Page 1

223 Delmhorst Cylindrical

Soil Moisture Block

Revision: 5/13

Copyright © 1991-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements............................................... 1

3. Initial Inspection .........................................................1

4. Quickstart .................................................................... 2

4.1 Installation............................................................................................2

4.2 Use SCWin to Program Datalogger and Generate Wiring Diagram ....2

5. Overview......................................................................6

6. Specifications .............................................................7

7. Operation.....................................................................8

7.1 Wiring ..................................................................................................8

7.2 Programming........................................................................................9

7.2.1 Control the Multiplexer.................................................................9

7.2.1.1 CRBasic..............................................................................9

7.2.1.2 Edlog ................................................................................10

7.2.2 Excite and Measure the 223........................................................10

7.2.3 Calculate Sensor Resistance........................................................11

7.2.4 Calculate Soil Water Potential ....................................................11

7.2.5 Example Programs ......................................................................14

7.2.5.1 Example CR1000 Program...............................................14

7.2.5.2 Example CR10(X) Program .............................................16

7.2.5.3 Example 21X Program.....................................................18

Figures

7-1. 223 wiring ............................................................................................8

7-2. Polynomial fit to typical block resistance vs. water potential ............13

7-3. Wiring for CR1000 example..............................................................14

7-4. Wiring for CR10(X) example ............................................................16

7-5. Wiring for example 21X program......................................................18

Tables

7-1. 223 Wiring ...........................................................................................8

7-2. Excitation and Voltage Ranges ..........................................................10

7-3. Typical Soil Water Potential, Rs and Vs / Vx......................................12

i

Page 6

Table of Contents

7-4. Polynomial Coefficients for Converting Sensor Resistance to Bars.. 13

7-5. Polynomial Error – 10 Bar Range ..................................................... 13

ii

Page 7

223 Delmhorst Cylindrical

Soil Moisture Block

1. Introduction

The 223 is a gypsum block that determines soil water potential by measuring

electrical resistance. When the 223 is wet, electrical resistance is low. As the

223 dries, resistance increases. This gypsum block connects to a datalogger via

an AM16/32-series, AM32, or AM416 multiplexer.

The 223 gypsum soil moisture block is configured for use with multiplexers.

The –L option on the model 223-L indicates that the cable length is user

specified. This manual refers to the sensor as the 223.

Before using the 223, please study

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 4, Quickstart

2. Cautionary Statements

• The black outer jacket of the cable is Santoprene

support combustion in air. It is rated as slow burning when tested

according to U.L. 94 H.B. and will pass FMVSS302. Local fire codes

may preclude its use inside buildings.

• Avoid installing in depressions where water will puddle after a rain storm.

• Don’t place the 223 in high spots or near changes in slope unless wanting

to measure the variability created by such differences.

• To maximize longevity, remove the gypsum blocks during the winter.

3. Initial Inspection

• Upon receipt of the 223, inspect the packaging and contents for damage.

File damage claims with the shipping company.

• The model number and cable length are printed on a label at the

connection end of the cable. Check this information against the shipping

documents to ensure the correct product and cable length are received.

®

rubber. This jacket will

1

Page 8

223 Delmhorst Cylindrical Soil Moisture Block

4. Quickstart

Please review Section 7, Operation, for wiring, CRBasic programming, and

Edlog programming.

4.1 Installation

1. Soak blocks in water for one hour then allow them to dry.

2. Repeat Step 1.

3. Make sensor access holes to the depth required.

4. Soak the blocks for two to three minutes.

5. Mix a slurry of soil and water to a creamy consistency and place one or

two tablespoons into the sensor access hole.

6. Place the blocks in the hole and force the slurry to envelope it. This will

insure uniform soil contact.

7. Back fill the hole, tamping lightly at frequent intervals.

4.2 Use SCWin to Program Datalogger and Generate Wiring Diagram

The simplest method for programming the datalogger to measure the 223 is to

use Campbell Scientific’s SCWin Short Cut Program Generator.

