Page 1

BUILT TO LAST

Electric Pressure

Washers

Operating Instructions

Carefully read and understand these instructions

before operating this pressure washer.

© 2003 Campbell Hausfeld

IN459000AV 10/03

1

8

5

0

P

S

I

P

r

e

s

s

u

r

e

W

a

s

h

e

r

1

.

9

G

P

M

Safety and Warning Information . . . . . . . . . . . . . . . 2 – 4

Pre-Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 7

Operation, Shutdown and Storage. . . . . . . . . . . . . . 7 – 9

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . 10 – 11

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Contents Page

1750 PSI

Pressure Washer

1.8 GPM

G

a

r

a

n

t

í

a

l

i

m

i

t

a

d

a

d

e

1

a

ñ

o

s

Limited

Warranty

G

a

r

a

n

t

i

e

l

i

m

i

t

é

e

d

e

1

a

n

s

E

C

P

For parts, product & service information

visit www.chpower.com

See Warranty on page 12 for important information about commercial use of this product.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Page 2

Pressure Washers

2

Safety and Warning Information

www.chpower.com

Safety Guidelines

This manual contains information that is very

important to know and understand. This information is provided for SAFETY and to PREVENT EQUIPMENT PROBLEMS. To help recognize this information, observe the following

symbols.

Danger indicates an imminently hazardous situation which, if

not avoided, WILL result in death or

serious injury.

Warning indicates a

potentially hazardous situation which,

if not avoided, COULD result in death

or serious injury.

Caution indicates a potentially hazardous situation which, if

not avoided, MAY result in minor or

moderate injury.

NOTE:

Information that requires special atten-

tion.

Important Safety Instructions

SAVE THESE INSTRUCTIONS

When using this product, basic precautions

should always be followed, including the following:

1. Read all instructions before using the prod-

uct.

2. To reduce the risk of injury, close supervi-

sion is necessary when a product is used

near children.

3. ALWAYS disconnect power before disas-

sembling or repairing the unit.

4. Follow all safety codes as well as the

Occupational Safety and Health Act

(OSHA).

5. Ensure safety devices are operating proper-

ly before each use. DO NOT remove or

modify any part of the gun or unit.

6. Know how to stop this product and bleed

pressure quickly. Be thoroughly familiar

with the controls.

7. Stay alert – watch what you are doing.

8. Do not operate the product when fatigued

or under the influence of alcohol or drugs.

9. Keep operation area clear of all persons.

10. Do not overreach or stand on unstable

support. Keep good footing and balance

at all times.

11. Follow the maintenance instructions specified in the manual.

12. This product shall be connected to a

power supply receptacle protected by a

ground fault circuit interrupter (GFCI).

13. If product is provided with a GFCI, be sure

to inspect cord and GFCI prior to use. Any

repair or replacement of the power cord

must be performed by a qualified (licensed

or certified) electrical technician.

Risk of injection or severe

injury. Keep clear of nozzle. Do not

discharge streams at persons. This

product is to be used only by trained

operators. Always remove lance from

gun before cleaning debris from tip.

• Keep clear of nozzle. NEVER direct high

pressure spray at any person, animal or self.

• Always wear safety glasses or goggles and

protective clothing when operating or performing maintenance.

• Never put hand or fingers over the spray tip

while operating the unit.

•Never try to stop or deflect leaks with any

body part.

• Always engage the trigger safety latch in

the safe position when spraying is stopped

even if only for a few moments.

• Always follow detergent manufacturer’s

label recommendations for proper use of

detergents. Always protect eyes, skin, and

respiratory system from detergent use.

SERVICING OF A DOUBLE-INSULATED

APPLIANCE

In a double-insulated product, two systems of

insulation are provided instead of grounding.

No grounding means are provided for a dou-

!

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

WARNING

!

DANGER

Garantía Limitada

1

. Duracion: De la fecha de compra por el comprador original y de acuerdo a las siguientes clasificaciones: Normas

(Standard Duty) – Un Año, Deber Serio (Serious Duty) - Dos Años, Deber Extremo (Extreme Duty) - Tres Años.

2. QUIEN OTORGA DA ÉSTA GARANTÍA (EL GARANTE): Campbell Hausfeld / Scott Fetzer Company, Harrison, Ohio,

45030, Teléfono: (800) 330-0712.

3. QUIEN RECIBE ÉSTA GARANTÍA (EL COMPRADOR): El comprador original (que no sea revendedor) de la

Lavadora de Presión Campbell Hausfeld.

4. PRODUCTOS CUBIERTOS POR ESTA GARANTÍA: Cualquier Lavadora de Presión Campbell Hausfeld fabricada o

distribuida por el garante.

5. LO QUÉ ÉSTA CUBIERTO POR ESTA GARANTÍA: Los defectos de material y/o de manufactura que ocurran dentro

del periodo de garantía con las excepciones anotadas abajo.

6. LO QUÉ NO ÉSTA CUBIERTO POR ESTA GARANTÍA:

A. Las garantías implícitas, incluyendo las garantías de comercialización y adecuación para un fin particular, son

limitadas a partir de la fecha de compra como se indica en el parrafo DURACIÓN. Si ésta lavadora de presión

es usada para trabajos comerciales, industriales o para renta, la garantía aplicada es de (90) días a partir de

la fecha de compra. En algunos estados no se permiten limitaciones a la duración de las garantías, en tal

caso esta limitacion no es aplicable.

B. CUALQUIER PERDIDA, DANO INCIDENTAL INDIRECTO O CONSECUENTE QUE PUEDE RESULTAR DE UN DEFEC-

TO, FALLA, O MALFUNCIONAMIENTO DE LA LAVADORA DE PRESIÓN CAMPBELL HAUSFELD. En algunos esta-

dos no se permiten la exclusión o limitación de daños incidentales o consecuentes y en tal caso esta limita-

cion o exclusión no es aplicable.

C. Cualquier falla que resulte por daños en la transportación, accidente, abuso, negligencia o incumplimiento

de las instrucciones de funcionamiento e instalacion indicadas en el manual suministrado con el producto.

D. El servicio al producto antes de la venta. Ejemplo ensamblaje, aceites o lubricantres, ajustes, etc.

E. Partes o ajestes requeridos normalmente en el mantenimiento de la lavadora de presión.

F. El motor de gasolina y sus componentes están expresamente excluídos de ésta garantía limitada. Estos com-

ponentes deben de ser devueltos por el comprador al fabricante original o a su taller de reparación autoriza-

do.

G. Partes adicionales no cubiertos en ésta garantía:

1. Desgaste normal en partes tales como mangueras de alta presión, sellos de agua o aceite, anillos, válvulas

y boquillas de spray.

2. Escobillas del motor (modelos eléctricos solamente).

3. Defectos esternos que no interfieren con su funcionamiento.

4. Componentes oxidados.

5. Desgaste de la bomba o daño de la válvula causado por uso de aceite inapropiado, contaminación del

aceite o por no seguir adecuadamente las recomendaciones de mantenimiento.

7. RESPONSABILIDADES DEL GARANTE BAJO ÉSTA GARANTÍA: Repare o reemplazar, como lo decida el garante, ya

sea la lavadora de presión o alguna de sus partes que se encuentre defectuoso, no funcione adecuadamente y/o

no cumpla de conformidad dentro del periodo de duración de la garantia.

8. RESPONSABILIDADES DEL COMPRADOR BAJO ESTA GARANTÍA:

A. Proporcionar prueba de la fecha de compra y registros de mantenimiento.

B. Entregar o enviar la lavadora de presión o su componente al centro de servicio autorizado Campbell

Hausfeld más cercano. Los costos de embarque, si son aplicables, serán pagados por el comprador.

C. Ser cuidadoso con el funcionamiento y mantenimiento de la lavadora de presión de acuerdo al manual(s) del

propietario.

9. CUANDO EFECTUARA EL GARANTE LA REPARACION O REEMPLAZO CUBIERTO POR ESTA GARANTÍA: La

reparación o reemplazo del equipo tomara el tiempo normal y de acuerdo a la carga de trabajo en ese momen-

to el el centro de servicio y de acuerdo a la disponibilidad de refacciones.

Esta garantía limitada es válida sólo en los EE.UU., Canadá y México y otorga derechos legales específicos. También

usted podría tener otros derechos los cuales varían de estado a estado o de país a país.

Lavadoras a Presión

Page 3

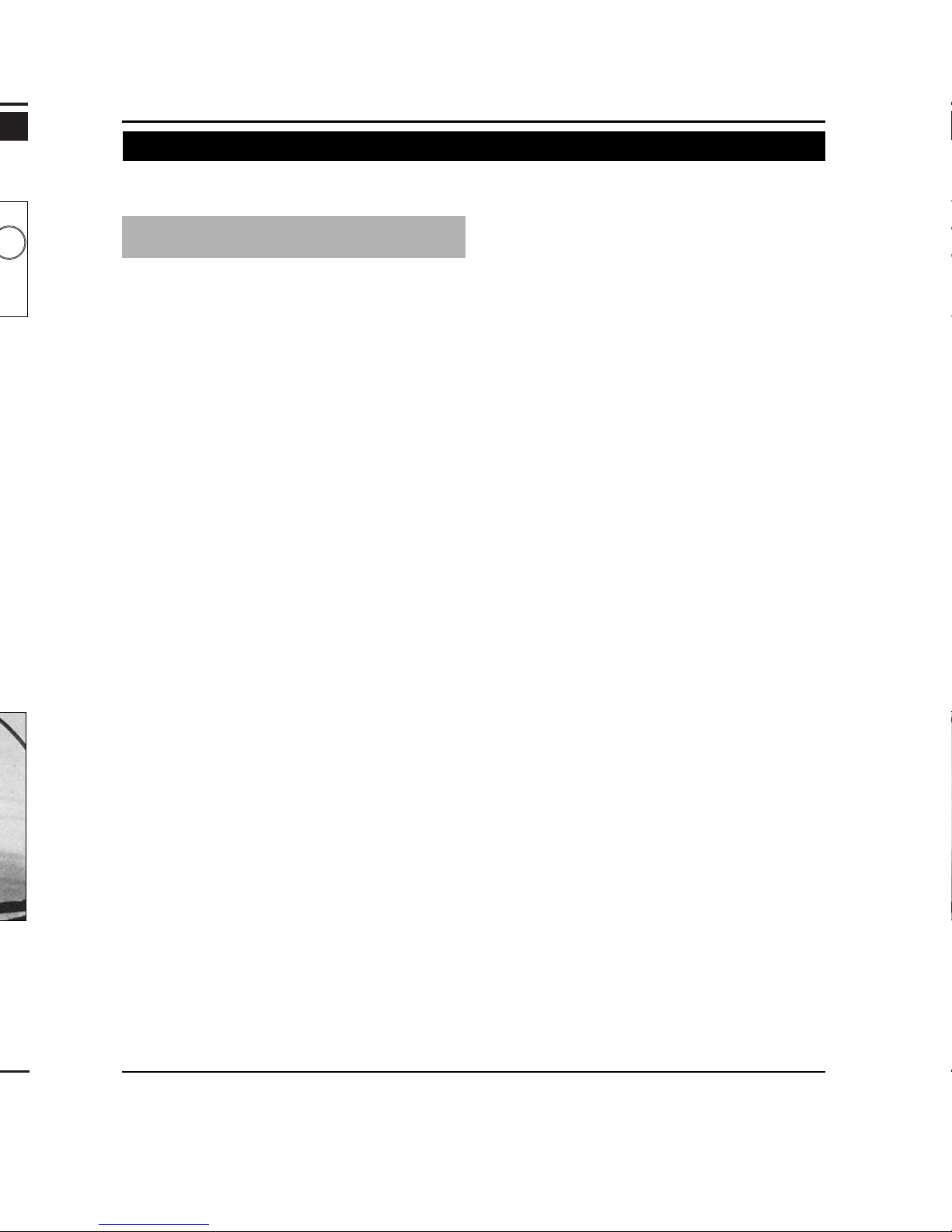

ble-insulated product, nor should grounding

means be added to the product. Servicing a

double-insulated product requires extreme

care and knowledge of the system, and should

be done only by qualified

service personnel.

