Page 1

precautions must be observed at all

times:

1.

Read all manuals

included with this

product carefully. Be

thoroughly familiar

with the controls and

the proper use of the equipment.

2. Follow all local electrical and safety

codes as well as in the US, National

Electrical Codes (NEC) and Occupational

Safety and Health Act (OSHA).

assistance or call the nearest Campbell

Hausfeld Authorized Service Center.

A listing of service center locations is

enclosed. Have the serial number,

model number, and parts list (with

missing parts circled) before calling.

Do not operate

unit if damaged

during shipping, handling or use.

Damage may result in bursting and

cause injury or property damage.

General Safety

Information

Since the air compressor and other

components (material pump, spray

guns, filters, lubricators, hoses, etc.)

used, make up a high pressure

pumping system, the following safety

!

WARNING

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could

result in personal injury and/or property damage! Retain instructions for future reference.

Description

Oilless compressors are designed for

do-it-yourselfers with a variety of home

and automotive jobs. These

compressors power spray guns, impact

wrenches and other tools. These units

operate without oil.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

C

aution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, MAY

cause damage to equipment.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may have

occurred during transit. Make sure to

tighten fittings, bolts, etc., before

putting unit into service. In case of

questions, damaged or missing parts,

please call 1-800-543-6400 for customer

NOTICE

!

CAUTION

!

WARNING

!

DANGER

Operating Instructions FP Series

IN609001AV 5/03

Breathable Air Warning

This compressor/pump is not

equipped and should not be used

“as is” to supply breathing quality

air. For any application of air for

human consumption, the air

compressor/pump will need to be

fitted with suitable in-line safety

and alarm equipment. This

additional equipment is necessary

to properly filter and purify the air

to meet minimal specifications for

Grade D breathing as described in

Compressed Gas Association

Commodity Specification G 7.1 1966, OSHA 29 CFR 1910. 134,

and/or Canadian Standards

Associations (CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used

for the purpose of breathing air

application and proper in-line

safety and alarm equipment is not

simultaneously used, existing

warranties shall be voided, and

Campbell Hausfeld disclaims any

liability whatsoever for any loss,

personal injury or damage.

!

DANGER

MANUAL

STOP!

Record the Model No., Serial No. and

date of purchase located on the

compressor serial number tag.

Model No. ____________________

Serial No. ____________________

Date of purchase _________________

Retain these numbers for future

reference.

Q

U

A

L

I

T

Y

A

S

S

U

R

A

N

C

E

P

R

O

G

R

A

M

Need

Assistance?

Call Us First!

1-800-543-8622

Oilless Air Compressors

DO NOT RETURN THE

PRODUCT TO THE

RETAILER!

For parts, product & service information

visit www.chpower.com

© 2003 Campbell Hausfeld/Scott Fetzer

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

See Warranty on page 8 for important information about commercial use of this product.

Page 2

Page 3

FP Series

3

Installation (Cont.)

compressor in a clean, well ventilated area

where the surrounding air temperature

will not be more than 100°F.

A minimum clearance of 18 inches

between the compressor and a wall is

required because objects could obstruct

air flow.

Do not locate the

compressor air

inlet near steam, paint spray, sandblast

areas or any other source of

contamination. This debris will damage

the motor.

ELECTRICAL INSTALLATION

All wiring and

electrical

connections should be performed by a

qualified electrician. Installation must be

in accordance with local codes and

national electrical codes.

Never use an extension

cord with this product. Use

additional air hose instead

of an extension cord to

avoid power loss and permanent motor

damage. Use of an extension cord voids

the warranty.