1. Open Short Cut and click on New Program.

2

Page 9

223 Delmhorst Cylindrical Soil Moisture Block

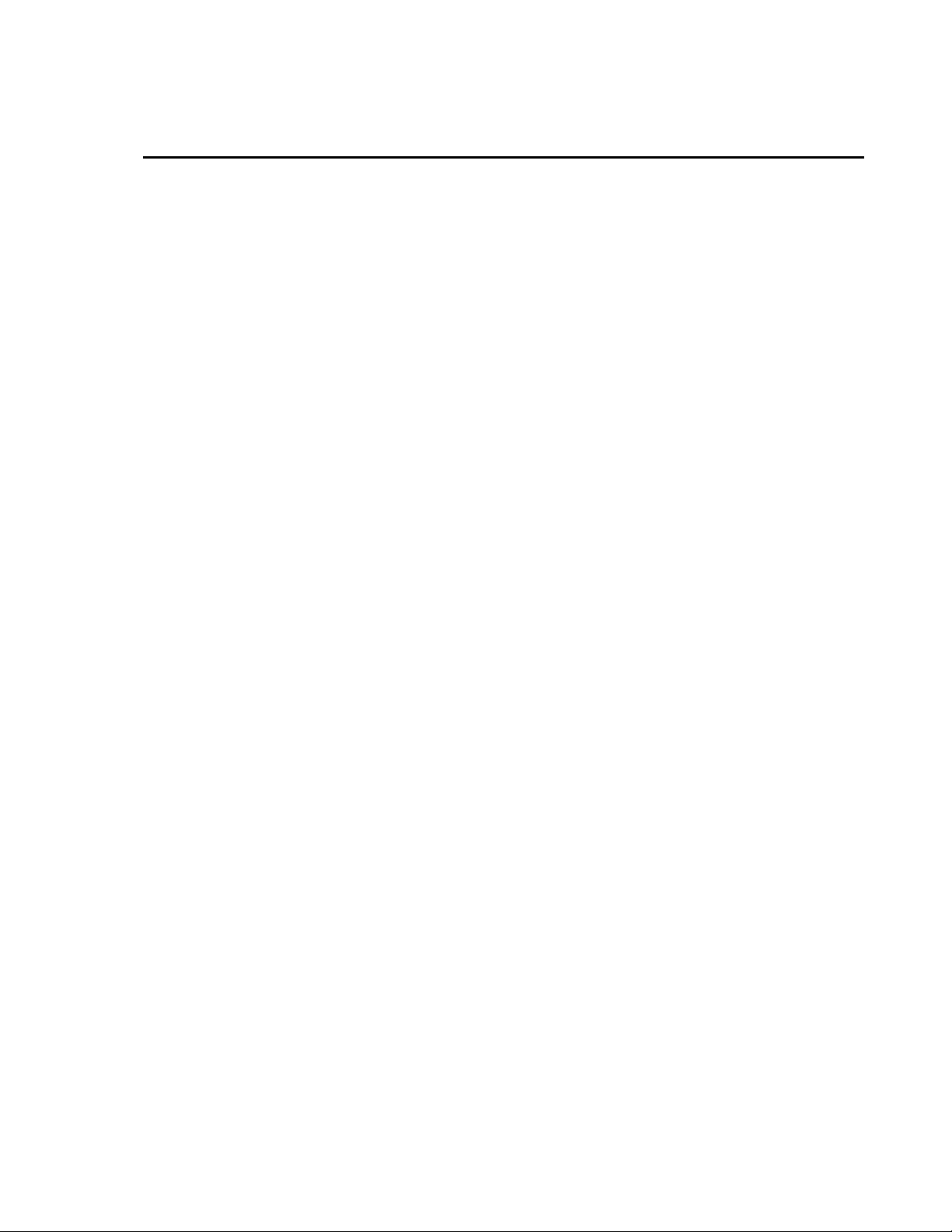

2. Select the Datalogger Model and enter the Scan Interval, and then select

Next.

NOTE

A scan rate of 30 seconds or longer is recommended when using

a multiplexer.

