Page 1

Operating Instructions & Parts Manual EZ5000 Series

Please read and save these instructions. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by

observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

The

HousePainter

®

IN423200AV 3/04

© 2004 Campbell Hausfeld/

Scott Fetzer

For parts, product & service information

visit www.chpower.com

Specifications

Motor . . . . . . . 1/4 HP, 120 Volt, 5 Amp

Delivery . . . . . . . 0.2 gallon per minute

Max. Pressure . . . . . . . . . . . . . . 2500 psi

Refer to product decal for exact

specifications.

FOR HOUSEHOLD USE ONLY

Description

Airless paint sprayers are capable of

spraying a variety of latex and oilbased paints, as well as stains, preservatives and other non-abrasive finishes.

The coatings that can be sprayed will

vary depending on the sprayer.

Unpacking

After unpacking the unit, inspect carefully for any damage that may have

occurred during transit. Make sure to

tighten all connection points before

putting into service. There will be

some lubricant in the sprayer head

from the testing process. Spray a short

burst onto a practice surface after filling the canister with paint. This will

clear the lubricant without affecting

the paint job or the coating.

General Safety

This manual contains information that

is very important to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this

information, observe the following

symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, WILL result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

See Warranty on page 17 for important information about

commercial use of this product.

BUILT TO LAST

!

DANGER

!

WARNING

Page 2

2

Operating Instructions & Parts Manual

www.chpower.com

General Safety (Cont.)

Caution indicates

a potentially hazardous situation which, if not avoided,

MAY result in minor or moderate

injury.

Notice indicates

important information that, if not followed, may

cause damage to the equipment.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS – To

reduce the risk of fire or explosion,

electrical shock and injury to persons, read and understand all

instructions included in this manual.

Be familiar with the controls and

the proper usage of the equipment.

ELECTRICAL SHOCK HAZARD:

To prevent electrical shock,

observe the following guidelines at all times:

GROUNDING INSTRUCTIONS

This product must be grounded. In

the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an

escape wire for the electric current.

This product is equipped with a cord

having a grounding wire with an

appropriate grounding plug. The

plug must be plugged into an outlet

that is properly installed and

grounded in accordance with all

local codes and ordinances, as well

as the National Electrical Code (NEC)

!

and, in the United States, the

Occupational Safety and Health Act

(OSHA).

Improper installa

tion of the

grounding plug is liable to result in

a risk of electric shock. When repair

or replacement of the cord or plug is

required, do not connect the

grounding wire to either flat blade

terminal. The wire with insulation

having an outer surface that is

green,with or without yellow

stripes, is the grounding wire.

Check with a qualified electrician or

serviceman when the grounding

instructions are not completely

understood, or when in doubt as to

whether the product is properly

grounded. Do not modify the plug

provided; if it does not fit the outlet, have the proper outlet installed

by a qualified electrician.

This product is for use on a nominal

120-V circuit and has a grounding

plug similar to the plug illustrated

in Figure 1. Only connect the product to an outlet having the same

configuration as the plug. Do not

use an adapter with this product.

Figure 1 - Grounded three-wire

extension cord

Gauge of Cord 18 16 14 12 10 8

Table 1 – Extension Cords for 120V/15 Amp Unit

Length of Cord (ft.) 25-50 50<100 100<150 150<250 250<400 400-500

CAUTION

NOTICE

!

DANGER

!

WARNING

TEST

RESET

Page 3

3

EZ5000 Series

www.chpower.com

General Safety (Cont.)

Extension Cords:

Use only a 3-wire extension cord

that has a 3-blade grounding plug,

and a 3-slot receptacle that accepts

the plug on the product. Make sure

the extension cord is not damaged.

When using an extension cord, be

sure to use one heavy enough to

carry the current the product draws.

An undersized cord results in a drop

in line voltage and loss of power

and overheating. See Table 1 on

Page 2.

Do not modify any of the electrical

components of this equipment.

To reduce the

risk of fire or

explosion:

• Do not spray flammable or combustible materials near an open

flame or sources of ignition such

as cigarettes, motors and electrical

equipment.

• Paint or solvent flowing through

the equipment is liable to result in

static electricity. Static electricity

creates a risk of fire or explosion

in the presence of paint or solvent

fumes. All parts of the spray system, including the pump, hose

assembly, spray gun and objects in

and around the spray area should

be properly grounded to protect

against static discharge and

sparks. Use only conductive or

grounded high-pressure airless

paint sprayer hoses specified by

the manufacturer.

• Verify that all containers and collection systems are grounded to

prevent static discharge.

• Connect to a grounded outlet

and use grounded extension cords.

Do not use a 3 to 2 adapter.

• Do not use a paint or a solvent

containing halogenated hydrocarbons as this attacks the aluminum

and increases the risk of bursting.

Examples of improper solvents are

methyl bromine, carbon tetrachloride and ethyl iodide.

• Keep spray area well-ventilated.

Keep a good supply of fresh air

moving through the area. Keep

pump assembly in a well-ventilated area. Do not spray pump

assembly.

• Do not smoke in the spray area.

• Do not operate light switches,

engines, or similar spark-producing products in the spray area.

• Keep area clean and free of

paint or solvent containers, rags

and other flammable materials.

• Know the contents of the paints

and solvents being sprayed. Read

all Material Safety Data Sheets

(MSDS) and container labels provided with the paints and solvents. Follow the paint and solvent

manufacturer’s safety instructions.

• Fire extinguisher equipment shall

be present and working.

• Due to flammability, use caution

when using solvents with flash

points less than 70F (21C) to clean

equipment. Examples of acceptable cleaning solvents include

water, mineral spirits and lacquer

thinner. Unacceptable cleaning solvents include naphtha, MEK, acetone, alcohol and toluene.

!

WARNING

Page 4

4

Operating Instructions & Parts Manual

www.chpower.com

General Safety (Cont.)

To reduce the risk

of skin injection:

• Do not aim the gun at or spray

any person or animal.

• Keep hands and other body

parts away from the discharge. Do

not try to stop leaks with any part

of the body.

• Always use the nozzle tip guard.

Do not spray without nozzle tip

guard in place.

• Only use a nozzle tip specified

by the manufacturer.

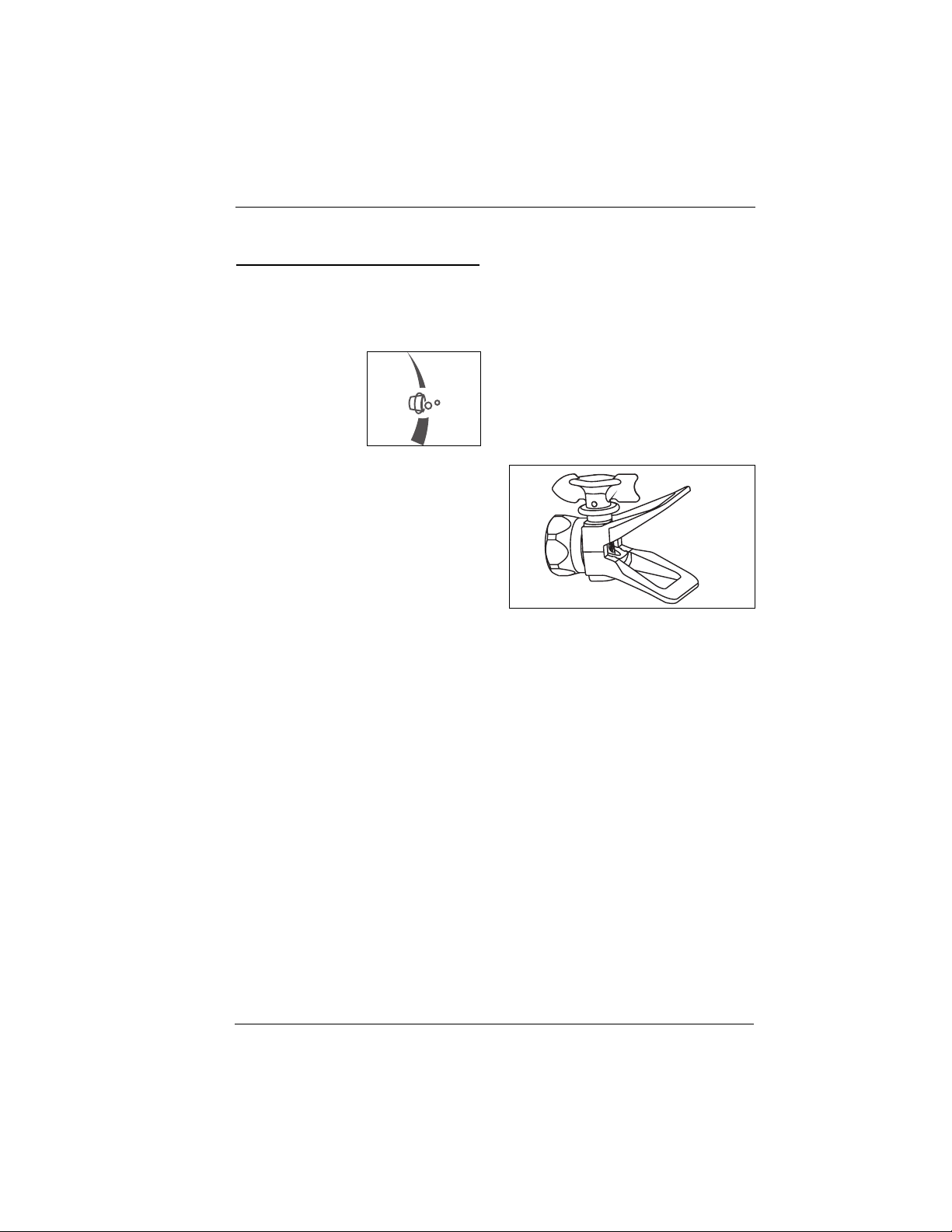

• Use caution when cleaning and

changing nozzle tips. If the nozzle

tip clogs while spraying:

engage the trigger lock (see

Figure 2)

turn tip insert handle to the

clean position (see Figure 3)

disengage

the trigger

lock and pull

the trigge.

engage the

trigger lock

and turn the

!

tip insert handle back to the

spray position

release the trigger lock and

continue spraying

• Do not leave the unit energized

or under pressure while unattended. When not in

use, turn the

unit Off (see

Figure 4) and

relieve pressure

by triggering

the gun in a safe

direction. Then

engage the trigger lock.