Replacement parts for a

double-insulated product

must be identical to the

original parts. A doubleinsulated product is marked with the words

“Double Insulation” or “Double Insulated.”

Product may also be marked with symbol

shown in Figure 1.

Do not use pressure that

exceeds the operating pressure of any

of the parts (hoses, fittings, etc.) in

the pressurized system. Ensure all

equipment and accessories are rated

to withstand the maximum working

pressure of the unit.

Explosion hazard.

•NEVER spray flammable liquids or use pres-

sure washer in areas containing combustible

dust, liquids or vapors.

•Never operate this machine in a closed build-

ing or in or near an explosive environment

Do not spray electrical

apparatus and wiring.

•Never disconnect the high pressure discharge

hose from the machine while the system is

pressurized. To depressurize machine, turn

power and water supply off, then press gun

trigger 2-3 times.

•Never permanently engage the trigger mech-

anism on the gun.

•Never operate the machine without all com-

ponents properly connected to the machine

(handle, gun/wand assembly, nozzle, etc.).

Equipment damage.

•ALWAYS turn water supply “ON” before turn-

ing pressure washer “ON.” Running pump

dry causes serious damage.

•Do not operate the pressure washer with the

inlet water screen removed. Keep screen

clear of debris and sediment.

•NEVER operate pressure washer with broken

or missing parts. Check equipment regularly

and repair or replace worn or damaged

parts immediately.

•Use only the nozzle supplied with this

machine.

•Never leave the wand unattended while the

machine is running.

•Never attempt to alter factory settings.

Altering factory settings could damage the

unit and will void the warranty.

•Always hold gun and wand firmly when starting and operating the machine.

•NEVER allow the unit to run with the trigger

released (off) for more than one (1) minute.

Resulting heat buildup will damage pump.

•Pressure washer is not meant to pump hot

water. NEVER connect it to a hot water supply as it will significantly reduce the life of

the pump.

•NEVER store the pressure washer outdoors or

where it could freeze. The pump will be

seriously damaged.

•Release trigger when changing from high to

low pressure modes. Failure to do so could

result in damage

Keep hose away from

sharp objects. Bursting hoses may

cause injury. Examine hoses regularly

and replace if damaged. Do not

attempt to mend a damaged hose.

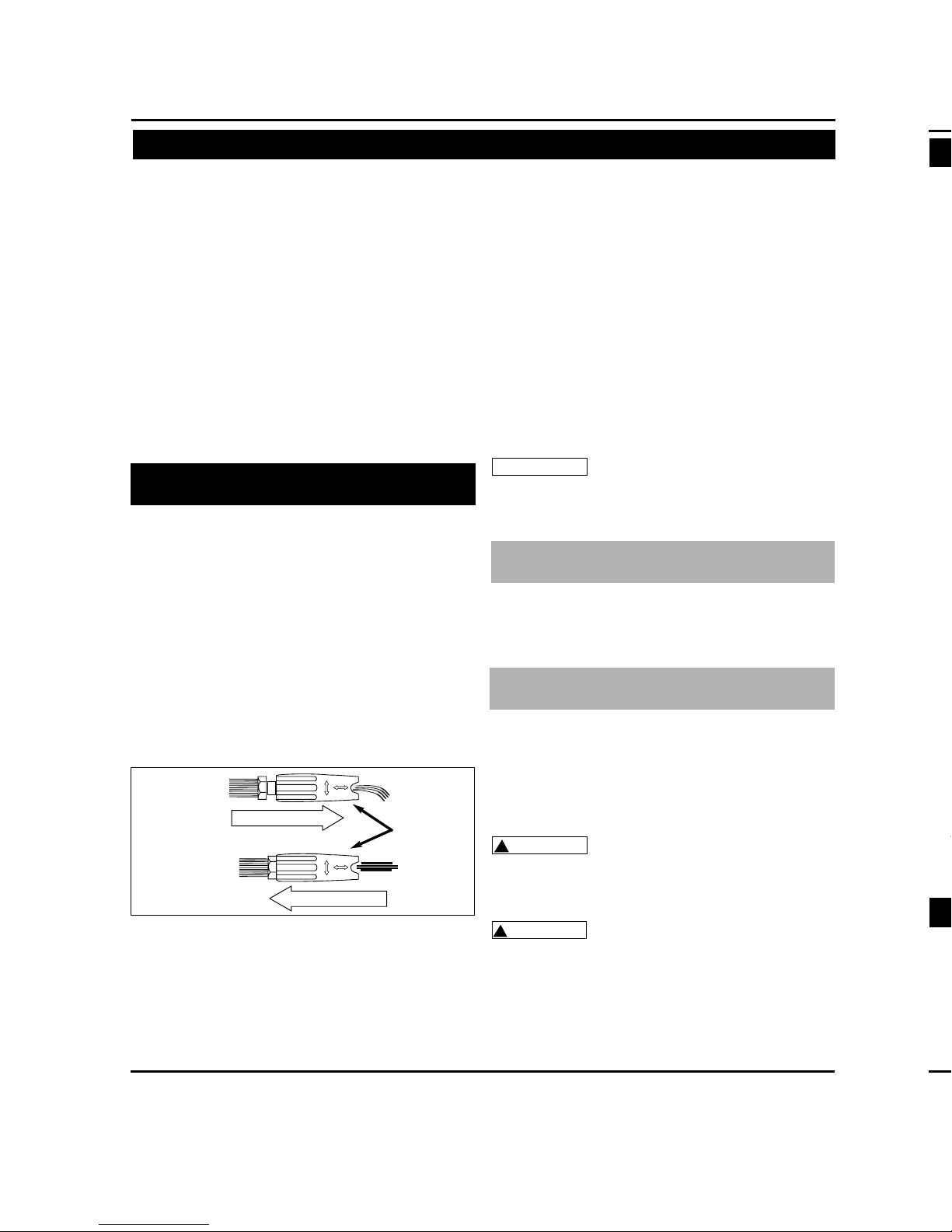

EXTENSION CORDS

If using an extension cord,

use only grounded, three wire extension

cords that are in good condition.

Use of an extension cord is not recommended. If

one is used, then use only wire sizes and lengths

shown in chart below.

Use only extension cords intended for outdoor

use. These are identified by the marking

“Acceptable for use with outdoor appliances;

store indoors while not in use.” Use only extension cords having an electrical rating equal to or

more than the rating of the product. Do not use

!

DANGER

!

CAUTION

!

WARNING

!

WARNING

!

WARNING

!

WARNING

3

Safety and Warning Information (Continued)

www.chpower.com

Figure 1 - Double

Insulated symbol

Page 4

Lavadoras a Presión

Guía de Diagnóstico de Averías

La lavadora a pre-

sión no se enciende.

La bomba no

alcanza la pre-

sión necesaria.

La presión

fluctúa.

El motor se

apaga inespe-

radamente.

Problema Posible(s) Causa(s) Acciones a Tomar

4

Safety and Warning Information (Continued)

www.chpower.com

damaged extension cords. Examine extension

cord before using and replace if damaged. Do

not abuse extension cord. Do not pull on the

cord to disconnect. Keep cord away from heat

and sharp edges. Always disconnect cord from

receptacle before disconnecting product from

extension cord.

Note: Do not use 16 or 18 AWG common

extension cords on this product.

Failure to follow these

instructions can result in serious

injury, including death.

To reduce the risk

of electrocution, keep all connections dry and off the

ground. Do not touch plug

with wet hands.

!

WARNING

!

DANGER

REFER TO ASSEMBLY INSTRUCTIONS FOR

ASSEMBLY, SET-UP AND

CONNECTION PROCEDURES

Pre-Operation

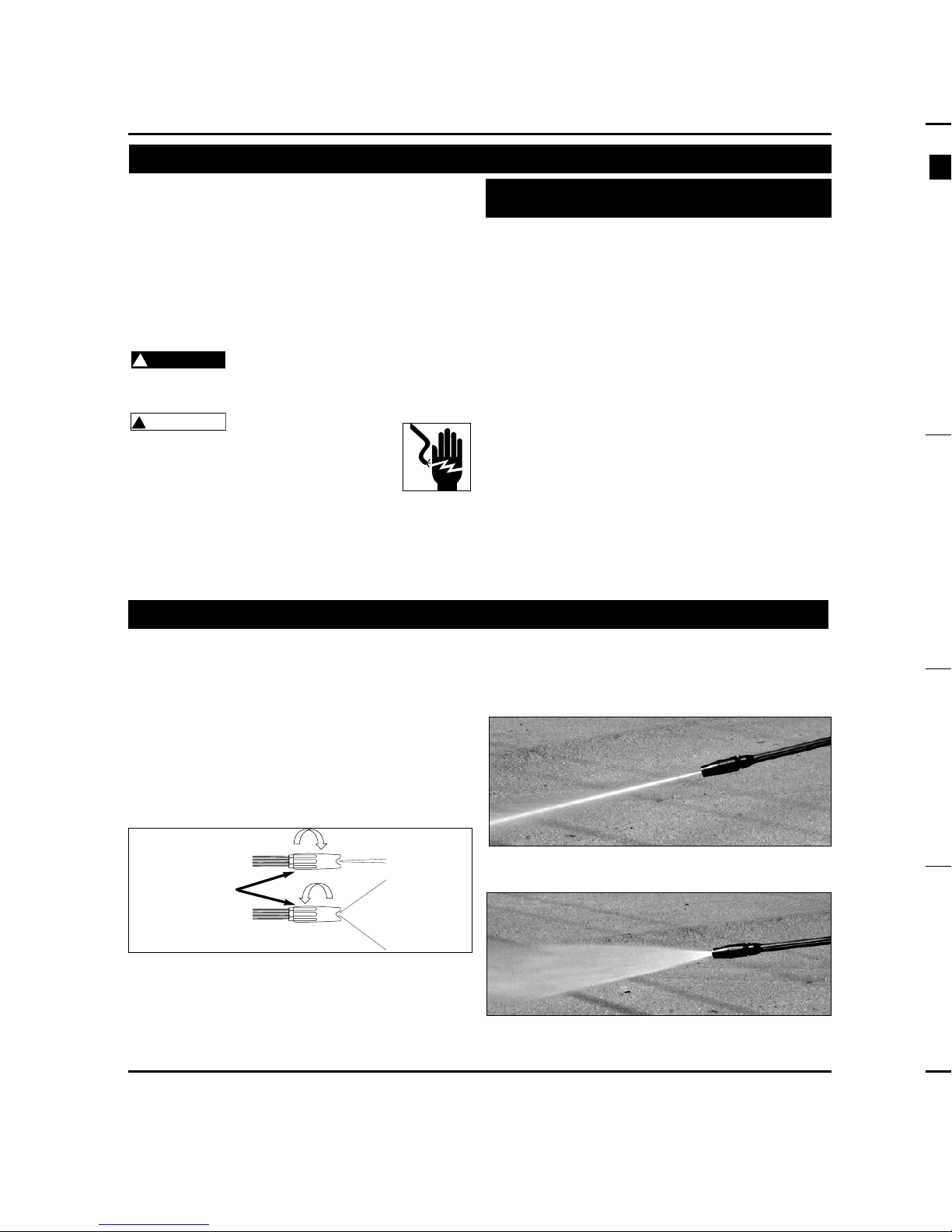

ADJUSTING FAN PATTERN

The angle of spray coming out of the lance

may be adjusted on some lances by rotating

the nozzle. This will vary the spray pattern

from approximately a 0˚ narrow high impact

stream to a 60˚ wide fan spray. (See Figure 2.)

