Page 1

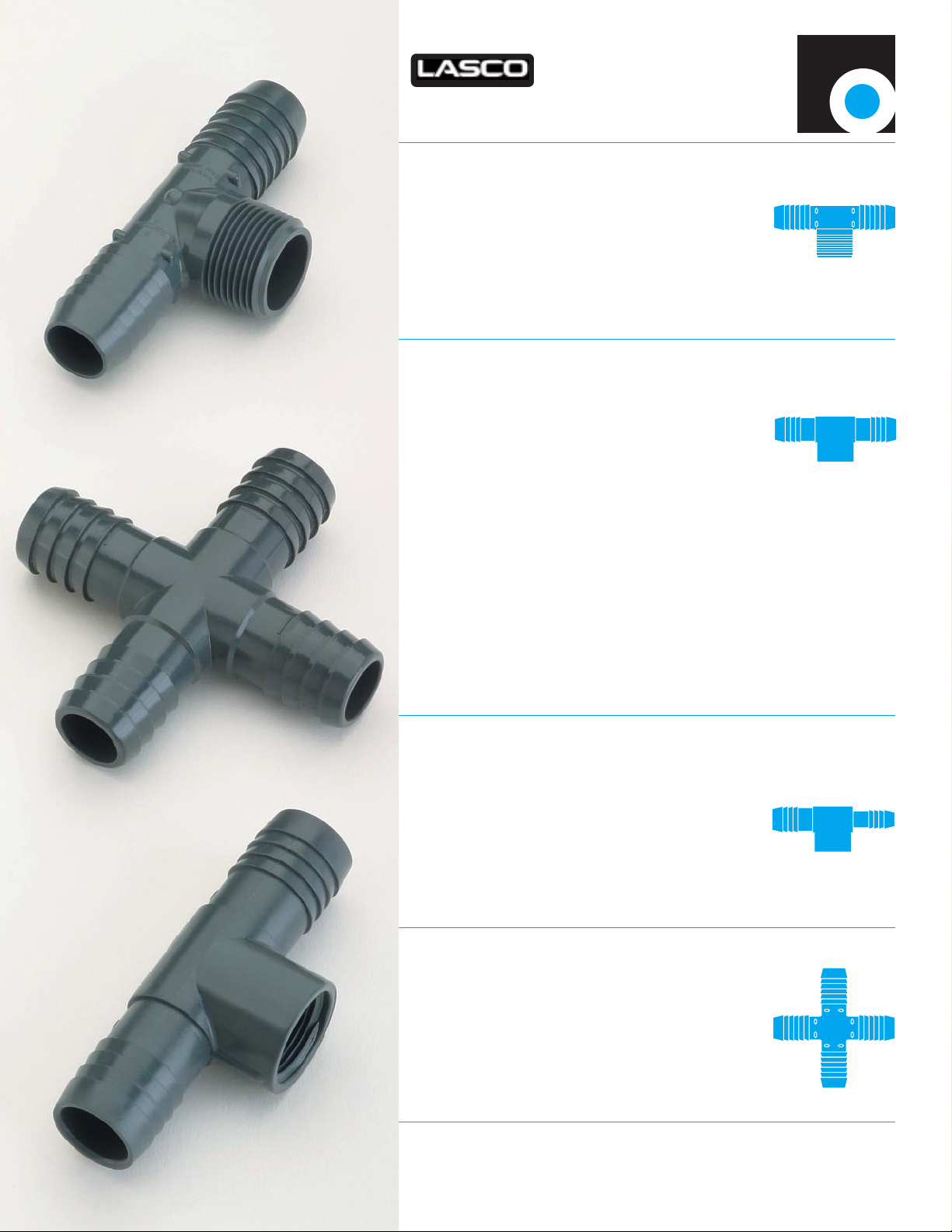

Metal Insert Fittings

Plastic Insert Fittings

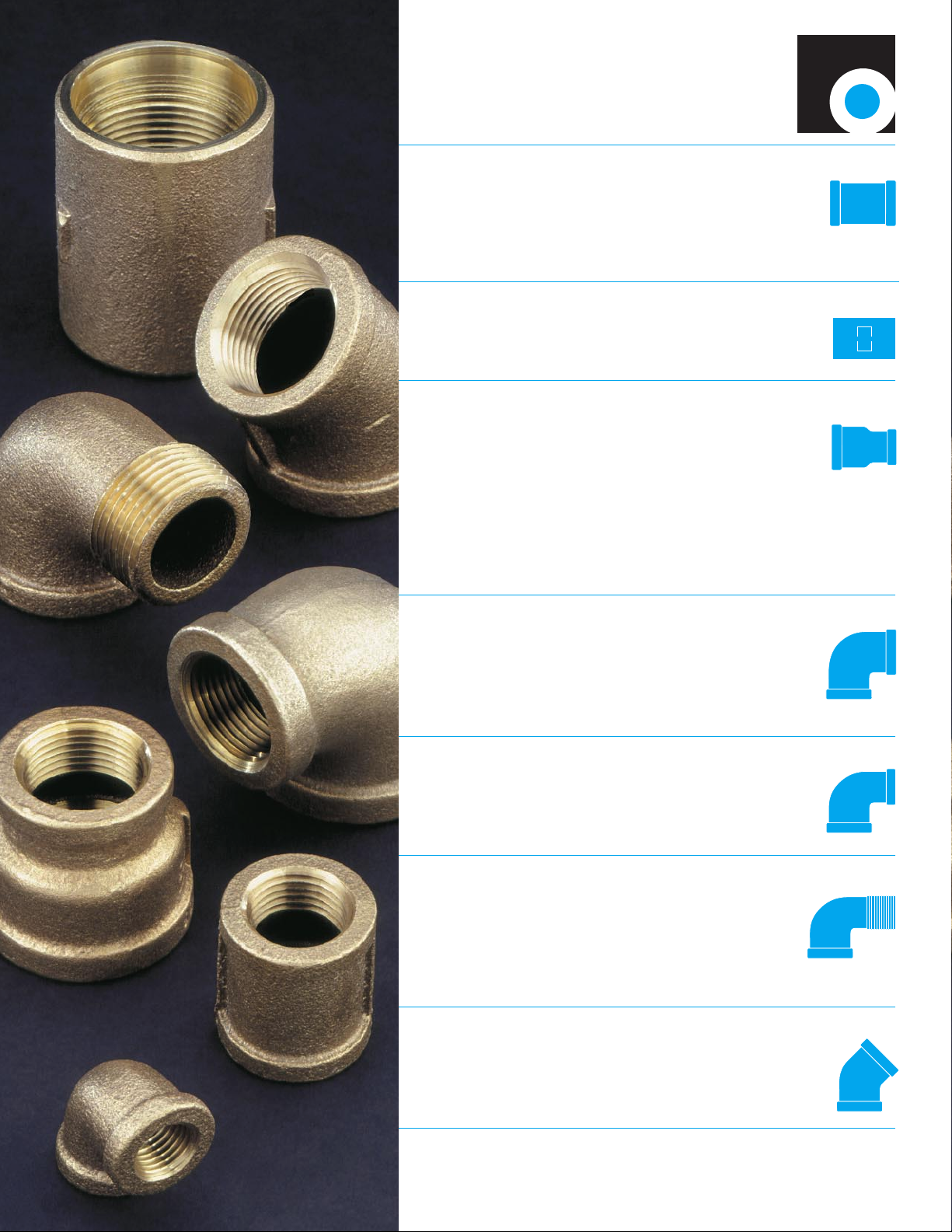

Metal Threaded Fittings

Nipples

Schedule 40 Fittings

Compression Fittings

Check & Foot Valves

Plumbing Valves

Miscellaneous Valves

Frostproof

Hydrants & Faucets

Well Seals

Well Caps

Pitless Adapters

Sewage Pump

Disconnects

Tank Tees &

Tank Fittings Packages

Driven Well Equipment

Ideal Clamps

Installation Accessories

Electrical Accessories

Filtration & Treatment

Monoflex

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

Phone 800-523-0224

Fax 610-369-3580

Email moreinfo@campbellmfg.com

Website www.campbellmfg.com

Page 2

Warranty, Terms & Conditions of Sale

Warranty

Campbell Manufacturing, Inc.’s (Campbell) warranty obligation is

limited to repairing or replacing (at Campbell’s cost) non-conforming

goods. The warranty period for Campbell’s products commences on

the date of purchase. Repair shall occur during Campbell’s normal

business hours during the warranty period. Examination and repair or

replacement of such Products will be effected on location or at

Campbell’s facilities, at Campbell’s option. Products to be examined,

replaced, or repaired at Campbell’s facilities must be returned to

Campbell by Purchaser within the warranty period, transportation

charges prepaid. If examined Products are found not to be defective

or are not for some other reason within the warranty coverage,

Campbell’s service time expended on and off location will be charged

to Purchaser.

Warranty Limitation and Exclusion

Purchaser agrees to use, maintain, and install Product in accordance

with recommendations and instructions of Campbell. Campbell will

have no warranty obligation under this agreement if the Product is

subjected to abuse, misuse, negligence, or accident. This warranty

does not cover or apply to any products or material supplied by, but

not manufactured by, Campbell and is limited to the actual warranty

extended to Campbell by its supplier.

Disclaimer of Warranties

The warranty printed above is the only warranty applicable to this

purchase. All other warranties, express or implied, including, but not

limited to, the implied warranties of merchantability and fitness for

a particular purpose are disclaimed and excluded. There are no

warranties which extend beyond the description on the face hereof.

These warranties are exclusive and substituted for all others, express

or implied, arising by law or otherwise. Under no circumstances shall

seller be liable for special, indirect, or consequential damages as

described in §2-715 of the uniform commercial code. The price

stated for the equipment is a consideration in limiting seller’s liability.

No action, whether in contract or tort, arising out of the transactions

under this agreement may be brought by Purchaser more than one

year after the cause of action accrued.

Limitation Liability

It is understood and agreed that Campbell’s liability and the remedy

of Purchaser or other third party whether in contract, in tort, whether

caused by Product failure or failure of Campbell to perform, under any

warranty, in negligence or otherwise, arising from sale or use of said

Product, shall be limited to and not exceed the return of the amount

of the purchase price paid by Purchaser.

Complaints

Complaints concerning defective goods or errors should be made

immediately in writing to Campbell Manufacturing, Inc., Bechtelsville,

PA.

Product Changes

The right is reserved to make changes in pattern, design, or materials

when deemed necessary, without prior notice. Products which have

become obsolete by reason of design change or discontinued as a

manufactured item may not be returned for credit.

Returned Goods

Materials must not be returned unless consent has first been obtained

in writing from Campbell. Returns of saleable goods subject to 25%

restocking charge.

Risk of Loss/Damage

All goods are at the risk of the Purchaser after they have been delivered

by us to the carrier and receipt obtained for same (in good order).

Orders

Orders are subject to acceptance at Campbell.

Responsibility

We will not be responsible for delays resulting from strikes, accidents,

failure of suppliers, negligence of carriers, or other causes beyond our

control.

Ordering Information

When ordering material, please use trade number, size, and other

definitive information necessary.

Standard Package Quantities

Order by standard packaged quantities shown in catalog. When

quantity is not shown, item is individually packaged or in bulk.

Special Products

Products made to customer’s specifications are not refundable

and requests for cancellation of orders will not be considered if the

manufacture of materials is in process when the request reaches

the home office.

Errors, Shortages, Etc.

Claims for errors, shortages, etc., must be made on receipt of goods,

otherwise no allowance will be made.

Prices and Quotations

All prices and quotations are subject to change without notice.

Items not listed in this catalog will be quoted on application. Prices

and quotations in Campbell product catalog do not constitute offers.

A request to purchase is to be construed as an offer and Campbell

retains all authority to accept or reject offers.

Taxes

Any tax that may be imposed by law on the sale of articles made or

sold by this company shall be added to the sale price of such articles.

Export

Handling, packaging, and documentation charges will be added to

invoice on export shipments, when applicable.

Minimum Charge

$15.00 per order.

Interest

Interest at 18% per annum will be charged on invoice not paid upon

maturity. No discount allowed after due date.

Freight

All prices F.O.B. factory. Freight on domestic orders within the 48

continental United States will be prepaid and allowed on $1000 net

orders east of the Mississippi River and $1250 net orders west of the

Mississippi River. Shipments to Canada will be prepaid on $3000 net

orders. Other shipments outside the 48 continental United States will be

prepaid and allowed to the closest inland point of exportation based on

the above net order minimums.

Te rm s

2% 15 days net 30.

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

Phone 800-523-0224

Fax 610-369-3580

Email moreinfo@campbellmfg.com

Website www.campbellmfg.com

5/05

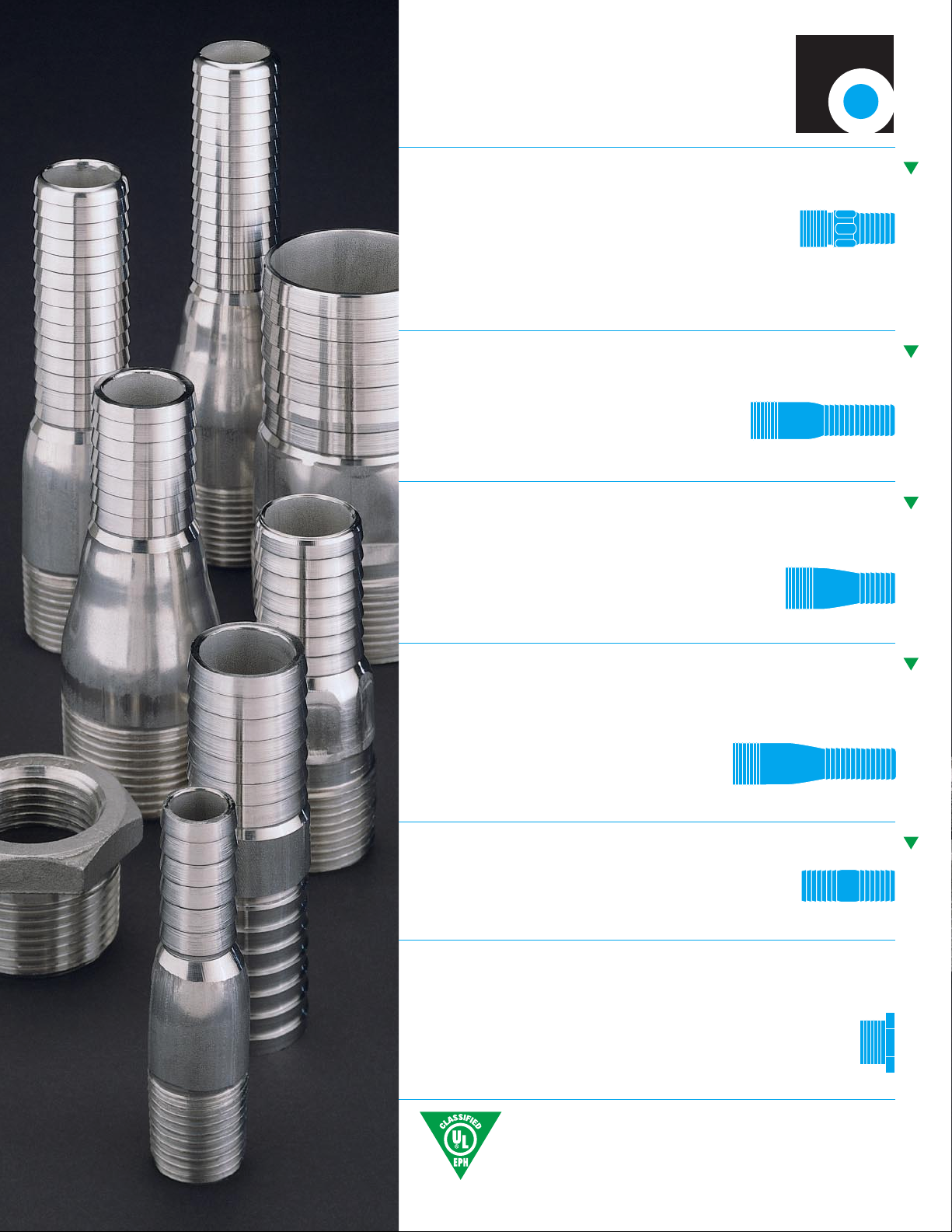

Page 3

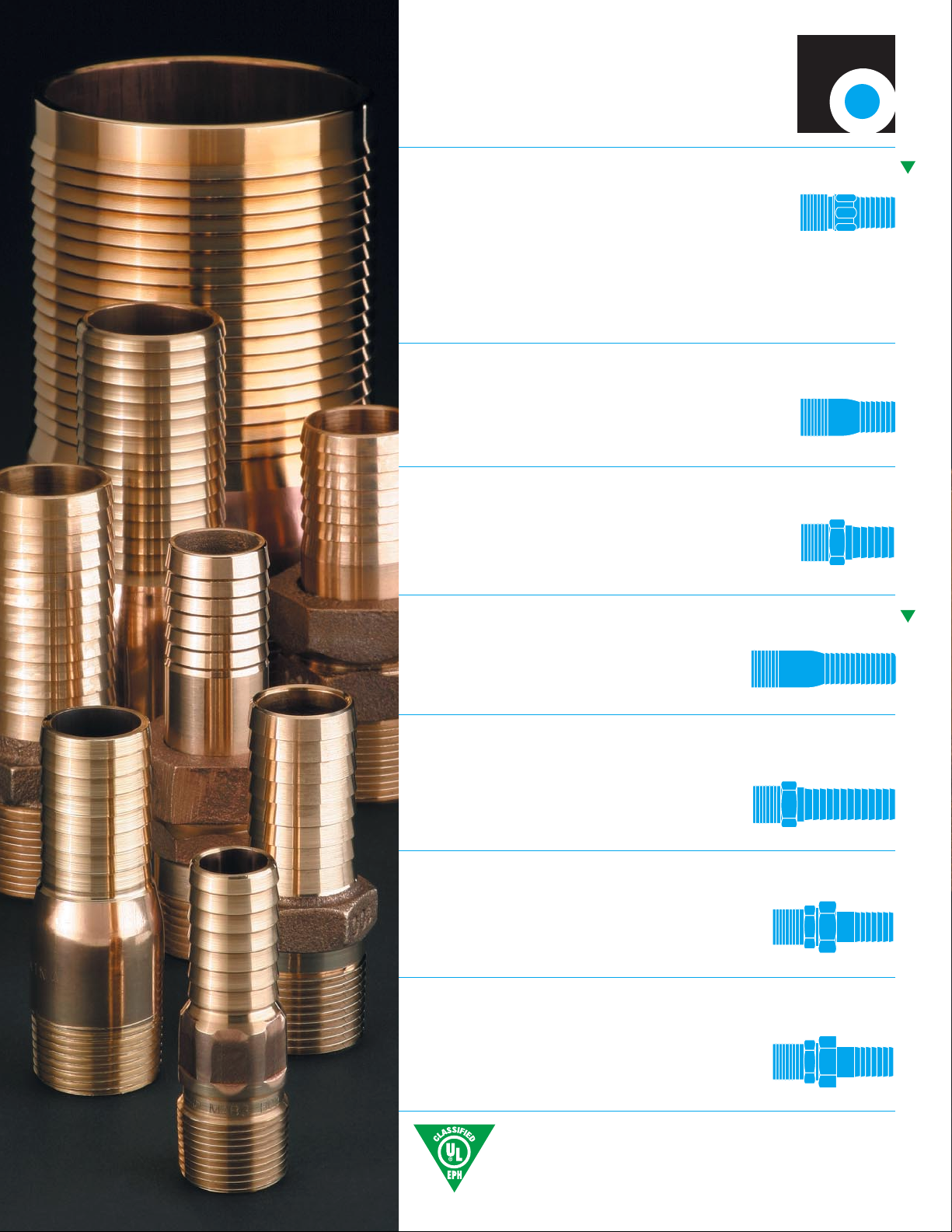

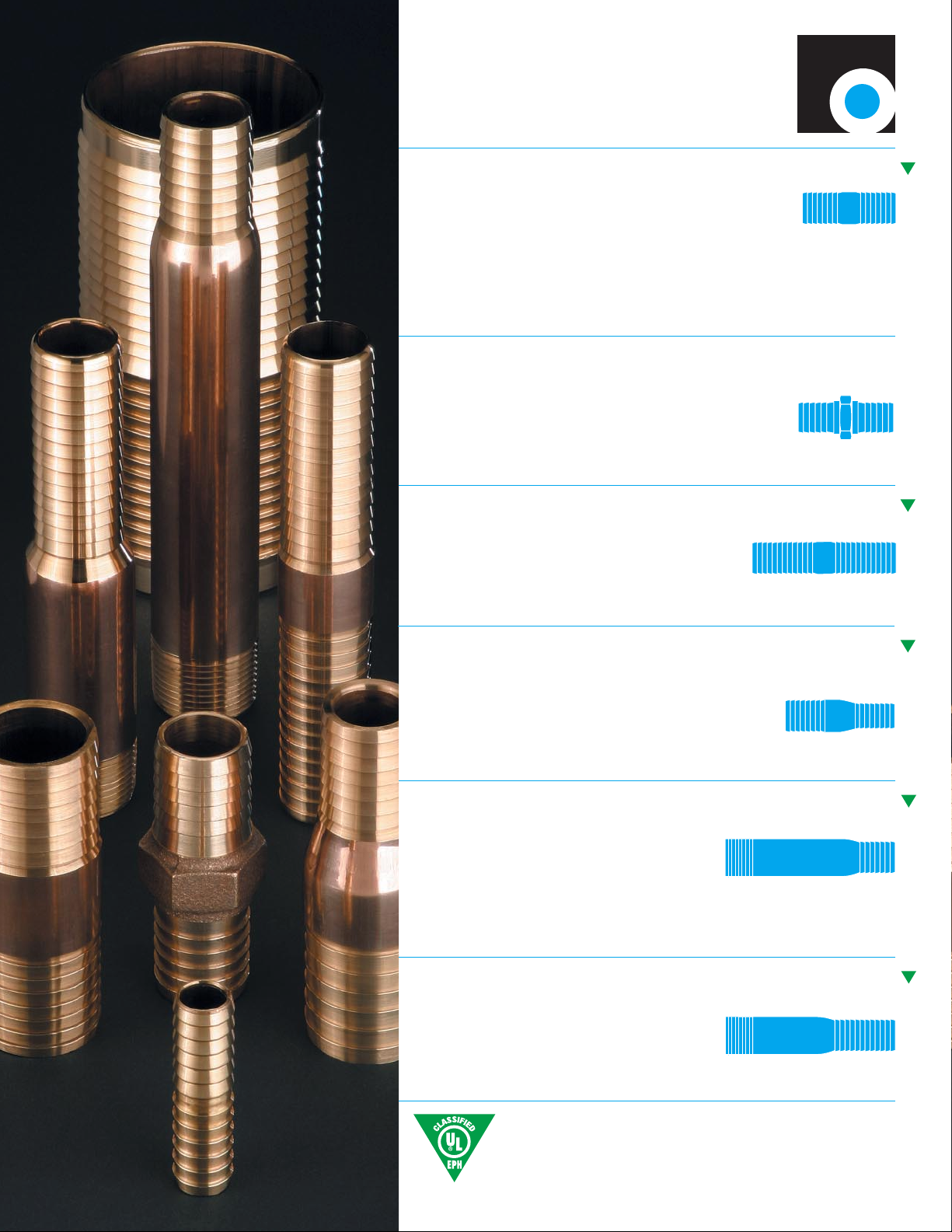

ANSI/NSF Standard 61

Drinking Water System Components.

