Page 1

110PV Surface

Temperature Probe

Revision: 10/11

Copyright © 2010-2011

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified on the corresponding

Campbell invoice. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any Campbell

products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9579. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

110PV Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. General .........................................................................1

1.1 Specifications............................................................................................2

2. Accuracy.......................................................................3

3. Installation and Wiring ................................................7

3.1 Placement on a Photovoltaic (PV) Module...............................................7

3.2 Mounting to a PV Module or Other Device .............................................8

3.3 Cable Strain Relief....................................................................................8

3.4 Submersion ...............................................................................................9

4. Wiring............................................................................9

5. Programming .............................................................10

5.1 CRBasic ..................................................................................................11

5.1.1 CRBasic Examples........................................................................11

5.1.1.1 Sample Program for CR200(X) Series Datalogger .............12

5.1.1.2 Sample Half Bridge Program for CR1000 Datalogger........13

5.1.1.3 Sample 4-Wire Half BridgeProgram for CR1000...............14

5.2 Edlog.......................................................................................................15

5.2.1 Example Edlog Program...............................................................15

5.3 Electrical Noisy Environments ...............................................................17

5.4 Long Lead Lengths.................................................................................17

6. Measurement..............................................................18

7. Maintenance, Removal, and Calibration..................19

7.1 Maintenance............................................................................................19

7.2 Removal from Measurement Surface .....................................................19

7.3 Recalibrations/Repairs............................................................................19

8. Troubleshooting ........................................................19

Appendices

A. Probe Material Properties

A.1 3M 9485PC Adhesive......................................................................... A-1

A.2 Santoprene .......................................................................................... A-1

i

Page 6

110PV Table of Contents

Figures

Tables

1-1. 110PV Temperature Probe ..................................................................... 1