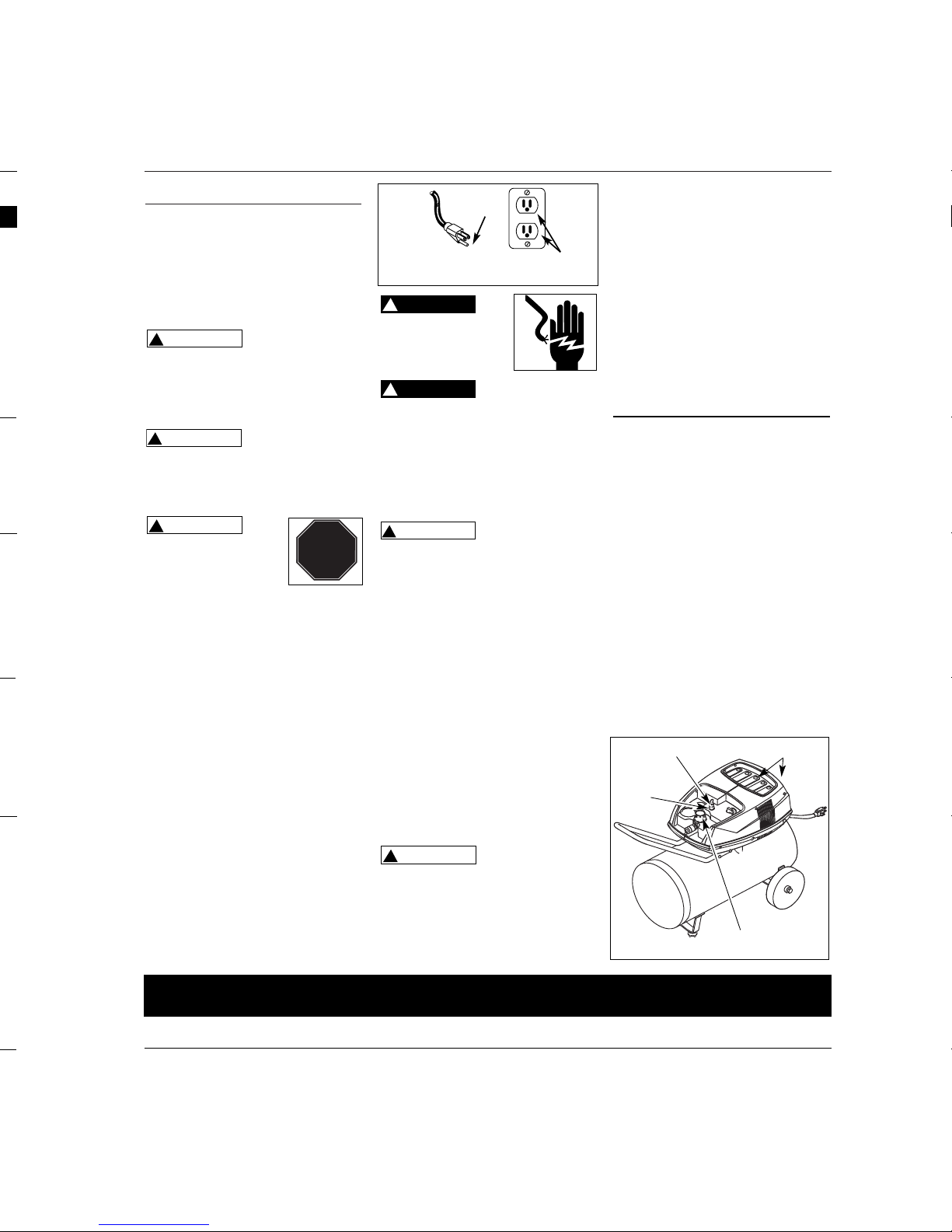

GROUNDING INSTRUCTIONS

1. This product is for use on a nominal

120 volt circuit and has a grounding

plug that looks like the plug illustrated

in Fig. 3. Make sure the product is

connected to an outlet having the

same configuration as the plug. This

product must be grounded. In the

event of an electrical short circuit,

grounding reduces risk of electrical

shock by providing an escape wire for

electric current. This product is

equipped with a cord having a

grounding wire with an appropriate

grounding plug. Plug must be plugged

into an outlet that is properly installed

and grounded in accordance with all

local codes and ordinances.

!

CAUTION

!

WARNING

!

CAUTION

Improper use of

grounding plug can result in a possible risk of

electrical shock!

Do not use a

grounding adapter

with this product!

2. If repair or replacement of cord or plug

is necessary, do not connect grounding

wire to either flat blade terminal. The

wire with insulation having an external

surface that is green (with or without

yellow stripes) is the grounding wire.

Never connect

green (or green and

yellow) wire to a live terminal.

3. Check with a qualified electrician or

serviceman if grounding instructions

are not completely understood, or if in

doubt as to whether product is

properly grounded. Do not modify

plug provided; if it will not fit outlet,

have proper outlet installed by a

qualified electrician.

WIRING

1.

Local electrical wiring codes differ from

area to area. Source wiring, plug and

protector must be rated for at least the

amperage and voltage indicated on

motor nameplate, and meet all electrical

codes for this minimum.

2. Use a slow blow fuse or a circuit

breaker.

Overheating, short

circuiting and fire

damage will result from inadequate

wiring, etc.

NOTE: 120 volt, 15 amp units can be

operated on a 120 volt circuit under the

following conditions:

!

CAUTION

!

WARNING

!

DANGER

!

DANGER

a. No other electrical appliances or lights

are connected to the same branch

circuit.

b. Voltage supply is normal.

c. Circuit is equipped with a 15 amp

circuit breaker or a 15 amp slow blow

fuse.

3. If these conditions cannot be met or if

nuisance tripping of current

protection device occurs, it may be

necessary to operate compressor from

a 120 volt, 20 amp circuit.

Operation

Pressure Switch - Auto/Off Switch - In

the ON position, the compressor shuts

off automatically when tank pressure

reaches the maximum preset pressure.

The compressor will automatically

restart when it reaches the minimum

preset pressure. In the OFF position,

the compressor will not operate. This

switch should be in the OFF position

when connecting or disconnecting the

power cord from the electrical outlet

or when changing air tools.

Regulator - The regulator controls the

amount of air pressure released at the

hose outlet.

ASME Safety Valve - This valve

automatically releases air if the tank

pressure exceeds the preset maximum.

TEST

RESET

Figure 3 - Grounding Method

STOP!