• High-pressure spray can inject

toxins into the body and cause

serious bodily injury. In the event

that injection occurs, seek medical

attention immediately.

• Check hoses and parts for signs

of damage. Replace any damaged

hoses or parts.

• This system is capable of producing 3000 psi. Only use replacement parts or accessories that are

specified by the manufacturer and

rated at a minimum of 3000 psi.

• Always engage the trigger lock

when not spraying (see Figure 2).

Verify the trigger lock is functioning properly by pulling the trigger. If the trigger lock is functioning properly the gun valve will

not spray.

• Verify that all connections are

secure before operating the unit.

• Know how to stop the unit and

bleed pressure quickly. To bleed

pressure quickly either

Figure 3 - Turn

tip insert handle

to clean position

Figure 2 - Engage trigger lock by

rotating lock as shown

Figure 4 - Icon

showing Off

position

WARNING

Page 5

Set-Up

TOOLS REQUIRED

Screwdriver

Two adjustable wrenches – or

two 3/4” open-end wrenches –

or any combination of the two

types

Extension cord – see Table 1 on

Page 2.

Remove all components from the

box. Remove the cap from the hose

adapter and attach one end of the

high pressure hose to the sprayer

(see Figure 7). Attach the other end

of the hose to the gun.

PREPARATION

Each sprayer is tested at the factory.

Residual amounts of test fluid will

remain in the pump. If you are using

an oil-based coating (one that

5

EZ5000 Series

www.chpower.com

General Safety (Cont.)

turn the unit to the Prime

position (see Figure 5) ...OR ...

turn the unit to the Off position (see Figure 6).

Be thoroughly familiar with the

controls.

To reduce the risk

of injury:

• Always wear appropriate gloves,

eye protection, and a respirator or

mask when painting.

• Do not operate or spray near

children. Keep children away from

equipment at all times.

• Do not overreach or stand on an

unstable support. Keep effective

footing and balance at all times.

• Stay alert and watch what you

are doing.

• Do not operate the unit when

fatigued or under the influence of

drugs or alcohol.

• Do not kink or over-bend the

hose.

• Do not expose the hose to temperatures or to pressures in excess

of those specified by the manufacturer.

• Do not use the hose to pull or

lift the equipment.

Figure 7 – Attach hose to sprayer

Figure 5 - Icon

showing Prime

position

Figure 6 - Icon

showing Off

position

!

WARNING

Page 6

Set-Up (Cont.)

cleans up with something other

than water), you should flush the

system with the cleaning fluid recommended by the coating manufacturer. To flush the system, follow the

instructions for priming – see Page

8. Allow the sprayer to run in the

prime position until you see clear

cleaning fluid coming through the

bypass tube. Also perform this procedure after the unit has been

stored with a storage fluid such as

Pump Protector.

When Painting Outside

It is best not to spray outside on a

windy day. The sprayer creates a

fine mist of coating and some of the

mist can be carried in the wind onto

cars, shrubbery, etc. To protect yourself from overspray, use a respirator

and safety glasses.

Painting Houses, Garages, Etc.

Move or cover any object or planting that could be damaged. Use

newspaper (taped in place) or plastic sheeting to protect windows,

Operating Instructions & Parts Manual

www.chpower.com

6

light fixtures, etc. that are not to be

painted the same color as the structure. For best results, remove any

hinges or fixtures – it may prove less

time consuming than covering them.

Painting Fences

Move or cover any object or planting

that could be damaged. Remove or

cover hinges, handles or other hardware that you don’t want to paint.

When Painting Inside

To protect yourself from overspray,

use a respirator and safety glasses.

Protect the areas outside of the

room being painted by hanging

plastic sheeting in the doorways.

Floors, Ceilings, Walls

Spraying is extremely efficient when

tackling items such as floors or popcorn ceilings. Use tape and newspaper or plastic sheeting to protect

windows, light fixtures, etc. that are

not to be painted the same color.

Wear protective shoes, not open

shoes like sandals. Be careful not to

accidentally spray feet.

Figure 8 – Cover plantings that could

be damaged

Figure 9 – Using the 24” Spray Wand

accessory

Page 7

After priming as usual, turn the One

Touch Control to

the roller position

(see Figure 12) and

roll away.

Doors

Your airless

sprayer gives a

beautiful, brush-free finish on all

kinds of doors: entry doors, cabinet

doors, louvered doors, etc. Take the

doors outside or to a well-ventilated

area in a basement or garage.

Protect the surrounding area with a

drop cloth. For efficiency, arrange

the doors so you can paint the sides

as well as the front or back surface. To

achieve a good spray pattern, use the

lowest pressure setting on your

sprayer.

Step 1 – Priming

Place both the suction and bypass

tubes in the coating container (see

Figure 13). Use the 1-gallon set of

tubes for 1-gallon paint containers,

and the 5-gallon set for 5-gallon paint

containers. Turn the One Touch

7

EZ5000 Series

www.chpower.com

Set-Up (Cont.)

To extend your reach for floors and

ceilings, consider using the 24”

Spray Wand accessory, which attaches between the gun and tip. For

floors, it angles the tip away from

your feet, while allowing a comfortable spraying position for your arm

and back. For ceilings, it keeps the

spray from being directly overhead

and gives you an extra 2’ that may

eliminate the need for a ladder.

More on Walls

If you aren’t comfortable spraying

interior walls, consider using the

Roller accessory. To use this accessory,

remove the spray tip from the gun

and attach the roller (see Figure 10).

Figure 12 - Icon

showing Roller

position

Figure 11 – Using roller attachment

Figure 10 – Attaching roller

Figure 13 – Suction and bypass tubes

Page 8

Operating Instructions & Parts Manual

www.chpower.com

8

Step 1 – Priming (Cont.)

Control to the Prime position (see

Figure 14). After a

few seconds, the

coating will come

up the suction tube

and then out the

bypass tube.

Initially, there will

be air bubbles in

the paint coming

out of the bypass tube. When you no

longer see bubbles, turn the One

Touch Control to the Spray position

(see Figure 15). If you have any diffi-

culty priming, please see the suggestions in the Troubleshooting chart

beginning on page 13.

Step 2 – Using Your

HousePainter

Setting The Pressure

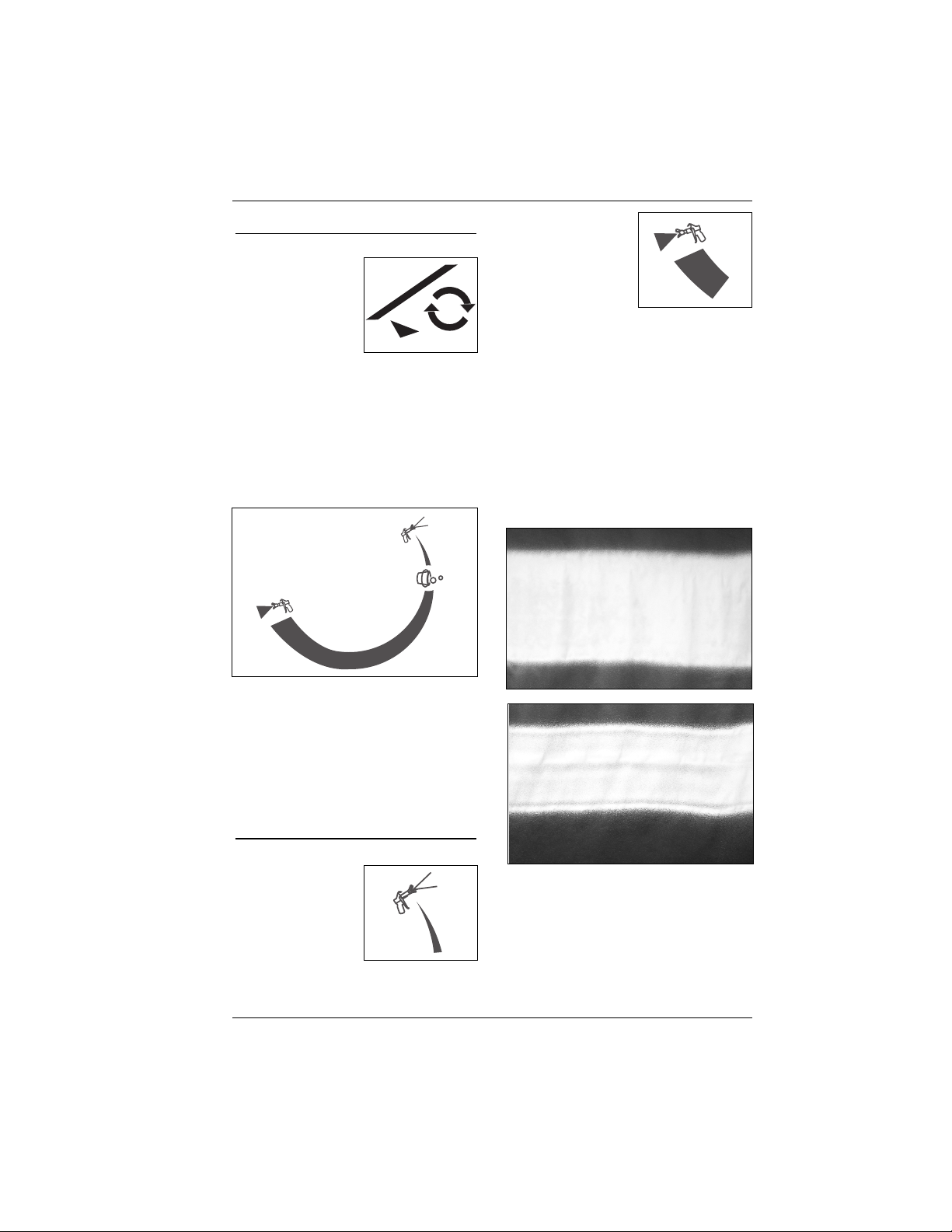

A range of pressure

settings on the

HousePainter gives

you the flexibility to

meet any painting

challenge. Use the

lowest pressure setting (see Figure 16)

for thin materials

such as water seals

and polyurethanes.