Red brass insert fittings are machined from

85% copper alloy seamless brass pipe

with .05% lead, except cast fittings which are

machined from 81% copper alloy brass castings.

Red Brass Insert Fittings

Campbell

A1

part size pcs/ctn master ctn MALE ADAPTER

MAB 2* 1/2 25 300

MAB 3 3/4 25 200

MAB 4 1 20 160

MAB 5 1-1/4 20 120

MAB 6 1-1/2 10 60

MAB 8 2 10 40

MAB 10* 2-1/2 Bulk –

MAB 12* 3 Bulk –

MAB 16* 4 Bulk –

*Without Wrench-Grip Shoulder

MAB 4TS 1 10 100 MALE ADAPTER

(imported)

XB4 1 25 – EXTRA LONG

XB5 1-1/4 Bulk – MALE ADAPTER

XB6 1-1/2 Bulk –

XB4T 1 10 100 EXTRA LONG

XB5T 1-1/4 10 100 MALE ADAPTER

(cast, imported)

MAB 2T 1/2 10 200 MALE ADAPTER

MAB 3T 3/4 10 100 (cast, imported)

MAB 4T 1 10 100

MAB 5T 1-1/4 10 100

MAB 6T 1-1/2 5 80

MAB 8T 2 5 40

UAB 4 1 1 – UNION ADAPTER

(cast)

UAB 4T 1 10 80 UNION ADAPTER

UAB 5T 1-1/4 10 40 (cast, imported)

MAB 16

XB 6

UAB 5T

UAB 4T

MAB 4TS

MAB 3

XB5T

UAB 4

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224

Fax 610-369-3580

Page 4

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224

Fax 610-369-3580

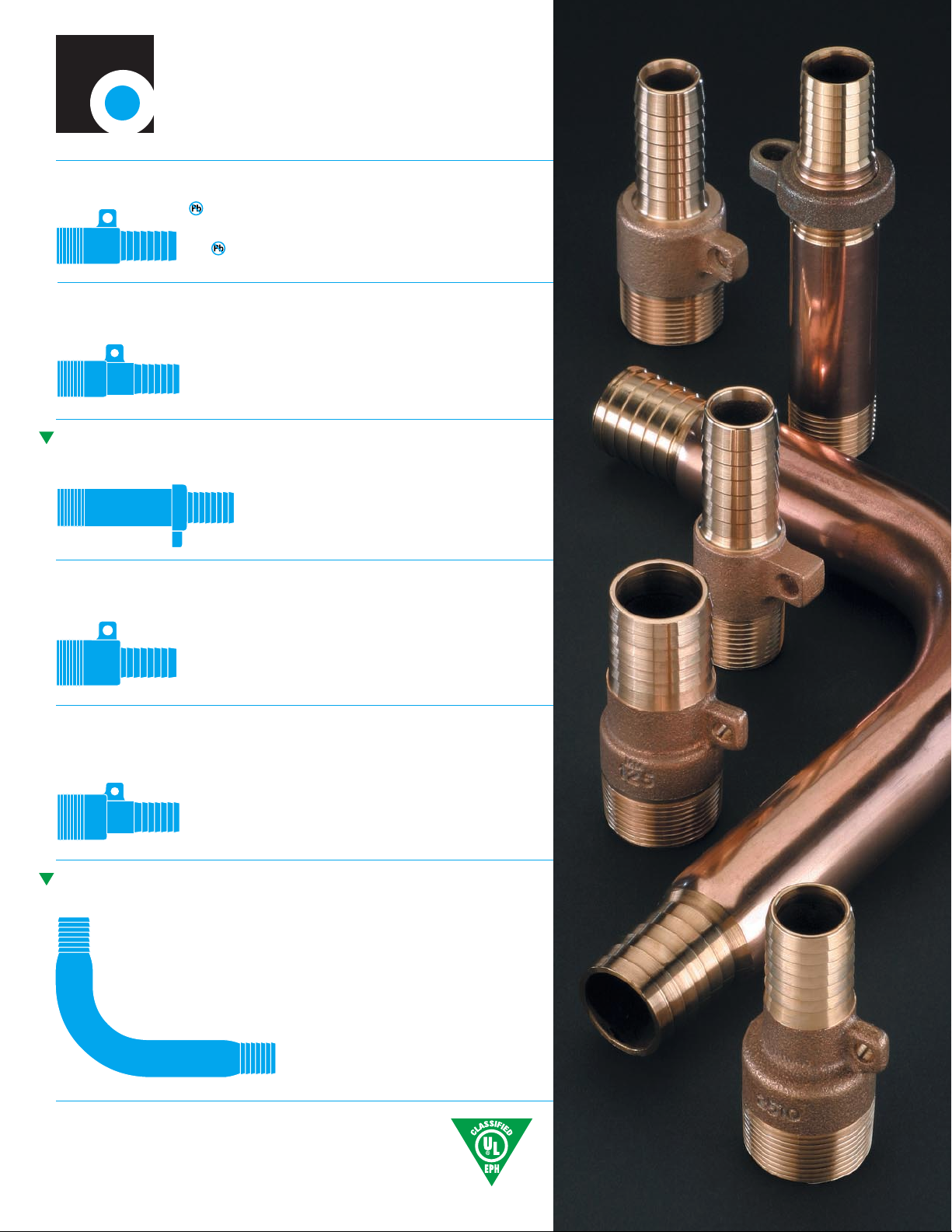

ANSI/NSF Standard 61

Drinking Water System Components.

Red brass insert fittings are machined

from 85% copper alloy seamless brass

pipe with .05% lead, except cast fittings which are

machined from 81% copper alloy brass castings.

Red Brass Insert Fittings

Campbell

A2

REDUCING part size pcs/ctn master ctn

ADAPTER RAB3-2 3/4 x 1/2 Bulk –

(mpt x insert) RAB4-3 1 x 3/4 Bulk –

RAB5-4 1-1/4 x 1 Bulk –

RAB6-5 1-1/2 x 1-1/4 Bulk –

RAB8-6 2 x 1-1/2 Bulk –

REDUCING RAB4-3T 1 x 3/4 10 100

ADAPTER RAB5-4T 1-1/4 x 1 10 100

(mpt x insert,

cast, imported)

REDUCING SAB3-2 3/4 x 1/2 Bulk –

ADAPTER SAB4-3 1 x 3/4 Bulk –

(insert x mpt) SAB5-4 1-1/4 x 1 Bulk –

SAB6-5 1-1/2 x 1-1/4 Bulk –

REDUCING SAB4-3T 1 x 3/4 10 100

ADAPTER SAB5-4T 1-1/4 x 1 10 100

(insert x mpt

cast, imported)

FEMALE ADAPTER FAB 2 1/2 25 –

FAB 3 3/4 25 –

FAB 4 1 20 –

FAB 5 1-1/4 20 –

FAB 6 1-1/2 10 –

FAB 8 2 10 –

FEMALE ADAPTER FAB 3T 3/4 25 100

(cast, imported) FAB 4T 1 20 100

FAB 5T 1-1/4 20 100

FAB 6

MAB 16

RAB5-4

SAB4-3T

FAB 4T

RAB3-2

SAB6-5

RAB 4-3T

Page 5

Red Brass Insert Fittings

Campbell

A3

CB 12

XVB4-6

VMAB4X8

CB 4T

CB 2

CB 2T 1/2 25 200 COUPLING

CB 3T 3/4 25 100 (cast, imported)

CB 4T 1 20 100

CB 5T 1-1/4 20 100

CB 6T 1-1/2 20 100

CB 8T 2 10 50

part size pcs/ctn master ctn COUPLING

CB 2 1/2 25 300

CB 3 3/4 25 300

CB 4 1 20 160

CB 5 1-1/4 20 120

CB 6 1-1/2 10 60

CB 8 2 10 40

CB 10 2-1/2 Bulk –

CB 12 3 Bulk –

CB 16 4 Bulk –

XCB4 1 Bulk – EXTRA LONG

XCB5 1-1/4 Bulk – COUPLING

RCB3-2 3/4 x 1/2 Bulk – REDUCING

RCB4-3 1 x 3/4 Bulk – COUPLING

RCB5-4 1-1/4 x 1 Bulk – (insert x insert)

RCB6-5 1-1/2 x 1-1/4 Bulk –

VMAB4X6 1 x 6 Bulk – VENTURI

VMAB4X8 1 x 8 Bulk – MALE ADAPTER

VMAB4X10 1 x 10 Bulk –

VMAB4X12 1 x 12 Bulk –

VMAB5X6 1-1/4 x 6 Bulk –

VMAB5X8 1-1/4 x 8 Bulk –

VMAB5X10 1-1/4 x 10 Bulk –

VMAB5X12 1-1/4 x 12 Bulk –

XVB4-6 1 x 6 Bulk – EXTRA LONG VENTURI

XVB4-8 1 x 8 Bulk – MALE ADAPTER

XVB5-6 1-1/4 x 6 Bulk –

XVB5-8 1-1/4 x 8 Bulk –

ANSI/NSF Standard 61

Drinking Water System Components.

Red brass insert fittings are machined from

85% copper alloy seamless brass pipe

with .05% lead, except cast fittings which are

machined from 81% copper alloy brass castings.

XCB4

CB 5

RCB5-4

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224

Fax 610-369-3580

Page 6

ANSI/NSF Standard 61

Drinking Water System Components.

Red brass insert fittings are machined from

85% copper alloy seamless brass pipe

with .05% lead, except cast fittings which are

machined from 81% copper alloy brass castings.

Red Brass Insert Fittings

Campbell

A4

ROPE ADAPTER part size pcs/ctn master ctn

(mpt x insert, cast) BRA4 1 10 –

BRA4LF 1 10 –

VENTURI ZAB4 1 Bulk –

ROPE ADAPTER ZAB5 1-1/4 Bulk –

(mpt x insert)

ROPE ADAPTER BRA4T* 1 10 100

(mpt x insert, BRA5T* 1-1/4 10 100

cast, imported)

REDUCING BRA5-4 1-1/4 x 1 10 –

ROPE ADAPTER

(mpt x insert, cast)

REDUCING BRA5-4T 1-1/4 x 1 10 100

ROPE ADAPTER

(mpt x insert,

cast, imported)

WELL SEAL ELBOW WLB4A 1 Bulk –

(insert x insert) WLB5A 1-1/4 Bulk –

Machined from lead-free alloys.

BRA5-4

ZAB4

BRA4

BRA5T

WLB5A

BRA5-4T

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224

Fax 610-369-3580

Page 7

Red Brass Insert Fittings

Campbell

A5

part size pcs/ctn master ctn ELBOW

LB3T 3/4 10 200 (insert x insert,

LB4T 1 10 100 cast, imported)

LB5T 1-1/4 10 50

FEB4T 1 8 80 COMBO ELBOW

(fpt x insert,

cast, imported)

HE-3 3/4 10 – HYDRANT ELBOW

(mpt x insert,

cast)

HE-3T 3/4 12 72 HYDRANT ELBOW

HE-4T 1 10 100 (mpt x insert,

HE4-3T 1 x 3/4 12 72 cast, imported)

HE-4XL 1 5 80 EXTRA LONG

HYDRANT ELBOW

(mpt x insert,

cast)

TB3T 3/4 10 100 TEE

TB4T 1 10 100 (insert x insert x insert,

TB5T 1-1/4 5 50 cast)

HT-4T 1 10 100 HYDRANT TEE

HT4-3T 1 x 3/4 10 100 (mpt x insert x insert,

cast)

TB4T

LB3T

HE-3

HE-3T

HT4-3T

FEB4T

HE-4XL

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Cast fittings are machined from

81% copper alloy brass castings.

Page 8

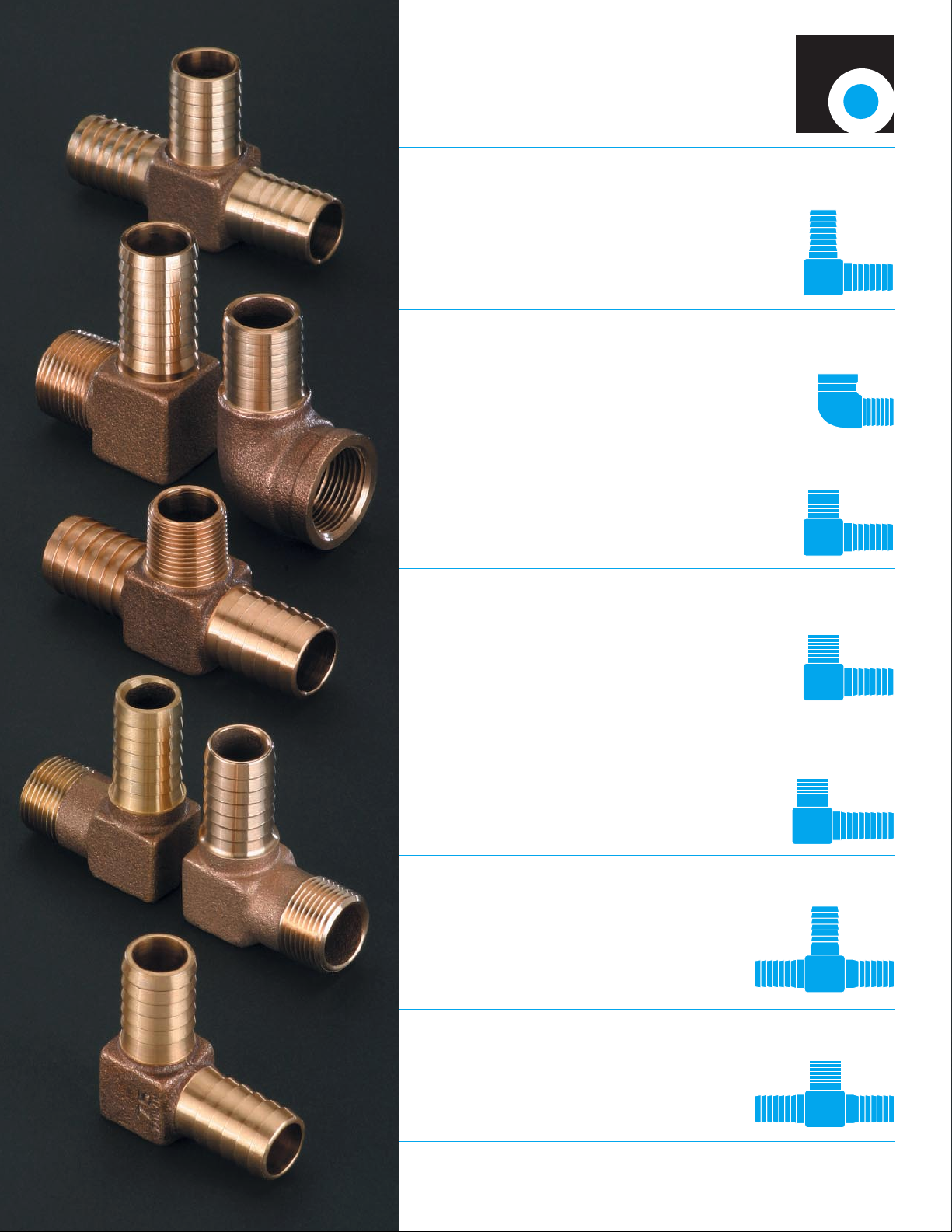

Yellow Brass Insert Fittings

Campbell

A6

MALE part size pcs/ctn

SOLDER ADAPTER YBS2 1/2 10

(insert x solder) YBS3 3/4 10

YBS4* 1 10

YBS5 1-1/4 10

YBS6 1-1/2 5

YBS8** 2 5

*YBS4 can be used as 1” male or 3/4” female sweat fitting.

**YBS8 is machined from 99.9% copper water pipe.

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Unless noted otherwise, yellow brass

insert fittings are machined from 63%

copper alloy free-cutting brass rod.

FEMALE YBS3F 3/4 10

SOLDER ADAPTER

(insert x solder)

MALE ADAPTER YBM2 1/2 10

(insert x mpt) YBM3 3/4 10

YBM4 1 10

YBM4-3 1 x 3/4 10

YBM5 1-1/4 10

YBM5-4 1-1/4 x 1 10

YBM6 1-1/2 5

YBM8*** 2 5

***YBM8 is machined from 81% copper alloy brass castings.

EXTRA LONG YBMX4 1 10

MALE ADAPTER

(insert x mpt)

FEMALE ADAPTER YBF2 1/2 10

(insert x fpt) YBF3 3/4 10

YBF4 1 10

YBF5 1-1/4 10

COUPLING YBC2 1/2 10

(insert x insert) YBC3 3/4 10

YBC4 1 10

YBC5 1-1/4 10

YBC6 1-1/2 5

YBC8** 2 5

**YBC8 is machined from 99.9% copper water pipe.

YBMX4

YBS3F

YBF3

YBS5

YBM5-4

YBC6

YBM2

Page 9

part size pcs/ctn ELBOW

YBL3 3/4 10 (insert x insert, cast)

YBL4 1 10

YBL5 1-1/4 10

YBL6* 1-1/2 1

YBL3LF 3/4 10

YBL4LF 1 10

YBL5LF 1-1/4 10

* Fabricated from a wrought copper fitting with lead-free solder.

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Yellow brass insert fittings are machined

from 81% copper alloy brass castings.

Yellow Brass Insert Fittings

Campbell

A7

Machined from lead-free alloys.