Grounding

Pin

Grounded Outlet

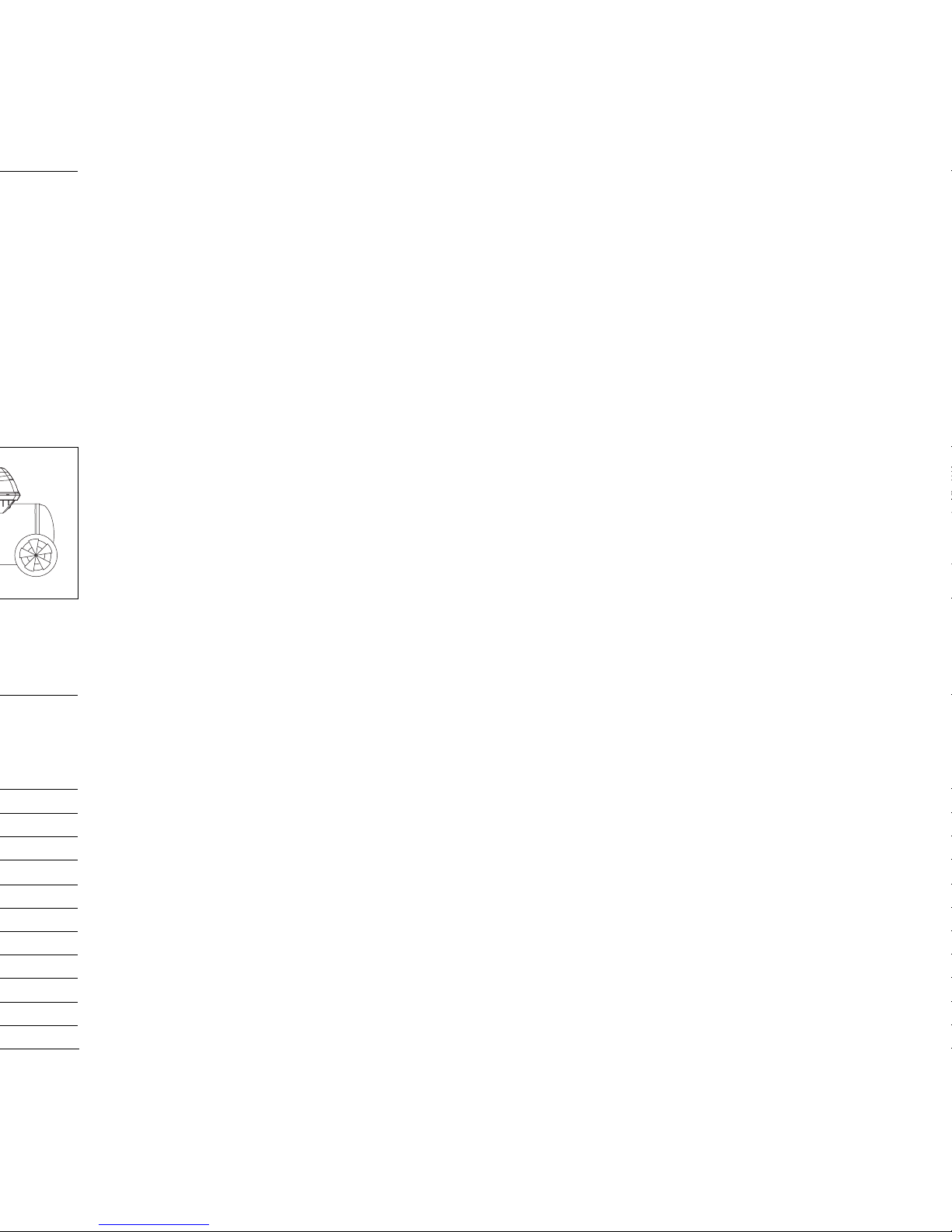

Figure 4

www.chpower.com

Tool Storage

Safety Valve

Pressure

Switch

Regulator

Gauge of Cord 18 14 12 10 88664

Extension cords for 120V/8 Amp Unit

Length of Cord (ft) 25 50 100 150 200 250 300 400 500

Page 4

Serie FP

Page 5

5

Maintenance

The compressor should be checked

often for any visible problems and the

following maintenance procedures

should be performed each time the

compressor is used.

1. Pull ring on safety valve and allow it

to snap back to normal position.

Safety valve must

be replaced if it

cannot be actuated or it leaks air after

ring is released.

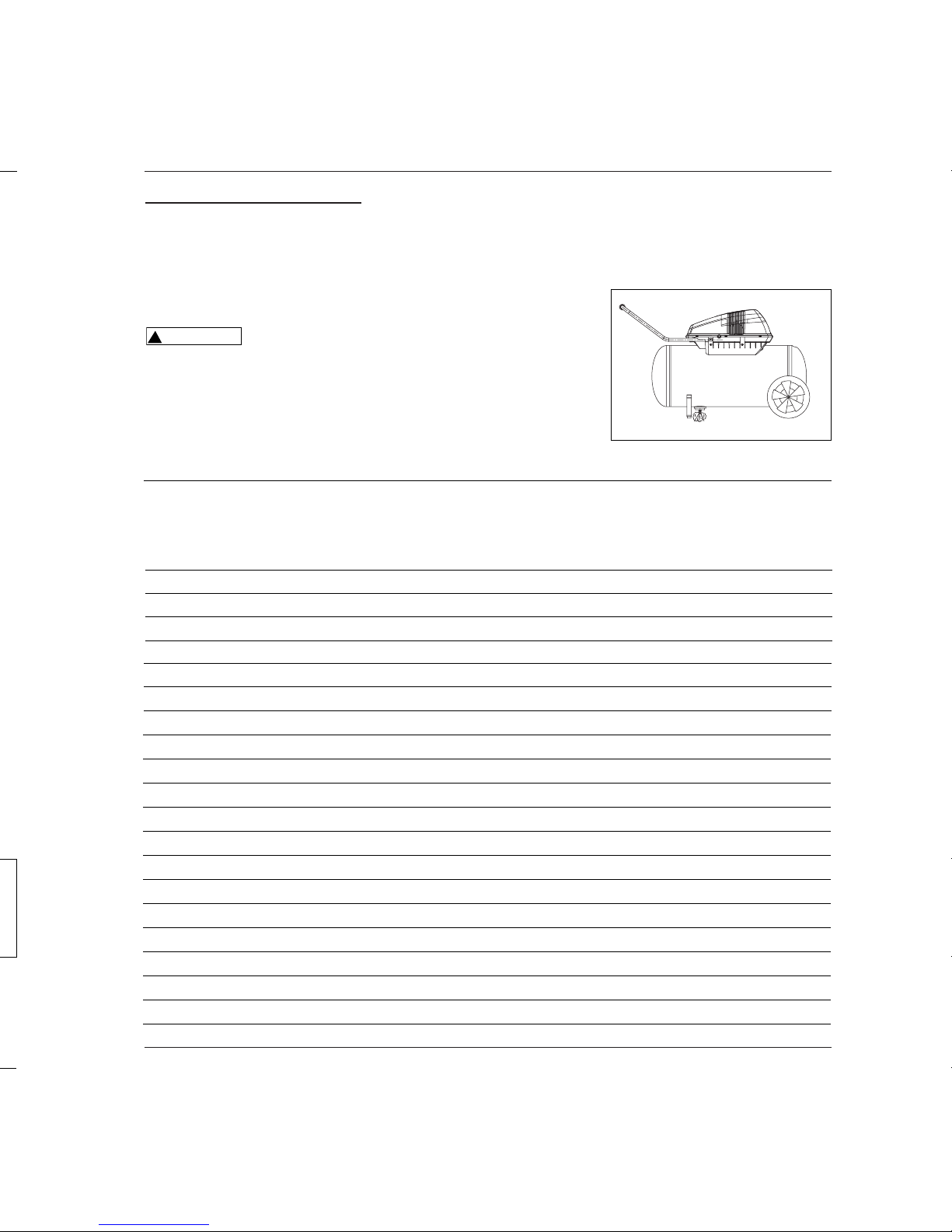

2. Place unit in the horizontal position

as shown in Figure 8. With

compressor shut off and pressure

released: Drain moisture from tank

!

WARNING

by opening drain cock underneath

tank.

3. Turn power OFF and clean dust and

dirt from pump cover, tank and air

lines.

IMPORTANT: Unit should be located as

far from spraying area as hose will

allow to prevent over-spray from

clogging filter.

LUBRICATION

This is an oilless type compressor

requiring no lubrication.

STORAGE

1. When not in use, hose and compressor should be stored in a cool dry

place.

