Page 1

INSTRUCTION MANUAL

Model 108 Temperature Probe

Copyright © 1985- 2014

Campbell Scientific, Inc.

Revision: 3/14

Page 2

Page 3

Limited Warranty

“Products manufactured by CSI are warranted by CSI to be free from defects in

materials and workmanship under normal use and service for twelve months

from the date of shipment unless otherwise specified in the corresponding

product manual. (Product manuals are available for review online at

www.campbellsci.com.) Products not manufactured by CSI, but that are resold

by CSI, are warranted only to the limits extended by the original manufacturer.

Batteries, fine-wire thermocouples, desiccant, and other consumables have no

warranty. CSI’s obligation under this warranty is limited to repairing or

replacing (at CSI’s option) defective Products, which shall be the sole and

exclusive remedy under this warranty. The Customer assumes all costs of

removing, reinstalling, and shipping defective Products to CSI. CSI will return

such Products by surface carrier prepaid within the continental United States of

America. To all other locations, CSI will return such Products best way CIP

(port of entry) per Incoterms ® 2010. This warranty shall not apply to any

Products which have been subjected to modification, misuse, neglect, improper

service, accidents of nature, or shipping damage. This warranty is in lieu of all

other warranties, expressed or implied. The warranty for installation services

performed by CSI such as programming to customer specifications, electrical

connections to Products manufactured by CSI, and Product specific training, is

part of CSI's product warranty. CSI EXPRESSLY DISCLAIMS AND

EXCLUDES ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. CSI hereby disclaims,

to the fullest extent allowed by applicable law, any and all warranties and

conditions with respect to the Products, whether express, implied or

statutory, other than those expressly provided herein.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction ................................................................. 1

2. Cautionary Statements ............................................... 1

3. Initial Inspection ......................................................... 1

4. Quickstart .................................................................... 1

5. Overview ...................................................................... 4

6. Specifications ............................................................. 4

7. Installation ................................................................... 6

7.1 Wiring to Datalogger ............................................................................ 6

7.2 Datalogger Programming ..................................................................... 6

7.2.1 CRBasic ........................................................................................ 7

7.2.2 Edlog ............................................................................................. 7

7.3 Air Temperature Installation ................................................................ 8

7.4 Water Temperature Installation .......................................................... 10

7.5 Soil Temperature ................................................................................ 10

8. Operation ................................................................... 10

8.1 Sensor Schematic ............................................................................... 10

8.2 Measurement and Output Linearization ............................................. 10

8.3 Electrically Noisy Environments........................................................ 12

8.4 Long Cable Lengths ........................................................................... 12

9. Troubleshooting and Maintenance ......................... 13

9.1 Troubleshooting ................................................................................. 13

9.2 Maintenance ....................................................................................... 14

9.3 Calibration .......................................................................................... 14

10. Attributions and References .................................... 14

Appendices

Importing Short Cut Code ...................................... A-1

A.

A.1 Importing Short Cut Code into a Program Editor ........................... A-1

A.1.1 CRBasic Datalogger ................................................................. A-1

A.1.2 Edlog ........................................................................................ A-2

i

Page 6

Table of Contents

B. Example Programs .................................................. B-1

B.1 Example CRBasic Program ............................................................. B-1

B.2 Example Edlog Program .................................................................. B-1

C. Conversion of Thermistor Resistance or

Voltage Ratio to Temperature .............................. C-1

Figures

6-1. Linearization error, where error is the difference between actual

and datalogger-computed temperature. ............................................ 5

7-1. 108 and 41303-5A Radiation Shield on a tripod mast ......................... 9

7-2. 108 and 41303-5A Radiation Shield on a CM200 Series Crossarm .... 9

8-1. 108 thermistor probe schematic ......................................................... 10

Tables

7-1. Wire Color, Function, and Datalogger Connection ............................. 6

8-1. 108 Measurement Details .................................................................. 11

8-2. 108 Temperature Calculation ............................................................ 11

C-1. Voltage Ratio, Resistance, and Temperature ................................... C-1

ii

Page 7

Model 108 Temperature Probe

1. Introduction

The 108 temperature probe uses a thermistor to measure temperature in air,

soil, and water. It is compatible with all current dataloggers except the

CR200(X) series and CR9000(X).

2. Cautionary Statements

Santoprene® rubber, which composes the black outer jacket of the 108 cable,

will support combustion in air. It is used because of its resistance to

temperature extremes, moisture, and UV degradation. It is rated as slow

burning when tested according to U.L. 94 H.B. and passes FMVSS302.

However, local fire codes may preclude its use inside buildings.

3. Initial Inspection

• Check the packaging and contents of the shipment. If damage occurred

during transport, immediately file a claim with the carrier. Contact

Campbell Scientific to facilitate repair or replacement.

4. Quickstart

• Check model information against the shipping documents to ensure the

expected products and the correct lengths of cable are received. Model

numbers are found on each product. On cables and cabled items, the

model number is usually found at the connection end of the cable. Report

any shortages immediately to Campbell Scientific.

Short Cut is an easy way to program your datalogger to measure the 108 probe

and assign datalogger wiring terminals. Use the following procedure to get

started.