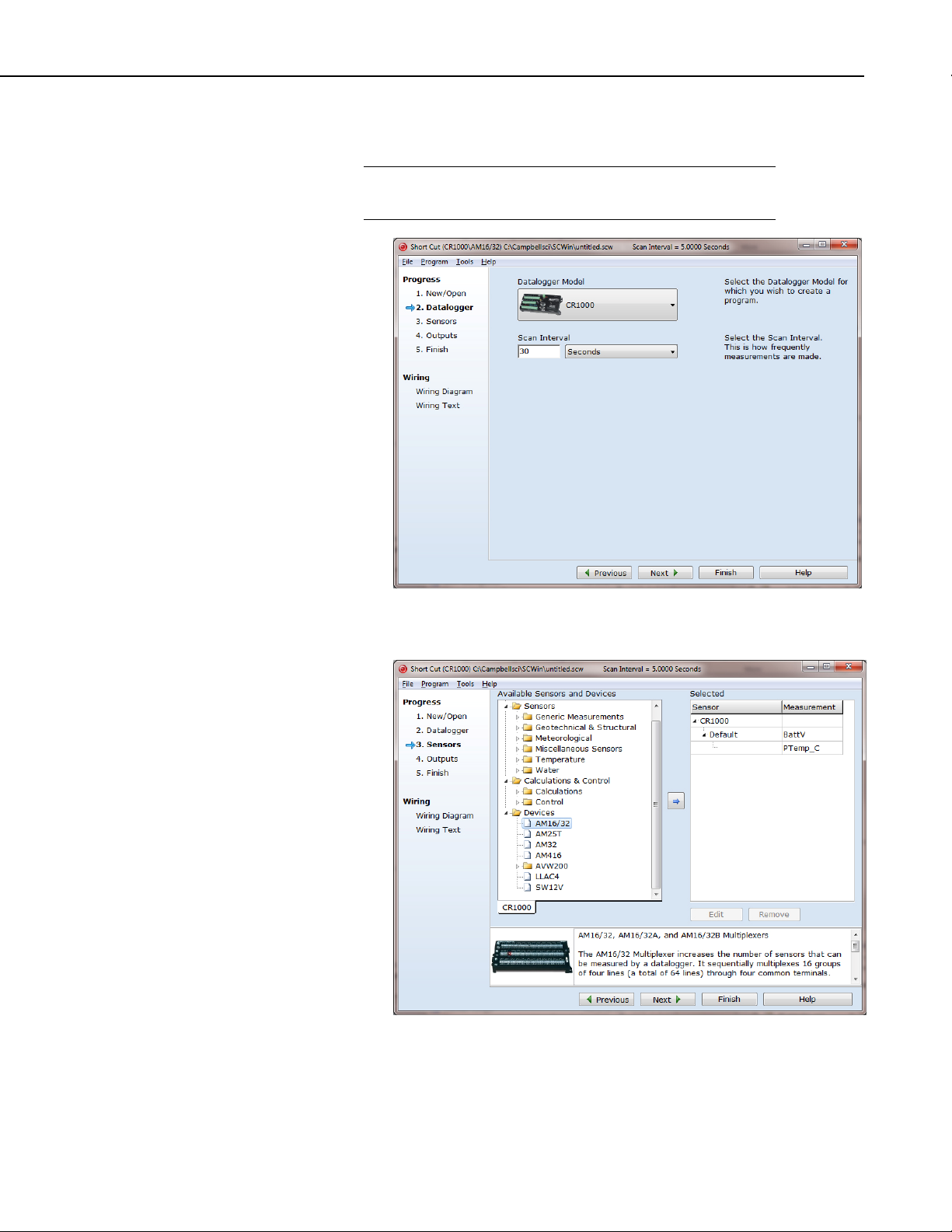

3. Under Devices, select AM16/32, and select the right arrow (in center of

screen) to add it to the list.

3

Page 10

223 Delmhorst Cylindrical Soil Moisture Block

4. Select 223 Soil Moisture Sensor, and select the right arrow (in center of

screen) to add it to the list of sensors to be measured. The Properties

window will appear after the right arrow is selected.

5. In the Properties window, enter the number of sensors, the Resistance

units, and the Soil Water Potential units. After entering the information,

click OK, and then select Next.

4

Page 11

223 Delmhorst Cylindrical Soil Moisture Block

6. Choose the Outputs and then select Finish.

7. In the Save As window, enter an appropriate file name and select Save.

8. In the Confirm window, click Yes to download the program to the

datalogger.

9. Click on Wiring Diagram and select the CR1000 tab. Wire the CR1000

to the AM16/32 according to the wiring diagram generated by SCWin

Short Cut.

5

Page 12

223 Delmhorst Cylindrical Soil Moisture Block

10. Select the AM16/32 tab and wire the 223 sensors to the AM16/32

according to the wiring diagram generated by SCWin Short Cut.

5. Overview

The 223 gypsum soil moisture block is configured for use with multiplexers.

The –L option on the model 223–L indicates that the cable length is user

specified. This manual refers to the sensor as the 223.