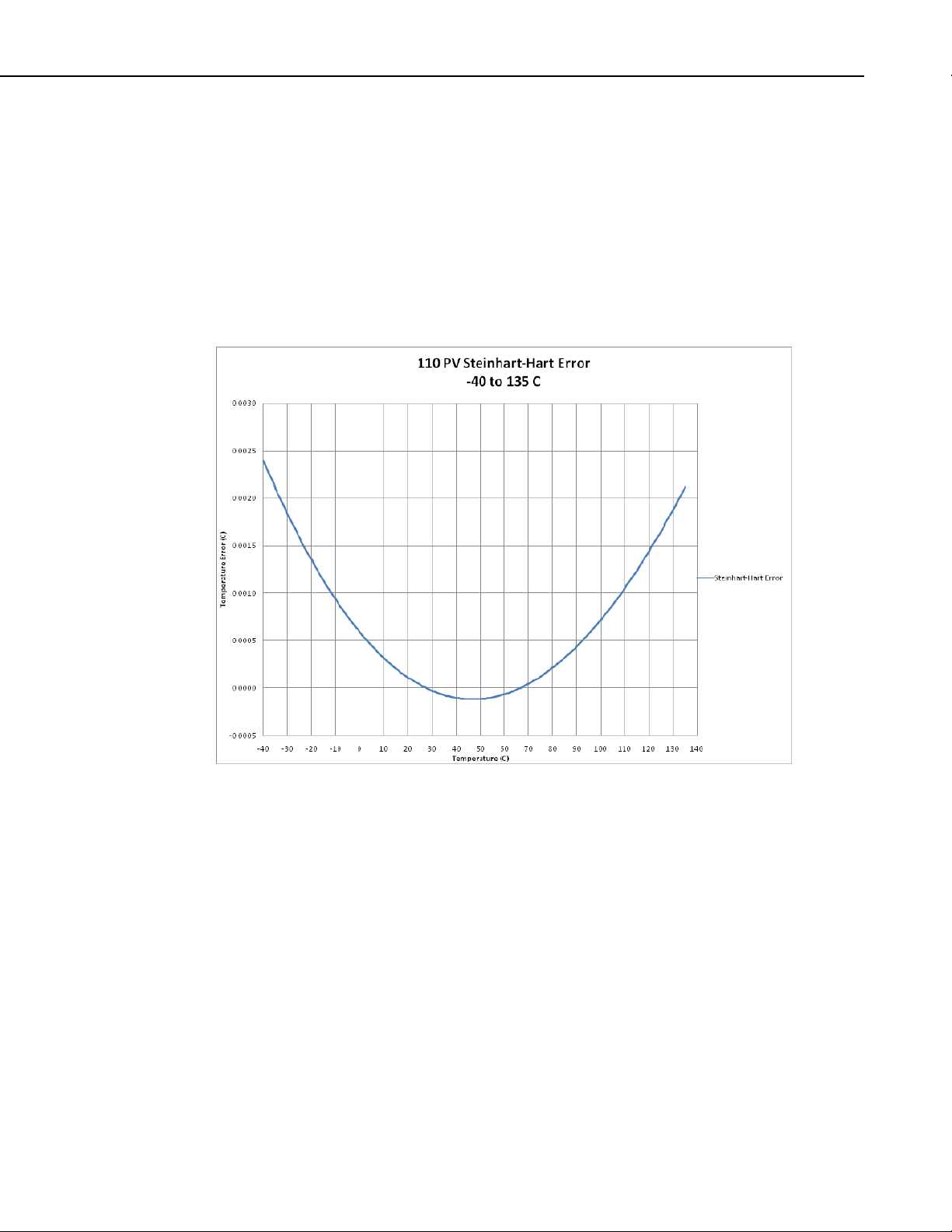

2-1. Steinhart-Hart Error................................................................................ 3

2-2. 110PV measured with a 3-wire half bridge ............................................ 4

2-3. 110PV measured with a CR1000 using a 4-wire half bridge ................. 4

2-4. 110PV measured with a CR1000 showing effects of cable length

when using a cable offset .................................................................... 5

2-5. 110PV measured with a CR1000 showing effects of cable length......... 5

2-6. 110PV measured with a CR200(X) showing effects of cable length

when a cable offset is used .................................................................. 6

2-7. 110PV measured with a CR200(X) showing effects of cable length ..... 6

3-1. 110PV mounted to a PV module ............................................................ 7

3-2. At left is a PV module with distinctive solar cells. At right is a PV

module that does not have distinctive solar cells. ............................... 7

3-3. 110PV mounted to a PV module using Kapton tape .............................. 8

3-4. 110PV’s strain relief label ...................................................................... 9

6-1. 110PV Thermistor Probe schematic ..................................................... 18

4-1. Connections to Campbell Scientific Dataloggers ................................. 10

5-1. Wiring for Example Programs.............................................................. 11

5-2. Wiring for Example Program ............................................................... 15

ii

Page 7

110PV Surface Temperature Probe

1. General

The 110PV-L temperature probe uses a thermistor to measure temperature.

The probe is designed for measuring the back of photovoltaic (PV) module

temperature but also can be used to measure other surface temperatures. The

110PV-L is compatible with all Campbell Scientific dataloggers.