The highest pressure setting (see

Figure 17) is used

for heavier coatings

like latex paint.

The best way to

determine the proper setting for your

job is to begin with the pressure on

the lowest setting and spray on a practice surface. Turn the pressure up

gradually and continue to spray test

swatches after each adjustment until

you no longer see ‘tails’ in the spray

pattern (see Figure 18). Using this

method to determine the proper pressure setting will provide the best spray

pattern while minimizing overspray as

Figure 16 - Icon

showing Lowest

Pressure position

Figure 17 - Icon

showing Highest

Pressure position

Figure 14 - Icon

showing Prime

position

Figure 15 - Icon showing Spray position

Figure 18 – Good spray pattern

shown in white area of top picture.

Bad spray pattern – ‘tails’ – shown in

white area of bottom picture.

2

Page 9

9

Step 2 – Using Your

HousePainter (Cont.)

much as possible. If you still have

‘tails’ at the highest pressure setting,

or if you have any other pattern problems, please see the suggestions in the

Troubleshooting chart beginning on

page 13.

Spraying

Position yourself so the spray tip is

10” – 12” from the surface being

sprayed. It is important to keep your

knuckles pointed at that surface to

make sure you only spray the intended

surface.

Begin moving the gun, then pull the

trigger. Hold the trigger throughout a

comfortable range of motion and

release the trigger prior to changing

direction or ending the stroke. In other

words, try not to activate or release

the trigger when your arm is not in

motion. You will get a build up of

paint at any point where the gun is

spraying without your arm being in

motion.

Rolling

If you use either of the roller accessories available, remove the spray tip

base from the spray gun. Screw the

roller attachment onto the spray gun

(see Figure 10).

Prime the sprayer as described on Page

8. When bubbles are no longer visible

in the bypass tube, turn the One Touch

Control to the Roller icon (see Figure

12). Use the gun trigger to load the

EZ5000 Series

www.chpower.com

Figure 19 – Paint beginning to dot

roller cover

12”

Holding Spray Gun

Thin Coat

Thin Coat

Heavy

Coat

Overspray

Overspray

Result of Flexing Wrist While Spraying

INCORRECT

Approx.

10-12”

Start

Stroke

Pull

Trigger

Release

Trigger

End

Stroke

Proper Way to Trigger Spray Gun

Page 10

www.chpower.com

10

Operating Instructions & Parts Manual

Step 2 – Using Your

HousePainter (Cont.)

roller with paint. When paint begins

to dot the roller cover (see Figure 19)

continue to hold the trigger and begin

rolling the wall . When the roller cover

is saturated, release the trigger and

continue rolling the surface. Only

depress the trigger when the roller

cover needs more paint.

The paint saved with this system is

approximately 1/3 of the amount a

manual roller uses. You also save time

and energy by eliminating the bending required when using a roller pan.

Refer to the roller instructions for

cleaning procedures.

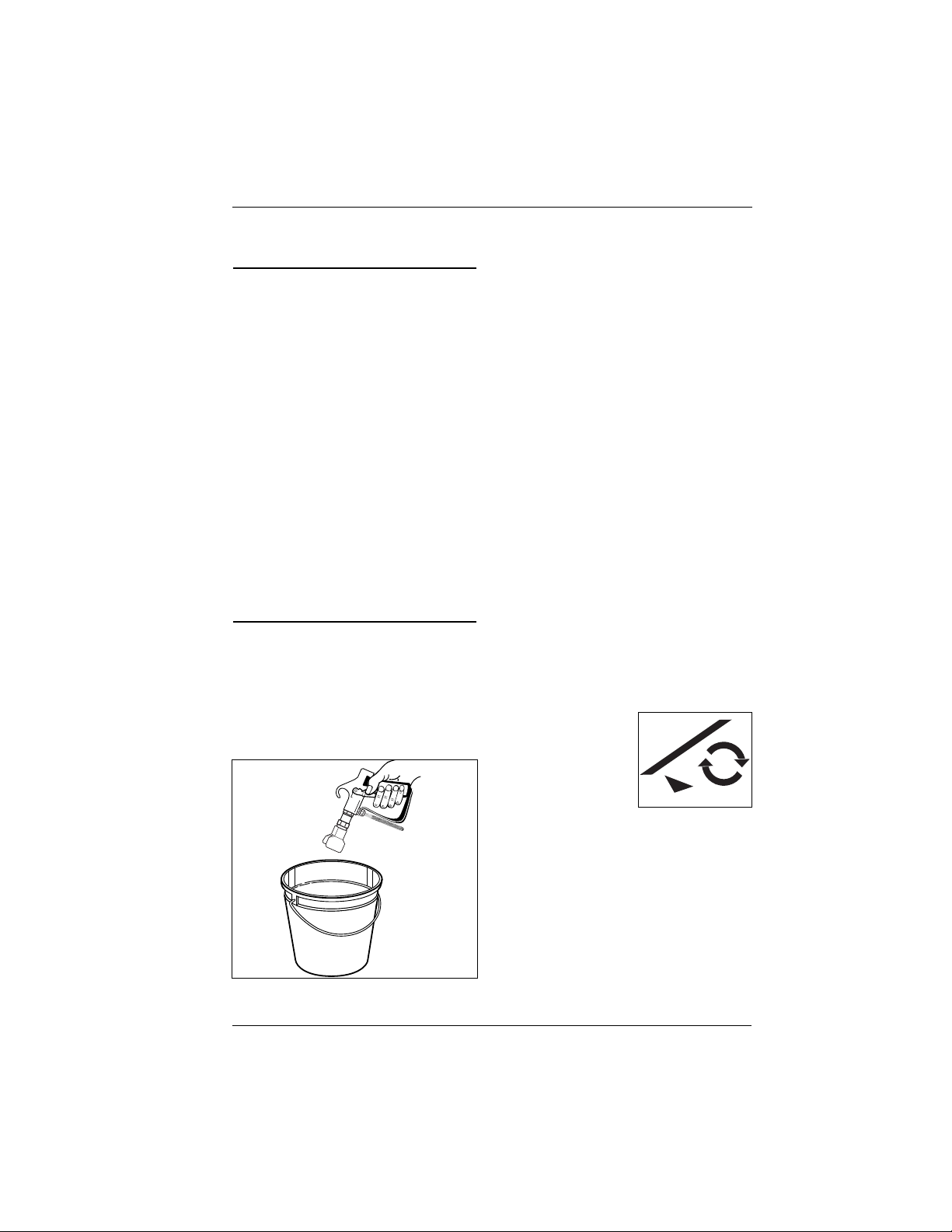

Step 3 – Cleaning &

Storage

Cleaning the HousePainter is very simple. It is basically just following the

same procedure with water or solvent

that you have just done with the coating. To speed the process, place the

bypass tube in a waste bucket so you

do not contaminate the cleaning fluid.

Use whatever material the paint manufacturer recommends for cleaning.

For overnight storage, submerge the

gun in a bucket of the appropriate

cleaning fluid (see Figure 20). Leave

the suction and bypass tubes in the

bucket of coating. Cover the tubes and

bucket with a damp towel, or if using

latex paint, pour a very thin layer of

water over top of paint. Stir water into

paint the next morning.

Coatings That Clean Up With Water.

When you are finished painting, turn

the One Touch Control knob to the

prime position (see Figure 14). Lift the

suction tube above the paint level and

allow any residual coating to flow into

the coating container from the bypass

tube. When there is little to no paint

coming out of the bypass tube, turn

the sprayer off.

Place the suction tube in a bucket of

warm water. If you use a waste bucket,

place the bypass tube in it. If not, the

bypass tube should also go into the

bucket of warm

water. Turn the One

Touch Control to

the clean pump

position (see Figure

21).

If using a waste

bucket, allow the

sprayer to run in this

mode until water is no longer coming

out of the bypass tube. If a waste

bucket is not being used, allow the

water to circulate for about 5 minutes.

Repeat this process at least once, or

until you see clear water coming out

of the bypass tube. Make sure to turn

the HousePainter off when

Figure 21 - Icon

showing Clean

Pump position

Figure 20– Submerge gun in bucket

of appropriate cleaning fluid

Page 11

EZ5000 Series

www.chpower.com

11

Step 3 – Cleaning &

Storage (Cont.)

changing buckets.

When you are sure that the pump is

clean, get one more bucket of water.

Place the suction tube in it and turn

the One Touch

Control knob to the

clean hose position

(see Figure 22). Turn

the reversible tip on

the gun to the clean

position.