The Delmhorst cylindrical block is composed of gypsum cast around two

concentric electrodes which confine current flow to the interior of the block,

greatly reducing potential ground loops. Gypsum located between the outer

electrode and the soil creates a buffer against salts which may affect the

electrical conductivity. Individual calibrations are required for accurate

readings of soil water potential.

The multiplexer that the 223 is connected to leaves the circuit open when no

measurements are being made. This blocks direct current flow from the 223 to

datalogger ground and prevents electrolysis from prematurely destroying the

sensor.

The 223 should not be connected directly to the datalogger. The 227

Delmhorst soil moisture block is available for direct connection and has

capacitors in the cable that block direct current flow.

Gypsum blocks typically last for one to two years. Saline or acidic soils tend

to degrade the block, reducing longevity. To maximize longevity, gypsum

blocks not used during the winter should be removed from the field. Shallow

blocks may become frozen and crack, while blocks located below the frost line

may not maintain full contact with the soil. Regardless of depth, blocks left in

the field over winter are subject to the corrosive chemistry of the soil.

6

Page 13

6. Specifications

Features:

Compatible Dataloggers: CR800

CR850

CR1000

CR3000

CR5000

CR7

CR10(X)

21X

CR23X

223 Delmhorst Cylindrical Soil Moisture Block

• Compatible with multiplexers allowing measurement of multiple

sensors

• Multiplexer connection prevents electrolysis from prematurely

destroying the soil moisture block

• Measures a wide range of matric potential

• Buffers salts in soil

• No maintenance required

• Compatible with most Campbell Scientific dataloggers

Diameter: ~2.25 cm (0.88 in)

Length: ~2.86 cm (1.25 in)

Material: Gypsum

Electrode Configuration: Concentric cylinders

Center electrode: Excitation

Outer electrode: Ground

Calibration: Measurements are affected by soil salinity,

including fertilizer salts. Individual

calibrations are required for accurate

measurement of soil water potential. The soil

water potential versus resistance values in

TABLE 7-3 are “typical” values supplied by

Delmhorst Corporation. Neither Delmhorst

nor Campbell Scientific make any claim as to

the accuracy of these values. The calibration

equations in Section 7.2.4, Calculate Soil

Water Potential, were fit to the values in

TABLE 7-3 to allow output of an estimated

water potential.

7

Page 14

223 Delmhorst Cylindrical Soil Moisture Block

7. Operation

CAUTION

7.1 Wiring

The black outer jacket of the cable is Santoprene® rubber.

This compound was chosen for its resistance to

temperature extremes, moisture, and UV degradation.

However, this jacket will support combustion in air. It is

rated as slow burning when tested according to U.L. 94

H.B. and will pass FMVSS302. Local fire codes may

preclude its use inside buildings.

The 223 is shown in FIGURE 7-1 and TABLE 7-1. The leads from the block

electrodes are connected directly to the H and L inputs on the AM16/32-series,

AM32, or AM416 multiplexer. The lead from the center electrode (white

stripe or solid white) connects to H and the lead from the outer electrode

(black) to L. A 1k resistor at the datalogger is used to complete the half bridge

measurement.

Black with

White Stripe

(or White) to H

Black

to L

FIGURE 7-1. 223 wiring

TABLE 7-1. 223 Wiring

Color Function Multiplexer

Black w/ White Stripe or White Excitation H

Black Signal Ground L

8

Page 15

7.2 Programming

223 Delmhorst Cylindrical Soil Moisture Block

NOTE

This section describes using CRBasic or Edlog to program the

datalogger. See Section 4.2, Use SCWin to Program Datalogger

and Generate Wiring Diagram, if using Short Cut.

Dataloggers that use CRBasic include our CR800, CR850, CR1000, CR3000,

and CR5000. Dataloggers that use Edlog include our CR10(X), 21X, CR23X,

and CR7. CRBasic and Edlog are included with LoggerNet, PC400, and

RTDAQ software.

The datalogger program needs to control the multiplexer, measure the sensor,

calculate the sensor resistance, and convert the resistance to potential in bars.

Example programs are provided in Section 7.2.5, Example Programs.

7.2.1 Control the Multiplexer

When a multiplexer is used, the measurements are placed within a loop. Each

pass through the loop, the multiplexer is clocked to the next channel and the

sensors connected to that channel are measured. The programming sequence

for using the multiplexer is shown in Section 7.2.1.1, CRBasic, and Section

7.2.1.2, Edlog. For more information, see the multiplexer manual.