2. Tank should be drained of moisture.

3. Hose should be disconnected and

hung open ends down, to allow any

moisture to drain.

Figure 8

FP Series

Notes

www.chpower.com

Page 6

Page 7

7

Troubleshooting Chart (Continued)

Symptom Possible Cause(s) Corrective Action

1. Excessive water in tank

2. High humidity

1. Defective pressure switch

2. Excessive air usage

1. Excessive condensation in tank

2. Air leaks in piping (on machine or in

outside system)

3. Tank check valve leaking

Check valve stuck in an open position

Belt broken

1. Drain tank

2. Move to area of less humidity; use air line filter

1. Replace switch

2. Decrease air usage; compressor not large enough for

air requirement

1. Drain more often

2. Replace leaking components or tighten as necessary

3. Replace or repair as necessary

Do not disassemble check valve

with air in tank; bleed tank

Remove and replace check valve

Do not disassemble check valve

with air in tank; bleed tank

Replace belt

!

DANGER

!

DANGER

Excessive moisture in

discharge air

Compressor runs

continuously

Excessive starting and

stopping (auto start)

Air leaking from

unloader on pressure

switch

Motor runs but no air

output

FP Series

www.chpower.com

Tool Recommendations for this Air Compressor

RECOMMENDED TOOLS FOR

CONTINUOUS USE

Home hobby spray guns

Brad nailers

Framing nailers

Grease guns

Caulk guns

Air brush kits

Pop rivets

Punch/flange tools

Drain cleaners

RECOMMENDED TOOLS FOR

INTERMITTENT USE

(Short powerful bursts)

Impact wrenches

Drills

Chisels

Butterfly impact wrench

Ratchets

Reciprocating saws

Screwdrivers

Engine cleaners

TOOLS NOT RECOMMENDED

Straight line sanders

Highspeed sanders

Dual action sanders

Jitterbug sanders

Die grinders

Cut-off tools

Air drills

Page 8

Page 9

système de haute pression, il est

nécessaire de suivre les précautions

suivantes:

1. Lire attentivement tous

manuels compris avec ce

produit. Se familiariser

avec ce produit, ses

commandes et son utilisation.

2. Suivre tous les codes de sécurité

locaux ainsi que les National Electrical

Codes (NEC) and Occupational Safety

and Health Act (OSHA) des É-U.

ou appeler un Centre De Service Autorisé

Campbell Hausfeld.

Une liste de centres de services est ciincluse. Prière d’avoir le numéro de série,

numéro de modèle et liste de pièces (avec

les pièces manquantes encerclées) avant

d’appeler.

Ne pas

utiliser un

modèle qui a été endommagé pendant le

transport, la manipulation ou l’utilisation.

Le dommage peut résulter en explosion et

peut causer des blessures ou dégâts

matériels.

Généralités Sur La

Sécurité

Puisque le compresseur d’air et les autres

pièces détachées (pompe, pistolets, filtres,

graisseurs, tuyaux, etc.) font partie d’un

!

AVERTISSEMENT

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser ou de procéder à l’entretien du produit

décrit. Se protéger ainsi que les autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels!

Conserver ces instructions comme référence.

9Fr

Description

Les compresseurs sans huile sont conçus

pour les bricoleurs avec projets

domestiques et d’automobile. Ces

compresseurs servent à faire fonctionner

les pistolets à peinture, clés à chocs et

autres outils. Ces modèles

fonctionnent sans huile.

Directives De Sécurité

Ce manuel contient de l’information très

importante qui est fournie pour la

SÉCURITÉ et pour ÉVITER LES PROBLÈMES

D’ÉQUIPEMENT. Rechercher les symboles

suivants pour cette information.

Danger

indique

une situation hasardeuse imminente qui

RÉSULTERA en perte de vie ou blessures

graves.

Avertis-

sement

indique une situation hasardeuse

potentielle qui PEUT résulter en perte de

vie ou blessures graves.

Attention

indique

une situation hasardeuse potentielle qui

PEUT résulter en blessures.

Avis

indique

de l’information importante pour éviter le

dommage de l’équipement.

Déballage

Lors du déballage de ce produit,

l’examiner soigneusement pour

rechercher toute trace de dommage

susceptible de s’être produit en cours de

transport. Veiller à serrer tous raccords,

boulons, etc., avant de mettre ce produit

en service. En cas de dommage ou de

pièces manquantes, S.V.P. composer le

1-800-543-8622 pour demander conseil

AVIS

!

ATTENTION

!

AVERTISSEMENT

!

DANGER

Instructions d’Utilisation Série FP

IN609001AV 5/03

Avertissement D’Air Respirable

Ce compresseur/pompe n’est pas

équipé pour et ne devrait pas être

utilisé “comme soi” pour fournir de l’air

respirable. Pour les applications d’air

pour la consommation humaine, il est

nécessaire d’équiper le compresseur

d’air/pompe avec de l’équipement de

sécurité en canalisation et d’alarme. Cet

équipement additionnel est nécessaire

pour filtrer et purifier l’air afin

d’atteindre les spécifications minimales

pour la respiration Grade D décrite

dans le Compressed Gas Association

Commodity Specification G 7.1 - 1966,

OSHA 29 CFR 1910. 134, and/or

Canadian Standards Associations

(CSA).

DÉNÉGATION DES GARANTIES

Si le compresseur est utilisé pour les

applications d’air respirable et

l’équipement de sécurité en

canalisation et d’alarme n’est pas utilisé

simultanément, les garanties en

existance seront annulées, et Campbell

Hausfeld dénie toute responsabilité

pour n’importe quelle perte, blessure

ou dommage.

!

DANGER

ARRÊT!

Enregistrer le No. de Modèle, No. de

Série, et la Date d’Achat située sur

l’étiquette avec le numéro de Série du

compresseur.

No. de Modèle ____________________

No. de Série ____________________

Date d’Achat ____________________

Garder ces numéros pour référence

Compresseurs d’Air Sans Huile

MANUEL

NE PAS RENVOYER LE

PRODUIT AU

MARCHAND!

© 2003 Campbell Hausfeld/Scott Fetzer

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Voir la Garantie à la page 16 pour de l’information importante sur l’utilisation commercial de ce produit.