A narrow stream has high impact force on the

cleaning surface and results in maximum deep

cleaning in a concentrated area. However, this

narrow high impact spray must be used cautiously, as it may damage some surfaces.

A wide fan pattern will distribute the impact

of the water over a larger area, resulting in

excellent cleaning action with a reduced risk

Figure 2 - Adjusting nozzle for fan pattern (not applicable on some nozzles)

Nozzle

Pressure Washers

Extension Allowable length

Cord size 25’ 50’

14 AWG Yes No

12 AWG Yes Yes

Figure 3 – Narrow high impact stream

Figure 4 – Wide fan pattern

Page 5

5

Pre-Operation (Continued)

www.chpower.com

of surface damage. Large surface areas can be

cleaned more quickly using a wide fan pattern.

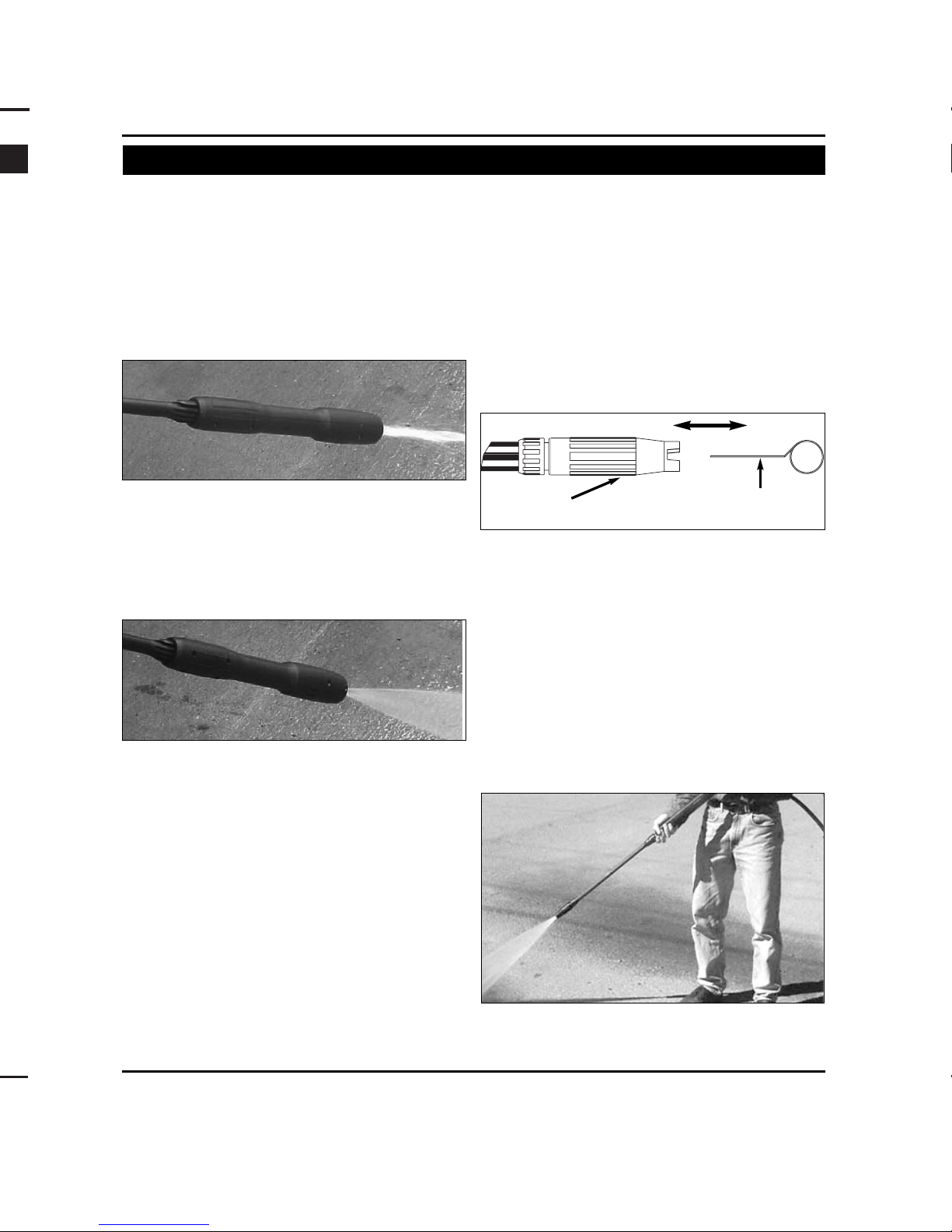

ADJUSTABLE PRESSURE NOZZLE

(NOT INCLUDED WITH ALL MODELS)

The adjustable pressure nozzle allows you to

vary the pressure of your spray by turning the

blue end of the nozzle. Turning the blue end

fully clockwise will reduce the pressure to its

minimum. If the pressure washer has a detergent tank system you must use this minimum

pressure setting in order to suction detergent.

Turning the blue end fully counter-clockwise

will increase the pressure to its maximum for

greatest cleaning efficiency. Turning the blue

end changes the pressure but not the fan pattern.

NOZZLE CLEANING INSTRUCTIONS

A clogged or partially clogged nozzle can

cause a significant reduction of water coming

out of the nozzle and cause the unit to pulsate

while spraying.

To clean out the nozzle:

•Turn off and unplug unit.

•Turn off water supply. Relieve any pressure

trapped in the hose by squeezing trigger 2-3

times.

• Separate lance from gun.

• Rotate nozzle to the narrow stream setting.

This opens up the fan blades.

• Using included tip cleaner, or an un-folded

paper clip, insert wire into the nozzle hole

and move back and forth until debris is dislodged. (See Figure 7.)

• Remove additional debris by back-flushing

water through the nozzle. To do this, place

end of a garden hose (with water running) to

end of nozzle for

30 – 60 seconds.

ANGLE TO THE CLEANING SURFACE

When spraying water against a surface, maximum impact is generated when the water

strikes the surface “head on." However, this

type of impact tends to cause dirt particles to

imbed in the surface, thereby preventing the

desired cleaning action.

The optimum angle for spraying water against

a cleaning surface is 45 degrees.

Figure 5 – Low Pressure Spray

Figure 6 – High Pressure Spray

Figure 7 – Insert tip cleaner in nozzle hole

and move back and forth until debris is dislodged.

Nozzle

Tip Cleaner

Figure 8 – Optimum Angle to Cleaning

Surface

Page 6

7. Deje que el detergente permanezca sobre la

superficie durante algunos minutos. Este es

un buen momento para usar un cepillo y cepil-

lar suavemente las áreas muy sucias. Nunca

deje que el detergente se seque sobre la

superficie de limpieza.

8.

Quite el aplicador de detergente de la pistola y

reemplácelo con la lanza, o quite el aplicador del

extremo de la lanza

9.

Enjuague el detergente de la superficie.

Nota: Lave el aplicador de detergente con un

chorro de agua limpia abundante después de

cada uso.

Siga las instrucciones del rÛtulo del fabricante

para combinar las concentraciones correctas

de jabÛn/detergente. La proporciÛn de

jabÛn/detergente y agua en la lavadora de

presiÛn debe ser cerca de 12% (1 a 8 partes).

ESTOS MODELOS NO NECESITAN UN

APLICADOR DE DETERGENTE

1. Retire la tapa del tanque de detergente y vier-

ta en su interior detergente para lavadora a

presión. Vuelva a poner la tapa.

2. Mueva el interruptor OFF/ON a la posición ON

(ENCENDIDO).

3. Corra la boquilla a la posición de baja presión

como se muestra en la figura 13, y aplique el

detergente de modo que cubra por completo

la superficie de limpieza.

Aplique el detergente de abajo hacia arriba

para evitar que el detergente se escurra para

abajo y cause vetas. Espere un par de minutos

para que el detergente afloje la mugre y la

Lavadoras a Presión

Operación (Continuación)

Unidades eléctricas con tanque de

detergente

Figura 13- Ajuste de la boquilla para presión

6

Pre-Operation (Continued)

www.chpower.com

Spraying water against a surface at this angle

provides for the most beneficial impact force

combined with efficient removal of debris from

the surface.

DISTANCE FROM CLEANING SURFACE

Another factor that determines the impact force

of the water is the distance from the spray nozzle to the cleaning surface. The impact force of

the water is increased as the nozzle is moved

closer to the surface.

HOW TO AVOID DAMAGING SURFACES

Damage to cleaning surfaces occurs because the

impact force of the water exceeds the durability

of the surface. The impact force can be varied by

controlling the three previously noted items.

Never use a narrow high impact stream or a

turbo/rotary nozzle on a surface that is susceptible to damage. Avoid spraying windows with a

narrow high impact stream or turbo nozzle as

this may cause breakage. The surest way to avoid

damaging surfaces is to follow these steps:

1.Before triggering the gun, adjust the nozzle to

a wide fan pattern.

2.Place the nozzle approximately 4-5 feet from

and 45 degrees to the cleaning surface, and

trigger the gun.

3.Vary the fan pattern spray angle and the distance to the cleaning surface until optimum

cleaning efficiency is achieved without damaging the surface.

TURBO NOZZLE (NOT INCLUDED WITH

ALL MODELS)

A turbo nozzle, sometimes referred to as a rotary

nozzle, is a very effective tool that can significantly reduce cleaning time. The turbo nozzle

combines the power of a narrow high impact

stream and the efficiency of a 25 degree fan pattern. This swirls the narrow high impact stream

into a cone shape that cleans a larger area.

Caution: Since a turbo nozzle uses a narrow

high impact stream, only use it in applications

where the cleaning surface cannot be damaged

by narrow high impact spray. Additionally, the

turbo nozzle is NOT adjustable and cannot be

used to apply detergent.

DETERGENTS

The use of detergents can dramatically reduce

cleaning time and assist in the removal of difficult stains. Some detergents have been customized for pressure washer use on specific

cleaning tasks. These detergents are approximately as thick as water. The use of thicker

detergents, such as dish soap, will clog the chemical injection system and prevent the application

of the detergent.