7.2.1.1 CRBasic

The generalized CRBasic programming sequence follows:

ACTIVATE MULTIPLEXER/RESET INDEX

Portset (1 ,1) 'Set C1 high to Enable Multiplexer

I=0

BEGIN MEASUREMENT LOOP

SubScan (0,sec,16) 'This example measures 16 sets

CLOCK PULSE AND DELAY

Portset (2,1) ‘Set port 2 high

Delay (0,20,mSec)

Portset (2,0) ‘Set port 2 low

INCREMENT INDEX AND MEASURE

I=I+1

‘223 measurement instruction

‘Storing results in Variable(I)

END MEASUREMENT LOOP

NextSubScan

DEACTIVATE MULTIPLEXER

Portset (1 ,0) 'Set C1 Low to disable Multiplexer

9

Page 16

223 Delmhorst Cylindrical Soil Moisture Block

7.2.1.2 Edlog

The generalized Edlog programming sequence follows:

ACTIVATE MULTIPLEXER/RESET INDEX

For the CR10(X) and CR23X, use Edlog instruction Do (P86) to set

the port high. For the 21X and CR7, use Edlog instruction Set

Port(s) (P20) to set the port high.

BEGIN MEASUREMENT LOOP

Use Edlog instruction Beginning of Loop (P87)

CLOCK PULSE AND DELAY

With the CR23X and CR10(X) the clock line is connected to a

control port. Instruction Do (P86) with the pulse port command

(71 – 78) pulses the clock line high for 10 ms. Instruction Excitation

with Delay (P22) can be added following the Do (P86) to delay an

additional 10 ms.

MEASURE SENSOR AND CALCULATE RESISTANCE

See Section 7.2.2, Excite and Measure the 223, and Section 7.2.3,

Calculate Sensor Resistance.

END MEASUREMENT LOOP

Use Edlog instruction End (P95).

DEACTIVATE MULTIPLEXER

For the CR10(X) and CR23X, use Edlog instruction Do (P86) to set

the port low. For the 21X and CR7, use Edlog instruction Set Port(s)

(P20) to set the port low.

7.2.2 Excite and Measure the 223

The sensor is excited and measured using the BrHalf instruction in CRBasic or

Instruction 5 (AC Half Bridge) in Edlog. Recommended excitation voltages

and input ranges are given in TABLE 7-2. TABLE 7-2 shows the excitation

and voltage ranges used with our dataloggers.

TABLE 7-2. Excitation and Voltage Ranges

Datalogger mV Excitation Full Scale Range

CR800/CR850 250 ±250 mV

CR1000 250 ±250 mV

CR3000 200 ±200 mV

CR5000 200 ±200 mV

21X 500 ±500 mV

CR7 500 ±500 mV

CR10(X) 250 ±250 mV

CR23X 200 ±200 mV

10

Page 17

223 Delmhorst Cylindrical Soil Moisture Block

The output from the BrHalf instruction or Instruction 5 is the ratio of signal

voltage to excitation voltage:

V

where, V

V

R

R

= Rs/(Rs + R1)

s/Vx

= Signal Voltage

s

= Excitation Voltage

x

= Sensor Resistance

s

= Fixed Bridge Resistor.

1

7.2.3 Calculate Sensor Resistance

The sensor resistance is calculated using an expression in CRBasic or Edlog

instruction BR Transform Rf[X/(1–X)] (P59). The expression or Edlog

instruction BR Transform Rf[X/(1–X)] (P59) takes the Half Bridge output

) and computes sensor resistance as follows:

(V

s/Vx

R

= R1(X/(1 – X))

s

where, X = V

s/Vx

The bridge transform multiplier would normally be 1000, representing the

fixed resistor (R

). A bridge multiplier of 1000 produces values of Rs larger

1

than 6999 ohms causing the datalogger to overrange when using low

resolution. To avoid overranging, a bridge multiplier of 1 should be used to

output sensor resistance (R

7.2.4 Calculate Soil Water Potential

) in terms of kohms.

s

The datalogger program can be written to store block resistance or can

calculate water potential from a block calibration. The soil water potential

versus resistance values in TABLE 7-3 are typical values supplied by

Delmhorst Corporation.