Page 10

Page 11

a été installée et mise à la terre

correctement en respectant tous les

codes et règlements locaux.

L’usage incorrect d’une fiche de

mise à la terre peut résulter

en secousse électrique!

Ne pas

utiliser un

adaptateur de mise à la terre avec ce

produit!

2. Si la réparation ou le remplacement du

cordon ou de la fiche est nécessaire, ne

pas connecter le fil de terre à ni une ni

l’autre borne plate. Le fil avec l’isolation

qui a une surface externe verte (avec ou

sans jaunes) est le fil de terre.

Ne jamais

brancher

le fil vert (ou vert et jaune) à une borne

électrisée.

3. Si vous ne comprenez pas les

instructions pour la mise à la terre ou si

vous n’êtes pas certains si le produit est

mis à la terre correctement, vérifier

avec un électricien ou une personne

qualifiée. Ne pas modifier la fiche

fournie; si la fiche n’est pas la bonne

taille pour la prise de courant, contacter

un électricien qualifié pour l’installation

d’une nouvelle prise de courant.

INSTALLATION DE FILS

1. Les codes électriques d’installation de

fils sont variables d’un endroit à

l’autre. Les fils d’alimentation, fiche et

protecteurs doivent être classifiés pour

au moins l’ampérage et la tension

indiqués sur la plaque indicatrice du

moteur et doivent répondre aux codes

électriques pour ce minimum.

2. Utiliser une fusée à retardement ou un

disjoncteur.

!

AVERTISSEMENT

!

DANGER

!

DANGER

Installation

ENDROIT

Une fois monté, le réservoir doit être

nivelé ou incliné un peu vers le robinet de

vidange afin de permettre le vidange

correct.

Il est très important d’installer le

compresseur dans un endroit propre et

bien ventilé où la température n’excédera

pas 38ºC (100ºF).

Un espace libre minimum de 45,7

centimètres entre le compresseur et un

mur est exigé pour éviter le stoppage d’air

par des objets.

Ne pas

situer la

prise d’air du compresseur près de la

vapeur, un jet pulvérisé de peinture,

endroits de décapage au sable ou autre

sources de contamination. Le débris

endommagera le moteur.

INSTALLATION ÉLECTRIQUE

Seul un

électricien

qualifié doit effectuer l’installation

électrique et raccordements électriques.

Respecter toutes les codes locals et

nationales de l’électricité.

Ne jamais utiliser un cordon

prolongateur avec ce produit.

Utiliser un tuyau flexible à air additionnel

au lieu d’un cordon prolongateur pour

éviter une perte de puissance et dommage

du moteur. Usage d’un cordon

prolongateur sert à annuler la garantie.

INSTRUCTIONS DE MISE À LA TERRE

1. Ce produit est conçu pour l’utilisation

d’un circuit de 120 volts et a une fiche

de mise à la terre comme celle indiquée

sur la Fig. 3. S’assurer que le modèle soit

branché à une prise de courant qui a la

même configuration que la fiche. Ce

produit doit être mis à la terre. Dans

l’évenement d’un court-circuit, la mise à

la terre diminue le risque de secousse

électrique en fournissant un fil

d’échappement pour le courant

électrique. Ce produit est équipé d’un

cordon qui a un fil de terre avec une

fiiche de terre. La fiche doit être

branchée dans une prise de courant qui

!

ATTENTION

!

AVERTISSEMENT

!

ATTENTION

Série FP

11 Fr

L’instal-

lation de

fils insuffisante peut résulter en

surchauffage, court-circuit et en

dommage d’incendie.

REMARQUE: Les modèles de 120 V, 15A

peuvent fonctionner sur un circuit de 120

V sous les conditions suivantes:

a. Aucun autre appareil électrique ou

lumière est connecté au même

branchement.

b. L’alimentation en tension est

normale.

c. Le circuit est équipé avec un

disjoncteur de 15 ampères ou une

fusée à retardement de 15 ampères.

3. S’il n’est pas possible d’atteindre les

conditions ci-dessus ou s’il y a un

déclenchement du protecteur de

courant à maintes reprises, il peut être

nécessaire de faire fonctionner le

compresseur sur un circuit de 120 volts,

20 ampères.

Fonctionnement

Manostat - Interrupteur Auto/Off. Dans

la position ON, le compresseur se coupe

automatiquement quand la pression du

réservoir arrive à la pression maximale

réglée d’avance. Le compresseur se

mettra en marche automatiquement

!

ATTENTION

TEST

RESET

Figure 3 - Méthode de mise à la terre

ARRÊT!

Broche

de Terre

Prise de Courant Mise de Terre

Calibre du Cordon 18 14 12 10 88664

Cordons Prolongateurs Pour Modèle De 120V/8 Ampères

Longueur du Cordon (m

) 7,62 15,24 30,48 45,72 60,96 76,2 91,44 121,92 152,4

Figure 4

Soupape de

sûreté

Soupape de sûreté

Manostat

Régulateur

Page 12

Page 13

13 Fr

Fonctionnement (Suite)

sens des aiguilles d’une montre.

3. La pression d’air à la sortie est réduite

en tournant le bouton au sens inverse

des aiguilles d’une montre.

4. Pour couper le débit d’air, tourner

complètement au sens inverse des

aiguilles d’une montre.

MANOMÈTRE DE SORTIE (OUTIL)

1. Ce manomètre indique la

pression d’air de sortie.

La pression d’air est

mesurée en kPa.

2. S’assurer que le manomètre est à ZERO

avant de changer les outils

pneumatiques ou avant de débrancher

le tuyau de la sortie.

MANOMÈTRE DU RÉSERVOIR

Le manomètre indique la

pression dans le réservoir ce

qui indique que le

compresseur fonctionne

bien.

Entretien

Débrancher de la source de

puissance et ensuite dissiper

toute la pression du système

avant d’essayer d’installer, de réparer, de

déplacer ou de procéder à l’entretien.

Inspecter le compresseur souvant et

suivre les procédés d’entretien suivants

pendant chaque utilisation du

compresseur.

1. Tirer sur l’anneau de la soupape de

sûreté et la laisser revenir à sa position

normale.

