Shield

Signal

Signal

Ground

CR5000

CR3000

CR1000

Switched

Excitation

Single-Ended

Input

CR510

CR500

CR10X

Switched

Excitation

Single-Ended

Input

AG

G

21X

CR7

CR23X

Switched

Excitation

Single-Ended

Input

1

Page 6

Model 237 Leaf Wetness Sensor

NOTE

The black outer jacket of the cable is Santoprene® rubber. This

compound was chosen for its resistance to temperature extremes,

moisture, and UV degradation. However, this jacket will support

combustion in air. It is rated as slow burning when tested

according to U.L. 94 H.B. and will pass FMVSS302. Local fire

codes may preclude its use inside buildings.

3. Programming

Refer to programming examples in Section 4 for suggested implementation of

measurement and processing concepts.

3.1 Measurement of Vs / Vx

The base measurement of the 237 sensor is Vs/Vx where Vs is the voltage

measured and Vx is the excitation voltage supplied by the datalogger. Vs/Vx is

measured by the datalogger with the instructions and parameters listed in

Table 2.

TABLE 2. Measurement Instructions, Parameters, Results

Measurement

Datalogger

CR510, CR10(X) P5 AC Half Bridge 2500 ±25 mV fast 1 0 Vs/Vx

CR7 P5 AC Half Bridge 5000 ±50 mV fast 1 0 Vs/Vx

CR200(X) ExDelSE () 2500 n/a 500 µs 0.0004 0 Vs/Vx

CR800, CR1000 BrHalf () 2500 ±25 mV 250 µs 1 0 Vs/Vx

CR3000, CR9000X BrHalf () 5000 ±50 mV 250 µs 1 0 Vs/Vx

Instruction

Excitation

(mV)

Input

Range

Integration/

Delay

Multiplier Offset Result

2

3.2 Calculating Sensor Resistance

With reference to Figure 1, sensor resistance (Rs), expressed in kΩ, is

calculated as follows:

Rs = R

Therefore,

Rs (kΩ) = 1/(Vs/Vx) - 101.

/ (Vs/Vx) - R2 - R1.

2

Page 7

Model 237 Leaf Wetness Sensor

3.3 Interpreting Resistance Values

Table 3 lists 237 sensor resistance ranges and their interpretation.

TABLE 3. 237 Resistance Interpretations

(Wet / Dry Threshold Set at 150 kΩ)

CR1000 CR200(X) CR10X

≤ -9999

a,b

Input Loca Low Res FSb

INF, ≥ 99999,

≤ -99999

±6999

Interpretation IEEE4a FP2b IEEE4

Wet 0 to 150

Slightly Wet 150 to ≥ 99999 150 to 7999 150 to ≥ 9999 150 to ≥ 99999 150 to 6999

Dryc

INF, ≥ 99999,

≤ -99999

INF, ±7999

-INF, ≥ 9999,

Voltage Input Over-ranged NAN NAN -100, -INF -101 -101

Bridge Over-rangee < 0

Missing Sensorf Any Value

a

Input Memory

b

Final Storage Memory

c

The 1 kΩ bridge resistor holds the input channel at 0 mV when the sensor is completely dry.

However, the measurement may intermittently deviate from zero slightly, but still be within the

resolution specifications of the datalogger. When this occurs, Rs = either a very large or a very

small number.

d

Voltage input over-range is a state wherein voltage from the sensor exceeds the recommended 25

mV input voltage range. This highly conductive state may occur if the sensor is very very wet with

very ionic water.

e

If the measured voltage exceeds 24.75 mV, but does not exceed the input voltage range, the result

of the bridge equation becomes negative.

f

When no sensor is connected, or a cable has been cleanly cut, a “floating” voltage can occur and

falsely indicate the presence of a missing sensor. In the CR1000, this can be avoided by using the

mv25c range code.

3.4 Calculating Wet Time Fraction

Fraction of time wet are common data derived from 237 measurements.

Calculating time fraction requires a wetness threshold. Refer to Section 5.4

Calibration for more information on determining the threshold.