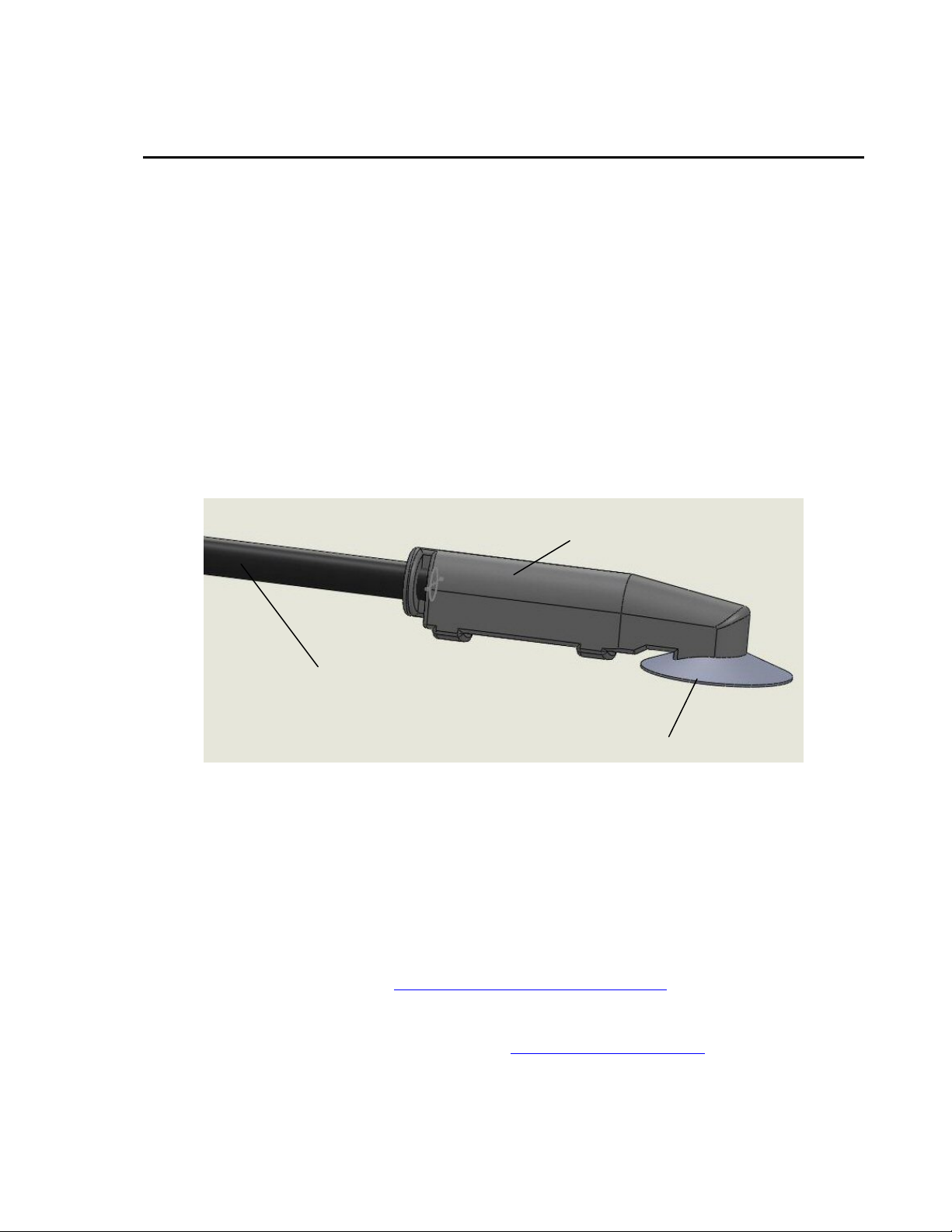

The 110PV-L consists of a thermistor encased in an aluminum disk (see Figure

1-1). The aluminum disk protects the thermistor and promotes heat transfer

from surfaces.

The probe measures temperature from –40° to +135°C. For temperatures up to

70°C, an adhesive tab on the probe’s aluminum disk fastens the 110PV to the

measurement surface. If the temperature may exceed 70°C, Kapton tape or

high temperature epoxy is recommend to secure the probe to the measurement

surface. Kapton tape (P/N 27015) is available from Campbell Scientific.

Overmolded joint

Santoprene-jacketed cable

Thermistor encased in an aluminum disk

FIGURE 1-1. 110PV Temperature Probe

The –L portion of the probes model number indicates the probe has a user

defined cable length which will be specified when the probe is ordered.

The probe’s cable can terminate in:

• Pigtails that connect directly to a Campbell Scientific datalogger (option

–PT).

• Connector that attaches to a prewired enclosure (option –PW). Refer to

www.campbellsci.com/prewired-enclosures

• Connector that attaches to a CWS900 Wireless Sensor Interface (option

–CWS). The CWS900 allows the 110PV to be used in a wireless sensor

network. Refer to www.campbellsci.com/cws900

For readability purposes, the probe will be referred to as the 110PV throughout

this document.

for more information.

for more information.

1

Page 8

110PV Surface Temperature Probe

The 110PV ships with:

1.1 Specifications

Temperature Range: -40° to +135°C

Survival Range: -50° to +140°C

110PV Temperature Uncertainty

-40° to 70°C: ±0.2°C

71° to 105°C: ±0.5°C

106° to 135°C: ±1°C

Time Constant (average):

Test

Still Air 252 seconds

Surface 25 seconds

1) Adhesive Backed 3 cm Cable Tie Mount

2) Cable Ties 8” UV Stabilized

3) Resource CD

τ

Water Submersion Depth: 50 ft (21 psi)

Linearization Error: Steinhart & Hart equation; maximum error is 0.0024°C at

-40°C.

Maximum Cable Length: 1000 ft

Disk Diameter: 1.0 in. (2.54 cm)

Overall Probe Length: 2.5 in. (6.35 cm)

Overmolded Joint Dimensions:

Width: 0.44 in. (1.12 cm)

Height: 0.58 in. (1.47 cm)

Length: 2.25 in. (5.72 cm

Cable Diameter: 0.245 in. (0.622 cm)

Material

Disk: Anodized Aluminum

Cable Jacket: Santoprene

Cable/Probe Connection: Santoprene

Weight: 0.2 lbs (90.7 g) with 10.5 ft (3.2 m) cable

2

NOTE

The black outer jacket of the cable is Santoprene

compound was chosen for its resistance to temperature extremes,

moisture, and UV degradation. However, this jacket will support

combustion in air. It is rated as slow burning when tested

according to U.L. 94 H.B. and will pass FMVSS302. Local fire

codes may preclude its use inside buildings.

®

rubber. This

Page 9

2. Accuracy

110PV Surface Temperature Probe

The overall probe accuracy is a combination of the thermistor's

interchangeability specification and the accuracy of the bridge resistor. The

Steinhart-Hart equation used to calculate temperature has a negligible error

(Figure 2-1). In a "worst case" the errors add to an accuracy of ±0.2°C over

the range of -40° to 70°C; ±0.5°C over the range of 71°C to 105°C; and ±1°C

from 106°C to 135°C. The major error component is the interchangeability

specification (tolerance) of the thermistor. The bridge resistor has a 0.1%

tolerance with a 10 ppm temperature coefficient. Figures 2-2 to 2-7 show the

possible worst case probe and measurement errors.