Spray into a waste

bucket until clear water comes out of

the gun. Submerge tip in water to

avoid splashing. Another way to

reduce splashing is to keep the tip

angled above the fluid level.

For storage of six months or more, use

a storage fluid such as Pump Protector.

Follow directions provided by the

manufacturer.

Coatings That Clean Up With

Something Other Than Water

When the coating manufacturer recommends mineral spirits or some other

cleaning fluid, pour enough of the

solution into a bucket to come about

an inch above the suction filter. Do not

use a waste bucket. Keep the bypass

tube in the fluid bucket with the suction tube. Allow the fluid to circulate

for 10 minutes in the clean pump position (see Figure 21).

Turn the One Touch Control to the

clean hose icon (see Figure 22). Turn

the reversible tip on the gun to the

clean position ( see Figure 23). Spray

into a waste bucket until there is no

more fluid in the suction bucket.

Submerge the tip in water to avoid

splashing. Another way to reduce

splashing is to keep the tip angled

above the fluid level.

Dispose of solvent according to local

ordinances.

For best results, repeat this process one

more time with fresh cleaning fluid.

You can strain and reuse the cleaning

fluid. Nothing else needs to be done

for long term storage.

Figure 22 - Icon

showing Clean

Hose position

Figure 23 – Rotate Spray Tip to

CLEAN Position.

2

Page 12

Operating Instructions & Parts Manual

www.chpower.com

12

Maintenance Detail

Item Check Replace Notes

Maintenance Chart

Product safety

labels

Trigger adjustment

Airless hose

Suction tube

Bypass tube

Suction filter

Gun filter

Roller nap

Outlet valve

Spray tip

Before each use

Before each use

Before each use

Before each use

Before each use

Before each use

and every 5 gal.

Before each use

Before each use

Before each use

As required

As required

As required

Every 100 gal.

or more often if

required

Every 100 gal.

As required

Every 100 gal.

Every 20-75 gal.

See parts listing for

location of product

safety labels and related part numbers.

Make sure gun shuts

off while spraying.

Read information on

the hang tag attached

to the high pressure

hose for instructions

on maintenance.

Check for nicks and

cuts.

Check for nicks and

cuts.

Do not attempt to

clean gun filter, only

replace.

Use 3/4” wrench –

torque to 150 in-lbs.

Use 13/16” wrench –

torque to 135 in-lbs.

Page 13

www.chpower.com

EZ5000 Series

13

Symptom Possible Cause(s) Corrective Action

Motor runs but won't

prime material

Sprayer builds pressure

but pressure drops

when gun is triggered

Unit primes but will

not build pressure

Gun continues to spray

when trigger is

released

1. Push the spring inside the inlet

valve & push on outlet valve

ball.

2. Tighten clamp.

3. Turn control to prime position.

4. Rebleed pressure valve: Turn

control between ON/OFF position and PRIME/CLEAN PUMP

position and allow motor to

run for a few minutes. Then

turn lever to prime position.

5. Clean or replace suction tube

filter.

6. Remove and clean or replace

inlet and outlet valve.

7. Thin, mix and strain all material to be sprayed.

1. Remove and replace valves as

needed.

2. Tighten clamp.

3. Replace suction filter.

4. Replace filter or tip.

5. Replace with smaller size tip.

6. Replace suction hose assembly.

1. Remove and replace valves as

needed.

2. Turn control to higher setting.

3. Check oil level. If low, fill to

1/4” from top of housing with

10W hydraulic oil (CH #

AL1702).

4. Thin and/or strain material.

5. Remove and clean or replace

valve (SCR).

1. Clean or replace gun valve.

2. Replace gun valve or replace

entire gun.

3. Adjust trigger by adjusting nut

behind trigger. Move nut

towards handle if trigger does

not move. Tighten nut by turning towards spray tip if trigger

moves too much.

4. Turn filter housing bolts about

1/2 turn counterclockwise.

Troubleshooting Chart

1. Inlet or outlet valve stuck.

2. Suction tube connection loose.

3. Control lever in spray or roll position.

4. Air in hydraulic system causing

loss of suction and no diaphragm

movement.

5. Suction tube filter clogged.

6. Inlet or outlet valves dirty or

worn.

7. Material is too thick or not

strained properly.

1. Inlet and/or outlet valves are

worn.

2. Suction tube connection loose.

3. Suction tube or suction filter

clogged.

4. Clogged gun filter or worn tip.

5. Tip is too large for material

being sprayed.

6. Suction hose assembly is damaged.

1.

*Dirty or worn inlet valve.

2. Pressure not turned up high

enough.

3.

*Oil level in the hydraulic hous-

ing is too low.

4. Material is too thick or not properly strained.

5.

*Dirty, stuck or worn

prime/spray valve causing fluid to

come through bypass tube while

unit is in spray position.

1. Paint build up inside gun valve

or gun valve is dirty.

2. Gun valve is worn.

3. Gun trigger is not properly

adjusted.

4. Filter housing is tightened down

too much.

* = Service Center Recommended

Page 14

Operating Instructions & Parts Manual

Symptom Possible Cause(s) Corrective Action

Sprayer motor doesn’t

start or just hums

Motor overheats and/or

cuts off

Oil leaks or oil in paint

Leaking paint from

sprayer

Unit primes and builds

pressure but will not

spray

1. Turn control to prime position

and pull gun trigger.

2. Turn unit off. Turn lever to

ON/OFF position then unplug

cord and allow unit to cool for

20-30 minutes.

3. Plug unit directly into an outlet

and extend hose length.

4. Replace fuse, reset circuit

breaker or use 20 amp circuit

breaker.

1. Get correct gauge size or plug

directly into outlet and use

additional spray hose.

2. Take to Service Center.

3. Thin, mix and strain all materials.

4. Move unit to an area with

good air circulation.

5. Check receptacles for too much

voltage/amperage.

1. Tighten block bolts in an X pattern. If oil is still leaking,

remove block and change

diaphragm. Be sure to use correct replacement part; call

1-800-626-4401.

2. a. Replace unit.

b. Contact Service Center to

have motor housing

replaced.

3. Contact Service Center to have

hydraulic housing and

diaphragm replaced.

1. Tighten block bolts in an X pattern or replace block.

2. Tighten clamp.

3. Remove and replace outlet

valve.

4. a. Tighten hose on outlet valve.

b. Check for damaged thread

on connector. Replace if necessary.

1. Turn spray tip to clean position,

squeeze trigger, then turn back

to spray position.

2. Replace gun filter, be sure filter

housing is clear of debris.

Troubleshooting Chart (Cont.)

1. Paint system is under pressure or

control is in spray or roll position.

2. Motor thermal overload switch is

tripped.

3. Use of extension cord that is too

long or too small in gauge.

4. Blown fuse or tripped circuit

breaker.

1. Extension cord is too long or

gauge is too small.

2. Paint overspray is being drawn

into motor causing it to overheat.

3. Material is too thick for paint

sprayer to prime.

4. Sprayer is being used in an area

of poor air circulation.

5. Tripped circuit breaker.

1.

*Leaking oil between block and

hydraulic housing.

2.

*Oil leaking from motor; defec-

tive motor seal.

3.

*Deep scratch in grooves by

diaphragm.

1.

*Leaking paint between block

and hydraulic housing.

2. Leaking paint from suction hose

connection.

3. Leaking paint around outlet

valve assembly; o-ring on outlet

valve is damaged.

4. Leaking paint from hose/outlet

valve connection.

1. Clogged spray tip.

2. Clogged gun filter.

* = Service Center Recommended

14

www.chpower.com

Page 15

Symptom Possible Cause(s) Corrective Action

Poor spray pattern –

tails, bursts of material,

splotches in pattern

1. Thin, mix and strain all material.

2. Clean or replace spray tip.

3. Remove and clean or replace

inlet and/or outlet valve.

4. Turn lever clockwise to increase

pressure to gun.

5. Clean or replace suction filter.

6. a.Remove gun filter.

b.Check for debris in filter hous-

ing.

c. If debris is found, force water

through gun while filter is

still removed.

d. Replace filter.

7. Replace with smaller tip size.

8. Turn spray tip to spray position.

Troubleshooting Chart (Cont.)

1. Material too thick or not

strained.

2. Spray tip dirty, worn or defective.

3. Dirty or worn inlet or outlet

valve.

4. Pressure is adjusted too low for

material being sprayed.

5. Clogged suction filter.

6. Clogged gun filter.

7. Tip is too large for material

being sprayed.

8. Spray tip in clean position.

To remove trash that has been caught in the valves, the

unit can be force fed. With pump on and prime/spray knob

turned to “prime” position, pour the appropriate solvent

into the suction tube and then fold hose as shown. While

firmly squeezing the suction tube, slide hand down toward

the pump and repeat until pump primes.*

*

This procedure will only work if the inlet valve is free.

“Force Feeding” Pump

EZ5000 Series

To Free a Stuck Inlet

Using either a screwdriver or your

finger, push where shown in picture

at right until inlet moves back and

forth freely.

15

www.chpower.com

Page 16

For Replacement Parts, Call 1-800-626-4401

Please provide following information:

-Model number

-Serial number (if any)

-Part descriptions and number

as shown in parts list

Address parts correspondence

to:

Campbell Hausfeld

100 Production Drive

Harrison, OH 45030 U.S.A.

Ref. No. Description Part Number Qty.