YBFC3** 3/4 10 FEMALE COMBO

YBFC4 1 10 ELBOW

YBFC5** 1-1/4 10 (insert x fpt, cast)

YBFC4LF 1 10

YBT3 3/4 10 TEE

YBT4 1 10 (insert x insert x insert, cast)

YBT4-3 1 x 1 x 3/4 10

YBT5 1-1/4 10

YBT5-4** 1-1/4 x 1-1/4 x 1 5

YBT6** 1-1/2 1

YBT3LF 3/4 10

YBT4LF 1 10

** Fabricated fittings with lead-free solder.

YBMC3 3/4 10 MALE COMBO

YBMC4 1 10 ELBOW

YBMC4-3 1 x 3/4 10 (insert x mpt, cast)

YBMC5** 1-1/4 10

YBMC6** 1-1/2 1

YBTF3** 3/4 10 FEMALE COMBO TEE

YBTF4** 1 10 (insert x insert x fpt, cast)

YBTF4-3** 1 x 1 x 3/4 10

YBTF5** 1-1/4 5

YBMC4

YBL6

YBTF3

YBL4

YBFC4

YBT4

Page 10

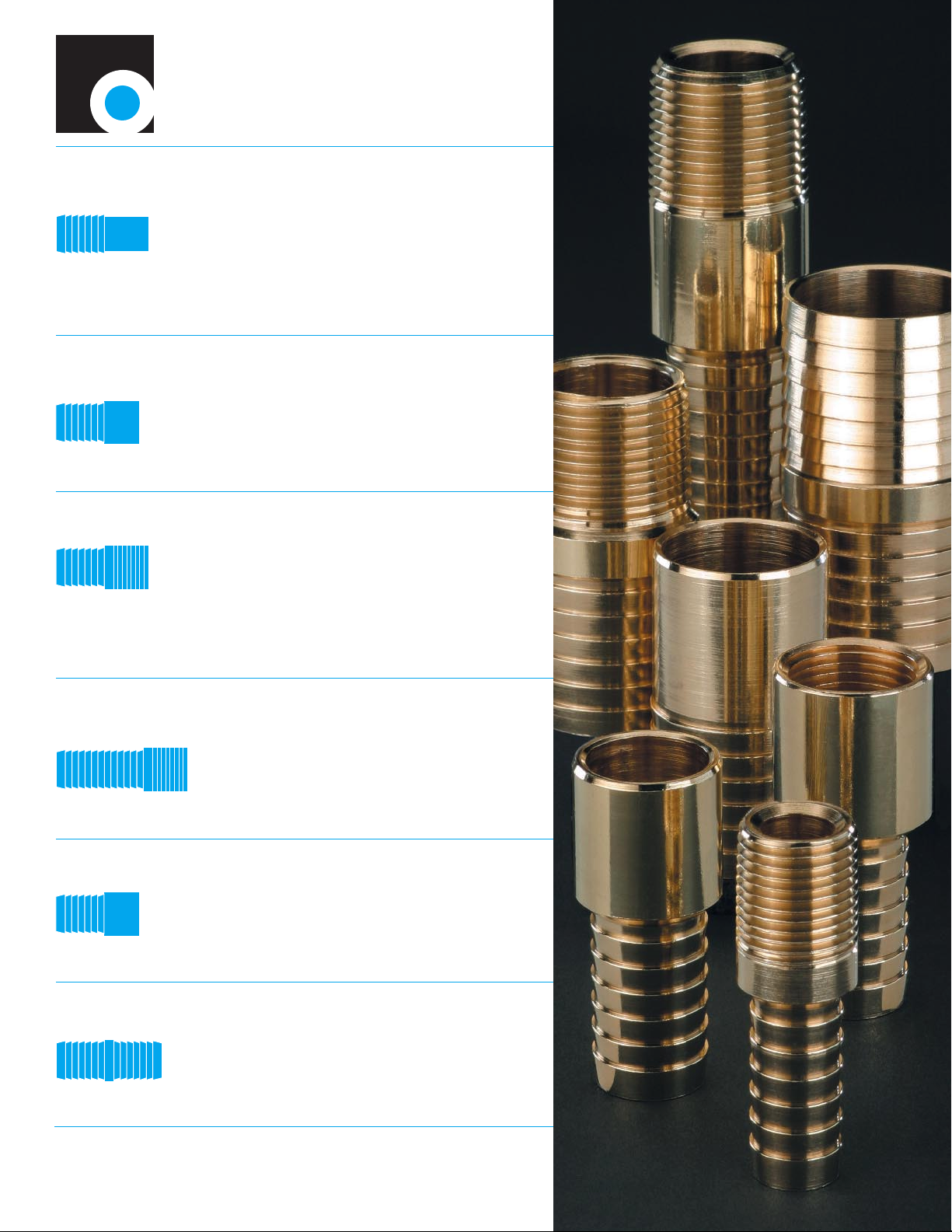

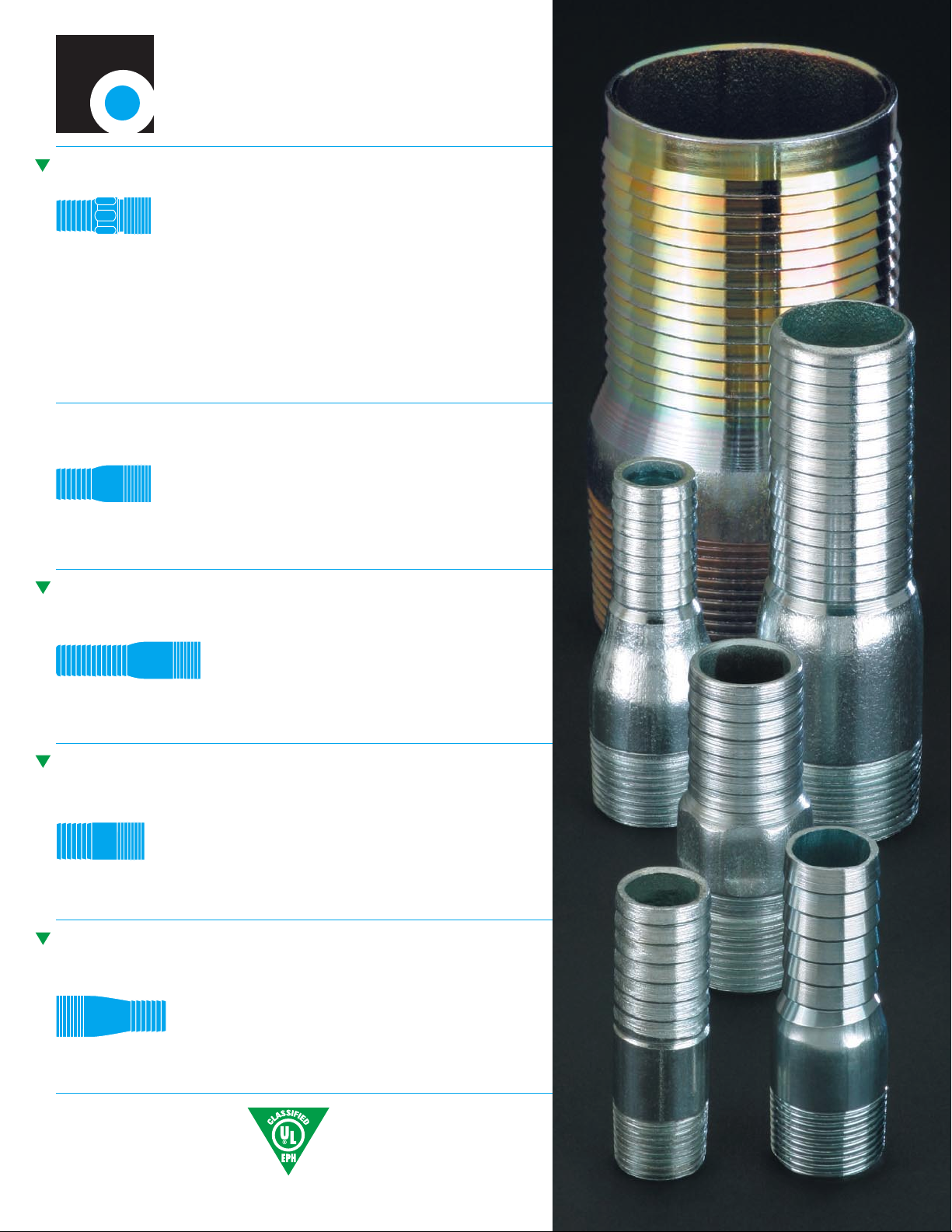

Steel Insert Fittings

Campbell

A8

MALE ADAPTER part size pcs/ctn master ctn

MAS 2* 1/2 25 300

MAS 3 3/4 25 200

MAS 4 1 20 160

MAS 5 1-1/4 20 120

MAS 6 1-1/2 10 60

MAS 8 2 10 40

MAS 10* 2-1/2 Bulk –

MAS 12* 3 Bulk –

MAS 16* 4 Bulk –

MAS 20* 5 Bulk –

MAS 24* 6 Bulk –

*Without Wrench-Grip Shoulder

MALE ADAPTER MAS 2T 1/2 Bulk –

(imported) MAS 3T 3/4 Bulk –

MAS 4T 1 Bulk –

MAS 5T 1-1/4 Bulk –

MAS 6T 1-1/2 Bulk –

MAS 8T 2 Bulk –

EXTRA LONG XS4 1 25 –

MALE ADAPTER XS5 1-1/4 Bulk –

XS6 1-1/2 Bulk –

REDUCING SAS3-2 3/4 x 1/2 Bulk –

MALE ADAPTER SAS4-3 1 x 3/4 Bulk –

(insert x mpt) SAS5-4 1-1/4 x 1 Bulk –

SAS6-5 1-1/2 x 1-1/4 Bulk –

REDUCING RAS3-2 3/4 x 1/2 Bulk –

MALE ADAPTER RAS4-3 1 x 3/4 Bulk –

(mpt x insert) RAS5-4 1-1/4 x 1 Bulk –

RAS6-5 1-1/2 x 1-1/4 Bulk –

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

ANSI/NSF Standard 61

Drinking Water System Components

All steel insert fittings are machined from

C.W. steel pipe and are clear zinc plated,

except sizes 2-1/2” or larger which are

plated with yellow chromate.

MAS 12

XS5

MAS 3T

MAS 4

RAS4-3

SAS3-2

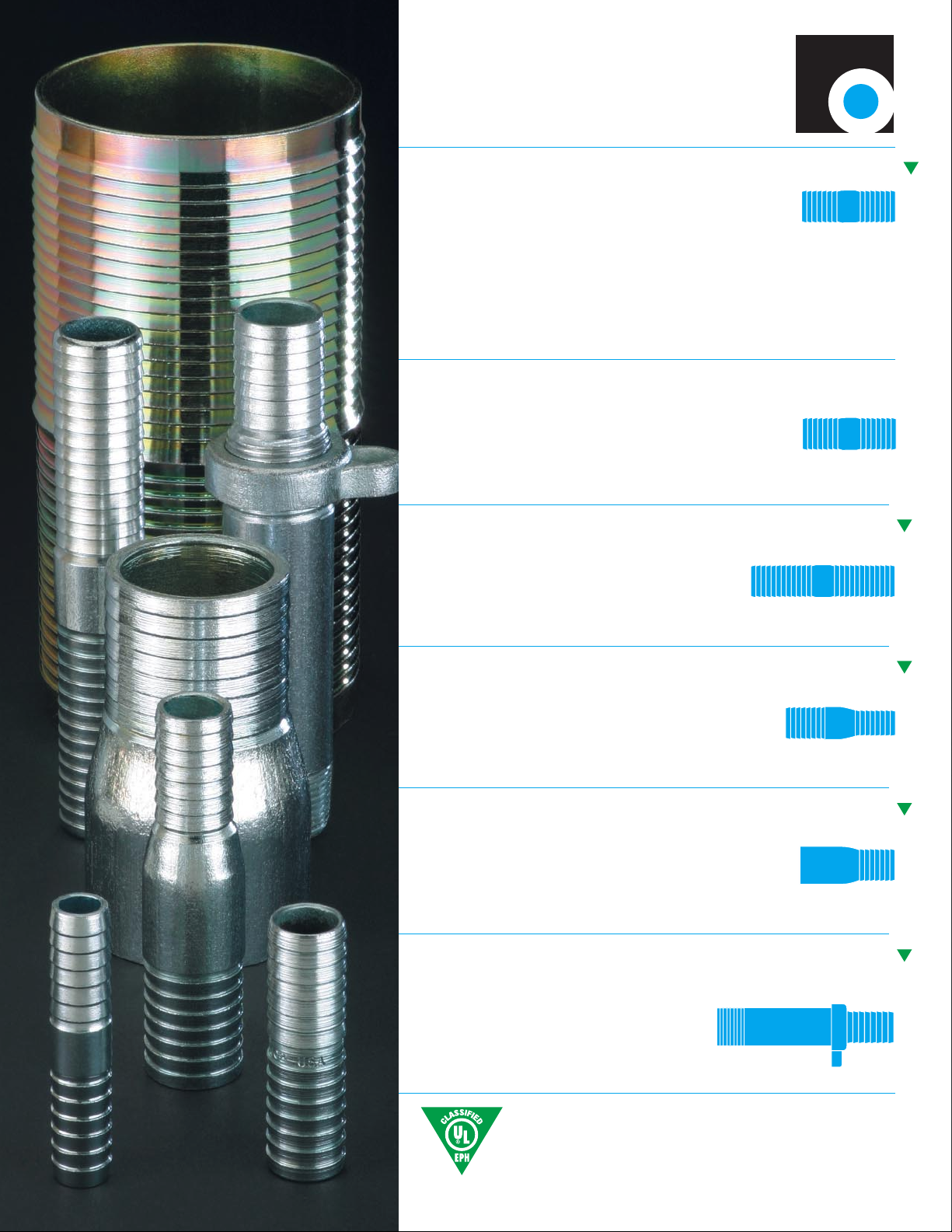

Page 11

Steel Insert Fittings

Campbell

A9

part size pcs/ctn master ctn COUPLING

CS 2 1/2 25 300

CS 3 3/4 25 300

CS 4 1 20 160

CS 5 1-1/4 20 120

CS 6 1-1/2 10 60

CS 8 2 10 40

CS 10 2-1/2 Bulk –

CS 12 3 Bulk –

CS 16 4 Bulk –

CS 20 5 Bulk –

CS 24 6 Bulk –

CS 2T 1/2 Bulk – COUPLING

CS 3T 3/4 Bulk – (imported)

CS 4T 1 Bulk –

CS 5T 1-1/4 Bulk –

CS 6T 1-1/2 Bulk –

CS 8T 2 Bulk –

XCS4 1 Bulk – EXTRA LONG

XCS5 1-1/4 Bulk – COUPLING

RCS3-2 3/4 x 1/2 Bulk – REDUCING

RCS4-3 1 x 3/4 Bulk – COUPLING

RCS5-4 1-1/4 x 1 Bulk –

FAS2 1/2 25 – FEMALE

FAS3 3/4 25 – ADAPTER

FAS4 1 20 –

FAS5 1-1/4 20 –

FAS6 1-1/2 10 –

FAS8 2 10 –

ZAS4 1 Bulk – VENTURI

ZAS5 1-1/4 Bulk – ROPE ADAPTER

– (mpt x insert)

CS 16

CS 2T

RCS4-3

FAS8

ZAS4

CS 3

XCS4

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224

Fax 610-369-3580

ANSI/NSF Standard 61

Drinking Water System Components

All steel insert fittings are machined from

C.W. steel pipe and are clear zinc plated,

except sizes 2-1/2” or larger which are

plated with yellow chromate.

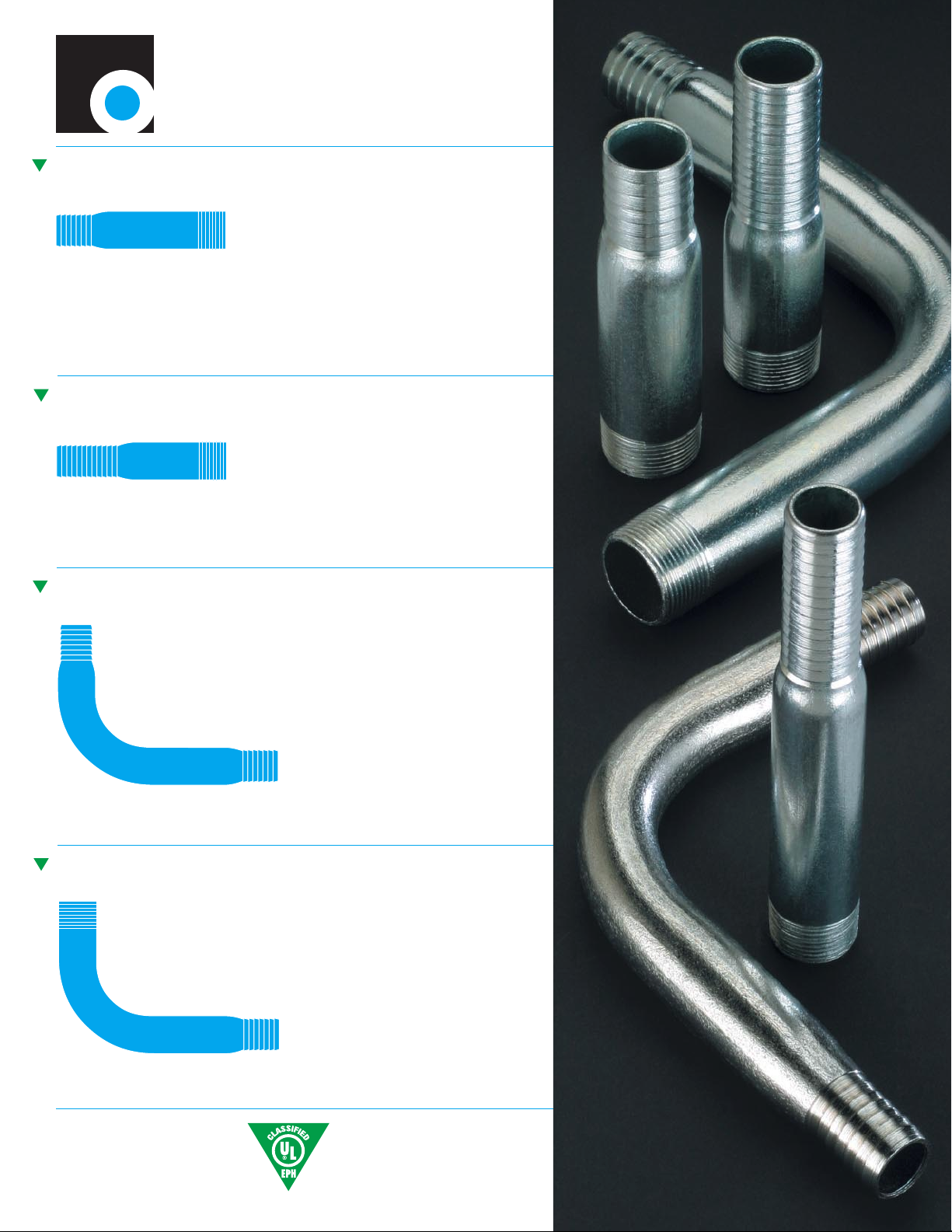

Page 12

WELL SEAL ELBOW WLS3A 3/4 Bulk

(insert x insert) WLS4A 1 Bulk

WLS5A 1-1/4 Bulk

WLS6A 1-1/2 Bulk

Steel Fittings

Campbell

A10

VENTURI part size pcs/ctn

MALE ADAPTER VMAS3X12 3/4 x 12 Bulk

VMAS4X6 1 x 6 Bulk

VMAS4X8 1 x 8 Bulk

VMAS4X10 1 x 10 Bulk

VMAS4X12 1 x 12 Bulk

VMAS5X6 1-1/4 x 6 Bulk

VMAS5X8 1-1/4 x 8 Bulk

VMAS5X10 1-1/4 x 10 Bulk

VMAS5X12 1-1/4 x 10 Bulk

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

ANSI/NSF Standard 61

Drinking Water System Components

Steel insert fittings are machined from

C.W. steel pipe and are zinc plated.

EXTRA LONG VENTURI XVS4-6 1 x 6 Bulk

MALE ADAPTER XVS4-8 1 x 8 Bulk

XVS5-6 1-1/4 x 6 Bulk

XVS5-8 1-1/4 x 8 Bulk

WELL SEAL ELBOW WLS4B 1 Bulk

(mpt x insert) WLS5B 1-1/4 Bulk

WLS4A

WLS5B

VMAS5X6

XVS4-8

XVS5-6

Page 13

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224

Fax 610-369-3580

Stainless Steel Fittings

Campbell

A11

part size pcs/ctn master ctn MALE

MASS 2 1/2 25 — ADAPTER

MASS 3* 3/4 25 —

MASS 4* 1 20 —

MASS 5* 1-1/4 20 —

MASS 6* 1-1/2 10 —

MASS 8* 2 10 —

*with Wrench-Grip Shoulder

ANSI/NSF Standard 61

Drinking Water System Components

Pipe-based insert fittings will be 304

or 316 alloy stainless steel, whichever

is available at time of shipment.