FIGURE 2-1. Steinhart-Hart Error

3

Page 10

110PV Surface Temperature Probe

Uncertainty on the graphs below is symmetric about 0.

FIGURE 2-2. 110PV measured with a 3-wire half bridge

4

FIGURE 2-3. 110PV measured with a CR1000 using a 4-wire half bridge

Page 11

110PV Surface Temperature Probe

FIGURE 2-4. 110PV measured with a CR1000 showing effects of cable length

when using a cable offset

FIGURE 2-5. 110PV measured with a CR1000 showing effects of cable length

5

Page 12

110PV Surface Temperature Probe

FIGURE 2-6. 110PV measured with a CR200(X) showing effects of cable length

when a cable offset is used

6

FIGURE 2-7. 110PV measured with a CR200(X) showing effects of cable length

Page 13

3. Installation and Wiring

3.1 Placement on a Photovoltaic (PV) Module

The 110PV should be centered on the back of the PV module (see Figure 3-1).

If the module has several distinctive photocells (see Figure 3-2), the 110PV

should also be centered on the back of a photocell.

110PV Surface Temperature Probe

FIGURE 3-1. 110PV mounted to a PV module

FIGURE 3-2. At left is a PV module with distinctive solar cells.

At right is a PV module that does not have distinctive solar cells.

7

Page 14

110PV Surface Temperature Probe

3.2 Mounting to a PV Module or Other Device

For mounting the probe to the back of a PV module or another device, the

110PV comes with an adhesive mounting disc adhered to its flat surface. To

mount the 110PV, remove the paper from the mounting disc and adhere it to

the back of the PV module or other device; refer to Section 3.1 for proper

placement on a PV module. The mounting disc must be adhered to a clean

surface for its adhesive to function properly.

If the temperature is expected to exceed 70°C, use Kapton tape, epoxy, or other

means to secure the probe to the measurement surface (see Figure 3-3); a roll

of Kapton tape (P/N 27015) is offered by Campbell Scientific as a Common

Accessory.

8

FIGURE 3-3. 110PV mounted to a PV module using Kapton tape

3.3 Cable Strain Relief

The 110PV’s cable must be properly strain relieved after mounting the probe to

the measurement surface. To accomplish this, the probe comes with cable ties

and a cable tie mount. A yellow label on the 110PV’s cable indicates where

you should tie down the cable (see Figures 3-3 and 3-4).

NOTE

Placement of the cable inside a rugged conduit is advisable for

long cable runs, especially in locations subject to digging,

mowing, traffic, use of power tools, animals, or lightning strikes.

Page 15

3.4 Submersion

110PV Surface Temperature Probe

FIGURE 3-4. 110PV’s strain relief label

The 110PV can be submerged to 50 ft. It must be adhered to a dry clean

surface before submerging. The probe’s adhesive mounting disc is not

intended for submersion. Therefore the 110PV must be mounted to the

measurement surface via a user-supplied method that is compatible with

submersion.

4. Wiring

Connections to Campbell Scientific dataloggers are given in Table 4-1. Most

CRBasic dataloggers can measure the 110PV using either a 4-wire half bridge

or 3-wire half bridge. The CR200(X) and Edlog dataloggers can only use a

3-wire half bridge. The 4-wire half bridge method is preferred because it

reduces cable errors (see Figures 2-2 and 2-3). The 4-wire half bridge method

requires two differential input channels and one voltage excitation channel.

The 3-wire half bridge method uses one single-ended input channel and one

voltage excitation channel.

Multiple probes can be connected to the same excitation channel. The number

of probes per excitation channel is physically limited by the number of lead

wires that can be inserted into a single voltage excitation terminal,

approximately six.

9

Page 16

110PV Surface Temperature Probe

TABLE 4-1. Connections to Campbell Scientific Dataloggers

Color

Black

Description

Voltage

Excitation

Red Signal

Purple

Signal

Reference

Blue

Signal

Reference

Clear Shield

Green Sense +

White Sense -

4-Wire

Half Bridge

CR800

CR850

CR3000

CR1000

CR5000

Switched

Voltage

Excitation

Differential

Input (H)

Differential

Input (L)

Differential

Input (H)

Differential

Input (L)

3-Wire

Half Bridge

CR200(X)

CR800

CR850

CR3000

CR1000

CR5000

Switched

Voltage

Excitation

SingleEnded Input

3-Wire

Half Bridge

CR510

CR500

CR10(X)

Switched

Voltage

Excitation

Single-Ended

Input

AG

3-Wire

Half Bridge

21X

CR7

CR23X

Switched

Voltage

Excitation

Single-Ended

Input

Not Used Not Used Not Used

G

Not Used Not Used Not Used

Not Used Not Used Not Used

5. Programming

NOTE

This section is for users who write their own datalogger

programs. A datalogger program to measure this sensor can be

generated using Campbell Scientific’s Short Cut Program

Builder software. You do not need to read this section to use

Short Cut.