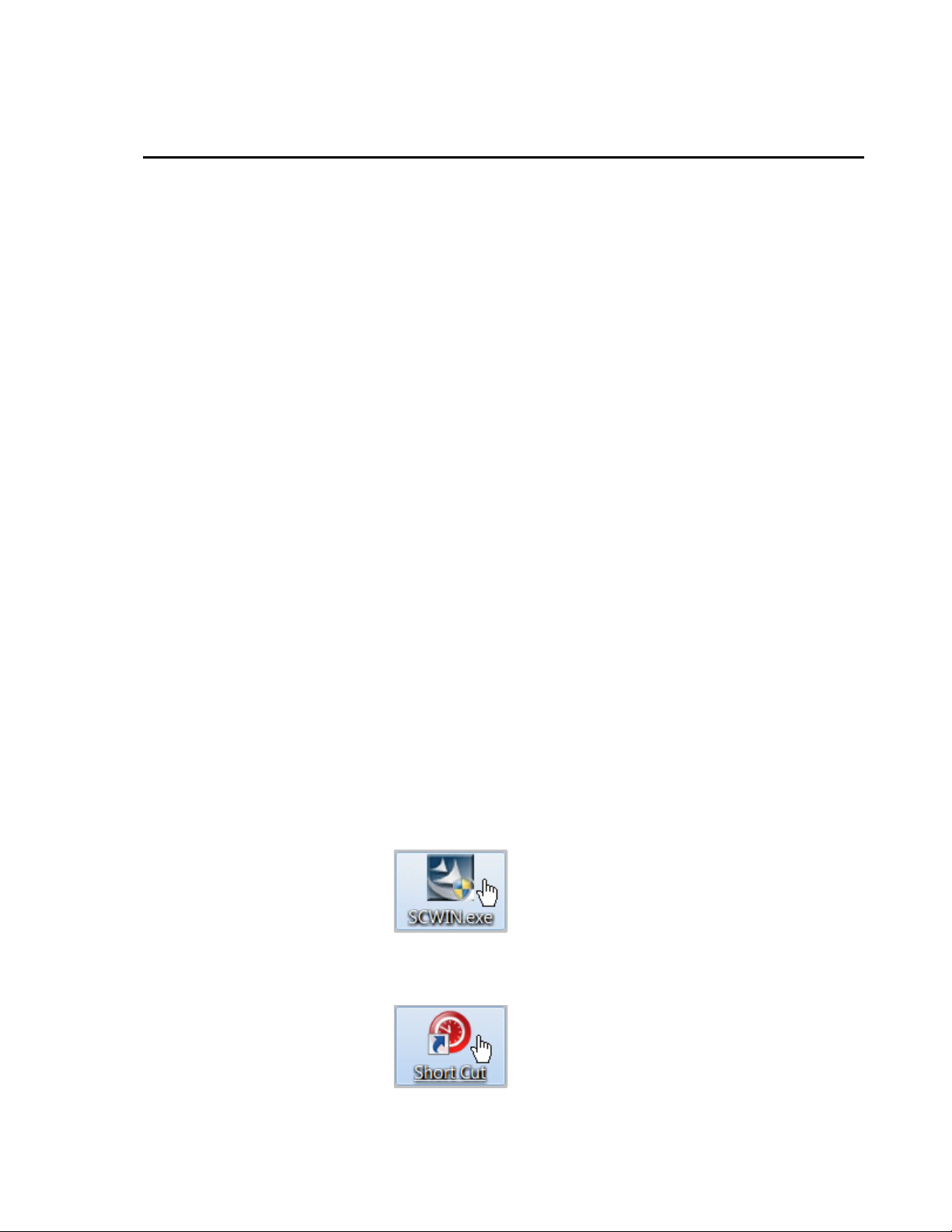

1. Install Short Cut by clicking on the install file icon. Get the install file

from either www.campbellsci.com, the ResourceDVD, or find it in

installations of LoggerNet, PC200W, PC400, or RTDAQ software.

2. The Short Cut installation should place a shortcut icon on the desktop of

your computer. To open Short Cut, click on this icon.