Fraction of time wet is calculated in all current Campbell Scientific

dataloggers, except the CR200(X), by using the Histogram instruction (P75 in

Edlog / Histogram () in CRBasic) with a single bin and closed form. The bin

select value for the histogram is the Input Location / Variable containing sensor

resistance (Rs). The lower limit of the histogram is zero, and the upper limit is

the wet / dry threshold. This will give the fraction of the output interval that

the sensor is wet. A fraction of time wet of .33 when the output interval is one

hour means that the sensor was wet for 20 minutes during that hour.

Refer to programming example 4.3 for information on calculating fraction of

time wet with the CR200(X).

3

Page 8

Model 237 Leaf Wetness Sensor

4. Programming Examples

Each example program measures leaf wetness and outputs a sample resistance

and a time fraction the sensor is wet. In these examples, the output interval is

set to 60 minutes, so a time fraction wet of .33 is equivalent to 20 minutes

during that hour. Wetness threshold is set at 150 kΩ.

4.1 CR1000 Program Example

Public Vs_Vx

Public Rs_kOhms

DataTable(Wetness,true,-1)

OpenInterval

DataInterval(0,60,Min,10)

Sample(1, Rs_kOhms, FP2)

Histogram(Rs_kOhms, FP2, 0, 1, 001, 1 , 0, 150) 'Enter threshold in 8th parameter

EndTable

BeginProg

Scan(60,Sec, 3, 0)

BRHalf(Vs_Vx, 1, mV25, 1, VX1, 1, 2500, True, 0, 250, 1, 0)

Rs_kOhms = (1 / Vs_Vx) - 101

CallTable Wetness

NextScan

EndProg

4.2 CR200(X) Programming

'CR200(X) Series Datalogger

Public Vs_Vx

Public Rs_kOhm

Public ScanIntervalWet

Public ScanIntervalSum

Public TimeFractionWet

DataTable (Wetness,1,-1)

DataInterval (0,60,min) 'Interval must match IfTime interval (below)

Sample (1,Rs_kohm)

Sample (1,TimeFractionWet)

EndTable

BeginProg

Scan (1,Min)

'Measure Wetness

ExDelSE(Vs_Vx,1,1,1,mV2500,500,.0004,0)

'Zero measurement when measurement < 0

If Vs_Vx < 0 Then Vs_Vx = 0

Rs_kOhm = (1 / Vs_Vx) - 101

'Sum Scan Intervals

ScanIntervalSum = ScanIntervalSum + 1

4

Page 9

Model 237 Leaf Wetness Sensor

'Check if Leaf wetness is below 150 kOhms transition and count as time dry

If Rs_kohm < 150 AND Rs_kohm > 0 Then

ScanIntervalWet = ScanIntervalWet + 1

EndIf

'Calculate Time Fraction Wet at top of each hour

If IfTime (0,60,Min) Then 'Interval must match data table interval

TimeFractionWet = ScanIntervalWet / ScanIntervalSum

ScanIntervalWet = 0

ScanIntervalSum = 0

EndIf

CallTable (Wetness)

NextScan

EndProg

4.3 CR10(X) Programming Example

*Table 1 Program

01: 60 Execution Interval (seconds)

1: AC Half Bridge (P5)

1: 1 Reps

2: 13 25 mV Fast Range

3: 1 SE Channel

4: 1 Excite all reps w/Exchan 1

5: 2500 mV Excitation

6: 1 Loc [ Vs_Vx ]

7: 1 Multiplier

8: 0 Offset

2: Z=1/X (P42)

1: 1 X Loc [ Vs_Vx ]

2: 2 Z Loc [ Rs_kOhms ]

3: Z=X+F (P34)

1: 2 X Loc [ Rs_kOhms ]

2: -101 F

3: 2 Z Loc [ Rs_kOhms ]

4: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

5: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

6: Sample (P70)

1: 1 Reps

2: 2 Loc [ Rs_kOhms ]

5

Page 10

Model 237 Leaf Wetness Sensor

7: Histogram (P75)

1: 1 Reps

2: 1 No. of Bins

3: 1 Closed Form

4: 2 Bin Select Value Loc [ Rs_kOhms ]

5: 0000 WV Loc Option [ _________ ]

6: 0 Low Limit

7: 150 High Limit ;<<<<<<<<<<<<<<<<<<Enter threshold here

NOTE

When compiling this program, the message “Warning: zero is an

invalid input address, Line: xx” will be returned from the

compiler. Ignore the message, so long as “Line: xx” corresponds

to the line number in the program where “WV Loc Option

[__________]” appears.