The datalogger is programmed using either CRBasic or Edlog. Dataloggers

that use CRBasic include our CR200(X) series, CR800, CR850, CR1000,

CR3000, CR5000, and CR9000(X); see Section 5.1. Dataloggers that use

Edlog include our CR10, CR10X, CR23X, and CR7; refer to Section 5.2.

CRBasic and Edlog are included in our LoggerNet, PC400, and RTDAQ

software.

The Steinhart-Hart equation is used to calculate the temperature. The

coefficients used for the Steinhart-Hart equation are as follows:

A=1.129241*10^-3

B=2.341077*10^-4

C=8.775468*10^-8

If applicable, please read “Section 5.3—Electrical Noisy Environments” and

“Section 5.4—Long Lead Lengths” prior to programming your datalogger.

Measurement details are provided in Section 6.

10

Page 17

5.1 CRBasic

110PV Surface Temperature Probe

The CR200(X)-series dataloggers use the ExDelSe instruction to measure the

110PV (see example in Section 5.1.1.1). The ExDelSe instruction has the

following syntax:

ExDelSE( Dest, Reps, SEChan, ExChan, ExmV, Delay, Mult, Offset )

The CR800, CR850, CR1000, CR3000, CR5000, and CR9000(X) can use

either the BrHalf4W instruction or BrHalf instruction to measure the 110PV

(see examples in Sections 5.1.1.2 and 5.1.1.3).

For these dataloggers, the BrHalf4W instruction is typically preferred because

it reduces cable errors (see Figures 2-2 and 2-3). The BrHalf instruction

requires fewer input channels.

A typical BrHalf4W instruction follows:

BrHalf4W (Dest,1,mV2500,mV2500,1,Vx1,1,2500,True ,True ,0,250,1.0,0)

A typical BrHalf instruction follows:

BrHalf (Dest,1,mV2500,1,Vx1,1,2500,True ,0,250,1.0,0)

A multiplier of 1.0 and offset of 0.0 should be used in the ExDelSe, BrHalf4W,

and BrHalf instructions to yield a temperature in degrees Celsius. For

Fahrenheit multiply the calculated Celsius temperature by 1.8 then add 32.

5.1.1 CRBasic Examples

TABLE 5-1. Wiring for Example Programs

Black Voltage Excitation VX1 or EX1 VX1 or EX1

Red Signal SE1 Diff 1H

Purple Signal Reference

Blue Signal Reference Not Used

Clear Shield

Green Sense + Not Used Diff 2H

White Sense - Not Used Diff 2L

Datalogger Connection Color Description

BrHalf BrHalf4W

Diff 1L

11

Page 18

110PV Surface Temperature Probe

5.1.1.1 Sample Program for CR200(X) Series Datalogger

'CR200 Series Datalogger

'This example program measures a single 110PV-L probe

'once a second using the ExDelSE instruction and stores

'the average temperature in degrees C every 10 minutes.

'110PV-L Wiring configuration for program example

'Lead Color CR200(X) Channel Description

'Black ------ VX1 ------------ Voltage Excitation

'Red -------- SE1------------- Signal

'Purple----- AG-------------- Signal Reference

'Blue ------- Not Used ------ N/A

'Green ----- Not Used ------ N/A

'White------ Not Used ------ N/A

'Clear------ AG-------------- Shield

'Declare variables for temperature measurement

Public T110PV_mV

Public T110PV_Res

Public T110PV_Temp_C

Public T110PV_Temp_F

'Declare constants to be used in Steinhart-Hart equation

Const A=1.129241*10^-3

Const B=2.341077*10^-4

Const C=8.775468*10^-8

Const R_cable=0 'see sensor cable for cable resistance

'Declare variable units

Units T110PV_mV= millivolts

Units T110PV_Res=Ohms

Units T110PV_Temp_C=Deg C

'Define a data table for 10 minute averages

DataTable (AvgTemp,1,1000)

DataInterval (0,10,min)

Average (1,T110PV_Temp_C,False)

EndTable

'Main Program

BeginProg

Scan (1,Sec)