1 1 gallon suction hose kit –

(includes suction hose, bypass

hose, clamps and suction filter) EZ500420SV 1

5 gallon suction hose kit –

(includes suction hose, bypass

hose, clamps and suction filter) EZ500430SV 1

2 Suction bell and filter AL005102SV 1

3 Outlet valve EZ500220SV 1

25’ Hose (not included) MP217600AJ 1

1

1

2

3

See product insert for spray tips and accessories

16

www.chpower.com

Operating Instructions & Parts Manual

Page 17

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty

Paint Application Systems and all Paint Application Accessories - 1 year, Serious Duty Paint

Application Systems - 3 years, Extreme Duty Paint Application Systems - 5 years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld/A Scott Fetzer Company,

100 Production Drive, Harrison, Ohio, 45030, Telephone: 1-800-626-4401.

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale or rental) of the Campbell Hausfeld Product.

4. WHAT PRODUCTS ARE COVERED BY THIS WARRANTY: All non-compressor driven paint

application systems, HVLP spraying systems, and paint application accessories supplied or

manufactured by the Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Defects in material and workmanship which

occur within the duration of the warranty period. Warrantor will also cover normal wear

items for a period of thirty days from the date of original purchase against defects in material and workmanship. These wear items are: HVLP-filters, motor brushes, gun packing, gun

canister seal, gun check valve and gun air flow ring; Airless-inlet valve, outlet valve, gun

valve, filters, tips, all seals and o-rings.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A. Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE

DURATION. If standard duty product is used for commercial or industrial purposes, the

warranty will apply for ninety (90) days from the date of original purchase. If product is

used for rental purposes, the warranty will apply for ninety (90) days from the date of

original purchase. Some states do not allow limitation on how long an implied warranty

lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE , OR EXPENSE THAT

MAY RESULT FROM ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL

HAUSFELD PRODUCT. Some states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser’s abuse, neglect or failure to oper-

ate products in accordance with instructions provided in the owner’s manual(s) supplied

with product. Accident, purchaser’s abuse, neglect or failure to operate products in

accordance with instructions shall also include the removal or alteration of any safety

devices. If such safety devices are removed or altered, this warranty is void.

D. Normal adjustments which are explained in the owner’s manual(s) provided with the

product.

E. Items or services that are normally required to maintain the product: HVLP-filters,

motor brushes, gun packing, gun canister seal, gun check valve and gun air flow ring;

Airless-inlet valve, outlet valve, gun valve, filters, tips, all seals and o-rings., or any other

expendable part not specifically listed, will only be covered for thirty days from date of

original purchase.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at

Warrantor’s option, products or components which are defective, have malfunctioned and/or

failed to conform within duration of the warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld product or component to the nearest Campbell

Hausfeld Authorized Service Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the products as described in

the owner’s manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY:

Repair or replacement will be scheduled and serviced according to the normal work flow at

the servicing location, and depending on the availability of replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific

legal rights. You may also have other rights which vary from state to state, or country to country.

17

Page 18

Page 19

Manuel de pièces et instructions de fonctionnement Série EZ5000

Si’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter,

installer, utiliser ou de procéder à l’entretien du produit décrit. Se protéger ainsi que les

autres en observant toutes les instructions de sécurité, sinon, il y a risque de blessure et / ou

dégâts matérials ! Conserver ces instructions comme référence.

Le

HousePainter

®

IN423200AV 3/04

© 2004 Campbell Hausfeld/

Scott Fetzer

Spécifications

Moteur. . . . . . . . . 1/4 HP, 120 volts, 5 A

Livraison. . . . . . . 0,2 gallon à la minute

Pression max. . . . . . . . . . . . . 17.238 kPa

Se reporter au décalque du

produit pour les spécifications

exactes.

RÉSERVÉ AUX APPLICATIONS

RÉSIDENTIELLES

Description

Les pulvérisateurs de peinture sans air

peuvent pulvériser une gamme de

peintures au latex et à l’huile en plus

de teintures, agents de conservation et

autres finis non abrasifs. Les revêtements pulvérisables varient selon le

pulvérisateur.

Déballage

Dès que l’appareil est déballé, l’inspecter attentivement pour tout signe

de dommages en transit. S’assurer de

resserrer tous les points de connexion

avant de le mettre en marche. Il y aura

un peu de lubrifiant dans la tête de

l’appareil à cause du processus de test.

Pulvériser une petite rafale sur une surface de pratique après avoir rempli le

contenant de peinture. Ceci libérera le

lubrifiant sans affecter le travail de

peinture ou le revêtement.

Sécurité générale

Ce manuel contient de l’information

très importante à connaître et à comprendre. L’information est fournie

pour la SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Pour

aider à reconnaître cette information,

observer les symboles suivants.

Danger indique une situation dangereuse imminente qui MÈNERA à la

mort ou à des blessures graves si elle

n’est pas évitée.

Avertissement indique une situation

potentiellement dangereuse qui, si elle

n’est pas évitée, RISQUE d’entraîner

des lésions corporelles graves ou

même la mort.

Voir la Garantie à la page 35 pour de l’information importante sur

l’utilisation commercial de ce produit.

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

BUILT TO LAST

!

DANGER

!

AVERTISSEMENT

Page 20

20

Manuel de pièces et instructions de fonctionnement

Attention indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée, POURRAIT risquer d’entraîner des lésions corporelles mineures ou

modérées.

Avis indique de l’information importante qui pourrait endommager

l’équipement si elle n’est pas respectée.

IMPORTANTES INSTRUCTIONS DE

SÉCURITÉ À CONSERVER –

Pour

réduire les risques d’incendie ou d’explosion, de chocs électriques et de

blessures, lire et comprendre toutes les

instructions incluses dans ce manuel.

Se familiariser avec les contrôles et la

bonne utilisation de l’équipement.

DANGER DE CHOC

ÉLECTRIQUE :

Pour éviter tout choc électrique, observer les directives

suivantes en tout temps :

INSTRUCTIONS DE MISE À TERRE

Ce produit doit être mis à terre. Dans le

cas d’un court circuit, la mise à terre

réduit le risque de choc électrique en

donnant une voie de moindre résistance au courant électrique. Ce produit

est doté d’un cordon électrique et

d’une fiche de mise à la terre. La fiche

doit être branchée dans une prise de

courant installée et mise à terre correctement conformément à tous les

codes et ordonnances locaux, en plus

du code national électrique (CNE) et

aux États-Unis, l’Occupational Safety

and Health Act (OSHA).

!

Une mauvaise installation de la prise

mise à la terre peut créer des risques

de chocs électriques. S’il faut remplacer ou réparer le cordon électrique

ou la fiche, ne pas brancher le fil de

terre à l’une ou l’autre borne de lame

plate. Le fil à l’isolant vert à l’extérieur (avec ou sans rayures jaunes)

est le conducteur de terre.

Consulter un électricien ou réparateur

qualifié si vous ne comprenez pas

toutes les instructions ou si vous n’êtes

pas certain que le produit est bien mis

à la terre. Ne pas modifier la fiche

fournie si elle n’entre pas correctement

dans la prise, faire installer une prise

convenable par un électricien qualifié.

Ce produit est conçu pour être utilisé

avec un circuit nominal de 120 volts et

a une fiche de terre semblable à celle

illustrée dans la figure 1. Brancher le

produit seulement à une prise qui a la

même configuration que la fiche. Ne

pas utiliser d’adaptateur avec ce produit.

Rallonges :

Utiliser seulement les rallonges à 3 fils

à fiches à 3 broches qui se branchent

dans des prises à 3 fentes et vérifier

que ces rallonges conviennent à la

fiche du produit. Vérifier que la ral-

Figure 1 - rallonge à trois fils mis à

terre

Calibre du cordon 18 16 14 12 10 8

Tableau 1 – Rallonges pour l’appareil de 120 volts/15 A

Longueur du cordon

(pieds) 25-50 50<100 100<150 150<250 250<400 400-500

ATTENTION

AVIS

!

ATTENTION

!

DANGER

TEST

RESET

Page 21

21

Série EZ5000

halogénés car cela attaque l’aluminium et augmente le risque d’éclatement. Voici des exemples de solvants

inappropriés : brome de méthyle,

tétrachlorure de carbone et iode

d’éthyle.

• Garder l’endroit de la pulvérisation

bien ventilé. Faire circuler de l’air

frais dans cet endroit. Garder le montage de la pompe dans un endroit

bien ventilé Ne pas pulvériser le

montage de pompe.

• Ne pas fumer dans l’endroit de pulvérisation.

• Ne pas faire fonctionner d’interrupteurs, de moteurs ou d’autres produits semblables produisant des étincelles dans le secteur de pulvérisation.

• Garder l’endroit propre et libre de

contenants de peinture ou de

solvants, de chiffons et d’autres

matériaux inflammables.

• Il faut connaître le contenu des

peintures et des solvants pulvérisés.

Lire les fiches signalétiques de sécurité des produits (FSSP) et les étiquettes des contenants de peintures

et de solvants. Suivre les instructions

de sécurité du fabricant de peintures

et de solvants.

• Avoir sur place de l’équipement

d’extinction en état de fonctionner.

• Ne pas utiliser de matériaux avec

un point d’éclair de moins de 21 °C

(70 °F) pour nettoyer cet équipement

à cause de leur inflammabilité.

Exemples de solvants de nettoyage

acceptables : eau, essence minérale

et diluant de laque. Voici des solvants

de nettoyage inacceptables : naphte,

méthyléthylcétone, alcool et toluène.

Pour réduire les risques d’injection

dans la peau :

• Ne pas pointer le pistolet ou pulvériser vers toute personne ou animal.

• Garder les mains et autres parts du

Sécurité générale

(suite)

longe n’est pas endommagée. En utilisant une rallonge, s’assurer d’en utiliser une suffisamment lourde pour transporter le courant que votre produit

débite. Un cordon sousdimensionné

provoquera une chute de tension de

ligne menant à une perte de courant et

à une surchauffe. Voir le tableau 1 de la

page 2.