1

Page 8

Model 108 Temperature Probe

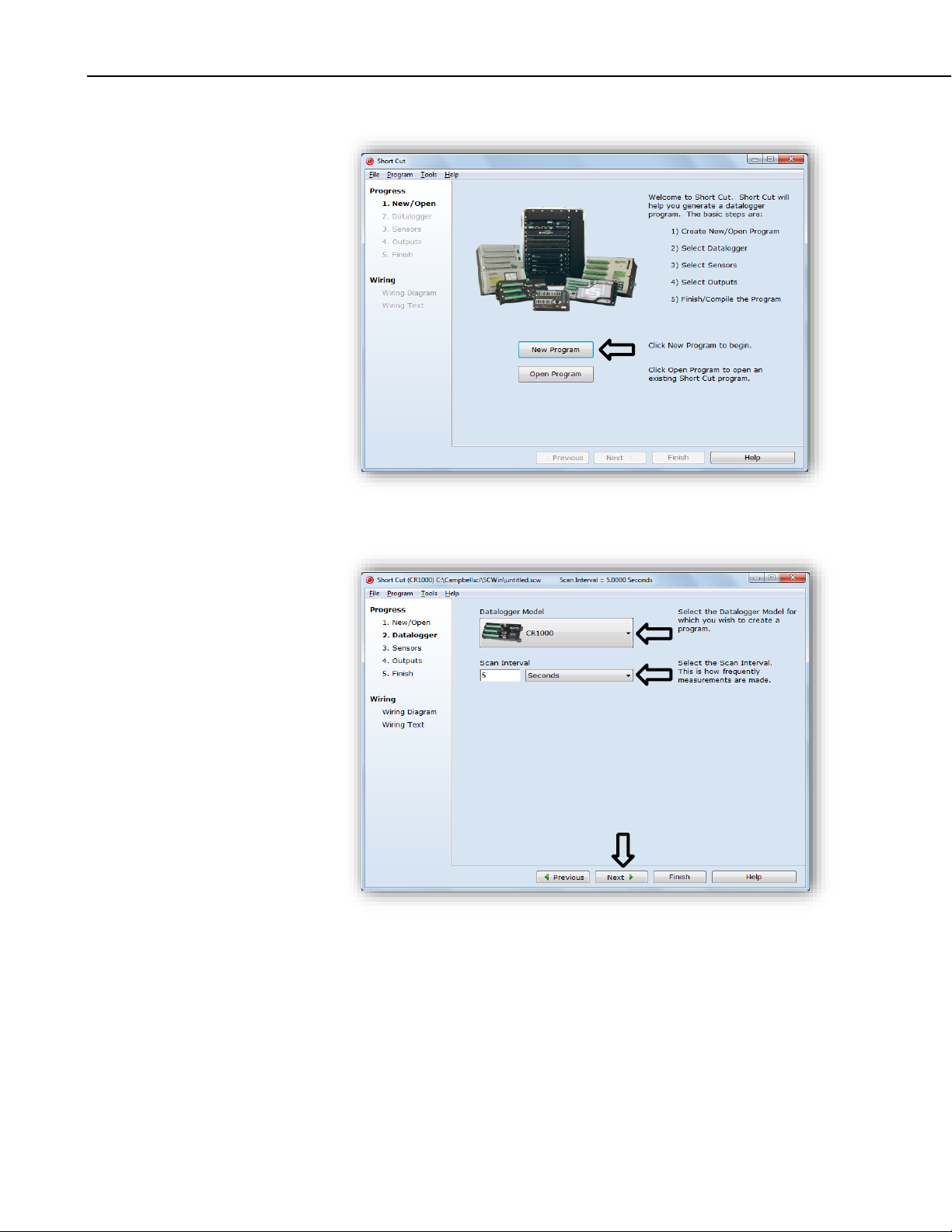

3. When Short Cut opens, select New Program.

4. Select Datalogger Model and Scan Interval (default of 5 seconds is OK

for most applications). Click Next.

2

Page 9

Model 108 Temperature Probe

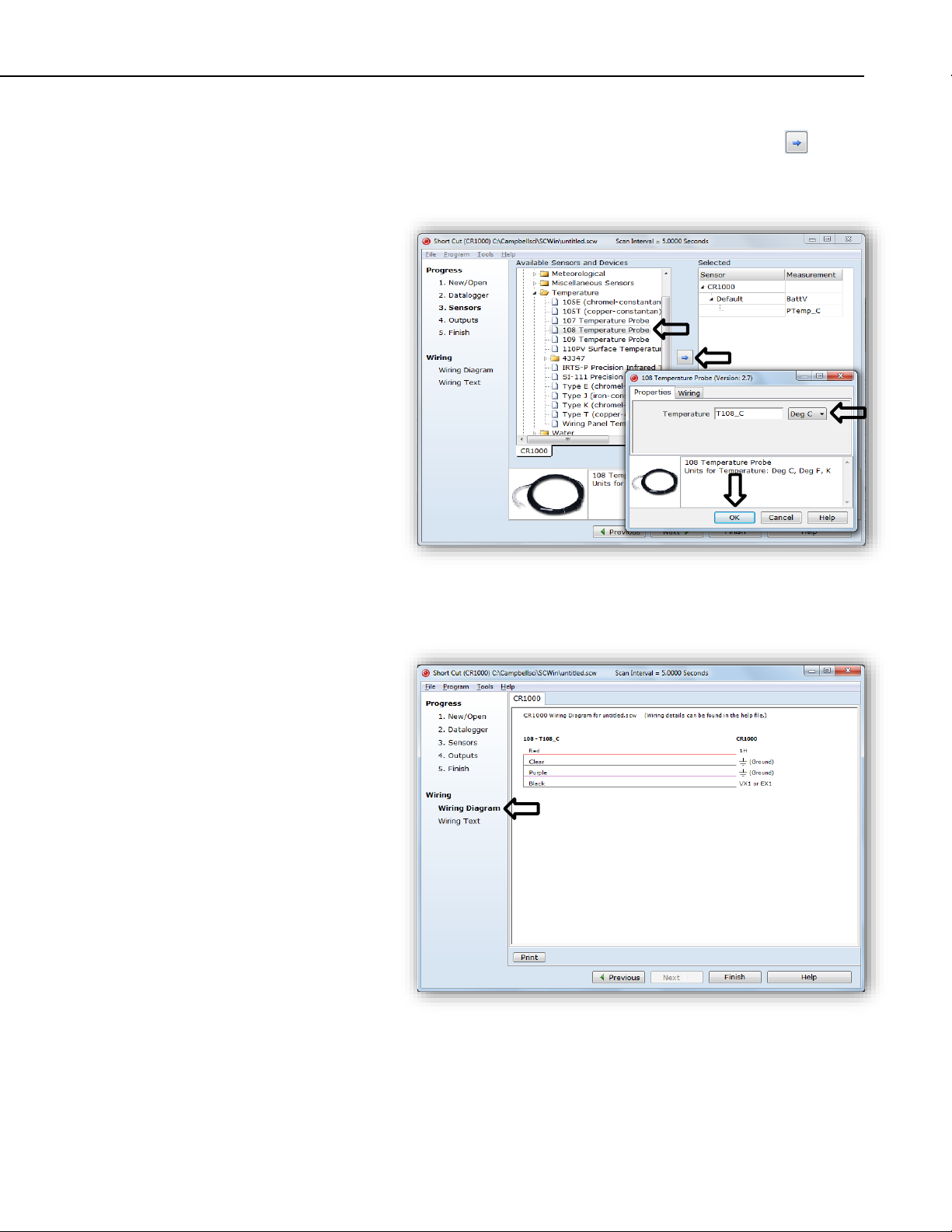

5. Under the Available Sensors and Devices list, select the Sensors |

Temperature folder. Select 108 Temperature Probe. Click to

move the selection to the Selected device window. Data defaults to degree

Celsius. This can be changed by clicking the Deg C box and selecting

Deg F, for degrees Fahrenheit, or K, for Kelvin.

6. After selecting the sensor, click at the left of the screen on Wiring

Diagram to see how the sensor is to be wired to the datalogger. The

wiring diagram can be printed out now or after more sensors are added.

7. Select any other sensors you have, and then finish the remaining Short Cut

steps to complete the program. The remaining steps are outlined in Short

Cut Help, which is accessed by clicking on Help | Contents |

Programming Steps.

3

Page 10

Model 108 Temperature Probe

8. If LoggerNet, PC400, RTDAQ, or PC200W is running on your PC, and the

9. If the sensor is connected to the datalogger, as shown in the wiring

5. Overview

The 108 is a rugged probe that accurately measures air, soil, or water

temperature in a variety of applications. The sensor consists of a thermistor

encapsulated in an epoxy-filled aluminum housing. This design allows the

probe to be buried or submerged in water to 15 m (50 ft) or 21 psi. When

measuring air temperature, a 41303-5A radiation shield is normally used to

mount the 108 and limit solar radiation loading. See Specifications for a

complete list of compatible dataloggers.