' Measure 110PV-L probe with SE1

ExDelSE (T110PV_mV,1,1,Ex1,mV2500,500,1.0,0)

' Convert mV to ohms

T110PV_Res = 4990*(2500/T110PV_mV)-4990

' Subtract off cable resistance (see 110PV-L cable for R_cable)

T110PV_Res = T110PV_Res-R_cable

' Using the Steinhart-Hart equation to convert resistance to temperature

T110PV_Temp_C = (1/(A+B*LOG(T110PV_Res)+C*(LOG(T110PV_Res))^3))-273.15

12

Page 19

110PV Surface Temperature Probe

'Convert Celsius to Fahrenheit

T110PV_Temp_F = T110PV_Temp_C * 1.8 + 32

'Call AvgTemp data table

CallTable AvgTemp

NextScan

EndProg

5.1.1.2 Sample Half Bridge Program for CR1000 Datalogger

'CR1000 Series Datalogger

'This example program measures a single 110PV-L probe utilizing

'the BrHalf instruction once a second and stores the average

'temperature in degrees C every 10 minutes.

'110PV-L Wiring Configuration

'Lead Color CR1000 Channel Description

'Black ------ VX1------------- Voltage Excitation

'Red -------- SE1 ------------- Signal

'Purple----- AG -------------- Signal Reference

'Blue ------- Not Used------- N/A

'Green------ Not Used------- N/A

'White ------ Not Used------- N/A

'Clear ------ AG -------------- Shield

'Declare variables for temperature measurement using Half Bridge configuration

Public T110PV_mV

Public T110PV_Res

Public T110PV_Temp_C

Public T110PV_Temp_F

'Declare Constants to be used in Steinhart-Hart equation

Const A=1.129241*10^-3

Const B=2.341077*10^-4

Const C=8.775468*10^-8

Const R_cable=0 'see sensor cable for cable resistance

'Declare variable units

Units T110PV_mV= millivolts

Units T110PV_Res=Ohms

Units T110PV_Temp_C=Deg C

Units T110PV_Temp_F=Deg F

'Define a data table for 10 minute averages

DataTable (AvgTemp,1,1000)

DataInterval (0,10,Min,10)

Average (1,T110PV_Temp_C,FP2,False)

EndTable

13

Page 20

110PV Surface Temperature Probe

BeginProg

Scan (1,Sec,3,0)

' Measure 110PV-L probe

BrHalf (T110PV_mV,1,mV2500,1,Vx1,1,2500,True ,0,_60Hz,1.0,0)

' Convert mV to ohms

T110PV_Res=4990*(1-T110PV_mV)/T110PV_mV

' Subtract off cable resistance (see 110PV-L cable for R_cable)

T110PV_Res= T110PV_Res-R_cable

' Using the Steinhart-Hart equation to convert resistance to temperature

T110PV_Temp_C = (1/(A+B*LOG(T110PV_Res)+C*(LOG(T110PV_Res))^3))-273.15

'Convert Celsius to Fahrenheit

T110PV_Temp_F = T110PV_Temp_C * 1.8 + 32

'Call AvgTemp data table

CallTable AvgTemp

NextScan

EndProg

5.1.1.3 Sample 4-Wire Half BridgeProgram for CR1000

'CR1000 Series Datalogger

'This example program measures a single 110PV-L probe utilizing the

'BRHalf4Winstruction once a second and stores the

'average temperature in degrees C every 10 minutes.

'110PV-L Wiring Configuration

'Lead Color CR1000 Channel Description

'Black ------ VX1/EX1 ------ Voltage Excitation

'Red -------- DIFF1H ------- Signal

'Purple----- DIFF1L-------- Signal Reference

'Blue ------- AG-------------- Signal Reference

'Green ----- DIFF2H ------- Sense +

'White------ DIFF2L-------- Sense 'Clear------ AG-------------- Shield

'Declare variables for temperature measurement using Half Bridge configuration

Public T110PV_mV

Public T110PV_Res

Public T110PV_Temp_C

Public T110PV_Temp_F

'Declare constants to be used in Steinhart-Hart equation

Const A=1.129241*10^-3

Const B=2.341077*10^-4

Const C=8.775468*10^-8

'Declare variable units

Units T110PV_mV= millivolts

Units T110PV_Res=Ohms

Units T110PV_Temp_C=Deg C

Units T110PV_Temp_F=Deg F

14

Page 21

110PV Surface Temperature Probe

'Define a data table for 10 minute averages

DataTable (AvgTemp,1,1000)

DataInterval (0,10,Min,10)

Average (1,T110PV_Temp_C,FP2,False)

EndTable

BeginProg

Scan (1,Sec,3,0)