XSS5-4

CSS4

RBSS5-4F

RASS5-4

XSS-4

MASS 4

MASS 2

MASS 8

XSS-4 1 Bulk — EXTRA LONG

XSS-5 1-1/4 Bulk — MALE

ADAPTER

RASS5-4 1-1/4 x 1 Bulk — REDUCING

MALE

ADAPTER

(mpt x insert)

XSS5-4 1-1/4 x 1 Bulk — EXTRA LONG

REDUCING

MALE

ADAPTER

(mpt x insert)

CSS4 1 Bulk — COUPLING

CSS5 1-1/4 Bulk —

RBSS5-4F 1-1/4 x 1 Bulk — HEX

BUSHING

Machined from 304 alloy stainless steel casting. Imported. (mpt x fpt)

Page 14

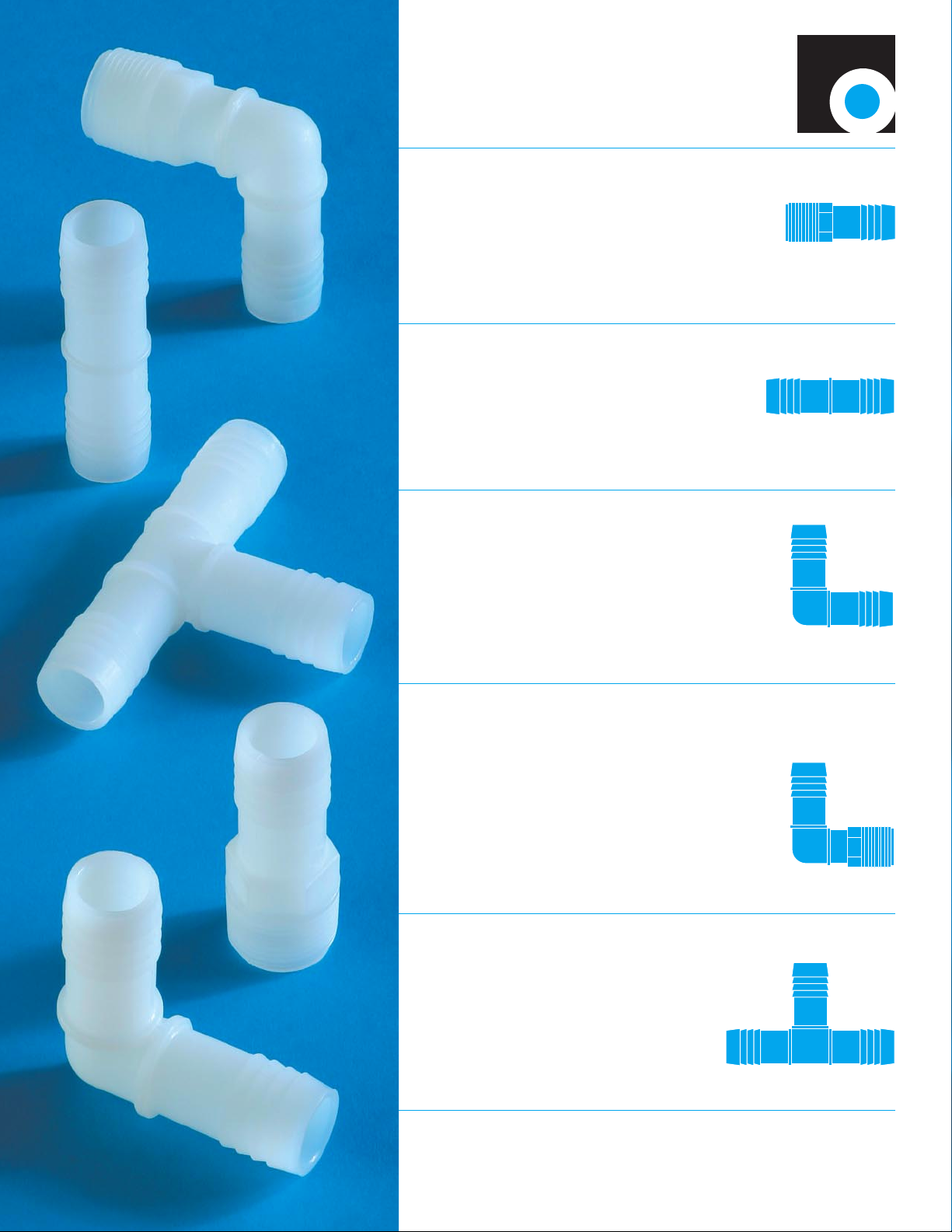

Nylon Insert Fittings

Campbell

B1

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Campbell part universal part size pcs/pkg MALE ADAPTER

MAN 2 N436-005 1/2 10

MAN 3 N436-007 3/4 10

MAN 4 N436-010 1 10

MAN 5 N436-012 1-1/4 10

MAN 6 N436-015 1-1/2 5

MAN 8 N436-020 2 5

CN 2 N429-005 1/2 10 COUPLING

CN 3 N429-007 3/4 10

CN 4 N429-010 1 10

CN 5 N429-012 1-1/4 10

CN 6 N429-015 1-1/2 5

CN 8 N429-020 2 5

LN 2 N406-005 1/2 10 ELBOW

LN 3 N406-007 3/4 10

LN 4 N406-010 1 10

LN 5 N406-012 1-1/4 5

LN 6 N406-015 1-1/2 5

LN 8 N406-020 2 5

CEN 2 N413-005 1/2 10 MALE COMBO

CEN 3 N413-007 3/4 10 ELBOW

CEN 4 N413-010 1 10 (insert x mpt)

CEN 5 N413-012 1-1/4 5

CEN 6 N413-015 1-1/2 5

CEN 8 N413-020 2 5

TN 2 N401-005 1/2 10 TEE

TN 3 N401-007 3/4 10

TN 4 N401-010 1 10

TN 5 N401-012 1-1/4 5

TN 6 N401-015 1-1/2 5

TN 8 N401-020 2 5

MAN 4

LN 4

TN 4

CN 4

CEN 4

Page 15

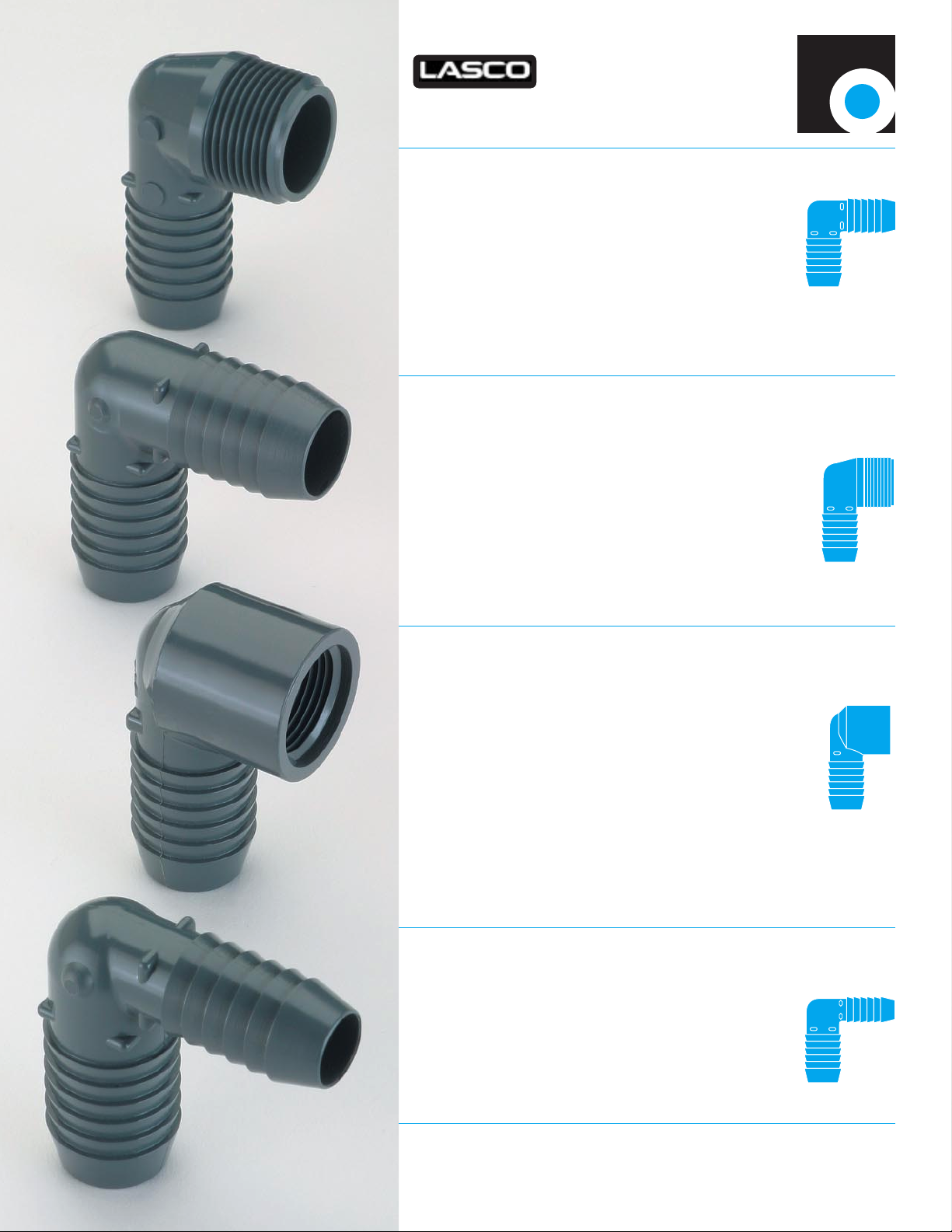

PVC Insert Fittings

Campbell

B2

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

MALE ADAPTER Campbell part universal part size pcs/ctn

MAP 2 1436-005 1/2 50

MAP 3 1436-007 3/4 50

MAP 4 1436-010 1 40

MAP 5 1436-012 1-1/4 20

MAP 6 1436-015 1-1/2 20

MAP 8 1436-020 2 10

MAP12 1436-030 3 10

MAP16 1436-040 4 8

REDUCING COUPLING RCP3-2 1429-101 3/4 x 1/2 50

(insert x insert) RCP4-2 1429-130 1 x 1/2 40

RCP4-3 1429-131 1 x 3/4 40

RCP5-3 1429-167 1-1/4 x 3/4 20

RCP5-4 1429-168 1-1/4 x 1 20

RCP6-3 1429-210 1-1/2 x 3/4 20

RCP6-4 1429-211 1-1/2 x 1 20

RCP6-5 1429-212 1-1/2 x 1-1/4 10

RCP8-4 1429-249 2 x 1 10

RCP8-5 1429-250 2 x 1-1/4 10

RCP8-6 1429-251 2 x 1-1/2 10

COUPLING CP 2 1429-005 1/2 50

CP 3 1429-007 3/4 50

CP 4 1429-010 1 40

CP 5 1429-012 1-1/4 20

CP 6 1429-015 1-1/2 20

CP 8 1429-020 2 10

CP 12 1429-030 3 10

CP 16 1429-040 4 8

REDUCING RMAP3-2A 1436-101 3/4 x 1/2 50

MALE ADAPTER RMAP4-3A 1436-131 1 x 3/4 30

(mpt x insert) RMAP5-3A 1436-167 1-1/4 x 3/4 25

RMAP5-4A 1436-168 1-1/4 x 1 25

RMAP6-4A 1436-211 1-1/2 x 1 25

RMAP6-5A 1436-212 1-1/2 x 1-1/4 20

RMAP8-6A 1436-251 2 x 1-1/2 10

REDUCING RMAP3-2B 1436-074 3/4 x 1/2 50

MALE ADAPTER RMAP4-3B 1436-102 1 x 3/4 50

(insert x mpt) RMAP5-4B 1436-132 1-1/4 x 1 15

RMAP6-4B 1436-133 1-1/2 x 1 15

RMAP6-5B 1436-169 1-1/2 x 1-1/4 10

RMAP8-6B 1436-213 2 x 1-1/2 10

FEMALE ADAPTER FAP2 1435-005 1/2 30

FAP3 1435-007 3/4 30

FAP4 1435-010 1 30

FAP5 1435-012 1-1/4 25

FAP6 1435-015 1-1/2 15

FAP8 1435-020 2 10

INSERT PLUG INS PLUG2 1449-005 1/2 100

INS PLUG3 1449-007 3/4 100

INS PLUG4 1449-010 1 40

INS PLUG5 1449-012 1-1/4 30

INS PLUG6 1449-015 1-1/2 20

INS PLUG8 1449-020 2 10

®

MAP 4

RMAP4-3A

RMAP4-3B

FAP4

INS PLUG4

CP 4

RCP4-3

Page 16

PVC Insert Fittings

Campbell

B3

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Campbell part universal part size pcs/ctn ELBOW

LP 2 1406-005 1/2 50

LP 3 1406-007 3/4 50

LP 4 1406-010 1 25

LP 5 1406-012 1-1/4 10

LP 6 1406-015 1-1/2 10

LP 8 1406-020 2 10

LP 12 1406-030 3 8

CREP2-2 1407-005 1/2 x 1/2 50 FEMALE COMBO

CREP3-2 1407-101 3/4 x 1/2 50 REDUCING ELBOW

CREP3-3 1407-007 3/4 x 3/4 25 (insert x fpt)

CREP4-2 1407-130 1 x 1/2 25

CREP4-3 1407-131 1 x 3/4 25

CREP4-4 1407-010 1 x 1 25

CREP5-2 1407-166 1-1/4 x 1/2 25

CREP5-3 1407-167 1-1/4 x 3/4 10

CREP5-4 1407-168 1-1/4 x 1 10

CREP5-5 1407-012 1-1/4 x 1-1/4 10

CREP6-4 1407-211 1-1/2 x 1 10

CREP6-5 1407-212 1-1/2 x 1-1/4 10

CREP6-6 1407-015 1-1/2 x 1-1/2 10

CREP8-6 1407-251 2 x 1-1/2 5

CREP8-8 1407-020 2 x 2 5

REP3-2 1406-101 3/4 x 1/2 25 REDUCING ELBOW

REP4-3 1406-131 1 x 3/4 10 (insert x insert)

REP5-4 1406-168 1-1/4 x 1 10

REP6-5 1406-212 1-1/2 x 1-1/4 10

CEP2 1413-005 1/2 25 MALE COMBO

CEP3 1413-007 3/4 25 ELBOW

CEP4 1413-010 1 10 (insert x mpt)

CEP5* 1413-012 1-1/4 10

CEP6* 1413-015 1-1/2 10

CEP8* 1413-020 2 10

*Hex Grip

®

LP 4

REP4-3

CREP4-3

CEP4

Page 17

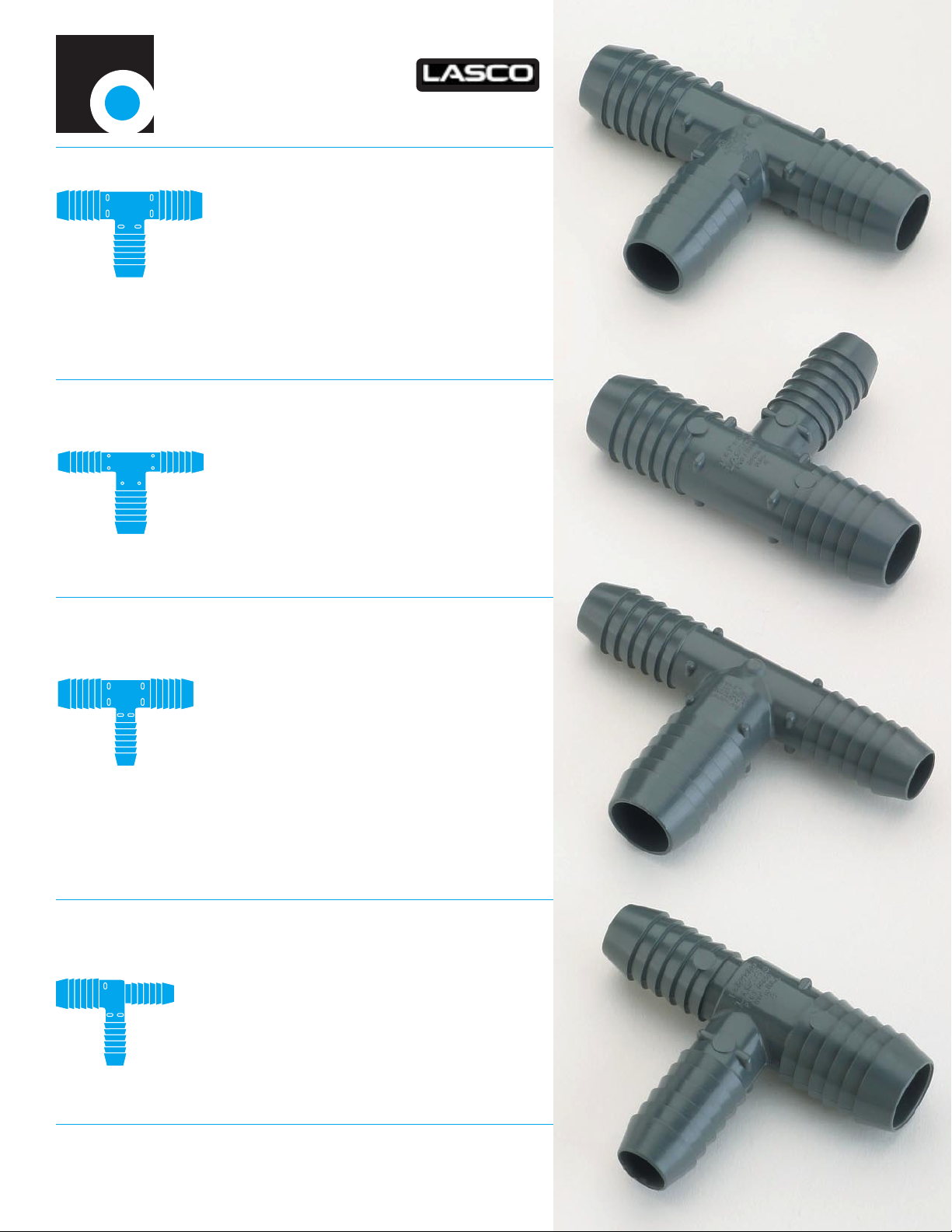

PVC Insert Fittings

Campbell

B4

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

REDUCING TEE RTP3-3-2A 1401-101 3/4 x 3/4 x 1/2 25

(insert x insert x RTP4-4-2A 1401-130 1 x 1 x 1/2 20

reducing insert) RTP4-4-3A 1401-131 1 x 1 x 3/4 20

RTP5-5-2A 1401-166 1-1/4 x 1-1/4 x 1/2 10

RTP5-5-3A 1401-167 1-1/4 x 1-1/4 x 3/4 10

RTP5-5-4A 1401-168 1-1/4 x 1-1/4 x 1 10

RTP6-6-2A 1401-209 1-1/2 x 1-1/2 x 1/2 5

RTP6-6-3A 1401-210 1-1/2 x 1-1/2 x 3/4 5

RTP6-6-4A 1401-211 1-1/2 x 1-1/2 x 1 5

RTP6-6-5A 1401-212 1-1/2 x 1-1/2 x 1-1/4 5

RTP8-8-2A 1401-247 2 x 2 x 1/2 5

RTP8-8-3A 1401-248 2 x 2 x 3/4 5

RTP8-8-4A 1401-249 2 x 2 x 1 5

RTP8-8-5A 1401-250 2 x 2 x 1-1/4 5

RTP8-8-6A 1401-251 2 x 2 x 1-1/2 5

REDUCING TEE RTP3-2-2B 1401-094 3/4 x 1/2 x 1/2 20

(insert x reducing insert x RTP4-3-3B 1401-125 1 x 3/4 x 3/4 20

reducing insert) RTP5-4-3B 1401-157 1-1/4 x 1 x 3/4 10

RTP5-4-4B 1401-158 1-1/4 x 1 x 1 10

RTP6-5-4B 1401-202 1-1/2 x 1-1/4 x 1 5

RTP6-5-5B 1401-203 1-1/2 x 1-1/4 x 1-1/4 5

BULLHEAD TEE BTP2-2-3 1401-074 1/2 x 1/2 x 3/4 10

(insert x insert x BTP3-3-4 1401-102 3/4 x 3/4 x 1 10

bullhead insert) BTP4-4-5 1401-132 1 x 1 x 1-1/4 5

TEE Campbell part universal part size pcs/ctn

TP 2 1401-005 1/2 40

TP 3 1401-007 3/4 25

TP 4 1401-010 1 20

TP 5 1401-012 1-1/4 10

TP 6 1401-015 1-1/2 10

TP 8 1401-020 2 10

TP 12 1401-030 3 5

®

TP 4

RTP4-4-3A

BTP3-3-4

RTP4-3-3B

Page 18

PVC Insert Fittings

Campbell

B5

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Campbell part universal part size pcs/ctn MALE COMBO TEE

CTP2 1403-005 1/2 25 (insert x insert x mpt)

CTP3 1403-007 3/4 20

CTP4 1403-010 1 10

CTP5 1403-012 1-1/4 10

CTP6 1403-015 1-1/2 5

CRTP2-2-2A 1402-005 1/2 x 1/2 x 1/2 50 FEMALE COMBO

CRTP3-3-2A 1402-101 3/4 x 3/4 x 1/2 25 REDUCING TEE

CRTP3-3-3A 1402-007 3/4 x 3/4 x 3/4 25 (insert x insert x fpt)

CRTP4-4-2A 1402-130 1 x 1 x 1/2 20

CRTP4-4-3A 1402-131 1 x 1 x 3/4 20

CRTP4-4-4A 1402-010 1 x 1 x 1 15

CRTP5-5-2A 1402-166 1-1/4 x 1-1/4 x 1/2 10

CRTP5-5-3A 1402-167 1-1/4 x 1-1/4 x 3/4 10

CRTP5-5-4A 1402-168 1-1/4 x 1-1/4 x 1 10

CRTP5-5-5A 1402-012 1-1/4 x 1-1/4 x 1-1/4 10

CRTP6-6-2A 1402-209 1-1/2 x 1-1/2 x 1/2 5

CRTP6-6-3A 1402-210 1-1/2 x 1-1/2 x 3/4 5

CRTP6-6-4A 1402-211 1-1/2 x 1-1/2 x 1 5

CRTP6-6-5A 1402-212 1-1/2 x 1-1/2 x 1-1/4 5

CRTP6-6-6A 1402-015 1-1/2 x 1-1/2 x 1-1/2 5

CRTP8-8-2A 1402-247 2 x 2 x 1/2 5

CRTP8-8-3A 1402-248 2 x 2 x 3/4 5

CRTP8-8-4A 1402-249 2 x 2 x 1 5

CRTP8-8-6A 1402-251 2 x 2 x 1-1/2 5

CRTP8-8-8A 1402-020 2 x 2 x 2 5

CRTP3-2-2B 1402-094 3/4 x 1/2 x 1/2 20 FEMALE COMBO

CRTP4-3-2B 1402-124 1 x 3/4 x 1/2 10 REDUCING TEE

CRTP4-3-3B 1402-125 1 x 3/4 x 3/4 10 (insert x reducing

CRTP5-4-2B 1402-156 1-1/4 x 1 x 1/2 10 insert x fpt)

CRTP5-4-3B 1402-157 1-1/4 x 1 x 3/4 10

PC 3 1420-007 3/4 10 CROSS

PC 4 1420-010 1 10

®

CRTP4-4-3A

PC 4

CTP4

Page 19

Repair Couplings

Campbell

B6

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

POLY-STRETCH™ length length pcs/

COUPLINGS part size retracted extended ctn

PSC-07 3/4 5-5/8 7-1/8 50

PSC-10 1 5-5/8 7-1/8 50

PSC-12 1-1/4 6-3/4 8-1/2 25

PSC-15 1-1/2 6-3/4 8-1/2 25

PSC-20 2 6-3/4 8-1/2 20

For repairing polyethylene irrigation pipe without digging up

the entire pipe.

to install:

1. Cut out and remove the damaged section of pipe.

2. Place clamps over both ends of the pipe.

3. Insert one end of the Poly-Stretch Coupling into the pipe.

Extend and insert the other (retracted) end of the Poly-Stretch

Coupling into the other side of pipe.