11

Page 18

223 Delmhorst Cylindrical Soil Moisture Block

TABLE 7-3. Typical Soil Water Potential,

BARS Rs (kohms) Vs/Vx

0.1 0.060 0.0566

0.2 0.130 0.1150

0.3 0.260 0.2063

0.4 0.370 0.2701

0.5 0.540 0.3506

0.6 0.750 0.4286

0.7 0.860 0.4624

0.8 1.100 0.5238

0.9 1.400 0.5833

1.0 1.700 0.6296

1.5 3.400 0.7727

and Vs / Vx

R

s

1.8 4.000 0.8000

2.0 5.000 0.8333

3.0 7.200 0.8780

6.0 12.500 0.9259

10.0 17.000 0.9444

11.0 22.200 0.9569

12.0 22.400 0.9573

13.0 30.000 0.9677

14.0 32.500 0.9701

15.0 35.000 0.9722

For the typical resistance values listed in TABLE 7-3, soil water potential

(bars) is calculated from sensor resistance (R

) using the 5th order polynomial

s

(FIGURE 7-2 and TABLE 7-4). TABLE 7-5 shows the polynomial error. The

nonlinear relationship of R

to bars rules out averaging Rs directly.

s

The polynomial is entered as an expression in CRBasic or by using Edlog

instruction Polynomial (P55). The polynomial to calculate soil water potential

is fit to the 0.1 to 10 bar range using a least square fit. TABLE 7-4 lists the

coefficients and equation for the 0.1 to 10 bar polynomial.

12

Page 19

223 Delmhorst Cylindrical Soil Moisture Block

Typical Values from TABLE 7-3

Block Resistance (kohms)

FIGURE 7-2. Polynomial fit to typical block resistance vs. water

potential

TABLE 7-4. Polynomial Coefficients for Converting Sensor Resistance to Bars

BARS = C0 + C1(Rs) + C2(Rs)2 + C3(Rs)3 + C4(Rs)4 + C5(Rs)5

(BARS) MULT. (R1) C0 C

C

1

C

2

C

3

C

4

5

0.1–10 0.1 0.15836 6.1445 –8.4189 9.2493 –3.1685 0.33392

TABLE 7-5. Polynomial Error – 10 Bar Range

BARS V

s/Vx

R

s

(kohms × 0.1)

BARS

COMPUTED ERROR

0.1 0.0566 0.006 0.1949 0.0949

0.2 0.115 0.013 0.2368 0.0368

0.3 0.2063 0.026 0.3126 0.0126

0.4 0.2701 0.037 0.3746 –0.0254

0.5 0.3506 0.054 0.4670 –0.0330

0.6 0.4286 0.075 0.5756 –0.0244

0.7 0.4624 0.086 0.6302 –0.0698

0.8 0.5238 0.11 0.7442 –0.0558

0.9 0.5833 0.14 0.8778 –0.0222

1.0 0.6296 0.17 1.0025 0.0025

1.5 0.7727 0.34 1.5970 0.0970

1.8 0.8000 0.40 1.7834 –0.0166

2 0.8333 0.50 2.0945 0.0945

3 0.8780 0.72 2.8834 –0.1166

6 0.9259 1.25 6.0329 0.0329

10 0.9444 1.70 9.9928 –0.0072

ERROR (BARS) = TABLE 7-3 VALUES – COMPUTED VALUES

13

Page 20

223 Delmhorst Cylindrical Soil Moisture Block

7.2.5 Example Programs

7.2.5.1 Example CR1000 Program

Below is a CR1000 program that measures five 223 sensors, calculates

resistance, and calculates soil water potential.

'CR1000

'Declare Variables and Units

Dim LCount

Public BattV

Public PTemp_C

Public kohms(5)

Public WP_kPa(5)

Units BattV=Volts

Units PTemp_C=Deg C

Units kohms=kilohms

Units WP_kPa=kPa

14

FIGURE 7-3. Wiring for CR1000 example

Page 21

223 Delmhorst Cylindrical Soil Moisture Block

'Define Data Tables

DataTable(Table1,True,–1)

DataInterval(0,60,Min,10)

Sample(1,kohms(1),FP2)

Sample(1,WP_kPa(1),FP2)

Sample(1,kohms(2),FP2)

Sample(1,WP_kPa(2),FP2)

Sample(1,kohms(3),FP2)

Sample(1,WP_kPa(3),FP2)

Sample(1,kohms(4),FP2)

Sample(1,WP_kPa(4),FP2)

Sample(1,kohms(5),FP2)