The cleaning power of detergents comes from

applying them to a surface and giving the chemicals time to break down the dirt and grime.

Detergents work best when applied at low pressure.

The combination of chemical action and high

pressure rinsing is very effective. On vertical surfaces, apply the detergent starting at the bottom

and work your way upward. This will prevent the

detergent from sliding down and causing

streaks. High pressure rinsing should also

progress from the bottom to top. On particularly

tough stains, it may be necessary to use a brush

in combination with detergents and high pressure rinsing.

Pressure Washers

Operation

The following cleaning procedure will help you

to organize your cleaning task, and ensure that

you achieve the most beneficial results in the

shortest amount of time. Remember to use the

spraying/ cleaning techniques previously listed.

Before starting a pressure washer cleaning job, it

is important to prepare the surface that is to be

cleaned. This is done by clearing the area of furniture, and making sure that all windows and

1. Surface Preparation

Page 7

-

7

Operation (Continued)

www.chpower.com

doors are closed tight. In addition, you should

make sure that all plants and trees adjacent to

the cleaning area are protected by a drop cloth.

This will ensure that your plants won’t be

sprayed by the detergents.

The next step is to spray the cleaning surface

with water to clear off any dirt or grime that

may have collected on the surface. This will allow

your detergent to attack the deep down dirt

that has worked its way into the cleaning surface. Before triggering the gun, adjust the nozzle to a wide fan pattern and slowly adjust to

the desired spray pattern. This will help you

avoid applying too much concentrated spray to

the surface which could cause damage.

USE THE INSTRUCTIONS APPROPRIATE

FOR MODEL PURCHASED

NOTE: Use only detergents formulated for pres-

sure washers.

NOTE: Test detergent in an inconspicuous area

before use.

Follow manufacturer's label directions for mixing

correct concentrations of soap/detergents. The

soap/detergent to water ratio through the pressure washer is approximately 5.4% (1 to 19).

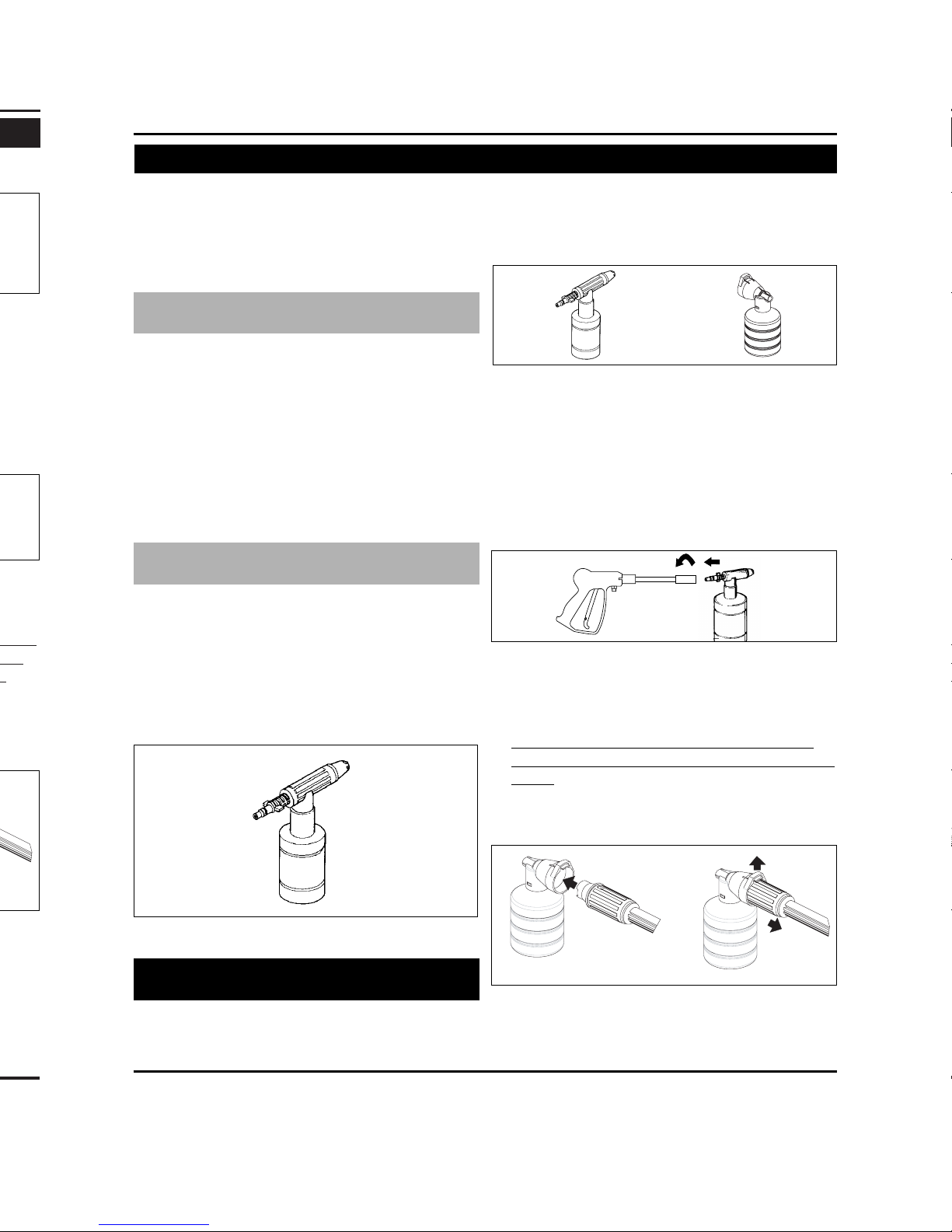

MODELS WITHOUT DETERGENT TANK

1.Unscrew top of detergent applicator and fill

applicator with detergent.

2.Replace top on applicator.

3.Remove lance from gun.

4.Attach detergent applicator to gun. (See Figure

11.)

5.For detergent applicators that fit on end of

lance, turn lance to obtain wide fan pattern.

(Deter

gent suction will not work when

lance is adjusted to provide a narrow pattern.) Connect applicator to end of lance.

Make sure connection is secured correctly. (See

figure 12.)

2. Initial High Pressure Rinse

3. Detergent Application

Figure 9 – Detergent application

Units with Detergent Applicator

Included

Figure 10 – Detergent Applicators

OR

Figure 11 – Attach applicator to gun

Figure 12 – Turn lance to obtain wide fan

pattern.

Page 8

DISTANCIA DE LA SUPERFICIE DE

LIMPIEZA

Otro factor que determina la fuerza de impacto

del agua es la distancia entre la boquilla de rocia-

do y la superficie de limpieza. La fuerza de

impacto del agua aumenta a medida que se acer-

ca la boquilla a la superficie.

CÓMO EVITAR EL DAÑO A LAS

SUPERFICIES

El daño a las superficies de limpieza ocurre

debido a que la fuerza de impacto del agua

excede la durabilidad de la superficie. La fuerza

de impacto puede variarse controlando los tres

puntos ya mencionados. Nunca use un chorro

angosto de alto impacto o una boquilla

turbo/rotativa sobre una superficie susceptible al

daño. Evite rociar las ventanas con un chorro

angosto de alto impacto o con una boquilla

turbo, pues puede ocasionar roturas. La manera

más segura de evitar el daño a las superficies es

seguir estos pasos:

1. Antes de presionar el gatillo de la pistola,

ajuste la boquilla a un patrón en abanico

ancho.

2. Coloque la boquilla aproximadamente de 4 a

5 pies de la superficie de limpieza y en ángulo

de 45 grados con la misma, y presione el gatil-

lo.

3. Varíe el ángulo de rociado en abanico y la dis-

tancia a la superficie de limpieza, hasta lograr

una óptima eficiencia de limpieza sin dañar la

superficie.

BOQUILLA TURBO (NO INCLUIDA

CON TODOS LOS MODELOS)

Una boquilla turbo, a veces llamada boquilla

giratoria, puede ser una herramienta muy efi-

caz que puede disminuir el tiempo de limpieza

Lavadoras a Presión

Pre-Operación (Continuación)

Operación

El siguiente procedimiento de limpieza le ayu-

dará a organizar su trabajo de limpieza, y asegu-

rará que obtenga los resultados más beneficiosos

en el menor tiempo posible. No olvide utilizar las

técnicas de rociado/limpieza previamente indi-

cadas.

8

Operation (Continued)

www.chpower.com

Pressure Washers

6.Apply detergent so it thoroughly covers cleaning surface. Apply from bottom to top to prevent detergent from sliding down and streaking.

7.Allow detergent to remain on the surface for a

few minutes. This is a good time to use a

brush to lightly scrub heavily soiled areas.

Never allow detergent to dry on the cleaning

surface.

8.Remove detergent applicator from gun and

replace with the lance, or remove applicator

from end of lance.

9.Rinse detergent from surface.

Note: Flush detergent applicator with clear

water following each use.

Follow manufacturer's label directions for mixing

correct concentrations of soap/detergents. The

soap/detergent to water ratio through the pressure washer is approximately 12% (1 to 8).

MODELS THAT DO NOT USE A DETERGENT

APPLICATOR

1.Remove cap from detergent tank and pour in

pressure washer detergent. Replace cap.

2.Turn OFF/ON switch to the ON position.

3.Slide nozzle to low pressure position (See

Figure 13.) and apply detergent so that it

thoroughly covers the cleaning surface.

Apply detergent from bottom to top to prevent

the detergent from sliding down and streaking.

Wait a couple of minutes for the detergent to

break down dirt and grime. This is a good time

to use a brush to lightly scrub heavily soiled

areas. Never allow detergent to dry on cleaning

surface.

IMPORTANT: Unit will only apply detergent

when adjustable nozzle is used and nozzle is in

low pressure position.

•Detergent injection may not work with extension hose or replacement hoses longer than 25

feet.

4.To rinse or return to high pressure, release trigger and slide nozzle to high pressure position.

Never slide nozzle from low

to high or high to low pressure when

gun is triggered.

Start final rinse at bottom and work upward.

Make sure you thoroughly rinse the surface and

that all detergent has been removed.

1. Be sure all detergent is flushed from system.

2.Turn off motor.

3.Turn off water supply.

4.After motor and water supply are turned off,

trigger gun to depressurize system.

NEVER turn water supply

off before turning motor off. Serious

damage could occur to the pump and/or

motor.

NEVER disconnect high

pressure discharge hose from machine

while system is pressurized. To depressurize, turn motor off, turn water supply

off and squeeze gun trigger 2–3 times.

!

WARNING

!

CAUTION

NOTICE

Units with Detergent Tank

Low Pressure

High Pressure

Figure 13 – Adjusting nozzle for pressure

Nozzle

4. Final Rinse

5. Shutdown

Page 9

9

Operation (Continued)

www.chpower.com

5.After each use, wipe all surfaces of the pressure

washer with a clean, damp cloth.

• Do not store pressure washer outdoors.

• Do not store pressure washer where it might

freeze.

TIPS FOR EXTENDING THE LIFE OF YOUR

PRESSURE WASHER

1.Never operate unit without water.

2.Pressure washer is not meant to pump hot

water. Never connect to hot water supply –

this will significantly reduce life of the pump.