4. Clamp both sides and you have a secure, buckle-free

connection.

material: ABS plastic

seal: BUNA 70 O-ring

lubricant: petroleum jelly

pressure rating: 160 psi

PSC-10

(retracted)

PSC-10

(fully extended)

Page 20

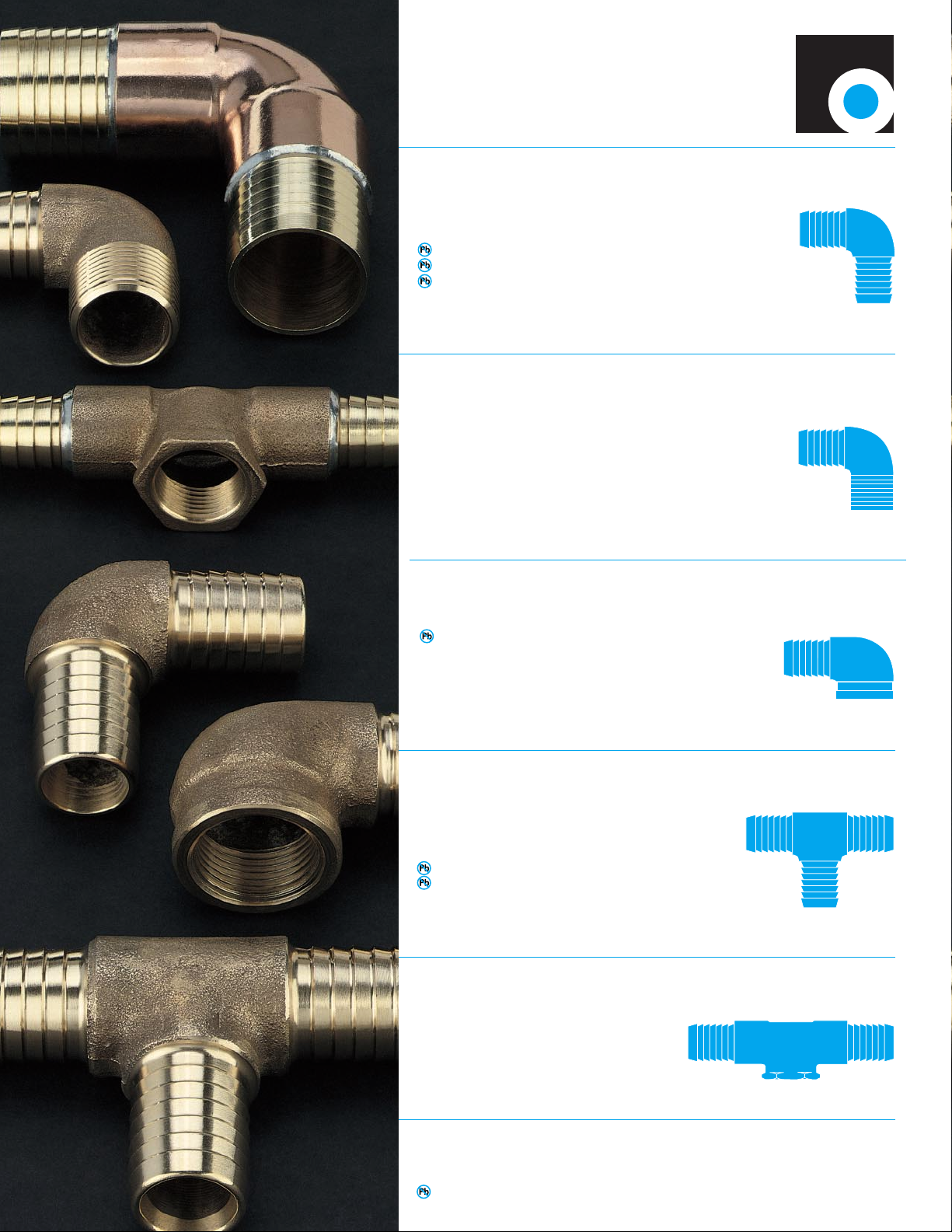

Red Brass Threaded Fittings

Campbell

C1

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

All red brass threaded fittings are machined

from 81% copper alloy bronze castings.

Other types and sizes available upon

request.

BDPC4 1 Bulk DROP PIPE COUPLING

BDPC5 1-1/4 Bulk

BTA1.5-1 3/8 x 1/4 Bulk REDUCING COUPLING

BTA2-1 1/2 x 1/4 Bulk

BTA2-1.5 1/2 x 3/8 Bulk

BTA3-1 3/4 x 1/4 Bulk

BTA3-2 3/4 x 1/2 Bulk

BTA4-3 1 x 3/4 Bulk

BTA5-3 1-1/4 x 3/4 Bulk

BTA5-4 1-1/4 x 1 Bulk

BTA6-4 1-1/2 x 1 Bulk

BTA6-5 1-1/2 x 1-1/4 Bulk

BTA8-4 2 x 1 Bulk

BTA8-5 2 x 1-1/4 Bulk

BTA8-6 2 x 1-1/2 Bulk

part size pcs/ctn COUPLING

BTA1 1/4 Bulk

BTA2 1/2 Bulk

BTA3 3/4 Bulk

BTA4 1 Bulk

BTA5 1-1/4 Bulk

BTA6 1-1/2 Bulk

BTA8 2 Bulk

BTB0 1/8 Bulk 90° ELBOW

BTB1 1/4 Bulk

BTB2 1/2 Bulk

BTB3 3/4 Bulk

BTB4 1 Bulk

BTB5 1-1/4 Bulk

BTB6 1-1/2 Bulk

BTB8 2 Bulk

BTB3-2 3/4 x 1/2 Bulk 90° REDUCING ELBOW

BTB4-3 1 x 3/4 Bulk

BTB5-4 1-1/4 x 1 Bulk

BTE0 1/8 Bulk 90° STREET ELBOW

BTE1 1/4 Bulk

BTE1.5 3/8 Bulk

BTE2 1/2 Bulk

BTE3 3/4 Bulk

BTE4 1 Bulk

BTE5 1-1/4 Bulk

BTE6 1-1/2 Bulk

BTE8 2 Bulk

BTD1 1/4 Bulk 45° ELBOW

BTD2 1/2 Bulk

BTD3 3/4 Bulk

BTD4 1 Bulk

BTD5 1-1/4 Bulk

BTD6 1-1/2 Bulk

BTD8 2 Bulk

BDPC5

BTD4

BTE4

BTB4-3

BTA4-3

BTA2

BTB1

Imported

Page 21

Red Brass Threaded Fittings

Campbell

C2

TEE part size pcs/ctn

BTC1 1/4 Bulk

BTC2 1/2 Bulk

BTC3 3/4 Bulk

BTC4 1 Bulk

BTC5 1-1/4 Bulk

BTC6 1-1/2 Bulk

BTC8 2 Bulk

All red brass threaded fittings are

machined from 81% copper alloy

bronze castings. Other types and

sizes available upon request.

REDUCING TEE BTC3-3-2 3/4 x 3/4 x 1/2 Bulk

BTC4-3-3 1 x 3/4 x 3/4 Bulk

BTC4-3-4 1 x 3/4 x 1 Bulk

BTC4-4-1 1 x 1 x 1/4 Bulk

BTC4-4-2 1 x 1 x 1/2 Bulk

BTC4-4-3 1 x 1 x 3/4 Bulk

BTC5-5-3 1-1/4 x 1-1/4 x 3/4 Bulk

BTC5-5-4 1-1/4 x 1-1/4 x 1 Bulk

SQUARE HEAD PLUG BTF0 1/8 Bulk

BTF1 1/4 Bulk

BTF1.5 3/8 Bulk

BTF2 1/2 Bulk

BTF3 3/4 Bulk

BTF4 1 Bulk

BTF5 1-1/4 Bulk

BTF6 1-1/2 Bulk

BTF8 2 Bulk

CAP BTG1 1/4 Bulk

BTG2 1/2 Bulk

BTG3 3/4 Bulk

BTG4 1 Bulk

HEX BUSHING BTH1-0 1/4 x 1/8 Bulk

(mpt x fpt) BTH1.5-1 3/8 x 1/4 Bulk

BTH2-0 1/2 x 1/8 Bulk

BTH2-1 1/2 x 1/4 Bulk

BTH2-1.5 1/2 x 3/8 Bulk

BTH3-0 3/4 x 1/8 Bulk

BTH3-1 3/4 x 1/4 Bulk

BTH3-1.5 3/4 x 3/8 Bulk

BTH3-2 3/4 x 1/2 Bulk

BTH4-0 1 x 1/8 Bulk

BTH4-1 1 x 1/4 Bulk

BTH4-2 1 x 1/2 Bulk

BTH4-3 1 x 3/4 Bulk

BTH5-1 1-1/4 x 1/4 Bulk

BTH5-2 1-1/4 x 1/2 Bulk

BTH5-3 1-1/4 x 3/4 Bulk

BTH5-4 1-1/4 x 1 Bulk

BTH6-3 1-1/2 x 3/4 Bulk

BTH6-4 1-1/2 x 1 Bulk

BTH6-5 1-1/2 x 1-1/4 Bulk

BTH8-3 2 x 3/4 Bulk

BTH8-4 2 x 1 Bulk

BTH8-5 2 x 1-1/4 Bulk

BTH8-6 2 x 1-1/2 Bulk

BTH10-8 2-1/2 x 2 Bulk

BTH12-8 3 x 2 Bulk

UNION BTJ2 1/2 Bulk

BTJ3 3/4 Bulk

BTJ4 1 Bulk

BTJ5 1-1/4 Bulk

BTJ6 1-1/2 Bulk

BTJ8 2 Bulk

BTC6

BTC4-4-2

BTH8-6

BTG5

BTF6

BTC1

BTJ2

BTH3-2

Imported

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Page 22

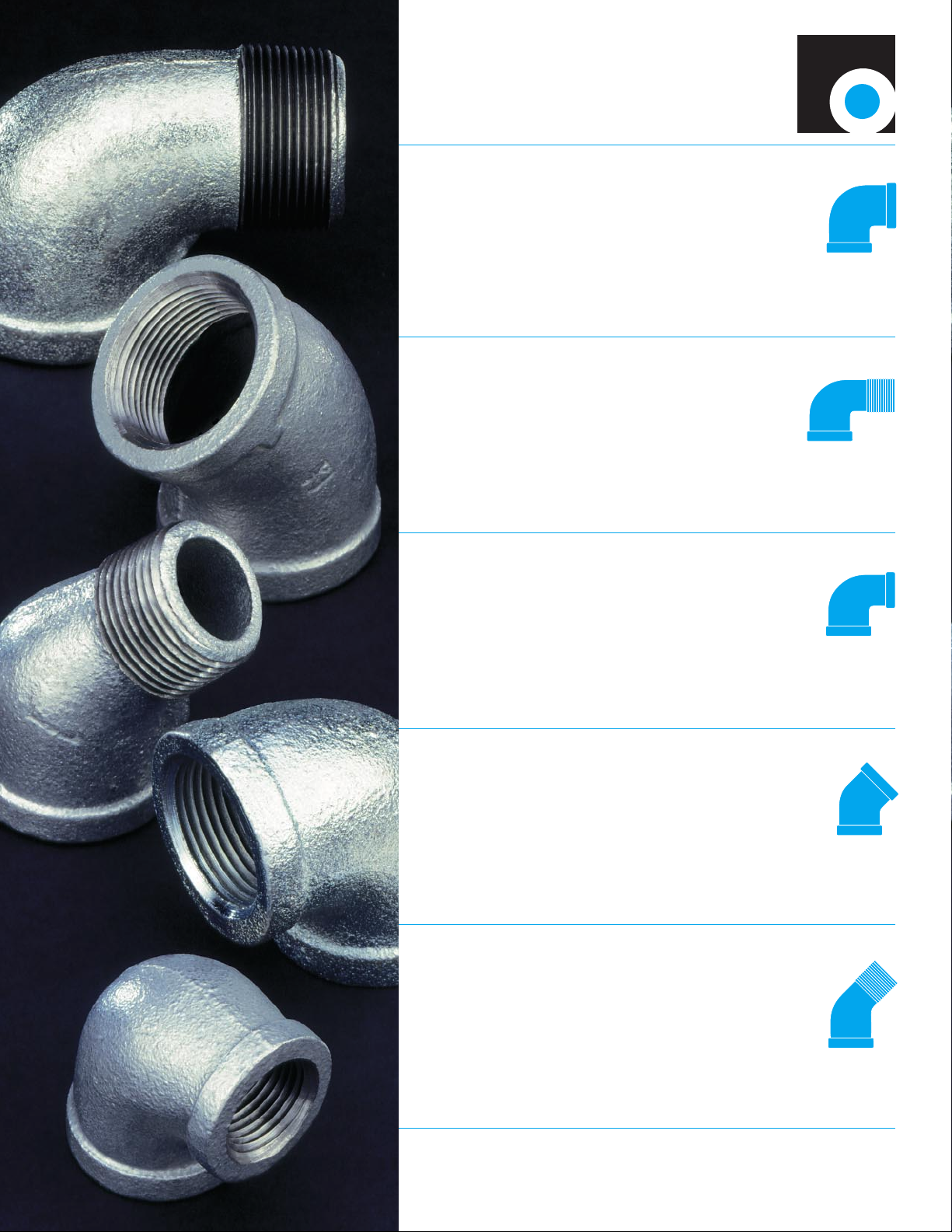

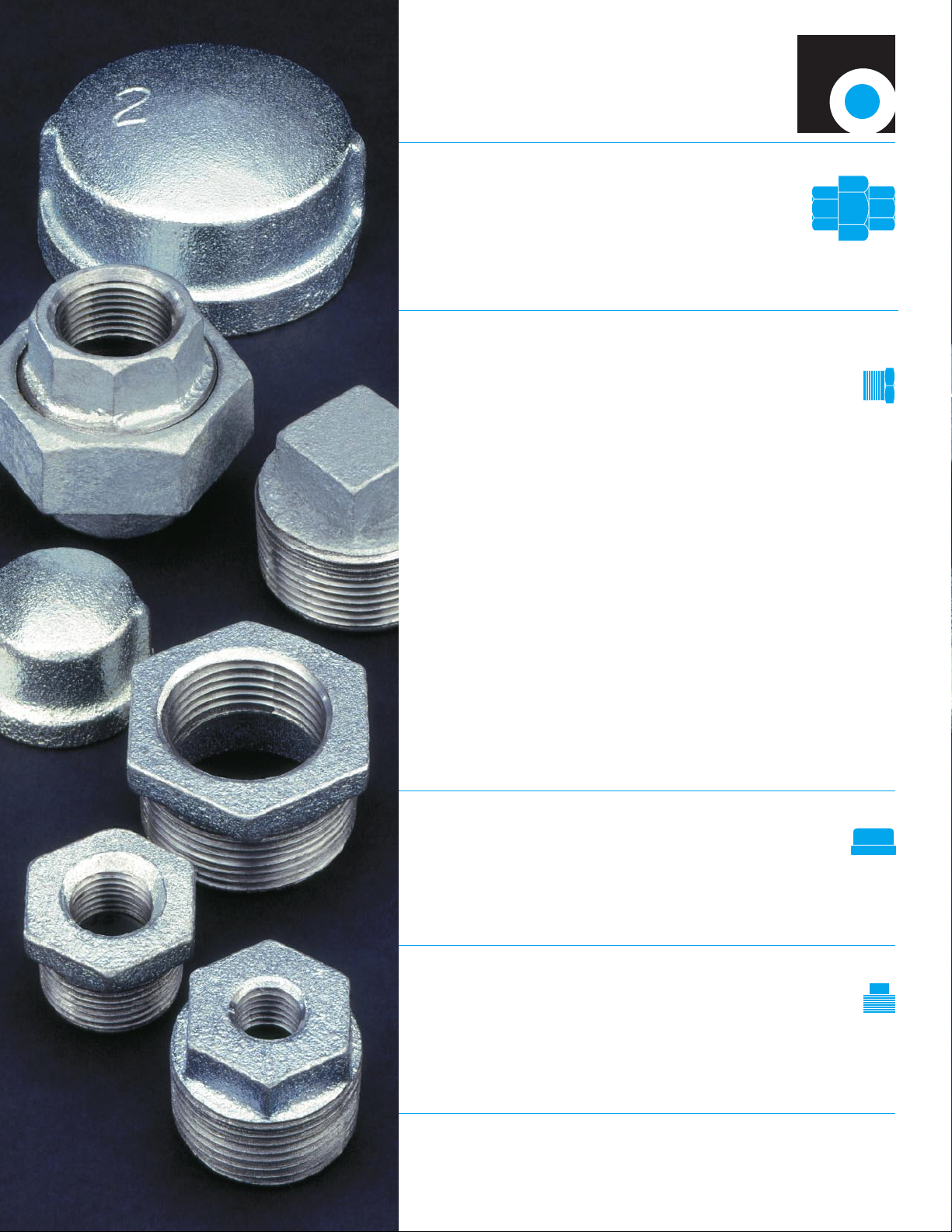

Imported Malleable Iron Fittings

Campbell

C3

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

All malleable fittings are zinc-plated. Other

types and sizes available upon request.

part size pcs/ctn 90° ELBOW

MFA1 1/4 Bulk

MFA1.5 3/8 Bulk

MFA2 1/2 Bulk

MFA3 3/4 Bulk

MFA4 1 Bulk

MFA5 1-1/4 Bulk

MFA6 1-1/2 Bulk

MFA8 2 Bulk

MFA12 3 Bulk

MFC3-1 3/4 x 1/4 Bulk 90° REDUCING ELBOW

MFC3-2 3/4 x 1/2 Bulk

MFC4-2 1 x 1/2 Bulk

MFC4-3 1 x 3/4 Bulk

MFC5-3 1-1/4 x 3/4 Bulk

MFC5-4 1-1/4 x 1 Bulk

MFC8-5 2 x 1-1/4 Bulk

MFB1 1/4 Bulk 90° STREET ELBOW

MFB2 1/2 Bulk

MFB3 3/4 Bulk

MFB4 1 Bulk

MFB5 1-1/4 Bulk

MFB6 1-1/2 Bulk

MFB8 2 Bulk

MFE1 1/4 Bulk 45° ELBOW

MFE2 1/2 Bulk

MFE3 3/4 Bulk

MFE4 1 Bulk

MFE5 1-1/4 Bulk

MFE6 1-1/2 Bulk

MFE8 2 Bulk

MFD1 1/4 Bulk 45° STREET ELBOW

MFD2 1/2 Bulk

MFD3 3/4 Bulk

MFD4 1 Bulk

MFD5 1-1/4 Bulk

MFD6 1-1/2 Bulk

MFD8 2 Bulk

MFB6

MFE5

MFA4

MFD4

MFC3-2

Page 23

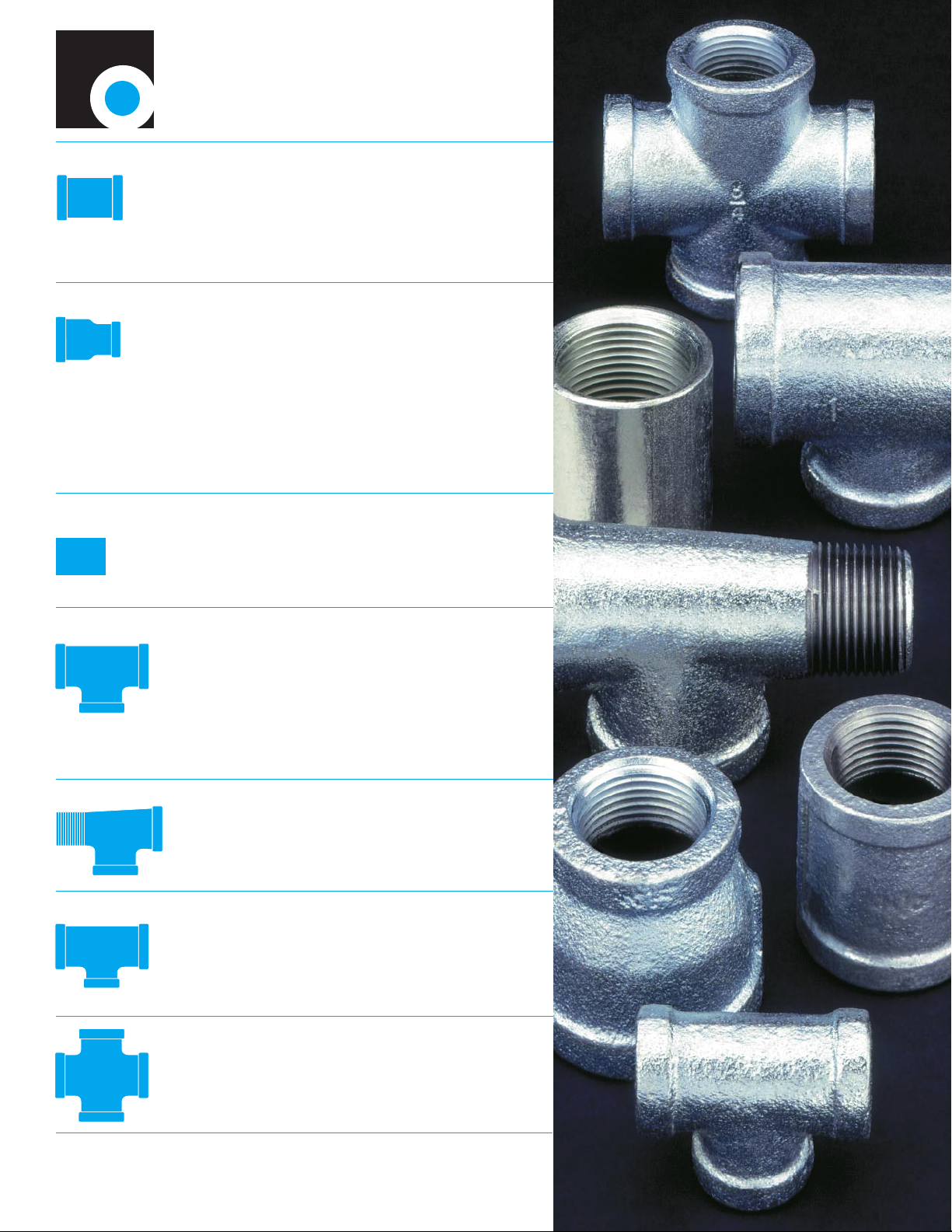

Campbell

C4

COUPLING part size pcs/ctn

MFL1 1/4 Bulk

MFL2 1/2 Bulk

MFL3 3/4 Bulk

MFL4 1 Bulk

MFL5 1-1/4 Bulk

MFL6 1-1/2 Bulk

MFL8 2 Bulk

MFL12 3 Bulk

Other types and sizes available upon request.