S’il y a

une fuite

après que la soupape soit lâchée ou si la

soupape ne fonctionne pas, elle devrait

être remplacée.

2. Placer l’appareil en position

horizontale tel qu’indiqué sous la

Figure 8. Avec le compresseur hors

circuit et la pression dissipée, purger

l’humidité du réservoir en ouvrant le

robinet de purge sous le réservoir.

!

AVERTISSEMENT

!

AVERTISSEMENT

3. Mettre hors circuit (OFF) et nettoyer

la poussière et la saleté du couvercle

de la pompe, du réservoir et des

canalisations d’air.

IMPORTANT: Situer le modèle aussi loin

de l’endroit de pulvérisation que possible

afin d’empêcher que le filtre deviennent

obstrué par la surpulvérisation.

GRAISSAGE

Ce modèle “sans huile” n’exige pas de

graissage.

ENTREPOSAGE

1. Entreposer les tuyaux et le compresseur dans un endroit frais et sec.

2. Le réservoir doit être purgé d’humidité.

3. Le tuyau doit être débranché et

suspendu avec les bouts ouverts face

en bas pour laisser couler l’humidité.

Série FP

PSI

PSI

Notes

kPa

kPa

Figure 8

Page 14

Page 15

15 Fr

Guide de Dépannage (Suite)

Symptôme Cause(s) Possible(s) Mesures Correctives

1. Eau excessive dans le réservoir

2. Humidité élevée

1. Manostat défectueux

2. Utilisation d’air excessive

1. Condensation excessive dans le

réservoir

2. Fuites d’air dans la tuyauterie (sur le

modèle ou dans le système extérieur)

3. Fuite du clapet de réservoir

Clapet grippé dans la position ouverte

Courroie brisée

1. Purger le réservoir

2. Déplacer à un endroit moins humide; utiliser un filtre

en canalisation d’air

1. Remplacer le manostat

2. Réduire l’utilisation d’air; le compresseur n’est pas

assez large pour la demande d’air

1. Purger le réservoir plus souvant

2. Remplacer les pièces qui ont des fuites ou serrer

3. Remplacer ou réparer si nécessaire

Ne pas démonter le

clapet s’il y a de l’air

dans le réservoir; vidanger le réservoir

Enlever et remplacer le clapet

Ne pas démonter le

clapet s’il y a de l’air

dans le réservoir; vidanger le réservoir

Remplacer la courroie

!

DANGER

!

DANGER

Humidité excessive dans

l’air de débit

Le compresseur

fonctionne

continuellement

Démarrage et coupage

excessif (démarrage

automatique)

Fuite d’air de l’appareil

de déchargement sur le

manostat

Le moteur fonctionne,

mais il n’y a pas de

débit d’air

Série FP

Outils Recommandés Pour Ce Compresseur D’Air

OUTILS RECOMMANDÉS POUR UNE

UTILISATION CONTINUE

Pistolets de pulvérisation pour maison et

loisirs

Pistolets à pointe

Cloueurs de charpente

Pistolets à graisse

Pistolets à calfeutrer

Trousses d'aérographe

Rivets aveugles

Outils de bride/poinçon

Dégorgeoirs

OUTILS RECOMMANDÉS POUR UN

USAGE INTERMITTENT

(Impulsions puissantes et courtes)

Clés à chocs

Burins pneumatiques

Clés à choc papillon

Clés à cliquet

Scies alternatives

Tournevis

Nettoyeurs à moteur

Micro die grinders

OUTILS NON RECOMMANDÉS

Ponceuses alternatives

Ponceuses à grande vitesse

Ponceuses à double action

Ponceuses à sautillement

Meules à rectifier

Machines à tronçonner

Perceuses Pneumatiques

Page 16

Page 17

Informaciones

Generales de Seguridad

Como el compresor de aire y otros

componentes usados (cabezales, pistolas

pulverizadoras, filtros, lubricadores,

mangueras, etc.), forman parte de un

sistema de bombeo de alta presión,

deberá seguir las siguientes medidas de

seguridad todo el tiempo:

1. Lea con cuidado todos los

manuales incluídos con este

producto. Familiarícese con

los controles y el uso

adecuado del equipo.

2. Siga todos los códigos de seguridad

laboral y electricidad establecidos en

daños o falten piezas, sírvase llamar al

1-800-543-8622 para obtener ayuda o

llame al Centro de Servicio Autorizado de

Campbell Hausfeld más cercano.

Se incluye una lista de las direcciones de

los centros de servicio. Tenga a mano el

número de serie, el número del modelo y

la lista de piezas (con las piezas que faltan

marcadas con un círculo) antes de llamar.

No debe

utilizar la

unidad si se ha dañado durante el envío,

manejo o uso. Los daños podrían

ocasionar una explosión y ocasionarle

heridas o daños a su propiedad.

!

ADVERTENCIA

Sírvase leer y guardar estas instrucciones.Lea con cuidado antes de tratar de armar, instalar, manejar o darle servicio al producto descrito en

este manual. Protéjase Ud. y a los demás observando todas las reglas de seguridad. El no seguir las instrucciones podría resultar en heridas y/o

daños a su propiedad. Guarde este manual como referencia.

17 Sp

Descripción

Los compresores sin aceite han sido

diseñados para una gran variedad de

trabajos domésticos y mecánica

automotriz. Estos compresores se utilizan

con pistolas rociadoras, llaves de impacto

y otras herramientas neumáticas. Estas

unidades funcionan sin aceite.

Medidas de Seguridad

Este manual contiene información que es

muy importante que sepa y comprenda.

Esta información se la suministramos

como medida de SEGURIDAD y para

EVITAR PROBLEMAS CON EL EQUIPO.

Debe reconocer los siguientes símbolos.

Ésto le

indica que

hay una situación inmediata que LE

OCASIONARIA la muerte o heridas de

gravedad.

Ésto le

indica que

hay una situación que PODRIA ocasionarle

la muerte o heridas de gravedad.

Ésto le

indica que

hay una situación que PODRIA ocasionarle

heridas no muy graves.

Ésto le

indica una

información importante, que de no

seguirla, le podría ocasionar daños al

equipo.