Sample(1,WP_kPa(5),FP2)

EndTable

DataTable(Table2,True,–1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

EndTable

'Main Program

BeginProg

'Main Scan

Scan(30,Sec,1,0)

'Default Datalogger Battery Voltage measurement 'BattV'

Battery(BattV)

'Default Wiring Panel Temperature measurement 'PTemp_C'

PanelTemp(PTemp_C,_60Hz)

'Turn AM16/32 Multiplexer On

PortSet(2,1)

Delay(0,150,mSec)

LCount=1

SubScan(0,uSec,5)

'Switch to next AM16/32 Multiplexer channel

PulsePort(1,10000)

'223 Soil Moisture Sensor measurements 'kohms()' and 'WP_kPa()' on the AM16/32 Multiplexer

BrHalf(kohms(LCount),1,mV250,1,1,1,250,True,20000,250,1,0)

'Convert resistance ratios to kilohms and kilohms to water potential

kohms(LCount)=kohms(LCount)/(1–kohms(LCount))

If kohms(LCount)<17 Then

WP_kPa(LCount)=kohms(LCount)*0.1

WP_kPa(LCount)=0.15836+(6.1445*WP_kPa(LCount))+(–8.4189*WP_kPa(LCount)^2)+(9.2493*WP_kPa(LCount)^3)+(–3.1685*WP_kPa(LCount)^4)+(0.33392*WP_kPa(LCount)^5)

WP_kPa(LCount)=WP_kPa(LCount)*100

Else

WP_kPa(LCount)=1000

EndIf

LCount=LCount+1

NextSubScan

'Turn AM16/32 Multiplexer Off

PortSet(2,0)

Delay(0,150,mSec)

'Call Data Tables and Store Data

CallTable(Table1)

CallTable(Table2)

NextScan

EndProg

15

Page 22

223 Delmhorst Cylindrical Soil Moisture Block

7.2.5.2 Example CR10(X) Program

CR10(X)

Multiplexer

FIGURE 7-4. Wiring for CR10(X) example

*Table 1 Program

01: 60.0000 Execution Interval (seconds)

01: Do (P86) ;Enable multiplexer

1: 41 Set Port 1 High

02: Beginning of Loop (P87) ;Start of measurement loop

1: 0 Delay

2: 16 Loop Count

03: Do (P86) ;Clock Multiplexer to next channel

1: 72 Pulse Port 2

04: Step Loop Index (P90) ;Step index by 2 each pass through loop

1: 2 Step

05: AC Half Bridge (P5) ;Measure the 2 connected 223 blocks

1: 2 Reps

2: 14 250 mV Fast Range

3: 1 SE Channel

4: 2 Excite all reps w/Exchan 2

5: 250 mV Excitation

6: 1-- Loc [ BlockR_1 ] ;-- >>> advance location by index

7: 1.0 Mult

8: 0.0 Offset

06: BR Transform Rf[X/(1–X)] (P59) ;Calculate resistance from Vs/Vx

1: 2 Reps

2: 1-- Loc [ BlockR_1 ]

3: 1 Multiplier (Rf)

07: End (P95)

16

Page 23

223 Delmhorst Cylindrical Soil Moisture Block

08: Do (P86) ;Turn off multiplexer

1: 51 Set Port 1 Low

;The following loop checks each block resistance and calculates

;water potential if BlockR < 17 kohms. Because 2 blocks are measured

;with each pass through the previous measurement loop, it is simpler

;to use a separate loop for the calculations.

;Leave out following loop if only recording block resistance.

09: Beginning of Loop (P87) ;Loop to calculate water potential

1: 0 Delay

2: 32 Loop Count

10: If (X<=>F) (P89) ;If Rs < 17, apply polynomial

1: 1-- X Loc [ BlockR_1 ]

2: 4 <

3: 17 F

4: 30 Then Do

11: Z=X*F (P37) ;Scale Rs for polynomial

1: 1-- X Loc [ BlockR_1 ]

2: .1 F

3: 33-- Z Loc [ WatPot_1 ]

12: Polynomial (P55) ;Convert Rs to bars with 10 bar polynomial

1: 1 Reps

2: 33-- X Loc [ WatPot_1 ]

3: 33-- F(X) Loc [ WatPot_1 ]

4: .15836 C0

5: 6.1445 C1

6: –8.4198 C2

7: 9.2493 C3

8: –3.1685 C4

9: .33392 C5

13: Else (P94) ;If Rs > 17 load over range value for potential

14: Z=F (P30)