6. Specifications

Features

PC to datalogger connection is active, you can click Finish in Short Cut

and you will be prompted to send the program just created to the

datalogger.

diagram in step 6, check the output of the sensor in the datalogger support

software data display to make sure it is making reasonable measurements.

• Measures air, soil, or water temperature

• Compatible with AM16/32-series multiplexers

• Easy to install or remove

• Durable

• Compatible with Campbell Scientific CRBasic dataloggers CR800

series, CR1000, CR3000, and CR5000. Also compatible with Edlog

dataloggers CR10(X), CR510, CR500, CR23X, 21X, and CR7(X).

Sensor Element: Measurement Specialties 100K6A1iA

thermistor

Survival Range: –50 to 100 °C

Measurement Range: –5 to 95 °C

Time Constant in Air: 200 ± 10 seconds

Maximum Cable Length: 1000 ft

1

Accuracy

Worst case: ±0.3 °C (–3 to 90 °C)

±0.7 °C (–5 to 95 °C)

Interchangeability Error: ±0.10 °C (0 to 70 °C)

±0.14 °C at –5 °C

±0.25 °C at 85 °C

±0.35 °C at 95 °C

CRBasic Therm108()

Steinhart-Hart

Equation Error: ≤ ±0.01 °C

4

Page 11

Model 108 Temperature Probe

Edlog Polynomial (P55)

Linearization Error: <±0.5 °C (–5 to 95 °C)

<±0.1 °C (–3 to 90 °C)

0.5

0.4

0.3

0.2

0.1

0.0

Error (°C)

-0.1

-0.2

-0.3

-0.4

-0.5

-10 0 10 20 30 40 50 60 70 80 90 100

Edlog Error

CRBasic Therm108() Error

Actual Temperature (°C)

FIGURE 6-1. Linearization error, where error is the difference between

actual and datalogger-computed temperature.

1

The overall probe accuracy is a combination of the thermistor interchangeability specification, the

precision of the bridge resistors, and the error of the Steinhart-Hart equation used in the CRBasic

instruction Therm108() (CRBasic dataloggers), or the error of the polynomial equation used in the

Edlog Polynomial (P55) instruction (Edlog dataloggers). The major error component is the

interchangeability specification of the thermistor. For the range of 0° to 50°C, the

interchangeability error is predominantly offset and can be determined with a single point

calibration. The offset can be entered in the measurement instruction Offset parameter. Bridge

resistors have 0.1% tolerance with a 10 ppm temperature coefficient.

Probe Length: 10.4 cm (4.1 in)

Probe Diameter: 0.762 cm (0.3 in)

Weight with 10 ft Cable: 136 g (5 oz)

5

Page 12

Model 108 Temperature Probe

TABLE 7-1. Wire Color, Function, and Datalogger Connection

NOTE

7. Installation

7.1 Wiring to Datalogger

If you are programming your datalogger with Short Cut, skip Section 7.1,

Wiring to Datalogger, and Section 7.2, Datalogger Programming. Short Cut

does this work for you. See Section 4, Quickstart, for a Short Cut tutorial.

Wire

Color

Black

Red Analog-voltage output

Purple Bridge-resistor lead

Clear EMF shield

Wire Function

Voltage-excitation

7.2 Datalogger Programming

Short Cut is the best source for up-to-date datalogger programming code.

Programming code is needed when:

• Creating a program for a new datalogger installation.

• Adding sensors to an existing datalogger program.

If your data acquisition requirements are simple, you can probably create and

maintain a datalogger program exclusively with Short Cut. If your data

acquisition needs are more complex, the files that Short Cut creates are a great

source for programming code to start a new program or add to an existing

custom program.

input

Datalogger Connection

Terminal

EX, VX

(voltage excitation)

SE

(single-ended analog-voltage

input)

AG or

(analog ground)

G

(power ground)

Short Cut cannot edit programs after they are imported and edited

in CRBasic Editor.

A Short Cut tutorial is available in Section 4, Quickstart. If you wish to import

Short Cut code into either Edlog or CRBasic Editor to create or add to a

customized program, follow the procedure in Appendix A.1, Importing Short

Cut Code into a Program Editor. Programming basics for CRBasic and Edlog

dataloggers are provided in the following sections. Complete program

examples for select dataloggers can be found in Appendix B, Example

Programs.

If the 108 probe is to be used with long cable lengths or in electrically noisy

environments, consider employing the measurement programming techniques

6

Page 13

7.2.1 CRBasic

Model 108 Temperature Probe

outlined in Section 8.3, Electrically Noisy Environments, and Section 8.4, Long

Cable Lengths.

Details of 108 probe measurement and linearization of the thermistor output

are provided in Section 8.2, Measurement and Output Linearization.

The Therm108() measurement instruction programs CRBasic dataloggers

(CR800-series, CR1000, CR3000, CR5000) to measure the 108 probe. It

supplies a 2500 mV excitation, makes a half-bridge measurement, and converts

the result to temperature using the Steinhart-Hart equation (see Section 8.2,

Measurement and Output Linearization, for more information):

Therm108(Dest,Reps,SEChan,VxChan,SettlingTime,Integ,Mult,Offset)

Variations:

• Temperature reported as °C — set Mult to 1 and Offset to 0

• Temperature reported as °F — set Mult to 1.8 and Offset to 32

• Ac mains noise filtering — set Integ to _60Hz or _50Hz (see Section

8.3, Electrically Noisy Environments)

• Compensate for long cable lengths — Set SettlingTime to 20000 (see

Section 8.4, Long Cable Lengths)

7.2.2 Edlog

The AC Half Bridge (P5) measurement instruction programs Edlog

dataloggers (CR10(X), CR510, CR500, CR23X, 21X, and CR7(X)) to measure

the 108 probe. It makes a half-bridge measurement, and the Polynomial (P55)

instruction converts the result to temperature using a fifth-order polynomial

(see Section 8.2, Measurement and Output Linearization, for more

information):

1: AC Half Bridge (P5)