Para Desempacar

Cuando desempaque la unidad,

inspecciónela cuidadosamente para

verificar si se han producido daños

durante el transporte. Asegúrese de

apretar todos los accesorios, pernos, etc.

que estén sueltos antes de poner la

unidad en servicio. En caso de que haya

AVISO

!

PRECAUCION

!

ADVERTENCIA

!

PELIGRO

Instrucciones para la Operacion Serie FP

IN609001AV 5/03

Advertencia sobre

el aire respirable

Este compresor/cabezal no viene listo de

fábrica para suministrarle aire respirable.

Antes de utilizarlos con este fin, deberá

instalarle un sistema de seguridad y alarma

incorporado a la línea. Este sistema adicional

es necesario para filtrar y purificar el aire

adecuadamente, para cumplir con las

especificaciones mínimas sobre aire

respirable de Grado D descritas en la

Especificación de Productos G 7.1 - 1966 de

la Asociación de Aire Compri-mido.

Igualmente, deberá cumplir los requisitos

establecidos por el Artículo 29 CFR 1910. 134

de la Organización norteamericana OSHA

y/o la Canadian Standards Associations

(CSA).

RENUNCIA A LAS GARANTIAS

Si el compresor se utiliza para producir aire

respirable SIN haberle instalado el sistema

de seguridad y alarma, todas la garantías se

anularán y la compañia Campbell Hausfeld

no asumirá NINGUNA responsabilidad por

pérdidas, heridas personales o daños.

!

PELIGRO

ALTO!

Anote el No. del modelo, el No. de

serie y la fecha de compra, ubicados

en la etiqueta con el No. de serie del

compresor.

No. del Modelo ______________________

No. de Serie ______________________

Fecha de Compra ____________________

Guarde estos números para

referencia en el futuro.

Compresores Sin Aceite

¡NO DEVUELVA EL

PRODUCTO AL

MINORISTA!

MANUAL

© 2003 Campbell Hausfeld/Scott Fetzer

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

Ver la Garantía en página 24 para información importante sobre el uso comercial de este producto.

Page 18

Page 19

2. Si necesita reparar o reemplazar el

cordón o el enchufe, no conecte el

cable de conexión a tierra a ninguno de

los terminales planos. El alambre cuya

superficie externa del aislante es verde,

con o sin rayas amarillas, es el cable de

conexión a tierra.

Nunca

conecte

los cables verdes o verde con rayas

amarillas, a un terminal con tensión.

3. Consúltele a un electricista calificado o

a un técnico de reparación, en caso de

que no comprenda bien las

instrucciones o si tiene dudas de que

esté conectado a tierra

adecuadamente. No modifique el

enchufe, si éste no entra en el

tomacorrientes, mande a instalar un

tomacorrientes adecuado con un

electricista calificado.

ALAMBRADO

1. Los códigos eléctricos varían de un área

a otra. Sin embargo, el alambrado,

enchufe y protectores se deben

seleccionar según las especificaciones

!

ADVERTENCIA

19 Sp

Ensamblaje

(Continuacíon)

Introduzca el perno a través del cubo

de la rueda. La cabeza hex del perno

debe estar en el lado opuesto a la pieza

sobresaliente del centro del cubo.

Instalación

UBICACION

Una vez que lo ensamble, el tanque debe

estar nivelado o un poco inclinado hacia

el lado donde está la llave de drenaje de

modo que pueda drenarlo

adecuadamente.

Es de suma importancia instalar el

compresor en un llugar limpio y bien

ventilado donde la temperatura ambiente

no sea mayor de 38˚ C (100˚F).

Se requiere un espacio mínimo de 45,7 cm

(18 pulgadas) entre el compresor y la

pared, para evitar obstrucciones en el

flujo de aire.

No

coloque la

entrada de aire del compresor cerca de

áreas con vapor, vapores de pintura,

chorros de arena o cualquier otra fuente

de contaminación. Los desperdicios

dañarán el motor.

INSTALACION ELECTRICA

Todas las

conexiones eléctricas y el alambrano deberán

ser llevados a cabo por un electricista

profesional. La instalación debe estar

conforme con los códigos locales y

nacionales de electricidad.

Nunca use un cordón de

extensión con este producto.

Use una manguera de aire adicional en

lugar de un cordón de extensión para

evitar la pérdida de potencia o daños

permanentes en el motor. El uso de un

cordón de extensión anulará la garantía.

CONEXION A TIERRA

1. Este producto está diseñado para

circuitos nominales de 120 voltios y

tiene un enchufe para conexión a tierra

similar al de la Figura 3. Cerciórese de

conectarlo a un tomacorrientes cuya

configuración sea similar a la del

!

PRECAUCION

!

ADVERTENCIA

!

PRECAUCION

enchufe. Este producto se debe

conectar a tierra. En caso de que ocurra

un cortocircuito, ésto evitaría el riesgo

de choque eléctrico al ofrecerle un

cable de desvío a la corriente eléctrica.

Este producto tiene un cordón con un

alambre y terminal de conexión a

tierra. Debe conectarlo a un

tomacorrientes que esté instalado

adecuadamente según los códigos y

ordenanzas locales.

El uso inadecuado del enchufe

con conexión a tierra podría

ocasionarle choques eléctricos.

No use

un

adaptador para conexión a tierra con este

producto.

!

PELIGRO

!

PELIGRO

de amperaje y voltaje indicados en la

placa del motor y cumplir con las

especificaciones mínimas.

2. Use fusibles de acción retardada tipo T

o un cortacircuito.

Si no

conecta

los cables adecuadamente podría haber

cortocircuitos, incendios, sobrecalentamiento, etc.

NOTA: Las unidades de 120 voltios, 15

amp se pueden utilizar en circuitos de 120

voltios bajo las siguientes condiciones:

a. Ningún otro artefacto eléctrico o

luces estén conectados al mismo

circuito.

b. El suministro de voltaje es normal.

c. Los cordones de extensión son los

adecuados y cumplen los requisitos

mínimos especificados en este

manual de instrucciones.

d. El circuito tiene un cortacircuito de

15 amperios o un fusible de acción

retardada de 15 amperios.

3. Si no puede satisfacer las condiciones

arriba enumeradas o si el cortacircuito

se activa frecuentemente, quizás tenga

que utilizar un circuito de 120 voltios,

20 amperios.