3.Using detergents other than Campbell

Hausfeld's brand may cause damage to pump

components (o-rings, seals, etc.). This also

applies to chemicals such as bleach, dish soap,

etc.

4.Never operate unit for more than one (1)

minute without spraying water. Resulting heat

buildup will damage pump.

5.Before adjusting nozzle for pressure (high-tolow or low-to-high) release trigger. Failure to

do so will reduce life of o-rings in lance.

6. Storage

Page 10

Lavadoras a Presión

Medidas de Seguridad y Advertencias (Continuación)

menor que los requisitos del aparato eléctrico. No

use cordones de extensión dañados. Examine el

cordón de extensión antes de usarlo y reempláce-

lo si está dañado. Tenga cuidado al manipular el

cordón de extensión y no lo hale para desconec-

tarlo. Mantenga el cordón lejos del calor y bordes

afilados. Siempre desconecte el cordón de exten-

sión del tomacorriente antes de desconectar la

hidrolavadora de la extensión. NOTA: Con este

producto no use las comunes cuerdas de exten-

siÛn 16 Û 18 AWG.

con estas instrucciones puede

ocasionar lesiones graves, incluso

la muerte.

!

PELIGRO

Pre-Operación

AJUSTE DEL PATRÓN DE ROCIADO EN

ABANICO

El ángulo de rociado que sale de la lanza se

puede graduar en algunas lanzas girando la

boquilla. Esto hará variar el patrón de rociado

desde aproximadamente un chorro angosto de

alto impacto de 0o hasta un abanico de rociado

de 600 de ancho (ver figura 2)

Un chorro angosto tiene una fuerza de alto

impacto sobre la superficie de limpieza y da

como resultado una limpieza máxima profunda

en una zona concentrada. Sin embargo, este

chorro angosto de alto impacto debe usarse con

precaución, pues puede dañar algunas superfi-

cies.

Un patrón en "abanico" ancho distribuye el

impacto del agua sobre un área mayor, lo que da

como resultado una excelente acción de limpieza

Figura 2 – Ajuste de la boquilla para el patrón de

rociado en abanico (no se aplica en algunas boquillas)

Boquilla

10

www.chpower.com

Pressure Washers

Pressure washer

does not start

up

Pump does not

reach necessary

pressure

Fluctuating

pressure

Motor stops

suddenly

1. Unit is pressurized

2. GFCI has tripped (If so

equipped)

3. Plug is not well connected

or electric socket is faulty

4. Extension cord too long or

wire size too small

5. Main voltage supply too low

6. Thermal safety switch has

tripped

1. Water inlet filter is clogged

2. Pump sucking air from hose

connections

3. Nozzle worn or not correct

size

4. Unloader clogged or worn

5. Valves clogged or worn

1. Pump sucking in air

2. Clogged nozzle

3. Valves dirty, worn or stuck

4. Water seals worn

1. Extension cord too long or

wire size too small

2. Thermal safety switch has

tripped due to overheating

1. Squeeze trigger on gun

2. Push reset button on plug

3. Check plug, socket and fuses

4. Remove extension cord (see

page 4)

5. Check that main supply voltage is adequate

6. Switch off unit and allow

motor to cool down

1. Clean water inlet filter

2. Check that connections and

locking ring are properly

tightened

3. Call 1-800-330-0712

4. Call 1-800-330-0712

5. Call 1-800-330-0712

1. Check that hoses and connections are tight

2. Clean with tip cleaner (see

page 5)

3. Call 1-800-330-0712

4. Call 1-800-330-0712

1. Remove extension cord (see

page 4)

2. Check that main supply voltage corresponds to specifications

Symptom Possible Cause(s) Corrective Action(s)

Troubleshooting Chart

Page 11

11

www.chpower.com

Pressure Washers

No detergent

suction – units

with tanks

No detergent

suction – units

with attachable

applicators

Unit begins to

smoke

1. Lance nozzle not in low pressure position

2. Using high pressure extension hose or high pressure

hose is too long

3. Injector clogged on pump

Detergent applicator clogged

Overheated, overloaded or

damaged motor

1. Slide lance nozzle into low

pressure position (see page 8)

2. Remove high pressure extension hose or use high pressure

hose shorter than 25 feet

3. Call 1-800-330-0712

1. Clean applicator with warm

water

2. Replace applicator

Turn off unit and call

1-800-330-0712

Symptom Possible Cause(s) Corrective Action(s)

Troubleshooting Chart

Page 12

Lavadoras a Presión

Medidas de Seguridad y Advertencias (Continuación)

cuando se use esta hidrolavadora, incluyendo las

siguientes:

1. Lea todas las instrucciones antes de usar la

hidrolavadora.

2. Para reducir el riesgo de lesiones, se necesita

una supervisión muy cercana cuando se use

la hidrolavadora cerca de niños.

3. SIEMPRE desconecte el suministro de fuerza

(unidades eléctricas) antes de desarmar o

reparar la unidad.

4. Siga todos los reglamentos de seguridad

locales así como la Ley de Seguridad y Salud

Ocupacional (“OSHA” en inglés).

5. Cerciórese de que los mecanismos de seguri-

dad estén funcionando debidamente antes

de cada uso. NO remueva o modifique

ninguna parte de la pistola o unidad.

6. Sepa como apagar la lavadora y liberar la

presión rápidamente. Familiarícese con

todos los controles.

7. Permanezca alerta. Esté consciente de lo que

está haciendo.

8. No opere esta hidrolavadora cuando esté

fatigado o bajo la influencia del alcohol o de

drogas.

9. Mantenga todas las personas alejadas del

área de trabajo.

10. No trate de alcanzar cosas que estén fuera

de su alcance ni se pare sobre una superficie

inestable. Manténgase siempre en buen

equilibrio, con sus pies sobre una superficie

segura.

11. Siga las instrucciones de mantenimiento

especificadas en los manuales.

12. Este producto debe conectarse a un toma-

corriente protegido por un interruptor de

circuito por fuga a tierra (sólo las lavadoras a

presión eléctricas).

13. Si el producto está provisto de un interrup-

tor de circuito por fuga a tierra, asegúrese

de inspeccionar dicho interruptor y el

cordón antes del uso. Cualquier reparación o

cambio del cordón de fuerza debe ser efec-

tuada por un técnico electricista calificado

(autorizado o certificado).

Limited Warranty

1. DURATION: From the date of purchase by the original purchaser as follows: Standard Duty - One Year, Serious

Duty - Two Years, Extreme Duty - Three Years.

2. WHO GIVES THIS WARRANTY (WARRANTOR): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Telephone: (800) 330-0712

3. WHO RECEIVES THIS WARRANTY (PURCHASER): The original purchaser (other than for purposes of resale) of

the Campbell Hausfeld pressure washer.

4. WHAT PRODUCTS ARE COVERED UNDER THIS WARRANTY: Any Campbell Hausfeld Pressure Washer supplied or

manufactured by the Warrantor.

5. WHAT IS COVERED UNDER THIS WARRANTY: Substantial defects on material and workmanship which occur

within the duration of the warranty period with the exceptions noted below.

6. WHAT IS NOT COVERED UNDER THIS WARRANTY:

A.Implied warranties, including those of merchantability and FITNESS FOR A PARTICULAR PURPOSE ARE LIMIT-

ED FROM THE DATE OF ORIGINAL PURCHASE AS STATED IN THE DURATION. If this pressure washer is used

for commercial, industrial or rental purposes, the warranty will apply for ninety (90) days from the date of

purchase. Some States do not allow limitation on how long an implied warranty lasts, so the above limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM

ANY DEFECT, FAILURE, OR MALFUNCTION OF THE CAMPBELL HAUSFELD PRESSURE WASHER. Some States do

not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

C. Any failure that results from shipping damage, accident, purchaser’s abuse, neglect or failure to install and

operate pressure washer in accordance with instructions provided in the owner’s manual(s) supplied with

product.

D.Pre-delivery service, i.e. assembly, oil or lubricants and adjustment.

E. Items or service normally required to maintain the pressure washer.

F. Gasoline engine and components are expressly excluded from coverage under this limited warranty. Such

components should be returned by the purchaser to the original manufacturer or to its authorized repair sta-

tions for service.

G. Additional items not covered under the warranty:

1. Normal wear items such as high pressure hoses, water and oil seals, o-rings, valves, lances and spray tips.

2. Motor brushes (Electric models only).

3. Cosmetic defects that do not interfere with functionality.

4. Rusted components.

5. Pump wear or valve damage caused by using improper oil, oil contamination or by failure to follow proper oil maintenance guidelines.

7. RESPONSIBILITIES OF WARRANTOR UNDER THIS WARRANTY: Repair or replace, at Warrantor’s option, pressure

washer or component which is defective, has malfunctioned and/or failed to conform within duration of the

warranty period.

8. RESPONSIBILITIES OF PURCHASER UNDER THIS WARRANTY:

A. Provide dated proof of purchase and maintenance records.

B. Deliver or ship the Campbell Hausfeld pressure washer or component to nearest Campbell Hausfeld

Authorized Service Center. Freight costs, if any, must be borne by the purchaser.

C. Use reasonable care in the operation and maintenance of the pressure washer as described in the owner’s

manual(s).

9. WHEN WARRANTOR WILL PERFORM REPAIR OR REPLACEMENT UNDER THIS WARRANTY: Repair or replacement

will be scheduled and serviced according to the normal work flow at the servicing location, and depending on

the availability of replacement parts.

This Limited Warranty applies in the U.S., Canada and Mexico only and gives you specific legal rights. You may

also have other rights which vary from state to state or country to country.

Pressure Washers

12

www.chpower.com

Page 13

BUILT TO LAST

Pulvérisateurs de

Lavage Électriques

Instructions d’Utilisation

Lire attentivement et comprendre les instructions suiv-

antes avant d’utiliser ce pulvérisateur de lavage

© 2003 Campbell Hausfeld IN459000AV 10/03

Généralités sur la Sécurité et Avertissements . . . . . . 2 – 4

Pré-Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . 4 – 7

Fonctionnement, Arrêt et Entreposage . . . . . . . . . . 7 – 9

Guide de Dépannage . . . . . . . . . . . . . . . . . . . . . . 10 –11

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table des Matières Page

1

8

5

0

P

S

I

P

r

e

s

s

u

r

e

W

a

s

h

e

r

1

.

9

G

P

M

1750 PSI

Pressure Washer

1.8 GPM

G

a

r

a

n

t

í

a

l

i

m

i

t

a

d

a

d

e

1

a

ñ

o

s

Limited

Warranty

G

a

r

a

n

t

i

e

l

i

m

i

t

é

e

d

e

1

a

n

s

E

C

P

Voir la Garantie à la page 11 Fr pour de l’information importante sur l’utilisation commercial de ce produit.

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

Page 14

Manque d’aspira-

tion de détergent

– modèles avec

applicateurs

amovibles

Modèle com-

mence à fumer

Symptôme Cause(s) Possible(s) Mesure(s) Corrective(s)

Guide De Dépannage

Garantie Limitée

1. DURÉE: À partir de la date d’achat par l’acheteur originel comme suit: Produits À Service Standard (Standard

Duty) - Un An, Produits À Service Sérieux (Serious Duty) - Deux Ans, Produits À Service Extrême (Extreme Duty) -

Trois Ans.