1: 1 Reps

2: 23 25 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 1 Excite all reps w/Exchan 1

5: 1000 mV Excitation

6: 1 Loc [ T108_C ]

7: 200 Multiplier

8: 0 Offset

2: Polynomial (P55)

1: 1 Reps

2: 1 X Loc [ T108_C ]

3: 1 F(X) Loc [ T108_C ]

4: -26.97 C0

5: 69.635 C1

6: -40.66 C2

7: 16.573 C3

8: -3.455 C4

9: 0.301 C5

7

Page 14

Model 108 Temperature Probe

7.3 Air Temperature Installation

Variations:

• Temperature reported as °F – add a multiplier (P37) of 1.8 and an

offset (P34) of 32

• Ac mains noise filtering — see Section 8.3, Electrically Noisy

Environments

• Compensate for long cable lengths — see Section 8.4, Long Cable

Lengths

For air temperature measurements, sensors should be located over an open

level area at least 9 m (EPA) in diameter. The surface should be covered by

short grass or the natural earth surface where grass does not grow. Sensors

should be located at a distance of at least four times the height of any nearby

obstruction, and at least 30 m (EPA) from large paved areas. Sensors should

be protected from thermal radiation and adequately ventilated.

Standard air temperature measurement heights:

1.25 to 2.0 m (WMO)

2.0 m (EPA)

2.0 m and 10.0 m temperature difference (EPA)

When exposed to sunlight, the 108 should be housed in a 41303-5A or 413035B six-plate solar radiation shield. The louvered construction of the shields

allows air to pass freely through, thereby keeping the probe at or near ambient

temperature. The white shields reflect solar radiation. The 41303-5A attaches

to a crossarm, mast, or user-supplied pipe with a 2.5 to 5.3 cm (1.0 to 2.1 inch)

outer diameter. The 41303-5B attaches to a CM500-series pole or a usersupplied pole with a 5.1 cm (2.4 inch) outer diameter.

Tools required for installing on a tripod or tower:

• 1/2 inch open-end wrench

• small screwdriver provided with datalogger

• small Phillips screwdriver

• UV-resistant cable ties

• small pair of diagonal-cutting pliers

8

Page 15

Model 108 Temperature Probe

41303-5A

108

Tripod Mast

or

41303-5A

108

Tripod Mast or

Tower Leg

CM200 Series Crossarm

Tower Leg

FIGURE 7-1. 108 and 41303-5A Radiation Shield on a tripod mast

FIGURE 7-2. 108 and 41303-5A Radiation Shield on a CM200 Series

Crossarm

The 108 is held within radiation shield by a mounting clamp on the bottom

plate of the 41303-5A (FIGURE 7-2). Loosen the two mounting clamp screws,

and insert the sensor through the clamp and into the shield. Tighten the screws

to secure the sensor in the shield and route the sensor cable to the instrument

enclosure. Secure the cable to the tripod/tower using cable ties.

9

Page 16

Model 108 Temperature Probe

7.4 Water Temperature Installation

7.5 Soil Temperature

The 108 can be submerged to 15 m (50 ft) or 21 psi. The 108 is not weighted,

so a weighting system should be added, or the probe secured to a fixed,

submerged object such as a piling.

The 108 tends to measure the average temperature over its length, so it should

generally be buried such that the measurement tip is horizontal to the soil

surface at the desired depth.

One or two coils of cable should also be buried in a shallow installation. Burial

of some cable mitigates the effect of solar heating of the above ground cable on

the temperature measurement.

Placement of the cable inside a rugged conduit may be necessary for long cable

runs, especially in locations subject to digging, mowing, traffic, use of power

tools, or lightning strikes.

The maximum burial depth for soil that could become saturated with water is

dictated by the maximum water pressure allowed for the sensor, which is 21

psi.

8. Operation

8.1 Sensor Schematic

8.2 Measurement and Output Linearization

FIGURE 8-1. 108 thermistor probe schematic

Campbell Scientific dataloggers measure the 108 probe thermistor and convert

the result to temperature. With reference to the previous FIGURE 8-1, 108

thermistor probe schematic, a precise excitation voltage is applied at the Vx

line and the voltage drop across the 1 kΩ resistor is measured at the Vs line.

10

The ratio of measured voltage (Vs) to excitation voltage (Vx) is related to

thermistor resistance (Rs), and the 1 kΩ and 40 kΩ fixed resistors as described

in the following equation:

Page 17

Model 108 Temperature Probe

TABLE 8-1. 108 Measurement Details

mV

Equation

TABLE 8-2. 108 Temperature Calculation

Vs/Vx = 1000 / (Rs + 40000 Ω + 1000 Ω)

Solving for Rs:

Rs + 41000 Ω = 1000 • (Vx/Vs)

Rs = 1000 • (Vx/Vs) – 41000 Ω

TABLE 8-1, 108 Measurement Details, and TABLE 8-2, 108 Temperature

Calculation, describe how measurement results Vs/Vx and Rs are converted to

temperature by Campbell Scientific dataloggers.

Datalogger

Model

CR800

CR1000

CR3000

CR5000

CR500

CR510

CR10

CR10X

21X

CR7(X)

CR23X

†Fixed series resistance is subtracted before applying Steinhart-Hart.

‡ Multiplier of 200 scales Vs/Vx for the polynomial fit.