All malleable fittings are zinc-plated.

* Domestic may be substituted.

REDUCING COUPLING MFH2-0 1/2 x 1/8 Bulk

MFH2-1 1/2 x 1/4 Bulk

MFH3-2 3/4 x 1/2 Bulk

MFH4-2 1 x 1/2 Bulk

MFH4-3 1 x 3/4 Bulk

MFH5-2 1-1/4 x 1/2 Bulk

MFH5-4 1-1/4 x 1 Bulk

MFH6-4 1-1/2 x 1 Bulk

MFH6-5 1-1/2 x 1-1/4 Bulk

MFH8-4 2 x 1 Bulk

MFH8-5 2 x 1-1/4 Bulk

MFH8-6 2 x 1-1/2 Bulk

MFH10-8 2-1/2 x 2 Bulk

MFH12-8 3 x 2 Bulk

STANDARD SMC2 1/2 Bulk

MERCHANT COUPLING* SMC3 3/4 Bulk

SMC4 1 Bulk

SMC5 1-1/4 Bulk

SMC6 1-1/2 Bulk

SMC8 2 Bulk

SMC12 3 Bulk

TEE MFF1 1/4 Bulk

MFF1.5 3/8 Bulk

MFF2 1/2 Bulk

MFF3 3/4 Bulk

MFF4 1 Bulk

MFF5 1-1/4 Bulk

MFF6 1-1/2 Bulk

MFF8 2 Bulk

MFF10 2-1/2 Bulk

MFF12 3 Bulk

MFF16 4 Bulk

STREET TEE MFQ3 3/4 Bulk

MFQ4 1 Bulk

REDUCING TEE MFG3-3-2 3/4 x 3/4 x1/2 Bulk

MFG4-3-3 1 x 3/4 x 3/4 Bulk

MFG4-3-4 1 x 3/4 x 1 Bulk

MFG4-4-1 1 x 1 x 1/4 Bulk

MFG4-4-2 1 x 1 x 1/2 Bulk

MFG4-4-3 1 x 1 x 3/4 Bulk

MFG5-5-4 1-1/4 x 1-1/4 x 1 Bulk

MFG8-8-5 2 x 2 x 1-1/4 Bulk

CROSS MFO3 3/4 Bulk

MFO4 1 Bulk

MFO6

MFG4-4-3

SMC4

MFQ3

MFL3

MFH4-3

MFF1

Imported Malleable Iron Fittings

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Page 24

Campbell

C5

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

part size pcs/ctn UNION

MFN2 1/2 Bulk

MFN3 3/4 Bulk

MFN4 1 Bulk

MFN5 1-1/4 Bulk

MFN6 1-1/2 Bulk

MFN8 2 Bulk

All malleable fittings are zinc-plated.

Other types and sizes available upon

request.

MFJ1-0 1/4 x 1/8 Bulk HEX BUSHING

MFJ2-1 1/2 x 1/4 Bulk (mpt x fpt)

MFJ2-1.5 1/2 x 3/8 Bulk

MFJ3-1 3/4 x 1/4 Bulk

MFJ3-1.5 3/4 x 3/8 Bulk

MFJ3-2 3/4 x 1/2 Bulk

MFJ4-1 1 x 1/4 Bulk

MFJ4-2 1 x 1/2 Bulk

MFJ4-3 1 x 3/4 Bulk

MFJ5-0 1-1/4 x 1/8 Bulk

MFJ5-1 1-1/4 x 1/4 Bulk

MFJ5-2 1-1/4 x 1/2 Bulk

MFJ5-3 1-1/4 x 3/4 Bulk

MFJ5-4 1-1/4 x 1 Bulk

MFJ6-1 1-1/2 x 1/4 Bulk

MFJ6-2 1-1/2 x 1/2 Bulk

MFJ6-3 1-1/2 x 3/4 Bulk

MFJ6-4 1-1/2 x 1 Bulk

MFJ6-5 1-1/2 x 1-1/4 Bulk

MFJ8-2 2 x 1/2 Bulk

MFJ8-3 2 x 3/4 Bulk

MFJ8-4 2 x 1 Bulk

MFJ8-5 2 x 1-1/4 Bulk

MFJ8-6 2 x 1-1/2 Bulk

MFJ10-8 2-1/2 x 2 Bulk

MFJ12-4 3 x 1 Bulk

MFJ12-5 3 x 1-1/4 Bulk

MFJ12-8 3 x 2 Bulk

MFJ12-10 3 x 2-1/2 Bulk

MFJ16-8 4 x 2 Bulk

MFJ16-10 4 x 2-1/2 Bulk

MFJ16-12 4 x 3 Bulk

MFK2 1/2 Bulk CAP

MFK3 3/4 Bulk

MFK4 1 Bulk

MFK5 1-1/4 Bulk

MFK6 1-1/2 Bulk

MFK8 2 Bulk

MFM0 1/8 Bulk SQUARE HEAD PLUG

MFM1 1/4 Bulk

MFM1.5 3/8 Bulk

MFM2 1/2 Bulk

MFM3 3/4 Bulk

MFM4 1 Bulk

MFM5 1-1/4 Bulk

MFM6 1-1/2 Bulk

MFM8 2 Bulk

MFM12 3 Bulk

MFK8

MFN3

MFM5

MFK2

MFJ5-4

MFJ3-1.5

MFJ4-1

Imported Malleable Iron Fittings

Page 25

Nipples

Campbell

D1

part length size pcs/ctn BRASS NIPPLES

BN1/4X_______________ 1/4 25

BN3/8X_______________ 3/8 25

BN1/2X_______________ 1/2 25

BN3/4X_______________ 3/4 25

BN1X_________________ 1 25

BN1 1/4X_ ____________ 1-1/4 10

BN1 1/2 X_____________ 1-1/2 10

BN2X_________________ 2 Bulk

available lengths: Close, 1 1/2”, 2”, 2 1/2”, 3”, 3 1/2”, 4”, 4 1/2”, 5”, 5 1/2”, and 6”.

Other sizes available upon request. To complete part number, add length to the

above part number. (Example: 3/8” brass nipple in 4 1/2” length, use part number

BN3/8X4 1/2). All nipples standard ips pipe size.

GN1/4X_______________ 1/4 Bulk GALVANIZED NIPPLES

GN3/8X_______________ 3/8 Bulk (imported)

GN1/2X_______________ 1/2 Bulk

GN3/4X_______________ 3/4 Bulk

GN1X_________________ 1 Bulk

GN1 1/4X_____________ 1-1/4 Bulk

GN1 1/2X_____________ 1-1/2 Bulk

GN2X_________________ 2 Bulk

available lengths: Close, 1 1/2”, 2”, 2 1/2”, 3”, 3 1/2”, 4”, 4-1/2”, 5”, 5-1/2”, and 6”.

Other sizes available upon request. To complete part number, add length to the

above part number. (Example: 3/8” galvanized nipple in 4 1/2” length, use part number

GN3/8X4 1/2). All nipples standard ips pipe size.

PN1/4X_______________ 1/4 50 SCHEDULE 80

PN1/2X_______________ 1/2 50 PVC NIPPLES

PN3/4X_______________ 3/4 50

PN1X_________________ 1 50

PN1 1/4X_____________ 1-1/4 25

PN1 1/2X_____________ 1-1/2 25

PN2X_________________ 2 10

available lengths: Close, 2”, 3”, 4”, 5”, and 6”. Other sizes available upon request.

To complete part number, add length to the above part number.

(Example: 3/4” pvc nipple in 4” length, use part number PN3/4X4).

NB3-2 3/4 x 1/2 Bulk BRASS SWAGED NIPPLES

NB4-3 1 x 3/4 Bulk

NB5-4 1-1/4 x 1 Bulk

NB6-5 1-1/2 x 1-1/4 Bulk

NB8-6 2 x 1-1/2 Bulk

NS3-2 3/4 x 1/2 Bulk STEEL SWAGED NIPPLES

NS4-3 1 x 3/4 Bulk

NS5-4 1-1/4 x 1 Bulk

NS6-5 1-1/2 x 1-1/4 Bulk

NS8-6 2 x 1-1/2 Bulk

Campbell part universal part size pcs/ctn LASCO

CNIP1/2X6 M481-005 1/2 x 6 50 CUT-OFF NIPPLES

CNIP3/4X1/2X6 M481-101 3/4 x 1/2 x 6 50

CNIP3/4X6 M481-007 3/4 x 6 25

Four-in-one, polyethylene Cut-Off Nipples allow you

to choose the size you need with just one nipple.

ANSI/NSF Standard 61

Drinking Water System Components

NB3-2

NS8-6

GN1/2X2

BN1/4X3

BN1/2XClose

PN1 1/4X4

CNIP1/2X6

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Page 26

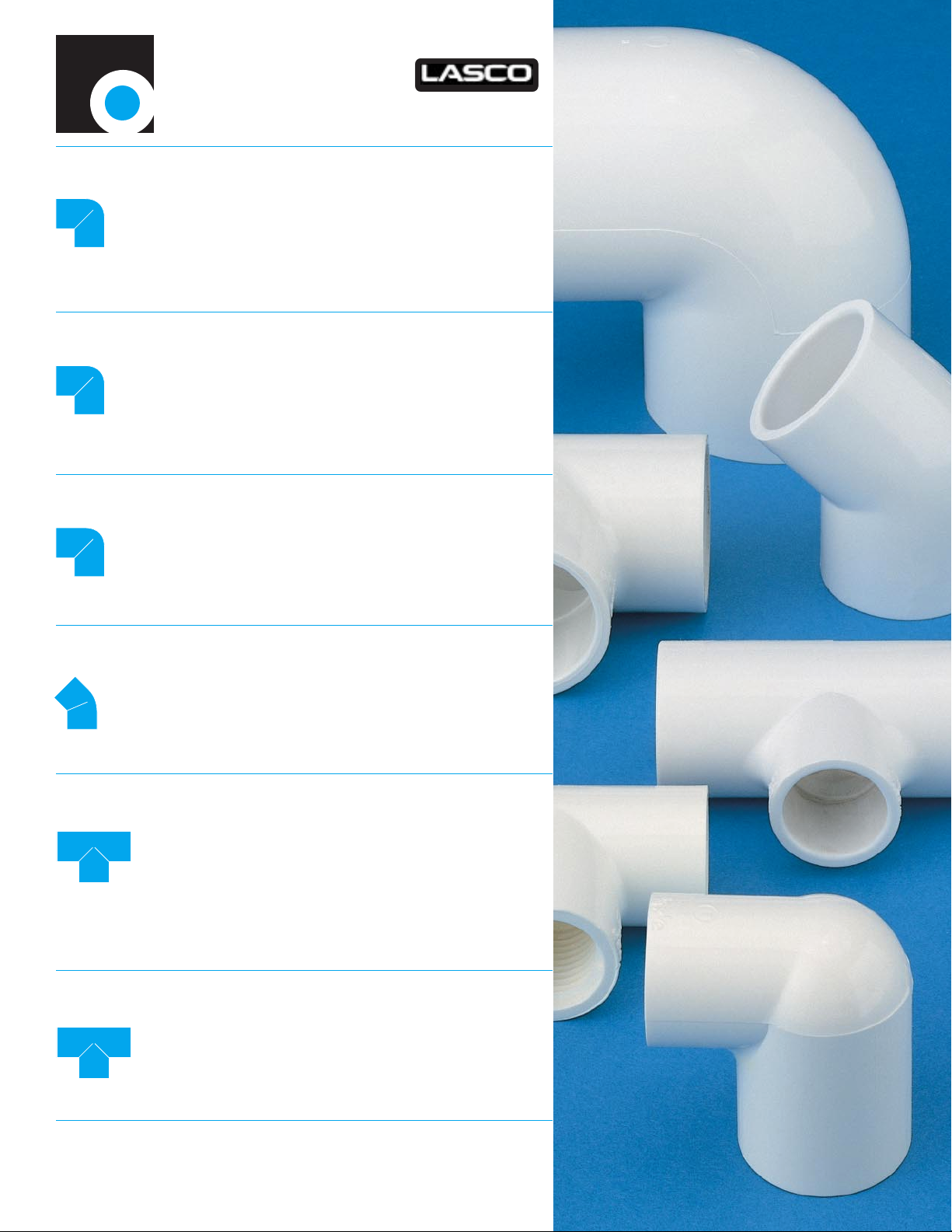

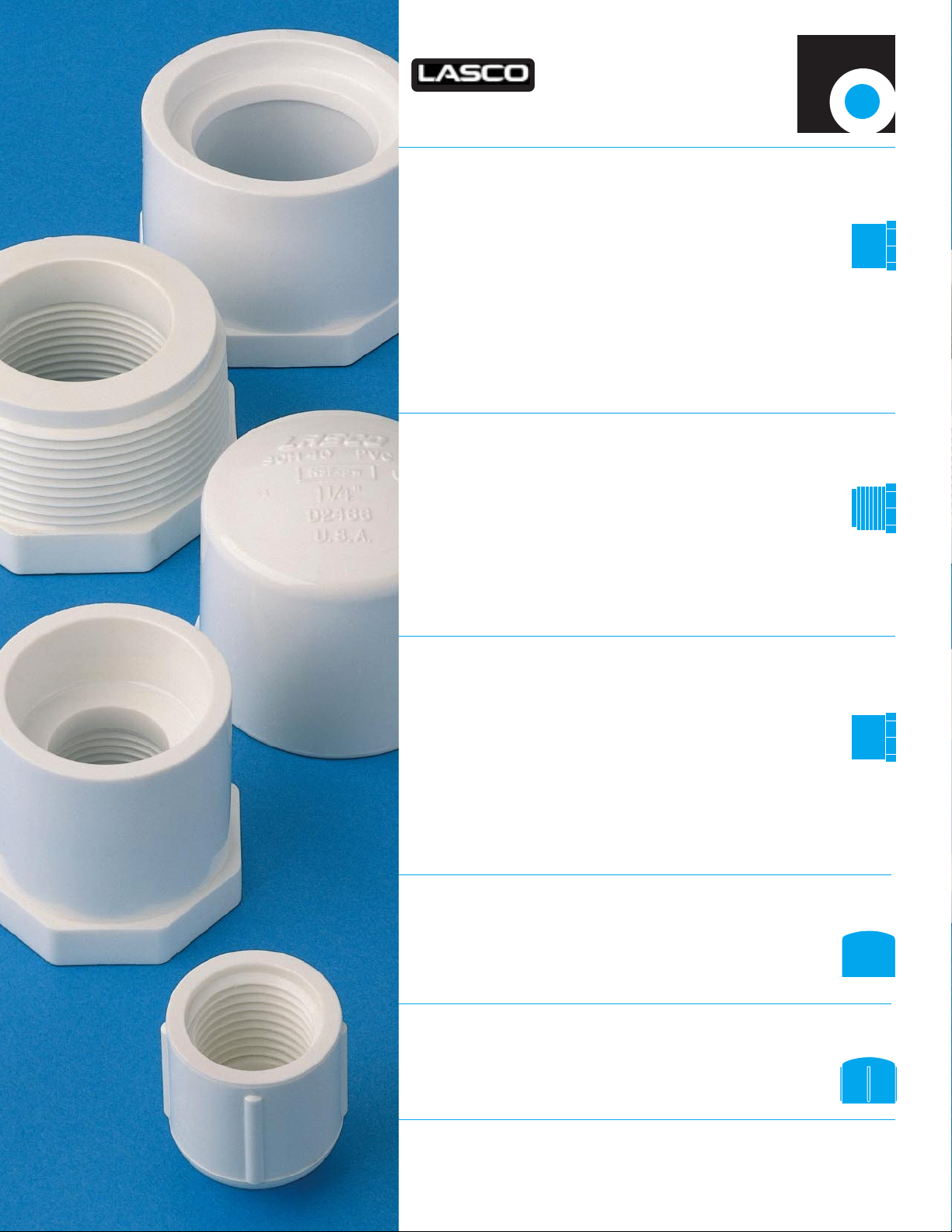

Schedule 40 Fittings

Campbell

E1

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Campbell part universal part size pcs/ctn MALE ADAPTER

40MA2 436-005 1/2 100 (mpt x slip)

40MA3 436-007 3/4 50

40MA4 436-010 1 50

40MA5 436-012 1-1/4 25

40MA6 436-015 1-1/2 25

40MA8 436-020 2 25

Other types and sizes of Lasco

fittings available upon request.

40MA2-3 436-074 1/2 x 3/4 50 REDUCING

40MA3-2 436-101 3/4 x 1/2 50 MALE ADAPTER

40MA3-4 436-102 3/4 x 1 50 (mpt x slip)

40MA4-3 436-131 1 x 3/4 50

40MA4-5 436-132 1 x 1-1/4 25

40MA5-4 436-168 1-1/4 x 1 25

40MA5-6 436-169 1-1/4 x 1-1/2 25

40MA6-5 436-212 1-1/2 x 1-1/4 25

40MA6-8 436-213 1-1/2 x 2 10

40MA8-6 436-251 2 x 1-1/2 10

40FA2 435-005 1/2 100 FEMALE ADAPTER

40FA3 435-007 3/4 50 (slip x fpt)

40FA4 435-010 1 50

40FA5 435-012 1-1/4 25

40FA6 435-015 1-1/2 25

40FA8 435-020 2 25

40SC2 429-005 1/2 100 SLIP COUPLING

40SC3 429-007 3/4 50 (slip x slip)

40SC4 429-010 1 50

40SC5 429-012 1-1/4 25

40SC6 429-015 1-1/2 25

40SC8 429-020 2 25

PDC4 ** 1 10 DROP COUPLING

PDC5 ** 1-1/4 10

Reamed and drifted coupling used to suspend Schedule 80 threaded

PVC drop pipe. Machined from custom-extruded PVC stock.

** Not LASCO.

40FC2 430-005 1/2 100 FEMALE COUPLING

40FC3 430-007 3/4 50 (fpt x fpt)

40DSC6 482-015 1-1/2 (2.169*) 25 DEEP SOCKET

40DSC8 482-020 2 (2.389*) 25 COUPLING

40DSC16 482-040 4 (3.625*) 5 (slip x slip)

*Socket depth, each end.

40INA3 474-007 3/4 50 INSERT SOCKET

40INA4 474-010 1 50 ADAPTER

(slip x insert)

PDC4

40MA8-6

40INA4

40FC3

40MA3

40SC2

40FA5

40DSC8

®

Page 27

Schedule 40 Fittings

Campbell

E2

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

90° ELBOW Campbell part universal part size pcs/ctn

(slip x slip) 40SE2 406-005 1/2 50

40SE3 406-007 3/4 50

40SE4 406-010 1 50

40SE5 406-012 1-1/4 25

40SE6 406-015 1-1/2 25

40SE8 406-020 2 25

Other types and sizes of Lasco

fittings available upon request.