5. Plant Pathology Application

Plant diseases are often associated with wet leaves. Duration of wetness and

air temperature during wetness are inputs to many disease models. When

estimating leaf wetness, the sensor emulates a leaf, thereby approximating the

wetness state of surrounding foliage. The sensor does not (and should not!)

come in contact with leaves. Water droplets that form at the onset of

condensation are often too small to bridge the electrodes and so remain

undetected. Droplets can be detected earlier in formation by application of a

non-conductive spreader to the surface of the sensing grid. The spreader most

commonly employed is flat latex paint.

5.1 Sensor Preparation

Campbell Scientific supplies only uncoated sensors since coating preferences

vary between applications.

NOTE

Campbell Scientific has not researched, nor does it recommend,

paint formulations. The following information regarding paint

formulation is intended only to introduce the concept.

6

Preparing the sensor surface with a thin coat of flat latex paint is a generally

accepted practice in plant disease applications. In addition to providing some

protection for the gold plated electrodes, flat

spread and bridge the electrodes. Gillespie and Kidd

had significant effects on performance and found off-white worked well. Their

paint was formulated with 1 part black pigment to 1000 parts white paint.

2

found that greater precision is obtained using a high quality flat latex

East

paint. Some researchers and agricultural weather networks do not paint the

sensor.

However the surface is prepared, the response of the sensor is, in reality, only

an index against which actual leaf wetness can be estimated. While the

absence of a spreader will decrease sensitivity and increase the chance of

scratching the gold plated electrodes, bare sensors may grant greater

consistency and less maintenance across a network.

latex allows tiny water droplets to

1

found that paint color

Page 11

Model 237 Leaf Wetness Sensor

5.2 Plant Pathology Application Programming

An exact range of measurements is impossible to give since the 237 is field

calibrated. The manufacture of the sensor is not precise and the quality of

water bridging the electrodes varies. As demonstrated in program examples in

Section 4, a common practice is to measures grid resistance in terms of kOhms

using a 1 bin histogram to calculate at what fraction of the output interval the

sensor is wet. If resistance is ≤ 150 kΩ, the grid is considered wet. Since the

output interval is 60 minutes, if the histogram fraction equals 0.33, the leaf was

wet for 20 minutes during that hour.