CRBasic Dataloggers

Measurement

Instruction

CRBasic

Therm108()

Edlog

AC Half

Bridge (P5)

Edlog

AC Half

Bridge (P5)

1

Excite

mV

1000 25 Vs/Vx

2000 50 Vs/Vx

Input

Range

Result Scaling

Multiply

by 200‡

Multiply

by 200‡

Applied to

Scaled Result

Steinhart-Hart

(automatically

applied)

5th order

polynomial

(use

Polynomial

(P55))

5th order

polynomial

(use

Polynomial

(P55))

Therm108() instruction measures the ratio Vs/Vx, calculates the thermistor

resistance Rs, and converts Rs to temperature using the Steinhart-Hart equation

T = 1 / (A + (B • ln(Rs))) + (C • ((ln(Rs))) ^ 3) – 273.15

where:

T = temperature in degrees Celsius

A = 8.271111E–4

B = 2.088020E–4

C = 8.059200E–8

Edlog Dataloggers

3

AC Half Bridge (P5) instruction measures the ratio Vs/Vx. Polynomial (P55)

instruction converts the measurement result Vs/Vx * 200 to temperature using a 5

order polynomial:

T = C0 + C1•X + C2•X^2 + C3•X^3 + C4•X^4 + C5•X^5

where:

T = temperature in Celsius

X = (Vs/Vx) • 200

C0 = –26.97

C1 = 69.635

2

:

th

11

Page 18

Model 108 Temperature Probe

C2 = –40.66

8.3 Electrically Noisy Environments

C3 = 16.573

C4 = –3.455

C5 = 0.301

1

CRBasic dataloggers are CR800, CR1000, CR3000, and CR5000.

2

Coefficients provided by the thermistor manufacturer.

3

Edlog dataloggers are CR10(X), CR510, CR500, CR23X, 21X, and CR7.

EMF noise emanating from the ac mains power grid can be a significant source

of measurement error. 60 Hz noise is common in the United States. 50 Hz

noise is common in Europe and other regions. Depending on the datalogger

model, this noise can usually be filtered out.

The following code examples filter 60 Hz noise. The key parameters are in

bold type.

CRBasic

Therm108(T108_C,1,1,Vx1,0,_60Hz,1.0,0.0)

Edlog

1: AC Half Bridge (P5)

1: 1 Reps

2: 23 25 mV 60 Hz Rejection Range ;CR23X:50 mV; 21X,CR7:50 mV slow range

3: 1 SE Channel

4: 1 Excite all reps w/Exchan 1

5: 1000 mV Excitation ;CR23X,21X,CR7: 2000 mV

6: 1 Loc [ T108_C ]

7: 200 Multiplier

8: 0 Offset

8.4 Long Cable Lengths

Long cable lengths may require longer than normal analog measurement

settling times. Settling times are increased by adding a measurement delay to

the datalogger program.

CRBasic

For CRBasic loggers, the 60 Hz and 50 Hz integration options include a 3 ms

settling time; longer settling times also can be entered into the Settling Time

parameter. The following example uses a 20000 µs settling time:

Therm108(T108_C,1,1,1,20000,_60Hz,1.0,0.0)

Edlog

12

If the 108 probe has cable lengths of more than 300 feet, use the Excite-Delay

(SE) (P4) instruction with a 20 ms delay to measure the temperature, as shown

in the following Edlog code.

Page 19

Model 108 Temperature Probe

NOTE

01: Excite-Delay (SE) (P4)

1: 1 Rep

2: 3 ±25 mV slow range ;CR23X,21X,CR7: 50 mV

3: 9 IN Chan

4: 3 Excite all reps w/EXchan 3

5: 2 Delay (units .01sec)

6: 1000 mV Excitation ;CR23X,21X,CR7: 2000 mV

7: 11 Loc [:Temp_C ]

8: .2 Mult ;CR23X,21X,CR7: 0.1

9: 0 Offset

02: Polynomial (P55)

1: 1 Reps

2: 11 X Loc [ Tmp108C ]

3: 11 F(X) Loc [ Tmp108C ]

4: -26.97 C0

5: 69.635 C1

6: -40.66 C2

7: 16.573 C3

8: -3.455 C4

9: .301 C5

9. Troubleshooting and Maintenance

All factory repairs and recalibrations require a returned material

authorization (RMA) and completion of the “Declaration of

Hazardous Material and Decontamination” form. Refer to the

Assistance page at the beginning of this manual for more

information.

9.1 Troubleshooting

Symptom: Temperature is reported as NAN, –INF, –9999, or –273.

Verify the red wire is connected to the correct single-ended analog input

channel as specified by the measurement instruction and the purple wire is

connected to datalogger ground.

Symptom: Temperature is reported as NAN or –26.

Verify the black wire is connected to the switched excitation channel

specified by the measurement instruction.

Symptom: Incorrect temperature is reported.

Verify the multiplier and offset arguments in the measurement

instructions are correct for the desired units (Section 7.2, Datalogger

Programming). Check the cable for signs of damage and possible

moisture intrusion.

Symptom: Unstable temperature is reported.

Most likely a result of electromagnetic interference. Try using the 60 or

50 Hz integration options, and/or increasing the settling time as described

in Section 8.3, Electrically Noisy Environments, and Section 8.4, Long

Cable Lengths. Make sure the clear shield wire is connected to datalogger

ground and the datalogger is properly grounded.

13

Page 20

Model 108 Temperature Probe

9.2 Maintenance

9.3 Calibration

The 108 probe requires minimal maintenance. For air temperature

measurements, check the radiation shield monthly to make sure the radiation

shield is clean and free from debris. Periodically check cabling for signs of

damage and possible moisture intrusion.

Calibration of the 108 probe is not necessary unless the application requires

removal of the thermistor interchangeability offset described in Section 6,

Specifications. If performing the one point calibration with an Edlog

datalogger, be aware of this precaution:

The value of the offset must be chosen so that the probe outputs the

temperature calculated by the polynomial, not the actual calibration

temperature. For example, a 108 probe placed in a calibration chamber at 0 °C

outputs 0.1 °C. An Offset argument of –0.15 is required for Edlog dataloggers

because at 0 °C, the polynomial calculates a temperature of –0.05 °C

(Appendix C, Conversion of Thermistor Resistance or Voltage Ratio to

Temperature).

10. Attributions and References

®

Santoprene

EPA installation standard: Quality Assurance Handbook for Air Pollution

Measurement Systems – Volume IV: Meteorological Measurements Version 2.0

WMO standard: WMO No. 8, Seventh edition, 6 Aug 2008 Guide to

Meteorological Instruments and Methods of Observation

is a registered trademark of Exxon Mobile Corporation.

14

Page 21

NOTE

Appendix A. Importing Short Cut Code

This tutorial shows:

• How to import a Short Cut program into a program editor for

additional refinement.