Ne pas modifier de composants électriques de cet équipement.

Pour réduire les risques d’incendie ou

d’explosion :

• Ne pas pulvériser de matériaux

combustibles ou inflammables près

de flammes nues ou de sources d’incendie telles que cigarettes, moteurs

et équipement électrique.

• La peinture et les solvants qui circulent dans l’équipement peuvent créer

de l’électricité statique. Cette électricité statique crée un risque d’incendie ou d’explosion en présence de

fumées de peinture ou de solvants.

Toutes les pièces du système de pulvérisation, y compris la pompe,

l’assemblage du boyau, le pistolet de

pulvérisation et les objets entourant

la région de pulvérisation doivent être

bien mises à terre pour se protéger

contre les étincelles et les décharges

statiques. Utiliser seulement des

tuyaux de pulvérisateurs de peinture

sans air haute pression mis à terre ou

conducteurs spécifiés par le fabricant.

• Vérifier que tous les contenants et

systèmes de cueillette sont mis à la

terre pour éviter toute décharge statique.

• Connecter votre pulvérisateur à

une prise mise à la terre et utiliser

des rallonges mises à la terre. Ne pas

utiliser d’adaptateur de 3 fiches à

2 fiches.

• Ne pas utiliser de peintures ou de

solvants contenant des hydrocarbures

!

AVERTISSEMENT

!

AVERTISSEMENT

Page 22

22

Manuel de pièces et instructions de fonctionnement

corps loin de la décharge. Ne pas

essayer d’arrêter les fuites avec toute

part du corps.

• Toujours utiliser un embout protecteur de la buse. Ne pas pulvériser

sans avoir l’embout protecteur de

buse en place.

• Utiliser seulement la buse spécifiée

par le fabricant.

• Prudence pour le nettoyage et le

changement de buses. Si la buse se

bloque pendant la pulvérisation :

engager le verrou de la gâchette

(voir figure 2)

tourner la poignée de la buse à

la position de nettoyage (voir figure 3)

désengager le verrou de la

gâchette et tirer

engager le verrou de la gâchette

et tourner la poignée de la buse

vers l’arrière à la position de pulvérisation

dégager le verrou de la gâchette

et continuer à pulvériser.

• Ne pas laisser l’appareil sous tension ou sous pression sans supervision. Lorsque l’appareil n’est pas utilisé, le mettre hors tension (voir figure 4) et retirer en tirant la gâchette

dans une direction sans danger.

Engager ensuite le verrou de la

gâchette.

• La pression haute

pression peut

injecter des toxines

dans le corps et

provoquer de

graves blessures.

S’il y a injection,

consulter immédiatement un

médecin.

• Vérifier les

tuyaux et les

pièces pour tout

signe de dommage. Remplacer

toutes les pièces et

tuyaux endommagés.

• Ce système peut

produire 3 000

lb/po2(205 bar).

Utiliser seulement

des pièces de rechange et des accessoires spécifiés par le fabricant et

d’une valeur nominale minimum de

3 000 lb/po2(205 bar).

• Toujours engager le verrou de la

gâchette lorsqu’on ne pulvérise pas

(voir la figure 2). Vérifier que le verrou fonctionne correctement en

tirant sur la gâchette. Si le verrou

fonctionne correctement, la soupape

du pistolet ne pulvérisera pas.

• Vérifier que toutes les connexions

sont bien en place avant de faire

fonctionner l’appareil.

• Il faut savoir comment arrêter l’appareil et purger la pression rapidement. Pour purger rapidement la

pression :

tourner l’unité à la position

prime (amorce) (voir la figure 5)

... OU ...

tourner l’unité à la position Off

(arrêt) (voir la figure 6)

Figure 3 Tourner la

poignée de la

buse à la position de nettoyage

Figure 2 - Engager le verrou de la

gâchette en tournant le verrou tel

qu’indiqué

Figure 4 - Icône

montrant la

position “Off”

(Arrêt).

Sécurité générale

(suite)

Page 23

Il faut aussi connaître les commandes.

Pour réduire les risques de blessures :

• Toujours porter des gants appropriés, une protection pour les yeux et

un respirateur ou un masque pendant la peinture.

• Ne pas faire fonctionner près d’enfants. Garder les enfants hors de

portée de l’équipement en tout

temps.

• Ne pas se pencher ou se tenir

debout sur un support instable.

Garder les pieds bien au sol et un

bon équilibre en tout temps.

• Il faut être vigilant et savoir ce

qu’on fait.

• Ne pas faire fonctionner l’appareil

fatigué ou sous l’influence de

drogues ou d’alcool.

• Ne pas replier ou trop couder le

tuyau.

• Ne pas exposer le tuyau à des températures ou à des pressions dépassant celles spécifiées par le fabricant.

• Ne pas utiliser le tuyau pour tirer

ou soulever l’équipement.

Installation

OUTILS NÉCESSAIRES :

Tournevis

Deux clés réglables - ou deux clés à

fourche de 3/4 po ( - ou toute combinaison de ces deux types)

Rallonge - voir le tableau 1 de la

page 2.

Retirer tous les composants de la

boîte. Retirer le capuchon de l’adaptateur du tuyau et fixer une extrémité

du tuyau haute pression au pulvérisateur (voir figure 7). Fixer l’autre

extrémité du tuyau au pistolet.

PRÉPARATION

Chaque pulvérisateur est testé en usine.

Les quantités résiduelles du fluide de

test resteront dans la pompe. Si l’on

utilise un revêtement à l’huile (qui se

nettoie avec autre chose que de l’eau),

on devrait purger le système avec le

fluide de nettoyage recommandé par

le fabricant du revêtement. Pour purg-

23

Série EZ5000

Figure 7 - Fixer le tuyau au pulvérisateur

Figure 5 - Icône

montrant la

position

d’amorçage.

Figure 6 - Icône

montrant la

position “Off”

(Arrêt).

Sécurité générale

(suite)

!

AVERTISSEMENT

Page 24

er le système suivre les instructions

d’amorce - voir la page 8. Laisser le

pulvérisateur fonctionner à la position

d’amorce jusqu’à ce qu’un fluide de

nettoyage clair sorte par le tube de

dérivation. Suivre aussi cette procédure

après que l’appareil ait été rangé avec

un fluide de storage tel qu’un protecteur de pompe.

En peignant à l’extérieur

Il est préférable de ne pas pulvériser à

l’extérieur par temps venteux. Le pulvérisateur crée un embrun fin de

revêtement et certaines brumes peuvent être transportées par le vent sur

les voitures, les buissons etc. Pour se

protéger de toute surpulvérisation,

utiliser un respirateur et des lunettes

de sécurité.

Peindre maisons, garages, etc.

Déplacer ou couvrir tout objet ou plantes

qui pourraient être endommagés.

Utiliser des journaux (collés en place)

ou des feuilles de plastique pour protéger les fenêtres, lampes etc. qui ne

seront pas peintes de la même couleur

que la structure. Pour de meilleurs

résultats, retirer toutes les charnières

ou fixtures - car cela pourrait être plus

rapide que les couvrir.

Peindre les clôtures

Déplacer ou couvrir tout objet ou

Manuel de pièces et instructions de fonctionnement

24

plantes qui pourraient être endommagés. Retirer ou couvrir les charnières,

les poignées et autres quincaillerie que

l’on ne veut pas peindre.

En peignant à l’intérieur

Pour se protéger de toute surpulvérisation, utiliser un respirateur et des

lunettes de sécurité. Protéger les

endroits à l’extérieur de la pièce à peindre en suspendant des feuilles de plastique dans les entrées.

Planchers, plafonds, murs

La pulvérisation est extrêmement efficace pour les articles tels que les

planchers et les plafonds noppés.

Utiliser du ruban et des journaux ou

des feuilles de plastique pour protéger

fenêtres, lampes etc. qui ne sont pas

peintes de la même couleur. Porter des

souliers protecteurs, non pas des

souliers ouverts tels que des sandales.

Attention de ne pas pulvériser accidentellement les pieds.

Pour prolonger la portée pour atteindre les planchers et les plafonds, considérer utiliser une baguette de pulvérisation de 61 cm (24 po) qui se fixe

entre le pistolet et la buse. Pour les

planchers, on place à un angle en

s’éloignant de vos pieds tout en permettant une position de pulvérisation confortable pour votre bras et votre dos.

Pour les plafonds, cela empêche la pul-

Figure 8 - Couvrir les plantes qui

pourraient être endommagées

Figure 9 - Utiliser la baguette de pulvérisation de 24 po

Page 25

sol ou du garage.

Protéger les environs

avec une toile de

protection. Pour une

plus grande efficacité, arranger les

portes pour peindre

les côtés en plus de

la surface avant et

arrière. Pour obtenir

un bon motif de pulvérisation, utiliser le réglage de pression le plus bas de votre pulvérisateur.

Étape 1 - Amorçage

Placer les tubes d’aspiration et de dérivation dans le contenant de revêtement (voir la figure 13). Utiliser le jeu

de tubes de 1 gallon pour les contenants de peintures d’un gallon et le

jeu de 5 gallons pour les contenants de

5 gallons. Tourner la touche unique

Commande de position d’amorçage (voir

la figure 14). Après quelques secondes, le

revêtement montera du tube d’aspiration et ensuite sortira du tube de dériva-

tion. Au début, il y aura des bulles d’air

dans la peinture sortant du tube de dérivation.

Lorsqu’il n’y a plus de bulles, tourner la

commande à touche unique à la position de pulvérisation (voir la figure 15).

25

Série EZ5000

vérisation directement au-dessus de la

tête et donne un autre 2 pieds éliminant ainsi le besoin d’une échelle.