1: –99999 F

2: 0 Exponent of 10

3: 33 Z Loc [ WatPot_1 ]

15: End (P95) ;End then do

16: End (P95) ;End loop

17: If time is (P92) ;Output Resistance and Water Potential each

Hour

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

18: Set Active Storage Area (P80) ;Fix the Array ID to 60

1: 1 Final Storage Area 1

2: 60 Array ID

17

Page 24

223 Delmhorst Cylindrical Soil Moisture Block

19: Real Time (P77) ;Output Day and Hour/Minute

1: 220 Day,Hour/Minute (midnight = 2400)

20: Sample (P70) ;Output resistances and Water Potentials

1: 64 Reps

2: 1 Loc [ BlockR_1 ]

7.2.5.3 Example 21X Program

21X

FIGURE 7-5. Wiring for example 21X program

*Table 1 Program

01: 10 Execution Interval (seconds)

01: Set Port (P20) ;Enable multiplexer

1: 1 Set High

2: 1 Port Number

02: Beginning of Loop (P87) ;Start of measurement loop

1: 0 Delay

2: 16 Loop Count

03: Excitation with Delay (P22) ;Clock Multiplexer to next channel

1: 1 Ex Channel

2: 1 Delay w/Ex (units = 0.01 sec)

3: 1 Delay After Ex (units = 0.01 sec)

4: 5000 mV Excitation

04: Step Loop Index (P90) ;Step index by 2 each pass through loop

1: 2 Step

Multiplexer

18

Page 25

223 Delmhorst Cylindrical Soil Moisture Block

05: AC Half Bridge (P5) ;Measure the 2 connected 223 blocks

1: 2 Reps

2: 14 500 mV Fast Range

3: 1 SE Channel

4: 2 Excite all reps w/Exchan 2

5: 500 mV Excitation

6: 1-- Loc [ BlockR_1 ] ; -- >>> advance location by index

7: 1.0 Mult

8: 0.0 Offset

06: BR Transform Rf[X/(1–X)] (P59) ;Calculate resistance from Vs/Vx

1: 2 Reps

2: 1-- Loc [ BlockR_1 ]

3: 1.0 Mult (Rf)

07: End (P95)

08: Set Port (P20) ;Turn off AM416

1: 0 Set Low

2: 1 Port Number

;The following loop checks each block resistance and calculates

;water potential if BlockR < 17 kohms. Because 2 blocks are measured

;with each pass through the previous measurement loop, it is simpler

;to use a separate loop for the calculations.

;Leave out following loop if only recording block resistance.

09: Beginning of Loop (P87) ;Loop to calculate water potential

1: 0 Delay

2: 32 Loop Count

10: If (X<=>F) (P89) ;If Rs < 17, apply polynomial

1: 1-- X Loc [ BlockR_1 ]

2: 4 <

3: 17 F

4: 30 Then Do

11: Z=X*F (P37) ;Scale Rs for polynomial

1: 1-- X Loc [ BlockR_1 ]

2: .1 F

3: 33-- Z Loc [ WatPo_1 ]

12: Polynomial (P55) ;Convert Rs to bars with 10 bar polynomial

1: 1 Reps

2: 33-- X Loc [ WatPo_1 ]

3: 33-- F(X) Loc [ WatPo_1 ]

4: .15836 C0

5: 6.1445 C1

6: –8.4198 C2

7: 9.2493 C3

8: –3.1685 C4

9: .33392 C5

13: Else (P94) ;If Rs > 17 load overrange value for potential

19

Page 26

223 Delmhorst Cylindrical Soil Moisture Block

14: Z=F (P30)

1: –99999 F

2: 33-- Z Loc [ WatPo_1 ]

15: End (P95) ;End then do

16: End (P95) ;End loop

17: If time is (P92) ;Output Resistance and Water Potential each

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

18: Set Active Storage Area (P80) ;Fix the Array ID to 60

1: 1 Final Storage Area 1

2: 60 Array ID

19: Real Time (P77) ;Output Day and Hour/Minute

1: 220 Day,Hour/Minute (midnight = 2400)

20: Sample (P70) ;Output resistances and Water Potentials

1: 64 Reps ;32 reps if not outputting water potential

2: 1 Loc [ BlockR_1 ]

Hour

20

Page 27

Page 28

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...