' Measure 110PV-L probe

BrHalf4W (T110PV_mV,1,mV2500,mV2500,1,Vx1,1,2500,True,True,0,_60Hz,1.0,0)

' Convert mV to ohms

T110PV_Res=4990 *T110PV_mV

' Use the Steinhart-Hart equation to convert resistance to temperature

T110PV_Temp_C = (1/(A+B*LOG(T110PV_Res)+C*(LOG(T110PV_Res))^3))-273.15

'Convert Celsius to Fahrenheit

T110PV_Temp_F = T110PV_Temp_C * 1.8 + 32

CallTable AvgTemp

NextScan

EndProg

5.2 Edlog

In Edlog, Instruction 5 is typically used to measure the 110PV-L. The ratio

metric output is then converted to resistance and finally to temperature (see

Section 5.2.1).

5.2.1 Example Edlog Program

TABLE 5-2. Wiring for Example Program

Color Description CR10X

Black Voltage Excitation E1

Red Signal SE1

Purple Signal Reference AG

Clear Shield G

Blue Not Used Not Used

Green Not Used Not Used

White Not Used Not Used

15

Page 22

110PV Surface Temperature Probe

Example Program for CR10X

;{CR10X}

;This program measures a single 110PV-L probe utilizing the

;P5 instruction once a second and stores the average

;temperature in degrees C every ten minutes.

*Table 1 Program

01: 1 Execution Interval (seconds)

;Measure 110PV-L Probe

1: AC Half Bridge (P5)

1: 1 Reps

2: 25 2500 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 1 Excite all reps w/Exchan 1

5: 2500 mV Excitation

6: 1 Loc [ V_Vx ]

7: 1.0 Multiplier

8: 0.0 Offset

;Convert ratio-metric output to resistance (next three instructions)

2: Z=1/X (P42)

1: 1 X Loc [ V_Vx ]

2: 2 Z Loc [ Vx_V ]

3: Z=X+F (P34)

1: 2 X Loc [ Vx_V ]

2: -1.0 F

3: 3 Z Loc [ Vx_V1 ]

4: Z=X*F (P37)

1: 3 X Loc [ Vx_V1 ]

2: 4990 F

3: 4 Z Loc [ Rx ]

;Correct for cable resistance (see 110PV-L cable label for resistance value F in Ohms)

5: Z=X+F (P34)

1: 4 X Loc [ Rx ]

2: 0.0 F

3: 5 Z Loc [ Rtherm ]

;Convert resistance to Temperature

6: Steinhart-Hart Equation (P200)

1: 1 Reps

2: 5 Source Loc (R)(Ohms) [ Rtherm ]

3: 6 Destination Loc (Deg C) [ Temp_C ]

4: 1.12924 A

5: -3 x 10^n

6: 2.34108 B

7: -4 x 10^n

8: 8.77547 C

9: -8 x 10^n

16

Page 23

110PV Surface Temperature Probe

;Every ten minutes set output flag high to write data final storage

7: If time is (P92)

1: 0000 Minutes (Seconds --) into a

2: 10 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

;Time stamp data record

8: Real Time (P77)^20972

1: 110 Day,Hour/Minute (midnight = 0000)

;Write 110PV-L 10 minute average to final storage

9: Average (P71)^4293

1: 1 Reps

2: 6 Loc [ Temp_C ]

*Table 2 Program

02: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

End Program

5.3 Electrical Noisy Environments

AC power lines, pumps, and motors, can be the source of electrical noise. If

the 110PV probe or datalogger is located in an electrically noisy environment,

the 110PV probe should be measured with the 60 or 50 Hz rejection option as

shown in the examples in Section 5.1.1.2 and Section 5.2.1.

5.4 Long Lead Lengths

It is recommended that the cable resistance of the 110PV-L be corrected for

noting it can contribute significant error (see Figure 2-6). The cable resistance

of each 110PV-L probe in ohms is printed on a heat shrink label found on the

sensor cable. When measuring the 110PV-L in three wire configurations the

cable resistance can be subtracted from the measured resistance value as shown

in the CR10X, CR200(X) and CR1000 Half Bridge program examples above.

Alternatively the 110PV-L is equipped with cable sense leads which can be

used to correct for cable resistance as seen in the CR1000 4-Wire Half Bridge

program example.

Additional settling time may be required for lead lengths longer than 300 feet,

where settling time is the delay before the measurement is made.

For the CR200(X)-series, CR800, CR850, CR1000, and CR3000, the 60 and

50 Hz integration options include a 3 ms settling time; longer settling times can

be entered into the Settling Time parameter.

17

Page 24

110PV Surface Temperature Probe

G

6. Measurement

Understanding the details in this section is not necessary for general operation

of the 110PV Probe with CSI's dataloggers.