Funcionamiento

Presostato - Automático - En la posición

ON (encendido) el compresor se apaga

automáticamente cuando la presión del

tanque alcanza el nivel máximo fijado en

la fábrica. El compresor se encenderá

automáticamente cuando alcance la

presión mínima fijada en la fábrica. En

la posición OFF, el compresor no

funcionará. El presostato debe colocarse

en OFF (apagado) para conectar o

desconectar el cordón eléctrico del

tomacorrientes o para cambiar la

herramienta neumática.

Regulador - El regulador controla la

cantidad de presión de aire expulsada por

la manguera.

Válvula de seguridad ASME - Esta

válvula automáticamente libera el aire si

la presión del tanque excede el valor

máximo fijado de fábrica.

Mango - Diseñado para mover el

compresor.

!

PRECAUCION

TEST

RESET

Figura 3 - Método de conexión a tierra

ALTO!

Terminal

de

conexión a

tierra

Tomacorrientes conectado a tierra

Serie FP

Calibre del cordón 18 14 12 10 88664

Cordones de extensión para los modelos de 120V/8 Amp

Longitud

del cordón (m) 7,62 15,24 30,48 45,72 60,96 76,2 91,44 121,92 152,4

Page 20

Page 21

Funcionamiento

(Continuacíon)

2. Gire la perilla en el mismo sentido de

las agujas del reloj para aumentar la

presión de aire suminstrado.

3. Gire la perilla en sentido contrario al de

las agujas del reloj para disminuir la

presión de aire suministrado.

4. Gire la perilla completamente en

sentido contrario a las agujas del reloj

para cerrar el suministro de aire

completamente.

MANOMETRO PARA MEDIR LA

PRESION DE SALIDA

(HERRAMIENTA)

1. Este manómetro le

permite verificar la

presión de salida muy

fácilmente. Esta presión se

mide en barras.

2. Cerciórese de que el manómetro esté

en CERO antes de cambiar de

herramientas neumáticas o desconectar

la manguera.

MANOMETRO DEL TANQUE

Mide la presión del tanque

para verificar que el sistema

está funcionando

adecuadamente.

21 Sp

Mantenimiento

Desconecte el cordón eléctrico

del tomacorrientes y libere

toda la presión del sistema

antes de tratar de instalar, darle servicio,

cambiar de lugar o darle cualquier tipo de

mantenimiento.

Este compresor se debe chequear con

frecuencia para ver si tiene algún tipo de

problemas y le debe dar el siguiente

mantenimiento antes de cada uso.

1. Hále el anillo de la válvula de seguridad

y deje que calce en su posición normal.

Debe

reemplazar la válvula de seguridad si no la puede

activar o si hay fugas de aire una vez que

haya soltado el anillo.

2. Coloque la unidad en posición

horizontal como indicado en la

Figura 8. Apague el compresor y libere

toda la presión, después: Abra la llave

de drenaje, ubicada debajo del tanque,

para drenarle toda la humedad.

3. APAGUE la unidad y limpie la tapa

del cabezal, el tanque y las líneas de

aire.

!

ADVERTENCIA

!

ADVERTENCIA

IMPORTANTE: Debe colocar el com-

presor lo más lejos posible del área de

trabajo, según lo permita la longitudud

de la manguera, para evitar que el filtro

se atasque.

LUBRICACION

Este compresor no requiere lubricación.

ALMACENAMIENTO

1. Mientras no lo esté usando debe

almacenar el compresor y las

mangueras en un sitio seco y frío.

2. Debe drenar el tanque.

3. Debe desconectar las mangueras y

colgarlas con los extremos hacia abajo

para que se drenen.

Serie FP

PSI

Notas

bar

Figure 8

PSI

bar

Page 22

Page 23

23 Sp

Guía de Diagnóstico de Averías (Continuación)

Problema Posible(s) Causa(s) Acción a tomar

1. Exceso de agua en el tanque

2. Humedad alta

1. El presostato está dañado

2. Consumo excesivo de aire

1. Condensación excesiva en el tanque

2. Hay fugas de aire en las tuberías (del

compresor o del sistema de conexión)

3. Fuga en la válvula de chequeo del

tanque

La válvula de chequeo está atascada y

no se puede cerrar

La correa está dañada

1. Drene el tanque

2. Mueva el compresor a una área menos húmeda; use

un filtro de aire incorporado a la línea

1. Reemplace el presostato

2. Disminuya el consumo de aire; el compresor es muy

pequeño para suministrar el aire requerido

1. Drénelo con más frecuencia

2. Reemplace las tuberías que tengan fugas o apriételas

según sea necessario

3. Reemplácela o repárela según sea necesario

Antes de desmantelar

la válvula de

chequeo purgue el aire del tanque

Desconecte y reemplace la válvula de chequeo

Antes de desmantelar

la válvula de

chequeo purgue el aire del tanque

Reemplace la correa

!

PELIGRO

!

PELIGRO

Exceseso de humedad

en el aire expulsado

El compresor funciona

continuamente

El compresor se

enciende y se apaga

automáticamente con

mucha frecueneia

Hay una fuga de aire en

el sistema de desfogue

del presostato

El motor gira pero no

sale aire

Serie FP

Recomendaciones De Herramientas Para Este Compresor De Aire

HERRAMIENTAS RECOMENDADAS

PARA USO CONTINUO

Pistolas rociadoras para hobby en el hogar

Martillos mecánicos para clavos pequeños

Martillos mecánicos para tirantería

Pistolas engrasadoras

Pistolas de calafatear

Juegos de cepillo neumático

Remachado

Herramientas para perforar/achaflanar

Limpiador de drenajes

HERRAMIENTAS RECOMENDADAS

PARA USO INTERMITENTE

(Impulsos potentes de corta

duración)

Llaves de choque

Buriladoras

Llave de choque de mariposa

Criques

Sierra neumática alternativa

Destornilladores

Limpiadores de motor

HERRAMIENTAS NO

RECOMENDADAS

Lijadoras de línea recta

Lijadoras de alta velocidad

Lijadoras de doble acción

Lijadoras de oscilación

Rectificadora neumática de matrices

Herramientas de corte

Taladros Neumáticos

Page 24

G

R

A

M

Loading...

Loading...