Quelques autres mots sur les murs

Si l’on n’est pas confortable pour pulvériser les murs intérieurs, considérer

utiliser l’accessoire à rouleau. Pour

utiliser cet accessoire, retirer la buse de

pulvérisation du pistolet et fixer le

rouleau (voir la figure 10).

Après avoir amorcé normalement,

tourner la commande à touche unique

à la position du rouleau (voir la

figure 12) et rouler.

Portes

Votre pulvérisateur donne un beau fini

sans pinceau sur tous les types de

portes : portes d’entrée, portes d’armoires, portes-persiennes, etc.

Apporter les portes à l’extérieur ou

dans un endroit bien ventilé du sous-

Figure 12 - Icône

montrant la

position du

rouleau

Figure 11 - Utiliser l’accessoire à

rouleau

Figure 10 – Fixer le rouleau

Figure 13 - Tubes d’aspiration et de

dérivation

Installation (suite)

Page 26

Manuel de pièces et instructions de fonctionnement

26

Si l’on éprouve des

difficultés

d’amorçage, voir les

suggestions sous le

tableau de dépannage commençant à

la page 13.

Étape 2 - Utiliser

votre HousePainter

Régler la pression

Une plage de réglages de pression sur

le HousePainter vous offre la flexibilité

voulue pour relever tout défi de peinture. Utiliser le

réglage de pression

le plus bas (voir la

figure 16) pour les

matériaux dilués tels

que les joints d’eau

et de polyuréthanes.

Les réglages de pression plus élevés (voir

la figure 17) servent

pour les revêtements

plus lourds tels que

la peinture au latex.

Le moyen le plus facile de déterminer

le bon réglage pour l’emploi et de

commencer avec la

pression la plus basse

et de pulvériser sur

une surface de pratique. Monter

graduellement la

pression et continuer

à pulvériser des essais

après chaque ajustement jusqu’à ce qu’il

n’y ait plus de

‘bavures’ dans le

motif de pulvérisation (voir la figure

18). Utiliser cette méthode pour déterminer le bon réglage de pulvérisation

et l’on aura le meilleur motif de pulvérisation tout en réduisant la surpulvérisation autant que possible. Si l’on a

encore des ‘bavures’ au réglage de

pression le plus élevé, ou si l’on a

d’autres problèmes de motifs, il faut

voir les suggestions du tableau de

dépannage commençant à la page 13.

Figure 16 - Icône

montrant la

position de pression la plus

basse

Figure 17 - Icône

montrant la

position de pression la plus

élevée

Figure 14 - Icône

montrant la

position

d’amorçage

Figure 15 - Icône montrant la position de pulvérisation

Figure 18 – Bon motif de pulvérisation montré dans la section blanche

de l’image supérieure Mauvais motif

de pulvérisation - ‘bavures’ - montré

dans la section blanche de l’image

inférieure.

Étape 1 - Amorçage

(suite)

2

Page 27

27

Pulvériser

Se placer pour que la buse de pulvérisation soit de 25 à 30 cm (10-12 po) de la

surface à pulvériser. Il est important de

garder les jointures pointant vers cette

surface pour faire en sorte de pulvériser seulement la surface prévue.

Commencer en déplaçant le pistolet,

puis tirer la gâchette. Tenir la gâchette

en se déplaçant confortablement et la

dégager avant de changer de direction

ou en terminant un mouvement. En

d’autres mots, essayer de ne pas activer

ou dégager la gâchette tandis que le

bras est en mouvement. Il y aura une

accumulation de peinture à tout point

où le pistolet pulvérise sans que le bras

ne se déplace.

Rouleau

Si l’on utilise l’un des accessoires à

rouleau disponible, retirer la base de la

buse de pulvérisation du pistolet. Visser

l’accessoire à rouleau sur le pistolet

(voir la figure 10).

Amorcer le pulvérisateur tel que décrit

à la page 8. Lorsqu’il n’y a plus de

bulles visibles dans le tube de dérivation, tourner la commande à touche

unique à l’icône à rouleau (voir la figure 12). Utiliser la gâchette de pistolet

pour charger le rouleau de peinture.

Lorsque la peinture commence à marquer l’enveloppe du rouleau (voir la

figure 19) continuer à tenir la gâchette

et commencer à rouler sur le mur.

Lorsque l’enveloppe du rouleau est saturée, dégager la gâchette et continuer

Série EZ5000

Figure 19 - Peinture commence à

marquer l’enveloppe du rouleau

12 po

Tenir le pistolet de pulvérisation

Couche

mince

Couche

mince

Couche

lourde

Surpulvérisation

Surpulvérisation

Résultat de la flexion du poignet

en pulvérisant

INCORRECT

Env.

10-12 po

Début du mouvement

Tirer la

gâchette

Dégager

la

gâchette

Fin du

mouvement

Bonne manière de tirer le pistolet

de pulvérisation

Étape 2 - Utiliser

votre HousePainter

(suite)

Page 28

Manuel de pièces et instructions de fonctionnement

à rouler la surface. Désengager la

gâchette seulement lorsque l’enveloppe du rouleau a besoin de plus de

peinture.

Avec ce système on économique environ 1/3 de la quantité de peinture utilisée pour le rouleau manuel. On gagne

aussi du temps et économise de l’énergie en éliminant le besoin de se

pencher pour utiliser le plateau à

rouleau.

Se reporter aux instructions du rouleau

pour les procédures de nettoyer.

Étape 3 – Nettoyage

et rangement

Il est très simple de nettoyer le

HousePainter. Il faut suivre tout simplement la même procédure avec de l’eau

ou du solvant que celle utilisée pour le

revêtement. Pour accélérer la procédure, placer le tube de dérivation dans

un seau à déchets pour ne pas contaminer le fluide de nettoyage. Utiliser

tout matériau que le fabricant de peinture recommande pour le nettoyage.

Pour le rangement d’une nuit, plonger

le pistolet dans un seau contenant le

fluide de nettoyage approprié (voir la

figure 20). Laisser les tubes d’aspiration

et de dérivation dans le seau de revêtement. Couvrir les tubes et le seau d’une

serviette humide ou si l’on utilise la

peinture au latex, verser une très mince

couche d’eau sur la peinture. Brasser

l’eau dans la peinture le lendemain

matin.

Revêtements qui se nettoient à l’eau

Après la peinture, tourner le bouton de

commande à touche unique à la position d’amorçage (voir la figure 14).

Soulever le tube d’aspiration au-dessus

du niveau de peinture et laisser tout

revêtement résiduel couler dans le contenant de revêtement du tube de dérivation. Lorsqu’il y a très peu ou

aucune peinture sortant du tube de

dérivation, fermer le pulvérisateur.

Placer le tube d’aspiration dans un seau

d’eau tiède. Si l’on utilise un seau de

déchet, placer le tube dans ce seau.

Sinon, le tube devrait aussi être placé

dans le seau d’eau tiède. Tourner la

commande à touche unique à la position de nettoyage de la pompe (voir la

figure 21).

Si l’on utilise un seau de déchets, laisser

le pulvérisateur fonctionner à ce mode

jusqu’à ce qu’il n’y

ait plus d’eau sortant

du tube de dérivation. Sinon, laisser

l’eau circuler pendant environ 5 minutes. Répéter ce

processus au moins

une fois ou jusqu’à

ce que de l’eau claire

sorte du tube de

dérivation. S’assurer

de fermer le HousePainter en

changeant de seau.

Lorsqu’on est certain que la pompe soit

propre, prendre un autre seau d’eau.

Placer le tuyau d’aspiration dans le

seau et tourner le bouton de la com-

Figure 21 - Icône

montrant la

position de nettoyage de la

pompe

Figure 20 - Plonger le pistolet dans

un seau contenant le fluide de nettoyage approprié

Étape 2 - Utiliser

votre HousePainter

(suite)

28

Page 29

Série EZ5000

29

mande à touche unique à la position

du nettoyage de tuyau (voir la figure 22). Tourner la buse réversible du

pistolet à la position de nettoyage.

Pulvériser dans un

seau de déchets

jusqu’à ce que de

l’eau propre sorte du

pistolet. Immerger la

buse pour éviter les

éclaboussures. Un

autre moyen de

réduire l’éclaboussure est de garder la

buse à angle audessus du niveau de

fluide.

Pour tout rangement de six mois ou

plus, utiliser un fluide de rangement tel

qu’un protecteur de pompe. Suivre les

directives fournies par le fabricant.

Revêtements se nettoyant avec autre

chose que de l’eau

Lorsque le fabricant du revêtement

recommande de l’essence minérale ou

tout autre fluide de nettoyage, verser

suffisamment de solution dans un seau

pour arriver à environ un pouce audessus du filtre d’aspiration. Ne pas utiliser de seau de déchets. Garder le tube de

dérivation dans le seau du fluide avec le

tube d’aspiration. Laisser le fluide circuler pendant 10 minutes dans la position de nettoyage de pompe (voir la figure 21).

Tourner la commande à touche unique à

la position de l’icône de nettoyage du

tuyau (voir la figure 22). Tourner la buse

réversible du pistolet à la position de

nettoyage (voir la figure 23). Pulvériser

dans un seau de déchets jusqu’à ce qu’il

n’y ait plus de fluide dans le seau d’aspiration. Immerger la buse dans l’eau pour

éviter les éclaboussures. Un autre moyen

de réduire l’éclaboussure est de garder la

buse à angle au-dessus du niveau de fluide.

Jeter le solvant conformément aux règlements locaux.

Pour les meilleurs résultats, répéter ce

processus une autre fois avec du fluide

de nettoyage frais.