Sense +

Volt Excite

BLACK

GREEN

THERMISTOR

Signal

WHITE

RED

PURPLE

BLUE

CLEAR (shield)

4.99 k

Ω

, 0.1%

Sense -

Signal Reference

Signal Reference

FIGURE 6-1. 110PV Thermistor Probe schematic

Simple half bridge measurement, ignoring cable resistance

The measured voltage, V, is:

=

EX

Where V

is the excitation voltage, 4,990 ohms is the resistance of the fixed

EX

resistor and R

990,4

990,4

is the resistance of the thermistor

t

RVV+

t

The resistance of the thermistor is:

V

R

t

⎛

⎜

V

⎝

EX

⎞

−= 1990,4

⎟

⎠

The Steinhart-Hart equation is used to calculate temperature from Resistance:

T++=

K

Where T

is the temperature in Kelvin. The Steinhart- Hart coefficients used

K

1

3

))(ln()ln(

RCRBA

TT

are:

-3

A = 1.129241x10

B = 2.341077x10

C = 8.775468x10

-4

-8

18

Page 25

110PV Surface Temperature Probe

7. Maintenance, Removal, and Calibration

7.1 Maintenance

The 110PV probe requires minimal maintenance. Periodically check cabling

for proper connections, signs of damage, and possible moisture intrusion.

7.2 Removal from Measurement Surface

Remove the 110PV from the measurement surface by heating the probe to 70°

to 80°C, and then pulling it off.

CAUTION

Prying the 110PV off without heating it will likely damage

both the probe and PV module.

7.3 Recalibrations/Repairs

For all factory repairs and recalibrations, customers must get returned materials

authorization number (RMA). Customers must also properly fill out a

“Declaration of Hazardous Material and Decontamination” form, and comply

with the requirements specified within. Refer to the “Assistance” page at the

front of this manual for more information.

8. Troubleshooting

Symptom: Temperature is NAN, -INF, -9999, -273

Verify the red wire is connected to the correct single-ended analog input

channel as specified by the measurement instruction, the black wire is

connected to the switched excitation channel as specified by the measurement

instruction, and the purple wire is connected to datalogger ground.

Symptom: Incorrect Temperature

Verify the multiplier and offset parameters are correct for the desired units

(Section 5). Check the cable for signs of damage and possible moisture

intrusion.

CAUTION

NOTE

If the 110PV needs to be sent to Campbell Scientific for

repairs, remember that the probe must be heated to 70° to

80°C before removing it from the measurement surface.

Prying the probe off without heating it will likely damage

both the probe and the PV module.

For all factory repairs, customers must get an RMA. Customers

must also properly fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements

specified in it. Refer to the “Assistance” page at the front of this

manual for more information.

19

Page 26

110PV Surface Temperature Probe

Symptom: Unstable Temperature

Try using the 60 or 50 Hz integration options, and/or increasing the settling

time as described in Sections 8 and 9. Make sure the clear shield wire is

connected to datalogger ground, and the datalogger is properly grounded.

20

Page 27

Appendix A. Probe Material Properties

The probe consists of 6061 aluminum (clear anodized), thermistor, 3M9485PC

adhesive, and Santoprene jacketed cable.

A.1 3M 9485PC Adhesive

Humidity Resistance: High humidity has a minimal effect on adhesive

performance. Bond strengths are generally higher after exposure for 7 days at 90°F

(32°C) and 90% relative humidity.

U.V. Resistance: When properly applied, nameplates and decorative trim parts are

not adversely affected by outdoor exposure.

Water Resistance: Immersion in water has no appreciable effect on the bond

strength. After 100 hours in room temperature water the bond actually shows an

increase in strength.

Temperature Cycling Resistance: Bond strength generally increases after cycling

four times through:

• 4 hours at 158°F (70°C)

• 4 hours at -20°F (-29°C)

A.2 Santoprene

• 16 hours at room temperature

Chemical Resistance: When properly applied, adhesive will hold securely after

exposure to numerous chemicals including gasoline, oil, Freon™ TF, sodium

chloride solution, mild acids and alkalis.

Heat Resistance: Adhesive 350 is usable for short periods (minutes, hours) at

temperatures up to 350°F (177°C) and for intermittent longer periods (days, weeks)

up to 250°F (121°C).

Low Temperature Service: -40°F (-40°C). Parts should be tested for low

temperature shock service.

The following information is from Advanced Elastomer Systems; Santoprene

Rubber Fluid Resistance Guide; pp 2, 3, 9; copyright 2000.

A-1

Page 28

Appendix A. Probe Material Properties

A-2

Page 29

Appendix A. Probe Material Properties

A-3

Page 30

Appendix A. Probe Material Properties

A-4

Page 31

Page 32

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...