90° ELBOW 40EL90-2 407-005 1/2 50

(slip x fpt) 40EL90-3 407-007 3/4 50

40EL90-3-2 407-101 3/4 x 1/2 50

40EL90-4 407-010 1 50

40EL90-5 407-012 1-1/4 25

40EL90-6 407-015 1-1/2 25

40EL90-8 407-020 2 10

90° ELBOW 40STEL2SPXS 409-005 1/2 50

(spigot x slip) 40STEL3SPXS 409-007 3/4 50

40STEL4SPXS 409-010 1 50

40STEL5SPXS 409-012 1-1/4 25

40STEL6SPXS 409-015 1-1/2 25

40STEL8SPXS 409-020 2 10

45° ELBOW 40EL45-2 417-005 1/2 50

(slip x slip) 40EL45-3 417-007 3/4 50

40EL45-4 417-010 1 50

40EL45-5 417-012 1-1/4 25

40EL45-6 417-015 1-1/2 25

40EL45-8 417-020 2 25

TEE 40ST2 401-005 1/2 50

(slip x slip x slip) 40ST3 401-007 3/4 50

40ST4 401-010 1 50

40ST5 401-012 1-1/4 25

40ST6 401-015 1-1/2 25

40ST8 401-020 2 25

40ST3-3-2 401-101 3/4 x 3/4 x 1/2 50

40ST4-4-2 401-130 1 x 1 x 1/2 50

40ST4-4-3 401-131 1 x 1 x 3/4 50

COMBINATION TEE 40CT2-2-2 402-005 1/2 x 1/2 x 1/2 50

(slip x slip x fpt) 40CT3-3-2 402-101 3/4 x 3/4 x 1/2 50

40CT3-3-3 402-007 3/4 x 3/4 x 3/4 50

40CT4-4-2 402-130 1 x 1 x 1/2 50

40CT4-4-3 402-131 1 x 1 x 3/4 50

40CT4-4-4 402-010 1 x 1 x 1 50

40SE6

40ST4

40EL45-4

40ST3-3-2

40CT2-2-2

40EL90-3-2

®

Page 28

Schedule 40 Fittings

Campbell

E3

Campbell part universal part size pcs/ctn REDUCING

40RB3-2 437-101 3/4 x 1/2 100 BUSHING

40RB4-2 437-130 1 x 1/2 100 (spigot x slip)

40RB4-3 437-131 1 x 3/4 100

40RB5-2 437-166 1-1/4 x 1/2 25

40RB5-3 437-167 1-1/4 x 3/4 25

40RB5-4 437-168 1-1/4 x 1 25

40RB6-2 437-209 1-1/2 x 1/2 25

40RB6-3 437-210 1-1/2 x 3/4 25

40RB6-4 437-211 1-1/2 x 1 25

40RB6-5 437-212 1-1/2 x 1-1/4 25

40RB8-2 437-247 2 x 1/2 10

40RB8-3 437-248 2 x 3/4 10

40RB8-4 437-249 2 x 1 10

40RB8-5 437-250 2 x 1-1/4 10

40RB8-6 437-251 2 x 1-1/2 25

Other types and sizes of Lasco

fittings available upon request.

40RB8-5

TRB3-2 439-101 3/4 x 1/2 50 REDUCING

TRB4-2 439-130 1 x 1/2 50 BUSHING

TRB4-3 439-131 1 x 3/4 50 (mpt x fpt)

TRB5-2 439-166 1-1/4 x 1/2 25

TRB5-3 439-167 1-1/4 x 3/4 25

TRB5-4 439-168 1-1/4 x 1 25

TRB6-2 439-209 1-1/2 x 1/2 25

TRB6-3 439-210 1-1/2 x 3/4 25

TRB6-4 439-211 1-1/2 x 1 25

TRB6-5 439-212 1-1/2 x 1-1/4 25

TRB8-4 439-249 2 x 1 10

TRB8-5 439-250 2 x 1-1/4 10

TRB8-6 439-251 2 x 1-1/2 10

40RB3SX2F 438-101 3/4 x 1/2 100 REDUCING

40RB4SX2F 438-130 1 x 1/2 100 BUSHING

40RB4SX3F 438-131 1 x 3/4 100 (spigot x fpt)

40RB5SX2F 438-166 1-1/4 x 1/2 25

40RB5SX3F 438-167 1-1/4 x 3/4 25

40RB5SX4F 438-168 1-1/4 x 1 25

40RB6SX2F 438-209 1-1/2 x 1/2 25

40RB6SX3F 438-210 1-1/2 x 3/4 25

40RB6SX4F 438-211 1-1/2 x 1 25

40RB6SX5F 438-212 1-1/2 x 1-1/4 25

40RB8SX3F 438-248 2 x 3/4 10

40RB8SX4F 438-249 2 x 1 10

40RB8SX5F 438-250 2 x 1-1/4 10

40RB8SX6F 438-251 2 x 1-1/2 10

40CAP2 447-005 1/2 100 CAP

40CAP3 447-007 3/4 100 (slip)

40CAP4 447-010 1 50

40CAP5 447-012 1-1/4 25

40CAP6 447-015 1-1/2 25

40CAP8 447-020 2 25

40CAP2F 448-005 1/2 100 FEMALE CAP

40CAP3F 448-007 3/4 100 (fpt)

40CAP4F 448-010 1 50

40CAP5F 448-012 1-1/4 25

40CAP6F 448-015 1-1/2 25

TRB8-5

40RB5SX3F

40CAP5

40CAP2F

®

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Page 29

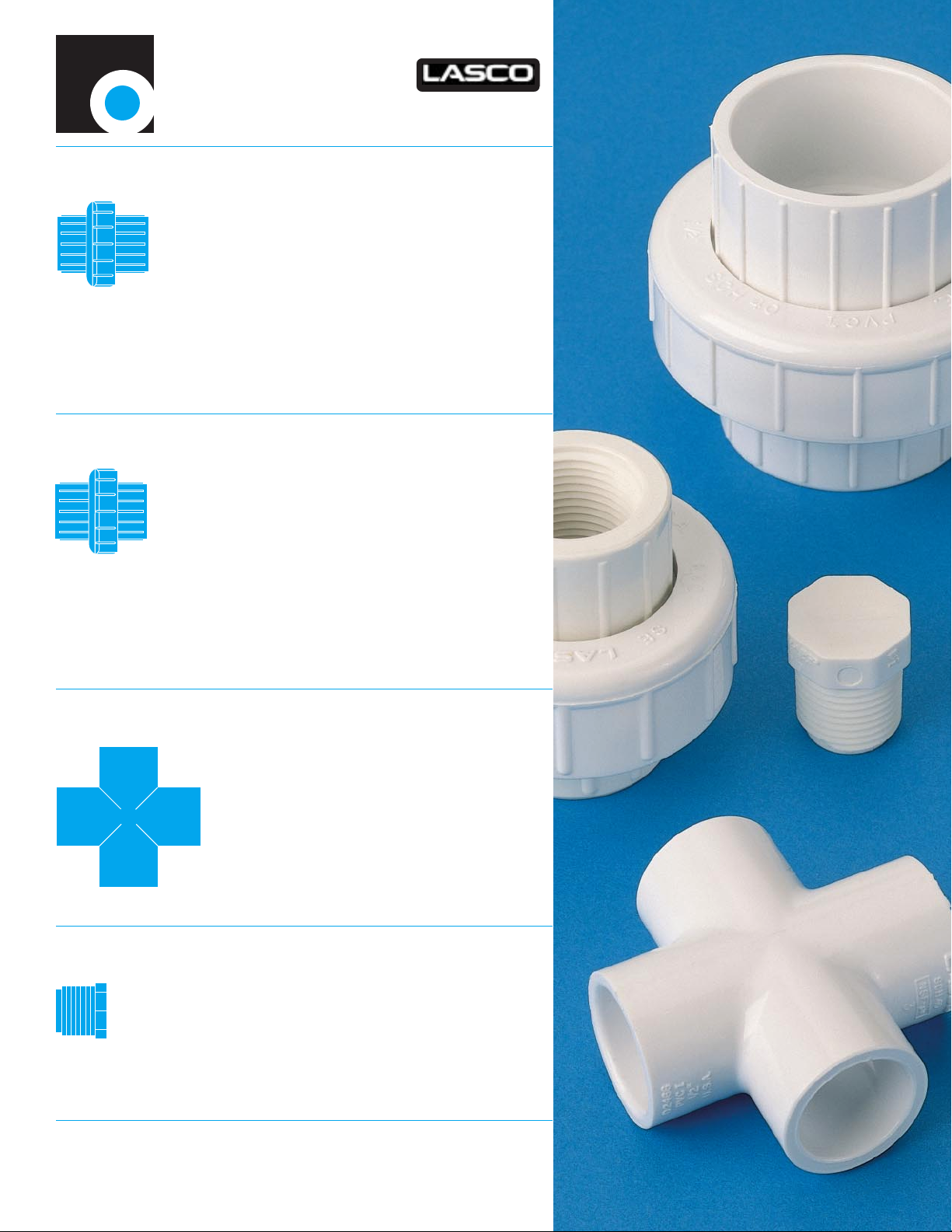

Schedule 40 Fittings

Campbell

E4

SLIP UNION Campbell part universal part size pcs/ctn

(slip x slip) 40SU2 457-005 1/2 10

40SU3 457-007 3/4 10

40SU4 457-010 1 10

40SU5 457-012 1-1/4 5

40SU6 457-015 1-1/2 5

40SU8 457-020 2 5

O-ring type. Pressure rated at 150 psi at 73.4°F.

Other types and sizes of Lasco

fittings available upon request.

FEMALE UNION 40FU2 458-005 1/2 10

(fpt x fpt) 40FU3 458-007 3/4 10

40FU4 458-010 1 10

40FU5 458-012 1-1/4 5

40FU6 458-015 1-1/2 5

40FU8 458-020 2 5

O-ring type. Pressure rated at 150 psi at 73.4°F.

CROSS 40CR2 420-005 1/2 50

(slip x slip x slip x slip) 40CR4 420-010 1 50

PLUG 40PM2 450-005 1/2 50

(mpt) 40PM3 450-007 3/4 50

40PM4 450-010 1 50

40PM5 450-012 1-1/4 25

40PM6 450-015 1-1/2 25

40PM8 450-020 2 10

40SU6

40PM2

40FU3

40CR2

®

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Page 30

PVCCompression Fittings

Campbell

F1

CT2 120-05 1/2 24 PVC THREADED TEE

CT3 120-07 3/4 20 (ips)

CT4 120-10 1 15

CT5 120-12 1-1/4 15

CT6 120-15 1-1/2 12

CT8 120-20 2 10

CT4C 120-10C 1 15 PVC THREADED TEE

CT5C 120-12C 1-1/4 15 (ips with

CT6C 120-15C 1-1/2 12 stainless steel collar)

CT8C 120-20C 2 10

Other sizes and types available

upon request.

Campbell Flo-Control PVC MALE ADAPTER

part part size pcs/ctn (ips)

MCA2 130-05 1/2 25

MCA3 130-07 3/4 20

MCA4 130-10 1 30

MCA5 130-12 1-1/4 20

MCA6 130-15 1-1/2 16

MCA8 130-20 2 12

MCA2FL 135-05 1/2 25 PVC MALE ADAPTER

MCA3FL 135-07 3/4 20 (ips with FloLock*)

MCA4FL 135-10 1 30

MCA5FL 135-12 1-1/4 20

MCA6FL 135-15 1-1/2 16

MCA8FL 135-20 2 12

*As cap is tightened, pressure causes the gripping ring

to bite into the pipe eliminating pullout.

CC2 110-05 1/2 28 PVC COUPLING

CC3 110-07 3/4 24 (ips)

CC4 110-10 1 15

CC5 110-12 1-1/4 10

CC6 110-15 1-1/2 16

CC8 110-20 2 12

CC10 110-25 2-1/2 3

CC12 110-30 3 3

CC16 110-40 4 3

CC24 110-60 6 1

CC2-CPVC 310-05 1/2 28 CPVC COUPLING

CC3-CPVC 310-07 3/4 24 (ips)

CTS 2 210-05 1/2 25 PVC COUPLING

CTS 3 210-07 3/4 28 (cts)

CTS 4 210-10 1 24

CTS 5 210-12 1-1/4 15

CTS 6 210-15 1-1/2 10

CTS 8 210-20 2 12

CTS2-CPVC 410-05 1/2 25 CPVC COUPLING

CTS3-CPVC 410-07 3/4 28 (cts)

CTS4-CPVC 410-10 1 24

117-05 117-05 1/2 28 PVC FLO-SPAN

117-07 117-07 3/4 24 COUPLING

117-10 117-10 1 15 (ips, with union)

117-12 117-12 1-1/4 10

117-15 117-15 1-1/2 16

117-20 117-20 2 12

118-25 118-25 2-1/2 3 PVC PRO-SPAN

118-30 118-30 3 3 COUPLING

118-40 118-40 4 3 (ips, non-union)

117-07

CT4C

CC4

CTS 2

MCA3

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Page 31

Campbell

F2

FLO-LOCK COUPLING part size pcs/pkg

(700-series) 710-07 3/4 35

710-10 1 24

710-12 1-1/4 15

710-15* 1-1/2 16

710-20* 2 12

FLO-LOCK COUPLING 810-07 3/4 24

(800-series) 810-10 1 15

810-12* 1-1/4 10

810-15* 1-1/2 12

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

710-07

PVCCompression Fittings

FLO-LOCK MALE ADAPTER 730-07 3/4 25

(700-series) 730-10 1 18

730-12 1-1/4 12

730-15 1-1/2 18

730-20* 2 12

FLO-LOCK MALE ADAPTER 830-07 3/4 20

(800-series) 830-10 1 28

830-12 1-1/4 16

830-15* 1-1/2 12

730-20

731-10

733-12

810-15

830-07

831-12

FLO-LOCK FEMALE ADAPTER 731-07 3/4 25

(700-series) 731-10 1 15

731-12 1-1/4 12

731-15 1-1/2 18

731-20* 2 12

FLO-LOCK FEMALE ADAPTER 831-07 3/4 20

(800-series) 831-10 1 28

831-12 1-1/4 15

831-15* 1-1/2 12

FLO-LOCK SPIGOT ADAPTER 733-07 3/4 18

(700-series) 733-10 1 18

733-12 1-1/4 12

733-15 1-1/2 18

733-20* 2 12

FLO-LOCK SPIGOT ADAPTER 833-07 3/4 20

(800-series) 833-10 1 28

833-12 1-1/4 16

833-15* 1-1/2 12

For use with Schedule 40 PVC tees and ells

700-series for use on polybutylene tube size SDR-9-250 PSI ASTMD-2666 or

polyethylene tube size SDR-9-160 & 200 PSI ASTMD-2737

800-series for use on polyethylene pipe size SIDR-7, 160 & 200 PSI ASTMD-2239

*Insert Stiffeners supplied with

this fitting must be used.

833-10

Page 32

Galvanized Compression Couplings

Campbell

F3

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

GCC8

GCC6

GCC5

GCC4

GCC3

GCC2

part size pcs/pkg GALVANIZED

GCC2 1/2 Bulk COMPRESSION

GCC3 3/4 Bulk COUPLING

GCC4 1 Bulk (compression x

GCC5 1 1/4 Bulk compression)

GCC6 1-1/2 Bulk

GCC8 2 Bulk

Malleable iron coupling with rubber gasket

comes completely assembled

• material: malleable iron (ASTM A197)

• finish: galvanized

• operating temperature: up to 120°F

• operating pressure: up to 125 psi

• testing: Quality Assurance Program requires

Air Pressure Testing on all these couplings.

note: Pipe ends must be restrained during use.

Imported

Page 33

Poly-Pipe Compression Fittings

Campbell

F4

how the HANFLO Poly-Pipe Compression Fitting works

The nut of the HANFLO fitting clamps the inside of the pipe onto the barbs of the fitting

tail to create a high-pressure seal. The nut also gives a permanent vice-like grip onto the

outside of the poly-pipe to prevent pull-out.

CS25-200

HANFLO

™

FEMALE 1/2 FA15-80/100 FA15-125/160 FA15-200

ADAPTER 1/2 x 3/4 FA1520-80/100 FA1520-125/160 FA1520-200

(poly x female) 3/4 FA20-80/100 FA20-125/160 FA20-200

1 FA25-80/100 FA25-125/160 FA25-200

1-1/4 FA32-80/100 FA32-125/160 FA32-200

1. Square-cut the poly pipe

to the required length with

pipe cutters, knife, or saw.

features & benefits

• Corrosion-proof and rust-proof

• No heating of pipe required

• No screwdrivers, nut drivers, or

clamps required

• No O-ring

• No crimping

• No solvent cement required

• Non-toxic and non-metallic

materials

• Body: glass fibre reinforced nylon

• Nut: glass fibre reinforced acetal

• Circlip: acetal

quick and easy assembly

3. Tighten by hand or with

wrench until nut is engaged

against the circlip.

2. Push the fitting onto the

pipe up to the housing of

the white circlip.

MALE

ADAPTER size

(poly x male) 1/2 MA15-80/100 MA15-125/160 MA15-200

1/2 x 3/4 MA1520-80/100 MA1520-125/160 MA1520-200

1/2 x 1 MA1525-80/100 MA1525-125/160 MA1525-200

3/4 MA20-80/100 MA20-125/160 MA20-200

1 MA25-80/100 MA25-125/160 MA25-200

1 x 1-1/4 MA2532-80/100 MA2532-125/160 MA2532-200

1-1/4 MA32-80/100 MA32-125/160 MA32-200

1-1/4 x 1 MA3225-80/100 MA3225-125/160 MA3225-200

SIDR 19/15

80/100 psi

SIDR 11.5/9

125/160 psi

SIDR 7

200 psi

COUPLING 1/2 CS15-80/100 CS15-125/160 CS15-200

(poly x poly) 3/4 x 1/2 CS2015-80/100 CS2015-125/160 CS2015-200

3/4 CS20-80/100 CS20-125/160 CS20-200

1 x 1/2 CS2515-80/100 CS2515-125/160 CS2515-200

1 x 3/4 CS2520-80/100 CS2520-125/160 CS2520-200

1 CS25-80/100 CS25-125/160 CS25-200

1-1/4 x 1 CS3225-80/100 CS3225-125/160 CS3225-200

1-1/4 CS32-80/100 CS32-125/160 CS32-200

Each fitting has color-coded nuts, tag, and barcode.Tan nuts fit SIDR 19/15, Blue nuts fit

SIDR 11.5/9, and Grey nuts fit SIDR 7 poly pipe. Also available for Canadian pipe sizes.

POLY PIPE

BARBED TAIL BARBS

WHITE CIRCLIP

BODY

NUT

MA25-80/100

FA25-125/160

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Approved by CSA for potable water under

ANSI/NSF 61. Tested for long-term pressure

tests (1000 hours at 2.1 times pressure rating)

and pipe pull-out tests to ISO requirements.

For ips (iron pipe size).

10 Male Adapters per package.

10 Female Adapters per package.

10 Couplings per package.

Page 34

Poly-Pipe Compression Fittings

Campbell

F5

TEE

size (poly x

1/2 TS151515-80/100 TS151515-125/160 TS151515-200 poly x

3/4 x 3/4 x 1/2 TS202015-80/100 TS202015-125/160 TS202015-200 poly)

3/4 TS202020-80/100 TS202020-125/160 TS202020-200

1 x 1 x 1/2 TS252515-80/100 TS252515-125/160 TS252515-200

1 x 1 x 3/4 TS252520-80/100 TS252520-125/160 TS252520-200

1 TS252525-80/100 TS252525-125/160 TS252525-200

1-1/4 x 1-1/4 x 1 TS323225-80/100 TS323225-125/160 TS323225-200

1-1/4* TS323232-80/100 TS323232-125/160 TS323232-200

TF252525-125/160

HANFLO

™

SIDR 19/15

80/100 psi

SIDR 11.5/9

125/160 psi

SIDR 7

200 psi

1/2 TF151515-80/100 TF151515-125/160 TF151515-200 FEMALE

3/4 x 3/4 x 1/2 TF202015-80/100 TF202015-125/160 TF202015-200 TEE

3/4 TF202020-80/100 TF202020-125/160 TF202020-200 (poly x

1 x 1 x 1/2 TF252515-80/100 TF252515-125/160 TF252515-200 female x

1 x 1 x 3/4 TF252520-80/100 TF252520-125/160 TF252520-200 poly)

1 TF252525-80/100 TF252525-125/160 TF252525-200

1-1/4 TF323232-80/100 TF323232-125/160 TF323232-200

1/2 BF1515-80/100 BF1515-125/160 BF1515-200 FEMALE

3/4 x 1/2 BF2015-80/100 BF2015-125/160 BF2015-200 ELBOW

3/4 BF2020-80/100 BF2020-125/160 BF2020-200 (poly x

1 x 1/2 BF2515-80/100 BF2515-125/160 BF2515-200 female)

1 x 3/4 BF2520-80/100 BF2520-125/160 BF2520-200

1 BF2525-80/100 BF2525-125/160 BF2525-200

1-1/4 BF3232-80/100 BF3232-125/160 BF3232-200

1/2 BS1515-80/100 BS1515-125/160 BS1515-200 ELBOW

3/4 BS2020-80/100 BS2020-125/160 BS2020-200 (poly x

1 BS2525-80/100 BS2525-125/160 BS2525-200 poly)

1-1/4 BS3232-80/100 BS3232-125/160 BS3232-200

1/2 BM1515-80/100 BM1515-125/160 BM1515-200 MALE

3/4 BM2020-80/100 BM2020-125/160 BM2020-200 ELBOW

1 BM2525-80/100 BM2525-125/160 BM2525-200 (poly x

1-1/4 BM3232-80/100 BM3232-125/160 BM3232-200 male)

TS252525-80/100

BS2525-200

BM2525-125/160

BF2525-80/100

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

Approved by CSA for potable water under

ANSI/NSF 61. Tested for long-term pressure

tests (1000 hours at 2.1 times pressure rating)

and pipe pull-out tests to ISO requirements.