• How to import a wiring diagram from Short Cut into the comments of

a custom program.

A.1 Importing Short Cut Code into a Program Editor

Short Cut creates files that can be imported into either CRBasic Editor or

Edlog program editor. These files normally reside in the

C:\campbellsci\SCWin folder and have the following extensions:

• .DEF (wiring and memory usage information)

• .CR1 (CR1000 datalogger code)

• .CR8 (CR800 datalogger code)

• .CR3 (CR3000 datalogger code)

• .CR5 (CR5000 datalogger code)

• .DLD (contain code for CR10(X), CR23X, CR500, CR510, 21X, or

CR7(X) dataloggers)

The following procedures show how to import these files for editing.

A.1.1 CRBasic Datalogger

Use the following procedure to import Short Cut code into CRBasic Editor

(CR1000, CR800, CR3000, CR5000 dataloggers).

1. Create the Short Cut program following the procedure in Section 4,

Quickstart. Finish the program and exit Short Cut. Make note of the file

name used when saving the Short Cut program.

2. Open CRBasic Editor.

3. Click File | Open. Assuming the default paths were used when Short Cut

was installed, navigate to C:\CampbellSci\SCWin folder. The file of

interest has a “.CR1”, “.CR8”, “.CR3”, or “.CR5” extension, for CR1000,

CR800, CR3000, or CR5000 dataloggers, respectively. Select the file and

click Open.

4. Immediately save the file in a folder different from \Campbellsci\SCWin,

or save the file with a different file name.

Once the file is edited with CRBasic Editor, Short Cut can no

longer be used to edit the datalogger program. Change the name

of the program file or move it, or Short Cut may overwrite it next

time it is used.

5. The program can now be edited, saved, and sent to the datalogger.

A-1

Page 22

Appendix A. Importing Short Cut Code

NOTE

6. Import wiring information to the program by opening the associated .DEF

file. Copy and paste the section beginning with heading “-Wiring for

CRXXX–” into the CRBasic program, usually at the head of the file.

After pasting, edit the information such that a ' character (single quotation

mark) begins each line. This character instructs the datalogger compiler to

ignore the line when compiling the datalogger code.

A.1.2 Edlog

Use the following procedure to import Short Cut code into the Edlog program

editor (CR10(X), CR500, CR510, CR23X, 21X, and CR7(X) dataloggers).

1. Create the Short Cut program following the procedure in Section 4,

Quickstart. Finish the program and exit Short Cut. Make note of the file

name used when saving the Short Cut program.

2. Open Edlog.

3. Click File | Document DLD File. Assuming the default paths were used

when Short Cut was installed, navigate to C:\CampbellSci\SCWin folder.

The file of interest has a “.DLD” extension. Select the file and click

Open. The .dld file, which is a type of ASCII machine code, is imported,

documented, and, when saved, given a “.CSI” extension.

4. Immediately save the file in a folder different from \Campbellsci\SCWin,

or save the file with a different file name.

Once the file is edited with Edlog, Short Cut can no longer be used

to edit the program. Change the name of the program file or move

it, or Short Cut may overwrite it.

5. The program can now be edited, saved, and sent to the datalogger.

6. Import wiring information to the program by opening the associated .DEF

file. Copy and paste the section beginning with heading “-Wiring for

CRXXX–” into the Edlog program, usually at the head of the file. After

pasting, edit the information such that a ; (semicolon) begins each line,

which instructs the datalogger compiler to ignore the line when compiling

the datalogger code.

A-2

Page 23

Appendix B. Example Programs

B.1 Example CRBasic Program

This example can be used directly with CR800 series, CR1000, CR3000, and

CR5000 dataloggers.

'Program measures one 108 temperature probe once a second and

'stores the average temperature every 60 minutes.

'Wiring Diagram

'==============

'108 Probe

'

' Wire

' Color Function CR1000

' ----- -------- -----' Black Voltage-excitation input VX1 or EX1

' Red Analog-voltage output SE1

' Purple Bridge resistor lead AG*

' Clear EMF Shield G

'*AG = Analog Ground (represented by ground symbol on CR1000 wiring panel

'Declare the variable for the temperature measurement

Public T108_C

'Define a data table for 60-minute averages

DataTable(Table1,True,-1)

DataInterval(0,60,Min,0)

Average(1,T108_C,IEEE4,False)

EndTable

BeginProg

Scan(1,Sec,1,0)

'Measure the temperature

Therm108(T108_C,1,1,Vx1,0,_60Hz,1.0,0)

'Call data table

CallTable(Table1)

NextScan

EndProg

B.2 Example Edlog Program

This example can be used directly with CR10X dataloggers. With minor

adaptations, it can also be used with CR10, CR500, CR510, CR23X, and

CR7X dataloggers. More adaptation will be needed with the 21X and CR7

dataloggers. Contact a Campbell Scientific application engineer for help with

any datalogger program.

B-1

Page 24

Appendix B. Example Programs

;{CR10X}

;Program measures one 108 temperature probe once a second

;and stores the average temperature every 60 minutes.

;Wiring Diagram

;==============

;108 Probe

;

; Wire

; Color Function CR10X

; ----- -------- ----; Black Voltage-excitation input E1

; Red Analog-voltage output SE1

; Purple Bridge resistor lead AG

; Clear EMF Shield G

*Table 1 Program

01: 1.0000 Execution Interval (seconds)

1: AC Half Bridge (P5)

1: 1 Reps

2: 23 25 mV 60 Hz Rejection Range

3: 1 SE Channel

4: 1 Excite all reps w/Exchan 1

5: 1000 mV Excitation

6: 1 Loc [ T108_C ]

7: 200 Multiplier

8: 0 Offset

2: Polynomial (P55)

1: 1 Reps

2: 1 X Loc [ T108_C ]

3: 1 F(X) Loc [ T108_C ]

4: -26.97 C0

5: 69.635 C1

6: -40.66 C2

7: 16.573 C3

8: -3.455 C4

9: 0.301 C5

3: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

4: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 101 Array ID

5: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

6: Average (P71)