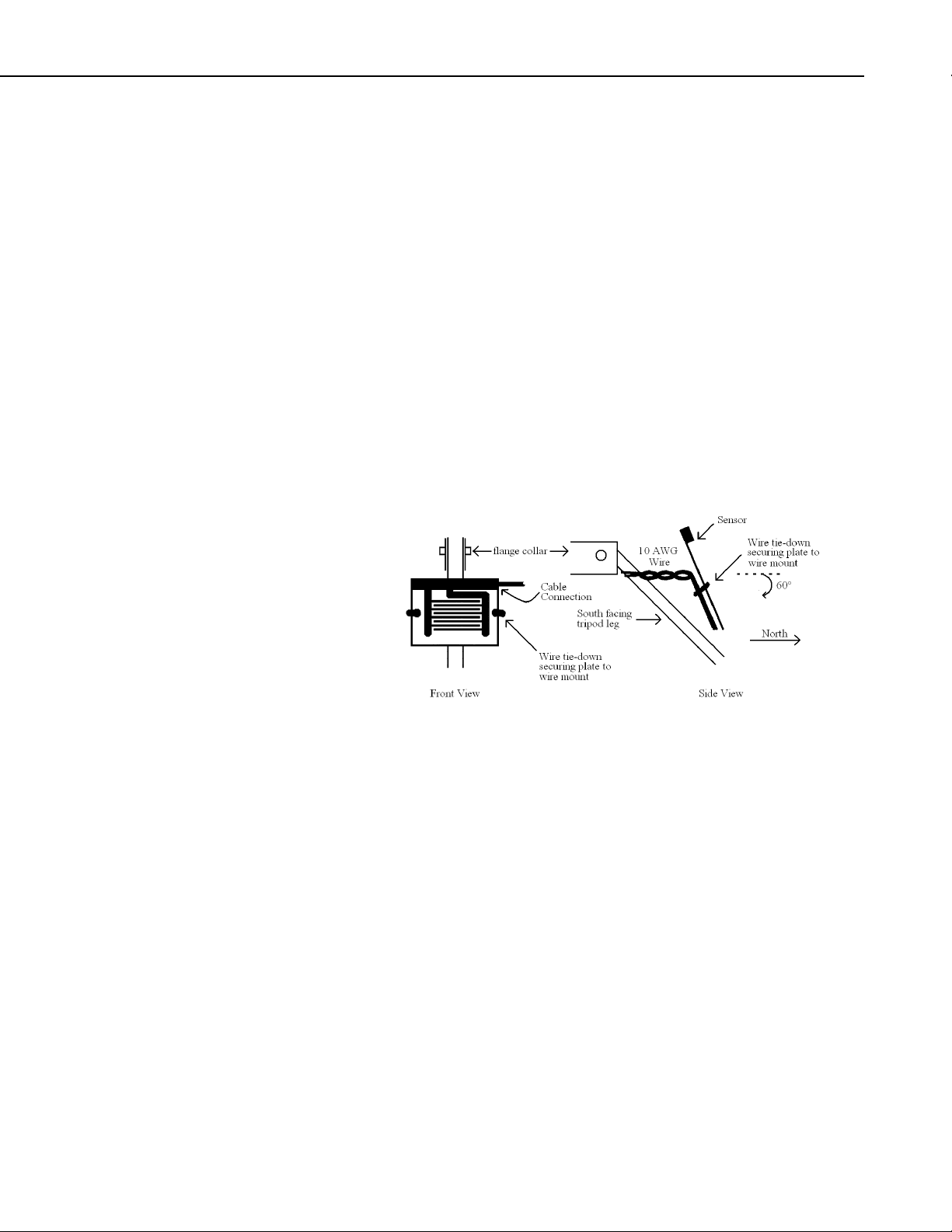

5.3 Sensor Deployment

The sensor is not supplied with a mounting bracket. Gillespie and Kidd1 found

that sensor orientation affects performance. As with surface preparation,

orientation varies across applications and users. A common practice is to

mount the sensor such that is receives minimal direct sunlight at mid-day

during the growing season. Gillespie and Kidd favor a 60 degree tilt on a north

facing sensor such that water runs away from the cable connection to minimize

puddling on the electrodes. Figure 2 shows a simple-to-construct mounting

bracket.

5.4 Calibration

FIGURE 2. Mounting the 237 Sensor

A wet / dry threshold of 150 kΩ is used in the programming examples in

Section 4. While this threshold may work well, refining the threshold for a

specific sensor and installation is recommended. A sharp change in resistance

occurs at the threshold on uncoated sensors. A less defined threshold occurs

with coated sensors. The threshold of uncoated sensors is normally between 50

and 200 kΩ. The threshold of the coated sensor is normally between 20 and

1,000 kΩ.

For best results, the sensor should be field calibrated. The transition point will

vary for different areas, vegetation, and water quality. Place the sensor in

vegetation, the wetness of which is to be monitored. Observe the vegetation

until it reaches the desired wetness. When the vegetation is at the desired

"wetness", the measured resistance can be used as a threshold. Sensitivity of

the sensor is changed by contaminants such as fingerprints and smudges.

Before painting and calibrating the sensor, clean it gently with alcohol.

7

Page 12

Model 237 Leaf Wetness Sensor

6. References

1

Gillespie, T.J. and Kidd, G.E. 1978. Sensing duration of leaf moisture

retention using electrical impedance grids. Can. J. Plant Sci. 58:179-187.

2

East, David (Ohio State University) 1994 Field Testing of Phone Accessible

Multi-Channel Datalogger for Tomato IPM Programs. Unpublished.

NOTE

The citation of researcher does not imply the endorsement of

Campbell Scientific products by any researcher or institution.

8

Page 13

Page 14

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...