Each fitting has color-coded nuts, tag, and barcode.Tan nuts fit SIDR 19/15, Blue nuts fit

SIDR 11.5/9, and Grey nuts fit SIDR 7 poly pipe. Also available for Canadian pipe sizes.

For ips (iron pipe size).

10 Tees per package.

*1-1/4” Tees are 5 per package.

10 Elbows per package.

10 Elbows per package.

10 Elbows per package.

10 Tees per package.

Page 35

Poly-Pipe Compression Fittings

Campbell

F6

Campbell Manufacturing, Inc.

127 East Spring Street

P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

KU25PP-125/160

Approved by CSA for potable water under

ANSI/NSF 61. Tested for long-term pressure

tests (1000 hours at 2.1 times pressure rating)

and pipe pull-out tests to ISO requirements.

HANFLO

™

KNUCKLE size part pcs/pkg

UNION 3/4 KU20MF 10

(male x female) 1 KU25MF 10

1-1/4 KU32MF 5

KNUCKLE size pcs/pkg

UNION 3/4 KU20PP-80/100 KU20PP-125/160 10

(poly x poly) 1 KU25PP-80/100 KU25PP-125/160 10

1-1/4 KU32PP-80/100 KU32PP-125/160 5

SIDR 19/15

80/100 psi

SIDR 11.5/9

125/160 psi

KNUCKLE 3/4 KU20FP-80/100 KU20FP-125/160 10

UNION 1 KU25FP-80/100 KU25FP-125/160 10

(female x poly) 1-1/4 KU32FP-80/100 KU32FP-125/160 5

KNUCKLE 3/4 KU20MP-80/100 KU20MP-125/160 10

UNION 1 KU25MP-80/100 KU25MP-125/160 10

(male x poly) 1-1/4 KU32MP-80/100 KU32MP-125/160 5

KU25FP-80/100

KU25MP-125/160

KU25MF

Each fitting has color-coded nuts, tag, and barcode.Tan nuts fit SIDR 19/15, Blue nuts fit

SIDR 11.5/9 poly pipe. Also available for Canadian pipe sizes.

For ips (iron pipe size).

Page 36

Domestic Brass Check Valves

Campbell

G1

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

part size pcs/ctn master ctn CHECK VALVE

CV-3 3/4 1 –

CV-4* 1 1 –

CV-5 1-1/4 1 –

CV-6 1-1/2 1 –

CV-8 2 1 –

*Smooth body design (see photo)

CVA-3 3/4 1 – CHECK VALVE

CVA-4 1 1 – (1/8” inlet tap)

CVA-5 1-1/4 1 –

CVA-6 1-1/2 1 –

CVA-8 2 1 –

features

• Heavy red brass casting

• Vertical or horizontal position

• Brass poppet with

abrasion-resistant rubber seal

BCV-8 2 1 per box – BREMER CHECK VALVE

• Neoprene poppet seat and packer

• Tapered seat and poppet for positive seal

BCV-8-KIT 2 1 per bag – BREMER CHECK VALVE

REPAIR KIT

• Includes: leather, 3 washers, nut, and neoprene sleeve

CVC-6

CVB-4

BCV-8

CV-4

CVA-3

CVB-3 3/4 1 – CHECK VALVE

CVB-4 1 1 – (1/8” inlet tap,

CVB-5 1-1/4 1 – 1/4” outlet tap)

CVB-6 1-1/2 1 –

CVB-8 2 1 –

CVC-4 1 1 – CHECK VALVE

CVC-5 1-1/4 1 – (1/8” inlet tap,

CVC-6 1-1/2 1 – 1/8” and 1/4” outlet taps)

CVC-8 2 1 –

CV-3SP 3/4 1 – CHECK VALVE

CV-4SP 1 1 – (two 1/4” taps)

CV-5SP 1-1/4 1 –

CV-6SP 1-1/2 1 –

CV-8SP 2 1 –

• Stainless steel springs

• 180°F maximum operating temperature

• 200 psi WOG

Page 37

Imported Brass Check Valves

Campbell

G2

CHECK VALVE part size pcs/ctn master ctn

CV-2T 1/2 10 100

CV-3T 3/4 10 100

CV-4T 1 10 60

CV-5T 1-1/4 5 40

CV-6T 1-1/2 5 20

CV-8T 2 5 20

CV-12T 3 1 –

CV-16T 4 1 –

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

CVB-5T

CHECK VALVE CVA-4T 1 10 60

(1/8” inlet tap) CVA-5T 1-1/4 5 40

CHECK VALVE CVB-3T 3/4 10 100

(1/8” inlet tap, CVB-4T 1 10 60

1/4” outlet tap) CVB-5T 1-1/4 5 40

CHECK VALVE CV-4FXMT 1 10 60

(fpt x mpt) CV-4FX5MT 1 x 1-1/4 10 60

features

• Certified red brass casting

• Stainless steel spring

• Non-corrosive nylon stem guide

• Machined exterior

• Abrasion-resistant NBR O-ring

• 200 psi WOG

• 190°F maximum operating temperature

• Individually boxed

CV-4FX5MT

CVA-4T

CV-2T

Page 38

Foot Valves

Campbell

G3

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

part size pcs/ctn master/ctn FOOT VALVE

FV-3 3/4 1 – (domestic)

FV-4 1 1 –

FV-5 1-1/4 1 –

FV-6 1-1/2 1 –

FV-8 2 1 –

• Heavy red brass casting

• Stainless steel screen, cap, and spring

• Brass poppet with abrasion-resistant rubber seal

• 200 psi WOG

FV-5

FV-4T

FV-3T

FV-5FX6MT

FV-2T 1/2 10 100 FOOT VALVE

FV-3T 3/4 10 100 (imported)

FV-4T 1 10 100

FV-5T 1-1/4 5 50

FV-6T 1-1/2 5 40

FV-8T 2 5 20

FV-12T 3 1 –

• Certified red brass casting

• Tapered stainless steel screen and cap

• Stainless steel spring

• Non-corrosive nylon stem guide

• Abrasion-resistant NBR O-ring

FV-3FX4MT 3/4 x 1 10 100 FOOT VALVE

FV-4FX5MT 1 x 1-1/4 10 100 (fpt x mpt, imported)

FV-5FX6MT 1-1/4 x 1-1/2 5 50

• Certified red brass casting

• Tapered stainless steel screen and cap

• Stainless steel spring

• Non-corrosive nylon stem guide

• Abrasion-resistant NBR O-ring

5820E* 1/2 1 10

4100E 3/4 1 100 FOOT VALVE

4101E 1 1 49 (60SE-series)

4102E** 1-1/4 1 49

4103E 1-1/4 1 36

4104E 1-1/2 1 25

4105E 2 1 16

4106E 2-1/2 1 1

4107E 3 1 1

4108E 4 1 1

• Unleaded Enviro-Check®body

• Stainless steel spring and screen

(*5820E model has a polyethylene screen)

• Nitrile (Buna-N) seal

• Non-spin acetal poppet

4102E

All Foot Valves individually packaged.

part fits pipe sizes pcs/bag master ctn FOOT VALVE

FV4IN1 3/4, 1, 1-1/4, and 1-1/2 1 – (plastic)

• Acetal celcon body & screen

• Stainless steel hardware

• 200 psi WOG

• Machined exterior

• 190°F maximum operating temperature

• 200 psi WOG

• Machined exterior

• 190°F maximum operating temperature

• 250 psi WOG maximum

(1/2” size: 150 psi)

• 180°F (80C)

maximum operating temperature

** Will pass through a 2” pipe.

FV-4IN1

UNLEADED

ENVIRO-CHECK

®

Page 39

Check Valves

Campbell

G4

part size pcs/ctn master/ctn

CHECK VALVE 4029E 1/2 1 100

(80E-series) 4030E 3/4 1 100

4031E 1 1 49

4032E 1-1/4 1 36

4033E 1-1/2 1 25

4034E 2 1 16

4035E* 2-1/2 1 –

4036E* 3 1 –

4037E* 4 1 –

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

4034E

4201E 1 1 49

CHECK VALVE 4202E 1-1/4 1 36

(100E-series)

4061E 1 1 49

CHECK VALVE 4062E 1-1/4 1 36

(80CE-series)

CHECK VALVE 4201SS2** 1 1 49

(80/100SS-series) 4202SS2** 1-1/4 1 36

4033SS2 1-1/2 1 25

4034SS2 2 1 16

CHECK VALVE 4031DI***

C

1149

(80DI-series) 4032DI***

C

1-1/4 1 36

4033DI***

C

1-1/2 1 25

7937

C

2116

7936 2-1/2 1 –

7938 3 1 –

7939 4 1 –

4088 5 1 –

4089 6 1 –

4090 8 1 –

• 1/8” inlet tap, two 1/4” outlet taps, and

1/8” outlet tap with brass plug

• Stainless steel spring

• Non-spin acetal poppet

• Nitrile (Buna-N) seal

• Stainless steel spring

• Non-spin acetal poppet

(* Unleaded bronze poppet on 2-1/2 thru 4” sizes)

• Nitrile (Buna-N) seal

• Hex shaped body for easy wrenching

• Stainless steel spring

• Non-spin acetal poppet

• Nitrile (Buna-N) seal

• 303 Stainless Steel one-piece body

(**1” and 1-1/4” sizes have hex-style body)

• Stainless steel spring

• Non-spin acetal poppet

• Nitrile (Buna-N) seal

• High strength epoxy-coated ductile iron body, disc,

and follower (

C

1” thru 2” sizes have cast steel body)

• Stainless steel spring fasteners

• Ductile iron poppet

(***1” thru 1-1/2” sizes have acetal poppet)

• Nitrile (Buna-N) seal

All models are rated at

400 psi WOG maximum pressure and

180°F (80C) maximum operating temperature

UNLEADED

ENVIRO-CHECK

®

UNLEADED

ENVIRO-CHECK

®

UNLEADED

ENVIRO-CHECK

®

4032DI

4061E

4201E

4201SS2

Page 40

Valves

Campbell

G5

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

BSC125 1-1⁄4 1 SUMP PUMP

BSC150 1-1⁄2 1 CHECK VALVE

(mpt x insert)

• Durable ABS thermoplastic for long life

• Full flow design for reduced pump cycling

• Buna-N flapper for positive seal

• Threads into pump discharge and adapts to

sump pump discharge hose kit or poly pipe

• Working pressure 25 psi max

Not recommended for use in gasoline

systems, or at working pressures in

excess of 200 psi.

part size pcs/ctn LINE CHECK VALVE

SLC-75 3⁄4 1 (with spring)

SLC-100 1 1

SLC-125 1-1/4 1

SLC-150 1-1/2 1

LC-75 3⁄4 1 LINE CHECK VALVE

LC-100 1 1 (without spring)

LC-125 1-1/4 1

LC-150 1-1/2 1

SFV-75 3⁄4 1 FOOT VALVE

SFV-100 1 1 (with spring)

SFV-125 1-1/4 1

SFV-150 1-1/2 1

FV-75 3⁄4 1 FOOT VALVE

FV-100 1 1 (without spring)

FV-125 1-1/4 1

FV-150 1-1/2 1

SS-75 3⁄4 Bulk STRAINER

SS-100 1 Bulk

SS-125 1-1/4 Bulk

SS-150 1-1/2 Bulk

features

• Can be installed horizontally or vertically

• Made from non-conductive, non-corrosive delrin

• For use in water well, irrigation, and other systems where

backflow prevention and loss of prime are required

BSC-125-SB 1-1⁄4 Bulk SUMP PUMP

BSC-150-SB 1-1⁄2 Bulk CHECK VALVE

BSC-200-SB 2 Bulk (with sleeves)

• Includes straight flexible rubber sleeves

for inlet and outlet sides of valve,

and 4 stainless steel clamps

FV-125

BSC-125- SB

SFV-75

SLC-125

LC-100

SS100

BSC125

Page 41

PVC Check Valves

Campbell

G6

SWING CHECK SC5 1500-12 1-1⁄4 12

(compression) SC6 1500-15 1-1⁄2 12

SC8 1500-20 2 12

SC12 1500-30 3 2

(clear body) 1500C-12 1500C-12 1-1⁄4 12

1500C-15 1500C-15 1-1⁄2 12

1500C-20 1500C-20 2 12

1500C-30 1500C-30 3 2

• Angled seat and weighted & shielded

pvc flapper for low pressure seal

• Designed for both horizontal or vertical uses

SPRING CHECK Campbell Flo-control ips

(fpt x fpt) part part size pcs/ctn

FCCV 2 1001-05 1⁄2 20

FCCV 3 1001-07 3⁄4 20

FCCV 4 1001-10 1 20

FCCV 5 1001-12 1-1⁄4 15

FCCV 6 1001-15 1-1⁄2 15

FCCV 8 1001-20 2 10

(clear body) 1001C-05 1001C-05 1⁄2 20

1001C-07 1001C-07 3⁄4 20

1001C-10 1001C-10 1 20

1001C-12 1001C-12 1-1⁄4 15

1001C-15 1001C-15 1-1⁄2 15

1001C-20 1001C-20 2 10

• Spring tension: 1⁄2 lb.

SPRING CHECK FCCV 2S 1011-05 1⁄2 20

(slip x slip) FCCV 3S 1011-07 3⁄4 20

FCCV 4S 1011-10 1 20

FCCV 5S 1011-12 1-1⁄4 15

FCCV 6S 1011-15 1-1⁄2 15

FCCV 8S 1011-20 2 10

(clear body) 1011C-05 1011C-05 1⁄2 20

1011C-07 1011C-07 3⁄4 20

1011C-10 1011C-10 1 20

1011C-12 1011C-12 1-1⁄4 15

1011C-15 1011C-15 1-1⁄2 15

1011C-20 1011C-20 2 10

• Spring tension: 1⁄2 lb.

SUMP PUMP SPCV1 1400-15 1-1⁄4 to 1-1⁄2 12

SWING CHECK

(compression) • Weighted Buna-N flapper and Buna-N gaskets

• Gaskets for both 1-1⁄4" and 1-1⁄2" provided with each valve

• Sump pumps with larger volume output use 1500 or 1520

series Swing Check.

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

SC8

Other Flo-Control products and sizes

available upon request.

ADJUSTABLE 1205-05 1205-05 1⁄2 20

SPRING CHECK 1205-07 1205-07 3⁄4 20

(fpt x fpt) 1205-10 1205-10 1 20

1205-12 1205-12 1-1⁄4 15

1205-15 1205-15 1-1⁄2 15

• Spring tension: 5 to 15 lbs. (Factory preset at 5 lb.)

ADJUSTABLE 1235-05 1235-05 1⁄2 20

SPRING CHECK 1235-07 1235-07 3⁄4 20

(fpt x mpt) 1235-10 1235-10 1 20

1235-12 1235-12 1-1⁄4 15

1235-15 1235-15 1-1⁄2 15

• Spring tension: 5 to 15 lbs. (Factory preset at 5 lb.)

FCCV 8

1500C-15

FCCV 4S

1011C-12

1001C-07

1205-05

1235-10

SPCV1

Page 42

PVC Check Valves

Campbell

G7

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

1720C-20

1520-05F 1520-05F 1/2 20 SWING CHECK

1520-07F 1520-07F 3/4 25 (fpt x fpt)

1520-10F 1520-10F 1 25

1520-12F 1520-12F 1-1⁄4 12

1520-15F 1520-15F 1-1⁄2 12

1520-20F 1520-20F 2 12

1520C-05F 1520C-05F 1/2 20 (clear body)

1520C-07F 1520C-07F 3/4 25

1520C-10F 1520C-10F 1 25

1520C-12F 1520C-12F 1-1⁄4 12

1520C-15F 1520C-15F 1-1⁄2 12

1520C-20F 1520C-20F 2 12

• Angled seat and weighted & shielded pvc flapper for low pressure seal

• Designed for both horizontal or vertical uses

Campbell Flo-control ips SWING CHECK

part part size pcs/ctn (slip x slip)

1520-05 1520-05 1/2 20

1520-07 1520-07 3/4 25

1520-10 1520-10 1 25

1520-12 1520-12 1-1⁄4 12

1520-15 1520-15 1-1⁄2 12

1520-20 1520-20 2 12

1520-30 1520-30 3 4

1520-40 1520-40 4 1

1520C-05 1520C-05 1/2 20 (clear body)

1520C-07 1520C-07 3/4 25

1520C-10 1520C-10 1 25

1520C-12 1520C-12 1-1⁄4 12

1520C-15 1520C-15 1-1⁄2 12

1520C-20 1520C-20 2 12

1520C-30 1520C-30 3 4

1520C-40 1520C-40 4 1

• Angled seat and weighted & shielded pvc flapper for low pressure seal

• Designed for both horizontal or vertical uses

1700-15 1700-15 1-1/2 12 TRUE UNION

1700-20 1700-20 2 12 SPRING CHECK

1700C-15 1700C-15 1-1/2 12 (clear body)

1700C-20 1700C-20 2 12

Spring tension: 1/2 lb.

1720-15 1720-15 1-1/2 12 TRUE UNION

1720-20 1720-20 2 12 SWING CHECK

1720C-15 1720C-15 1-1/2 12 (clear body)

1720C-20 1720C-20 2 12

1790-15 1790-15 1-1/2 15 COMPACT

1790-20 1790-20 2 10 TRUE UNION

SPRING CHECK

1790C-15 1790C-15 1-1/2 15 (clear body)

1790C-20 1790C-20 2 10

Spring tension: 1/2 lb.

Other Flo-Control products and sizes

available upon request.

1790-20

1700-15

1520-20

1520C-12F

1520C-12

1520-10F

Page 43

Cast Iron Foot Valves

Campbell

G8

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

FOOT VALVE part pipe size

(ips) FV540-4 1

FV540-5 1-1/4

FV540-6 1-1/2

FV540-8 2

FV540-10 2-1/2

FV540-12 3

FV540-16 4

FV540-20 5

FV540-24 6

FV540-32 8

All valves painted

FOOT VALVE strainer size

REPLACEMENT PARTS RP1 1

RP2 1-1/4

RP3 1-1/2

RP4 2

RP5 2-1/2 or 3

RP7 4

RP8 5

RP9 6

RP10 8

seat plate size

RP11 1

RP12 1-1/4

RP13 1-1/2

RP14 2

RP15 2-1/2 or 3

RP17 4

RP18 5

RP19 6

RP20 8

valve assembly size

RP21 1

RP22 1-1/4

RP23 1-1/2

RP24 2

RP25 2-1/2 or 3

RP27 4

RP28 5

RP29 6

RP30 8

o.d.

valve leather size leather

RP31 1 2-1/2

RP32 1-1/4 2-3/4

RP33 1-1/2 3

RP34 2 4-1/4

RP35 2-1/2 or 3 5-1/2

RP37 4 7

RP38 5 9

RP39 6 9-3/4

RP40 8 13

STEEL SUCTION part size o.d hole size

STRAINER SSS6 1-1/2 4-7/8 3/8

SSS8 2 6 3/8

SSS10 2-1/2 6-1/2 3/8

SSS12 3 6-1/2 3/8

SSS16 4 6-7/8 3/8

SSS20 5 8-1/4 3/8

SSS24 6 9-1/16 1

Constructed of zinc-plated, 16 gauge, cold-rolled steel

FV540-12

SSS10

FV540-6

Page 44

Check Valves

Campbell

G9

Campbell Manufacturing, Inc.

127 East Spring Street, P.O. Box 207

Bechtelsville, PA 19505-0207

800-523-0224, Fax 610-369-3580

part inlet size outlet size pcs/ctn CHECK VALVE

CH-150S 1-1/2 1-1/2 Bulk (sleeve x sleeve)

• For vertical or horizontal in-line applications

• Strong, durable, corrosion-resistant ABS body

• Stainless steel clamps

CH-150S

part inlet size outlet size pcs/ctn 4-WAY

H-125/150MT 1-1/4 or 1-1/2 mpt 1-1/4 or 1-1/2 Bulk CHECK VALVE

(mpt x sleeve)

• Threads directly into 1-1/4” or 1-1/2” pump discharge

• Sleeve is reversible to fit 1-1/4” or 1-1/2”

black, galvanized, or DWV (Sch. 40) pipe

• Strong, durable, corrosion-resistant ABS body

• Stainless steel clamps

part inlet size outlet size pcs/ctn 2-WAY SUMP

DJ545 1-1/4 or 1-1/2 1-1/4 or 1-1/2 Bulk CHECK VALVE

(sleeve x sleeve)

• Sleeve is reversible to fit 1-1/4” or 1-1/2”