On peut filtrer et réutiliser le fluide de

nettoyage. Rien d’autre à faire pour le

rangement à long terme.

Figure 22 - Icône

montrant la

position de nettoyage du tuyau

Figure 23 - Tourner la buse de pulvérisation en position de nettoyage.

Étape 3 – Nettoyage

et rangement (suite)

2

Page 30

Manuel de pièces et instructions de fonctionnement

30

Entretien Détail

Article Vérification Remplacer Notes

Tableau d’entretien

Étiquettes de

sécurité du

produit

Ajustement de

la gâchette

Tuyau sans air

Tube d’aspiration

Tube de dérivation

Filtre d’aspiration

Filtre du pistolet

Duvet du

rouleau

Soupape de

sortie

Buse de pulvérisation.

Avant chaque

utilisation

Avant chaque

utilisation

Avant chaque

utilisation

Avant chaque

utilisation

Avant chaque

utilisation

Avant chaque

utilisation et

tous les 19 L

(5 gallons)

Avant chaque

utilisation

Avant chaque

utilisation

Avant chaque

utilisation

Au besoin

Au besoin

Au besoin

Tous les 378 L

(100 gallons) ou

plus souvent au

besoin

Tous les 378 L

(100 gallons)

Au besoin

Tous les 378 L

(100 gallons)

Tous les 20 à

75 gallons

Consulter la liste de

pièces pour l’emplacement des étiquettes

de sécurité du produit

et les numéros de

pièces s’y rapportant

S’assurer que le pistolet s’éteigne pendant

la pulvérisation

Lire l’information sur

l’étiquette fixée au

tuyau de pression

élevée pour les

instructions d’entretien.

Vérifier pour tout

signe de coupures et

entailles.

Vérifier pour tout

signe de coupures et

entailles.

Ne pas essayer de nettoyer le filtre du pistolet, le remplacer seulement.

Utiliser une clé de

3/4 po - au couple de

1,75 kg/m (150 po-lb)

Utiliser une clé de

13/16 po - au couple

de 135 po-lb

Page 31

Série EZ5000

Symptôme Causes possibles Mesure corrective

Moteur tourne

mais n’amorce pas

le matériau

Le pulvérisateur

accumule de la

pression, mais la

pression chute

lorsque le pistolet

est tiré.

L’appareil

s’amorce, mais

n’accumule aucune

pression.

1. Pousser le ressort à l’intérieur de la soupape d’entrée et pousser sur le bouton de la soupape de sortie

2. Resserrer la pince.

3. Tourner la commande à la

position d’amorçage.

4. Repurger la soupape de

pression. Tourner la commande entre la position

MARCHE/ARRÊT et la position AMORÇAGE/NETTOYAGE DE LA POMPE et laisser le moteur tourner pendant quelques minutes.

Tourner ensuite le levier à

la position d’amorçage.

5. Nettoyer ou remplacer le

filtre du tube d’aspiration.

6. Retirer et nettoyer ou remplacer la soupape d’entrée

et de sortie.

7. Diluer, mélanger et filtrer

tout le produit à pulvériser.

1. Retirer et remplacer les

soupapes au besoin

2. Resserrer la pince.

3. Remplacer le filtre d’aspiration.

4. Remplacer le filtre ou la

buse.

5. Remplacer avec une buse

plus petite.

6. Remplacer le montage du

tuyau d’aspiration.

1. Retirer et remplacer les

soupapes au besoin

2. Tourner la commande à un

réglage plus élevé.

3. Vérifier le niveau d’huile. Si

bas, remplir jusqu’à 1/4 po

du haut du boîtier avec de

l’huile hydraulique 10 W

(CH # AL1702).

4. Diluer et/ou filtrer tout

matériau.

5. Retirer et nettoyer ou remplacer la soupape (SCR).

Tableau de dépannage

1. Soupape d’entrée ou de sortie

coincée

2. Connexion du tube d’aspiration

desserré

3. Levier de commande en position de pulvérisation ou du

rouleau

4. De l’air dans le système

hydraulique provoquant une

perte d’aspiration et aucun

déplacement du diaphragme.

5. Filtre du tube d’aspiration bloqué

6. Soupapes d’entrée ou de sortie

sales ou usées.

7. Matériau est trop épais ou n’a

pas été filtré correctement.

1. Soupapes d’entrée et/ou de sortie sont usées.

2. Connexion du tube d’aspiration

desserrée

3. Tube d’aspiration ou filtre

d’aspiration bloqué.

4. Filtre du pistolet bloqué ou

buse usée.

5. Buse est trop large pour le

matériau à pulvériser.

6. La membrane du tuyau d’aspiration est endommagée.

1. *Soupape d’entrée sale ou

usée.

2. La pression n’est pas assez

élevée.

3. * Le niveau d’huile du boîtier

hydraulique est trop bas.

4. Le matériau est trop épais ou

n’est pas filtré correctement.

5. *La soupape d’amorçage/pulvérisation sale, coincée ou usée

et le fluide passe dans le tube

de dérivation tandis que l’appareil est en position de pulvérisation.

* = centre de service recommandé.

31

Page 32

Manuel de pièces et instructions de fonctionnement

Symptôme Causes possibles Mesure corrective

Le pistolet continue

à pulvériser lorsque

la gâchette est

dégagée.

Le moteur du pulvérisateur ne

démarre pas ou ne

fait que ronfler.

Le moteur surchauffe et/ou s’arrête

1. Nettoyer ou remplacer la

soupape du pistolet

2. Remplacer la soupape du pistolet ou remplacer tout le

pistolet.

3. Ajuster la gâchette en ajustant l’écrou derrière la

gâchette. Déplacer l’écrou

vers la poignée si la gâchette

ne bouge pas. Resserrer

l’écrou en tournant vers la

buse de pulvérisation si la

gâchette se déplace trop.

4. Tourner les boulons du boîtier du filtre d’environ 1/2 tour

dans le sens contraire des

aiguilles d’une montre.

1. Tourner la commande à la

position d’amorçage et tirer

sur la gâchette du pistolet.

2. Éteindre l’appareil. Mettre le

levier en position

MARCHE/ARRÊT puis

débrancher le cordon et

laisser l’appareil refroidir de

20 à 30 minutes.

3. Brancher l’appareil directement dans la prise et sortir la

longueur du tuyau.

4. Remplacer le fusible, réenclencher le disjoncteur ou

utiliser le disjoncteur de 20

ampères.

1. Choisir le bon calibre ou

brancher directement dans la

prise et utiliser un autre

tuyau de pulvérisation supplémentaire.

2. Apporter à un centre de service.

3. Diluer, mélanger et filtrer

tous les matériaux.

4. Déplacer l’appareil à un

endroit à bonne circulation

d’air.

5. Vérifier les prises pour trop

de tension/ampérage.

Tableau de dépannage (suite)

1. L’accumulation de peinture à

l’intérieur de la soupape du pistolet ou la soupape du pistolet

est sale.

2. La soupape du pistolet est usée.

3. La gâchette du pistolet n’est

pas ajustée correctement.

4. Le boîtier du filtre est trop serrée vers le bas.

1. Le système de peinture est sous

pression ou la commande est en

position de pulvérisation ou de

rouleau.

2. La surcharge thermique du

moteur déclenchée

3. Utilise une rallonge trop longue

ou le calibre est trop petit.

4. Fusible grillé ou disjoncteur

déclenché

1. La rallonge est trop longue ou

le calibre est trop petit.

2. La surpulvérisation de peinture

est tirée dans le moteur provoquant la surchauffe.

3. Matériau est trop épais pour

que le pulvérisateur de peinture

s’amorce.

4. Le pulvérisateur est utilisé dans

un endroit à mauvaise circulation.

5. Disjoncteur déclenché.

* = centre de service recommandé.

32

Page 33

Symptôme Causes possibles Mesure corrective

Fuites d’huile ou

huile dans la peinture.

Fuite de peinture du

pulvérisateur

L’appareil s’amorce

et accumule de la

pression mais ne

pulvérise pas.

Mauvais motif de

pulvérisation ‘bavures’, rafales de

matériau, roussissement du motif

1. Resserrer les boulons du

bloc dans un motif en X. Si

l’huile coule encore, retirer

le bloc et changer le

diaphragme. S’assurer d’utiliser la bonne pièce de

rechanger, appeler : 1-800626-4401.

2. a. Remplacer l’appareil

b. Contacter le centre de

service pour faire remplacer le boîtier du moteur.

3. Contacter le centre de service pour faire remplacer le

boîtier hydraulique et le

diaphragme.

1. Resserrer les boulons du

bloc en un motif en X ou

remplacer le bloc.

2. Resserrer la pince.

3. Retirer et remplacer la

soupape de sortie.

4. a. Resserrer le tuyau sur la

soupape de sortie.

b. Vérifier le filet endommagé sur le connecteur.

Remplacer au besoin.

1. Tourner la buse de pulvérisation pour la position de

nettoyage, presser la

gâchette, puis remettre à la

position de pulvérisation.

2. Remplacer le filtre du pistolet, s’assurer que le boîtier du filtre soit libre de

débris.

1. Diluer, mélanger et filtrer

tous les matériaux.

2. Nettoyer ou remplacer la

buse de pulvérisation.

3. Retirer et nettoyer ou remplacer la soupape d’entrée

et/ou de sortie.

4. Tourner le levier dans le

sens des aiguilles d’une

montre pour augmenter la

pression au pistolet.

5. Nettoyer ou remplacer le

filtre d’aspiration.

Tableau de dépannage (suite)

1. *Fuite d’huile entre le bloc

et le boîtier hydraulique.

2. * Fuite d’huile du moteur,