2. GARANTIE ACCORDÉE PAR (GARANT): Campbell Hausfeld / Scott Fetzer Company, 100 Production Drive,

Harrison, Ohio, 45030, Téléphone: (800) 330-0712

3. BÉNÉFICIAIRE DE CETTE GARANTIE (ACHETEUR): L’acheteur originel (sauf en cas de revente) du pulvérisateur

de lavage Campbell Hausfeld.

4. PRODUITS COUVERTS PAR CETTE GARANTIE: Tous les Pulvérisateurs de Lavage Campbell Hausfeld qui sont four-

nis ou fabriqués par le Garant.

5. COUVERTURE DE LA PRÉSENTE GARANTIE: Défauts de matière et de fabrication considérables qui se révèlent

pendant la période de validité de la garantie avec les exceptions indiquées ci-dessous.

6. LA PRÉSENTE GARANTIE NE COUVRE PAS:

A.Les garanties implicites, y compris celles de commercialisabilité et D’ADAPTION À UNE FONCTION PARTIC-

ULIÈRE SONT LIMITÉES À PARTIR DE LA DATE D’ACHAT INITIALE TELLE QU’INDIQUÉE DANS LA SECTION

DURÉE. Si le pulvérisateur de lavage est utilisé pour une fonction commerciale, industrielle ou pour la loca-

tion, la durée de la garantie sera quatre-vingt-dix (90) jours à compté de la date d’achat. Quelques Provinces

(États) n’autorisent pas de limitations de durée pour les garanties implicites. Les limitations précédentes peu-

vent donc ne pas s’appliquer.

B. TOUT DOMMAGE, PERTE OU DÉPENSE FORTUIT OU INDIRECT POUVANT RÉSULTER DE TOUT DÉFAUT, PANNE

OU MAUVAIS FONCTIONNEMENT DU PULVÉRISATEUR CAMPBELL HAUSFELD. Quelques Provinces (États) n’au-

torisent pas l’exclusion ni la limitation des dommages fortuits ou indirects. La limitation ou exclusion précé-

dente peut donc ne pas s’appliquer.

C. Toute panne résultant d’un accident, de dommage pendant l’expédition, d’une utilisation abusive, de la nég-

ligence ou d’une utilisation ne respectant pas les instructions données dans le(s) manuel(s) accompagnant le

produit.

D.Service avant livraison; montage, huile ou lubrifiants, et réglages par exemple.

E. Articles ou service normalement requis pour l’entretien du pulvérisateur de lavage.

F. Les moteurs à essence et les pièces détachées sont expressément exclus de cette garantie limitée. L’acheteur

doit retourner les pièces détachées du moteur à essence au fabricant originel ou à son centre de service

autorisé.

G. Articles additionnels qui ne sont pas couverts sous cette garantie:

1. Articles d’usure normal tels que; tuyaux haute pression, joints d’huile et hydrauliques, joints toriques,

soupapes, lances, et buses de pulvérisation.

2. Brosses de moteur (Modèles électriques seulement).

3. Les défauts esthétiques qui n’affectent pas la fonction.

4. Pièces détachées rouillées.

5. Usure de la pompe ou le dommage aux soupapes causé par l’utilisation de type d’huile incorrect, la con-

tamination de l’huile ou par le manque de suivre les directives d’entretien d’huile.

7. RESPONSABILITÉS DU GARANT AUX TERMES DE CETTE GARANTIE: Réparation ou remplacement, au choix du

Garant, du pulvérisateur de lavage ou de pièce détachée qui se sont révélés défectueux pendant la durée de la

garantie.

8. RESPONSABILITÉS DE L’ACHETEUR AUX TERMES DE CETTE GARANTIE:

A. Fournir une preuve d’achat datée et un état d’entretien.

B. La livraison ou expédition du pulvérisateur de lavage ou pièce détachée Campbell Hausfeld au Centre De

Service Autorisé Campbell Hausfeld. Taux de frais, si applicables, sont la responsabilité de l’acheteur.

C. Utilisaton et entretien du pulvérisateur de lavage avec un soin raisonable, ainsi que le décri(vent)t le(s)

manuel(s) d’utilisation.

9. RÉPARATION OU REMPLACEMENT EFFECTUÉ PAR LE GARANT AUX TERMES DE LA PRÉSENTE GARANTIE: La

réparation ou le remplacement sera prévu et exécuté en fonction de la charge de travail dans le centre de serv-

ice et dépendra de la disponabilité des pièces de rechange.

Cette Garantie Limitée s’applique aux É.-U., au Canada et au Mexique seulement et vous donne des droits juridiques

précis. L’acheteur peut également jouir d’autres droits qui varient d’une Province, d’un État ou d’un Pays à l’autre.

Généralités sur la Sécurité et Avertissements

Généralités Sur La Sécurité

Ce manuel contient de l’information qui est très

importante à connaître et à comprendre. Cette

information est fournie pour LA SÉCURITÉ et pour

ÉVITER DES PROBLÈMES D’ÉQUIPEMENT. Pour

vous aider à reconnaître cette information,

observer les symboles suivants:

Danger indique une

situation hasardeuse qui RÉSULTERA en

perte de vie ou en blessures graves.

Avertissement

indique une situation hasardeuse potentielle qui PEUT résulter en perte de vie

ou en blessures graves.

Attention indique

une

situation hasardeuse potentielle qui

PEUT résulter en blessures.

REMARQUE: Informations spéciaux.

Instructions de Sécurité Importantes

CONSERVER CES INSTRUCTIONS

Il est nécessaire de suivre des précautions

générales pendant l’utilisation de ce produit y

compris les suivantes:

1. Lire toutes les instructions avant d’utiliser le

produit.

2. Il est nécessaire de bien surveiller les enfants

si le produit est utilisé près d’eux afin de

réduire le risque de blessure.

3. TOUJOURS débrancher la source d’alimenta-

tion (modèles électriques) avant de démonter ou de réparer le modèle.

4. Respecter tous les codes locaux de sécurité

ainsi que le Occupational Safety and Health

Act (OSHA).

5. S’assurer que les appareils de sécurité fonc-

tionnent correctement avant chaque usage.

NE PAS enlever ni modifier aucune partie

du pistolet ou du modèle.

6. Savoir arrêter ce produit et purger la pres-

sion rapidement. Bien se familiariser avec

les commandes.

7. Soyez alerte - faites attention à ce que vous

faites.

8. Ne pas faire fonctionner ce produit lorsque

vous êtes fatigués ni sous l’influence de

drogues ou d’alcool.

9. Garder l’endroit de travail libre d’autres personnes.

10. Ne pas s’étendre le bras ni se tenir debout

sur un support instable. Toujours rester bien

équilibré.

11. Suivre toutes les instructions d’entretien spécifiées dans les manuels.

12. Ce produit sera branché à une prise de

courant protégée par un appareil DDFT (disjoncteur qui protège contre un dérangement dû à une mise accidentelle à la terre).

13. Si le produit est fourni d’un DDFT, s’assurer

d’inspecter le cordon et l’appareil DDFT

avant l’usage. Toutes réparations et remplacement du cordon d’alimentation doivent

être effectués par un technicien qualifié (certifié ou diplômé).

Risque d’injection

ou de blessure grave -Se tenir à l’écart

de la buse - Ne pas diriger le jet vers

une autre personne ni vers un animal Seules les personnes qualifiées doivent

se servir du produit. Toujous enlever la

lance du pistolet avant de nettoyer le

débris du bout.

• Se tenir à l’écart de la buse. NE JAMAIS diriger

un jet haute pression vers une personne, un

animal, ni vers soi-même.

•Toujours porter des lunettes de sécurité et des

vêtements protecteurs pendant l’utilisation

ou l’entretien.

• Ne jamais se mettre la main ni les doigts sur

la buse lorsque le modèle est en marche.

• Ne jamais essayer d’arrêter ni de faire dévier

les fuites avec n’importe quelle partie du

corps.

•Toujours engager le mécanisme de sécu

rité

!

AVERTISSEMENT

!

AVERTISSEMENT

!

ATTENTION

!

AVERTISSEMENT

!

DANGER

2 Fr

Page 15

Pulvérisateurs de Lavage

3 Fr

Information de Sécurité et Avertissements (Suite)

de gâchette dans la position de sécurité

lorsque la pulvérisation est arrêtée même

pour quelques moments.

•Toujours suivre les recommandations du fabricant sur l’étiquette du produit détersif pour

assurer l’usage correct. Toujours se protéger

les yeux, la peau et le système respiratoire

contre le détergent.

ENTRETIEN D’UN APPAREIL À

DOUBLE ISOLATION

Dans un appareil à double isolation, deux systèmes d’isolation sont fournis à la place d’une

mise à la terre. Aucun système de mise à la terre

n’est fourni sur un appareil à double isolation et

aucun moyen de mise à la terre ne doit y être

ajouté. Faire l’entretien d’un appareil à double

isolation demande des soins attentifs et une connaissance parfaite du système et ne sera exécuté

que par des personnes compétentes. Les pièces

de rechange pour un appareil à double isolation

doivent être identiques aux

pièces qu’elles remplacent.

Un appareil à double isolation doit porter l’inscription

“DOUBLE ISOLATION”

(Double Insulated). Le symbole peut aussi se trouver

sur l’appareil.

Ne pas utiliser une

pression qui dépasse la pression de service de n’importe quelle pièce détachée

(tuyaux, raccords, etc.) dans le système

pressurisé. S’assurer que tout

l’équipement et les accessoires soient

classifiés pour la pression de service

maximum du modèle.

Risque d’explosion.

• NE JAMAIS pulvériser des liquides inflamma-

bles, ni utiliser le pulvérisateur de lavage là où

il y a de la poussière, liquides ou vapeurs com-

bustibles.

• Ne jamais faire fonctionner cette machine

dans un bâtiment clos ni dans un environnement explosif.

Ne pas pulvériser les

appareils électriques ni le câblage

• Ne jamais débrancher le tuyau de décharge de

haute pression du modèle pendant que le système soit pressurisé. Pour dépressuriser le modèle, mettre hors circuit et couper l’eau.

Appuyer sur la gâchette du pistolet 2-3 fois.

• Ne jamais engager le mécanisme de gâchette

sur le pistolet de façon permanente.

•Ne jamais faire fonctionner la machine si

toutes les pièces détachées ne sont pas fixées

correctement au modèle. (manche, montage

de pistolet/baguette buse, etc.)

Dégâts d’équipement

•TOUJOURS alimenter la source d’eau “ON”

avant de mettre le pulvérisateur de lavage en

marche “ON.” Le fonctionnement de la

pompe à sec causera le dommage sérieux.

•Ne pas faire fonctionner le pulvérisateur de

lavage sans filtre d’arrivée d’eau. Garder le filtre libre de débris et de sédiment.

• NE JAMAIS faire fonctionner le pulvérisateur

de lavage avec des pièces manquantes ou

cassées. Inspecter l’équipement régulièrement

et remplacer les pièces usées ou endommagées immédiatement.

•Utiliser seulement la buse fournie avec cette

machine.