1: 1 Reps

2: 1 Loc [ T108_C ]

B-2

Page 25

TABLE C-1. Voltage Ratio, Resistance, and Temperature1

Actual

100K6A1iA

P5 Edlog

P55 Edlog

CRBasic

-10

612407

0.31

-9.02

-10.00

-9

578366

0.32

-8.20

-9.00

-8

546408

0.34

-7.37

-8.00

-7

516394

0.36

-6.51

-7.00

-6

488196

0.38

-5.63

-6.00

-5

461695

0.40

-4.74

-5.00

-4

436779

0.42

-3.83

-4.00

-3

413346

0.44

-2.91

-3.00

-2

391300

0.46

-1.97

-2.00

-1

370551

0.49

-1.01

-1.00

0

351017

0.51

-0.05

0.00

1

332620

0.54

0.93

1.00 2 315288

0.56

1.91

2.00 3 298954

0.59

2.91

3.00

4

283555

0.62

3.91

4.00

5

269034

0.65

4.91

5.00 6 255335

0.67

5.93

6.00 7 242408

0.71

6.94

7.00 8 230206

0.74

7.96

8.00 9 218684

0.77

8.98

9.00

10

207801

0.80

10.00

10.00

11

197518

0.84

11.02

11.00

12

187799

0.87

12.04

12.00

13

178610

0.91

13.05

13.00

14

169921

0.95

14.07

14.00

15

161700

0.99

15.08

15.00

16

153921

1.03

16.09

16.00

17

146558

1.07

17.09

17.00

18

139586

1.11

18.10

18.00

19

132983

1.15

19.09

19.00

20

126727

1.19

20.09

20.00

21

120799

1.24

21.08

21.00

22

115179

1.28

22.07

22.00

23

109850

1.33

23.06

23.00

24

104795

1.37

24.05

24.00

25

100000

1.42

25.04

25.00

26

95449

1.47

26.02

26.00

27

91129

1.51

27.01

27.00

28

87027

1.56

27.99

28.00

29

83131

1.61

28.98

29.00

30

79430

1.66

29.96

30.00

Appendix C. Conversion of Thermistor Resistance or Voltage Ratio to Temperature

Temperature

(°C)

Thermistor

Resistance (Ω)

Instruction

= Vs/Vx * 200

Instruction Output

(°C)

Therm108()

Output (°C)

C-1

Page 26

Appendix C. Conversion of Thermistor Resistance or Voltage Ratio to Temperature

31

75913

1.71

30.95

31.00

32

72569

1.76

31.94

32.00

33

69390

1.81

32.94

33.00

34

66367

1.86

33.93

34.00

35

63491

1.91

34.93

35.00

36

60755

1.97

35.93

36.00

37

58150

2.02

36.93

37.00

38

55670

2.07

37.93

38.00

39

53309

2.12

38.94

39.00

40

51060

2.17

39.94

40.00

41

48917

2.22

40.95

41.00

42

46875

2.28

41.96

42.00

43

44929

2.33

42.97

43.00

44

43073

2.38

43.98

44.00

45

41303

2.43

44.99

45.00

46

39615

2.48

46.00

46.00

47

38005

2.53

47.01

47.00

48

36467

2.58

48.02

48.00

49

35000

2.63

49.02

49.00

50

33599

2.68

50.03

50.00

51

32262

2.73

51.03

51.00

52

30984

2.78

52.03

52.00

53

29763

2.83

53.03

53.00

54

28596

2.87

54.03

54.00

55

27481

2.92

55.03

55.00

56

26415

2.97

56.03

56.00

57

25395

3.01

57.02

57.00

58

24420

3.06

58.02

58.00

59

23487

3.10

59.01

59.00

60

22594

3.14

60.00

60.00

61

21740

3.19

61.00

61.00

62

20922

3.23

61.99

62.00

63

20138

3.27

62.98

63.00

64

19388

3.31

63.98

64.00

65

18670

3.35

64.97

65.00

66

17981

3.39

65.97

66.00

67

17322

3.43

66.96

67.00

68

16689

3.47

67.96

68.00

69

16083

3.50

68.96

69.00

70

15502

3.54

69.96

70.00

71

14945

3.57

70.96

71.00

72

14410

3.61

71.97

72.00

73

13897

3.64

72.97

73.00

74

13405

3.68

73.98

74.00

75

12932

3.71

74.98

75.00

76

12478

3.74

75.99

76.00

77

12043

3.77

77.00

77.00

78

11625

3.80

78.01

78.00

79

11223

3.83

79.01

79.00

80

10837

3.86

80.02

80.00

81

10466

3.89

81.03

81.00

82

10109

3.91

82.04

82.00

83

9767

3.94

83.04

83.00

84

9437

3.97

84.04

84.00

85

9121

3.99

85.04

85.00

86

8816

4.01

86.03

86.00

C-2

Page 27

Appendix C. Conversion of Thermistor Resistance or Voltage Ratio to Temperature

87

8523

4.04

87.02

87.00

88

8241

4.06

88.01

88.00

89

7970

4.08

88.99

89.00

90

7708

4.11

89.97

90.00

91

7457

4.13

90.94

91.00

92

7215

4.15

91.90

92.00

93

6982

4.17

92.86

93.00

94

6758

4.19

93.80

94.00

95

6541

4.21

94.75

95.00

96

6333

4.23

95.68

96.00

97

6132

4.24

96.60

97.00

98

5939

4.26

97.52

98.00

99

5753

4.28

98.42

99.00

100

5573

4.29

99.32

100.00

1

Data from Measurement SpecialtiesTM

C-3

Page 28

Appendix C. Conversion of Thermistor Resistance or Voltage Ratio to Temperature

C-4

Page 29

Page 30

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific (Beijing) Co., Ltd.

8B16, Floor 8 Tower B, Hanwei Plaza

7 Guanghua Road

Chaoyang, Beijing 100004

P.R. CHINA

www.campbellsci.com • info@campbellsci.com.cn

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

14532 – 131 Avenue NW

Edmonton AB T5L 4X4

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Loading...

Loading...