• Ne jamais laisser la baguette sans surveillance

pendant que la machine fonctionne.

• Ne jamais essayer de modifier les réglages de

l’usine. Modifier les réglages de l’usine pourrait endommager le modèle et niera la

garantie.

•Toujours tenir le pistolet et la baguette fermement pendant le démarrage et le fonctionnement de la machine.

• NE JAMAIS permettre que le modèle fonctionne avec la gâchette relâchée (off) pendant

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

Figure 1 – Symbol

Double Isolation

Page 16

Pulvérisateurs de Lavage

fonctionnera pas avec les tuyaux prolonga-

teurs ou les tuyaux de rechange qui sont plus

longs que 25 pieds.

4. Pour rincer ou pour retourner à la position

haute pression, relâcher la gâchette et glisser

la buse à la position haute pression.

buse de bas à haut ou de haut à bas

lorsque la gâchette est actionnée.

Le rinçage final devrait commencer du bas en

haut. S’assurer de bien rinçer la surface afin

d’enlever tout le détergent.

1. S’assurer que tout le détergent soit purgé du

système.

2. Mettre le moteur hors circuit (off).

3.Couper la source d’eau.

4. Une fois que le moteur et la source d’eau

soient coupés, actionner la gâchette pour

dépressuriser le système.

source d’eau avant de mettre le moteur

hors circuit. Ceci peut endommager la

pompe et/ou le moteur.

débrancher le tuyau de décharge

haute pression de la machine pendant

que le système soit pressurisé. Pour

dépressuriser le système, mettre le

moteur hors circuit (off), couper la

source d’eau et actionner la gâchette 2-3

fois.

!

AVERTISSEMENT

!

ATTENTION

AVIS

4. Rinçage Final

5. Arrêt

4 Fr

plus qu’une minute. L’accumulation de la

chaleur endommagera la pompe.

• Le pulvérisateur de lavage n’est pas conçu

pour pomper l’eau chaude. NE JAMAIS

brancher le pulvérisateur à une source d’eau

chaude. Ceci pourrait diminuer la durée de

la pompe de façon spectaculaire.

• NE JAMAIS entreposer le pulvérisateur de

lavage dehors ni là où il peut geler. La

pompe sera endommagée de façon sérieuse.

• Relâcher la gâchette lorsque vous changez du

mode pression haute au mode pression

basse. Sinon vous risquez d’endommager

la buse.

Garder le tuyau à l’écart d’objets pointus. Les tuyaux qui

éclattent peuvent causer des blessures.

Inspecter les tuyaux régulièrement et

les remplacer si endommagés. Ne pas

essayer de réparer un tuyau endommagé.

CORDONS PROLONGATEURS

Si vous utilisez un

cordon prolongateur, utiliser seulement des cordons prolongateurs mis à

la terre, à trois broches et en bon état

de marche.

L’utilisation d’un cordon prolongateur n’est pas

recommandé. Si vous utilisez un cordon prolongateur, consultez le tableau ci-dessous et utilisez

seulement les tailles et longueurs recommandées.

Utiliser seulement les cordons prolongateurs

conçus pour l’usage à l’extérieur. Ceux-ci sont

indiqués “Acceptable pour l’usage avec appareils

à l’extérieur; ranger à l’intérieur si hors usage”.

Utiliser seulement les cordons prolongateurs avec

une classification électrique égale ou supérieure à

la classification du produit. Ne pas utiliser un cordon prolongateur endommagé. Inspecter le cordon prolongateur avant chaque usage et le remplacer si endommagé. Ne pas abuser le cordon

prolongateur. Ne pas tirer sur le cordon pour

débrancher l’appareil. Garder le cordon à l’écart

de la chaleur et des bords tranchants. Toujours

débrancher le cordon de la prise de courant

avant de débrancher le produit du cordon prolongateur.

Remarque: Ne pas utiliser des cordons prolongateurs ordinaires de 16 ou 18 AWG avec ce produit.

Manque de suivre

ces instructions peut résulter en

blessures graves, y compris la mort.

Pour

réduire le risque de secousse

électrique, garder tous les raccordements secs et au dessus

de la terre. Ne touchez pas la

fiche avec les mains trempes.

RÉGLAGE DE CONFIGURATION

!

AVERTISSEMENT

!

DANGER

!

DANGER

!

ATTENTION

Information de Sécurité et Avertissements (Suite)

Taille de Cordon Longeur permise

Prolongateur 7,7 m 15,2 m

14 AWG Oui Non

12 AWG Oui Oui

SE RÉFÉRER AUX INSTRUCTIONS DE

MONTAGE POUR LES MÉTHODES DE

MONTAGE ET DE BRANCHEMENT

Pré-Fonctionnement

L’angle du jet de pulvérisation de la lance peut

être réglé (sur quelques types de lances) en

tournant la buse. Ceci pourra régler la configuration de pulvérisation d’un jet de chute puissant étroit 0˚ à une configuration évantail

large de 60˚. (Voir Figure 2).

Un jet étroit a une force à impact élevé sur la

surface de nettoyage et peut nettoyer à font

dans un endroit concentré. Utiliser ce jet avec

précaution, il peut endommager certaines surfaces.

Une configuration large “Évantail” distribue

Page 17

Pulvérisateurs de Lavage

5 Fr

Pré-Fonctionnement (Suite)

l’impact de l’eau à travers un endroit plus large

et nettoie bien avec moins de risque de dommage à la surface. Nettoyez les surfaces larges

plus rapidement avec une configuration évantail

large.

BUSE DE PRESSION AJUSTABLE (NON

INCLUSE AVEC TOUS LES MODÈLES)

La buse de pression ajustable vous permet de

varier la pression de votre pulvérisation en

tournant l'extrémité bleue de la buse. Tourner

l'extrémité bleue entièrement dans le sens des

aiguilles d'une montre réduira la pression au

minimum. Si le pulvérisateur de lavage a un

système à réservoir de détergent, vous devez

utiliser ce réglage de pression minimum pour

aspirer le détergent.

Tourner l'extrémité bleue entièrement dans le

sens contraire des aiguilles d'une montre augmentera la pression à son niveau maximum

d'efficacité de nettoyage. Tourner l'extrémité

bleue change la pression, mais non pas le

motif en éventail.

INSTRUCTIONS DE NETTOYAGE DE LA

BUSE

Une buse obstruée pourrait diminuer le volume d’eau que sort de la buse et pourrait

causer la vibration du modèle pendant la pulvérisation.

Pour nettoyer la buse:

• Mettre le modèle hors service (off) et

débrancher le modèle.

• Couper la source d’eau. Dissiper la pression

du tuyau en serrant la gâchette 2-3 fois.

• Détacher la lance du pistolet.

•Tourner la buse au réglage de jet afin d’ouvrir les lames de l’évantail.

• Utiliser le nettoyeur de bout (compris) ou

une trombone, introduire le fil dans le trou

de la buse et le dépacer avec un mouvement

avant-arrière afin de déloger l’obstruction.

(Voir Figure 7.)

• Faire la chasse d’eau inverse en plaçant le

bout d’un tuyau d’arrosage (avec l’eau qui

coule) contre le bout de la buse pendant 30-

Figure 2 - Réglage de la buse pour configuration évantail (applicable selon le

modèle)

Buse

Figure 3 – Jet étroit à impact élevé

Figure 4 – Configuration évantail large

Figure 5 – Pulvérisation basse pression

Figure 6 – Pulvérisation haute pression

Page 18

Pulvérisateurs de Lavage

Pré-Fonctionnement (Suite)

Fonctionnement

L’utilisation des détergents tels que le savon à

vaiselle peut obstruer le système d’injection de

produit chimique et peut empêcher l’application

du détergent.

La puissance de nettoyage des détergents est

dérivée de l’application du produit à la surface et

le temps que le produit décompose la saleté.

Pour un meilleur résultat, les détergents

devraient être appliqués avec une pression basse.

Utiliser la méthode de nettoyage suivante

pour organiser votre application de nettoyage

et pour assurer un bon résultat en moins de

temps. Utiliser les techniques indiquées

précédemment.

Préparer la surface avant de commencer la pul-

vérisation. Enlever tous les meubles et s’assurer

que toutes les fenêtres et les portes soient

bien fermées. Protéger toutes les plantes et les

arbres qui sont situés près de la surface avec

une toile afin d’éviter qu’ils soient pulvérisés

de détergent.

La prochaine étape est de pulvériser la surface

avec de l’eau afin d’enlever la saleté de sur-

face. Ceci permet que le détergent nettoie la

saleté qui est sous la surface. Avant d’action-

ner le pistolet, régler la buse à une configura-

tion évantail large et régler lentement à la

configuration désirée. Ceci aide à empêcher

trop de pulvérisation concentrée sur la surface

(ce qui peut causer du dommage).

UTILISER LES INSTRUCTIONS CONVEN-

ABLES AU MODÈLE UTILISÉ

REMARQUE: Utiliser seulement les détergents

formulés pour les pulvérisateurs de lavage.

REMARQUE: Faire l’essai du détergent dans un

1. Préparation de la Surface

2. Premier Rinçage Haute Pression

3. Application de Détergent

6 Fr

Pré-Fonctionnement (Suite)

60 secondes afin d’enlever du débris additionnel.

ANGLE À LA SURFACE

Lors de la pulvérisation d’eau sur une surface,

l’impact maximum est produite lorsque l’eau

fait contact à la surface directement, mais ce

type de contact peut causer le collage de particules de saleté à la surface ce qui empêche le nettoyage à fond.

L’angle de pulvérisation optimum d’eau contre

une surface propre est 45 degrés.

La pulvérisation d’eau contre une surface à cet

angle fournit l’impact la plus efficace pour l’enlevage de débris de la surface.

DISTANCE DE LA SURFACE

Un autre facteur qui détermine la force d’impact

de l’eau est la distance de pulvérisation de la

buse à la surface. La force d’impact de l’eau est

augmentée quand la buse s’approche à la surface.

EMPÊCHER LE DOMMAGE AUX SURFACES

Les surfaces peuvent s’endommager si la force

d’impact de l’eau dépasse la durabilité de la surface. La force d’impact est variable et peut être

réglée avec le contrôle des trois articles précédents. Ne jamais utiliser un jet étroit à impact

élevé ni une buse Turbo/rotative sur une surface

sensible au dommage. Éviter la pulvérisation des

fenêtres avec un jet étroit à impact élevé car ceci

peut les casser. Suivre les étapes suivantes afin

d’éviter le dommage aux surfaces:

1. Avant d’actionner le pistolet, régler la buse à

une configuration évantail large.

2. Placer la buse approximativement 1,2-1,5 m

de/et 45 degrés à la surface, et appuyer sur la

gâchette du pistolet.

3. Régler l’angle de la configuration de pulvérisation évantail ainsi que la distance à la surface

jusqu’à ce que le degré de nettoyage désiré

soit atteint sans endommager la surface.

BUSE TURBO (PAS COMPRISE AVEC

TOUS LES MODÈLES)

Une buse turbo (rotative), peut être un outil efficace qui réduit le temps de nettoyage d’une

manière significative. La buse turbo mélange la

puissance de nettoyage d’un jet étroit à impact

élevé avec l’efficacité d’une configuration évantail de 25 degrés. La buse fait tournoyer un jet

étroit à impact élevé dans une configuration

conique qui peut nettoyer un endroit plus large.

Attention: Puisque la buse turbo utilise un jet

étroit à impact élevé, l’utiliser seulement dans les

applications où la surface ne peut être endommagée par la pulvérisation à jet étroit à impact

élevé. La Buse Turbo n’est PAS réglable et ne

peut pas être utilisée pour l’application de détergent.

DÉTERGENTS

L’usage de détergents peut réduire de façon

spectaculaire, le temps de nettoyage et peut

aider à enlever les taches difficiles. Plusieurs

détergents sont formulés pour les tâches de nettoyage spécifiques avec les pulvérisateurs de

lavage. Ces détergents ont la consistance d’eau.

Figure 8 – Angle à la Surface

Figure 7 – Introduire le nettoyeur dans le

trou de la buse et déplacer avec un mouvement avant-arrière afin de déloger l’obstruction.

Buse

Nettoyeur de buse

Page 19

Pulvérisateurs de Lavage

7 Fr

Pré-Fonctionnement (Suite)

Fonctionnement

L’utilisation des détergents tels que le savon à

vaiselle peut obstruer le système d’injection de

produit chimique et peut empêcher l’application

du détergent.

La puissance de nettoyage des détergents est

dérivée de l’application du produit à la surface et

le temps que le produit décompose la saleté.

Pour un meilleur résultat, les détergents

devraient être appliqués avec une pression basse.

La combinaison d’action chimique et de rinçage

haute pression est très efficace. Sur les surfaces

verticales, appliquer le détergent du fond en

haut, Ceci empêchera les traînées de détergent.

Le rinçage haute pression devrait aussi s’appliquer du fond en haut. Pour les taches très difficiles, il peut être nécessaire d’utiliser une brosse

avec les détergents et le rinçage haute pression.

Utiliser la méthode de nettoyage suivante

pour organiser votre application de nettoyage

et pour assurer un bon résultat en moins de

temps. Utiliser les techniques indiquées

précédemment.

Préparer la surface avant de commencer la pulvérisation. Enlever tous les meubles et s’assurer

que toutes les fenêtres et les portes soient

bien fermées. Protéger toutes les plantes et les

arbres qui sont situés près de la surface avec

une toile afin d’éviter qu’ils soient pulvérisés

de détergent.

La prochaine étape est de pulvériser la surface

avec de l’eau afin d’enlever la saleté de surface. Ceci permet que le détergent nettoie la

saleté qui est sous la surface. Avant d’actionner le pistolet, régler la buse à une configuration évantail large et régler lentement à la

configuration désirée. Ceci aide à empêcher

trop de pulvérisation concentrée sur la surface

(ce qui peut causer du dommage).

UTILISER LES INSTRUCTIONS CONVENABLES AU MODÈLE UTILISÉ

REMARQUE: Utiliser seulement les détergents

formulés pour les pulvérisateurs de lavage.

REMARQUE: Faire l’essai du détergent dans un

endroit peu voyant avant l’utilisation.

Suivre les instructions du fabricant sur l’étiquette

pour le mélange correct de savon/détergent. La

proportion de savon/détergent par rapport à

l’eau à travers le pulvérisateur de lavage est

approximativement 5.4% (1 to 19).

POUR MODÈLES SANS RÉSERVOIR DE DÉTERGENT

1. Dévisser le couvercle de l’applicateur de

détergent et remplir l’applicateur de détergent.

2. Remplacer le couvercle de l’applicateur.

3. Enlever la lance du pistolet.

1. Préparation de la Surface

2. Premier Rinçage Haute Pression

3. Application de Détergent

Figure 9 – Application de Détergent

Modèles Électriques avec Applicateur

de Détergent (Inclus)

Figure 10 – Applicateurs de détergent

– ou –

Page 20

8 Fr

4. Fixer l’applicateur de détergent au pistolet.

(Voir Figure 11.)

5. Pour les applicateurs de détergent qui s’ajustent au bout de la lance, tourner la lance au

réglage de configuration évantail large.

(L

’aspiration de dé-tergent ne fonction-

nera pas si la lance est réglée à une

configuration étroite). Brancher l’applica-

teur au bout de la lance. S’assurer que le

branchement soit sûr. (Voir figure 12.)

6. Appliquer le détergent afin de couvrir la surface de nettoyage. Appliquer de bas en haut

pour empêcher que le détergent coule et

cause du traînage.

7. Permettre que le détergent reste sur la surface pendant quelques minutes. Ce moment

est idéal pour utiliser une brosse légèrement

sur les endroits plus sales. Ne jamais permettre que le détergent sèche sur la surface de

nettoyage.

8. Enlever l’applicateur de détergent du pistolet et le remplacer avec la lance, ou enlever

l’applicateur du bout de la lance.

9. Rincer le détergent de la surface.

Remarque: Faire la chasse d’eau de l’applicateur

de détergent après chaque usage.

Suivre les instructions du fabricant sur l’étiquette

pour le mélange correct de savon/détergent. La

proportion de savon/détergent par rapport à

l’eau à travers le pulvérisateur de lavage est

approximativement 12% (1 to 8).

MODÈLES SANS APPLICATEUR DE DÉTERGENT

1. Enlever le capuchon du réservoir de détergent et verser le détergent pour pulvérisateurs à lavage. Remplacer le capuchon.

2. Tourner l’interrupteur de marche/arrêt

(OFF/ON) à la position ON (marche).

3. Glisser la buse à la position de basse pression telle qu’indiquée sur la Figure 13 et

appliquer le détergent pour couvrir la surface de nettoyage complètement.

Appliquer le détergent du bas en haut afin

d’empêcher la traînée de détergent. Laisser

le détergent pendant quelques minutes.

Brosser légèrement si nécessaire pour les

endroits très sales. Ne jamais permettre que

le détergent sèche sur la surface de nettoyage.

IMPORTANT: Le modèle peut seulement appliquer le détergent si une buse réglable est utilisée et si la buse est dans la position de basse

pression.

• Il est possible que l’injection de détergent ne

Fonctionnement

Figure 11 – Fixer l'applicateur de détergent

au pistolet

Figure 12 – Tourner la lance afin

d’obtenir une configuration évantail

large.

Modèles Électriques avec Réservoir

de Détergent

Low Pressure

High Pressure

Figure 13 – Régler la buse pour la pression

Nozzle

Pulvérisateurs de Lavage

Pré-Fonctionnement (Suite)

l’impact de l’eau à travers un endroit plus large

et nettoie bien avec moins de risque de dom-

mage à la surface. Nettoyez les surfaces larges

plus rapidement avec une configuration évantail

large.

BUSE DE PRESSION AJUSTABLE (NON

INCLUSE AVEC TOUS LES MODÈLES)

La buse de pression ajustable vous permet de

varier la pression de votre pulvérisation en

tournant l'extrémité bleue de la buse. Tourner

Figure 2 - Réglage de la buse pour config-

uration évantail (applicable selon le

modèle)

Buse

Figure 3 – Jet étroit à impact élevé

Figure 4 – Configuration évantail large

Figure 5 – Pulvérisation basse pression

Page 21

Pulvérisateurs de Lavage

9 Fr

fonctionnera pas avec les tuyaux prolongateurs ou les tuyaux de rechange qui sont plus

longs que 25 pieds.

4. Pour rincer ou pour retourner à la position

haute pression, relâcher la gâchette et glisser

la buse à la position haute pression.

Ne jamais glisser la

buse de bas à haut ou de haut à bas

lorsque la gâchette est actionnée.

Le rinçage final devrait commencer du bas en

haut. S’assurer de bien rinçer la surface afin

d’enlever tout le détergent.

1. S’assurer que tout le détergent soit purgé du

système.

2. Mettre le moteur hors circuit (off).

3.Couper la source d’eau.

4. Une fois que le moteur et la source d’eau

soient coupés, actionner la gâchette pour

dépressuriser le système.

NE JAMAIS couper la

source d’eau avant de mettre le moteur

hors circuit. Ceci peut endommager la

pompe et/ou le moteur.

NE JAMAIS

débrancher le tuyau de décharge

haute pression de la machine pendant

que le système soit pressurisé. Pour

dépressuriser le système, mettre le

moteur hors circuit (off), couper la

source d’eau et actionner la gâchette 2-3

fois.

5. Après chaque usage, essuyer toutes les surfaces du pulvérisateur de lavage avec un torchon propre et humide.

• Ne pas ranger le pulvérisateur de lavage à

l’extérieur.

• Ne pas ranger le pulvérisateur de lavage là où

il pourrait geler.

CONSEILS POUR PROLONGER LA

DURÉE DE VOTRE PULVÉRISATEUR DE

LAVAGE

1. Ne jamais faire fonctionner le modèle sans

eau.

2.Votre pulvérisateur de lavage n’est pas conçu

pour le pompage d’eau chaude. Ne jamais

brancher votre pulvérisateur de lavage à une

source d’eau chaude, car ceci pourrait réduire

la durée de la pompe de façon spectaculaire.

3. Utiliser des détergents autrement que la marque Campbell Hausfeld pourrait endommager

les pièces détachées de la pompe (joints

toriques, joints etc.). Ceci s’applique aux produits chimiques tels que les produits de blanchissement, le savon de vaisselle, etc.

4. Faire fonctionner le modèle pendant plus que

1 minute sans pulvériser de l’eau peut causer

l’accumulation de chaleur dans la pompe,

éviter ceci.

5.Lâcher la gâchette avant de régler la buse pour

la pression (haute à basse ou basse à haute).

Manque de suivre cette directive pourrait

diminuer la durée des joints toriques dans la

lance.

!

AVERTISSEMENT

!

ATTENTION

AVIS

4. Rinçage Final

6. Entreposage

5. Arrêt

Page 22

10 Fr

Le pulvérisateur

de lavage ne se

démarre pas

La pompe n’atteint pas la pression nécessaire

Pression fluctuante

Moteur s’arrête

subitement

Manque d’aspiration de détergent

– modèles avec

réservoirs

1. Le modèle est pressurisé

2. L’appareil DDFT est déclenché

(si équipé)

3. La fiche n’est pas bien

branchée ou la prise de

courant est défectueuse

4. Cordon prolongateur trop

long ou taille de fil trop petite

5. La source de tension principale

est trop basse

6. L’interrupteur de protection

thermique enclenchée

1. Le filtre d’arrivée d’eau est

obstrué

2. La pompe aspire de l’air des

raccords de tuyaux

3. Buse usée ou de mauvaise

taille

4. Déchargeur obstrué ou usé

5. Soupapes obstruées ou usées

1. Pompe aspire de l’air

2. Buse obstruée

3. Soupapes sales, usées ou grippées

4. Joints hydrauliques usés

1. Cordon prolongateur trop

long ou taille de fil trop petite

2. L’interrupteur de protection

thermique s’est enclenché à

cause du surchauffage

1. Buse de lance n’est pas dans la

position de basse pression

2. L’usage d’un tuyau prolongateur haute pression ou le

tuyau haute presson est trop

long

3. Injecteur de la pompe obstrué

1. Serrer la gâchette sur le pistolet

2. Appuyer sur le bouton de réenclenchement sur la fiche